Page 1

OMEGA

Floor Grinder

Instruction manual (USA)

Page 2

Instruction manual OMEGA

- 2 -

CONTEC® GmbH Hauptstrasse 146, 57518 Alsdorf, Deutschland/ Germany/ Allemagne © CONTEC® 2011

info@contecnorthamerica.com, www.contecnorthamerica.com

INDEX

1. EU-Declaration of Conformity …3

2. Machine applications ...4

3. Technical data ...4

4. Tool applications ...4

5. Safety rules for the operation of the OMEGA floor grinder ...5

6. Operating ...6

7. Changing and replacing of the tools ...7

8. Appendix ...7

Page 3

Instruction manual OMEGA

- 3 -

CONTEC® GmbH Hauptstrasse 146, 57518 Alsdorf, Deutschland/ Germany/ Allemagne © CONTEC® 2011

info@contecnorthamerica.com, www.contecnorthamerica.com

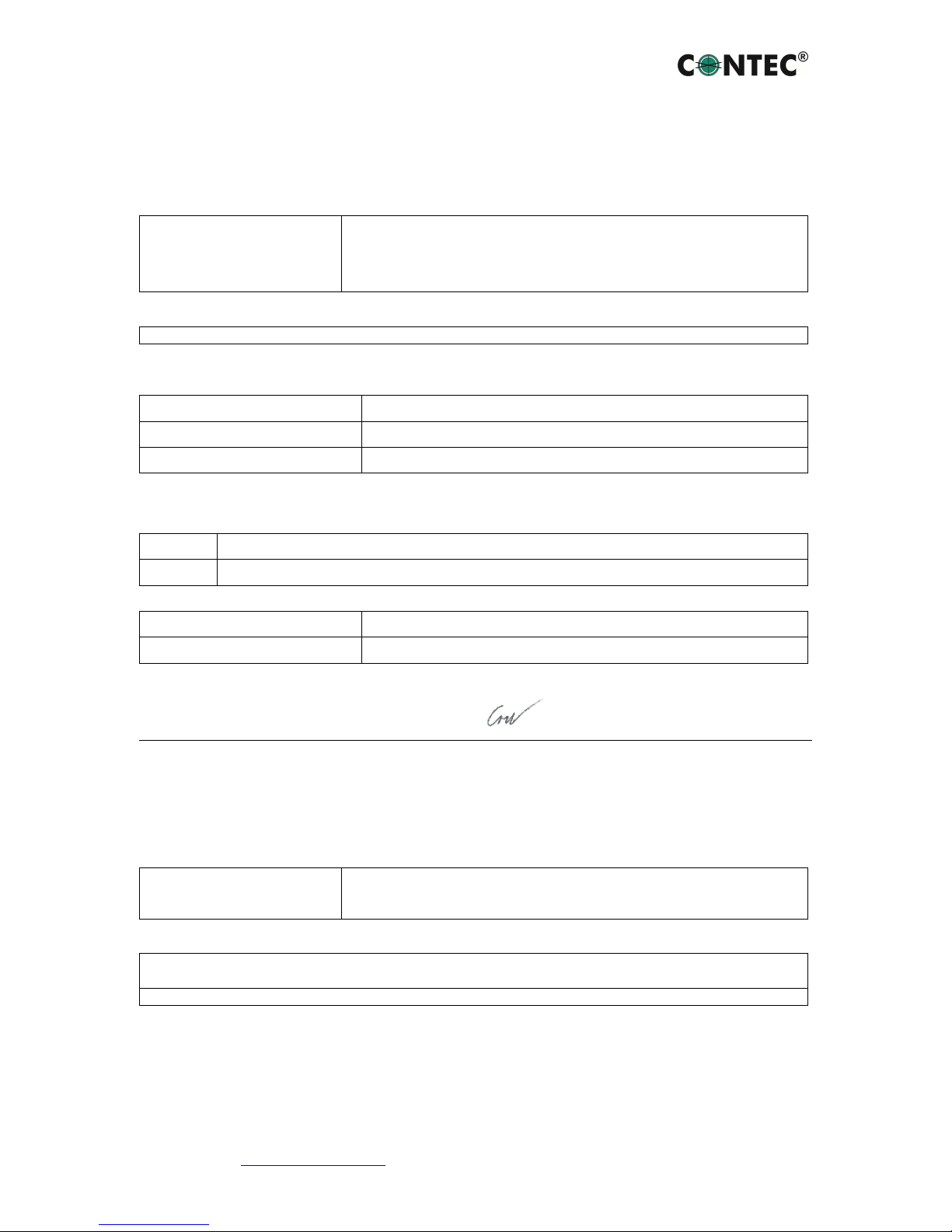

Declaration of Conformity according to EN ISO/IEC 17050-1

EC-Declaration of Conformity

Month.Year: .

