Continental Belt V-Belts Catalog Page

77

2015 Power Transmission Products V-Belt

Specialty V-belts

When equipment calls for metric precision, you need a belt that

not only measures up, but one that won’t get lost in translation.

Metric belts belts are engineered to universal metric profiles,

but manufactured by Continental ContiTech in North America,

so you do not have to go elsewhere to get them.

Strong, flexible and able to work in wide temperature ranges,

metric belts replaces many common metric cross section belts

such as XPZ, XPA, SPA, XPB, SPB, XPC and SPC.

Double-V or Hex belts

A variation of the Classical belt, Hex belts come in AA, BB, CC

or a deep CCP cross section. These belts transfer power from

either side in serpentine drives. A drive design using Hex belts

is more complicated and engineering manuals should be

consulted when replacing or troubleshooting these drives.

Fractional Horsepower belts (FHP)

The 3L, 4L and 5L light-duty FHP belts are part of the

V-belt line also. As the name implies, these belts are used

solely on drives of 1 horsepower or less.

Narrow V-belts

Effectively handling drives from 1 to 1,000 horsepower, these

belts rank high in horsepower-hours per dollar, the ultimate

measure of drive value. The Narrow belt cross sections (3V, 5V

and 8V), offer higher power capacity for any sheave size

and weight.

The Narrow or “wedge” design provides more tensile member

support than Classical V-belts. Narrow belts handle an

equivalent load, but with narrower face width and smaller

diameters than the traditional Classical V-belts. These features

allow the use of smaller belts or fewer belts to transmit the load,

an important advantage if your goal is to maximize power

transmission efficiency by reducing drive weight and size.

Classic V-belts

The most widely used V-belts are A, B, C and D Classical belts.

Used more out of habit and convenience than design, these

belts can handle fractional to 500 horsepower drives, usually

at the lowest cost. However, they occupy more space and the

drives weigh more than Narrow belt drives. Also, Classical belts

are usually less efficient than Narrow belts. But their versatility

and wide range of sizes and types make them an attractive

alternative to wedge belts.

Many Classical belts are used for replacement because it is

considered too costly to replace sheaves when upgrading from

Classical to Narrow or other belt types. Therefore, when

replacing Classical sheaves, it is an opportune time to upgrade

to Narrow or other belt types .

V-Belts

Not only traditional Classical and

Narrow profiled belts, but also

Double-V and FHP belts

When synchronization or timing is not required, V-belts make

an excellent low-cost, quiet and efficient means of transmitting

power. However, not all V-belts perform the same. Depending

on your application and your objectives, some V-belts will be

better at getting you closer to your end goal.

General InformationAutomotive & TruckSpecialtyBushing HardwareV-BeltBandedSynchronousOverview

78

2015 Power Transmission Products V-Belt

Cogged, raw-edge construction vs.

envelope construction

Continental ContiTech provide a complete offering of cogged,

raw-edge belts in Narrow, Classical and FHP styles. Designated

3VX, 5VX, AX, BX, CX, 4L and 5L, cogged, raw-edge V-belts

have higher capacity and efficiency and they use smaller

sheaves than traditional envelope (wrapped) belts. These belts

have a higher coefficient of friction and are more aggressive,

which makes them a very efficient belt for power transmission.

Unlike conventional fabric-covered V-belts, raw-edge belts have

no cover. Thus, the cross-sectional area normally occupied by

the cover is used for more load-carrying cord. Cogs on the

inner sur face of the belt increase air flow to enhance cooler

running. They also increase flexibility, allowing the belt to

operate with smaller sheaves. With Classical V-belts, certain

under-designed or problem drives can be upgraded to

“satisfactory” by substituting Classical cogged belts for

Classical envelope belts without replacing sheaves.

Because of their higher coefficient of friction, cogged belts tend

to be more sensitive to alignment. While envelope belts can

tolerate some misalignment, cogged belts are more likely to

turn over under the same conditions. Cogged belts should not

be used in clutching drives , drives with severe shock loads and

drives that have changing center distances, such as shaker

screens. In these applications, the aggressive nature and

flexibility of cogged belts can cause vibration, belt turnover

and belt breakage. Cogged belts should also be avoided in

drives that require slippage during frequent stops and starts.

OverviewSynchronousBandedV-BeltBushing HardwareSpecialtyAutomotive & TruckGeneral Information

79

2015 Power Transmission Products V-Belt

Applications

Premium, longer-life narrow-profile belts for compact,

high-horsepower drives. Excellent in short-centered drives or

where high shock loads are present; can be used any place

you find traditional Narrow V-belts, but require a more robust

composition for improved service life.

Key features & benefits

›

Homogenous design.

› Specialty blended, fiber rich compounding.

› Higher modulus, higher denier cord.

› Virtually no maintenance.

› Static conduc tive,* with oil-resistant surface, for greater peace

of mind.

› Supreme durability and wear resistance.

*Dr ive condi tio ns and service variables in com bin ati on with t ime in

ope ration c an result in a l oss of static con ducti vit y. I t is re comme nded

that a conductivity check be added to drive preventive maintenance

programs where belt static conductivity is a requirement.

Construc ted with a homogenous, one-piece design, the

Wedge TLP™ Narrow V-belt delivers total lasting performance

that is virtually maintenance free. Its high-modulus, high-denier

cord can handle a significant increase in horsepower over our

current HY-T® Wedge.

Little maintenance with no worries

Wedge TLP™’s unique advanced construction process includes

use of a specialized reinforcement and compounds that make

this Narrow V-belt virtually maintenance free. Install this belt

the first time with proper installation techniques and take

advantage of reduced downtime and maintenance.

Increase savings by using fewer belts

With its greater horsepower capacity, Wedge TLP™ allows

you to deliver the same amount of horsepower with a lesser

number of belts. Fewer belts mean fewer sheave grooves; the

combination of the two means lower-cost belt drives.

Durability that goes the distance

Wedge TLP™ belts offer supreme durability and wear resistance

– plus better fit even in worn sheaves. That is all because

of its two envelope plies and specialty blended, fiber-rich

compounding that help support increased horsepower, with

less deformation under tension.

Wedge TLP™ Narrow V-Belts

Better belt performance is now

within reach

Introducing the newest, longest-lasting narrow V-belt in

the Continental ContiTech lineup.

Part Number: 3VT950

3VT 0.38 in. top width – Narrow profile

950 95 in. nominal outside length

Envelope uncogged

construction shown

General InformationAutomotive & TruckSpecialtyBushing HardwareV-BeltBandedSynchronousOverview

80

2015 Power Transmission Products V-Belt

Part #

Eff ective

Length (in.) Part #

Eff ective

Length (in.) Part #

Eff ective

Length (in.)

