Continental Belt HY-T Wedge Torque Team Belts Catalog Page

67

the belt. The cushion is made of fiber-reinforced, engineered

compounds providing oil, heat, ozone and abrasion resistance.

Wedge or envelope constructions provide

optimum performance

HY-T® Wedge Torque Team® belts are available in a raw edge

construction with cogs for increased flexibility and heat

dissipation or envelope construction for drives where pulsation,

shock loads, high tension and long center are involved.

HY-T® Wedge Torque Team® cogged belts have high-horsepower

belt construction and are identified with a 3VX or 5VX prefix

and are available in lengths up to 140 inches. The cogged

construction provides the high flexibility required for short

center distances. The cogs also provide a larger surface area

to dissipate heat and prolong belt life. Improved material

properties and advanced construction technology result in

an average horsepower increase of 30% over standard joined

“Classical” V-belts.

HY-T® Wedge Torque Team® envelope belts are identified with

a 3V, 5V or 8V prefix and are recommended for drives where

pulsation, shock loads, high tension and long centers are

involved. They feature a continuous V-section that is protected

by a wide angle, synthetic fabric-impregnated, high-quality

rubber compound. The unique envelope achieves the high

strength that the HY-T® Wedge Torque Team® belts need to

withstand high loading forces. It also helps provide the torsional

rigidity in long center drives delivering the traction needed for

accurate tracking and precision performance.

Pulsation, vibration, shock loads and misalignment are problems

for any team of V-belts, no matter how perfectly matched the

individual units. These conditions often lead to chronic belt

whip or to belt turnover, resulting in premature wear or sudden

failure of one or more belts. Of course, when one belt goes, the

whole team has to be replaced.

Each rib in a HY-T® Wedge Torque Team® belt is free to wedge

into the sheave groove for maximum trac tion, maximum power

and transmission efficiency.

Operating in standard sheave grooves without sheave or drive

modification, they can tame any problem drives now in operation.

Or they can fit right in with your new drive designs without

special modifications.

Designed and built to deliver

superior performance

V-belt performance begins with the tension members, so we

built HY-T® Wedge Torque Team® V-belts with super strong

Vytacord.® It provides the high-strength, high-horsepower

rating capacity needed to effectively transmit drive power.

And it is tough enough to tolerate the misalignment that

quickly destroys belts. The Vytacord® material is a polyester

construction with excellent strength and minimal elongation.

Drive performance is consistent, reliable and predictable over

the life of the belt.

We then add a tough oil- and abrasion-resistant fabric backing

to provide maximum longitudinal flexibility and lateral strength

to withstand the dynamic forces acting within a joined belt .