For the machine described below

Product denomination:

Model:

Serial number:

Floor Grinder

Omega

Herewith we declare, that the machine is complying with all the essential requirements of the

Machine Directive 2006/42/EC of the EUROPEAN PARLIAMENT of the 17th of Mai 2006

The person authorized to compile the relevant technical documentation (According to Appendix II Nr.

1. A. Nr. 2, 2006/42/EG):

Name, Surname: Greb, Johannes

Function: Technical Manager

Address: Neuer Weg 17, 57518 Alsdorf, Germany

More information on the compliance with the directive is contained in Appendix 1.

This Declaration is given by the manufacturer:

Name: Contec® Maschinenbau & Entwicklungstechnik GmbH

Address: Hauptstraße 146, 57518 Alsdorf, Deutschland / Germany

Given by:

Name, Surname: Greb, Johannes

Function: Technical Manager

Alsdorf, 22.12.2010

Place/Date Signature

Appendix 1 of the Declaration of Conformity

Month.Year: .

For the machine described below

Product denomination:

Model:

Floor Grinder

Omega

Herewith we declare, that the machine is complying with all the essential requirements of the:

Directive 2004/108/EC of the EUROPEAN PARLIAMENT of the 15th of December 2004 on

Electromagnetic Compatibility

Directive 2006/42/EC of the EUROPEAN PARLIAMENT of the 17th of Mai 2006

Harmonised Standards used:

EN 12100 - 1 „Safety of Machinery – Basic concepts“

EN 12100 - 2 „Safety of Machinery – Technical principles”

Page 4

Instruction manual OMEGA

- 4 -

CONTEC® GmbH Hauptstrasse 146, 57518 Alsdorf, Deutschland/ Germany/ Allemagne © CONTEC® 2011

info@contecnorthamerica.com, www.contecnorthamerica.com

2 Machine applications

Grinding of horizontal, dry floors such as concrete and steel surfaces with or without a coating and asphalt using

CONTEC® grinding tools. The use of the machine outside is only possible in dry weather.

