Continental Hydraulics CEM-AA-B Installation Manual

Continental Hydraulics Installation Manual

CEM-AA-B

Description:

This adaptable power amplifier is configurable to drive either single or dual solenoid, or two

independent proportional valve coils up to 2.6A. A wide range of analog or digital signals are

accepted dependent on the configuration. User may select either voltage, current or digital input

mode. These inputs are easily scaled to match system requirements.

The CEM-AA-B module has three selectable function modes:

Function mode AA for operating one single or dual solenoid Proportional Control Valve

Function mode A-B for operating independently two single solenoid Proportional Control

Valves

Function mode RA, This mode accepts 3 independent switch inputs, each which has

independently adjustable speed and ramp controls. Inputs are additive, for up to 8 unique

preset speed and ramp profiles.

Independent Ramp of acceleration and deceleration, IMIN and IMAX, PWM, DITHER settings are

programmable. In addition the valve characteristics can also be linearized via 10 X-Y points per

solenoid output.

The module is disabled if the coil outputs are shorted or open. If command current signal is

outside of the proper range, the module is disabled.

This module is easily adapted to a variety of system requirements. All variables are user adjusted

with easy to use CHI-PC software on your Microsoft Windows laptop. Control variables are

stored in non-volatile memory internal to the module. All variables can be read by the laptop, and

reproduced exactly on other modules.

