Page 1

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

INSTALLATION

AND OPERATING

INSTRUCTIONS

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS: CSA 2.33, ANSI Z21.88 FOR VENTED GAS FIREPLACE HEATERS.

CDI-44N

NATURAL GAS

CDI-44P

1

PROPANE

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI/CSA METHODS.

SAFETY INFORMATION

!

WARNING

If the information in these instructions are

not followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

- Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do

not use any phone in your building.

Immediately call your gas supplier from

a neighbour’s phone. Follow the gas

supplier’s instructions.

If you cannot reach your gas supplier,

call the fire department.

- Installation and service must be

performed by a qualified installer, service

agency or the supplier.

APPLY SERIAL NUMBER LABEL FROM CARTON

Serial No.

MODEL NO.

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 4Y8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)722-6031 • www.continentalfireplaces.com • ask@continentalfire.on.ca

$10.00

1.9

W415-0318 / 03.05.09

Page 2

2

TABLE OF CONTENTS

1.0 INTRODUCTION 3

1.1 WARRANTY 4

1.2 DIMENSIONS 5

1.3 GENERAL INSTRUCTIONS 6

1.4 GENERAL INFORMATION 7

1.5 CARE OF GLASS 7

1.6 CARE OF PLATED PARTS 7

2.0 INSTALLATION 8

2.1 INSERT VENT CONNECTION 8

2.2 CHIMNEY CONNECTION 8

2.3 GAS INSTALLATION 10

2.4 WALL SWITCH / THERMOSTAT 10

2.5 OPTIONAL ACCESSORY REQUIREMENTS 10

3.0 FINISHING 11

3.1 ALUMINUM EXTRUSION TRIM KIT INSTALLATION 11

3.2 LOG PLACEMENT 12

3.3 GLOWING EMBERS 13

3.4 DOOR INSTALLATION 13

3.5 MINIMUM MANTEL CLEARANCE 14

4.0 OPERATION 15

4.1 REAR BURNER CONTROL 16

5.0 MAINTENANCE 16

6.0 REPLACEMENT BLOWER INSTALLATION 16

7.0 ADJUSTMENTS 17

7.1 VENT RESTRICTION 17

7.2 PILOT BURNER ADJUSTMENT 18

7.3 VENTURI ADJUSTMENT 18

7.4 PRESSURE ADJUSTMENT 19

7.5 FLAME ADJUSTMENT 19

7.6 FLAME CHARACTERISTICS 19

8.0 REPLACEMENTS 20

9.0 TROUBLE SHOOTING 23

10.0 SERVICE HISTORY 25

11.0 NOTES 26

NOTE: CHANGES, OTHER THAN EDITORIAL, ARE DENOTED BY A VERTICAL LINE IN THE MARGIN.

W415-0318 / 03.05.09

Page 3

1.0 INTRODUCTION

• Do not operate heater before reading and understanding operating instructions. Failure to operate heater according to

operating instructions could cause fire or injury.

• Risk of fire or asphyxiation do not operate heater with fixed glass removed.

• Do not connect 110 volts to the control valve.

• Risk of burns. The heater should be turned off and cooled before servicing.

• Do not install damaged, incomplete or substitute components.

• Risk of cuts and abrasions. Wear protective gloves and safety glasses during installation. Sheet metal

edges may be sharp.

• Do not burn wood or other materials in this heater.

• Adults and especially children should be alerted to the hazards of high surface temperatures and should stay away to

avoid burns or clothing ignition. Supervise young children when they are in the same room as the heater.

• Clothing or other flammable material should not be placed on or near the heater.

• Due to high temperatures, the heater should be located out of traffic and away from furniture and draperies.

• Ensure you have incorporated adequate safety measure to protect infants/toddlers from touching hot surfaces.

• Even after the heater is out, the glass and/or screen will remain hot for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children from hot

surfaces. These screens and guards must be fastened to the floor.

• Any safety screen or guard removed for servicing must be replaced prior to operating the heater.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the heater and

venting system are kept clean. The heater and its venting system should be inspected before use and at least annually

by a qualified service person. More frequent cleaning may be required due to excessive lint from carpeting, bedding

material, etc. The heater area must be kept clear and free from combustible materials, gasoline and other flammable

vapors and liquids.

• Under no circumstances should this heater be modified.

• This heater must not be connected to a chimney flue pipe serving a separate solid fuel burning appliance.

• Do not use this heater if any part has been under water. Immediately call a qualified service technician to inspect the

heater and to replace any part of the control system and any gas control which has been under water.

• Do not operate the heater with the glass door removed, cracked or broken. Replacement of the glass should be done

by a licensed or qualified service person.

• Do not strike or slam shut the heater glass door.

• This heater uses and requires a fast acting thermocouple. Replace only with a fast acting thermocouple supplied by

Wolf Steel Ltd.

• Pressure relief doors must be kept closed while the heater is operating to prevent exhaust fumes containing carbon

monoxide, from entering into the home. Temperatures of the exhaust escaping through these openings can also cause

the surrounding combustible materials to overheat and catch fire.

• Only doors / optional fronts certified with the unit are to be installed on the appliance.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As with all plastic

bags, these are not toys and should be kept away from children and infants.

!

WARNING

3

W415-0318 / 03.05.09

Page 4

4

1.1 WARRANTY

CONTINENTAL® products are manufactured under the strict Standard of the world recognized ISO 9001 :

CONTINENTAL® products are designed with superior components and materials assembled by trained

craftsmen who take great pride in their work. The burner and valve assembly are leak and test-fired at a

quality test station. The complete heater is again thoroughly inspected by a qualified technician before

packaging to ensure that you, the customer, receives the quality product that you expect from

CONTINENTAL® GAS FIREPLACE PRESIDENT’S LIFETIME LIMITED WARRANTY

The following materials and workmanship in your new CONTINENTAL® gas heater are warranted against

defects for as long as you own the heater. This covers: combustion chamber, heat exchanger, stainless

steel burner, phazer™ logs and embers, rocks, ceramic glass (thermal breakage only), gold plated parts

against tarnishing, porcelainized enameled components and aluminum extrusion trims.*

Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves, thermal switch,

switches, wiring, remote controls, ignitor, gasketing, and pilot assembly are covered and CONTINENTAL®

will provide replacement parts free of charge during the first year of the limited warranty.*

Labour related to warranty repair is covered free of charge during the first year. Repair work, however,

requires the prior approval of an authorized company official. Labour costs to the account of

CONTINENTAL® are based on a predetermined rate schedule and any repair work must be done through

an authorized CONTINENTAL® dealer.

* Construction of models vary. Warranty applies only to components included with your specific heater.

2000 Quality Assurance Certificate.

CONTINENTAL®.

CONDITIONS AND LIMITATIONS

CONTINENTAL® warrants its products against manufacturing defects to the original purchaser only. Registering your warranty is not necessary. Simply

provide your proof of purchase along with the model and serial number to make a warranty claim. CONTINENTAL® reserves the right to have its

representative inspect any product or part thereof prior to honouring any warranty claim. Provided that the purchase was made through an authorized

CONTINENTAL® dealer your heater is subject to the following conditions and limitations:

This factory warranty is non-transferable and may not be extended whatsoever by any of our representatives.

The gas heater must be installed by a licensed, authorized service technician or contractor. Installation must be done in accordance with the installation

instructions included with the product and all local and national building and fire codes.

This limited warranty does not cover damages caused by misuse, lack of maintenance, accident, alterations, abuse or neglect and parts installed from other

manufacturers will nullify this warranty.

This limited warranty further does not cover any scratches, dents, corrosion or discoloring caused by excessive heat, abrasive and chemical cleaners nor

chipping on porcelain enamel parts, mechanical breakage of PHAZER™ logs and embers.

