Page 1

PC-HELPER

High Speed Bi-directional

Digital I/O Board for PCI Express

DIO-32DM-PE

User’s Guide

CONTEC CO.,LTD.

Page 2

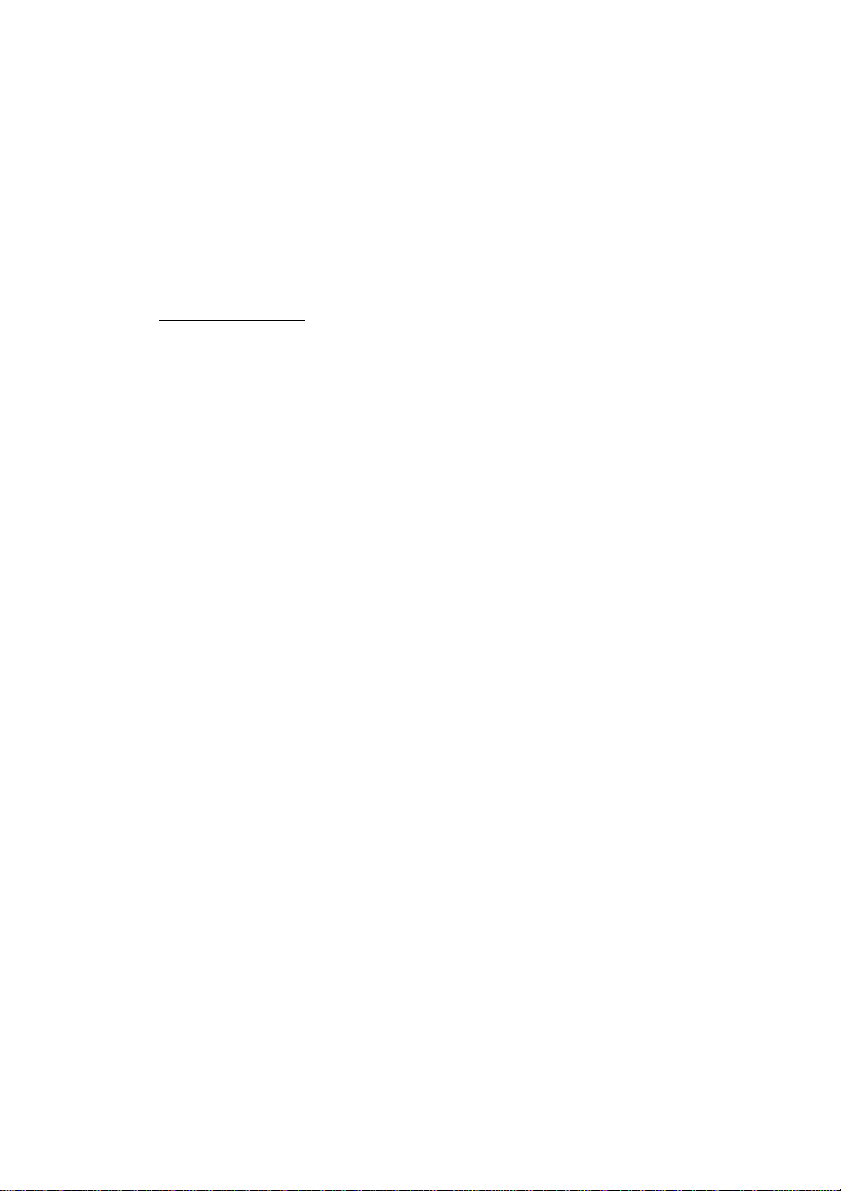

Check Your Package

Thank you for purchasing the CONTEC product.

The product consists of the items listed below.

Check, with the following list, that your package is complete. If you discover damaged or missing

items, contact your retailer.

Product Configuration List

- Board [DIO-32DM-PE] …1

- SC Cable(10cm) …1

- First step guide …1

- CD-ROM *1 [API-PAC(W32)] …1

*1 The CD-ROM contains the driver software and User’s Guide (this guide)

Board SC Cable(10cm) First step guide CD-ROM *1

[API-PAC(W32)]

DIO-32DM-PE

i

Page 3

Copyright

Copyright 2013 CONTEC CO., LTD. ALL RIGHTS RESERVED

No part of this document may be copied or reproduced in any form by any means without prior written

consent of CONTEC CO., LTD.

CONTEC CO., LTD. makes no commitment to update or keep current the information contained in this

document. The information in this document is subject to change without notice.

All relevant issues have been considered in the preparation of this document. Should you notice an

omission or any questionable item in this document, please feel free to notify CONTEC CO., LTD.

Regardless of the foregoing statement, CONTEC assumes no responsibility for any errors that may

appear in this document or for results obtained by the user as a result of using this product.

Trademarks

MS, Microsoft, Windows and Windows NT are trademarks of Microsoft Corporation. Other brand and

product names are trademarks of their respective holder.

DIO-32DM-PE

ii

Page 4

Table of Contents

Check Your P ackage................................................................................................................................ i

Copyright .................................................................................................................................................ii

Trademarks ..............................................................................................................................................ii

Table of Contents ...................................................................................................................................iii

1. BEFORE USING THE PRODUCT 1

About the Bo ard ......................................................................................................................................1

Features............................................................................................................................................. 1

Support Software.............................................................................................................................. 2

Cable & Connector (Opt ion) ........................................................................................................3

Accessories (Option).....................................................................................................................3

Customer Su pport.................................................................................................................................... 4

Web Site ...........................................................................................................................................4

Limited Th ree-Years Warranty............................................................................................................... 4

How to Obta in Service............................................................................................................................ 4

Liability ...................................................................................................................................................4

Safety Precautions................................................................................................................................... 5

Safety Information ...........................................................................................................................5

Handling Precautions....................................................................................................................... 6

Environment..................................................................................................................................... 7

Inspection ......................................................................................................................................... 7

Storage.............................................................................................................................................. 7

Disposal ............................................................................................................................................7

2. SETUP 9

What is Setup?......................................................................................................................................... 9

Using the Board under Wi ndows Using the Driver Library API-PAC(W32)............................... 9

Using the Board under Windows Using Software Other than the Driver Library

API-PAC(W32)................................................................................................................................9

Using the Board under an OS Other than Windows..................................................................... 10

Step 1 Installing the Software...............................................................................................................11

About the d river to be used............................................................................................................ 11

Starting th e Install Pr o gram...........................................................................................................12

Select API-DIO(WDM) .................................................................................................................13

Select API-DIO(98/PC) .................................................................................................................14

Step 2 Sett ing the Hardw are .................................................................................................................16

Parts of the Board and Fa ctory Defaults ....................................................................................... 16

Setting the Board ID ......................................................................................................................17

Plugging the Board......................................................................................................................... 18

DIO-32DM-PE

iii

Page 5

Step 3 Installing the Hardware..............................................................................................................19

Turning on the PC ..........................................................................................................................19

When Using API-DIO(WD M ) .......................................................................................................19

When Using API-AIO(98 / PC).......................................................................................................22

Step 4 Initi alizing the Software.............................................................................................................25

When Using API-DIO(WD M ) .......................................................................................................25

When Using API-DIO(98 / PC).......................................................................................................27

Updating the Settings .....................................................................................................................27

Step 5 Oper a tion Checks .......................................................................................................................28

Check Metho d.................................................................................................................................28

When Using API-DIO(WD M ) .......................................................................................................28

When Using API-DIO(98 / PC).......................................................................................................31

Setup Troubleshooting...........................................................................................................................33

Symptoms and Actions...................................................................................................................33

If your problem cannot be resolved ...............................................................................................33

3. EXTERNAL CONNECTION 35

How to conn e ct the connectors .............................................................................................................35

Connector shape .............................................................................................................................35

Connector Pin Assignment.............................................................................................................36

Relationships between API-PAC(W32 ) Logical Ports/Bits and Connector Signal Pins.............3 7

Connection method to the external device -Data I/O-..........................................................................39

Connecting the data I/O signal(DIOA0* - DIOD0*)....................................................................39

Detailed Data I/O Signal Circuit....................................................................................................39

Connection method to the external device -Control I/O-.....................................................................40

Connection to the control signal (EXT**) ....................................................................................40

Detailed C o ntrol Input Signal Circ uit ............................................................................................40

Detailed C o ntrol Outpu t Signal Cir cuit.........................................................................................41

What is the Control Signal? ...........................................................................................................41

Synchroniz ation Contr ol Connecto r s ....................................................................................................43

SC Connecto r s ................................................................................................................................43

Connecting the SC Connectors ( CN2,CN3)..................................................................................44

4. FUNCTION 45

Function Outline ....................................................................................................................................45

Overview.........................................................................................................................................45

Sampling f u nction / gen erating fun c t i on .......................................................................................45

Bus Master T r a nsfer .......................................................................................................................45

Interrupt ( at the time o f bus master transfer).................................................................................46

Status, count....................................................................................................................................46

Sampling function..................................................................................................................................47

Sampling control.............................................................................................................................47

DIO-32DM-PE

iv

Page 6

Generating function...............................................................................................................................48

Generating control.......................................................................................................................... 48

General-purpose I/O fu nction ...............................................................................................................49

Data input .......................................................................................................................................49

Data output .....................................................................................................................................49

Monitoring the output data ............................................................................................................49

Interrupt Control Func tion.................................................................................................................... 50

Disabling/enabling In terrupts ........................................................................................................50

Clearing th e Interrupt S t atus and Int errupt Signal........................................................................50

5. ABOUT SOFTWARE 51

CD-ROM Directory Stru c ture ..............................................................................................................51

About Soft w are for Windows............................................................................................................... 52

Accessing the Help File .................................................................................................................52

Using Sampl e Programs.................................................................................................................53

Uninstalling the Driver Libraries ..................................................................................................55

About Soft w are for Linux .....................................................................................................................58

Driver Software Instal l Procedure .................................................................................................58

Accessing the Help File .................................................................................................................59

Using Sampl e Programs.................................................................................................................59

Uninstalling the driver ...................................................................................................................59

6. ABOUT HARDWARE 61

Hardware sp e cification ......................................................................................................................... 61

Block Diagr am ......................................................................................................................................63

Difference s between DI O - 32DM-PE and PIO-32DM(P CI)................................................................ 64

DIO-32DM-PE

v

Page 7

DIO-32DM-PE

vi

Page 8

1. Before Using the Product

1. Before Using the Product

This chapter provides information you should know before using the product.