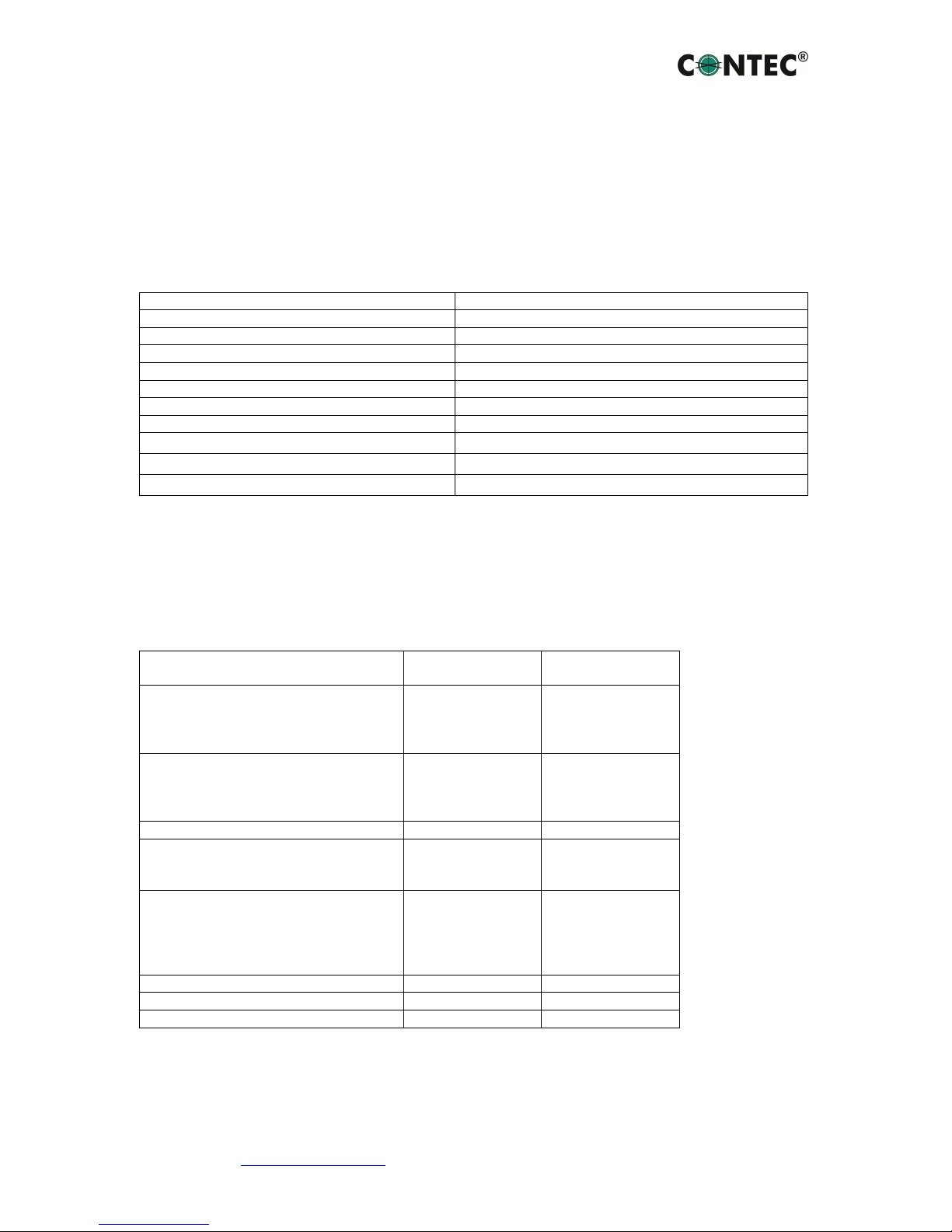

3 Technical Data

Width of grinding 290 mm (11.4 in)

Width 33 cm (13 in)

Length 75 cm (30 in)

Height 95 cm (38 in)

Weight 65 kg (143 Ibs)

Hose diameter 50 mm (2.04 in)

Height adjustment Hand wheel

Motor 3.7 kW (5 hp), 230 V, single phase, 60 Hz, 21 A

Average value of acceleration ahv * 10.2 m/s2

Noise level Lwa * 105 dB(A)

Noise level Leq * 95 dB(A)

* Data: VÜA Verein zur Überwachung technischer Anlagen e.V.

4 Tool applications

4.1 General applications

Tool

Application

Diamond PCD

Grinding of plain floors,

- Smooth surface

- Semi rough surface

- Rough surface

A

A

A

C

B

A

Levelling of uneven surfaces

- Smooth surface

- Semi rough surface

- Rough surface

A

A

B

A

A

A

Levelling of Steps, corners, joints etc.

B A

Renovation

Repair

Faults in concrete

A

A

A

B

B

B

Grinding of

- Hard concrete

- Oily and greasy floors

- Painted floors

- Epoxy coatings

A

A

A

A

B

B

A

A

Removal of floor surfaces up to 5 mm

A C

Removal of carpet and tile glue

C A

Grinding of asphalt

B A

A Suitable B Less suitable C Unsuitable

Page 5

Instruction manual OMEGA

- 5 -

CONTEC® GmbH Hauptstrasse 146, 57518 Alsdorf, Deutschland/ Germany/ Allemagne © CONTEC® 2011

info@contecnorthamerica.com, www.contecnorthamerica.com

4.2 Application of diamond discs

Grinding of:

Description: Colour:

Hard floors CS16 / PCD grit silver

Normal concrete CS40 / VS2 Blue / red

Aggressive concrete CA1 / CA2 Brown / green

Terrazzo MBC line

Epoxy / PU glue PCD plate and grit silver

5 Safety rules for the operation of the OMEGA floor grinder

Intended application and operation:

Grinding of flat, horizontal, dry surfaces that are typically concrete, asphalt or steel and with

or without a coating. For optimum performance and compatibility always use tools supplied

by CONTEC. Operation of the grinder outdoors is only permitted if the weather is dry.

Attention ! The OMEGA floor grinders are constructed according to existing safety rules

and regulations. These technical precautions must not be removed or changed

under any circumstances. While operating the grinder the following points

should also be kept in mind:

1. The floor grinder may only be operated by trained professionals. The operators have read

and be familiar the contents of this manual.

