Continental Belt HY-T Wedge Belts Catalog Page

81

HY-T® Wedge Cogged belt s are high-horsepower belt

constructions that are identified with a 3VX and 5VX prefix

and are available in lengths up to 200 inches. The cogged

construction provides the high flexibility required for short

center distances. The cogs also provide a larger surface area

to dissipate heat and prolong belt life. Improved material

properties and advanced construction technology results in an

average horsepower increase of 30% over standard “Classical”

V-belt and wedge belts.

HY-T® Wedge envelope belts are identified with a 3V, 5V or 8V

prefix and are recommended for drives where pulsation, shock

loads, high tension and long centers are involved. It features

a continuous V-section that is protected by a wide angle,

synthetic fabric impregnated with high-quality engineered

rubber compound. This unique envelope achieves the high

strength HY-T® Wedge belt s need to withstand high loading

forces. It also provides the torsional rigidity required in long

center drives delivering the traction needed for accurate

tracking and precision performance.

*Dr ive condi tio ns and service variables in com bin ati on with t ime in

ope ration c an result in a l oss of static con ducti vit y. I t is re comme nded

that a conductivity check be added to drive preventive maintenance

programs where belt static conductivity is a requirement.

A wedge cross-section means the belts are narrower and weigh

less . Narrower belts allow for the use of thinner and lighter

sheaves, resulting in a more efficient drive.

The savings continue through the higher horsepower capacity

provided by Continental ContiTech HY-T® V-belt construction.

Vytacord® tension members provide strength and dimensional

stability. Higher horsepower capacity is also provided through a

tough engineered rubber compound cushion, adding to

belt strength.

HY-T® Wedge, with its narrow cross-section, makes it possible to

achieve a required horsepower with fewer HY-T® Wedge belts

than with standard V-belts, reducing sheave size, sheave costs

and belt costs even more.

Since less power is required to run the smaller, lighter drives,

more power gets to the load. Therefore, you may be able to

downsize drive motors and/or increase drive efficiency for even

more savings.

Matchmaker

®

performance

HY-T® Wedge belts eliminate mismatch problems as each

Matchmaker® belt is mirrored in size and performance to every

other HY-T® Wedge belt in that size, no matter when or where it

was produced.

Cut-edge or envelope constructions

provide optimum performance

HY-T® Wedge belts are produced with a highly engineered

EPDM compound available in a cut-edge cogged construction

for increased flexibility and heat dissipation with a broader

temperature range than ever before (-40F to 230F/-40C to

110C). This belt can handle extremely high temperatures and

is also available in envelope construction for drives where

pulsation shock loads, high tension and long centers are involved.

