Contemporary Controls BAST-221C, BASstat 221C-B2, BASstat Series, BASstat 221C-BW2 User Manual

Page 1

BAST-221C

BACnet Communicating Thermostat for Multi-Stage Relay Heating/Cooling/Ventilation

BASstat

Binary (B2-BW2) User Manual

# UM-15090000-AA4

Page 2

Trademarks

Contemporary Control Systems, Inc.

Tel:

+1-630-963-7070

2431 Curtiss Street

Fax:

+1-630-963-0109

Downers Grove, Illinois 60515 USA

E-mail:

info@ccontrols.com

Contemporary Controls Ltd

Tel:

+44 (0)24 7641 3786

14 Bow Court

Fax:

+44 (0)24 7641 3923

Fletchworth Gate

E-mail:

info@ccontrols.co.uk

Coventry CV5 6SP UK

Contemporary Controls (Suzhou) Co.

Tel:

+44 (0)24 7641 3786

11 Huoju Road

Fax:

+44 (0)24 7641 3923

Industrial Park — Science &

E-mail:

info@ccontrols.com.cn

New District, Suzhou

Contemporary Controls GmbH

Tel:

+49 (0)341 520359 0

Fuggerstraße 1 B

Fax:

+49 (0)341 520359 16

D-04158 Leipzig Deutschland

E-mail:

info@ccontrols.de

BASautomation, Contemporary Controls, and CTRLink are registered trademarks of

Contemporary Control Systems, Inc. BACnet is a registered trademark of the American Society

of Heating, Refrigerating and Air-Conditioning Engineers, Inc. Powered by Sedona Framework

is a trademark of Tridium, Inc. Other product names may be trademarks or registered

trademarks of their respective companies.

Copyright

© Copyright 2018, by Contemporary Control Systems, Inc. All rights reserved. No part of this

publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or

translated into any language or computer language, in any form or by any means, electronic,

mechanical, magnetic, optical, chemical, manual, or otherwise, without the prior written

permission of:

Ltd

Technology

PR China 215009

Disclaimer

Contemporary Control Systems, Inc. reserves the right to make changes in the specifications of

the product described within this manual at any time without notice and without obligation of

Contemporary Control Systems, Inc. to notify any person of such revision or change.

UM-15090000-AA4 Page 2

Page 3

Contents

1 Introduction .............................................................................................................. 4

1.1 Features and Benefits ........................................................................................ 4

1.2 Product Image and Main Features ..................................................................... 6

2 Specifications ........................................................................................................... 7

2.1 Inputs ................................................................................................................. 7

2.2 Outputs .............................................................................................................. 7

2.3 Communication .................................................................................................. 7

2.4 Electrical ............................................................................................................ 7

2.5 Environmental .................................................................................................... 8

2.6 Electromagnetic Compatibility ............................................................................ 8

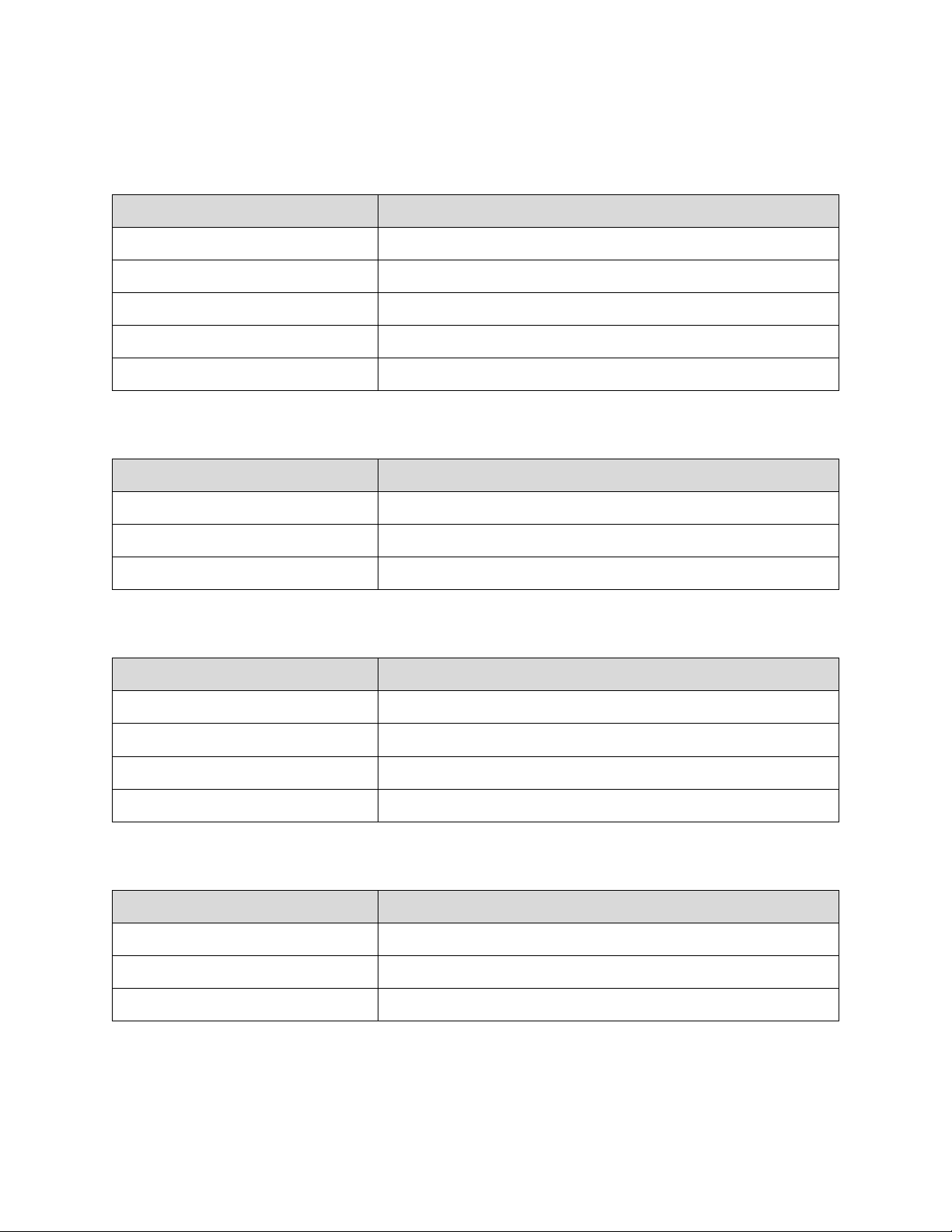

2.7 Mechanical (all dimensions are in mm) .............................................................. 9

3 Installation .............................................................................................................. 11

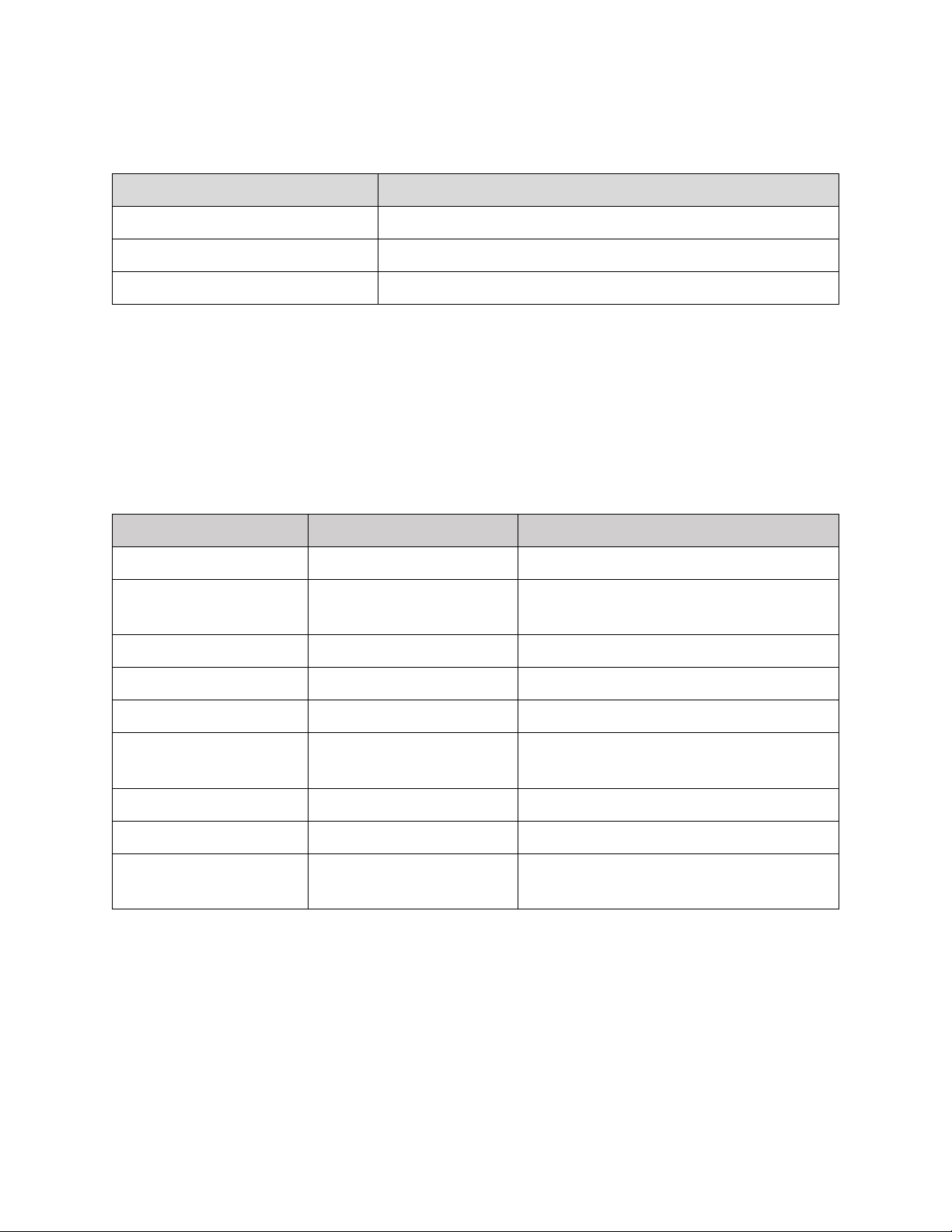

3.1 Terminal Block Pin Assignments ...................................................................... 11

3.2 Limited Power Source ...................................................................................... 12

3.3 Power Supply Precautions ............................................................................... 13

3.4 Wiring Diagram ................................................................................................ 13

4 Operation ............................................................................................................... 14

4.1 User Mode........................................................................................................ 14

4.2 Control Type..................................................................................................... 16

4.3 Engineering Mode Menu .................................................................................. 20

4.4 BACnet Objects and Network Configuration .................................................... 30

5 Warranty ................................................................................................................ 52

6 Returning Products for Repair ................................................................................ 53

7 Declaration of Conformity ....................................................................................... 54

UM-15090000-AA4 Page 3

Page 4

1 Introduction

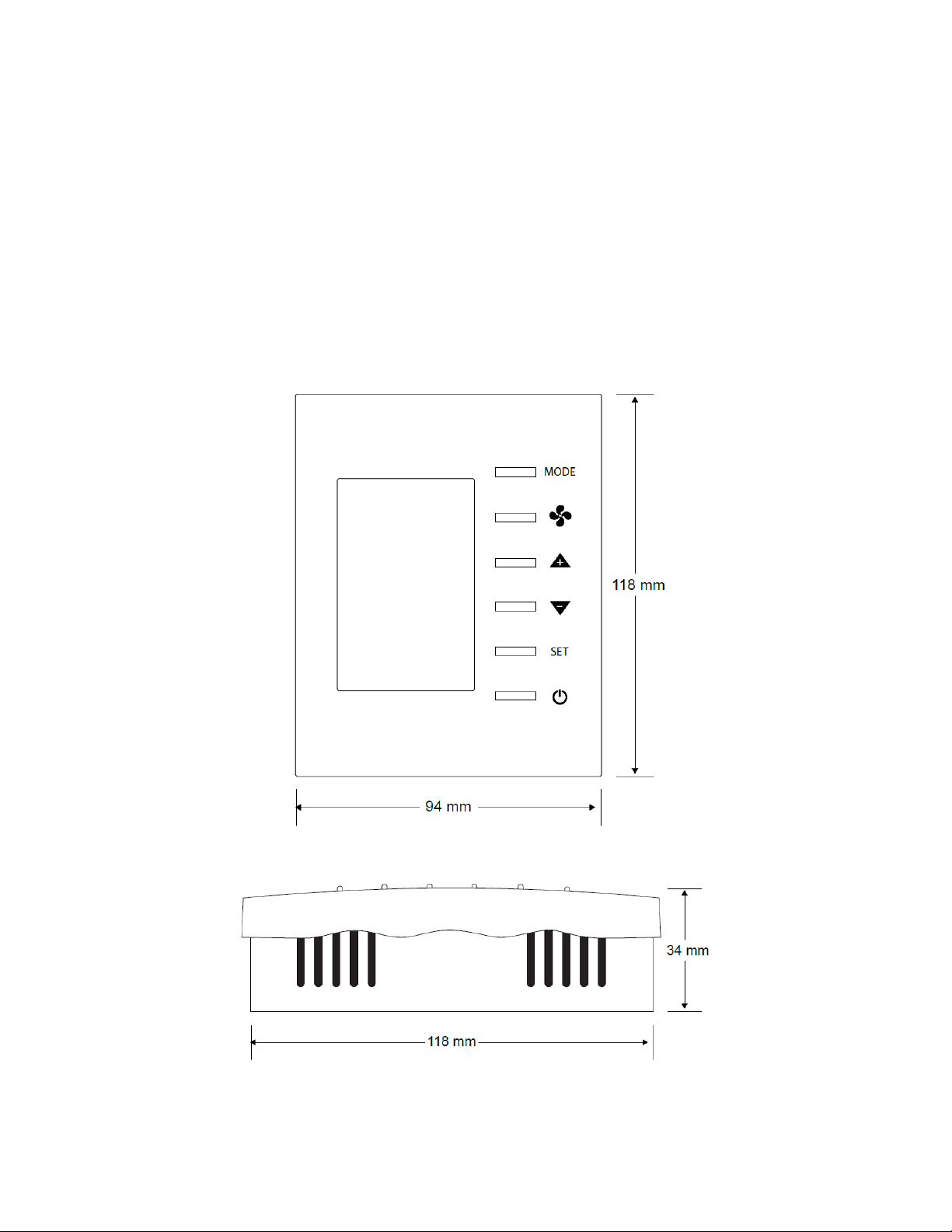

The BAST-221C is a member of the BASstat BACnet Communicating Thermostat series. It

provides multi-stage heating and cooling control in an attractive wall-mounted enclosure with a

large LCD display. Intended for use with rooftop units (RTUs), the thermostat can control one or

two stages of heating and one or two stages of Direct Expansion (DX) cooling. The BASstat is

BACnet compliant and BTL listed to ensure seamless integration into BACnet networks. There

are two models with the only difference being the way the thermostat communicates to a

BACnet client. One model (B2) is BACnet MS/TP connected and can be routed to BACnet/IP

clients using a BASrouter (BASRT-B)

be integrated into any 802.11 b/g/n Wi-Fi network. User-side comfort control is accomplished

with six buttons – Mode (Heat, Cool, or Ventilation), Fan, Raise (Up Arrow), Lower (Down

Arrow), Set, and Power. There also are options to lock select buttons or all buttons on the

thermostat. A large and easy to read LCD display indicates setpoint, space temperature and

current mode of operation using graphical icons.

The BASstat has a built-in space temperature sensor with provision for remote wired 3kΩ NTC

thermistor sensor or temperature value can be sent by another communicating device over the

BACnet network. Both models have five relays – two for stage heating, two for stage cooling

and one for fan. The BASstat is configurable using its buttons and entering the Engineering

Menu or via a network connection to a BACnet client. Contemporary Controls’ free

Discovery Tool can be used for initial discovery and configuration of the thermostat over

BACnet. Control algorithm parameters such as deadband, proportional gain, integral rate, stage

trip points and stage widths are all configurable. The BASstat also features configurable shortcycle protection, maximum cycles per hour, fan control and occupancy selection. All states and

pending delays are indicated by graphical icons on the thermostat display.

The numerous features available in the BASstat can be configured by the systems integrator to

meet user requirements in two different ways. One way is using a button sequence on the

thermostat in order to enter the Engineering Menu - which requires physical access to the

thermostat. Optionally, the buttons could be locked to limit user access to Engineering Menu

after installation is complete. The second method is configuring the thermostat over the BACnet

network using a BACnet client device or software such as Contemporary Controls’ free

Discovery Tool (BDT). All features available are configurable using both methods.

. The other model, (BW2) is BACnet/IP over Wi-Fi and can

BACnet

BACnet

1.1 Features and Benefits

• Fully stand-alone thermostat algorithm or fully BACnet network-controllable

• BTL listed with B-ASC device profile for seamless integration into BACnet networks

• 24VAC (+/-10%) power input

• Manual-changeover or Auto-changeover control types

• Two models of thermostats for BACnet communication options:

-B2 model - BACnet MS/TP with baud rate selections up to 76.8kbps

-BW2 model -BACnet/IP over Wi-Fi model can be integrated into any 802.11 b/g/n Wi-Fi

network

• Suitable for single to multi-stage heat/cool control applications with manual or automatic

changeover between heating and cooling modes

UM-15090000-AA4 Page 4

Page 5

• Adjustable algorithm applied to multi-stage step control

• Adjustable minimum on/off time staging for optimizing runtime

• Effective run time accumulation for system runtime for energy consumption metering

• Full configurable control parameters such as deadband, proportional gain, integral rate,

stage trip points, and cycle time

• Adjustable minimum/maximum set point ranges

• Three options for temperature reading:

-Built-in temperature sensor, or

-Remote sensor (RS) input for wiring in a remote temperature sensor (NTC 3kΩ), or

-BACnet network temperature override

• Occupancy status can be switched from thermostat buttons by occupants or using

BACnet network command.

