Page 1

F&eIT Series

10/100/1000M AUTO-MDIX

Industrial switchingHUB

For DIN rail, 8 ports

SH-9008H-FIT

User’s Manual

CONTEC CO., LTD.

Page 2

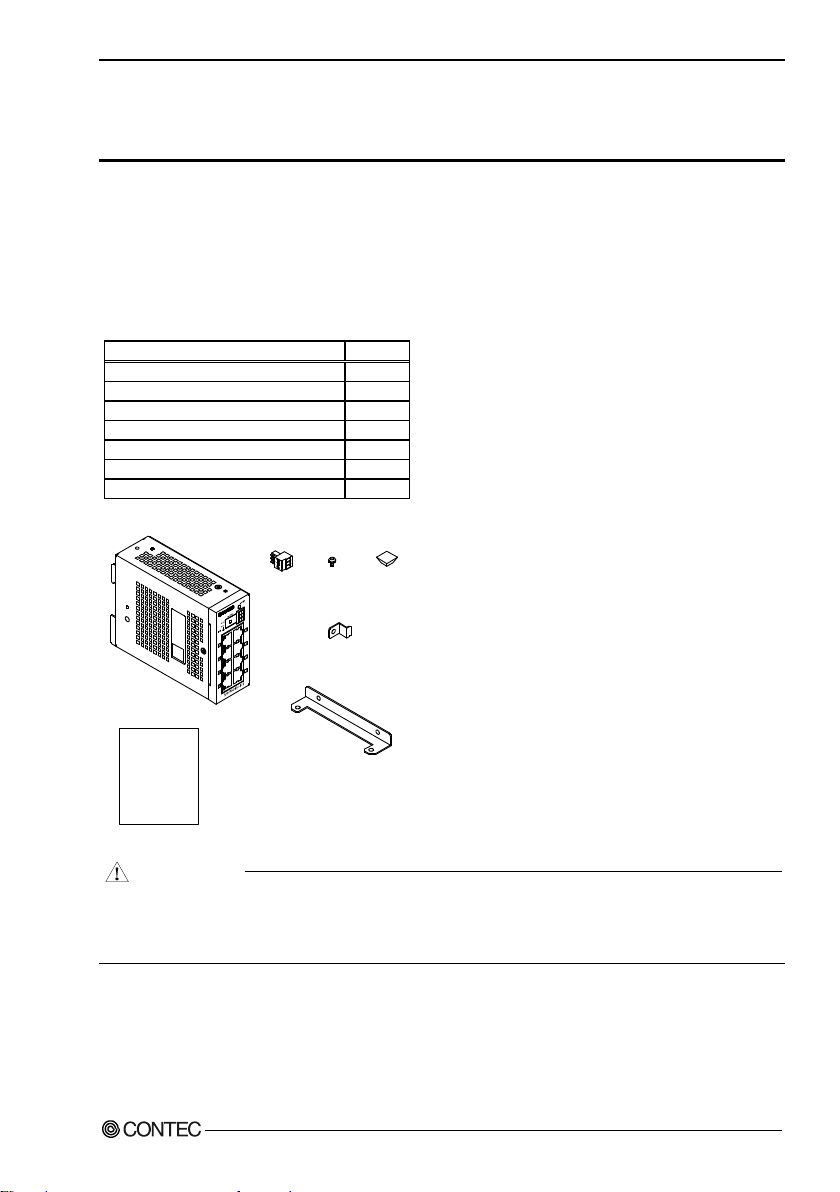

Name

Pcs.

Unit 1 Setup Guide

1

Acceptable connector

1

Connecto r omis sio n pre vent io n meta l fitt ings

1

Flat putting fixing bracket

2

Fixed screw M3×6

5

Rubber foot

4

x 2

x 5 x 4

Setup Guide

Unit

Acceptable

connector

Fixed

screw

Flat putting

fixing bracket

Connector omission

preventi on metal fi ttings

Rubber

foot

CAUTION

Check Your Package

Thank you for purchasing the CONTEC product.

The product consists of the items listed below.

Check, with the following list, that your package is complete. If you discover damaged or missing

items, contact your retailer.

Product Configuration List

* The manu al of this product can be downloaded from CONTEC homepage (http://www.contec.com/) free of charge.

To operate this product, a power supply (12-24VDC±5%) is required sep arat el y.

For power supply, see Chapter 3, Nomenclature of unit Components and Th eir Settin gs, “About of

Power Supply”.

SH-9008H-FIT

i

Page 3

Copyright

Copyright 2016 CONTEC CO., LTD . ALL R IGH TS RE S ER VED

No part of this document may be copied or reproduced in any form by any means without prior written

consent of CONTEC CO., LTD.

CONTEC CO., LTD. makes no commitment to update or keep current the information c ontained in

this document. The information in this document is subject to change without notice.

All relevant issues have been considered in the preparation of this document. Should you notice a n

omission or an y q uestionable item in this document, please feel fre e to noti f y CONTEC C O., LTD.