2. The floor grinder must not be operated in areas where the hazard of explosion or fire

exists.

3. The floor grinder can only be started when the tools are not in contact with the floor. Do

always start the machine in a tipped position.

4. The tools and discs may be hot after use. Take care when changing them.

5. Never operate the floor grinder on a sloping surface.

6. Take care when moving the machine on a sloping surface, substantial rolling forces can be

produced.

7. The machine should always be stored in a warm, dry place when not in use.

8. The floor grinder may only be operated with the dust guard (Appendix diagram No.3).

9. Only CONTEC original tools and spare parts are to be used.

10. The grinder should only be operated with all safety guards in position.

11. When changing tools, during transportation, cleaning, repair or maintenance the grinder

must be disconnected from the mains.

12. The operator must never leave the machine unattended during operation.

13. Before leaving the machine all rotary parts must be brought to a standstill. Electric models

must be disconnected from the power supply. Ensure the machine cannot roll or move by

itself.

Page 6

Instruction manual OMEGA

- 6 -

CONTEC® GmbH Hauptstrasse 146, 57518 Alsdorf, Deutschland/ Germany/ Allemagne © CONTEC® 2011

info@contecnorthamerica.com, www.contecnorthamerica.com

14. After any maintenance and adjustment all safety guards must be refitted.

15. Ear protectors must be worn.

16. Eye protectors must be worn.

17. Safety shoes with steel caps must be worn.

18. When operating the grinder produces large volumes of dust the grinder should be

connected to a suitable dust collector.

19. Depending on the floor (floor coating) grinding can produce gases. The operator must be

held responsible if the gases generated are hazardous and whether protection is necessary.

Grinding floors containing asbestos is especially dangerous and can cause health

problems. Special masks must be worn which keep the breathing air clean. A dust

collector must be used and should be equipped with filters suitable for asbestos dust.

20. The floor must be brushed before grinding to prevent loose material collecting in the tools

and then being thrown out with force. Anchor screws and bolts in the floor can also be

seen better if the area is clean. If the grinding head strikes an anchor screw or bolt then

serious damage can be caused to the machine and grinding head.

6 Operating

After mounting the appropriate tools, the operation of the OMEGA grinder can begin.

Connect the hose of the dust collector to the hose port of the grinder.

Adjust the grinder by turning the hand wheel of the height adjustment (see diagram No.

35/36) so that the motor axis is 90° level to the floor. Lift the tool from the floor by tilting the

machine onto it's back wheels. Switch the motor on.

Attention ! When switching on the motor the machine jumps slightly.

After the motor has reached full rotation place the tools carefully on to the floor. If the

machine is correctly adjusted (see above) it is easier to move across the floor. If the machine

pulls to the left or right, the machine has to be re-adjusted with the hand wheel of the height

adjustment.

Attention ! Never switch the motor on while the tools still touch the floor.

Page 7

Instruction manual OMEGA

- 7 -

CONTEC® GmbH Hauptstrasse 146, 57518 Alsdorf, Deutschland/ Germany/ Allemagne © CONTEC® 2011

info@contecnorthamerica.com, www.contecnorthamerica.com

7 Changing and replacing of the tools

Attention ! Before working on the grinder allow the motor to come to a complete stand still

and disconnect from the mains.

- Tilt the machine onto the back wheels and rest it on the handlebar.

- All tools are fixed with 3 screws on the tool bracket.

- Loosen and remove the screws with a 6 mm Alan key.

- Check the grinding tool for wear and tear for the next application.

- Fix a new tool with the 3 screws on the tool bracket.

- Adjust the different heights of the tools with the hand wheel of the height adjustment. The

motor axis of the grinder has to be 90° level to the floor.

- Different tools need different heights for the rubber sealing around the discs.

8 Appendix

Diagrams

Wire diagram

Tools

Part list

Page 8

Page 9

Page 10

Page 11

Page 12

OMEGA Stückliste / Parts List

Artikel-Nr. / Part-No.

