Page 1

Seaim _nvlcisa "_alning and Edu_etion

I

Electric

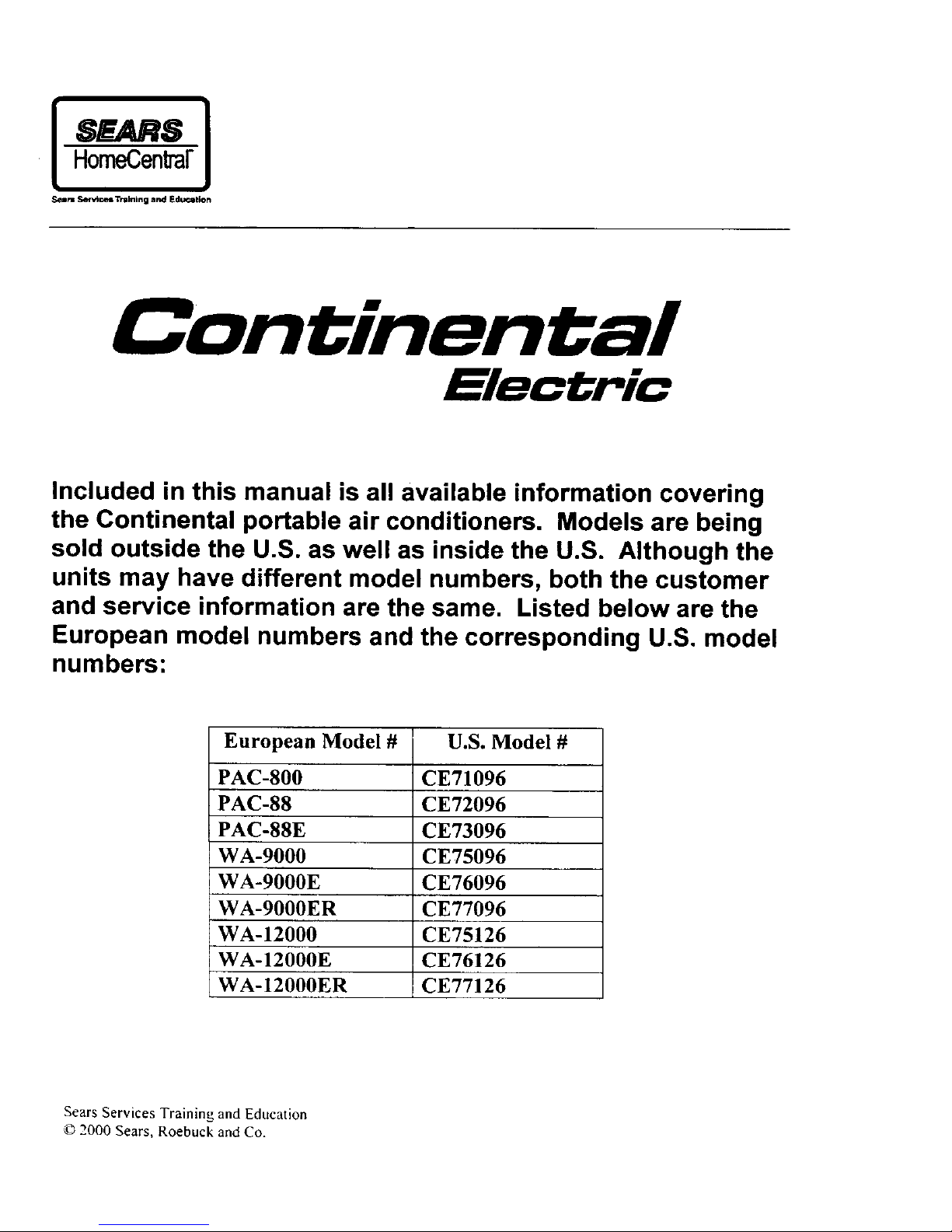

Included in this manual is all available information covering

the Continental portable air conditioners. Models are being

sold outside the U.S. as well as inside the U.S. Although the

units may have different model numbers, both the customer

and service information are the same. Listed below are the

European model numbers and the corresponding U.S. model

numbers:

European Model # U.S. Model #

PAC-800 CE71096

PAC-88 CE72096

PAC-88E CE73096

WA-9000 CE75096

WA-9000E CE76096

WA-9000ER CE77096

WA-12000 CE75126

WA-12000E CE76126

WA-12000ER CE77126

Sears Services Training and Education

© 2000 Sears, Roebuck and Co.

Page 2

Electric

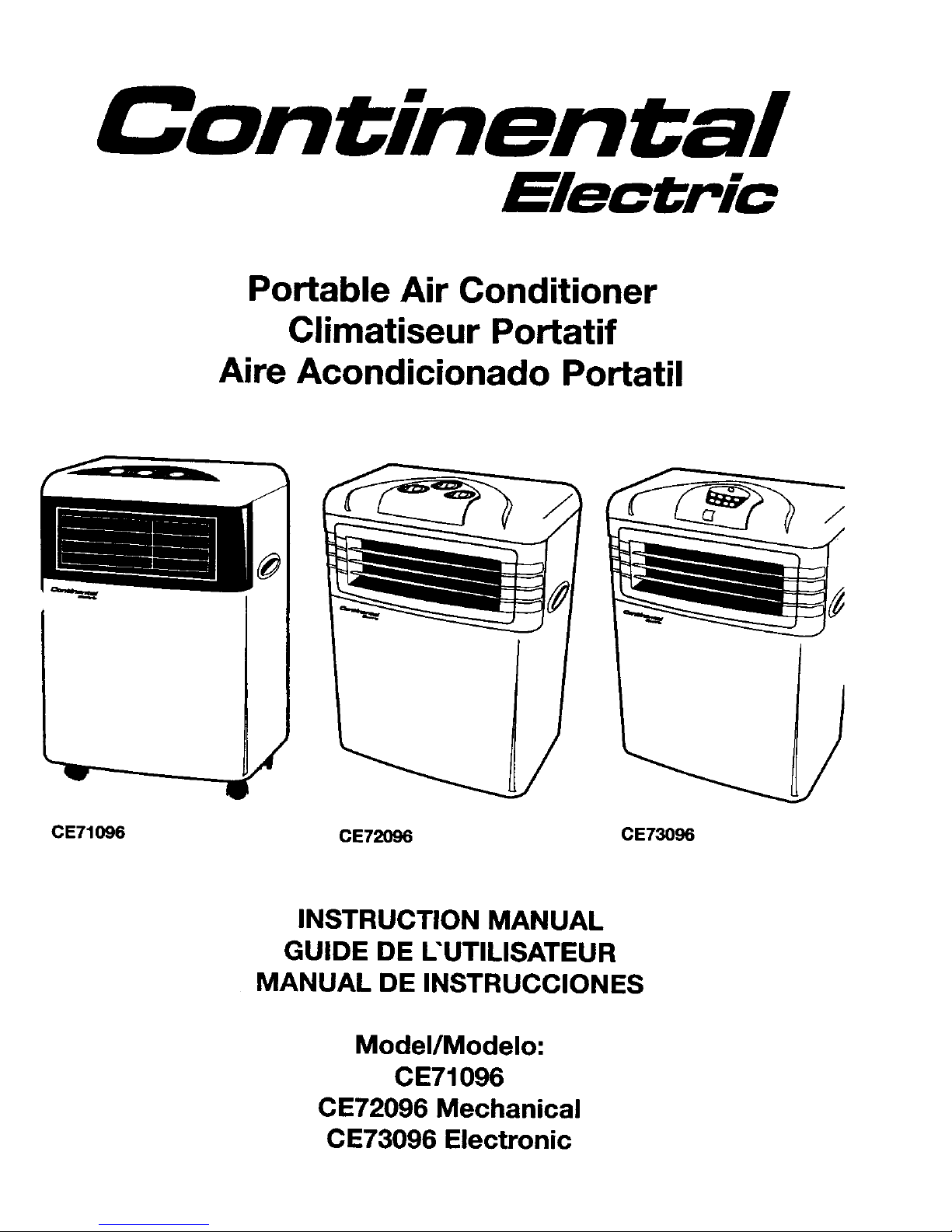

Portable Air Conditioner

Climatiseur Portatif

Aire Acondicionado Portatil

V --""-_

II

CE71096 CE72096 CE73096

INSTRUCTION MANUAL

GUIDE DE L'UTILISATEUR

MANUAL DE INSTRUCCIONES

Model/Modelo:

CE71096

CE72096 Mechanical

CE73096 Electronic

Page 3

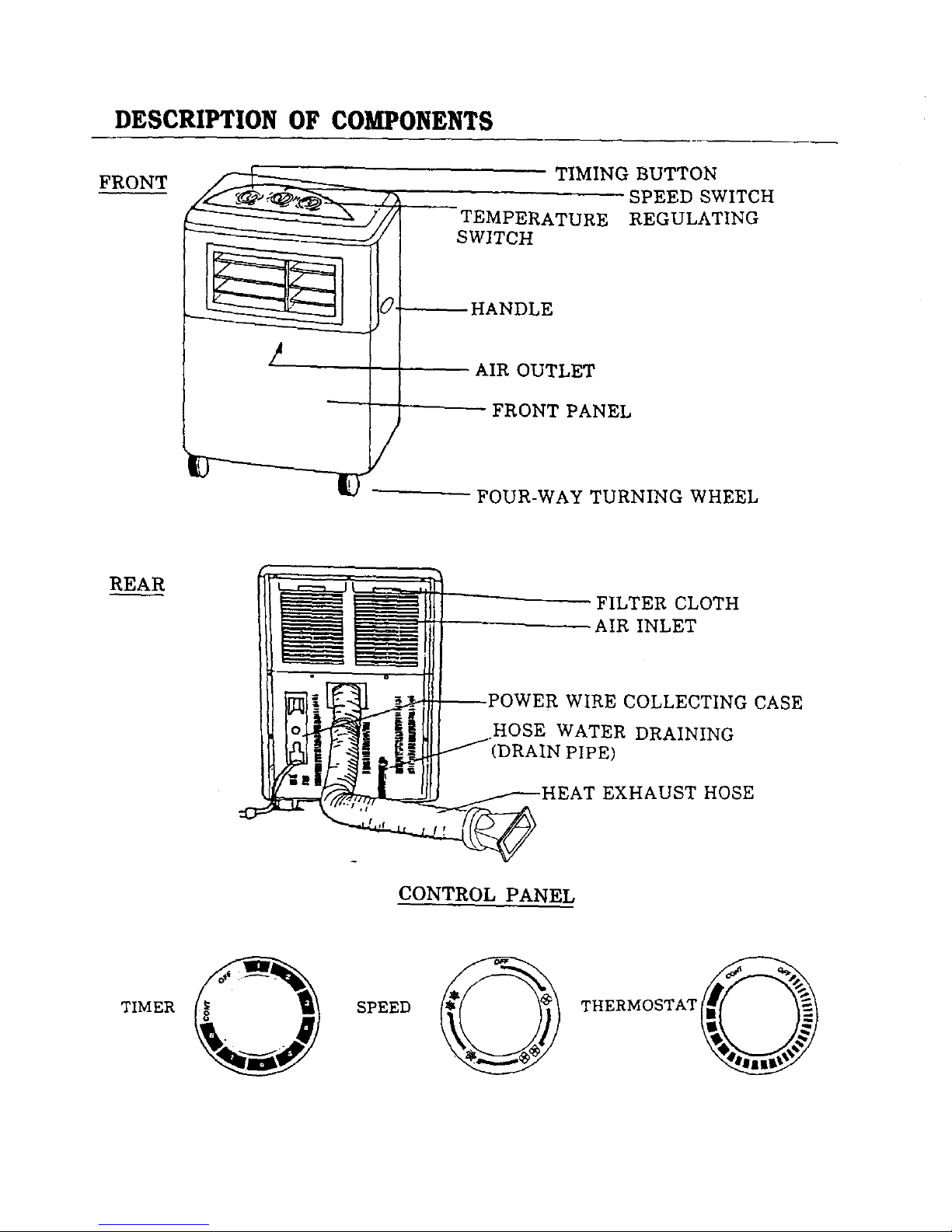

DESCRIPTION OF COMPONENTS

FRONT

TIMING BUTTON

SPEED SWITCH

TEMPERATURE REGULATING

SWITCH

_HANDLE

AIR OUTLET

-- FRONT PANEL

FOUR-WAY TURNING WHEEL

REAR

FILTER CLOTH

AIR INLET

JL-..-]I -_- _POWER WIRE COLLECTING CASE

_Y-----1,_i HOSE WATER DRAINING

_-._K _ /'(DRAIN PIPE)