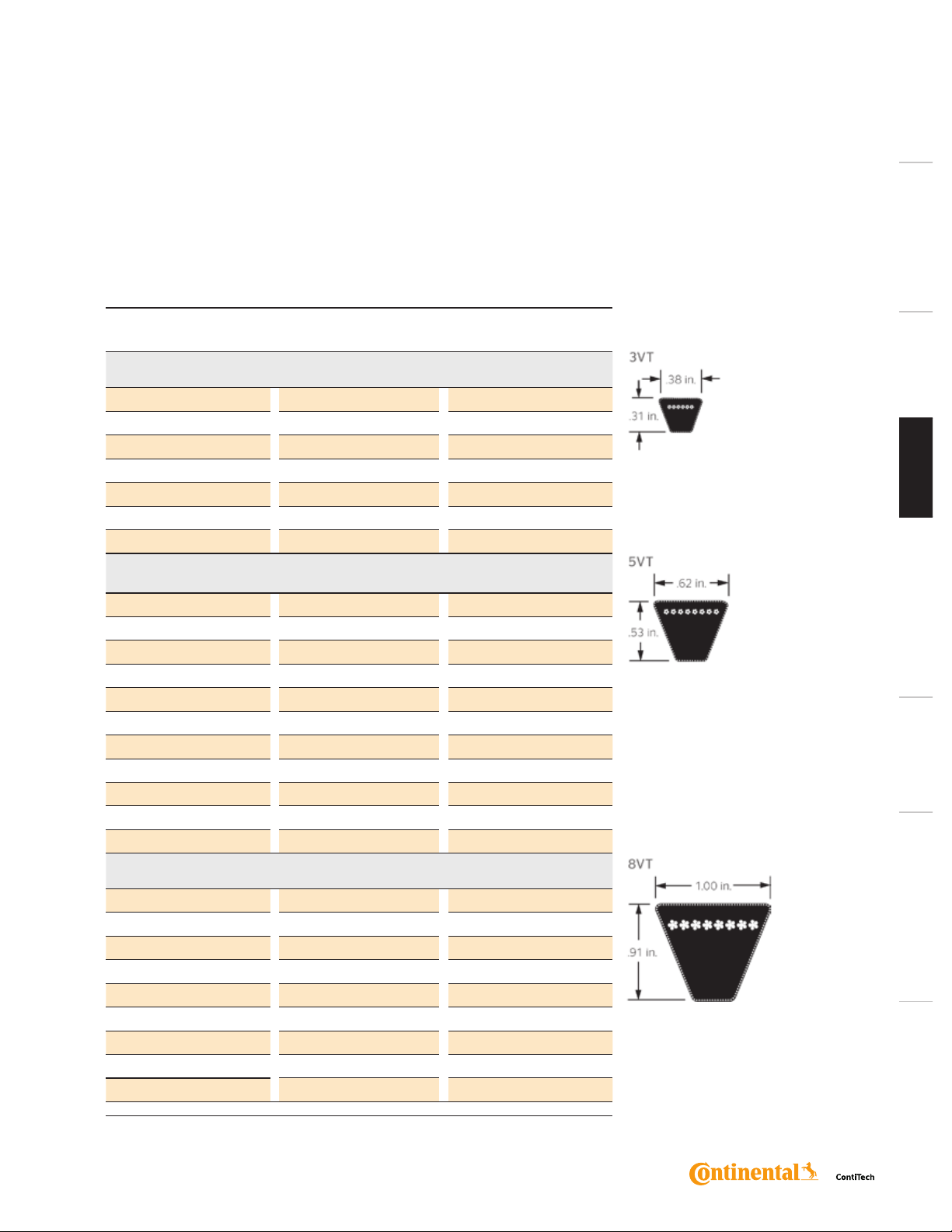

3VT

3VT500 50.0 3VT750 75.0 3VT1120 112 .0

3VT530 53.0 3V T80 0 80.0 3VT1180 118 . 0

3VT560 56.0 3VT850 85.0 3VT1250 125. 0

3VT600 60.0 3VT900 90.0 3VT1320 132 .0

3VT630 63.0 3V T950 95.0 3VT1400 140 .0

3VT670 67.0 3VT1000 100.0

3VT710 71.0 3V T1060 106. 0

5VT

5VT530 53 .0 5V T1000 100 .0 5VT1900 19 0.0

5VT560 56.0 5VT1060 106. 0 5VT2000 200.0

5VT600 60.0 5VT1120 112 .0 5VT2120 212.0

5VT630 63.0 5VT1180 118 .0 5VT2240 224.0

5VT670 67.0 5VT1250 12 5. 0 5VT2360 236.0

5VT710 71. 0 5VT1320 132 .0 5VT2500 250.0

5VT750 75.0 5VT1400 14 0. 0 5V T2650 265.0

5VT800 80.0 5VT1500 15 0.0 5V T2800 280.0

5VT850 85.0 5V T1600 160 .0 5VT3000 300.0

5VT900 90.0 5VT1700 17 0. 0 5VT3150 315.0

5VT950 95.0 5VT1800 180. 0

8VT

8VT1000 100. 0

8VT1800

180 .0 8VT3000 300.0

8VT1120 112. 0 8VT1900 190. 0 8VT3150 315.0

8VT1180 118 . 0 8VT2000 200.0 8VT3350 335.0

8VT1250 12 5. 0 8V T2120 212.0 8V T3550 355.0

8VT1320 132 .0 8VT2240 224.0 8VT3750 375.0

8VT1400 14 0.0 8VT2360 236.0 8VT4000 400.0

8VT1500 150. 0 8V T2500 250.0 8VT4250 425.0

8VT1600 160. 0 8VT2650 265.0 8VT4500 450.0

8VT1700 17 0. 0 8VT2800 280.0

Wedge TLP™ Narrow V-Belts

Cross Sections and Lengths Available

OverviewSynchronousBandedV-BeltBushing HardwareSpecialtyAutomotive & TruckGeneral Information

81

HY-T® Wedge Cogged belt s are high-horsepower belt

constructions that are identified with a 3VX and 5VX prefix

and are available in lengths up to 200 inches. The cogged

construction provides the high flexibility required for short

center distances. The cogs also provide a larger surface area

to dissipate heat and prolong belt life. Improved material

properties and advanced construction technology results in an

average horsepower increase of 30% over standard “Classical”

V-belt and wedge belts.

HY-T® Wedge envelope belts are identified with a 3V, 5V or 8V

prefix and are recommended for drives where pulsation, shock

loads, high tension and long centers are involved. It features

a continuous V-section that is protected by a wide angle,

synthetic fabric impregnated with high-quality engineered

rubber compound. This unique envelope achieves the high

strength HY-T® Wedge belt s need to withstand high loading

forces. It also provides the torsional rigidity required in long

center drives delivering the traction needed for accurate

tracking and precision performance.

*Dr ive condi tio ns and service variables in com bin ati on with t ime in

ope ration c an result in a l oss of static con ducti vit y. I t is re comme nded

that a conductivity check be added to drive preventive maintenance

programs where belt static conductivity is a requirement.

