Continental Belt Banded Belts Catalog Page

65

2015 Power Transmission Products Banded

Banded Belts

Because of their banded or joined

construction, these belts tend to prevent

rollover and reduce vibration tendencies

Banded belts are usually better suited to unusual drive

situations than are matched belt sets. They are available in the

Classical cross sections (A, B, C and D), Narrow cross sections

(3V, 5V and 8V) and Poly-V® cross sections (H, J, L and M).

Classical and Narrow Banded V-belts

Typical applications for Banded V-belts include vertical shaft

drives, clutching drives and V-flat drives. ( V-belt drives are

where the inside of the belt drives a flat pulley on the slower

speed shaft.)

Banded V-belts are recommended for use where belt vibration

or belt whip causes unsatisfactory results when conventional

multiple single V-belts are used. Such situations are not

uncommon on drives with a combination of long belt spans

and/or pulsating loads as created by an internal combustion

engine or reciprocating pumps and compressors. In such cases,

belt whip may become so severe that belts interface with each

other and turn over in the grooves or even jump out of the

grooves. Banded V-belts eliminate such problems.

Another advantage of Banded V-belts is the considerable degree

of design flexibility they can provide since they operate just as

effectively when they, in turn, are used as match sets. A two-belt

unit for example, has sufficient lateral rigidity so as to not

interface with the units in adjacent grooves.

Tor qu e Tea m Plu s® (aramid-reinforced

Banded V-belts)

These belts are available for low-speed, high-power applications

which were previously considered to be in the domain of chain

or gears. Aramid-reinforced Torque Team Plus® 5V and 8V

Banded belts are ideally suited to handle many of the

applications that have been reserved for chain or gears.

Poly-V® (V-ribbed)

Poly-V® belts are flat belts with a series of longitudinal ribs on

the driving face that mate with grooves in the sheave rim.

Relatively thin, with a well-supported tensile member, these

belts perform better than V-belts on drives with small sheave,

high speeds, reverse bends and high-speed ratios. Poly-V®

belts generally run smoother than V-belts and their low weight

makes them suitable for high-speed drives.

Three cross sections, designated J, L and M, handle the same

range of industrial applications as Narrow or Classical belts.

A smaller section, H, is used for small sheave and miniature

drives. Finally, the K section Poly-V® is of ten located in the

automotive industry.

General InformationAutomotive & TruckSpecialtyBushing HardwareV-BeltBandedSynchronousOverview

66

2015 Power Transmission Products Banded

Available in a wide variety of sizes

Continental ContiTech Torque Team® Laminated V-belts are

available in the 5VL belt cross section and in most standard

lengths. The 5VL laminated V-belt is interchangeable with all

standard 5V and 5VX V-belts currently found on these drives.

They can also be cut to a variety of rib widths, depending on

your drive requirements. This ensures a perfectly-matched set

of V-belts that can further enhance drive performance.

