Page 1

Operation, Installation and

Instruction Manual

For

Undercounter Refrigerators and Freezers

and

Pizza Preparation Tables

A Division of National Refrigeration & Air Conditioning Products, Inc.

539 Dunksferry Road • Bensalem, PA 19020-5908

215-244-1400 • 1-800-523-7138 • Fax: 215-244-9579

www.continentalrefrigerator.com

REV1004

Page 2

Operators Manual

Table of Contents Page

Receiving Your New Model ........................................................................................3

General Information And Important Operating Facts ................................................3

Uncrating Your New Model ........................................................................................4

Installation And Location ............................................................................................4

Clearances ..........................................................................................................4

Ventilation ............................................................................................................4

Floor Loads..........................................................................................................6

Installing Legs And Leveling ................................................................................7

Installing Casters And Leveling ..........................................................................8

Installing Condensate Evaporator........................................................................9

Removal Of Doors And Door Adjustment ..........................................................10

Self-Closing Hinge Mechanism Mounting ..........................................................11

Removal And Replacement Of Hinge Mechanism ............................................12

Initial Cleaning Procedure ........................................................................................12

Start-Up Procedure....................................................................................................13

Electrical Connections ........................................................................................13

115 Volt, 60 Hz, 1 Phase Connection ................................................................13

208-230 Volt, 60 Hz, 1 Phase Connection ........................................................14

Special Voltage Connections ..............................................................................14

Start-Up Checklist ..............................................................................................14

Remote Applications ..........................................................................................14

Operation ..................................................................................................................15

Thermometer Calibration ....................................................................................15

Pizza Preparation Table Operation ....................................................................15

Pizza Rail System Switch ..................................................................................15

Pizza Prep Temp Adjustment - Bottom Storage Compartment ..........................15

Pizza Prep Temp Adjustment - Coldwall Rail ....................................................16

Undercounter Refrigerator System And Adjustment ..........................................16

Undercounter Freezer System And Adjustment ................................................16

Defrost Operation ..............................................................................................17

Evaporator Assembly..........................................................................................17

Interior Accessories ..................................................................................................18

Shelving Installation............................................................................................18

Optional Accessories ................................................................................................19

Optional Overhead Or Double-Overhead Shelf..................................................20

Optional Stacking Collar Adapter Kit ..................................................................20

Safety Precautions ....................................................................................................22

Maintenance ..............................................................................................................22

Periodic Cleaning Procedure..............................................................................22

General Preventative Maintenance ....................................................................23

Parts And Service ..............................................................................................23

Troubleshooting And Servicing Guide ......................................................................25

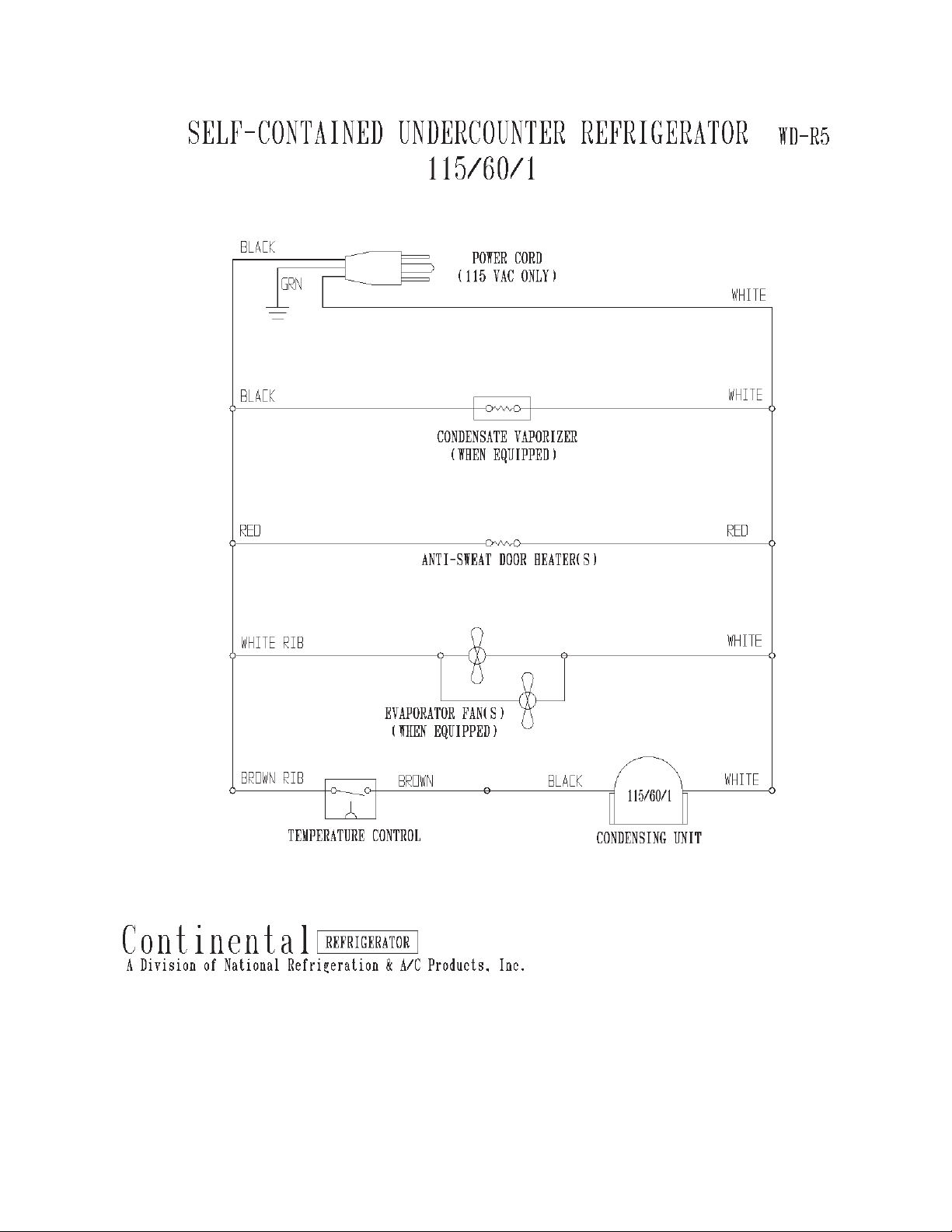

Wiring Diagrams ........................................................................................................28

Warranty ....................................................................................................................31

Page 3

RECEIVING YOUR NEW MODEL

Congratulations on your recent purchase of Continental Refrigerator superior food

equipment products! When your shipment arrives, please thoroughly examine the

shipping crate for any punctures, dents, or signs of rough handling. It is in your best

interest to partially remove or open the shipping container in order to examine the

model for any concealed damages which may have occurred during shipment. If the

model is damaged, it must be noted on the delivering carrier's delivery slip or bill of

lading (see “filing a damage claim” under warranty section).

GENERAL INFORMA

TION AND IMPORTANT OPERATING FACTS

This manual has been compiled to aid in the installation, operation and maintenance

of your new equipment. Please take the time to read all of the material in order to

become more familiar with your equipment and its operation, and enjoy optimum

performance.

No floor drains or plumbing connections are required since all models are completely

self-defrosting and use an automatic defrost condensate water evaporating system

(see “condensate evaporator pan installation” under installation and location section).

All cabinets must be given sufficient time to reach normal operating temperature

before placing any food inside cabinet or pans (if equipped). For refrigerators,

approximately 1 hour of operation is required to lower the cabinet and pan

temperature to 40°F. During pull-down of open top models, pans should be in

place and top lid should be kept closed. Freezers require approximately

2 hours of operation to lower the cabinet temperature to 0°F (see “operation”

section for further information).

On all open top refrigerators with salad pans, it is strongly recommended that the top

lid be kept in the closed position when the unit is not in use or between rush periods.

This is extremely important during the summer months and in hot kitchens. Do not

keep the top lid open for prolonged periods of time and never operate open top

models without all pans in place. Please note that sandwich and pizza preparation

tables are not intended for overnight food storage in the open top pans.

Prior to factory shipping, all models are performance run tested for a minimum of

12 hours providing a highly sophisticated temperature analysis recording exclusive

to each individual cabinet. This recording is supplied within this manual packet. A

final leak check, vibration, noise level and visual examination is made by a qualified

quality control team to assure a quality product. The carrier signs to this effect when

he accepts the product for shipping. To insure the maximum in safety and sanitation,

all models are listed under the reexamination service of underwriter's laboratories

and with the national sanitation foundation.