Regardless of the foreg oi n g statem en t, C ONTEC a ssum es no resp onsi bi lit y for an y error s tha t ma y

appear in this document or for results obtained by the user as a result of using this product.

Trademarks

Other brand and product names are trademarks o f t heir respective holder.

SH-9008H-FIT

ii

Page 4

Table of Contents

Check Your Package ............................................................................................................................ i

Copyright ............................................................................................................................................ ii

Trademarks ......................................................................................................................................... ii

Table of Contents ............................................................................................................................... iii

1. Before Using the Product 1

About the Unit .................................................................................................................................... 1

Features ........................................................................................................................................ 1

Customer Support ............................................................................................................................... 2

Web Site ....................................................................................................................................... 2

Limited One-Year Warranty ............................................................................................................... 2

How to Obtain Service........................................................................................................................ 2

Liability ............................................................................................................................................... 2

Safety Precaution s .............................................................................................................................. 3

Safety Information ....................................................................................................................... 3

Handling Precautions ................................................................................................................... 3

Environment ................................................................................................................................. 5

Inspection ..................................................................................................................................... 5

Storage ......................................................................................................................................... 5

Disposal........................................................................................................................................ 5

2. Setup of Hardware 7

Mounting or Removed DIN rail ......................................................................................................... 7

Mounting on a DIN rail ............................................................................................................... 7

Removed DIN rail ........................................................................................................................ 8

Mounting of Flat putting fixing bracket and rubber foot ................................................................. 11

Mounting .................................................................................................................................... 11

Mount of connector omission prevention metal fittings .................................................................. 13

Mounting .................................................................................................................................... 13

Installation Conditions ...................................................................................................................... 14

Installation orientation ............................................................................................................... 14

Spacing between th e system unit and any surroundin g objects ................................................ 17

3. Nomenclature of unit Components and Their Settings 19

Name of unit Components and Fun ct ion .......................................................................................... 19

4. Connecting to a Network 21

Network Cables ................................................................................................................................. 21

SH-9008H-FIT

iii

Page 5

Connecting a Personal Computer, another HUB unit or bridge ....................................................... 21

Connection Restrictions with 100BA SE-TX Repeater HUBs .................................................. 22

Connection Restrictions with 10B AS E-T Repeater HUBs ....................................................... 22

5. System Reference 23

Specification ..................................................................................................................................... 23

Physical Dimensions ......................................................................................................................... 25

Differences from SH-9008-FIT ........................................................................................................ 26

SH-9008H-FIT

iv

Page 6

1. Before Using the Product

1. Before Using the Product

This chapter provides information you should know before using the product.

About the Unit

SH-9008H-FIT is a compact -sized [39(W) × 120(D) × 94(H) mm] industria l switching HUB unit that

is compliant with the IEEE802.3ab (1000BASE-T)/IEEE802.3u (100BASE-TX)/IEEE802.3

(10BASE-T) standards.

Its features include Jumbo Frame support, AutoMDI/MDI-X, auto-negotiation, and aut omati c p ower

adjusting functi on. Th e aut omat ic p ower ad ju sti n g funct ion can redu ce th e p ower c on sumpti on b y up

to 60%. *1

With fan less configuration, SH-9008H-FIT is suit ab le for plac es wh ere si len ce is required. In

addition, the adoption of metal casing with great radiation performance enables the unit to be used in

ambient temperatures of 0 to 50°C. A DIN rail mounting mechanism and the mounting brackets

provided with the unit enable various types of installation.

Please read this manua l ca refu ll y so that you can b ui ld a syst em b y conn ectin g the s witch in g HUB uni t

to external d ev ices.

Features

- Compact-sized (39 (W) × 120 (D) ×94 (H) mm) unit equipped with 8 ports capable of 1000BASET

The compact-sized unit en clo su re (3 9 (W) ×120 (D) ×94 (H) mm) is equipped with the 8 ports that

are compliant with IEEE802.3ab (1000BASE-T)/IEEE802.3u (100BASE-TX)/IEEE802.3

(10BASE-T).

With fan less configuration, this product is sui tab le fo r pla c es where s i le nce is required. In

addition, the adopti on of meta l casin g with gr eat rad ia ti on per form anc e pro vid es th e operat in g

ambient temperature of 0 to 50°C.

- For jumbo frame

It is compatible with Jumbo Frame that increases transfer rate. C onn ection with Jumbo Frame

compatible devices increases d ata transfer ra te and contributes to increased transfer rat e and

reduced CPU load.

- Auto MDI/MDI-X feature, auto-n eg otiati on f eature

The Auto MDI/MDI-X feature can automatically recognize the cable type, st raigh t-through cable

or crossover cable, to prevent problems using the wrong cable type.

Also, the auto-nego t iation featur e can automatically recognize and choose the best communication

rate (10/100/1 000Mbps) and method (half/full duplex) available.

- Automatic power adjusting function

This function can automatically adjust the power consumption of unus ed ports, enab ling reduced

power consumption by up to 60% . * 1

- Flexible installation ori entati on.