Page 1 of 33 CEM-AA-B CHI 1020611 01/2016

Continental Hydraulics Installation Manual

Table of Contents

Information Description Page #

Technical Data - All Function Modes for CEM-AA-B …………………….………..…………… 3

LED Indications - All Function Modes …………………………………………………………… 4

Steps to install and configure a new application ……………………….………………………. 5

Module Mounting Location ………………………………………….…………………………….. 6

Power Supply ………………………………………………………………………………….…… 6

Wiring to Valve …………………………………………………………………………………….. 6

Dimensions …………………………………………….…………………………………………… 6

Circuit Diagram Function AA …………………………………………………………………... 7

Terminal Identification AA Function …………………………………………………………….. 8

Parameter List Function AA …………………………………………….………………….… 9

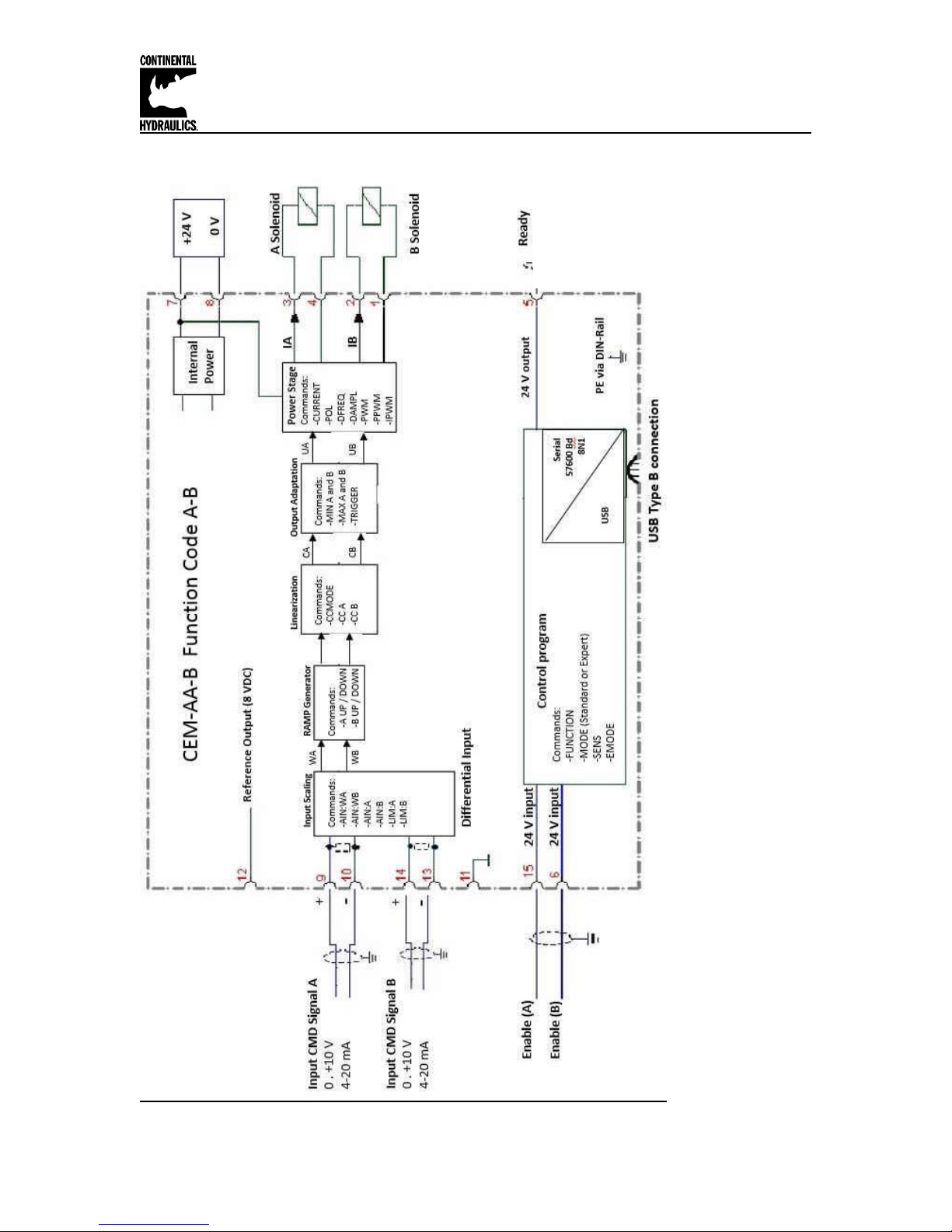

Circuit Diagram Function A-B …………………………………………………………………… 10

Terminal Identification A-B Function …………………………………………………………….. 11

Parameter List Function A-B ………………………………………………….……………… 12

Circuit Diagram Function RA …………………………………………………………………… 13

Terminal Identification RA Function …………………………………………………………….. 14

Parameter List Function RA ……………………………………………………….…………… 15

Command Parameter Descriptions

FUNCTION……………………………………………………………………………..… 16

LG (Language)…………………………………………………………………………… 16

MODE……………………………………………………………………………………... 16

SENS ……………………..……………………………………………………. ………... 17

CCMODE………………………………………………………………………………… 17