3

Page 4

UNCRATING YOUR NEW MODEL

The shipping container should remain on your model as protection against

dents or scratches while transporting it to the actual set-up location. Remove

the shipping container only at the last possible moment by following these

simple steps:

1. Using a pry bar, pry off and remove crate end bottom staples.

2. Pry off and remove crate front and rear bottom staples.

3. Slide crate upward and remove it, being careful not to rub against cabinet.

There are up to four (4) bolts securing the cabinet to the wooden skid. The bolts are

located at each end on the underside of the skid. In order to remove these bolts it is

advisable to tilt the cabinet backwards and place wooden blocks at each end in order

to hold it in its tilted position. Using a

3

/4" socket or open end wrench, remove the bolts

and carefully slide the model off of the skid. After skid removal, the cabinet should

never be moved without dollies or rollers to avoid damage to the cabinet bottom or

floor.

Important Note: Do not under any circumstances lay your new model on its front

or sides. Only for a brief period, may you lay the model on its back and only then,

when its properly blocked so as not to crush the louvered venting panel and also

to allow provision for your hands in order to set it in its upright position without

inflicting damage to the cabinet. Do not plug in and operate model for at least

three (3) hours after cabinet is set upright from being on its back as damage

could result to the compressor.

INSTALLATION AND LOCATION

CLEARANCES

Before moving the cabinet to its final point of installation, accurately measure all doorways or passages to assure clearance. If additional clearance is needed, cabinet doors

can be easily removed (see instructions outlined in “removal of doors” section) and, or

hood assembly (when equipped) can be easily removed (see instructions outlined in

“removal of hood” section).

VENTILATION

The final location site of your air-cooled refrigerator or freezer must be able to provide

a large quantity of cool, clean air. The refrigeration system operates most efficiently

and trouble-free with cool, dry air circulation. Avoid locations near heat and moisture

generating equipment such as stoves, ovens, cooking ranges, fryers, dish washers,

steam kettles, etc., and also direct sunlight where temperatures can be in excess of

100°F. Also, do not select a location in an unheated room or area where temperatures

may drop below 55°F. Air supply to the condensing unit is equally important. Restricting

the air supply will place an excessive heat load on the condensing unit and adversely

affect its operating efficiency.

4

Page 5

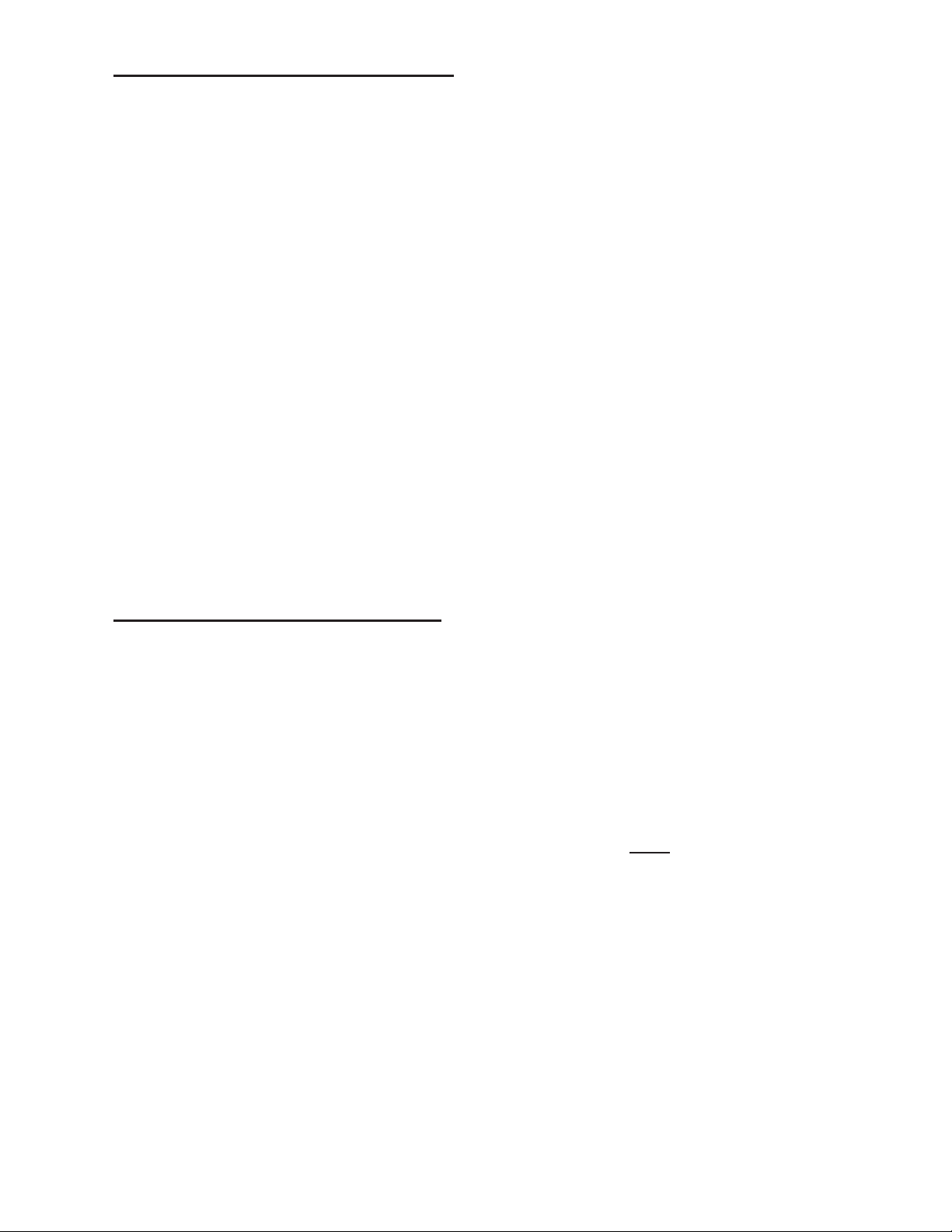

Important Note: To assure maximum operating efficiency, your new “SW” series

model should be located where an unrestricted air supply can circulate underneath

and behind the cabinet. For optimum performance, the cabinet must be installed on

legs or casters (see “installing legs or installing casters” later in this section) and a minimum of 3" on each side and rear of the cabinet must be provided (see figure 1a). Your

model has been designed to operate sufficiently without legs or casters and directly on

the floor as long as a minimum clearance of 8" is provided from the rear venting louvers and the rear wall (see figure 1b). Cabinet side clearance is not required when

mounting your model directly on the floor without legs or casters. If

necessary, special venting or air supply ducts must be installed by the installer if

any of the above conditions cannot be achieved. Do not at any time obstruct the

grill area in the rear of the cabinet in any way, and never place or store anything

inside of the cabinet machine compartment. These rules are essential for maximum

cooling capacity and long life of refrigeration parts.

