Page 1

BASR

Versatile Building Automation Appliance

BAS Remote

User Manual

# TD040300-0MF

(for firmware version 3.1.x)

Page 2

Contemporary Control Systems, Inc.

Tel:

+1-630-963-7070

2431 Curtiss Street

Fax:

+1-630-963-0109

Downers Grove, Illinois 60515 USA

E-mail:

info@ccontrols.com

WWW:

http://www.ccontrols.com

Contemporary Controls Ltd

Tel:

+44 (0)24 7641 3786

14 Bow Court

Fax:

+44 (0)24 7641 3923

Fletchworth Gate

E-mail:

info@ccontrols.co.uk

Coventry CV5 6SP UK

WWW:

http://www.ccontrols.co.uk

Contemporary Controls Ltd

Tel:

+44 (0)24 7641 3786

14 Bow Court

Fax:

+44 (0)24 7641 3923

Fletchworth Gate

E-mail:

info@ccontrols.co.uk

Coventry CV5 6SP UK

WWW:

http://www.ccontrols.eu

Contemporary Controls GmbH

Tel:

+49 (0)341 520359 0

Fuggerstraße 1 B

Fax:

+49 (0)341 520359 16

D-04158 Leipzig Deutschland

E-mail:

info@ccontrols.de

WWW:

http://www.ccontrols.eu

WARNING — This is a Class A product as defined in EN55022.

In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

Trademarks

Contemporary Controls and CTRLink are registered trademarks of Contemporary Control Systems, Inc.

BACnet is a registered trademark of the American Society of Heating, Refrigerating and Air-Conditioning

Engineers, Inc. Powered by Sedona Framework is a trademark of Tridium, Inc. Other product names

may be trademarks or registered trademarks of their respective companies.

Copyright

© Copyright 2012, by Contemporary Control Systems, Inc. All rights reserved. No part of this publication

may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language

or computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical,

manual, or otherwise, without the prior written permission of:

Disclaimer

Contemporary Control Systems, Inc. reserves the right to make changes in the specifications of the

product described within this manual at any time without notice and without obligation of Contemporary

Control Systems, Inc. to notify any person of such revision or change.

TD040300-0MF

2

Page 3

1 Table of Contents

1 TABLE OF CONTENTS ..................................................................................................... 3

2 INTRODUCTION ................................................................................................................. 6

2.1 Features and Benefits ...................................................................................................... 8

2.2 Software .......................................................................................................................... 9

2.3 Product Image (Master Module) ..................................................................................... 9

3 SPECIFICATIONS ............................................................................................................. 10

3.1 Universal Input/Outputs — Channels 1–6 .................................................................... 10

3.2 Relay Outputs — Channels 7–8 .................................................................................... 10

3.3 Communications ........................................................................................................... 10

3.4 Protocol Compliance ...................................................................................................... 11

3.5 Power Requirements ..................................................................................................... 11

3.6 General Specifications .................................................................................................. 11

3.7 LED Indicators ............................................................................................................... 12

3.8 Electromagnetic Compatibility ..................................................................................... 12

3.9 Field Connections ......................................................................................................... 13

3.10 Ordering Information .................................................................................................... 13

3.11 Dimensional Drawing ................................................................................................... 14

3.12 PICS Statement ............................................................................................................. 15

4 INSTALLATION ................................................................................................................ 16

4.1 Power Supply ................................................................................................................ 16

4.1.1 Power Supply Precautions ........................................................................................ 17

4.1.2 Limited Power Sources ............................................................................................. 17

4.2 Connecting Expansion Equipment ................................................................................ 18

4.2.1 BAS Remote Expansion Module Connections ......................................................... 18

4.2.2 Modbus Serial Bus Connections ............................................................................... 19

4.2.3 Cabling Considerations ............................................................................................. 20

5 FIELD CONNECTIONS .................................................................................................... 21

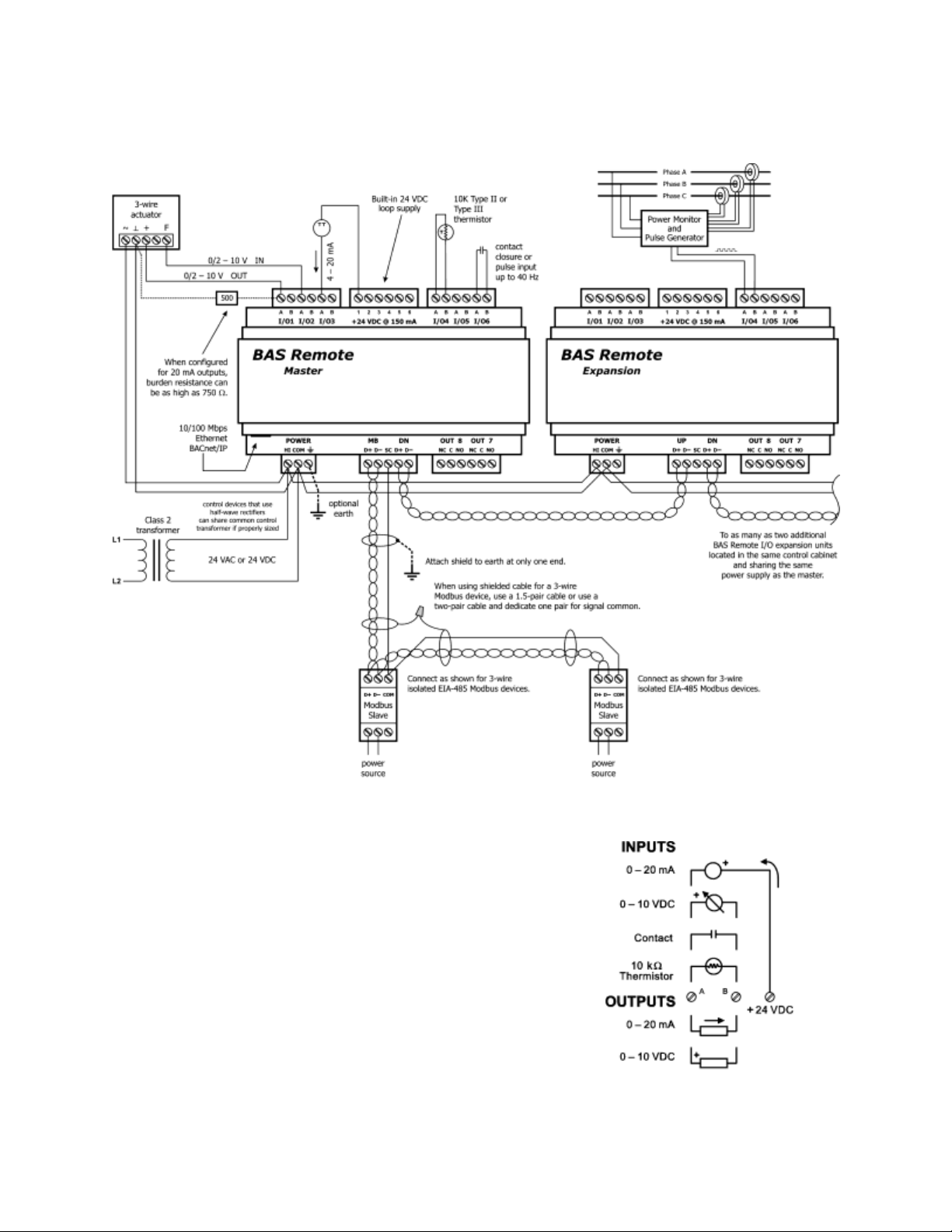

5.1 Sample BAS Remote Wiring Diagram ......................................................................... 21

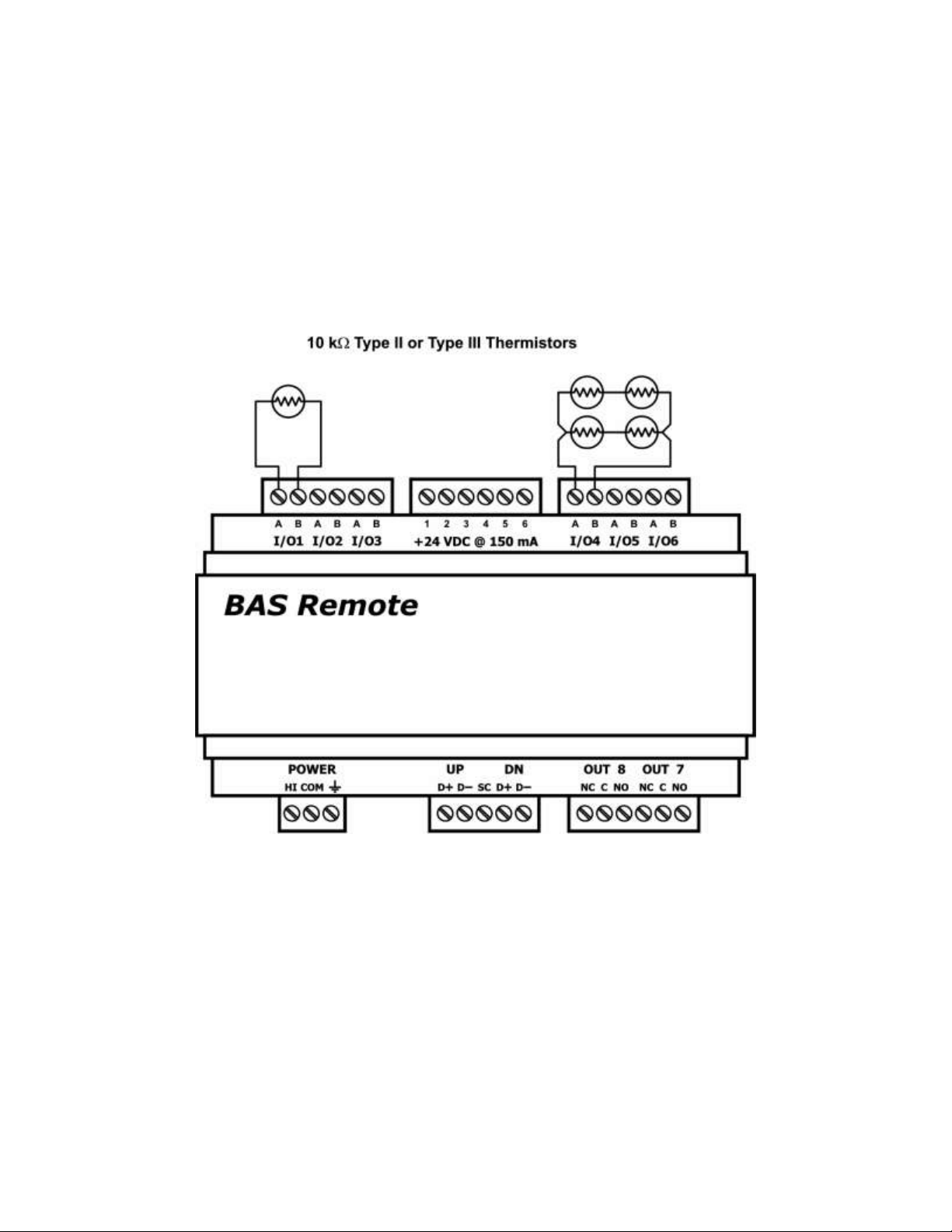

5.2 Thermistors ................................................................................................................... 22

5.3 Contact Closure ............................................................................................................. 22

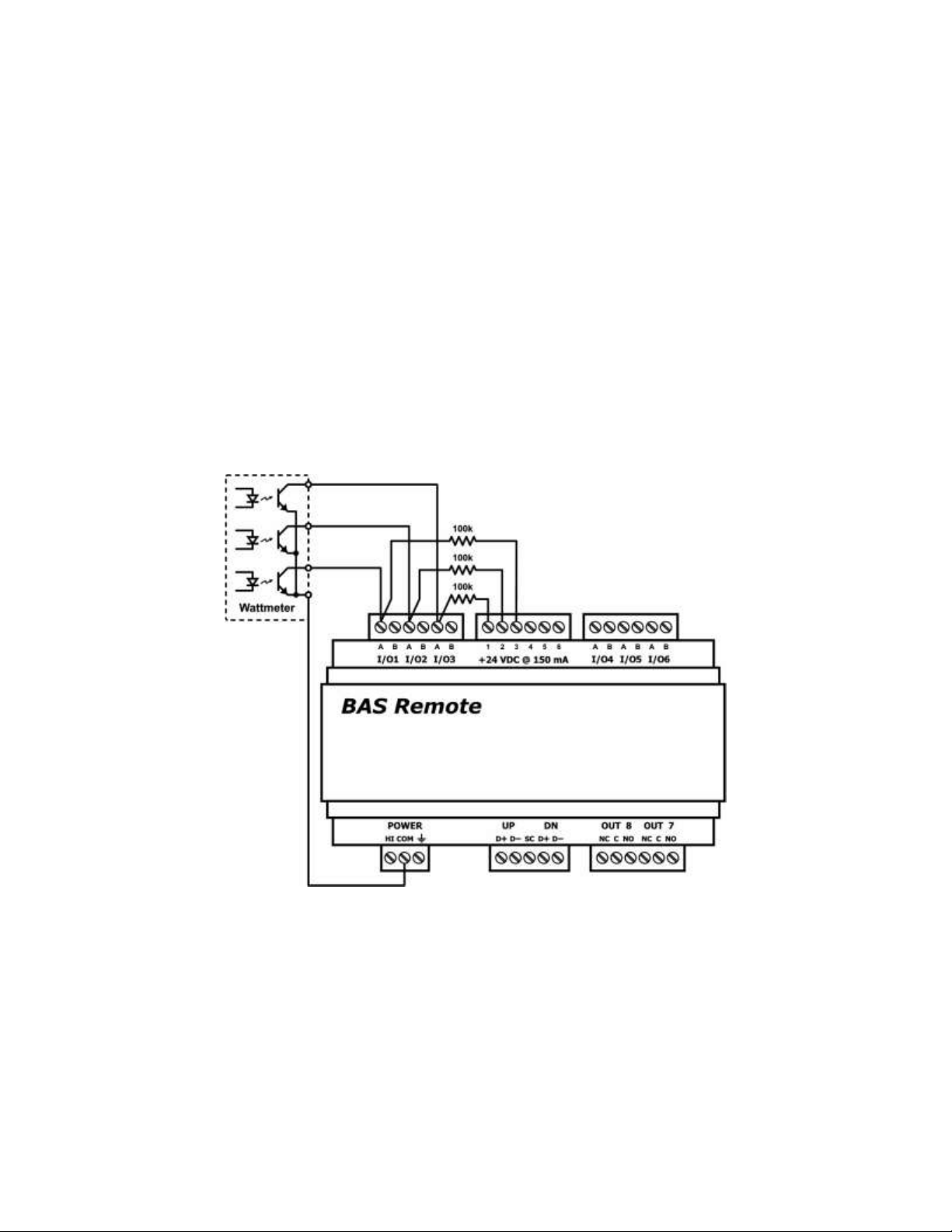

5.4 Pulse Inputs ................................................................................................................... 24