SOLENOIDS……………………………………………………………………………... 17

PIN:6………………………………………………………………………………………. 18

USCALE………………………………………………………………………………….. 18

ENABLE_B……………………………………………………………………………….. 18

LIM………………………………………………………………………………………… 19

POL……………………………………………………………………………………….. 20

AINA / AINB………………………………………………………………………………. 20

AIN…………………………………………………………………………………………. 21

AA:I / AB:I (RAMP Time)…………………………………………..………………….... 22

RMODE…………………………………………………………………………………… 23

S:0 – S:7………………………………………………………………………………….. 23

RA:0 – RA:7………………………………………………………………………………. 24

CCA / CCB……………………………………………………………………………..… 25

CC (Characteristics Linearization)…………………………………………………….. 26

MIN………………………………………………………………………………………... 27

MAX……………………………………………………………………………………... 27

TRIGGER………………………………………………………………………………... 27

CURRENT……………………………………………………………………………….. 29

DFREQ…………………………………………………………………………………… 29

DAMPL…………………………………………………………………………………… 29

PWM……………………………………………………………………………………… 30

ACC………………………………………………………………………………………. 30

PPWM / IPWM…………………………………………………………………………… 31

PROCESS DATA (Monitoring)…………………………………………………………………… 32

Failure Monitoring………………………………………………………………………………….. 33

Troubleshooting…………………………………………………………………………………….. 33

Page 2 of 33 CEM-AA-B CHI 1020611 01/2016

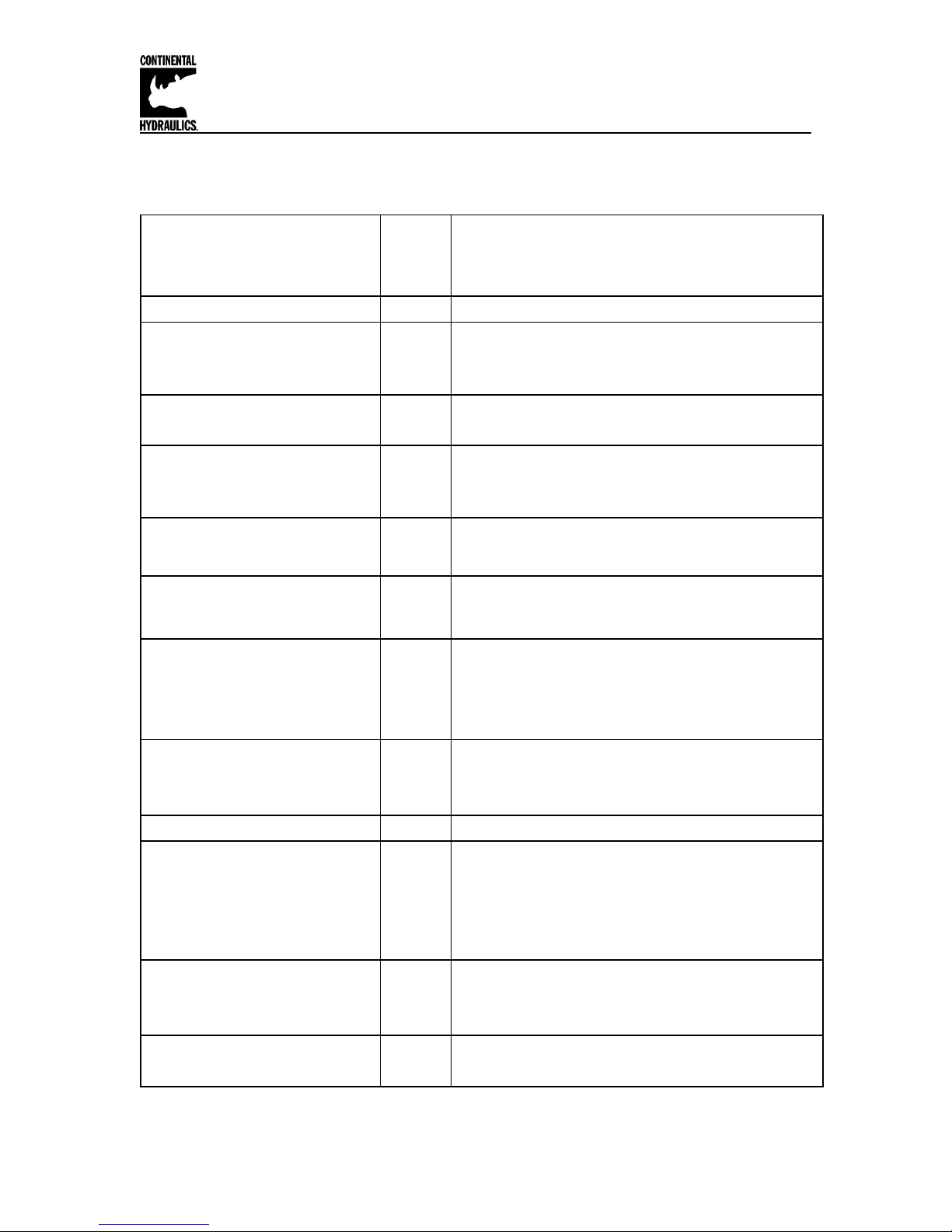

Continental Hydraulics Installation Manual

Power supply

[VDC]

12… 30 (incl. ripple)

Power consumption max.

