Page 1

CONTA-Sign CS 5.2

Easy-Marking-System

Manual

Labeling Software CONTA-Sign CS 5.2

Release: July 16, 2014

Page 1 of 67

©

Page 2

Manual

labeling software 5.2

Table of contents

1. System requirements

2. Software installation

3. Output devices supported by the program

4. Basic program functions

5. Brief instruction

5.1 Choosing the labeling or engraving device

5.2 Select the labeling / engraving element

5.3 Labeling elements

5.4 Output of labeling data on output device

6. Manage and display of projects

7. Select, Copy, Paste, Delete

8. Instruction on how to use the labeling software

8.1 Choosing the labeling device

8.2 Select the labeling element

8.3 Labeling elements

8.4 Extended input of labeling data

8.4.1 Multiple labeling

8.4.2 Consecutive labeling

8.4.3 Importing labeling data from files

8.5 Insert graphical elements or pictures

9. Output of labeling data

9.1 Output on plotter

9.2 Output on engraver

9.3 Printing on an office printer

9.4 Printing on thermo transfer printer

10. Create layouts on tags

Page 2 of 67

Page 3

11. Designer /Layouter

11.1 Setting up marking tags and strips for plotters

11.1.1 Design a marking element with one tag group (one size)

11.1.2 Design marking elements with more than one group (multiple sizes)

11.1.3 Design marking strips

11.2 Setting up engraving tags for the engraving units

11.2.1 Design an engraving element with one tag group (one size)

11.2.2 Design engraving elements with more than one group

(multiple sizes)

11.2.3 Design a marking strip

11.3 Setting up label sheets for office printers

11.4 Setting up endless labels and strips for thermo transfer printers

11.4.1 Design endless labels

11.4.2 Design endless strip

12. Import/Export of labeling elements and labels created with various

designer versions

13. Special functions using plotter and engraving versions

13.1 Import of CAD files and output on plotter and engraving units

13.2 Shift of start point and correction of scale factor

13.3 Base plates and segments

13.4 Control print of the labeling data

13.5 Calibrating plotter and engraver versions

13.6 Assign the support plate to the labeling element

14. General information and adjustments

14.1 Zoom function

14.2 Select program language

14.3 Display and switching within open project files

14.4 Specify the standard font type

14.5 Preset the standard pen size

14.6 Software version

14.7 Check for updates

14.8 Help files

Page 3 of 67

Page 4

1. System requirements

PC with 1.8 GHz (min.), 512 MB RAM, graphic resolution 1024 x 768,

40 GB hard drive, USB interface / Windows 2000, XP, Vista and Windows 7/8

2. Software installation

First close all other applications.

Insert the software installation CD into your CD-ROM drive.

Installation will begin automatically. You should follow the on-screen instructions. If the

auto-start feature has been switched off on your PC, double-click to start the program

XXXX_setupx.x.xxxx_xxxxxx.exe.

When installation is complete, you can start the program by double-clicking on the

program icon. Install the driver for the output device from the CD acc. to your

operating system and follow the instructions.

Language selection is automatic according to the country-specific version of Windows.

For country-specific versions of Windows where the program provides no individual

language version, the English version is automatically installed. You can override the

settings under > Options

> Language setting.

3. Output devices supported by the program

The labeling and engraving software version 5.2 supports the following output

devices:

- Plotter

Labeling devices for labeling all current labeling elements that are used in switch

cabinets and plant construction.

- Plotter full size (DIN A3)

- Plotter Basic half size (DIN A4)

- Engraving Unit (option)

Engraving device for engraving plastic, aluminum and brass plates.

Connecting the engraving unit to one of the plotter versions provides you with access

to the following engraving devices:

- Engraver full size (DIN A3)

- Engraver Basic half size (DIN A4)

- Engraving Unit (dedicated)

- Engraver full size (DIN A3)

- Engraver half size (DIN A3)

Note:

The plotter versions and the engraving units can be run with this program solely via a

USB connection

.

Page 4 of 67

Page 5

- Office printer

To print any type of label sheet (DIN A3/A4).

- Thermo transfer printer

To print endless labels and endless strips

4. General program functions

Basic software structure

Various labeling devices such as plotters, engravers, office and thermo transfer

printers can be controlled using the labeling software. All labeling elements stored in

the database are assigned to the relevant labeling devices. When the labeling device

has been selected, the only labeling elements provided will be those that the particular

device can print or engrave.

If, for example, the office printer is selected as the output device, the label sheets set

up in the database are automatically provided for selection.

The corresponding designer enables new templates for various output devices to be

set up quickly and easily.