About the Board

This product is a PCI Express bus-compliant interface board that supports transfer by bus mastering and

performs input/output between the external device and digital signal. This product features unisolated

LVTTL level (Operating voltage : 3.3V) I/O 32channels and you can select input / output in 16 un its.

Bus master transfer makes it possible to sample quickly large data with transfer rate at 20MHz

maximum. It can be used as a pattern generator that outputs arbitrary digital patterns at high speed.

It can also be used as a general-purpose I/O board when bus mastering is not used.

Windows/Linux driver is bundled with this product.

Using the dedicated library VI-DAQ makes it possible to create each application for LabVIEW.

Features

- 32channels of unisolated LVTTL level I/O (32 input channels / each 16channels for I/O / 32 output

channels are selected.)

This product has the 32channels (operating voltage 3.3VDC, positive logic) of unisolated LV TTL leve l

I/O whose response speed is 50nsec. They can be used for 32bit input, 16bit input plus 16bit output, or

for 32bit output.

Other than I/O bit, this product has the control signal (clock, start, stop and handshake signal (REQ,

ACK) that can control starting and stopping the sampling (input) / generating (output)).

- Sampling and generating with transfer rate at 20MHz maximum

Bus master transfer makes it possible to sample (input) or generate (output) large data with transfer rate

at 20MHz maximum. As the sampling and generating features have their own bus mastering blocks

each made up of two independent channels, the board can generate 16 signals while sampling 16

signals.

- A synchronization control connector is provided for synchronized control of multiple boards.

A synchronization control connector is provided for synchronized control of up to 16 boards. It is also

easy to synchronize operation with other CONTEC boards that have a synchronization control

connector.

- You can use Max. 4 input signals as interrupt request signals at the time of using the general-purpose

I/O.

You can use Max. 4 input signals as interrupt request signals and also disable or enable the interrupt in

bit units at the time of using the general-purpose I/O.

- Windows/Linux compatible driver libraries are attached.

Using the attached driver library API-PAC(W32) makes it possible to create applications of

Windows/Linux. In addition, a diagnostic program by which the operations of hardware can be

checked is provided.

DIO-32DM-PE

1

Page 9

1. Before Using the Product

- Functions and connectors are compatible with PCI compatible board PIO-32DM(PCI).

The functions same with PCI compatible board PIO-32DM(PCI) are provided. In addition, as there is

compatibility in terms of connector shape and pin assignments, it is easy to migrate from the existing

system.

- LabVIEW is supported by a plug-in of dedicated library VI-DAQ.

Using the dedicated library VI-DAQ makes it possible to create each application for LabVIEW.

Support Software

You should use CONTEC support software according to your purpose and development environment.

Windows version of digital I/O driver

A PI-DIO(WDM) / API-DIO(98/PC)

[Stored on the bundled CD-ROM driver library API-PAC(W32)]

The API-DIO(WDM) is the Windows version driver library software that provides products in the form of Win32 API

functions (DLL). Various sample programs such as Visual Basic and Visual C++, etc and diagnostic program *1

useful for checking operation is provided.

< Operating environment >

OS Windows 7, Vista, XP, Server 2003

Adaptation language Visual Basic, Visual C++, Visual C#, Delphi, C++ Builder

For more details on the supported OS, applicable language and how to download the updated version, please visit the

CONTEC’s Web site (http://www.contec.com/apipac/).

*1 : For API-DIO(98/PC), check the device operation by using the sample program.

Linux version of digital I/O driver

API-DIO(LNX)

[Stored on the bundled CD-ROM driver library API-PAC(W32)]

The API-DIO(LNX) is the Linux version driver software which provides device drivers (modules) by shared library

and kernel version. Various sample programs of gcc are provided.

< Operating environment >

OS RedHatLinux, TurboLinux

(For details on supported distributions, refer to Help available after installation.)

Adaptation language gcc

For more details on the supported OS, applicable language and how to download the updated version, please visit the

CONTEC’s Web site (http://www.contec.com/apipac/).

Data acquisition VI library for LabVIEW

(Available for downloading (free of charge) from

VI-DAQ

the CONTEC web site.)

This is a VI library to use in National Instruments LabVIEW.

VI-DAQ is created with a function form similar to that of LabVIEW's Data Acquisition VI, allowing you t o use

various devices without complicated settings.

See http://www.contec.com/vidaq/ for details and download of VI-DAQ.

DIO-32DM-PE

2

Page 10

1. Before Using the Product

Cable & Connector (Option)

Shield Cable with 96-Pin Half-Pitch Connectors at Both Ends : PCB96PS-0.5P (0.5m)

: PCB96PS-1.5P (1.5m)

Flat Cable with 96-Pin Half-Pitch Connectors at Both Ends : PCB96P-1.5 (1.5m)

Shield Cable with 96-Pin D-SUB Connector at One End : PCA96PS-0.5P (0.5m)

: PCA96PS-1.5P (1.5m)

Flat Cable with 96-Pin Half-Pitch Connectors at One End : PCA96P-1.5 (1.5m)

Half Pitch 96P Female Connector Set(5 Pieces) : CN5-H96F

Accessories (Option)

Screw Terminal Unit (M3 x 96P) : EPD-96A *1*2

Screw Terminal Unit (M3.5 x 96P) : EPD-96 *1

Terminal Unit for Cables (M3 x 96P) : DTP-64A *1

*1 PCB96P or PCB96PS optional cable is required separately.

*2 "Spring-up" type terminal is used to prevent terminal screws from falling off.

* Check the CONTEC’s Web site for more information on these options.

DIO-32DM-PE

3

Page 11

1. Before Using the Product

Customer Support

CONTEC provides the following support services for you to use CONTEC products more efficiently

and comfortably.

Web Site

Japanese http://www.contec.co.jp/

English http://www.contec.com/

Chinese http://www.contec.com.cn/

Latest product information

CONTEC provides up-to-date information on products.

CONTEC also provides product manuals and various technical documents in the PDF.

Free download

You can download updated driver software and differential files as well as sample programs available in

several languages.

Note! For product information

Contact your retailer if you have any technical question about a CONTEC product or need its price,

delivery time, or estimate information.

Limited Three-Years Warranty

CONTEC products are warranted by CONTEC CO., LTD. to be free from defects in material and

workmanship for up to three years from the date of purchase by the original purchaser.

Repair will be free of charge only when this device is returned freight prepaid with a copy of the

original invoice and a Return Merchandise Authorization to the distributor or the CONTEC group office,

from which it was purchased.

This warranty is not applicable for scratches or normal wear, but only for the electronic circuitry and

original products. The warranty is not applicable if the device has been tampered with or damaged

through abuse, mistreatment, neglect, or unreasonable use, or if the original invoice is not included, in

which case repairs will be considered beyond the warranty policy.

How to Obtain Service

For replacement or repair, return the device freight prepaid, with a copy of the original invoice. Please

obtain a Return Merchandise Authorization number (RMA) from the CONTEC group office where you

purchased before returning any product.

* No product will be accepted by CONTEC group without the RMA number.

Liability

The obligation of the warrantor is solely to repair or replace the product. In no event will the

warrantor be liable for any incidental or consequential damages due to such defect or consequences that

arise from inexperienced usage, misuse, or malfunction of this device.

DIO-32DM-PE

4

Page 12

1. Before Using the Product

Safety Precautions

Understand the following definitions and precautions to use the product safely.

Safety Information

This document provides safety information using the following symbols to prevent accidents resulting

in injury or death and the destruction of equipment and resources. Understand the meanings of these

labels to operate the equipment safely.

DANGER

WAR NI NG

CAUTION

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury or in property damage.

DIO-32DM-PE

5

Page 13

1. Before Using the Product

Handling Precautions

DANGER

Do not use the product where it is exposed to flammable or corrosive gas. Doing so may result in

an explosion, fire, electric shock, or failure.

CAUTION

- There are switches and jumpers on this product that need to be set in advance.

Be sure to check these before installing to the expansion slot.

- Only set the switches and jumpers on this product to the specified settings.

Otherwise, this product may malfunction, overheat, or cause a failure.

- Do not strike or bend this product.

Otherwise, this product may malfunction, overheat, cause a failure or breakage.

- Do not touch this product's metal plated terminals (edge connector) with your hands.

Otherwise, this product may malfunction, overheat, or cause a failure.

If the terminals are touched by someone's hands, clean the terminals with industrial alcohol.

- Do not install or remove this product to or from the expansion slot while the computer's power or

expansion unit is turned on.