• Separate adjustable occupied set points for heating and cooling mode

• Separate adjustable unoccupied set points for heating and cooling mode

• Fan can be set to run continuously or automatically depending upon fan mode

• Non-volatile memory (EEPROM) retains user settings during power outage

• Thermostat buttons are selectively lockable to prevent unauthorized control

• °C or °F display

• Control outputs disabled during “OFF” state for safety

UM-15090000-AA4 Page 5

Page 6

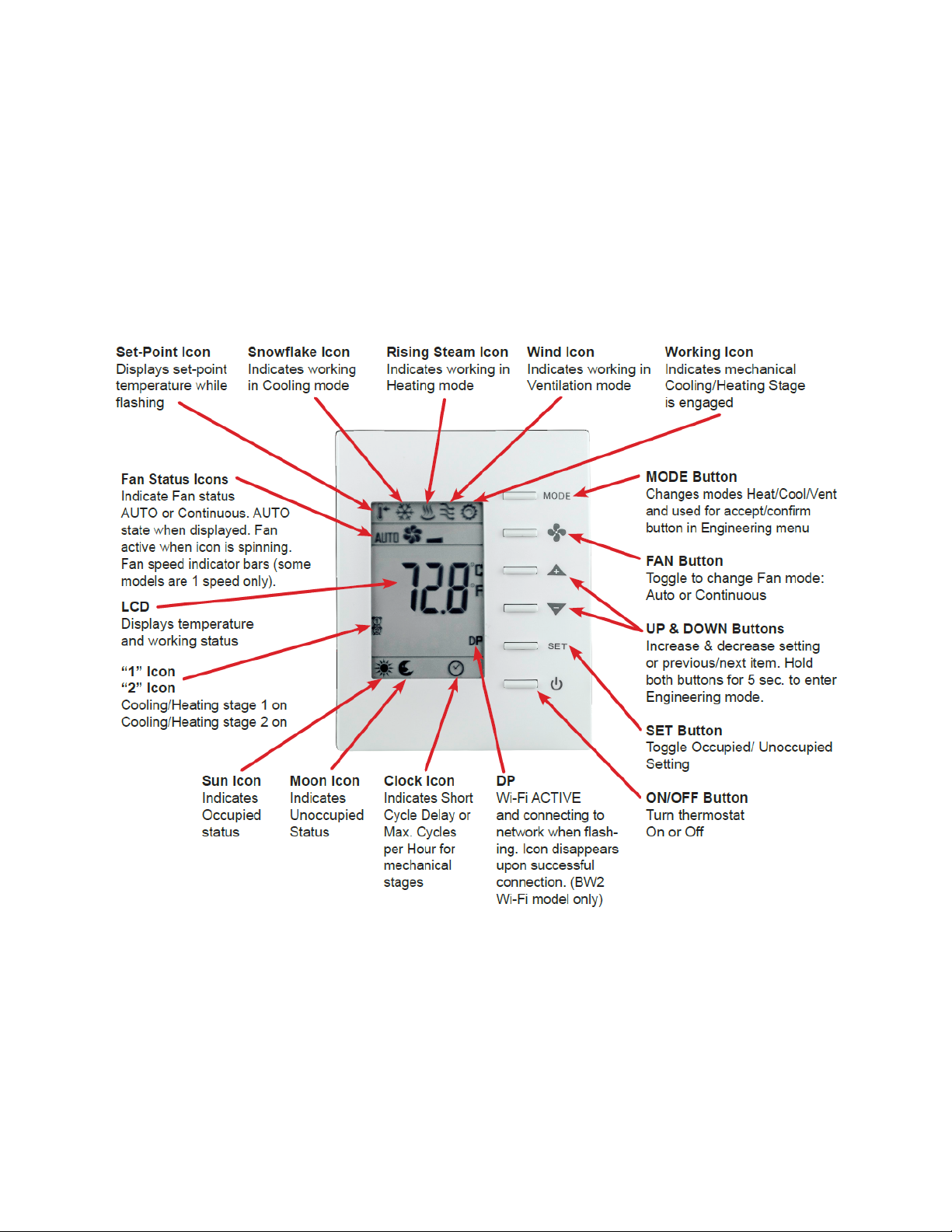

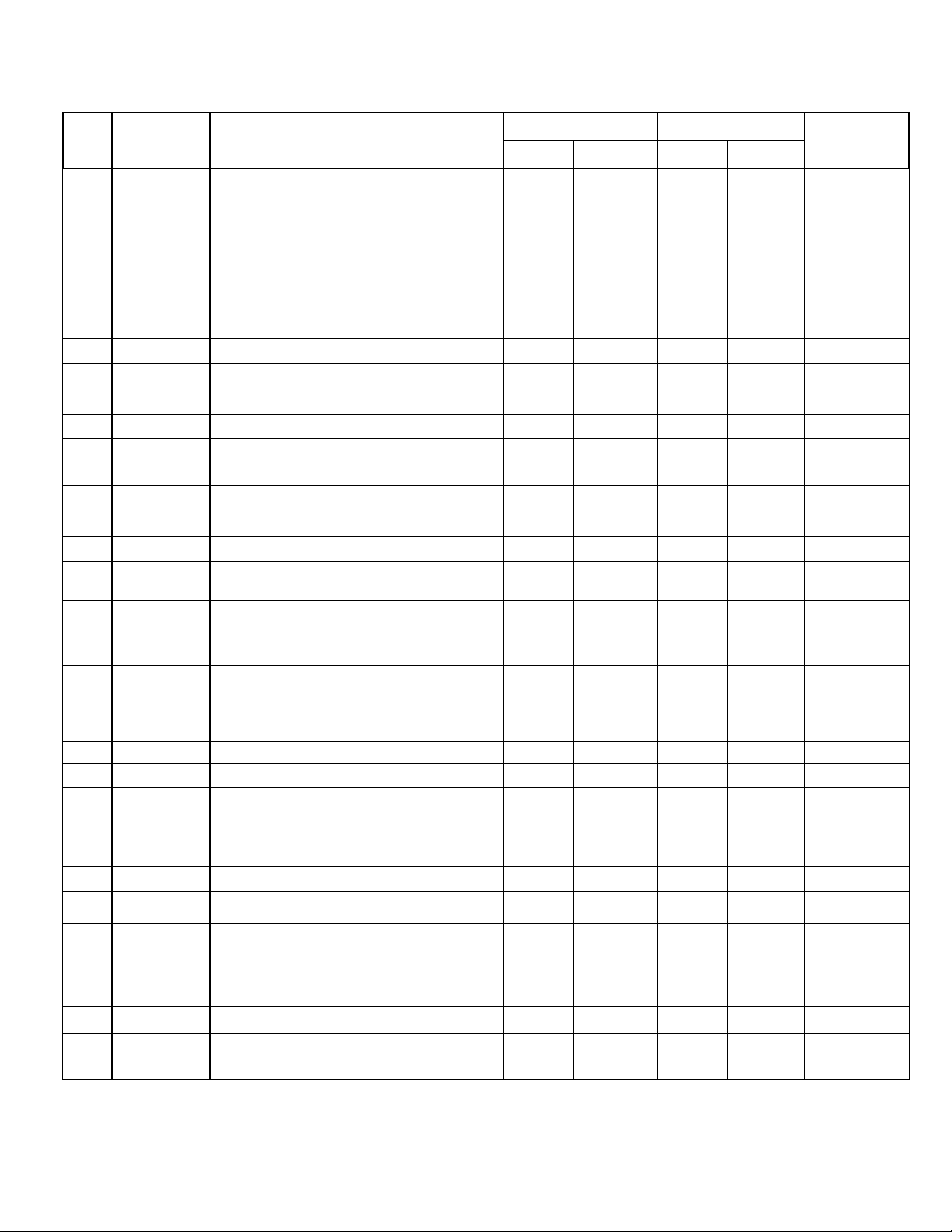

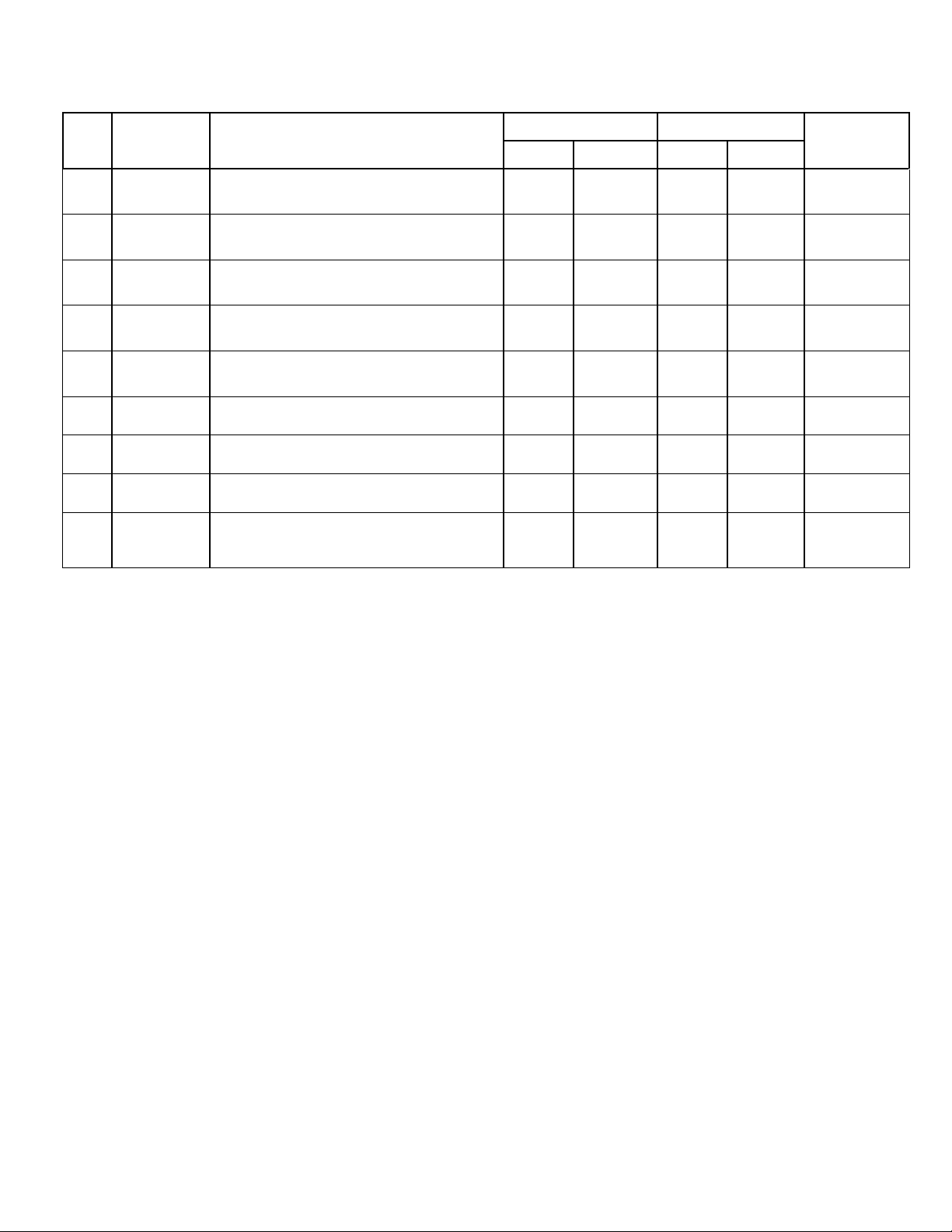

1.2 Product Image and Main Features

BASstat 221C-B2 and BASstat 221C-BW2

UM-15090000-AA4 Page 6

Page 7

2 Specifications

Item

Description

Temperature Display Range

14 to 140°F (-10 to 60°C)

Temperature Display Resolution

0.1°F (0.1°C)

Temperature Accuracy

±1.8°F (±1.0°C) with all outputs off

Setpoint Range

32-122°F (0-60°C) in 0.5° (°F or °C) increments

Remote Temperature Sensor

Provision for NTC Type 3kΩ thermistor

Item

Description

Relay Outputs

Heating 1, Heating 2, Cooling 1, Cooling 2, Fan

Contact Rating

SPST 2A at 30 VAC with inductive load

Minimum contact life

100,000 cycles

Item

Description

Protocol Compliance

BACnet MS/TP or BACnet/IP with B-ASC, BTL Listed

Physical Layer

2-wire, non-isolated EIA-485, no built-in EOL termination

Baud Rate

9.6, 19.2, 38.4, 76.8 kbps (default 38.4 kbps), N81 format

Cabling

Single-pair twisted 24GA with shield

Item

Description

Supply Voltage and Current

24 VAC (±10%) 5 VA

Power Source Class

NFPA 70 (NEC) Article 725 Part III Class 2

Internal Power Supply

Half-wave rectified and filtered DC

2.1 Inputs

2.2 Outputs

2.3 Communication

2.4 Electrical

UM-15090000-AA4 Page 7

Page 8

2.5 Environmental

Item

Description

Operating Temperature

32°F to 122°F (0 to 50°C)

Storage Temperature

-40°F to +85°F (-40°C to 30°C)

Relative Humidity

5 to 95% non-condensing

Standard

Test Method

Description

EN 61000-6-2

IEC 61000-4-2

Electrostatic Discharge Immunity

EN 61000-6-2

IEC 61000-4-3

Radiated, Radio-Frequency,

EN 61000-6-2

IEC 61000-4-4

Electrical Fast Transit/Burst Immunity

EN 61000-6-2

IEC 61000-4-5

Voltage Surge Immunity

EN 61000-6-2

IEC 61000-4-6

Immunity to Conducted Disturbances

EN 61000-6-2

IEC 61000-4-8

Power Frequency Magnetic Field

EN 61000-6-2

IEC 61000-4-11

Voltage Dips and Interruptions

EN 61000-6-3

IEC 61000-3-2

Limits for Harmonic Current Emissions

EN 61000-6-3

IEC 61000-3-3

Limitation of Voltage Fluctuations and

2.6 Electromagnetic Compatibility

The BAST-221C complies with the following specifications and bears the CE mark in

accordance with the provisions of the Electromagnetic Compatibility (EMC) Directive

2004/108/EC based on the following specifications:

Electromagnetic Field Immunity

Immunity

Flicker in Low Voltage Supply Systems

UM-15090000-AA4 Page 8

Page 9

2.7 Mechanical (all dimensions are in mm)

Mounts directly onto wall, panel, standard 65×65mm junction box (hole pitch 60 mm) or

standard 2×4-inch vertical junction box (hole pitch 83.5mm)

Width: 94mm

Height: 118mm

Depth: 34mm

UM-15090000-AA4 Page 9

Page 10

UM-15090000-AA4 Page 10

Page 11

3 Installation

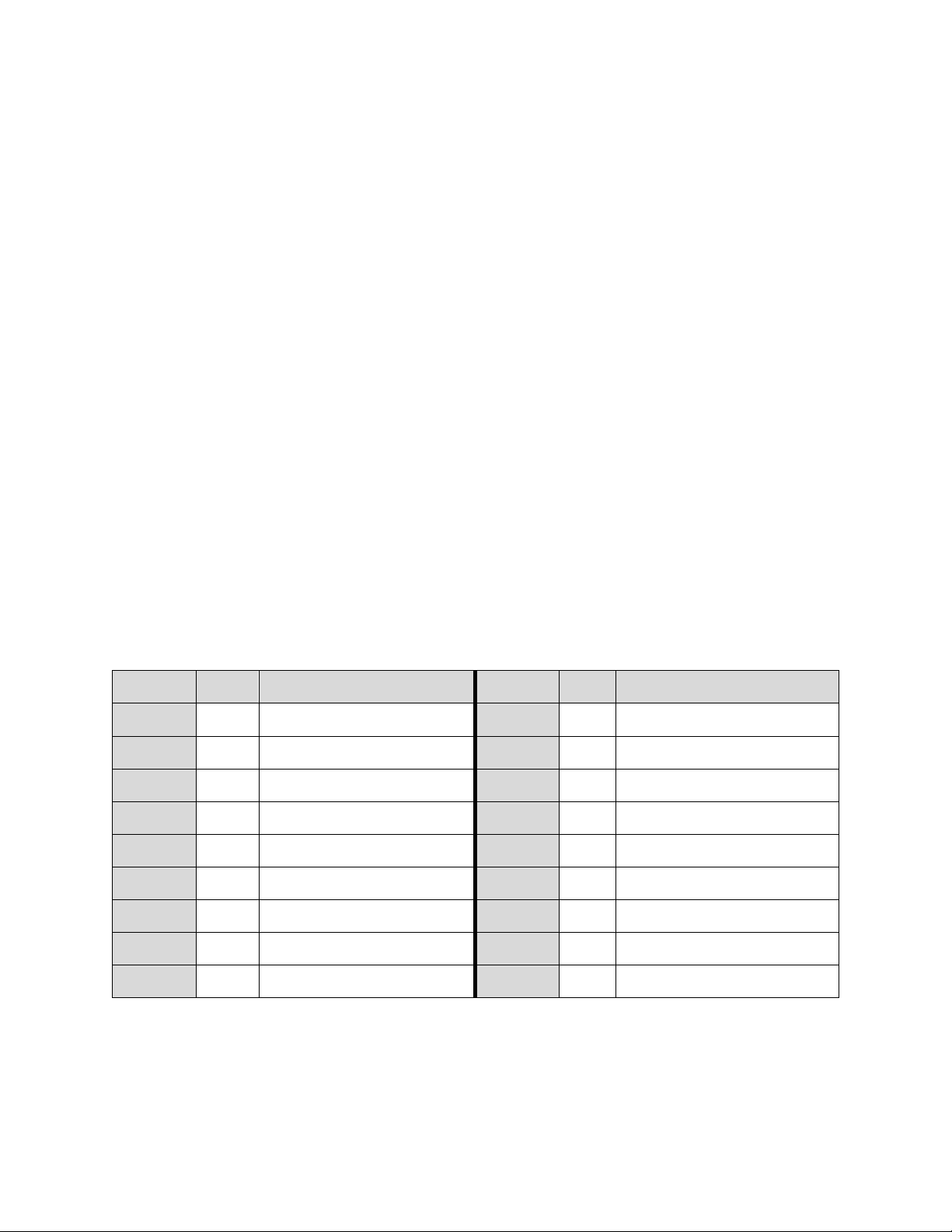

Number

Mark

Comment

Number

Mark

Comment

1

R

24 VAC high-side

10

2

C

24 VAC common

11

3

Y1

Cooling Stage 1

12

4

13

RS

Remote Sensor Input

5

Y2

Cooling Stage 2

14

GND

Ground

6

W1

Heating Stage 1

15

7

W2

Heating Stage 2

16

D+

BACnet MS/TP Data +

8

G

Fan

17

D-

BACnet MS/TP Data -

9

18

The BASstat is intended for surface-mount installation at eye-level on a wall, not subjected to

direct sunlight or direct air movement. The display (top half) can be removed from its base by

loosening the small Philips screw at the bottom of the display. There is no need to remove the

screw. Once the display is removed from the base, the base can be mounted onto the wall with

appropriate fasteners. The dimensions of the oval mounting holes are 4mm x 6mm allowing for

perfect fit adjustments. If a single-gang electrical junction box is to be used, the top and bottom

mounting holes will align with the screw holes in the junction box. Thanks to its EEPROM, the

BASstat will store its configuration in the event of power loss.