A wedge cross-section means the belts are narrower and weigh

less . Narrower belts allow for the use of thinner and lighter

sheaves, resulting in a more efficient drive.

The savings continue through the higher horsepower capacity

provided by Continental ContiTech HY-T® V-belt construction.

Vytacord® tension members provide strength and dimensional

stability. Higher horsepower capacity is also provided through a

tough engineered rubber compound cushion, adding to

belt strength.

HY-T® Wedge, with its narrow cross-section, makes it possible to

achieve a required horsepower with fewer HY-T® Wedge belts

than with standard V-belts, reducing sheave size, sheave costs

and belt costs even more.

Since less power is required to run the smaller, lighter drives,

more power gets to the load. Therefore, you may be able to

downsize drive motors and/or increase drive efficiency for even

more savings.

Matchmaker

®

performance

HY-T® Wedge belts eliminate mismatch problems as each

Matchmaker® belt is mirrored in size and performance to every

other HY-T® Wedge belt in that size, no matter when or where it

was produced.

Cut-edge or envelope constructions

provide optimum performance

HY-T® Wedge belts are produced with a highly engineered

EPDM compound available in a cut-edge cogged construction

for increased flexibility and heat dissipation with a broader

temperature range than ever before (-40F to 230F/-40C to

110C). This belt can handle extremely high temperatures and

is also available in envelope construction for drives where

pulsation shock loads, high tension and long centers are involved.

Part Number: 5V1400

5V 0.62 in. top width – Narrow profile

1400 140 in. nominal outside length

Envelope uncogged

construction shown

HY-T® Wedge Belts

A narrower cross section and

stronger construction reduces

drive costs

The savings start in the basic wedge or narrow design of

the HY-T® Wedge belt. It has a narrower cross section than

standard V-belts so it distributes stresses more uniformly to

deliver more consistent, more reliable power transmission.

Applications

Narrow profile belts for compact, high horsepower drives, high

shock loading on short centers and small diameters. For designing

compact , heavy-duty drives where space limitation is a factor.

Key features & benefits

› Narrow profile provides savings through eff iciency.

› Greater horsepower than the Classical belt.

› Strong Vytacord® (polyester) tensile members.

› High-grade engineered rubber.

› Heat, ozone and abrasion resistant.

› Available i n raw- edge construction wi th cog s or envelope co nst ruc tion.

› Matchmaker® to eliminate mismatch.

› Static conductive.*

› Operates in a wide ambient temperature range (-400F to 2300F/- 40 0C to 1100C).

› EPDM construction (cut-edge cogged only).

General InformationAutomotive & TruckSpecialtyBushing HardwareV-BeltBandedSynchronousOverview

2015 Power Transmission Products V-Bel t2015 Power Transmission Products V-Bel t

82

Part #

Eff ective

Length (in.) Part #

Eff ective

Length (in.) Part #

Eff ective

Length (in.)

3VX

3VX250 25.0 3VX450 45.0 3VX850 85.0

3VX265 26.5 3V X475 47.5 3VX900 90.0

3VX280 28.0 3V X500 50.0 3VX950 95.0

3VX30 0 30.0 3VX530 53.0 3VX1000 100 .0

3VX315 31.5 3VX560 56.0 3V X1060 106. 0

3VX335 33.5 3V X600 60.0 3VX1120 112 .0

3VX350 35.0 3VX630 63.0 3VX1180 118 . 0

3VX355 35.5 3VX650 65.0 3VX1250 12 5. 0

3VX360 36.0 3VX670 67.0 3VX1320 132 .0

3VX375 37.5 3VX710 71.0 3VX1400 14 0. 0

3VX400 40.0 3VX750 75.0 3VX1500 150 .0

3VX425 42. 5 3VX800 80.0

5VX

5VX450 45.0 5VX690 69.0 5VX1030 103.0

5VX470 47.0 5VX710 71.0 5VX1060 106.0

5VX490 49.0 5VX730 73.0 5VX1080 108 .0

5VX500 50.0 5VX740 74. 0 5V X1120 112 . 0

5VX510

51. 0

5VX750

75.0

5VX1150

115 .0

5VX530 53.0 5VX780 78 .0 5V X1180 11 8. 0

5VX540 54.0 5VX800 80.0 5VX1230 12 3. 0

5VX550 55.0 5VX810 81.0 5V X1250 12 5. 0

5VX560

56.0

5VX830

83.0

5VX1277

122 .7

5VX570 57.0 5VX840 84.0 5VX1320 132 .0

5VX580 58.0 5VX850 85.0 5VX1400 140. 0

5VX590 59.0 5VX860 86.0 5VX1500 150. 0

5VX600 60.0 5V X880 88.0 5VX1600 160 .0

5VX610 61.0 5VX900 90.0 5VX1700 17 0. 0

5VX630 63.0 5VX930 93.0 5VX1800 180 .0

5VX650 65.0 5VX950 95.0 5VX1900 190 .0

5VX660 66.0 5VX960 96.0 5VX2120 212.0

5VX670 67.0 5VX1000 100. 0

5VX680 68.0 5V X1017 101. 7

8VX

8VX100 0 100. 0 8VX1320 132 .0 8VX1800 180. 0

8VX1060 106. 0 8VX1400 140 .0 8V X1900 190 .0

8VX1120

112 .0

8VX1500

150 .0

8VX2000

200.0

8VX1180 118 .0 8VX160 0 160. 0

8VX1250 125 .0 8VX1700 170. 0

*Cut-edge cogged construction. EPDM -400 F to 2300 F (-400C to 1100C) temperature range.

Cross Sections and Lengths Available

Cogged Sizes*

OverviewSynchronousBandedV-BeltBushing HardwareSpecialtyAutomotive & TruckGeneral Information

83

HY-T® Wedge Belts

Cross Sections and Lengths Available

Part #

Eff ective

Length (in.) Part #

Eff ective

Length (in.) Part #

Eff ective

Length (in.)

