Page 1

STANDARD PRACTICE

MAINTENANCE

MANUAL

SPARK IGNITED ENGINES

Technical Portions Accepted by the Federal Aviation Administration

Publication M-0, Revision 1 CHANGE 3

©

2023 CONTINENTAL AEROSPACE TECHNOLOGIES, INC. JAN 2023

Page 2

Supersedure Notice

This manual incorporates maintenance and service information contained in Continental Aerospace Technologies™

Service Documents common to the horizontally opposed, spark ignition, aviation gasoline (AvGas) engines

conforming to Type Certificate held by Continental Motors, Inc. This document is supplemental to the Instructions

for Continued Airworthiness provided in the manuals listed in Section 1-1.1. Instructions contained in the Service

Documents listed in Section 1-2.4 are superseded by instructions in this manual upon release, except for those

Mandatory Service Bulletins (MSBs) and Critical Service Bulletins (CSBs) linked to Airworthiness Directives.

Effective Changes for this Manual

0 ..... 15 September 2019

1 ...........1 February 2021

2 ............26 August 2021

3 ............ 6 January 2023

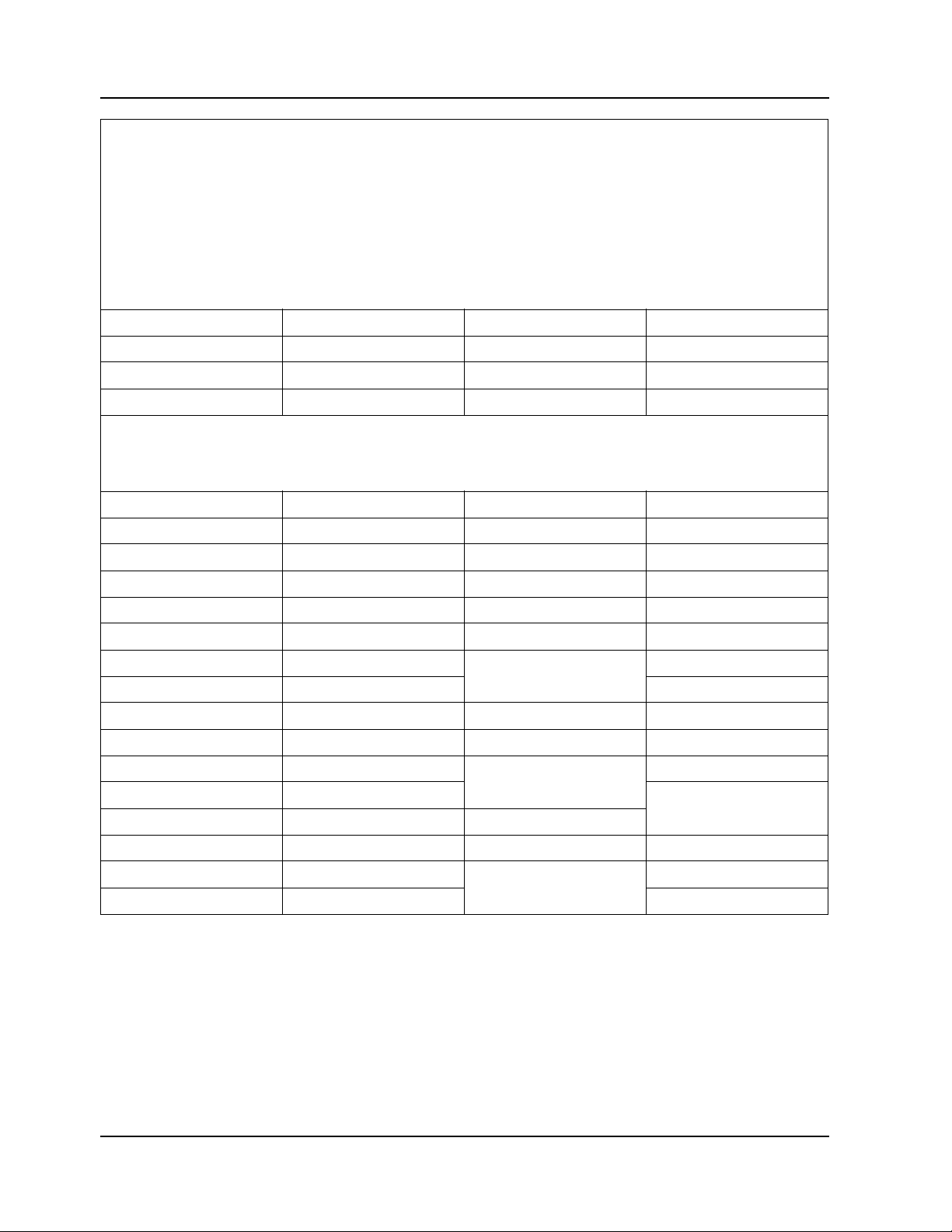

List of Effective Pages

Document Title: Standard Practice Maintenance Manual

Publication Number: M-0 Initial Publication Date: 15 September 2019

Page Change Page Change Page Change Page Change

Cover............................3 3-7 ................................0 6-6 thru 6-16 ................ 0 6-54..............................3

A...................................3 3-8 thru 3-12.................2 6-17.............................. 3 6-55..............................0

B thru C (added)........... 3 3-13 ..............................0 6-18.............................. 1 6-56.............................. 1

i thru xviii ......................2 3-14 ..............................2 6-19 thru 6-32 .............. 0 6-57 thru 6-63...............0

1-1 ................................ 0 3-15 thru 3-17...............0 6-33.............................. 1 6-64.............................. 3

1-2 ................................ 3 3-18 thru 3-19...............2 6-33.1 thru

1-4 thru 1-11................. 0 3-20 thru 3-22 ...............0 6-154............................ 3

6-33.2 (added) ............. 1

6-65 thru 6-153............. 0

1-12 thru 1-13............... 3 3-23 thru 3-24...............2 6-34 thru 6-48 .............. 0 6-155 thru 6-156........... 2

1-14 thru 1-16............... 0 4-1 thru 4-2 ...................0 6-49.............................. 1 6-157 thru 6-164........... 0

2-1 thru 2-7...................1 5-1 thru 5-6 ...................0 6-49.1 thru

2-8 thru 2-24................. 0 5-7 ................................1 6-165.1 thru

6-49-4 (added) ............. 1

3-1 ................................ 1 5-8 ................................0 6-50 thru 6-51 .............. 1

6-165............................ 3

6-165.8 (added)............ 3

3-2 thru 3-3...................0 6-1 thru 6-3 ...................0 6-52 thru 6-53 .............. 0 6-166 thru 6-180........... 0

3-4 thru 3-5...................3 6-4 ................................3 6-53.1 thru

3-6 ................................ 1 6-5 ................................1 7-3 thru 7-4...................3

Published and printed in the U.S.A. by Continental Motors, Inc. dba Continental Aerospace Technologies

Available exclusively from the publisher: P.O. Box 90, Mobile, AL 36601

Copyright © 2019, 2021, 2023 Continental Aerospace Technologies, Inc. All rights reserved. This material may not be reprinted, republished,

broadcast, or otherwise altered without the publisher's written permission. This manual is provided without express, statutory, or implied

warranties. The publisher will not be held liable for any damages caused by or alleged to be caused by use, misuse, abuse, or misinterpretation

of the contents. Content is subject to change without notice. Other products and companies mentioned herein may be trademarks of the

respective owners.