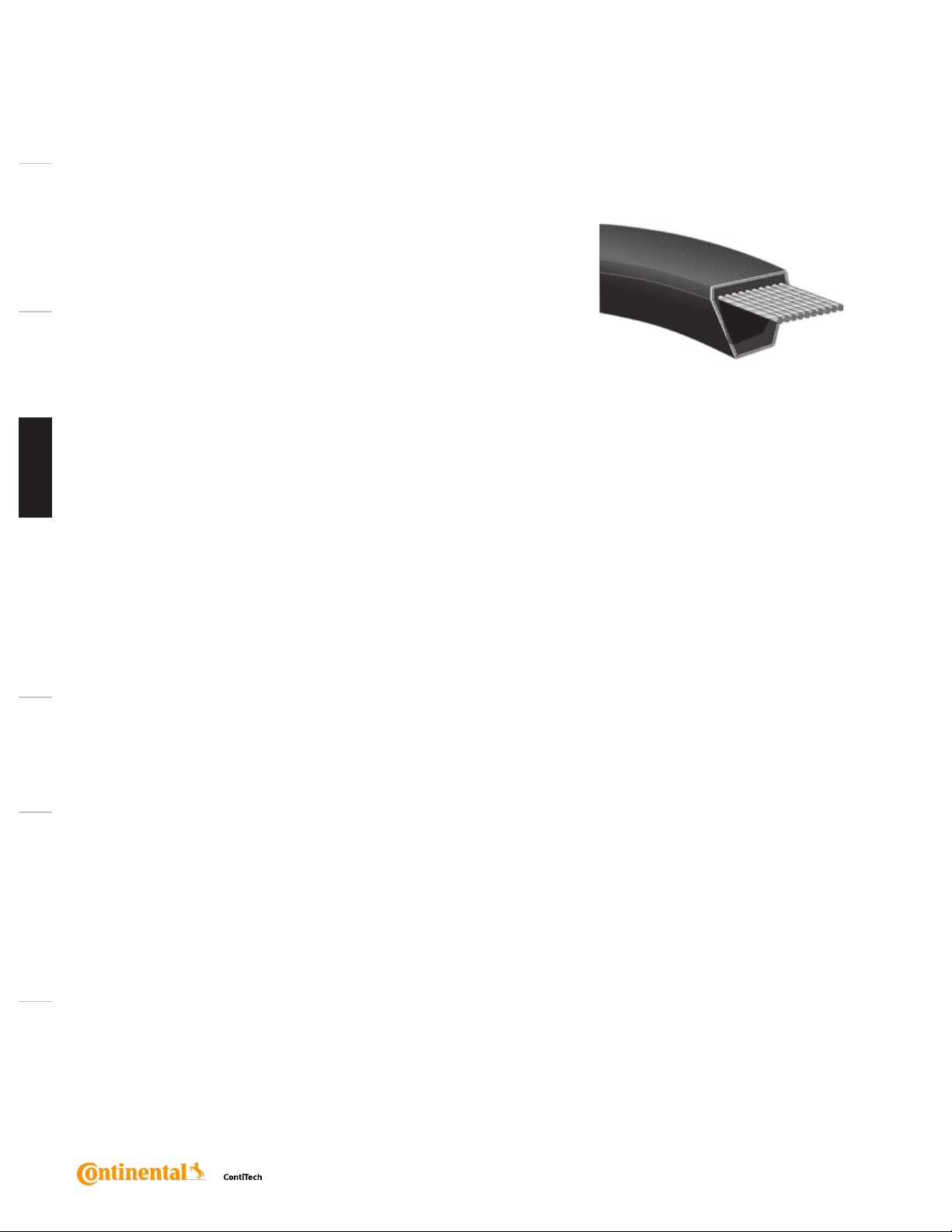

Part Number: 5V1400

5V 0.62 in. top width – Narrow profile

1400 140 in. nominal outside length

Envelope uncogged

construction shown

HY-T® Wedge Belts

A narrower cross section and

stronger construction reduces

drive costs

The savings start in the basic wedge or narrow design of

the HY-T® Wedge belt. It has a narrower cross section than

standard V-belts so it distributes stresses more uniformly to

deliver more consistent, more reliable power transmission.

Applications

Narrow profile belts for compact, high horsepower drives, high

shock loading on short centers and small diameters. For designing

compact , heavy-duty drives where space limitation is a factor.

Key features & benefits

› Narrow profile provides savings through eff iciency.

› Greater horsepower than the Classical belt.

› Strong Vytacord® (polyester) tensile members.

› High-grade engineered rubber.

› Heat, ozone and abrasion resistant.

› Available i n raw- edge construction wi th cog s or envelope co nst ruc tion.

› Matchmaker® to eliminate mismatch.

› Static conductive.*

› Operates in a wide ambient temperature range (-400F to 2300F/- 40 0C to 1100C).

› EPDM construction (cut-edge cogged only).

General InformationAutomotive & TruckSpecialtyBushing HardwareV-BeltBandedSynchronousOverview

