Contect SP800 Service manual

Infusion Pump

SP 800

Service Manual

Contect Medical Systems . CO.LTD

I

Foreword

Introduction

This Operator's Manual provides a detailed introduction of the hardware components, installation,

dismantling, testing and troubleshooting of this product and its parts, which may effectively help

repair staff handle commonly seen problems. It does not provide in-depth information on the

structure and design of the product. If you experience problems that cannot be solved, please contact

our after-sale service department.

Information in this Operator's Manual is based on a fully configured product, some of which may

not be applicable to the product you're repairing. If you have any questions, please contact our aftersale service department.

Before carrying out any repair work, please ensure that you can properly repair the product by

carefully reading and fully understanding the content of this Operator's Manual. This way, damage

to the product or physical injuries may be avoided.

For use by:

Professional biomedical engineers responsible for the maintenance of this product, authorized

repair staff or after-sale service representatives.

Version Information

The version number of this Operator's Manual may be updated without notice at any time due to

changes in software or technical specifications. The version information of this Operator's Manual

is as follows.

◼ Version No.: 2.0

◼ Time of Publication: 2013-11

1

Contents

Chapter 1 Safety .................................................................................................................... 1

1.1 Safety Information ................................................................................................ 1

1.1.1 Dangers ......................................................................................................... 2

1.1.2 WARNING .................................................................................................... 2

1.1.3 CAUTION ..................................................................................................... 3

1.1.4 NOTE ............................................................................................................ 3

1.2 Equipment Symbols .............................................................................................. 4

Chapter 2 Design ................................................................................................................... 5

2.1 Description ............................................................................................................ 5

2.2 System decomposition .......................................................................................... 5

2.3 Hardware configuration......................................................................................... 7

2.3.1 Control Board ................................................................................................ 8

2.3.2 Pump body .................................................................................................... 9

2.3.3 Control Board .............................................................................................. 10

2.3.4 Bubble pressure board ................................................................................. 11

2.3.5 Door-opening detection board ..................................................................... 12

2.3.6 Drop rate sensor .......................................................................................... 12

Chapter 3 Testing and maintenance ..................................................................................... 13

3.1 Description .......................................................................................................... 13

3.1.1 Testing report............................................................................................... 14

3.1.2 Recommended frequency ............................................................................ 14

3.2 Visual inspection ................................................................................................. 15

3.3 Startup test ........................................................................................................... 15

3.4 Infusion Flow test ................................................................................................ 16

3.5 Pressure sensor test ............................................................................................. 17

3.6 Battery performance test ..................................................................................... 18

3.7 Electrical safety test ............................................................................................ 19

3.7.1 Housing leakage current test ....................................................................... 20

3.7.2 Patient leakage current test .......................................................................... 20

3.8 Cleaning and Disinfection ................................................................................... 21

Chapter 4 Common failures and Troubleshooting ............................................................... 23

4.1 Overview ............................................................................................................. 23

4.2 Components replacement .................................................................................... 23

4.3 Common failures and Troubleshooting ............................................................... 24

2

Chapter 5 Maintenance and Disassembly ............................................................................ 27

5.1 Tools .................................................................................................................... 27

5.2 Preparation for disassembly ................................................................................ 27

5.3 Disassembly procedure ....................................................................................... 28

5.3.1 Separate the front and rear housing ............................................................. 28

5.3.2 Disassembly of Control Board .................................................................... 30

5.3.3 Removal of the Pump body ......................................................................... 31

5.3.4 Remove the Sensor board and Pressure sensor ........................................... 35

5.3.5 Change the battery ....................................................................................... 36

Chapter 6 Components......................................................................................................... 37

6.1 Host components ................................................................................................. 37

6.1.1 Main parts lists ............................................................................................ 38

6.2 Pump Body Assembly ......................................................................................... 39

1

Chapter 1 Safety

1.1 Safety Information

The safety statements presented in this chapter refer to basic safety information that the

operator must pay attention to and abide by during maintenance operations of the infusion

pump. There are additional safety statements in other chapters or sections, which may be the

same as or similar to the following, or specific to particular operations.

DANGERS

⚫ Indicates an imminent hazard that, if not avoided, could result in death, serious

injury or damage to product/property.

WARNING

⚫ Indicates a potential hazard or unsafe maintenance practice that, if not avoided,

could result in death, serious injury or damage to the product/property.