5.5 Analog Input ................................................................................................................. 25

5.6 Analog Output ............................................................................................................... 26

TD040300-0MF

3

Page 4

6 OPERATION ...................................................................................................................... 27

6.1 General Considerations ................................................................................................. 27

6.1.1 Ethernet Port on the Master Module ......................................................................... 27

6.1.2 LEDs ......................................................................................................................... 27

6.1.3 Accessing and Configuring the Web Server on the Master Unit .............................. 28

6.1.4 Web Server Screen Overview ................................................................................... 35

6.1.5 On-Screen Help ......................................................................................................... 36

6.2 Input/Output Channels (I/O) ....................................................................................... 37

6.2.1 Universal I/Os ........................................................................................................... 37

6.2.2 Relay Outputs ............................................................................................................ 37

6.3 Channel Configuring ..................................................................................................... 38

6.3.1 Analog Voltage Input Configuring ........................................................................... 38

6.3.2 Analog Voltage Output Configuring ........................................................................ 39

6.3.3 Binary Input Configuring .......................................................................................... 40

6.3.4 Current Input Configuring ........................................................................................ 41

6.3.5 Current Output Configuring ...................................................................................... 42

6.3.6 Thermistor Input Configuring ................................................................................... 43

6.3.7 Pulse Input Configuring ............................................................................................ 44

6.3.8 Relay Output Configuring ......................................................................................... 46

6.4 Channel Forcing ............................................................................................................ 47

6.4.1 Analog Input Forcing ................................................................................................ 47

6.4.2 Binary Input Forcing ................................................................................................. 48

6.4.3 Current Input Forcing ............................................................................................... 48

6.4.4 Thermistor Input Forcing .......................................................................................... 49

6.4.5 Relay Output Forcing ................................................................................................ 49

6.5 Instance Numbers.......................................................................................................... 50

6.6 Flash File System and Custom Web Pages ................................................................... 50

6.7 Web Services ................................................................................................................ 51

6.8 Set Time ........................................................................................................................ 51

7 APPENDIX .......................................................................................................................... 52

7.1 Troubleshooting Ethernet Connectivity of the Master Unit ......................................... 52

7.2 BACnet Object Model .................................................................................................. 52

7.2.1 Device ....................................................................................................................... 52

7.2.2 Analog Input .............................................................................................................. 53

7.2.3 Analog Output ........................................................................................................... 53

7.2.4 Analog Value ............................................................................................................ 53

7.2.5 Binary Input .............................................................................................................. 54

7.2.6 Binary Output ............................................................................................................ 54

TD040300-0MF

4

Page 5

7.2.7 BIBBs ........................................................................................................................ 55

7.3 Sedona for Control ........................................................................................................ 57

7.3.1 Getting Started with a Sedona Tool .......................................................................... 57

7.3.2 Virtual Points ............................................................................................................ 59

7.4 Modbus Server Operation ............................................................................................. 60

7.4.1 Modbus Register Organization ................................................................................. 61

7.4.2 Modbus Function Codes ........................................................................................... 64

7.5 Mapping Modbus Variables to BACnet/IP ................................................................... 64

7.5.1 General Mapping Principles...................................................................................... 64

7.5.2 Mapping Scheme ...................................................................................................... 64

7.5.3 Project Builder .......................................................................................................... 65

7.5.4 Viewing the Mapping Status in the BAS Remote .................................................... 71

7.6 Modbus Utility .............................................................................................................. 72

7.7 Linux License................................................................................................................ 74

TD040300-0MF

5

Page 6

2 Introduction

The BAS Remote Master provides the ultimate in flexibility. It can be used for

Expansion I/O at remote locations where an Ethernet connection exists. Its built-in

router and gateway capability addresses unique integration needs where more than one

communications protocol is involved. It can function as a controller with its resident

Sedona Virtual Machine. Powered by a Linux engine, the BAS Remote Master can

operate as BACnet/IP or Modbus TCP remote I/O, Sedona controller, Modbus Serial to

Modbus TCP router, Modbus Serial to BACnet gateway, and Modbus master to

attached Modbus slaves – all at the same time. The BAS Remote also supports web

services. You can customize the unit via custom web pages that utilize special java

applets provided in the device. A 10/100 Mbps Ethernet port allows connection to IP

networks and popular building automation protocols such as Modbus TCP, BACnet/IP,

and Sedona SOX. Six universal I/O points and two relay outputs can be configured

through resident web pages using a standard web browser and without the need of a

special programming tool. A 2-wire Modbus serial port can greatly expand the I/O count

with built-in routing to Modbus TCP clients. If BACnet mapping is preferred, the unit

incorporates a Modbus serial to BACnet/IP gateway. Additional universal I/O can be

achieved with the simple addition of BAS Remote Expansion modules. The BAS

Remote Master PoE has the same capabilities as the BAS Remote Master except it is

powered over the Ethernet connection — thereby providing a “One Cable Solution.”

Both the BAS Remote Master and BAS Remote Expansion modules have the same

I/O capability. Six universal input/output points are provided on each module.

Depending upon configuration, each unit can accommodate a contact closure from a

digital point, a thermistor, voltage or current analog input from a field transmitter or

supervisory controller. Analog inputs can range from 0–5 VDC, 0–10 VDC or 0–20 mA.

Inputs can be scaled to accommodate ranges such as 1–5 VDC, 2–10 VDC, and 4–20

mA. Input point resolution is 10-bits.

Type II and III 10 kΩ thermistor calibration curves are resident in the BAS Remote. Singlepoint calibration of temperature is accomplished using the internal web server. Inputs can

accept pulse trains in the range of 0–40 Hz (50% duty cycle) to measure flow rates.

Analog outputs can be 0–10 VDC or 0–20 mA. However, scaling for 2–10 V, 0–5 V,

1–5 V and 4–20 mA is possible. LED indicators identify the state of I/O points. Output

point resolution is 12 bits.

There are two relay outputs available with both normally open (NO) and normally closed

(NC) contacts. The relay output rating is 30 VAC/VDC, 2A.

There are two non-isolated 2-wire EIA-485 Expansion ports on the Master module. The

downstream port (DN) is intended for Expansion modules while the Modbus (MB) port

functions as either a Modbus TCP router or Modbus serial to BACnet gateway — allowing

for the attachment of Modbus 2-wire or 3-wire EIA-485 serial devices. On BAS Remote

Expansion modules, the two ports are marked UP and DN, and are dedicated for

communication with the BAS Remote Master module and other Expansion modules.

All field connectors are removable — making field replacement of units quick and simple.

A single RJ-45 shielded connector provides the 10/100 Mbps twisted-pair Ethernet

connection. The unit supports auto-negotiation of data rate and duplex. A resident web

TD040300-0MF

6

Page 7

server facilitates commissioning and troubleshooting. Configuration is accomplished via

Ethernet. Java must be enabled in the browser used to access the BAS Remote.

Power for the BAS Remote can be derived from a 24 VAC Class 2 transformer capable

of delivering 17 VA or from a 24 VDC power supply capable of at least 10 W. Since the

unit incorporates a half-wave rectified power supply, attached I/O points and the power

supply can share a common ground. Therefore, the BAS Remote can be powered by

the same control transformer used to power other half-wave rectified control equipment.

The BAS Remote can be DIN-rail mounted into a control panel. If panel mounting is

required, use the supplied mounting tabs.

The BAS Remote conforms to the BACnet/IP standard and therefore allows field I/O to

be directly accessed via Ethernet without the need of a router. A standard web browser

with Java enabled is used for commissioning and troubleshooting. The BAS Remote

adheres to the BACnet Application Specific Controller (B-ASC) profile.

TD040300-0MF

7

Page 8

2.1 Features and Benefits

Versatile Control Device — remote I/O, router, gateway and controller

Web-page configuration

BACnet/IP Remote I/O

Modbus TCP Remote I/O

Modbus Serial to Modbus TCP Router

Modbus Serial to BACnet/IP Gateway

Modbus Master to Attached Modbus Slaves

Powered by Sedona Controller

Power over Ethernet (PoE)

Java Applets for customisable web pages

Web Services

Flexible Input/Output — expandable by adding modules

Six universal input/output points — web-page configurable

Two relay outputs

Thermistor, voltage, current, contract closure and pulse inputs

Voltage, current and relay outputs

2-wire Modbus Serial Expansion port

2-wire Expansion port for up to three Expansion modules

TD040300-0MF

8

Page 9

I/O Ports 1–3

I/O Ports 4–6

Reset

24 V Loop Supply

Input Power

Output Relays

Ethernet Port

DIN-rail Release Tab

Expansion Ports

2.2 Software

The provided CD-ROM contains:

This User Manual

A copy of the Installation Guide that is packaged with the product

Additional information of interest

2.3 Product Image (Master Module)

Figure 1 — BAS Remote Master Module Main Features

TD040300-0MF

9

Page 10

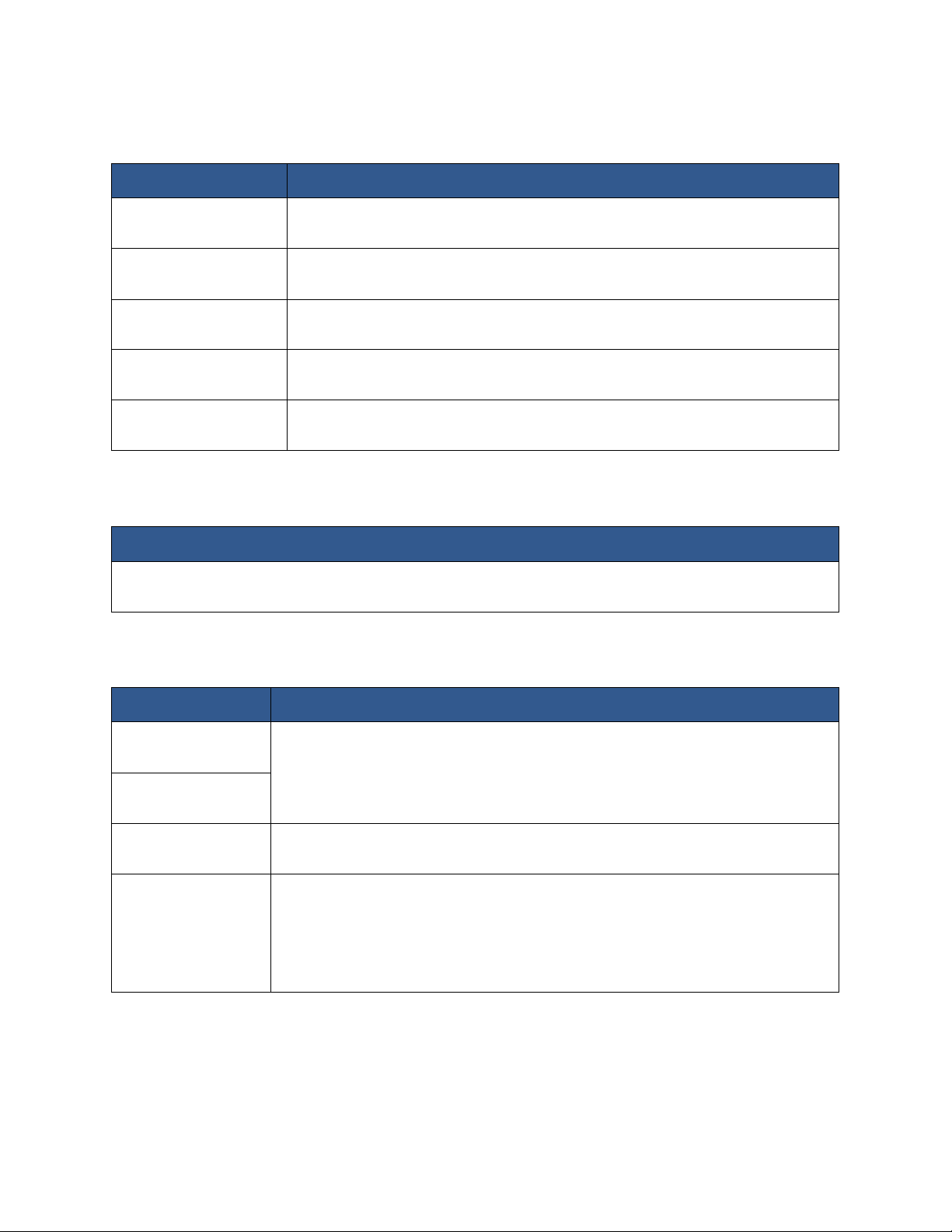

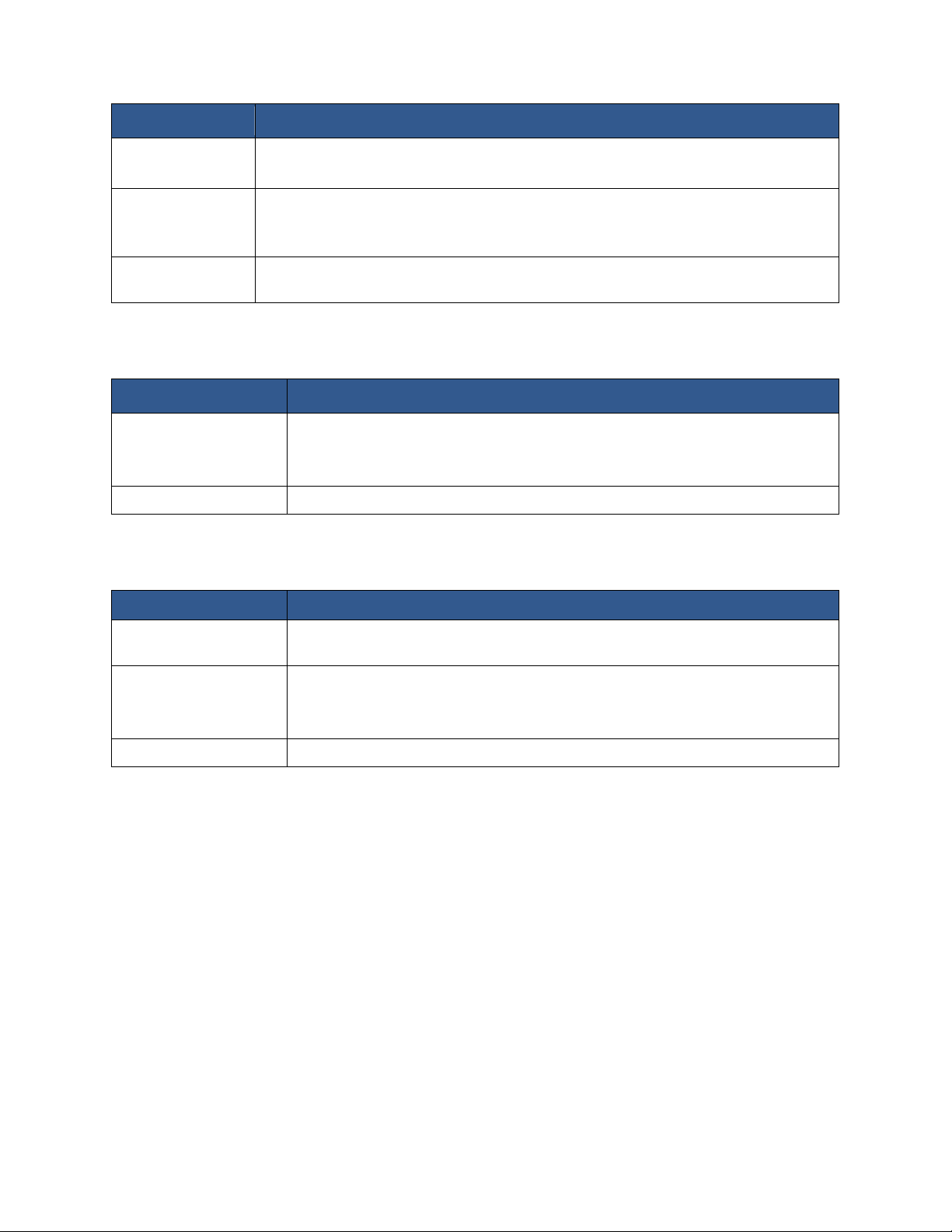

Configured As

Limits

Analog Input

0–5 VDC, 0–10 VDC or 0–20 mA scalable by user. 10-bit resolution.

Input impedance 100 kΩ on voltage and 250 Ω on current.

Temperature Input

Type II or Type III thermistors

+40°F to +110°F (+4.4°C to +44°C)

Contact closure input

Excitation current 2 mA. Open circuit voltage 24 VDC.

Sensing threshold 0.3 VDC. Response time 20 ms.

Pulse input

0–10 VDC scalable by user. User adjustable threshold.

40 Hz maximum input frequency with 50% duty cycle.

Analog Output

0–10 VDC or 0–20 mA scalable by user. 12-bit resolution.

Maximum burden 750 Ω when using current output.

Limits

Form “C” contact with both NO and NC contacts available.

30 VAC/VDC 2 A. Class 2 circuits only.

Protocol

Data Link and Physical Layers

BACnet/IP

— Master only

ANSI/IEEE 802.3 10/100 Mbps Ethernet.

10BASE-T, 100BASE-TX, auto-negotiation of speed and duplex.

Auto-MDIX. 100 m maximum segment length.

Default IP address is 192.168.92.68/24.

Modbus TCP

— Master only

Expansion Bus

(UP/DN)

Modified Modbus serial protocol. 2-wire non-isolated EIA-485

57.6 kbaud. Maximum segment length 100 m.

Modbus Serial

— Master only

(MB Bus)

Modbus serial ASCII or RTU protocol.

2-wire non-isolated EIA-485.

2.4, 4.8, 9.6, 19.2, 38.4, 57.6, 115.2 kbps.

Max segment length 100 m.

Jumper selectable bias and termination.

3 Specifications

3.1 Universal Input/Outputs — Channels 1–6

3.2 Relay Outputs — Channels 7–8

3.3 Communications

TD040300-0MF

10

Page 11

Protocol

Compliance

BACnet/IP

ASHRAE 135-2008 annex J.

Application specific controller device profile B-ASC.

Modbus TCP

Modbus Application Protocol Specification V1.1b Dec. 28, 2006, Modbus.org.

Modbus Messaging on TCP/IP Implementation Guide V1.0b October 24, 2006,

Modbus.org.

Modbus serial

Modbus over Serial Line Specification and Implementation Guide V1.02 December

20, 2006, Modbus.org.

Item

Limits

Input power

Master module: 24 VAC/VDC ± 10%, 47–63 Hz, 17 VA

Master PoE module: 48 VDC ± 10% 10 W

Expansion module: 24 VAC/VDC ± 10%, 47–63 Hz, 17 VA

Loop supply

+24 VDC nom, 150 mA maximum

Item

Description

Protection

All inputs and outputs (except for relay outputs and communications ports) are

over-voltage protected up to 24 VAC and short-circuit protected.

Environmental

Operating temperature 0° to +60°C.

Storage temperature –40°C to +85°C.

Relative humidity 10 to 95%, non-condensing.

Weight

0.6 lbs. (0.27 kg).