The unit is equipped with a 35mm DIN rail mounting mechanism as standard. Also, the mounting

brackets provided with the unit make installation in any ori entati on pos sible (f loor, ceilin g, etc. ).

- Capable of running on a wide range of input voltages (12 to 24VDC)

The unit will function normally even if input voltage fluctuat es with in th e acc eptab le ran g e. In

addition, th e power connector includes an FG terminal.

*1 The comparison result of measur ed va lue s whe n a ll (e ig ht ) po rt s are in o per ation with t ho se w he n all ( e ig ht) ports are u nus ed .

SH-9008H-FIT

1

Page 7

1. Before Using the Product

Customer Support

CONTEC provides the following support services for you to use CONTEC products more efficiently

and comfortably.

Download the latest d riv ers from CO NTEC ’s Web s it e to use. In addition, as documents such as

precautions are also provided on the Web site, have a look on CONTEC’s Web site.

Web Si t e

Japanese http://www.contec.co.jp/

English http://www.contec.com/

Chinese http://www.contec.com.cn/

Latest product information

CONTEC provides up-to-date information on products.

CONTEC also provides product manuals and various technical documen ts in th e P DF.

Free download

You can download updated driver software and differential fi les as well as sample programs ava ilable

in several languag es.

Note! For product information

Contact your retailer if you h ave any technical question ab out a CONTEC product or need its price,

delivery time, or est imat e in fo rmati on .

Limited One-Year Warranty

CONTEC F&eIT products are war ra nt ed by CO NTEC CO. , LTD. t o be free f rom defect s in mater ia l

and workmanship for up to one year from the date of purchase by the original purchaser.

Repair will be free of cha rg e onl y wh en this product is returned freight prepai d wi th a c opy of th e

original invoice and a Return Merchandis e Authorization t o the distributor or the CONTEC group

office, from which it was purchased.

This warranty is not app licab le f or s crat ch es or nor ma l wear , but on ly for th e elec tr onic ci rcu itry and

original products. The warranty is not applicable if the device has been tamper ed with or damag ed

through abuse, mistreatment, neglect, or unr easonable use, or if the original invoice is not included, in

which case repairs wi ll be c onsid ere d bey ond th e wa rrant y p olic y.

How to Obtain Service

For replacement or r epai r, ret u rn the d evic e frei ght p r epaid , with a cop y of th e orig in al in voic e. Plea s e

obtain a Return Merchandise Authorization Number (RMA) from the CON TEC gr oup of fic e wher e

you purchased before returning any product.

* No product will be accepted by CONTEC group without the RMA number.

Liability

The obligation of th e warran to r is so lely t o repai r o r rep lace th e p roduct . In no even t will th e

warrantor be liable for any incidental or consequential damages due to such defect or consequences

that arise fro m inexperienced usage, misuse, or malfunction o f this device.

