Page 1

EISC Series

Ethernet Configurable Switch Hubs

User Manual

# TD021000-0MB

Page 2

Trademarks

Contemporary Controls and CTRLink are registered trademarks of Contemporary Control Systems, Inc.

Other product names may be trademarks or registered trademarks of their respective companies.

Copyright

© Copyright 2003, by Contemporary Control Systems, Inc. All rights reserved. No part of this publication

may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language

or computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical,

manual, or otherwise, without the prior written permission of:

Contemporary Control Systems, Inc. Tel: +1-630-963-7070

2431 Curtiss Street Fax: +1-630-963-0109

Downers Grove, Illinois 60515 USA E-mail: info@ccontrols.com

WWW: http://www.ccontrols.com

Contemporary Controls Ltd Tel: +44 (0)24 7641 3786

Sovereign Court Two, UWSP Fax: +44 (0)24 7641 3923

Sir William Lyons Road E-mail: info@ccontrols.co.uk

Coventry CV4 7EZ UK WWW: http://www.ccontrols.eu

Contemporary Controls GmbH Tel: +49 (0)341 520359 0

Fuggerstraße 1 B Fax: +49 (0)341 520359 16

04158 Leipzig Germany E-mail: info@ccontrols.de

WWW: http://www.ccontrols.eu

Disclaimer

Contemporary Control Systems, Inc. reserves the right to make changes in the specifications of the

product described within this manual at any time without notice and without obligation of Contemporary

Control Systems, Inc. to notify any person of such revision or change.

WARNING — This is a Class A product as defined in EN55022.

In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

TD021000-0MB

2

Page 3

1

Table of Contents

1 TABLE OF CONTENTS ..................................................................................................... 3

2 INTRODUCTION................................................................................................................. 5

3 VERSIONS OF THE EISC.................................................................................................. 6

4 SPECIFICATIONS............................................................................................................... 7

4.1 Electrical ......................................................................................................................... 7

4.2 Environmental................................................................................................................. 7

4.3 Functional ....................................................................................................................... 7

4.4 RJ-45 Connector Pin Assignments ................................................................................. 8

4.5 Console Port (EIA-232) Pin Assignments ...................................................................... 8

4.6 Console Port (EIA-232) Communication Parameters..................................................... 8

4.7 Compliance ..................................................................................................................... 9

4.8 Mechanical.................................................................................................................... 10

4.8.1 16-Port Version......................................................................................................... 10

4.8.2 12-Port Version......................................................................................................... 10

5 INSTALLATION ................................................................................................................ 11

5.1 Hardware....................................................................................................................... 11

5.1.1 Mounting................................................................................................................... 11

5.1.2 Connecting to Power................................................................................................. 12

5.1.3 Connecting to the Network ....................................................................................... 14

5.1.4 Connecting to the Configuring Device ..................................................................... 15

5.1.5 Connecting to the Fault Relay................................................................................... 15

5.2 Software ........................................................................................................................ 16

6 PLUG-AND-PLAY OPERATION .................................................................................... 17

6.1 LED Indicators.............................................................................................................. 17

6.2 Switching ...................................................................................................................... 17

6.3 Data Storage.................................................................................................................. 17

6.4 Data Forwarding ........................................................................................................... 17

6.5 Flow Control ................................................................................................................. 17

6.6 Broadcast Storm Control............................................................................................... 17

TD021000-0MB

3

Page 4

7 ADVANCED OPERATION .............................................................................................. 18

7.1 General Considerations................................................................................................. 18

7.2 EISC Configurator ........................................................................................................ 18

7.2.1 Initial Configuration.................................................................................................. 19

7.2.2 Setup Options............................................................................................................ 21

7.2.3 Setting Parameters for Twisted-Pair (RJ-45) Ports................................................... 21

7.2.4 Configuring the Port Monitor ................................................................................... 22

7.2.5 Setting the Fault Relay.............................................................................................. 22

7.2.6 Advanced Features.................................................................................................... 23

7.2.7 QoS Function ............................................................................................................ 26

7.2.8 Saving Settings to EEPROM .................................................................................... 28

7.2.9 Saving and Retrieving Configuration Files............................................................... 28

7.2.10 Port Signal Strength .................................................................................................. 29

8 SERVICE............................................................................................................................. 30

8.1 Warranty ....................................................................................................................... 30

8.2 Technical Support ......................................................................................................... 30

8.3 Warranty Repair............................................................................................................ 31

8.4 Non-Warranty Repair.................................................................................................... 31

8.5 Returning Products for Repair ...................................................................................... 31

9 APPENDICES ..................................................................................................................... 32

9.1 Declaration of Conformity............................................................................................ 32

9.1.1 Applied Council Directives: ..................................................................................... 32

9.1.2 Standards to which Conformity is Declared ............................................................. 32

9.1.3 Manufacturer:............................................................................................................ 32

9.1.4 Authorized Representative:....................................................................................... 32

9.1.5 Type of equipment .................................................................................................... 32

9.2 Modbus Operation ........................................................................................................ 33

9.3 Modbus Registers.......................................................................................................... 33

9.3.1 WRITE/READ.......................................................................................................... 33

9.3.2 READ Only............................................................................................................... 36

TD021000-0MB

4

Page 5

2

Introduction

The EISC configurable switch in the CTRLink® family provides capabilities beyond those

found in standard Plug and Play (PnP) switches. Besides conventional features (autonegotiation, 10/100 Mbps data rate, half- or full-duplex operation, flow control), the EISC

has advanced features such as VLAN, trunking, Quality of Service (QoS) and a

programmable fault relay that can be connected to a supervisory system. Individual

port parameters can be configured by a Windows-based workstation. Ports can also be

monitored using the Modbus protocol, making it easy to interface the EISC with

supervisory control equipment. These features and more, make the EISC one of the

most versatile of Industrial Ethernet switches available.

The EISC boasts advanced features typically available only in high-end switches.

VLAN allows the physical network to be configured as multiple virtual local area

networks — limiting broadcast/multicast domains and improving performance.

Trunking allows ports to be associated in groups of four — each group functioning

as a high-speed backbone to another EISC configurable switch.

QoS provides message priority with any of three schemes: port-based priority, IP

packet or Diff/Serv priority (RFC 2474) or IEEE 802.1p priority.

Programmable Fault Relay provides a dry contact to a supervisory system if the

switch senses a condition such as the loss or addition of a link.

Configuration is typically done through a console port connected to a Windows-based

configuration program included with the product. Modbus protocol and register

information are also provided so the switch can be configured or monitored by a

Modbus master device. Port parameters (data rate, duplex, flow control) can be pre-set

via the console port or auto-negotiated. And a unique feature displays a dynamic signal

strength bar graph for each port.

Each port supports the PAUSE function for full-duplex links, and uses the backpressure

scheme for half-duplex segments.

The EISC is powered from wide-range, low-voltage AC or DC sources — and redundant

power connections are available for backup considerations. It comes with the ability for

either DIN-rail or panel mounting. The switch front panel features a power LED, a Fault

Relay LED and bi-color LEDs for the link status, activity, and data rate of each port.

