Page 1

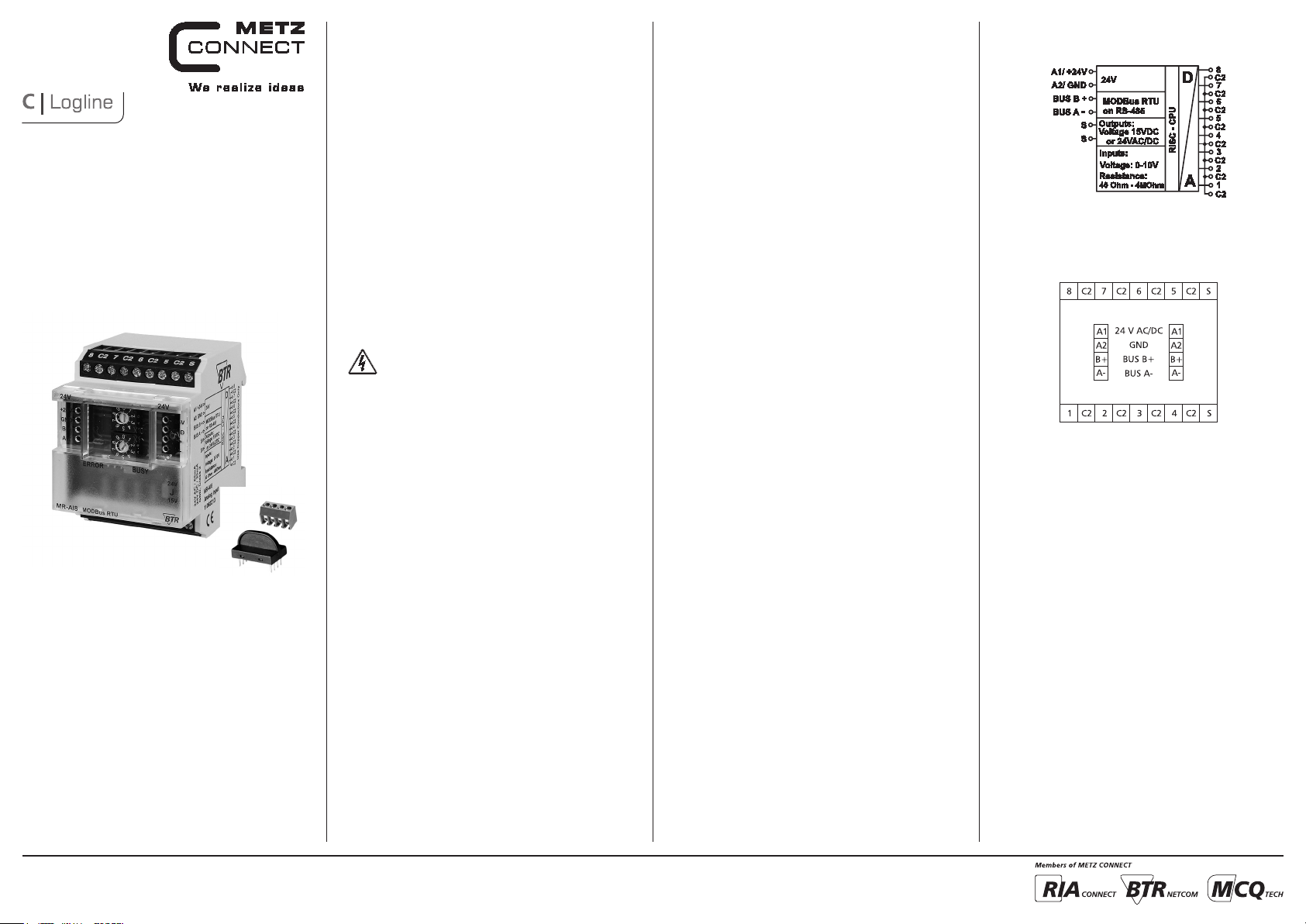

Analog Input Module

MR-AI8

11083213

1. Description

The Modbus module with 8 individually configurable

resistance or voltage inputs is designed for local switching

operations. It is suitable to record resistance or voltage values of

for example passive and active temperature sensors electrical

ventilation or mixing valves, valve positions etc. The inputs are

universally configurable and can be scanned via a Modbus-Master.