CAUTION

⚫ Indicates a potential hazard or unsafe maintenance practice that, if not avoided,

could result in minor personal injury, product malfunction or damage to

product/property.

NOTE

⚫ Provides application tips or other useful information to ensure that you achieve

better maintenance of the product

2

1.1.1 Dangers

DANGERS

⚫ The infusion tube must be installed straight and level in the bottom of the groove

on the infusion pump.

1.1.2 WARNING

WARNING

⚫ Only authorized professional maintenance technicians can disassemble the

Infusion pump; Pump maintenance and upgrades must be carried out by

maintenance technicians trained and licensed by the manufacturer.

⚫ To prevent fire or explosion, do not operate this infusion pump in the presence of

anesthetic, flammable or explosive materials.

⚫ This infusion pump belongs to Class II (type of electric shock protection); the

supplied Type I power cord PE earth terminal should not be used as ground

protection and functional earthing.

⚫ The packaging materials must be disposed of in compliance with local laws and

regulations or the hospital policy on waste management. They must be kept out

of the reach of children.

3

1.1.3 CAUTION

CAUTION

⚫ Electromagnetic fields may influence the performance of the infusion pump.

Therefore, equipment or devices used in the vicinity of the infusion pump must

meet the EMC standard. Mobile phones, X ray and MRI equipment are all

potential interference sources because of their high-intensity electromagnetic

radiation.

⚫ Avoid exposing this infusion pump to high-pressure sterilization or chemical

materials.

⚫ Before the infusion pump is connected to the power supply, make sure the

voltage and frequency of the power supply comply with the label on the pump or

the specific requirements outlined in this Operator’s Manual.

⚫ In the maintenance process, please pay attention to protect the pump from

damage from drops, impacts, violent shaking or other external mechanical

forces.

1.1.4 NOTE

NOTE

⚫ For detailed operating instructions and other information about the infusion

pump, please refer to the Operator's Manual.

⚫ This Service Manual describes all the settings and functions of the infusion

pump in its most complete functional configuration. The infusion pump you are

handling may not have some of the settings or functions described herein.

⚫ Do not insert devices that are not specified by the manufacturer into the data

ports.