6-53.6 (added) ............. 1

7-1 thru 7-2...................0

™

A Standard Practice Maintenance Manual

CHANGE 3 6 January 2023

Page 3

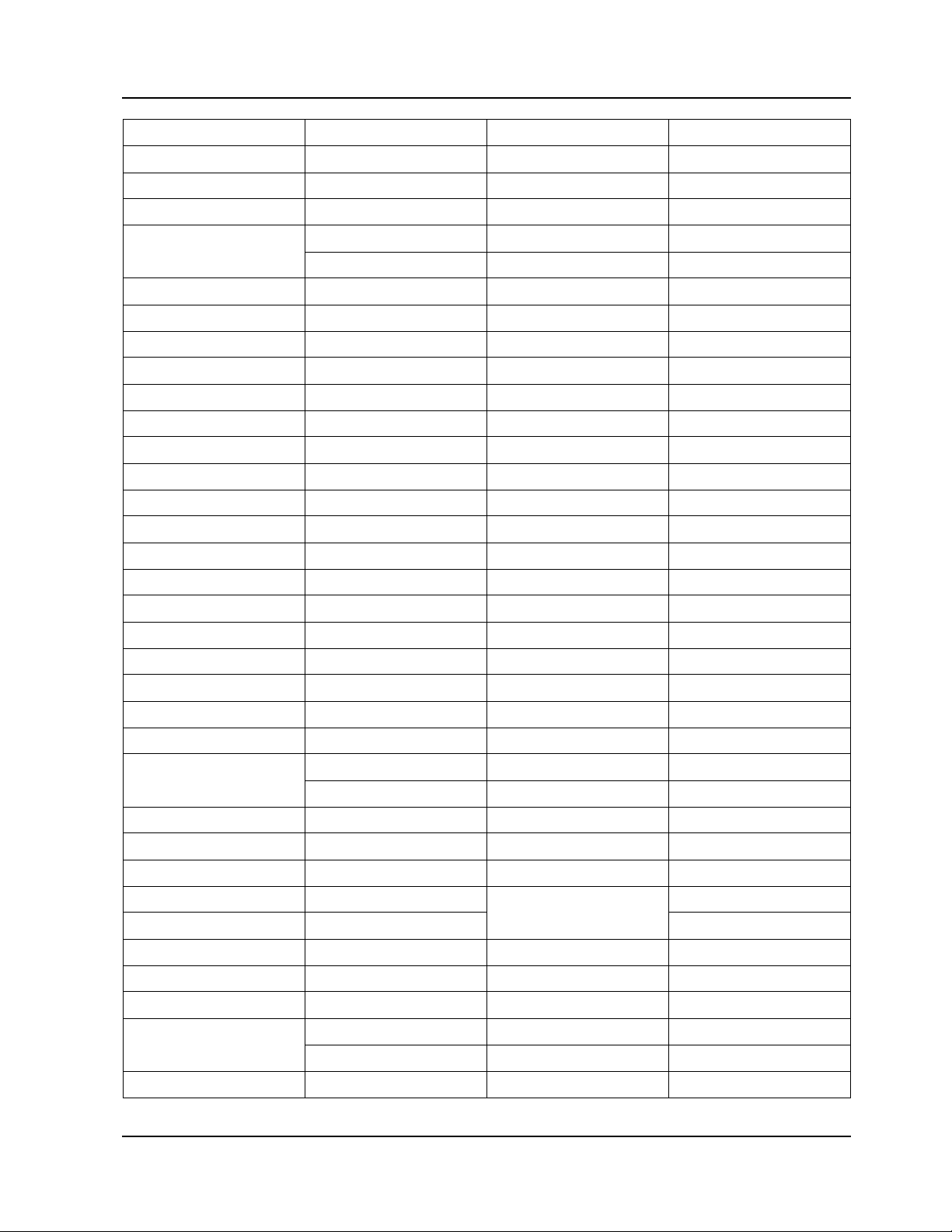

Page Change Page Change Page Change Page Change

7-5 thru 7-30.................0 12-1 thru 12-8 .............. 0

8-1 thru 8-18.................0 A-1 thru A-6 ................. 0

8-19 thru 8-20...............1 B-1 thru B-9 ................. 0

8-20.1 thru

8-20.6 (added)..............1

8-21 thru 8-25...............0 B-12 ............................. 2

8-26 ..............................1 B-13 thru B-16 ............. 0

8-27 thru 8-28 (added) .1 C-1 thru C-18 ............... 0

9-1 thru 9-3...................0 C-19 ............................. 3

9-4 ................................3 C-20 thru C-24 ............. 0

9-5 ................................0 C-25............................. 2

9-6 ................................1 C-26............................. 0

9-7 ................................0

9-8 thru 9-10 (added) ...1

10-1 thru 10-8...............0

10-9 ..............................3

10-10 ............................0

10-11 ............................3

B-10 ............................. 2

B-11 ............................. 3

10-12 ............................2

10-13 ............................3

10-14 thru 10-51...........0

10-52 ............................3

10-53 thru 10-55...........0

10-55.1 thru

10-55.16 (added)..........3

10-56 thru 10-63...........0

10-64 thru 10-65...........3

10-66 thru 10-68...........0

10-69 ............................3

10-70 thru 10-85...........0

10-86 ............................2

10-87 thru 10-107.........0

10-108 ..........................1

10-109 thru

10-114 (added).............1

11-1 thru 11-8...............0

Standard Practice Maintenance Manual B

6 January 2023 CHANGE 3

Page 4

Intentionally Left Blank

C Standard Practice Maintenance Manual

CHANGE 3 6 January 2023

Page 5

Preface

This manual was developed in accordance with Title 14, Code of Federal Regulations (CFR) Part

33, §33.4 as the Instructions for Continued Airworthiness (ICA) for Standard Practices.

Continental Motors, Inc. provides ICAs based on the design, testing, and certification of engines

and parts. Continental Motors, Inc. is the holder of the Type Certificate (TC) or Parts Manufacture

Approval (PMA) issued by the Federal Aviation Administration (FAA). Instructions in

Continental manuals, which include maintenance, repair limits, and overhaul instructions, are

applicable only to Continental Aerospace Technologies™ (Continental®) engines and parts.

Except for authorized owner preventive maintenance (defined in Title 14, Code of Federal

Regulations (CFR) Part 43 §§43.3 and 43.13), Continental ICAs are written for exclusive use by

FAA (or equivalent authority) licensed mechanics or FAA (or equivalent authority) certified

repair station employees.

Information and instructions contained in this manual anticipate the user possesses and applies the

knowledge, training, and experience commensurate with the requirements to meet the prerequisite

FAA license and/or certification requirements. No other use is authorized. It is the responsibility

of the owner to verify the mechanic or facility operating, maintaining, or servicing the engine uses

the most current ICA, including manual change pages, service documents, and FAA

Airworthiness Directives (ADs), to perform those functions.

Aftermarket parts installed on a Continental engine constitutes a deviation from type-design

criteria. Continental has not participated in design, test, or certification of any aftermarket parts.

Continental does not provide product manufacturing specifications to aftermarket parts

manufacturers and accepts no liability for the suitability, durability, longevity, or safety of such

parts installed on Continental engines. Installation of aftermarket parts on a Continental engine

must be performed using ICAs prepared by the manufacturer and found acceptable by the FAA

for the subject installation. Continental ICAs must not be used for such parts.

WARNING

Ensure you have the latest revision of this manual, any

applicable change pages, FAA Airworthiness Directives and

Continental service documents prior to commencing engine

service, inspection, maintenance, or overhaul.

To facilitate the use of current data, Continental provides the latest information on the Continental

web site (http://www.continental.aero). This information (applicable to current versions) includes

an index of manuals, links to active service documents, FAA Airworthiness Directives, and other

information applicable to the ICAs. Additionally, Continental technical publications (the current

version in electronic or printed format) are available through our publications distributor, Aircraft

Technical Publishers (ATP) (www.atp.com). Refer to “Related Publications” in Section 1-2.5. for

additional information about service subscriptions and ATP contact information (see Table 1-2).

Standard Practice Maintenance Manual i

15 Sep 2019

Page 6

Intentionally Left Blank

ii Standard Practice Maintenance Manual

15 Sep 2019

Page 7

Table of Contents

TABLE OF CONTENTS

Chapter 1. Introduction

1-1. Scope and Purpose of This Manual.............................................................................................. 1-1

1-1.1. Instructions for Continued Airworthiness........................................................................... 1-1

1-1.2. Advisories ........................................................................................................................... 1-3

1-1.3. Effectivity Symbols ............................................................................................................ 1-3

1-1.4. Using this Manual............................................................................................................... 1-4

1-1.5. Compliance......................................................................................................................... 1-6

1-1.6. Order of Precedence ........................................................................................................... 1-7

1-2. Publications .................................................................................................................................. 1-7

1-2.1. Publication Access.............................................................................................................. 1-7

1-2.2. Publication Changes ........................................................................................................... 1-7

1-2.3. Update/Change Distribution ...............................................................................................1-8

1-2.4. Service Documents ........................................................................................................... 1-10

1-2.4.1. Service Documents Incorporated in this Manual.................................................... 1-11

1-2.4.2. Service Documents Released After Publication ..................................................... 1-13

1-2.5. Related Publications ......................................................................................................... 1-15

1-2.5.1. Suggestions and Corrections................................................................................... 1-15