[W]

60 (depending on type of solenoid, two solenoids are

active)

External fuse

[A]

3 medium time lag

Reference voltage

[V]

8 (maximum 25 mA)

Digital inputs

[V]

logic 0: < 2

[V]

logic 1: > 10

Input resistance

[kΩ]

25

Digital outputs

[V]

logic 0: < 2

[V]

logic 1: > 12 (50 mA)

Analogue inputs

[V]

±10 / 0… 10; 90 kΩ

[mA]

4...20; 390 Ω

Resolution

[%]

< 0.01

Nominal PWM output current

[mA]

500… 2600; broken wire monitored and short circuit

proof.

PWM frequency

[Hz]

61...2604; adjustable in steps

Sample time (process control)

[ms]

1

Sample time (solenoid current

control)

[ms]

0.125

Interface

USB type B

Virtual COM port driver (CHI-PC):

9600… 57600 Baud (Default = 57600),

1 Stop bit, No parity, No handshake

Housing

Snap On Module EN 50022

Polyamide PA 6.6

Combustibility class V0 (UL94)

Weight

[kg]

0.190

Protection class

IP20

Temperature range

[°C]

-20… 60

Storage temperature

[°C]

-20 …70

Humidity

[%]

<95 (not condensing)

Vibration

-

IEC 60068-2-6 (category C)

Connections

USB type B

4 x 4 pol. screw terminals

PE: direct via DIN rail

EMC

EN 61000-6-2: 8/2005

EN 61000-6-4: 6/2007 ; A1:2011

Technical Data - All Function Modes:

Page 3 of 33 CEM-AA-B CHI 1020611 01/2016

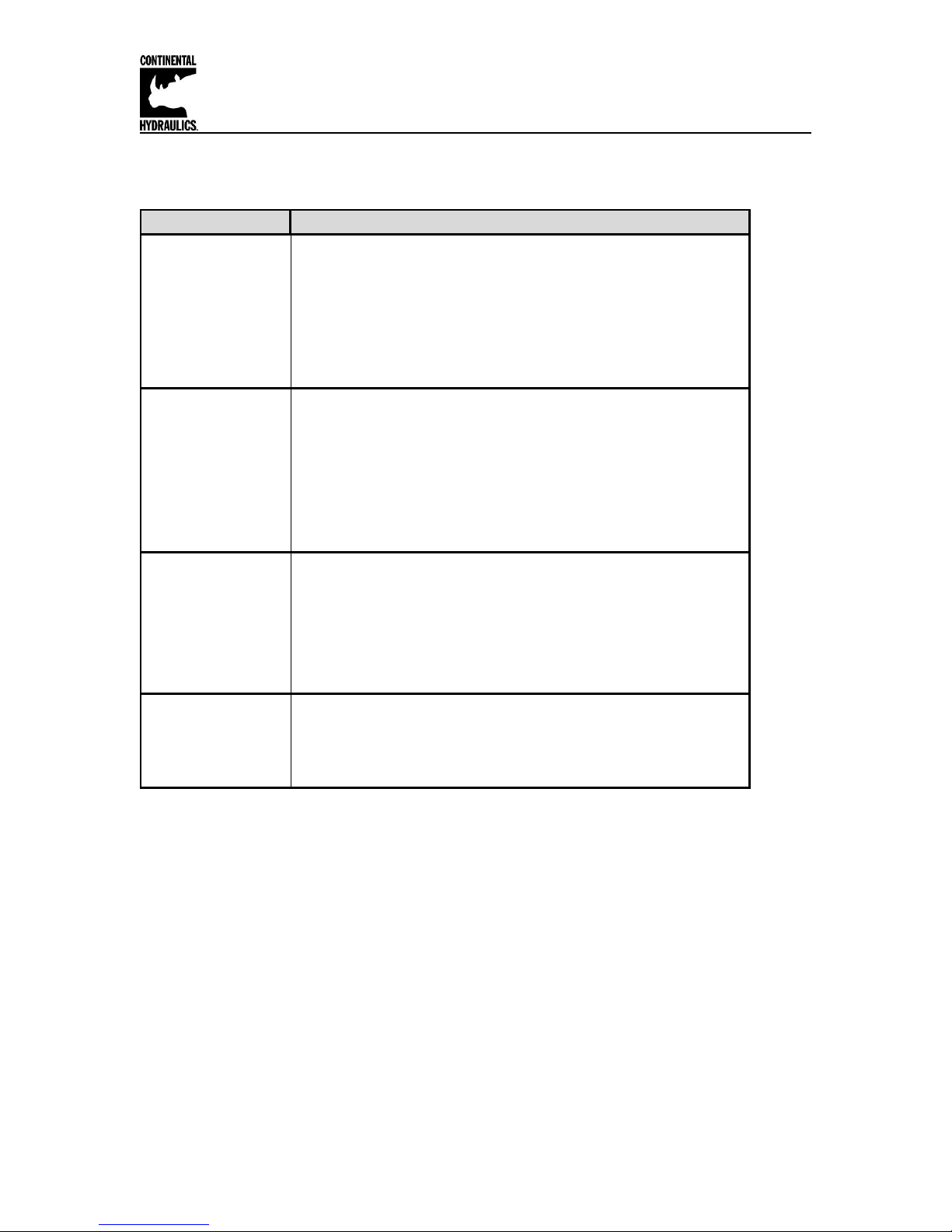

Continental Hydraulics Installation Manual

LED's Description of the LED function

1. Chasing light (over all LEDs): The bootloader is active.

No normal functions are possible.

2. All LEDs flash shortly every 6 s: An internal data error was

detected and corrected automatically! The module still works

regularly. To acknowledge the error the module has to have

power cycled.

Yellow + Yellow

Both yellow LEDs flash oppositely every 1 s: The nonvolatile

stored parameters are inconsistent! To acknowledge the error

the data has to be saved with the SAVE command or the

corresponding Function button in the CHI-PC program. If one of

the FUNCTION parameter is changed to an incorrect value, that

parameter value is deleted purposely, and set to default

values. In this case the LEDs indicate no error.

Identical to the READY output.

OFF: No power supply or ENABLE is not activated

ON: System is ready for operation

Flashing: Error detected (e. g. valve solenoid or 4… 20 mA).

Not active when SENS = OFF.

LED in the middle position = Current, Channel A; the intensity

is proportional to the output current

LED in the right position = Current, Channel B; the intensity is

proportional to the output current

GREEN + YELLOW

GREEN

YELLOW

LED Indications - All Function Modes:

Page 4 of 33 CEM-AA-B CHI 1020611 01/2016

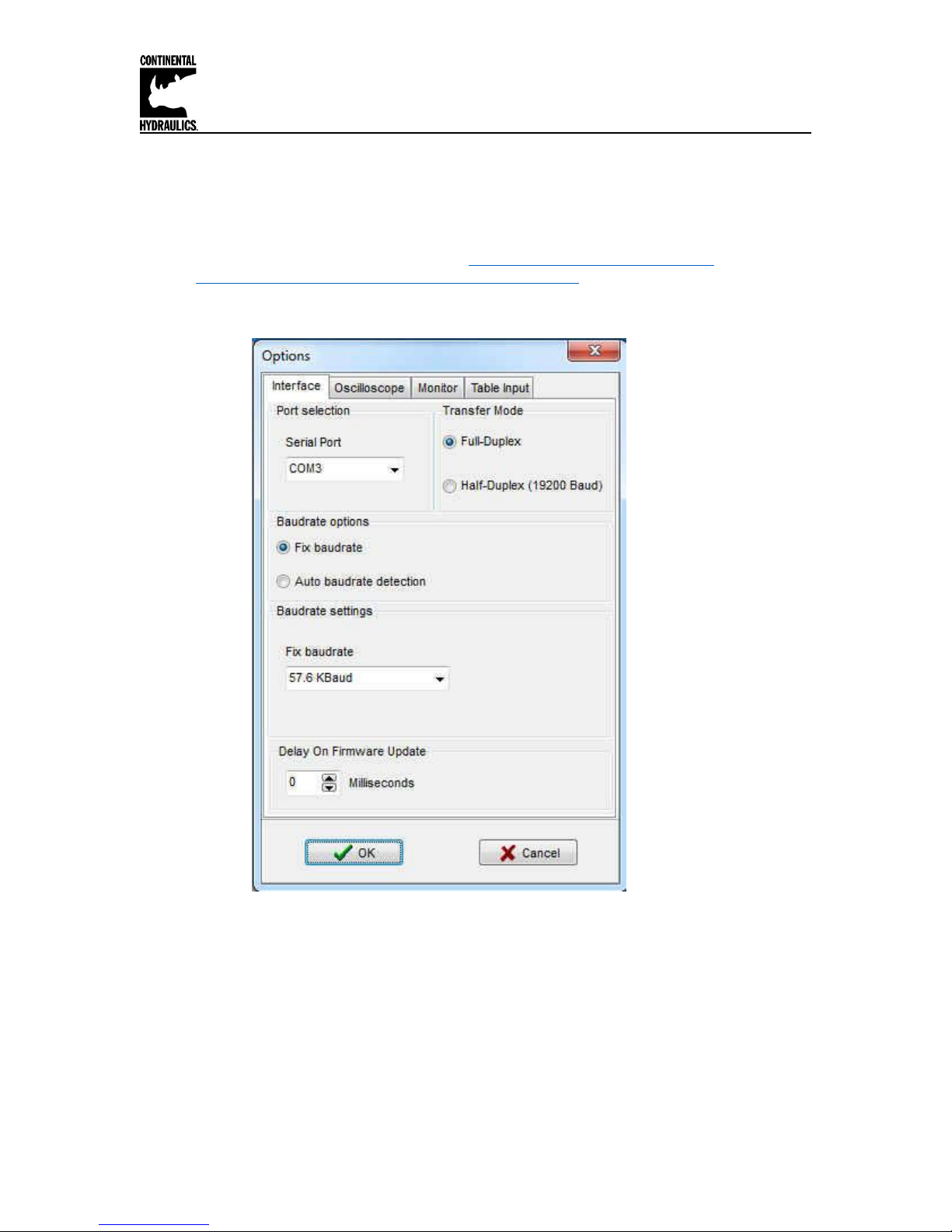

Continental Hydraulics Installation Manual

Steps to install and configure a new application:

All parameters are adjusted using VEA-BUSB programming cable and CHI-PC Microsoft

Windows application.

1. Mount the module in a suitable location

2. Connect the power supply and valve solenoids

3. Down load and open the GUI program (www.continentalhydraulics.com/wp-

content/uploads/2015/01/setup-CEWMPC-10-v3.5.0.zip )

4. Connect to Laptop via USB to USB Type B communication cable.

5. Open the Options Tab and in setting, verify that the correct com port, full-Duplex and

57.6K Baud rates are selected.

Page 5 of 33 CEM-AA-B CHI 1020611 01/2016

6. Select Desired Function (AA / A-B / RA) for your application as desired, Click the ID

button to update the Parameter list.

7. Adjust current range to match valve

8. Adjust PWM / Dither to optimize performance of the valve

9. Adjust analog input to voltage or current, and scale input if required.

10. Adjust ramping (if desired)

11. Adjust internal monitor functions (if desired)

12. Adjust current output to the valve for the flow / pressure required (if desired)

Continental Hydraulics Installation Manual

4.5"

3.9"

0.9"

Module Mounting Location:

This module is to be mounted in a cabinet for protection from the local environment.

Ensure there is adequate free space around the module to allow for cooling air flow.

This module is designed to snap onto an industry standard 35mm DIN rail.

Do not mount near other modules that emit high power electrical interference, such as motor

controllers and high power contactors.

Power Supply:

This module is designed to operate on DC power from a regulated power supply ranging from 12

to 30 volts. Match valve solenoid voltage rating to power supply, typically 12 or 24 volts.

A 3 amp medium action fuse is recommended in the “+” power supply line.

Wiring to Valve:

Two conductors are required for each solenoid. There is no need for shielding on these power

conductors.

Wire size is chosen to provide an acceptable voltage drop between the module and the valve

solenoid. The following chart is based on 5% drop for 12v and 24v applications. The listed cable

length is distance from module to valve, and includes the voltage drop of the return conductor.