General procedure for using the labeling software

1. Choosing the labeling or engraving device

2. Select the labeling / engraving element

3. Labeling elements

4. Output of labeling data on the output device

Page 5 of 67

Page 6

5. Brief instruction on how to use the labeling software

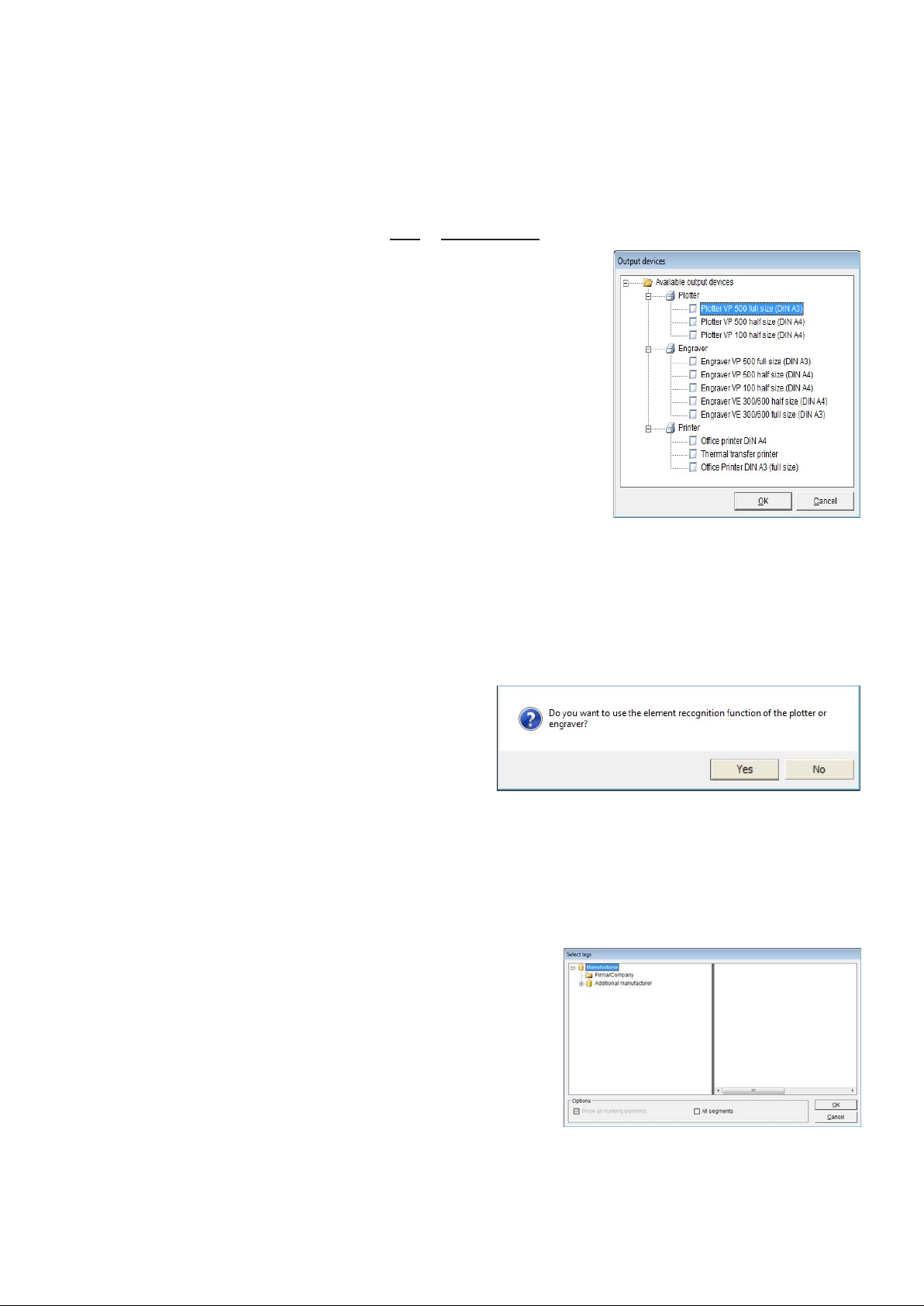

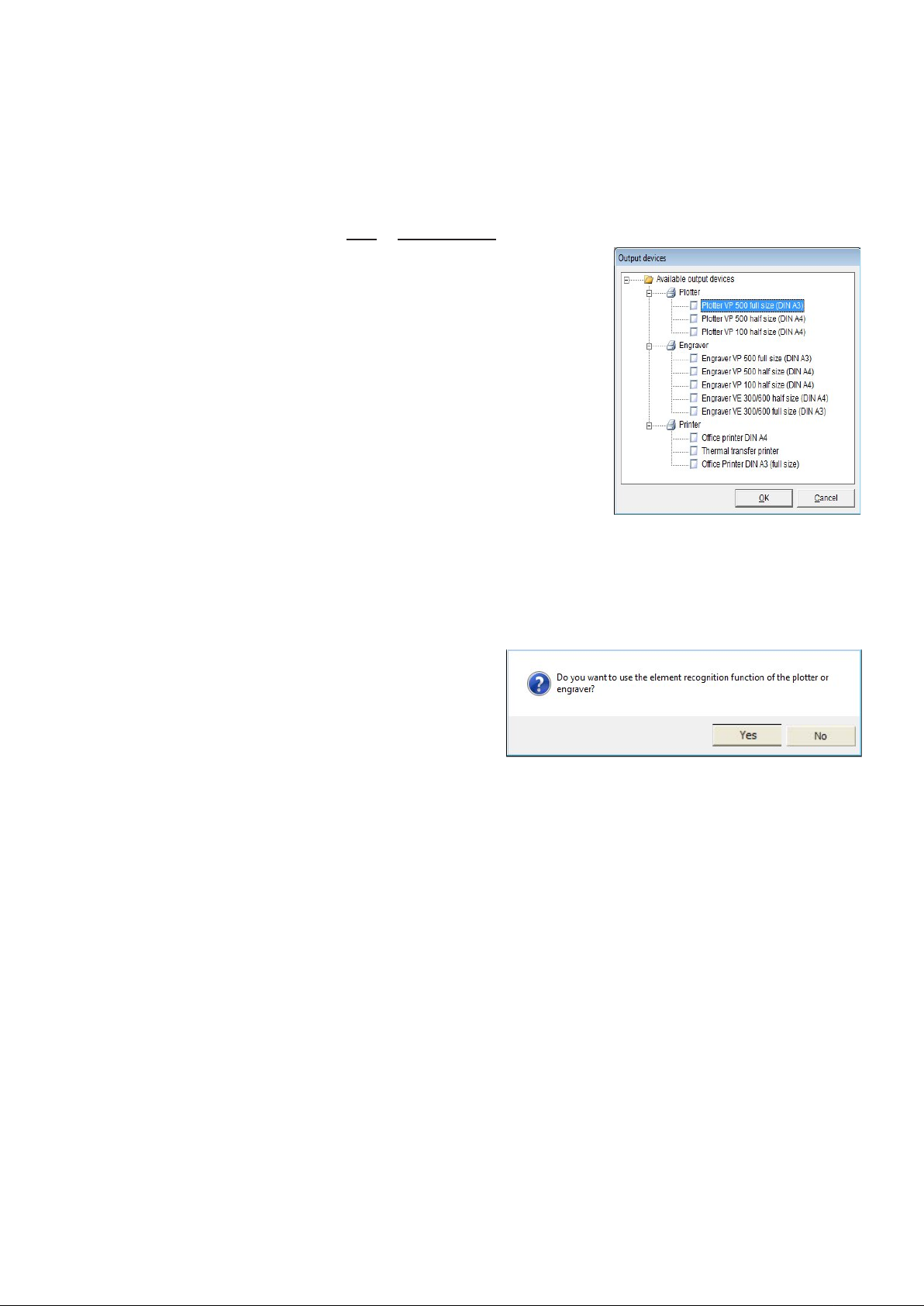

5.1 Choosing the labeling or engraving device

From the menu bar, select > File > New project. The window to select the labeling or

engraving device opens. When you have chosen and

confirmed the relevant output device, the program

provides you with a list of all labeling element

manufacturers for the output device used.

You can pre-select the output device to be used by

clicking with the right mouse button on the device name

and select as standard. Opening a new project by

clicking on the Icon New Project selects always the

standard device.

When you have chosen the plotter or engraver and the

respective device is switched on and connected to your

PC via the USB cable, you can preselect the labeling

elements.

In this instance, the message appears:

> Do you want to use the element recognition function of the plotter or

engraver? <.

If you confirm by answering Yes, the software imports the identification of the

support plates placed from the plotter and only provides you with the manufacturers of

the labeling elements that can be printed

or engraved on the support plates used.

Note: Only for full size plotter / engraving

option

5.2 Select the labeling element

Click on the relevant manufacturer to select the labeling element required. It is then

displayed on screen.

If you have switched on element recognition for

the plotter or engraver, the individual segments

will be displayed on screen. Double-click on the

segment required. This displays only the

manufacturers of labeling elements that can be

used with the support plate fitted.

Page 6 of 67

Page 7

Double-click to select the manufacturer and then the element to be printed.

The relevant template appears on screen.

5.3 Labeling elements

You can choose from a variety of options to label tags or labels.

- Label straight onto the tag

Click on the tag to be labeled. The tag is selected and the toolbar shows the default

settings for selecting the font style, font size, etc.

You can change the settings and enter the

labeling text directly.

When you have labeled individual tags, you can copy, paste, insert, delete, cut or

remove tags as well as add new tags.

A detailed description of how to select, copy,

paste, delete tags you can find within

Chapter 7 of this manual.

