Contherm MITRE 4150, MITRE 4000 SERIES, MITRE 4200, MITRE 4400 Service Manual

Scientific Ltd

SERVICE MANUAL

MITRE 4000 SERIES

Sterilising - Standard/Tropicool/Cooled Models

CO2CELL CULTURE INCUBATORS

CONTHERM SCIENTIFIC LIMITED

P O BOX 30-605 LOWER HUTT 5040

TEL: (0064-4) 568 8034

FAX: (0064-4) 568 8095

EMAIL: contherm@xtra.co.nz

WARRANTY STATEMENT

* * * * * * *

CONTHERM Scientific Company will guarantee CONTHERM equipment for

a period of twelve months from the date of installation against faulty

workmanship and fabricated materials. This guarantee covers the

replacement of component parts found to be defective and authorised

labour charges during this period.

Should a malfunction occur or condition develop beyond reasonable

acceptance the company will accept responsibility for returning the unit to

its factory specification at no cost to the Purchaser providing that the

operating instructions have been observed and the defect is due solely to

faulty design, material and workmanship. That the defective part be

returned, freight paid to the nearest sales service office. Units outside the

warranty period will be accepted and repairs will be covered under an

extension of the above for 90 days.

In remote installations where it is not possible for the company's or

agents' engineers to attend, authority may be given to allow the Purchaser

to arrange such service.

The Purchaser is required to remit the purchase price of the unit to the

supplier within the terms of that supplier's condition of sale. CONTHERM

Scientific Company will accept no liability or shall its agents for

consequent damage of any kind due to a malfunction or component

failure.

* * * * * * *

MANUALP/4000_SERVICE_0712 July2012

4

STATEMENT of CONFORMITY

This CONTHERM cabinet conforms to the following standards:

• Electrical Safety: Designed to NZS6200 / AS3100:1994

• EMC: Complies with AS/NZS 2064: 1997

MANUALP/4000_SERVICE_0712 July2012

5

CONTENTS

SECTION 1 Definition of Terms

SECTION 2 Introduction and Specifications

SECTION 3 Installation

SECTION 4 Operating Instructions

SECTION 5 Calibration

SECTION 6 Theory of Operation

SECTION 7 Customer Troubleshooting and Maintenance

SECTION 8 Spare Parts Lists

SECTION 9 Fault / Alarm Codes

SECTION 10 Servicing / Replacing Parts

IMPORTANT All electrical servicing must be carried out by

suitably qualified personnel only.

MANUALP/4000_SERVICE_0712 July2012

6

SECTION 1 DEFINITION OF TERMS

For the purpose of our standard specifications the following definitions shall

apply:

a) WORKING SPACE

That portion of the internal space which is above the lowest shelf and

not less than 5cm from any wall (including roof).

b) CHAMBER TEMPERATURE

That temperature at the centre of the working space.

c) SPATIAL VARIATION

The difference between the midrange of all measured temperatures

obtained at one site and that at another site for those sites which give the

greatest difference.

d) TEMPORAL VARIATION

The maximum value of the temperature range obtained for the standard

site with the greatest range throughout the test interval.

e) TEMPERATURE OVERSHOOT

Any excess of actual over desired chamber temperature during a

heating up period.

f) TEMPERATURE REPRODUCIBILITY

Temperature regained without alteration to controls.

g) TEST INTERVAL

Interval of time to which the steady state characteristics apply (Max 1

hour).

NB: All the above apply with an empty chamber.

For definitions and test methods refer: AS2853 : 1986 (and Appendices)

MANUALP/4000_SERVICE_0712 July2012

7

SECTION 2 INTRODUCTION AND SPECIFICATIONS

The CONTHERM CAT4000 Mitre Series of Co2 Culture Incubators has been

expressly designed to give the widest choice of operating conditions consistent

with high reliability and low cost, the addition of microprocessor control gives

additional versatility and resolution while improving the degree of temperature

control. These Incubators are fitted with a UVC (254nm) SERILISING UV lamp.

All specifications are quoted for an enclosure temperature of +37oC with an

ambient Temperature of +20oC for Standard and Tropicool cabinets and for an

enclosure temperature of +20oC for cooled cabinets.

• Construction - Combination of High quality stainless steel and zinc plated

mild steel; epoxy coated exterior, full fibreglass insulation, High quality

stainless steel interior with full access door and magnetic door catch

• Safety - Fitted with an independent factory set Hi-Limit and user adjustable

Hi-Limit completely separate from normal controls.

• Convection - All units come with mechanical convection fan systems.

• Electrical - Designed to NZS6200 / AS3100:1994 240V AC M.E.N

• EMC - Complies with AS/NZS 2064: 1997

• All performances quoted at 20

o

C, ZP22 Microprocessor control System.