4

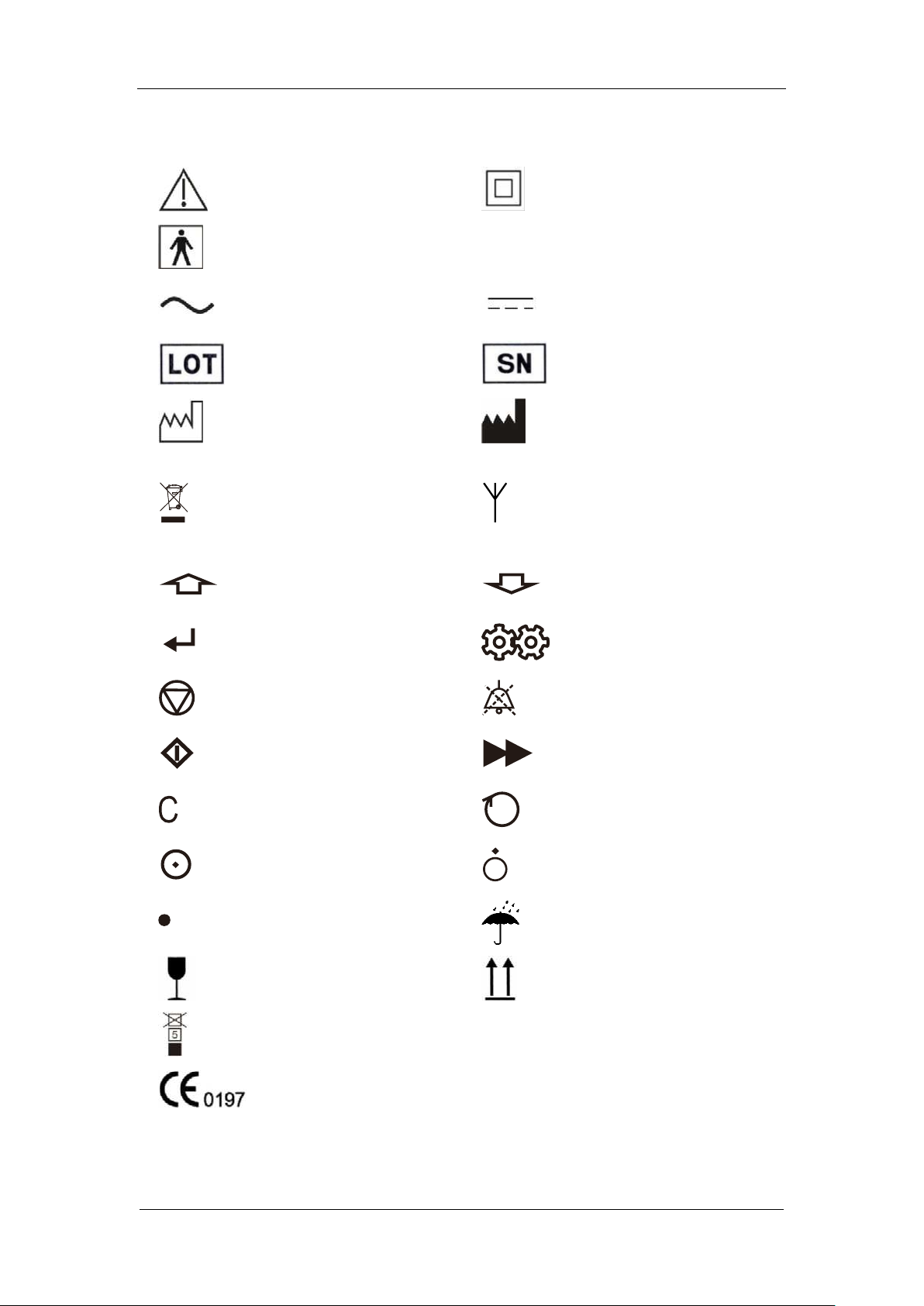

1.2 Equipment Symbols

Attention! Refer to the

manual

Class II equipment

Class BF device

IP21

Splash-proof

Alternating current power

supply (AC)

Direct current power

supply (DC)

Batch number

Serial number

Date of manufacture

Manufacturer

Electronic equipment:

dispose of separately to

avoid polluting the

environment

Wireless transceiver

Up or increase value

Down or decrease value

Confirm

Set Stop

Cancel alarm

Start

Bolus

Clear

Select

Turning on the pump

Turning off the pump

Decimal point

Protect from rain during

transport

Fragile item, handle

with care

Keep upright during

transport

Maximum stack height

without additional

CE marked product, complies with EU directive MDD 93/42/EEC and

annex I thereof.

5

Chapter 2 Design

2.1 Description

This infusion pump is for use in wards, operating theaters, and observation rooms for

accurate and continuous infusion to patients.