The backing also has special adhesion characteristics that

enable it to bond to the V-sections to maintain the integrity of

Part Number: 3/8V1900

3/ 3 rib joined construction

8V 1 in. top width – Narrow profile rib

1900 190 in. nominal outside length

Single envelope ply on 5Vs

2 envelope plies on 8Vs

Envelope uncogged

construction shown

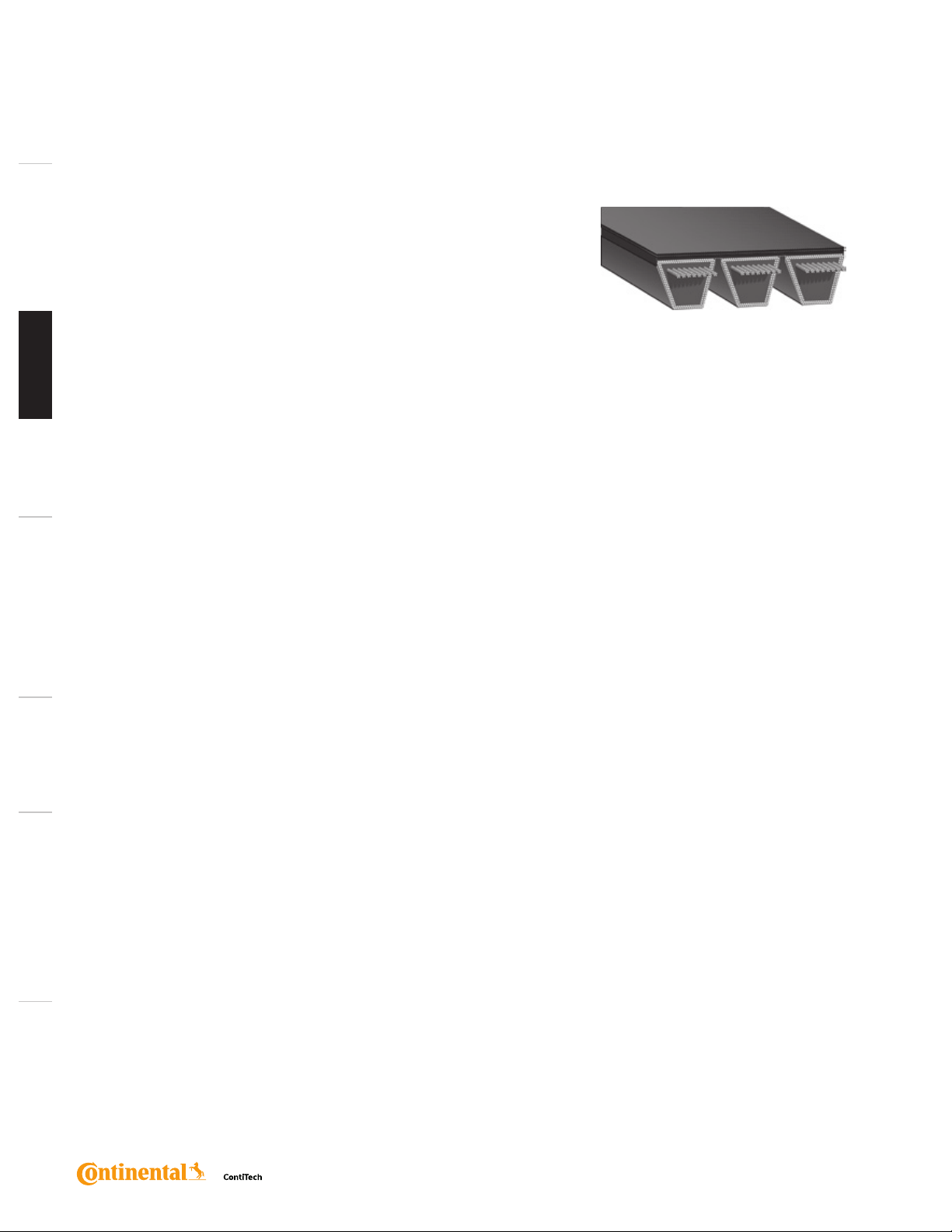

HY-T® Wedge Torque Team® Belts

Tame your problem drives

Built with multiple belts joined by a tough, rubber-impregnated

fabric backing that regulates belt travel so all ribs pull

together as a single, perfectly matched team.

General InformationAutomotive & TruckSpecialtyBushing HardwareV-BeltBandedSynchronousOverview

68

2015 Power Transmission Products Synchron ou s2015 Power Transmission Products Synchron ou s 2015 Power Transmission Products Banded

Matchmaker® performance

Our Matchmaker® technology results in belt consistency run

to run. That means each HY-T® Wedge Torque Team® is equal

in size and performance to every other HY-T® Wedge Torque

Team® belt in that size, no matter when or where it

was produced.

By eliminating mismatch problems, there is no costly and

complicated belt matching to get a drive back on line; no

problems with belts that are too tight or too loose.

Available in the most extensive stock line

in the industry

HY-T® Wedge Torque Team® belts are available from stock in

any number of belts per team, up to the number of ribs

indicated. Nonstock lengths are also available in these rib

counts, up to a maximum of 730 inches (180 inches for

3V cross sections).

