Contech Corrugated Metal Pipe Brochure

Corrugated Metal Pipe

Customer Proven Innovation

Contech® provides a full range of Corrugated Metal Pipe for

severe-to-normal conditions

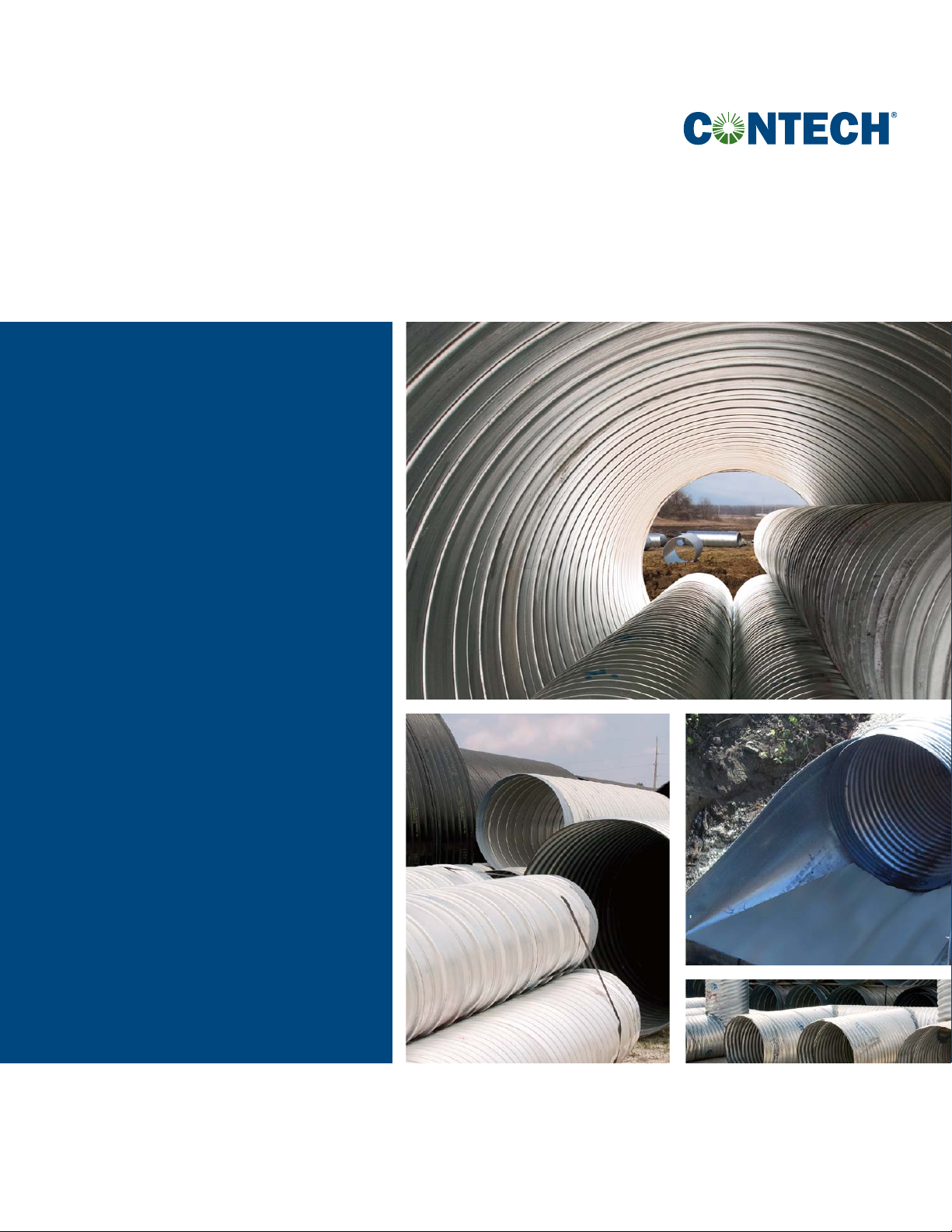

Coast-to-coast, engineers and contractors rely

on Contech Corrugated Metal Pipe for culverts,

storm sewers, small bridges, stormwater detention

systems, conduits and windmill foundations.

