Page 1

AI-USB Series

A Line of ARCNET® Fixed-Port Active Hubs with USB Interface

INSTALLATION GUIDE

INTRODUCTION

The AI-USB Series of hubs work like AI Series hubs, but also

provide computer access via USB. Each device acts as a hub

with three-ports, two external and one internal. The internal

port connects to USB ARCNET adapter circuitry within the

hub. A USB front panel socket gives access to a laptop or

desktop PC.

The AI-USB complies with the USB 2.0 and USB 1.1 standards

to provide fast, convenient access to an ARCNET LAN with no

need of a network interface module in the computer.

The AI-USB can permanently connect to the ARCNET

network as a bus extender while giving a laptop computer

temporary access. Thus, field wiring is undisturbed while a

computer connects to monitor, configure or test the devices on

the ARCNET network. There are coaxial, twisted-pair and

AC- or DC-coupled EIA-485 models.

The internal USB adapter consists of a COM20022 ARCNET

controller and high-speed microcontroller. The 128K bytes of

receiver buffering aids reception of broadcast messages. With

a 480 Mbps USB link, dropped ARCNET packets are rare.

The AI-USB has the same power connectors as the AI Series of

hubs and requires only low-voltage power from either an AC

(8–24 volts) or DC (10–30 volts) source. Approved companion

transformers are available for UL and CE Mark applications.

Provisions exist for redundant power connections. Each unit is

shipped with both panel and DIN-rail mounting hardware and a

disk containing AI-USB software for

USB cable is also provided.

