Page 1

CANISA

CANbus® Network Interface Module for ISA Bus Computers

INST ALLA TION GUIDE

INTRODUCTION

The CANISA is a Controller Area Network (CAN) adapter for ISA bus

computers. CAN is the data link layer technology used by DeviceNet and

Smart Distributed System. The CANISA supports 8-bit transfers and takes

advantage of the additional interrupts on the expanded bus.

The CANISA incorporates the Philips SJA1000 CAN stand-alone controller

chip which is used widely in both the automotive and general industrial

environments. Besides being backward compatible with the older 82C200,

the SJA1000 has more features than its predecessor. The 82C200 is

restricted to BasicCAN (11-bit identifiers) while the SJA1000 operates in

either BasicCAN or a new mode called PeliCAN™ which supports the CAN

2.0B specification (29-bit identifiers). The SJA1000 maintains extended

frame passivity while in the BasicCAN mode.

The SJA1000 features a 16 MHz clock, a larger receive buffer and better

acceptance-filtering — including the ability to extend the acceptance mask

to the data field. It has the ability to operate at data rates as great as 1 Mbps.

The CANISA incorporates the DeviceNet physical layer with an optically

isolated transceiver providing reverse voltage and short-circuit protection.

Field connectors include the DeviceNet 5-position open style and DB-9 as

defined by CAN in Automation (CiA).

The PeliCAN mode includes:

• Error counters with read/write access

• Programmable error warning limit

• Last error code register

• Error interrupt for each CANbus error

• Arbitration lost interrupt with detailed bit position

• Single-shot transmission (no re-transmission)

• Listen only mode (no acknowledge, no active error flags)

• Hot plugging support (software driven bit rate detection)

• Acceptance filter extension (4-byte code, 4-byte mask)

• Reception of ‘own’ messages (self reception request)

Page 2

SPECIFICATIONS

Power Requirements ISA Bus CANbus

+5 V

80 mA

Environmental

Operating temperature: 0°C to +60°C

Storage temperature: -40°C to +85°C

Data Rates

50 kbps, 100 kbps, 125 kbps, 250 kbps, 500 kbps, 1 Mbps

Dimensions

4.20" x 6.50" (106 mm x 165 mm)

Shipping Weight

1 lb. (.45kg)

I/O Mapping — BasicCAN

The CANISA can occupy any of the following 32-byte blocks of I/O space.

000 020 040 060 080 0A0 0C0 0E0 100 120 140 160 180 1A0 1C0 1E0

200 220 240 260 280 2A0 2C0 2E0 300 320 340 360 380 3A0 3C0 3E0

I/O Mapping — PeliCAN

The CANISA can occupy any of the following 128-byte blocks of I/O space.

+24 V

80 mA

000 080 100 180 200 280 300 380

Interrupt Lines

Supports selection of IRQ3 through IRQ15

Compatibility

Compliant with CAN 2.0A and CAN 2.0B

Regulatory Compliance

CE Mark

CFR 47, Part 15 Class A

TD990520-0IE

2

Page 3

INSTALLATION

HARDWARE: The CANISA can be installed in any ISA computer bus.

With power removed from the computer, remove its cover. Take care when

installing the CANISA because both it and the exposed computer

motherboard are sensitive to electrostatic discharge. To prevent inadvertent

damage, touch the metal chassis of the internal power supply to discharge

yourself, then remove the CANISA from its protective ESD package.

Before proceeding with the installation, configure the jumpers according to

the instructions in the section entitled “Configuring Jumper Settings.”

After the jumpers are properly set, insert the CANISA into any available

ISA bus slot. Once the CANISA is mounted, it can be attached to the

CANbus with either the screw terminals or the DB-9 connector. To

facilitate use of the screw terminals, a mating female connector has been

provided. The CANISA complies to the physical layer specification for

isolated ports, therefore bus power (V+, V-) must be present in order for its

transceiver to function. Hardware installation is completed by replacing the

computer’s cover.