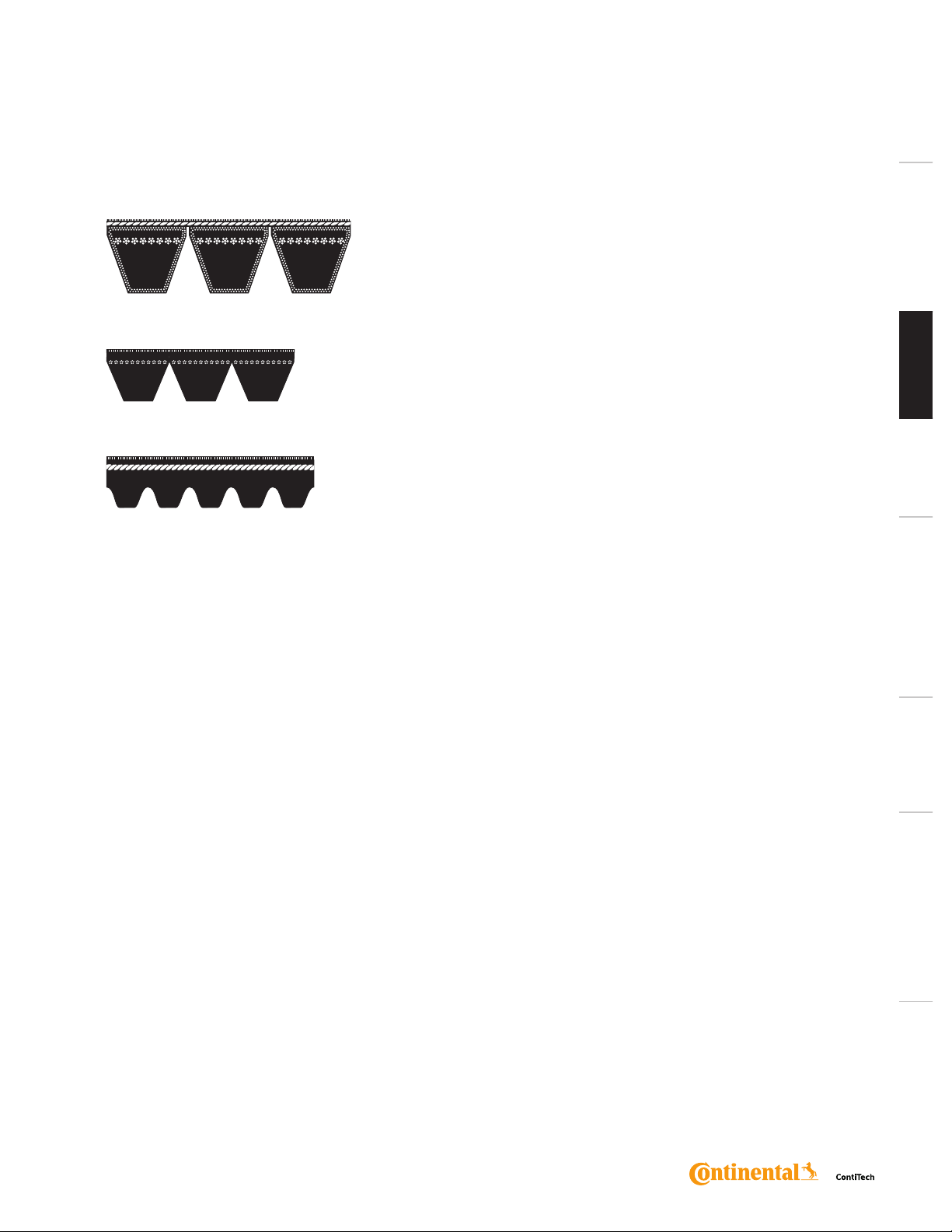

Envelope 5V, 8V Cross Section

Cut Edge 3VX, 5VX Cross Section

Cut Edge Side View

Applications

For shock load applications. Ideal for pulsating loads, high

capacity drives and for short-center, heavy-duty drives.

Key features & benefits

›

Narrow profile ribs provide savings through efficiency.

› Joined construction for problem drives.

› Strong Vytacord® tensile members.

› Toug h fabr ic backi ng .

› Oil, heat, ozone and abrasion resistant.

› Available in raw edge construction with cogs or

envelope construction.

› Matchmaker® to eliminate mismatch.

› Static conductive.*

*Dr ive condi tio ns and service variables in com bin ati on with t ime in

ope ration c an result in a l oss of static con ducti vit y. I t is re comme nded

that a conductivity check be added to drive preventive maintenance

programs where belt static conductivity is a requirement.

OverviewSynchronousBandedV-BeltBushing HardwareSpecialtyAutomotive & TruckGeneral Information

Loading...

Loading...