3V

3V250 25.0 3V475 47.5 3V90 0 90.0

3V265 26.5 3V500 50.0 3V950 95.0

3V280 28.0 3V530 53.0 3V1000 100. 0

3V300 30.0 3V560 56.0 3V1060 106 .0

3V315 31.5 3V600 60.0 3V1120 112 .0

3V335 33.5 3V630 63.0 3V1180 11 8. 0

3V355 35.5 3V670 67.0 3V1250 125 .0

3V375 37.5 3V710 71.0 3V1320 132 .0

3V400 40.0 3V750 75.0 3V1400 140 .0

3V425 42.5 3V80 0 80.0

3V450 45.0 3V X850 85.0

5V

5V500 50.0 5V1060 106. 0 5V2000 20 0.0

5V560 56.0 5V1120 112 . 0 5V2120 212.0

5V630 63.0 5V1180 118 .0 5V2240 224.0

5V670 67.0 5V1250 125 .0 5V2360 236.0

5V710 71.0 5V1320 132 .0 5V2500 250.0

5V750 75.0 5V1400 14 0. 0 5V2650 265.0

5V800 80.0 5V1500 15 0.0 5V2800 280 .0

5V850 85.0 5V1600 160. 0 5V300 0 300.0

5V900 90.0 5V1700 170 .0 5V3150 315.0

5V950 95.0 5V1800 180.0 5V3350 335.0

5V1000 100. 0 5V1900 19 0.0 5V3550 355.0

8V

8V1000 10 0.0 8V1800 18 0.0 8V3150 315.0

8V1060 10 6.0 8V1900 190. 0 8V3350 335.0

8V1120 112 . 0 8V2000 200.0 8V3550 355.0

8V1180 118 . 0 8V2120 212.0 8V3750 375.0

8V1250 12 5. 0 8V2240 224.0 8V4000 400.0

8V1320 13 2.0 8V2360 236 .0 8V4250 425. 0

8V1400 14 0. 0 8V2500 250.0 8V4500 450.0

8V1500 15 0.0 8V2650 265.0 8V4750 475.0

8V1600 16 0.0 8V2800 280.0 8V5000 500.0

8V1700 17 0. 0 8V3000 300.0 8V5600 560.0

Noncogged Sizes

General InformationAutomotive & TruckSpecialtyBushing HardwareV-BeltBandedSynchronousOverview

2015 Power Transmission Products V-Bel t2015 Power Transmission Products V-Belt

84

Part Number: B75

B 0.66 in. top width – Classical profile

75 Approximate 75 in. inside length

Vytacord® provides the high-strength, high-horsepower rating

capacity needed to effectively transmit today’s drive power. It is

even tough enough to tolerate slight sheave misalignment that

would quickly destroy ordinary belts.

The Vytacord® tensile member provides dimensional stability.

As a result, each belt of a given size will maintain its length

consistency, no matter when or where it was produced.

The exceptional dimensional stability properties of HY-T® Plus

eliminates matching problems, improves performance and

increases service life.

Improved materials are the key to the

durability and versatility of HY-T® Plus

The vast improvements in all components of HY-T® Plus

construction complement the quality of the Vytacord®

tensile member.

Our engineered heat- and oil-resistant rubber compound is

used in both the cushion and insulation sections of HY-T® Plus.

Belt construction provides the flexibility on small pulleys. As a

result the belt is able to serve a dual purpose for both Classical

and FHP, while offering more versatility than any other

Classical belt.

The HY-T® Plus envelope construction assures optimum warp

and fill thread angle, providing belt flexibility. In addition, the

fabric is treated with Continental ContiTech exclusive

engineered rubber compound for long wear and resistance to

heat, oil and other environmental hazards. The envelope also

assures that the belt dissipates static electricity, as specified in

ARPM bulletin IP3-3.

The cushion is also crush-resistant and cool running to maintain

its shape, fit and strength longer. And with the longer service

life achieved by HY-T® Plus belts, replacement of belts is less

frequent. Overall, belt costs are reduced, downtime is

minimized and equipment productivity is maintained.

Less inventory required

The HY-T® Plus can be used in FHP applications.

Conversely, rarely do FHP belts perform in HY-T® Plus

(Classical) applications.

The result is a reduced inventory that equates to dollars taken

off the shelves and into your pockets.

Applications

Designed for operating at high speeds over small diameter

pulleys and short center distances. Also for use in multiple

V-belt drives where high shock load and heavy-duty load

s

are encountered.

Key features & benefits

›

Universal Classical profile.

› High-strength Vytacord® tensile members.

› Engineered rubber-impregnated envelope.

› Engineered rubber compound cushion and insulation.

› Dual branded (Classical and FHP part numbers).

› Oil, heat, ozone and abrasion resistant.

› Matchmaker® to eliminate mismatch.

› Static conductive.*

HY-T® Plus (Classical) Belts

Less elongation is the key

to performance

Whether you are talking about rubber belts or metal chains,

most materials will elongate when put to use. The secret to

reliable performance is not to eliminate elongation, but to

control it so that it is minimal, predictable and uniform. To

achieve these criteria, we developed the Vytacord®

tensile member.

OverviewSynchronousBandedV-BeltBushing HardwareSpecialtyAutomotive & TruckGeneral Information

*Dr ive condi tio ns and service variables in com bin ati on with t ime in

ope ration c an result in a l oss of static con ducti vit y. I t is re comme nded

that a conductivity check

programs where belt static conductivity is a requirement.

be added to drive preventive maintenance

85

HY-T® Plus (Classical) Belts

Cross Sections and Lengths Available

Part #

App rox.

Outside

Length (in.) Part #

App rox.

Outside

Length (in.) Part #

App rox.

Outside

Length (in.)

A20 (4L220) 22 A51 (4L530) 53 A82 (4L840) 84

A21 (4L230) 23 A52 (4L540) 54 A83 (4L850) 85

A22 (4L240) 24 A53 (4L550) 55 A84 (4L860) 86

A23 (4L250) 25 A54 (4L560) 56 A85 (4L870) 87

A24 (4L260) 26 A55 (4L570) 57 A86 (4L880) 88

A25 (4L270) 27 A56 (4L580) 58 A87 (4L890) 89

A26 (4L280) 28 A57 (4L590) 59 A88 (4L900) 90

A27 (4L290) 29 A58 (4L600) 60 A89 (4L910) 91

A28 (4L300) 30 A59 (4L610) 61 A90 (4L920) 92

A29 (4L310) 31 A60 (4L620) 62 A91 (4L930) 93

A30 (4L320) 32 A61 (4L630) 63 A92 (4L940) 94

A31 (4L330) 33 A62 (4L640) 64 A93 (4L950) 95

A32 (4L340) 34 A63 (4L650) 65 A94 (4L960) 96

A33 (4L350) 35 A64 (4L660) 66 A95 (4L970) 97

A34 (4L360) 36 A65 (4L670) 67 A96 (4L980) 98

A35 (4L370) 37 A66 (4L680) 68 A97 (4L990) 99

A36 (4L380) 38 A67 (4L690) 69 A98 (4L1000) 100

A37 (4L390) 39 A68 (4L700) 70 A10 0 (4 L1020 ) 102

A38 (4L400) 40 A69 (4L710) 71 A10 3 105

A39 (4L410) 41 A70 (4L720) 72 A10 5 107

A40 (4L420) 42 A71 (4L730) 73 A11 0 112

A41 (4L430) 43 A72 (4L740) 74 A112 114

A42 (4L440) 44 A73 (4L750) 75 A12 0 12 2

A43 (4L450) 45 A74 (4L760) 76 A128 13 0

A44 (4L460) 45 A75 (4L770) 77 A133 13 5

A45 (4L470) 47 A76 (4L780) 78 A136 13 8

A46 (4L480) 48 A77 (4L790) 79 A1 44 14 6

A47 (4L490) 49 A78 (4L8 00) 80 A15 8 160

A48 (4L500) 50 A79 (4L810) 81 A173 17 5

A49 (4L510) 51 A80 (4L820) 82 A18 0 182

A50 (4L520) 52 A81 (4L830) 83

A Section

General InformationAutomotive & TruckSpecialtyBushing HardwareV-BeltBandedSynchronousOverview

2015 Power Transmission Products V-Bel t2015 Power Transmission Products V-Belt

86

Part #

App rox.