TD021000-0MB

5

Page 6

3 Versions of the EISC

EISC16-100T

EISC12-100T/FC

EISC12-100T/FT

Figure 1 — The EISC Family

TD021000-0MB

6

Page 7

4

Specifications

4.1 Electrical

Input Voltage .............................. 10-36 VDC ................................. 8-24 VAC

Input Power (max)......................10 W........................................... 10 VA

Input Frequency .........................N/A .............................................47-63 Hz

Fault Relay Contacts.................. 24 V, 500 mA (max)

4.2 Environmental

Operating Temperature..................0°C to +60°C

Storage Temperature................ –40°C to +85°C

Humidity ....................................... 10% to 95% ........................Non-Condensing

4.3 Functional

Operating Systems for

EISC Configurator : ................. Windows 98/ME/2K/XP

Aging (typical) ............................300 seconds

DC AC

Connectors : Type Function Attached Wiring

RJ-45, shielded....................... Fieldbus ........................Category 5

DB-9........................................Console......................... Null-Modem Cable

Screw, 2-terminal.................... Fault Relay.................... 16-22 AWG, solid

Screw, 4-terminal.................... Power ............................ 16-22 AWG, solid

LED Indicators : Function Color

Power............................ Green

Link/Activity ................... Green/Yellow

Status............................ Green/Yellow

Flow Control : Half-Duplex Full-Duplex

Backpressure.................................... PAUSE (IEEE 802.3x)

Transceiver Parameters : Twisted-Pair Fiber

Signaling .......................................... 10BASE-T/100BASE-TX.................. 100BASE-FX, 1300 nm

Data Rates ....................................... 10/100 Mbps..................................... 100 Mbps

Port Count ........................................ 16 or 10 ............................................0 or 2

Connectors....................................... RJ-45, shielded................................. SC or ST

Segment length (max)...................... 100 m................................................ 2 km, multimode

15 km, single mode

TD021000-0MB

7

Page 8

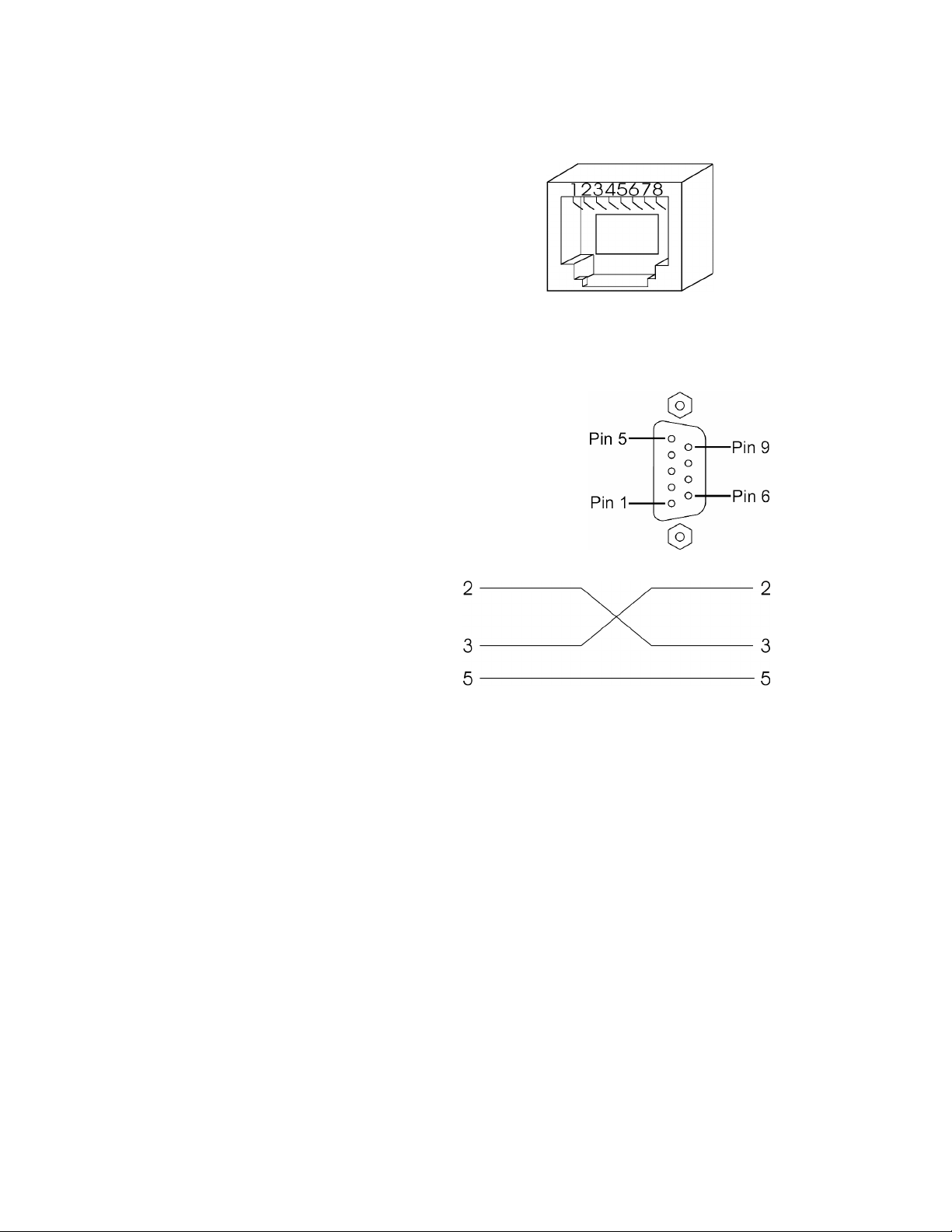

4.4

RJ-45 Connector Pin Assignments

PIN MDI-X Port 16X

1 TD+ RD+

2 TD– RD–

3 RD+ TD+

6 RD– TD–

(All other pins are unused.)

4.5 Console Port (EIA-232) Pin Assignments

PIN Signal Function

2 RXD Receive Data

3 TXD Transmit Data

5 GND Ground

(All other pins are unused.)