3.4 Protocol Compliance

3.5 Power Requirements

3.6 General Specifications

TD040300-0MF

11

Page 12

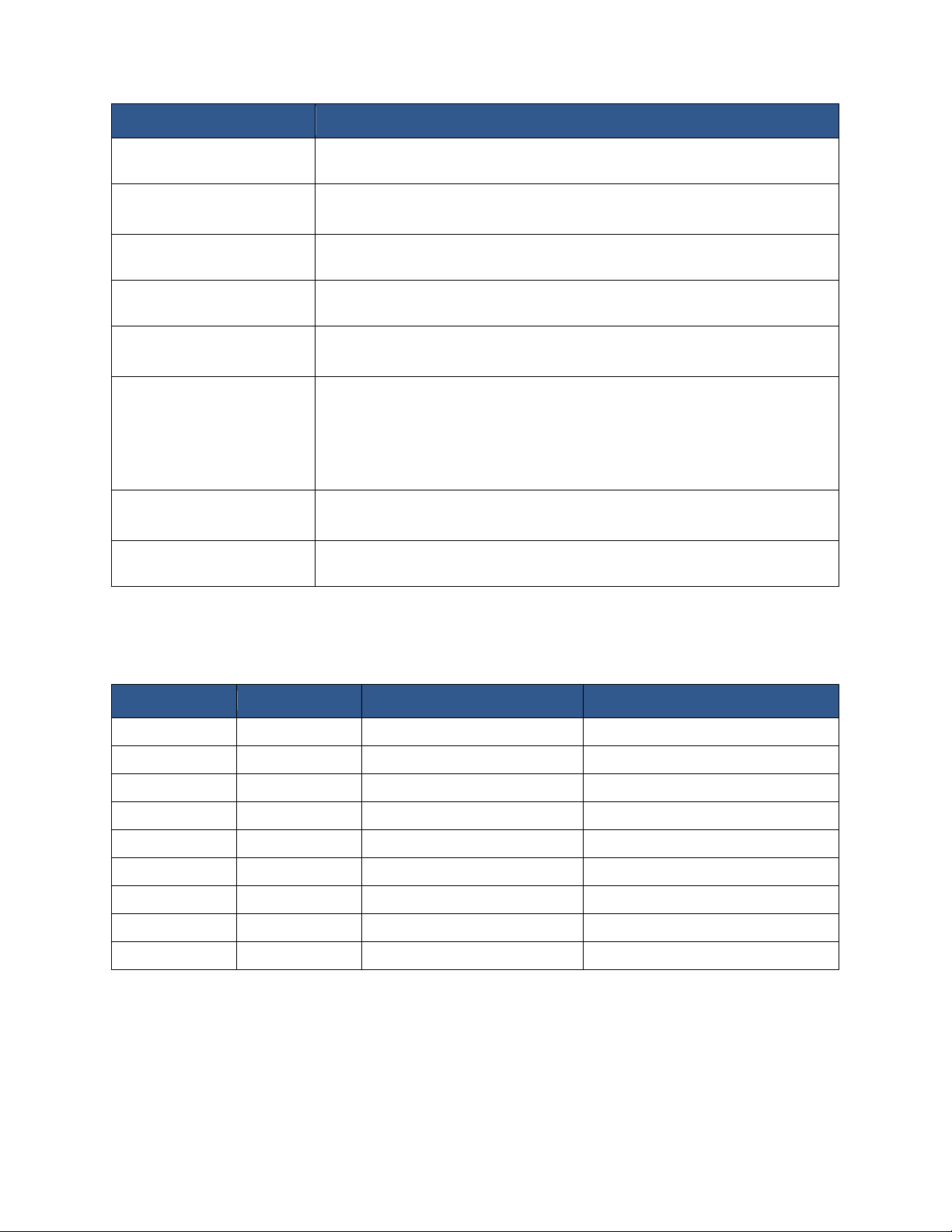

LED Indicator

Indication

I/O 1–6 configured as

Analog input

Green: > 1% of range, otherwise off

I/O 1–6 configured as

Temperature input

Green: sensor detected

Red: open

I/O 1–6 configured as

Contact input

Green: contact closed, otherwise off

I/O 1–6 configured as

Pulse input

Green: pulse sensed, otherwise off

I/O 1–6 configured as

Analog output

Green: commanded output

Red: expected output not within 40 mV on voltage or 0.2 mA on current

Status

Red: device in reset

Green flashing: booting up

Green: running application

Green flashing: Modbus serial activity after application is running —

Master only

Ethernet — Master

module only

Yellow: 10Mbps; flashes with activity

Green: 100 Mbps; flashes with activity

Network — Expansion

module only

Green flashing: Expansion bus activity

Standard

Test Method

Description

Test Levels

EN 55024

EN 61000-4-2

Electrostatic Discharge

6 kV contact

EN 55024

EN 61000-4-3

Radiated Immunity

10 V/m, 80 MHz to 1 GHz

EN 55024

EN 61000-4-4

Fast Transient Burst

1 kV clamp & 2 kV direct

EN 55024

EN 61000-4-5

Voltage Surge

1 kV L-L & 2 kV L-Earth

EN 55024

EN 61000-4-6

Conducted Immunity

10 V (rms)

EN 55024

EN 61000-4-11

Voltage Dips & Interruptions

1 Line cycle, 1–5 s @100% dip

EN 55022

CISPR 22

Radiated Emissions

Class A

EN 55022

CISPR 22

Conducted Emissions

Class B

CFR 47, Part 15

ANSI C63.4

Radiated Emissions

Class A

3.7 LED Indicators

3.8 Electromagnetic Compatibility

TD040300-0MF

12

Page 13

Terminal

Power — Master Module*

Power — Expansion Module

HI

High AC or DC +

High AC or DC +

COM

AC or DC common

AC or DC common

Earth

Optional earthing connection

No connection

Model

Description

BASR-8M

BAS Remote Master with eight I/O points

BASR-8X

BAS Remote Expansion with eight I/O points

BASR-8M/P

BAS Remote Master PoE with eight I/O points

Terminal

Universal I/Os 1 – 3

I/O 1 A

Universal I/O point 1 high

I/O 1 B

Universal I/O point 1 low

I/O 2 A

Universal I/O point 2 high

I/O 2 B

Universal I/O point 2 low

I/O 3 A

Universal I/O point 3 high

I/O 3 B

Universal I/O point 3 low

Terminal

Universal I/Os 4 – 6

I/O 4 A

Universal I/O point 4 high

I/O 4 B

Universal I/O point 4 low

I/O 5 A

Universal I/O point 5 high

I/O 5 B

Universal I/O point 5 low

I/O 6 A

Universal I/O point 6 high

I/O 6 B

Universal I/O point 6 low

Terminal

Relay Outputs

OUT 8 NC

Output 8 normally-closed contact

OUT 8 C

Output 8 common

OUT 8 NO

Output 8 normally-open contact

OUT 7 NC

Output 8 normally-closed contact

OUT 7 C

Output 8 common

OUT 7 NO

Output 8 normally-open contact

Terminal

+24 VDC @ 150 mA Loop Supply

1

+24 VDC

2

+24 VDC

3

+24 VDC

4

+24 VDC

5

+24 VDC

6

+24 VDC

Terminal

Expansion Ports — Master Module

Terminal

Expansion Ports — Expansion Module

MB-D+

Modbus Serial Bus positive terminal

UP-D+

Upstream Expansion positive terminal

MB-D–

Modbus Serial Bus negative terminal

UP-D–

Upstream Expansion negative terminal

SC

Modbus signal common

SC

Not used

DN-D+

Downstream Expansion positive terminal

DN-D+

Downstream Expansion positive terminal

DN-D–

Downstream Expansion negative terminal

DN-D–

Downstream Expansion negative terminal

3.9 Field Connections

* BASR-M model only

3.10 Ordering Information

TD040300-0MF

13

Page 14

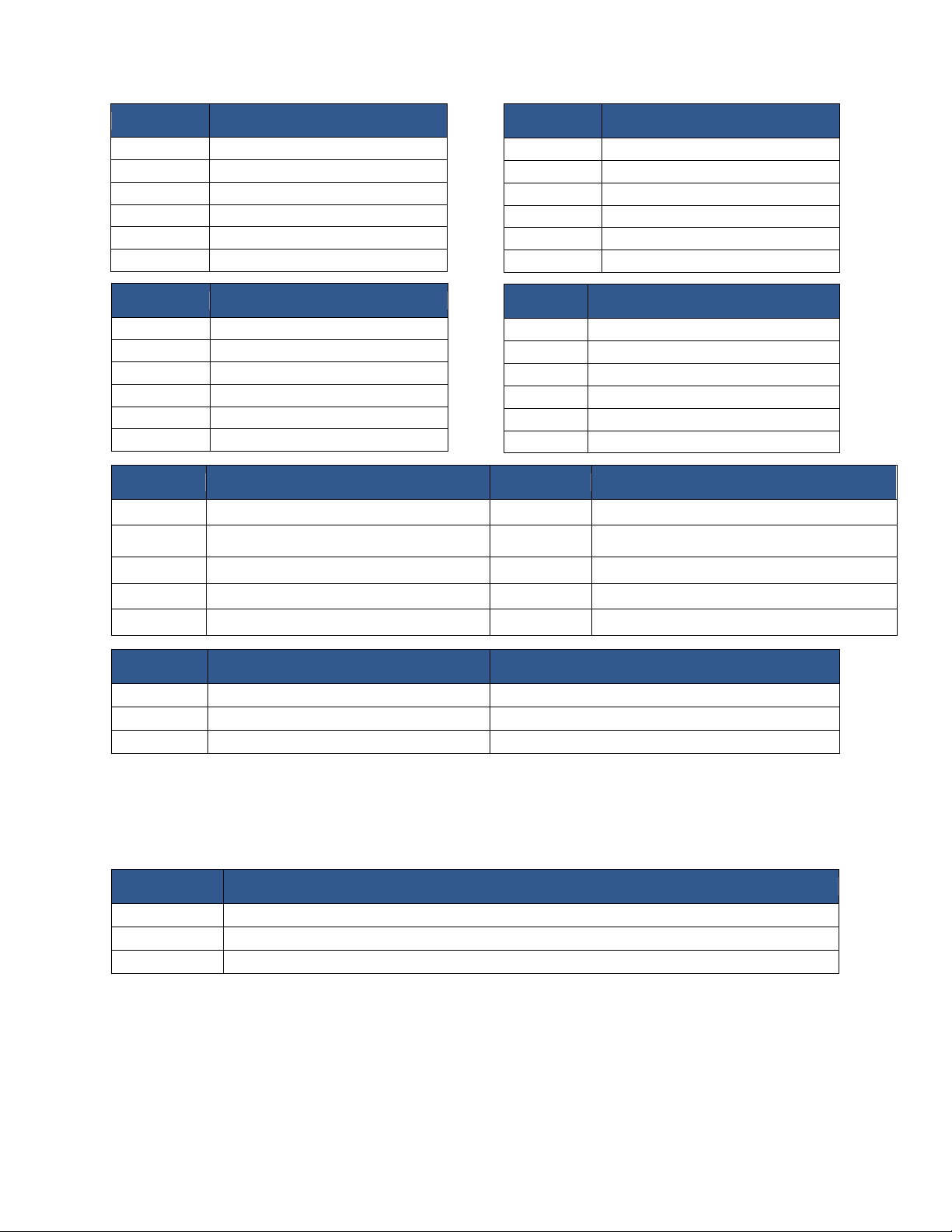

3.11 Dimensional Drawing

Figure 2 — BAS Remote Dimensions

TD040300-0MF

14

Page 15

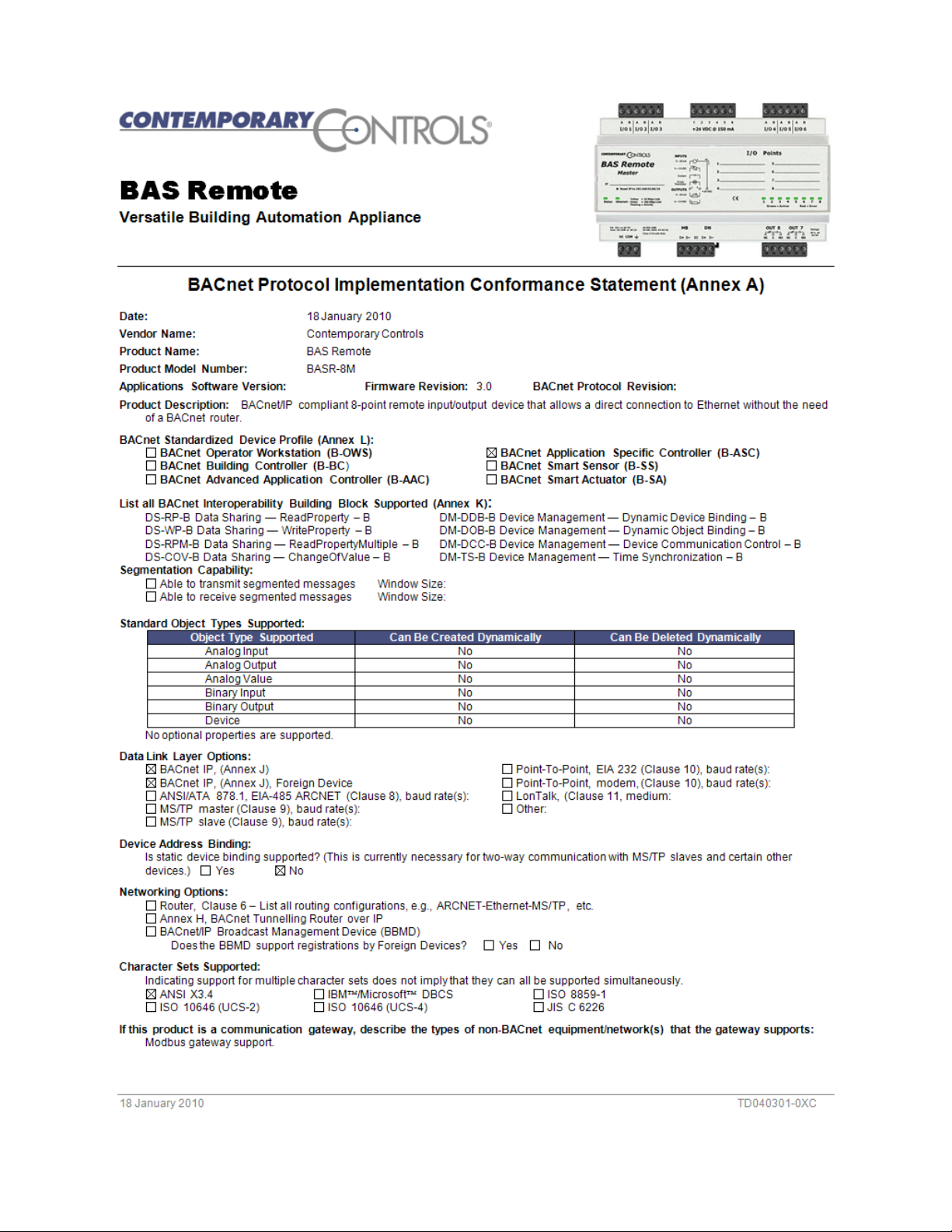

3.12 PICS Statement

TD040300-0MF

15

Page 16

4 Installation

The BAS Remote is intended to be mounted in an industrial enclosure or wiring closet

on 35-mm DIN-rail or panel-mounted with screws (not provided). The panel-mounting

tabs are packaged in a plastic bag within the shipping box. To use these tabs, Figure 3

illustrates how the two studs of each tab are press fitted into their respective holes in

opposing corners of the case.

Figure 3 — Attaching Panel-Mounting Tabs

4.1 Power Supply

The power source for the internal supply is applied via the three terminals labelled

Earth, COM, and HI. Earth allows external connection to earth if better EMC

compliance is needed. COM is for the power source return and also serves as the BAS

Remote common ground connection. Primary 24 VAC/VDC (± 10%) power is applied to

HI and COM. HI connects to a diode accomplishes half-wave rectified power — while

providing reverse input voltage protection.

Internally, the BAS Remote provides the 24 VDC loop supply to power external devices

attached as inputs to the BAS Remote — you do not need a separate loop supply.

Since the BAS Remote can source current via its analog outputs, an internal source of

24 VDC is provided for powering outputs. Collectively, the sum of input and output

power cannot exceed 150 mA.

Maximum current draw for any I/O channel is 20 mA — yielding a total draw of 120 mA

for all six channels. Analog output current sources from the same internal supply, so an

external source of 24 VDC is unneeded — but a return common is. Six +24 VDC pins

are present to serve external transmitters, so they do not need a separate loop supply.

However, the power supply must serve only its own BAS Remote module.