Otherwise, this product may malfunction, overheat, or cause a failure.

Be sure that the personal computer power is turned off.

- Make sure that your PC or expansion unit can supply ample power to all the products installed.

Insufficiently energized products could malfunction, overheat, or cause a failure.

- The specifications of this product are subject to change without notice for enhancement and quality

improvement.

Even when using this product continuously, be sure to read the user’s guide and understand the

contents.

- Do not modify this product. CONTEC will bear no responsibility for any problems, etc., resulting

from modifying this product.

- Regardless of the foregoing statements, CONTEC is not liable for any damages whatsoever

(including damages for loss of business profits) arising out of the use or inability to use this

CONTEC product or the information contained herein.

DIO-32DM-PE

6

Page 14

1. Before Using the Product

Environment

Use this product in the following environment. If used in an unauthorized environment, the product

may overheat, malfunction, or cause a failure.

Operating temperature

0 - 50°C

Operating humidity

10 - 90%RH (No condensation)

Corrosive gases

None

Floating dust particles

Not to be excessive

Inspection

Inspect the product periodically as follows to use it safely.

- Check that the bus connector

of the board and its cable have

been plugged correctly.

- Check that the board has

no dust or foreign matter

adhering.

~

~

- The gold-plated leads of the bus

connector.

Storage

When storing this product, keep it in its original packing form.

(1) Put this product in the storage bag.

(2) Wrap it in the packing material, then put it in the box.

(3) Store the package at room temperature at a place free from direct sunlight, moisture, shock,

vibration, magnetism, and static electricity.

Disposal

When disposing of the product, follow the disposal procedures stipulated under the relevant laws and

municipal ordinances.

DIO-32DM-PE

7

Page 15

1. Before Using the Product

DIO-32DM-PE

8

Page 16

2. Setup

2. Setup

This chapter explains how to set up the board.

What is Setup?

Setup means a series of steps to take before the product can be used.

Different steps are required for software and hardware.

The setup procedure varies with the OS and software used.

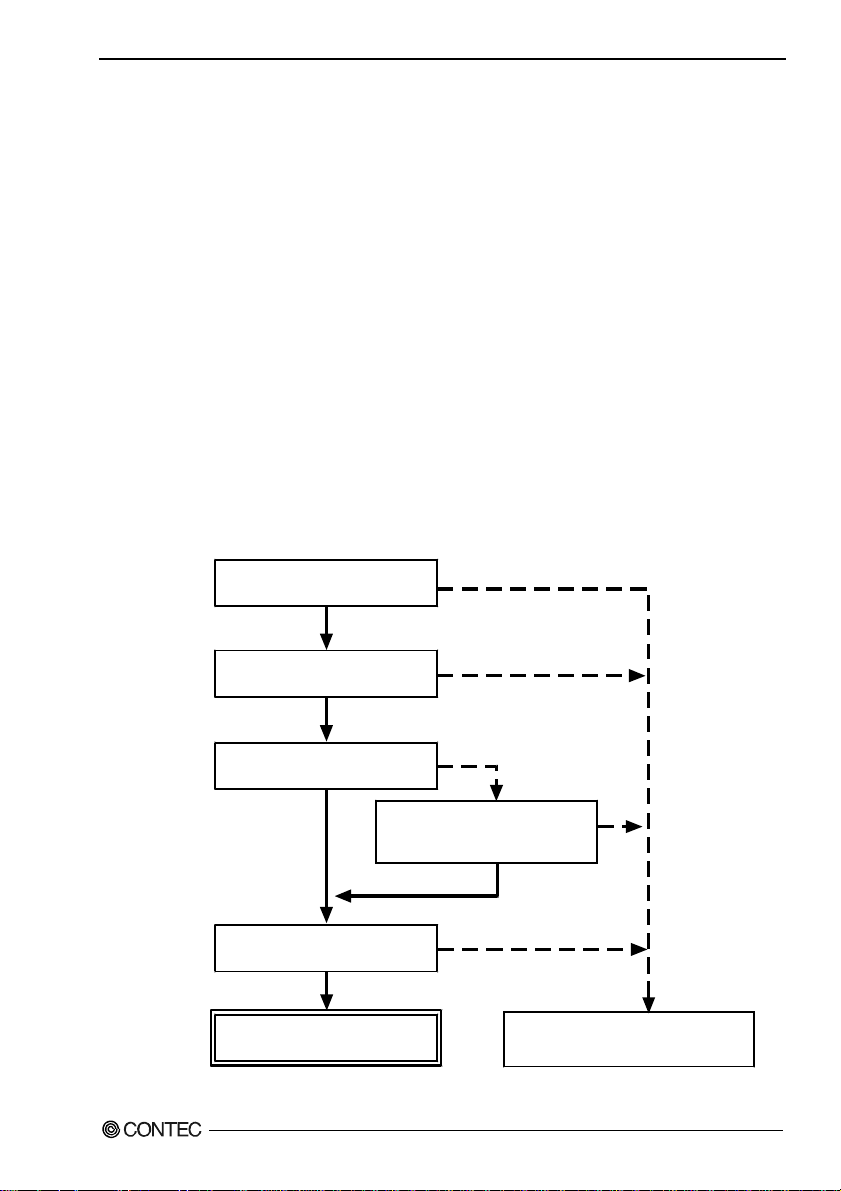

Using the Board under Windows

Using the Driver Library API-PAC(W32)

This section describes the setup procedure to be performed before you can start developing application

programs for the board using the bundled CD-ROM “Driver Library API-PAC(W32)”.

Taking the following steps sets up the software and hardware. You can use the diagnosis program

later to check whether the software and hardware function normally.

Step 1 Installing the Software

Step 2 Setting the Hardware

Step 3 Installing the Hardware

Step 4 Initializing the Software

Step 5 Operation Checks

If Setup fails to be performed normally, see the “Setup Troubleshooting” section at the end of this

chapter.

*1 : For API-DIO(98/PC), check the device operation by using the sample program.

*1

Using the Board under Windows

Using Software Other than the Driver Library API-PAC(W32)

For setting up software other than API-PAC(W32), refer to the user’s guide for that software. See also

the following parts of this user’s guide as required.

This chapter Step 2 Setting the Hardware

This chapter Step 3 Installing the Hardware

Chapter 3 External Connection

Chapter 6 About Hardware

DIO-32DM-PE

9

Page 17

2. Setup

Using the Board under an OS Other than Windows

For using the board under an OS other than Windows, see the following parts of this user’s guide.

This chapter Step 2 Setting the Hardware

Chapter 3 External Connection

Chapter 6 About Hardware

DIO-32DM-PE

10

Page 18

2. Setup

Step 1 Installing the Software

This section describes how to install the Driver libraries.

Before installing the hardware on your PC, install the Driver libraries from the bundled

API-PAC(W32) CD-ROM.

The following description assumes the operating system as Windows XP. Although some user

interfaces are different depending on the OS used, the basic procedure is the same.

About the driver to be used

Two Analog I/O drivers are available : API-DIO(WDM) and API-DIO(98/PC).

API-DIO(WDM) is a new driver to perform analog I/O under Windows.

API-DIO(WDM) was developed to improve the conventional product version of API-DIO(98/PC) in the

ease of use and functionality.

It is advisable to use API-DIO(WDM) for you to use an analog I/O device. API-DIO(WDM) will

support new OS and devices in the future but will not support Windows NT 4.0, Windows 95, ISA bus.

Use API-DIO(98/PC) if your operating environment contains such an unsupported piece of software or

hardware.

Check the following selection guide to easily select the driver to be used.

OS to be used

Windows Vista

Windows XP/Windows 2000

PCI bus, PC Card

Use the digital board for

the fisrt time?

Ye s

Language to be used

VC.Net, VB.Net, VC#.Net

VC6, VB6

API-DIO(WDM)

DIO-32DM-PE

Device type

Windows Me/98/95

Windows NT 4.0

ISA Bus

Already used.

The existing system

upgrade using

API-DIO(98/PC)?

No

VC2, 4, 5, VB4, 5,

Delphi, C++Builder

Ye s

API-DIO(98/PC)