Page 7 of 67

Page 8

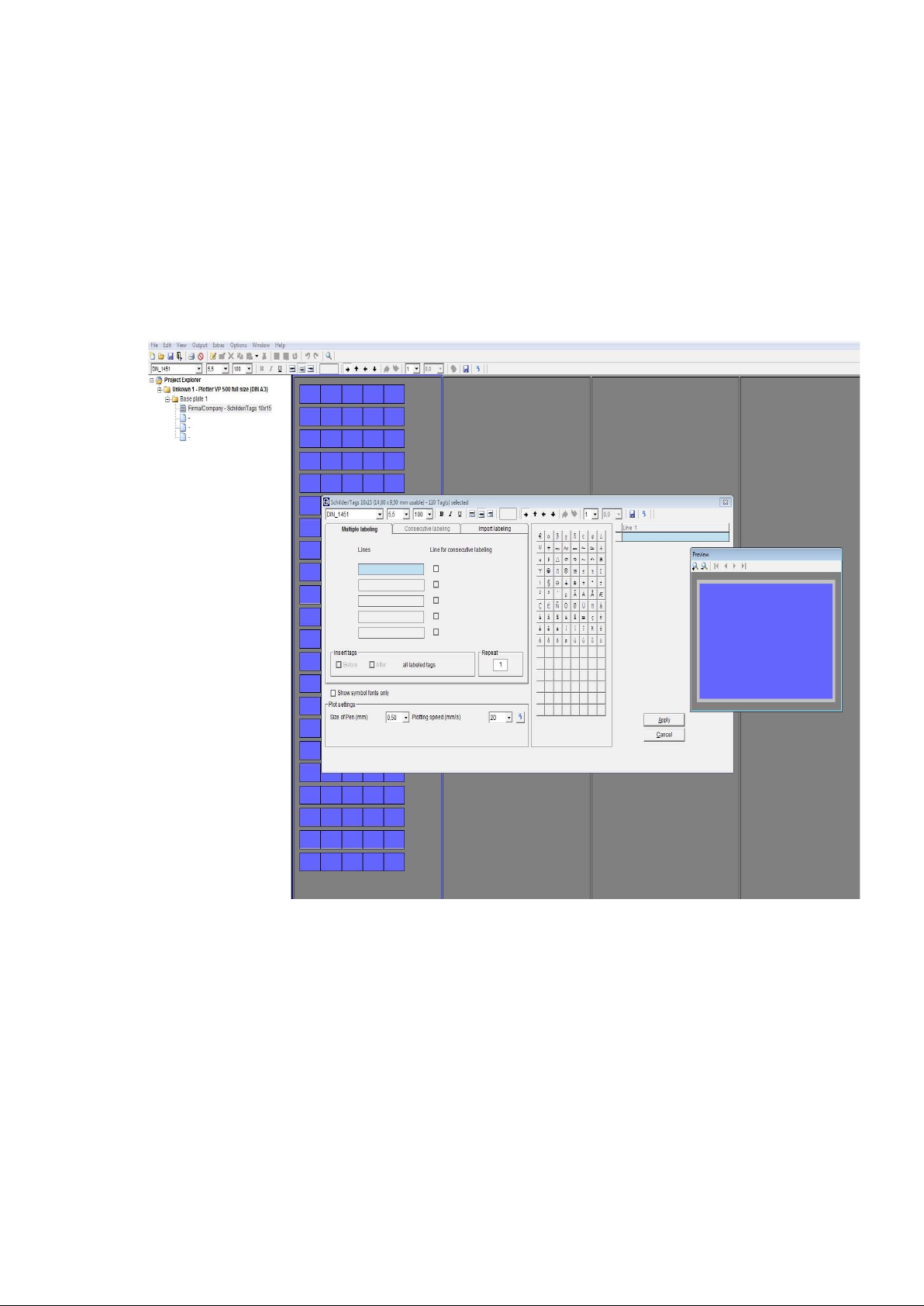

- Extended input of labeling data

If you wish to create multiple labels or consecutive labeling, or if you want to import

data from Excel or text files, double-click on the tag where labeling should begin.

A window subsequently opens enabling you to use the extended input options to

create labeling data. Click on Apply to go back show the entries on the tags.

More details you can find within Chapter 8.4.

5.4 Output of labeling data to the output device

When you have entered all labeling data, click on the printer icon in the toolbar.

The window for the relevant output device appears. You can then use this to enter all

the settings you require. More details you can find within Chapter 9.