_I--7-HEATEXHAUSTHOSE

CONTROL PANEL

TIMER

O

SPEED

O

Page 4

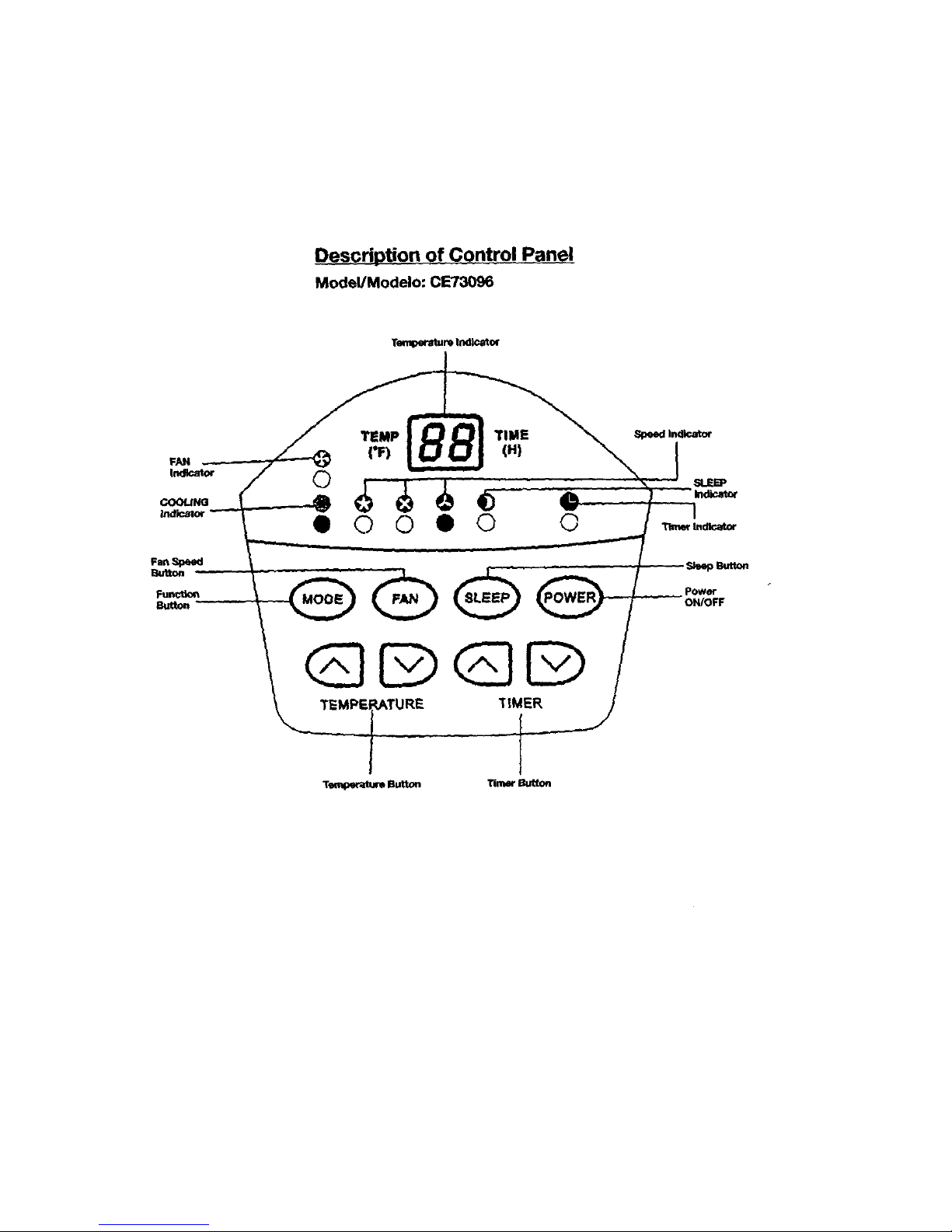

Description of Contro! panel

Model/Modelo: CE73096

Teml_raturetndicatm

FAN

Imllcato¢

COOLING

IndOor

TEMP

0

• Q 0

TIME

(HI

• 0 0

MOOE POWER

_Button

power

ON/OFF

GDGD

T_:_-'_u.m Button Trier Button

Page 5

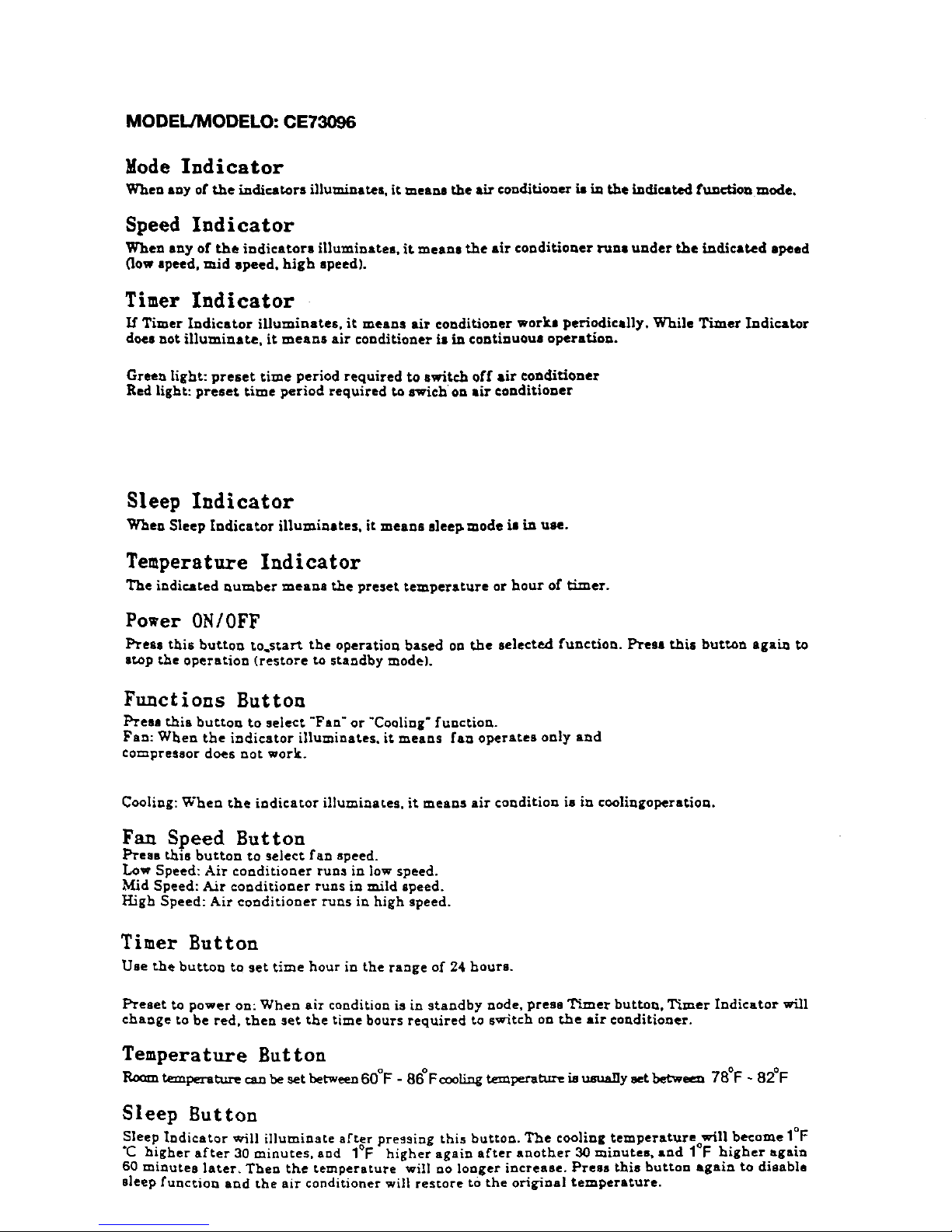

MODEL/MODELO: CE73096

Mode Indicator

When any of the indicators illuminates, it means the air conditioner is in the indicated function mode,

Speed Indicator

When any of theindicatorsilluminates, it meansthe airconditionerruns under the indicated speed

_ow speed, mid speed, high speed).

Timer Indicator

If Timer Indicator illuminates, it means air conditioner works periodically, While Timer Indicator

does not illuminate, it means air conditioner is in continuous operation.

Green light: preset time period required to switch off air conditioner

Red light: preset time period required to swich on air conditioner

Sleep Indicator

When Sleep Indicator illuminates, it means sleel_mode is in use.

Temperature Indicator

The indicated number means the preset temperature or hour of timer.

Power 0N/0FF

Press this button to.start the operation based on the selected function. Press this button again to

stop the operation (restore to standby mode).

Functions Button

Press this button to select"Fan" or "Cooling"function.

Fan: When the indicator illuminates,itmeans fan operates only and

compressor does not work.

Cooling:When the indicatorilluminates,itmeans air condition is in coolingoperation.

Fan Speed Button

Press thisbutton to selectfan speed.

Low Speed: Air conditioner runs inlow speed.

Mid Speed: Air conditioner runs in mild speed.

High Speed: Air conditioner runs inhigh speed.

Timer Button

Use the button to set time hour in the range of 24 hours.

Preset to power on:When air conditionisin standby node, press TLmer buttou,Timer Indicator will

change to be red, then set the time bours required to switch on the air conditioner.

Temperature Button

temperature can be setbetween60°F - 86 °F c_ting t_npex'atu_ iJ usuallysetbetwe_ 78°F ~ 82°F

Sleep Sutton

Sleep Indicator will illuminateafterpressing thisbutton.The coolingtemperatureo,wi!lbecome 1°[:

higher after 30 minutes, and 1 F higher again after another 30 minutes, and I r nigher again

60 minutes later, Then the temperature will no longer increase. Press this button again to disable

sleepfunction and the air conditionerwillrestoretOthe originaltemperature.

Page 6

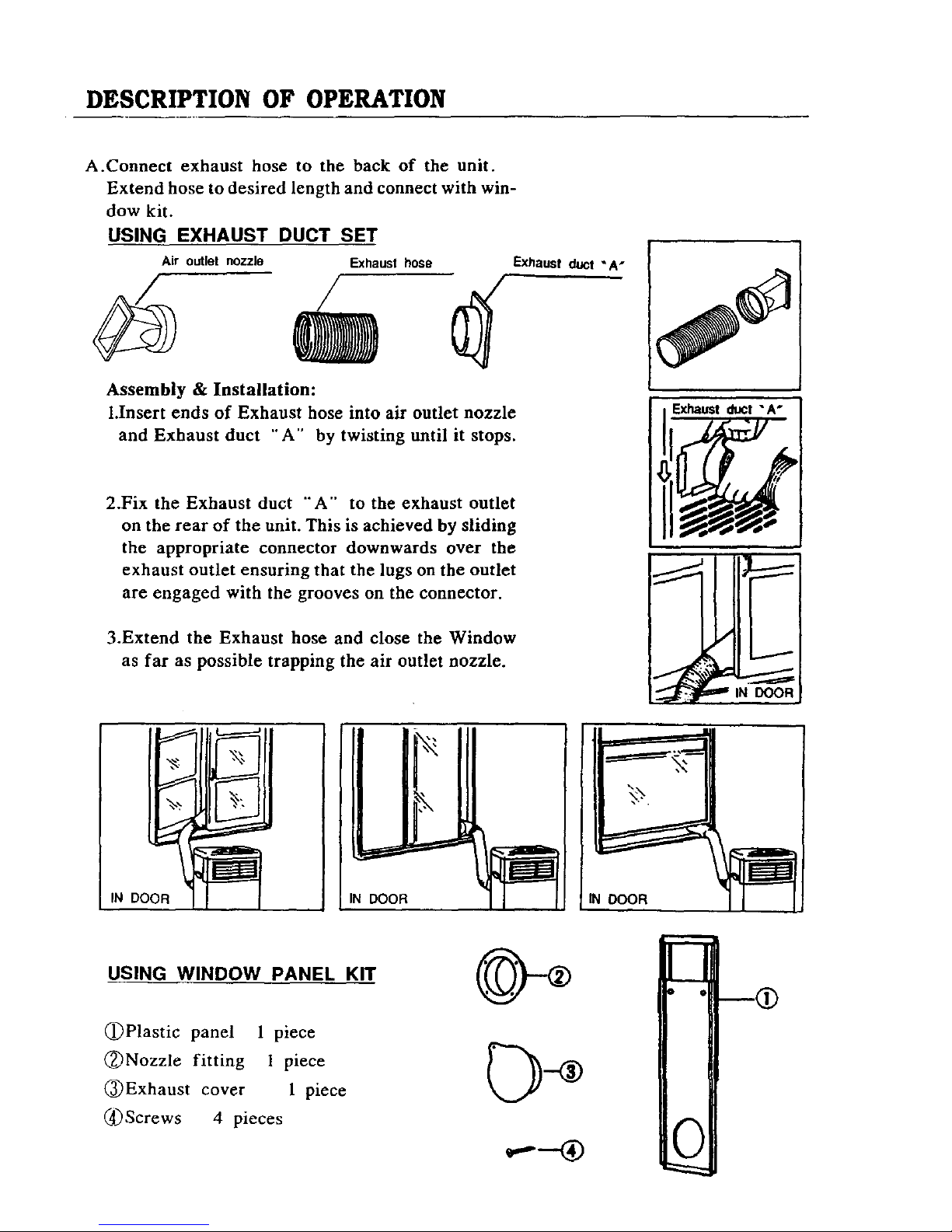

DESCRIPTION OF OPERATION

A.Connect exhaust hose to the back of the unit.

Extend hose to desired length and connect with win-

dow kit.

USING EXHAUST DUCT SET

Air outlet nozzle Exhaust hose

EXhaust duct "A n

Assembly & Installation:

l.Insert ends of Exhaust hose into air outlet nozzle

and Exhaust duct "A" by twisting until it stops.

2.Fix the Exhaust duct "A'" to the exhaust outlet

on the rear of the unit. This is achieved by sliding

the appropriate connector downwards over the

exhaust outlet ensuring that the lugs on the outlet

are engaged with the grooves on the connector.

3.Extend the Exhaust hose and close the Window

as far as possible trapping the air outlet nozzle.

EXhaust duct "A"

DOOR IN

I

IN DOOR

USING WINDOW PANEL KIT

(_)Plastic panel 1 piece

(_)Nozzle fitting 1 piece

(_)Exhaust cover 1 piece

(4) Screws 4 pieces

n

D OI

i

0

Page 7

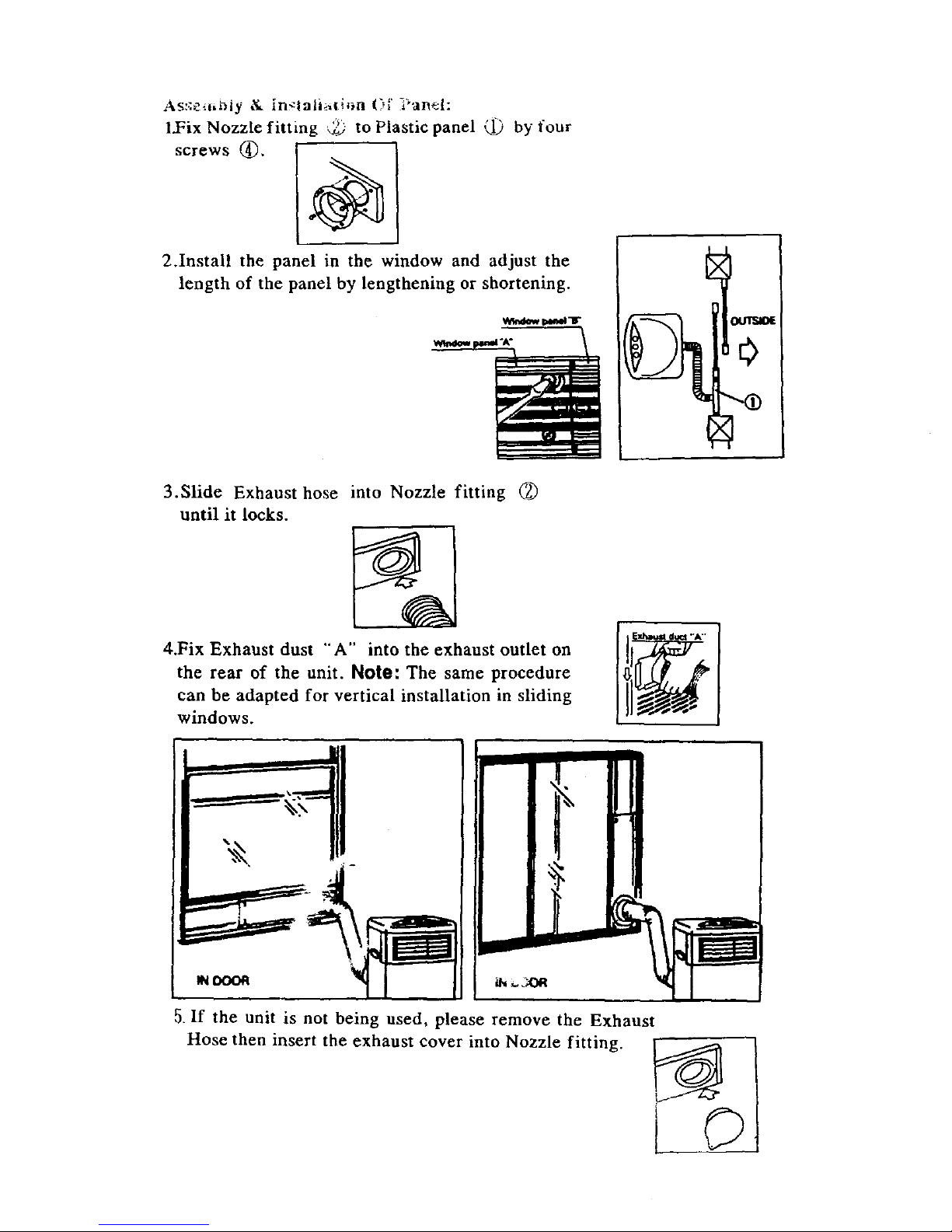

As:.:e.,_tLl-_ty & in_lati_li_a _3_' _anel:

l.Fix Nozzle fitting , :'_ to Plastic panel _ by four

screws I

2.Install the panel in the window and adjust the

length of the panel by lengthening or shortening.

|lol !

3.Slide Exhaust hose into Nozzle fitting (_

until it locks.

4.Fix Exhaust dust "A" into the exhaust outlet on

the rear of the unit. Note: The same procedure

can be adapted for vertical installation in sliding

windows.

iN,.,,X_

5. If the unit is not being used, please remove the Exhaust

Hose then insert the exhaust cover into Nozzle fitting.