Description 1

Description 2

D-Nr

Weight KG

90-27-03-00 Clamp Omega 1 240,00

70-23-96-00 Rubber Sealing Omega 3 0,72

70-23-96-01 Rubber Sealing for Flail Head Omega 3 0,90

14-17-10-05 Tool Bracket for Omega/Delta I+II 5 1,22

90-25-10-01 Rubber Coupling For Drive Omega/Delta 7 0,50

18-17-06-01 Bracket for Coupling Omega 9 1,12

18-10-01-00 Machine Frame Omega 11 12,00

18-10-29-06 Bracket disc Plates Omega 11 3,40

90-21-50-17 Front Handle Aluminium 140 mm Omega 13 114,00

18-10-04-01 Bracket for Swing Arm Omega 17 212,00

18-10-04-02 Swing Arm Omega 19 1,40

30-10-08-04 Rear Axis Omega 21 324,00

80-20-52-22 Rear Wheel Omega 23 1,45

60-33-12-25 Connecting Pin for lifting Rod Omega 25 0,00

18-10-05-01 Height Control with Dustpiepe Omega 27 1,60

18-10-05-01-H Height Control with Dustpiepe for Honda Engine Omega 27 1,70

18-10-05-02 Height Adjustment Screw Omega/Delta II 29 0,33

14-10-09-03 Spacer Height Control Omega/Delta I+II 31 0,05

18-10-01-05 Handle Arm Cover Omega 33 0,88

90-21-95-50 Level Adjustment Hand Wheel Omega 35 0,38

90-21-95-51 Revolving Pin for Handwheel Omega 36 80,00

70-21-26-11 Rubber Grip open Side Omega 39 60,00

18-10-07-01 Handle Omega/CT200 41 1,40

50-20-10-20-K Switch-Socket-Combination Omega/CT200 for Motor 2 KW, 230 Volt, 50 HZ 43 0,61

50-20-10-30-K Switch-Socket-Combination Omega/CT200 for Motor 3 KW, 400 Volt, 50 HZ 43 0,63