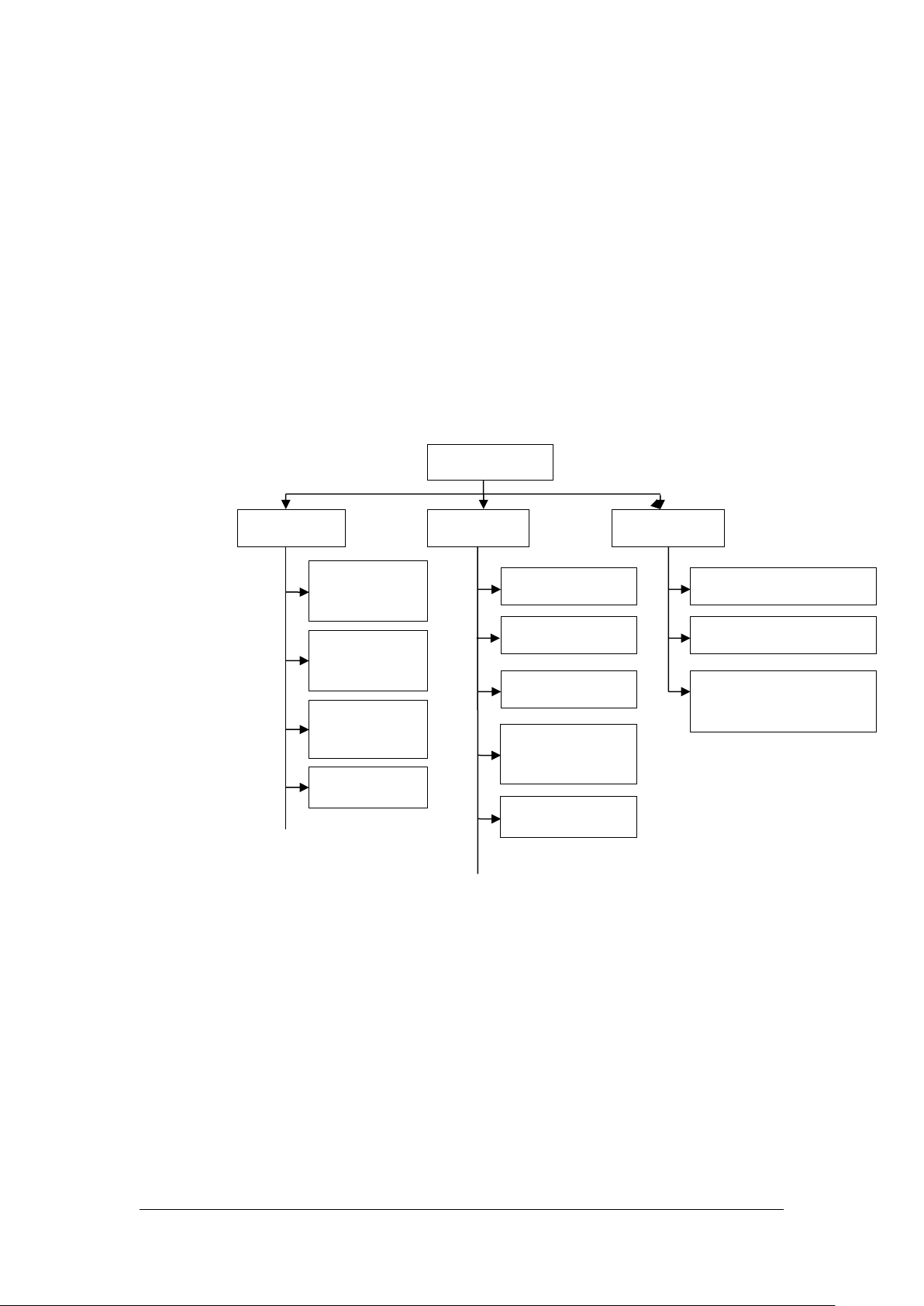

2.2 System decomposition

The system is decomposed according to Machinery, Hardware and Software three aspects,

with the composition chart as follows:

System

Hardware

Software

Control Board

Sensor Board

System software

Driver software

Bubble pressure board

driver

Drop sensor

Battery

Drop sensor

Door-opening

detection board

Front housing

assembly

Pump

assembly

Rear housing

assembly

Machinery

6

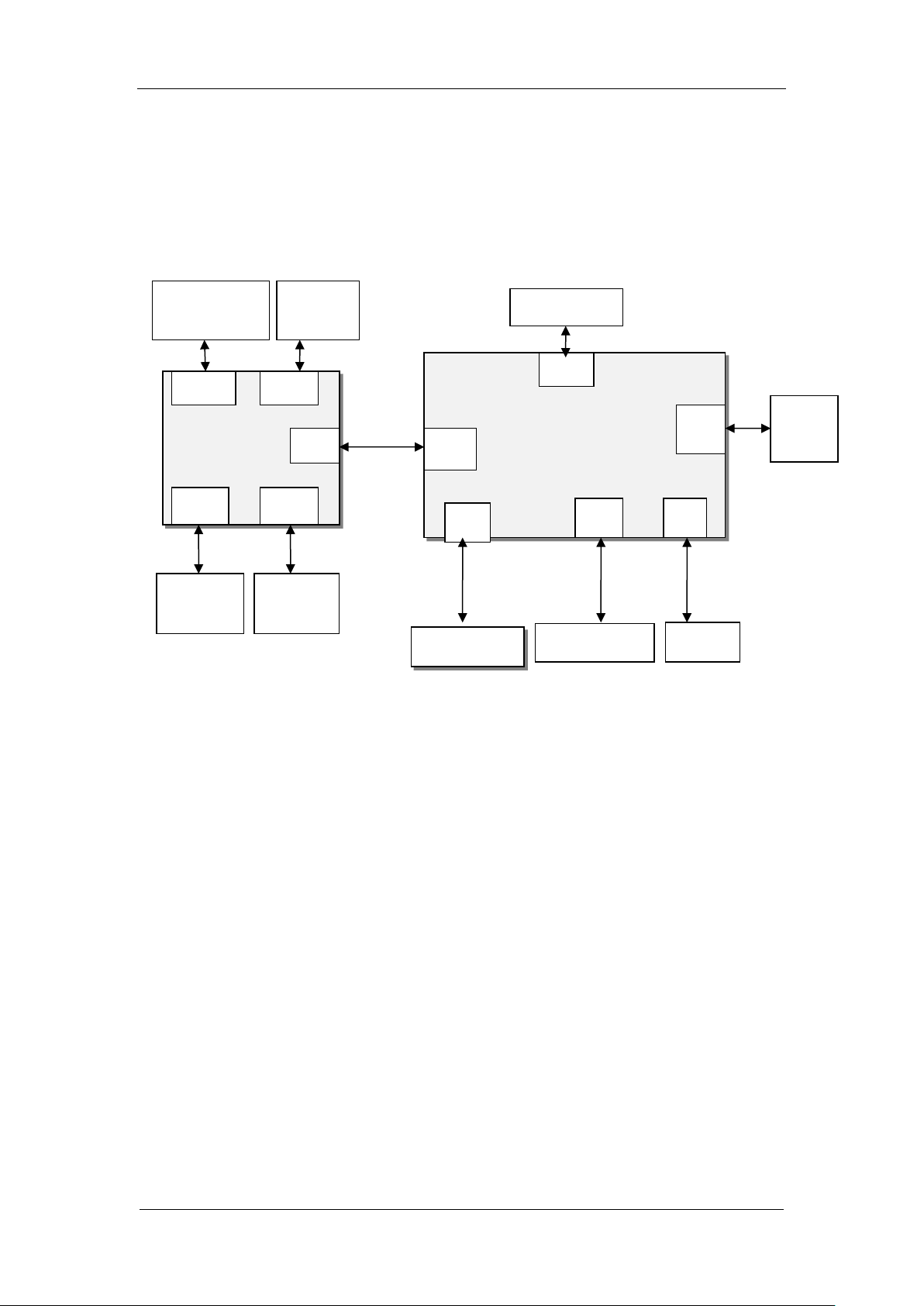

System Board connection diagram is as follows:

Bubble pressure

board

Control Board

FPC1

Stepper motor

CN1

Loudspeaker

Battery

PS5

P1

Qpyl

1

CN2

P_TX1

P_RX1

Ultrasonic

emission

Ultrasonic

reception

Door-opening

detection board

Pressure

sensor

P_Gate

PYL_1

Flash2

Drop

sensor

Display screen

7

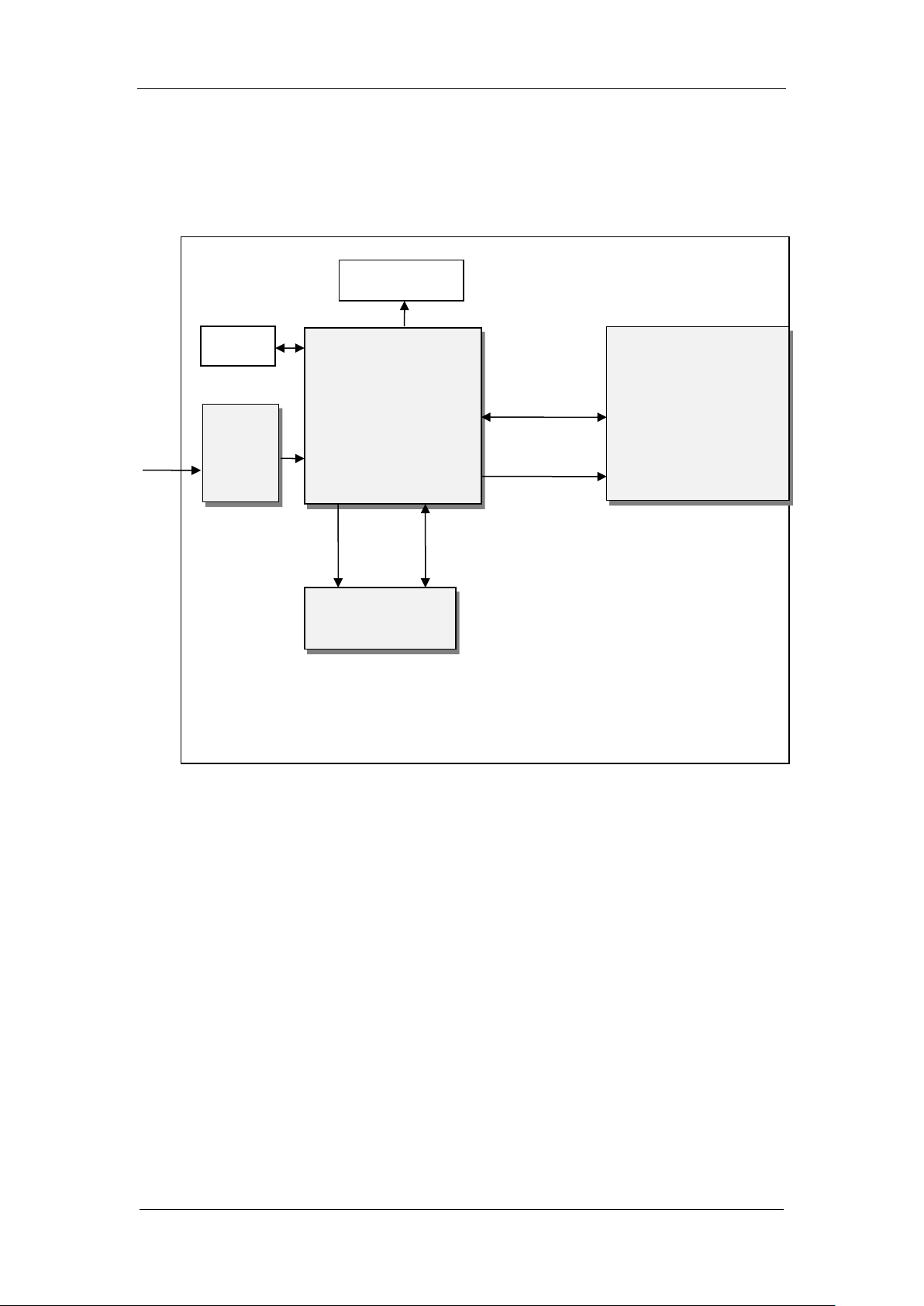

2.3 Hardware configuration

Functional block diagram:

AC

The core of the system is the Control Board. Screen display and power supply is carried out by

Control Board; measurements and status information for each module are sent to the Control

module after treatment in the Driver module, and finally displayed on the computer screen by

Control Board; Control Board is also responsible for controlling Buzzer and Status indicator

lights. Current supply for all the modules are provided by the Power Board; the Driver module

is also responsible for driving of the motor, measurement of each sensor and integrated

treatment of the status information.

Driver module

Control module

Bubble pressure

board

Battery

Stepper motor

Battery

cover

plate

Serial

Communication

3.3V/5V

Current supply

5V Current

supply

Serial

Communication

8

2.3.1 Control Board

Control Board is information integration of the entire system, providing resources and support

for the entire system. It controls the LCD, keypad input, buzzer sounds and set the parameter's

storage capabilities.