PERFORMANCE:

a) Temperature:

Nominal Range: Standard (Ambient +5oC) to +50oC

Tropicool (Ambient -5oC) to +50oC

*Cooled +15oC to +50oC

Temporal Variation Standard +_ 0.2oC

(Tropicool) +_ 0.3oC

(Cooled) +_ 0.4oC

Spatial Variation Standard +_ 0.4oC

(Tropicool) +_ 0.4oC

(Cooled) +_ 1.5oC

Initial Overshoot +2.0oC

Reproducibility +_0.5oC

Dial resolution 0.1oC

Operating Ambient 10oC - 35oC

Mains Voltage Range 230-250 AC 50Hz

*NB: Can only be operated on 60Hz when cooled units fitted with a special

refrigeration compressor.

MANUALP/4000_SERVICE_0712 July2012

8

NB: The lowest temperature performance is only achievable in a maximum

ambient of +20oC

NB: If fitted with a HEPA filter, the spatial specification is downgraded by a

further ± 0.4

o

C

b) Relative Humidity -

With the standard tray of water inside a standard cabinet the humidity will

typically rise to 80% RH or more at a temperature of 37.0oC. The

maximum achievable humidity will be less in a Tropicool or Cooled

cabinet.

NB: On COOLED units the supplied stainless steel water tray should be placed

on the cabinet floor and pushed so that the sloping side firmly touches the rear

wall.

c) Carbon Dioxide:

Range: 0.5 - 20 % CO

2

Fluctuation (@35Kpa / 5PSI) ±0.2% CO

2

Accuracy: (@37oC, 85% RH) ±0.5% CO

2

CAUTION: This chamber has been fitted with a SPECIAL UVC Sterilising lamp

located behind the stainless steel rear duct. Note that this ULTRA-VIOLET

lamp is HARMFUL to the eyes and MUST NOT be viewed directly or indirectly

for any period.

The lamp is automatically turned OFF when the outer door is opened and turns

on for 5 minutes when the outer door is reclosed.

If for ANY reason the glow from the lamp can be seen when the outer door is

opened, the cabinet must be turned OFF and the cause investigated by a

qualified service engineer.

SPECIAL NOTE for COOLED incubators

COOLED chambers may be fitted with a ‘FRIDGE’ switch located on the RHS

monitor panel. If fitted, this switch allows the user to turn the refrigeration

system OFF when operating at higher temperatures and low ambient condition

(for example at 37oC in an air-conditioned room).

If the ‘FRIDGE’ switch is turned ON or OFF when the chamber has stabilised at

temperature, the control temperature may be disturbed for a short period while

the chamber re-stabilises at the new load setting.

When operating at 37oC in an air-conditioned room, it is recommended to

set the ‘FRIDGE’ switch to OFF.

MANUALP/4000_SERVICE_0712 July2012

9

SECTION 3 INSTALLATION

The CAT 4000 Mitre Series Incubators are designed to be installed into a

suitable well ventilated room with a preferred minimum clear space of at least

150mm on all sides to allow access for servicing. Mount the enclosure in its

final place ensuring that adequate space is allowed for the door to open. The

enclosure may be placed on the floor or a bench.

NB: On Tropicool and Cooled units ensure a space of at least 150mm is

allowed at the rear of the cabinet for air circulation – On Tropicool units ensure

that the unit can not be pushed too close to a rear wall. Locate the two stainless

perforated “butterfly wings” at the rear sides of the Tropicool unit and gently

bend to an angle of 90o.

The chamber requires a 240Volt 50HZ 10Amp Single phase EARTHED

electricity supply.

Total electrical load is upto 0.75Kw (4400C).

Maximum shelf loading is 30Kg/shelf, maximum total for cabinet is 100Kg.

The chamber should be thoroughly inspected for any signs of mechanical

damage that may have occurred in transit before any attempt is made to apply

power to the unit.

1) Connect a bottle of DRY FOOD GRADE CO2fitted with a two stage

Pressure Regulator set at 35kpa (5psi) to the Hosetail No 1 at the rear

of the enclosure.

2) If the enclosure is fitted with the automatic CO2CHANGEOVER option fit

the second gas bottle to Hosetail No 2. This bottle will automatically be

selected when bottle No 1 is empty.

3) Install the shelf guides in the desired positions. Slide the shelves into

guides.

4) On cooled / Tropicool units a large stainless steel or plastic tray is used to

both provide and collect water from the refrigeration system evaporator.

Ensure this tray is pushed firmly against the rear wall of the cabinet. If

elevated humidity conditions are desired partially fill the tray with distilled

or deionised water.

NOTE: The hosetail is a nominal ¼” brass barb. Typically use 6.0mm ID PVC

beverage tubing or similar to connect to the gas bottle regulator output. The

tubing should be secured to the hosetail using S/S hose clips.