Null Modem Cable

4.6 Console Port (EIA-232) Communication Parameters

Baud Rate 9600 bps

Data Bits 8

Parity No Parity

Stop Bit 1

TD021000-0MB

8

Page 9

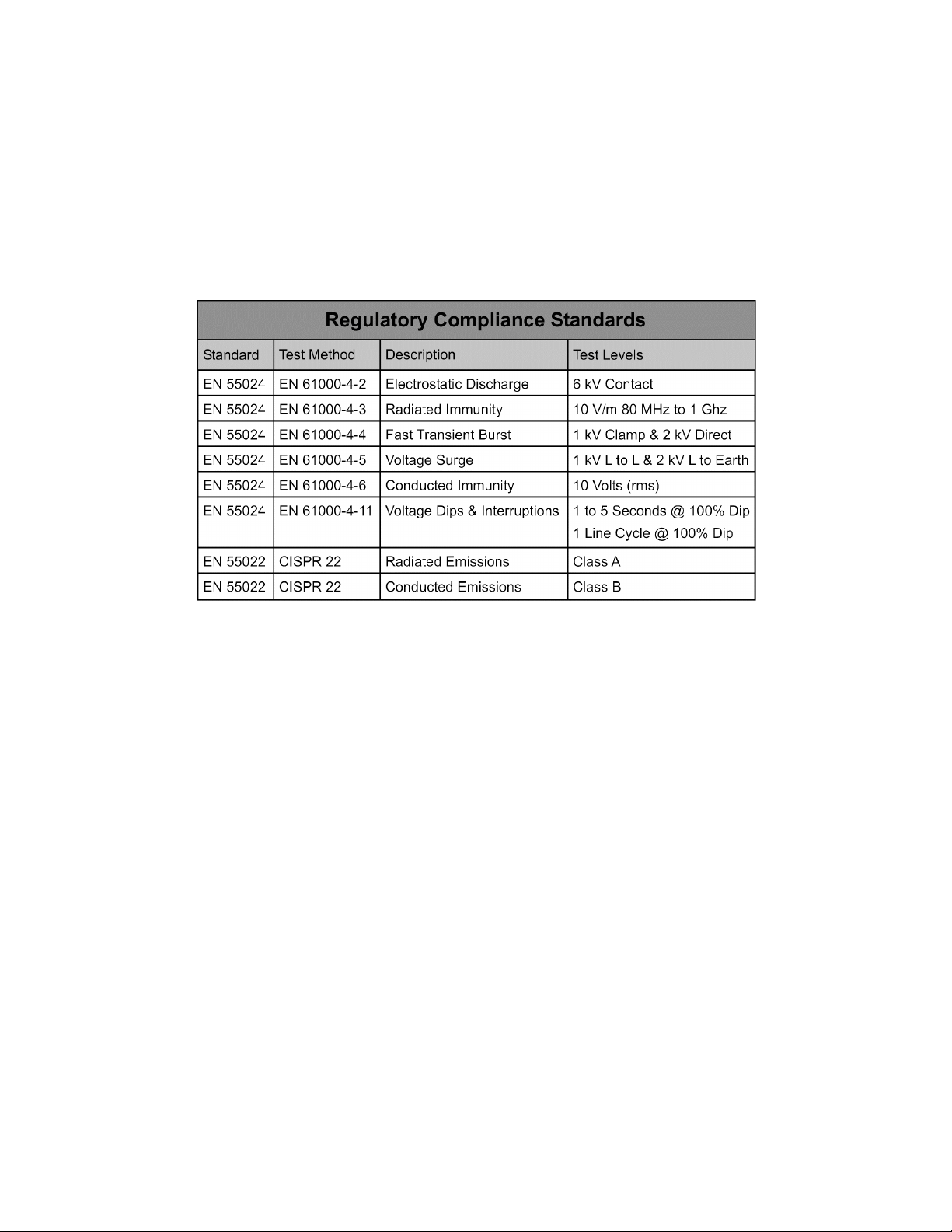

4.7

Compliance

Compatibility Compliant with ANSI/IEEE 802.3

Regulatory Compliance CE Mark

FCC Part 15 Class A

UL 508 Listed, Industrial Control Equipment

TD021000-0MB

9

Page 10

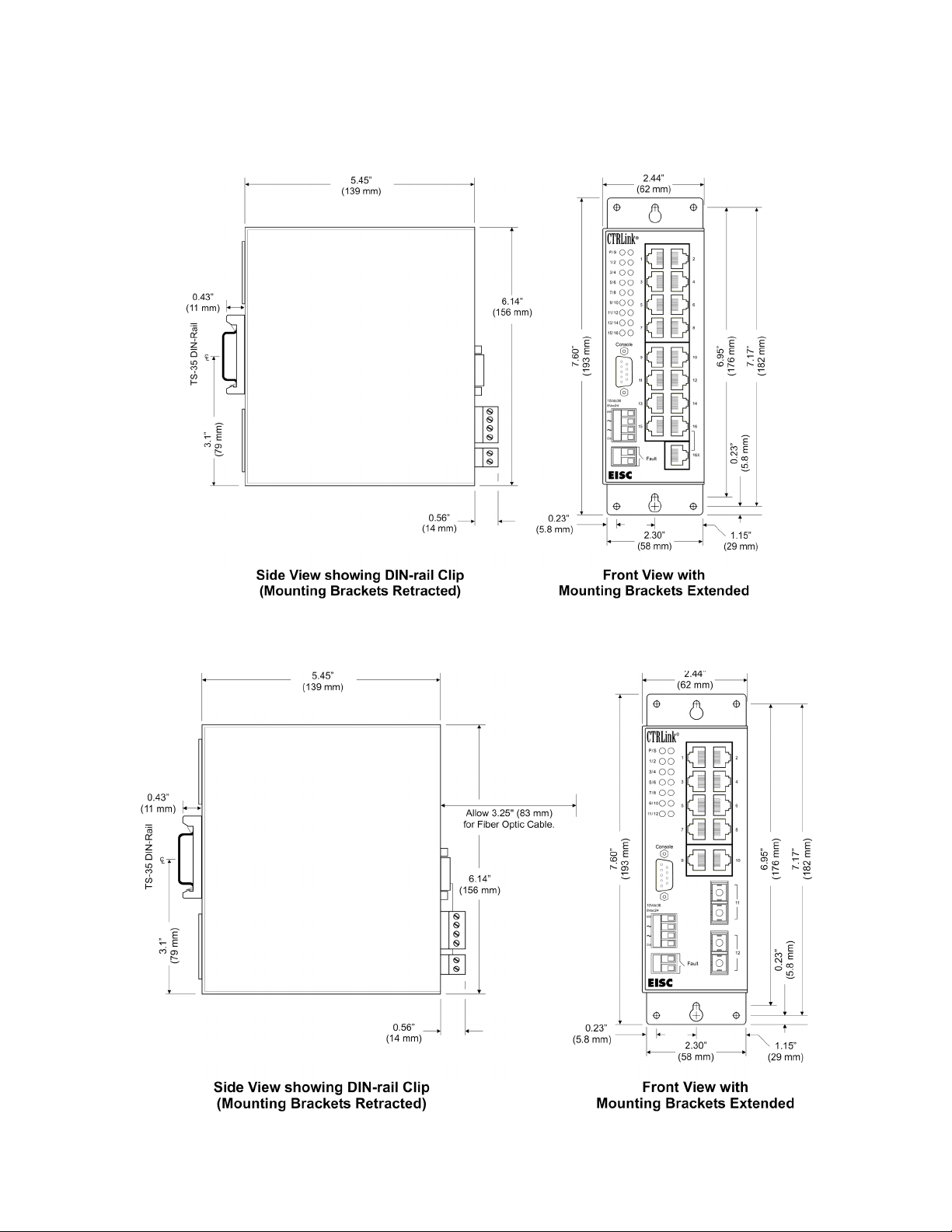

4.8

4.8.1 16-Port Version

Mechanical

4.8.2 12-Port Version Dimensions of EISC12-100T/FC (below) match those of EISC12-100T/FT.