SH-9008H-FIT

2

Page 8

1. Before Using the Product

DANGER

WARNING

C

AUTION

DANGER

CAUTION

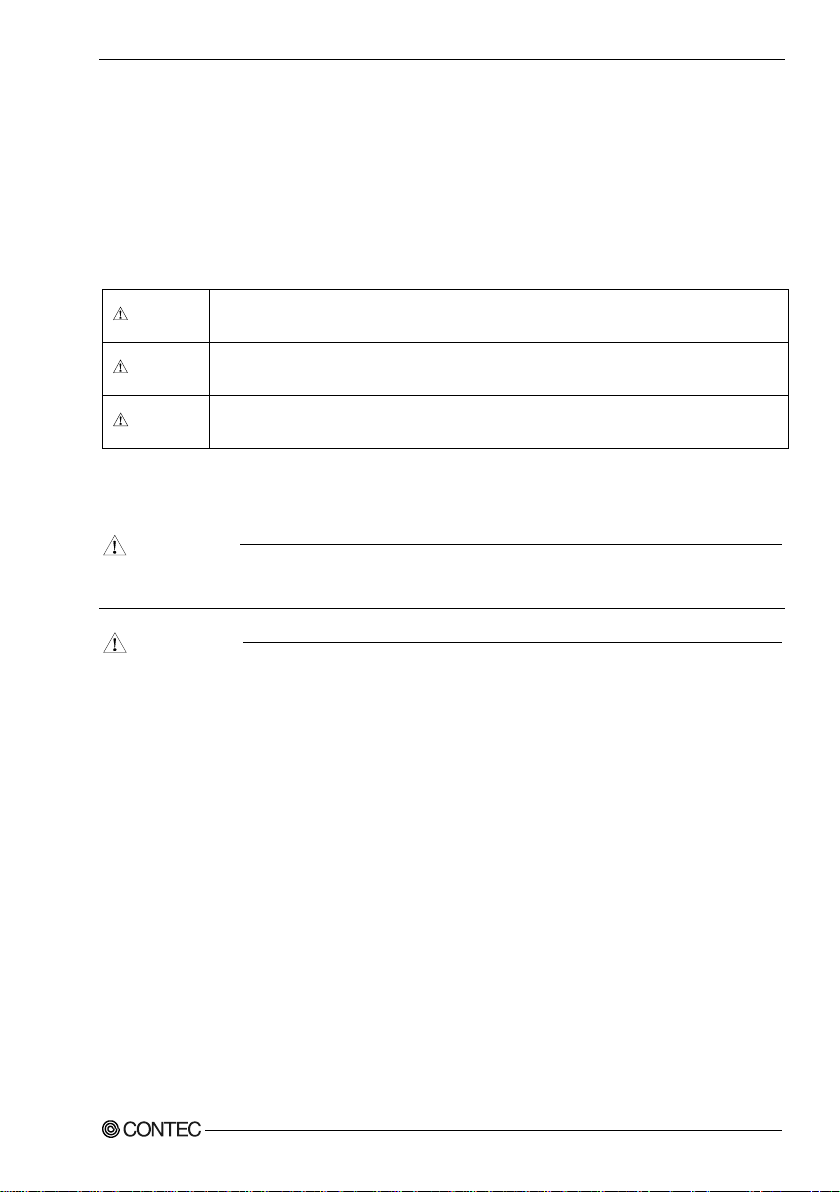

Safety Precautions

Understand the following definitions and precautions to use the produ ct safely.

Safety Information

This document provides safety information using the following symbols to prevent accidents resulting

in injury or death and the destruction of equipment and resources. Understand the meanings of these

labels to operate th e equip m ent saf el y.

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a potentially hazardous s ituation which, if not avoided, may

result in minor or moderate injury or in property damage.

Handling Precautions

Do not use the product where it is exposed to flammable or corrosive gas. Doing so may result in

an explosion, fire, el ect ric sh ock, or fai lure.

- The link speed value (e.g., 1000Mbps) of the transmission rate used in the Manual (this document) is

the theoretical maximum value of the wired LAN standard and do not indicate the actual data

transmission speed.

- The frame loss could occur depending on the connection destination or installed environment.

- When attempt is made to perform communication for devices that are not Jumbo Frame

compatible, communi cat i on effi ci enc y ma y drop extremely. There are also cases where

communication is disconnected.

- As this product contains precision electronic components, do not use or store magnetic field or

radio waves. They may cause the malfunction, heat generation, fault, or damage.

- Do not use or store the equipment in a hot or cold place, or in a place that is subject to severe

temperature changes. They may cause the malfunction, heat generation, fault, or damage.

- Do not use or store the equipment in a place subject to direct sunlight or near a heating device,

such as a stove. And do not use or store the product near equipment generating a strong magnetic

field or radio waves. They may cause the malfunction, heat genera tion, fault, or damage.

- Do not use or store this product in the presence of chemic a ls.

- Do not use this product in extremely humid or dusty locations. It is extremely dangerous t o use

this product with its interior penetrated by water or any other fluid or conductive dust. If this

product must be used in such an environment, install it on a dust-proof control panel, for example.

SH-9008H-FIT

3

Page 9

1. Before Using the Product

This equipment ha

s been tested and found to comply wi

th the limits for a Class A digital

device,

p

ursuant to part 15 of the FCC Rules.

Thes

e limits are designed to provide re

asonable protection

ag

ainst harmful interference w

hen the equipment is operat

ed in commercial enviro

nment.

T

his equipment generates, us

es, and can radiate

radio frequen

cy energy and, if not instal

led and

used i

n accordance with the

in

struction m

anual, may cause h

armful interference to

radio

com

munications. Operation

of th

is equipment in a res

idential

area is likely to

cause harmful

interferen

ce at his

own expense.

NOTE

Change or modifi

cations not expressly approv

ed the manufacturer can vo

id the us

er'

s authority to

operate this equipment

.

WARNING TO USER

- If you noticing abnormal odor or overheat, please unplug the power cord immediately.

- When you find faults or abnormalities (bad smell or excessive heat), pull the power cord off, then

contact the shop you bought the product or our information center.

- The product could be very hot in the operation. Please do not touch by hands or body. It may

cause burns.

- To avoid electric shock, please do not touch the system with a wet hand.

- Do not open the unit casing. CONTEC will disclaim any responsibility for equipment whose casing

has been opened.

- Do not modify the unit. CONTEC will bear no responsibility for any problems, etc., resulting from

modifying this unit.

- To clean this product, gently wipe it wi th a soft cloth soaked with water or a neut ra l det ergen t. D o

not use benzene, a thinner, or other volatile solvents as they can cause the coating to discolor or

peel off.

- Do not modify the product. CONTEC will bear no responsibility for any problems, etc., resulting

from modifying this product.

- If you move or transfer the p r o d u ct, make sure to attach the Setup Guide (thi s document).