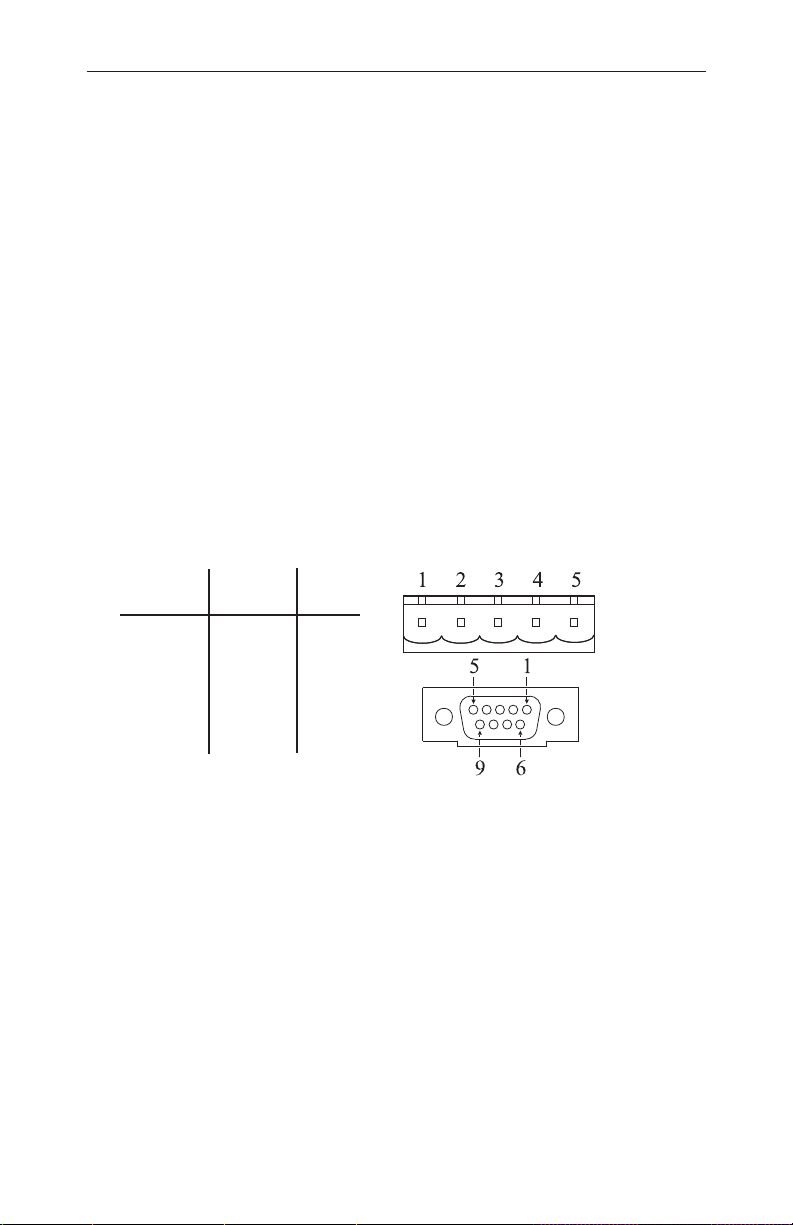

Screw

Function

CAN_L

Drain

CAN_H

Not Used

Terminal DB-9

V –

V +

Connector Pin Assignments

1 3,6

2 2

3 5

4 7

5 9

— 1,4,8

SOFTWARE:

files which allows the operating system to allocate computer resources to the

card. The instructions for installing these files are provided on the disk in

the file named README.TXT.

The CANISA comes with a disk which contains the driver

TD990520-0IE

3

Page 4

CONFIGURING JUMPER SETTINGS

Power Selection

A set of four jumpers, labeled POWER, offers the choice between powering

the CANISA transceiver circuitry from the host computer or from the

CANbus. By default the jumpers are set to INT. To power the transceiver

from the CANbus, move all four jumpers to the EXT setting.

DeviceNet Reverse Voltage Protection

By default, diode D1 protects the CANISA from overvoltage which would

occur if the DeviceNet power connections were accidentally reversed. This

protection results in the CANISA ground being about 700 mV different from

the CAN ground. If desired, the CANISA ground potential can be made

equal to the CAN ground by installing a jumper on JP7.

Termination

If the CANISA is located at the end of a trunk, line-matching impedance is

required. A 121-ohm resistor is supplied for this purpose. If a different

impedance is needed, jumper JP8 should be removed and the alternative

impedance connected to screw terminals CAN_H and CAN_L.

Interrupts

Jumper block JP6 makes available all possible interrupt selections.

Interrupt 5 has been chosen as the default.

I/O Address Map

The CANISA has two modes of operation—BasicCAN and PeliCAN—that

affect how the I/O space is defined. I/O addressing is set with jumper block

JP9 using jumpers S0–S4 and RA. By default, jumper RA (Range) is open

causing the I/O space to be 32 contiguous bytes in size. This setting is used

in BasicCAN, but may also be used in PeliCAN. For full PeliCAN

functionality, jumper RA must be installed, extending the I/O space to 128

contiguous bytes.