Page 8

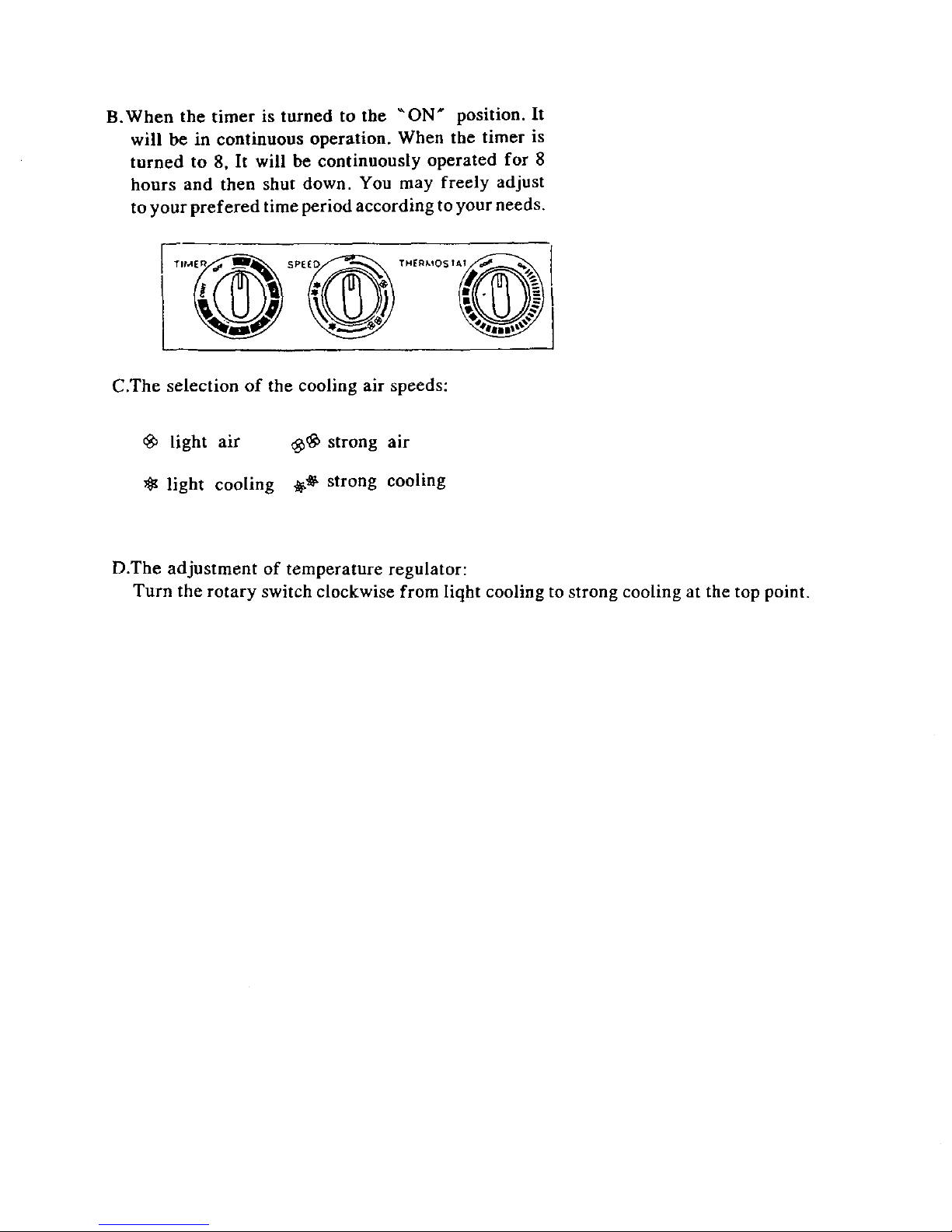

B.When the timer is turned to the "ON" position. It

will be in continuous operation. When the timer is

turned to 8. It will be continuously operated for 8

hours and then shut down. You may freely adjust

to your prefered time period according to your needs.

C.The selection of the cooling air speeds:

light air _b_ strong air

:_ light cooling _ strong cooling

D.The adjustment of temperature regulator:

Turn the rotary switch clockwise from liqht cooling to strong cooling at the top point.

Page 9

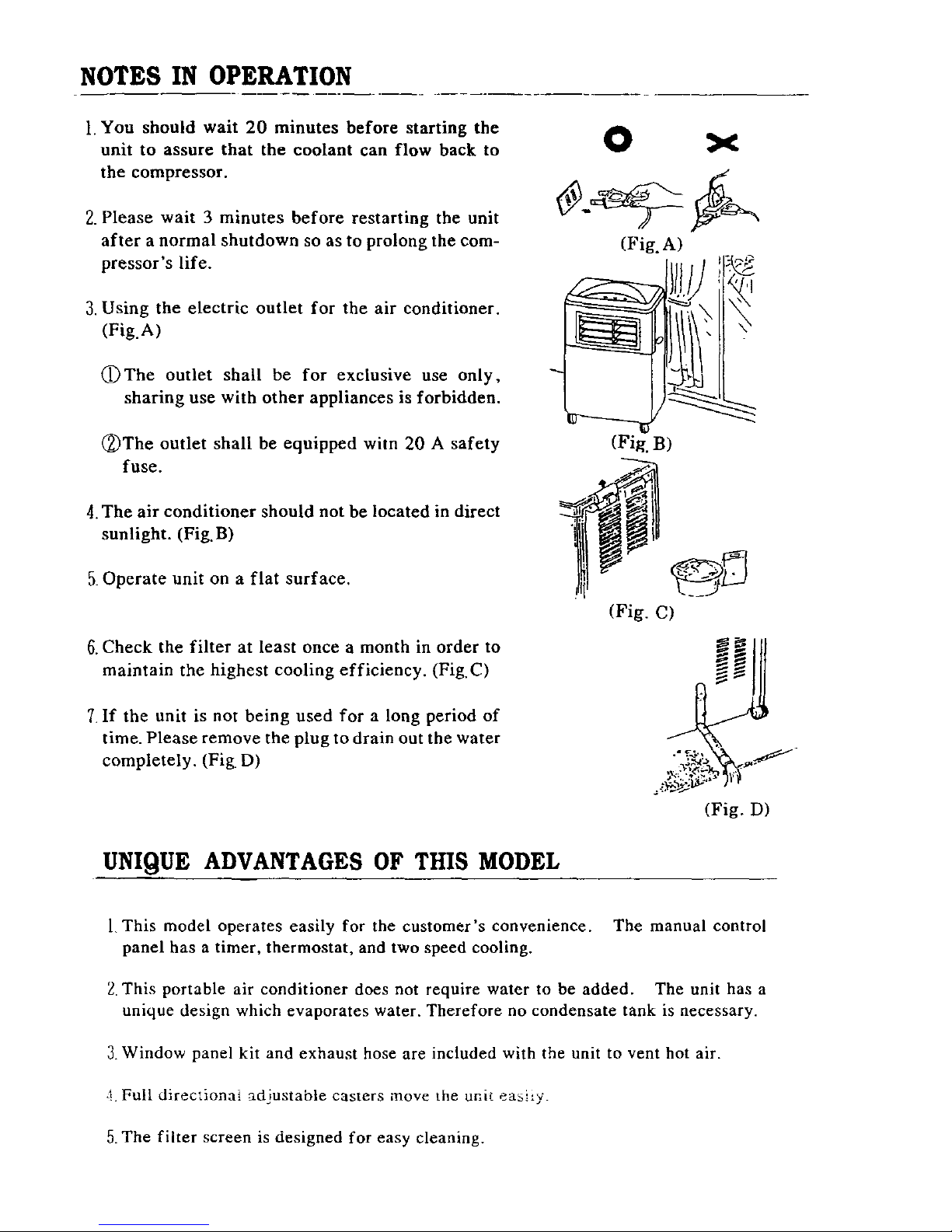

NOTES IN OPERATION

1. You should wait 20 minutes before starting the

unit to assure that the coolant can flow back to

the compressor.

2. Please wait 3 minutes before restarting the unit

after a normal shutdown so as to prolong the com-

pressor's life.

3. Using the electric outlet for the air conditioner.

(Fig.A)

(DThe outlet shall be for exclusive use only,

sharing use with other appliances is forbidden.

(_)The outlet shall be equipped wim 20 A safety

fuse.

4. The air conditioner should not be located in direct

sunlight. (Fig.B)

5. Operate unit on a flat surface.

6. Check the filter at least once a month in order to

maintain the highest cooling efficiency. (Fig.C)

7.If the unit is not being used for a long period of

time. Please remove the plug to drain out the water

completely. (Fig. D)

O

(Fig.A)

_ /r

-3

(Fig. B)

(Fig. C)

(Fig. D)

UNIQUE ADVANTAGES OF THIS MODEL

l, This model operates easily for the customer's convenience. The manual control

panel has a timer, thermostat, and two speed cooling.

2. This portable air conditioner does not require water to be added. The unit has a

unique design which evaporates water. Therefore no condensate tank is necessary.

3. Window panel kit and exhaust hose are included with the unit to vent hot air.

-! Full directional adjustable casters move the unit easiiy.

5. The filter screen is designed for easy cleaning.

Page 10

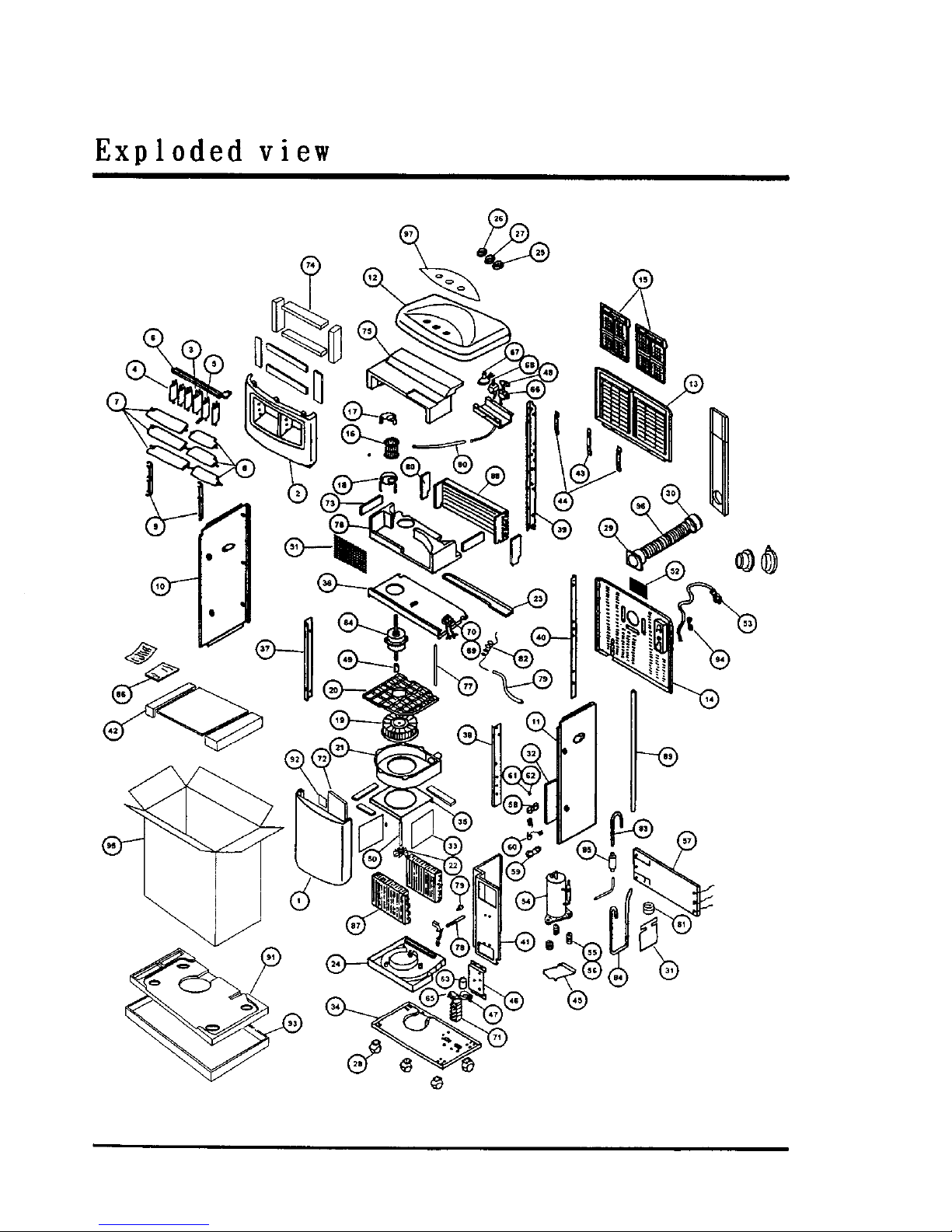

Exploded view

Page 11

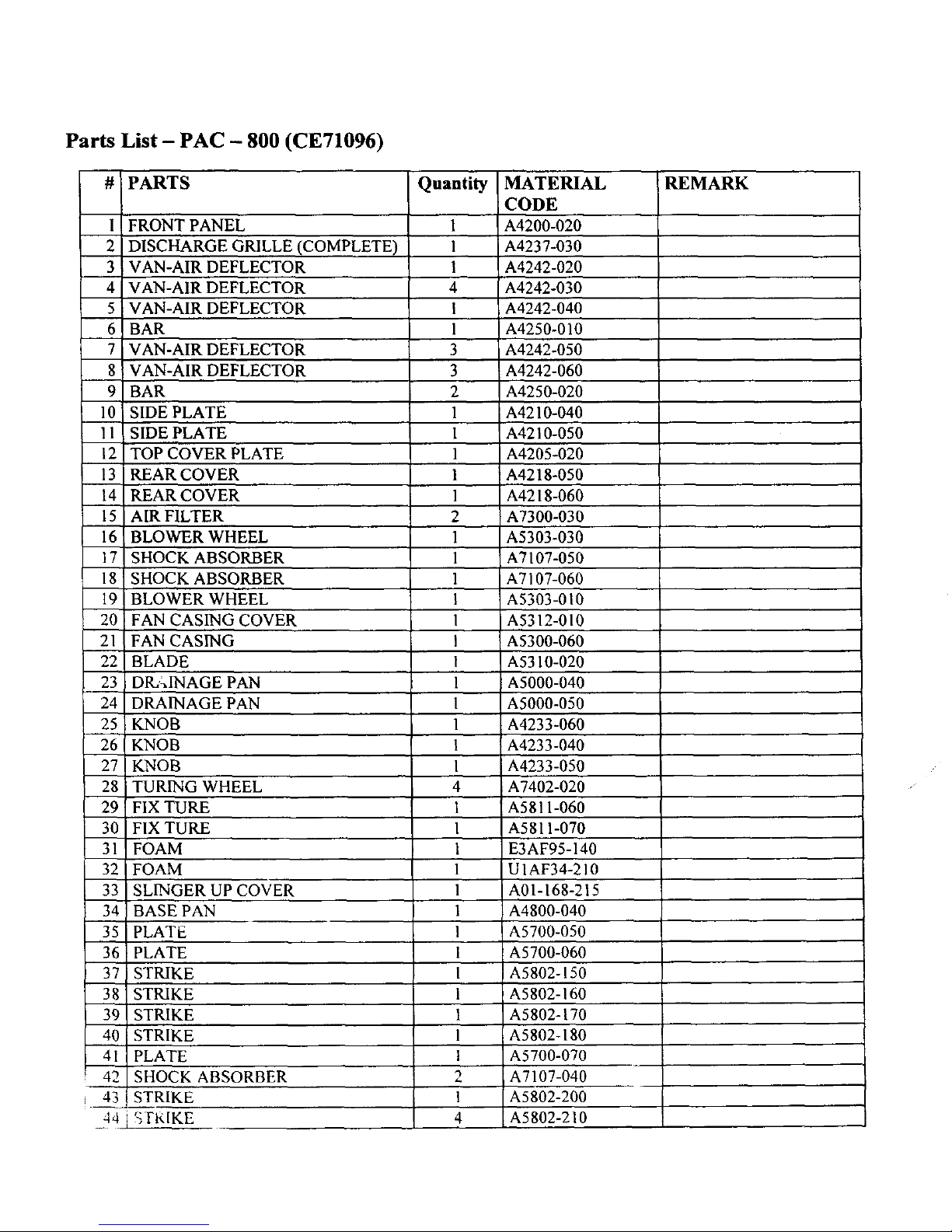

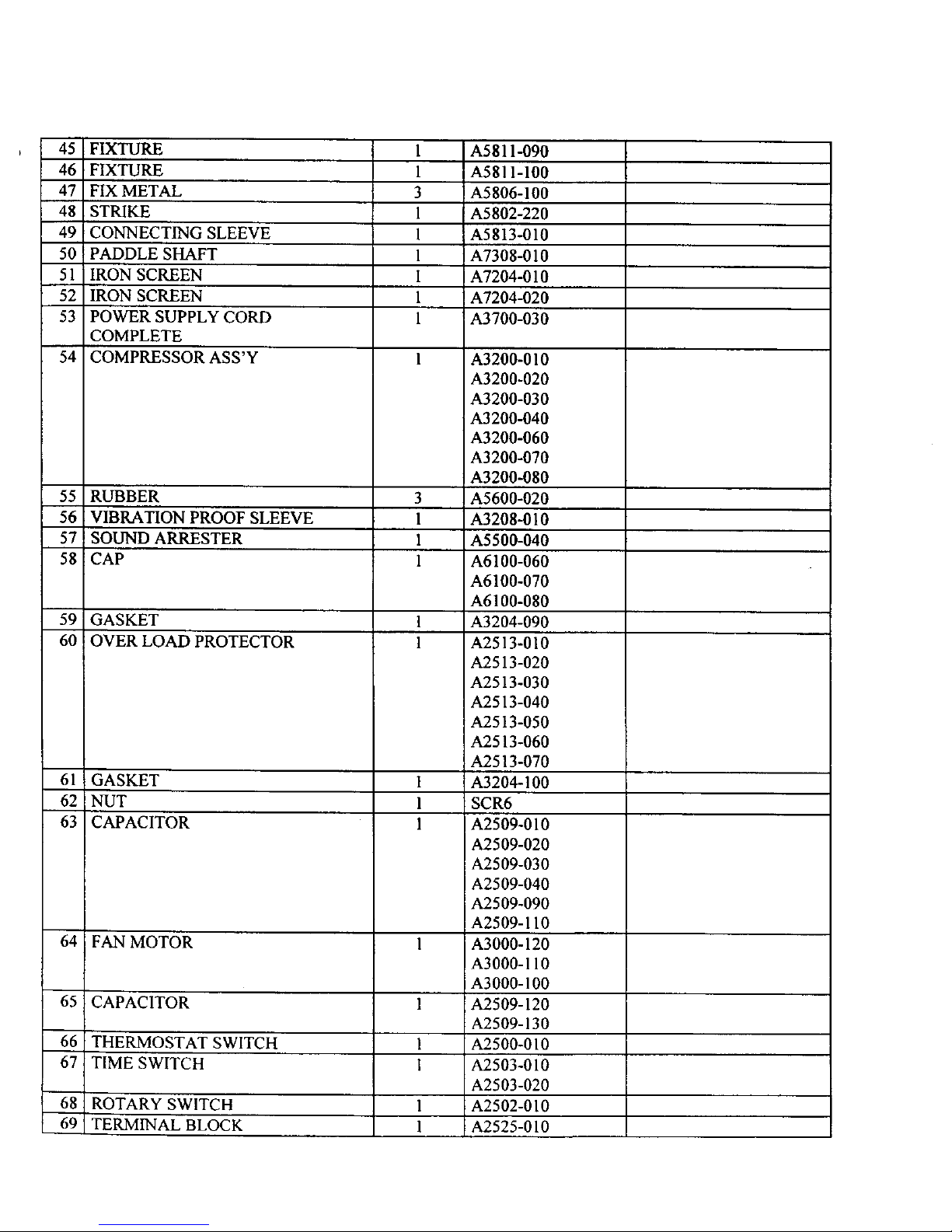

Parts List - PAC - 800 (CE71096)