TD021000-0MB

10

Page 11

5

Installation

5.1 Hardware

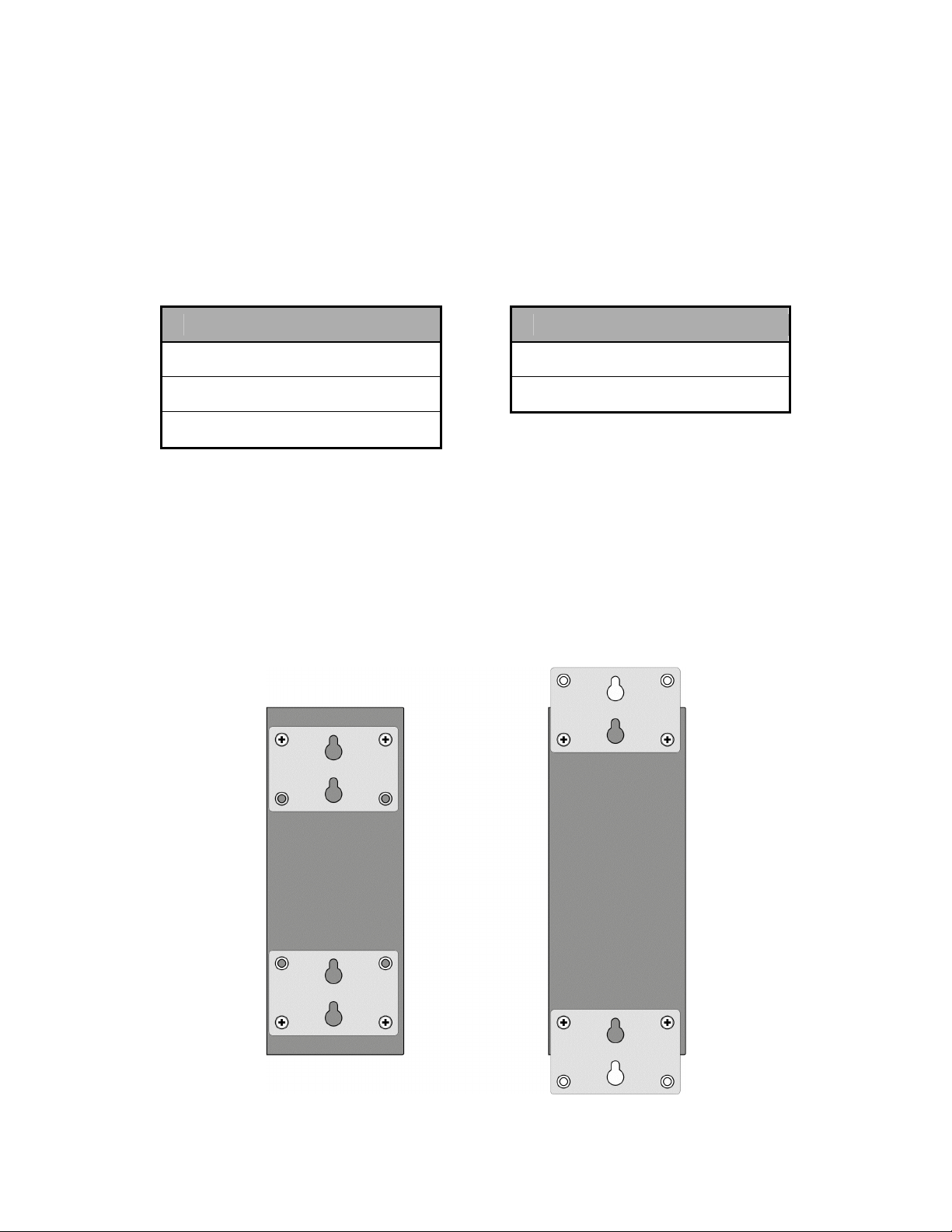

5.1.1 Mounting

The EISC is designed for mounting in an industrial enclosure or wiring closet using

either set of the provided mounting hardware listed below:

TS-35 DIN-rail Mounting

DIN-rail clip

DIN-rail clip support bracket

4-40 screws, pan-head (2)

Panel Mounting

Panel mounting bracket

4-40 screws, flat-head (4)

For quick snap-mounting to 35 mm DIN-rail, a reinforced DIN-rail clip is pre-attached to

the back of the EISC enclosure with two #4-40 pan-head screws. If the clip is removed,

the EISC can be panel-mounted by extending the top and bottom brackets which are

shipped in retracted position. The extended brackets can then anchor the EISC to a

wall or other flat vertical surface with two #8 pan-head screws (not provided). The left

illustration of Figure 2 shows a rear view of the EISC with brackets in retracted position.

The right illustration of Figure 2 shows the brackets extended and secured to the EISC

enclosure with the same screws used in retracted position.

Figure 2 — Using the Panel-Mounting Brackets

TD021000-0MB

11

Page 12

5.1.2

Connecting to Power

The EISC requires power via its four-pin connector. The

keyed plug is removable and is included with the switch.

The applied voltage may be either AC or DC. For power

requirements, consult the specifications. Conductors in

the range of 12–24 AWG are secured in the plug by

screw terminals. The various power options are

explained below.

NOTE: This device is intended for use with Class 2

circuits.

Figure 3 — The Power Connector

5.1.2.1 DC Powered

The EISC accepts a voltage range of 10-36 VDC and draws a value of current

commensurate with 12-watt power consumption. Power conductors should be sized

accordingly. Ground is directly connected to zero volts and the equipment chassis is

isolated from zero volts. The input connections are reverse-polarity protected.

Figure 4 — DC Powered

5.1.2.2 Redundant DC Powered

Redundant diode-isolated DC power inputs are provided so the EISC can operate

despite the loss of primary power. Both sources must provide 12 watts of power.

Figure 5 — Redundant DC Powered

TD021000-0MB

12

Page 13

5.1.2.3

AC Powered

The EISC can be powered by an AC voltage in the range of 8-24 V capable of delivering

12 VA of apparent power. Two auxiliary power supplies are available: The AI-XFMR is

for use with 120 VAC. The AI-XFMR-E is for use with 230 VAC.

Figure 6 — AC Powered

Figure 7 — AC Powered with Grounded Secondary

5.1.2.4 AC Powered with Battery Backup

The EISC can also operate in the AC mode with a backup battery providing power, if the

AC source fails. The EISC does NOT charge the battery, so separate provisions are

required for charging.

Figure 8 — AC Powered with Battery Backup

TD021000-0MB

13

Page 14

5.1.3

Connecting to the Network

When attaching network cables to the EISC, Table 1 should be considered.

Medium Signaling and

Data Rate

Copper 10BASE-T

Minimum Required

Cable

Maximum Segment

Distance

Category 3 UTP 100 m (328 ft)

10 Mbps

Copper 100BASE-TX

Category 5 UTP 100 m (328 ft)

100 Mbps

Fiber 100BASE-FX

100 Mbps

Fiber 100BASE-FX

100 Mbps

1300 nm, multimode

50/125 or 62.5/125 m

2 km (6562 ft)

(Full-Duplex only)

1300 nm, single-mode 15 km (49213 ft)

(Full-Duplex only)

Table 1 — Cabling Considerations

Observe in Table 1 that segment distance is very limited when using copper media —

regardless of the data rate. Although 10BASE-T segments can successfully use

Category 3, 4 or 5 cable, 100BASE-TX segments must use Category 5 or higher cable.

A popular choice for improved distance is fiber—which also gives good electromagnetic

noise immunity and optimum protection from lightning strikes. Considerable distance

can be achieved in multimode—and the greatest distance can be realized with singlemode fiber.

Note: The EISC allows fiber operation in full-duplex mode only.

The EISC switch supports RJ-45 field connectors. All are wired MDI-X — allowing DTE

equipment to connect via straight-through cables — except Port 16X, which is wired

MDI to permit the cascading of switches without the need of a crossover cable.