No other type of drainage structure offers the

range of structural strength that’s available with

Corrugated Metal Pipe—it performs where rigid

pipe fails.

Contech Engineered Solutions LLC

manufactures to repeatable and exacting

standards HEL-COR

pipe—which has a 0.012 Manning’s “n”—in

galvanized, Aluminized Steel Type 2, polymer

coated and aluminum.

Numerous industry standards for pipe

configurations, coatings and linings have been

conceived and developed by Contech. That is how

we have earned the reputation as the world leader

in pipe design and innovation.

®

and ULTRA-FLO

®

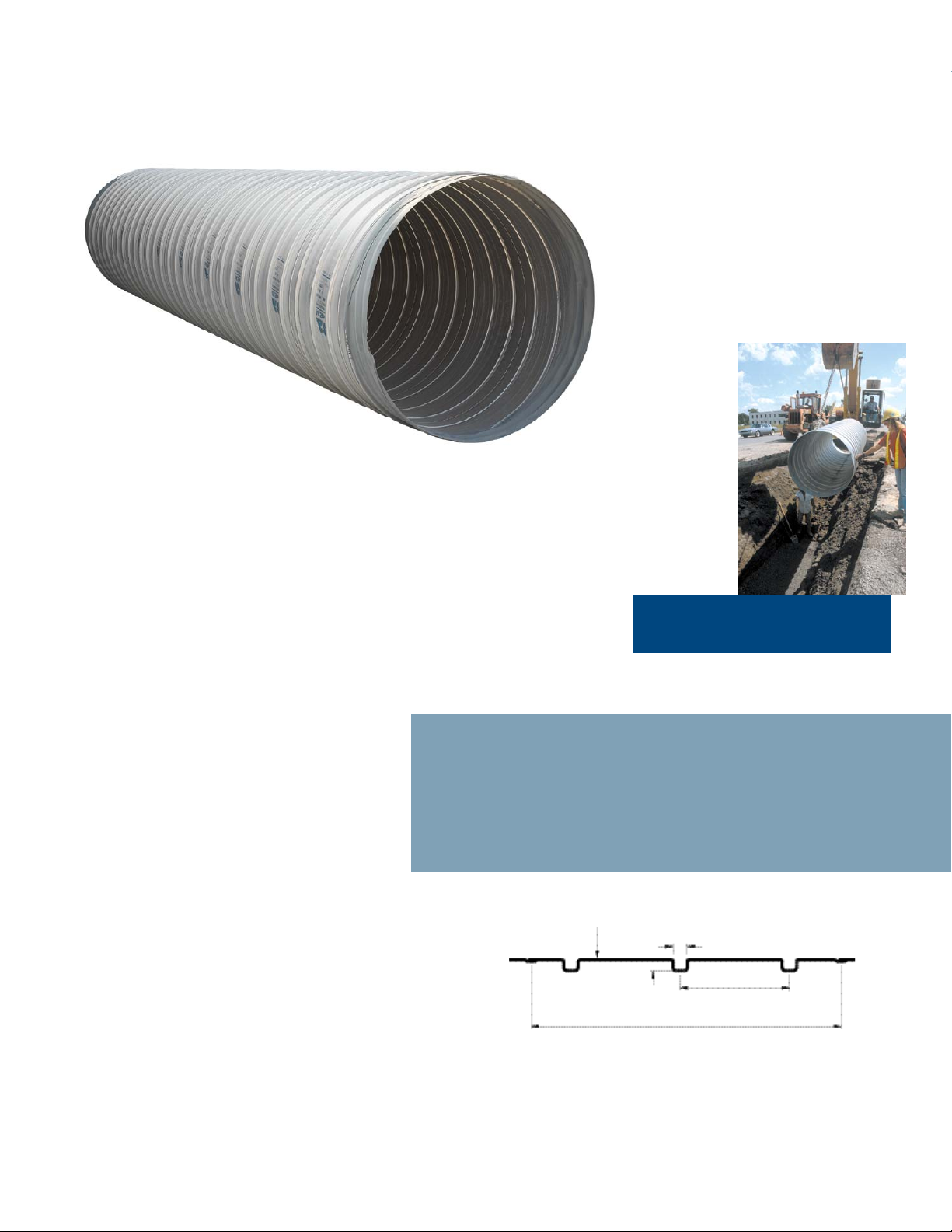

Long light weight sections make corrugated

steel pipe easy to install.