CONTINENTAL® warrants its stainless steel burners against defects in workmanship and material for life, subject to the following conditions: During the first

10 years CONTINENTAL® will replace or repair the defective parts at our option free of charge. From 10 years to life, CONTINENTAL® will provide

replacement burners at 50% of the current retail price.

In the first year only, this warranty extends to the repair or replacement of warranted parts which are defective in material or workmanship provided that the

product has been operated in accordance with the operation instructions and under normal conditions.

After the first year, with respect to this President’s Lifetime Limited Warranty, CONTINENTAL® may, at its discretion, fully discharge all obligations with

respect to this warranty by refunding to the original warranted purchaser the wholesale price of any warranted but defective part(s).

CONTINENTAL® will not be responsible for installation, labour or any other expenses related to the reinstallation of a warranted part and such expenses

are not covered by this warranty.

Notwithstanding any provisions contained in the President's Lifetime Limited Warranty, CONTINENTAL’S responsibility under this warranty is defined as

above and it shall not in any event extend to any incidental, consequential or indirect damages.

This warranty defines the obligations and liability of CONTINENTAL® with respect to the CONTINENTAL® gas heater and any other warranties expressed

or implied with respect to this product, its components or accessories are excluded.

CONTINENTAL® neither assumes, nor authorizes any third party to assume, on its behalf, any other liabilities with respect to the sale of this product.

CONTINENTAL® will not be responsible for: over-firing, downdrafts, spillage caused by environmental conditions such as rooftops, buildings, nearby trees,

hills, mountains, inadequate vents or ventilation, excessive venting configurations, insufficient makeup air, or negative air pressures which may or may not

be caused by mechanical systems such as exhaust fans, furnaces, clothes dryers, etc.

Any damages to heater, combustion chamber, heat exchanger, brass trim or other components due to water, weather damage, long periods of dampness,

condensation, damaging chemicals or cleaners will not be the responsibility of CONTINENTAL®.

ALL SPECIFICATIONS AND DESIGNS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE DUT TO ON-GOING PRODUCT IMPROVEMENTS.

CONTINENTAL® IS A REGISTERED TRADEMARK OF WOLF STEEL LTD. PATENTS U.S. 5.303.693.801 - CAN. 2.073.411, 2.082.915 © WOLF STEEL LTD.

W415-0318 / 03.05.09

Page 5

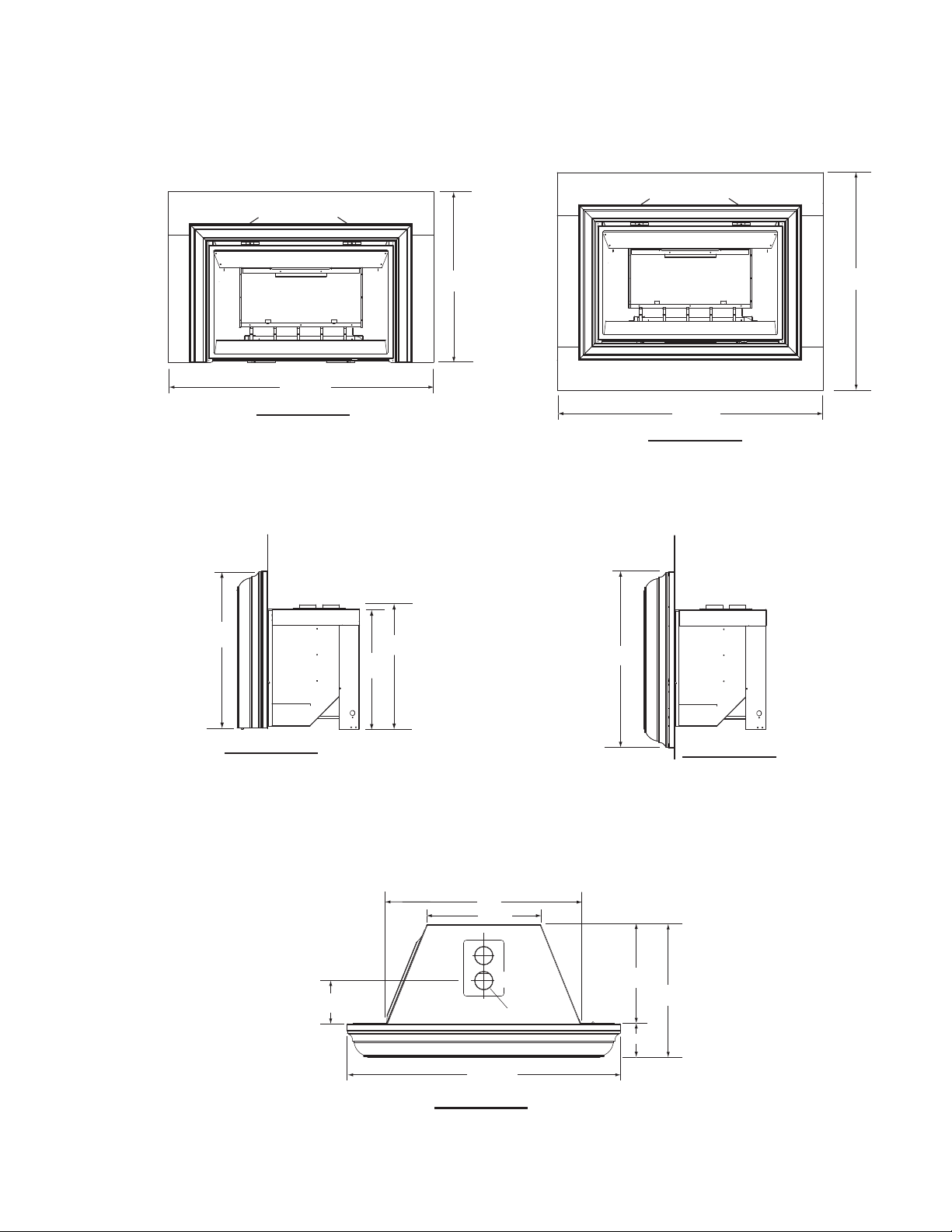

1.2 DIMENSIONS

43 7/8"

18 ½"

32"

15 ½"

6 ½"

AIR

INLET

EXHAUST

3"ø

5 ¼"

20 ¾"

30 ½"

21"

22"

27 ¼"

52 1/8"

42 ¾"

ALUMINUM TRIM

52 1/8"

33 ½"

ALUMINUM TRIM

5

3 SIDED BACKER PLATE - FRONT VIEW

FIGURE 1.2a

3 SIDED BACKER PLATE - SIDE VIEW

4 SIDED BACKER PLATE - FRONT VIEW

FIGURE 1.2b

4 SIDED BACKER PLATE - SIDE VIEW

FIGURE 1.2c

FIGURE 1.2d

TOP VIEW

FIGURE 1.2e

W415-0318 / 03.05.09

Page 6

6

1.3 GENERAL INSTRUCTIONS

Always light the pilot whether for the first time or if the gas supply has ran out, with the glass door

Provide adequate accessibility clearance for servicing and operating the fireplace.

Never obstruct the front opening of the fireplace.

Objects placed in front of the fireplace must be kept a minimum of 48” from the front face of the unit.

This product must be installed by a licensed plumber or gas fitter when installed within the commonwealth

THIS GAS FIREPLACE SHOULD BE INSTALLED AND SERVICED BY A QUALIFIED INSTALLER to conform with local

codes. Installation practices vary from region to region and it is important to know the specifics that apply to your area, for

example in Massachusetts State:

• The fireplace damper must be removed or welded in the open position prior to installation of a fireplace insert or gas log.