MANUALP/4000_SERVICE_0712 July2012

10

WARNING: To prevent FIRE or SHOCK hazard, DO NOT expose this

product to rain or any type of moisture.

FOR YOUR SAFETY

To ensure safe operation the three-pin plug supplied must be inserted

ONLY into a standard three-pin power outlet which is effectively earthed

through the normal building wiring.

Extension cords are NOT recommended.

The fact that the equipment operates satisfactorily does NOT imply that

the power outlet is earthed and that the installation is completely safe. For

your safety, if in any doubt about the effective earthing of the power outlet,

consult a qualified electrician.

This appliance should be regularly tested (or after any service work on

the appliance) according to the procedures prescribed in AS/NZS 3760.

The basic safety checks and tests on electrical appliances required by

AS/NZS 3760 are:

a) A visual check to ensure that there is no mechanical damage, that

controls etc. are in good working order and that no parts are

missing.

b) An earth continuity test. (Maximum allowed resistance is 1 )

An insulation resistance test. (Minimum insulation resistance is

1 M)

WARNING: This cabinet is fitted with a UV Sterilising Lamp

UVC refers to shorter UV wavelengths, usually 200 to 280 nM. Wavelengths

in the UVC range, especially from the low 200's to about 275 nM, are

especially damaging to exposed cells. Such shortwave UV is often used for

germ killing purposes. The typical wavelength for ‘sterilising’ purposes is

253nM.

CAUTION: This chamber has been fitted with a SPECIAL UVC Sterilising lamp

located behind the stainless steel rear duct. Note that this ULTRA-VIOLET

lamp is HARMFUL to the eyes and MUST NOT be viewed directly or indirectly

for any period.

The UV lamp is automatically turned OFF when the outer door is opened and

turns on for 5 minutes when the door is reclosed.

MANUALP/4000_SERVICE_0712 July2012

11

SECTION 4 OPERATING INSTRUCTIONS

This appliance is NOT intended for use by young children or infirm persons

without supervision.

To set up unit for operation after unpacking and checking for damage proceed

as follows:

1) Follow any installation procedures (See SECTION 3).

OPERATING CONTROLLER:

This example will demonstrate how to set the cabinet for the following

conditions:

Temperature = 37.0oC Carbon Dioxide = 5.0%

TO SET TEMPERATURE

Press and hold the TEMP button. The display will blank for 2 seconds, release

the button. The SET LED above the temperature display will turn on indicating

that this parameter is now in the temperature set mode and the current set point

will be displayed. Use the UP and DOWN buttons to adjust the Set Point to

37.0oC.

When the adjustment is complete the controller will return to normal operation if

the buttons are not pressed. This is indicated by the TEMP SET LED going off.

TO SET THE CO

2

CONCENTRATION

Press and hold the CO2button. The display will blank for 2 seconds, release

the button. The SET LED above the CO2display will turn on indicating that this

parameter is now in the set mode and the current set point will be displayed.

Use the UP and DOWN buttons to adjust the set point to 5.0%.

When the adjustment is complete the controller will return to normal operation if

the buttons are not pressed. This is indicated by the CO2SET LED going out.

HEPA FILTER (If Fitted): To change the HEPA Filter, undo the two

knurled nuts holding the filter to the inside top tray and withdraw the

filter.

RELATIVE HUMIDITY

There is no electronic control of humidity in these enclosures, the humidity is

maintained either by placing a small plastic tray of water in the tray support and

attaching this to a vacant shelf ladder near the bottom of the cabinet or by

partially filling the large stainless tray on cooled units. The humidity level will

usually equilibrate to a relative humidity of above 80%. (typically 60% - 70% on

Tropicool and Cooled units.

MANUALP/4000_SERVICE_0712 July2012

12

To display the Relative Humidity (Non INFRA-RED Models ONLY): Press

the CO2button momentarily and the CO2display will indicate the %RH. After a

few seconds the display will return to displaying the CO2reading.

CONDENSATION:

It is normal for a small amount of condensation to appear on the side walls

and glass door(s) and floor when operating with humidities above 85%

RH. Any water accumulating on the floor of the cabinet should be

removed at regular intervals.

CAUTION: This chamber has been fitted with a SPECIAL UVC Sterilising lamp

located behind the stainless steel rear duct. Note that this ULTRA-VIOLET

lamp is HARMFUL to the eyes and MUST NOT be viewed directly or indirectly

for any period.

The lamp is automatically turned OFF when the outer door is opened and turns

ON for 5 minutes when the door is reclosed.

CONFIRMATION OF OPERATING PARAMETERS

Contherm check the Temperature, and CO2calibration in the factory in the final

testing stages. For your confidence it is advisable to obtain your own calibration

so as to ensure the enclosure is operating to your satisfaction. This must be

carried out in the enclosures final operating environment. A full procedure for

calibrating the enclosure in given in the CALIBRATION Chapter.