#

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

2O

21

22

23

24

25

26

27

28

29

30

31

32

33

PARTS

FRONT PANEL

DISCHARGE GRILLE (COMPLETE)

VAN-AIR DEFLECTOR

VAN-AIR DEFLECTOR

VAN-AIR DEFLECTOR

BAR

VAN-AIR DEFLECTOR

VAN-AIR DEFLECTOR

BAR

SIDE PLATE

SIDE PLATE

TOP COVER PLATE

REAR COVER

REAR COVER

AIR FILTER

BLOWER WHEEL

SHOCK ABSORBER

SHOCK ABSORBER

BLOWER WHEEL

FAN CASING COVER

FAN CASING

BLADE

DR, ,INAGE PAN

DRAINAGE PAN

KNOB

KNOB

KNOB

TURING WHEEL

FIX TURE

FIX TURE

FOAM

FOAM

SLINGER UP COVER

Quantity

1

1

1

4

|

1

3

3

2

1

1

1

1

1

2

1

1

1

1

1

I

1

1

1

1

1

1

4

1

1

1

1

1

MATERIAL

CODE

A4200-020

A4237-030

A4242-020

A4242-030

A4242-040

A4250-010

A4242-050

A4242-060

A4250-020

A4210-040

A4210-050

A4205-020

A4218-050

A4218-060

A7300-030

A5303-030

A7107-050

A7107-060

A5303-010

A5312-010

A5300-060

A5310-020

A5000-040

A5000-050

A4233-060

A4233-040

A4233-050

A7402-020

A5811-060

A5811-070

E3AF95-140

U1AF34-210

A01-168-215

34 BASE PAN 1 A4800-040

35 PLATE 1 A5700-050

36 PLATE 1 A5700-060

37 i STRIKE 1 A5802-150

38 STRIKE 1 A5802-160

39 STRIKE 1 A5802-170

40 ' STRIKE 1 A5802-180

41 PLATE 1 A5700-070

42 SHOCK ABSORBER 2 A7107-040

43 STRIKE 1 A5802-200

44 _FI<IKE 4 A5802-210

REMARK

Page 12

45 FIXTURE

46 FIXTURE

47 FIX METAL

48 STRIKE

49 CONNECTING SLEEVE

50 PADDLE SHAFT

51 IRON SCREEN

52 IRON SCREEN

53 POWER SUPPLY CORD

COMPLETE

54 COMPRESSOR ASS'Y

55 RUBBER

56 VIBRATION PROOF SLEEVE

57 SOUND ARRESTER

58 CAP

1

1

3

1

1

1

1

1

1

3

1

1

1

59 GASKET 1

60 OVER LOAD PROTECTOR 1

61 GASKET

62 NUT

63 CAPACITOR

64 FAN MOTOR

65 CAPACITOR

66 THERMOSTAT SWITCH

67 TIME SWITCH

68 ROTARY SWITCH

69 TERMINAL BLOCK

1

1

1

1

1

I

1

1

A5811-090

A5811-100

A5806-100

A5802-220

A5813-010

A7308-010

A7204-010

A7204-020

A3700-030

A3200-010

A3200-020

A3200-030

A3200-040

A3200-060

A3200-070

A3200-080

A5600-020

A3208-010

A5500-040

A6100-060

A6100-070

A6100-080

A3204-090

A2513-010

A2513-020

A2513-030

A2513-040

A2513-050

A2513-060

A2513-070

A3204-100

SCR6

A2509-010

A2509-020

A2509-030

A2509-040

A2509-090

A2509-110

A3000-120

A3000-110

A3000-100

A2509-120

A2509-130

A2500-010

A2503-010

A2503-020

A2502-010

A2525-010

Page 13

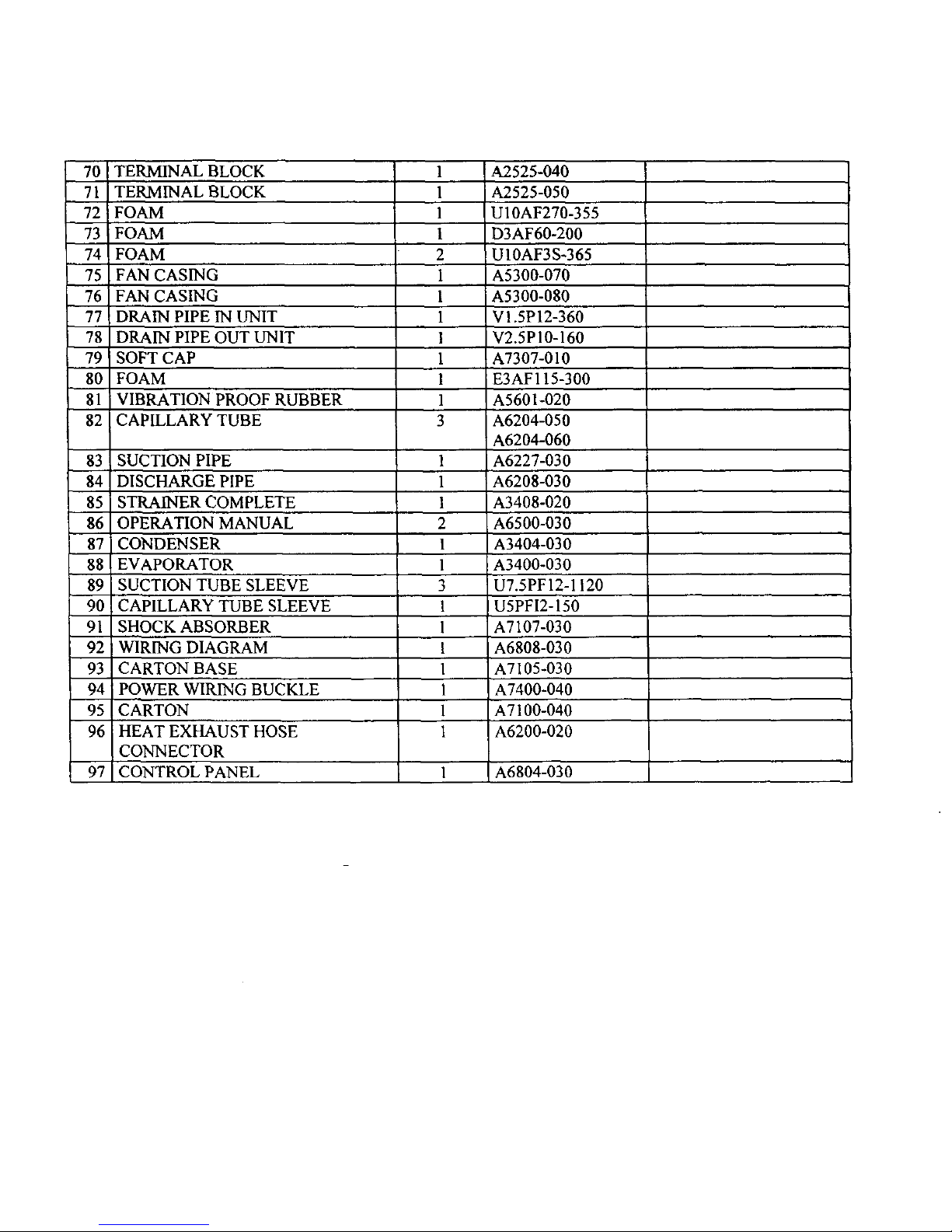

70 TERMINAL BLOCK

71 TERMINAL BLOCK

72 FOAM

73 i FOAM

74 FOAM

75 FAN CASING

76 FAN CASING

77 ! DRAIN PIPE IN UNIT

78 DRAIN PIPE OUT UNIT

79 I SOFT CAP

80 FOAM

81 VIBRATION PROOF RUBBER

82 CAPILLARY TUBE

1

1

1

1

2

1

l

1

!

1

l

1

3

83 SUCTION PIPE 1

84 DISCHARGE PIPE 1

85 STRAINER COMPLETE 1

86 OPERATION MANUAL 2

87 CONDENSER 1

88 EVAPORATOR 1

89 SUCTION TUBE SLEEVE 3

90 CAPILLARY TUBE SLEEVE !

91 SHOCK ABSORBER 1

92 WIRING DIAGRAM !

93 CARTON BASE 1

94 POWER WIRING BUCKLE 1

95 CARTON 1

96 HEAT EXHAUST HOSE 1

CONNECTOR

97 CONTROL PANEL 1 A6804-030

A2525-040

A2525-050

U10AF270-355

D3AF60-200

UIOAF3S-365

A5300-070

A5300-080

VI.SP12-360

V2.5P10-160

A7307-010

E3AF115-300

A5601-020

A6204-050

A6204-060

A6227-030

A6208-030

A3408-020

A6500-030

A3404-030

A3400-030

U7.5PFI2-1120

U5PFI2-150

A7107-030

A6808-030

A7105-030

A7400-040

A7100-040

A6200-020

Page 14

Continental

_ec_r'ic

Portable Air Conditioner

Climatiseur Portatif

Aire Acondicionado Portatil

INSTRUCTION MANUAL

GUIDE DE L'UTILISATEUR

MANUAL DE INSTRUCCIONES

Model/Modble/Modelo:

CE77126/CE75096/CE76096/CE77096

Page 15

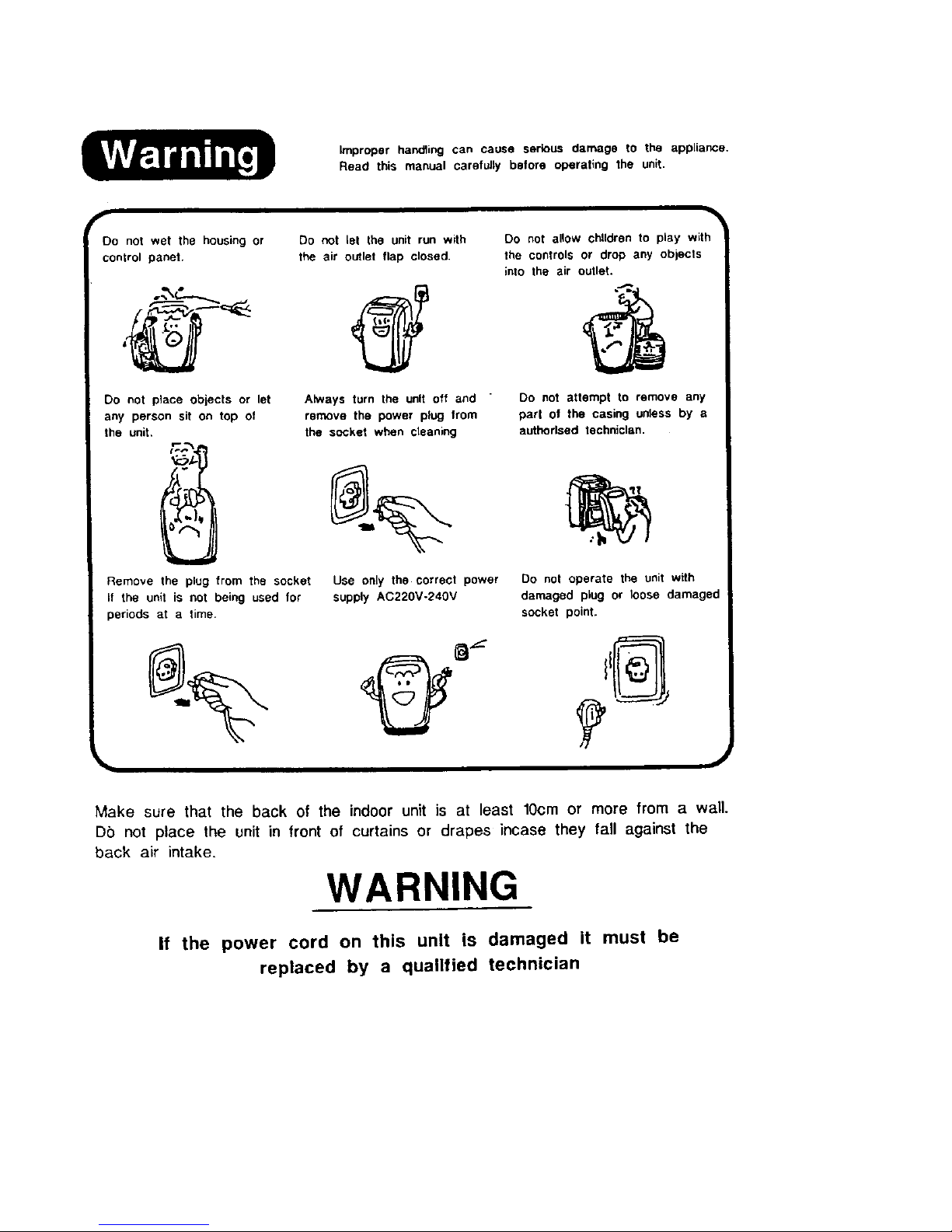

Improper handling can cause serious damage to the appliance.

Read this manual carefully before operating the unit.

f

Oo not wet the housing or

control panel

Do not place obiects or let

any person sit on top of

the unit.

_c_

C

Remove the plug from the socket

if the unit is not being used for

periods at a time.

Do not let the unit run with

the air outlet flap closed.

Always turn the unit off and "

remove the power plug from

the socket when cleaning

Use only the correct power

supply AC220V-24OV

Do not allow chUdren to play with

the controls or drop any objects

into the air outlet.

Do not attempt to remove any

part of the casing unless by a

authorlsed technician.

Do not operate the unit with

damaged plug or loose damagec

socket point.

Make sure that the back of the indoor unit is at least lOcm or more from a wall.

Do not place the unit in front of curtains or drapes incase they tall against the

back air intake.