5

FIGURE 1a

MINIMUM CLEARANCE DIMENSIONS FOR OPTIMUM CONDITIONS

Page 6

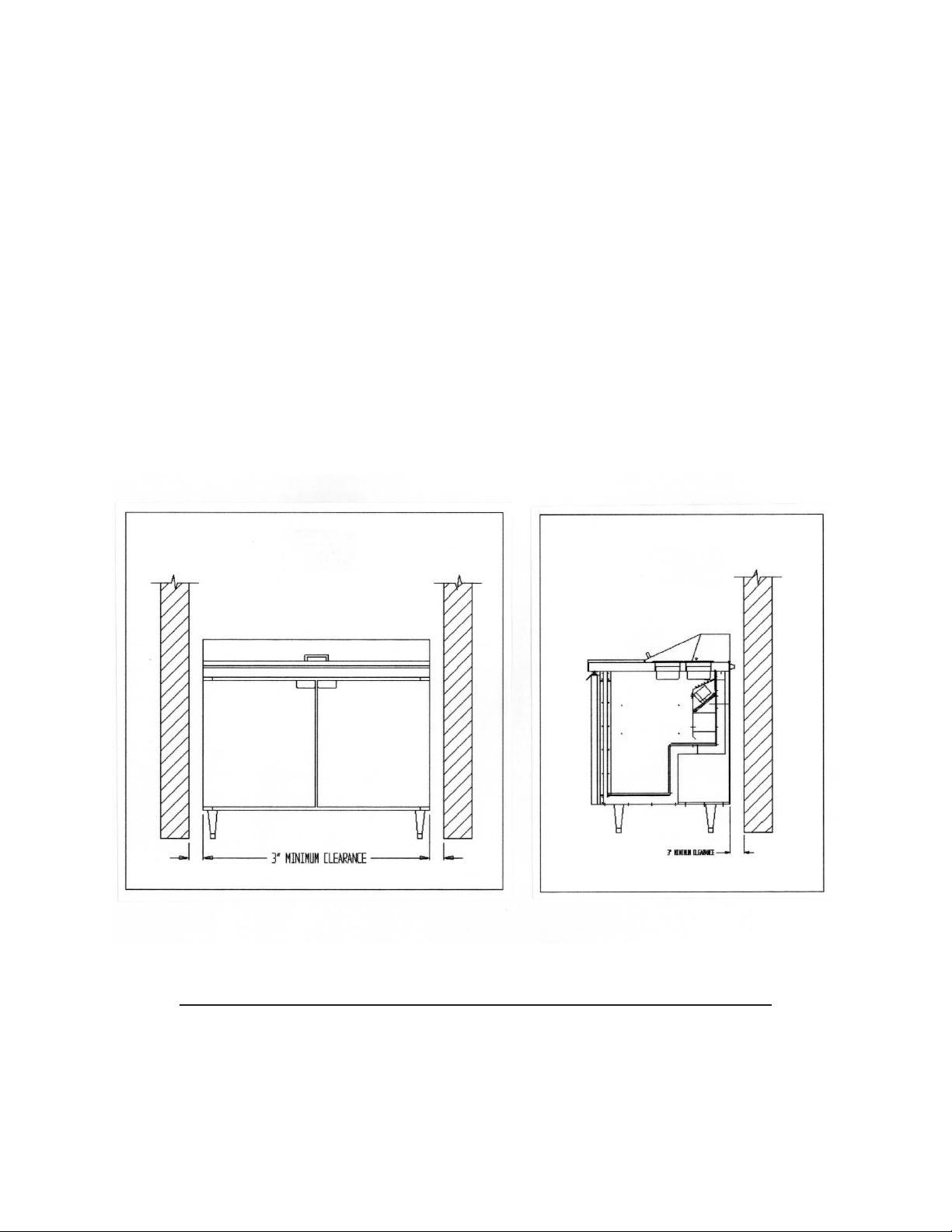

FIGURE 1b

MINIMUM CLEARANCE DIMENSIONS WITHOUT LEGS

FLOOR LOADS

The floor at the final location site must be level, free of vibration and strong enough

to support the total combined weights of your new model plus the maximum product

load which might be placed into it. A fully loaded reach-in model may reach 2,000 3,000 pounds. To estimate the possible product load weight, assume that each cubic

foot of storage space weighs approximately 35 pounds. Multiply 35 pounds by the

amount of cubic feet in the cabinet and obtain the product load weight. For example,

a 20 cubic foot refrigerator can hold approximately 700 pounds of product (35 x 20)

and assuming the refrigerator itself weighs 300 pounds, the total combined weight

of cabinet and product is approximately 1000 pounds. Therefore, the floor in this

example must be capable of supporting up to 1000 pounds.

6

Page 7

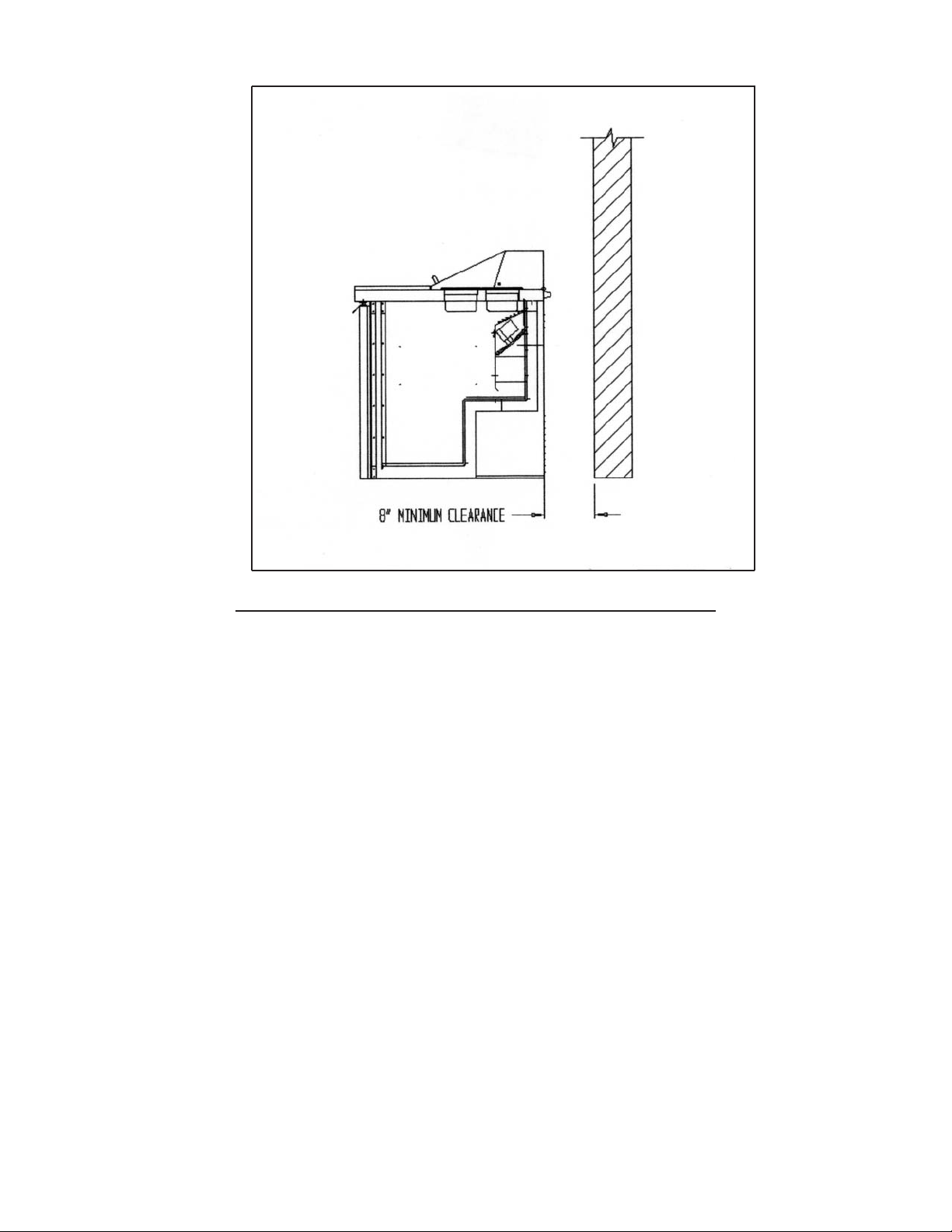

INSTALLING LEGS AND LEVELING

Your new “SW” series model is supplied with adjustable type legs for leveling

purposes. Each SW27, SW48, SW60 and SW72 model has four leg mounting

holes on its case bottom. Legs are packed in the accessory carton from which

they must be removed and installed on the cabinet case bottom (see figure 2).

In order to install the legs, carefully tip the cabinet rearward adding four (4) 2"

wood blocks underneath and simply screw the threaded leg studs into the case

bottom front leg holes. Repeat this procedure by tilting the cabinet in the opposite

direction and install the remaining legs. Make sure the legs are tightened extremely

well or the entire model will sway or rock with each opening or closing of the doors,

possibly causing damage to the case bottom. This procedure should be performed

close to the final installation site and allow access to the rear of the cabinet for

condensate evaporator installation (see “condensate evaporator installation” under

installation and location section).

To assure your cabinet is level, all legs are equipped with bullet-type leveling bolts.

These bolts can be turned by hand or by wrench, clockwise or counterclockwise to

level the cabinet.

7

FIGURE 2

LEG INSTALLATION

Page 8

Important Note: It is extremely important that your new model is perfectly

level for proper operation. If it is not level, the following adverse conditions will

become apparent:

1. The door(s) will not be properly aligned and consequently will not provide

a good seal.

2. You model will run excessively due to improper door seal(s).

3. An excessive amount of ice will accumulate inside the cabinet, around the

door opening(s) and especially on the finned evaporator coil. If allowed to

continue, ice will eventually block the coil and the model will fail. This will

result in the loss of all food stored within the cabinet.

4. Defrost water will fail to drain properly and will overflow the evaporator coil

drain pan and into the cabinet of both refrigerator and freezer models.