Note: Port 16 and Port 16X may NOT be used at the same time.

TD021000-0MB

14

Page 15

5.1.4

Connecting to the Configuring Device

If advanced operation is to be implemented, the Console port

must be connected via a null-modem cable to a machine that is

capable of configuring or monitoring the EISC.

5.1.5 Connecting to the Fault Relay

In advanced operation, the Fault Relay is available for use. To

monitor the Fault Relay, connect a supervisory machine to the

EISC via its two Fault Relay terminals.

Figure 9 — The

Console Port &

Fault Relay

Connector

TD021000-0MB

15

Page 16

5.2

The provided CD-ROM contains :

The software installation procedure is discussed in the readme.txt file.

Software

• The EISC Configurator Windows application and set up utility

• This User Manual

• An Ethernet Glossary

• Additional information of interest

TD021000-0MB

16

Page 17

6 Plug-and-Play Operation

6.1 LED Indicators

(All LEDs are tested each time the EISC is powered up.)

P Power

This LED glows green when power is

supplied to the EISC.

S Fault Relay Status

This LED glows green by default, but has no

function in Plug-and-Play mode.

#s Link/Activity

Each port has one of these LEDs. If a link is

established, it glows green for 100 Mbps

operation or yellow for 10 Mbps operation. It

flashes as data transfer occurs. Even LEDs

are on the right; odd LEDs are on the left.

Figure 10 — LEDs

Figure 6 shows how Ports 3 and 4 (for

example) are numbered.

6.2 Switching

The EISC uses an 8K-address look-up table augmented with 128 entries of Content

Addressable Memory to eliminate hash-collision problems. An address-hashing

algorithm is used to update the table. Addresses are aged in about 300 seconds.

Illegal frames that are always discarded include bad CRC packets, runt packets (less

than 64 bytes) and oversized packets (greater than 1536 bytes).

6.3 Data Storage

Data storage buffer for Ethernet packets consists of 512 kB.

6.4 Data Forwarding

An entire Ethernet packet must be received before forwarding occurs. The EISC wire

speed forwarding rate (non-blocking) is 148,800 packets per second at 100 Mbps and

includes a special design to resolve head-of-line-blocking problems.

6.5 Flow Control

Each twisted-pair port automatically negotiates flow control and half- or full-duplex

operation. In full-duplex mode, the IEEE 802.3x PAUSE function is supported. In halfduplex mode, the backpressure method is used. To prevent the connected repeater

from being partitioned due to excessive collisions, backpressure allows the forwarding

of one packet after 48 collisions.

6.6 Broadcast Storm Control

Using a storm-control counter, each port will pass 64 continuous broadcast packets

before dropping extra ones. The counter will reset every 800 ms or after receiving a

non-broadcast packet.

TD021000-0MB

17

Page 18

7

Advanced Operation

7.1 General Considerations

Configuration is accomplished while the EISC is connected to a suitable device — either

a computer running the provided EISC Configurator Windows application or a Modbuscapable user device. For monitoring and configuring the EISC with Modbus, refer to

Section 9.2.

7.2 EISC Configurator

When first launched, the EISC Configurator appears as in Figure 11 with no parameters

configured and Setup and Signal Strength menus not available (dimmed). Configuring

the switch is discussed on the following pages. The portions of Figure 11 outlined in red

will be unavailable (dimmed) for models EISC12-100T/FC and EISC12-100T/FT.

Figure 11 — The EISC Configurator

TD021000-0MB

18

Page 19

7.2.1

Initial Configuration

With a null-modem cable connecting the EISC to a suitable computer, launch the EISC

Configurator, select a COM port and then click the “Connect” button. If the EISC

Configurator cannot connect to the EISC, the error message of Figure 12 may appear.

If this should happen, check that a proper null-modem cable is used for the connection

and that suitable power is applied to the EISC. If the error in Figure 13 appears, a new

COM port must be chosen.

Figure 12 — Error Connecting to EISC Figure 13 — COMPORT Error

Once the Configurator has connected to the EISC, the display of Figure 14 should

appear — with the Setup and Signal Strength menus now available. The File menu

will remain dimmed so long as the EISC is in communication with the EISC Configurator.

The portions of Figure 14 shown outlined in red will be unavailable (dimmed) for models

EISC12-100T/FC and EISC12-100T/FT.

TD021000-0MB

19

Page 20

y

Link condition is

indicated by color:

green = active

(100 Mbps)

yellow = active

(10 Mbps)

Used to connect

to console port

Displays

configuration

of each port

If port monitoring is

enabled, a port fault

condition will be

displayed until it is

cleared by the

“Clear Faults” button.

Port Monitoring

can be disabled.

Displays

state of

Fault

Rela

Fault Relay

status is

indicated

by color:

green = okay

yellow = fault.

If not dim,

Trunk Group

is enabled.

LED will glow

if trunk is

intact.

Active only

if relay is

configured

for manual

reset.

Clears all

fault

indicators

Figure 14 — EISC Ready for Configuration

TD021000-0MB

20

Page 21

7.2.2

Setup Options

The Setup pull-down menu offers the options

shown in Figure 15:

Set the Individual Port Behaviors

Define How the Fault Relay Responds

Set Trunking, VLAN and Flow Control

Set the QoS Options

Lock in Your Settings

Restore All Default Settings

Set the Modbus Slave Address

Figure 15 — Setup Options

The first order of business is to configure the port parameters.

7.2.3 Setting Parameters for Twisted-Pair (RJ-45) Ports

When the “Port Parameters” option is chosen, the display shown in Figure 16 appears.

By default, each RJ45 port is set to auto-negotiate with full-duplex flow control. The

portion of Figure 16 outlined in red will be dimmed for models EISC12-100T/FC and

EISC12-100T/FT. Fiber ports are permanently set to 100 Mbps and full-duplex.

Figure 16 — Port Parameters

Each RJ-45 port has a pull-down menu so the port can be set

with any of the parameters shown in Figure 17. If either Half

Duplex option is chosen, the Full Duplex Flow Control check box

will be dimmed. In this case, half-duplex flow control will be set

by the Backpressure Flow Control option under Advanced

Features. Otherwise, full-duplex flow control may be engaged or

disengaged for each RJ-45 port on an individual basis.

TD021000-0MB

21

Figure 17 —

RJ45 Port Options

Page 22

7.2.4

Configuring the Port Monitor

Figure 18 displays the features of the Port Monitor which can watch each port for a fault

condition specific to that port. The portion of Figure 18 shown outlined in red will be

unavailable (dimmed) for models EISC12-100T/FC and EISC12-100T/FT.

Figure 18 — The Port Monitor

Each port can be monitored for one of three options shown in

Figure 19. The default setting is for the Port Monitor to “Ignore”

the situation of a given port. If the user chooses the “No Link”

option, the monitor will report a fault if proper link pulses are not

received by the given port. Selecting the “Link Present” option

provides a means for alerting the network administrator if an

unauthorized link has been established.

Figure 19 —

Port Monitor Options

7.2.5 Setting the Fault Relay

At the bottom of the Port Monitor window shown in Figure 18 there are four Fault Relay

settings: “Port Monitoring” must be enabled for the relay to function. The user may

choose for the relay to either “make” or “break” on fault. Following power up, the relay

action can be delayed for up to 999 seconds. Finally, the user can elect to reset the

relay manually or have it reset automatically once the fault clears.