Corrugated Steel Pipe …

The Core of Strength

Corrugated steel pipe is similar to the superstructure

of a building in that it supports the interior walls and

gives structure to the facade. Steel is the proven, strongshouldered material that is coated with zinc, Aluminized

Steel Type 2, tough polymer or asphalt to increase durability

for prolonged design life. Corrugated steel pipe is the

strength at the core of all coatings and linings.

Contech’s Corrugated Steel Pipe provides the power and tenacity

to your culverts, storm sewers and stormwater detention systems

to withstand severe environmental conditions and burial depths.

We offer coatings and linings to increase the life of installations

up to 100 years as well as provide products with a Manning’s

“n” equivalent to other smooth wall drainage products.

Two primary shapes

Full-round pipe is recommended for most applications.

However, for limited headroom conditions, Contech

produces a pipe-arch shape. The low, wide pipe-arch

design distributes the area horizontally to provide adequate

capacity without raising the grade.

Corrugations and wall thicknesses

Both Contech Pipe and Pipe-Arch are produced in six wall

thicknesses including 18, 16, 14, 12, 10 and 8 gage, which

are available with either helical or annular corrugations.

Contech HEL-COR

with continuous locked seams, and with rerolled annular

ends. Contech riveted pipe is furnished with annular

corrugations only.

Corrugations include 1economical and efficient metal use in small diameters;

3” x 1” and 5” x 1” offer high sectional properties in largediameter pipe.

The wide variety of corrugations and thicknesses permits

selection of materials for a balanced design to meet specific

jobsite conditions. Each project can be designed individually

for the most cost-effective combination of corrugations,

thicknesses, sizes, materials and installations, maximizing

your investment on a job-by-job basis. For guidance, call

your local Contech sales representative.