• The appliance off valve must be a “T” handle gas cock.

• The flexible connector must not be longer than 36 inches.

• A Carbon Monoxide detector is required in all rooms containing gas fired appliances.

• The appliance is not approved for installation in a bedroom or bathroom unless the unit is a direct vent sealed

combustion product.

!

WARNING

opened or removed.

of Massachusetts.

The installation must conform with local codes or, in absence of

local codes, the National Gas and Propane Installation Code

CSA B149.1 in Canada, or the National Fuel Gas Code,

ANSI Z223.1 / NFPA 54 in the United States. Suitable for mobile

home installation if installed in accordance with the current

standard CAN/CSA Z240MH Series, for gas equipped mobile

homes, in Canada or ANSI Z223.1 and NFPA 54 in the United

States.

The fireplace and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 psig (3.5 kPa). The fireplace must be isolated from the

gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig (3.5 kPa).

A 1/8” NPT plug, accessible for test gauge connection, must be installed immediately upstream of the gas supply

connection to the fireplace insert.

The fireplace insert must be electrically connected and grounded in accordance with local codes. In the absence of local

codes, use the current CSA C22.1 CANADIAN ELECTRICAL CODE in Canada or the ANSI/NFPA 70 NATIONAL

ELECTRICAL CODE in the United States. The blower power cord must be connected into a properly grounded receptacle.

The grounding prong must not be removed from the cord plug.

TP -DV_INSERT_GENERAL INSTRUCTIONS

W415-0318 / 03.05.09

Page 7

1.4 GENERAL INFORMATION

f

FOR YOUR SATISFACTION, THIS FIREPLACE INSERT HAS BEEN TEST-FIRED TO ASSURE ITS

OPERATION AND QUALITY!

Minimum inlet gas supply pressure is 4.5 inches water column for natural gas and 11 inches water column for

propane. Maximum inlet gas pressure is 7 inches water column for natural gas and 13 inches water column

for propane. Manifold pressure under fl ow conditions is 3.5 inches water column for natural gas and 10 inches

water column for propane. When the fi replace is installed at elevations above 4,500ft, and in the absence of

specifi c recommendations from the local authority having jurisdiction, the certifi ed high altitude input rating

shall be reduced at the rate of 4% for each additional 1,000ft.

Expansion / contraction noises during heating up and cooling down cycles are normal and to be expected.

Maximum input is 40,000 BTU/hr for natural gas and propane. In order to achieve maximum turn down rate,

the rear burner must be turned off. See Operating Instructions in the

owner's manual for more information.

Maximum output for natural gas and propane is 27,600 BTU/hr at an

effi ciency of 69% with the fan on.

This fi replace insert is not approved for closet or recessed installations.

It is approved for bathroom, bedroom and bed-sitting room installations

and is suitable for mobile homes. The natural gas model is suitable for

installation in a mobile home that is permanently positioned on its site

and fuelled with natural gas.

This insert must be recessed into a vented noncombustible wood-burning fi replace (prefabricated or masonry) only.

7

61.4%

CDI44

The minimum fi replace opening size in which the heater is to be installed is:

HEIGHT 21 inches WIDTH 32 inches DEPTH 16 inches

The minimum allowable chimney fl ue size is 7" round.

The minimum distance, from the bottom of a combustible mantle projecting 3" maximum from the wall to the

top of the aluminium trim, is 12". A hearth must protrude a minimum of 12" from the unit.

1.5 CARE OF GLASS

If the glass is not kept clean permanent discolouration and / or

blemishes may result. Normal operation of your pellet heater will

produce a build-up on the glass that should be wiped off daily. However,

poor quality pellets or extended burning on the low setting will cause

the glass to “smoke up” faster.

Refer to “REPLACEMENT PARTS” section to find out what this product

is equipped with. Use only replacement glass available from your

Authorized dealer.

DO NOT CLEAN GLASS WHEN HOT!

If necessary, clean the glass with a soft cloth or paper towel. You could use “wood stove” glass cleaner to remove heavy

build-up.

Do not operate the heater with broken glass, as leakage of flue gases may result.

1.6 CARE OF PLATED PARTS

If the appliance is equipped with plated parts, you must clean

operating the appliance for the first time. Use a glass cleaner or vinegar and towel to clean. If not cleaned properly before

operating for the first time, the marks can cause permanent blemishes on the plating. After the plating is cured, the

fingerprints and oils will not affect the finish and little maintenance is required, just wipe clean as needed.

NOTE: The protective wrap on plated parts is best removed when the assembly is at room temperature but this

can be improved if the assembly is warmed, using a hair dryer or similar heat source.

!

WARNING

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

ingerprints or other marks from the plated surfaces before

TP - CARE OF GLASS

TP - CARE OF PLATED PARTS

W415-0318 / 03.05.09

Page 8

8

2.0 INSTALLATION

Clean out ashes from the inside of the wood-burning fi replace. Make sure that the chimney and wood-burning

fi replace are in a clean and sound condition and constructed of non-combustible materials. If necessary have

any repair work done by a qualifi ed person before installing the insert. Remove the existing fi replace damper or

lock into an open position.

Using screws, attach the fi replace warning tag (W385-0199) to the inside of the fi rebox of the fi replace into

which the insert is being installed.

The sheet-metal parts of the fi replace, in which the gas

fi replace insert is to be installed, must not be cut.

If the wood-burning factory-built fi replace has no gas

access hole(s) provided, an access hole of 1½ inch or less

may be drilled through the lower sides or bottom of the

fi replace in a proper workman like manner. This access

hole must be plugged with non-combustible insulation after the gas supply line has been installed.

Ensure that existing chimney cleanouts fi t properly.

The refractory, glass doors, screen rails, screen mesh and log grates may be removed from the fi replace

before installing the gas fi replace insert.

Smoke shelves, shields and baffl es may be removed if attached by mechanical fasteners.

The ventilation openings in the fi replace may be obstructed by the backer plates, aluminium trim etc. but these

parts are not to be applied so as to have an airtight seal.

WARNING: THIS FIREPLACE HAS BEEN CONVERTED FOR USE WITH A GAS FIREPLACE

INSERT ONLY AND CANNOT BE USED FOR BURNING WOOD OR SOLID FUELS UNLESS

ALL ORIGINAL PARTS HAVE BEEN REPLACED AND THE FIREPLACE IS RE-APPROVED

BY THE AUTHORITY HAVING JURISDICTION.

ATTENTION: CE FOYER A ETE CONVERTI AFIN D'ETRE UTILISE SEULEMENT COMME

FOYER ENCASTRE AU GAZ ET NE PEUT ETRE UTILSE POUR BRULER DU BOIS OU

TOUT AUTRE COMBUSTIBLE SOLIDE, SANS QUE TOUTES LES PIECES ORIGINALES

AIENT ETE REMPLACEES ET QUE LE FOYER SOIT APPROUVE DE NOUVEAU PAR

AUTORITES AY ANT JURIDICTION.