TROPICOOL UNITS:

This type of cabinet is fitted with Contherm’s ‘Tropicool’ peltier cooling option.

The Tropicool unit uses a peltier cooling device to obtain lower temperatures,

typically allowing operation to 5oC below ambient. The ‘Tropicool’ unit runs

continuously.

COOLED UNITS:

This type of cabinet is fitted with a special refrigeration unit, the lowest

temperature of which is factory set via a ‘evaporator pressure regulator’ to

minimise the dehumidifying effect of the cooling coils. The minimum attainable

temperature will be about +15oC. The refrigeration unit runs continuously.

MANUALP/4000_SERVICE_0712 July2012

13

ALARMS

There are TWO types of alarm used in the Contherm Mitre series enclosures.

Standard Alarms and Special Alarms

STANDARD ALARMS

[1-.-] [2-.-] [4-.-] [5-.-] [6-.-] [7-.-] [8-.-] [11.-] [12.-]

These alarm numbers indicate a problem with cabinet control, ie. overtemperature, faulty sensor ,etc.

To CANCEL all the alarms except [2-.-] Press and Hold the TEMP button until

the temperature display blanks. To cancel the [2-.-] alarm, press and hold the

CO2button until the CO2display blanks. To assist any service enquiries later

please note the number of the alarm and what was done to eliminate the cause.

SPECIAL ALARMS

[3-.-] [9-.-]

These alarms can ONLY be cancelled by using the procedure outline below.

These alarms indicate that the cabinet may have lost some of its settings [3-.-],

OR that Electrical Interference [9-.-] has corrupted the cabinets internal

operating system.

To cancel the [3-.-] or [9-.-] alarms it is necessary to go into SET MODE and

check both Temperature and CO2set points. Once the set points of the CO2and

Temperature and the Temperature calibration has been checked the alarms will

cancel.

MANUALP/4000_SERVICE_0712 July2012

14

POWER CONTROL AND HI-LIMIT PANEL (RIGHT HAND SIDE)

The Power Control and Hi-Limit Panel is fitted at the top right hand side of the

enclosure. This panel contains the ON/OFF Switch, FUSE and user adjustable

Temperature HI-LIMIT thermostat.

1 CO

2

SAMPLE PORT

This fitting allows the user to SAMPLE the atmosphere inside the cabinet.

The fitting cover MUST be fitted after sampling to minimise CO

2

loss.

Note: A sample should NOT be taken within 5 seconds of the CO

2

INJECT LED coming on.

2 TEMPERATURE HI-LIMIT THERMOSTAT

This is a mechanical thermostat which directly monitors the temperature

of the enclosure. If the temperature exceeds this setting the power to the

element will be switched off and the associated Hi-Limit (3) neon will

illuminate when the controller applies power to the element. This can be

observed by watching the HEAT LED on the front panel. This thermostat

should be set to operate just above the set point temperature. See

Setting Hi-Limit Thermostat below.

3 HI-LIMIT NEON

This RED neon lights whenever the Hi-Limit Thermostat is activated.

Whenever the neon is illuminated no power is being supplied to the

enclosure heating elements (this is an additional safety against

inadvertent enclosure overheating).

4 ON/OFF SWITCH

This turns the power on or off. The fitting also contains an electrical

noise filter.

5 FUSE : The fitting contains a 5AMP fuse.

6 POWER LEAD SOCKET: The power lead plugs into this socket.

7 FRIDGE ON/OFF SWITCH:

If fitted, this turns the fridge on or off. When operating at 37oC in an airconditioned room, it is recommended to set the ‘FRIDGE Switch’ to OFF.