Wire size 2.6A 12v 1.6A 24v 0.86A 24v

12 gauge 66 ft max 215 ft max 400 ft max

14 gauge 49 ft max 159 ft max 295 ft max

16 gauge 31 ft max 100 ft max 186 ft max

18 gauge 19 ft max 63 ft max 117 ft max

20 gauge 13 ft max 39 ft max 73 ft max

22 gauge 8 ft max 25 ft max 46 ft max

Dimensions:

Page 6 of 33 CEM-AA-B CHI 1020611 01/2016

Continental Hydraulics Installation Manual

Circuit Diagram Function AA

Page 7 of 33 CEM-AA-B CHI 1020611 01/2016

Continental Hydraulics Installation Manual

Connection Supply

PIN 7

Power supply (see technical data)

0 V (GND) Power supply (ground).

Attention, PIN 8 and PIN 11 are connected internally. PIN 11 is used

as the GND potential for the command and feedback signals..

Connection Reference voltages output

PIN 12

Reference output voltage (8 V).

Connection PWM output

PIN 3 / 4

Current controlled PWM outputs for solenoid A.

PIN 1 / 2

Current controlled PWM outputs for solenoid B.

Connection Analogue input signals

PIN 9 / 10

Com m and (input) signal (W), range -100…100 % corresponds with 10…10 V or 4…20 m A

0 V reference for the signal inputs.

Attention, PIN 8 and PIN 11 are connected internally

Connection Digital inputs and outputs

Enable Input:

This digital input signal initializes the application.

The output and the READY signal will be activated.

By deactivating, error signals are reset.

S1 input:

Function depends on parameter PIN:6 (USCALE/RAMP).

OFF: Output current depends on parameter USCALE; ramp

function is deactivated.

ON: Output current is not scaled by USCALE, ramp function is

activated.

READY output:

ON: Module is ready, no errors are detected

OFF: ENABLE (PIN 15) is deactivated or an error is detected.