Windows® 2000/XP

. A

Page 2

SPECIFICATIONS

Electrical

Input voltage: 10–36 volts 8–24 volts

Input power: 7 W 7 VA

Input frequency: N/A 47–63 Hz

DC AC

Environmental

Operating temperature: 0°C to +60°C

Storage temperature: –40°C to +85°C

Humidity: 10% to 95%, non-condensing

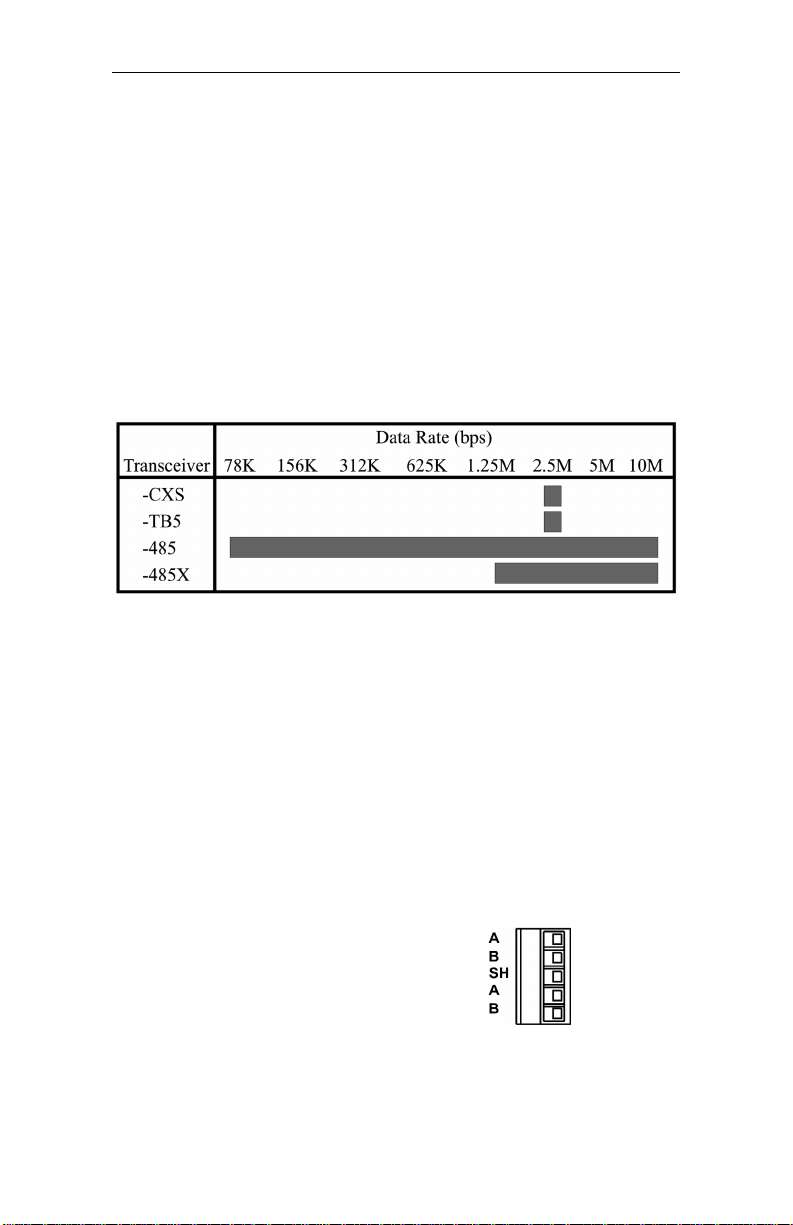

ARCNET Data Rates

Table 1 — ARCNET Data Rates

Shipping Weight

1 lb. (.45 kg)

Compatibility

ANSI/ATA 878.1

LED Indicators

Port Activity — green

Recon — yellow

Status — green

USB — green

Regulatory Compliance

CE Mark; CFR 47, Part 15 Class A

UL 508 Listed Device (intended for use with Class 2 circuits)

Connector Pin Assignments (

485 485X

A Line + Line

B Line – Line

SH Shield Shield

TD030500-0IB

5-pin screw terminal

Figure 1 — 5-pin Screw Terminal

2

)