1 2

3 4 5 67

MANUALP/4000_SERVICE_0712 July2012

15

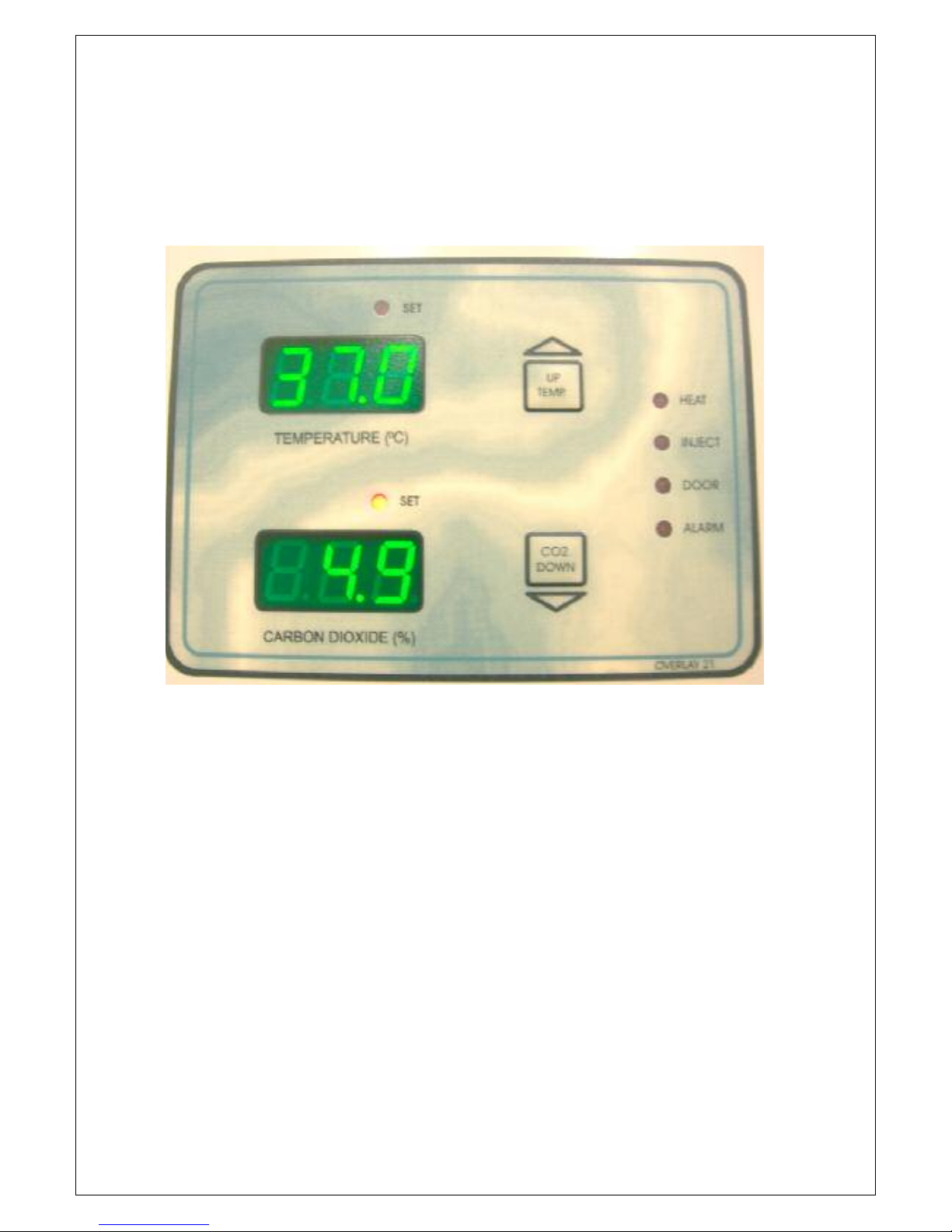

OPERATING CONTROL PANEL

The Control Panel on the outer door is used to access the operating conditions

for the enclosure.

UP/TEMP

This button is used to increase the parameter value, to display the enclosure

Temperature and the Temperature set point. This will sometimes be referred to

as the TEMP or the UP button.

DOWN/CO

2

This button is used to decrease the parameter value, to display the CO2 set

point and the Relative Humidity (Non INFRA-RED Models ONLY). This will

sometimes be referred to as the CO2or the DOWN button.

SET

These LED’s indicate if the Temperature or CO2displays are in SET MODE.

MANUALP/4000_SERVICE_0712 July2012

16

HEAT

Indicates when power is being supplied to the heating element. This will remain

steady when large changes in conditions are occurring eg warming up or if the

door has been opened. When the enclosure is at the temperature set point, the

LED will pulse.

INJECT

Indicates when CO2is being injected. This will usually be accompanied by an

audible click of the CO2inject solenoid.

DOOR

Indicates that the outer door is open. If the door is opened a door switch is

activated, the internal fan, heater and CO2solenoid are disabled until the door is

closed. Leaving the outer door ajar for prolonged periods will affect the internal

control of the cabinet atmosphere.

ALARM

Indicates when an ALARM condition has been triggered. The alarm will be

accompanied by a beep and will display the Alarm Code in the Temperature

Display.

MANUALP/4000_SERVICE_0712 July2012

17

SECTION 5 CALIBRATION

It is important to note that the calibration of this enclosure is valid only when it is

calibrated in its final operating environment. Contherm calibrates the enclosure

to our internal standards in the final testing stages of manufacture. This means

that when the enclosure arrives at the customer site, the calibration carried out

in the factory may no longer be valid. Contherm wishes to make it clear that

calibration is a CUSTOMER responsibility. Contherm has ensured that a

complete acceptable calibration procedure is available for the customer to

follow.

Calibration of the enclosures is achieved by checking the enclosure temperature

display against a customer supplied calibrated thermometer and CO

2

monitoring device. It is important that the calibration is carried out at the

temperature of interest.