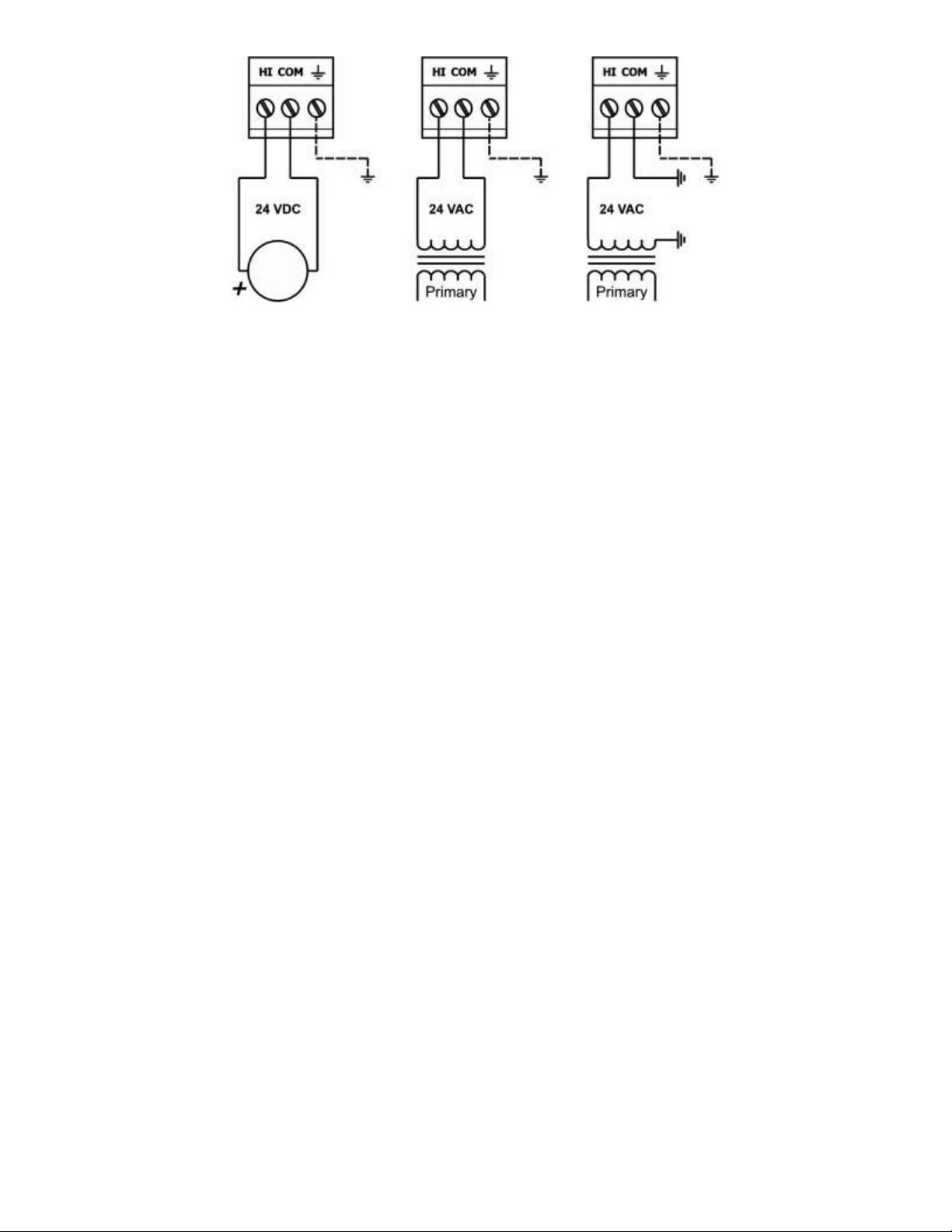

The BAS Remote requires 24 VDC or VAC from a source via a three-pin removable keyed

connector. The proper connections for various power options are shown in Figure 4.

Note that the BAS Remote Master PoE derives its power from the Ethernet cable and

therefore no internal connection exists for the HI pin on the input power connector.

The recommended size for power conductors is 16–18 AWG (solid or stranded). Ground

is directly connected to zero volts. Input connections are reverse-polarity protected.

NOTE: This device is intended for use with Class 2 circuits.

TD040300-0MF

16

Page 17

Figure 4 — Power Options

WARNING: Powering devices can present hazards. Read the next two sections carefully.

4.1.1 Power Supply Precautions

Internally, the BAS Remote utilizes a half-wave rectifier and therefore can share the

same AC power source with other half-wave rectified devices. Sharing a common DC

power source is also possible. Sharing AC power with full-wave rectified devices is

NOT recommended. Full-wave rectified devices usually require a dedicated AC power

source that has a secondary elevated above ground. Both secondary connections are

considered HOT. AC power sources that power several half-wave devices have a

common secondary connection called COMMON, LO, or GROUND. This connection

might be tied to earth. The other side of the secondary is considered the HOT or HI

side of the connection. Connect the HOT side of the secondary to the HI input on the

BAS Remote and the LO side to COM on the BAS Remote. All other half-wave devices

sharing the same AC power source need to follow the same convention. When using a

DC power source, connect its positive terminal to the HI input on the BAS Remote and the

negative terminal to COM on the BAS Remote. Reversing polarity to the BAS Remote

will not damage the BAS Remote.

WARNING: Devices powered from a common AC source could be damaged if a mix of

half-wave and full-wave rectified devices exist. If you are not sure of the type of rectifier

used by another device, do not share the AC source with it.

4.1.2 Limited Power Sources

The BAS Remote should be powered by a limited power source complying with the

requirements of the National Electric Code (NEC) article 725 or other international

codes meeting the same intent of limiting the amount of power of the source. Under

NEC article 725, a Class 2 circuit is that portion of the wiring system between the load

side of a Class 2 power source and the connected equipment. For AC or DC voltages

up to 30 volts, the power rating of a Class 2 power source is limited to 100 VA. The

transformer or power supply complying with the Class 2 rating must carry a

corresponding listing from a regulatory agency such as Underwriters Laboratories (UL).

TD040300-0MF

17

Page 18

4.2 Connecting Expansion Equipment

Input/output points beyond those available from the BAS Remote Master module can

be increased by adding BAS Remote Expansion modules or by attaching Modbus serial

devices to the MB bus. The MB port is used for connecting to 2-wire Modbus serial

devices while the DN port is used for connecting to BAS Remote Expansion modules.

Both ports are non-isolated EIA-485 compatible.

When installing equipment, make a record that identifies the power source, equipment

locations, IP and MAC ID numbers, protocol in use, baud rate, cable colour coding, etc.

— anything that will be helpful for future staff.

4.2.1 BAS Remote Expansion Module Connections

Expansion modules are intended to occupy positions to the right or left of the Master

module on the same DIN-rail or on additional DIN-rails within the same control panel. In

this situation only a short 2-wire twisted-pair cable is needed for making connections

between DN on the Master module and UP on the first Expansion module. Up to three

Expansion modules can attach to the Master module using a daisy-chain wiring

scheme. The second Expansion module has its UP port connected to the preceding

Expansion module’s DN port. The last Expansion module will have a vacant UP port.

The D+ terminal on one device must attach to the D+ terminal on the other. The same

applies to the D– terminals. Bias and termination exists on the UP terminals. See

Figure 6 for wiring details. For short connections, unshielded cable can be used.

Expansion modules are automatically assigned Modbus addresses beginning with 2

based upon its position to the Master within the daisy-chain wiring.

4.2.1.1 Bias and Termination

Each Master and Expansion module has two Expansion ports. The Master ports are

labelled MB and DN; the Expansion ports are UP and DN. These are shared buses

where only one device drives the bus at any one time. When no device is driving the

bus, the bus floats. To prevent noise from being interpreted as data, the bus must be

biased to a valid state. (The Modbus Serial specification calls this polarization.) With

no data on the bus, the D+ pin is biased to be more positive than the D– pin. Bias is

applied at only one point on the bus: the Master provides bias internally on its MB port,

the Expansion does so on its UP port.

4.2.1.2 Communicating from Master to Expansion Modules

The Master uses the downstream port DN to communicate to the upstream port UP on

the Expansion. If additional Expansion modules are used, they are cascaded such that

the DN port of the Expansion module nearest the Master is connected to the UP port on

the added Expansion module. Commands received by an Expansion module’s UP port

are relayed to its DN port while being read by the module itself. Similarly, a response

received at the DN port is transferred to the UP port — eventually arriving at the Master.

Thus all connections (Master-Expansion and Expansion-Expansion) are point-to-point

with termination and bias in each UP transceiver. DN ports have termination only.

TD040300-0MF

18

Page 19

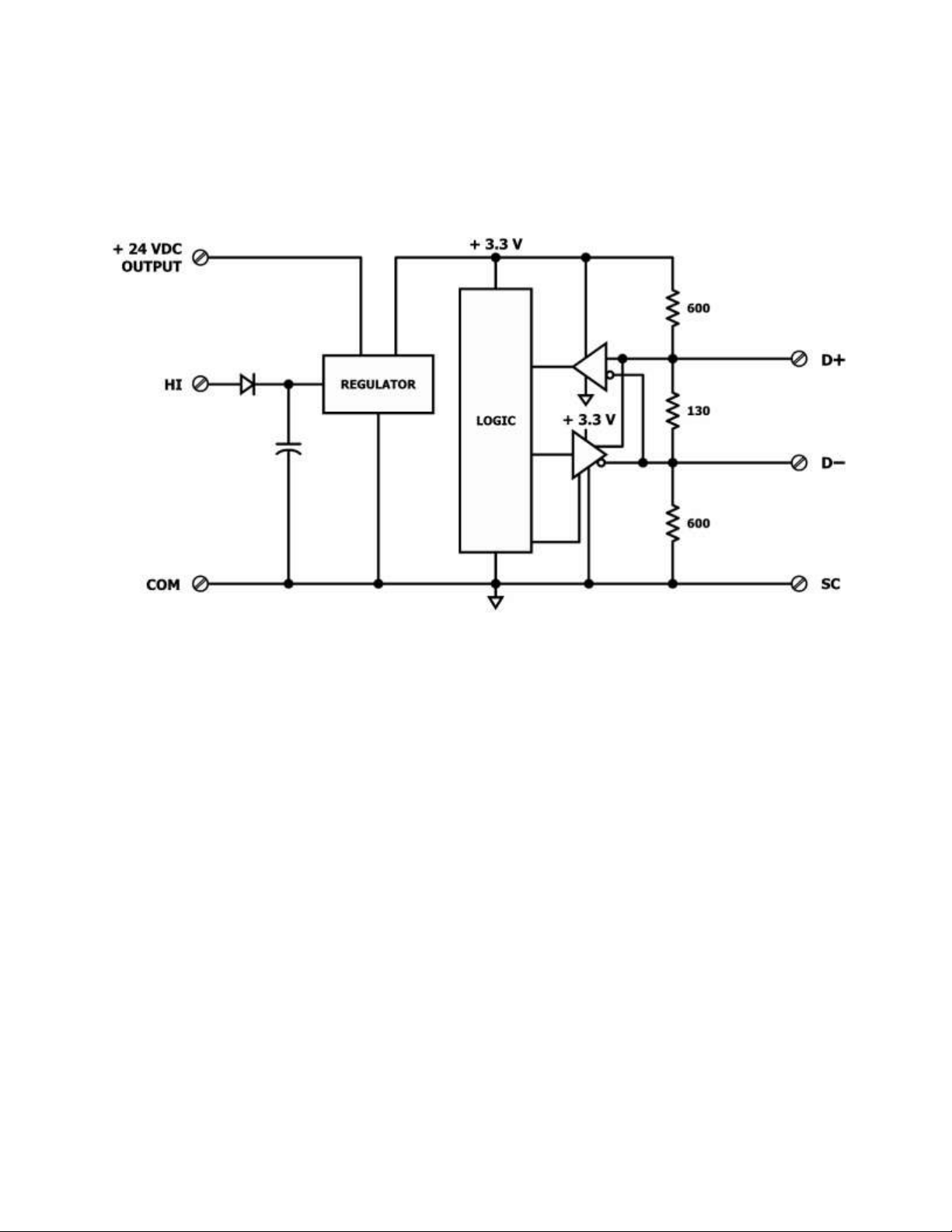

4.2.2 Modbus Serial Bus Connections

The Modbus serial Expansion port (MB) on the BAS Remote Master module is nonisolated EIA-485 compatible. When connecting to other non-isolated devices, care

must be exercised to ensure that all non-isolated Modbus devices share the same

ground reference (COM) with the BAS Remote Master module. This is usually

accomplished by sharing the same power source. Configure the Modbus baudrate and

protocol using the BAS Remote Modbus port web page.

Figure 5 — Internal Termination and Bias

When connecting to an isolated 3-wire Modbus device, the signal common of the

isolated device must be connected to the SC pin between the MB and DN ports. This ties

the two reference points together for reliable communications. Refer to Figure 6 for wiring

details.

Modbus serial device can only be attached to the MB port on the Master module. Refer

to Figure 5 for details on the bias and termination network present on the MB port.

Together, these resistors approximate one 120 Ω terminating resistor. Terminal D+

represents the more positive connection for the EIA-485 Modbus serial network while

D– represents the less positive connection. Make corresponding connections to

Modbus serial devices. The last device on the bus should have applied bias and

termination or just termination. A shielded twisted-pair cable should be used with

interconnecting devices. Connect the shields together and attached to chassis at only

one point. Refer to Figure 6 for wiring details.