1-3. Contact Information ................................................................................................................... 1-16

1-4. Service Parts............................................................................................................................... 1-16

1-4.1. Service Part Applicability and Availability....................................................................... 1-16

1-4.2. Part Supersedure ............................................................................................................... 1-16

Chapter 2. Tools

2-1. Special Tools ................................................................................................................................ 2-1

2-1.1. Vendor Contact Information ...............................................................................................2-7

2-2. Mechanic’s Tools ....................................................................................................................... 2-24

Chapter 3. Lubricants, Sealants, and

Adhesives

3-1. Engine Oil Specifications............................................................................................................. 3-1

3-1.1. Oil Brand Selection ............................................................................................................ 3-1

3-2. Oil Change Intervals .................................................................................................................... 3-3

3-3. Additives ...................................................................................................................................... 3-3

3-4. Sealant, Lubricant, and Adhesive Applications............................................................................ 3-4

3-4.1. General Sealant Application Instructions ..........................................................................3-11

3-4.1.1. Four Cylinder Engine Crankcase Threading........................................................... 3-12

3-4.1.2. Six Cylinder Engine Crankcase Threading............................................................. 3-14

3-4.2. Scavenge Pump Body Sealant and Threading.................................................................. 3-18

3-4.3. Oil Pump Assembly Sealant and Threading ..................................................................... 3-19

3-4.4. Starter Adapter Assembly Sealant and Threading ............................................................ 3-23

3-4.5. Starter Adapter Accessory Drive Cover Sealant and Threading....................................... 3-24

Standard Practice Maintenance Manual iii

26 Aug 2021 CHANGE 2

Page 8

Table of Contents

Chapter 4. Airworthiness Limitation Section

Chapter 5.Engine Removal & Installation

5-1. Engine Removal ........................................................................................................................... 5-1

5-1.1. Tools and Consumable Supplies ......................................................................................... 5-1

5-1.2. Engine Removal Procedure ................................................................................................5-1

5-2. Engine Installation........................................................................................................................ 5-2

5-2.1. Common Tools and Consumable Supplies .........................................................................5-2

5-2.2. Engine Receipt and Handling .............................................................................................5-3

5-2.3. Uncrating the Engine ..........................................................................................................5-3

5-2.4. Crating an Engine for Shipping .......................................................................................... 5-3

5-2.5. Acceptance Inspection ........................................................................................................ 5-3

5-2.6. Engine Transport................................................................................................................. 5-4

5-2.7. Engine Installation Procedures ...........................................................................................5-4

5-2.8. Engine Adjustments and Component Replacement by OEMs and STC Converters.......... 5-5

5-2.9. Engine Pre-oiling ................................................................................................................ 5-7

Chapter 6. Engine Inspection and Service

6-1. Engine Inspection Introduction ....................................................................................................6-1

6-2. Inspection and Maintenance Schedule ......................................................................................... 6-1

6-3. Time Between Overhaul............................................................................................................... 6-1

6-4. Scheduled Inspections .................................................................................................................. 6-5

6-4.1. One Time Post - Installation Inspections............................................................................6-6

6-4.2. 25-Hour Initial Operation Inspection..................................................................................6-6

6-4.3. 50-Hour Engine Inspection................................................................................................. 6-8

6-4.4. 100-Hour (Annual) Engine Inspection ............................................................................... 6-9

6-4.5. 500-Hour Engine Inspection............................................................................................. 6-11

6-4.6. Visual Inspection............................................................................................................... 6-12

6-4.7. Engine Operational Check ................................................................................................6-14

6-4.7.1. Fuel Injection System Specifications ......................................................................6-15

6-4.7.2. Maintenance Preflight Inspection............................................................................ 6-20

6-4.7.3. Oil Pump Operational Check .................................................................................. 6-22

6-4.7.4. Fuel System Operational Check.............................................................................. 6-23

6-4.7.5. Magneto RPM Drop Check..................................................................................... 6-31

6-4.7.6. Engine Shutdown .................................................................................................... 6-32

6-4.8. Engine Oil Servicing......................................................................................................... 6-33

6-4.8.1. Check and Replenish Engine Oil Level ..................................................................6-33

6-4.8.2. Oil Change and Filter/Screen Replacement ............................................................ 6-49

6-4.8.3. Check for Oil Leaks ................................................................................................ 6-52

6-4.8.4. Oil Sample Collection ............................................................................................. 6-52

6-4.8.5. Oil Trend Monitoring and Spectrographic Oil Analysis......................................... 6-53

6-4.9. Ignition System Maintenance ........................................................................................... 6-54

6-4.9.1. Ignition Timing ....................................................................................................... 6-54

6-4.9.2. Spark Plug Maintenance.......................................................................................... 6-62

6-4.9.3. Ignition Harness Maintenance.................................................................................6-66

6-4.10. Engine Adjustments........................................................................................................ 6-68

6-4.10.1. Oil Pressure Adjustment........................................................................................ 6-68

6-4.10.2. Fuel System Adjustment ....................................................................................... 6-70

6-4.10.3. Manifold Pressure Adjustment.............................................................................. 6-91

iv Standard Practice Maintenance Manual

CHANGE 2 26 Aug 2021

Page 9

Table of Contents

6-4.10.4. Belt Tension Check and Adjustment .................................................................... 6-96

6-4.11. Cylinder Inspections..................................................................................................... 6-102

6-4.11.1. Cylinder Visual Inspection.................................................................................. 6-103

6-4.11.2. Differential Pressure Test.................................................................................... 6-105

6-4.11.3. Cylinder Borescope Inspection ........................................................................... 6-113

6-4.11.4. Cylinder to Crankcase Mounting Deck Inspection............................................. 6-117

6-4.11.5. Baffle Inspection ................................................................................................. 6-118

6-4.11.6. Cowling Inspection ............................................................................................. 6-122

6-4.12. Crankcase Inspection.................................................................................................... 6-122

6-4.12.1. Crankcase Critical Stress Areas .......................................................................... 6-125

6-4.13. Engine Mount Inspection.............................................................................................. 6-129

6-4.14. Induction System Inspection ........................................................................................ 6-129

6-4.15. Ignition System Inspection ........................................................................................... 6-131

6-4.15.1. Impulse Coupling Functional Check................................................................... 6-133

6-4.15.2. Starting Vibrator Functional Check .................................................................... 6-134

6-4.15.3. Magneto Drive Coupling Inspection................................................................... 6-134

6-4.16. Engine Gauge Inspection.............................................................................................. 6-135

6-4.17. Fuel System Inspection................................................................................................. 6-136

6-4.18. Throttle and Mixture Control Lever Inspection............................................................ 6-137

6-4.19. Engine Control Linkage Inspection.............................................................................. 6-139

6-4.20. Induction System Drain Inspection .............................................................................. 6-141

6-4.20.1. Induction System Drain Inspection (Naturally Aspirated Engines).................... 6-142

6-4.20.2. Induction System Drain Inspection (Turbocharged Engines)............................. 6-143

6-4.21. Turbocharger and Exhaust System Inspection.............................................................. 6-144

6-4.21.1. Turbocharger Oil Supply Check Valve Inspection ............................................. 6-149

6-4.22. Alternator Inspection .................................................................................................... 6-153

6-4.22.1. Alternator Drive Coupling Inspection ................................................................ 6-154

6-4.22.2. Alternator Drive Coupling Inspection ................................................................ 6-155

6-5. Unscheduled Maintenance ....................................................................................................... 6-158

6-5.1. Propeller Strike ............................................................................................................... 6-158

6-5.1.1. Propeller Strike Inspection.................................................................................... 6-158

6-5.2. Hydraulic Lock Inspection ............................................................................................. 6-159

6-5.3. Engine Overspeed Inspections........................................................................................ 6-160

6-5.3.1. Category I Overspeed Inspection.......................................................................... 6-161

6-5.3.2. Category II Overspeed Inspection......................................................................... 6-161

6-5.3.3. Category III Overspeed Inspection ....................................................................... 6-162

6-5.4. Turbocharger Overboost................................................................................................. 6-162

6-5.5. Lightning Strike Inspection ............................................................................................ 6-162

6-5.6. Contaminated Fuel System Inspection ........................................................................... 6-163

6-5.7. Foreign Object Contamination Inspection...................................................................... 6-163

6-5.8. Sticking or Stuck Valves................................................................................................. 6-164