11

Page 19

2. Setup

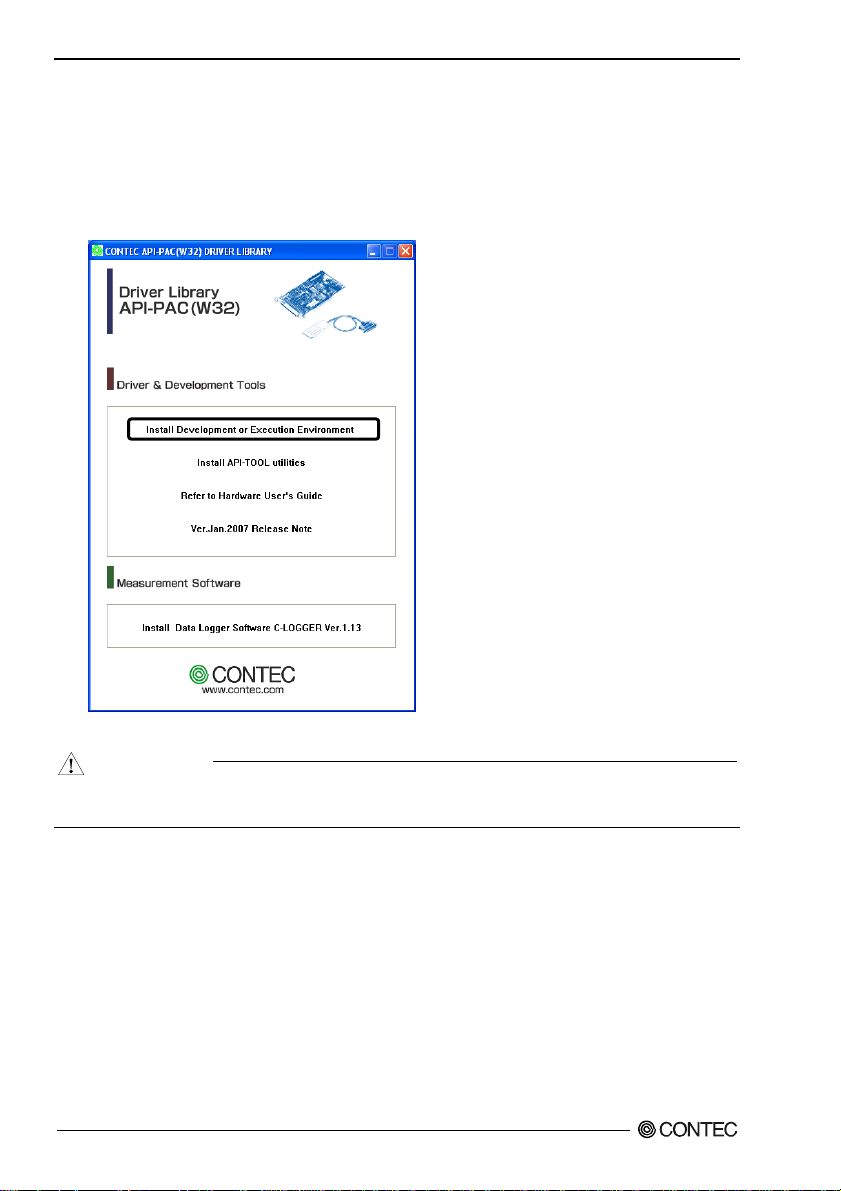

Starting the Install Program

(1)

Load the CD-ROM [API-PAC(W32)] on your PC.

(2)

The API-PAC(W32) Installer window appears automatically.

If the panel does not appear, run (CD-ROM drive letter):\AUTORUN.exe.

(3)

Click on the [Install Development or Execution Environment] button.

* When using the Windows Vista, driver is automatically installed.

CAUTION

Before installing the software in Windows Vista, XP, Server 2003 and 2000, log in as a user with

administrator privileges.

DIO-32DM-PE

12

Page 20

2. Setup

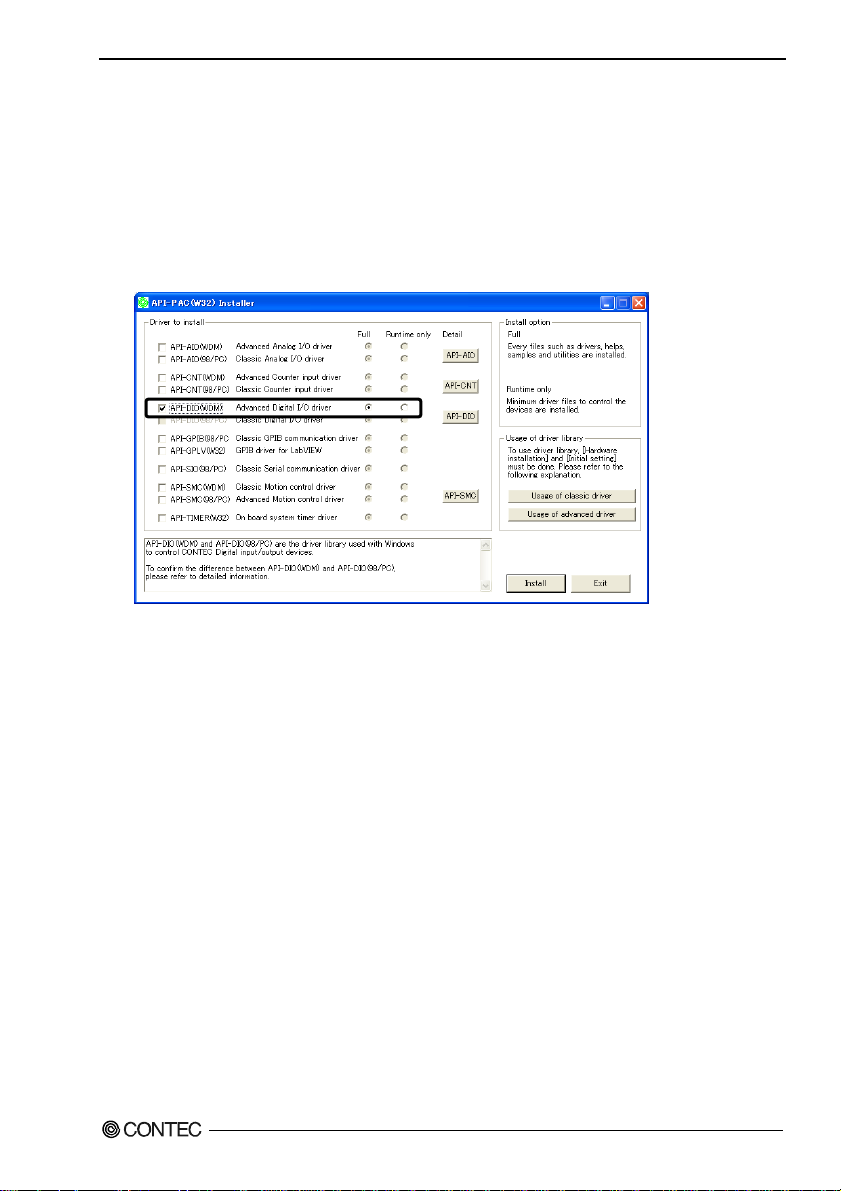

Select API-DIO(WDM)

Selecting API-DIO(WDM)

(1)

The following dialog box appears to select “Driver to install” and “Install option”, “Usage of

driver library”.

(2)

Select the "Advanced Digital I/O driver".

(3)

Click on the [Install] button.

* Clicking the [API-DIO] button under the “Detail” displays detailed information about

API-DIO(WDM) and API-DIO(98/PC).

Run the installation

(1)

Complete the installation by following the instructions on the screen.

(2)

The Readme file appears when the installation is complete.

DIO-32DM-PE

13

Page 21

2. Setup

Select API-DIO(98/PC)

Selecting API-DIO(98/PC)

(1)

The following dialog box appears to select “Driver to install” and “Install option”, “Usage of

driver library”.

(2)

Select “Classic Digital I/O driver”.

(3)

Click on the [Install] button.

* Clicking the [API-DIO] button under the “Detail” displays detailed information about

API-DIO(WDM) and API-DIO(98/PC).

DIO-32DM-PE

14

Page 22

2. Setup

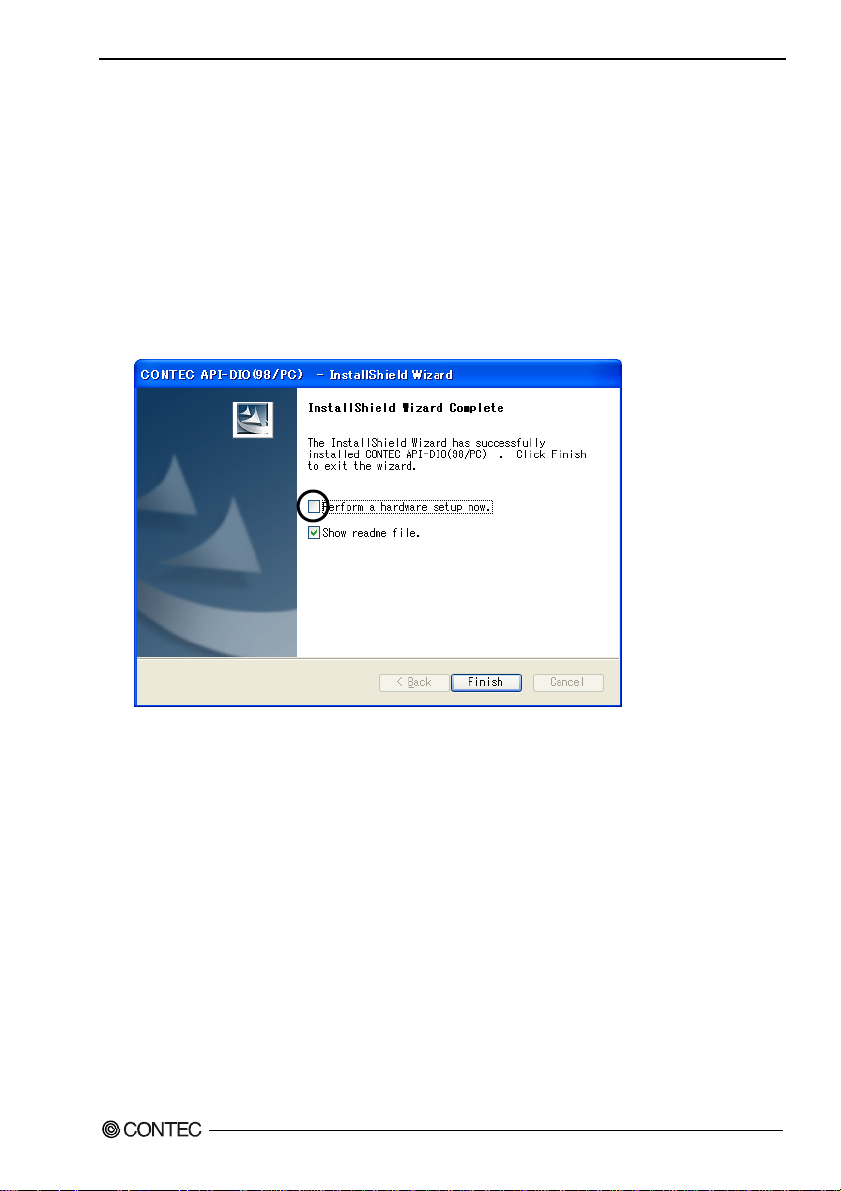

Executing the Installation

(1)

Follow the on-screen instructions to proceed to install.