®

Pipe (helical corrugations) is furnished

1

/2” x 1/4” and 2-2/3” x 1/2” for

2

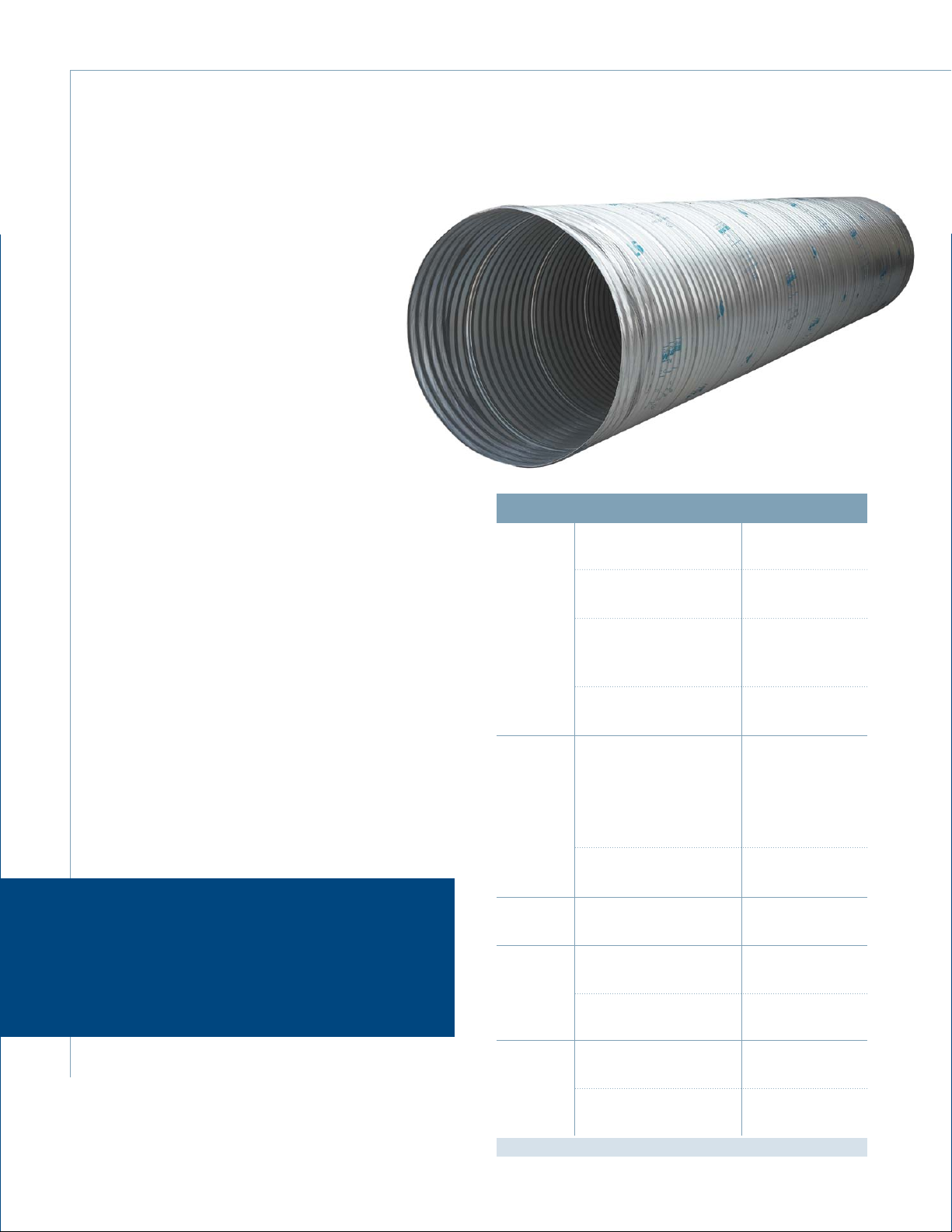

HEL-COR® Corrugated

Steel Pipe

Helically corrugated HEL-COR steel pipe, available in round

and pipe-arch shapes, has over 55 years of proven

performance. It is manufactured with continuous

locked seams with annular corrugated ends to use

with soil-tight HUGGER

Typical applications are culverts, stormwater

detention systems, small bridges, conduits and

storm sewers. A wide variety of wall thicknesses

(gages), corrugations, diameters and pipe section

lengths permit a choice of materials to meet

specic job site requirements.

Durability requirements are addressed by a wide choice

of materials: Galvanized Steel, Aluminized Steel Type 2

and polymer-coated steel. For increased hydraulic efciency,

HEL-COR SmoothCor

SMOOTH-FLO

lining.

Standard ttings include tees, wyes, elbows, saddle

branches, reducers and manifolds for detention systems.

Manholes and catch basins are fabricated to meet specic

job requirements.

As a construction shaft liner, HEL-COR Pipe, with or without

ring beam stiffeners, can be supplied in diameters to 171”.

Protective coatings and linings meet the requirements of the

following specications:

®

®

Bands.