For convenience, Port Monitoring can also be controlled from the bottom of the main

Configurator panel where the relay state is reported and where faults can be cleared

and the relay manually reset (if enabled).

TD021000-0MB

22

Page 23

7.2.6

7.2.6.1 Port Trunking

Advanced Features

Port Trunking allows four ports to be grouped together with the resulting group behaving

as a single logical link. Each trunk is constructed of four fixed physical ports — with one

status “LED” for each Trunk Group shown in the main screen of the configuration

program. This “LED” will glow solid green when the trunk is enabled and operating

properly. If the link for any physical port of a trunk fails, then all of the physical ports of

the trunk are treated as defective and the trunk “LED” will no longer glow — thus

indicating a fault condition.

Model EISC16-100T supports four trunks and the trunk selection in its Advanced

Settings display will appear as shown in Figure 20.

Figure 20 — Trunk Options :

EISC16-100T

Figure 21 — Trunk Options :

EISC12-100T/FC & EISC12-100T/FT

Models EISC12-100T/FC and EISC12-100T/FT support two trunks and the trunk options

in their Advanced Settings display will appear as shown in Figure 21.

To keep frames in order, packets with identical source/destination MAC addresses are

sent over the same trunk path — but the reverse path may follow a different link. A

hash algorithm is used to balance the load between links in a trunk.

TD021000-0MB

23

Page 24

7.2.6.2 Port-Based VLAN Function

In the Advanced Settings window, port-based (also called Layer 1) VLAN functionality

can be selected. The number of VLANs available varies with the EISC model.

Model ESIC16-100T supports 14 or 15 VLANs as shown in Figure 22. If 14 VLANs are

chosen, each of Ports 1–14 becomes an independent VLAN. All 14 VLANs can

communicate with Ports 15 and 16 which are termed common ports. If 15 VLANs are

defined, Port 15 ceases to act as a common port and acts, instead, as one of the

independent VLAN ports — and then Ports 1–15 can communicate with the only

remaining common port, Port 16.

Figure 22 — VLAN Options :

EISC16-100T

Figure 23 — VLAN Options

EISC12-100T/FC & EISC12-100T/FT

Figure 23 depicts the VLAN options for models EISC12-100T/FC and EISC12-100T/FT.

As shown, each 12-port model can support 11 VLANS, with Port 12 (one of the fiber

optic ports) performing the function of the common port.

When VLANs are enabled, a frame received from a VLAN port will only be forwarded to

the common port[s]. If the destination port belongs to another VLAN, the frame will be

discarded. If the source of the frame is a common port, then the frame can be

forwarded to any destination. This topology allows networks to share a server or router

via the common port[s], but use different VLANs for security or performance reasons.

Figure 24 — VLANs with a Common Server

TD021000-0MB

24

Page 25

7.2.6.3

7.2.3.6.1 Broadcast Storm Control

Global Features

(applying to ALL ports)

The EISC can enable or disable broadcast storm filtering. When enabled, each port will

drop broadcast packets — those with a Destination MAC ID of FF FF FF FF FF FF — after

receiving 64 continuous broadcast packets. The counter will be reset to 0 every 800 ms

or on receiving a packet with a Destination MAC ID other than FF FF FF FF FF FF.

Figure 25 — Global Features

7.2.3.6.2 Backpressure Flow Control

Backpressure flow control is applied globally — affecting all half-duplex ports or none. If

this feature is disabled, the destination of the incoming packet is checked and, if found

to be congested, the packet is discarded to avoid blocking the packet stream.

TD021000-0MB

25

Page 26

r

7.2.7 QoS Function

The EISC can recognize QoS priority information for incoming frames. With this

information, each affected frame is assigned an appropriate level of priority.

7.2.7.1 Priority Queues.

The EISC has two

queues, one for High-priority frames and one for

Low-priority frames. The queue service rate uses

the Weighted Round Robin algorithm where the

weight ratio of high-to-low priority queuing can

be 2:1, 4:1, 8:1 or "Always high priority first". For

example, if the “4:1” option is selected, the Highpriority queue is serviced 4 times as often as the

Low-priority queue.

7.2.7.2 Auto-off Flow Control.

If a port receives a high-priority frame, flow control

Figure 26 — Round Robin Priority

can be disabled for 1–2 seconds and automatically re-enabled after no priority frames

have been received for a period of 1–2 seconds — when this option is enabled.

The EISC offers three

kinds of QoS priority:

• DiffServ Priority

(IP Packet);

• 802.1p/Q Tagging;

• Port-Based Priority.

Figure 27 — Other QoS Settings

7.2.7.3 Port-Based Priority.

When this is

applied, any frame received via a high priority

port is given high priority. In the EISC, Ports 1

and 2 can be designated high priority ports — o

Ports 1–4 can be assigned — or all of Ports 1–8

can be given high-priority. Whatever port group

is defined, frames received via this group are

buffered into the High-priority queue while

frames from all other ports are relegated to the

Low-priority queue.

Figure 28 — Port Based Prority

TD021000-0MB

26

Page 27

7.2.7.4 ToS/DiffServ Priority.

IP protocol frames include in their network headers

an 8-bit Type of Service (ToS) field for packet prioritization. The first three of these bits

specify 8 levels of priority. The next three bits provide the QoS refinement known as

Differentiated Services (DiffServ or DS) which efficiently manages traffic by categorizing

packets into classes to apply rules for packet delay and discarding. The two remaining

bits of the ToS octet are not yet defined.

Differentiated Services can offer:

• Expedited Forwarding (EF) for low loss, low latency, low jitter and assured bandwidth;

• Assured Forwarding (AF) specifies drop precedence to apply when traffic becomes congested;

• Best Effort, which uses any bandwidth not allocated to EF and AF.

DiffServ allows nodes that are either ignorant of or incapable of DS coding to use the

network with best-effort forwarding by using the default value in the DS field.

If ToS/DiffServ priority is applied, the EISC can read this information (defined in

RFC2474) from the DS field byte. Recommended codepoints are defined in RFC2597

to distinguish traffic by different service classes. The EISC can read this 6-bit value —

in either IPv4 or IPv6 frames — and can then identify the incoming packet priority as

shown in Table 2:

DS Field Value Priority Per Hop Behavior

101110 EF (Expected Forwarding)

001010, 010010, 011010, 100010 AF (Assured Forwarding)

110000, 111000

All others values Low Uncharacterized

High

Network Control

Table 2 — DiffServ Packet Priority

7.2.7.5 802.1p/Q Priority Tagging.

When this EISC option is enabled, VLAN

“tagged” frame priority is recognized. In the data link header, the 802.1p supplement

provides priority coding which was never specified in the 802.1Q VLAN-tagging

standard. Within the VLAN tag space, a 3-bit code is applied so that “tagged” frames

can specify priority. Values 4–7 are assigned to the EISC High-priority queue and

values 0–3 to the Low-priority queue. Switches and other network equipment, can set

these priority bits.

The IEEE suggests a priority scheme, but does not mandate a definition. This method

represents a simple, best-effort Layer 2 prioritization for network adapters and switches

— requiring no bandwidth reservation.

Note: Since the data link header is only read at the switch level, networks which have

routers cannot use this method unless special mapping is implemented.