Page 8 of 67

Page 9

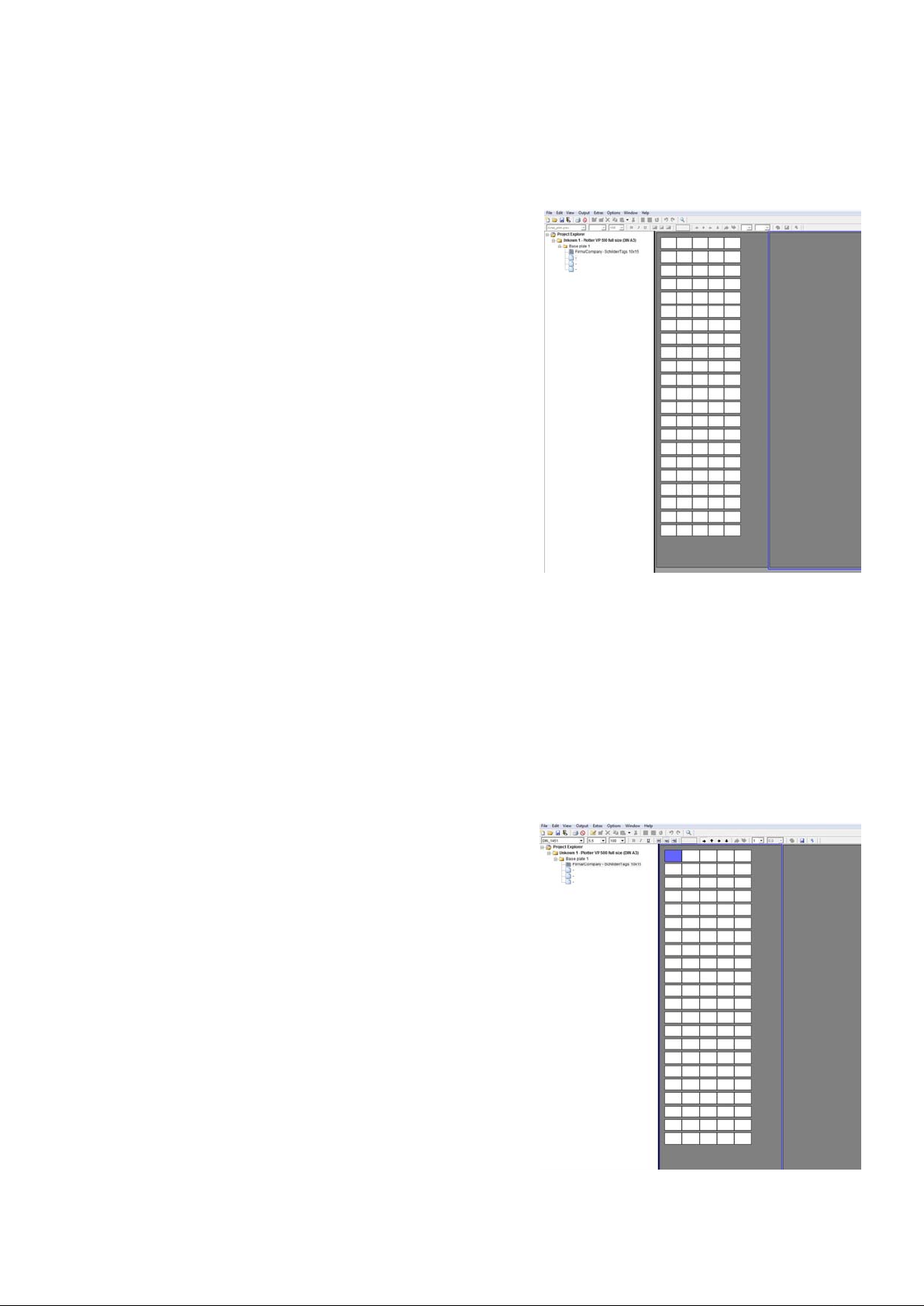

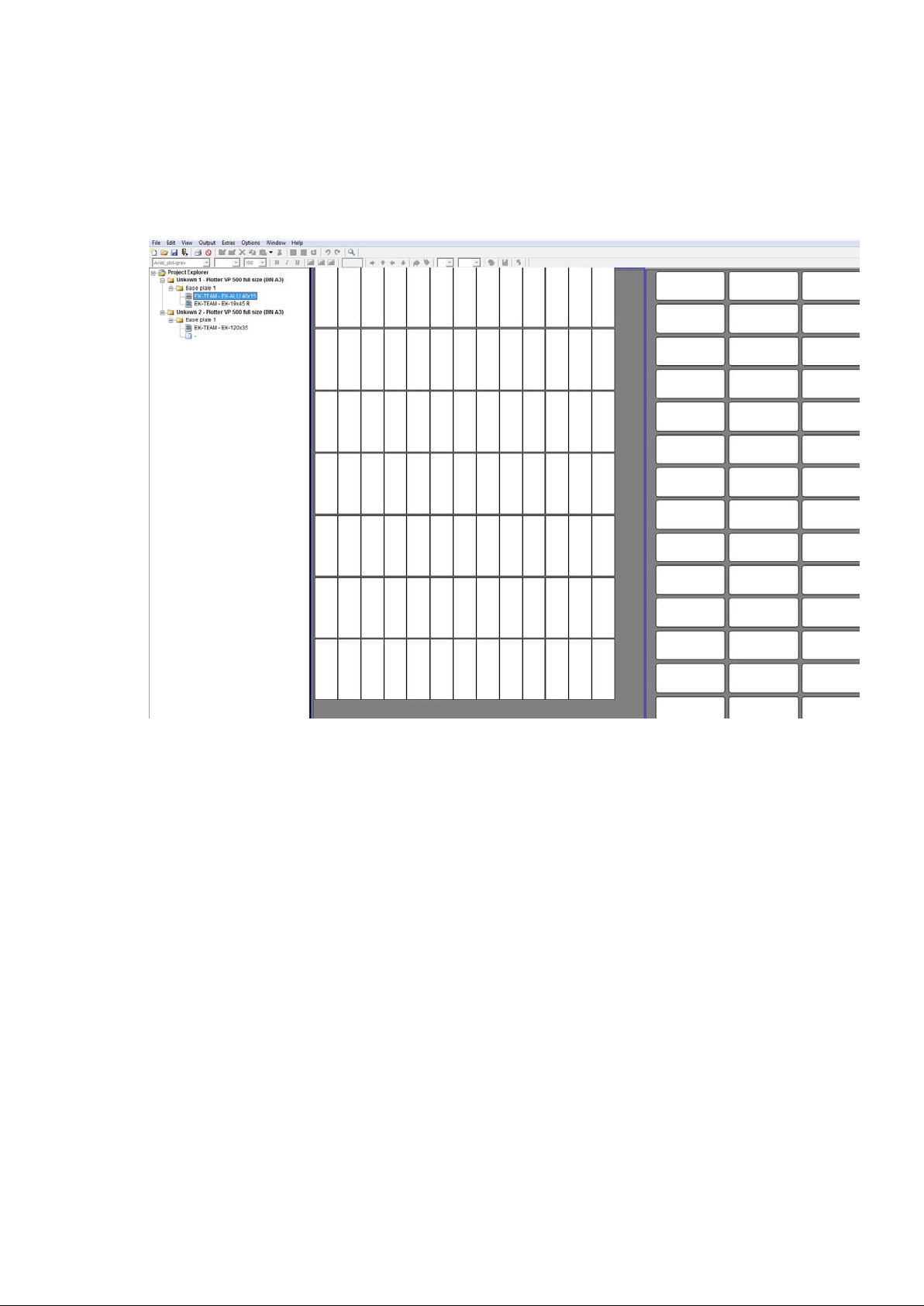

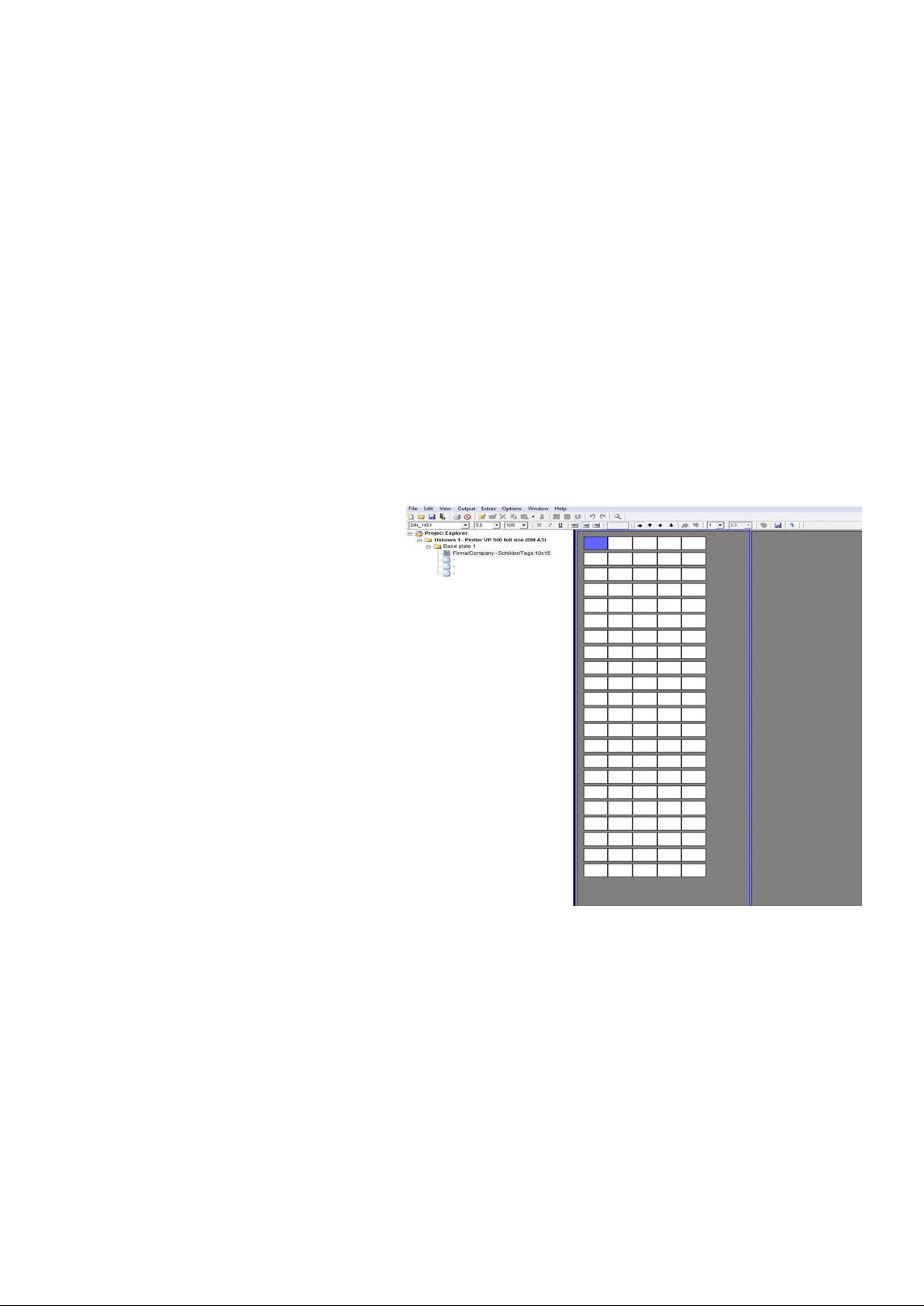

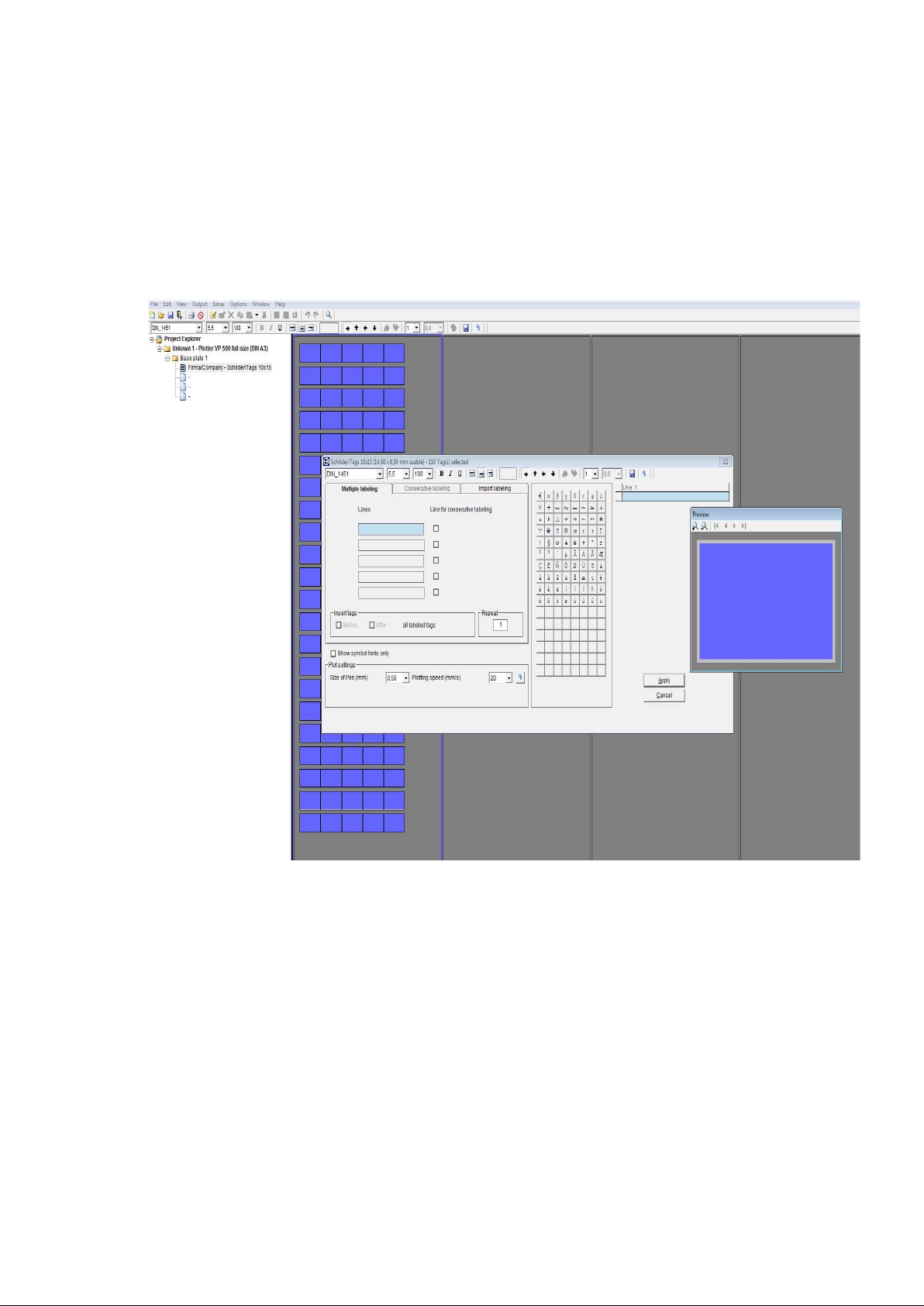

6. Manage and display projects

As soon as you have opened or created a new project the Project Explorer is shown at

the left side of the screen.

Within the explorer view all open projects with the respective base plates and

segments are shown, providing a complete overview.

With each project the name, output device, number of base plates and segments used

are displayed.

Additional tags can be placed by clicking on segments not used.

Page 9 of 67

Page 10

7. Select, Copy, Paste, Delete

The software provides multiple functions in order to select, copy, paste, insert, delete

tags.

Select tags

- Single click on one tag

Selecting the tag for labeling directly

- Double click on one tag

Selecting one tag and all blank tags following for labeling until next tag with text

- Double click on one tag

Selecting one tag and all blank tags following for labeling until next tag with different

number of lines or justification appears

Select a tag and open context menu with right mouse button

- All labeling new

Starting from the selected tag all following tags on the base plate are highlighted

despite of having labeling already