Page 3

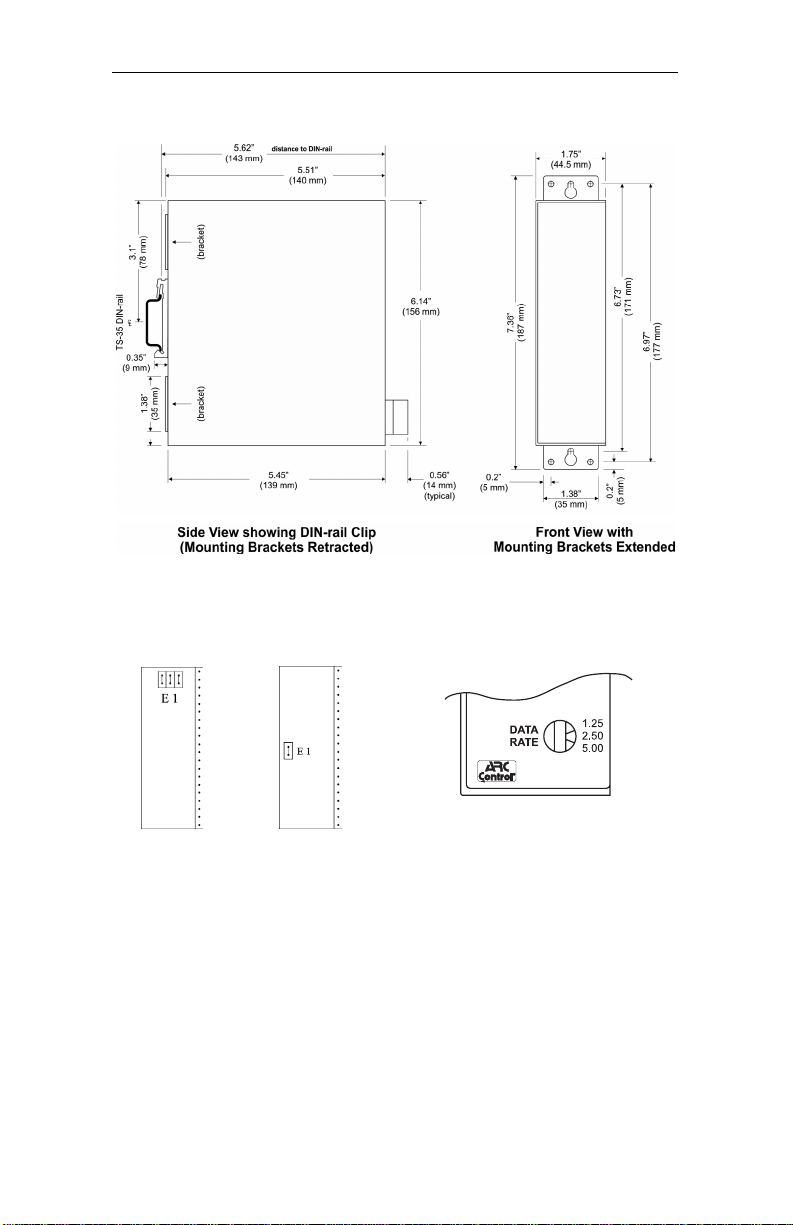

MECHANICAL

Figure 2 — AI-USB Dimensions

Daughter Board Jumper Blocks

for EIA Bias and Termination

Figure 3

DC-Coupled

Figure 4

AC-Coupled

Figure 5 — EIA-485

Data Rate Switch

EIA-485 ROTARY DATA RATE SWITCH

Although the switch in Figure 5 displays stops for only 3 data

rates, every rate in Table 1 has a stop. Count the clicks to

determine the five unlabelled rates. At one stop clockwise past

the 5.00 position, you get 10 Mbps. The next clockwise stop

selects the 78 kbps rate — then 156 kbps, 312 kbps and 625

kbps in turn — until the 1.25 (Mbps) label is reached.

TD030500-0IB

3

Page 4

INSTALLATION

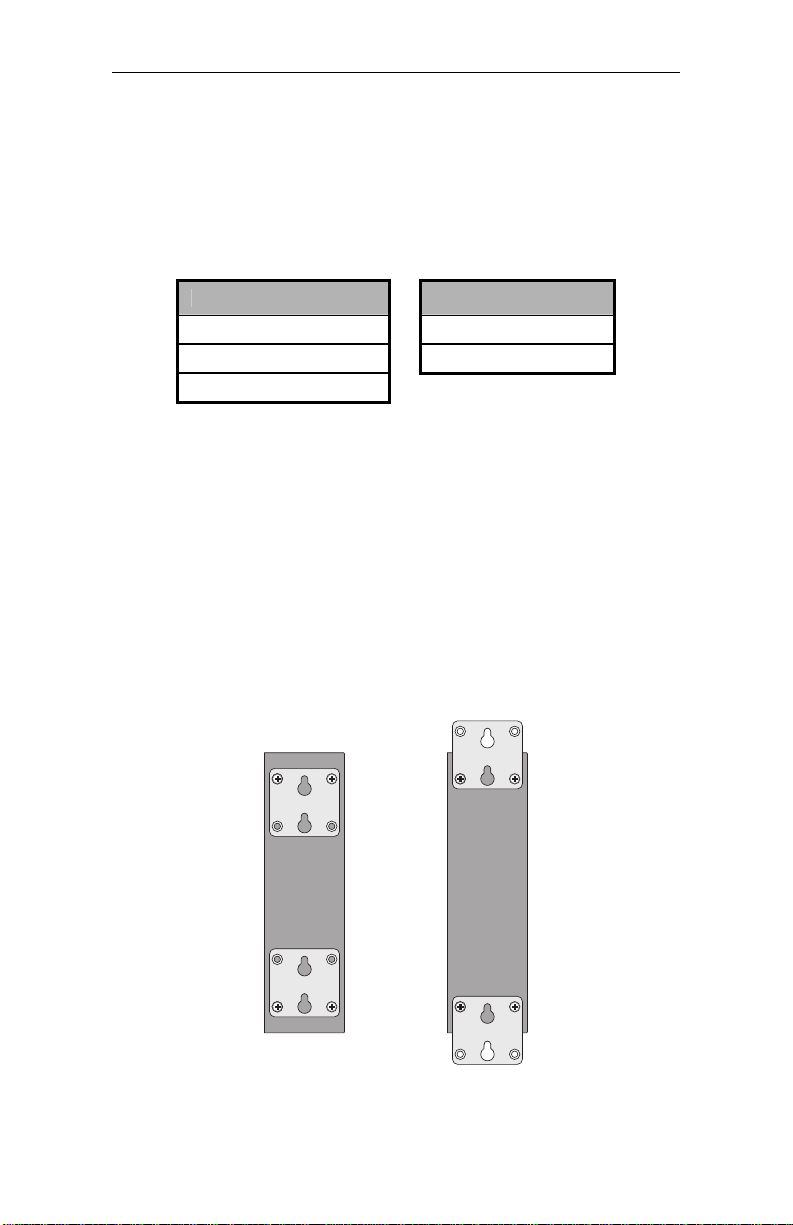

Mounting

The AI-USB is designed for mounting in a wiring closet or an

industrial enclosure using either set of the provided mounting

hardware listed below:

TS-35 DIN Rail Mounting

DIN rail clip

DIN rail clip support bracket

4-40 screws, pan-head (2)

Panel Mounting

Panel mounting bracket

4-40 screws, flat-head (4)

For quick snap-mounting to 35 mm DIN rail, a reinforced DIN

rail clip is pre-attached to the back of the enclosure with two

#4-40 pan-head screws. If the clip is removed, the unit can be

panel-mounted by extending the top and bottom brackets which

are shipped in retracted position. The extended brackets can

then anchor the unit to a wall or other flat vertical surface with

two #8 pan-head screws (not provided). The left illustration of

Figure 6 shows a rear view of the AI-USB with brackets in

retracted position. The right illustration of

Figure 6

shows the

brackets extended and secured to the AI-USB enclosure with

the same screws that were used in the retracted position.

Figure 6 — Using the Panel-Mounting Brackets

TD030500-0IB

4

Page 5

+

+

+

Software

Driver installation instructions are provided in the readme file

located on the disk that accompanies the product.

Powering The AI-USB

The AI-USB requires low voltage AC or DC power applied to

its four-pin removable keyed plug. Consult the Specifications

page for the power requirements. Several methods to provide

power are described below.

DC Powered

Make connections as shown in

DC-DC converter that accepts a wide range of voltage (

which it converts for internal use. The “0 Vdc” terminal is not

connected to chassis within the AI-USB. The input connections

are reverse-voltage protected.

Figure 7

. The AI-USB uses a

10–30 VDC

)

0Vdc

Figure 7 — DC Powered

Redundant DC Powered

Redundant diode-isolated DC power inputs are provided on the

AI-USB for when a concern exists that the AI-USB remain

operational in the event of a primary power failure. Make the

connections as shown in

Figure 8

. Each power supply must be

capable of powering the AI-USB. Do not assume that input

currents from the two supplies will be balanced.

0Vdc

Figure 8 — Redundant DC Power

TD030500-0IB

5

Page 6

+

AC Powered

If AC power is desirable, the AI-USB can be powered by the

secondary of a low-voltage transformer (

Figure 9

) whose

primary is connected to the AC mains. The secondary voltage

must be in the range of 8–24 VAC and must not be grounded.

When using a grounded secondary transformer, refer to Figure

10. For convenience, two AC power adapters are available

from Contemporary Controls: the AI-XFMR is for 120 VAC

primary power and the AI-XFMR-E is for 230 VAC primary

power.

0Vdc

Figure 9 — AC Powered

0Vdc

Figure 10 — AC Power with Grounded Secondary

AC Powered with Battery Backup

The AI-USB can also be powered from both an AC and DC

source. Usually the DC source is from a battery connected as

the DC-powered option. Refer to

this application the AI-USB does not charge the battery, so

separate provisions are required for charging. If the AC source

fails, the AI-USB will operate from the battery.

0Vdc

Figure 11 — AC Power with Battery Backup

Figure 11

for details. In

TD030500-0IB

6

Page 7

Indicator Lights

PORT (#s): Any of the three port activity LEDs will glow

green whenever data is passing through its associated port.

RECON: This LED will flash yellow in response to any

ARCNET reconfiguration event. Repeated flashing of this

LED indicates a fault with cabling or a node device.

STATUS: During boot, this LED flashes green to indicate that

the AI-USB is in standby mode. Once traffic is received on

one of the ARCNET ports and the hub begins to regenerate the

traffic, this LED glows solid to indicate the unit is operational.

USB: This LED glows green so long as a valid active USB

connection exists to an attached computer. This connection is

required before the port 3 LED can turn on.

Electromagnetic Compatibility

All AI-USB units comply with Class A radiated and conducted

emissions as defined by EN55022 and CFR 47, Part 15. This

equipment is intended for use in non-residential areas.

Warning

This is a Class A product as defined in EN55022. In a domestic

environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Field Connections

The AI-USB Series is available in four transceiver options for

connecting to an ARCNET LAN with a particular type of

cable. Each transceiver is identified by a three-character suffix

(CXS, TB5, 485 or 485X) separated from the model number by

a forward slash mark.

The implementation considerations of the various transceiver

options are described in the following pages.