55-03-01-22 Motor 2,2 KVA, 230 Volt AEG Omega new Version 03/2004 45 24,30

55-03-01-50 Motor 5 HP US Version Omega 45 24,30

55-03-02-22 Motor 2,2 KVA, 230 Volt, 50 HZ, Omega ADDA 45 18,00

55-03-03-20 Motor 1,8 KVA, 230 Volt, 60 HZ, Omega Korea Version 45 24,30

55-14-00-30 Motor 3 KVA, 400 Volt Omega 45 22,20

55-15-00-30 Motor 3 KVA, 200 Volt, 3 Phase Omega 45 17,80

18-10-02-01 Distance Ring Motor Omega 47 0,68

18-10-02-02 Distance Ring Motor 110 Volt Omega 47 0,83

18-10-08-02 Bracket for Spindel Front Wheel Omega 49 1,10

Seite 1 von 5

Page 13

OMEGA Stückliste / Parts List

18-10-08-01 Height Adjustment Screw Frontwheel Omega/Delta 51 0,33

18-21-C1 Diamond Plate C1 Yellow 51 0,26

18-21-C2 Diamond Plate C2 Aubergine 51 0,26

18-21-CA1 Diamond Plate CA1 Brown 51 0,27

18-21-CA2 Diamond Plate CA2 Green 51 0,26

18-21-CS06 Diamond Plate CS06 Red 51 0,26

18-21-CS16 Diamond Plate CS16 Silver 51 0,27

18-21-CS40 Diamond Plate CS40 Blue 51 0,26

18-21-CS6/16 Diamond Plate CS6/16 Gold 51 0,26

18-21-MBC0 Diamond Plate MBC0 Brown round 51 0,26

18-21-MBC0+ Diamond Plate MBC0+ Silver round 51 0,26

18-21-MBC1 Diamond Plate MBC1 Black round 51 0,26

18-21-MBC2 Diamond Plate MBC2 Green round 51 0,26

18-21-MBC3 Diamond Plate MBC3 Blue round 51 0,26

18-21-MBC4 Diamond Plate MBC4 Yellow round 51 0,27

80-20-62-80 Frontwheel Omega/Delta 53 0,77

18-21-120-N Resignbond Wet Grid 120 Black 57 0,09

18-21-120-T Resignbond Dry Grid 120 Black 57 0,09

18-21-1800-N Resignbond Wet Grid 1800 Blue 57 0,09

18-21-1800-T Resignbond Dry Grid 1800 Blue 57 0,09

18-21-220-N Resignbond Wet Grid 220 Red 57 90,00

18-21-220-T Resignbond Dry Grid 220 Red 57 0,09

18-21-3000-N Resignbond Wet Grid 3000 Grey 57 0,09

18-21-3000-T Resignbond Dry Grid 3000 Grey 57 0,09

18-21-30-N Resignbond Wet Grid 30 Brown 57 0,09

18-21-30-T Resignbond Dry Grid 30 Brown 57 0,09

18-21-400-N Resignbond Wet Grid 400 Yellow 57 0,09

18-21-400-T Resignbond Dry Grid 400 Yellow 57 0,09

18-21-5000-N Resignbond Wet Grid 5000 Pink 57 0,09

18-21-60-N Resignbond Wet Grid 60 Green 57 0,09

18-21-60-T Resignbond Dry Grid 60 Green 57 0,09

18-21-800-N Resignbond Wet Grid 800 White 57 0,09

18-21-800-T Resignbond Dry Grid 800 White 57 0,09

18-10-29-02 Bracket for Sandpaper Disc with Rubber Omega 59 6,00

18-17-10-02-US Bearing Axis for 110 V Omega US Version 61 0,79

18-22-00-12 Sandpaper 300 mm Diameter Graining 12 61 0,29

Seite 2 von 5

Page 14

OMEGA Stückliste / Parts List

18-22-00-16 Sandpaper 300 mm Diameter Graining 16 61 0,29

18-22-00-24 Sandpaper 300 mm Diameter Graining 24 61 0,23

18-22-00-24-ST Sandpaper 300 mm Diameter Graining 24 61 0,23

18-22-00-40 Sandpaper 300 mm Diameter Graining 40 61 0,18

18-22-00-60 Sandpaper 300 mm Diameter Graining 60 61 0,16

18-22-00-60-ST Sandpaper 300 mm Diameter Graining 60 61 0,16

18-22-00-80 Sandpaper 300 mm Diameter Graining 80 61 0,15

18-22-01-20 Sandpaper 300 mm Diameter Graining 120 61 0,14

18-22-02-20 Sandpaper 300 mm Diameter Graining 220 61 0,13

18-10-29-07 Grinder Head for Flails for 12 Axis Omega. 63 4,50

61-20-60-06 Bearing for Omega Bearing Housing US Version Electric or Honda Petrol 63 0,12

23-16-01-10 Axis for Flails with 12 Omega 64 0,05

18-17-10-01-US Bearing Housing for 110 V Omega US Version 65 1,27

23-16-01-08 Flails for Grinder Head Tipped Tungston Carbide Omega/Alpha 65 0,03

18-17-10-03-US Ring for Bearing Axis for 110 V Omega US Version 67 0,07

23-16-02-08 Flails for Grinder Head Full Tungston Carbide Omega/Alpha 67 0,04

90-24-01-80-2-US Pulley for Bearing Housing Omega US Version 230 Volt / Petrol Engine Honda 69 2,91

90-24-01-80-1-US Pulley for Bearing Housing Omega US Version 110 Volt 70 2,07

18-10-09-00-US HT-Frame for Belt Drive US Version and Honda Omega 73 5,80

70-24-10-762-US Belt Omega US Version 75 0,07

18-10-21-00 Motor fixing Plate Omega Petrol 76 2,05

18-10-21-00-110-US Belt tesioner 110 Volt Omega US Version 76 0,88

18-10-21-00-US Belt tensioner 230 Volt Omega US Version 76 1,84

90-24-20-12-28 Taperlock Bearing Housing Omega US Version 230 Volt / Petrol Honda 77 0,70

90-24-56-1-US Pulley for 110 Volt Omega US Version 79 0,45

90-24-75-2-US Pulley for 230 Volt Omega US Version 230 Volt and Petrol Honda 79 0,44