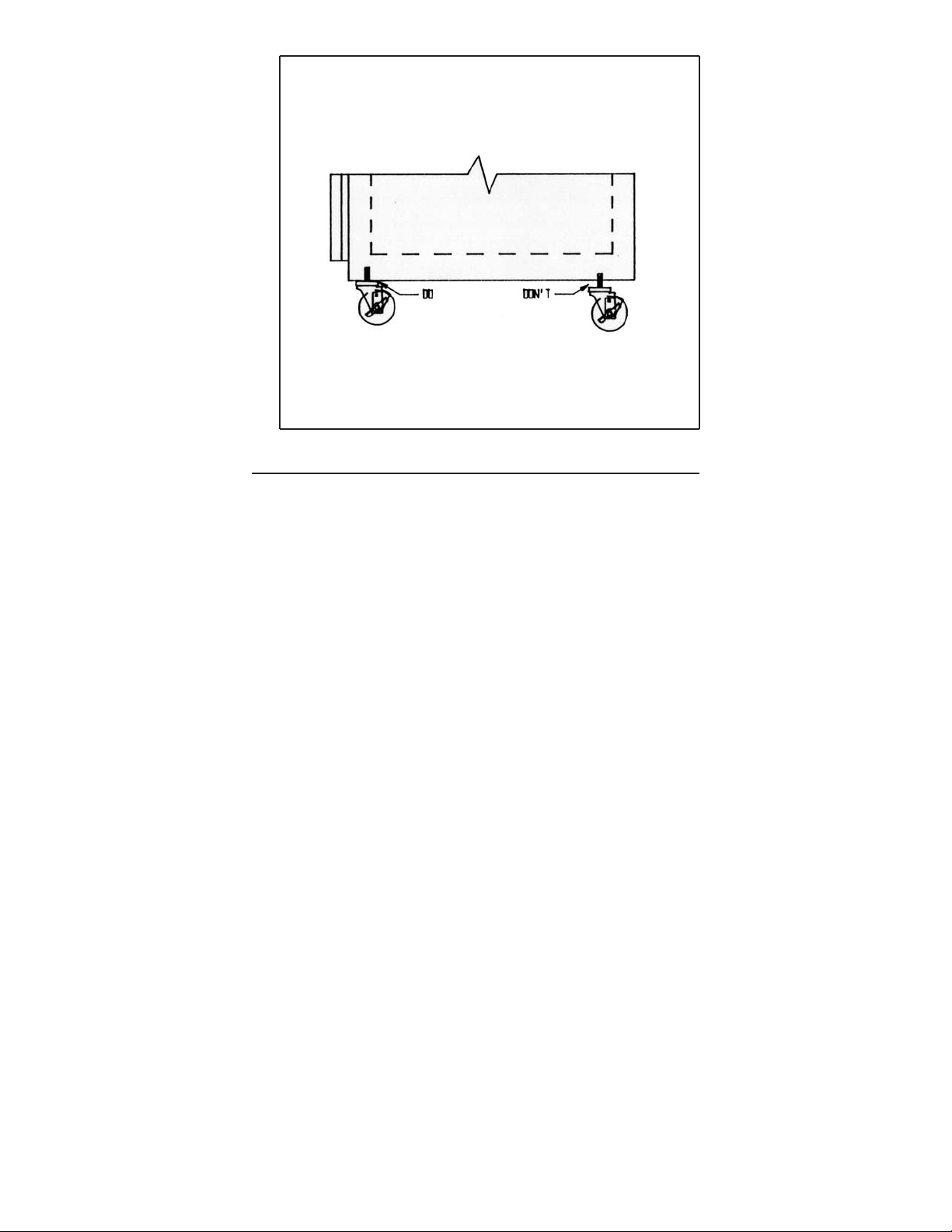

INSTALLING CASTERS AND LEVELING

Your new “CRB” and “CPT” series models are supplied with non-adjustable casters.

To install casters on your new model, follow the steps above for “installing legs” to

install the casters, making sure again that the casters are tightened extremely well

(see figure 3). If the casters are not installed tightly, the cabinet will sway or rock

with each opening or closing of the doors, possibly causing damage to the case

bottom.

To assure that your cabinet is level, caster cups must be installed under the casters

which need leveling. Caster cups are not provided with your new model but can be

purchased at most hardware or furniture stores. Do not attempt to level casters

by unscrewing them from the case bottom as this will cause damage to the

cabinet bottom and leg hole threads, voiding all warranties.

8

Page 9

FIGURE 3

CASTERS MUST BE TIGHT T

O CABINET BOTTOM

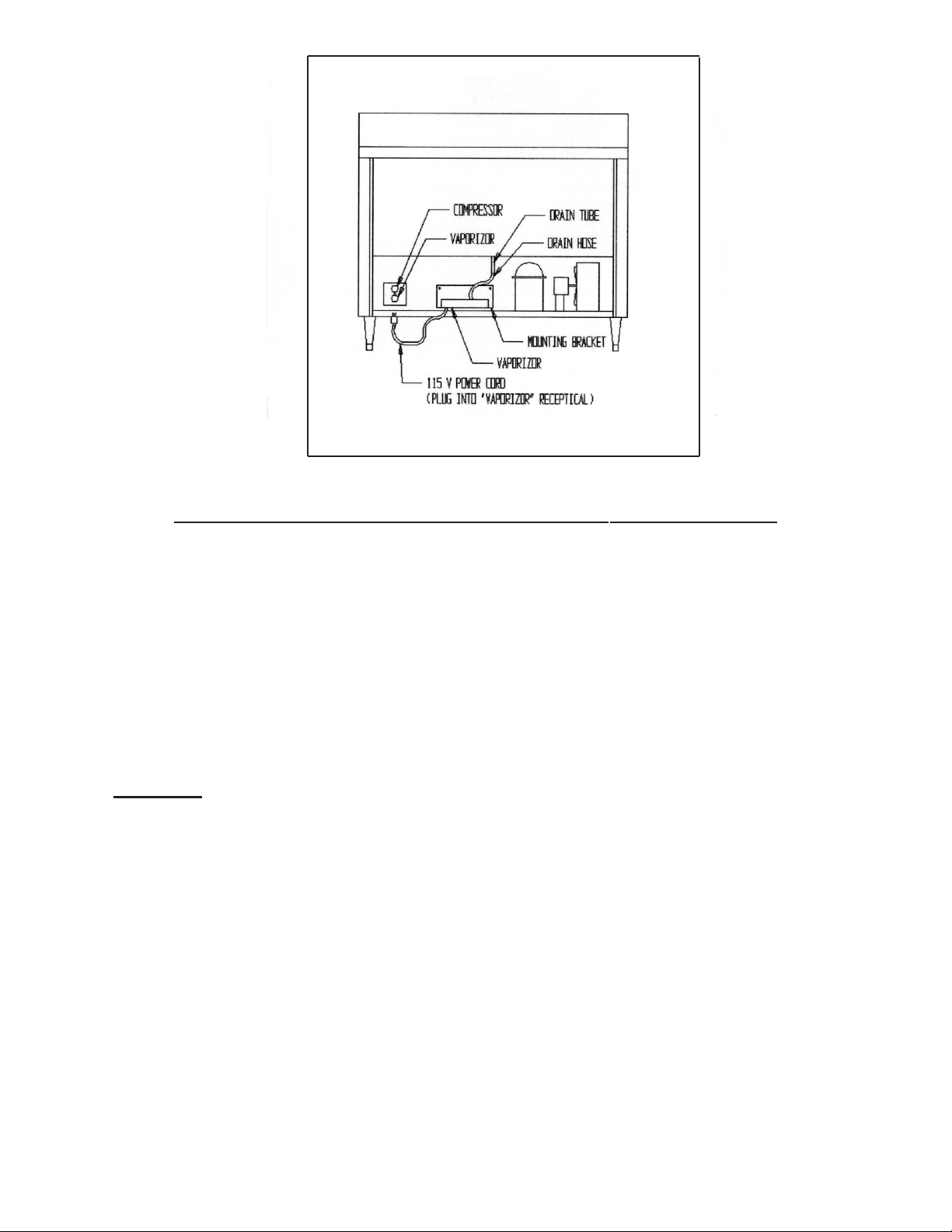

INSTALLING CONDENSATE EVAPORATOR

No floor drains or plumbing connections are required since all models use an

automatic condensate water evaporating system. All models utilize a unique

hot air condensate water evaporating system which is completely self-contained

and no further assembly or maintenance is required. In some adverse conditions

such as high ambient temperature, high humidity, extremely heavy usage, frequent

loading for prolonged periods of time, and heavy pan loading, an optional electric

condensate evaporator pan may be purchased as an accessory. An electric

condensate evaporator pan is also supplied with all remote models. To install the

condensate pan, remove all rear cabinet cover screws and install the mounting

bracket on the case rear next to and behind the compressor as shown in figure 4.

Slide the condensate pan onto the bracket, install the drain tube into the pan

making sure it is not blocked or kinked, and plug the ten foot power cord into the

receptacle labeled “vaporizer” located on the compressor compartment electrical

box.

Important Note: It is extremely important to be sure that the condensate pan is

plugged into its correct receptacle labeled “vaporizer” and that the condensing

unit is plugged into its correct receptacle labeled “condensing unit”.