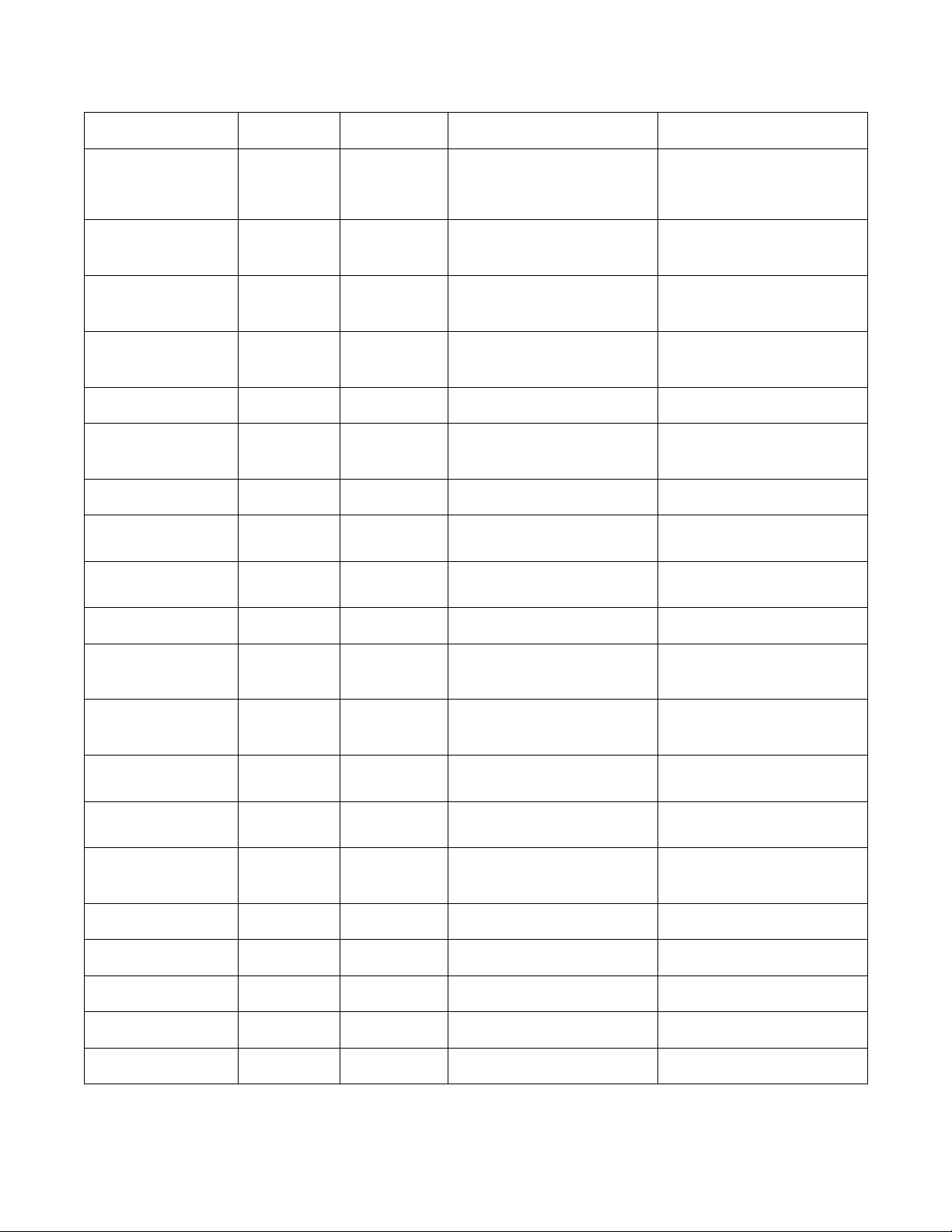

3.1 Terminal Block Pin Assignments

Two 9-pin terminal blocks provide for all field connections. Terminal markings for mechanical

equipment follow NEMA DC 3-2003 convention. For single-stage operation, connect Y wire to

Y1 and W wire to W1. BACnet MS/TP data communication connections can be found at

terminals 16 and 17 and are polarity sensitive. The BASstat (B2 MS/TP model) does not provide

End-of-Line termination. If the BASstat-B2 is the first or last device on the MS/TP bus, a

termination resistor (120Ω) must be applied across pins 16 and 17 of the input terminal. The

remote sensor input (RS) is at terminals 13 and 14. The BASstat is intended to be powered by a

Class 2 compliant power source and only accepts 24VAC.

UM-15090000-AA4 Page 11

Page 12

3.2 Limited Power Source

The BASstat thermostats accept 24VAC only with no more than 5VA of power consumption and

should be powered by a limited power source complying with the requirements of the National

Electric Code (NEC) article 725 or other international codes meeting the same intent of limiting

the amount of power of the source. Under NEC article 725, a Class 2 circuit is that portion of the

wiring system between the load side of a Class 2 power source and the connected equipment.

For AC or DC voltages up to 30 volts, the power rating of a Class 2 power source is limited to

100 VA. The transformer or power supply complying with the Class 2 rating must carry a

corresponding listing from a regulatory agency such as Underwriters Laboratories (UL).

UM-15090000-AA4 Page 12

Page 13

3.3 Power Supply Precautions

Internally, the BASstat utilizes a half-wave rectifier and therefore can share the same AC power

source with other half-wave rectified devices. Sharing AC power with full-wave rectified devices

is NOT recommended. Full-wave rectified devices usually require a dedicated AC power source

that has a secondary elevated above ground. Both secondary connections are considered HOT.

AC power sources that power several half-wave devices have a common secondary connection

called COMMON, LO, or GROUND. This connection might be tied to earth. The other side of

the secondary is considered the HOT or HI side of the connection. Connect the HOT side of the

secondary to the 24 VAC high side input on the BASstat and the LO side to 24 VAC common on

the BASstat. All other half-wave devices sharing the same AC power source need to follow the

same convention.

WARNING: Devices powered from a common AC source could be damaged if a mix of halfwave and full-wave rectified devices exist. If you are not sure of the type of rectifier used by

another device, do not share the AC source with it.

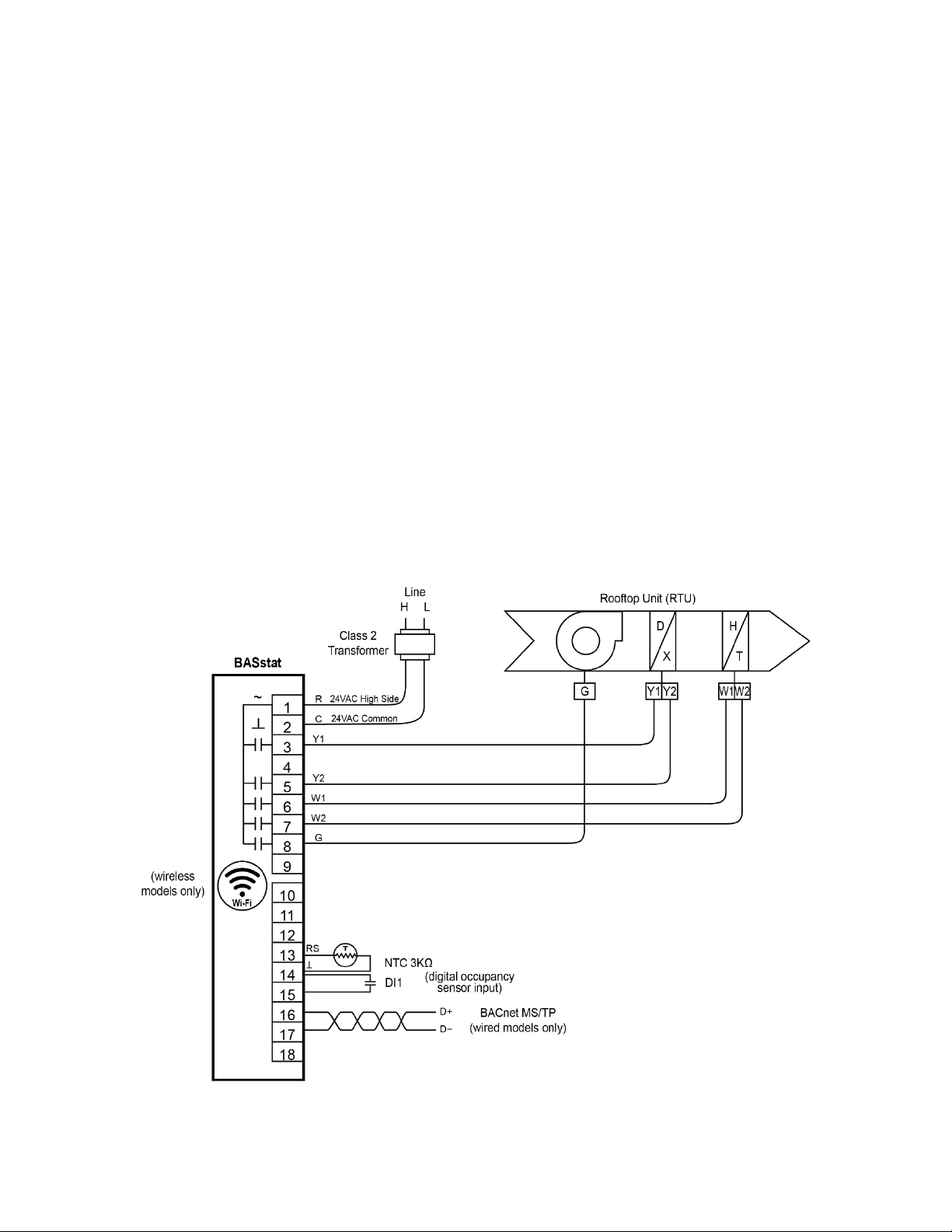

3.4 Wiring Diagram

UM-15090000-AA4 Page 13

Page 14

4 Operation

4.1 User Mode

User-side comfort control is accomplished with six buttons – MODE (Heat, Cool, or Ventilate),

FAN (Auto or Continuous), UP, DOWN, SET, and POWER. There are also options to lock

select buttons or all buttons on the thermostat to limit user access if required in certain

applications. A large LCD display indicates setpoint, space temperature, occupancy status,

and current mode of operation using graphical icons.

System modes (Cool, Heat, Ventilate) available to the user are dependent on control type

chosen from Engineering Menu (tyPE) or BACnet object [MSV7] Control Type for BW2 model

and [MSV8] Control Type for B2 model. (See section 4.2 Control Type of this manual).

System modes and button operation may be limited by installation engineer, especially if the

thermostat is completely controlled over BACnet network.

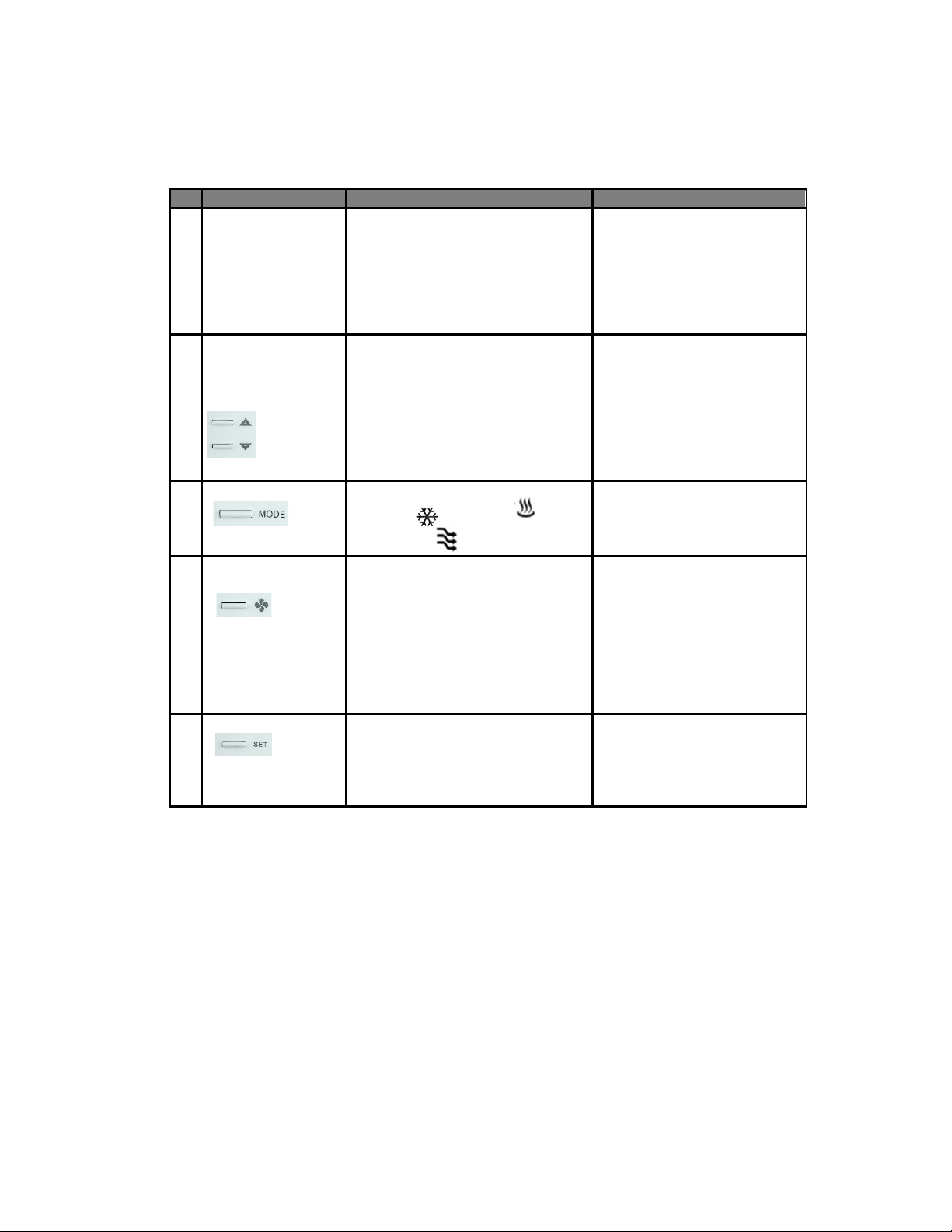

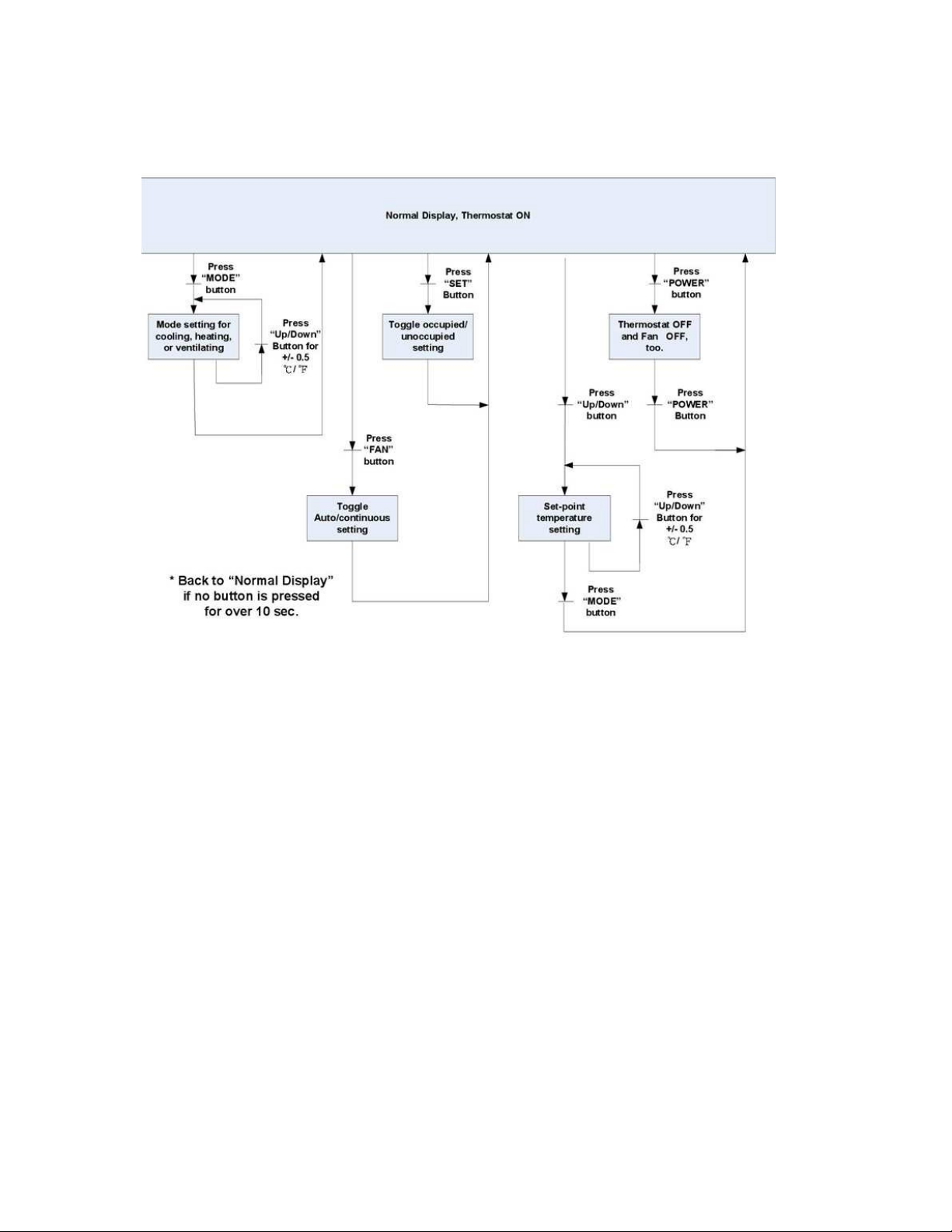

The first tier of operation includes the following settings as shown below. To operate the

thermostat:

1.