WARNING

If the power cord on this unit is damaged it must be

replaced by a qualified technician

Page 16

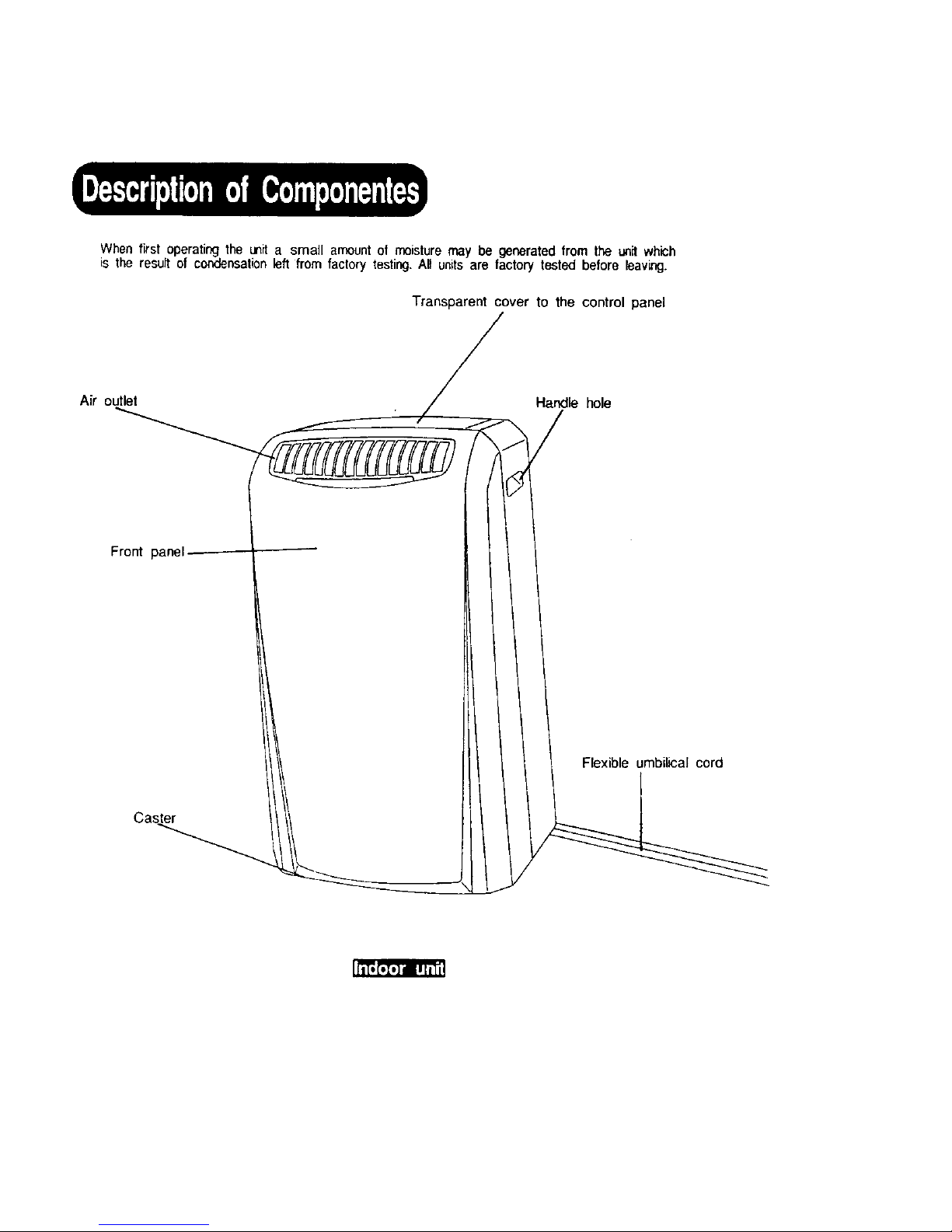

When first operating the unit a small amount of moisture may be generated lrom the unit which

is the result of condensation left from factory testing. All units are factory tesled before leaving.

Transparent cover to the control panel

Air outlet Handle hole

Front panel

Flexible umbilical cord

Caster

Page 17

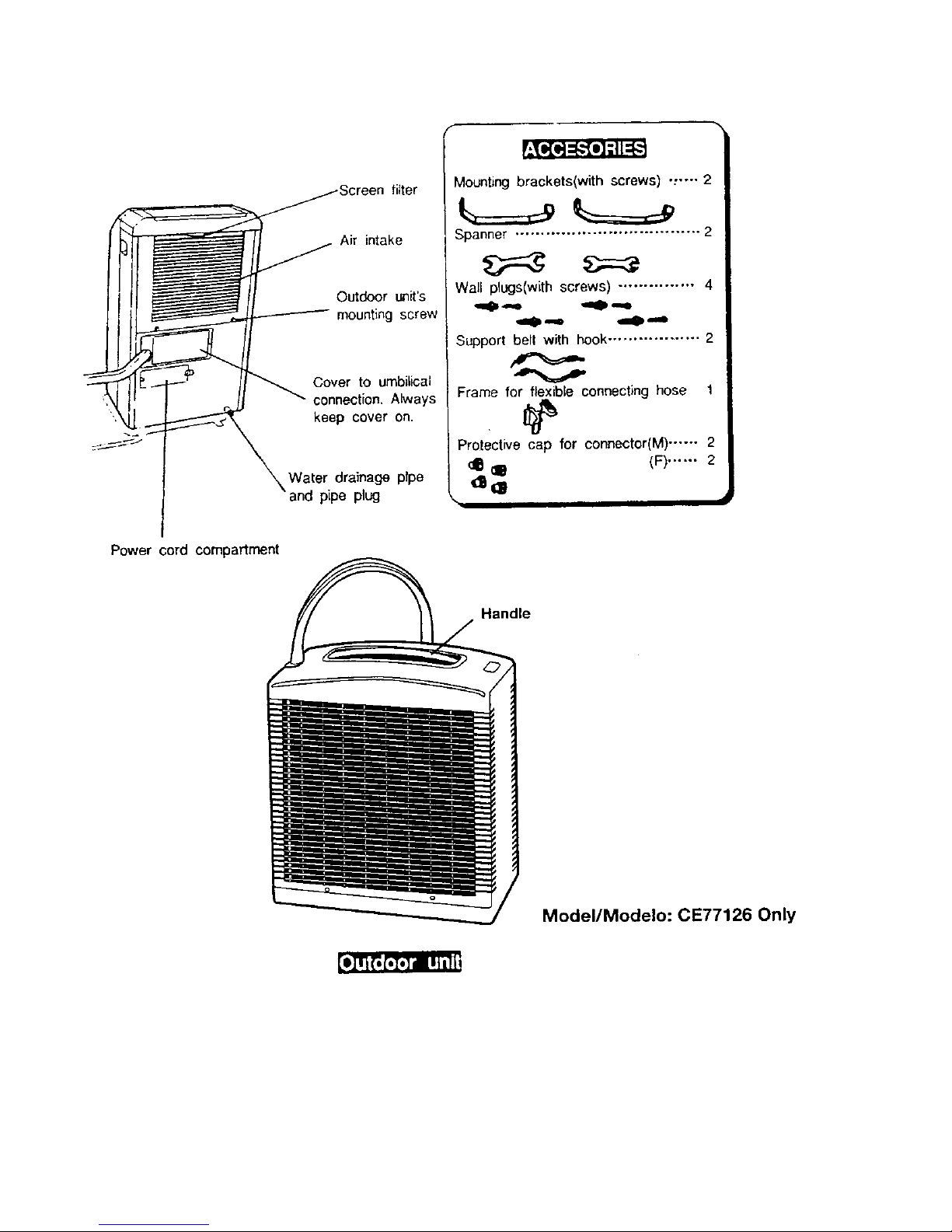

Screenfilter

tl _ II O.,_r _i,'s

"_,_ ._ _ _" kO:npe_toOerAon.ays

Mounting brackets(with screws) ._--. 2

_=__ /

,Spanner .................................... 21

Wall plugs(with screws) ............... 4|

"---- "=-- /

Support _hook .................. 2/

Frame,or b,econnectinghose'/

Protective cap for connector(M) ...... 2/

_IB (ll (F)...... 2/

/

\ ,,, , J

Power cord compartment

Handle

Model/Modelo: CE77126 Only

Page 18

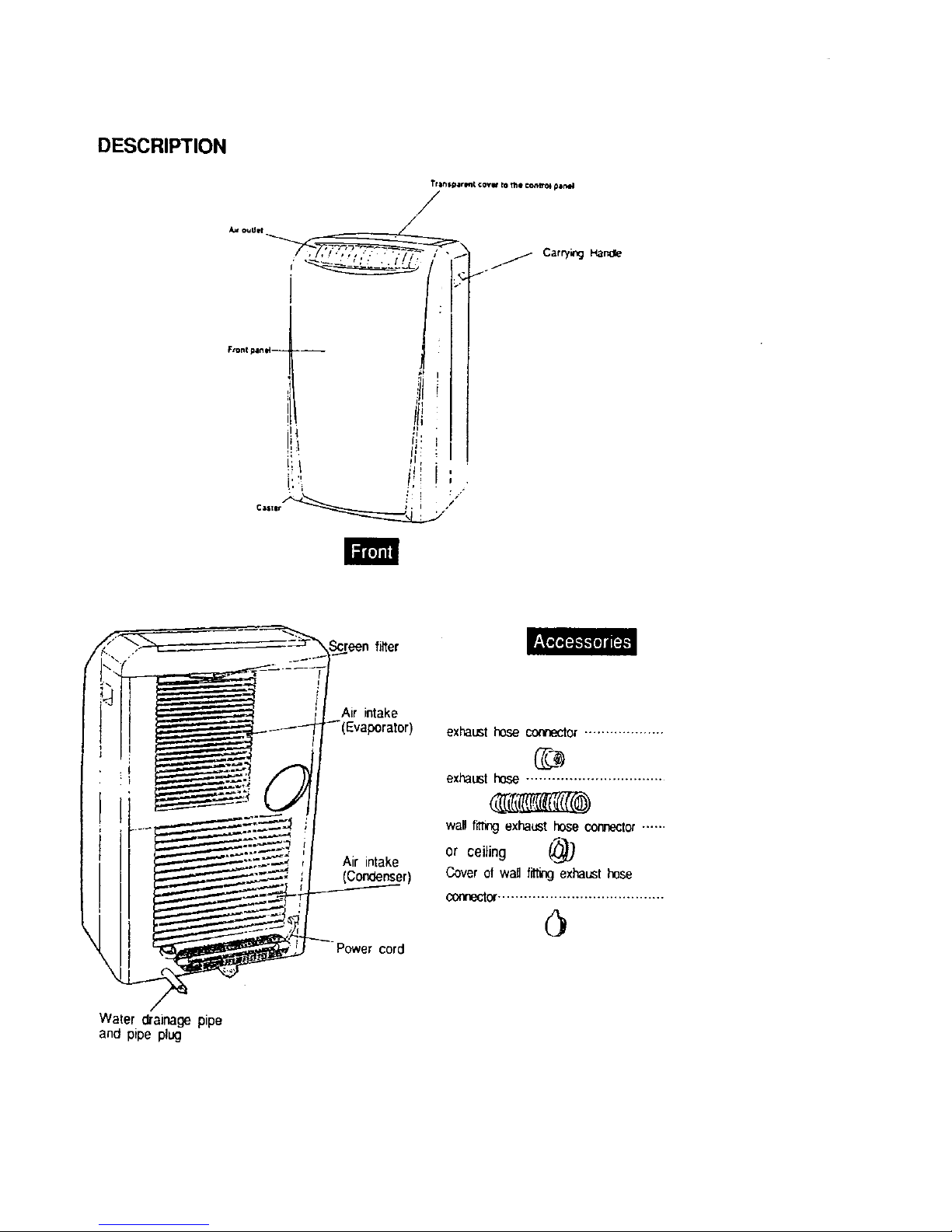

DESCRIPTION

Tr_$_r_t COVW to the ¢entto_ panel

/

FtQnlplnl_-- .__

P,

!_ Iii

Care!w',gHande

Air intake

Air intake

(Condenser)

Power cord

exhaust hose connector ...................

exhaust hose ................................

wan fit_ exhaust hose connector ......

or ceiling (,_

Cover ol wai_fitting exhausthose

connector .......................................

Water draina_;epipe

and pipe plug

Page 19

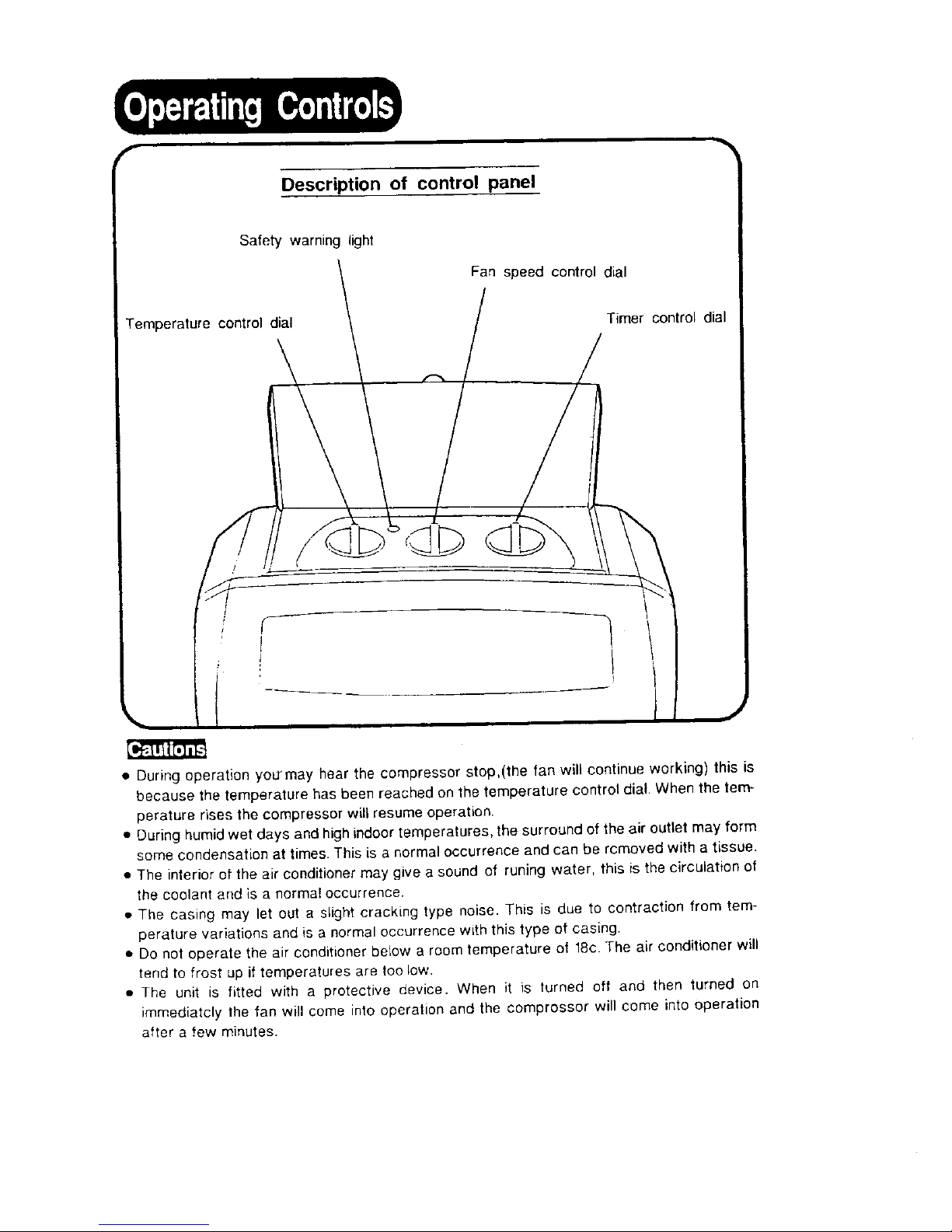

Description of control panel

Safety warnin0 light

Fan speed control dial

Temperature control dial

Timer control dial

• During operation yoU_may hear the compressor stop,(the fan will continue working) this is

because the temperature has been reached on the temperature control dial. When the tem-

perature rises the compressor will resume operation.

• During humid wet days and high indoor temperatures, the surround of the air outlet may form

some condensation at times. This is a normal occurrence and can be rcmoved with a tissue.

• The interior of the air conditioner may give a sound ot runing water, this is the circulation of

the coolant and is a normal occurrence.

• The casing may let out a slight cracking type noise. This is due to contraction from tem-

perature variations and is a normal occurrence with this type of easing.

• Do not operate the air conditioner below a room temperature ot 18c The air conditioner will

tend to frost up if temperatures are too low.

• The unit is fitted with a protective device. When it is turned off and then turned on

immediately the fan will come into operation and the comprossor will come into operation

after a few minutes.