9

Page 10

FIGURE 4

OPTIONAL

ELECTRIC CONDENSATE EVAPORA

TOR INSTALLATION

REMOVAL OF DOORS AND DOOR ADJUSTMENT

During installation, it may become necessary to remove the cabinet doors to facilitate

passage through narrow doorways or hallways. To remove a door, swing the door to

the open-door position (90°) and remove the two screws marked “a” (figure 5) while

carefully holding the door open. Care must be taken to hold the door fully open during

the screw removal since the top hinge is spring loaded and may snap towards the door

when the screws are removed. After removing both screws, carefully lift the door

straight upward to avoid bending the bottom hinge pin. To reinstall the door, reverse

the above procedure.

Caution: The top hinge is spring loaded and may snap towards the door when

the mounting screws are removed. Be sure to hold door fully open before

removing mounting screws.

All doors have been aligned at the factory, however vibration during transportation

may cause doors to shift and realignment may be necessary. If the door(s) require

realignment, proceed as follows:

1. Swing the door to the open-door position and loosen but do not remove

the screws marked “A” on both top and bottom hinges (see figure 5).

2. Relocate the door to its required position by hand or by tapping on the

door edges with a hammer and a block of wood.

3. Securely tighten all screws “A”.

10

Page 11

FIGURE 5

DOOR ADJUSTMENT AND REMOVAL

SELF-CLOSING HINGE MECHANISM MOUNTING

For proper operation of the self-closing doors on all sandwich unit and prep models,

the hinge mechanism must be mounted to apply tension in the direction shown in figure 6. When the hinge is moved to the open-door position the hinge should be tensionfree. However, when the hinge is moved back into the closed position, it should snap

back. Caution should be taken when checking the spring loading as the hinge could

snap back on fingers. If the hinge does not respond as described above, follow these

steps:

1. Using the hinge upside down as a wrench, turn the mechanism in the

door 180 in either direction. The mechanism should snap to a null point.

2. Remount the hinge as shown in figure 6.

3. Repeat the test procedure as described above until the hinge snaps

back when it is moved from the open-door position towards the

closed-door position.

11

Page 12

REMOVAL AND REPLACEMENT OF HINGE MECHANISM

To remove the hinge mechanism from the door, remove the door from the cabinet

as explained above. As shown in figure 6, remove the hinge plate from the hinge

mechanism by removing the hinge pin screw. Also remove the horseshoe spring.

Reinstall the hinge pin screw only partially leaving about

1

/8" of exposed screw

threads. Now, the hinge mechanism mounting screws can be removed thus

allowing the mechanism to be removed by pulling on the hinge pin screw. If the

mechanism does not readily slide out of the door, slide a claw hammer or forked

prybar under the hinge pin screw head and using a block of wood for leverage,

lift the entire mechanism out of the door. To install the new hinge mechanism,

reverse the above procedure.

INITIAL CLEANING PROCEDURE

Prior to start-up and before placing any food inside of your new model, the interior

of the cabinet should be thoroughly cleaned. Washing with a mild soap and warm

water solution is recommended for cleaning the aluminum and stainless steel

surfaces of your cabinet. This should be followed by cleaning with a baking soda

solution (three (3) tablespoons of baking soda to each quart of warm water).

Rinse thoroughly with clear water and dry with a clean, soft cloth.

12

Page 13

Important Note: Never use harsh detergents, cleaners, scouring powders or

chemicals when cleaning your model. Failure to dry the interior surfaces after

cleaning may result in a streaking or staining of the metal.

Complete cleaning procedures and precautions are listed in the “periodic cleaning

procedure” under the maintenance section.

START-UP

PROCEDURE

ELECTRICAL CONNECTIONS

To insure proper operation, your new model must be connected to an individual

circuit that can supply the full voltage as stated on the cabinet serial data plate.

For correct voltage, power draw, and wire accommodations, check the data on the

serial data plate located on the inner right wall of your new model. Verify that this

information exactly matches the electrical characteristics at the installation location.

An electrical wiring diagram, located on the inside compressor compartment rear,

next to the electrical console box, should also be consulted during connection. For

reference, a copy of each electrical wiring diagram is located at the rear of this

manual in the “maintenance” section.

Important Note: The condensing unit supplied with all self-contained models is

designed to operate with a voltage fluctuation of + 10 % of the voltage indicated

on the cabinet serial data plate. Full voltage of the correct service, on an individual

line not affected by the operation of other electrical appliances, must be available

to the condensing unit at all times. Burnout of the compressor due to exceeding the

high or low voltage limits is easily detected and will automatically void the factory

warranty.

115 VOLT, 60 HZ, 1 PHASE CONNECTION

All 115 volt models are provided with a U.L. approved power cord and polarized

plug which is factory installed.

Warning: Any alterations to this cord and plug could cause an electrical

hazard and will void the factory warranty.

To insure proper operation, this equipment must be plugged into a NEMA 5-15r

compatible, grounded receptacle that can supply the full voltage as stated on the

serial data plate.

13

Page 14

208-230 VOLT, 60 HZ, 1 PHASE CONNECTION

All 208-230 volt models are to be permanently connected and are provided with

four (4) field wiring leads which exit the electrical console box located in the

machine compartment rear, next to the compressor. The cabinet circuitry is 115

volts and the condensing unit is 208-230 volts in which the wiring includes a

neutral and a mechanical ground. This wiring should be connected to the

appropriate power source by a qualified electrician and must conform to all

local electrical codes.

SPECIAL VOLTAGE CONNECTIONS

When models are ordered from the factory with special, optional voltages,

connections should be made as required on the electrical wiring diagram

provided on the inside compressor compartment rear next to the electrical

console box.

START-UP CHECKLIST

After your model has been installed, leveled, cleaned, and electrically connected

in accordance with this manual, please take the time before start-up to observe the

following precautions to assure trouble free operation:

1. Check that all exposed refrigeration lines are free of severe dents or kinks.

2. Check the condenser fan and evaporator fans for freedom to rotate without

any obstructions

3. Make sure that the cabinet is properly leveled (see “leveling” under

installation and location section).

The system should run smoothly and quietly in accordance with generally accepted

commercial standards. If any unusual noises are heard, turn the unit off immediately

and check for any obstructions of the condenser or evaporator fans. Fan motors, fan

blades, or fan housings can be jarred out of position through rough handling in transit

or during installation.

Caution: If unit is unplugged or disconnected for any reason, allow several

minutes (5-6 minutes) before turning the unit back on to allow the system

pressures to equalize. Disregarding this procedure could cause an overload

and prevent the unit from operating.

REMOTE APPLICATIONS

All models are available for purchase as remote models in which case the condensing

unit is purchased separately and installed at the time of installation. All remote models

are equipped with an expansion valve located within the evaporator coil housing, and

both liquid and suction lines stubbed and extending out from the cabinet rear behind

the rear cover. Installation of the refrigeration accessories, condensing unit, and

electrical hook-up should be performed by qualified refrigeration personnel of a

competent refrigeration company only.

14

Page 15

OPERATION

All cabinets must be given sufficient time to reach normal operating temperature

before placing any food inside cabinet or pans (if equipped). Refrigerators are

designed to maintain an ideal cabinet and pan temperature of 38°F to 40°F

(3.3°C to 4.4°C) and approximately 1 hour of operation is required to reach this

temperature. During pull-down of open top models, pans should be in place and

top lid should be kept closed. Freezers are designed to maintain an ideal cabinet

temperature of to 0°F (-17.8°C) and approximately 2 hours of operation are required

to reach this temperature.

THERMOMETER CALIBRATION

Your new “SW” series model has a non adjustable hanging thermometer

located inside the cabinet, mounted on the coil housing cover (see figure 7).

This thermometer is maintenance-free and needs no further calibration. "CRB"

and “CPT” series models have a hanging thermometer in the accessory carton

to mount on any shelf inside the cabinet.

PIZZA PREPARATION TABLE OPERATION

Pizza prep tables are designed and factory set to maintain an average cabinet and

pan rail product temperature of 38°F. In order to maintain pan temperatures in the

raised rail within N.S.F. parameters of 33 - 41°F, your pizza prep table is equipped

with a coldwall rail. The coldwall rail must maintain a freezing temperature so that

the pan product temperature can be maintained.

PIZZA RAIL SYSTEM SWITCH

A rail “On - Off” switch is located on the front grill so that the refrigeration can be

turned “On” to the rail during use and shut “Off” at the end of the day to save

energy and defrost the frost build up on the rail. Product should be removed

from the rail during the evening and stored in the refrigerated base. The rail

may need to be turned “Off” for periodic defrosting during the day if frost build

up becomes excessive. Product must not be left in the rail during this defrosting

period.