18-10-09-04-US Lit for Belt Drive 110 Volt US Version Omega 81 0,83

56-GXV-160-K1 Motor 5,5 HP for Omega 83 18,00

90-24-10-08-US Taperlock for Motor Pulley Omega 110 V US Version 93 0,13

90-24-12-10-P Taperlock for Motor Pulley Omega Petrol Honda Engine 93 0,22

90-24-12-10-US Taperlock for Motor Pulley Omega 230 V US Version 93 0,20

90-24-16-10-28 Taper Bush for Bearing Housing Omega US Version 93 0,33

51-10-10-01 Switch Box For Motor Protective Omega 111 0,00

51-20-30-01-US Low Voltage Protective Omega US-Version 120 Volt, 60 HZ 113 0,10

51-10-0-20-US Switch Motor Protective Omega 230 Volt 3 HP US Version 115 0,00

51-10-0-20-US Switch Motor Protective Omega 110 Volt 1,5 HP US Version 115 0,00

Seite 3 von 5

Page 15

OMEGA Stückliste / Parts List

18-10-01-08 Cover 110 V for Switch CT200/Omega 286,00

18-10-08-00 Front Wheel for Grinder Head Omega 2,20

18-10-11-00 Extra weight 6 KG for Omega/Delta 6,00

18-10-29-01 Bracket for Tungsten Disc Omega 5,95

18-10-29-01/R Centre Ring Karborundum Disc Omega 0,40

18-10-29-05 Grinder Head for Flails with 6 Blocks including axis Omega. 6,90

18-10-29-10 0,20

18-10-29-11 Plate for Diamond Dotts 0,20

18-10-50-01 Bracket for Brush Tool Disc Omega 5,95

18-10-50-03 Bracket for Polishing Tools Omega 5,90

18-16-29-01 Tungston Ring rough grade Omega 2,10

18-16-29-02 Tungston Ring fine grade Omega 2,10

18-16-HSG Tungston rough grade Omega 0,26

18-21-30-RAP Diamond Disk Raptor Omega 6,10

18-21-PKD-PL Diamond PCD Plate left !ATTENTION TURNING DIRECTION DISC LEFT! 0,26

18-21-PKD-PR Diamond PCD Plate right !ATTENTION TURNING DIRECTION DISC RIGHT! 0,26

18-21-PKD-S Diamond Plate PCD in Segment 0,26

18-21-PKD-S-US Diamond Plate PCD in Segment on HTC Plate 0,27

18-23-00-100 Brush Tool for Cleaning Steel and Concrete Omega 0,90

18-23-00-60 Karborundum Rings Graining 16 for Concrete Omega 700,00

18-23-00-65 Karborundum Rings Graining 16 for Steel Omega 700,00

18-23-10-65 Karborundum Rings Graining 60 for Steel Omega 700,00

23-16-01-08-12 Flails for Grinder Head Tipped Tungston Carbide Omega/Delta 12 Pieces = 1 Set 360,00

23-16-01-08-24 Flails for Grinder Head Tipped Tungston Carbide Omega/Delta 24 Pieces = 1 Set 720,00

23-16-01-09 Axis for Flails Omega 46,00

23-16-02-08-12 Flails Full Tungston Carbide Omega/Delta 12 Stück = 1 Set inkl. Washer 504,00

23-16-02-08-24 Flails Head Full Tungston Omega 24 Stück = 1 Set with Washers 1.008,00

50-10-11-16 230 Volt Plug Omega 0,00

50-20-20-14 Reverse plug 16 A, 400 Volt Omega 0,00

50-25-11-30 Kabel between Plug / Switch 2 KW 230 Volt Omega 0,00

50-25-11-31 Kabel between Switch / Plug 3 KW 400 Volt Omega 0,00

50-25-11-32 Kabel between Motor / Switch 230 Volt 2 KW Omega 0,00

50-25-11-33 Kabel between Motor / Switch 400 Volt 3 KW Omega 0,00

51-20-30-01 Motor Protective 2 KVA, 230 Volt Omega 0,31

51-20-30-02 Motor Protective 3 KW, 400 Volt Omega 0,00

51-20-30-03 Low Voltage Protective 400 Volt Omega 0,00

Seite 4 von 5

Page 16

OMEGA Stückliste / Parts List

51-20-30-04 Low Voltage Protective 230 Volt Omega 0,00

55-03-01-21 Ventilator Cover for Motor Omega 2 KVA, 230 Volt 400,00

55-14-00-31 Ventilator Cover for Motor 3 KVA, 400 V 400,00

56-GXV-99 Lever for Petrol Engine Delta/Omega 200,00

70-21-26-10 Rubber Grip Handle 60,00

70-23-29-01 Rubber for Sandpaperdisc Omega 200,00

70-23-40-40 Dustring Omega 0,25

70-25-40-40 Flexible Hose 40 mm Diameter Omega 0,13

90-09-SW-5 Allenwrensch 5 mm Omega/Delta 40,00

90-09-SW-6 Allenwrensch 6 mm Omega/Delta 60,00

Seite 5 von 5

Loading...

Loading...