Setting of the slave address, bit rate and parity is done with the

two address switches (x1 / x10) on the front. Possible settings

are addresses 00 to 99 and baud rates 1200, 2400, 4800, 9600,

19200, 38400, 57600 und 115200 Bd.

The device does not participate in bus communication if the

address is 00 (reserved for broadcast commands).

2. Declaration of Conformity

The device was tested according to the applicable standards.

Conformity was proofed. The declaration of conformity is

available at the manufacturer BTR NETCOM GmbH.

Notes Regarding Device Description

These instructions include indications for use and mounting of

the device. In case of questions that cannot be answered with

these instructions please consult supplier or manufacturer.

The indicated installation directions or rules are applicable to

the Federal Republic of Germany. If the device is used in other

countries it applies to the equipment installer or the user to

meet the national directions.

Safety Instructions

Keep the applicable directions for industrial safety and prevention of accidents as well as the VDE rules.

Technicians and/or installers are informed that they have to

electrically discharge themselves as prescribed before installation or maintenance of the devices.

Only qualified personnel shall do mounting and installation

work with the devices, se e section “qualified personnel”.

The information of these instruc tions have to be read and understood by every person using this device.

7170/899289

Symbols

Warning of dangerous electrical voltage

Dange r

means that non- obser vance may cause risk of life,

grievous bodily harm or he avy material damage.

Qualified Personnel

Qualified personnel in the sense of these instructions are

persons who are well versed in the use and installation of such

devices and whose professional qualification meets the requirements of their work.

This includes for example:

• Qualification to conne ct the device according to the VDE

specifications and the local regulations and a qualific ation to

put this device into operation, to power it down or to activate

it by respecting the internal directions.

• Knowledge of safety rules.

• Knowledge about application and use of the device within the

equipment system etc.

Modbus Interface

Protocoll Modbus RTU

Transmission rate 1200 ... 115200 Bd

(factory set ting 19200 Bd Even)

Cabling RS485 two wire bus with voltage

equalizing cable in bus / line

topology

Supply

Operating volt age range 20 ... 28 V AC/DC (SELV)

Current consumption 65 mA (AC) / 25 mA (DC)

Relative duty cycle 100 %

Input

Resistance range 40 W to 4 MW

Voltage input 0 ... 10 V DC

Resolution 1 mV

Error

Voltage input about ±10 mV

Resistance input < 12 kW = 0,1 % / > 12 kW = 1 %

Housing

Dimensions Wx HxD 2.0 x 2.8 x 2.6 in. (50 x 70 x 65 mm)

Weight 104 g

Mounting position any

Mounting standard rail TH35 per IEC 60715

Mounting in series the maximum quantit y of modules

without space connected in line is limited to 15 or to

a maximum power consumption of

2 Amps (AC or DC) per conne ction to

the power supply.

For any similar block of additional

modules a separate connection to the

power supply is mandatory.

Material

Housing Polyamide 6.6 V0

Terminal blocks Polyamide 6.6 V0

Cover plate Polycarbonate

Type of protection

(IEC 60529)

Housing IP40

Terminal blocks IP20

Terminal blocks

Supply and bus

4 pole ter minal block max. AWG 16 (1,5 mm²) solid wire

max. AWG 18 (1,0 mm²) stranded wire

Wire diameter min. 0.3 mm up to max. 1.4 mm

(terminal block and jumper plug are

included to each packing unit)