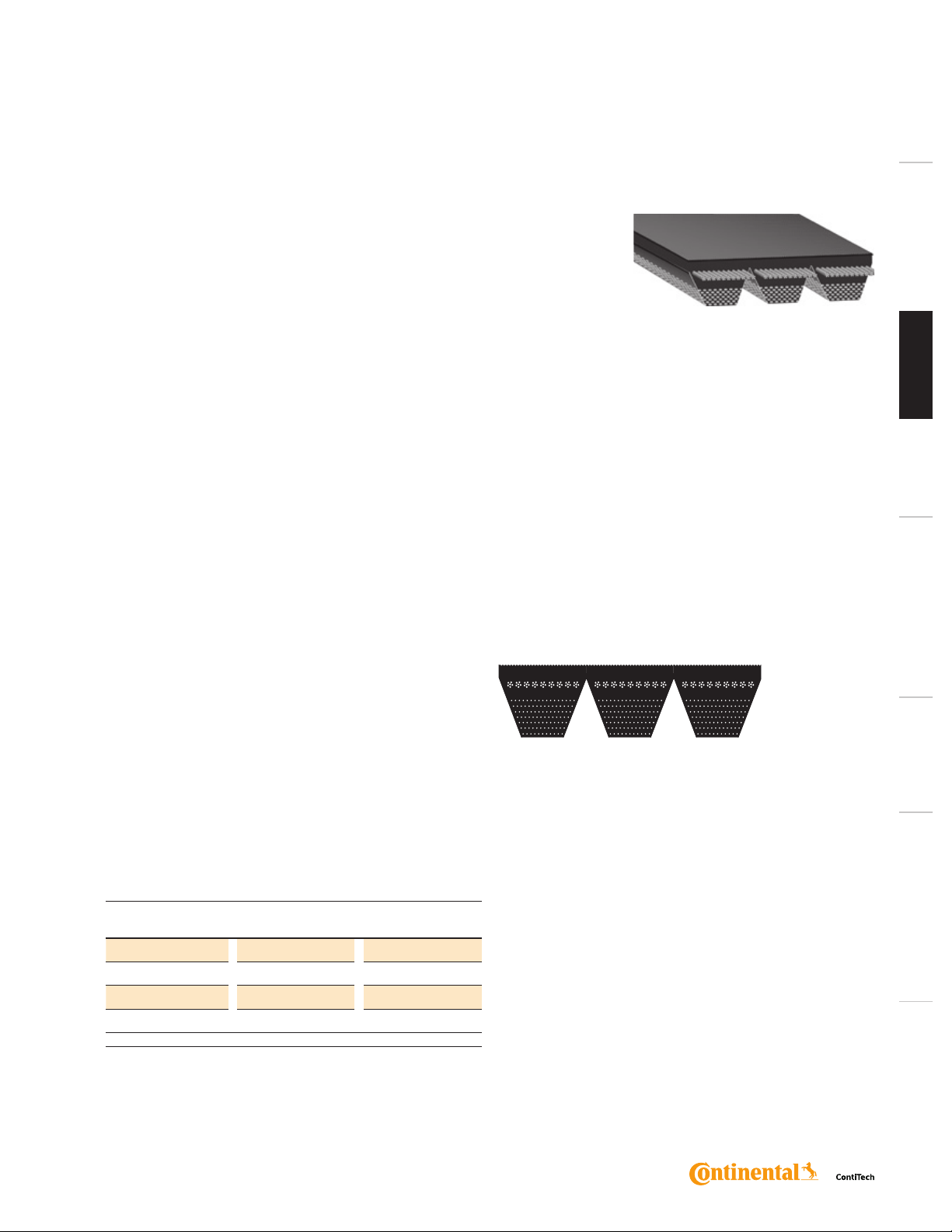

5VL Cross Section View

Applications

Some of the most common drives recommended for

consideration include:

› Debarkers › Gang saws

› Chip-n-saws › Deck saws

› Cut-off saws › Tri mm er s

› Chippers

Key features & benefits

›

Narrow profile ribs provide savings through efficiency.

› Joined construction for problem drives.

› High horsepower capacity.

› High-strength Vytacord® tensile members.

› Laminated construction engineered to slip.

› Toug h fabr ic backi ng .

› Oil, heat, ozone and abrasion resistant.

› Static conductive.*

*Dr ive condi tio ns and service variables in com bin ati on with t ime in

ope ration c an result in a l oss of static con ducti vit y. I t is re comme nded

that a conductivity check be added to drive preventive maintenance

programs where belt static conductivity is a requirement.

Reduce downtime and maintenance

Continental ContiTech Torque Team® Laminated V-belts can

withstand the punishment that results from jams in log and

lumber processing applications.

Standard V-belts resist slipping when a jam occurs, causing

excessive heat buildup that can lead to belt failure and costly

downtime. But that won’t happen with Torque Team®

Laminated V-belts on the job.

The special sidewall of Torque Team® Laminated V-belts acts

as a control switch, allowing the belts to slip as needed until the

obstruction is cleared. As a result, the superior wear-resistant

capabilities of Torque Team® Laminated V-belts are maintained,

increasing belt life up to four times longer than standard V-belts.

High strength for long life

Continental ContiTech Torque Team® Laminated V-belts feature

our powerful Vytacord® tensile members. Vytacord® provides

high strength and horsepower ratings, yet serves as a more

forgiving reinforcement that will give under excessive tension

instead of snapping. That means increased belt life.

Part Number: 3/5VL800

3/ 3 rib joined construction

5V 0.62 in. top width – Narrow

profile rib

L Laminated construction

800 80.0 in. nominal outside length

Torque Team® (Laminated) V-Belts

Solve the toughest sawmill

drive problems

Continental ContiTech Torque Team® Laminated V-belts are

particularly effective when installed on drives that experience

frequent slippage caused by logs and heavy lumber that jam

or impact the equipment.

Sizes

5VL800 5VL1000 5VL1250

5VL850 5VL1060 5VL1320

5VL900 5VL1120 5VL1700

5VL950 5VL1180

For lon ger 5V, as well as 3V a nd 8V l aminat ed pro files not li ste d he re, co ntact your

PTP Industrial Distributor.