The POWER button toggles between ON or OFF states to start / stop the

thermostat. This will disable control (ON/OFF control can be accomplished over BACnet

as well).

2.

At power ON, press any button to start the User Mode operation. Press the MODE

button to toggle between different HVAC operating modes such as Cool,

Heat, or Ventilate@Cool and Ventilate@Heat.

Press the UP/ DOWN buttons to increase/decrease temperature

setpoint or rotate the values of a setting. Press the FAN button to toggle fan

modes of AUTO or CONTINUOUS. If no AUTO icon is displayed, the fan is in

CONTINUOUS fan mode and it will run continuously until commanded off using button

on thermostat or BACnet command. If AUTO icon is flashing, the fan is operating

under delay timer and will shut off automatically when delay timer expires.

Press the SET button and use UP/ DOWN buttons to

toggle the unit between Occupied or Unoccupied states when outside of scheduled

operation. Use SET or MODE to apply (SET button can be locked in applications

forbidding occupancy state user control).

3.

Thermostat will return to normal display with the last known setting if there’s no button

pressed for 10 seconds.

UM-15090000-AA4 Page 14

Page 15

User Mode Thermostat Operation

# Item

Description

Remarks

1

Normal Display

Display current room or set-point

Use the (SP) parameter in

point temperature on display.

2

Temperature

Set the desired temperature

The [AV0] / [AV3] Cool / Heat

Occupied and [

Unoccupied

t

BACnet

objects can be used to write or

force the setpoint to a desired

value from

3

Mode Select

Select the working mode:

Ventilating (

).

After pressing the MODE

4

Fan Auto/

Change the Fan mode between

When AUTO is displayed, the

continuously until commanded

off.

5

Occupancy Setting

Press SET, Used UP and DOWN

apply.

The SET button could be

locked for applications

forbidding user occupancy

state

Setpoint Setting

using Up/Down

Arrows

Continuous

temperature

Cooling ( ), Heating ( ), or

Auto or Continuous.

the Engineering Menu or

[MSV6] Display Option for

BW2 or [MSV7] Display

Option for B2 model to

choose Current room or Set-

AV8] / [AV9]

Cool / Heat

emperature setpoints

BACnet supervisor.

button, press the UP/ DOWN

button to rotate the selections.

Dependent on Control Type.

fan is handled automatically.

When AUTO is flashing, the

fan is working under a delay

timer. When FAN icon is

spinning but AUTO is not

displayed, the fan will run

UM-15090000-AA4 Page 15

arrows to toggle between the

Occupied and Unoccupied setting.

Use MODE or SET buttons to

control.

Page 16

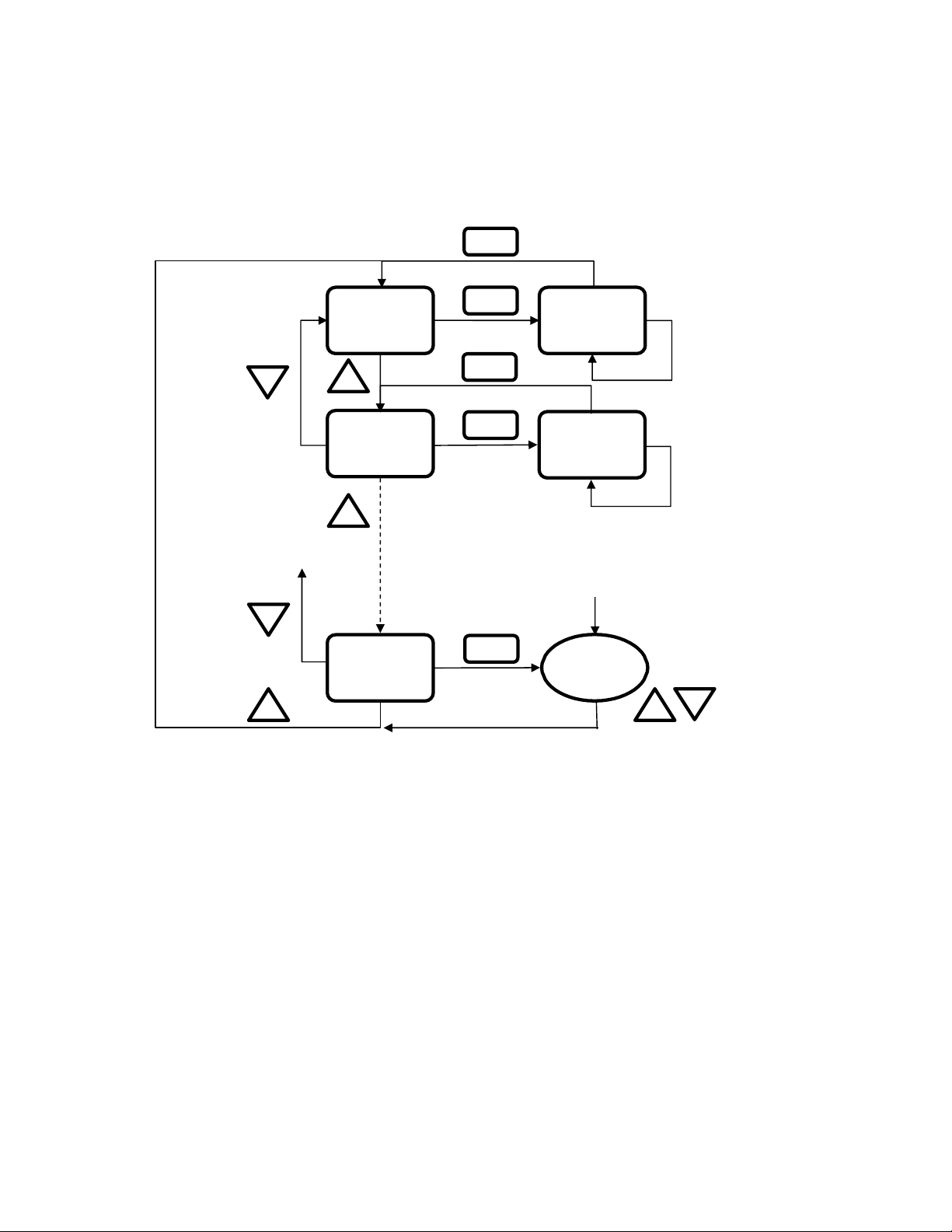

User Mode Flow Chart

4.2 Control Type

Control Type, System Mode and Algorithm Configuration

Both binary thermostat models (B2 and BW2) support two different control types, selectable in

Engineering Menu item (tyPE) or BACnet object [MSV8] Control Type for B2 model or [MSV7]

Control Type for BW2 model.

Control type unlike thermostat system mode, is not selectable by the end user, only configurable

by the installation engineer using Engineering Mode Menu (manual) or BACnet supervisor using

BACnet commands (commanded by BACnet supervisor). The engineer installing the thermostat

must decide the control type suitable for the application, set it to a static value, or program the

BACnet supervisor to change the control type automatically based on logic for the application

requirements such as change of seasons or geolocation. The default control type is set to 2stage Heating and Cooling with Auto Changeover. This is the most common control type. 2stage Heating and Cooling with Manual Changeover can be used to limit frequent automatic

change of system modes (Cool or Heat).

UM-15090000-AA4 Page 16

Page 17

System modes available to the user are dependent on control type chosen from Engineering

Menu (tyPE) or BACnet object [MSV7] Control Type for BW2 model and [MSV8] Control Type

for B2 model.

Dual Stage Heat and Cool with Auto Changeover - The default control type in the thermostat is

set to Heat and Cool with Auto Changeover. Mostly used for standalone operation. Based on an

algorithm using setpoint, current temperature, and deadband, the thermostat will switch

between Cool and Heat modes automatically. In this control type, the user will be presented with

a choice of Heat or Ventilation@Heat when the thermostat is in Heat mode (automatic), and

Cool or Ventilation@Cool when the thermostat is in Cool mode (automatic).

Dual Stage Heat and Cool with Manual Changeover – This control type is similar to Heat and

Cool with Auto Changeover but in this control type the thermostat will wait for a command from

user or BACnet supervisor to switch between Cool and Heat modes. In this control type, the

user will be presented with a choice of Heat or Ventilation@Heat when the thermostat is in Heat

mode (manual command), and Cool or Ventilation@Cool when the thermostat is in Cool mode

(manual command). The user can also choose to switch between Cool and Heat modes using

the MODE button.

BACnet controlled – The built-in thermostat algorithm can be bypassed completely, and the

thermostat can be controlled over the BACnet network with commands from supervisor device.

The logic executing in the supervisor (such as Niagara or Sedona logic) can control the

thermostat over the BACnet network. To put the thermostat in BACnet network control mode,

use the Lock [AV18] object bit 9: Control DOs by thermostat algorithm “0” (default) or BACnet

supervisor “1” (add decimal=512).

Cool Only (nullified/disabled in firmware), and Heat Only (nullified/disabled in firmware) control

types are listed in the BACnet object and Engineering Menu object but are not available for use.

They are nullified/disabled in the firmware.

Fan Output in Heat Mode

By default, the BASstat thermostat will not provide Fan output signal when in Heat Mode since

most HVAC comfort systems such as RTU systems provide their own fan control signal based

on a delay after a call for heating. This can be configured from Engineering Menu item (F-Ht) or

BACnet object [BV15] Fan Output For Heating. The default value is “0”. To enable fan control

signal output for heating coming from the BASstat, set this value to “1”.

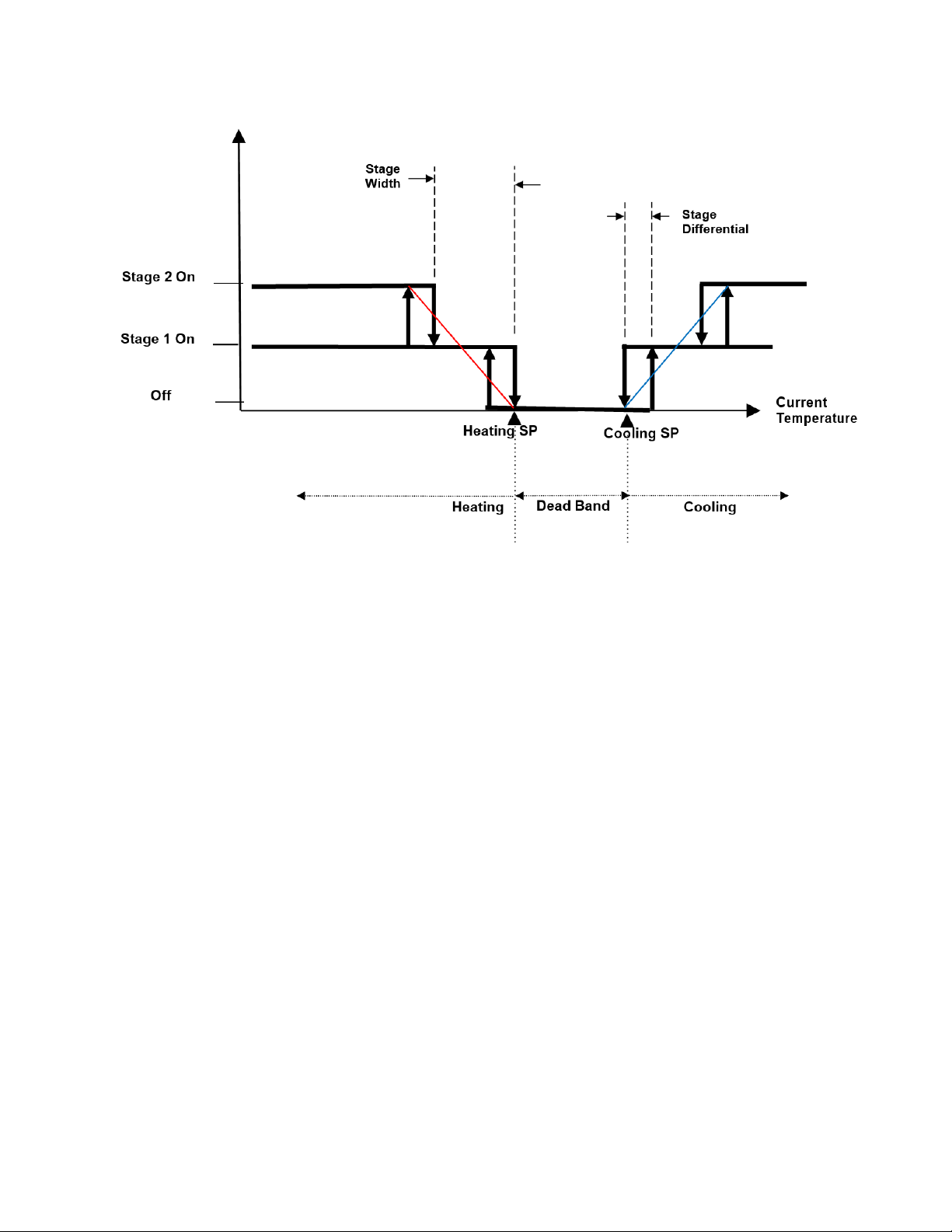

Algorithm

• A PID adaptive control algorithm is applied to minimize overshoot, in addition to

proportional band (Stage Width) and derivative (Differential) calculation.

• When the thermostat is active (either the heating or cooling stage is on), a “Working

( )” icon will be shown on the LCD.

• Stage 1 operation will show the icon ( ). Stage 2 operation will display ( ).

UM-15090000-AA4 Page 17

Page 18

System Mode

• The default control type is 2-stage cooling and heating with automatic changeover.

This makes the thermostat operate fully stand-alone. Control Type can be selected

in (tyPe) or [MSV7] or [MSV8]. Manual Changeover control type allows restriction of

mode selection to Cool only or Heat only in applications where necessary.

• Occupied Cooling [AV0] and Heating [AV3] set points and Unoccupied Cooling

[AV8] and Heating [AV9] setpoints can be set individually for cooling and heating

modes, with either manual or automatic changeover control. Minimum deadband

[AV7] can be programmed as well.

• For cooling/ heating with manual changeover control, cooling or heating can be

selected by pressing the MODE button or using a BACnet command to object [

MSV1]. In application where user control needs to be limited, the lock button

function can be used to disable MODE button.

Fan Control Output

• Fan Output for Heating - the fan output for Heat mode is disabled “0” in [BV15] by

default. The thermostat lets the RTU circuity control the fan during Heat mode. Fan

output can be enabled “1” for Heat mode if desired [BV15].

• Lowest Fan Speed is the speed the fan will default to after a control action (Heating

or Cooling). If the lowest fan speed [MSV4] is set as “Stop (1)”, the fan will be

automatically shut off after the control action (Heating or Cooling) and a 2-minute

fan-off time delay. During this delay time, the AUTO icon will be flashing, and the fan

will shut off after the 2-minute time delay expires. If lowest fan speed is set to “Low

UM-15090000-AA4 Page 18

Page 19

(2)” the fan will run continuously after a control action. This feature is useful for

thermostat models with multiple fan speeds.

• Fan Mode can be toggled between AUTO or CONTINUOS by using the FAN button

on the thermostat (user) or BACnet object [MSV0] Fan Mode (BACnet supervisor).

By default, this value is set to “Auto(1)”, the AUTO icon is displayed and the fan will

be controlled automatically. To put the fan in CONTINUOS mode set to “Low(2)”

this will cause the fan to run continuously (no AUTO icon is displayed). Fan icon

spinning when fan is active. Optionally, the FAN button can be locked to limit user

access to this feature or the BACnet supervisor can be programmed to default the

thermostat to certain state at the end of an occupancy cycle.