TD021000-0MB

27

Page 28

A

A

7.2.8 Saving Settings to EEPROM

fter configuring the EISC, the new parameters

will apply, but only so long as the switch has

power. If it is desired to retain settings in EEPROM

for use after a power interruption, choose the

“Save Settings to Non-Volatile Memory” option in

the Setup pull-down menu. The message

shown in Figure 29 confirms the action.

Figure 29 — Save Settings to Switch

7.2.9 Saving and Retrieving Configuration Files

To save the EISC configuration to a file for later use, it

is first necessary to disconnect the EISC from the

EISC Configurator. Once this has been done, choose

the “Save As …” option in the File pull-down menu.

standard “Save As” pop-up window will then allow the

user to create a file name for the saved file. The file

type will be *.eic.

Figure 30 —

Saving or Opening a File

A saved configuration file can be retrieved and

downloaded to the EISC. Once this is done, the

retrieved parameters are implemented automatically.

Retrieve the file by choosing the “Open…” option

under the File pull-down menu. Once the file is

opened, the title bar of the EISC Configurator

window will report the file name and the Setup

pull-down menu will become active. At this point,

the retrieved file can be modified before it is

downloaded to the EISC. Modifiable options are

indicated as active in the Setup pull-down menu.

Figure 31 — Retrieved File

Note: A retrieved file will NOT be retained in the switch EEPROM unless the user chooses

the “Save Settings to Non-Volatile Memory” option in the Setup pull-down menu.

TD021000-0MB

28

Page 29

(

7.2.10

Port Signal Strength

Only for 100 Mbps RJ-45 ports)

The EISC can display the signal strength received at its RJ-45 ports in four graduated

steps. Each port display can thereby indicate the robustness of its communication

channel. Although an attached device could cause problems, the usual concern with

signal strength is the nature of

attached twisted-pair cable.

A port label will only display as

active if it is receiving proper

Link Pulses. If a port is not

attached to a working partner,

its label will be dim and its bar

graph completely gray.

To read the display properly,

the user must have knowledge

of the cabling attached to the

EISC. As more cable length is

used to connect an EISC port

to a remote device, weaker

signal strength will be seen.

As the 100-m cable length limit

is approached, the smallest

signal strength step will be

displayed in red (as with Port

11 in Figure 32). A disparity

between two ports does not

necessarily imply a problem

with the weaker one; the two

ports may simply be attached

to different lengths of cable.

Figure 32 — Twisted-Pair Signal Strength

Example: In Figure 32, a comparison of Port 10 and Port 11 should only be interpreted

as problematic if the segment lengths for Ports 10 and 11 are approximately equal. On

the other hand, if Port 10 has only 15 m of attached cable while Port 11 has 85 m of

attached cable, the example display would be normal.

Note: There is no requirement for all segments of a trunk to be equal in length. Thus,

Ports 9–12 in Figure 32, could be displaying a properly functioning trunk.

Note for 12-port models: The signal strength display applies only to Ports 1

–8. For

Ports 9–12 the bar graph will be completely blank — even if the port is working.

Although there is no signal strength indication for Ports 9–12, the status of these ports

can be determined by simply observing the port label . If the label is not dimmed, the

port is active. But if the label is dimmed, the port is not in use.

TD021000-0MB

29

Page 30

8

Service

8.1 Warranty

Contemporary Controls (CC) warrants its product to the original purchaser for one year

from the product’s shipping date. If a CC product fails to operate in compliance with its

specification during this period, CC will, at its option, repair or replace the product at no

charge. The customer is, however, responsible for shipping the product; CC assumes

no responsibility for the product until it is received. This warranty does not cover repair

of products that have been damaged by abuse, accident, disaster, misuse, or incorrect

installation.

CC’s limited warranty covers products only as delivered. User modification may void the

warranty if the product is damaged during installation of the modifications, in which case

this warranty does not cover repair or replacement.

This warranty in no way warrants suitability of the product for any specific application.

IN NO EVENT WILL CC BE LIABLE FOR ANY DAMAGES INCLUDING LOST

PROFITS, LOST SAVINGS, OR OTHER INCIDENTAL OR CONSEQUENTIAL

DAMAGES ARISING OUT OF THE USE OR INABILITY TO USE THE PRODUCT

EVEN IF CC HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, OR

FOR ANY CLAIM BY ANY PARTY OTHER THAN THE PURCHASER.

THE ABOVE WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED OR STATUTORY, INCLUDING THE WARRANTIES OF

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE OR USE, TITLE AND

NONINFRINGEMENT.

Repair or replacement as provided above shall be the purchaser's sole and exclusive

remedy and CC's exclusive liability for any breach of warranty.

8.2 Technical Support

Technical support is available each weekday (except holidays) during the office hours

listed below. Outside these hours, voice-mail messages can be left in our mailbox after

contacting the main phone number. Requests can also be submitted by fax or by e-mail

to the numbers listed below, but please leave a detailed description of the problem. We

will contact you the next business day by the method requested by the customer. If the

problem cannot be resolved by technical support, the customer will be given an RMA

number in order that the product may be returned to CC for repair.

Support Option Contemporary Controls (USA) Contemporary Controls Ltd (UK)

Office Hours

Voice

Fax

Email

Web Site

8:00 a.m. — 5:00 p.m. Central time 8:00 a.m. — 5:00 p.m. United Kingdom time

+1-630-963-7070 +44 (0)24 7641 3786

+1-630-963-0109 +44 (0)24 7641 3923

techsupport@ccontrols.com support@ccontrols.co.uk

www.ccontrols.com www.ccontrols.co.uk

TD021000-0MB

30

Page 31

8.3

Warranty Repair

Products under warranty that were not subjected to misuse or abuse will be repaired at

no charge to the customer. The customer, however, pays for shipping the product back

to CC while CC pays for the return shipment to the customer. CC normally ships

ground. International shipments may take longer. If the product has been determined to

be misused or abused, CC will provide the customer with a quotation for repair. No

work will be done without customer approval.

8.4 Non-Warranty Repair

CC provides a repair service for all its products. Repair charges are based upon a fixed

fee basis depending upon the complexity of the product. Therefore, Customer Service

can provide a quotation on the repair cost at the time a Returned Material Authorization

(RMA) is requested. Customers pay the cost of shipping the defective product to CC

and will be invoiced for the return shipment to their facility. No repair will be performed

without customer approval. If a product is determined to be unrepairable, the customer

will be asked if the product can be replaced with a refurbished product (assuming one is

available). Under no circumstances will CC replace a defective product without

customer approval. Allow ten working days for repairs.

8.5 Returning Products for Repair

To schedule service for a product, please call CC Customer Service support directly at

+1-630-963-7070 (U.S.) or +44 (0)24 7641 3786 (U.K.). Have the product model and

serial number available, along with a description of the problem. A Customer Service

representative will record the appropriate information and issue, via fax, an RMA

number—a code number by which we track the product while it is being processed.

Once you have received the RMA number, follow the instructions of the Customer

Service support representative and return the product to us, freight prepaid, with the

RMA number clearly marked on the exterior of the package. If possible, reuse the

original shipping containers and packaging. In any event, be sure you follow good ESDcontrol practices when handling the product, and ensure that antistatic bags and

packing materials with adequate padding and shock-absorbing properties are used. CC

is not responsible for any damage incurred from improper packaging. Shipments

should be insured for your protection.