Module connection

Input/Output max. AWG 12 (4.0 mm²) solid wire

max. AWG 14 (2.5 mm²) stranded wire

Wire diameter min. 0.3 mm up to max 2.7 mm

Temperature range

Operation -5 °C ... +55 °C

Storage -20 °C ... +70 °C

Protective circuitr y polarity reversal protection of

operating voltage

polarity reversal protection of supply

and bus

Display

Operating and bus activity green LED

Error indication red LED

4. Wiring Diagram3. Technical Data

5. Connection Diagram

METZ CONNECT | Im Tal 2 | 78176 Blumberg | Germany | Phone +49 7702 533-0 | Fax +49 7702 533-433

Distributed by RIA CONNECT GmbH and BTR NETCOM GmbH

Mounting instruction see www.metz-connect.com

Page 2

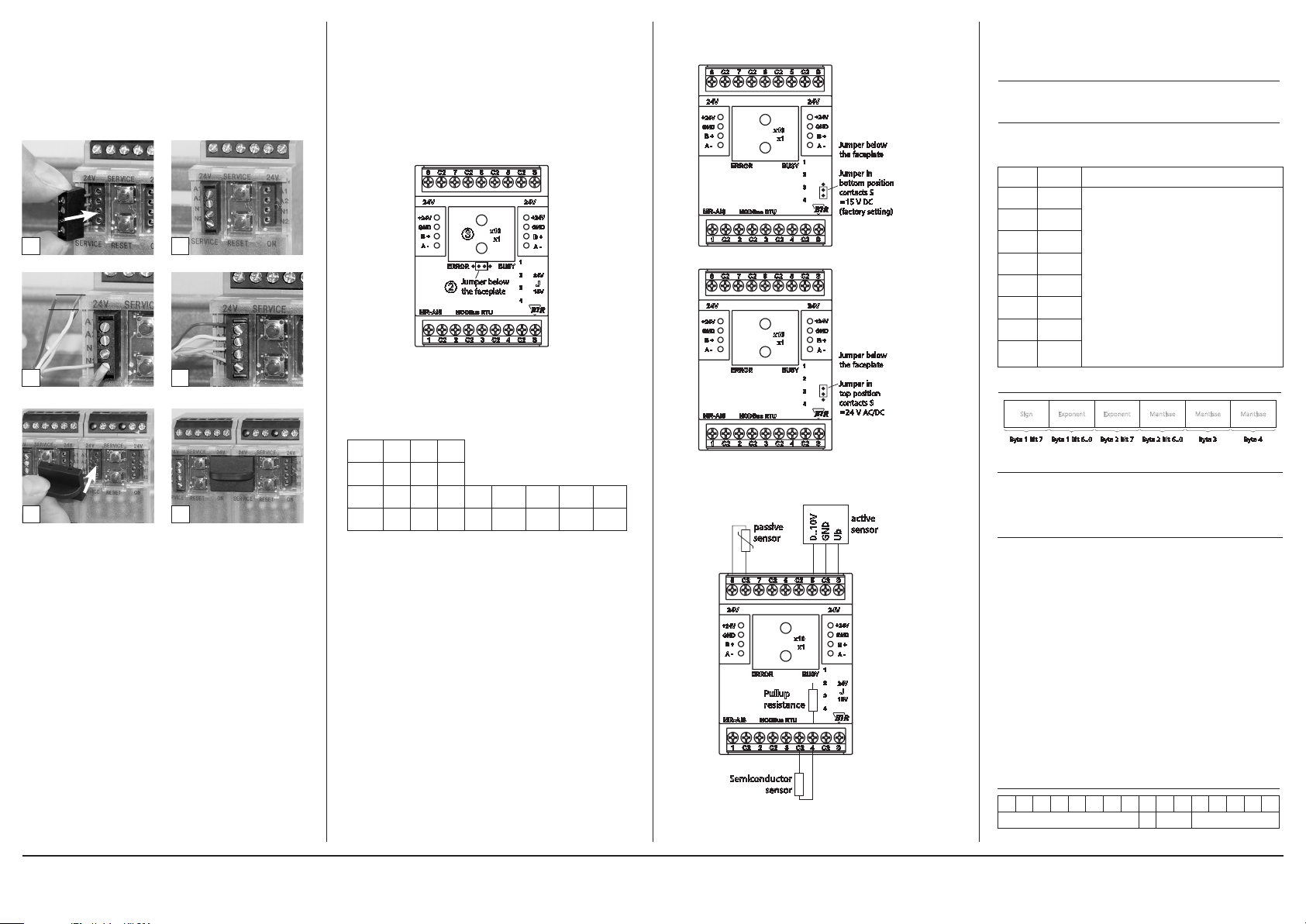

6. Mounting

Power down the equipment

Mount the module on standard rail (TH35 per IEC 60715 in

junction boxes and/or on distribution panels).

Installation

Electric ins tallat ion and device te rminat ion shal l be done by

qualified persons only, by respecting all applicable

specifications and regulations.

Plug in th e terminal bloc k for bus co nnection

21

Conne ct the ca ble for bus supply

5 mm

43

Mounting in series

65

The module can be aligned w ithout interspace. Use the jumper

plug to connect bus and supply voltage when the modules are

mounted in series.

The max imum quantity o f modules conne cted in l ine is lim ited to 15 or to a ma ximum power consumption of 2 Amps

(AC or DC ) per connecti on to the power supply. For any

simila r block of additi onal mod ules a se parate co nnection

to the power suppl y is manda tory.

7. Bit rate and Parity setting

The bit rate and parity can be set in the programming mode

when ajumper is plugged behind the front cover of the module.

This jumper is removed in normal mode. A connection to the

bus is not require d during bit rate setting.

The bit rate of the modules can be set in the following way:

1. remove the front cover of the module;

2. plug a jumper to the two middle pins of the 4 pole header

between the red and green LED ( Á);

3. set the desired parity and bit rate with the address s witches

(Â) in accordance to the chart below.

7

C2C2C2

24V 24V

+24V

GND

B+

A -

ERROR

MODBus RTU

MR-AI8

182

C2

4. switch on the supply voltage of the module; it is now permanently saving the bit rate in an EEPROM;

5. switch off the supply voltage of the module;

6. remove the jumper from the header and place the front

cover.

Switch

1 2 3

x10

C26

x10

x1

Jumper below

the faceplate

3C2

BUSY

5

S

+24V

GND

B+

A -

1

2

24V

J

3

15V

4

4

C2C2S

Parity even odd none

Switch

1 2 3 4 5 6 7 8

x1

Bitrate

1200 2400 4800 9600 19200 38400 57600 115200

(Bit/s)

If the settings differ from the settings specified in the chart the

factory setting applies.

Factor y setting: 19200 Bd Even

8. Jumper Positions for Voltage feeding of Active Sensors

7

C2C2C2

24V 24V

+24V

GND

B+

A -

ERROR

MODBus RTU

MR-AI8

182

C2

7

C2C2C2

24V 24V

+24V

GND

B+

A -

ERROR

MODBus RTU

MR-AI8

182

C2

5

S

C26

+24V

GND

x10

B+

x1

BUSY

4

3C2

5

C26

x10

x1

BUSY

4

3C2

1

2

3

4

C2C2S

1

2

3

4

C2C2S

+24V

GND

A -

S

B+

A -

Jumper below

the faceplate

Jumper in

bottom position

contacts S

=15VDC

(factory setting)

Jumper below

the faceplate

Jumper in

top position

contacts S

=24VAC/DC

9. Connection examples

active

passive

sensor

7

C2C2C2

24V 24V

+24V

GND

B+

A -

ERROR

Pullup

resistance

MODBus RTU

MR-AI8

182

C2

Semiconductor

sensor

D

sensor

Ub

0..10V

GN

5

S

C26

+24V

GND

x10

B+

x1

A -

1

BUSY

2

24V

J

3

15V

4

4

C2C2S

3C2

10. Software Description

10.1 I/O Commands

„04 (0x04) Read Input Registers“

Request:

Valid Starting Address 0 .. 15

Valid Quantity of Registers 1 .. 16 (1 to 8 inputs)

Response:

Byte Count 2 x Quantity o. R.