Page 20

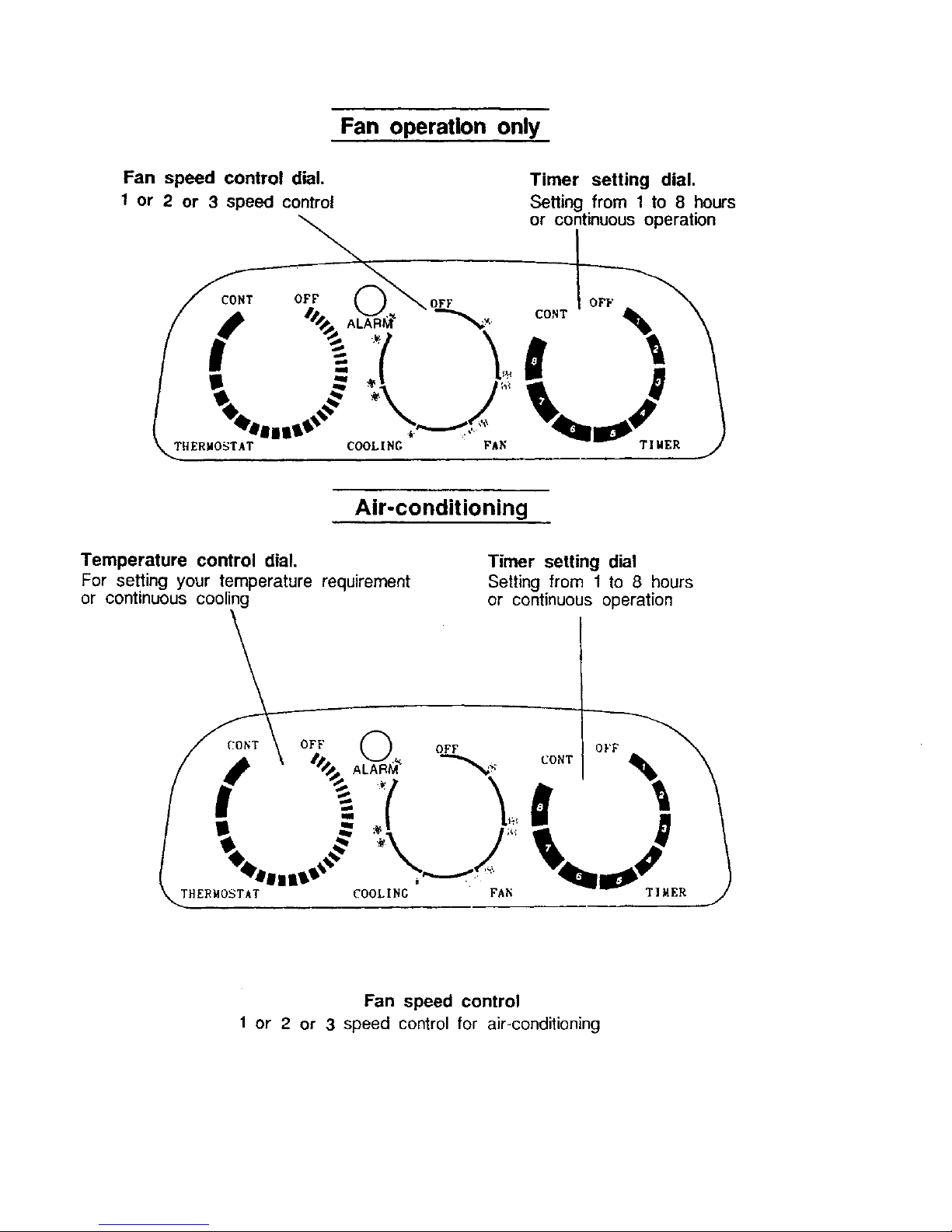

Fan operation only

Fan speed control dial.

t or 2 or 3 speed control

CONT OFF

Timer setting dial.

Setting from 1 to 8 hours

or continuous operation

OFF OFF

THERMOSTAT COOLING P; TIMER

Air-conditioning

Temperature control dial.

For setting your temperature requirement

or continuous cooling

Timer setting dial

Setting from 1 to 8 hours

or continuous operation

OFF

CONT

TII4ER

Fan speed control

1 or 2 or 3 speed control for air-conditioning

Page 21

Control Panel

Model/Modelo: CE76096 Only

[_oe [_]o ,_

_o0 _o_ o o

@@®©@@

(( (

12 "On/OfF key

13 Alarm light: comes on when the condensatecollecting tank

isfull.

14 "Function" key: (or selectingthe operating mode:ventilation

only or air conditioning: the light (a) or (b) comes on

depending on the mode chosen.

15 Ventilation speedselectionkey

Light{c)on: slow ventilation speed

Light (d) on: medium ventilation speed

Light (e) on: high ventilation speed

16 "Night operation" key:the light (f) comeson.

17 "Programming" keys: according to the type of program-

ming chosen (see page 10), a green or red light comes

on(g).

18 Temperatureselectionkeys

19 Digital display dial

REMOTE CONTROL

Model/Modelo: CE77096 Only

25 KeyForenabling and settingthe timer

26 Key for enabJing the night mode ©

27 Keyfor selectingthe ventilation speed

28 Keybr selecting the operating mode

29 Key On/Off

Page 22

• Periodiccleaning and maintenance may maximize the

air condition'sfunctions and optimal condition.

• Prior to cleaning and maintenance, please make sure

to temove the plug from power socket to ensure safety.

#,r

Filter cleaning

Check once a week

• Use lukewarm water and very mild

detergent when washing fgter rinse

with clean cold water

• Use a vacuum or brush to remove

fluff/dust from the filter.

Maintenance on the front

panel and housing

• Do not use chemicals or solvents

for cleaning the unit.

• Use a damp cloth for cleaning.

You may use a mild detergent to

remove stubborn stains.

Maintenance for the

outdoor unit

• Check the out door unit periodicallyand

ctear any foreign objects, leaves and paper

that may be there. If possible try to keep

the unit shaded from strong direct sun light.

End of season maintenance

1.Removethe water drainirE:Jplug located at

the rear bottom of the air conditioner,

replace the plug after the condensation

has been drained from the water tank.

2.Turm on the fan operation for a period

ot time to dry the interior of the air

conditioner.

3.Stop the operation,and remove the power

cord plug Item the wallpower socket and

store it into the power cord comparment

located on the rear of the indoorunit+

4.Wipe clean the outdoorunit and hang it to

the back of the indoor unit.

5.Coverthe air conditionerbefore putting it in

the storage.

Page 23

p,-

Clean the filter periodically

• When using it in normal conditions,

please clean the filter at least once

every two weeks

.....

• it you are using the unit in an area

with excessive dust/fluff make sure

you check and clean filter each week.

- ...

• If the screen is not kept clean it can

increase your power consumption

and reduce the cooling efficiency.

• Pedodls cleaning, maintenance and proper

use may not only maximize the air

conditioner's functions, but also can avoid

increasing unnecessary expense.

Take note of the following

points

• Avoid direct sun lighton the unit

• Maintain proper ventilation around

lhe unit.

• Avoid opening doors and windows

as much as possible.

• Avuid excessive number of peopre

in the room.

Page 24

Steps in disassembly

t,Turn off the air conditioner,and remove

the plug from the power sucket

Upon turning off the air conditioner, leave

it idle for at least 30 minutes; the

disassembly can then be implemented

after the system has been stabilized.

%

2.Use a Philips-head screw driver to

remove the cover.

3Disconnect the electrical connector

by pressing clip holders.

4,Remove the metal holding brackets

5.Remove the insulatingfoam around

the upper connector.

• This procedure should be carried out by

a professional person to avoid expensive

mistakes.

6.Use the 2 spanners provided to

disconnect the 2 pipes,

Make sure the tubes and connectors

are kept level while disconnecting to

avoid coolant leaking.

7,Screw the protective caps onto the

ends after disconnection of each pipe

8.Separate the clamping tie on the black

Water pipe, Gradually release the water

pipe and place your finger over the end

to prevent water in the tube coming out.

Have a conta_,ler ready to collect any

excess water from the tube.

Steps in connecting

• Always remember to keep the

connecting pipes level with

the connecing point when

re-assembllog

• When re-connecting the uni[ follow the

above steps in reverse.

• Use your fingers to connectthe threads

and then t_hten with the spanners

provided

• After connectionplease use soap suds

to check for leaks in the coolant pipe.

Please remember, this procedure must be

followed each time.

J

MODEL/MODELO: 0E77126

Page 25

F

IMPORTANT: Do not have any sharp hands or twisting

it the umbilicalcord.

For permancnt installation follow instructlens. If you are

not sure contact a service company.

The Indoor Unit

• METHOD I :

The umbilical cord can pass through partly open door or window.

The location of the indoor unit must

have at lease 10cm space at the rear

and away from curtains/drapes.

_,METHOD II :

The umbilical cord can be passed through a hole in the window or the window

frame were a gap has been shaped out.

When using the later use the

plastic frame supplied. When the

air conditioner is being stored

away cap can be placed over the

frame to seal the hole off.

• METHOD tll :

For fitting through a hole in the wall disconnectthe umbilical cord as described

on page 8 and pass cord through the hole from the outside. Use the plastic

tramo for the umbilical cord when using this mcthod.

• if you are not sure or happy

disconnecting and reconnecting

the cord contact a

local service person.

• Remember to use soap suds

to check for refrigerant leaks

after conncctlen each time,

II

Page 26

The Installation of heat exhaust hose

Model/Modelo: CE75096, CE76096, CE77096

USING EXHAUST DUCT SET

1.Connect one heat exhaust hose connector anti-clockwise to the heat exhaust

hose.

2.Connect the other heat exhaust hose anti-clockwise to the other end of

heat exhaust hose then connect the connector to the appliance clockwise.

&Extend the exhaust hose and close the window as far as possible trapping

the heat exhaust hose connector.

U

i

k

INDOOR

DOOR

USING WINDOW PANEL KIT

j_Plastic panel 1 piece

._Nozzle fitting 1 piece

.,3)Exhaust cover 1 piece

:4_>Screws 4 pieces

!===='IN DOOR

C3

D 0 m(_)

0

Page 27

The Installation of window panel kit

Model/Modelo: CE75096, CE76096, CE77096

Assembly & Installation Of Panel:

1.Fix Nozzle fittin ,_ to Plastic )anel .U_with four screws _)

\

®

2.Install the panel in the window and adjust

the length of the panel by lengthening or

shortening.

3.Connect the heat exhaust hose connector anti-clockwise to the heat exhaust hose; then slide

the hose into Nozzle fitting 2 until it locks.

4.Connect the other heat exhaust hose anti-clockwise to the another end of heat exhaust hose;

then connect the connector to the appliance clockwise.4.

Note:The same procedure can be adapted for vertical installation in sliding widows.

- ..'t-

I

14 DOOR

5 If the unit is not being used. please remove the Exhaust Hose; then insert the exhaust cover

into nozzle fitting, r_

©l

Page 28

Warning

Each time you bring the outdoor unit insidealways turn the air eondilioneroff at the

power supply If you do not and move the insideunit the debumidif'_l water in the

container inside the unit couldactivate the water pump and discard water from the

tube on the outdoor unit,

The Outdoor Unit

Model: CE77126 Only

• METHOD I :

The outdoor unit may be placed on outdoorpatio or flower planer directly, so it

does not require the special mounting brackets.

PTease make sure that the drainage

pipe is not pressed by the outdoor

unit! 5_,,

120¢i

(Open space) 1

• METHOD II :

The outdoor unit may be mounted on the wall by utilizing the enclosed accessories

(mounting brackets, wall plug and the screws).

When using this method you can

extend the drainage tube and direct

it to where you wish tl'_. water to

discharge. You can lift t_-.._ _,utside

unit off the brackets at .mv time.

If you intend a permanent fitting, for

the outside unit we recommend to

make a cover for it to prevent water

getting inside in heavy rains.

• METHOD III :

For short-term application, please use the enclosed belts to hang the outdoor unit

outside the window.

• With this method we recommend

in heavy rain storms and wind to

turn the unit off and lift inside if you

do not have the unit suitably covered•

Always use the belts on the mounting

brackets, do not tie belts on handle.

Page 29

PROBLEM

Air conditioner stops

operating

Airconditlonerstopsinthemiddle

of the operation.

Air conditioner pauses

on and off irregularly

Air conditioner functions but

the room is not cooled.

Motor runningsound when

unit has turnedoff

• A majority of malfunctions are small, and

triggered by problems that can easily be resolved;

before calling for service, please refer to the

following table for sequential inspection.

CAUSES

• Power failure

• The plug has not been

plugged in.

•The timersettingdial hasnot

been set.

• The fan speed control dial

has not been set.

• The waming light is on - the.

internal safety switch has

been activated.

• The indoortemperature has

reached the designated

temperature.

• The designated operating

time is up

• The warninglight ison- The

unit'sinterrnalsafety switch

has been activated

• The outdoor unit'selectrical

connector has not been

connected securely.

• Maffunclion.

• Window or door is left open

inthe room.

• Heat source in the room or

excessive numberof people

in it.

• Saturated filter

• Temperature setting too

high.

• The water pump isemptying

excess water from the

container inside the unit.

RESOLUTIONS

• Wait for the power to come

back on.

• Insert theplug.

• Set the timer setting dial to

proper position.

•Set the fan speed control dial

to correct position

•Turn allswitches off andwait

5 rains and turn on again.

If still not working contact

place of purchase.

• Reset the temperature.

• Reset thetimer

• Contact the service center.

• Disconnect power and take

umbilical cover off to check

it electrical connector is firm.

if this keeps happening call

the distributor.

• Close all windowand door

- Eliminate heat source.

. Clean the filter.

• Lower the temperature set-

ling

• This will automatically stop

in a few minutes,

Page 30

121

[]

o

[]

17 J

®@®©@

Page 31

I

J ii

_f_l

[]

Page 32

12 "On/Off" key

13 Alarm light:comesonwhenthecondensatecollectingtank

is ElL

14 "Function"key:forselectingtheoperatingmode:ventilation

only or air conditioning: the light (a) or (b) comeson

dependingon themodechosen.

15Ventilationspeedselectionkey

Light(c)on:slowventilationspeed

Light(d)an: mediumventilationspeed

Light(e) on:high ventilationspeed

16 "Night operation"key:thelight(f) comesan.

17 "Programming" keys:accordingto the type of program-

ming chosen(seepage 10), a greenor red lightcomes

on Ig).

18Temperatureselectionkeys

19Digitaldisplaydial

25 Key br enablingandsettingthetimer

26 Key forenablingthenightmode ©

27 Keyfor selectingtheventilationspeed

28 Keyfor selectingtheoperatingmode

29 KeyOn/Off

Page 33

(_b NEW WIDETECH

PORTABLEAIRCONDITIONER

II

III

WA-9000 WA-9000E WA-9000ER

In I I I • II /11 I

Page 34

SPECIFICATION

Dcs,:ript im+ of product

+_k;d e I

Size uf _!_¢i1 (W+H*D)

Area (m)

, ,, ,,,,,,,,, ,,,,, ,,,,

Voltage /Freguency

(Derating cycie(V)

('_01i_,_c:,pa,i{y( B.T.U.,

+4o+.,:-tre r_+m,.,,at ( L iH )

Opera'ir_g cyc!e (A)

inptt! pO_eF (W)

A+r flow vo+,+mc+.mih r +

t4odel

:.npu T po'_vcr

('ompr,%_o: Operatirg cycie

?ro[¢c_or

t4ot or input

I4odcl

Uperat {ng cyc I e

},1ode 1

0tl'doetrt0_;.,r ()at p-it pOWer

0petal{rig cyc!_"

Ttnbine fan +',lode]

_et;,r Out pt,t power

Eva>>ra to:{ K" S./FPI )

('onden_er (R/SiFPI)

Capi!]ary (().!)._!.D.i[+)

Cooianti(g)

Etp+irormer" temperature((")

l\+ei gh t (kg_,)

Remarks

, i

Portable air conditioner

\VA-9000 / WA-9OOOE ] WA-9000ER

46cm*78cm*32cm

13-19

, ,,, ,,, , ,

115/60 220-240t50

103.5- 126.5 207 -253

9OO0

l 6

8,1 4.0

900 900

320

KIIq('It:.4?,BBB[_DQBI25CL12C K](7"Z2EI.i_.BD OBI34PL12("

?(IOW 820W 600\_' 705 / 728_'

55uf/250V 35-_f/370V 17ufJ4OOV 25uf14OOV

"[ 0_.0_ glt+A_2{V:_-12{i2(' ERW_II55-q{}H) ¢;b:\_2i112-121;2_

33+6A 48A 16 .SA iSA

++TC+13A +'1'C- 13(;

34.2\V 30\v

4uF1250\ iuF/4-OOV

VCTC- 43A _\'TC- 43G

40.7_V 43\\+

,lt_Iz/250V i . 5uF/450\

X_/A-90S 1 \VA-90S2

15XV 12\V

' + _ "112,D !