Short Cycle and Maximum Cycles per Hour

• There are short cycle and maximum cycles per hour protection for both cooling and

heating modes [AV23 – 26] Cooling Short Cycle Delay, Cooling Maximum Cycles

per Hour and Heating Short Cycle Delay, Heating Maximum Cycles per Hour.

• The short cycle time (in minutes) will determine the minimum on time and minimum

off time of each stage before changing its state. The default setting is 3 minutes.

• Maximum cycles per hour will count the number of cycles in an hour. When the cycle

count reaches the maximum cycles in an hour, it won’t allow additional cycles until

the next hour.

• When a stage change is pending due to a Short Cycle Delay or a Maximum Cycle

count, the Clock icon ( ) will appear on the LCD.

• To disable short cycle checking, set the short cycle to 0 minutes. NOTE: Do not use

this value unless the heating and cooling equipment is equipped with an internal

timer. Damage to equipment may occur.

Occupancy Setting

There are three ways to define thermostat occupancy state.

• Occupancy status (occupied/unoccupied) can be set by a BACnet supervisor using

writable object Occupancy Command [BV14]. Use “0” for occupied (occupied setpoints

used, sun icon displayed), and “1” for unoccupied (unoccupied setpoints used, moon

icon displayed). Occupancy Status [BI0] is a read-only BACnet object indicating

current thermostat occupancy state - “0” for occupied, and “1” for unoccupied. The

BACnet occupancy command can work in conjunction with SET button (user control)

on last-write-wins basis.

• User control of occupancy state is allowed from the SET button. Pressing the SET

button and UP/DOWN buttons will toggle the occupancy state. Press MODE or SET

buttons to confirm. The SET button can work in conjunction with BACnet occupancy

Command [BV14] on last-write-wins basis. The SET button could be locked to limit

user control (use Lock [AV18] BACnet object or (LOC) engineering menu item to lock

SET button). In this case only the BACnet supervisor can set occupancy states.

Occupancy Status [BI0] is a read-only BACnet object indicating current occupancy

state.

UM-15090000-AA4 Page 19

Page 20

• When in unoccupied state, a Moon ( ) icon will be displayed on the LCD and the

thermostat will change the set-point temperatures for Cooling and Heating to the

Unoccupied Cool Setpoint and Unoccupied Heat Setpoint [AV8 – 9]. When the state

changes back to occupied, the thermostat will return to the occupied set-point values for

Cooling Temperature Setpoint and Heating Temperature Setpoint [AV0, AV3] and a

sunlight icon( ) will be displayed to indicate occupied state on LCD.

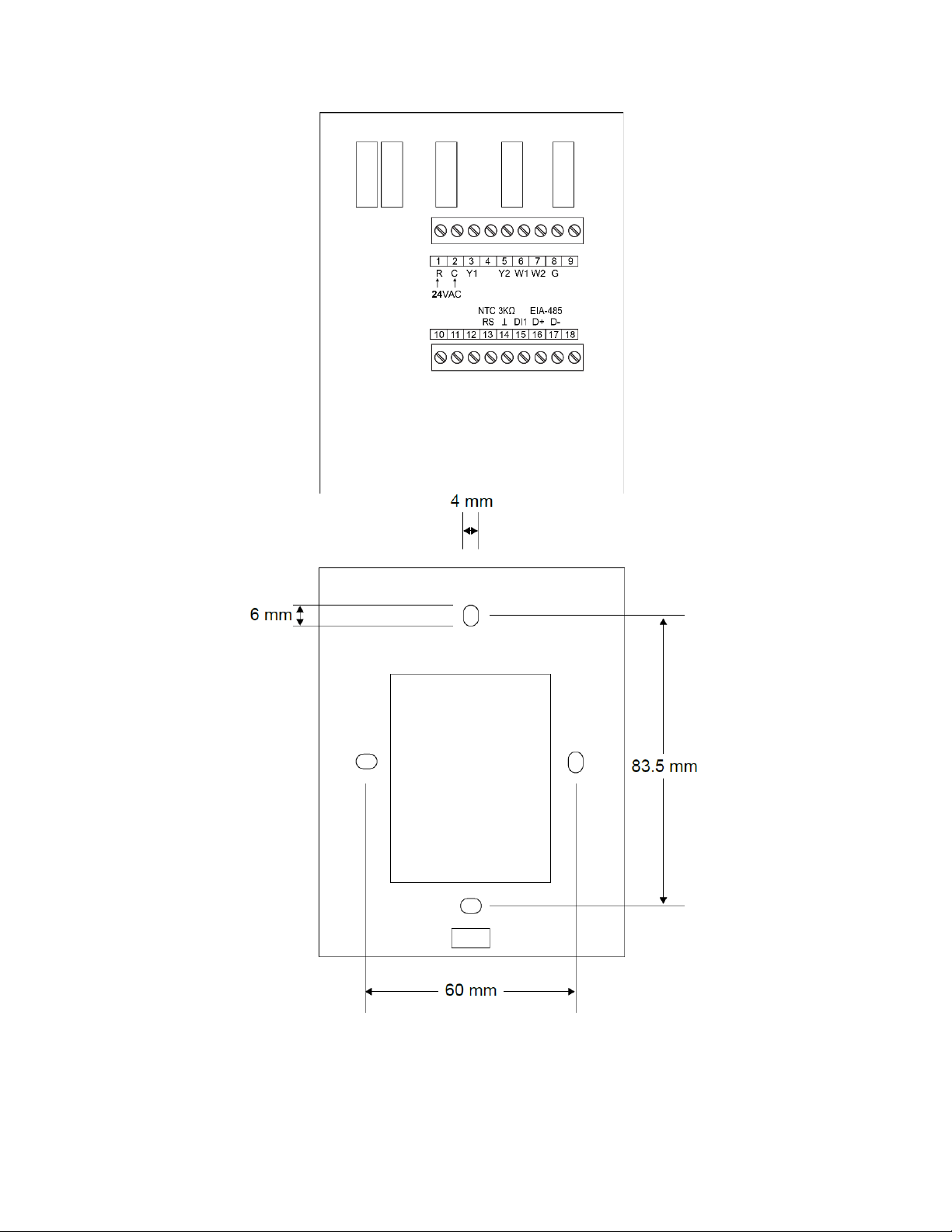

4.3 Engineering Mode Menu

Thermostat configuration can be performed using the engineering mode menu described

below or BACnet objects using a BACnet client tool such as Contemporary Controls free

BACnet Discovery Tool (BDT)

trained engineers only, because it is related to system parameters that will affect the control

results.

Operation of Engineering Menu

. It is highly suggested that engineering mode be operated by

• At power “ON”, press and hold both the UP and DOWN buttons simultaneously for 5

seconds to enter Engineering Mode menu.

• Press the UP (ascending order of objects in table) or DOWN (descending order of

objects in table) buttons to rotate through the menu items. The last item loops back

to first item at the end of items in menu. Press the MODE button to enter a submenu

item.

• Press the UP or DOWN button to change the setting in the submenu item or hold to

speed up setting value change. Press the MODE button to confirm the setting and

return to menu item selection. If no button is pressed for 10 seconds, the display will

return to the menu item selection. After another 10 seconds, the display will return

back to User mode. Settings are not changed unless confirmed using the MODE

button.

• To leave Engineering Mode, rotate till (End) menu item appears and press the MODE

button. Alternately, pressing no buttons for 10 seconds will return the thermostat back

to User mode.

UM-15090000-AA4 Page 20

Page 21

Engineering Menu Flow Chart

Press Up/down

for over 5s

MODE

MODE

E01

E01 Setting

_

+

MODE

MODE

E02

E02 Setting

+

Previous

No button pressed

for 10s under menu

item selection

_

MODE

End

User Mode

+

+

_

UM-15090000-AA4 Page 21

Page 22

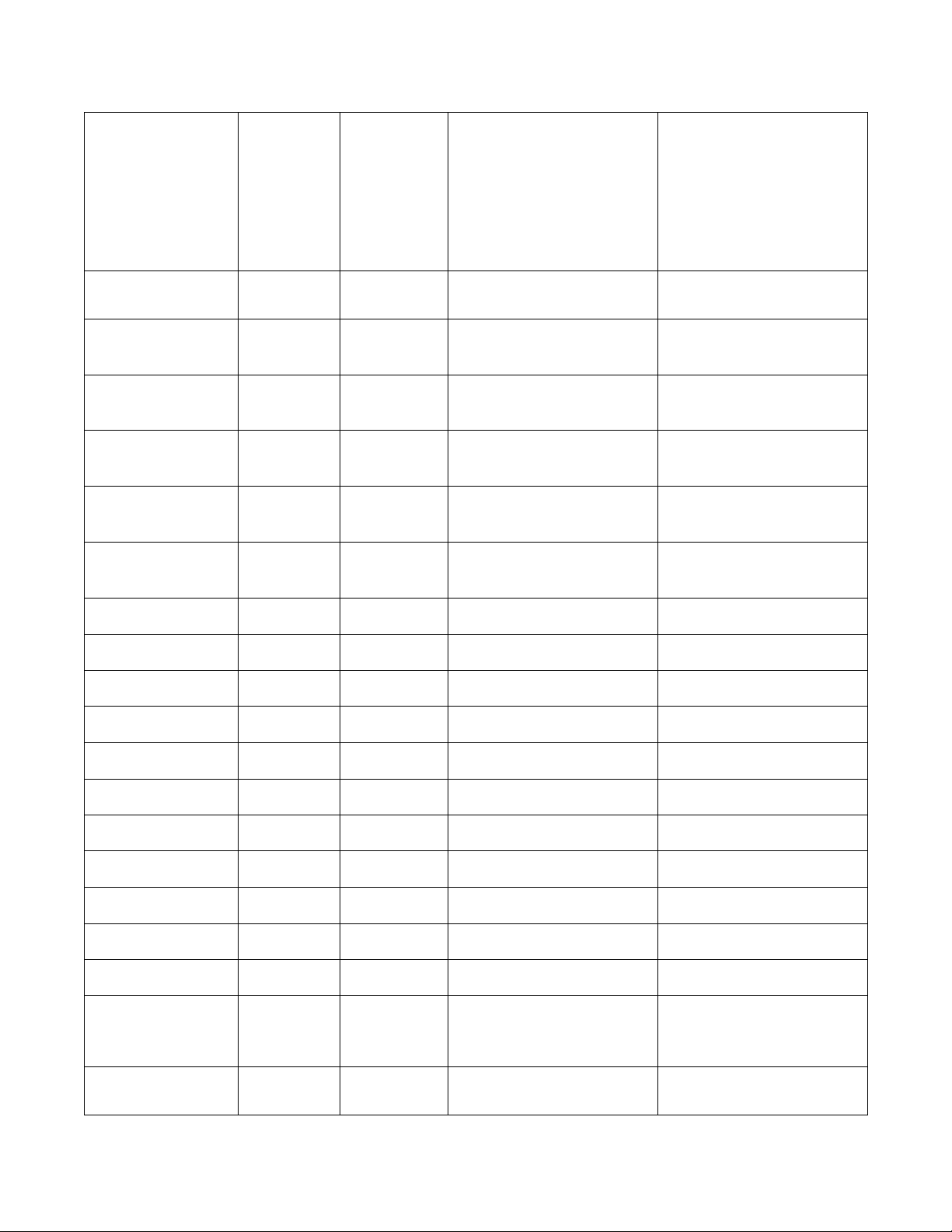

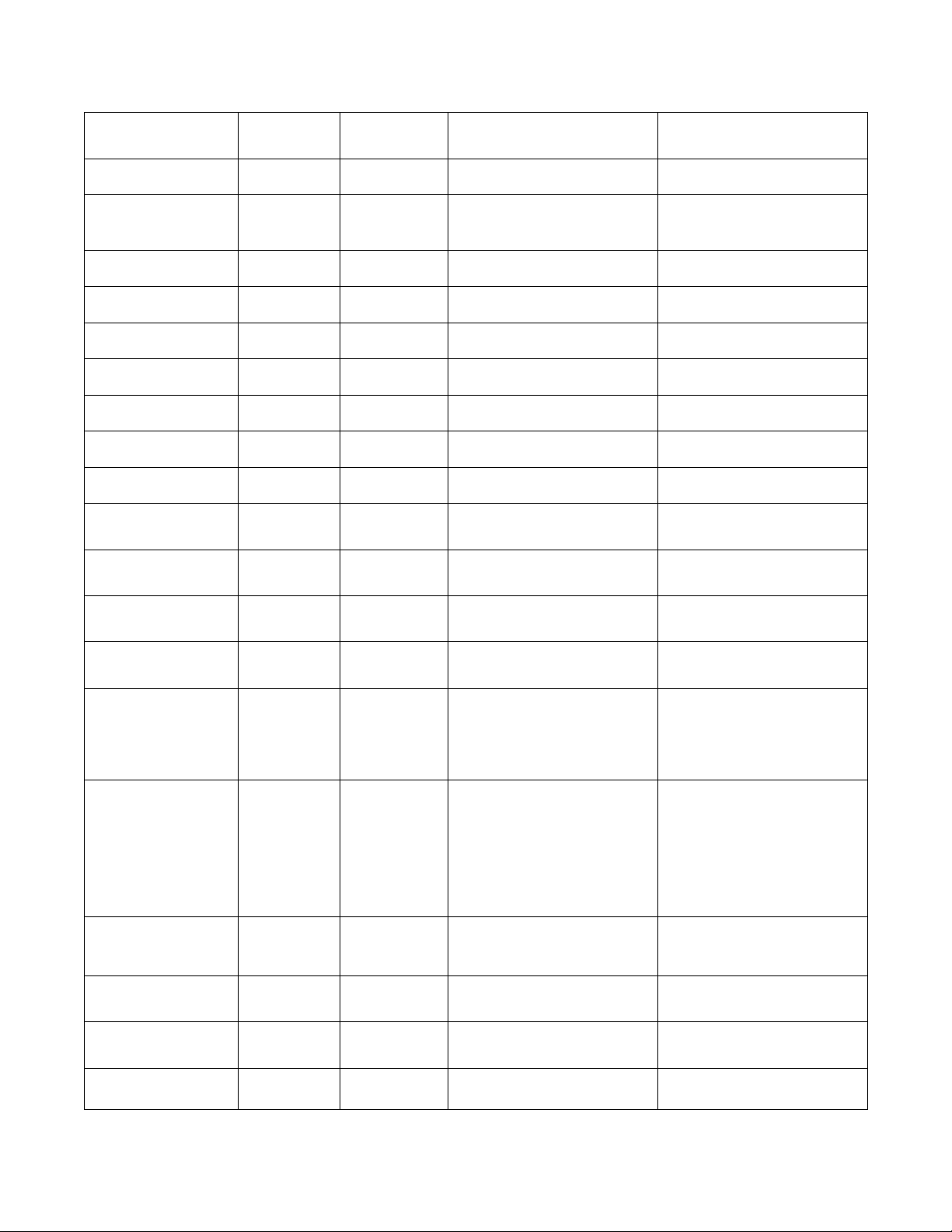

Engineering Menu Items Table – BW2 Model (BACnet/IP Wi-Fi)

Unoccupied(ESI) cooling set point

Unoccupied(ESI) heating set point

Integral Time and Output Cycle Time

(seconds)

Low limit for temperature set point

High limit for temperature set point

Bit Definition:

Bit Value

parameters

Item

E1

E2

E3

E4

E5

E6

E7

E8

E9

E10 Pb Proportional band or stage width 1.5 0~10.0 3.0 0~18.0 0.1 (°C/°F)

E11 diFF Stage differential 0.5 0.1~1.0 1.0 0.1~1.8 0.1 (°C/°F)

E12 LOC

Mnemonic

db Deadband 2.0 0~10 4.0 0~18 0.5 (°C/°F)

ESIC

ESIH

I-t

OPL1 Not used

SPA1 Not used

SP-L

SP-H

OFSt Current temperature offset 0.0 -10.0~10.0 0.0 -18.0~18.0 0.1 (°C/°F)

0: MODE button (dec=1)

1: Down buttons (dec=2)

2: Up button (dec=4)

3: FAN SPEED button (dec=8)

4: Power On/Off button (dec=16)

5: SET (or ℃/℉) button (dec=32)

6: ESI contact detection (dec=64)

7: Door/Window contact

detection (dec=128)

8: Modification for communication

parameters (dec=256)

i.e. baud rate, MAC addr, device inst.

9: Control DOs by thermostat algorithm

(0) or BACnet sup. (1) (dec=512)

10~15: reserved/unused

Description

°C Scale °F Scale

Default Range Default Range

28 25~35 82.5 77~95 1.0 (°C/°F)

15 10.0~22.0 59 50.0~72.0 1.0 (°C/°F)

60 0~500 60 0-500 10 (Sec.)

10 0~50 50 32~122 1.0 (°C/°F)

30 0~50 95 32~122 1.0 (°C/°F)

64

0-1023

64

0-1023

Step

1

Examples (add dec values to lock multiples)

Unlock/enable all (0)

Lock MODE Button (1)

Lock Down Button (2)

Lock MODE & Down Buttons (3 = 1+2)

Lock Power On/Off button (4)

Lock MODE & Power & Down (7 = 1+2+4)

Lock SET button (32)

Lock MODE & Down & Power & SET (39 =

1+2+4+32)

ESI contact disable (64)

Lock the modification for communication

DOs control commanded by BACnet (512)

UM-15090000-AA4 Page 22

0: Unlock / enable

1: Lock / disable

(256)

Page 23

0: built-in

ense

BACnet

Display present temperature value of or

0

0

applicable to all models)

0: N.O.