Important Note: Sandwich and pizza preparation tables are not intended for

overnight food storage in the top pan rail.

PIZZA PREP TEMP ADJUSTMENT - BOTTOM STORAGE COMPARTMENT

If an adjustment is necessary to maintain the average cabinet temperature range

of 38°F only, place a screwdriver into the thermostat slot (located inside of the

cabinet on the side of the evaporator coil fan housing) and turn clockwise for a

colder cabinet temperature or counterclockwise for a warmer cabinet temperature.

Further adjustments out of the factory design temperature range must be made

by a qualified refrigeration mechanic only.

15

Page 16

PIZZA PREP TEMP ADJUSTMENT - COLDWALL RAIL

If an adjustment is necessary to maintain the coldwall rail temperature, a pressure

control is located behind the front grill which controls the compressor operation and

the temperature range of the rail. The factory recommended settings for this low

pressure control are the following:

CUT IN = 45#

DIFFERENTIAL = 20#

Before making any adjustments to the pressure control out of the factory design

temperature range, please consult factory or a qualified refrigeration mechanic.

UNDERCOUNTER REFRIGERATOR SYSTEM AND ADJUSTMENT

All self-contained undercounter refrigerators are designed and factory set to

maintain an average cabinet temperature of 38°F. The temperature control is

accessible inside of the cabinet product compartment, on the right back wall

next to the evaporator coil (see figure 7 for thermostat location). If an adjustment

is necessary to maintain the above temperature range only, place a screwdriver

into the thermostat slot and turn clockwise for a colder cabinet temperature or

counterclockwise for a warmer cabinet temperature. Further adjustments out of

the factory design temperature range must be made by a qualified refrigeration

mechanic only.

Important Note: All refrigerators are designed with an automatic, “off-cycle”

defrost system which means that defrosting occurs automatically when the

compressor is not operating during an off-cycle. Do not set the thermostat too

cold where the cabinet temperature will fall below 35°F because the evaporator

will become blocked by ice since the compressor off-cycle will be considerably

shortened. This will result in loss of food stored within the cabinet and require

service to defrost the evaporator and re-adjust the thermostat.

UNDERCOUNTER FREEZER SYSTEM AND ADJUSTMENT

All self-contained undercounter freezers are designed and factory set to maintain

an average cabinet temperature of 0°F. All freezers are designed for the purpose

of holding pre-frozen food and although they are capable of freezing small quantities

of fresh food, they are not to be used as fast or blast freezers. Do not attempt to

freeze bulk quantities of fresh foods. The temperature control is accessible inside

of the cabinet product compartment, on the right back wall next to the evaporator

coil (see figure 7 for thermostat location). If an adjustment is necessary to maintain

the above temperature range only, place a screwdriver into the thermostat slot and

turn clockwise for a colder cabinet temperature or counterclockwise for a warmer

cabinet temperature. Further adjustments out of the factory design temperature

range must be made by a qualified refrigeration mechanic only.

16

Page 17

DEFROST OPERATION

All freezer models are equipped with an automatic, electric defrost system consisting

of an electric evaporator coil heater, evaporator drain pan heater, automatic electric

defrost time clock, and defrost high limit switch. The defrost system is time initiated

by the time clock and temperature terminated by the high limit switch. The time clock

is preset for three (3) defrost periods per day at eight (8) hour intervals and a fail safe

cut-off time of 20 minutes. Please note that defrost settings are not programmable.

The defrost time clock is located in front of the electrical console box in the rear

machine compartment of your freezer. If desired, to pre-set the initiation of the

defrost cycle to the time of day on the defrost time clock, turn the knob on the

center dial of timer face clockwise until the unit defrost cycle begins (compressor

and all fans will terminate). Defrost will begin at this same time every day at eight

(8) hour intervals. For example, if an 8:00 am defrost is desired, at 8:00 am turn

the defrost manual set knob to initiate defrost and a defrost cycle will start every

day at 8:00 am, 4:00 pm, 12:00 am. It will be necessary to reset the time of

defrost on the timer if the freezer is turned off or has loss of power.

EVAPORATOR ASSEMBLY

All sandwich units, undercounter refrigerators and freezers have an easily

accessible, easily serviceable, performance rated, forced-air evaporator assembly

which utilizes a plasticized fin coil for extended life. All models utilize a full length,

extra large evaporator coil with a uniquely directed air flow distribution which keeps

pan product and compartment product at uniformly constant temperatures. The

complete evaporator assembly is shown in figure 7.

17

Page 18

FIGURE 7

EVAPORATOR ASSEMBLY

INTERIOR ACCESSORIES

The standard interior accessory package that is supplied from the factory with your

new sandwich unit model consists of standard pilaster strips with pilaster clips (four

(4)clips per shelf), and one (1) epoxy coated shelf per section.

SHELVING INSTALLATION

Pilaster strips which support the shelving are secured to the cabinet walls with

special pilaster screws which allow the strips to be readily removed for cleaning

without the use of tools. Shelf clips are easily installed by inserting them into the

pilasters at the desired shelf location and shelf installation is as simple as placing

the shelf on the clips as shown in figure 8.

Important Note: When loading shelves with food product, allow space between

rows of product for proper air circulation, and do not load product to block back wall

above step (leave at least 2" of air space between product and back wall above step).

18

Page 19

FIGURE 8

ST

ANDARD SHELF PILASTER

OPTIONAL ACCESSORIES

In addition to the optional heavy-duty pilaster and clip as shown in figure 9, all

models are available with an overhead or double-overhead shelf. Models can

even be stacked with a heavy duty stacking collar adapter kit as shown in figure

10. Please consult the price list for additional interior and exterior options and

accessories available from the factory for your model.

19

Page 20

FIGURE 9

OPTIONAL

HEAVY-DUTY PILASTER

OPTIONAL OVERHEAD OR DOUBLE-OVERHEAD SHELF

All open top models are available with an optional overhead or double-overhead shelf.

To install either the overhead or the double-overhead shelf, place the shelf into

position on the work top (if your model was ordered with the overhead shelf,

mounting holes will be added on the cabinet at the factory), line up holes and

secure overhead shelf with the supplied screws. If the overhead shelf was

ordered separately, follow the mounting instructions supplied with the shelf.