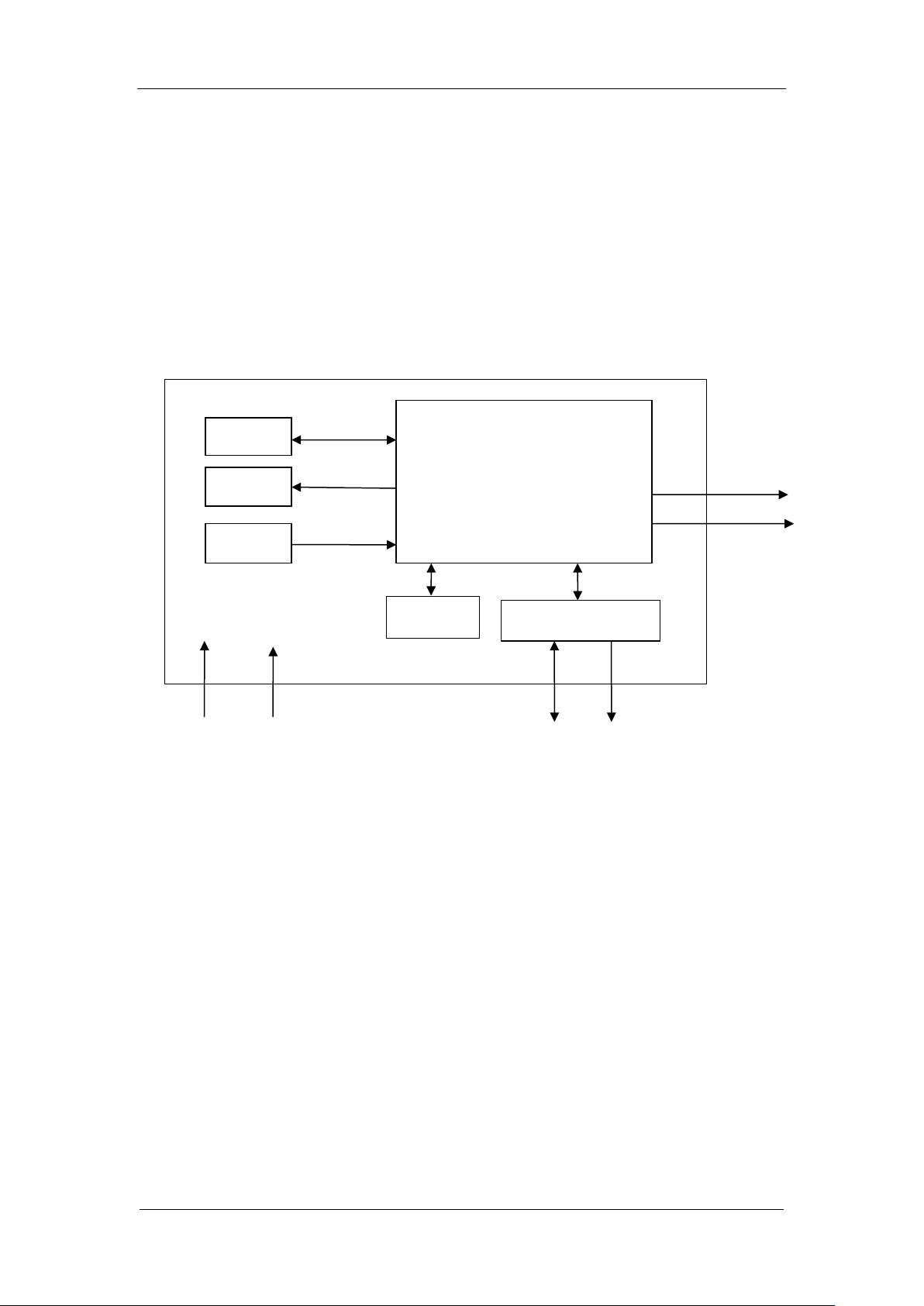

2.3.1.1 Functional block diagram

2.3.1.2 Function introduction

➢ Control Board makes communications with the Power module or the ZIGBEE

wireless module on the Control Board through the serial ports of the logical gate

circuit extension modules;

➢ Control Board provides display information for the display screen, and detects key-

press to implement user interface;

➢ Control Board controls the Buzzer to realize the function of alarm tone and

key tone;

➢ Control Board controls running of the indicator light via the logical circuit;

➢ SRAM realizes data staging and procedures operation, and EEPROM serves as

machine configuration memory.