Registers Values Quantity o. R x 2 Bytes

Input

Register

Information

1 0-1

2 2-3

3 4-5

4 6-7

5 8-9

6 10-11

7 12-13

8 14-15

Figure 1

Sign

Byte 1 Bit 7 Byte 1 Bit 6..0 Byte 2 Bit 7 Byte 2 Bit 6..0 Byte 3 Byte 4

Configuration Registers

Input circuit and measuring range, data type and value unit and

the sensor characteristic for usual temperature sensors are set for

the 8 inputs with the 8 configuration registers.

Register contents is stored in an EEPROM.

Modbus functions:

“03 (0x03) Read Holding Registers” (max. 20 at once)

“06 (0x06) Write Single Register”

“16 (0x10) Write Multiple Registers” (max. 20 at once)

Holding Register 0-15 Offset Register is added to the measured

value in 2 succeeding registers,

(Input 1 = Register 0 - 1)

Float in both or Signed Integer 16 in the

first one, same as for measured value

Holding Register 16-23 Configuration register (EEPROM)

used to set measuring range,

data type of the measure d value

(Float / Integer 16),

unit of the measured value and the

sensor characteristic

(Input 1 = Register 16)

Holding Register 24-63 Register for interpolation charts

(EEPROM),

alternately temperature and resistance,

Float in two succeeding registers

Configuration Register for voltage or resistance measurement:

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Values are supplied in 2 registers (4 Bytes).

Data type in registers can be configured

(see Registers 16 to 23):

Float value needs 2 registers (fig. 1)

signed int value is in 1st register

signed int 0 fills 2nd register

Value remains 0 until a measurement takes place

Data types composed from 2 registers start at an even

address

Exponent Exponent Mantisse Mantisse Mantisse

0 0 range number

METZ CONNECT | Im Tal 2 | 78176 Blumberg | Germany | Phone +49 7702 533-0 | Fax +49 7702 533-433

Distributed by RIA CONNECT GmbH and BTR NETCOM GmbH

Mounting instruction see www.metz-connect.com

Page 3

Continuation Software Description

Bit 15-8: occupied

Bit 7: 0 = voltage or resistance

Bit 6-5: range, defines input circuit or measuring range

0 0 voltage 0to10 V (factory setting)

0 1 voltage 0to10 V, with Pullup 2k at 5 V

1 0 resistance

1 1 occupied

Bit 4-0: number, defines presentation of value

Voltage measurement:

0 value with data type float, unit = 1V

(factory setting)

1 value with data type signed int,

unit = 10.24 V/2

2-31 reserved for other presentations

Resistance measurement:

0 value with data type float,

unit = 1 W

1 value with data type signed int,

unit = 0.1 W (max. 3.2767 kW)

2 value with data type signed int,

unit = 1 W (max. 32.767 kW)

3 value with data type signed int

unit = 10 W (max. 327.67 kW)

4 value with data type signed int

unit = 100 W (max. 3276.7 kW)

5-31 reserved for other presentations

Configuration Register for voltage or resistance measurement:

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 1 number

Bit 15-8: occupied

Bit 7: 1 = temperature with sensor characteristic

Bit 6-1: number, serves to distinguish between sensor and

measuring range

0 Sensor PT100 (-50..150 °C)

1 Sensor PT500 (-50..150 °C)

2 Sensor PT1000 (-50..150 °C)

3 Sensor NI1000-TK5000 (-50..150 °C)

4 Sensor NI1000-TK6180 (-50..150 °C)

5 Sensor BALCO 500 (-50..150 °C)

6 Sensor KTY81-110 (-50..150 °C)

7 Sensor KTY81-210 (-50..150 °C)

8 Sensor NTC-1k8 (-50..150 °C)

9 Sensor NTC-5k (-50..150 °C)

10 Sensor NTC-10k (-50..150 °C)

11 Sensor NTC-20k (-50..150 °C)

12 Sensor LM235 (-40..120 °C)

13-55 reserved for other sensors

56-61 use of interpolations chart see below

62-63 occupied

Bit 0: Data type of value

0 float, unit 1°C

1 signed int, unit 0,1°C

Configuration Register for the use of the Interpolation chart:

This chart can be used to linearize individually de fined sensor

characteristics.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 1 7 range Int

15

= 1V/3200 = 0.3125 mV

Type

Type

Continuation Software Description Continuation Software Description Continuation Software Description

Bit 15-8: occupied

Bit 7: 1 = temperature with sensor characteristic

Bit 6-4: 7 = interpolation chart

Bit 3-2: range, defines input circuit or measuring range

0 0 voltage 0-10V

0 1 voltage 0-10V, Pullup 2k at 5V

1 0 resistance

1 1 occupied

Bit 1: selection of interpolation

0 sensor characteristic is approx. linear

1 sensor characteristic is approx.

exponential (NTC)

Bit 0: data type of value

0 float, unit 1 °C

1 signed int, unit 0.1 °C

Configurations Registers are shown above in a way to display

the meaning of the individual bit. F or the application it is more

convenient if the register conte nts is displayed as a whole, see

the following chart.

Dez Hex Measuring range Data type Unit Maximum

0 0x00 Voltage 0-10 V float 1 V

1 0x01 Voltage 0-10 V signed int 0,3125 mV 10,24 V

32 0x20 Voltage/Pullup float 1 V

33 0x21 Voltage/Pullup signed int 0,3125 mV 10,24 V

64 0x40 Resistance float 1 W

65 0x41 Resistance signed int 0,1 W 3,2767 kW

66 0x42 Resistance signed int 1 W 32,767 kW

67 0x43 Resistance signed int 10 W 327,67 kW

68 0x44 Resistance signed int 100 W 3276,7 kW

Temperature measurement with data type float.

(Value charts for sensors see annex):

128 0x80 Sensor PT100 float 1 °C (-50..150 °C)

130 0x82 Sensor PT500 float 1 °C (-50..150 °C)

132 0x84 Sensor PT1000 float 1 °C (-50..150 °C)

134 0x86 Sensor NI1000-TK5000 float 1 °C (-50..150 °C)

136 0x88 Sensor NI1000-TK6180 float 1 °C (-50..150 °C)

138 0x8A Sensor BALCO 500 float 1 °C (-50..150 °C)

140 0x8C Sensor KTY81-110 float 1 °C (-50..150 °C)

142 0x8E Sensor KTY81-210 float 1 °C (-50..150 °C)

144 0x90 Sensor NTC-1k8 float 1 °C (-50..150 °C)

146 0x92 Sensor NTC-5k float 1 °C (-50..150 °C)

148 0x94 Sensor NTC-10k float 1 °C (-50..150 °C)

150 0x96 Sensor NTC-20k float 1 °C (-50..150 °C)

152 0x98 Sensor LM235 float 1 °C (-40..120 °C)

Voltage or

resistance

Dez Hex Measuring range Data type Unit Maximum

Temperature measurement with data type signed int,

register contents is larger by 1 as above:

129 0x81 Sensor PT100 signed int 0,1 °C (-50..150 °C)

131 0x83 Sensor PT500 signed int 0,1 °C (-50..150 °C)

133 0x85 Sensor PT1000 signed int 0,1 °C (-50..150 °C)

135 0x87 Sensor NI1000-TK5000 signed int 0,1 °C (-50..150 °C)

137 0x89 Sensor NI1000-TK6180 signed int 0,1 °C (-50..150 °C)