CEM-AA-B Function AA Input and Output Terminals

PIN 8

PIN 11

PIN 15

PIN 6

PIN 5

Page 8 of 33 CEM-AA-B CHI 1020611 01/2016

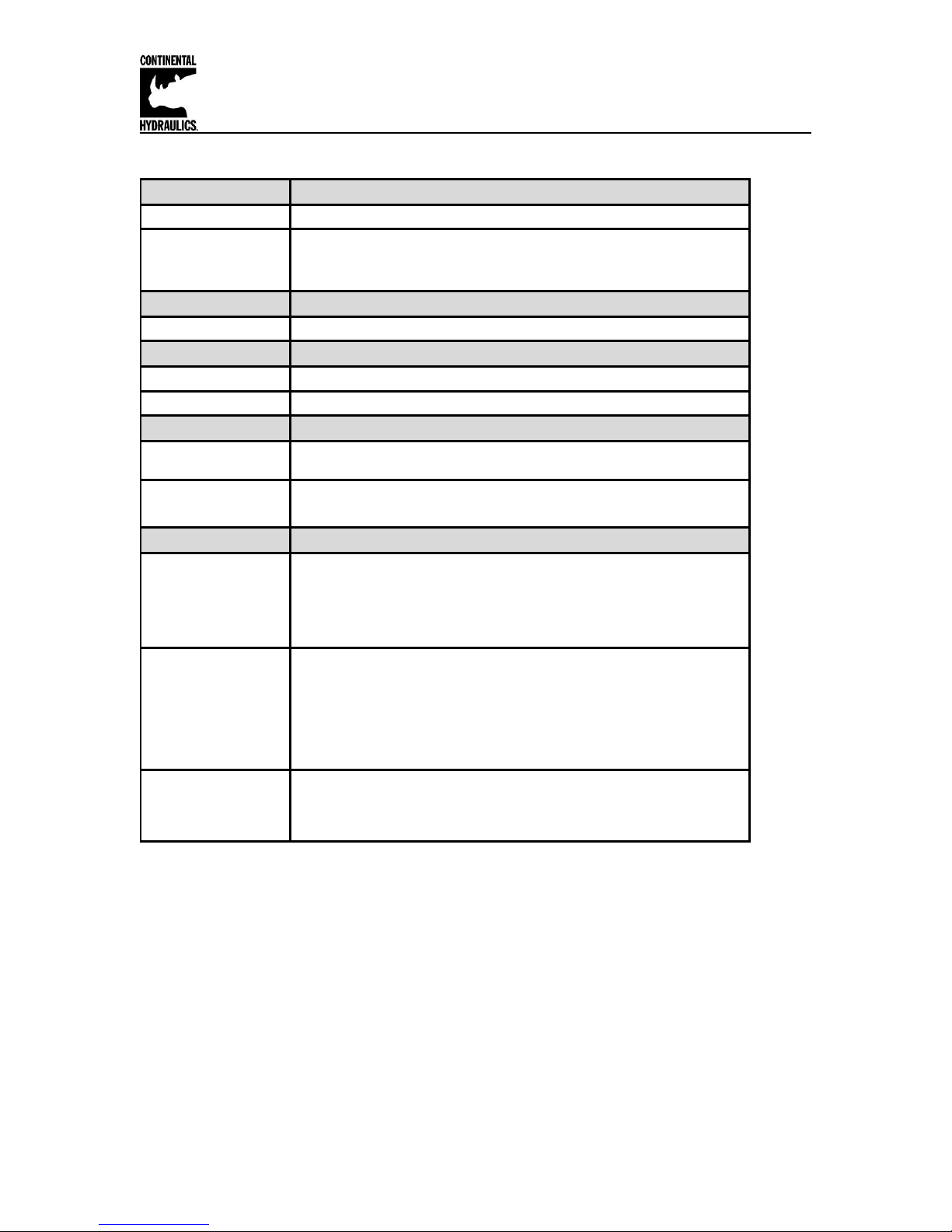

Continental Hydraulics Installation Manual

Ref Page

Command Parameter Help / Description STD EXP

16 FUNCTION AA Function mode (AA / A-B / RA) Press ID button after selection X X

16 LG EN EN English X X

16 MODE EXP Standard / Expert mode X X

17 SENS AUTO Malfunction monitoring [ON / OFF /AUTO] X X

17 CCMODE OFF Characteristics linearization [ON / OFF] X

18 PIN:6 USCALE Function of PIN 6 [USCALE / RAMP] X

18 USCALE 10000 Output current scale in 0.01% X

19 LIM 0 Range control input signal in 0.01% X

20 POL + Output polarity (+/-) X X

20 AINA V Input switching, voltage or current [V/C] (Voltage default) X

20 AIN:A 1000 1000 0 V Input scaling via linear equation X

22 AA:1 100 Ramptime acceleration A in ms X X

22 AA:2 100 Ramptime deceleration A in ms X X

22 AA:3 100 Ramptime acceleration B in ms X X

22 AA:4 100 Ramptime deceleration B in ms X X

26 CC characteristic curve Free definable characteristic linearization

27 MIN:A 0 Compensation of the Deadband in 0.01% X X

27 MIN:B 0 Compensation of the Deadband in 0.01% X X

27 MAX:A 10000 Output Scaling in 0.01% X X

27 MAX:B 10000 Output Scaling in 0.01% X X

27 TRIGGER 200 Trigger point of the MIN function in 0.01% X X

29 CURRENT 1000 Rated solenoid current 500…. 2600 mA X X

29 DAMPL 500 Dither amplitude in 0.01% of rated current X X

29 DFREQ 121 Dither frequency in Hz X X

30 PWM 2604 PWM frequency in Hz X

30 ACC ON Auto Adjustment of the current loop [OFF / ON] X

31 PPWM 7 P-Gain of the current loop X

31 IPWM 40 I-Gain of the current loop X

MODE

Parameter List Function AA

Page 9 of 33 CEM-AA-B CHI 1020611 01/2016

Continental Hydraulics Installation Manual

Circuit Diagram Function A-B

Page 10 of 33 CEM-AA-B CHI 1020611 01/2016

Loading...

Loading...