2RII_S/_ ,,, ,

2R / I 3S I i 6F[:U

2.6mmll .4mral6OOmm 2.6ram/1.4mm!9OOmm

R221440g

18-35

32

Page 35

DescriptionofComponents

III I III I II I II

Air outlet

Transparent cover to the control panel

_ .J"

Frompa,.el ...........

Page 36

Screen filter

/

R_ar upper co\el

Heat exhaust ho

............ Rear lower cove

Power wi re

/

Waterdrainage _ipe

P pe plug

'I

Page 37

' t.

\x,,A- 9000

Alarm

Fan speed control dial

;:: :i:

\

4

i.arnp

{:au,_speed control dial

," OI __") _" ">spr_*dcontra7

Page 38

WA-9000E

WA-9OOOER

Control panel

. ,_.. * C23

L

_lll U l II

-- Siec|_

}:im _-e¢i --7 r-1 Tim_-r orJ_¢d I_im_! olfl _',:ce I_J

/ _ o _. ,½. I I \

F_II _Ix%*d J l--- Nk.'_g:*

Page 39

w A-9000ER

l:_,at_a:y co_:c.:_.BACK )

" (Remote ( ontr+_I

Page 40

Outdoor Radiator Drum

OutdoorMotor

Liquidaccumulator

/ Capillary

/

C0oli_S_st_mO:._.ztimDh_ram

WA-9000

IRE-D)

' i

rIMERi FANs_Tt'K T_ERMOsTAT

,o'_=-_ _ IL.LI...................L7

_.I_,._,__qi¢-" i ''_ill__

_LUE) l'SuF145_'ti

._.___. - .......... _B.L.UE) _ (._LU_ 25uF/370Vi {BLUE}I

(BLUE}_

Schematic Wi6n_ Diagrams

Page 41

SchematicWiringDiagrams ,,,,,

WA-9OOOE

J ,

BOhRD

22oONZz4Ova" E

--- (WHITE)

_i:_

w

(ZO_TROL F_)_RD ]l[('R{I TEIP

i S'ITC'I N'%E_SOR

p1 _£2.a ,,

_ r...a1,...,= I i z,a

: _ , i li

i_"............_.... _ (RED)

• _ H ua

_--- m=!i_ _i ,. +_..t=--+

(BLUE) 'IuF/45OV 250FI3"IOVi(BLUE_l.SuFt450_

BLUE)

SchematicWiringDiagrams

WA-9OOOER

1

CO%TROI,P,()\l+l:, REgOT[; _IICRO TE_II'

s_-:,;so_,......*s_,,'rt:,I"ls_:xst_

P'I P2P3 P4I _ o H

: _.. g--,.a • J + 1

25UF!a70v{

_____,--..,..___:_ (eLUE

t _i<ORi_IGE) o

i +++".............._' iuJ

.,/-:::::q+-1"t I.... + mOARD _ (RED)_ _ o

--_ ....._ E_ '_-- Hi

220-240V I ! i[+pOOR([VI_

soxz ' I i CN_ i,o'r0e ,,_J_.

J _(VVHITE) _-- -J

_! cc_ (BLUE) tuFI450V

RED) =_

_j P_p_

1.5uFI450V i

(BLUE)

SchematicWiringDia_r:.:ms

Page 42

THEREASONOFBREAKDOWNANDTHEWAYTOSOLVEIT,

PROBLEM

Air conditioner not

working

Air conditioner _topu

buddently

POSSIBLE REASONS

OPower failure.

()Did not plug on.

ODid not set the timer.

_Did not set the air speed switch.

OWarning light is on (safety switch

is workmg ).

i)Waming light gave the wrong

indication.

OThe set time is complete.

(_The room temperature reached the

set temperature.

OWarning light is on (safety switch

is working ).

()Warning light gave the wrong

indication.

WAYS TO SOLVE IT.

QWait for the electri_,ity.

,[',Plug on.

OSet the timer switch to the proper

position.

@Sr_t the air speed switch to the

proper position.

_'heck turbine fan motor for damage.

![)Check whether the wires of the

micro switch is connected.

QRe-set the timer.

@Re-set the temperature.

OCheck for damage of the turbine

fan motor.

C)Try nor to move or shake the air

conditidner when the mechine is

operating.

Alrconelitienernet,_o.'kmLeroperlyOThe wires is not firmly connected. OCheck for loose wires.

onandoff.0nandoff

_'ind c0_ing 0nt o[ the uir OThe air speed switch did not setto t|Scttheairspeedst_itch toaircondition-

outlet bul the cnmpresbnr air conditioning, ln_posinon.

i_ not m0'_ln; (['.The thermostate did not set to the @Set the thermostateto theproper position.

proper position. OCheck the wires.

OThe wires of the compressor are not '['Chan_ethecompressor.

connected properly.

[_Compressor is out of order.

('0mpress0tis;_'orkin_butno,._indOThe wires in the motor of the indoor OCheck the wires.

unit did not connected properly. ()Change the motor.

;0meoutoflheairoutlel [)The motor is out of order.

Themototoftheoutdo0ru_itis OThe wires in the motor of the outdoor OCheck the wires.

unit did not connected properly. Q"Change the motor.

u0t_0rking ::)The motor is out of order.

Airconditioner notcool

Water leakage

OThcre are open '_indows in the room.

@:I'oomany people or there is heat

source in the room.

OThe filter is too dirty.

:-')The set te]nperaturc i,. too high.

OLeakage of coolant.

t|Turbine fan motor out ot order.

('Switch of full water out of order.

Oi.oose pipes.

QCIo_e all the open windows.

;)Get rid of the heat sources.

OClean the filter.

()Lower the set temperature.

OCheck for the Icaka_geof coolant.

OCheck the turbine, fan motor.

"_.Chcck the full water switch.

QCheck the joint connection of

every pipe:,.

Page 43

COOLINGSYSTEMFLOkCHART,

I

POWER FAILURE H

I

CHECKTHEMAINS_'ITCHH

ANDFUSEWIRE

AIR CONDITIONER]

NOT WORKING I

NOT COOL H

I

TIMER OUTOF ORDER

I L0WERTE_IPERATURESETUP t

AIRSPEEDSWITCHADJUST]

TOAIRCONDIT1DNING I

I

CAPACITOR BREAKDOWN

I

H

I I

LOMPREbS{RNOTWORKING

I I

I

!

LEAKAGEOF COOLANT]

!

I

SYSTEM REPAIR [

I

USE DISCHARGE TO FILL N:15kg/cm'. [

THEN TEST FOR LEAKAGE

I

I

-I V "

USE _ELDIN(,TOFILL THEHOLE.

I

I TODRAIOUTTHEAIRBYVACUUM

FORATLEAST15_,tlNUTES

I

I RETRY AFTER REFILLING 445g

OF R-22 COOLANT

I

I

PROTECTORBREAKDOWN

I

Page 44

WA-9000EXPLODEDIAGRAM

ACCESSOR

Page 45

NO.I

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

2O

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

WA-9000 AIR CONDITIONER PARTS LIST (CE75096)

MATERIAL

NO.

A7402-010

A4800-010

A3200-010

A5600-010

A6100-010

A5811-030

A4237-020

A5811-050

A6204-010

A6208-010

A6227-010

V1PI3-130

A7307-010

A6200-010

A5700-030

A4233-010

A2500-010

A2502-010

A3408-010

A6215-010

A6215-020

A5000-010

A4233-030

A5400-010

A3404-010

A6219-010

A6219-020

A6212-010

A6202-010

A5310-010

A3000-150

A5802-060

A5407-010

A5404-010

A5409-010

A2506-010

A5300-010

A5300-020

A5303-020

A3000-040

A2509-030

A5802-070

A5802-080

ENGLISH NAME

TURING WHEEL

BASE PAN

COMPRESSOR ASS'Y

RUBBER

CAP

FIX TURE

DISCHARGE

GRILLE(COMPLETE)

FIX TURE

'_APILLARY TUBE

DISCHARGE PIPE

SUCTION PIPE

DRAINAGE PIPE

SOFT CAP

HEAT EXHAUST HOSE

CONNECTOR

PLATE

KNOB

THERMOSTAT SWITCH

ROTARY SWITCH

STRAINER-COMPLETE

OUT TUBE

OUT TUBE

DRAINAGE PAN(COND)

KNOB

DRAIN BUCKET

CONDENSER

IN TUBE

INTUBE

MANIFOLD TEBE

SERVICE PIPE

BLADE

STRIKE WATER MOTOR

STRIKE

DRAIN BUCKET COVER

FLOAT

RENK

MICRO SWITCH

FAN CASING

FAN CASING

BLOWER WHEEL

FAN MOTOR

CAPACITOR

STRIKE

STRIKE

SPECIFICATION

D=45mm M6

SPCC T=1.4mm

220-240V/50Hz

NBR65%

ABS

ABS

PE

ABS

1/4" T=0.6mm

_/16" T=0.6mm

PVC60% D 15xd 13xL 130mm

PVC60%

D=112mm L=1200mm

ABS

ABS

TB-Y 100,250V,20A

4R.H AC250V, 16A

P.P.

1/4" T=0.6mm

1/4" T=0.6mm

p.p.

ABS

ABS

2RI2SI6FPI

1/4" T=0.6mm

1/4" T=0.6mm

1/4" T=0.6mm

1/4" T=0.6mm

ABS

220V/50Hz

SGCC T=1.2mm

ABS

POLYLON

ABS

X3M306K2KA 250V 16(6)A

ABS

ABS

ABS

220V/50Hz

SGCC T=1.2mm

SGCC T=1.2mm

QUANTITY

4

1

1

3

1

1

I

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

I

1

I

1

1

I

1

1

1

1

1

I

1

REMARK

Coating

Page 46

44

45

46

47

48

49

5O

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

A4200-010

A4233-020

A4237-010

A4242-010

A5303-010

A5300-030

A5300-040

A3000-030

A5802-030

A5802-040

A2509-020

A2509-010

A2525-010

A2525-020

A5802-020

A5802-010

A5806-010

A5806-020

A5700-020

A5700-010

A3400-010

A5900-010

A6215-030

A6219-030

A5000-020

A4215-010

A4210-010

A4210-020

A4218-010

A4218-020

A4205-010

A3700-010

A7300-010

A5800-010

A2503-010

A4253-010

A6804-010

A2527-010

A7100-010

FRONT PANEL

KNOB

DISCHARGE

GRILLE(COMPLETE)

VAN-AIR DEFLECTOR

BLOWER WHEEL

FAN CASING

FAN CASING

FAN MOTOR

STRIKE

STRIKE

CAPACITOR

CAPACITOR

TERMINAL BLOCK

TERMINAL BLOCK

STRIKE

STRIKE

FIX METAL(LEFT)

FIX METAL(RIGHT)

PLATE

PLATE

EVAPORATOR

TOP BOARD

OUT TUBE

IN TUBE

DRAINAGE PAN

TRANSPARENT COVER

SIDE PLATE

SIDE PLATE

REAR COVER

REAR COVER

iTOP COVER

ABS

ABS

ABS

ABS

ABS D=200mm

ABS

ABS

220V/50Hz

SGCC T=1.2mm

SGCC T=1.2mm

HP-T4009-2

T3020

SGCC T=l.2mm

SGCC T=1.2mm

SGCC T=1.2mm

SGCC T=l.2mm

SGCC T=1.2mm

SGCC T=l.2mm

12R11S18FPI

!SGCC T=1.2mm

1/4" T=0.6mm

5/16" T=0.6mm

IABS

ABS

ABS

ABS

ABS

ABS+PP-NET

ABS

POWER SUPPLY CORD COMPLETE

AIR FILTER

RAIL

TIME SWITCH

CONTROL PLATE

CONTROL PANEL

LAMP

CARTON

ABS

SGCC T=1.2mm

1

1

1

1

1

1

1

1

1

1

I

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

I

t

2

1

1

1

1

1

ABS

PVC T=0.3mm

220V RED

DOUBLE WALL

CORRUGATED BOARD

83 A7100-030 CARTON BASE DOUBLE WALL 1

CORRUGATED BOARD

84 A7107-010 SHOCK ABSORBER P.S. 1

85 A6800-010 NAME PLATE 1

86 A6500-010 OPERATION MANUAL I

Page 47

WA-9000E

WA-9000EREXPLODEDIAGRAM

WA-9000ER

ACCESSOR

Page 48

WA-9000E(WA-9000ER) AIR CONDITIONER PARTS LIST (CE76096-CE77096)

qO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

MATERIAL

NO.

A7402-010

A4800-010

A3200-0|0

A5600-010

A6100-010

A5811-030

A4237-020

A5811-050

A6204-010

A6208-010

A6227-010

VIPI3-130

A7307-010

A6200-010

A5700-030

A4215-010

A2524-010

A2529-010

A3408-010

A6215-010

A6215-020

A5000-010

A2520-010

A5400-010

A3404-010

A6219-010

A6219-020

A6212-010

A6202-010

A5310-010

A3000-150

A5802-060

A5407-010

A5404-010

A5409-010

A2506-0 [0

ENGLISH NAME

TURING WHEEL

BASE PAN

COMPRESSOR ASS'Y

RUBBER

CAP

FIX TURE

DISCHARGE

GRILLE(COMPLETE)

FIX TURE

CAPILLARY TUBE

DISCHARGE PIPE

SUCTION PIPE

DRAINAGE PIPE

SOFT CAP

HEAT EXHAUST HOSE

CONNECTOR

PLATE

TRANSPARENT COVER

SENSOR

REMOTE CONTROL

STRAINER-COMPLETE

OUT TUBE

OUT TUBE

DRAINAGE PAN(COND)

PC BOARD

DRAIN BUCKET

CONDENSER

]IN TUBE

[NTUBE

MANIFOLD TEBE

SERVICE TUBE

BLADE

STRIKE WATER MOTOR

STRIKE

DRAIN BUCKET COVER

FLOAT

RENK

MICRO SWITCH

SPECIFICATION QTY REMARK

D=45mm M6 4

SPCC T=1.4mm I Coating

t

NBR65% 3

ABS 1

ABS 1

PE 1

ABS

1/4" T=0.6mm

5/16" T=0.6mm

PVC60%

Dl5xdl3xL130mm

PVC60%

D=112mm L=1200mm

ABS

ABS

I

I

I

1

1

P.P.

1/4" T=0.6mm

1/4" T=0.6mm

p.p.

220V/50Hz

ABS

2RI2SI6FPI

I/4" T=0.6mm

I/4" T=0.6rnrn

1/4" T=0.6mm

I/4" T 0.6mm

ABS

220V/50Hz

SGCC 7`= 1.2ram

ABS

POLYLON

ABS

X3M306K2KA 250V

_6(6)A

1

1

1

t

I

I

I

I

I

I

1

I

I

1

I

i

FOR WA-9000ER ONLY

FOR WA-9000ER ONLY

Page 49

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

8O

81

A5303-020

A3000-040

A2509-030

A5802-070

A5802-080

A4200-010

A6100-020

A4237-0 t 0

A4242-010

A5303-010

A5300-030

A5300-040

A3000-030

A5802-030

A5802-040

A2509-020

A2516-010

A5811-040

A2509-010

A2525-010

A2525-020

A5802-020

A5802-010

A5806-010

A5806-020

A5700-020

A5700-010

A3400-010

A5900-010

A6215-030

A6219-030

A5000-020

A6804-040

A4210-010

A4210-020

A4218-010

A4218-020

A4205-010

A3700-010

A7300-010

A5800-010

A4253-020

A7100-010

BLOWER WHEEL

FAN MOTOR

CAPACITOR

STRIKE

STRIKE

FRONT PANEL

CAP

DISCHARGE

GRILLE(COMPLETE)

VAN-AIR DEFLECTOR

BLOWER WHEEL

FAN CASING

FAN CASING

FAN MOTOR

STRIKE

STRIKE

CAPACITOR

CONTROL BOARD

FIX TURE

CAPACITOR

TERMINAL BLOCK

TERMINAL BLOCK

STRIKE

STRIKE

FIX METAL(LEFT)

FIX METAL(RIGHT)

_DLATE

7'LATE

EVAPORATOR

TOP BOARD

OUT TUBE

IN TUBE

DRAINAGE PAN

CONTROL PANEL

SIDE PLATE

SIDE PLATE

REAR COVER

REAR COVER

TOP COVER

POWER SUPPLY CORD

COMPLETE

AIR FILTER

RAIL

gONTROL PLATE

'UA RTON

ABS

220V/50Hz

SGCC T=1.2mm

SGCC T=1.2mm

ABS

ABS

ABS

ABS

ABS D=200mm

ABS

ABS

220V/50Hz

SGCC T= 1.2mm

SGCC T= 1.2mm

220V/50Hz

ABS(94V0)

HP-T4009-2

T3020

SGCC T= 1.2mm

SGCC T=1.2mm

SGCC T =1.2mm

SGCC T= 1.2mm

SGCC T=1.2mm

SGCC T-1.2ram

2RI IS18FPI

SGCC T = 1.2ram

5/16" T=0.6mm

1/4" T=0.6mm

ABS

PVC T=0.3mm

ABS

ABS

ABS

ABS+PP-NET

ABS

ABS

SGCC T= 1.2ram

ABS

DOUBLE WALL

CORRUGATED BOARD

1

I

I

1

1

1

I

1

1

1

I

1

1

1

1

I

I

I

I

1

2

2

I

1

1

I

I

1

1

1

I

I

1

I

I

I

1

1

I

2

1

1

Page 50

I[_ NEW WIDETECH

SPLITPORTABLEAIRCONDITIONER

WA-12000WA-12000EWA-12000ER

SERVICEMANUAL

Page 51

SPECIFICATION

De,trip!ion of producl

[,IOd e I

Size of shell ( g-*lt*D )

Area (Ill:)

\oltage /Freg,uency

Operating cyc:e( V )

(.'oolin_ capa,:ib ' B.T.U. !