139 0x8B Sensor BALCO 500 signed int 0,1 °C (-50..150 °C)

141 0x8D Sensor KTY81-110 signed int 0,1 °C (-50..150 °C)

143 0x8F Sensor KTY81-210 signed int 0,1 °C (-50..150 °C)

145 0x91 Sensor NTC-1k8 signed int 0,1 °C (-50..150 °C)

147 0x93 Sensor NTC-5k signed int 0,1 °C (-50..150 °C)

149 0x95 Sensor NTC-10k signed int 0,1 °C (-50..150 °C)

151 0x97 Sensor NTC-20k signed int 0,1 °C (-50..150 °C)

153 0x99 Sensor LM235 signed int 0,1 °C (-40..120 °C)

Voltage or

resistance

Temperature measurement with interpolation chart:

240 0xF0 Voltage 0-10 V float linear

241 0xF1 Voltage 0-10 V signed int linear

242 0xF2 Voltage 0-10 V float exponentiell

243 0xF3 Voltage 0-10 V signed int exponentiell

244 0xF4 Voltage/Pullup float linear

245 0xF5 Voltage/Pullup signed int linear

246 0xF6 Voltage/Pullup float exponentiell

247 0xF7 Voltage/Pullup signed int exponentiell

248 0xF8 Resistance float linear

249 0xF9 Resistance signed int linear

250 0xFA Resistance float exponentiell

251 0xFB Resistance signed int exponentiell

Register 24- 63 (0x18- 0x3F ) interpolation chart

This chart can be used to convert and linearize values for sensors

without a charac teristic alre ady defined in the device. The chart

contains up to 10 nodes of the sensor characteristic to interpolate between.

Example: conversion from resistance to temperature with temperature sensors.

Register contents is stored in the EEPROM.

The description refers to temperature sensors. Other sensors

than temperature sensors (e.g. humidity) are also possible and it

is also possible to measure voltage instead of resistance.

These proper ties can be set in the configuration register:

Measuring range: voltage

voltage, Pullup 2k at 5V (e.g. for LM235)

resistance (normal case with temperature

sensors)

Interpolation: sensor characteristic is approx. linear

sensor characteristic is approx. exponential

(für NTCs)

Data type of value: float (unit 1 °C)

signed int (unit 0.1 °C)

Modbus-Funktionen

“03 (0x03) Read Holding Registers”

“16 (0x10) Write Multiple Registers”

Node Register Register

The nodes (up to 10) are filled from the beginning of the chart,

it ends with

Temperature = resistance = 0, if less nodes ex ist.

Temperature and resistance values have to be sorted in ascen -

ding or descending order.

Data type in register s: float temperature, resistance

10.2 Bit rate setting with Modbus command

Parity and bit rate have the same value as when se tting them by

address switch.

If Parit y or Bit has the value 0, no setting or storage is carried out.

The register content is stored in the EEPROM.

“06 (0x06) Write Single Register”

Request

Valid Register Address 0x41 ( 65 )

Valid Register Value 2 Bytes

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Bit 15-8: Magic-Number 0x53 = 83 as protection against

accidental writing.

The command will be further analysed only with this

number.

Bit 7-4 1 2 3

Parity even odd none

Bit 3-0 1 2 3 4 5 6 7 8

Bit rate 1200 2400 4800 9600 19200 38400 57600 115200

Response

Echo of Request

Temperature Resistance

1 24-25 26-27

2 28-29 30-31

3 32-33 34-35

4 36-37 38-39

5 40-41 42-43

6 44-45 46-47

7 48-49 50-51

8 52-53 54-55

9 56-57 58-59

10 60-61 62-63

0x53 Parity Bit rate

METZ CONNECT | Im Tal 2 | 78176 Blumberg | Germany | Phone +49 7702 533-0 | Fax +49 7702 533-433

Distributed by RIA CONNECT GmbH and BTR NETCOM GmbH

Mounting instruction see www.metz-connect.com

Page 4

Continuation Software Description

Example for a frame:

Slave address 0x12 Setting of rotary switch (18)

Function 0x06 Write Single Register

Register address Hi 0x00

Register address Lo 0x41 Bit rate and parity (65)

Register contents Hi 0x53 Magic-Number

Register contents Lo 0x15 Parity Even, 19200 Baud

All devices can be switched simultaneously with a Broadcast command (Slave address 0x00) However, it is advised not to do so as

this can c ause problems:

- Devices from other manufacturers may have under this

address a register for a different purpose that will then be

operated in the wrong way.