(2) When the required files have been copied, the “Perform a hardware setup now(API-TOOL

Configuration)” and “Show readme file” check boxes are displayed.

When you are installing the software or hardware for the first time:

1) Uncheck “Perform a hardware setup now”.

2) Click on the [Finish] button.

Go to Step 2 to set and plug the hardware.

* When the hardware has already been installed:

Check “Perform a hardware setup now(API-TOOL Configuration)”, then go to Step 4

“Initializing the Software”.

You have now finished installing the software.

DIO-32DM-PE

15

Page 23

2. Setup

ace connecto

(

)

Step 2 Setting the Hardware

This section describes how to set the board and plug it on your PC.

The board has some switches to be preset.

Check the on-board switches before plugging the board into an expansion slot.

The board can be set up even with the factory defaults untouched. You can change board settings later.

Parts of the Board and Factory Defaults

Figure 2.1. shows the names of major parts on the board.

Note that the switch setting shown below is the factory default.

DIO-32DM-PE

CN2, CN3 SW1

BOARD ID

- Interf

(CN1)

r

Figure 2.1. Component Locations

- SC Connector

CN2, CN3

(CN2) (CN3)

-Board ID setting switch

SW1

BOARD ID

8

9

7

A

6

B

5

4

3

E

2

F

1

0

C

D

DIO-32DM-PE

16

Page 24

2. Setup

Setting the Board ID

If you install two or more boards on one personal computer, assign a different ID value to each of the

boards to distinguish them.

The board IDs can be set from 0 - Fh to identify up to sixteen boards.

If only one board is used, the original factory setting (Board ID = 0) should be used.

Setting Procedure

To set the board ID, use the rotary switch on the board. Turn the SW1 knob to set the board ID as

shown below.

SW1

BOARD ID

8

9

7

A

6

B

5

C

4

D

3

E

2

F

Factory setting:

0

1

Figure 2.2. Board ID Settings (SW1)

(Board ID= 0)

DIO-32DM-PE

17

Page 25

2. Setup

Plugging the Board

(1) Before plugging the board, shut down the system, unplug the power code of your PC.

(2) Remove the cover from the PC so that the board can be mounted.

(3) Plug the board into an expansion slot.

(4) Attach the board bracket to the PC with a screw.

(5) Put the cover back into place.

CAUTION

- Do not touch the board's metal plated terminals (edge connector) with your hands.

Otherwise, the board may malfunction, overheat, or cause a failure.

If the terminals are touched by someone's hands, clean the terminals with industrial alcohol.

- Do not install or remove the board to or from the slot while the computer's power or expansion unit is

turned on.

Otherwise, the board may malfunction, overheat, or cause a failure.

Be sure that the personal computer power is turned off.

- Make sure that your PC or expansion unit can supply ample power to all the boards installed.

Insufficiently energized boards could malfunction, overheat, or cause a failure.

DIO-32DM-PE

18

Page 26

2. Setup

Step 3 Installing the Hardware

For using an expansion board under Windows, you have to let the OS detect the I/O addresses and

interrupt level to be used by the board. The process is referred to as installing the hardware.

In the case of using two or more boards, make sure you install one by one with the Add New Hardware

Wizard.

Turning on the PC

Turn on the power to your PC.

CAUTION

- The board cannot be properly installed unless the resources (I/O addresses and interrupt level) for

the board can be allocated. Before attempting to install the board, first determine what PC

resources are free to use.

- The resources used by each board do not depend on the location of the PCI Express bus slot or the

board itself. If you remove two or more boards that have already been installed and then remount

one of them on the computer, it is unknown that which one of the sets of resources previously

assigned to the two boards is assigned to the remounted board. In this case, you must check the

resource settings.

When Using API-DIO(WDM)

(1) The “Found New Hardware Wizard” will be started.

Select “No, not this time” and then click the “Next” button.

DIO-32DM-PE

19

Page 27

2. Setup

(2) When “Multimedia Controller” is displayed, select “Install from a list or s

location[Advanced]” and then specify that folder on the CD-ROM which contains the setup

information (INF) file to register the board.

When the model name of hardware is displayed, select “Install the software automatically

[Recommended]” and then click on the “Next” button.

Source folder

The setup information (INF) file is contained in the following folder on the bundled CD-ROM.

Windows Vista, XP, Server 2003, 2000 \INF\Wdm\Dio

pecific

API-PAC version may be

different.

\INF\Wdm\Dio

DIO-32DM-PE

20

Page 28

2. Setup

* The name of the board

you have just added is

displayed.

- DIO-32DM-PE

You have now finished installing the hardware.

DIO-32DM-PE

21

Page 29

2. Setup

When Using API-AIO(98/PC)

(1) The “Found New Hardware Wizard” will be started.

If you are using Windows NT 4.0, the “Found New Hardware Wizard” is not started.

Go to Step 4 “Initializing the Software”.

Select “No, not this time” and then click the “Next” button.

(2) Select “Install from a list or s

pecific location[Advanced]” and then click the “Next” button.

DIO-32DM-PE

22

Page 30

2. Setup

(3) Specify that folder on the CD-ROM which contains the setup information (INF) file to register the

board.

* The name of the board

you have just added is

displayed.

- DIO-32DM-PE

Source folder

The setup information (INF) file is contained in the following folder on the bundled CD-ROM.

Windows Vista, XP, Server 2003, 2000 \INF\Win2000\Dio\PCI

Example of specifying the folder for use under Windows XP

DIO-32DM-PE

\INF\Win2000\Dio\PCI

23

Page 31

2. Setup

CAUTION

In Windows XP, the Hardware Wizard displays the following alert dialog box when you have

located the INF file. This dialog box appears, only indicating that the relevant driver has not

passed Windows Logo testing, and it can be ignored without developing any problem with the

operation of the board.

In this case, click on the [Continue Anyway] button.

You have now finished installing the hardware.

* The name of the board

you have just added is

displayed.

- DIO-32DM-PE

DIO-32DM-PE

24

Page 32

2. Setup

Step 4 Initializing the Software

The driver library requires the initial setting to recognize the execution environment. It is called the

initialization of the Driver library.

When Using API-DIO(WDM)

API-DIO(WDM) is initialized automatically during hardware installation. Therefore, if you want to

use it with its initial settings, you can skip the setting procedure described in Step 4. To change the

device name, follow the setting procedure shown below.

Setting the device name

(1) Run Device Manager. From [My Computer] - [Control Panel], select [System] and then select the

[Device Manager] tab.

(You can also open Device Manager by right clicking on My Computer and selecting Properties.)

* The name of the board

you have just added is

displayed.

- DIO-32DM-PE “DIO000”

(2) The installed hardware appears under the CONTEC Devices node. Open the CONTEC Devices

node and select the device you want to setup (the device name should appear highlighted). Click

[Properties].

DIO-32DM-PE

25

Page 33

2. Setup

(3) The property page for the device opens.

Enter the device name in the common settings tab page and then click [OK].

The device name you set here is used later when programming.

* The name of the board

you have just added is

displayed.

- DIO-32DM-PE

* The initial device name that appears is a default value. You can use this default name if you wish.

* Make sure that you do not use the same name for more than one device.

You have now finished installing the initial setting of Software.

DIO-32DM-PE

26

Page 34

2. Setup

Whe n Us ing API-DIO(98/PC)

(1) Open the Start Menu, then select “Programs” – “CONTEC API-PAC(W32)” – “API-TOOL

Configuration”.

(2) Click the [DIO] icon.

API-TOOL Configuration detects boards automatically.

The detected boards are listed.

Updating the Settings

(1) Select “Save setting to registry…” from the “File” menu.

You have now finished installing the initial setting of Software.

DIO-32DM-PE

27

Page 35

2. Setup

Step 5 Operation Checks

You must make sure that the board and driver software operate normally. By taking this step, you can

make sure that the board has been set up correctly.

Check Method

Connect the board to a remote device to test the input/output and check the execution environment.

Set the board in the default factory.

To connect an external device, see Chapter 3 “External Connection”.

When Using API-DIO(WDM)

Use the diagnostic program to check the operation.

Starting the Diagnosis Program

Open the “Properties” page of the device that was used for the software initialization, and press the

[Diagnosis] button.

DIO-32DM-PE

28

Page 36

2. Setup

Checking Digital Inputs and Outputs

The main panel of the Diagnosis Program appears.

You can check the current operation states of the board in the following boxes:

“Input Port” : Displays input values bit by bit at fixed time intervals.

“Output Port” : Mouse operation allows the data to output or display.

“Interrupt” : Displays the number of interrupts detected bit by bit.

* The name of the board

you have just added is

displayed.

- DIO-32DM-PE

* Switch the I/O direction.

To use the function execution time measurement feature, click on the [Measurement Time] button.