®

has a steel lining and HEL-COR

has a smooth, fully circumferential asphalt

Reference Specifications

Material Galvanized Steel AASHTO M218*

ASTM A 929

Aluminized Steel Type 2 AASHTO M274*

ASTM A 929

Polymer-Coated Steel AASHTO M246*

ASTM A 742

ASTM A 849

Aluminum Alloy AASHTO M197*

ASTM B 744

Pipe Steel (Galvanized and Aluminized AASHTO M36*

Steel Type 2, CSP and Ultra Flo) ASTM A 760

Steel (Polymer-Coated, CSP, ASHTO M36*

Ultra Flo, and SmoothCor) AASHTO M245*

ASTM A 762

Over 55 years of proven

performance

Aluminum (Corlix, Ultra Flo) AASHTO M196*

ASTM B 745

Coating/Lining

ASTM A 849

Design Steel (CSP, Ultra Flo, SmoothCor) AASHTO Section 12*

ASTM A 796

Aluminum (Corlix, Ultra Flo) AASHTO Section 12*

ASTM A 790

Installation Steel (CSP, Ultra Flo, SmoothCor) AASHTO Section 26*

ASTM A 798

Aluminum (Corlix, Ultra Flo) AASHTO Section 26*

ASTM A 788

*AASHTO Standard Specification for Highway Bridges

Asphalt AASHTO M190*

3

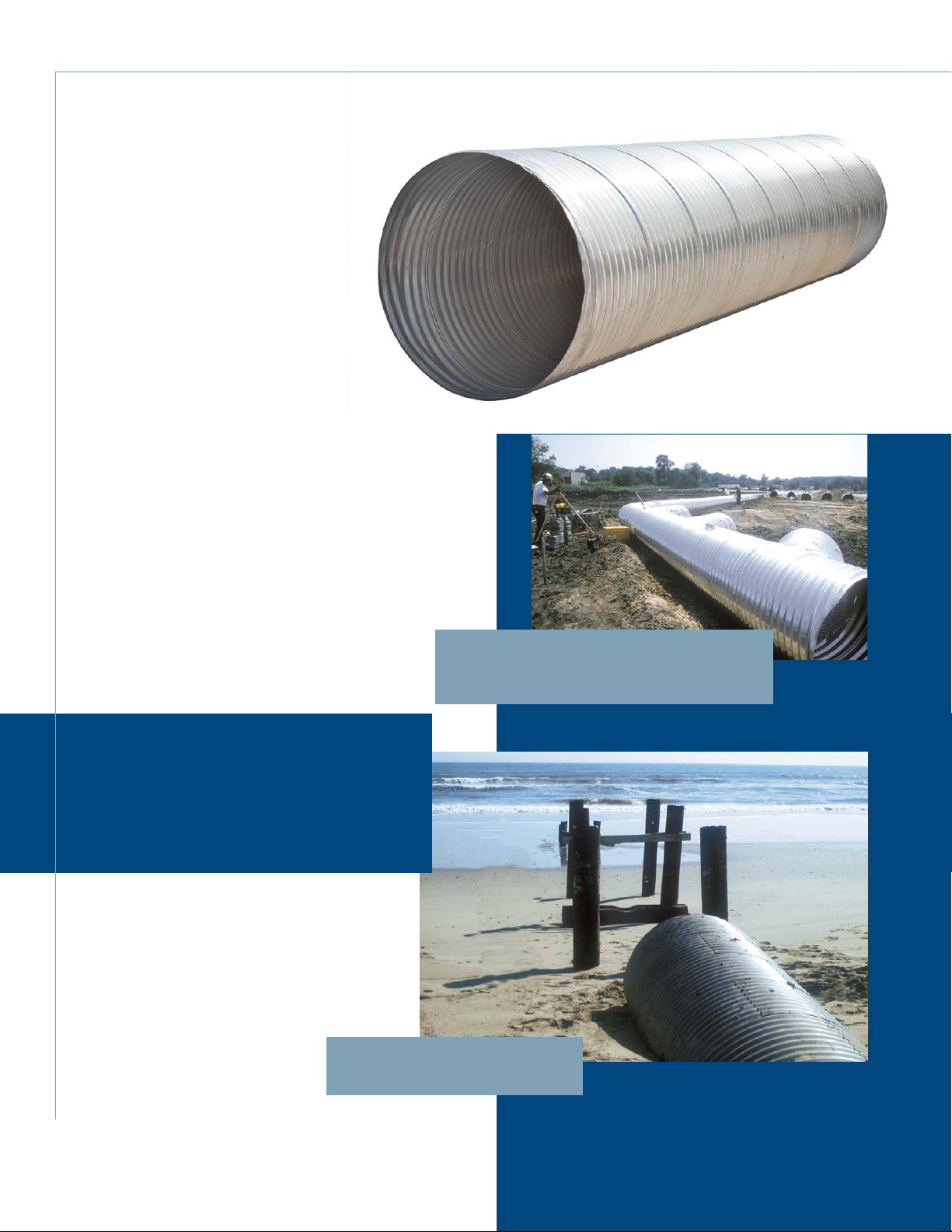

CORLIX® Aluminum Pipe

Long Service Life … Economical

Contech’s CORLIX Aluminum Pipe provides a

predictable service life of more than 75 years

when installed in the recommended soil/water

environment. It is ideal for municipal storm

sewers, underground stormwater detention

systems or any standard drainage project that

must withstand corrosive environments.

Economical

Lower initial cost begins with CORLIX pipe’s weight.

It weighs only 1/35 as much as reinforced concrete.

Lighter weight means easier installation. Trench width

and depths are reduced due to the smaller outside

diameters, resulting in time and cost savings for both

excavation and backll.

Single lengths up to 40 feet ensure more accurate

pipe alignment at time of placement and through the

life of the system. Longer lengths save installation time

with fewer joints. Even more footage per truckload is

possible with bundles of nested pipe—and unloading

time is minimal.

A CORLIX underground detention system with prefabricated stubs

eliminates the need for forming concrete junction boxes.

Predictable service life of more

than 75 years

CORLIX Aluminum Pipe can be installed in salt water

environments.

4

Installed Cost Savings

Storm Sewer Products

®

ULTRA FLO

smooth interior corrugated

storm sewer pipe

Manning’s “n” of 0.012 … Equal to Concrete Pipe

ULTRA FLO has over 25 years of proven performance