- To use the product in places affected by overcurr ent or overvo lt ag e (li ghtni ng su rge, etc. ), s elect

appropriate surge protection device (SPD) for all entry paths (power line, LAN, ground, etc.). For

selection/introducti on /installation of SPD, please consult a specialist.

- Regardless of th e fo regoi n g stat emen ts , CON TEC is not liab le f or an y da mages what s oever

(including damages for loss of business profits) arising out of the use or inability to use this

CONTEC product or the information contained herein.

FCC PART15 class A Notice

SH-9008H-FIT

4

Page 10

1. Before Using the Product

1

3

5

7

2

4

6

8

i

i

+

V

V

POWER

12-24VDC

FG

( )

* The ventilation slits are not covered, and neither dust

nor ali en substanc e is attached to the venti lation sl its.

Environment

Use this product in the following environment. If used in an unauthorized environment, the board may

overheat, malfunc ti on, or caus e a fail ur e.

Operating temperatu re

0 - 50° C

Operating humidity

10 - 90%RH (No condensation)

Corrosive gases

None

Floating dust particles

Not to be excessive

Inspection

Inspect the product periodically as follows to use it safely.

* The ventilation slits are not covered, and neither dust

nor alien substance is attached to the ventilation slits.

Storage

When storing this product, keep it in its original packing form.

(1) Put the unit in the storage bag.

(2) Wrap it in the packing material, th en put it in the box.

(3) Store the package at room temperature at a place free f rom di rect sun li ght , m oistu re, sh ock,

vibration, magnet ism , and st ati c el ectr ici t y.

Disposal

When disposing of the product, follow the disposal procedures stipulated under the relevant laws and

municipal ordinances.

SH-9008H-FIT

5

Page 11

1. Before Using the Product

SH-9008H-FIT

6

Page 12

2. Setup of Hardware

2. Setup of Hardware

Mounting or Removed DIN rail

Mounting on a DIN rail

(1) Hook the clips on the upper DIN rail fixation metal fittings to the groove on the upper DIN rail,

then push the lower part of the product to the DIN rail.

Figure 2.1. Mounting on a DIN rail < 1 / 2 >

(2) The Latch metal fittings is automatically locked, and the unit can be mounted in one-touch.

Figure 2.2. Mounting on a DIN rail < 2 / 2 >

SH-9008H-FIT

7

Page 13

2. Setup of Hardware

WARN

IN

G

Removed DIN rail

A Phillips-head s c rew dri ver o r a flat h ead sc rew d river i s req ui red to r emov e the unit from the DIN

rail.

Remove LAN cab l es and power cabl es connected to the unit before r emoval from the DIN rail.

For a Phillips-head screw driver

(1) Push a phillips-head screw driver (diameter: 6-7mm ) into the lat ch metal fi ttin g on th e lower part

of product. Do not put too much force in doing that. The DIN rail fixation metal fittings or the

product may be damaged .

Figure 2.3. Removing the unit from the DIN rail with phillips-head screw driver < 1 / 3 >

(2) The latch metal fitting is pushed do wn and th e produ ct can b e remo ved fr om th e D IN rail.

Figure 2.4. Removing the unit from the DIN rail with phillips-head screw driver < 2 / 3 >

SH-9008H-FIT

8

Page 14

2. Setup of Hardware

(3) By lifting the uni t, you can ea si ly rem ove it f rom th e D IN rail.

Figure 2.5. Removing th e u ni t from the DIN rail with phillips-head screw driver < 3 / 3 >

For a flathead screw dri ver

(1) Push the flathead screw driver (tooth width 5.5 - 7mm) into the latch metal fitting at the lo wer

section of the unit, and th en push it down vertically.

Do not put too much force in doing that. The DIN rail fixation metal fittings or the product may be

damaged.

Figure 2.6. Removing the unit f rom the DIN ra il with flathead screw driver < 1 / 3 >

(2) The latch metal fitting is pushed down and the product can be removed from the DIN rail.

Figure 2.7. Removing the unit from the DIN rail with flathead screw driver < 2 / 3 >

SH-9008H-FIT

9

Page 15

2. Setup of Hardware

(3) By lifting the uni t, you can ea si ly rem ove it f rom th e D IN rail.

Figure 2.8. Removing the unit from the DIN rail with flathead screw driver < 3 / 3 >

SH-9008H-FIT

10

Page 16

2. Setup of Hardware

Mounting of Flat putting fixing bracket and rubber foot

Mounting

Remove the four location screws used for fixing the unit and the DIN rail mounting brackets, and then

remove the DIN rail mount in g brac k ets fr om th e unit. Thi s op eration is performed for both flat putting

fixing brackets an d rub b er feet.

Figure 2.9. Removed of DIN rail fixing bracket

Flat putting fixing bracket

Fixes the unit with screws supplied with this product.

Figure 2.10. Mounting of fl at putting fixing bracket

SH-9008H-FIT

11

Page 17

2. Setup of Hardware

Rubber foot

Align wi t h th e fou r corners on the unit ov ervi e w level s id e, and m ount t h e rubber feet supp li ed with

this product.