TD030500-0IB

7

Page 8

CXS Coaxial Star

There are generally two types of coaxial cables that are used

with ARCNET, RG-59/u and RG-62/u. RG-59/u is 75-ohm

cable which does not match the impedance of the transceivers

used on the AI ports. This cable will work, but communication

distances are reduced compared to RG-62/u because of the

higher attenuation of RG-59/u cable. We recommend RG-62/u

because it is a better match to the transceivers and a full 2000

foot segment distance can be achieved using this cable. Both

cables support male BNC connectors which the CXS port

accommodates. When connecting to a CXS port, do not apply

a terminator or BNC “T” connector to the port. Simply connect

the coaxial cable directly to the BNC port.

Figure 12 — Typical Connections for the AI-USB/CXS

TB5 Twisted-pair Bus

The TB5 transceiver accommodates twisted-pair cabling via a

pair of RJ-45 jacks. This option allows the insertion of a hub at

any point along a bus segment. Usually IBM type 3 unshielded

twisted-pair cable (UTP) is used, although shielded cable can

be used as well. End devices require a passive terminator that

matches the impedance of the cable (typically 100 ohms).

The dual connectors allows daisy-chaining of the hub at any

location on the bus segment and provides continuous shielding

between devices. When the TB5 port is located at the end of a

bus segment, passive termination to match the cable impedance

is required at the unused jack. For this purpose, a 100-ohm

terminator in an RJ-45 module (part number TB5-TER) is

supplied with the hub.

TD030500-0IB

8

Page 9

485 DC-Coupled EIA-485

A removable 5-position screw connector (

Figure 1

) is provided

for each DC-coupled EIA-485 segment. Two terminals are

provided for differential signal phase A and two for phase B.

The middle pin connects directly to chassis (the enclosure). A

DC-coupled segment can be up to 900 feet of IBM type 3 (or

better) STP or UTP cable, and as many as 17 nodes can occupy

a segment. Make sure the phase integrity of the wiring remains

intact. All phase A signals on the network interface modules

and hubs must be connected together. The same applies to

phase B. If shielded cable is used, the shield should tie to the

middle pin on the connector. Be sure the data rate is the same

for all network devices (see

Figure 5

and associated explanation).

Termination

Each end of the 485 segment must be terminated in the

characteristic impedance of the cable. An internal resistance

can be invoked with a jumper on the EIA-485 daughter board.

With the middle jumper inserted at E1 on the daughter board,

120 ohms of resistance is applied across the twisted-pair. With

the jumper removed, no termination is applied. To apply

external termination instead, remove this jumper and install a

120-ohm 1/4 watt resistor across pins A and B of the screw

ter m i nal connector. A valu e under 120 ohms is not recommended

because it may excessively load the EIA-485 transceivers.

Bias

In addition to termination, bias must be applied to the ends of a

twisted-pair network (and nowhere else) so that when the line is

floated, differential receivers will not assume an invalid logic

state. There are two precision bias resistors of equal value on

the daughter board, one tied to +5 V and the other to ground.

Each resistor has a jumper associated with it. If both jumpers

are installed, the resistor tied to +5 V is connected to the (+)

signal and the grounded resistor is connected to the (–) line.

The termination and bias rules are simple: If the AI-USB is at

the segment end, install all three jumpers at location E1 on the

daughter board (

Figure 3

). Otherwise, remove all jumpers.

To use external termination, remove the middle jumper at E1.

TD030500-0IB

9

Page 10

Ground

For EIA-485 DC operation, it is important that all devices on

the segment be referenced to the same ground potential so the

common mode voltage requirement (+/–7 Vdc) of the EIA-485

specification is achieved. This can be accomplished by a

separate ground wire tied to all devices or using the third wire

ground of the power connector. Alternately, connect the DC

common of each node to a cold water pipe. Connected systems

having different grounds, can cause unreliable communications

or can damage the drivers. Therefore, adequate grounding

must be implemented. A ground connection can be made to

the middle terminal of .

485X AC-Coupled EIA-485

The AC-coupled EIA-485 transceiver offers advantages over

the DC-coupled version. No bias adjustments are needed and

wiring polarity is unimportant. Much higher common mode

voltage levels can be achieved with AC coupling because the

transformer coupling has a breakdown rating of 1000 VDC.