The temperature sensor that is used by the electronic thermal control system is

also used to indicate the control temperature. This sensor is in the duct of the

air circulation system and is not directly in the work space, therefore it is

necessary to adjust any offset between the work space and the indicated

temperature. Calibration entails adjusting the CALIBRATION FACTOR so that

the work space temperature matches the indicated temperature. The

CALIBRATION FACTORS are stored in an Electrically Erasable Read Only

Memory (EEROM). EEROM retains its stored memory even with the power off.

TEMPERATURE CALIBRATION

1 Place a calibrated reference thermometer that has been checked to the

customers satisfaction into the enclosure. The usual place for this is in

the centre of the work space. Place it so that it is able to be read without

opening the glass inner door.

2 Ensure the enclosure has stabilised at the temperature of interest for at

least 6 hours.

3 Press and hold the TEMP button until the display momentarily blanks,

this will access the SET POINT mode and the SET LED above the

temperature display will be on.

4 Press both TEMP and CO2buttons at the same time. The temperature

display will show [Cal] for 2-3 seconds and then show the current

temperature.

5 Adjust the value displayed to read the same as your reference

thermometer.

MANUALP/4000_SERVICE_0712 July2012

18

6 Release all buttons. After about 3 seconds the temperature display will

show [---] then a HEXIDECIMAL number for about 2 seconds (This

number may be noted as a reference to the current calibration) then

another [---] and beep. The enclosure will now begin to adjust itself so

that the reference thermometer temperature matches the SET POINT

temperature. The indicated temperature will show a temperature offset

from the SET POINT Temperature immediately after the calibration. This

is normal as the controller is now endeavoring to match the SET POINT

to the work space reference thermometer.

The procedure may need to be repeated to obtain the best final calibration.

The temperature should be recorded on a daily basis by placing a thermometer

in the workspace so that it can be read without opening the inner glass doors

and the long term temperature performance can then be plotted to give an

assurance of correct temperature performance. Similarly, the CO2should be

checked and monitored regularly using the independent monitor. Record these

for long term assurance.

CO2CALIBRATION – THERMAL CONDUCTIVITY SENSOR

There are two modes of calibration for the THERMAL CONDUCTIVITY CO

2

system. An AUTO-CALIBRATION (AUTO-CAL) and MANUAL CALIBRATION

(MAN-CAL). Both types perform the same operation. AUTO-CAL enables the

enclosure to perform the calibration at ‘quiet’ times of operation, whereas MAN-

CAL is used when the cabinet has been empty of CO2for a long period. Both

require the enclosure to be stabilised at the desired set Temperature.

AUTO-CAL

The normal method of calibrating the CO2concentration is by using the

AUTO-CAL facility. To force the controller to carry out an AUTO-CAL the

following procedure is recommended.

1 Change the Temperature Set Point by 0.1oC (eg. if your normal operating

Temperature Set Point is 37.0oC change it to 36.9oC).

2 The CO2display should now be flashing, this indicates that the CO2is

now out of calibration. Note that the operation of the CO2gas inlet

solenoid(s) will be inhibited while the CO2display is flashing.

3OPEN both the outer and inner incubator doors, and leave them open for

at least 30 seconds. (This is to flush the enclosure of CO2gas).

4 CLOSE both doors.

MANUALP/4000_SERVICE_0712 July2012

19

5 CHANGE the Temperature Set Point back to your normal setting, ie.

37°C

6LEAVE the enclosure (preferably without opening the doors) until the

CO2display stops flashing. This indicates that normal CO2control has

returned.

MAN-CAL

1 Flush the enclosure of CO2by opening the doors for at least 30 seconds.

2 Press and Hold the CO2button until the CO2display momentarily blanks.

3 Press both the TEMP and CO2buttons together until the display shows

[Cal].

4 Release all buttons and wait. The display will show [---] and beep. The

CO2display will automatically reset itself to [0.3%] when the current

temperature next reaches the Temperature Set Point.

NOTE AUTO-CAL and MAN-CAL will assume that there is no CO2in the

enclosure when the calibration sequence begins.

CO

2

SPAN CALIBRATION

As there is no facility to adjust the span of the CO2display, it is necessary to

check the CO2concentration by independent means and if necessary REPEAT

the AUTO-CAL procedure until satisfactory calibration is achieved.

CONTHERM recommends a FYRITE is used to check the CO2concentration.

Any other means that is satisfactory to the customer may be substituted.

1 Let the enclosure stabilise at its operating conditions for at least 6 hours.

2 Monitor the CO2level via the CO2SAMPLE PORT with the independent

CO2monitor ensuring that the CO2injection solenoid does not operate

during the sampling time. Note the reading of the independent monitor.

3 If the MONITOR value is within ± 0.5% of the DISPLAYED CO2 reading

no further action is necessary.

4 Repeat the AUTO-CAL calibration procedure until a satisfactory result is

achieved.