OverviewSynchronousBandedV-BeltBushing HardwareSpecialtyAutomotive & TruckGeneral Information

67

the belt. The cushion is made of fiber-reinforced, engineered

compounds providing oil, heat, ozone and abrasion resistance.

Wedge or envelope constructions provide

optimum performance

HY-T® Wedge Torque Team® belts are available in a raw edge

construction with cogs for increased flexibility and heat

dissipation or envelope construction for drives where pulsation,

shock loads, high tension and long center are involved.

HY-T® Wedge Torque Team® cogged belts have high-horsepower

belt construction and are identified with a 3VX or 5VX prefix

and are available in lengths up to 140 inches. The cogged

construction provides the high flexibility required for short

center distances. The cogs also provide a larger surface area

to dissipate heat and prolong belt life. Improved material

properties and advanced construction technology result in

an average horsepower increase of 30% over standard joined

“Classical” V-belts.

HY-T® Wedge Torque Team® envelope belts are identified with

a 3V, 5V or 8V prefix and are recommended for drives where

pulsation, shock loads, high tension and long centers are

involved. They feature a continuous V-section that is protected

by a wide angle, synthetic fabric-impregnated, high-quality

rubber compound. The unique envelope achieves the high

strength that the HY-T® Wedge Torque Team® belts need to

withstand high loading forces. It also helps provide the torsional

rigidity in long center drives delivering the traction needed for

accurate tracking and precision performance.

Pulsation, vibration, shock loads and misalignment are problems

for any team of V-belts, no matter how perfectly matched the

individual units. These conditions often lead to chronic belt

whip or to belt turnover, resulting in premature wear or sudden

failure of one or more belts. Of course, when one belt goes, the

whole team has to be replaced.

Each rib in a HY-T® Wedge Torque Team® belt is free to wedge

into the sheave groove for maximum trac tion, maximum power

and transmission efficiency.

Operating in standard sheave grooves without sheave or drive

modification, they can tame any problem drives now in operation.

Or they can fit right in with your new drive designs without

special modifications.

Designed and built to deliver

superior performance

V-belt performance begins with the tension members, so we

built HY-T® Wedge Torque Team® V-belts with super strong

Vytacord.® It provides the high-strength, high-horsepower

rating capacity needed to effectively transmit drive power.

And it is tough enough to tolerate the misalignment that

quickly destroys belts. The Vytacord® material is a polyester

construction with excellent strength and minimal elongation.

Drive performance is consistent, reliable and predictable over

the life of the belt.

We then add a tough oil- and abrasion-resistant fabric backing

to provide maximum longitudinal flexibility and lateral strength

to withstand the dynamic forces acting within a joined belt .

The backing also has special adhesion characteristics that

enable it to bond to the V-sections to maintain the integrity of

Part Number: 3/8V1900

3/ 3 rib joined construction

8V 1 in. top width – Narrow profile rib

1900 190 in. nominal outside length

Single envelope ply on 5Vs

2 envelope plies on 8Vs

Envelope uncogged

construction shown

HY-T® Wedge Torque Team® Belts

Tame you r proble m drives

Built with multiple belts joined by a tough, rubber-impregnated

fabric backing that regulates belt travel so all ribs pull

together as a single, perfectly matched team.

General InformationAutomotive & TruckSpecialtyBushing HardwareV-BeltBandedSynchronousOverview

68

2015 Power Transmission Products Synchron ou s2015 Power Transmission Products Synchron ou s 2015 Power Transmission Products Banded

Matchmaker® performance

Our Matchmaker® technology results in belt consistency run

to run. That means each HY-T® Wedge Torque Team® is equal

in size and performance to every other HY-T® Wedge Torque

Team® belt in that size, no matter when or where it

was produced.

By eliminating mismatch problems, there is no costly and

complicated belt matching to get a drive back on line; no

problems with belts that are too tight or too loose.

Available in the most extensive stock line

in the industry

HY-T® Wedge Torque Team® belts are available from stock in

any number of belts per team, up to the number of ribs

indicated. Nonstock lengths are also available in these rib

counts, up to a maximum of 730 inches (180 inches for

3V cross sections).