P,Ioi :,Iute remo',at i l, +"H ',

Opera! ing cycle ( A )

:nput power (W)

Air flo_ volume I :a, h r

r,Io,:1e I

Input pov, e r

Comp:e:,_or Operating cycle

Pro:.¢c:or

_aot o r inpu:

[_lod e 1

In2oerm,.,:or Out put po',:er

OpcraI in_ c'ic [e

[',lod e 1

0_l&0r racq0r Out put po_er

Operaling cyc t

Mode ]

%'.er pump

()_t p'.;_ po_cr

E_aporatorIR,S. FPI,

Condel:ser (R; Si FP[ )

Capill:ar:, (O.D.,'I.D.i[,)

Cool an ti(g)

Enx[ rollmcn: [cmpc]'at ttrc(" C )

\Yeight(kgs)

Remarks

Spl i t Por'i able Air Cond_ t loner

WA- 12000 / \\A- l 2OOOE 1 \\A- 1200OER

,a6 qcra,.Slcm_-31.-mllndimr U[Iil )£5,'Itl*4fi_'lll"ll}¢lli(IR [ tlo kt:lIt]

19_-25

12000

1.6

320

220_-240150

207_253

6.2

1200

K2"r('2o7Et.F?,-F

1180/11 '-;5_',

25uf/;IO0\

h:_idc

_i'F --4")LiH-2

] . 5 ut=/_150\

.1SC - 45 (]

; 5uF1150\

N_.IE

:6\',

2NI i2S/ igFPI

2R/14:';I i ,IFPl

2.6mmil.J.mm!'_2Oi)mm " 3 pc>,

R2217()_g

\L\- _OOO.:,"; >. W,\-,20!)OEI_;A-i2OOOR:16-32

[ndoor unit :32 Oaldoor uni: : :5

Page 52

DescriptionofComponents

Air outlet

Transparent cover

\

\

\

to the control panel

Top covei

Handlehole

Sideplate

Frontpanel

Castor

Page 53

Screen filter

%

Rear upper cover

Outdoor unit's mounting

screw

to umbilical connection.

Always keep cover on.

Power cord compartment

Rear cover down

Water drainage pipe

and pipe plug

Cabinet

Flexible umbilical cord

\

Handle \

\,

\,

\

Base pan

_,_y ¸.¸.4 ;

] _,. _'J_ Wall plugs_,with _crews)

"-_._. flexible '_

Spanner "_'_ Frame for

connecting house Protective cap Mounting brackets

sj

/ /, ../ f

i Support belt

i for connector with hook

Page 54

WA- 12000

Alarm Fan speed control dial

\

Temperature _ Timercontrol

cortrol dial \ // dial

\

f

/

Fan speed control dial

' O1 or2 or3 slk-"_dcor|trol

/

/

(.-,,

/

• /

Temperature control dial/

OFor selting your temperature

requirt'men! or cont inuou...,cooling

(18-35"C_

.€.o.a.tml.o.az_

' Timer control dial

\

OSctling from 1-_,hour_

or conlmuous operation

Page 55

WA-12000E

WA-12000ER

Control panel

l

/

/

/

Page 56

WA-12000ER

Adjust

OAdj ust tempe rature Io

. . • o

.su tabt¢cond t]on(16-J C)

÷

Power switch

Battary cover(BACK)

OU_e two No.4 batteries

Remote Control

Page 57

CoolingSystemOperating&SchematicwiringDiagrams

[Mo'orJ {E+,,_or,,,o,.

!_ 77

f

'L

[agu,dac£umut!_t,.Li

i

!i ' /+

+i

+i:++il

i F--

i " ;-q

! t

J

Coolin+.SystemOt+eratin_Diagram

WA-12000

I;_IWERSOUI_CE

j + l.. _ •

TIMER RE[)+FL'tS|IT('!I +RED+TfiE+t

............ -+---+.:.;+.,c,c.,++ _,,,--, ic+ c+--

tRI-D+ BRII_',NI

_bRi;WP,h

Ix++RPUWI'(")

WItk';; ,+]Wl!

tOR '_bk;EJ +H_

_'tEli.O's\%

• K ,

IN I_'_18 (£"_])

{YELtOWl

- + _ :; . . ! ];£4 t+l_+R

i t

;':x'Ii[T[,++!+II;E+,\VHl';i itBLLIE!

+ -_ i+;

+WIIl+J[, BLIII-+

3.5d'100\ !

l

i

I

r

I

- -[

Schemati,+"_"\Virin_,o Diagrams,,'

Page 58

SchematicWiringDiagrams

WA-12000E

50Hz I

?

i (BLUE) 1,5UFI4 50V

i (RED) !

(BLUE)

SchematicWirin_oDiLorams

WA-12000ER

r...--.._ C:::lC::3 r..-1

I , _,=i=_l___JI t t

i r = _ J

pOllER J

= ie UE "--

; (BL )

[

(BLUE) 1,5uFI4S0V 25uFI400Vi 3.5UFI400V

(BLUE)

Schematic Wirin_ Diagrams

Page 59

T' F : ' I :: _ 'T

•HER.ASONO:BREAKDOINANDTHEIIAkTO_OLkEh.

PROBLEM

Air cond]t_or.cr no:

'ao r k Ih ,2

POSSI BLE REASONS

• Pov, cr fail ure.

i)id nor plug on,

O])id nol _1:fl'.:" hmcr.

!)Jd _]o[ ,._: :]lc uir "_p¢¢d _v, ]Ici'.

_\\ amiilg '.Lilt is oil (Safe!:, ,.v. it¢i:

]', v,c,rkin,.z 1.

. "_\';II'I_H_ [_{11 gR_.,_ the 9,,roll,.:

I i:_dica:ion.

\','AYS TO SOLVE [T.

_\\'ai: for th_ _k'clrici::,.

P:L:gOll.

_St': !he ::m¢l -,a irciEio :h= proper

pOM::O::.

Sol :he au speed ,".'.!tchto th¢

p]'op_' r poM:iull.

OL'::c,'k L;rbi':u :'an mntor ."or ,Jal._agr

: ' ?cck '.,.hcti:c:" the u iI'¢b or 1!:¢

::::,::(_:>v,[t,.:h is con:letted.

Page 60

COOLINGSYSTEMFLOWCHART,

POWER FAILURE H

I

CHEt'KTHEMAINS_'IT(.'HH

ANDFUSEERE

AIR CONDITIONER

NOT WORKING

NOT COOL

TII_IEROUTOF ORDER

I

LO_'ERTEMPERATURESETUP

[._lR SPEEDSIITCHADJUST]

TOAIRCOHDITIDRIIIGI

CAPACITORBREAKDOWN

I

H COUPRESSORNOTfORKING

I

I LEAKAGEOF COOLANTI

I

SYSTEM REPAIR

I

USE DISCHARGE TO FILL N:lSkg/cm _,

THEN TEST FOR LEAKAGE

I

l USE V,'ELDINGTO FILL THE HOLE.

I

I TODRAIOUTTHEAIRBY\',_('UU_I]

FOR,_TLEAST15_li_UTES I

I

I RETRY AFTER REFILLING 445g

I

OF R-22 COOLANT I

!

PROTECTORBREAKDOWN

I

Page 61

WA-12000(WA-12000EWA-12000ER)EXPLODEDIAGRAM(INDOORUNIT

ACCESSOR ,.--, ._:_

WA-12000

WA-12000E

Page 62

WA-12000(WA-12000EWA-12000ER)EXPLODEDIAGRAM(OUTDOORUNIT)

®

Page 63

WA-12000 (CE75126), WA-12000E (CE76126), WA-12000ER (CE77126)

SPLIT PORTABLE AIR CONDITIONER PARTS LIST

NO:

l°

2.

.

4.

5.

6.

7.

8.

.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19,

20.

21,

22,

23.

24,

25

26

27

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

MATERIAL

CODE

A4205-010

A4215-010

A4253-010

_4233-010

A42334)20

A4233-030

A4200-010

A4237-010

A4210010

A4210-020

A421gO30

A7300-020

A5811-110

A6100-030

A5811-010

A42184)40

A5400-010

A54074I_)

_5409-020

IA5000-030

A6204-030

A5303-010

A5300-030

A5300-040

A6100-020

A5811-040

VB02Pll-33

A7307-010

A4800-010

A4800-030

A6201-010

A5700-010

A5802-030

A5802-040

A4210-030

A5900-020

A5700-020

A5802-010

A5802-020

A58064)10

A5806-020

A5800-010

A5802-050

A7700-010

PARTS NAME

TOP COVER PLATE

TRANSPARENT

CO_

CONIROL PLATE

KNOB

KNOB

KNOB

FRONr PANEL

DISCARGE GRILLE

(COMPLETE)

SIDE PLATE

SIDE PLATE

REAR COVER

AIR FIL_

FIX TURE

CAP

FIX'lURE

REAR COVER

DRAIN BUCKET

_ _COVER

LENK

!DRAINAGE PAN

CAPILLARY TUBE

BLOWER WHEEL

FAN CASING

FAN CASING

CAP

FIX TURE

WATERTANK

DRAINAGE PIPE

SOFT CAP

BASE PAN

BASE PAN

AUTOCLAVE TUBE

PLATE

STRIKE

STRIKE

SIDE PLATE

TOP BOARD

PLATE

STRIKE

STRIKE

FIXMETAL

FIX METAL

RAIL

STRIKE

ELECTRONIC BOX

SPECIFICATION Q'IY REMARK

ABS

ABS, TRANSPARENT

1

1

ABS 1 WA-12000E

ABS 1

ABS 1

ABS 1

ABS 1

ABS 1

ABS

ABS

M3S

:ABS+WHITE PE NET

ABS

ABS

!ABS

ABS

ABS

SECC, T= 1.0mm

P.P

2.6"1.4"3200mm

ABS,I)=200mm

ABS

ABS

ABS

ABS

BLACK ,PVC,

D15*dl l*T2*L330mm

BLACK ,PVC60%

SPCC,T=1.4ram

SPCC,T=I.5mm

3/8" L=3000mm

SGCC, T= 1.2ram

SGCC,T--1.2mm

SGCC,T=1.2ram

SGCC,T=I.2mm

SGCC,T=1.2ram

SGCC ,T=1.2ram

SGCC ,T=l.2mm

SGCC ,T=1.2ram

SGCC ,T=1.2ram

SGCC ,T=1.2ram

SGCC ,T= 1.2ram

SGCC ,T=1.2ram

SGCC ,T=1.2ram

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1 WA- 12000E

1 WA- 12000E

1

1

1

1

1

l

1

1

1

1

1

2

2

1

I

2

1

1

Page 64

45. A3204-080

46 A5806-060

47. A5806-070

48. A5806-080

49. A5806-090

50. A3200-050

51. A2509-030

52. A62234)10

53. A5500-030

54. A3703-140

55. A3413-030

56. A3413-040

57. A3004-010

58. A2506-010

59. A3000-090

60. AZ5_-.010

61. A2503-010

62. A2502-010

63. A2500-010

64. A2520-010

65. A2516-010

66. A2529-010

67. A4256-010

68. A4800-020

69. A5300-050

70. A2527_10

71.A3700-010

72. A6208-020

73. A6227-020

74. A3400-020

75. A3404.020

76. A6219-060

77. A6212-010

78. A6213-030

79. A3413-010

80 A3413-020

81. A6213-080

82. A62134Y_

835A5802-100

84.1A7402..010

85. A5404.ff20

86. A5306-010

87. A4257-010

GASKET

FIX METAL

FIX METAL

FIX METAL

FIX METAL

COMPRESSOR ASS'Y

CAPACIIOR

FLEXIBLE PIPE

SOUND ARRKglER

LEAD WIRE

COMPLETE

QUICK

CONNECTOR

QUICK

CONNECTOR

PUMP

MICRO swIrcH

FAN MOTOR

CAPACrlOR

TIME SWITCH

ROTARY swn'cH

SWITCH

PC BOARD

CONTROL BOARD

REMOTE

CONTROL

CABINET

BASE PAN

FAN CASING

LAMP

POWER SUPPLY CORB

DISCHARGE PIPE

SUCIK)N PIPE

EVAPORATOR

CONDENSER

IN TUBE

MANIFOLD TEBE

DDNNECrlON TUBE

_.JICKCONNECIOR

QUICKC_qNECIOR

CONNECTION

TUBE

CONNECTION

I'UBE

STRIKE

_G WHEtt

FLOAT

PROPELLER FAN

HANDLE

SGCC ,T=1.2ram

SGCC ,T=1.2ram

SGCC ,T=1.2ram

SGCC ,T=l.2mm

SGCC ,T=l.2mm

220-240V 50Hz

220-240V 50Hz

PVC,L=2800mm

UPE

YELLOW, I8AWG

BROWN,18AWG

118"

5/16"

220-240V 50Hz

X3M306K2KA,250V,16(6)

A

220-240V 50Hz

AMr-a SO

4RH AC250V, I 6A

TB-Y 100,250V,20A

220W50Hz

220V/50Hz

ABS

ABS

_BS

220V, RED

5/1 _i"(C 7.94) T=0.7

3/8"([] 9.52) T=0.7

2RI2S19FPI

2RI4S14FPI

5/16"(OUT)

IYTYPE, l/4"T=0.6mm

il/4"(U 6.35), T--0.7mm

3/8"

5/16"

L TYPE 1/4" T--0.7mm

L TYPE 1/4" T=0.7mm

SGCC,T=1.6mm

M6,D=50mm

POLON

ABS,D=380mm

ABS

1

I

1

1

1

1

1

1

1

1

1

1

1

1

1

1 WA-12000E

1 WA-12000E

1 WA-12000ER

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

4

1

1

1

Page 65

88.

89.

90.

91,

92.

93.

94.

95.

96.

97.

98.

99.

100.

101.

102.

103.

A6101_10

A5802-140

A5811-020

A4242-010

A5802-090

A6100-050

SWT4

A7202-010

A680_020

A7409-010

A7304-010

A7302-010

A6202-020

A3000-120

A7700-020

A5802-110

SCREW "lOPCOVt_

STRIKE

FIX TURE

VAN AIR

DEFLECTOR

STRIKE

CAP

SCREW CLIP

HANG BOLT

NAME PANEL

SCREW PLASTIC

BELT

BELT

SPANNER

SERVICE TUBE

FAN MOTOR

ELECTRONIC BOX

STRIKE

PVC60%

ABS

ABS

SGCC,T=1.2mm

RED

D=4mm

M5"35

P.P, T=0.5mm

4*40

T=3mm,SPCC

1/4"(- 6.35)T=0.7mm

220-240V 50Hz

SGCC,T=0.Smm

SGCC,T = 1.6mm

2

1

1

1

2

4

7

2

1 WA-12000E

4

2

1

1

1

1

2

Page 66

ELIMINATE

ACCIDENTS

toW r fdy.'

Loading...

Loading...