LES

w385-0199

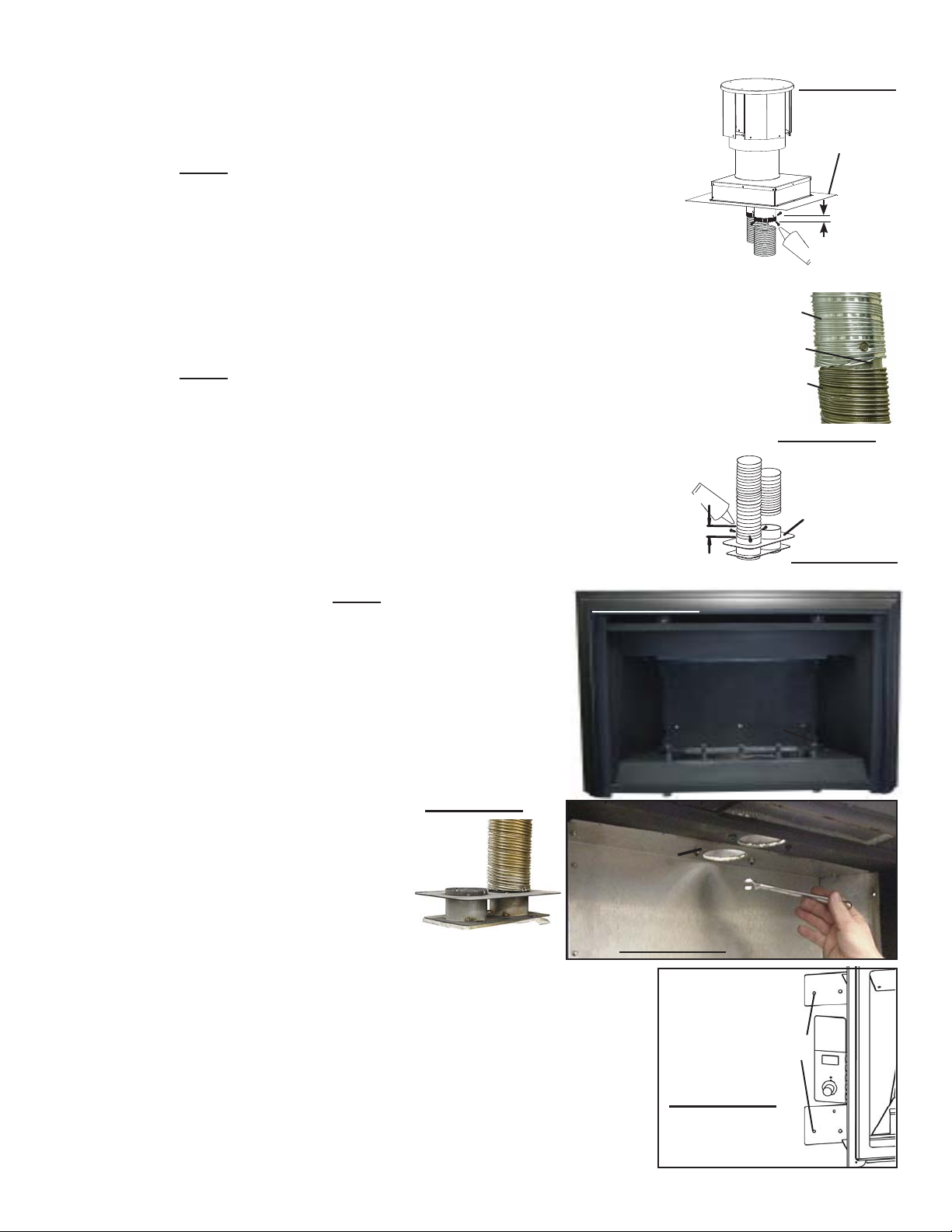

2.1 INSERT VENT CONNECTION

Move the insert close to its fi nal position inside the wood-burning fi replace. This unit is equipped with 6 lev-

elling screws located as follows: two are on either side of the circulation blower on the rear panel; four are

located front and back on either side beneath the log support. Level using four of the levelling screws. Levelling the unit will eliminate rocking or excessive noise when the fan is in operation. Once the unit is level, move

it partially into place within the fi replace to allow for all connections to be made. It is not practical to level the

insert once it has been installed. Determine the required depth prior to installing the unit and adjust the four

levelling screws accordingly.

2.2 CHIMNEY CONNECTION

Chimney installation must conform to both national and local code requirements. The chimney must be lined

with one 2" or 3" diameter liner for intake and one 3" diameter liner for exhaust. The minimum and maximum

vent lengths are 10 and 35 feet respectively. Recommended Continental® kits come in 3 lengths:

1-2" & 1-3" DOUBLE PLY ALUMINUM LINER-INLET AND EXHAUST &

2-3" TO 2" REDUCER:

GDI-2320KT VENT KIT 20FT

GDI-2325KT VENT KIT 25FT

GDI-2335KT VENT KIT 35FT

2-3" DOUBLE PLY ALUMINUM LINER-INLET AND EXHAUST:

GDI-320KT VENT KIT 20FT

GDI-325KT VENT KIT 25 FT

GDI-335KT VENT KIT 35 FT

While the liners must be continuous from the fi replace to the chimney cap, to achieve the needed length, they

may be coupled, using an aluminium coupler, provided installation is sealed & secured.

We recommend that exhaust vents that pass through unheated spaces, such as a garage or attic, be

wrapped in a protective sleeve to minimize condensation and reverse fl ow symptoms.

This unit is approved for use with a 2" liner for air intake and a 3" liner for exhaust. For best

performance, however, it is recommended to use two 3" liners.

If a 2" liner is used for the intake, it is necessary to adjust the primary air shutter. See "Air Shutter

Settings".

W415-0318 / 03.05.09

Page 9

9

2.2.1 OUTSIDE: Slip the one end of a liner a minimum of 2" over the collar of the

air terminal. Secure using 3 screws. Then seal the joint and screw heads

with high temperature sealant. Repeat with the other liner to the exhaust

collar of the terminal.

NOTE: Connect the supplied 3' of stainless steel fl ex liner to the

exhaust liner (already attached to the terminal) using the coupler

(also supplied). Secure and seal before dropping down the

chimney.

EXHAUST

2.2.2 Gently stretch the liners to the required lengths and insert into the

chimney. Place the terminal onto the top of the chimney cap and fi t

the fl ashing plate to suit. Make weather tight by sealing with caulking

(not supplied) and fasten to the chimney with screws and plugs

(not supplied).

2.2.3 NOTE: If there is not enough ceiling height between the fi replace and

the insert to allow the fl ex liner connection on the top of the unit to be

made, see 2.2.4.

If there is enough ceiling height, connect the 3" stainless steel fl ex liner to

the exhaust collar closest to the top front on the unit. Connect the intake

fl ex liner to the remaining rear collar. Secure and seal.

HI-TEMP

2.2.4 Both the log support and the back wall must be removed in

order to gain access to the vent connection assembly.

Both the back wall and log support are detached by removing

SEALANT

2" OVERLAP

the 12 perimeter screws of the back wall and the 3 screws

located at the back of the log support. Remove the vent

connection assembly. NOTE: The vent connection

assembly collars are not specifi c until the stainless

FIGURE 2.2.4b

steel fl ex liner has been attached to one side. This

now designates the side as exhaust. The exhaust

collar must be positioned closest to the front

opening of the insert. Secure and seal the fl ex liners.

INTAKE

ALUMINUM

FLEX LINER

COUPLER

STAINLESS

STEEL

FLEX LINER

BACK WALL

FIGURE 2.2.1

FLASHING

PLATE

2"

OVERLAP

SEALANT

HI-TEMP

FIGURE 2.2.2

VENT

CONNECTION

ASSEMBLY

FIGURE 2.2.4a

2.2.5 To reinstall the vent connection assembly, reach in

through the insert and manoeuvre the vent connection

assembly through the opening in the fi rebox top. T ake

care not to damage the gasket. Secure the assembly

using the four studs and ¼-20

FIGURE 2.2.5

hex nuts.

2.2.6 Reinstall the back wall, followed

by the log support, using the

perimeter screws removed in

2.2.4. The insert may now be

pushed into its fi nal position

inside the wood burning fi replace.