6-6. Inspection Checklists ............................................................................................................... 6-166

Chapter 7. Engine Operation

7-1. Introduction .................................................................................................................................. 7-1

7-2. Flight Prerequisites....................................................................................................................... 7-1

7-2.1. Oil Change Interval ............................................................................................................ 7-1

7-2.2. Engine Fuel Requirements.................................................................................................. 7-2

7-2.3. Engine Operation after Cylinder Replacement and/or Major Overhaul............................. 7-6

7-2.4. Flight Check and Break-In ................................................................................................. 7-8

Standard Practice Maintenance Manual v

26 Aug 2021 CHANGE 2

Page 10

Table of Contents

7-2.4.1. Engine Break-In ........................................................................................................7-8

7-2.4.2. Flight Check .............................................................................................................. 7-9

7-3. Normal Operation.......................................................................................................................7-18

7-3.1. Pre-operational Requirements........................................................................................... 7-18

7-3.2. Engine Start....................................................................................................................... 7-19

7-3.2.1. Cold Start................................................................................................................. 7-20

7-3.2.2. Flooded Engine ....................................................................................................... 7-20

7-3.2.3. Hot Start .................................................................................................................. 7-21

7-3.3. Ground Run-up .................................................................................................................7-22

7-3.4. Engine Shutdown.............................................................................................................. 7-24

7-4. Engine Operation in Abnormal Environments ........................................................................... 7-25

7-4.1. Engine Operation in Extreme Cold................................................................................... 7-25

7-4.1.1. Engine Preheating ................................................................................................... 7-26

Chapter 8. Troubleshooting

8-1. General Troubleshooting.............................................................................................................. 8-2

8-1.1. General Troubleshooting for Engines equipped with a Carburetor.................................... 8-2

8-1.2. General Troubleshooting for Engines with Continental Continuous Flow Fuel Injection

Systems .........................................................................................................................................8-3

8-1.3. Engine Runs Rough ............................................................................................................ 8-4

8-1.3.1. Engine Runs Rough (equipped with Carburetor)...................................................... 8-4

8-1.3.2. Engine Runs Rough (equipped with Continental Continuous Flow Fuel Injection Sys-

tem).........................................................................................................................................8-5

8-1.4. Engine Will Not Run........................................................................................................... 8-6

8-1.5. Engine Indication Malfunctions.......................................................................................... 8-7

8-1.6. Engine Performance Malfunctions ..................................................................................... 8-8

8-2. Induction System.......................................................................................................................... 8-9

8-2.1. Engine Will Not Start.......................................................................................................... 8-9

8-2.2. Engine Will Not Run......................................................................................................... 8-10

8-2.3. Engine Lacks Power/Manifold Pressure Low (Naturally Aspirated Models) .................. 8-10

8-2.4. Engine Lacks Power/Manifold Pressure Low (Turbocharged Models)............................ 8-11

8-3. Continental Continuous Flow Fuel Injection System.................................................................8-12

8-3.1. Engine Will Not Start........................................................................................................ 8-12

8-3.2. Fluctuating or Erroneous Fuel Flow ................................................................................. 8-13

8-3.3. Poor Acceleration.............................................................................................................. 8-13

8-3.4. Fuel Injector Operational Check....................................................................................... 8-14

8-4. Charging System ........................................................................................................................8-16

8-5. Starting System...........................................................................................................................8-16

8-6. Ignition System........................................................................................................................... 8-17

8-6.1. Ignition Harness and Spark Plug Diagnostics................................................................... 8-18

8-7. Lubrication System.....................................................................................................................8-19

8-8. Engine Cylinders ........................................................................................................................ 8-21

8-9. Crankcase ................................................................................................................................... 8-23

8-9.1. Excess Crankcase Pressure ............................................................................................... 8-24

8-10. Turbocharger and Exhaust System ...........................................................................................8-25

8-10.1. Freeing Turbine Shafts Dragging or Frozen by Corrosion ............................................. 8-26

8-10.2. Oil Leaking from Turbocharger...................................................................................... 8-27

vi Standard Practice Maintenance Manual

CHANGE 2 26 Aug 2021

Page 11

Table of Contents

Chapter 9. Engine Preservation and Storage

9-1. Preserving and Storing an Engine................................................................................................ 9-1

9-1.1. Engine Preservation Checklist............................................................................................9-1

9-1.2. New or Unused Engine Storage.......................................................................................... 9-1

9-1.3. Installed Engine, Temporary Storage ................................................................................. 9-1

9-1.4. Installed Engine, Indefinite Storage ................................................................................... 9-3

9-1.5. Crated Engine, Indefinite Storage ...................................................................................... 9-4

9-1.6. Return an Engine to Service after Storage.......................................................................... 9-6

9-2. Turbocharger Preservation and Storage ....................................................................................... 9-8

9-2.1. Short Term Storage (on shelf)............................................................................................. 9-8

9-2.2. Short Term Storage (on aircraft) .........................................................................................9-8

9-2.3. Long Term Storage (on shelf) .............................................................................................9-8

9-2.4. Long Term Storage (on aircraft) ......................................................................................... 9-8

9-2.5. Shelf Life ............................................................................................................................ 9-8

9-2.6. Turbocharger Pre-Lubrication (not installed) ..................................................................... 9-9

9-2.7. Turbocharger Pre-Lubrication (on aircraft) ........................................................................ 9-9

Chapter 10.Non-Overhaul Repair and

Replacement

10-1. Parts Replacement.................................................................................................................... 10-1

10-2. Fuel Injector Replacement ....................................................................................................... 10-3

10-2.1. Nozzle Identification ...................................................................................................... 10-3

10-2.2. Fuel Injector Removal (Turbocharged Engines) ............................................................ 10-4

10-2.3. Fuel Injector Installation (Turbocharged Engines)......................................................... 10-4

10-2.4. Fuel Injector Removal (Naturally Aspirated Engines) ................................................... 10-6

10-2.5. Fuel Injector Installation (Naturally Aspirated Engines)................................................ 10-6

10-3. Induction Drain Connector Replacement................................................................................. 10-8

10-3.1. Induction Drain Connector Removal and Cleaning ....................................................... 10-8

10-3.2. Induction Drain Connector Installation .......................................................................... 10-8

10-4. Alternator Replacement............................................................................................................ 10-9

10-4.1. Gear Driven Alternator Replacement, Forward Mount ................................................ 10-9

10-4.1.1. Gear Driven Alternator Removal ......................................................................... 10-9

10-4.1.2. Alternator Drive Coupling Removal .................................................................. 10-11

10-4.1.3. Alternator Drive Coupling Installation .............................................................. 10-11

10-4.1.4. Alternator Drive Coupling Slippage Inspection ................................................. 10-12

10-4.1.5. Gear Driven Alternator Installation ................................................................... 10-13

10-4.2. Gear Driven Alternator Replacement, Aft Mount ....................................................... 10-14

10-4.2.1. Gear Driven Alternator Removal ....................................................................... 10-14

10-4.2.2. Alternator Drive Hub Removal .......................................................................... 10-16

10-4.2.3. Alternator Drive Hub Installation ...................................................................... 10-16

10-4.2.4. Gear Driven Alternator Installation ................................................................... 10-18

10-4.3. Alternator Service Instructions ..................................................................................... 10-19

10-5. Magneto Replacement............................................................................................................ 10-21

10-5.1. Continental Magneto Removal..................................................................................... 10-21

10-5.2. Continental Magneto Installation ................................................................................. 10-22

10-5.3. Champion (Slick) Magneto Removal ........................................................................... 10-24

10-5.4. Champion (Slick) Magneto Installation ....................................................................... 10-25

10-5.5. Magneto Filter Replacement ........................................................................................ 10-27

10-5.5.1. Continental Magneto Filter Replacement ........................................................... 10-27

Standard Practice Maintenance Manual vii

26 Aug 2021 CHANGE 2

Page 12

Table of Contents

10-5.5.2. Champion (Slick) Magneto Filter Replacement..................................................10-29

10-6. Cylinder Repairs..................................................................................................................... 10-31

10-6.1. Cylinder Replacement................................................................................................... 10-32

10-6.1.1. Cylinder Removal ............................................................................................... 10-32

10-6.1.2. Cylinder Installation............................................................................................ 10-34

10-6.1.3. Cylinder Torque .................................................................................................. 10-37

10-6.2. Cylinder Position Numbers........................................................................................... 10-38