Figure 2.11. Mounting of rubber foot

SH-9008H-FIT

12

Page 18

2. Setup of Hardware

Mount of connector omission prevention metal fittings

Mounting

(1) Connect an appropriat e connector to the power connector, mount the connector detaching

prevention metal fitting.

Figure 2.12. Mount of connector omission prevention metal fittings

SH-9008H-FIT

13

Page 19

2. Setup of Hardware

(Top)

(Bottom)

(Bottom)

W

AR

N

I

N

G

1

3

5

7

2

4

6

8

i

i

+VV

POWER

12-24VDC

FG

( )

1

3

5

7

2

4

6

8

135

7

246

8

135

7

246

8

i

i+

V

V

POWER

12-24VDC

FG

( )

ii+V

V

POWER

12-24VDC

FG

( )

i

i+

V

V

POWER

12-24VDC

FG

( )

Ceil

ing

Floor

Installation Conditions

Even within the temp eratu re sp eci fic ati on ra n ge, make su re th e heat in th e unit can let off

adequately in the case o f hi gh temp eratu r e envi ron ment application.

Installation orientation

When DIN rail mounted

Avoid installation on unsuitable insta llation directions as insufficient heat dissipation may occur.

Suitable

installation

directions

(Top)

Unsuitable

installation

directions

(Bottom)

(Top)

Figure 2.13. Installation direction (when the DIN rail fixing brackets mounted)

SH-9008H-FIT

14

Page 20

2. Setup of Hardware

(Top)

1

3

5

7

2

4

6

8

1

3

5

7

2

4

6

8

i

i

+

V

V

POWER

12-24VDC

FG

( )

i

i

+VV

POWER

12-24VDC

FG

( )

Wall

Wall

Wall

Wall

POWER

12-24VDC

12-24VDC

Ceiling

Floor

Flat putting fixing bracket mounted

Installation in all directions is possible if flat putting fixing brackets are mounted. However, as heat

dissipation may be not adequate compa red with ins ta llat i on in oth er di rect i ons, k eep th e di stanc e f rom

surrounding objects as long as possible in cas e of high temperature environment application.

Suitable

installation

directions

(Bottom)

(Top)

(Bottom)

Figure 2.14. Installation direction (when flat putting fixing brackets mounted)

SH-9008H-FIT

15

Page 21

2. Setup of Hardware

(Top)

(Bottom)

(Top)

(Bottom)

135

7

246

8

i

i+

V

V

POWER

12-24VDC

FG

( )

SH-9008H-F IT

Floor

1

3

5

7

2

4

6

8

135

7

246

8

1

3

5

7

2

4

6

8

ii+V

V

POWER

12-24VDC

FG

( )

ii+V

V

POWER

12-24VDC

FG

( )

SH-9008H-FI T

i

i

+

V

V

POWER

12-24VDC

FG( )

Floor Floor Floor

Floor Floor

Rubber foot mounted

Mount the rubber feet to install it if fixing brackets are n ot mounted in the case of horizontal

installation. Avoid installa ti on on unsuitable installation directions as this may cause insufficient heat

dissipation and overturning.

Suitable

installation

directions

Unsuitable

installation

(Bottom)

(Top)

directions

Figure 2.15. Installation direction (in the case of rubber feet)

16

SH-9008H-FIT

Page 22

2. Setup of Hardware

W

AR

NI

N

G

50 or more

1

3

5

7

2

4

6

8

7.5

100 or more

i

i

+VV

POWER

12-24VDC

FG

( )

50 or more

50 or more

50 or more50 or more

or more

[mm]

Spacing between the system unit and any surrounding objects

Do not locate the module in a fully enclosed housing.

DIN rail mounted

Secure a distance of at least 50mm between the top/bottom of the main unit and any surrounding

objects and also a dista nc e of at lea st 50mm bet ween each sid e of the un it and any su rr oundin g objec ts

(5.8mm for the unit overvi e w level sid e).

Figure 2.16. Spacing be tw een the system unit and any surrounding objects while the DIN rail mounted

SH-9008H-FIT

17

Page 23

2. Setup of Hardware

1

3

5

7

2

4

6

8

i

i

+

V

V

POWER

12-24VDC

FG

( )

50 or more

100 or more

50 or more

50 or more

50 or more

50 or more

50 or more

[mm]

When flat putting fixing brackets and rubber feet mounted

Secure a distance of at least 50/5.8mm between the top/bottom of the main unit and any surr ounding

objects and also a distance of at least 50mm between each side of the unit and any surrounding objects.

Figure 2.17. Spacing between the system unit and any surrounding objects while flat putting fixing brackets and rubber feet mounted

SH-9008H-FIT

18

Page 24

3. Nomenclature of unit Components and Their Settings

Name

Status

Color

Content of Display

POWER LED

POWER

Green

OFF : Power off

ON : Power on

LED:A

10Mbps

Yellow

OFF : No LINK

100Mbps

Green

ON : LINK

LED:B

1000Mbps

Green

Flashing : ACT(Data send/

receive)

Name

Function

Power supply

Acceptable connector(Appending):MC1,5/3-ST-3,5(PHOENIX CONTACT)

. (In the length of the cable, it is a

condition to fill the power supply specification.)