Enter the I/O start port and the number of ports, then press the measurement button. The time for each

execution of a function will be measured.

DIO-32DM-PE

29

Page 37

2. Setup

Diagnosis Report

(1) Clicking on the [Show Diagnosis Report] button displays detailed data such as board settings and

the diagnosis results while saving them in text format.

The Diagnosis Program performs “board presence/absence check”, “driver file test”, “board setting

test”, and so on.

CAUTION

Before executing diagnosis report output, unplug the cable from the board.

* The name of the board

you have just added is

displayed.

- DIO-32DM-PE

(2) A diagnosis report is displayed as shown below.

* The name of the board

you have just added is

displayed.

- DIO-32DM-PE

DIO-32DM-PE

30

Page 38

2. Setup

When Using API-DIO(98/PC)

C

heck the device operation by using the sample program.

Running a Sample Program

From the “Start” menu, select [Programs] – [CONTEC API-PAC(W32)] – [Dio] – [PIO-32DM] –

[SAMPLE Output 32bit].

(1) Enter in [GrpNo:] the “Group No.” which you set in “API-TOOL Configuration”, and then press

the [DioOpen] button. Make sure that the [Ret:] field displays the following information.

(2) Press the [Condition...] button to display the “Generating Condition” window, and then press the

[OK] button.

DIO-32DM-PE

31

Page 39

2. Setup

(3) Press the [Data…] button to create output data.

(4) Press the [DataSet] button to set the output data in the buffer for the bus master.

(5) Pressing the [Start] button starts bus master transfer, and once the output is completed, the

following information appears.

DIO-32DM-PE

32

Page 40

2. Setup

Setup Troubleshooting

Symptoms and Actions

No output can be obtained.

Use API-TOOL Configuration to check whether the board name setting is wrong.

The board works with the Diagnosis Program but not with an application.

The Diagnosis Program is coded with API-TOOL functions. As long as the board operates with the

Diagnosis Program, it is to operate with other applications as well. In such cases, review your program

while paying attention to the following points:

- Check the return values of functions.

- Refer to the source code of sample program.

The OS won't normally get started or detect the board.

< For using the

Refer to the “Troubleshooting” in API-DIO(WDM) HELP

< For using the

Turn off the power to your PC, then unplug the board . Restart the OS and delete the board settings of

API-TOOL Configuration. Turn off the PC again, plug the board, and restart the OS. Let the OS

detect the board and use API-TOOL Configuration to register board settings.

API-DIO(WDM) >

API-DIO(98/PC) >

If your problem cannot be resolved

Contact your retailer.

DIO-32DM-PE

33

Page 41

2. Setup

DIO-32DM-PE

34

Page 42

3. External Connection

3. External Connection

This chapter describes the interface connectors on the product and the external I/O circuits.

Check the information available here when connecting an external device.

How to connect the connectors

Connector shape

To connect an external device to this product, plug the cable from the device into the interface

connector (CN1) shown below.

Interface connector (CN1)

B48 A48

B47 A47

B02 A02

B01 A01

* Please refer to chapter 1 for more information on the supported cable and accessories.

Figure 3.1. Interface Connector and Applicable Cable Connector

- Connector used

PCR-E96LMD+

[mfd. by HONDA TSUSHIN

KOGYO CO., LTD.]

or equivalence to it

- Compatible connectors

PCR-E96FA+

[mfd. by HONDA TSUSHIN

KOGYO CO., LTD.]

or equivalence to it

DIO-32DM-PE

35

Page 43

3. External Connection

Connector Pin Assignment

GND

B48 A48

GND

B47 A47

GND

B46 A46

EXTCLK1

B45 A45

GND

EXTSTART1

B44 A44

B43 A43

GND

B42 A42

EXTSTOP1

B41 A41

B48 A48

GND

B40 A40

EXTREQ1

B39 A39

GND

B38 A38

EXTACK1

B37 A37

GND

B36 A36

GND

B35 A35

GND

B34 A34

DIOD07

B33 A33

GND

B32 A32

DIOD06

B31 A31

GND

B30 A30

DIOD05

B29 A29

GND

B28 A28

DIOD04

B27 A27

GND

B26 A26

DIOD03

B25 A25

GND

B24 A24

DIOD02

B23 A23

GND

B22 A22

DIOD01

B21 A21

GND

B20 A20

DIOD00

B19 A19

GND

B18 A18

DIOC07

B17 A17

GND

B16 A16

DIOC06

B15 A15

GND

B14 A14

DIOC05

B13 A13

GND

B12 A12

DIOC04

B11 A11

GND

B10 A10

DIOC03

B09 A09

B01

GND

B08 A08

DIOC02

B07 A07

GND

B06 A06

DIOC01

B05 A05

GND

B04 A04

DIOC00

B03 A03

N.C.

B02 A02

N.C.

B01

[49]

[96]

[1]

[48]

- [ ] shows the pin No. of HONDA TSUSHIN KOGYO CO., LTD. specification.

* Can be used as an interrupt signal when used as general-purpose I/O.

A01

A01

GND

GND

GND

EXTCLK0

GND

EXTSTART0

GND

EXTSTOP0

GND

EXTREQ0

GND

EXTACK0

GND

GND

GND

DIOB07

GND

DIOB06

GND

DIOB05

GND

DIOB04

GND

DIOB03

GND

DIOB02

GND

DIOB01

GND

DIOB00

GND

DIOA07

GND

DIOA06

GND

DIOA05

GND

DIOA04

GND

DIOA03 *

GND

DIOA02 *

GND

DIOA01 *

GND

DIOA00 *

N.C.

N.C.

DIO-32DM-PE

36

Page 44

3. External Connection

I/O signal DIOA00 - DIOA07

DIOA00 - DIOA07

DIOA00 - DIOA07 I/O signal DIOA00 - DIOA07

DIOB00 - DIOB07 I/O signal DIOB00 - DIOB07

DIOC00 - DIOC07 I/O signal DIOC00 - DIOC07

DIOD00 - DIOD07 I/O signal DIOD00 - DIOD07

EXTCLK0 - EXTCLK1 External clock input

EXTSTART0 - EXTSTART1 External start signal

EXTSTOP0 - EXTSTOP1 External stop signal

EXTREQ0 - EXTREQ1 REQ signal

EXTACK0 - EXTACK1 ACK signal

GND This is connected to GND of slot.

N.C. This pin is left unconnected.

DIOA00 - DIOA03 can be used as interrupt signal DIOIn00 - DIOIn03 at

the time of general-purpose I/O..

Figure 3.2. Pin Assignments of Interface Connector

Relationships between API-PAC(W32) Logical Ports/Bits and Connector Signal Pins

The following table lists the relationships between the connector signal pins and the logical port/bit

numbers used for I/O functions when applications are written with API-PAC(W32).

CAUTION

The logical port and logical bit numbers are virtual port and bit numbers that enable programming

independent of board I/O addresses or board types.

For details, refer to API-DIO HELP available after installing API-PAC(W32).

Setup1

Table 3.1. Logical Ports, Logical Bits, and Connector Signal Pins < Setup1 >

D7 D6 D5 D4 D3 D2 D1 D0

Input Logical

Ports0

Input Logical

Ports1

Input Logical

Ports2

Input Logical

Ports3

DIOA07

DIOA06

DIOA05

DIOA04

DIOA03

DIOA02

[7]

[6]

[5]

[4]

[3]

DIOB07

DIOB06

DIOB05

DIOB04

[15]

[14]

[13]

DIOC07

DIOC06

[22]

DIOD06

[30]

DIOC05

[21]

DIOD05

[29]

[23]

DIOD07

[31]

Note : DIOAxx, DIOBxx, DIOCxx and DIODxx represents the CN1 input signal.

[xx] represents the logical bit.

[12]

DIOC04

[20]

DIOD04

[28]

DIOB03

[11]

DIOC03

[19]

DIOD03

[27]

[2]

DIOB02

[10]

DIOC02

[18]

DIOD02

[26]

DIOA01

[1]

DIOB01

[9]

DIOC01

[17]

DIOD01

[25]

DIOA00

[0]

DIOB00

[8]

DIOC00

[16]

DIOD00

[24]

DIO-32DM-PE

37

Page 45

3. External Connection

Setup2

Table 3.2. Logical Ports, Logical Bits, and Connector Signal Pins < Setup2 >

D7 D6 D5 D4 D3 D2 D1 D0

Input Logical

Ports0

Input Logical

Ports1

Output Logical

Ports2

Output Logical

Ports3

DIOA07

DIOA06

DIOA05

DIOA04

DIOA03

DIOA02

DIOA01

[7]

[6]

[5]

[4]

[3]

[2]

DIOB07

DIOB06

DIOB05

DIOB04

DIOB03

[15]

[14]

[13]

[12]

D7 D6 D5 D4 D3 D2 D1 D0

DIOC07

DIOC06

DIOC05

[23]

[22]

DIOD07

DIOD06

[31]

[30]

Note :

DIOAxx and DIOBxx represents the CN1 input signal and DIOCxx and DIODxx

represents the CN1 output signal.

[xx] represents the logical bit.