10-6.3. Cylinder Head Repair ................................................................................................... 10-38

10-6.4. Cylinder Fin Tip Repair................................................................................................ 10-39

10-6.5. Cylinder Bore Inspection ..............................................................................................10-39

10-6.6. Cylinder Barrel Repair.................................................................................................. 10-39

10-6.7. Cylinder Bore Honing................................................................................................... 10-40

10-6.8. Cylinder Stud Replacement .......................................................................................... 10-41

10-6.9. Spark Plug Heli-coil Replacement................................................................................ 10-42

10-6.10. Cylinder Protective Coatings ...................................................................................... 10-43

10-6.11. Cylinder Bore and Piston Fit Specifications............................................................... 10-44

10-6.12. Legacy Product Replacement Valves.......................................................................... 10-53

10-7. Crankcase Repair.................................................................................................................... 10-56

10-8. Piston Replacement ................................................................................................................ 10-56

10-9. Crankshaft Repair................................................................................................................... 10-57

10-9.1. Crankshaft Counterweight Inspection and Repair ........................................................ 10-57

10-9.1.1. Crankshaft Counterweight Removal ................................................................... 10-76

10-9.1.2. Counterweight Identification............................................................................... 10-77

10-9.1.3. Crankshaft Counterweight Inspection................................................................. 10-82

10-9.1.4. Crankshaft Counterweight Bushing Bore Inspection.......................................... 10-83

10-9.1.5. Crankshaft Counterweight Bushing Replacement .............................................. 10-85

10-9.1.6. Crankshaft Hanger Blade Bushing Inspection ....................................................10-88

10-9.2. Oil Control Plug Replacement...................................................................................... 10-90

10-9.3. Crankshaft Plating Overhaul......................................................................................... 10-92

10-9.4. Connecting Rod Replacement ......................................................................................10-93

10-9.4.1. Connecting Rod Dimensional Inspection............................................................ 10-93

10-9.4.2. Connecting Rod Piston Pin Bushing Replacement ............................................. 10-98

10-9.4.3. Connecting Rod Piston Pin Bushing Boring..................................................... 10-100

10-10. Crankshaft Nose Oil Seal Replacement .............................................................................10-101

10-10.1. Solid Nose Oil Seal Removal ................................................................................... 10-101

10-10.2. Solid Nose Oil Seal Installation................................................................................ 10-102

10-10.3. Split Nose Oil Seal Removal .................................................................................... 10-104

10-10.4. Split Type Nose Oil Seal Installation ........................................................................ 10-104

10-11. Exhaust Flange to Cylinder Installation ............................................................................. 10-106

10-12. Lubrication System Maintenance....................................................................................... 10-108

10-12.1. Oil Filters Adapters................................................................................................... 10-108

10-12.2. Oil Filter Adapter Stud Replacement........................................................................ 10-110

10-12.3. Lubrication System Priming ..................................................................................... 10-112

10-12.3.1. Alternate Priming Method 1(470, 520, 550 engines only).............................. 10-112

10-12.3.2. Alternate Priming Method 2............................................................................ 10-112

10-13. Crankcase Breather System Maintenance .......................................................................... 10-114

Chapter 11. Non-Destructive Inspection

11-1. Visual Inspection ...................................................................................................................... 11-1

11-1.1. Gear Tooth Inspection..................................................................................................... 11-2

11-2. Fluorescent Penetrant Inspection.............................................................................................. 11-3

viii Standard Practice Maintenance Manual

CHANGE 2 26 Aug 2021

Page 13

Table of Contents

11-3. Magnetic Particle Inspection.....................................................................................................11-4

11-3.1. Connecting Rod Magnetic Particle Inspection ................................................................11-6

11-4. Ultrasonic Inspection.................................................................................................................11-7

11-4.1. Ultrasonic Inspection Certification..................................................................................11-7

11-4.2. Crankshaft Ultrasonic Inspection ....................................................................................11-8

Chapter 12. Engine Cleaning

12-1. Engine and Component Cleaning............................................................................................. 12-1

12-1.1. Cylinder Cleaning........................................................................................................... 12-6

12-1.2. Piston Cleaning............................................................................................................... 12-7

12-1.3. Cleaning Exhaust Parts................................................................................................... 12-8

12-1.4. Cleaning Aluminum Alloy Parts..................................................................................... 12-8

12-2. Dry Blasting ............................................................................................................................. 12-9

12-3. Vapor Blasting .......................................................................................................................... 12-9

12-4. Protective Coatings ................................................................................................................ 12-10

12-4.1. Alodine.......................................................................................................................... 12-10

12-4.2. Aviation Oil................................................................................................................... 12-10

12-4.3. Paint ...............................................................................................................................12-11

Appendix A.Glossary

A-1. Abbreviations/Acronyms.............................................................................................................A-1

A-2. Terms and Definitions .................................................................................................................A-3

Appendix B.Torque Specifications

B-1. General Information ....................................................................................................................B-1

B-1.1. Torque Tips ........................................................................................................................B-2

B-2. Part Supersedure..........................................................................................................................B-3

B-3. Torque Wrench and Extension Calculations................................................................................B-4

Appendix C.Maintenance Standards

C-1. Handling Parts .............................................................................................................................C-1

C-2. Replacement Parts .......................................................................................................................C-3

C-2.1. Background ........................................................................................................................C-3

C-2.2. Acceptable Replacement Parts...........................................................................................C-3

C-2.2.1. Know Your Supplier ................................................................................................C-3

C-2.3. 100% Parts Replacement Requirements ............................................................................C-4

C-2.4. Mandatory Overhaul Replacement Parts ...........................................................................C-5

C-2.5. Authorized Oversize/Undersize Parts ................................................................................C-8

C-2.6. Special Instructions............................................................................................................C-8

C-2.7. Engine Data Plate Replacement.........................................................................................C-8

C-2.7.1. Removal and Installation of Engine Data Plate........................................................C-8

C-3. Safety Wiring Hardware............................................................................................................C-10

C-4. Tab Washer Installation .............................................................................................................C-12

C-5. Heli-Coil® Insert Replacement.................................................................................................C-13

C-5.1. Heli-Coil Removal ...........................................................................................................C-14

C-5.2. Heli-Coil Insertion ...........................................................................................................C-15

C-6. Stud Replacement......................................................................................................................C-16

Standard Practice Maintenance Manual ix

26 Aug 2021 CHANGE 2

Page 14

Table of Contents

C-6.1. Stud Removal .................................................................................................................. C-16

C-6.1.1. Size-on-Size Rosan® Stud Removal..................................................................... C-16

C-6.1.2. Step-Type Rosan® Stud Removal......................................................................... C-17

C-6.2. Stud Installation .............................................................................................................. C-18

C-6.2.1. Rosan® Stud Installation....................................................................................... C-19

C-7. Cotter Pin Installation ............................................................................................................... C-20

C-8. Fuel System Service ................................................................................................................. C-21

C-8.1. Fuel System Purge........................................................................................................... C-21

C-9. Gasket Maker® Application..................................................................................................... C-22

C-10. Gasket Installation .................................................................................................................. C-23

C-10.1. Crush Washer Installation ............................................................................................. C-23

C-11. Hose and Tubing Installation .................................................................................................. C-24

C-12. Harness Routing...................................................................................................................... C-25

C-13. Plug and Fitting Removal ....................................................................................................... C-25

LIST OF TABLES

Table 1-1. Service Documents Incorporated in Manual .............................................. 1-11

Table 1-2. Related Publications ...................................................................................1-15

Table 2-1. Special Tools List .........................................................................................2-1

Table 2-2. Tools, Accessories, and Supply Vendors ..................................................... 2-7

Table 2-3. Common Tools ...........................................................................................2-24

Table 3-1. Qualified SAE J1899 Ashless Dispersant Engine Oil .................................. 3-2

Table 3-2. Qualified SAE J1966 Non-Dispersant Mineral Oil ......................................3-2

Table 3-3. Break-in Oil ..................................................................................................3-2

Table 3-4. Preservative Oil ............................................................................................3-2

Table 3-5. Sealants .........................................................................................................3-4

Table 3-6. Lubricants .....................................................................................................3-5

Table 3-7. Adhesives .....................................................................................................3-8

Table 3-8. Miscellaneous ...............................................................................................3-9

Table 5-1. Authorized Adjustments and Replacements ................................................5-6