TD040300-0MF

19

Page 20

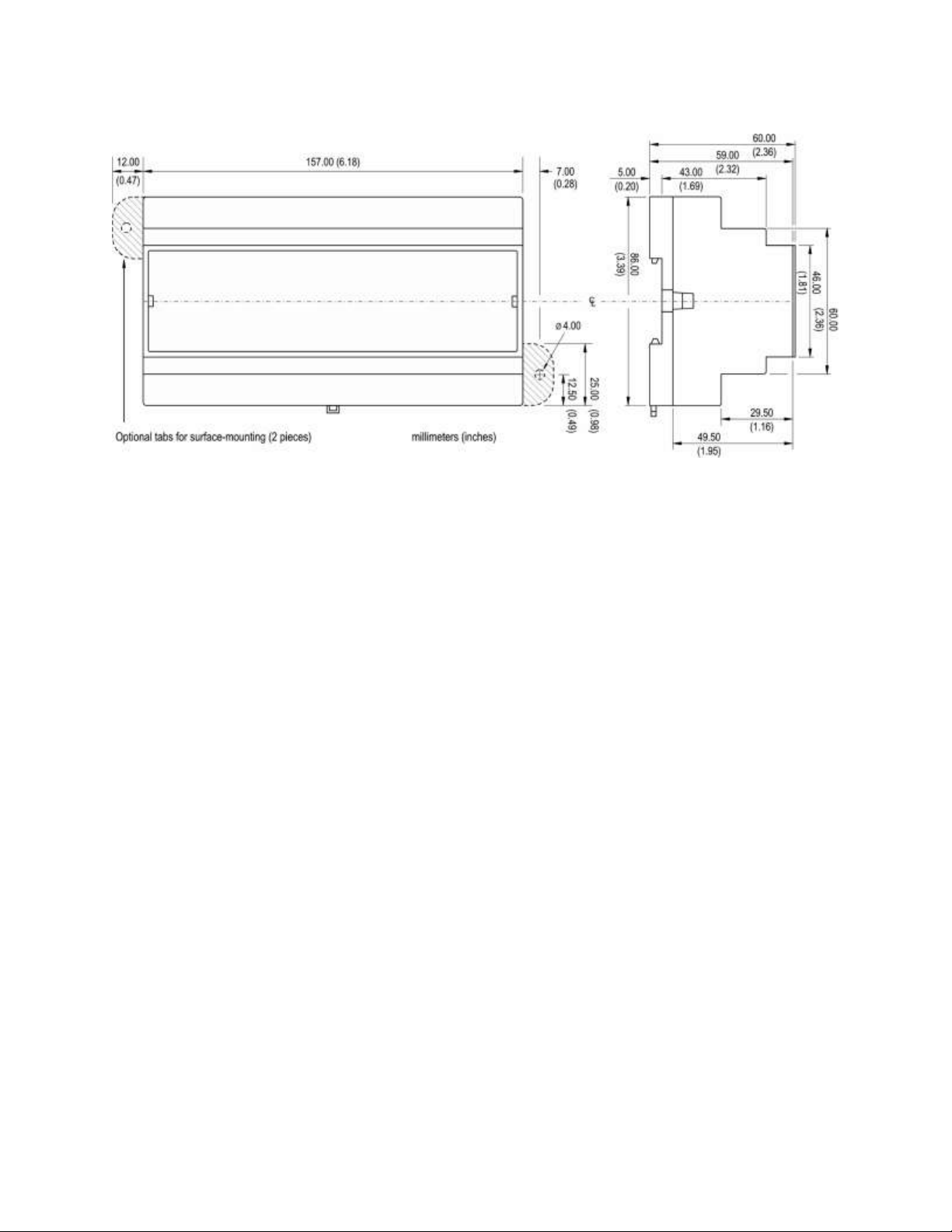

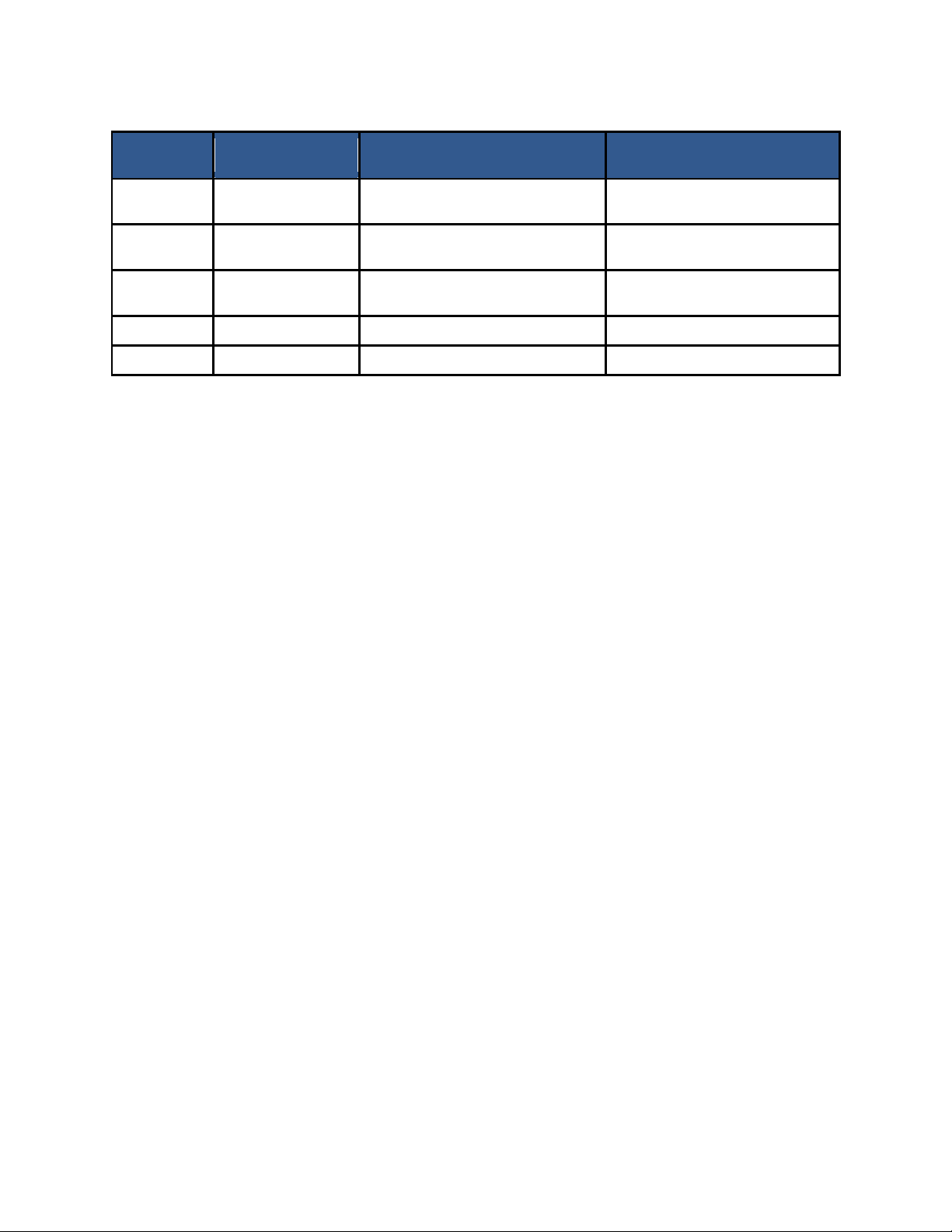

Function

Signalling and

Data Rate

Minimum Required Cable

Maximum Segment Distance

Ethernet

10BASE-T

10 Mbps

Category 3 UTP

100 m (328 ft)

Ethernet

100BASE-TX

100 Mbps

Category 5 UTP

100 m (328 ft)

I/O

Unspecified

Solid: 16–22 AWG

Stranded: 16–18 AWG

Unspecified

Expansion

Unspecified

Belden® 9841 or equivalent*

100 m (328 ft)

Modbus

Varied

Belden® 3106A or equivalent*

100 m (328 ft)

4.2.3 Cabling Considerations

When attaching cables to the BAS Remote, Table 1 should be considered.

Table 1 — Cabling Considerations

* If using shielded cable, connect to chassis at only one point.

NOTE: Wire size may be dictated by electrical codes for the area where the equipment

is being installed. Consult local regulations.

Observe in Table 1 that 10BASE-T segments can successfully use Category 3, 4 or 5

cable — but 100BASE-TX segments must use Category 5 cable. Category 5e cable is

highly recommended as the minimum for new installations.

The Ethernet port of the BAS Remote employs Auto-MDIX technology so that either

straight-through or crossover cables can be used to connect to the network.

TD040300-0MF

20

Page 21

5 Field Connections

5.1 Sample BAS Remote Wiring Diagram

Figure 6 — Sample BAS Remote Wiring Diagram

Wire Channels 1–6 so the most positive wire goes to

the “A” terminal and the most negative wire to the “B”

terminal.

The wiring options for Channels 1–6 are shown in

Figure 7. For each case in which polarity matters,

proper polarity is indicated.

Considerations in making field connections for various

types of input and output devices are discussed in the

following pages.

Figure 7 — I/O Options (Channels 1–6)

TD040300-0MF

21

Page 22

5.2 Thermistors

The BAS Remote has built-in calibration curves for 10 kΩ Type II or Type III thermistors.

These devices have a non-linear with a negative coefficient of resistance to temperature

and provide a nominal resistance of 10 kΩ at 25°C. Using the web server, configure an

input for either Type II or Type III thermistor. As shown in Figure 8, connect the twowire thermistor to points A and B. Polarity is not an issue. If averaging of temperature

is desired, connect multiple thermistors in a series-parallel combination so that the nominal

resistance remains at 10 kΩ as shown. Make sure that all devices are of the same type.

The effective range of temperature measurement is from +40° to +110°F (+4.4° to

+44°C). An open input results in a fault condition that produces a red LED indication for

that channel.

Figure 8 — Thermistor Connections

5.3 Contact Closure

The BAS Remote can sense the make or break of a contact from a relay or push-button.

The contacts being sensed must be absent of any applied source of energy, and be

rated for low-voltage, low-current switching. The BAS Remote will provide the electrical

energy to be sensed. Using the web server, configure an input for contact closure. As

shown in Figure 9, simply connect the contacts between points A and B. For common

mechanical contacts, polarity is not an issue. The open-circuit voltage is 24 VDC and the

short-circuit current is 2 mA.

TD040300-0MF

22

Page 23

Figure 9 — Contact Closure Connections

For solid-state switches, there are further concerns. It is recommended that a solidstate device have an opto-isolated open-collector NPN transistor output stage with a

collector-emitter output voltage (Vce) of at least 30 V. Output sinking current should be

greater than 5 mA. The collector-emitter saturation voltage should be less than 0.2 V

when sinking 2 mA. The emitter should be connected to point B and the collector to

point A which is the more positive point. This polarity must be observed when using

solid-state devices. When an input is configured for a contact closure, the BAS Remote

sets the low-threshold to 2 V and the high-threshold to 3 V. When a contact is made or

the solid-state switch is on (resulting in a saturated output), the voltage at point A is

close to zero volts. The corresponding LED for that channel will be on. If the contact is

opened or the solid-state switch is turned off, the voltage at point B will quickly begin to

rise towards 24 V. Once the voltage passes the 3 V high-threshold, the input channel

will sense the “off” state. To return to the “on” state, this voltage needs to return to 2 V.

The one-volt difference is called hysteresis. There is no need to add an external pull-up

resistor when using a contact closure input.

Contact closure inputs are sampled every 10 ms and for a change of state to be

recognized, the input state must be stable for two consecutive samples. Therefore,

contact closure response is from 20–30 ms.

TD040300-0MF

23

Page 24

5.4 Pulse Inputs

A variation on contact closure inputs is pulse inputs. In this situation speed is critical so

the input filtering that limits the time response is removed. When an input is configured

for Pulse Input, a pulse rate up to 40 Hz can be measured, assuming a 50% duty cycle.

The pulse device could have an opto-isolated open-collector NPN transistor output

stage like the one identified under Contact Closure, or it could provide an active

sinusoidal output signal that needs to be detected. Data can be in the form of frequency

or pulse count.

The Pulse Input voltage range is 0–10 VDC and the installer can set both the lowthreshold and high-threshold on the Pulse Input web page. The difference in the two

thresholds is the hysteresis. You can detect sinusoidal input signals by setting the high

threshold below the positive peak and the low threshold above the negative peak.

Setting the two thresholds well toward the centre of the sinusoidal waveform (rather than

near its peaks) offers some noise immunity. It is not necessary for the input signal to

swing from zero to 10 V. Any substantial swing within this range can be detected. The

input impedance using Pulse Input is 100 kΩ. Connect the output of the pulse device to

point A and the common to BAS Remote common as shown in Figure 10.

Figure 10 — Pulse Input Connections

The pulse output could be sinusoidal with no DC offset so the BAS Remote could

experience both positive and negative excursions of the signal. The BAS Remote can

only detect positive voltages so the negative excursions will be ignored. It is still

possible to detect the input signal by only sensing the positive excursions.

When interfacing to a pulse device that has an opto-isolated open-collector output, a pull-up

resistor must be added to the device output. In Figure 10, a 3-phase wattmeter has three

opto-isolated open-collector outputs, each requiring an external pull-up resistor. Since

TD040300-0MF

24

Page 25

each of the opto-isolators is rated for 60 VDC, install a 100 kΩ pull-up resistor between

each output and the +24 V loop supply. The common of the opto-isolators connects to

the common of the BAS Remote. Since each BAS Remote input has a 100 kΩ input

impedance, the resulting voltage divider sets the off-state voltage to 12 V. Even though

the BAS Remote input range is 0–10 VDC, this will not harm it. Set the two thresholds

to 2 V and 3 V. The threshold points on digital signals are not critical. Consult the pulse

device manual for more guidance.

5.5 Analog Input

An analog input can measure voltage in the range of 0–5 VDC or 0–10 VDC or it can

measure current in the range of 0–20 mA. Transmitters that produce an elevated “zero”

such as 1–5 VDC, 2–10 VDC or 4–20 mA can be measured as well. Using the web

page, configure the input for either voltage or current and select an appropriate range.

Scaling the input is accomplished by assigning the low and high points to engineering

units. When set as a voltage input, the input impedance is 100 kΩ and for a current

input, the impedance is 250 Ω.

With voltage measurement, connect the more positive voltage to point B and the less

positive to BAS Remote common as shown in Figure 11. On three-wire devices such

as damper actuators, the output signal is referenced to the damper’s power supply

common. That common must be at the same reference as the BAS Remote common.

Notice the connections in the diagram. In this situation it is only necessary to attach the

transmitter output to point A on the BAS Remote input.