The CANISA uses an I/O space within the range 0x000–0x3FF as illustrated

in Tables 1–3. Regardless of the RA setting, jumpers S0–S4 are used to

select the address at which the I/O space begins. The default setting is

0x300. Remember, RA determines only the size of the I/O space: 32 or 128

bytes.

An unused jumper may be left on the board with no effect, by attaching the

jumper to only one of the two pins that constitute a jumper pair.

TD990520-0IE

4

Page 5

BasicCAN Jumper Settings

(� = jumper installed)

Table 1 — 32-byte Addressing for BasicCAN

RA S4 S3 S2 S1 S0 I/O Address

� � � � � 000

� � � � 020

� � � � 040

� � � 060

� � � � 080

� � � 0A0

� � � 0C0

� � 0E0

� � � � 100

� � � 120

� � � 140

� � 160

� � � 180

� � 1A0

� � 1C0

� 1E0

� � � � 200

� � � 220

� � � 240

� � 260

� � � 280

� � 2A0

� � 2C0

� 2E0

� � � 300

� � 320

� � 340

� 360

� � 380

� 3A0

� 3C0

3E0

TD990520-0IE

5

Page 6

PeliCAN Jumper Settings

(� = jumper installed

= don’t care)

X

Table 2 — 32-byte Addressing Table 3 — 128-byte Addressing

RA S4 S3 S2 S1 S0 I/O RA S4 S3 S2 S1 S0 I/O

Address Address

� � � � � 000 � � � �

� � � � 080 � � �

� � � � 100 � � �

� � � 180 � �

� � � � 200 � � �

� � � 280 � �

� � � 300 � �

� � 380 � X 380

X

X

X

X

X

X

X

X

X 000

X 080

X 100

X 180

X 200

X 280

X 300

CAN Operation

CAN is currently described by ISO 11898. In terms of the Open Systems

Interconnection model (OSI), CAN partially defines the services for layer 1

(physical) and layer 2 (data link). Higher-layer protocols such as DeviceNet

and Smart Distributed System define additional services of the seven layer

OSI model. Both of these protocols use CAN circuitry and, therefore,

comply with the data link layer defined by CAN.

Medium access control (MAC) is accomplished through non-destructive bitwise arbitration. If a station attempting transmission fails to confirm that its

data is being accurately propagated, it assumes a higher priority message is

present on the network. Consequently, it halts transmission and reverts to

receiving mode. The highest priority message gets through and lower

priority messages are resent later. In this way network collisions do not

destroy data and eventually all stations gain access to the network.

TD990520-0IE

6

Page 7

NEED MORE HELP INSTALLING THIS PRODUCT?

More information can be found on our web site at www.ccontrols.com. Browse

the Technical Support section of our site for a look at our on-line technical

manuals, downloadable software drivers and utility programs that can test

the product. When contacting us, just ask for technical support.

Warranty

Contemporary Controls (CC) warrants its new product to the original purchaser for two years from the product shipping date. Product returned to CC

for repair is warranted for one year from the date that the repaired product is

shipped back to the purchaser or for the remainder of the original warranty

period, whichever is longer.

If a CC product fails to operate in compliance with its specification during the

warranty period, CC will, at its option, repair or replace the product at no

charge. The customer is, however, responsible for shipping the product; CC

assumes no responsibility for the product until it is received.

CC’s limited warranty covers products only as delivered and does not cover

repair of products that have been damaged by abuse, accident, disaster, misuse, or incorrect installation. User modification may void the warranty if the

product is damaged by the modification, in which case this warranty does not

cover repair or replacement.

This warranty in no way warrants suitability of the product for any specific

application. IN NO EVENT WILL CC BE LIABLE FOR ANY DAMAGES

INCLUDING LOST PROFITS, LOST SAVINGS, OR OTHER INCIDENTAL

OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OR

INABILITY TO USE THE PRODUCT EVEN IF CC HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY

ANY PARTY OTHER THAN THE PURCHASER.

THE ABOVE WARRANTY IS IN LIEU OF ANY AND ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED OR STATUTORY, INCLUDING THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR

PARTICULAR PURPOSE OR USE, TITLE AND NONINFRINGEMENT.

Returning Products for Repair

Return the product to the location from which it was purchased by following

the instructions at the URL below:

www.ccontrols.com/rma.htm

DECLARATION OF CONFORMITY

Information about the regulatory compliance of this product can be found at the

URL below:

www.ccontrols.com/compliance.htm

TD990520-0IE

7

Page 8

[This page was deliberately left blank.]

TD990520-0IE

8

Loading...

Loading...