E

Lowest Fan speed in Auto fan mode

0: stop

0~999

0~999

(if ID-H

<=4193)

(if ID-H

<=4193)

E22

devL

Device instance no. - Low bytes

1

0~302

(if ID-H

1

0~302

(if ID-H

1

= 4194)

= 4194)

UDP Port Number

47808

0~65535

(0~FFFF)

47808

0~65535

(0~FFFF)

-

30.0

1: Enable

Item

E13

E14 rE-C Not used

E15 rE-H Not used

E16

E17

E18 door

19

E20 Pct Output Percentage (not used)

E21 devH Device instance no. - Hi bytes 100

Mnemonic

ESI

rS

-SP-

LFAn

Description

ESI (DI1) digital sensor contact definition

Present Temperature is getting from built-in

temperature Sensor, remote temperature

sensor, or assigned through communication

current set-point for LCD

Door or Windows contact definition (not

Default Range Default Range

0

0

0

0

0

°C Scale °F Scale

0~1

0~2

0~1

0~1 0 0~1

0~1

0~100

0 0~100 1%

0~4194 100 0~4194

0

0

0

0~1

0~2

0~1

0~1

Step

0: N.O.

1: N.C.

1: remote s

2: assigned

through

0: display PV

1: display SP

1: N.C.

1: low

1

E23 UdP

E24 rHSt Relative Humidity Offset (not used)

E25 F-Ht Fan Output for Heating

E26 dLyC Cooling Short Cycle Delay

E27

E28 dLyH

E29

cycC

cycH

Cooling Maximum Cycles per

Hour

Heating Short Cycle

Heating Maximum Cycles per

Hour

(BAC0)

0

0

3

1~3

4

3

0~3

4

30.0~

0/1

2~6

2~255

(BAC0)

0

0

0/1

3

1~3

4

3

0~3

4

-30.0~30.0

2~6

2~255

1

0.1%RH

0: Disable

1 (minutes)

1 (cycles/hour)

1 (minutes)

1 (cycles/hour)

UM-15090000-AA4 Page 23

Page 24

Item

0: C

1: C&H Manual

2:

3: Heating

disabled

E31

OPL2

Minimum Output for AO2 (not used)

E32

SPA2

Span Offset for AO2 (not used)

E33

CO2L

CO2 Input Low Value (not used)

E34

CO2H

CO2 Input High Value (not used)

E35

C2PB

CO2 Control Output Proportional

Band

E36

C2SP

CO2 Setpoint (not used)

E37

C2Lo

CO2 Control Minimum Output (not used)

E38

AFtH

After Hour Extension Time (not used)

E39

VALL

Input Low Value of Valve Feedback

(not used)

E40

VALH

Input High Value of Valve Feedback

(not used)

E41

AI-L

Analog Input Low Value (not used)

E42

AI-H

Analog Input High Value (not used)

E43

AItp

Analog Input Type (not used)

E44

rhLO

Humidity Input Low Value (not used)

E45

rhHI

Humidity Input High Value (not used)

E46

nFAn

Minimum Fan Output (not used)

E47

hFAn

Maximum Fan Output (not used)

E48

FAnL

Low Fan Speed Setting (not used)

E49

FAn2

Med. Fan Speed Setting (not used)

E50

FAnH

Hi Fan Speed Setting (not used)

E51

Run

Modulating Fan Speed Run Type

(not used)

E52

OFFt

Minimum Off Time

180

0~600

180

0~600

5 (seconds)

E53

On-t

Minimum On Time

0

0~600

0

0~600

E54

Str

Floating Motor Full Stroke Time (not used)

E55

Phy1

MAC address 1st & 2nd bytes

hhhh

hhhh

h: 0~F in hex

E56

Phy2

MAC address 3rd & 4th bytes

hhhh

hhhh

E30

Mnemonic

tyPE

Description

Control Type

(not used)

°C Scale °F Scale

Default Range Default Range

2

1~2

2

1~2

Step

ooling Only

C&H Auto

Only

NOTE: Cool

only and Heat

only types

UM-15090000-AA4 Page 24

5 (seconds)

h: 0~F in hex

Page 25

Item

E57

Phy3

MAC address 5th & 6th bytes

hhhh

hhhh

E58

IP-1

1st byte of IPv4 address

192

0~255

192

0~255

E59

IP-2

2nd byte of IPv4 address

168

0~255

168

0~255

E60

IP-3

3rd byte of IPv4 address

0

0~255

0

0~255

E61

IP-4

4th byte of IPv4 address

1

0~255

1

0~255

E62

tESt

Self-Diagnostic – toggle all LCD features and

all

Use

Caution!

Press MODE to

engage test

E63

boot

Reset Wi-Fi parameters to factory defaults

Press MODE to

reset

E64

rSt

Reset all parameters including communication

and control algorithm to the factory defaults

Use

Caution!

Press MODE to

reset

E65

Exit Engineer Mode Menu

Press MODE to

exit engineering

menu

Mnemonic

Description

°C Scale °F Scale

Default Range Default Range

Step

h: 0~F in hex

1

1

1

1

End

relays. Use only to test

Lock Function Setup and Examples

The 16-bit binary encoded decimal register accessed through Lock [AV17] BACnet object and

LOC engineering menu item is used to enable/disable features in the thermostat. The first 10

bits are used (bit 0 ~ bit 9), bits 10~15 are reserved/unused. Bits are represented by their

decimal values and are added or subtracted to toggle from “0” to “1”. Add a bit’s decimal value

to toggle to “1” or subtract a bit’s decimal value to toggle to “0”. See table below.

UM-15090000-AA4 Page 25

Page 26

Add decimal values to lock multiples. Bold decimal number is

Bit Definition: Decimal Value to Write:

0: MODE button (dec=1)

1: DOWN button (dec=2)

2: UP button (dec=4)

3: FAN SPEED button (dec=8)

4: POWER On/Off button (dec=16)

5: SET (or ℃/℉) button (dec=32)

6: ESI contact detection (dec=64)

7: Door/Window contact

detection (unused) (unused)

8: Modification for communication

parameters (dec=256)

i.e. baud rate, MAC addr, device inst.

9: Control DOs by thermostat algorithm

(0) or BACnet sup. (1) (dec=512)

10~15: reserved/unused (unused)

Bit Value:

0: Unlock / enable

1: Lock / disable

the example value to write to Lock object. Examples:

Unlock/enable all (0) – this will also enable ESI DI1 (add 64 to all values

below to maintain default occupancy selection over BACnet).

Lock MODE button (1)

Lock DOWN button (2)

Lock MODE & DOWN (3 = 1+2)

Lock UP button (4)

Lock MODE & DOWN & UP (7 = 1+2+4)

Lock FAN SPEED button (8)

Lock MODE & DOWN & UP & FAN (15 = 1+2+4+8)

Lock POWER button (16)

Lock MODE & DOWN & UP & FAN & POWER (31 = 1+2+4+8+16)

Lock SET button (32)

Lock MODE & DOWN & UP & FAN & POWER & SET (63 =

1+2+4+8+16+32)

ESI contact disable (64 – default). When the default value of 64 is

maintained, occupancy is set over BACnet and SET user button.

Lock MODE & DOWN & UP & FAN & POWER & SET & disable ESI DI1

(127 = 1+2+4+8+16+32+64)

Door/Window contact detection (unused)

Lock the modification for communication parameters such as baud rate

and mac address (256)

Lock MODE & DOWN & UP & FAN & POWER & SET & disable ESI DI1

& modification for communication parameters (383 =

1+2+4+8+16+32+64+256)

DOs control commanded by BACnet (512)

UM-15090000-AA4 Page 26

Page 27

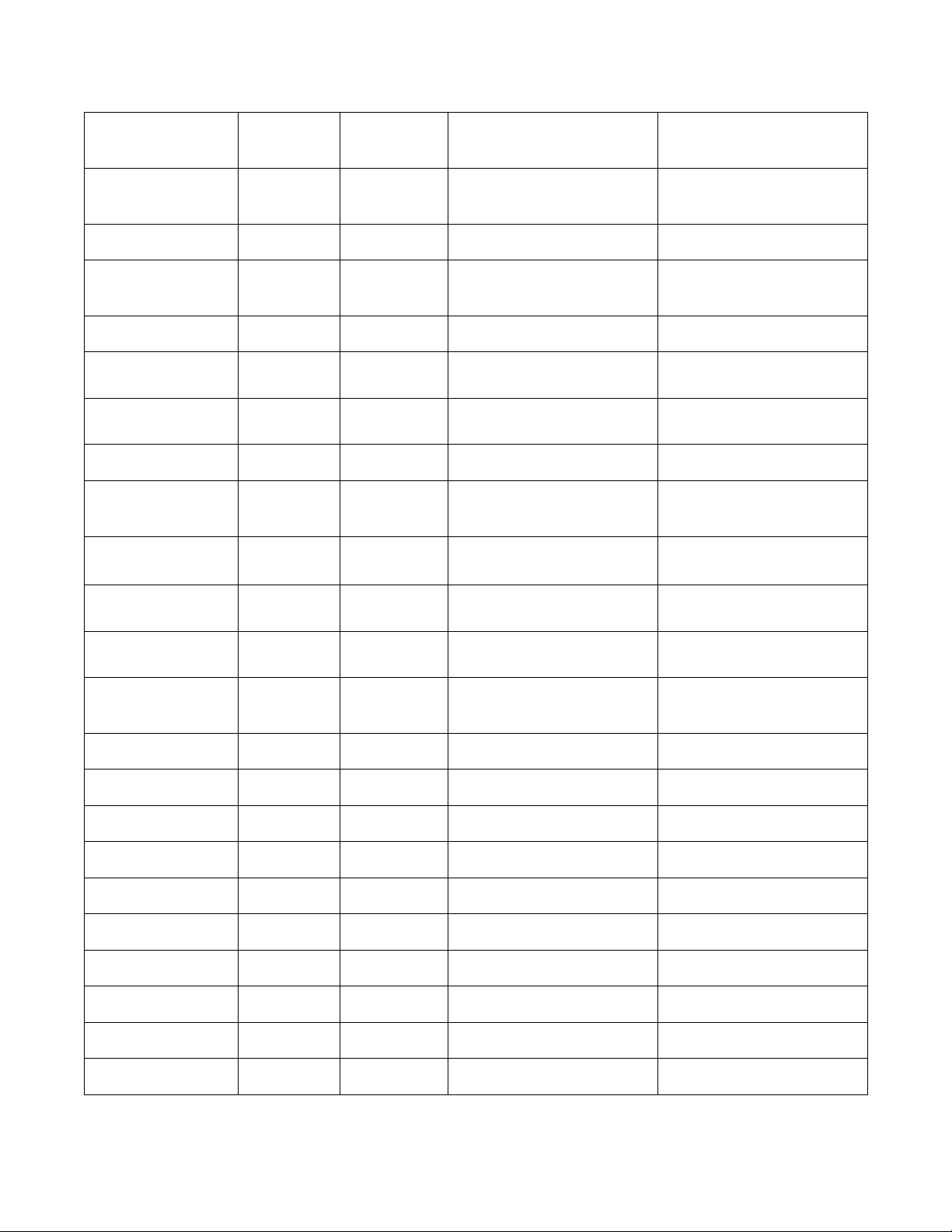

Engineering Menu Items Table – B2 Model (BACnet MS/TP)

Unoccupied(ESI) cooling set point

Unoccupied(ESI) heating set point

Integral Time and Output Cycle Time

(seconds)

Low limit for temperature set point

High limit for temperature set point

Bit Definition:

Bit Value

parameters

Item

E1

E2

E3

E4

E5

E6

E7

E8

E9

E10 Pb Proportional band or stage width 1.5 0~10.0 3.0 0~18.0 0.1 (°C/°F)

E11 diFF Stage differential 0.5 0.1~1.0 1.0 0.1~1.8 0.1 (°C/°F)

E12 LOC

Mnemonic

db Deadband 2.0 0~10 4.0 0~18 0.5 (°C/°F)

ESIC

ESIH

I-t

OPL1 Not used

SPA1 Not used

SP-L

SP-H

OFSt Current temperature offset 0.0 -10.0~10.0 0.0 -18.0~18.0 0.1 (°C/°F)

0: MODE button (dec=1)

1: Down buttons (dec=2)

2: Up button (dec=4)

3: FAN SPEED button (dec=8)

4: Power On/Off button (dec=16)

5: SET (or ℃/℉) button (dec=32)

6: ESI contact detection (dec=64)

7: Door/Window contact

detection (dec=128)

8: Modification for communication

parameters (dec=256)

i.e. baud rate, MAC addr, device inst.

9: Control DOs by thermostat algorithm

(0) or BACnet sup. (1) (dec=512)

10~15: reserved/unused

Description

°C Scale °F Scale

Default Range Default Range

28 25~35 82.5 77~95 1.0 (°C/°F)

15 10.0~22.0 59 50.0~72.0 1.0 (°C/°F)

60 0~500 60 0-500 10 (Sec.)

10 0~50 50 32~122 1.0 (°C/°F)

30 0~50 95 32~122 1.0 (°C/°F)

64

0-1023

64

0-1023

Step

1

Examples (add dec values to lock multiples)

Unlock/enable all (0)

Lock MODE Button (1)

Lock Down Button (2)

Lock MODE & Down Buttons (3 = 1+2)

Lock Power On/Off button (4)

Lock MODE & Power & Down (7 = 1+2+4)

Lock SET button (32)

Lock MODE & Down & Power & SET (39 =

1+2+4+32)

ESI contact disable (64)

Lock the modification for communication

DOs control commanded by BACnet (512)

UM-15090000-AA4 Page 27

0: Unlock / enable

1: Lock / disable

(256)

Page 28

0: built-in

sense

BACnet

Display present temperature value of or

0

0

applicable to all models)

0: N.O.

E

Lowest Fan speed in Auto fan mode

0: stop

38.4

9.6kbps

38.4

9.6kbps

9.6kbps

0~999

0~999

(if ID-H <=

(if ID-H

E24

devL

Device instance no. - Low bytes

1

4193) 1

<=4193)

1

0~302

0~302

( if ID-H

( if ID-H

= 4194)

= 4194)

Max_Master -- The highest allowed MAC

address for BACnet MS/TP master nodes

30.0

1: Enable

Item

E13

Mnemonic

ESI

Description

ESI (DI1) digital sensor contact definition

E14 rE-C Not used

E15 rE-H Not used

Present Temperature is getting from built-in

E16

E17

rS

-SP-

E18 door

19

LFAn

temperature Sensor, remote temperature

sensor, or assigned through communication

current set-point for LCD

Door or Windows contact definition (not

E20 Pct Output Percentage (not used)

E21

Baud BACnet MS/TP Baud rate

°C Scale °F Scale

Step

Default Range Default Range

0

0~1

0

0~1

0: N.O.

1: N.C.

1: remote

0

0~2

0

0~2

2: assigned

through

0~1

0

0

0

0~1 0 0~1

0~3

0~100

19.2kbps

0 0~100 1%

0

38.4kbps

57.6kbps

76.8kbps

0~1

0~1

19.2kbps

38.4kbps

57.6kbps

76.8kbps

0: display PV

1: display SP

1: N.C.

1: low

19.2kbps

38.4kbps

57.6kbps

76.8kbps

E22

Addr

BACnet MS/TP MAC address

E23 devH Device instance no. - Hi bytes 100

E25 AdrH

E26 rHSt Relative Humidity Offset (not used)

E27 F-Ht Fan Output for Heating

E28 dLyC Cooling Short Cycle Delay

E29

cycC

Cooling Maximum Cycles per

Hour

UM-15090000-AA4 Page 28

1

0~127

127

1~127

0

0

3

1~3

4

1

0~127

0~4194 100 0~4194

-30.0~

0/1

2~6

127

0

0

3

4

1~127

-30.0~30.0

0/1

1~3

2~6

1

1

1

0.1%RH

0: Disable

1 (minutes)

1 (cycles/hour)

Page 29

Item

0: Cooling Only

1: C&H Manual

2: C&H Auto

3: Heating Only

disabled

E33

OPL2

Minimum Output for AO2 (not used)

E34

SPA2

Span Offset for AO2 (not used)

E35

CO2L

CO2 Input Low Value (not used)

E36

CO2H

CO2 Input High Value (not used)

E37

C2PB

CO2 Control Output Proportional

Band

E38

C2SP

CO2 Setpoint (not used)

E39

C2Lo

CO2 Control Minimum Output (not used)

E40

AFtH

After Hour Extension Time (not used)

E41

VALL

Input Low Value of Valve Feedback

(not used)

E42

VALH

Input High Value of Valve Feedback

(not used)

E43

AI-L

Analog Input Low Value (not used)

E44

AI-H

Analog Input High Value (not used)

E45

AItp

Analog Input Type (not used)

E46

rHLO

Humidity Input Low Value (not used)

E47

rHHI

Humidity Input High Value (not used)

E48

nFAn

Minimum Fan Output (not used)

E49

hFAn

Maximum Fan Output (not used)

E50

FAnL

Low Fan Speed Setting (not used)

E51

FAn2

Med. Fan Speed Setting (not used)

E52

FAnH

Hi Fan Speed Setting (not used)

E53

Run

Modulating Fan Speed Run Type

(not used)

E54

OFFt

Minimum Off Time

180

0~600

180

0~600

5 (seconds)

E55

On-t

Minimum On Time

0

0~600

0

0~600

E56

Str

Floating Motor Full Stroke Time (not used)

E57

tESt

Self-Diagnostic – toggle all LCD features and

all relays. Use only to test

Use

Caution!

Press MODE to

Mnemonic

Description

°C Scale °F Scale

Default Range Default Range

Step

E30 dLyH

E31

E32

cycH

tyPE

Heating Short Cycle

Heating Maximum Cycles per

Hour

Control Type

(not used)

3

0~3

4

2

2~255

1~2

3

0~3

4

2~255

2

1~2

1 (minutes)

1 (cycles/hour)

NOTE: Cool

only and Heat

only types

UM-15090000-AA4 Page 29

5 (seconds)

Page 30

Item

engage test

E58

rSt

Reset all parameters including communication

and control algorithm to the factory defaults

Use

Caution!