Table 6-1. Engine Time Between Overhaul (TBO) .......................................................6-3

Table 6-2. Engine Inspection and Maintenance Schedule .............................................6-5

Table 6-3. Engine Operation Prerequisites ..................................................................6-14

Table 6-4. Fuel System Adjustment Values ................................................................6-15

Table 6-5. Static Ground Setup Compensation Table ................................................. 6-19

Table 6-6. IO-240-A, B With Standard Fuel Pump .....................................................6-20

Table 6-7. Magneto Timing Specifications - Geared Engines ....................................6-54

Table 6-8. Magneto Timing Specifications - Direct Drive Engines ............................ 6-54

Table 6-9. Spark Plug Application Chart ....................................................................6-63

Table 6-10. Spark Plug Rotation Chart .......................................................................... 6-65

Table 6-11. IO-360-D/DB Engine Altitude Leaning Schedule .....................................6-84

Table 6-12. IO-360-ES Engine Altitude Leaning Schedule ..........................................6-85

Table 6-13. IO-360-ES (Cirrus SR20) Engine Altitude Leaning Schedule ................... 6-86

Table 6-14. IO-550-A Engine Altitude Leaning Schedule ............................................6-87

Table 6-15. IO-550-B Engine Altitude Leaning Schedule ............................................ 6-88

Table 6-16. IO-550-C Engine Altitude Leaning Schedule ............................................ 6-89

Table 6-17. IO-550-D, E, F, & L Engine Altitude Leaning Schedule ...........................6-90

Table 6-18. VAPC Parameters ...................................................................................... 6-95

x Standard Practice Maintenance Manual

CHANGE 2 26 Aug 2021

Page 15

Table of Contents

Table 6-19. Cylinder Inspection Tasks and References ...............................................6-102

Table 6-20. Additional Cylinder Service Document References .................................6-102

Table 6-21. Differential Pressure Test Results ............................................................6-111

Table 6-22. Borescope Inspection Objectives and Corrective Actions .......................6-114

Table 6-23. Crankcase Casting Numbers .....................................................................6-122

Table 6-24. Exhaust Inspection Criteria ......................................................................6-144

Table 6-25. Overspeed Categories ...............................................................................6-160

Table 6-26. Engine Operational Checklist ...................................................................6-167

Table 6-27. 25-Hour Initial Operation Inspection Checklist .......................................6-169

Table 6-28. 50-Hour Engine Inspection Checklist ......................................................6-171

Table 6-29. 100-Hour Engine Inspection Checklist ....................................................6-173

Table 6-30. 500-Hour Engine Inspection Checklist ....................................................6-175

Table 6-31. Cylinder Inspection Checklist ..................................................................6-177

Table 7-1. Aviation Fuel Specifications ........................................................................7-3

Table 7-2. Authorized Fuels by Engine Model ..............................................................7-3

Table 7-3. IO-360-D/DB Engine Altitude Leaning Schedule .....................................7-11

Table 7-4. IO-360-ES Engine Altitude Leaning Schedule ..........................................7-12

Table 7-5. IO-360-ES (Cirrus SR20) Engine Altitude Leaning Schedule ...................7-13

Table 7-6. IO-550-A Engine Altitude Leaning Schedule ............................................7-14

Table 7-7. IO-550-B Engine Altitude Leaning Schedule ............................................7-15

Table 7-8. IO-550-C Engine Altitude Leaning Schedule ............................................7-16

Table 7-9. IO-550-D, E, F, & L Engine Altitude Leaning Schedule ...........................7-17

Table 9-1. Engine Preservation Checklist ......................................................................9-7

Table 10-1. Non-Overhaul Parts Replacement Reference .............................................10-1

Table 10-2. Parts Repair Reference ...............................................................................10-2

Table 10-3. Parts Handling Guidelines ..........................................................................10-2

Table 10-4. Alternator Drive Coupling Slippage .........................................................10-12

Table 10-5. Alternator Cross Reference ......................................................................10-20

Table 10-6. Cylinder Repair vs. Replacement Guidelines ...........................................10-31

Table 10-7. Cylinder Bore Surface Finish Specifications ...........................................10-41

Table 10-8. 5.250 Inch Cylinder Barrel Dimensions ...................................................10-45

Table 10-9. 5.250 Inch Cylinder Barrel Dimensions ...................................................10-46

Table 10-10. 5.250 Inch Piston to Cylinder Clearance ..................................................10-46

Table 10-11. 5.250 Inch Piston to Cylinder Clearance ..................................................10-46

Table 10-12. 5.250 Inch Piston to Cylinder Clearance ..................................................10-46

Table 10-13. 5.000 Inch Cylinder Barrel Dimensions ...................................................10-47

Table 10-14. 5.000 Inch Piston to Cylinder Clearance ..................................................10-47

Table 10-15. 5.000 Inch Piston to Cylinder Clearance ..................................................10-47

Table 10-16. 4.438 Inch Cylinder Barrel Dimensions ...................................................10-48

Table 10-17. 4.438 Inch Piston to Cylinder Clearance ..................................................10-48

Table 10-18. 4.062 Inch Cylinder Barrel Dimensions ...................................................10-49

Table 10-19. 4.062 Inch Piston to Cylinder Clearance ..................................................10-49

Table 10-20. Ring Gap Specifications ...........................................................................10-50

Table 10-21. Ring Gap Specifications ...........................................................................10-51

Table 10-22. Ring Gap Specifications ...........................................................................10-51

Table 10-23. Ring Gap Specifications ...........................................................................10-51

Standard Practice Maintenance Manual xi

26 Aug 2021 CHANGE 2

Page 16

Table of Contents

Table 10-24. Ring Gap Specifications ...........................................................................10-51

Table 10-25. Engine to Piston Cross Reference ............................................................10-52

Table 10-26. Engines Serial Number Applicability ......................................................10-53

Table 10-27. Replacement Components for Low Compression Ratio Cylinders .........10-54

Table 10-28. Cylinder Part Number Conversion ........................................................... 10-54

Table 10-29. Engine Power Train .................................................................................. 10-58

Table 10-30. Crankshaft Assembly Part Number History .............................................10-65

Table 10-31. Crankshaft Assemblies ............................................................................. 10-70

Table 10-32. Crankshaft Hanger Blade Bushing Sizes .................................................10-73

Table 10-33. Wide Rod Crankshaft ...............................................................................10-74

Table 10-34. Counterweight Supersedure .....................................................................10-76

Table 10-35. Counterweight Bushing Bore Dimensions ............................................... 10-84

Table 10-36. Counterweight Bushing Bore Dimensions ............................................... 10-87

Table 10-37. Counterweight Hanger Blade Bushing Dimensions .................................10-89

Table 10-38. Crankshaft Oil Plug Installation Specifications .......................................10-90

Table 10-39. Connecting Rod Specifications ................................................................10-96

Table 10-40. Exhaust Gaskets, Nuts, and Nut Torque Values .................................... 10-107

Table 11-1. Parts Requiring Fluorescent Penetrant Inspection .....................................11-3

Table 11-2. Magnetic Particle Inspection Reference .....................................................11-5

Table 11-3. Connecting Rod Magnetic Particle Inspection Criteria .............................. 11-6

Table 11-4. Crankshaft Ultrasonic Inspection Pass/Fail Action ....................................11-8

Table 12-1. Aircraft Engine Parts Cleaning Guidelines ................................................ 12-2

Table 12-2. Cleaning Tips ............................................................................................. 12-5

Table 12-3. Painting External Parts .............................................................................12-11

Table B-1. Appendix B, Quick Table Reference .......................................................... B-1

Table B-2. Component Specific Torque Specifications ................................................ B-6

Table B-3. Specific Torque Specifications (Non-Lubricated Hardware) .................... B-13

Table B-4. FADEC Components (Non-Lubricated Hardware) ................................... B-13

Table B-5. General Torque Specifications .................................................................. B-14

Table B-6. Hydraulic Line Torque Specifications ...................................................... B-14

Table B-7. Straight Thread Fitting Torque Specifications .......................................... B-15

Table B-8. Hose Fitting (“B” Nut) Torque Specifications .......................................... B-15

Table C-1. Mandatory Overhaul Replacement Parts ..................................................... C-5

Table C-2. Rosan® Stud Primary & Secondary Bore Specifications ......................... C-17

Table C-3. High Strength Sealant and Adhesive Part Numbers .................................. C-25