VENT CONNECTION

ASSEMBLY

Secure the insert to the fi replace

using perforated strapping attached to the two securing holes on

either side of the unit as shown. We recommend that the trim be

installed before the unit is placed into its fi nal position.

LOG SUPPORT

VENT

CONNECTION

ASSEMBLY

FIGURE 2.2.6a

SECURING

HOLES

FIGURE 2.2.6b

W415-0318 / 03.05.09

Page 10

10

2.3 GAS INSTALLATION

Risk of fire or explosion. Do not use open flame for testing.

Support gas control when attaching gas supply pipe to prevent damaging gas line.

Always light the pilot whether for the first time or if the gas supply has run out with the glass door

opened or removed. Assure that a continuous gas flow is at the burner before closing the door.

Ensure adequate ventilation. For gas and electrical locations, see “DIMENSION” section.

All gas connections must be contained within the appliance when complete.

Installation and servicing to be done by a qualified installer.

2.3.1

● Move the fireplace into position and secure to the floor .

2.3.2

● The fireplace is designed to accept 1/2” gas line. The

fireplace is equipped with a 1/2” manual shut-off valve.

● Connect the gas supply in accordance to local codes. In the absence thereof, install according to the

2.3.3

National Installation Code.

!

WARNING

High pressure will damage valve.

FIGURE 2.3.3

● When flexing any gas line, support the gas valve so that the lines are not bent or kinked.

2.3.4

● Check for gas leaks by brushing on a soap and water solution.

2.3.4

2.4 WALL SWITCH / THERMOSTAT

For ease of accessibility, an optional remote wall switch or millivolt thermostat may be installed in a convenient

location. Route 2-strand solid core millivolt wire from the gas fi replace insert to the wall switch / millivolt ther-

mostat. The recommended maximum lead length depends on the wire size:

WIRE SIZE MAX. LENGTH

14gauge 100 feet

16gauge 60 feet

18gauge 40 feet

Do not connect either the wall switch, thermostat or gas valve to electricity (110 VOLTS).

2.5 OPTIONAL ACCESSORY REQUIREMENTS

2.5.1 This appliance may be used with a wall switch, wall mounted thermostat and/or a remote control.

2.5.2 Wiring for optional Continental® approved accessories should be done now to avoid reconstruction.

Follow instructions that come with those accessories.

OPTIONAL REMOTE CONTROL RECEIVER LOCATION

2.5.3 Optional remote control receiver must be located at the bottom of the unit, behind the left operable door.

TP - GAS INSTALLATION DV INSERT

W415-0318 / 03.05.09

Page 11

3.0 FINISHING

In order to close off the fi replace opening or if the opening is larger than the 3- or 4-sided aluminium extrusion

trim kits, it is recommended to reduce the opening using a noncombustible material such as ceramic tile, marble, etc or the GDIBP3 or GDIBP4 backer plate kits. The GDIBP3 backer plate is able to fi t an opening of 52" x

33½". The GDIBP4 backer plate is able to fi t an opening of 52" x 42¾". The outside edge of the backer plate is

fi nished off with gold trim included in each kit. A GDIBP3D 3 sided deluxe backer plate complete with marquis

trim may also be used to complete the installation

installation instructions are included with each kit.

If this unit is being installed into an existing wood burning, zero clearance fi replace, then be aware of this

precaution: Any circulation air opening may be covered (with material) but not sealed!

3.1 ALUMINUM EXTRUSION TRIM KIT INSTALLATION

The insert can be equipped

with either a 3- or 4-sided

trim kit to fi nish off the

fi replace opening. Slide the

trim assembly over the

keyholes (2 per side) and

drop into place. If installing

the optional 3- or 4-sided

backer plate (GDIBP3 or

GDIBP4), it must be hung

prior to the trim kit

installation using the same

keyholes.

TO ADJUST THE TRIM:

If the mitre is out of alignment, open each side and loosen the two screws at

either side trim hinge. Slide the trim up or down to adjust and re-tighten screws.

There is also a very slight in/out adjustment that can be made.

FIGURE 3.1a

. This kit is able to fi t an opening of 57" x 33½". Detailed

11

FIGURE 3.1b

SLIDE TO

ADJUST

LOOSEN

SCREWS

NOTE: Since the side panels open and close, to access the controls, a gap

is necessary at the mitre joint.

The top trim piece has an adjustable securing bracket which enables the trim to

be secured to the fi rebox shell.

FIGURE 3.1c

FIGURE 3.1d

W415-0318 / 03.05.09

Page 12

12

3.2 LOG PLACEMENT

Logs must be placed in the exact location in heater. Do not change from the proper log positions,

since heater may not function properly and delayed ignition may occur.

POSITIONING THE LOGS IMPROPERLY WILL CAUSE FLAME IMPINGEMENT AND CARBONING.

!

WARNING

The logs are fragile and should be handled with care.

1

3

2

LOCATING PIN

A

The rear log should be centred on the log support

and rest against the rear wall.

CENTRE

SUPPORT

LOCATING PIN

4

6

C

Log (#6) has a leg that fi ts into an indentation on

the top of log (#3). Log (#4) rests in the indentations on the tops of logs (#2) and (#1).

B

Log #3 rests against the far left grate post and

onto the locating pin on the centre support. Log

#2 rests against the far right grate post and over

the locating pin on the centre support and against

the tip of log #3. NOTE: Skewering log#2 onto

the locating pin may be necessary.

5

7

D

Logs (#5) and (#7) fi t onto the indentations of the

lower logs.

TP - LOG PLACEMENT

W415-0318 / 03.05.09

Page 13

3.3 GLOWING EMBERS

Tear the embers into pieces and place along the front row of ports covering all of the burner area in front of

logs (#2 & #3). Care should be taken to shred the embers into thin, small irregular pieces as only the exposed

edges of the fi bre hairs will glow. The ember material will only glow when exposed to direct fl ame; how-

ever, care should be taken to not block the burner ports.

Blocked burner ports can cause an incorrect fl ame pattern, carbon deposits and delayed ignition. PHAZER

logs glow when exposed to direct fl ame. Use only certifi ed "glowing embers" and PHAZERTM logs available

from your Continental® dealer.

3.4 DOOR INSTALLATION

Glass may be hot, DO NOT touch glass until cooled.

The door latches are part of a safety system and must be properly engaged. Do not operate the fi replace

Do not strike, slam or scratch glass. Do not operate fi replace with glass removed, cracked, broken or

!

WARNING

with latches disengaged.

scratched.

TM

13

FIGURE 3.4.1

3.4.1 Insert the tool supplied (which is

located behind the left side trim) into

spring loaded door latch.

3.4.2 Pull and turn the latch 90°.

3.4.3 Release the latch.

3.4.4 Tilt the top of the door forward until you

can grab the sides of the door. Lift up

and out of the bottom door retainer.

3.4.5 To install, reverse the order of these

instructions.

FIGURE 3.4.2 FIGURE 3.4.3

FIGURE 3.4.4

W415-0318 / 03.05.09

Page 14

14

3.5 MINIMUM MANTEL CLEARANCE

This can vary according to the mantle depth. Use the graph to help evaluate the clearance needed.

FIGURE 3.5a

6” MANTEL

5”

4”

3”

M

A

N

H

15

14

15”

14”

13”

12”

E

I

G

T

13

H

E

T

L

FIGURE 3.5b

12

0

35

4

6

MANTEL DEPTH

W415-0318 / 03.05.09

Page 15

4.0 OPERATION

If you do not follow these instructions exactly, a fire or explosion may result causing property

Do not operate the main burner of the insert with the door removed.