You can prevent connectors from being omitted by connector omission

Power Supply Connector

MC1,5/3-G-3,5 (PHOENIX CONTACT)

Pin Number

Signal

Description

1

Vi+

Power (12-24VDC±5%)

2

Vi-

Power(GND)

3

FG

Frame Ground

1

3

5

7

2

4

6

8

i

i

+VV

POWER

12-24VDC

FG( )

POWER LED

Power supply connector

LED: A

LED: B

10BASE-T/100BASE-TX/

1000BASE-T port

LED: A

LED: B

Vi+

Vi-

FG

12

3. Nomenclature of unit Components and

Their Settings

Name of unit Components and Function

Figure 3.1 shows t he nomenclature of unit components.

Figure 3.1. Names of unit Components

Table 3.1. LED Indicators

Table 3.2. Connectors

Connector

SH-9008H-FIT

The correspondence cable is AWG28-16

prevention metal fittings. You can connect cables by screw cramps.

- 24VDC

19

Page 25

3. Nomenclature of unit Components and Their Settings

Name

Function

10BASE-T/

Ports 1 - 8

and other HUB units and

Use connector

JC0-0182NL(Pulse)

Pin name

Signal

Description

1

TRD+(0 )

Data0 is transmitted and received(+)

2

TRD-(0)

Data0 is transmitted and received(-)

3

TRD+(1 )

Data1 is transmitted and received(+)

4

TRD+(2 )

Data2 is transmitted and received(+)

5

TRD-(2)

Data2 is transmitted and received(-)

6

TRD-(1)

Data1 is transmitted and received(-)

7

TRD+(3 )

Data3 is transmitted and received(+)

8

TRD-(3)

Data3 is transmitted and received(-)

1

8

Input voltage (V)

Time (ms)50

25.2

24

12

11.6

Table 3.3. 10BASE-T/100BASE-TX/1000BASE-T port

100BASE-TX/

1000BASE-T port

This is the port for connecting the PC (LAN adapter)

bridges.

Auto-negotiation of communication rates (10Mbps/100Mbps/1000Mbps), and

communication methods(Half/Full duplex). By Auto MDI/MDI-X function,

straight cable and the cross cable are recognized automatically.

About of P o wer S upply

For power supply, use the power supply that rises within an input voltage range of 11.6VDC or higher

within 50msec. The power supply that cannot m eet this requirement may cause devic e fai lu re or

accident.

Figure 3.2. Graph of Rise Time of Power Supply

SH-9008H-FIT

20

Page 26

4. Connecting to a Network

WA

RNING

SH-9008H-FIT

CPU-CA20(FIT)GY,

CPU-CA10(FIT)GY .,etc

Straight or cross c ables

4. Connect i ng t o a Ne tw or k

Network Cables

Cables meeting the following specifications should be used:

- 10BASE-T : Equal to greater than Category 3 UTP, STP cable 100 m or le ss

- 100BASE-TX : Equal to greater than Category 5 UTP, STP cab le 100 m or less

- 1000BASE-T : Equal to greater than Category 5e UTP, STP cab le 100m or less

- There are straight/ cr oss U TP and STP cab les. Aut o MD I/MD I-X feat u re a llows c onnec t i on of

your Switching HUB unit to a personal computer (LAN adapter) or another HUB unit and a

bridges using either a straight or cross cable.

Connecting a Personal Computer, another HUB unit or bridge

When connecting the Switching HU B unit to a personal comput er, an F&e IT seri es con t oroller uni t,

another HUB unit or a bridge, use any 10BASE-T/100BASE-TX/1000BASE-T port and either a

straight or cross cab le.

When using Jumbo Frame, it is necessary for other network devices of the communication partner,

such as LAN adapters, t o be Jumb o Fra me comp ati b le.

Figure 4.1. An example for connection with PC or other HUBs and control modules

SH-9008H-FIT

21

Page 27

4. Connecting to a Network

SH-9008H-FIT

(1) (2)

- Use UTP and STP cables with category 5 or higher for cables (1)(2)(3).

- The total length of cables (1)(2)(3) should be set to 205m or less.

- The length of cable (2) should be 5m or less.

100BASE-TX HUB(Cl ass II)

(3)

100BASE-TX HUB(Cl ass II)

SH-9008H-FIT

10BASE-T HUB

Connection Restrictions with 100BASE-TX Repeater HUBs

Cascade connecti on with 100B ASE-TX repeater HUBs at Class I is possible. Up to two stages of

cascade connect ion between 100BASE-TX Class II repeaters i s possible. In addition, the total

maximum cable length of cab les (1)( 2)(3 ) is 205 m or l ess . For d etai ls, s ee the operat i on manual o f

your100BASE-TX repeater HUB.