Outside

Length (in.)

Part #

App rox.

Outside

Len gth (in .) Part #

App rox.

Outside

Length (in.)

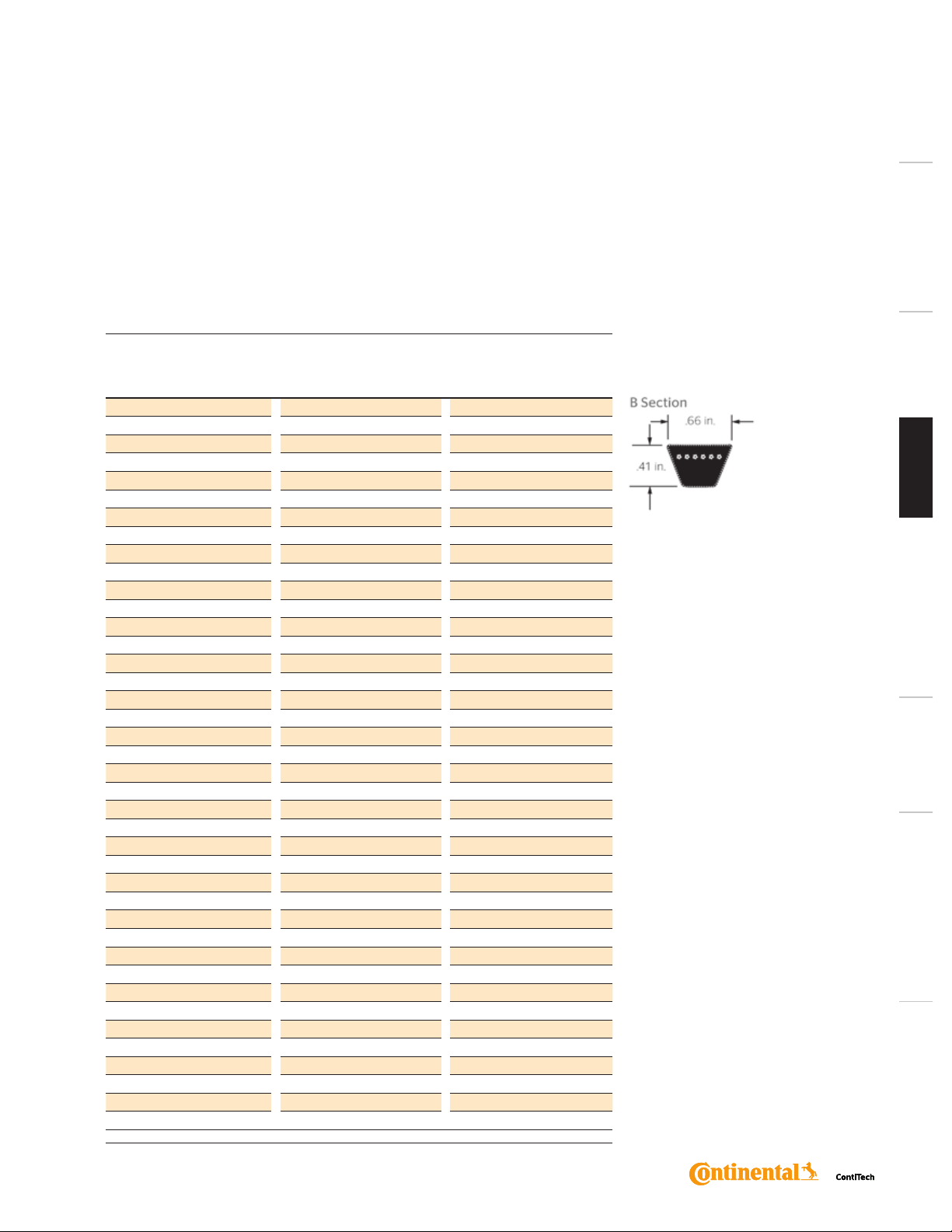

B22 (5L250) 25 B62 (5L650) 65 B103 10 6

B23 (5L260) 26 B63 (5L660) 66 B104 107

B24 (5L270) 27 B64 (5L670) 67 B105 10 8

B25 (5L280) 28 B65 (5L680) 68 B108 111

B26 (5L290) 29 B66 (5L690) 69 B111 114

B27 (5L300) 30 B67 (5L700) 70 B112 115

B28 (5L310) 31 B68 (5L710) 71 B115 118

B29 (5L320) 32 B69 (5L720) 72 B116 11 9

B30 (5L330) 33 B70 (5L730) 73 B118 12 1

B31 (5L340) 34 B71 (5L740) 74 B120 123

B32 (5L350) 35 B72 (5L750) 75 B124 12 7

B33 (5L360) 36 B73 (5L760) 76 B126 129

B34 (5L370) 37 B74 (5L770) 77 B128 131

B35 (5L380) 38 B75 (5L780) 78 B133 13 6

B36 (5L390) 39 B76 (5L790) 79 B136 13 9

B37 (5L400) 40 B77 ( 5L800) 80 B140 143

B38 (5L410)

41

B78 ( 5L810)

81

B144

147

B39 (5L420) 42 B79 (5L820) 82 B148 151

B40 (5L430) 43 B80 (5L830) 83 B150 15 3

B41 (5L440) 44 B81 (5L840) 84 B154 15 7

B42 (5L450)

45

B82 (5L850)

85

B158

161

B43 (5L460) 46 B83 (5L860) 86 B162 165

B44 (5L470) 47 B84 (5L870) 87 B173 17 6

B45 (5L480) 48 B85 (5L880) 88 B180 18 3

B46 (5L490)

49

B86 (5L890)

89

B190

193

B47 (5L500) 50 B87 (5L900) 90 B195 19 8

B48 (5L510) 51 B88 (5L910) 91 B205 208

B49 (5L520) 52 B89 (5L920) 92 B210 213

B50 (5L530) 53 B90 (5L930) 93 B225 227

B51 (5L540) 54 B91 (5L940) 94 B240 242

B52 (5L550) 55 B92 (5L950) 95 B255 257

B53 (5L560) 56 B93 (5L960) 96 B270 272

B54 (5L570) 57 B94 (5L970) 97 B285 287

B55 (5L580) 58 B95 (5L980) 98 B300 302

B56 (5L590) 59 B96 (5L990) 99 B315 317

B57 (5L600) 60 B97 (5L1000) 100 B330 332

B58 (5L610) 61 B98 (5L1010) 101 B360 362

B59 (5L620) 62 B99 (5L1020) 102 B394 396

B60 (5L630) 63 B100 103

B61 (5L640) 64 B101 10 4

B Section

OverviewSynchronousBandedV-BeltBushing HardwareSpecialtyAutomotive & TruckGeneral Information