Always light the pilot whether for the first time or if the gas supply has ran out with the glass door

opened or removed. When lit for the first time, the fireplace will emit an odor for a few hours. This is a normal

temporary condition caused by the "burn-in" of paints and lubricants used in the manufacturing process and

will not occur again. After extended periods of non-operation such as following a vacation or a warm weather

season, the fireplace may emit a slight odor for a few hours. This is caused by dust particles in the heat

exchanger burning off. In both cases, open a window to sufficiently ventilate the room.

FOR YOUR SAFETY READ BEFORE LIGHTING:

A. This fireplace is equipped with a pilot which must be lit by hand. While following these instructions exactly.

B. Before operating smell all around the fireplace area for gas and next to the floor because some gas is heavier than air and

will settle on the floor.

C. Use only your hand to turn the gas control knob. Never use tools. If the knob will not turn by hand, do not try to repair it.

Call a qualified service technician. Force or attempted repair may result in a fire or explosion.

D. Do not use this fireplace if any part has been under water. Immediately call a qualified service technician to inspect the

fireplace and replace any part of the control system and any gas control which has been under water.

● Turn off all gas to the fireplace.

● Open windows.

● Do not try to light any appliance.

● Do not touch any electric switch; do not use any phone in your building.

● Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

● If you cannot reach your gas supplier, call the fire department.

!

WARNING

damage, personal injury or loss of life.

WHAT TO DO IF YOU SMELL GAS:

PILOT BURNER

THERMOCOUPLE

15

THERMOPILE

LIGHTING INSTRUCTIONS:

When lighting and re-lighting, the gas knob cannot be turned from pilot to off unless the knob is depressed slightly.

1. Stop! Read the above safety information on this label.

2. Turn off all electrical power to the fireplace and remove batteries.

3. Turn the gas knob clockwise to off.

4. Wait five (5) minutes to clear out any gas. If you smell gas including near the floor,

STOP! Follow “B” in the above safety information on this label. If you don’t smell gas

go to the next step.

FLAME ADJUSTMENT

KNOB

P

I

T

ON/OFF

KNOB

L

O

5. If fireplace is equipped with flame adjustment valve turn clockwise to off.

6. Find pilot located in front of back log.

7. Turn gas knob counter-clockwise to pilot.

8. Depress slightly and hold gas knob while lighting the pilot with the push button ignitor. Keep knob depressed for one

minute, then release. If pilot does not continue to burn, repeat steps 3 through 7.

9. With pilot lit, depress and turn gas knob counter-clockwise to on.

10. If equipped with flame adjustment valve, push and turn knob to high.

11. If equipped with remote on-off switch/thermostat, main burner may not come on when you turn valve to on. Remote

switch must be in the on position to ignite burner.

12. Turn on all electric power to the fireplace.

TO TURN OFF GAS

1. Turn off all electrical power to the fireplace if service is to be preformed.

2. Push in gas control knob slightly and turn clockwise to off. Do not force.

TP - OPERATION_ROBERT SHAW

W415-0318 / 03.05.09

Page 16

16

4.1 REAR BURNER CONTROL

The purpose of the rear burner is to increase heat output or BTUs of the unit and will

only operate when the main burner is functioning. To turn the rear burner on, simply

depress the burner control knob (located in the valve compartment at the left hand

side below the piezo ignitor) and rotate the knob counter-clockwise to 'high'.

In order to achieve maximum turn down rate, the rear burner must be turned off.

5.0 MAINTENANCE

TURN OFF THE GAS AND UNPLUG ELECTRICAL POWER BEFORE SERVICING THE FIREPLACE INSERT!

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing. This insert and its venting system should be inspected

before use and at least annually by a qualifi ed service person. The fi replace area must be kept clear and free of

combustible materials, gasoline or other fl ammable vapours and liquids. The fl ow of combustion and ventilation air

must not be obstructed.

5.0.1 In order to properly clean the burner and pilot assembly , remove the logs exposing both assemblies.

5.0.2 Keep the control compartment, logs, burner, air shutter opening and the area surrounding the logs clean by

vacuuming or brushing, at least once a year.

Rear burner

control knob

FIGURE 4.1

5.0.3 Check to see that all burner ports are burning. Clean out any of the ports which may not be burning or are not

burning properly .

5.0.4 Check to see that the pilot fl ame is large enough to engulf the thermocouple on one leg and reaches toward the

burner on the other leg.

5.0.5 Replace the cleaned logs.

5.0.6 Check to see that the main burner ignites completely on all openings when the gas knob for the burner is turned on.

A 5-10 second total light-up period is satisfactory. If ignition takes longer , consult your Authorized dealer/distributor.

5.0.7 Check that the door gasketing is not broken or missing. Replace if necessary .

6.0 REPLACEMENT BLOWER INSTALLATION

The Continental® gas fi replace insert comes standard with a blower, a heat sensor, variable on/off speed con-

trol and a power cord. Because the blower is thermally activated, when turned on, it will automatically start approximately 15 minutes after lighting the fi replace and will run for approximately 30 minutes after the fi replace

has been turned off. Use of the fan increases the output of heat. Air, drawn in through the lower slot, is driven

up the back of the fi rebox, and exhausted as hot air through the upper slot.

6.0.1 Turn off the electrical power and the gas supply to the fi replace insert.

6.0.2 Remove the fi re viewing door. Remove the logs,

log support and back wall.

FIGURE 6.0.3

BLOWER

ACCESS

DOOR

SHOWN WITH LOG SUPPORT AND BACK WALL REMOVED.

6.0.3 Remove the blower

access door held on

with 10 screws.

Replace the blower

access door gasket

when changing the

blower.

FIGURE 6.0

black

THERMAL DISC

white

BLOWER

red

SPEED

CONTROL

SWITCH

W415-0318 / 03.05.09

Page 17

6.0.4 Disconnect the two blower wires. Remove the

blower bracket secured with one wing nut and

lock washer. For thermodisc replacement:

Remove the "Z" shaped mounting bracket

secured to the fi rebox wall behind the left side

control door. Remove the thermodisc from the

bracket and replace.

17

FIGURE 6.0.4a

BLOWER THROUGH ACCESS DOOR

6.0.5 Replace the blower using the existing bracket. Slide

the vibration reducing pad (A) into the clip (C) and

up against the threaded stud (B) at the other end.

The blower must be able to be positioned entirely

onto the pad.

Slide the blower into the clip (C). Secure to the

threaded stud using the existing lock washer and

wing nut. Ensure that the blower does not touch the

fi replace base or the fi rebox.

6.0.6 Reconnect the two wires. Holding the replacement

gasket in place, re-attach the blower access door.

Replace the backwall, logs and log support.

Reinstall the fi re viewing door.

6.0.7 Turn the gas supply and electricity back on.

Drywall dust will penetrate into the blower

bearings causing irreparable damage and must

be prevented from coming into contact with the

blower or its compartment. Any damage resulting

from this condition is not covered by the warranty

policy.

BLOWER WIRES

THERMODISC BRACKET

ASSEMBLY

FIGURE 6.0.4b

B

b

a

A

FIGURE 6.0.5a

C

FIGURE 6.0.5b

7.0 ADJUSTMENTS

7.1 VENT RESTRICTION

Vertical terminations running longer than fi fteen feet may display a

very active fl ame. When this is not desirable, a vent restrictor could

be installed. This restrictor plate will reduce the velocity of the exhaust

gases, slowing down the fl ame pattern and creating a more traditional

appearance.

7.1.1 Remove the glass viewing door and logs.

7.1.2 Secure the restrictor plate as described.

7.1.3 Replace logs and viewing door.

Line up the holes on the vent restrictor with the holes on the bracket

attached to the roof of the fi rebox.

Secure the vent restrictor into position using the two screws supplied.