Press MODE to

E59

Exit Engineer Mode Menu

Press MODE to

exit engineering

menu

Mnemonic

Description

°C Scale °F Scale

Default Range Default Range

Step

End

4.4 BACnet Objects and Network Configuration

Transmission types (model dependent)

BASstat B2:

• Physical layer: EIA-485

• Protocol: BACnet MS/TP

• Baud rate: 9600-76800bps (38400bps default)

• MAC address: 1 (default)

• Device Instance: 100001

load reset

BASstat BW2:

• Physical layer: Wi-Fi 802.11 b/g/n

• Protocol: BACnet/IP

• UDP Port Number: BAC0 (47808)

• MAC address: Wi-Fi chip MAC address found written on the back side of thermostat or

in Engineering Menu item (Phy3). This can assist when multiple Wi-Fi thermostats are installed.

• Device Instance: 100001

UM-15090000-AA4 Page 30

Page 31

Initial Configuration

Initial communication configuration differs depending on whether you are using the BACnet

MS/TP model (B2) or BACnet/IP over Wi-Fi model (BW2). All configuration parameters are

settable through use of the buttons on thermostat by entering the Engineer Menu, or once

installed on the BACnet network, configuration can also be altered using BACnet commands.

Network command-based configuration can also be accomplished on the bench using a BACnet

router (B2 MS/TP model) or Wi-Fi enabled laptop/computer/tablet/smart phone (BW2 Wi-Fi

model) and our free BACnet Discovery Tool.

B2 model - MS/TP Communication Configuration

Overview

The BASstat MS/TP thermostat is preconfigured with a MAC address of 1 and default baud rate

of 38400bps. To alter this configuration, enter the Engineering Menu by holding down the UP

and DOWN buttons simultaneously for 5 seconds. Use the UP and DOWN buttons to navigate

through the menu and change menu item values. Use the MODE button to enter a menu item

and accept/confirm a selected value. To exit the Engineering Menu, navigate to menu item

(End) and press MODE to confirm, or the menu will exit automatically when not used after 5

seconds. BACnet MS/TP model configuration requires setting the baud rate or using the default

baud rate of 38.4kbps. A unique MS/TP MAC address is required to distinguish it from other

MS/TP devices on the bus (default MAC address = 1). When more than one BASstat is installed

at the same time, their MAC addresses must be configured prior to communicating on the

BACnet MS/TP bus or communication will fail due to duplicate MAC addresses. A unique

Device Instance Number throughout the entire BACnet internetwork is also required to

distinguish the device from all other BACnet devices.

End-of-Line Termination

The BASstat does not provide End-of-Line termination. If the BASstat is the first or last device

on the MS/TP bus, a termination resistor (120Ω) must be applied across pins 16 and 17 of the

input terminal.

Addressing

The MAC address can be set from Engineering Menu item (Addr) with values of 1 - 127.

The Baud rate can be set from Engineering Menu item (bAud) 9.6kbps – 76.8kbps.

A unique Device Instance Number throughout the entire BACnet internetwork is also required to

distinguish the device from all other BACnet devices. Device instance can be modified in

Engineering Menu items (dEVH) – high bytes and (dEVL) – low bytes.

Device Instance = (dEVH)*1000+(dEVL). Device Instance example: if (dEVH) is set to 4194 and

(dEVL) is set to 7, the Device Instance Number = 4194007. Device Instance Number can also

be changed by writing to BACnet object [AV21] Device Instance once the thermostat is online.

Max masters setting can be set from Engineering Menu item (AdrH), default value is 127.

UM-15090000-AA4 Page 31

Page 32

Reset Settings

Thanks to its EEPROM, the BASstat will store configuration in the event of power loss. All

settings can be reset back to default from Engineering Menu item (rSt). Use caution because

once this item is selected (MODE button to select), all settings will be reset to their default

values.

BW2 model - Wi-Fi Communication Configuration

Overview

The BASstat Wi-Fi thermostat is preconfigured with a BACnet Device Instance of 100001 and a

UDP Port Number of 47808 (decimal) equivalent to BAC0 (hexadecimal). To alter this

configuration, enter the Engineering Menu by holding down the UP and DOWN buttons

simultaneously for 5 seconds. Use the UP and DOWN buttons to navigate through the menu

and change menu item values. Use the MODE button to enter a menu item and accept/confirm

a selected value. To exit the Engineering Menu, navigate to menu item (End) and press MODE,

or the menu will exit automatically when not used after 5 seconds.

Addressing

A unique Device Instance Number throughout the entire BACnet internetwork is required to

distinguish the device from all other BACnet devices. When more than one BASstat is installed

at the same time, their Device Instance Number must be configured prior to connecting to the

BACnet/IP network or BACnet communication will fail due to duplicate device instances.

Device instance can be modified in Engineering Menu items (dEVH) – high bytes and (dEVL) –

low bytes. Device Instance = (dEVH)*1000+(dEVL). Device Instance example: if (dEVH) is set

to 4194 and (dEVL) is set to 7, Device Instance Number = 4194007. Device Instance Number

can also be changed by writing to BACnet object [AV21] Device Instance once the thermostat is

online. The BACnet UDP Port Number can be configured in Engineering Menu item (UdP).

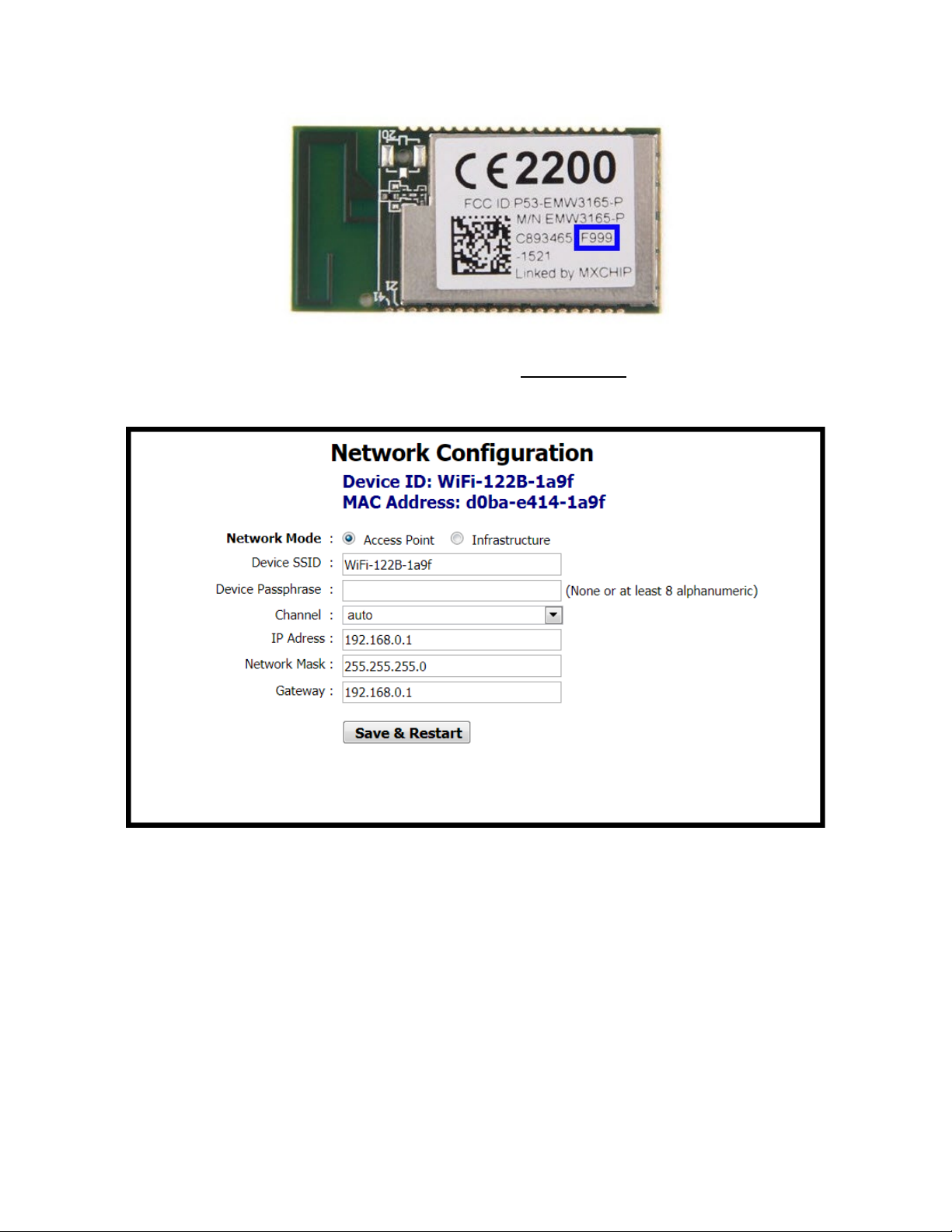

BACnet/IP Wi-Fi (BW2) model will initially boot up as a Wi-Fi Access Point to allow for IP

configuration. This requires connecting to the thermostat as an access point for initial

configuration using a Wi-Fi enabled laptop/computer/tablet/smart phone. Look for the BASstat221C-BW2 with its unique SSID of “WiFi-122B-xxxx” and no access point passphrase by default

(simply click to connect to Access Point). The digits “xxxx” in “122B-xxxx” are the last 4 digits of

the thermostat’s Wi-Fi chip MAC address found written on the back side of the Wi-Fi module.

This ensures a unique SSID for discovery and configuration and it can assist in identification of

thermostats when multiple Wi-Fi stats are installed on the same site (unique identifier outlined in

blue in the image below). This unique identifier can also be viewed in Engineering Menu item

(Phy3).

UM-15090000-AA4 Page 32

Page 33

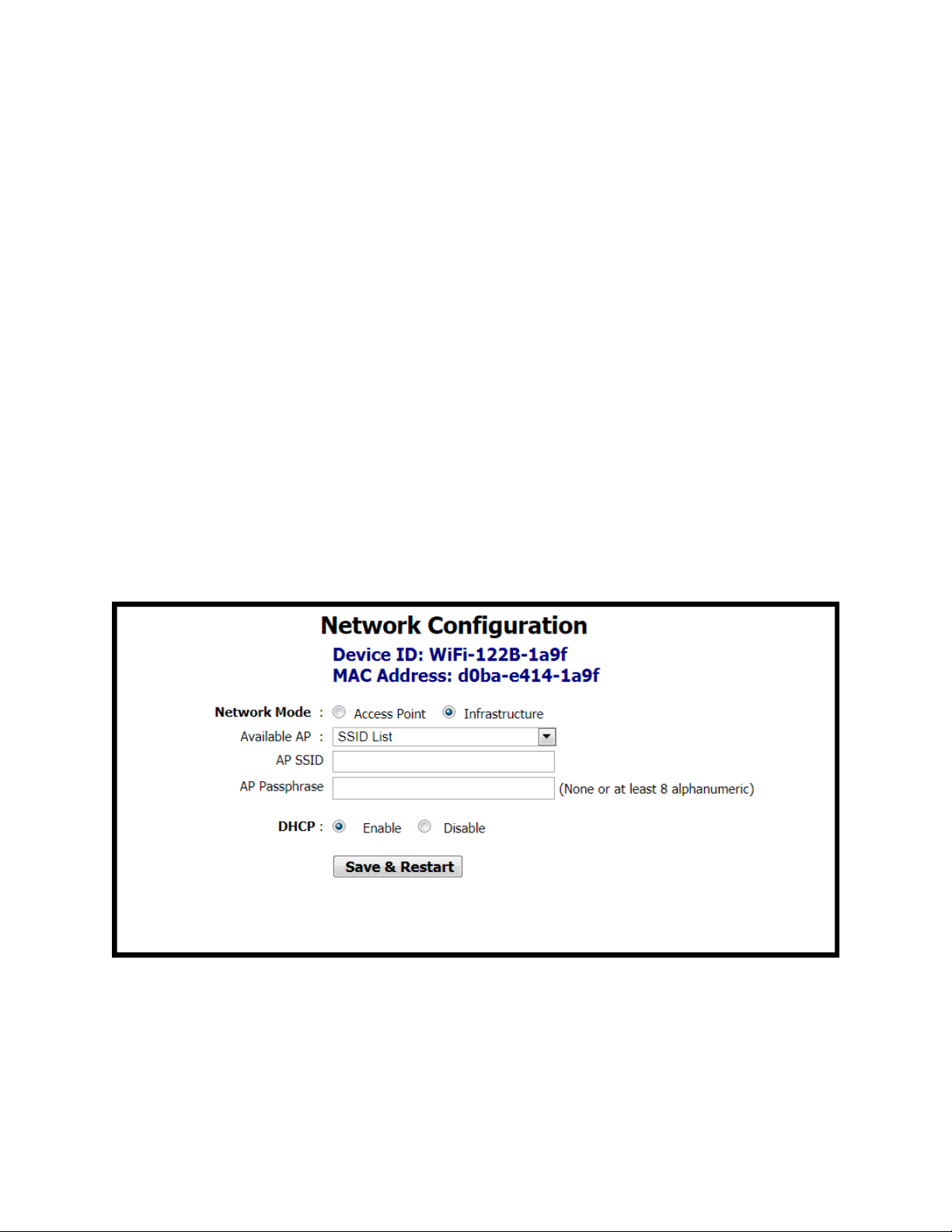

Once connected to the thermostat as an access point, open its web page by typing its default

address of 192.168.0.1 with admin for username and no password. Web page pictured below

will be presented for IP Network Configuration. The default IP configuration is shown below.

After initial connection using laptop or tablet or smart phone, the Wi-Fi mode in the thermostat

can be changed to Infrastructure mode. The local Wi-Fi router/access point can be selected

from the Available AP drop-down list, or an AP SSID can be entered manually. Enter the AP

Passphrase to authenticate and connect to the AP.

ATTENTION: When setting up the Wi-Fi router (Access Point) the thermostats will be connected

to, make sure you set up a strong access point passphrase (password)! This is required for WiFi client devices to connect to the Wi-Fi router and it is essential to cyber security. Creating a

good Wi-Fi password is the first step in creating a secure environment that is inaccessible to

unauthorised parties. Use the following tips when creating a Wi-Fi access point passphrase:

UM-15090000-AA4 Page 33

Page 34

• Passphrase should be a minimum of eight characters (maximum 15 characters), the

more random the better. Use a mix of letters (uppercase and lowercase), numbers, and

symbols.

• Misspelling commonly used words and replacing some of the letters with numbers or

symbols is a good practice and makes passwords difficult to guess.

• Avoid using instances like "abc1234", "123456789", "password", "qwerty", "111111",

"admin", "iloveyou" and "aaaaaa".

• Do not reuse or repeat passwords across router installations or job sites.

• Change WiFi password regularly (not required but very secure). Provides guidelines for

building maintenance personnel.

• Disable broadcast of SSID. This is a very simple setting which stops the broadcast of the

access point SSID, and only authorized parties who know the SSID can connect to it.

This is configured in the Wi-Fi router.

• Store passwords in a safe place, limit access to authorized parties only, and provide

instructions for password reset and reconfiguring a strong password in cases of

reconfiguring the network in the future.

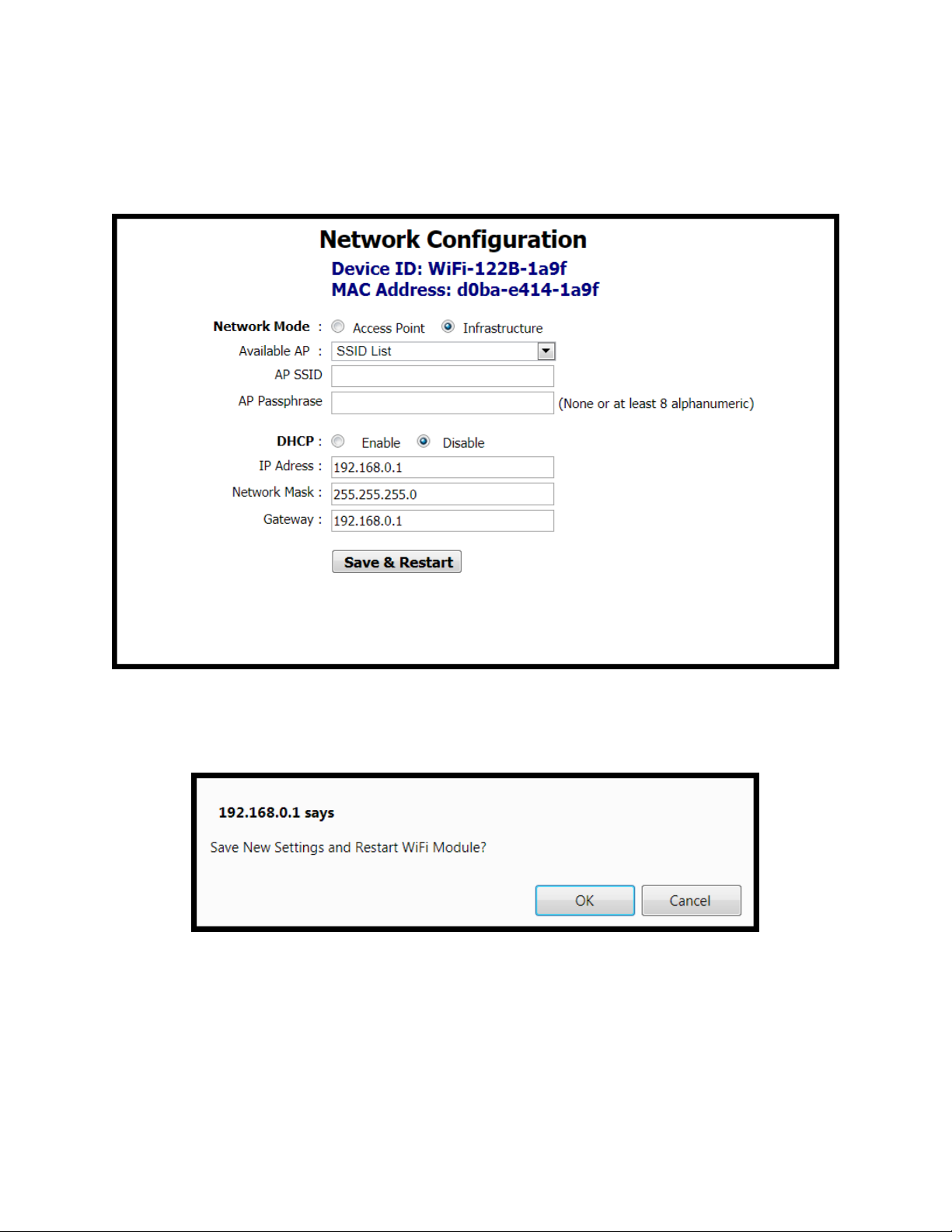

Choose an option for DHCP addressing using the radio buttons.