[21]

DIOD05

[29]

DIOC04

[20]

DIOD04

[28]

[11]

DIOC03

[19]

DIOD03

[27]

DIOB02

[10]

DIOC02

[18]

DIOD02

[26]

[1]

DIOB01

[9]

DIOC01

[17]

DIOD01

[25]

DIOA00

[0]

DIOB00

[8]

DIOC00

[16]

DIOD00

[24]

Setup3

Table 3.3. Logical Ports, Logical Bits, and Connector Signal Pins < Setup3 >

D7 D6 D5 D4 D3 D2 D1 D0

Output Logical

Ports0

Output Logical

Ports1

Output Logical

Ports2

Output Logical

Ports3

DIOA07

DIOA06

DIOA05

DIOA04

DIOA03

DIOA02

[7]

[6]

[5]

[4]

[3]

DIOB07

DIOB06

DIOB05

DIOB04

[15]

[14]

[13]

DIOC07

DIOC06

[22]

DIOD06

[30]

DIOC05

[21]

DIOD05

[29]

[23]

DIOD07

[31]

Note : DIOAxx, DIOBxx, DIOCxx and DIODxx represents the CN1 output signal.

[xx] represents the logical bit.

[12]

DIOC04

[20]

DIOD04

[28]

DIOB03

[11]

DIOC03

[19]

DIOD03

[27]

[2]

DIOB02

[10]

DIOC02

[18]

DIOD02

[26]

DIOA01

[1]

DIOB01

[9]

DIOC01

[17]

DIOD01

[25]

DIOA00

[0]

DIOB00

[8]

DIOC00

[16]

DIOD00

[24]

DIO-32DM-PE

38

Page 46

3. External Connection

Connection method to the external device

-Data I/O-

Connecting the data I/O signal(DIOA0* - DIOD0*)

These lines input from and output to external devices and can be configured in 16bit with the software.

Input and output and setting procedures are the same whether these lines are used for general-purpose

digital I/O or bus master transferring and they can be configured in three different settings as shown

below:

Table 3.4. I/O signal

Signal name Setup1 Setup2 Setup3

DIOA00 - DIOA07 Input Input Output

DIOB00 - DIOB07 Input Input Output

DIOC00 - DIOC07 Input Output Output

DIOD00 - DIOD07 Input Output Output

When settings 1 and 2 are used for general-purpose digital I/O, DIOA00 through DIOA03 can be used

as interrupts (rising edge).

Detailed Data I/O Signal Circuit

SN74LV245A

Ω

22

Figure 3.3. Data I/O Signal Circuit

DIO-32DM-PE

Board

DIO A**

DIO B**

DIO C**

DIO D**

INPUT/OUTPUT

GND GND

External circuit

5V TTL IC or LVTTL IC

39

Page 47

3. External Connection

Connection method to the external device

-Control I/O-

Connection to the control signal (EXT**)

In order to control bus mastering from outside, five signals are provided each for pattern I/O. Before

using the signals to be input as control signals please verify their pulse widths.

"0" at the end of a signal name indicates a pattern input signal and "1" a pattern output signal.

Table 3.5. Control signal

Signal name Direction Usage Signal name Direction Usage

EXTCLK0 In Pattern input clock EXTCLK1 In Pattern output clock

EXTSTART0 In Pattern input start signal EXTSTART1 In Pattern output start signal

EXTSTOP0 In Pattern input stop signal EXTSTOP1 In Pattern output stop signal

EXTREQ0 In Pattern input REQ signal EXTREQ1 Out Pattern output REQ signal

EXTACK0 Out Pattern input ACK signal EXTACK1 In Pattern output ACK signal

Detailed Control Input Signal Circuit

Control signals to be input include clock, start, stop, and handshake input signals.

GND

EXTCLK0/1

EXTSTART0/1

EXTSTOP0/1

EXREQ0

EXTACK1

External circuit

5V TTL IC or LVTTL IC

SN74LV245A

Board

22

Ω

Input pin

Figure 3.4. Control signal input circuit

DIO-32DM-PE

40

Page 48

3. External Connection

Detailed Control Output Signal Circuit

Control signals to be output include handshake output signals.

SN74LV125A

Board

Output pin

GND

EXTACK0

EXTREQ1

External circuit

5V TTL IC or LVTTL IC

Figure 3.5. Control signal output circuit

What is the Control Signal?

External clock signal (EXTCLK0/EXTCLK1)

These signals input external pacer clocks. The maximum frequency is 10MHz.

When the external clock input is set as the clock source, pattern input or output occurs at the falling

edge of this signal.

EXTCLK0

EXTCLK1

tPWH tPWL

tPWH : Clock pulse high width 50ns (Min.)

tPWL : Clock pulse low width 50ns (Min.)

Figure 3.6. External clock signal

Eternal start signal (EXTSTART0/EXTSTART1)

These input signals start bus mastering with an external signal. The signal level is LVTTL and you

can select and enable the rising or falling edge with the software. In order to detect the signal edge, a

high- and low-level hold time of 50ns is needed at minimum.

EXTSTART0

EXTSTSRT1

tHIH tHIL tHIH

tHIH : High level hold time 50ns (Min.)

tHIL : Low level hold time 50ns (Min.)

Figure 3.7. External start signal

DIO-32DM-PE

41

Page 49

3. External Connection

External stop signal (EXTSTOP0/EXTSTOP1)

These input signals stop bus mastering with an external signal. The signal is LVTTL level and you can

select and enable the rising or falling edge with the software. In order to detect the signal edge, a highand low-level hold time of 50ns is needed at minimum.

Handshake Signal (EXTREQ0/EXTACK0/ EXTREQ1/EXTACK1)

These signals handshake with external devices. The signal is LVTTL level and controlled with

negative logic.

Input

EXTREQ0 (In)

DATA (In)

(1)

tREQIL

Invalid Valid

EXTACK0 (Out)

tREQIL : EXTREQ0 low width 50ns (Min.)

tACKOL : EXTACK0 low width 100ns

tHSIN : Handshaking time 100ns (Min.)

(2) (3)

tACKOL

tHSIN

Figure 3.8. Handshake Signals at the Time of Input

(1) After setting the handshaking operation, this product samples the EXTREQ0 signal and starts

pattern input when it recognizes a low pulse of more than 50ns. Pattern data prior to that time is

disabled.

(2) The board generates a cycle to write data input from an external device to the PC memory by bus

mastering.

(3) At the end of writing data, the board outputs acknowledge signal EXTRACK0 to notify the external

device.

Output

EXTREQ1 (Out)

tREQIL

DATA (Out)

EXTACK1 (In)

tREQOL : EXTREQ1 low width 100ns

tACKOL : EXTACK1 low width 50ns (Min.)

(1)

Valid

tACKOL

Next

(2)

Figure 3.9. Handshake Signals at the Time of Output

(1) After setting the handshaking operation, this product outputs the EXTREQ1 signal.

(2) The board begins sampling acknowledge signals from external devices. The board recognizes the

end with a low pulse of more than 100ns and, at the leading edge, starts preparing to output the next

data.

DIO-32DM-PE

42

Page 50

3. External Connection

Synchronization Control Connectors

SC Connectors

Controlling simultaneous operations between boards or controlling in sync with events is in part

dependent on software performance. In order to enhance the reliability of the entire system and to solve

these problems, the board is equipped with SC (Synchronization Control) connectors.

Connecting the SC connectors allows boards of the same or different models to operate in sync with one

another.

From the boards connected with the SC cable, select one master board and use others as slaves. On the

master board, set the signal to be supplied to the slave boards with the software. On the slave boards,

the signal from the master board can be set to either the pacer clock operation start or stop factor.

All board operations can also be stopped with a stop request from the master in case of an error, for

example, or when requested from a slave board. A maximum of 16 boards can be connected including

the master.

For more information on the setup procedure, see the driver software online help. When the SC is not

connected, use the board with stand-alone settings.

Example 1: When clock start and stop requirements are set the same for multiple boards

In order to synchronize master clock start and stop with slave boards you can build a synchronous

system which does not depend on software processing capabilities.

If the board model is the same, data remains synchronized among boards even when channels are

expanded. When board models are different, data still remains compatible since operating clock start

and stop are dependent on the master.

(1) Connect the SC cable.

(2) Designate master/slave with the software.

(3) Assign to the connectors the clock start and stop signals to be output from the master.

(4) Set up slave boards so they can utilize all signals.

(5) Start in order of slave to master boards.

CAUTION

- When the clock signal is assigned to a synchronization control connector, the maximum clock

frequency available is 5 MHz.

- When each signal is assigned to a synchronization control connector, the slave board causes a delay

of about 100nsec.

DIO-32DM-PE

43

Page 51

3. External Connection

Example 2: When controlling slave operations with master's internal events

By outputting an internal event (interrupt) occurring on the master board, the slaves can start operating

in sync with that signal.

(1) Connect the SC cable.

(2) Designate master/slave with the software.

(3) Assign to the connector the event signal to be output from the master.

(4) Set signals from the master to the start requirements on the slave boards.

(5) Start in order of slave to master boards.

Connecting the SC Connectors (CN2,CN3)

This board is equipped with sync signal control connectors (CN2 and CN3) for connecting a sync signal

cable. When the cable is connected, multiple boards can operate in sync with one another.

Connection Procedure

Connect the sync signal cable when two or more boards need to operate in sync with one another.

Connect CN2 with a smaller ID number to CN3 with a greater ID number with the cable. You should

only use the cable that came with the board.

ID = 0

ID = 1

ID = 2

Figure 3.10. Connecting Cables

DIO-32DM-PE

44

Page 52

4. Function

4. Function

This section describes the features of the product.

Function Outline

Overview

As this product supports transfer by bus mastering, it can be used as a pattern generator that samples or

outputs arbitrary digital patterns at high speed. It can also be used as a general-purpose I/O board

when bus mastering is not used.