FIGURE 7.1a

FIGURE 7.1b

W415-0318 / 03.05.09

Page 18

18

FLAME MUST

ENVELOPE

UPPER 3/8" TO 1/2" OF

THERMOCOUPLE &

THERMOPILE

PILOT

BURNER

THERMOCOUPLE

THERMOPILE

7.2 PILOT BURNER ADJUSTMENT

Remove the pilot screw cap. Adjust the pilot screw to

provide properly sized fl ame. Turn in a clockwise

direction to reduce the gas fl ow. Replace the pilot

screw cap.

PILOT SCREW

PILOT ON/OFF

KNOB

7.3 VENTURI ADJUSTMENT

This unit is approved for use with a 2" liner for air intake and a 3" liner for exhaust. For best performance, however, it is recommended to use two 3" liners.

Air shutter settings will differ depending on the liner system used. Use the charts below to determine the correct air shutter setting:

O

L

I

T

P

FIGURE 7.2a

FIGURE 7.2b

3"/ 3" LINER SYSTEM

FRONT REAR

NG 1/16" 3/16"

LP 3/16" 7/16"

AIR SHUTTER SETTING

2"/ 3" LINER SYSTEM

FRONT REAR

NG 1/8" 1/4"

LP 1/4" 5/8"

AIR SHUTTER SETTING

Closing the air shutter will cause a more yellow fl ame, but can lead to carboning. Opening the air shutter will

cause a more blue fl ame, but can cause fl ame lifting from the burner ports. The fl ame may not appear yellow

immediately; allow 15 to 30 minutes for the fi nal fl ame colour to be established.

Air shutter adjustment must

only be done by a qualifi ed gas

installer!

FIGURE 7.3

AIR SHUTTER OPENING

ORIFICE

VENTURI BURNER

W415-0318 / 03.05.09

Page 19

7.4 PRESSURE ADJUSTMENT

19

Inlet pressure can be checked by turning screw (A) counter-clockwise until

loosened and then placing pressure gauge tubing over the test point.

Gauge should read 7” (minimum 4.5”) water column for natural gas or 13”

(11” minimum) water column for propane. Check that main burner is

operating on “HI”.

Outlet pressure can be checked the same as above using screw (B).

Gauge should read 3.5” water column for natural gas or 10” water

column for propane. Check that main burner is operating on “HI”.

AFTER TAKING PRESSURE READINGS, TIGHTEN SCREWS FIRMLY TO SEAL. DO NOT OVER

TORQUE. LEAK TEST.

7.5 FLAME ADJUSTMENT

TURN COUNTER-CLOCKWISE TO

DECREASE FLAME HEIGHT

A

FIGURE 7.4

TURN CLOCKWISE TO INCREASE

FLAME HEIGHT

B

P

I

L

O

T

7.6 FLAME CHARACTERISTICS

It is important to periodically perform a visual check of the pilot and burner fl ames. Compare them to the

illustrations provided.

FIGURE 7.6a

FIGURE 7.5

PILOT

BURNER

THERMOPILE

3/8” - 1/2”

THERMOCOUPLE

FIGURE 7.6b

FLAME MUST ENVELOP

UPPER 3/8” TO 1/2” OF

THERMOCOUPLE AND

THERMOPILE

W415-0318 / 03.05.09

Page 20

20

8.0 REPLACEMENTS

Failure to position the parts in accordance with this manual or failure to use only parts

specifically approved with this appliance may result in property damage or personal injury.

** This is a fast acting thermocouple. It is an integral safety component. Replace only with a fast acting

Contact your dealer or the factory for questions concerning prices and policies on replacement parts. Normally all parts

can be ordered through your Authorized dealer / distributor.

For warranty replacement parts, a photocopy of the original invoice will be required to honour the claim.

When ordering replacement parts always give the following information:

● Model & Serial Number of appliance

● Installation date of appliance

● Part number

● Description of part

● Finish

* Identifies items which are not illustrated. For further information, contact your authorized dealer.

REF NO. PART NO. DESCRIPTION

1 W725-0039 RBT SHAW VALVE - NG

1 W725-0040 RBT SHAW VALVE - LP

2 W100-0075 BURNER TUBE

3 W010-0893 BURNER PAN

4* W455-0065 #45 FRONT BURNER ORIFICE - NG

4* W455-0047 #56 FRONT BURNER ORIFICE - LP

4* W455-0017 #42 REAR BURNER ORIFICE - NG

4* W455-0059 #53 REAR BURNER ORIFICE - LP

5 W010-0800 PILOT ASSEMBLY - LP

5 W010-0801 PILOT ASSEMBLY - NG

6 W455-0068 PILOT INJECTOR - LP

6 W455-0070 PILOT INJECTOR - NG

7** W680-0005 THERMOCOUPLE

8 W680-0004 THERMOPILE

9* W573-0007 HIGH TEMPERATURE SEALANT

10* W357-0001 PIEZO IGNITOR

11 GL-635 LOG SET COMPLETE

12 W135-0030 LOG # 1

13 W135-0160 LOG # 2

14 W135-0161 LOG # 3

15 W135-0033 LOG # 4

16 W135-0034 LOG # 5

17 W135-0035 LOG # 6

18 W135-0036 LOG # 7

19* W361-0016 GLOWING EMBERS

20 GZ552 BLOWER

21* W385-0334 Continental® LOGO

22 W010-

2025 DOOR C/W GLASS

!

WARNING

thermocouple supplied by Wolf Steel Ltd.

COMPONENTS

TP - REPLACEMENTS

W415-0318 / 03.05.09

Page 21

COMPONENTS

REF NO. PART NO. DESCRIPTION

23* W290-0063 BLOWER ACCESS GASKET

24* W430-0013 MAGNETIC CLOSURE

25* W660-0009 ON/OFF SWITCH

26* W690-0002 THERMAL DISC

27* W380-0002 VARIABLE SPEED SWITCH KNOB

28* W660-0019 VARIABLE SPEED SWITCH

29* W450-0023 PAL NUT

30*

31* W175-0204 3" COUPLER

32 W010-0888 VENT CONNECTION ASSEMBLY

33* W290-0076 VENT CONNECTION ASSEMBLY GASKET

W730-0024 3" STAINLESS FLEX LINER X 3'

TERMINAL KITS

REF NO. PART NO. DESCRIPTION

34 GDI-226 TERMINAL KIT

VENT KITS

REF NO. PART NO. DESCRIPTION

1-2" & 1-3" DOUBLE PLY ALUMINUM LINER-INLET AND EXHAUST & 2-3" TO 2" REDUCER:

35* GDI-2320KT VENT KIT 20FT

35* GDI-2325KT VENT KIT 25FT

35* GDI-2335KT VENT KIT 35FT

2-3" DOUBLE PLY ALUMINUM LINER-INLET AND EXHAUST:

36* GDI-320KT VENT KIT 20FT

36* GDI-325KT VENT KIT 25FT

36* GDI-335KT VENT KIT 35FT

46ACCESSORIES46

REF NO. PART NO. DESCRIPTION

37* W690-0001 MILLIVOLT THERMOSTAT

38* W660-0010B REMOTE CONTROL - ADVANTAGE

38* W660-0011B REMOTE CONTROL - ADVANTAGE PLUS

39* GD660 REMOTE WALL SWITCH C/W 20FT WIRE

40 GI826KT DECORATIVE BRICK PANELS

41* W175-0202 NATURAL GAS TO PROPANE CONVERSION KIT

42 GDIBP3 3 SIDED BACKER PLATE C/W ACCENT TRIM

43 GDIBP4 4 SIDED BACKER PLATE C/W ACCENT TRIM

44 GDITRM3 ALUMINIUM EXTRUSION - MATTE BLACK

44 GDITRM3-K ALUMINIUM EXTRUSION - POLISHED BLACK

44 GDITRM3-B ALUMINIUM EXTRUSION - POLISHED BRASS

45 GDITRM4 ALUMINIUM EXTRUSION - MATTE BLACK

45 GDITRM4-K ALUMINIUM EXTRUSION - POLISHED BLACK

45 GDITRM4-B ALUMINIUM EXTRUSION - POLISHED BRASS

46 GDIUT UPPER DOOR TRIM - BRASS

46 GDIUT-G UPPER DOOR TRIM - GOLD

47 GDIBP3D BACKER PLATE 3 SIDED DELUXE

21

W415-0318 / 03.05.09

Page 22

22

20

40

43

44

42

1

5

8

7*

6

45

22

2

11

3

46

47

12

15

18

16

17

13

14

32

34

W415-0318 / 03.05.09

Page 23

9.0 TROUBLE SHOOTING

Always light the pilot whether for the first time or if the gas supply has fan out, with the glass door

!