MANUALP/4000_SERVICE_0712 July2012

20

Notes on Calibration Procedures for THERMAL CONDUCTIVITY Sensors

• The CO

2

SET POINT can be left as it is for the duration of the AUTO-CAL

and MAN-CAL calibration sequences. Once the CO

2

display has stopped

flashing the controller will adjust the workspace CO2level to the SET POINT.

• AUTO-CAL is best done last thing at night as the calibration usually takes

from 1 to 4 hours to complete.

• CONTHERM recommends that AUTO-CAL is carried out at least every two

months OR if a Temperature Calibration has taken place.

CO2CALIBRATION – INFRA-RED CO2SENSOR (IR)

There are two modes of calibration for the INFRA-RED CO2system. A USERCALIBRATION and FACTORY CALIBRATION. Use the user calibration for

small calibration adjustment and can be carried out via the front panel buttons.

The factory calibration is used when the user calibration can not obtain the

correct result and when the sensor is replaced and is carried out by qualified

service personnel. Both require the enclosure to be stabilised at the desired set

Temperature. A detailed IR calibration procedure can be found on Servicing

Section.

USER IR CO2CALIBRATION

This is used for small calibration adjustments (approx ±0.5%) and may be

carried out by the user via the front panel buttons.

Press and hold the CO2button until the display momentarily blanks, this will

access the SET POINT mode and the SET LED above the temperature display

will be on.

Press both TEMP and CO2buttons at the same time. The temperature display

will show [Cal] for 2-3 seconds and then show the current co2reading.

Adjust the value displayed to read the same as your reference co2monitoring

device.

When exiting the user calibration routine a calibration constant (0.0 to 3.2) will

be displayed, this number should be noted down.

MANUALP/4000_SERVICE_0712 July2012

21

FACTORY IR CO2CALIBRATION

(For use only if correct result cannot be obtained from USER Calibration)

These adjustments are normally carried out by a qualified service person and

require a DC Voltmeter.

There are two modes of calibration for the infra-red CO2system.

1. Zero Offset Calibration (This should never require adjustment)

2. Span calibration. (This may require a slight adjustment if the CO2 calibration

is incorrect)

NB:These adjustments do not calibrate the accuracy of the CO2concentration

measurement, but only adjust the output to match the measuring device.

Before carrying out these procedures insure that the cabinet has been allowed

to stabilise for at least 6 hours.

Before attempting these settings the CALIBRATION CONSTANT should be

centered to read 1.6 to allow for maximum user adjustment from the front

panel in the future.

E.G If the user calibration constant is 0.9 the easiest way to get it to read 1.6

is to follow the user calibration routine but when adjusting the calibration value

press the ‘UP’ button seven times (0.9 + 7 = 1.6). Wait for the calibration

constant to be displayed, if it doesn’t read 1.6 repeat above (either UP or

DOWN) until it does.

CO

2

ZERO OFFSET CALIBRATION

To adjust the ZERO of the CO2display, it is necessary to proceed as follows:

1 Connect a voltmeter to the CO2sensor board output terminals.

2 With JP5 OPEN, connect the shorting jumper onto pins of JP4, use the

‘UP’ or ‘DOWN’ buttons on the CO2PCB to adjust the voltmeter to read

0.005 volts DC. (The cabinet display will read about 0.2% CO2)

3 REMOVE the shorting jumper from pins of JP4.

CO2SPAN CALIBRATION

To adjust the SPAN of the CO2display, it is necessary to proceed as follows:

1 Connect a voltmeter to the CO2sensor board output terminals (V0 &

COM).

2 With JP5 CLOSED, connect the shorting jumper onto pins of JP4, use

the ‘UP’ or ‘DOWN’ buttons on the DCS-300 INFRA-RED CO2PCB to

adjust the voltmeter to read 0.650 volts DC. (The cabinet display will read

MANUALP/4000_SERVICE_0712 July2012

22

about 16.5% CO2). This value may be raised or lowered to achieve the

exact CO2calibration result. (‘Normal’ range is from 0.550 – 0.750). If the

cabinet display is reading too high when the CO2concentration is

compared with a test instrument (‘Fyrite’ etc) then the reference voltage

should be adjusted slightly DOWN.

Just press either the ‘UP or ‘DOWN’ button VERY briefly and then WAIT

for the meter reading to change as the reading will lag the button press

by several seconds.

3 REMOVE any shorting jumpers from pins of JP4 & JP5. Recheck

calibration if necessary.

MANUALP/4000_SERVICE_0712 July2012

23

VERIFYING CABINET PERFORMANCE

There are two basic tests that may be carried out to verify cabinet performance.

NB: These tests MUST be carried out with the cabinet EMPTY and at the

specified ambient of +20

o

C.

TEMPORAL PERFORMANCE:

The cabinet should be set to operate at the Contherm specified calibration

conditions.