Figure 11 — Analog Input Connections

TD040300-0MF

25

Page 26

When measuring current, remember the BAS Remote sinks current to ground. A 250 Ω

impedance is effectively applied between points A and B on the input. To measure

current, it must be driven into point A with respect to point B. For two-wire current

transmitters, the more positive point on the transmitter attaches to the +24 V on the BAS

Remote loop supply or it can attached to an external loop supply as long as that loop

supply has a common connection with the BAS Remote. The less positive connection

is made to point A on the input.

Care should be exercised when connecting to a three-wire current transmitter. These

are usually non-isolated devices between the power source and signal output. The BAS

Remote will sink current from its input to ground so the transmitter must source current

from a positive potential to ground. If the three-wire transmitter works in this manner, it

can be accommodated.

Four-wire transmitters usually have isolation between power supply and signal output so

their output stage can usually be treated as a two-wire transmitter.

5.6 Analog Output

Either voltage in the range of 0–10 VDC or current in the range of 0–20 mA can be

outputted by assigning analog outputs. Configure an output using a web page. Select

the appropriate range. For DC voltage, the output voltage is applied to point A with

respect to common. For DC current, the output current is sourced from point A to

common so there is no need for a loop supply. A current output can

source up to 20 mA into a resistive load not exceeding 750 Ω. Verify the

burden that a current output device will present. The BAS Remote cannot

generate enough voltage to drive loads with higher resistance.

Figure 12 — Analog Output Connections

Figure 12 illustrates connections to a three-wire damper actuator. The damper requires

a 0–10 V command signal which can easily be accomplished by the BAS Remote.

However, if a current output is desired it is possible to set the BAS Remote analog

output to 4–20 mA and install an external 500 Ω resistor that will convert the 4–20 mA

signal to 2–10 V.

TD040300-0MF

26

Page 27

If the I/O channel is …

Green indicates …

Red indicates …

a Relay output

the coil is energized.

(not used for relay output.)

an Analog output

the command is greater than zero.

10% deviation from command

a Contact input

the contact is made.

(not used for contact input.)

a Pulse input

the input state changed.

(not used for pulse input.)

a Thermistor

current flow is detected

No current flow detected

an Analog input

the signal is greater than 1% of span.

(not used for analog input.)

6 Operation

6.1 General Considerations

Configuration is accomplished while the unit is connected to a computer running a web

browser (Java-enabled) that accesses the unit’s built-in web server.

6.1.1 Ethernet Port on the Master Module

Auto-Negotiation

The Ethernet port on the BAS Remote Master unit offers full auto-negotiation. A single

cable links two Ethernet devices. When these devices auto-negotiate, the data rate will

be 100 Mbps only if both are capable of that speed. Likewise, full-duplex will only be

selected if both can support it. If only one device supports auto-negotiation, then it will

default to half-duplex mode and match the data rate of the non-auto-negotiating device.

Auto-MDIX (Auto-Crossover)

The Ethernet port offers Auto-MDIX. When interconnecting two Ethernet devices, a

straight-through cable or crossover cable can be used — but if one device uses AutoMDIX, the cable wiring does not matter; Auto-MDIX adjusts for either type.

Reset Switch

To reset the Master module to its default values of the IP address (192.168.92.68),

gateway address (192.168.92.1) and netmask (/24 or 255.255.255.0), use a paperclip

or similar tool to press the reset switch (see Figure 1 for location) while the unit is

repowered and until the reboot is complete. Once the Status LED stops flashing,

release the reset switch. T he unit will now use the default values.

6.1.2 LEDs

To aid in troubleshooting, several LEDs have been provided.

The Status LED flashes green during boot up — then glows solid green while operation is

fault-free. If a fault occurs, the LED glows solid red. On the Master module, this LED

flashing green (after boot up) indicates Modbus serial activity.

The Master module has an Ethernet LED that glows green when properly linked to

equipment operating at 100 Mbps (yellow for 10 Mbps) and indicates activity by flashing.

The Expansion module has a Network LED that flashes green to indicate data transfers.

I/O LEDs 1–8 follow the behaviour described in the chart below :

TD040300-0MF

27

Page 28

6.1.3 Accessing and Configuring the Web Server on the Master Unit

6.1.3.1 Web Browser

The Master contains an interactive web server, accessible from any Internet-compatible

PC on the local network. It is compatible with recent versions of Internet Explorer (5.0 or later,

suggested) or Netscape Navigator (7.1 or later, required). It is factory-programmed with

a default IP address of 192.168.92.68 and a Class C subnet mask of 255.255.255.0.

Once configured, changing the BAS Remote IP address is strongly encouraged.

6.1.3.2 Initial Access

The hardware arrangement for initially setting the Master

IP address appears in Figure 13. The PC should be

temporarily disconnected from the Ethernet LAN in

case the Master’s default address matches that of a

device on the existing LAN. The procedure for altering

the IP address creates a temporary LAN composed of

nothing but the Master, the PC used to configure it and

a CAT5 cable connecting the two. Since the Master

supports Auto-MDIX, either straight-through or crossover

cable can be used.

For initial configuration, the PC chosen for the

procedure should temporarily have its IP address

modified as shown in Figure 14 — which employs a

Windows® 2000 example.

Figure 13 — Setup for Initial IP Address

Configuration by Web Browser

Figure 14 — Steps for Changing the IP Address of the PC Used for Setup

TD040300-0MF

28

Page 29

Figure 14 suggests an IP address for the PC of 192.168.92.69, but the final quad of the

address could be any value from 1 to 254 — except for 68 which is used by the Master.

After the IP address of the PC has been set to the same LAN as the Master, a browser

can access the Master’s default IP address. The Master does not support DHCP.

Figure 15 displays just the relevant upper portion of the screen that appears when you

access the Master. Just beneath the device image is a link named “Configure Settings”.

Clicking this link opens another window where you can configure the values discussed

in the next four sections (see Figures 17–20).

Figure 15 — Master Main Page (Partial View)

Figure 16 — Expansion Main Screen (Partial View)

Figure 16 displays a view of a main screen (for one of three Expansion units) that is

faded — except for those elements that differ from the Master screen.

TD040300-0MF

29

Page 30

6.1.3.3 System Configuration

Four tabs exist on the configuration screen. Select System if it is not already highlighted.

System Name Give your system any name you wish.

IP Address Changing the default value of 192.168.92.68 is recommended.

Subnet Mask The default value of 255.255.255.0 is adequate for most users.

Gateway Address If your Ethernet LAN has a gateway (router) enter its address here.

Main Unit Name Give your Master module any name you wish.

Expansion Units Choose from the default of 0 to as many as 3 units. This value will

set the number of tabs that you see atop the main screen.

NOTE: Whether you are configuring System, BACnet,

Modbus or Virtual values, clicking “UPDATE” will save

your values to internal memory, but you must reboot

the Master module by cycling power before the new

values will apply!

After the Master has been given its initial configuration, it will be ready for use in the full

original Ethernet network. The temporary Ethernet network constructed in Figure 13

should be dismantled and the PC re-configured to restore its original IP address.

Figure 17 — Configuring System in the Master Module

TD040300-0MF

30

Page 31

6.1.3.4 BACnet Configuration

Device Instance This is a 22-bit value (0–4,194,303). Each BACnet network device

must have a unique device instance. The default value is 2749.

UDP Port The default value of 0xBAC0 should usually not be changed.

BBMD IP Address Enter the address of the BBMD with which the BAS Remote will

perform Foreign Device Registration (FDR) if the BBMD is not

located on the same subnet as the BAS Remote.

BBMD Reg Time Enter the interval (in seconds) between successive foreign device

registrations.

Figure 18 — Configuring BACnet in the Master Module

TD040300-0MF

31

Page 32

6.1.3.5 Modbus Configuration

Modbus configuration (see Figure 19) is only required if Modbus serial devices are

attached to the MB bus. Communication settings between the Master module and the

Expansion modules are preset and cannot be changed.

Modbus Address Address 1 is pre-assigned to the Master module while

Expansion modules are assigned addresses 2, 3 and 4

assuming Expansion units exist. The actual Expansion

address depends upon the order of cabling to the Master.

In addition to address 1, the Master module is also preassigned addresses 8 and 9 for internal functions. It is

best to assume that addresses 1 through 9 are reserved

for BAS Remote equipment so assign addresses from 10

to 247 to attached Modbus devices.

Baudrate All Modbus devices attached to the MB bus must have the

same baud rate. Baud rates range from 2,400 to 115,200.

The default is 19,200.

Protocol All Modbus devices attached to the MB bus must use the

same protocol. The choices are RTU and ASCII. The

default is RTU.

Parity All Modus devices attached to the MB bus must use the

same parity. The choices are NONE, ODD or EVEN. The

default is EVEN.

Command Timeout Set how long the Master will wait for a slave to respond.

The range is 50–3000 ms with a default of 1,000. If a

device fails to respond, it is placed into an offline queue.

Devices in this queue are checked every offline poll period.

Inter Scan Delay Set the desired delay between each poll cycle from 100-

30,000 ms. The default is 2,000.

Offline Poll Period Set how often the Master will check to see if a slave device

is back online. The range is 2,000-30,000 ms. The default

is 15,000.

Consecutive Read Delay Sets the delay between back-to-back accesses of the

same slave device. The range is 0-100 ms and the default

is 0.

Inter-Character Gap This maximum (1.5 character times) is what Modbus allows

between characters. If a device exceeds the allowable

time, set this to the highest possible value for the device.

The default of 0 is recommended, but settings between 0

and 10 ms are possible.

TD040300-0MF

32

Page 33

Figure 19 — Configuring Modbus in the Master Module

TD040300-0MF

33

Page 34

6.1.3.6 Virtual Point Configuration

The BAS Remote can store data independent of I/O Channel values. These stored

values are called Virtual Points because they are not required to be related to physical

I/O points. These virtual points can be treated as Modbus registers, BACnet objects or

Sedona Framework components. See Section 7.3.2 for more information.

Instance This read-only number is created from the BACnet Type. It is of the

form 8xyyyy, where the x defaults to 4 (register) but after the Apply

Object Changes button is clicked it will become 0 if the Type is

Binary Output or 1 if the Type is Binary Input. The value of yyyy is

automatically incremented as objects are added to the list of Virtual

Points in the left side of Figure 20. This virtual object can be written

or read via its Modbus/TCP address. Its address will be 8 and the

register number will be YYYY. The binary input/output can be

written/read via 0YYY or 1YYY.

Object Name Give the Virtual Point any name you wish. This will be the BACnet

object name for this virtual object.

BACnet Description Give the BACnet channel any name you wish.

BACnet Type Select the Type from the drop-down menu. Below, check the

“Retentive” box to preserve counts despite a power failure. “Float”

indicates how this virtual object will be accessed via Modbus/TCP.

If checked, this object will be accessed as a 32-bit float value. If

unchecked, it will be accessed as a 16-bit register. NOTE: Analog

Value, Analog Input and Binary Input types will not be writeable via

BACnet. Analog output and Binary Input can be written via BACnet.

BACnet Unit Group Select the Unit Group from the drop-down menu.

BACnet Unit Value Select the Unit Value from the drop-down menu.

BACnet COV Increment Once the channel value changes by this amount (up or down), a

COV message is sent to subscribers.

Figure 20 — Configuring Virtual Points in the Master Module

TD040300-0MF

34

Page 35

6.1.4 Web Server Screen Overview

From the Web Server Screen (Figure 21) you can configure all I/O channels, view their

status or force them as part of a commissioning process. (The figure uses the Master unit

as an example, but the Expansion unit appears very similar and functions the same.)

Immediately beneath the right side of the banner, the following links are displayed:

Help displays a new window (Figure 23) with context-sensitive information.

Visit Our Website links to our WWW home page for further helpful information.

Figure 21 — Web Server Page

The Configure Settings button (just below the device image) provides access to the basic

device configuration fields already discussed (Figure 17).

The BAS Remote image includes graphic representations of each I/O Channel. Each of the

8 channels has two icons ( and ) that open additional windows used for configuring

or forcing each Channel. The use of these links is discussed in Section 6.3.

TD040300-0MF

35

Page 36

Other buttons located beneath and to the right of the device image are:

Map This accesses the Modbus Mapping function (Section 7.5) which shows

the status of all mapped objects — including mapped Modbus variables,

virtual objects and all points within the BAS Remote.

Modbus Utility This accesses the Modbus Utility function (Section 7.6).

Set Time This accesses the Set Time window where you can manually set the

values of time and date.

The large grey section at the bottom of the screen labelled Current Settings is the device

“Monitor” — a read-only display of information for the BAS Remote module currently

selected. The tab in bold face near the top of the screen indicates the module selected.

Figure 22 below is an example in which Expansion Unit 2 has been selected.

NOTE: The number of tabs displayed is determined by the number of

Expansion Units selected in the Master Configuration Screen (Figure 17).

Figure 22 — The Tab in Bold Face Indicates the Selected Module

In the upper-left portion of the Monitor shown in Figure 21, two values (Unit Name and

Modbus Address) are displayed for the currently selected module.

To the right of the Modbus Address value is a box which reports one of two possible

pieces of information — depending on the type of BAS Remote module currently selected.