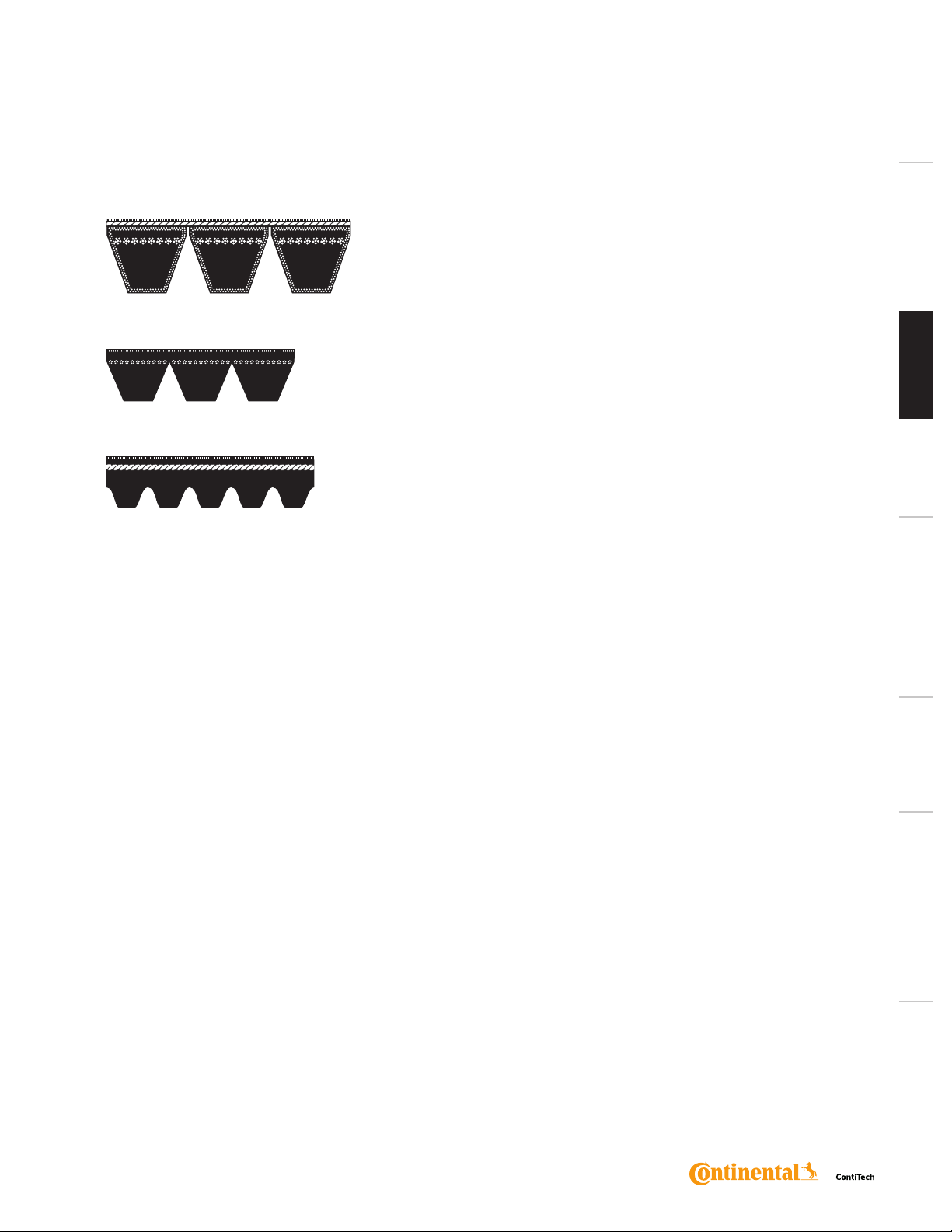

Envelope 5V, 8V Cross Section

Cut Edge 3VX, 5VX Cross Section

Cut Edge Side View

Applications

For shock load applications. Ideal for pulsating loads, high

capacity drives and for short-center, heavy-duty drives.

Key features & benefits

›

Narrow profile ribs provide savings through efficiency.

› Joined construction for problem drives.

› Strong Vytacord® tensile members.

› Toug h fabr ic backi ng .

› Oil, heat, ozone and abrasion resistant.

› Available in raw edge construction with cogs or

envelope construction.

› Matchmaker® to eliminate mismatch.

› Static conductive.*

*Dr ive condi tio ns and service variables in com bin ati on with t ime in

ope ration c an result in a l oss of static con ducti vit y. I t is re comme nded

that a conductivity check be added to drive preventive maintenance

programs where belt static conductivity is a requirement.

OverviewSynchronousBandedV-BeltBushing HardwareSpecialtyAutomotive & TruckGeneral Information

Loading...

Loading...