2015 Power Transmission Products V-Bel t2015 Power Transmission Products V-Bel t

82

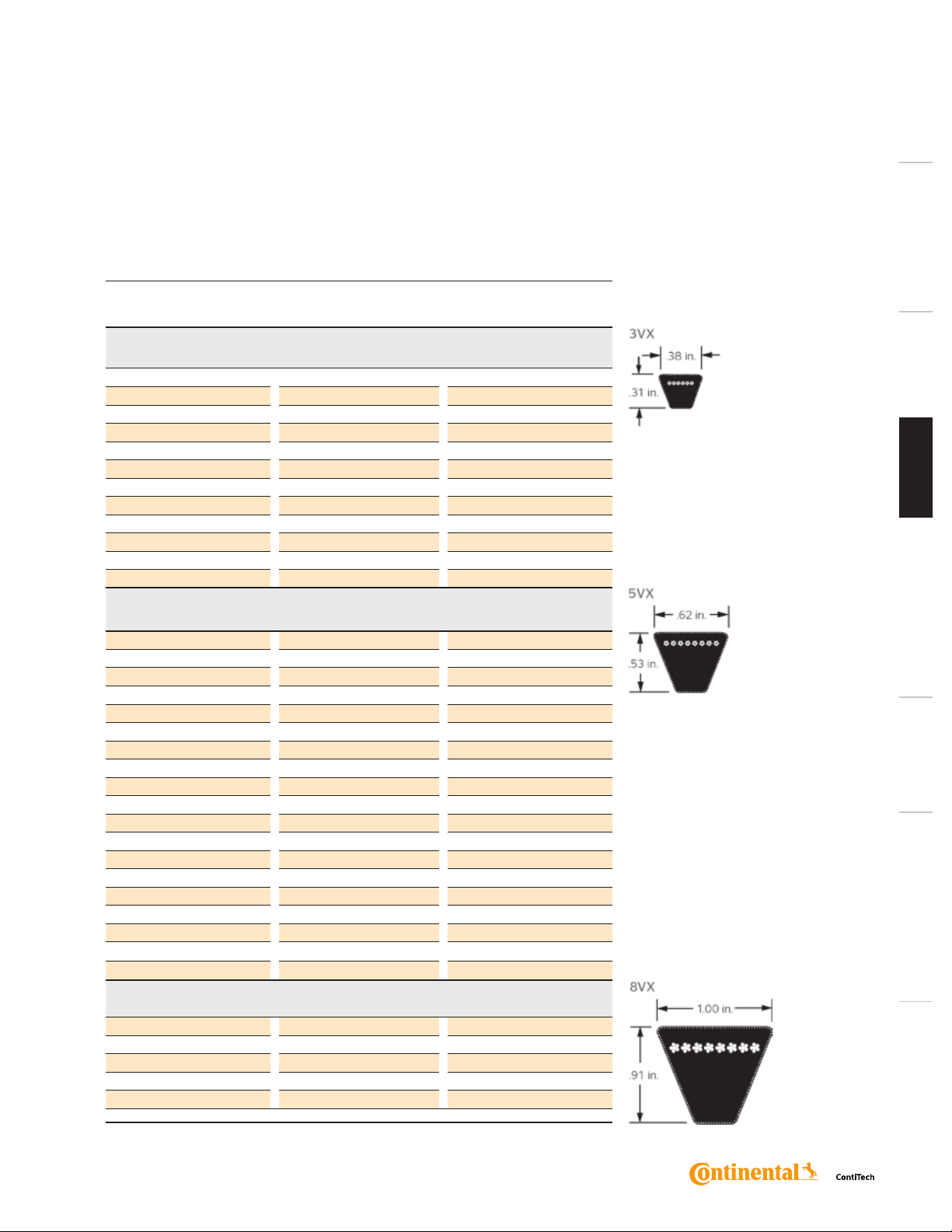

Part #

Eff ective

Length (in.) Part #

Eff ective

Length (in.) Part #

Eff ective

Length (in.)

3VX

3VX250 25.0 3VX450 45.0 3VX850 85.0

3VX265 26.5 3VX475 47.5 3VX900 90.0

3VX280 28.0 3VX500 50.0 3V X950 95.0

3VX30 0 30.0 3V X530 53.0 3VX1000 100 .0

3VX315 31.5 3VX560 56.0 3VX1060 106 .0

3VX335 33.5 3VX600 60.0 3V X1120 112 .0

3VX350 35.0 3VX630 63.0 3VX1180 118 . 0

3VX355 35.5 3VX650 65.0 3VX1250 125 .0

3VX360 36.0 3VX670 67.0 3VX1320 13 2. 0

3VX375 37.5 3VX710 71.0 3VX1400 14 0. 0

3VX400 40.0 3VX750 75. 0 3VX1500 150 .0

3VX425 42.5 3VX800 80.0

5VX

5VX450 45.0 5VX690 69.0 5VX1030 103.0

5VX470 47.0 5VX710 71.0 5V X1060 106. 0

5VX490 49.0 5VX730 73.0 5VX1080 108 .0

5VX500 50.0 5VX740 74. 0 5V X1120 112 .0

5VX510

51. 0

5VX750

75.0

5VX1150

115 .0

5VX530 53.0 5VX780 78.0 5VX1180 11 8. 0

5VX540 54.0 5VX800 80.0 5VX1230 12 3. 0

5VX550 55.0 5VX810 81.0 5VX1250 12 5. 0

5VX560

56.0

5VX830

83.0

5VX1277

122 .7

5VX570 57.0 5VX840 84.0 5VX1320 13 2. 0

5VX580 58.0 5VX850 85.0 5VX1400 14 0.0

5VX590 59.0 5VX860 86.0 5VX1500 15 0.0

5VX600 60.0 5V X880 88.0 5VX1600 16 0.0

5VX610 61.0 5V X900 90.0 5VX1700 17 0. 0

5VX630 63.0 5VX930 93.0 5VX1800 180 .0

5VX650 65.0 5VX950 95.0 5VX1900 190 .0

5VX660 66.0 5VX960 96.0 5VX2120 212.0

5VX670 67.0 5VX1000 10 0.0

5VX680 68.0 5V X1017 101. 7

8VX

8VX100 0 100 .0 8VX1320 132. 0 8VX1800 180. 0

8VX1060 106 .0 8VX1400 140 .0 8V X1900 190 .0

8VX1120

112 .0

8VX1500

150 .0

8VX2000

200.0

8VX1180 118 . 0 8V X1600 160 .0

8VX1250 125 .0 8VX1700 170 .0

*Cut-edge cogged construction. EPDM -400 F to 2300 F (-400C to 1100C) temperature range.

Cross Sections and Lengths Available

Cogged Sizes*

OverviewSynchronousBandedV-BeltBushing HardwareSpecialtyAutomotive & TruckGeneral Information

Loading...

Loading...