Sampling function / generating function

This product can be used in three I/O modes: 32channels input, 16channels input/output,

32channels output. As the sampling and generating features have their own bus mastering blocks each

made up of two independent channels, the product can generate 16 signals while sampling 16 sign als.

For sampling and generating, this product can input and output patterns at up to 20 MHz using the

internal clock. If it is too late for transfer because of failing to seize a bus, it causes an error and stops

transfer because it uses bus mastering. Note that it depends, for example, on the operating status of

applications on the PC whether the product can perform continuous transfer at 20 MHz.

For sampling and generating, this product can input/output data in various combinations of the start,

clock, and stop conditions.

Bus Master Transfer

Bus mastering by this product enables DMA for direct transfer between the product and the memory

space allocated for the application when the PCI Express bus is free. For the application's memory

space, a static area is specified, which is allocated by normal definition of a variable. Under the

Windows operating system, memory space for applications is represented by logical addresses and

physical addresses make up noncontiguous address spaces. This product transfers data continuously to

the noncontiguous address space. Bus mastering enables transfer to up to 64 megabytes of physical

memory space. When the area for an application to transfer data to is set, the amount of allocatable

memory depends on the type of the OS and on the actual memory size of the PC.

For bus mastering, the product supports one-time transfer and ring transfer different in how it uses

memory. During one-time transfer, the product completes transfer when it reaches the end of the

allocated memory area. During ring transfer, the product starts transfer over again from the beginning

of the allocated memory area when it reaches its end. Ring transfer continues until a stop condition is

satisfied or until it is terminated by software.

DIO-32DM-PE

45

Page 53

4. Function

Interrupt (at the time of bus master transfer)

The product provides the following two interrupt functions during bus mastering:

- Causes an interrupt each time the specified number of items are transferred.

- Causes an interrupt upon completion of transfer.

These interrupts can be posted to applications by using the function of API-PAC(W32).

If transfer is completed with an error when no bus can be seized or when it is missed, for example, this

product stops the transfer and generates a transfer completion interrupt. You can tell whether a

transfer error has occurred by checking the status.

Status, count

The following types of bus mastering status (error) are provided.

Status Contents

DIODM_STATUS_BMSTOP

DIODM_STATUS_PIOSTART

DIODM_STATUS_PIOSTOP

DIODM_STATUS_TRGIN

DIODM_STATUS_OVERRUN

Error Contents

DIODM_STATUS_FIFOEMPTY

DIODM_STATUS_FIFOFULL

DIODM_STATUS_SGOVERIN

DIODM_STATUS_TRGERR

DIODM_STATUS_CLKERR

DIODM_STATUS_SLAVEHALT

DIODM_STATUS_MASTERHALT

These types of status can be obtained by using the function of API-PAC(W32).

The 32bit or 64bit transfer count can be obtained by using the function of API-PAC(W32). The

transfer count is obtained as the number of data items already transferred to user application memory in

input mode or as the number of data items already output to an external device in output mode.

Indicates that bus master transfer has been completed.

Indicates that PIO input/output has been started.

Indicates that PIO input/output has been stopped.

Indicates that a start signal has been input in external start mode.

Indicates that a start signal has been input twice or more in external start mode.

Transfer can continue with no problem.

Indicates that the FIFO buffer is empty. This is mainly because of a heavy load

on the system that makes it late for bus master transfer. Take action such as

decreasing the transfer rate or system load.

Indicates that the FIFO buffer is full. This is mainly because of a heavy load on

the system that makes it late for bus master transfer. Take action such as

decreasing the transfer rate or system load.

Indicates a buffer overflow. The number of data items to be transferred exceeds

the buffer size. Increase the buffer size.

Indicates that the start and stop signals have been input at the same time in

external start mode. Check how the external start and stop signals are input.

Indicates that the next clock signal is input during data input in external clock.

If the status is set, sampling cannot be done by using the specified external clock.

Consider decreasing the period of external clock.

Indicates that a stop trigger from the slave has caused forced termination.

Check for any error on the slave side.

Indicates that a stop trigger from the master has caused forced termination.

Check for any error on the master side.

DIO-32DM-PE

46

Page 54

4. Function

Sampling function

Sampling control

This product can obtain sampling data at fixed intervals using a sampling clock. The table below lists

the sampling clock, sampling start trigger, and sampling stop trigger factors.

Table 4.1. Sampling clock, starting trigger, stopping trigger

Item Factor Contents

Sampling clock

Sampling

starting trigger

Sampling

stopping trigger

Internal clock

External clock

Handshake Fall of handshake signal (EXTREQ0)

SC connector

Software Software command

Rise of external signal Rise of external start signal (EXTSTART0)

Fall of external signal Fall of external start signal (EXTSTART0)

Pattern match When matched with the specified input pattern

SC connector Start signal from synchronization control connector

Software Software command

Rise of external signal Rise of external stop signal (EXTSTOP0)

Fall of external signal Fall of external stop signal (EXTSTOP0)

Specified number of items Termination when the specified number of items is reached

SC connector Stop signal from synchronization control connector

Bus master transfer error When FIFO buffer becomes full

- The product obtains the first sampling data at the falling edge of the sampling clock signal after

input of the sampling start trigger. From then on, the product obtains sampling data in

synchronization with the sampling clock signal.

- The product stops sampling upon input of the sampling stop trigger. The product does not obtain

sampling data when and after sampling is stopped.

Internal clock (50ns to 107s)

25ns unit

Fall of external clock input (EXTCLK0)

(Maximum frequency response: 10 MHz)

Clock input from synchronization control connector

(Maximum frequency response: 5 MHz)

DIO-32DM-PE

47

Page 55

4. Function

Generating function

Generating control

This product can output (generate) pattern data at fixed intervals using a generating clock. The table

below lists the generating clock, generating start trigger, and generating stop trigger factors.

Table 4.2. generating clock, start trigger, stop trigger

Item Factor Contents

Generating

clock

Generating

start trigger

Generating

stop trigger

Internal clock

External clock

Handshake Rise of handshake signal (EXTACK1)

SC connector

Software Software command

Rise of external signal Rise of external start signal (EXTSTART1)

Fall of external signal Fall of external start signal (EXTSTART1)

SC connector Start signal from synchronization control connector

Software Software command

Rise of external signal Rise of external stop signal (EXTSTOP1)

Fall of external signal Fall of external stop signal (EXTSTOP1)

Specified number of times Termination when the specified number of items is reached

SC connector Stop signal from synchronization control connector

Bus master transfer error When FIFO buffer becomes empty

- The product outputs the first pattern data at the falling edge of the generating clock signal after

input of the generating start trigger. From then on, the product outputs pattern data in

synchronization with the generating clock signal.

- The product stops pattern data output upon input of the generating stop trigger.

Internal clock (50ns to 107s)

25nsec unit

Fall of external clock input (EXTCLK1)

(Maximum frequency response: 10 MHz)

Clock input from synchronization control connector

(Maximum frequency response: 5 MHz)

DIO-32DM-PE

48

Page 56

4. Function

General-purpose I/O function

Data input

When input data is high level, [1] is input to the corresponding bit.

When input data is low level, in contrast, [0] is input to the corresponding bit.

Data output

When [1] is output to the corresponding bit, [High level] is output.

When [0] is output to the corresponding bit, in contrast, [Low level] is output.

CAUTION

- The entire product is set for input immediately after the power is turned on.

- It is Low level after setting to output.

Monitoring the output data

The product can read the status of the current output data without affecting the output data.

DIO-32DM-PE

49

Page 57

4. Function

Interrupt Control Function

The product can use up to four input signals as interrupt request signals at the time of using the

general-purpose I/O.

DIOA00 to DIOA03 can be used as interrupt request signals.

The product can generate an interrupt request signal to th e PC when the input signal change from Low

to High.

Disabling/enabling Interrupts

Interrupt mask bits can be used to disable or enable the individual bits for interruptions.

Once a certain bit has been interrupt-disabled, no interrupt occurs even when the corresponding input

signal changes its level.

To let interrupts occur, enable the corresponding interrupt mask bit for interruptions.

CAUTION

All of the interrupt mask bits are interrupt-disabled when the power is turned on.

Clearing the Interrupt Status and Interrupt Signal

Interrupt status bits are used to identify the input signal bit being used for requesting an interrupt.

When an interrupt status is input, the interrupt request signal and the in terrupt status are cleared

automatically.

CAUTION

- All of the interrupt status bits are set to 0 when the power is turned on.

- As long as the interrupt mask bit is set to disable interrupts, no interrupt status bit can be set even

when the input signal changes.

DIO-32DM-PE

50

Page 58

5. About Software

5. About Software

CD-ROM Directory Structure

\

|– Autorun.exe Installer Main Window

| Readmej.html Version information on each API-TOOL (Japanese)

| Readmeu.html Version information on each API-TOOL (English)

.

.

|–––APIPAC Each installer

| |––AIO

| | |––DISK1

| | |––DISK2

| | |––……

| | |––DISKN

| |––AioWdm

| |––CNT

| |––DIO

| |––……

.

.

| ––HELP HELP file

| |––Aio

| |––Cnt

| |––……

.

.

| ––INF Each INF file for OS

| |––WDM

| |––Win2000

| |––Win95

.

.

|––linux Linux driver file

| |––cnt

| |––dio

| |––……

.

.

| ––Readme Readme file for each driver

.

.

| ––Release Driver file on each API-TOOL