87

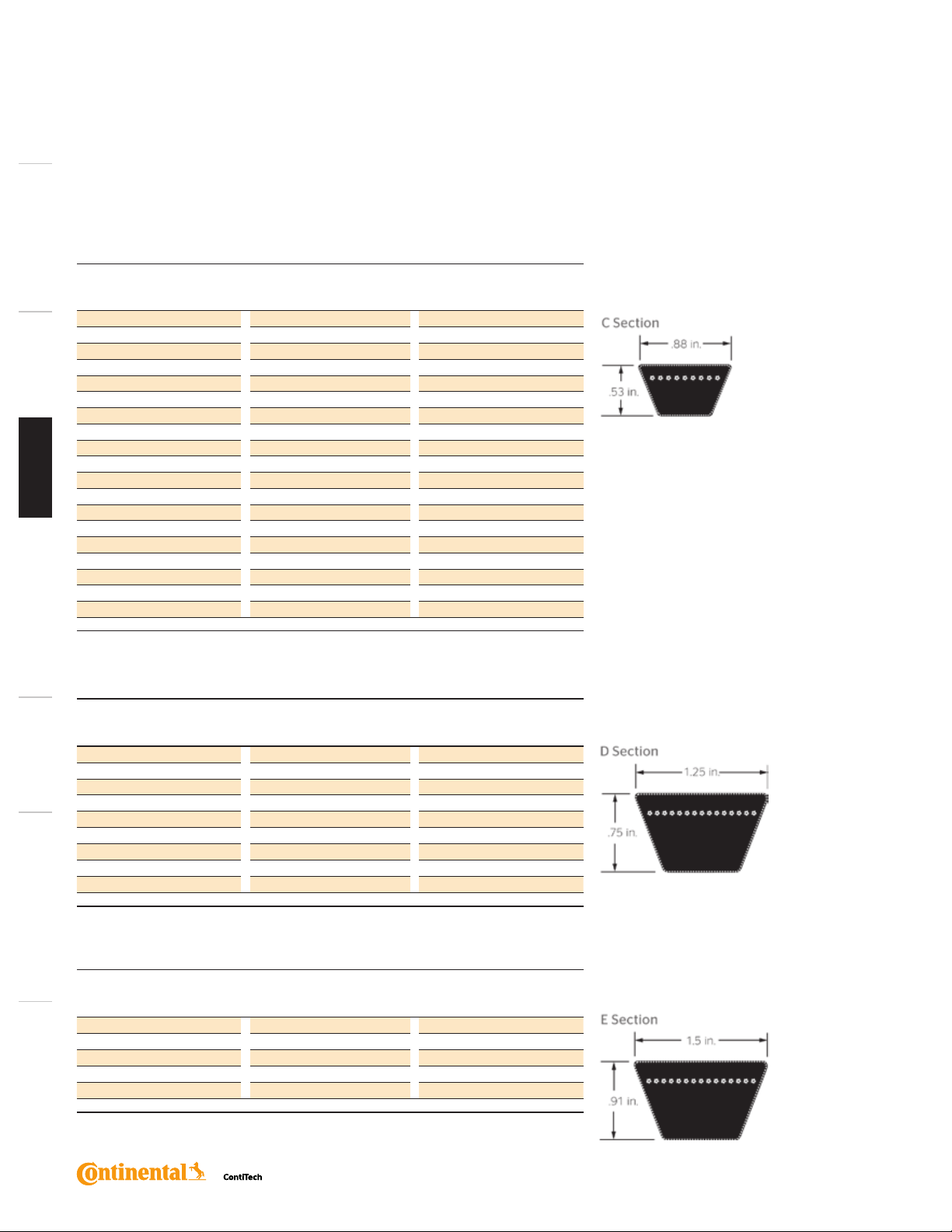

Part #

App rox. Ou tsid e

Length (in.) Part #

App rox. Ou tsid e

Length (in.) Part #

App rox. Ou tsid e

Length (in.)

E180 187 E300 304 E480 484

E195 202 E330 334 E540 544

E210 217 E360 364 E600 604

E240

244

E390

394

E270 274 E420 424

E Section

Part #

App rox. Ou tsid e

Length (in.) Part #

App rox. Ou tsid e

Length (in.) Part #

App rox. Ou tsid e

Length (in.)

C48 52 C103 107 C173 17 7

C5054C105

109

C180

184

C51 55 C106 11 0 C190 19 4

C55 59 C108 112 C195 199

C60 64 C109 113 C210 214

C62 66 C110 114 C225 227

C6872C112

116

C240

242

C71 75 C115 11 9 C255 257

C72 76 C120 124 C270 272

C75 79 C124 12 8 C285 287

C78 82 C128 13 2 C300 302

C8084C136

140

C315

317

C81 85 C144 14 8 C330 332

C85 89 C148 152 C345 347

C90 94 C150 154 C360 362

C93 97 C156 160 C390 392

C9498C158

162

C420

422

C100 10 4 C162 166

C101 10 5 C165 169

C Section

Part #

App rox. Ou tsid e

Length (in.) Part #

App rox. Ou tsid e

Length (in.) Part #

App rox. Ou tsid e

Length (in.)

D112 117 D210 215 D345 348

D120 12 5 D225 228 D360 363

D128 13 3 D240 243 D390 393

D144 149 D255 258 D420 423

D158 163 D270 273 D450 453

D162 167 D285 388 D480 483

D173 178 D300 303 D540 543

D180 185 D315 318

D195

200

D330

333

D Section

HY-T® Plus (Classical) Belts

Cross Sections and Lengths Available

General InformationAutomotive & TruckSpecialtyBushing HardwareV-BeltBandedSynchronousOverview

2015 Power Transmission Products V-Bel t2015 Power Transmission Products V-Belt

88

Part Number: BX75

B 0.66 in. top width – Classical profile

X Premium cogged construction

75 Approximate 75 in. inside length

Cut-edge, molded cog

construction shown

Torque-Flex® V-belts are fully cogged to provide the flexibility

needed to keep their high-traction rubber edges in contact with

the sheave grooves. This high efficiency allows you to achieve

the horsepower you need at a lower total drive cost.

Produced with a highly engineered EPDM compound, cut-edge

cogged construction belts operate in a broader temperature

range than ever before (-400F to 2300F/-4 00C to 1100C).

Torq ue -Flex® V -b elts can handle e xt rem el y h igh te mp erat ures .

Exacting precision and uniformity

Rigid quality assurance programs imposed during Torque-Flex®

V-belt manufacture result in belt angles and belt lengths whic

h

are more exact than standard belts. This results in quiet,

smooth-running and long-lasting belts. Think what that can

save in reduced downtime and belt maintenance.