on municipal, transportation, residential development,

shopping center and airport storm sewer and stormwater

detention projects. ULTRA FLO’s rapid acceptance is based

on its Manning’s “n” of 0.012, structural strength and

faster/lower-cost installation than concrete. Plus, ULTRA

FLO is available in galvanized steel, Aluminized Steel Type

2, polymer coated and aluminum to meet a wide variety of

environmental and service life requirements. For projects

with limited headroom, ULTRA FLO is available

in pipe-arch.

—

Millions of feet of ULTRA FLO have been installed in

thousands of storm sewer projects nationwide, providing

significant cost savings. Because steel ULTRA

FLO weighs less than 10% of concrete pipe,

handling and installation costs are greatly

reduced. Aluminum ULTRA FLO has only

1

/35 the weight of concrete pipe. Lower

labor costs also result from fast and easy

®

joining. Contech QUICK STAB

coupling bands do

not require special

skills or tools. Twenty-

foot standard

lengths mean fewer joints

and faster laying. And, longer

lengths are available on special order.

ULTRA FLO’s smaller outside diameter

permits a reduction in trench widths

and depths, providing time and cost

savings for both excavation and

backfilling operations.

Shop-fabricated

fittings save

installation time in

the field while

providing hydraulically efficient junctions.

Reduced excavation—because of ULTRA FLO’s

smaller outside diameter—lowers cost.

joints or

Superior Hydraulics

Research at Utah State University shows that

ULTRA FLO Storm Sewer Pipe Systems are

hydraulically equivalent to reinforced concrete pipe.

The Water Research Laboratory performed hydraulic

tests on ULTRA FLO spiral-rib pipe with

3

/4” x 3/4” x 7 1/2” continuous ribs. At full flow, the Manning’s

“n” was 0.012 (Report No. 1277 and 1278, 2002). For

further reference, see FHWA Hydraulic Design

Series No. 5, December 1996.

ULTRA FLO is one of the most hydraulically efficient storm

sewer systems available because of its smooth interior

surface and longer lengths, resulting in fewer joints and

hydraulically efficient prefabricated junctions: elbows,

manholes and catch basins.

Smooth interior of ULTRA FLO pipe improves

hydraulic capacity while the exterior box ribs

provide structural strength.

Interior Pipe Wall

3/4”

3/4”

22 1/2” o.c.

External Rib Profile

7 1/2”

5

Loading...

Loading...