When the Master is selected, the box will display the BACnet Device Instance of the

Master. If an Expansion module is selected, the box will report the module’s status: It will

be ONLINE if its connection to the Master is valid or OFFLINE if the connection is invalid.

An OFFLINE report usually means the Expansion module cannot communicate with the

Master due to a cabling issue.

In the upper-right portion of the Monitor, the status of each channel (point) is reported with

the Override indicators and the LED Status indicators. All of these LEDs are refreshed at

the rate of once per second.

The lower portion of the Monitor displays the Channel Names and their Present Values.

6.1.5 On-Screen Help

There are several screens used in the BAS Remote. The upper-right portion of each

screen displays a Help option. Clicking this option launches another browser window

with helpful information about the current screen.

Figure 23 — Help Window

TD040300-0MF

36

Page 37

6.2 Input/Output Channels (I/O)

6.2.1 Universal I/Os

Six identical universal I/O channels allow any mix of inputs and outputs requiring only

two connections labelled A and B. Pin A is always more positive than pin B. Channels

are labelled I/O 1 through I/O 6 and are divided equally between two six-pin terminal

blocks. One terminal block is for I/O 1–3 and the other is for I/O 4–6. Configuring is

done via the built-in web server. Input resolution is 10 bits; output resolution is 12 bits.

Schottky barrier diodes protect the electronics from over-voltage faults on inputs A and

B. Also, a PPTC (polymeric positive temperature coefficient) resettable fuse protects

terminal B from over-voltage when driven to ground.

Pin A can be an input or output. Pin B can be an input or ground. A D/A converter is

used for generating analog voltage or current outputs, and for providing excitation

current for contact closure sensing and for thermistor measurement.

In current output mode, pin B is grounded. The output burden applied to pins A and B

can range from 0 to 750 Ω. Since the internal burden is 250 Ω, the output voltage at pin

A can range from 0–20 volts when driving 20 mA.

When measuring input voltages, pin A receives input while pin B is held at ground. Any

DC voltage in the range of 0–5 V or 0–10 V can be measured.

When measuring current, pin B is unused and the input on pin A sees a 250 Ω load.

To sense contact closure, 2 mA is output at pin A while pin B is grounded. Then the

voltage at pin A is measured. Any value below 0.3 volts (150 Ω) is considered a closed

circuit. Dry-contact or solid-state switches being sensed must withstand an opensource voltage of 24 VDC and a current of 2 mA. For solid-state switches, the most

positive connection is at pin A and a saturation voltage under 0.3 V is required.

A 10 kΩ thermistor is applied between pins A and B. Thermistors are non-linear heat

sensing devices with a negative temperature coefficient of resistance. At nominal room

temperature (77 °F), the resistance of a Type II or Type III thermistor is 10 kΩ. Both

have curves with an accuracy of ±0.36 °F from 32 °F to 158 °F. Because higher

resistance thermistors (such as 10 kΩ) introduce error due to the self-heating effect, lower

thermistor current is used — thus minimizing self-heat and measurement inaccuracy.

6.2.2 Relay Outputs

There are two independent SPDT relay outputs. For each output, both the NO and NC

contacts are brought out to a six-pin terminal block. Contacts are rated at 2A at 30 VAC

and 2A at 30 VDC. Wiring to the BAS Remote should only be Class 2. To control

higher voltages, the safer approach is to connect the coils of Class 2 interposing relays

to the contacts of the BAS Remote and have the contacts of the interposing relays

connect to the Class 1 circuits. These interposing relays should be further from the

BAS Remote and closer to the Class 1 equipment.

TD040300-0MF

37

Page 38

6.3 Channel Configuring

To configure a channel, access the Web Server Page, click on the icon for the channel

of interest and make adjustments in the new screen that appears. Your selected channel is

confirmed by the large number on the left side of the new screen. As Figure 24 shows,

clicking on the Save button is confirmed by the button briefly changing from light blue to dark

blue. If you attempt to set an illegal value, the button will not change colour.

6.3.1 Analog Voltage Input Configuring

You can define any channel 1–6 as “INPUT: 0–10V Analog” or “INPUT: 0–5V Analog” (As an

example, Figure 24 uses Channel 1 and 0–10V). Such a channel can accept an input voltage in

the range of 0–10 volts or 0–5 volts. The channel BACnet type will be Analog Input. On this

screen, you can adjust these parameters:

BACnet Unit Group The Electrical default can be set to any option in the list.

Channel Name You can rename the channel using no more than 63 characters.

This will be the object name for this channel (followed by the

channel number). For example, “Analog Input-1”.

BACnet Unit Group The Electrical default can be set to any option in the list.

BACnet Unit Value The VOLTS default can be set to any option in the list. The available

options depend on the BACnet Unit Group you specify.

BACnet COV Increment Once the channel value changes by this amount (up or down), a

COV message is sent to subscribers.

BACnet Description You can enter any string using no more than 63 characters.

ACTUAL HIGH This specifies the highest value within the range.

ACTUAL LOW This specifies the lowest value within the range.

SCALED HIGH You can set a physical value corresponding to the high value.

SCALED LOW You can set a physical value corresponding to the low value.

Figure 24 — Analog Input Configuration

TD040300-0MF

38

Page 39

6.3.2 Analog Voltage Output Configuring

You can set any channel 1–6 as type “OUTPUT: 0–10V Analog” as shown in Figure 25, using

Channel 1 as an example. Such a channel can supply an output voltage in the range of 0–10 V.

The channel BACnet type will be Analog Output. On this screen, you can adjust any of the

following parameters.

Channel Name You can rename the channel using no more than 63 characters.

This will be the object name for this channel (followed by the

channel number). For example, “Analog Output-1”.

BACnet Unit Group The Electrical default can be set to any option in the list.

BACnet Unit Value The VOLTS default can be set to any option in the list. The available

options depend on the BACnet Unit Group you specify.

BACnet COV Increment Once the channel value changes by this amount (up or down), a

COV message is sent to subscribers.

BACnet Description You can enter any string using no more than 63 characters.

ACTUAL HIGH This specifies the highest value within the range.

ACTUAL LOW This specifies the lowest value within the range.

SCALED HIGH You can set a physical value corresponding to the high value.

SCALED LOW You can set a physical value corresponding to the low value.

Initial Value (Scaled) The Off default outputs 0, but you can preset a Scaled value.

Figure 25 — Analog Output Configuration

TD040300-0MF

39

Page 40

6.3.3 Binary Input Configuring

You can define any channel 1–6 as type “INPUT: Binary” as shown in Figure 26 which uses

Channel 1 as an example. The channel BACnet type will be Binary Input. On this screen, you

can adjust the following parameters.

Channel Name You can name the channel using no more than 63 characters. This

will be the object name for this channel (followed by the channel

number). For example, “Binary Input-1”.

BACnet Unit Group The Others default can be set to any option in the list.

BACnet Unit Value The NO_UNITS default can be set to any option in the list. The

available options depend on the BACnet Unit Group you specify.

BACnet Description You can enter any string using no more than 63 characters.

Figure 26 — Binary Input Configuration

TD040300-0MF

40

Page 41

6.3.4 Current Input Configuring

You can define any channel 1–6 as type “INPUT: 0–20 mA“ as shown in Figure 27 which uses

Channel 1 as an example. Such a channel accepts an input current in the range of 0–20 mA.

The channel BACnet type will be Analog Input. On this screen, you can adjust any of the

following parameters.

Channel Name You can rename the channel using no more than 63 characters.

This will be the object name for this channel (followed by the

channel number). For example, “Current Input-1”.

BACnet Unit Group The Electrical default can be set to any option in the list.

BACnet Unit Value The MILLIAMPERES default can be set to any option in the list. The

available options depend on the BACnet Unit Group you specify.

BACnet COV Increment Once the channel value changes by this amount (up or down), a

COV message is sent to subscribers.

BACnet Description You can enter any string using no more than 63 characters.

ACTUAL HIGH This specifies the highest value within the range.

ACTUAL LOW This specifies the lowest value within the range.

SCALED HIGH You can set a physical value corresponding to the high value.

SCALED LOW You can set a physical value corresponding to the low value.

Figure 27 — Current Input Configuration

TD040300-0MF

41

Page 42

6.3.5 Current Output Configuring

You can define any channel 1–6 as type “OUTPUT: 0–20 mA“ as shown in Figure 28 which

uses Channel 1 as an example. Such a channel provides an output current in the range of 0–20

mA. The channel BACnet type will be Analog Output. On this screen, you can adjust any of the

following parameters.

Channel Name You can rename the channel using no more than 63 characters.

This will be the object name for this channel (followed by the

channel number). For example, “Current Input-1”.

BACnet Unit Group The Electrical default can be set to any option in the list.

BACnet Unit Value The MILLIAMPERES default can be set to any option in the list. The

available options depend on the BACnet Unit Group you specify.

BACnet COV Increment Once the channel value changes by this amount (up or down), a

COV message is sent to subscribers.

BACnet Description You can enter any string using no more than 63 characters.

ACTUAL HIGH This specifies the highest value within the range.

ACTUAL LOW This specifies the lowest value within the range.

SCALED HIGH You can set a physical value corresponding to the high value.

SCALED LOW You can set a physical value corresponding to the low value.

Figure 28 — Current Output Configuration

TD040300-0MF

42

Page 43

6.3.6 Thermistor Input Configuring

You can define any channel 1–6 as a Type II or III thermistor input as shown in Figure 29 which

uses a Type 3 thermistor and Channel 1 as an example. The channel BACnet type will be

Analog Input. On this screen, you can adjust any of the following parameters.

Channel Type You can select a Type II or Type III thermistor profile.

Channel Name You can name the channel using no more than 63 characters. This

will be the object name for this channel (followed by the channel

number). For example, “Thermistor Input-1”.

BACnet Unit Group The Temperature default can be set to any option in the list.

BACnet Unit Value Set the DEGREES_FAHRENHEIT default to any option in the list.

Available options depend on the BACnet Unit Group you specify.

BACnet COV Increment Once the channel value changes by this amount (up or down), a

COV message is sent to subscribers.

BACnet Description You can enter any string using no more than 63 characters.

Offset You can specify a (+) or (–) number of degrees offset — if, for

example, the thermistor in use is known to be delivering an

inaccurate reading. Either type of thermistor can normally measure

from 40º and +110º Fahrenheit.

Temp Units The Fahrenheit default scale can be changed to Celsius.

Figure 29 — Thermistor Input Configuration

TD040300-0MF

43

Page 44

6.3.7 Pulse Input Configuring

You can define any channel 1–6 as type “INPUT: Pulse” as shown in Figure 30 which uses

Channel 1 as an example. Such a channel can accept a pulse train in the range of 0–40 Hz.

The channel BACnet type will be Analog Value.

NOTE: The value reported by this channel via BACnet will be a 32-bit float as this is an Analog

Value. To provide accurate values when counting input pulses, this value will rollover at 224–1.

To reset the pulse input value, you can (via BACnet) take the channel out of service and write a

desired value — such as 0 — and then put the channel back in service to allow pulse counting

to continue. This value can also be reset by writing a new value to it using one of the following

four methods:

via the map web page — displayed by clicking the Map button (Figure 15)

via Modbus/TCP

via Web Services

via a custom webpage (which can write to the instance associated with this channel)

On the screen of Figure 30, you can adjust any of the following parameters.

Channel Name You can rename the channel using no more than 63 characters.

This will be the object name for this channel (followed by the

channel number). For example, “Pulse Input-1”.

BACnet Unit Group The Others default can be set to any option in the list.

BACnet Unit Value Set the NO_UNITS default to any option in the list. The available

options depend on the BACnet Unit Group you specify.

BACnet COV Increment Once the channel value changes by this amount (up or down), a

COV message is sent to subscribers.

BACnet Description You can enter any string using no more than 63 characters.

ACTUAL HIGH This specifies the highest value within the range.

ACTUAL LOW This specifies the lowest value within the range.

SCALED HIGH You can set a physical value corresponding to the high value.

SCALED LOW You can set a physical value corresponding to the low value.

Period If the “Rate” option has been selected, this specifies the period in

seconds — otherwise, this field is not present on the screen.

Rate This specifies that the rate of the input is being obtained.

Accumulate This specifies that the input pulses are being accumulated (absolute

count) — with no limit to the time during which pulses are counted.

High Level (V) You can specify a value from 10 down to (but more than) the “Low Level”.

Low Level (V) You can specify a value from 0 up to (but less than) the “High Level”.

TD040300-0MF

44

Page 45

Figure 30 — Pulse Input Configuration

TD040300-0MF

45

Page 46

6.3.8 Relay Output Configuring

Channels 7 and 8 are fixed as type “OUTPUT: Relay” as shown in Figure 31 which uses

Channel 8 as an example. Each channel provides a relay contact rated at 30 VAC/DC, 2A.

Each relay has a normally-open and a normally-closed set of contacts. The channel BACnet

type will be Binary Output. On this screen, you can adjust the following parameters.

Channel Name You can name the channel using no more than 63 characters. This

will be the object name for this channel (followed by the channel

number). For example, “Relay Output-1”.

BACnet Unit Group The Others default can be set to any option in the list.

BACnet Unit Value The NO_UNITS default can be set to any option in the list. The