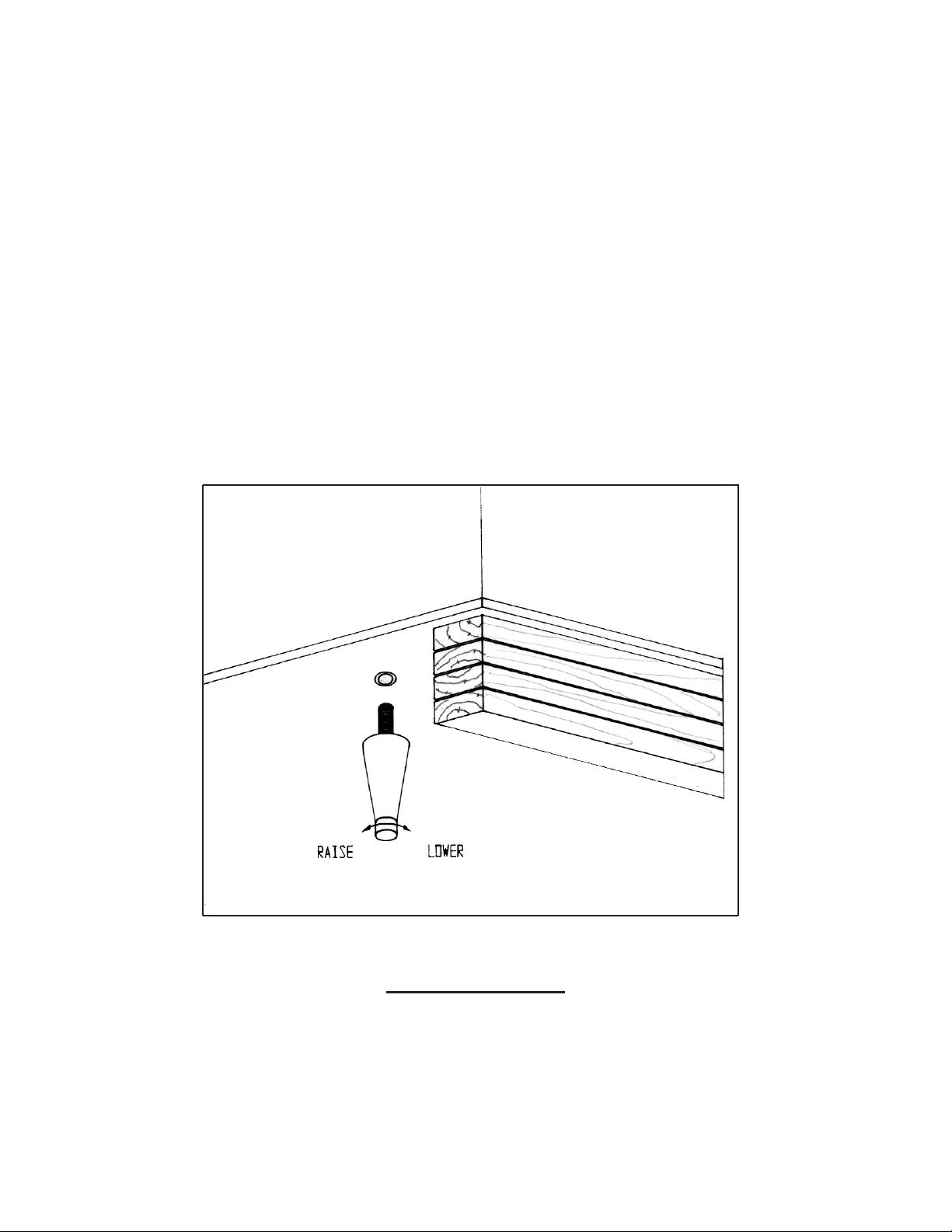

OPTIONAL STACKING COLLAR ADAPTER KIT

All SW27, SWF27, SW48, SWF48 solid top models can be stacked one on top

of the other with the use of a heavy duty, stainless steel stacking collar as shown

in figure 10. When stacking a refrigerator and freezer, it is always best to place

the freezer model on the bottom for maximum efficiency. The front grill which is

attached to the stacking collar body is attached with easily removable thumbscrews

and should be removed periodically for cleaning. The front grill should always be

clean and clear of debris and never blocked.

20

Page 21

To stack your models, the following instructions should be followed:

1. Decide which model is to be on “top” and which model is to be on “bottom".

2. On “top” model, remove both bottom rear cover screws on “bottom” model,

remove both top joggle clip screws with bumpers.

3. Carefully install four legs on “top” model and set this model on the work top

of the “bottom” model. (adjust all leg bullets outward (ccw) about three full

turns prior to installing)

4. Install stacking collar as shown in figure 10, making sure all rear screw hole

slots line up on both top and bottom models where screws were removed

from in step #2. If screw hole slots do not line up (left to right) with screw

holes then the stacking collar has been mounted upside down. Remove and

re-install correctly.

21

FIGURE 10

OPTIONAL STACKING COLLAR

5. Leg bullets can now be lowered (cw) by reaching in front access of stacking

collar so that top model is snug against the stacking collar. Once snug,

install the rear screws that were removed in step #2 and peel off the

adhesive tape backing strip around the side flanges of the stacking collar

so that both units are bonded together.

6. Align the front grill holes with the stacking collar holes and secure both

thumbscrews.

Page 22

SAFETY PRECAUTIONS

The following safety precautions should be followed when operating any appliances:

Always disconnect the power cord before attempting to work on or clean

any equipment.

Disconnect the power cord when the appliance will be idled for a long

period of time.

Do not attempt to service this unit yourself as removing any covers may

cause exposure to dangerous voltage.

Always route the power cord so that it is not likely to be walked on or

pinched by other appliances. Never use extension cords.

Do not overload outlets with more than one appliance. This can result in

fire or electrical shock.

Your model is equipped with a grounded and polarized plug. Do not

defeat the purpose of this plug by removing the ground post or using a

non-polarized adapter without properly grounding the outlet.

When a replacement part is required, always insist on factory authorized

parts only.

MAINTENANCE

PERIODIC CLEANING PROCEDURE

It is best to clean your refrigerator or freezer when the product load is at its

lowest level inside your cabinet. To clean the interior or exterior cabinet surfaces,

the following procedure should be followed:

1. Disconnect your model from its power supply and remove all food product

from inside.

2. Open all doors and allow the cabinet to reach room temperature. Remove

all accessories (shelves, racks, pilasters, clips, etc.) From within the model,

wash with a baking soda and warm water solution, and rinse thoroughly with

clear water. Dry all of the accessories completely with a soft clean cloth.

3. Once the cabinet has reached room temperature, wash the entire cabinet

inside and out with a baking soda and warm water solution. For slightly

more difficult cleanups, ammonia or vinegar in warm water can be used.

Rinse thoroughly with clear water and dry with a soft clean cloth. Failure

to dry all surfaces completely may cause water stains or streaking on the

aluminum or stainless steel finish.

4. Return all accessories to their respective positions and return electric supply

power to the model.

22

Page 23

Precautions

1. Never use harsh detergents, cleaners, scouring powders, or chemicals when

cleaning your model.

2. Strong bleaches tend to corrode many materials and should never come in

contact with stainless steel.

3. Tincture of iodine, or iron should not come in contact with stainless steel.

These solutions, which cause stainless steel to discolor, should be rinsed off

immediately if contact occurs.

4. Some foods, such as mustard, mayonnaise, lemon juice, dressings or salts,

may attack or corrode stainless steel.

5. Gritty, hard abrasives will mar the finish of stainless steel and aluminum and

are not recommended.

GENERAL PREVENTATIVE MAINTENANCE

Performance of the air cooled condensing unit located inside of the compressor

machine compartment of your new model, depends exclusively upon the amount of

air passing through the condenser fins. Your refrigerator or freezer will run more

efficiently, consume less current, and provide a maximum of trouble-free service

throughout its lifetime if the condenser is kept clean and an adequate supply of

clean, cool air is provided at all times. Periodically (at least once a month) inspect

the condenser coil, which is located directly behind the rear panel grill, to check for

debris or blockage.

If the condenser coil is dirty or blocked, disconnect the power supply to your model

and using a stiff brush, brush the dirt from the condenser fins until the condenser is

clear from any debris. Using a vacuum cleaner with a brush attachment may aid in

this cleaning process. After cleaning, restore electrical service to your model.

PARTS AND SERVICE

Always provide the cabinet model and serial number (located on the data plate on the

inside right wall of the cabinet) whenever contacting the factory or your dealer regarding questions or when ordering parts.

23

Page 24

MODEL # ____________________________Serial#________________

Notes: ______________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

24

Page 25

TROUBLESHOOTING AND SERVICING GUIDE

25

PROBLEM PROBABLE CAUSE CORRECTION

Condensing unit will 1.Line Disconnected, Switch Open. 1.Close Start Or Disconnect Switch

not start - no hum. 2.Fuse Removed Or Blown. 2.Replace Fuse.

3.Overload Protector Blown. 3.Determine Reason And Correct/

Replace.

4.Control “Off” Due To Cold Location. 4.Relocate Control.

5.Control Stuck In Open Position. 5.Repair Or Replace Control.

6.Wiring Improper Or Loose. 6.Check Wiring Against Diagram.

Condensing unit will 1.Improperly Wired 1.Check Wiring Against Diagram.

not start - hums but 2.Low Voltage To Unit. 2.Determine Reason And Correct.

trips on overload 3.Starting Capacitor Defective. 3.Determine Reason And Replace

protector. 4.Relay Failing To Close. 4.Determine Reason And Replace.

5.Compressor Motor Has A Shorted Or Open 5.Replace Compressor.

Winding.

6.Internal Mechanical Trouble In Compressor. 6.Replace Compressor.

7.Insufficient Air Supply. 7.Clear Condenser&Allow Compressor

To Cool Down.

Condensing unit

1.Additional Current Passing Through Overload 1.Check Wire Diagram. Check For

starts and runs, but

Protector. Added Components Connected To

short cycles on

Wrong Side Of Overload Protector.

overload protector.

2.Low Voltage Unit. 2.Determine Reason And Correct.

3.Overload Protector Defective. 3.Check Current, Replace Protector.

4.Run Capacitor Defective. 4.Determine Reason And Replace.

5.Excessive Discharge Pressure. 5.Check Ventilation, Restrictions In

Cooling Medium Or Refrig. System.

6.Excessive Suction Pressure. 6.Check For Misapplication.

7.Insufficient Air Supply 7.Clear Condenser & Allow

Compressor To Cool Down.

Condensing unit 1.Improperly Wired 1.Check Wiring Against Diagram.

starts, but fails to 2.Low Voltage To Unit. 2.Determine Reason And Correct.

switch off of “start” 3.Relay Failing To Open. 3.Determine Reason And Replace.

winding. 4.Run Capacitor Defective. 4.Determine Reason And Replace.

5.Excessively High Discharge Pressure. 5.Check Discharge Shut-Off Valve,

Possible Overcharge.

6.Compressor Motor Has A Shorted Or Open 6.Replace Compressor.

Winding.