UM-15090000-AA4 Page 34

Page 35

The thermostat supports DHCP addressing and will acquire an IP address from the

router/access point automatically if you chose Enable next to DHCP. If you chose Disable, you

must assign an IP Address, Network Mask, and Gateway Address within the Wi-Fi router IP

subnet manually.

A reboot of the thermostat is required for new IP configuration to take effect. Click the Save &

Restart button to reboot the thermostat, and you will be prompted to confirm the restart. Click

OK to Save New Settings and Restart or click Cancel to revisit IP configuration.

When OK is clicked a confirmation is displayed to indicate configuration is stored in the

thermostat’s EEPROM. After reboot, the new thermostat credentials will be admin for user name

and the newly configured Access Point’s password for password.

UM-15090000-AA4 Page 35

Page 36

Click OK on the confirmation message and wait 20 seconds for the reboot process to complete.

While rebooting, the thermostat will display “DP” icon in the lower right corner to indicate it is in

the process of searching and connecting to the AP. Once the “DP” stops flashing, the

thermostat has successfully connected to Wi-Fi access point. After reboot of the thermostat, the

new Infrastructure mode with new IP settings will be used. The thermostat will now be

connected to the local Wi-Fi network AP selected in configuration screen and will not show up

as an access point itself any more. If you are unsure of the thermostat’s IP address, it could be

viewed through the Engineering Menu in items (IP-1) for the first octet, (IP-2) for the second

octet, (IP-3) for the third, and (IP-4) for the fourth octet of the IP address, or if you have access

to the Wi-Fi access point, its “statistics” or “connected devices” web page will show the BASstat

BW2’s IP address as well as MAC address (the same address in Engineering Menu items Phy1,

Phy2, and Phy3 and the printed MAC on the back of the thermostat Wi-Fi module (outlined in

blue above).

Reset Settings

Thanks to its EEPROM, the BASstat will store configuration in the event of power loss. If

configuration fails or the thermostat needs to be configured to use a different Wi-Fi access point,

the thermostat must be reset and reconfigured. There are 2 reset settings options for the Wi-Fi

thermostat:

- Boot will restore Wi-Fi communication parameters to default, but it will maintain control

algorithm settings. Select (boot) engineering menu item and press MODE to confirm.

- Reset will restore all values to default and can be selected from engineering menu (rSt).

UM-15090000-AA4 Page 36

Page 37

BACnet Object Table - B2 Model (BACnet MS/TP)

Object name

Type & Instance

Object Property

(Readable/Writable)

Range

BACnet Thermostat

Model Name (R)

Type &

Instance

Readable/

Writable

℃/°F

(32.0~122.0°F)

Built-in

Remote

Current Humidity

AI 4 R

Current Humidity

0~1000: 0.0~100.0%RH

℃/°F

Current CO2

Reading

Control Valve

Feedback

Modulating/

Floating Output 1

Modulating/ Floating Output

1

0~100: 0~100 %

Modulating/

Floating Output 2

Modulating/ Floating Output

2

0~100: 0~100 %

Modulating Fan

Output

0~100: 0~100 %

CO2 Control Output

Percentage

CO2 Control Output

Percentage

Voltage Input Value

Voltage Input Value

0~150 (0.0~15.0 VDC)

Analog Input 1

Value

Analog Input 1 Percentage

Value

Device 100001

Application Software Version (R)

Object Identifier (R)

Object Name (R/W) 32 characters (max.)

Object name

Current

Temperature

Temp SP Status

Temperature

Sensor

Temperature

Sensor

Current Dew Point

AI 0

AI 1

AI 2

AI 3

AI 5

Max_Master (R/W)

Description Range and Definition

R

R

R

R

R

Current Temperature

Active Temperature SetPoint

Built-in Temperature

Sensor Reading

Remote Temperature

Sensor Reading

Current Dew Point

1~127

-999~9999: -99.9~999.9

°C :0~500 (0.0~50.0℃)

°F : 320~1220

-999~9999:-99.9~999.9

℃/°F

-999~9999:-99.9~999.9

℃/°F

-999~9999: -99.9~999.9

UM-15090000-AA4 Page 37

AI 6

AI 7

AI 8

AI 9

AI 10

AI 11

AI 12

AI 13

R

R

R

R

R

R

R

R

Current CO

Control Valve Feedback

Modulating Fan Output

Reading

2

0~3000: 0~3000 ppm

0~1000 (0.0%~100.0%)

0~100: 0~100 %

0~1000 (0.0%~100.0%)

Page 38

Analog Input 2

Value

AI 14

Analog Input 2 Percentage

Value

Analog Input 3

Value

Analog Input 3 Percentage

Value

(32.0~122.0°F)

Temperature

AV 1

Assigned Current

Timer Off (Only for Models

0: Disable

AV 3

Heating Temperature Set

For Writing.

AV 5

Running Time of Valve

Sec-Running

AV 6

Running Time of Valve

AV 7

Deadband

Unoccupied Cooling Setpoint

°F)

AV 9

R/W

Integral-Cycle

Time

Integral Time and Output

Cycle Time

Analog Minimum

AV 11

R/W

Minimum Output Voltage in

Span Offset

Span Offset for AO1

(32.0~122.0°F)

(32.0~122.0°F)

R

0~1000 (0.0%~100.0%)

Cooling Setpoint

Override

Timer Off

Heating Setpoint

Hr-Running Time

M-Running Time

Time

AI 15

AV 0

AV 2

AV 4

R

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Cooling Temperature Set

Point

Temperature

with Countdown Timer

Function

Available).

Point

Running Time of Valve (Hr.)

(M.)

(Sec.)

0~1000 (0.0%~100.0%)

°C :0~500 (0.0~50.0℃)

°F: 320~1220

-999~9999

(-99.9~999.9℃/°F)

0~24: 0~24 Hours Count

Down

-999~9999: -99.9~999.9

℃/°F

0~65535 (Hr.) For

Reading But 0~30000 (Hr.)

0~59 (Minute)

0~59 (Sec.)

Deadband

Unoccupied Cool

Setpoint

Unoccupied Heat

Setpoint

Output

Low Setpoint Limit

High Setpoint Limit

AV 8

AV 10

AV 12

AV 13

AV 14

R/W

R/W

R/W

R/W

R/W

R/W

Unoccupied Heating

Setpoint

Digital Value When Reach

Low Limit for AO1

Low Limit for Set-Point

Temperature

High Limit for Set-Point

Temperature

°C: 0~100 (0.0~10.0 °C)

°F: 0~180 (00~18.0 °F)

°C: 250~300 (25.0~30.0

°C)

°F: 770~860 (77.0~86.0

°C: 100~220 (10.0~22.0

°C)

°F: 500~715(50.0~71.5°F)

0~500 (Sec.)

0~125 (LSB)

-55~0 (LSB)

°C :0~500 (0.0~50.0℃)

°F: 320~1220

°C :0~500 (0.0~50.0℃)

°F: 320~1220

UM-15090000-AA4 Page 38

Page 39

Temperature Offset

°F)

Proportional Band-

°F: 0~180 (00~18.0 °F)

AV 17

R/W

°F: 1~18 (0.1~1.8 °F)

Bit Definition:

(dec=512)

Bit Value

AV 19

R/W

Percentage of Modulating/

MAC Address

MAC address

AV 15

R/W

Offset for Current

Temperature

°C: -100~100 (- 10.0~10.0

°C)

°F: -180~180 (-18.0~18.0

Stage

Width

Stage Differential

Lock

AV 16

AV 18

R/W

RW

Proportional Band or Stage

Width

Stage Differential

LOCK

°C :0~100 (00~10.0 °C)

°C :1~10 (0.1~1.0 °C)

0: MODE button

(dec=1)

1: Down

buttons (dec=2)

2: Up button

(dec=4)

3: FAN SPEED button

(dec=8)

4: Power On/Off button

(dec=16)

5: SET (or ℃/℉) button

(dec=32)

6: ESI contact

detection (dec=64)

7: Door/Window

contact

detection (dec=128)

8: Modification for

communication

parameters (dec=256)

i.e. baud rate, MAC addr,

device inst.

9: Control DOs by

thermostat algorithm

(0) or BACnet sup. (1)

10~15: reserved/unused

Control Out

Percentage

UM-15090000-AA4 Page 39

AV 20

R/W

Floating Control Output

0: Unlock / enable

1: Lock / disable

Examples (add dec values to

lock multiples) For more details

see Lock Function Setup and

Examples section of this manual

0~100 (0%~100%)

0~127

Page 40

0~4194302

needs to unlock modification

LOCK(AV17) for details)

AV 22

R/W

%RH)

Cooling Short Cycle

AV 23

R/W

Cooling Short Cycle Delay

Cooling Maximum

AV 24

R/W

Heating Short Cycle

AV 25

R/W

Heating Short Cycle Delay

Heating

AV 26

R/W

AV 27

R/W

Minimum Output Voltage in

Span Offset for

AO2

Span Offset for AO2

CO2 Input Low

Value

CO2 Input Low Value

CO2 Input High

Value

CO2 Input High Value

CO2 Control Output

Proportional Band

CO2 Control Output

Proportional Band

CO2 Setpoint

CO2 Setpoint

CO2 Control

Minimum Output

CO2 Control Minimum

Output Percentage

After Hour Extension

Time

After Hour Extension Run

Time

Input Low Value of

Valve Feedback

Input Low Value of Control

Valve Feedback

Input High Value of

Valve Feedback

Input High Value of Control

Valve Feedback

Analog Input Low

Value

Analog Input Low Value

Analog Input High

Value

Analog Input High Value

%RH)

Humidity Input High

%RH)

Device Instance

AV 21

R/W

Device Instance

(Note: Changing this value

for communication

parameters in advance.

i.e. AV17=0~255 or

512~768. Please refer to

Humidity Offset

Cycles

per Hour

Maximum Cycles

per Hour

Minimum Output for

AO2

AV 28

AV 29

AV 30

AV 31

R/W

R/W

R/W

R/W

Humidity Offset Value

Cooling Maximum Cycles

per Hour

Heating Maximum Cycles

per Hour

Digital Value When Reach

Low Limit for AO2

-300~300 (-30.0~30.0

1~3 Minutes

2~6 Cycles

0~3 Minutes

2~8 Cycles

0~125 (LSB)

-55~0 (LSB)

0~1000 ppm

1000~3000 ppm

100~2000 ppm

Humidity Input Low

Value

Value

UM-15090000-AA4 Page 40

AV 32

AV 33

AV 34

AV 35

AV 36

AV 37

AV 38

AV 39

AV 40

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Humidity Input Low Value

Humidity Input High Value

600~1000 ppm

0~20%

5~20(0.5~2.0) Hour

0~1000 (0.0~100.0 %)

0~1000 (0.0~100.0 %)

0~1000 (0.0~100.0 %)

0~1000 (0.0~100.0 %)

0~1000 (0.0~100.0

0~1000 (0.0~100.0

Page 41

Minimum Fan

Output

AV 41

R/W

Minimum Fan Output at Auto

Maximum Fan

AV 42

R/W

Maximum Fan Output at

Low Fan Speed

Low Fan Speed Setting (for

Med. Fan Speed

AV 44

R/W

Med. Fan Speed Setting (for

Hi Fan Speed

Setting

Hi Fan Speed Setting(For

Modulating Fan Application)

Minimum Off

0~180 seconds

Minimum On Time

0~180 seconds

Stroke Time

Stroke time

Set Point for

AV 49

R/W

Set Point for Humidity

Dew Point Set

Dew Point Temperature

℃/°F

Occupancy Status

1: Room Unoccupied

Window-Door Status

1: Door/Window Open

BI 2

R

Status of Cooling/Heating

Relay 1 Status

Status of Relay 1

(Cooling Stage 1)

Relay 2 Status

Status of Relay 2

(Cooling Stage 2)

Relay 3 Status

Status of Relay 3

(Heating Stage 1)

Relay 4 Status

Status of Relay 4

(Heating Stage 2)

Relay 5 Status

Status of Relay 5

Relay 6 Status

Status of Relay 6

Relay 7 Status

Status of Relay 7

Fan

Dl 1 Status

Status of Digital Input 1

Dl 2 Status

Status of Digital Input 2

Dl 3 Status

Status of Digital Input 3

Fan Mode (for Modulating

Fan Application)

0%~Reg 51

Output

Setting

Setting

Time

Humidity

Point

AV 43

AV 45

AV 46

AV 47

AV 48

AV 50

BI 0

R/W

R/W

R/W

R/W

R/W

R/W

R

Auto Fan Mode (for

Modulating Fan Application)

Modulating Fan Application)

Modulating Fan

Application)

Minimum Off Time

Minimum On Time

Control

Set Point

Status of Occupancy

Reg 50~100%

0%~Reg 53

Reg 52~Reg54

Reg 53~100%

10~1600 sec.

0~1000 (0.0~100.0

%RH)

-999~9999: -99.9~999.9

0: Room Occupied

Cooling-heating

Status

BI 1

BI 3

BI 4

BI 5

BI 6

BI 7

BI 8

BI 9

BI10

BI11

BI12

R

R

R

R

R

R

R

R

R

R

R

Window/ Door Status

Control

Output

0: Door/Window Closed

0: Close & Off 1: Open & On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

UM-15090000-AA4 Page 41

Page 42

Dl 4 Status

BI13

Status of Digital Input 4

Dl 5 Status

Status of Digital Input 5

Dl 6 Status

Status of Digital Input 6

Dl 7 Status

Status of Digital Input 7

Fan Status

Fan Status

Flow Switch Status

Differential Pressure (Air

Flow) Switch Status

Trip Status

Trip Alarm Status

Filter Status

Filter Dirty Alarm Status

Smoke/ Fire

Alarm Status

Smoke/ Fire Alarm

Status

Local/ Remote

Switch Status

Local/ Remote Switch

Status

Disconnect

Switch Status

Disconnect Switch Status

Maintenance

Switch Status

Maintenance Switch

Status

Frozen Alarm

Status

Frozen Alarm Status

1: After Hour

Occupancy Contact

model specific)

1: N.C.

Modulating Cooling Direct/

1: Reverse (10 To 0V)

Modulating Heating Direct/

1: Reverse (10 To 0V)

Fan Runs at Set 3

Modulating Fan)

Fan Runs at Set 3 Speeds or

and Max Fan Output at Auto

Fan Application)

Window-Door

1: N.C.

On-Off Control

On/Off Control of Thermostat

BV 6

R/W

Relay 1 Control

On/Off Control of Relay 1

R

0: Off, 1: On

After Hour Status

BI14

BI15

BI16

BI17

BI18

BI19

BI20

BI21

BI22

BI23

BI24

BI25

BI26

R

R

R

R

R

R

R

R

R

R

R

R

R

After Hour Status

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Off, 1: On

0: Normal Hour

Definition

Cooling DirectReverse Acting

Heating DirectReverse Acting

Speeds or Free

Speed at Auto Fan

Mode(For

Contact Definition

Temperature Scale

BV 0

BV 1

BV 2

BV 3

BV 4

BV 5

R/W

R/W

R/W

R/W

R/W

R/W

Occupancy(DI1) Contact

Definition

Reverse Signal Output

Reverse Signal

Output

Free Speed between Min

Fan Mode(For Modulating

Door or Windows(DI2)

Contact Definition

°C/ °F

(this feature is

0: N.O.

0: Direct (0 To10v)

0: Direct (0 To10v)

0(Free Speed) ~1(3 Speeds)

0: N.O.

0: Off, 1: On

0: °C

1: °F

UM-15090000-AA4 Page 42

BV7

R/W

(Cooling Stage 1)

0: Off, 1: On

Page 43

Relay 2 Control

BV8

On/Off Control of Relay 2

(Cooling Stage 2)

Relay 3 Control

On/Off Control of Relay 3

(Heating Stage 1)

Relay 4 Control

On/Off Control of Relay 4

(Heating Stage 2)

Relay 5 Control

On/Off Control of Relay 5

Relay 6 Control

On/Off Control of Relay 6

Relay 7 Control

On/Off Control of Relay 7

Fan

Occupancy

Room Occupancy Setting

1: Unoccupied

Fan Output for

Disable/ Enable Fan

1: Enable

Sensor type

Select Sensor type

1: RH

MSV 0

Working Mode: Heat, Cool or

Mode

5: 2 Hrs. Sleep

Modbus

Lowest Fan

Lowest Fan speed in

Fan Speed Status

Fan Speed Status

4: 76800 bps

& CO2

R/W

0: Off, 1: On