- There is no feedback from the individual devices.

Consequently the control cannot immediately recognize if

the command was correctly received.

It is safe r to addre ss and switch each device individually.

The device will then answer with the old settings of parity and

bit rate. Switching will take place only afterwards. However, the

answer can get lost if the bus is disturbed.

When all devices are switched; it is advised to check communication. Any function of the device providing a feedback is suit able.

If a single function is to be used being independent from the

process periphery then the function „Diagnostic“ sub-function

„Return Quer y Data“ is suitable, it returns the transferred data.

If bit rate and parity setting of a device are unknown it is possible

to address the device successively with all combinations of bit

rate and parity until the device answers. Try the most likely

combinations first. Try the lower bit rates last as they take longer.

10.3 General Commands

“08 (0x08) Diagnostics”

Subfunction “0 ( 0 x0000) Return Quer y Data”

Data Field Any

Response: Echo of Request

Subfunction “1 (0x0001) Restart Communication Option”

Data Field 0x0000 or 0xFF00

Response: Echo of Request

Action: Clears all Error Counters, Restarts node

Subfunction “4 (0x0004) Force Listen Only Mode”

Data Field 0x0000

No Response

Action: No response until Node Reset or Function

Code 08 Subcode 01

Subfunction “10 ( 0x000A) Clear Counters”

Data Field 0x0000

Response: Echo of Request

Action: Clears all Error Counters

Subfunction “11 ( 0x000B) Return Bus Message Count”

Data Field 0x0000

Response: Quantity of messages that the remote device has

detected on the communications system since its last restart,

clear counters operation, or power–up.

Subfunction “12 ( 0x000C) Return Bus Communication Error

Count”

Data Field 0x0000

Response: Quantity of errors encountered by the remote

device since its last restart, clear counters operation,

or power–up. (CRC, Length <3, Parity, Frame)

Continuation Software Description

Subfunction “13 ( 0x000D) Re turn Bus Exception Error Count”

Data Field 0x0000

Response: Quantity of MODBUS exception responses returned

by the remote device since its last restart, clear counters

operation, or power–up.

Subfunction “14 (0x000E) Return Slave Message Count”

Data Field 0x0000

Response: quantity of messages addressed to the remote

device, or broadcast, that the remote device has processed

since its last restart, clear counters operation, or power–up.

Subfunction “15 (0x000F) Return Slave No Response Count”

Data Field 0x0000

Response: Quantity of messages addressed to the remote

device for which it has returned no response (neither a normal

response nor an exception response), since its last restart, clear

counters operation, or power–up.

“43 /14 (0x2B / 0x0E) Read Device Identification”

Request

Read Device ID code: 0x01

Object ID 0x00

Response

Device ID code 0x01

Conformity level 0x01

More follows 0x00

Next object ID 0x00

Number of objects 0x03

Object ID 0x00

Object Length 0x03

Object Value “BTR”

Object ID 0x01

Object Length 0x06

Object Value “MR-AI8”

Object ID 0x02

Object Length 0x04

Object Value “V1.0”

METZ CONNECT | Im Tal 2 | 78176 Blumberg | Germany | Phone +49 7702 533-0 | Fax +49 7702 533-433

Distributed by RIA CONNECT GmbH and BTR NETCOM GmbH

Mounting instruction see www.metz-connect.com

Loading...

Loading...