7.Internal Mechanical Trouble In Compressor. 7.Replace Compressor.

Page 26

PROBLEM PROBABLE CAUSE CORRECTION

Condensing unit 1.Overload Protector. 1.See Problem # 3.

runs, but shorts 2.Thermostat. 2.Differential Must Be Widened.

cycles on: 3.High Pressure Cut-Out Due To: 3.

(a) Insufficient Air Supply (a) Check Air Supply To Condenser.

(b) Overcharge. (b) Evacuate And Re-charge.

(c) Air In System. (c) Evacuate And Re-charge.

4.Low Pressure Cut-Out Due To: 4.

(a) Valve Leak. (a) Replace, Evacuate And

Re-charge.

(b) Undercharge. (b) Evacuate And Re-charge.

(c) Restriction In Expansion Device. (c) Replace Expansion Device.

Condensing unit 1.Shortage Of Refrigerant. 1.Fix Leak, Evacuate And Re-Charge

runs, but for 2.Control Contacts Stuck Closed. 2.Clean Contacts Or Replace Control.

prolonged periods 3.Excessive Heat Load Placed Into Cabinet. 3.Allow Unit Sufficient Time For

or continuous. Removal Of Latent Heat.

4.Prolonged Or Too Frequent Door Openings. 4.Plan Or Organized Schedule To

Correct Condition.

5.Evaporator Coil Iced . 5.Defrost Evaporator Coil.

6.Restriction In Refrigeration System. 6.Determine Location And Remove

7.Dirty Condenser. 7.Clean Condenser Coil.

8.Filter Drier Clogged. 8.Replace, Evacuate And Re-charge.

Start capacitor open,

1.Relay Contact Not Opening Properly. 1.Clean Contacts Or Replace Relay

shorted or blown.

2.Prolonged Operation On Start Cycle: 2.

(a) Low Voltage To Unit. (a) Determine Reason And Correct.

(b) Improper Relay (b) Replace With Correct Relay.

(c) Starting Load Too High. (c) Correct By Using Pump Down.

3.Excessive Short Cycling. 3.Determine Reason For Short Cycle,

(See Problem # 5) And Correct.

4.Improper Capacitor. 4.Determine Correct Size And

Replace.

Run capacitor open, 1.Improper Capacitor.. 1.Check Size And Replace.

shorted or blown. 2.Excessively High Line Voltage, Over 110% Of 2.Determine Reason And Correct.

Rated Maximum.

Relay defective or 1.Incorrect Relay. 1.Check Relay And Replace.

blown out. 2.Incorrect Mounting Angle. 2.Remount Relay In Correct Position.

3.Voltage Too Low Or Too High. 3.Determine Reason And Correct.

4.Excessive Short Cycling. 4.Determine Reason And Correct

(See Problem # 5).

5.Loose Or Vibrating Mounting Position. 5.Remount Rigidly.

6.Incorrect Run Capacitor. 6.Replace With Proper Capacitor.

7.Loose Wiring On Relay Or Overload. 7.Tighten All Wiring Screws.

26

Page 27

PROBLEM PROBABLE CAUSE CORRECTION

Product zone 1.Control Setting Too High. 1.Adjust T-Stat.

temperature too 2.Inadequate Air Circulation. 2.Rearrange Product Load To

high.

Improve Air Circulation.

3.Dirty Condenser 3.Clean Condenser Coil

Suction line frosted 1.Overcharge Of Refrigerant. 1.Evacuate And Re-charge.

or sweating. 2.Evaporator Fan Not Running. 2.Determine Reason And Correct.

3.Expansion Valve Stuck Open. 3.Clean Valve, Evacuate And

Re-charge.

4.Expansion Valve Superheat Too Low. 4.Adjust Superheat To Required

Setting.

Liquid line frosted, 1.Restriction In Drier Strainer. 1.Replace Drier, Evacuate And

cold, or sweating. Re-charge.

2.Liquid Line Service Valve Partially Closed. 2.Open Valve Fully Or Replace If

Necessary.

Noisy condensing 1.Loose Parts or Mountings 1.Tighten All Mounting Parts And

unit. Shroud Cover.

2.Tubing Rattle Or Vibration. 2.Reform Tubing To Be Free Of

Contact.

3.Bent Fan Blade Causing Excessive Vibration. 3.Replace Fan Blade.

4.Fan Bearings Worn. 4.Replace Fan Motor.

Thermometer reads 1.Calibration. 1.Consult Operations Manual And

different than actual Calibrate.

Temperature 2.Defective. 2.Replace.

Water leak inside 1.Condensate Drain Pan Not Installed Properly. 1.Consult Operations Manual For

unit.

Install Instruction.

2.Unit Not Level. 2.Make Sure Unit Is Level Or Pitched

Back Slightly.

3.Drain Pan Misaligned. 3.Make Sure Drain Pan Is Aligned

Properly.

4.Defective Drain Pan. 4.Replace.

Doors Misaligned. 1.Shifted During Shipping. 1.Refer To Operation Manual For

Hinge Adjustment.

27

Page 28

28

WIRING DIAGRAMS

Page 29

29

Page 30

30

Page 31

Continental Warranty Procedure

Our warranty is 1 year on parts and labor, and 5 years on the compressor from date

of original installation on any unit installed after January 1, 1999. Any unit installed

before January 1, 1999 has a warranty of 90 days labor, 1 year parts and 5 years

on the compressor, from the date of installation.

Please consult factory before any warranty service work. We will issue a 4 digit

work authorization # to put on the service invoice for payment. Exceptions will

be made. Example; after hours, you must contact the factory at 1-800-523-7138

at extension 113 or 134. Provide the model and serial number, place of business,

where the unit is located and if possible the installation date. Contact the factory

the following business day during normal business hours 8 A.M. to 5 P.M. Eastern

time.

**Not covered under warranty are temperature adjustments, calibration, leveling,

dirty condensers, any preventive maintenance and any mis-application i.e. not

enough ventilation.

Consult factory for any parts needed under warranty. We will issue a 4 digit

return goods authorization# (RGA#) to put on the outside of the box to return

to the factory, freight prepaid. Exceptions will be made. If you use a part from

your truck stock, we can replace it with our own part.

31

Page 32

32

Warranty Compressor Procedures

If the compressor fails within the first (12) months of use or (20) months by the

date code on the compressor, an “over-the-counter exchange” must be made through

a Tecumseh or Copeland dealer.

After the first year the additional (4) year compressor warranty is through

Continental Refrigeration, and can be handled by one of the following methods:

(1)Continental will supply the replacement compressor at no charge and

pay for regular ground freight.

(2)Continental will supply the compressor at no charge and the end user,

dealer or service company pays for the freight, other than regular

ground (COD, Visa or Mastercard).

(3)A compressor can be purchased locally and Continental will either

replace the compressor for stock or offer an allowance towards its pur

chase. The end user is to pay the difference:

(A)

1

/

5 h.p. to

1

/

3 h.p.-Up to $100

(B)

1

/2 h.p. to 3/4 h.p.-Up to $250

(C) 1 h.p. to 2 h.p.-Up to $350

Exceptions will be made depending on circumstances, but in all cases,

Continental must be notified prior to any transaction, if possible. The tag from the

defective compressor or the information (if unable to remove) must be returned for

proof of failure after the first year. Please contact the service department with any

further questions.

Thank You,

The Service Department

Page 33

33

Items NOT Covered Under Warranty

Consult your owner's manual for detailed information on the

following (page #'s listed beside each line item).

I. Preventative Maintenance

A. Dirty Condenser (20)

B. General Hardware Adjustments

1. Casters/Legs (5-6)

2. Handles

3. Hinges (8-10)

4. Light Bulb Replacement

II. Compressor Failure Due to Poor Air Circulation

A. Reach-In, Roll-In Models, Warmers (White)*

1. 12" Above Grill Area (2-3)

2. 3" On Sides, Back & Underneath (Reach-In only) (2-3)

B. Backbar, Keg, Bottle Cooler Units & Glass, Plate Chiller Units (Green)*

1. 3" On Sides & Back (2-3)

C. Undercounter, Sandwich & Pizza Prep Units (Yellow)*

1. 3" On Sides, Back & Underneath (2-4)

D. Front Breather Units (Yellow)*

1. Minimal Ventilation Needed

III. Temperature Adjustments / Calibrations (12-14)

IV. Leveling (5-6)

** FAILURES DUE TO LACK OF MAINTENANCE, POOR INSTALLATION

OR INAPPROPRIATE OPERATION OF THE UNIT MAY VOID CUSTOMER'S

WARRANTY**

Please contact the Service Dept. with any questions pertaining to the above.

Thank You,

The Service Dept.

*Color of owner's manual.

Loading...

Loading...