Of course, with such exacting production requirements, our

Torque-Flex® V-belts also achieve consistent uniformity from

run to run. This outstanding consistency means you can be

sure that two belts of the same size designation will match, no

matter when they were produced. As a result:

› You el imi nat e m ismatchi ng proble ms caus ed by ind ivi dual

belts that may be too loose or too tight.

› You simplify ordering procedures – no lengthy specifications,

detailing match-ups and sizing.

› No complicated time-consuming matching. Your

Continental ContiTech belts are automatically matched when

you buy them.

› You reduce your in-plant inventory. The Matchmaker®

system covers your needs with a minimum of belts to

save you space and inventory dollars.

More savings from fewer belts

The high-strength and high horsepower capacity of

Torque-Flex® V-belts means you need fewer belts and fewer

sheave grooves to deliver the same amount of horsepower.

Energy-saving efficiency

The same design and construction features which lead to

high horsepower ratings for Torque -Flex® V-belts also lead to

improvements in energy efficiency of up to 4%, depending on

sheave diameter.

Applications

Designed for the tough, small sheave, high-tension drives.

Key features & benefits

›

Premium Classical profile construction.

› 25%–30% higher power ratings than standard V-belts .

› Strong Vytacord® (polyester) tensile members.

› Engineered cushion compound.

› Cut-edge cogged construction on most sizes.

› Heat, ozone and abrasion resistant.

› Matchmaker® to eliminate mismatch.

› Static conductive.*

› Operates in a wide ambient temperature range (-400F to

2300F/- 400C to 1100C).

› EPDM construction (cut-edge cogged only).

Torq ue -Fl ex

®

V-Belts

More horsepower per dollar

Your drives can deliver the horsepower you want at a lower

component cost – and with lower energy costs – when

you include Continental ContiTech Torque-Flex® V-belts in

the design.

98

96

94

92

90

88

Sheave Diameter (in.)

Belt Efficiency

2 3 4 5 6 7 8 9

Efficiency, %

Cogged vs. Noncogged Belt Efficiency

Cogged

Noncogged

*Drive conditions and

service variables in

combin ati on wit h t ime

in o pe rat ion can result

in a lo ss of static

con duc tivit y. I t is

recomm ended th at a

con duc tivit y che ck be

added to drive

preventive maintenance

programs whe re bel t

sta tic co nductivity is a

require ment .

OverviewSynchronousBandedV-BeltBushing HardwareSpecialtyAutomotive & TruckGeneral Information

89

Torq ue -Fl ex

®

V-Belts

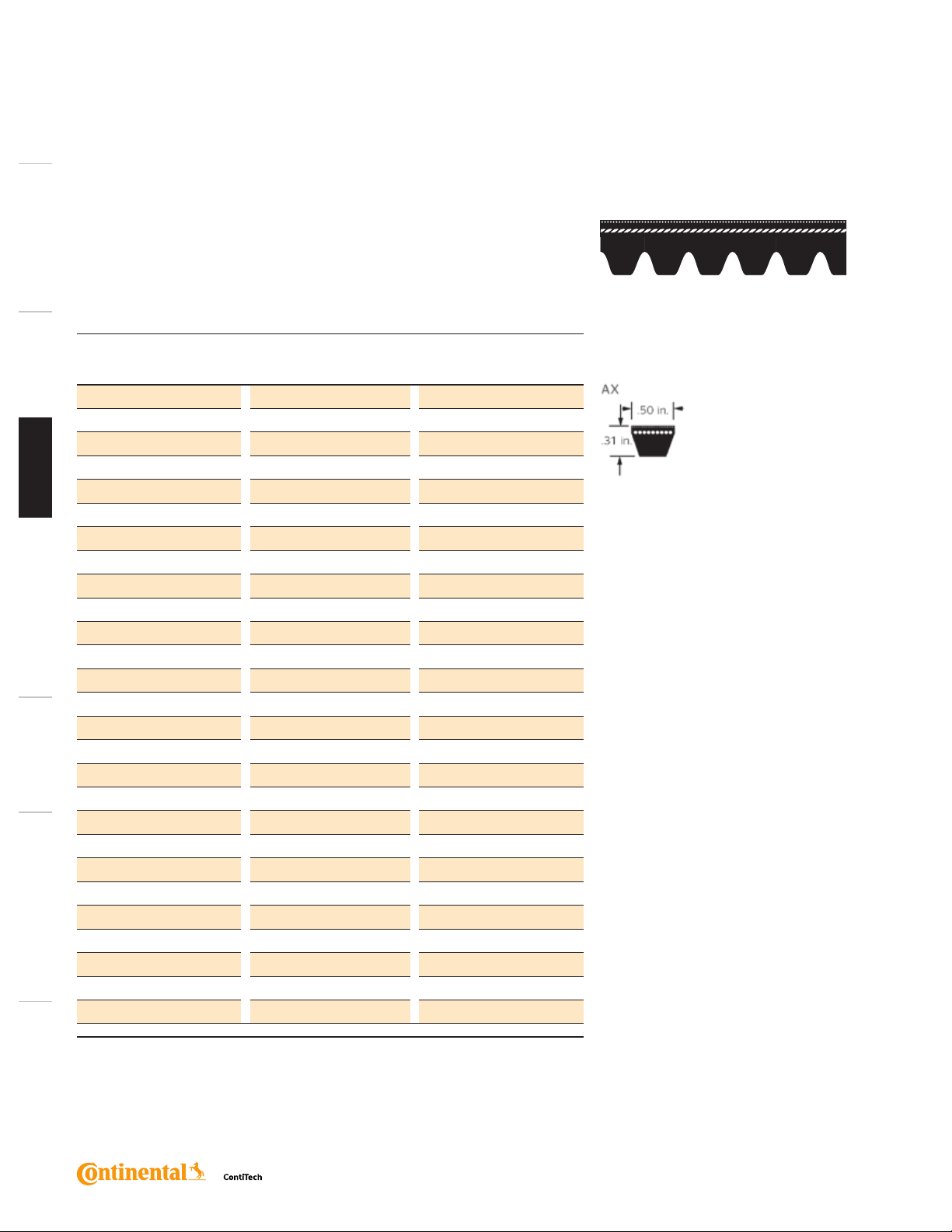

Cross Sections and Lengths Available

Part #

App rox. Ou tsid e

Length (in.) Part #

App rox. Ou tsid e

Length (in.) Part #

App rox. Ou tsid e

Length (in.)