MCU

EEPROM

Display

Keys

SRAM

Logical gate circuit

Buzzer

Run_LED

5V

3.3V

Serial port1: Power Board

Serial port2: ZIGBEE

wireless module

9

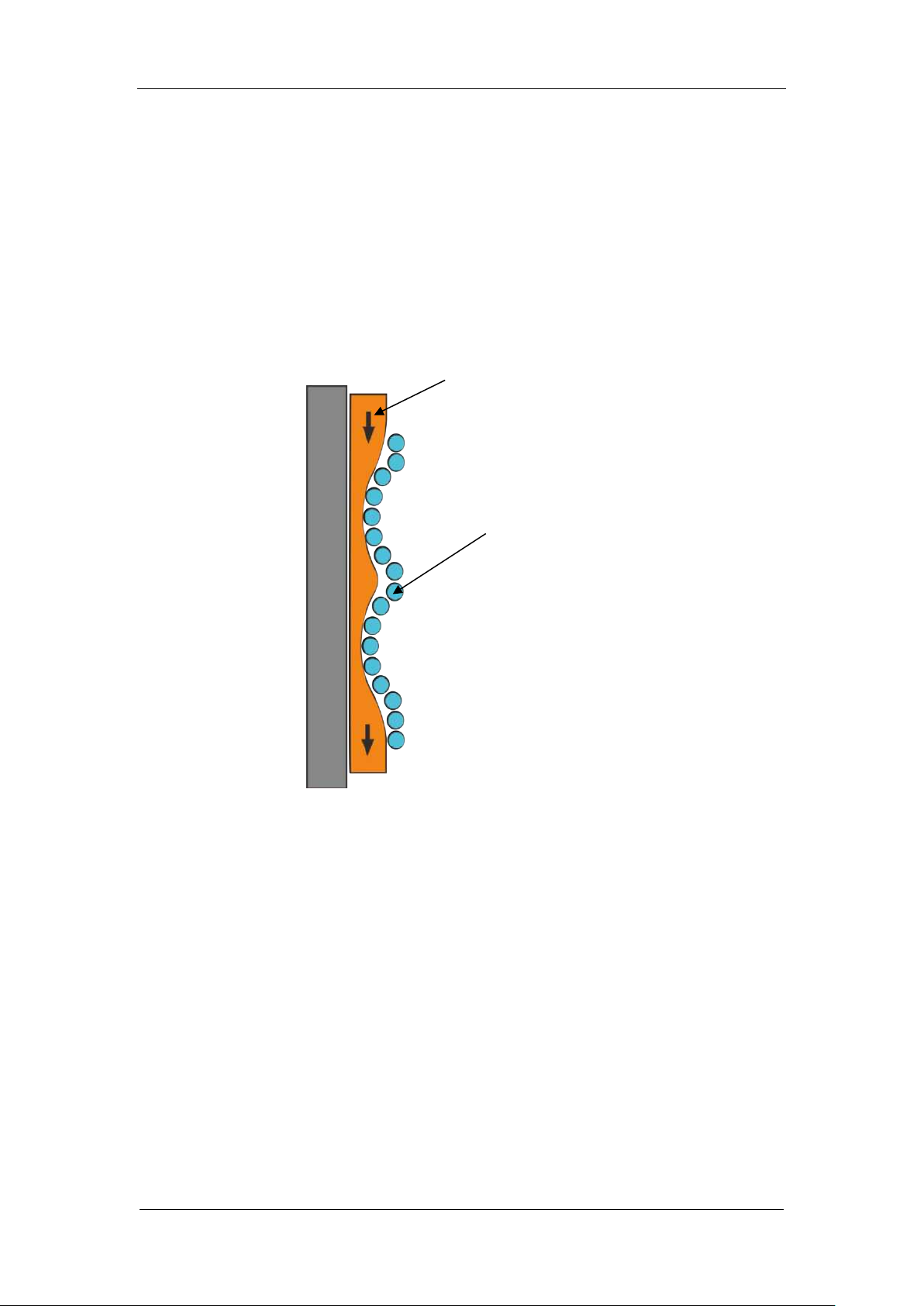

2.3.2 Pump body

Pump body device is the power provider of the whole system and the power source for liquid

transportation. During work, the stepper motor driven camshaft rotation makes the pump

moving up and down according to a certain order and motion law, such as waves to squeeze

the intravenous infusion tube, and let the fluid inside make a directional flow at a certain speed.

Functional schematic diagram

Tube

Pump tablet

10

2.3.3 Control Board

Control Board synthesizes the functional information detected from Bubble pressure board and

then sends it to CPU, and it also sends an information to drive the stepper motor. Control Board

also converts the input power (including mains and battery) into the power required for each

board, and supports the battery charging simultaneously.

2.3.3.1 Functional block diagram

AC/DC

Switching

power supply

Boost

Circuit

LDO

MCU

Charging

Circuit

Battery

Driver

Circuit

Logical

gate circuit

Power-on

Circuit

Motor

Detection

circuit

5V

7.4V

12V

18.9V

AC

Input

Serial port

3.3V

Stepper motor

Enable input

Loading...

Loading...