LIST OF FIGURES

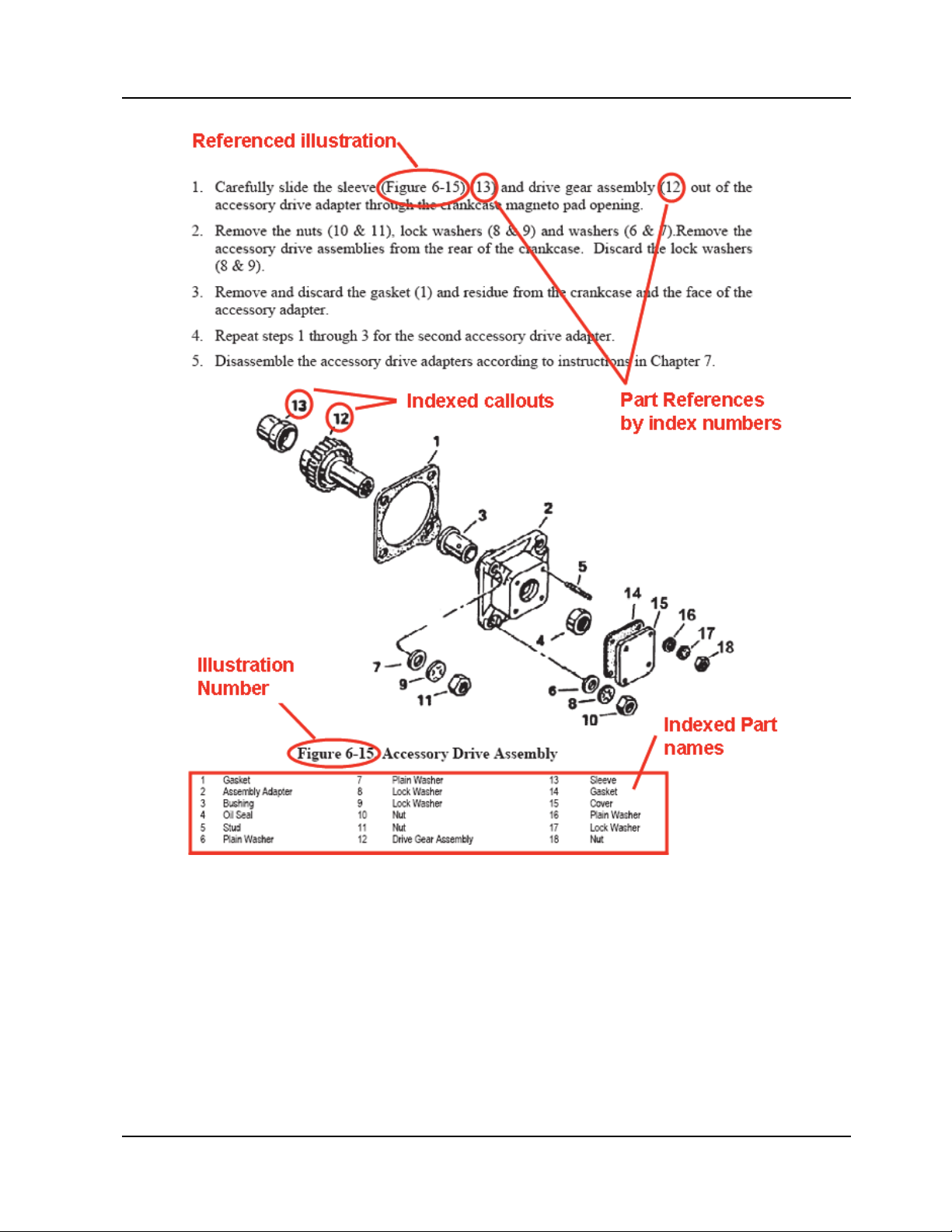

Figure 1-1. Figure and Index Reference .........................................................................1-5

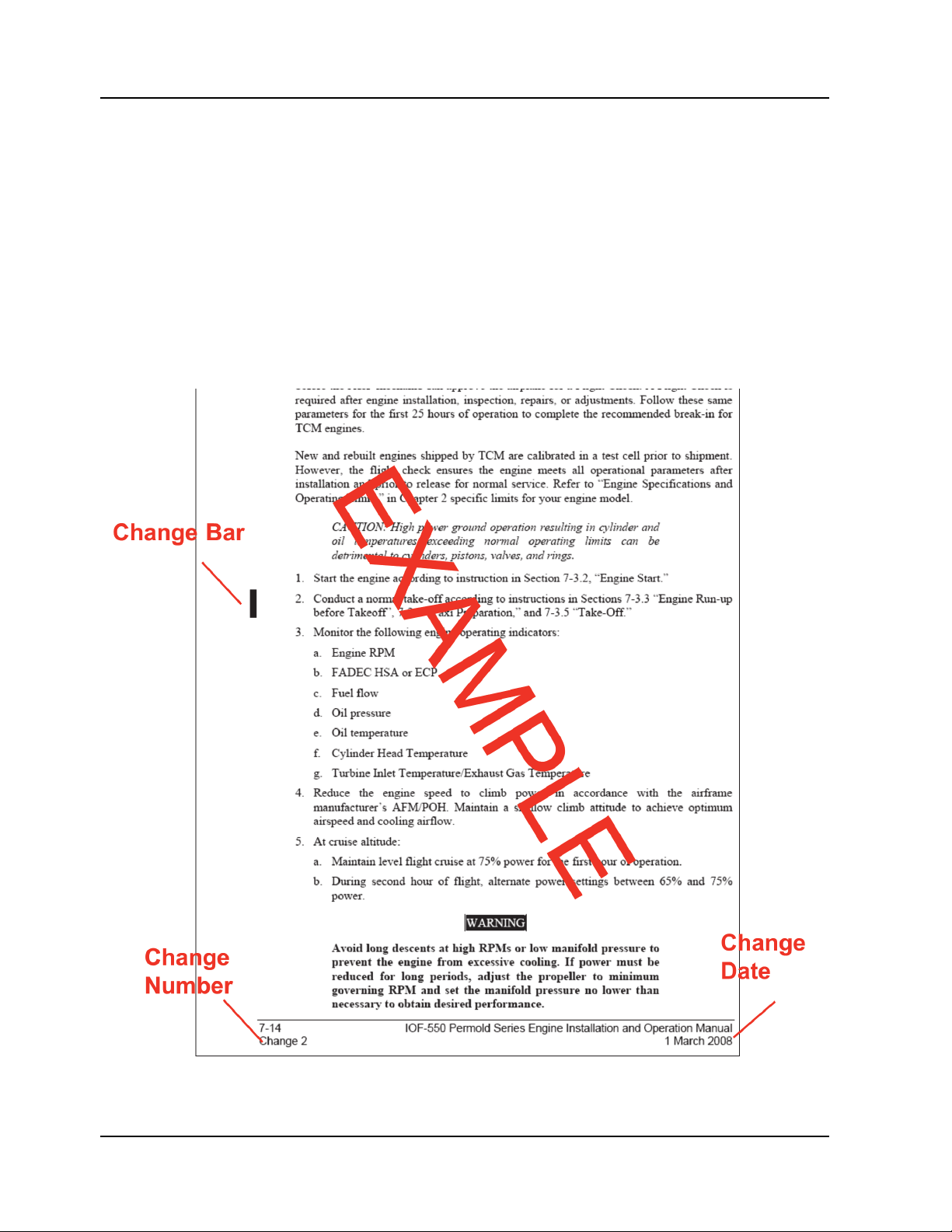

Figure 1-2. Change Page Identification ..........................................................................1-8

Figure 1-3. List of Effective Pages .................................................................................1-9

Figure 2-1. Model E2M Differential Pressure Tester (built in Master Orifice Tool) .....2-9

Figure 2-2. Borescope (Autoscope®) .............................................................................2-9

Figure 2-3. Pulley Alignment Tool ...............................................................................2-10

Figure 2-4. Porta-Test Model 20 ATM-C .....................................................................2-10

Figure 2-5. Gear Driven Alternator Drive Hub Torque Tool .......................................2-11

Figure 2-6. Alternator Drive Hub Torque Tool ............................................................2-12

xii Standard Practice Maintenance Manual

CHANGE 2 26 Aug 2021

Page 17

Table of Contents

Figure 2-7. Worm Shaft Tool and Starter Adapter Disassembly Tool ..........................2-12