AX21 23 AX49 51 AX76 78

AX22 24 AX50 52 AX77 79

AX23 25 AX51 53 AX78 80

AX24 26 AX52 54 AX79 81

AX26 28 AX53 55 AX80 82

AX27 29 AX54 56 AX81 83

AX28 30 AX55 57 AX82 84

AX29 31 AX56 58 AX83 85

AX30 32 AX57 59 AX84 86

AX31 33 AX58 60 AX85 87

AX32 34 AX59 61 AX86 88

AX33 35 AX60 62 AX87 89

AX34 36 AX61 63 AX88 90

AX35 37 AX62 64 AX89 91

AX36 38 AX63 65 AX90 92

AX37 39 AX64 66 AX91 93

AX38 40 AX65 67 AX93 95

AX39 41 AX66 68 AX94 96

AX40 42 AX67 69 AX95 97

AX41 43 AX68 70 AX96 98

AX42 44 AX69 71 AX97 99

AX43 45 AX70 72 AX98 10 0

AX44 46 AX71 73 AX100 102

AX45 47 AX72 74 AX103 10 5

AX46 48 AX73 75 AX105 107

AX47 49 AX74 76 AX110 112

AX48 50 AX75 77 AX112 114

*Cut-edge cogged construction. EPDM -400 F to 2300 F (-400C to 1100C) temperature range.

AX*

Side View

General InformationAutomotive & TruckSpecialtyBushing HardwareV-BeltBandedSynchronousOverview

2015 Power Transmission Products V-Bel t2015 Power Transmission Products V-Belt

90

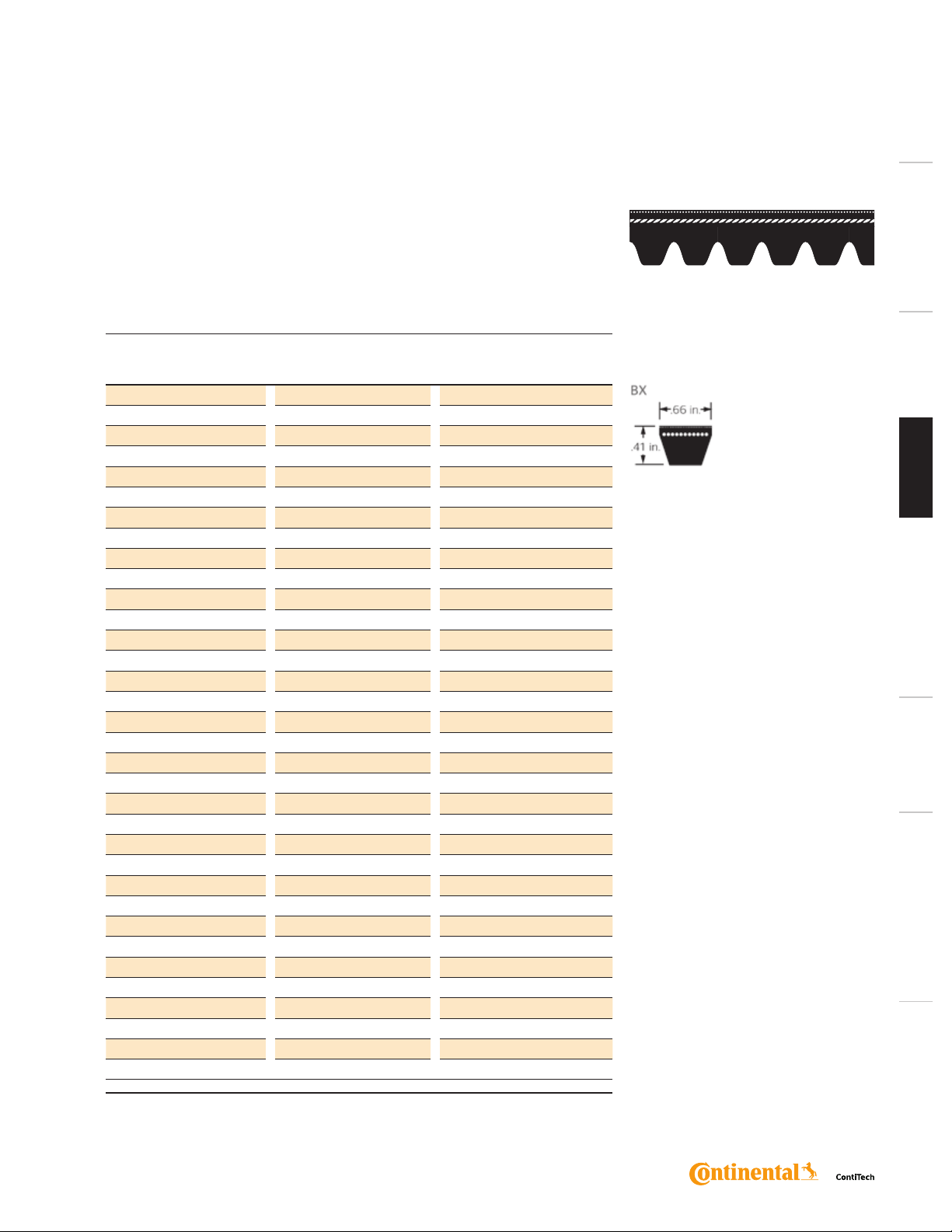

Part #

App rox. Ou tsid e

Length (in.) Part #

App rox. Ou tsid e

Length (in.) Part #

App rox. Ou tsid e

Length (in.)

BX28 31 BX67 70 BX103 10 6

BX31 34 BX68 71 BX105 108

BX3235BX6972BX106

109

BX34 37 BX70 73 BX108 111

BX35 38 BX71 74 BX112 115

BX3639BX7275BX113

116

BX38 41 BX73 76 BX115 118

BX40 43 BX74 77 BX116 119

BX41 44 BX75 78 BX120 123

BX42 45 BX76 79 BX123 12 6

BX43 46 BX77 80 BX124 12 7

BX44 47 BX78 81 BX126 12 9

BX45 48 BX79 82 BX128 131

BX46 49 BX80 83 BX133 13 6

BX47 50 BX81 84 BX136 139

BX48 51 BX82 85 BX140 143

BX49 52 BX83 86 BX144 14 7

BX50 53 BX84 87 BX148 151

BX51 54 BX85 88 BX150 153

BX52 55 BX86 89 BX154 157

BX53 56 BX87 90 BX158 161

BX54 57 BX88 91 BX162 165

BX55 58 BX89 92 BX173 17 6

BX56 59 BX90 93 BX180 183

BX5760BX9194BX191

194

BX58 61 BX92 95 BX195 198

BX59 62 BX93 96 BX210 213

BX6063BX9497BX225

228

BX61 64 BX95 98 BX240 243

BX62 65 BX96 99 BX255 258

BX6366BX97

100

BX270

273

BX64 67 BX98 101 BX300 303

BX65 68 BX99 102

BX66 69 BX100 103

*Cut-edge cogged construction. EPDM -400 F to 2300 F (-400C to 1100C) temperature range.

BX*

Side View

OverviewSynchronousBandedV-BeltBushing HardwareSpecialtyAutomotive & TruckGeneral Information

Loading...

Loading...