However, AC-coupling also has disadvantages. AC-coupled

segments are shorter (700 feet max) and are limited to 13 nodes

compared to the 17 nodes of DC-coupling. Also, AC-coupled

transceivers operate only at 1.25, 2.5 and 5.0 Mbps while DCcoupled transceivers function over all six standard data rates.

Cabling rules for 485X are similar to those for 485. Wire nodes

in a daisy-chain fashion. On the end devices, insert a jumper at

E1 on both 485X daughter boards (

Figure 4

) to invoke 120

ohms of termination or leave the jumpers open and install a

120-ohm, ¼ watt resistor across pins A and B of the screw

terminals at each end of the bus segment. Refer to for

connector wiring. Termination should not be applied to any

device located between the two ends of the segment. Do not

mix 485 and 485X devices on the same segment; however,

bridging the technologies is possible with active hubs having

appropriate transceivers. To extend 485X segments, use a hub

as discussed under the 485 section, but the active hub ports

must now be 485X types. Cable inversion is insignificant. Be

.

sure that the data rate is the same for all network devices (see

Figure 5

and its associated explanation).

TD030500-0IB

10

Page 11

NEED MORE HELP INSTALLING THIS PRODUCT?

More information can be found at www.arccontrol.com. This

includes our online technical manuals, downloadable software

drivers and utility programs that can test the product. When

contacting one of our offices, just ask for Technical Support.

Warranty

Contemporary Controls (CC) warrants its product to the original

purchaser for two years from the product’s shipping date. Product

returned to CC for repair is warranted for one year from the date that

the repaired product is shipped back to the purchaser or for the

remainder of the original warranty period, whichever is longer.

If a CC product fails to operate in compliance with its specification

during the warranty period, CC will, at its option, repair or replace the

product at no charge. The customer is responsible for shipping the

product; CC assumes no responsibility for the product until it is received.

CC’s limited warranty covers products only as delivered and does not

cover repair of products that have been damaged by abuse, accident,

disaster, misuse, or incorrect installation. User modification may

void the warranty if the product is damaged by the modification, in

which case this warranty does not cover repair or replacement.

This warranty in no way warrants suitability of the product for any

specific application. In no event will cc be liable for any damages

including lost profits, lost savings, or other incidental or

consequential damages arising out of the use or inability to use

the product even if cc has been advised of the possibility of such

damages, or for any claim by any party other than the purchaser.

The above warranty is in lieu of any and all other warranties, expressed

or implied or statutory, including the warranties of merchantability,

fitness for particular purpose or use, title and noninfringement.

Returning Products for Repair

Before returning a product for repair, contact Customer Service.

A representative will instruct you on our return procedure.

Contemporary Control Systems, Inc.

2431 Curtiss Street

Downers Grove, Illinois 60515 USA

Tel: +1-630-963-7070

Fax: +1-630-963-0109

E-mail: info@ccontrols.com

WWW: http://www.ccontrols.com

TD030500-0IB

Contemporary Controls Ltd

Sovereign Court Two, UWSP

Sir William Lyons Road

Coventry CV4 7EZ UK

Tel: +44 (0)24 7641 3786

Fax: +44 (0)24 7641 3923

E-mail: info@ccontrols.co.uk

11

Page 12

DECLARATION OF CONFORMITY

Applied Council Directives:

Electromagnetic Compatibility Directive, 89/336/EEC Council

Directive as amended by Council Directive 92/31/EEC &

Council Directive 93/68/EEC

General Product Safety Directive 92/59/EEC

Standards to which Conformity is Declared

EN 55022:1995 CISPR22: 1993, Class A, Limits and Methods

of Measurement of Radio Disturbance Characteristics of

Information Technology Equipment

EN 55024:1998, Information Technology Equipment — Immunity

Characteristics — Limits and Methods of Measurement

Manufacturer: Authorized Representative:

Contemporary Control Systems, Inc.

2431 Curtiss Street

Downers Grove, IL 60515 USA

Contemporary Controls Ltd

Sovereign Court Two, UWSP

Sir William Lyons Road

Coventry CV4 7EZ UK

Type of Equipment:

Industrial local area network hub

Models:

AI-USB/CXS

AI-USB/TB5

AI-USB/485

AI-USB/485X

I, the undersigned, hereby declare that the products specified

above conform to the listed directives and standards.

George M. Thomas, President July, 2005

TD030500-0IB

12

Loading...

Loading...