Figure 4.2. Connection restrictions with 100BASE-TX repeater HUB (Class II)

Connection Restrictions with 10BASE-T Repeater HUBs

As many as four stages of 10BASE-T repeater HUBs can be connected using cascade connection. In

addition, the maximum length of UTP and STP cables between cascad ed HUBs i s 100m . For d etai ls,

see the operation manual of your 10BASE-T repeater HUB.

Figure 4.3. Connection restrictions with 10BASE-T repeater HUBs

SH-9008H-FIT

22

Page 28

5. System Reference

Item

Specification

Ethernet standards

IEEE802.3/IEEE802.3u /IEEE802.3ab –compliant

Data transfer rate

10Mbps/100Mbps/1000Mbps (auto-negotiation)

Access method

CSMA/CD

Communications method

All ports: Full/Half duplex (auto-negotia tion)

Topology

Star topology

Half Duplex :Back pressure

Number of effective ports

8

Address table

8,192 entries

Jumbo fra me*1

9.6Kbyte

Buffer capacity

512Kbyte

Aging time

300sec (Max.)

100M(Green), LINK/ACT 1000M( Green)

Power supply voltage

12V - 24VDC±5%

FG pin

Power supply connector equipped with FG pin

Power consumption (Max.)

When inputting 12V : 0.65A, When inputting 24V : 0.35A

Physical dimensions (mm)

39(W) x 120(D) x 94(H) (exclusive of protrusions)

the flat putting fixing bracket is installed)

Module installation method

One-touch attachment of a 35mm DIN rail. (Mounting

e flat putting fixing

5. System Reference

Specification

Table 5.1. Specifications

Flow control Full Duplex : IEEE802.3x compliant flow control

Switching method Store and forward

LED indicator POWER(G reen), LINK/ACT 10M(Yellow), LINK/ACT

Weight 360g (410g when the DIN rail fixation metal fittings(standard) or

mechanism is equipped with the main body as standard),

Fixation with the mounting phase by using th

bracket and rubber feet.

When using Jumbo Frame, it is necessary for other network devices on the communication route to

*1

be Jumbo Frame compatible.

SH-9008H-FIT

23

Page 29

5. System Reference

Operating temperature

0 - 50°C

Storage temperature

-10 - 60°C

Floating dust particles

Not to be excessive

Corrosive gases

None

Line-noise

AC line/2kV, Signal lin e/1kV (JIS C61000-4-4Level 3, EN61000-4-4Level 3)

Static electricity

resista nce

Contact discharge/4kV (JIS C61000-4-2Level 2, EN61000-4-2Level 2)

Atmospheric discharge/8kV (JIS C61000-4-2Level 3, EN61000-4-2Level 3)

(JIS C60068-2-6-compliant, IEC60068-2-6-compliant)

Impact resistance

15G, half-sine shock for 11ms in X, Y, and Z directions

Grounding

Class D grounding (previous class 3 grounding)

Table 5.2. Installation Environment Requirements

Item Specification

Humidity 10 - 90%RH(No condensation)

Line-Noise

resista nce

Vibration

resista nce

Sweep resistance

10 - 57Hz/semi-amplitude 0.15mm,57 - 150Hz/2.0G

40minutes each in X, Y, and Z directions

(JIS C60068-2-27-compliant, IEC60068-2-27-compliant)

SH-9008H-FIT

24

Page 30

5. System Reference

39

94

120

6.5

1

3

5

7

2

4

6

8

47

(9)

i

i

+

V

V

12-24VDC

FG( )

[mm]

39

94

119

1

3

5

7

2

4

6

8

45

25

70

10

100

108

118

4-φ4

i

i

+

V

V

12-24VDC

FG

( )

[mm]

Physical Dimensions

Figure 5.1. Physical dimens ions when Din rail fixation metal fittings (standard) are installed

Figure 5.2. Physical dimensions when flat putting fixing brackets is installed

SH-9008H-FIT

25

Page 31

5. System Reference

Differences from SH-9008-FIT

SH-9008H-FIT, the high er-grade model of the conventional SH-9008-FIT, has the main differences as

follows:

SH-9008-FIT SH-9008H-FIT

Capacity of buffer 176Kbyte 512Kbyte

Power consumption (Max.) For 12V input : 0.6A,

For 24V input : 0.4A

For 12V input : 0.65A,

For 24V input : 0.35A

SH-9008H-FIT

26

Page 32

Page 33

SH-9008H-FIT

User’s Manual

CONTEC CO., LTD. May 2016 Edition

3-9-31, Himesato, Nishiyodogawa-k u, Osak a 555 -0025 , Japan

Japanese http://www.contec.co.jp/

English http://www.contec.com/

Chinese http://www.contec.com.cn/

No part of this document may be copied or reproduced in any form by any means without prior written

consent of CONTEC CO., LTD.

[05252016] Management No. NA05016

Parts No. LYTZ191

Loading...

Loading...