Ship the product, freight prepaid, to the location from which it was purchased:

Contemporary Control Systems, Inc.

2431 Curtiss Street

Downers Grove, IL 60515

U.S.A.

Contemporary Controls Ltd

Sovereign Court Two, UWSP

Sir William Lyons Rd.

Coventry CV4 7EZ

U.K.

TD021000-0MB

31

Page 32

9

Appendices

9.1 Declaration of Conformity

9.1.1 Applied Council Directives:

Electromagnetic Compatibility Directive, 89/336/EEC Council Directive as amended by

Council Directive 92/31/EEC & Council Directive 93/68/EEC

General Product Safety Directive 92/59/EEC

9.1.2 Standards to which Conformity is Declared

EN 55022:1995 CISPR22: 1993, Class A, Limits and Methods of Measurement of Radio

Disturbance Characteristics of Information Technology Equipment

EN 55024:1998, Information Technology Equipment — Immunity Characteristics —

Limits and Methods of Measurement

9.1.3 Manufacturer:

Contemporary Control Systems, Inc.

2431 Curtiss Street

Downers Grove, IL 60515 USA

9.1.4 Authorized Representative:

Contemporary Controls Ltd

Sovereign Court Two, UWSP

Sir William Lyons Road

Coventry CV4 7EZ

UNITED KINGDOM

9.1.5 Type of equipment

— Ethernet configurable switching hub.

For regulatory compliance, refer to Section 4.7

Manufacturer’s Declaration: I, the undersigned, hereby declare that the product

specified above conform to the listed directives and standards.

George M. Thomas, President January 1, 2004

TD021000-0MB

32

Page 33

9.2

Modbus Operation

For Modbus operation, the EIA-232 parameters must be set as follows :

Baud Rate = 9600 bps, Data Bits = 8, Stop Bit = 1, No Parity

9.3 Modbus Registers

9.3.1 WRITE/READ

40001-40016: Port Settings: Auto-negotiation or set speed/duplex per port

Bit 0 – Auto-negotiation (enabled = 1, disabled = 0) – default = 1

Bit 1 – 10Mbps(0) or 100Mbps (1)

Bit 2 – Half duplex (0) or full duplex (1)

Bit 3 – Enable full duplex flow control (enabled = 1, disabled = 0) – default = 1

40001: Port Settings port 1

40002: Port Settings port 2

40003: Port Settings port 3

40004: Port Settings port 4

40005: Port Settings port 5

40006: Port Settings port 6

40007: Port Settings port 7

40008: Port Settings port 8

40009: Port Settings port 9

40010: Port Settings port 10

40011: Port Settings port 11

40012: Port Settings port 12

40013: Port Settings port 13

40014: Port Settings port 14

40015: Port Settings port 15

40016: Port Settings port 16

TD021000-0MB

33

Page 34

[40017-40128: Port Settings port 17 – port 128 reserved]

40129: Reserved for future use

40130: Reserved for future use

40131: Reserved for future use

40132: Relay Setting1

Bit 0: Relay Active State (0- Disengaged, 1-Engaged) default = 0

Bit 1: Relay Reset Method (0 – Self-recovering, 1- Reset by user) default = 0

Bit 2: Monitoring Status (0 – Disabled, 1 – Enabled) default = 1

Bit 3: Clear Faults (1 = Clear)

Bit 4: Reset Relay (1 = Reset)

40133: Relay Activation Time after power up (in secs)

40134: Port monitor setting1 (ports 1-8): Energize relay upon matching condition

00 – Don’t care

01 – Link_Lost

10 – Link_Up

11 – Don’t care

Port8 Port7 Port6 Port5 Port4 Port3 Port2 Port1

Bit 15,14 13,12 11,10 9,8 7,6 5,4 3,2 1,0

40135: Port monitor setting2 (ports 9-16): Energize relay upon matching condition

00 – Don’t care

01 – Link_Lost

10 – Link_Up

11 – Don’t care

Port16 Port15 Port14 Port13 Port12 Port11 Port10 Port9

Bit 15,14 13,12 11,10 9,8 7,6 5,4 3,2 1,0

40136-40149: (reserved for 128 port switch)

TD021000-0MB

34

Page 35

40150: QOS Settings (all disabled by default)

Bit 6: Enable Flow Control Automatic disable

Bit 5: Enable DiffServ Priority QOS

Bit 4-3: Enable Port based Priority QOS

00 – disable(default)

01 – Ports 0&1 high priority

10 – Ports 0-3 high priority

11 – Ports 0-7 high priority

Bit 2-1: Enable Weighted Round Robin Priority

It is the service rate ratio of High-Priority queue to Low-Pri Queue

11 – always high priority queue first(default)

10 – 8:1

01 – 4:1

00 – 2:1

Bit 0: Enable 802.1p VLAN Tag Priority based QOS

40151: Misc. Feature Settings

(all disabled by default, except for backpressure and Broadcast Storm Control)

Bit 7: Enable Backpressure (0=disabled, 1=enabled) – default:enabled

Bit 6: VLAN Type (0 = 14 VLANS, 1 = 15 VLANS)

Bit 5: Enable VLAN

Bits 4-1: Enable Port Trunking and select trunks (0-3)

Bit 4: 1 – Enable Port Trunk 3

Bit 3: 1 – Enable Port Trunk 2

Bit 2: 1 – Enable Port Trunk 1

Bit 1: 1 – Enable Port Trunk 0

Bit 0: Enable Broadcast Storm control – default: enabled.

40152: Modbus Slave Address

Modbus Address of the switch

40153: Offline Mode (1 = Offline & MAC in Reset)

40154: Write EEPROM with current switch settings (1= write)

40155: Write Switch with default settings (1 = write)

TD021000-0MB

35

Page 36

9.3.2

READ Only

41001-41016: Port 1-16 status:

Bit 0: Duplex (0 = half, 1= full)

Bit 1: Speed (0 = 10Mbps, 1 = 100Mbps)

Bit 2: Link (0 = no link, 1=link active)

Bit 3-6: Reserved

Bit 7: 1 = Relay Activation due to fault on this port

41001: Port status port 1

41002: Port status port 2

41003: Port status port 3

41004: Port status port 4

41005: Port status port 5

41006: Port status port 6

41007: Port status port 7

41008: Port status port 8

41009: Port status port 9

41010: Port status port 10

41011: Port status port 11

41012: Port status port 12

41013: Port status port 13

41014: Port status port 14

41015: Port status port 15

41016: Port status port 16

[41017-41128: Port status port 17- port 128 reserved]

41129: Trunk Status:

Bit 0: Trunk 0 status (0 = Disabled, 1 = Enabled)

Bit 1: Trunk 1 status (0 = Disabled, 1 = Enabled)

Bit 2: Trunk 2 status (0 = Disabled, 1 = Enabled)

Bit 3: Trunk 3 status (0 = Disabled, 1 = Enabled)

41130: MISC Status:

Bit 0: Relay Status (0= Relay Active, 1= Relay Inactive)

Active state could be engaged/disengaged, depending on the value set in

register 40132, bit 0.

41134: Firmware Version

TD021000-0MB

36

Loading...

Loading...