WARNING

open or removed.

23

SYMPTOM

Main burner goes out;

pilot stays on.

Main burner goes out;

pilot goes out.

PROBLEM

Pilot flame is not large enough or

not engulfing the thermopile.

Thermopile shorting.

Remote wall switch wire is too

long; too much resistance in the

system.

Faulty thermostat or switch.

Refer to “MAIN BURNER GOES

OUT; PILOT STAYS ON”

Vent is blocked

Vent is re-circulating

Flexible vent has become

disconnected from fireplace.

Thermopile shorting or faulty.

TEST SOLUTION

- Turn up the pilot flame.

- Replace pilot assembly.

- Clean thermopile connection tot he valve. Reconnect.

- Replace thermopile / valve.

- Shorten wire to connect length or wire gauge.

- Replace.

- Check for vent blockage.

- Check joint seals and installation

- Re-attach to fireplace.

- Cap was not replaced.

- Loosen and tighten thermocouple.

- Clean thermocouple and valve connection.

- Replace thermocouple.

- Replace valve.

Pilot goes out when

the gas knob is

released.

The gas valve has an

interlock device

which will not allow

the pilot burner to be

lit until the thermocouple has cooled.

Allow approximately

60 seconds for the

thermocouple to

cool.

Remote wall switch is

in ’OFF’ position; main

burner comes on

when gas knob is

turned to ‘ON’ position.

Vent is reversing.

System is not correctly purged.

Out of propane gas.

Pilot flame is not large enough.

Pilot flame is not engulfing the

thermocouple

Thermocouple shorting / faulty.

Faulty valve.

Air shutter is not set to specifica-

tions.

Wall switch is mounted upside down.

Remote wall switch is grounding.

Remote wall switch wire is grounding.

- Check all venting and insert seals.

- Check that door is properly sealed. If the appliance is allowed

to burn with the door off when purging the unit, exhaust

products may escape through the air intake pipe and reverse

the venting action. Let the unit cool down to correct the

reversed venting action.

- Purge the gas line.

- Fill the tank.

- Turn up the pilot flame.

- Gently twist the pilot head to improve the flame pattern around

the thermocouple.

- Loosen and tighten thermocouple.

- Clean thermocouple and valve connection.

- Replace thermocouple.

- Replace valve.

- Replace.

- Check and adjust air shutter to correspond with the fuel type

and air intake size.

- Reverse.

- Replace.

- Check for ground (short); repair ground or replace wire.

Faulty valve.

- Replace.

TP - TROUBLE SHOOTING_RS

W415-0318 / 03.05.09

Page 24

24

SYMPTOM PROBLEM

Pilot burning; no gas

to main burner; gas

knob is on ‘HI’; wall

switch / thermostat is

on.

Thermostat or switch is defective

Wall switch wiring is defective.

TEST SOLUTION

- Connect a jumper wire across the wall switch terminals; if main burner

lights, replace switch / thermostat.

- Disconnect the switch wires & connect a jumper wire across terminals

1 & 3; if the main burner lights, check the wires for defects and / or

replace wires.

Pilot will not light.

PILOT

BURNER

THERMOPILE

THERMOCOUPLE

Pilot goes out while

standing; Main burner

is in ‘OFF’ position.

Flames are very

aggressive.

Main burner orifice is plugged.

Faulty valve.

No spark at pilot burner.

Out of propane gas.

Spark gap is incorrect.

No gas at the pilot burner.

Gas piping is undersized.

Door is ajar.

Venting action is too great.

- Remove stoppage in orifice.

- Replace.

- Check if pilot can be lit by a match.

- Check that the wire is connected to the push button igniter.

- Check if the push button igniter needs tightening.

- Replace the wire if the wire insulation is broken or frayed.

- Replace the electrode if the ceramic insulator is cracked or broken.

- Replace the push button ignitor

- Fill the tank.

- Spark gap should be 0.150” to 0.175” (5/32” to 11/64” approx.) from

the electrode tip and the pilot burner. To ensure proper electrode

location, tighten securing nut (finger tight plus 1/4 turn).

- Check that the manual valve is turned on.

- Check the pilot orifice for blockage.

- Replace the valve.

- Call the gas distributor.

- Turn on all gas appliances and see if pilot flame flutters, diminishes

or extinguishes, especially when main burner ignites. Monitor

appliance supply working pressure.

- Check if supply piping size is to code. Correct all undersized piping.

- Tighten screws holding door in place.

- Restrict vent exit with restrictor vent kit.

Main burner flame is a

blue, lazy, transparent

flame.

Carbon is being

deposited on glass,

logs or combustion

chamber surfaces.

White / grey film

forms.

Exhaust fumes

smelled in room,

headaches.

TP - TROUBLE SHOOTING_RS

W415-0318 / 03.05.09

Blockage in vent.

Incorrect installation.

Air shutter has become blocked.

Flame is impinging on the logs or

combustion chamber.

Sulphur from fuel is being deposited on

glass, logs or combustion chamber

surfaces.

Fireplace is spilling.

- Remove blockage. In really cold conditions, ice buildup may occur on

the terminal and should be removed as required.

- Refer to Figure 31 to ensure correct location of storm collars.

-

Ensure air shutter opening is free of lint or other obstructions. Check

and adjust air shutter to correspond with the fuel type and air intake size.

- Check that the logs are correctly positioned.

- Open air shutter to increase the primary air.

- Check the input rate: check the manifold pressure and orifice size

as specified by the rating plate values.

- Check that the door gestating is not broken or missing and that the

seal is tight.

- Check that both vent liners are free of holes and well sealed at all

joints.

- Check that minimum rise per foot has been adhered to for any

horizontal venting.

- Clean the glass with a recommended gas fireplace glass cleaner.

DO NOT CLEAN GLASS WHEN HOT.

- If deposits are not cleaned off regularly, the glass may become

permanently marked.

- Ensure exhaust bracket gasket seal.

- Check door seal and relief flap seal.

- Check for chimney blockage and that chimney is installed to building code.

- Room is in negative pressure; increase fresh air supply.

- Check cap gasket on the flue pipe assembly.

Page 25

10.0 SERVICE HISTORY

25

Service Performed Special ConcernsDealer Name

Name

Appliance Service History

This heater must be serviced annually depending on usage.

Date Service Technician

TP - SERVICE HISTORY

W415-0318 / 03.05.09

Page 26

26

11.0 NOTES

TP - NOTES

W415-0318 / 03.05.09

Page 27

27

W415-0318 / 03.05.09

Page 28

28

W415-0318 / 03.05.09

Loading...

Loading...