Figure 2-8. Oil Control Plug Installation Tool - 360 Engines .......................................2-13

Figure 2-9. Oil Control Plug Installation Tool - 470 Engines .......................................2-13

Figure 2-10. Oil Control Plug Installation Tool - 520/550 Permold Engines .................2-14

Figure 2-11. Oil Control Plug Installation Tool - 470/520/550 Sandcast Engines .........2-14

Figure 2-12. Oil Control Plug Leak Test Fixture ............................................................2-15

Figure 2-13. Needle Bearing Installation Tool - Part 1 ...................................................2-16

Figure 2-14. Needle Bearing Installation Tool - Part 2 ...................................................2-17

Figure 2-15. Bearing Installation Tool ............................................................................2-18

Figure 2-16. Crankcase Needle Bearing Installation Tool, Permold ..............................2-19

Figure 2-17. Crankcase Needle Bearing Installation Tool, Sandcast ..............................2-19

Figure 2-18. Valve Guide Seal Installation Tool ............................................................2-20

Figure 2-19. O-Ring Installation Tool .............................................................................2-21

Figure 2-20. Oil Seal Tool ...............................................................................................2-21

Figure 2-21. Helical Coil Extraction Tool ......................................................................2-22

Figure 2-22. Helical Coil Insertion Tool .........................................................................2-22

Figure 2-23. Helical Coil Expanding Tool ......................................................................2-23

Figure 2-24. Rosan® Stud Removal Tool .......................................................................2-23

Figure 3-1. Anti-Seize Lubricant Application ...............................................................3-11

Figure 3-2. Fuel Injection Sealant Application .............................................................3-11

Figure 3-3. Crankcase Threading Diagram - C75, C85, C90, O200 .............................3-13

Figure 3-4. Crankcase Threading Diagram - O240, IO240, IOF240 ............................3-13

Figure 3-5. Crankcase Threading Diagram - O300 .......................................................3-15

Figure 3-6. Crankcase Threading Diagram - IO360, L/TSIO360 .................................3-15

Figure 3-7. Crankcase Threading Diagram - 520/550 Permold ....................................3-16

Figure 3-8. Crankcase Threading Diagram - 470/520/550 Sandcast ............................3-16

Figure 3-9. Crankcase Threading Diagram - GTSIO520 ..............................................3-17

Figure 3-10. Scavenge Pump Body Threading Diagram ................................................3-18

Figure 3-11. Oil Pump Assembly Threading Diagram ...................................................3-19

Figure 3-12. Oil Pump Assembly Threading Diagram ...................................................3-20

Figure 3-13. Oil Pump Assembly Threading Diagram ...................................................3-21

Figure 3-14. Oil Pump Assembly Threading Diagram ...................................................3-22

Figure 3-15. Oil Pump Assembly Threading Diagram ...................................................3-22

Figure 3-16. Starter Adapter Assembly Threading Diagram ..........................................3-23

Figure 3-17. Accessory Drive Cover Threading Diagram ..............................................3-24

Figure 6-1. Part No. MS51523-B4 Swivel Tee .............................................................6-25

Figure 6-2. Porta-Test Model 20 ATM-C .....................................................................6-26

Figure 6-3. Typical Naturally Aspirated Fuel System Schematic .................................6-27

Figure 6-4. Typical Naturally Aspirated Fuel System Schematic .................................6-27

Figure 6-5. Typical Turbocharged Fuel System Schematic ..........................................6-28

Figure 6-6. Typical Turbocharged Fuel System Schematic ..........................................6-28

Figure 6-7. C-75, C-85, C-90 & O-200-A Oil Servicing Points, typical ......................6-34

Figure 6-8. O-200-D & X Oil Servicing Points, typical ...............................................6-34

Figure 6-9. IO-240-B Oil Servicing Points, typical ......................................................6-35

Figure 6-10. IO-360 Oil Servicing Points, typical ..........................................................6-36

Figure 6-11. IO-360-AF/ES Oil Servicing Points, typical ..............................................6-37

Standard Practice Maintenance Manual xiii

26 Aug 2021 CHANGE 2

Page 18

Table of Contents

Figure 6-12. TSIO-360 Oil Servicing Points, typical .....................................................6-38

Figure 6-13. O-470 Oil Servicing Points, typical ...........................................................6-39

Figure 6-14. IO-470/TSIO-470 Oil Servicing Points, typical ......................................... 6-40

Figure 6-15. GTSIO-520 Oil Servicing Points, typical ..................................................6-41

Figure 6-16. IO-550-A, B & C Oil Servicing Points, typical .........................................6-42

Figure 6-17. IO-550-D, E & F Oil Servicing Points, typical ..........................................6-43

Figure 6-18. IO-550-G & N Oil Servicing Points, typical ..............................................6-44

Figure 6-19. IO-550-L Oil Servicing Points, typical ......................................................6-45

Figure 6-20. IO-550-P Oil Servicing Points, typical ......................................................6-46

Figure 6-21. IO-550-R Oil Servicing Points, typical ......................................................6-47

Figure 6-22. TSIO-550 Oil Servicing Points, typical .....................................................6-48

Figure 6-23. 1000 Micron Stainless Steel Oil Strainer ...................................................6-49

Figure 6-24. Suction Screen Oil Types and Part Numbers .............................................6-50

Figure 6-25. O-200 28° BTC Timing .............................................................................6-56

Figure 6-26. O-200 24° BTC Timing .............................................................................6-56

Figure 6-27. Timing Disk and TDC Locator Installed ....................................................6-57

Figure 6-28. No. 1 Cylinder Positioned at Top of Intake Stroke ....................................6-58

Figure 6-29. Crankshaft Positioned at TDC ....................................................................6-58

Figure 6-30. Cylinder No. 1 Top of Compression Stroke ............................................... 6-59

Figure 6-31. No. 1 Cylinder Full Advance Firing Position ............................................6-60

Figure 6-32. Spark Plug Inspection Criteria ...................................................................6-62

Figure 6-33. Lubricate Ignition Wire with MS-122AD, only where shown ...................6-66

Figure 6-34. Elbow Kit Assembly ..................................................................................6-67

Figure 6-35. Oil Pressure Relief Valve Adjustment Screw Locations ...........................6-69

Figure 6-36. Fuel Pump, Naturally Aspirated Engine without

Integral Mixture Control ............................................................................6-72

Figure 6-37. Fuel Pump, Naturally Aspirated Engine with Integral Mixture Control ....6-72

Figure 6-38. Throttle and Metering Assembly ................................................................6-73

Figure 6-39. Throttle and Control Assembly, Front View ..............................................6-73

Figure 6-40. Throttle and Control Assembly, Side View ...............................................6-74

Figure 6-41. Altitude Compensating Fuel Pump (Auto-Lean),

Naturally Aspirated Engine (without adjustable orifice) ...........................6-77

Figure 6-42. Altitude Compensating Fuel Pump (Auto-Lean),

Naturally Aspirated Engine (with adjustable orifice) ................................6-77

Figure 6-43. Aneroid Equipped Fuel Pump, Turbocharged Engine ............................... 6-78

Figure 6-44. Aneroid and Mixture Control Equipped Fuel Pump,

Turbocharged Engine .................................................................................6-78

Figure 6-45. Fuel Pressure Regulator, Turbocharged Engine ......................................... 6-80

Figure 6-46. Altitude Leaning Schedule Adjustment Example ......................................6-82

Figure 6-47. Altitude Leaning after Correction .............................................................. 6-83

Figure 6-48. IO-360-D/DB Altitude Leaning Schedule ..................................................6-84

Figure 6-49. IO-360-ES Altitude Leaning Schedule ......................................................6-85

Figure 6-50. IO-360-ES in Cirrus SR20 Altitude Leaning Schedule .............................6-86

Figure 6-51. IO-550-A Altitude Leaning Schedule ........................................................ 6-87

Figure 6-52. IO-550-B Altitude Leaning Schedule ........................................................6-88

Figure 6-53. IO-550-C Altitude Leaning Schedule ........................................................6-89

xiv Standard Practice Maintenance Manual

CHANGE 2 26 Aug 2021

Page 19

Table of Contents

Figure 6-54. IO-55-D, E, F & L Altitude Leaning Schedule ..........................................6-90

Figure 6-55. Fixed Wastegate, typical ............................................................................6-92

Figure 6-56. Fixed Wastegate (TSIO-520-T), typical .....................................................6-93