Temporal performance is tested by placing a suitable (calibrated) test probe in

the centre of the workspace and recording the readings for up to 1 hour AFTER

the cabinet has FULLY STABILISED. The cabinet has fully stabilised when the

average temperature is no longer increasing or decreasing over time.

The result should be within the quoted specification. This result is a function of

the cabinet control system, sensor and airflow.

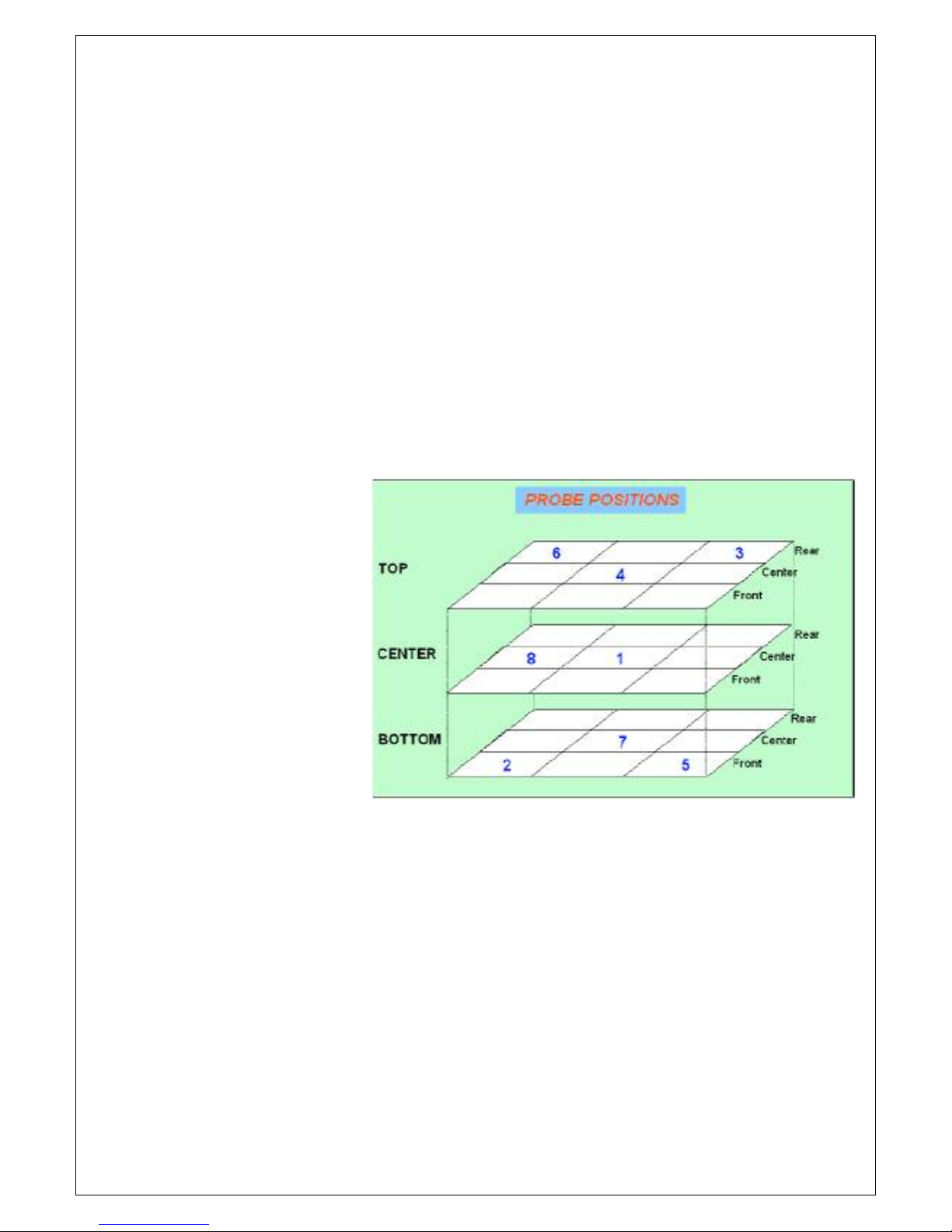

SPATIAL

PERFORMANCE:

The cabinet should be

set to operate at the

Contherm specified

calibration conditions.

Check Spatial Variation

@ 37

o

C

(Refer manual for

specification, 8 points

as per diagram)

Spatial performance is

tested by placing

suitable (calibrated) test

probes (usually

thermocouples) in the eight specified positions and recording the readings for up

to 1 hour AFTER the cabinet has FULLY STABILISED. The cabinet has fully

stabilised when the average temperature is no longer increasing or decreasing

over time.

The sensors must be no closer than 30mm to any wall or roof and must be

above the lowest shelf position by at least 30mm.

The spatial test must be performed with all doors, vents etc CLOSED and the

measuring sensors must be very closely matched at the specified temperature.

Loading...

Loading...