- Select all of the labeled tags same type

Starting from the selected tag all following tags with the same number of lines and

justification, even through further base plates, are highlighted for changing parameter

settings in the tool bar.

- New labeling

Starting from the selected tag all following tags are highlighted until next tag with

different number of lines or justification appears

- Edit labeling

Edit selected tag

Page 10 of 67

Page 11

Additional features selecting tags

- Selecting groups of tags in order to edit, copy, paste and delete

Click on the tag with the left mouse button you like to start to select the group and drag

with the mouse the area you like to select. If you like to select another group or single

tags in addition, hold down the Control button and select in the same way the tags.

Note: Only tags of the same type can be selected at the same time for making

changes such as Edit, Copy, New, Delete using the context menu.

Do you want to send only dedicated tags or labeling areas to the output device, select

as described before and click on the printer icon.

- Selecting areas for labeling

Hold down the Alt button and click with the left mouse button you like to start to select

the group and drag with the mouse the area you like to select. If you like to select

another area, group or single tags in addition, hold down the Alt button and select in

the same way. Once selected, send the labeling to the output device by clicking on the

printer icon.

- Copy, paste and delete of selected tags

After selecting the tags as described above, you can copy, paste and delete tags using

the context menu.

There are three options available to paste selected tags.

If you like to carry all labeling information with to the next tags, such as number of

lines, justification, font settings etc. click on the first tag you like to start to paste the

copied tags, then open with the right mouse button the context menu and select

> Paste labeling special

or use Control I to paste the information. Already existing

tags with text or symbols could be overwritten.

If you like to carry only the text information to the next tags, click on the first tag you

like to start to paste the copied tags, then open with the right mouse button the context

menu and select > Paste labeling

or use Control V to paste the information as text

only with the default settings. Already existing tags with text or symbols could be

overwritten.

Further, if you like to paste labelings with reverse sequence select and copy the group

of tags with the separator used. Click on the first tag you like to start to paste the

copied tags, then open with the right mouse button the context menu and select

> Paste labeling with reversed sequence based on separator

in addition select the separator used.

(Example: copy from the left, paste to the right)

Page 11 of 67

Page 12

8. Instruction on how to use the labeling software

8.1 Choosing the labeling or engraving device

Follow the menu path > File > New project. The window to select the labeling or

engraving device opens. When you have chosen and

confirmed the relevant output device, the program

provides you with a list of all labeling element

manufacturers for the output device used.

You can assign the output device by selecting and

setting with the right mouse button as standard.

When you have chosen the plotter or engraver and the

respective device is switched on and connected to your

PC via the USB cable, you can preselect the labeling

elements.

In this instance, the message appears:

> Do you want to use the element recognition function of the plotter or

engraver? <.

If you confirm by answering Yes, the

software imports the identification of the

support plates placed from the plotter and

only provides you with the manufacturers

of the labeling elements that can be printed

or engraved on the support plates used.

Note: Only for full size (A3) plotter / engraving option

Page 12 of 67

Page 13

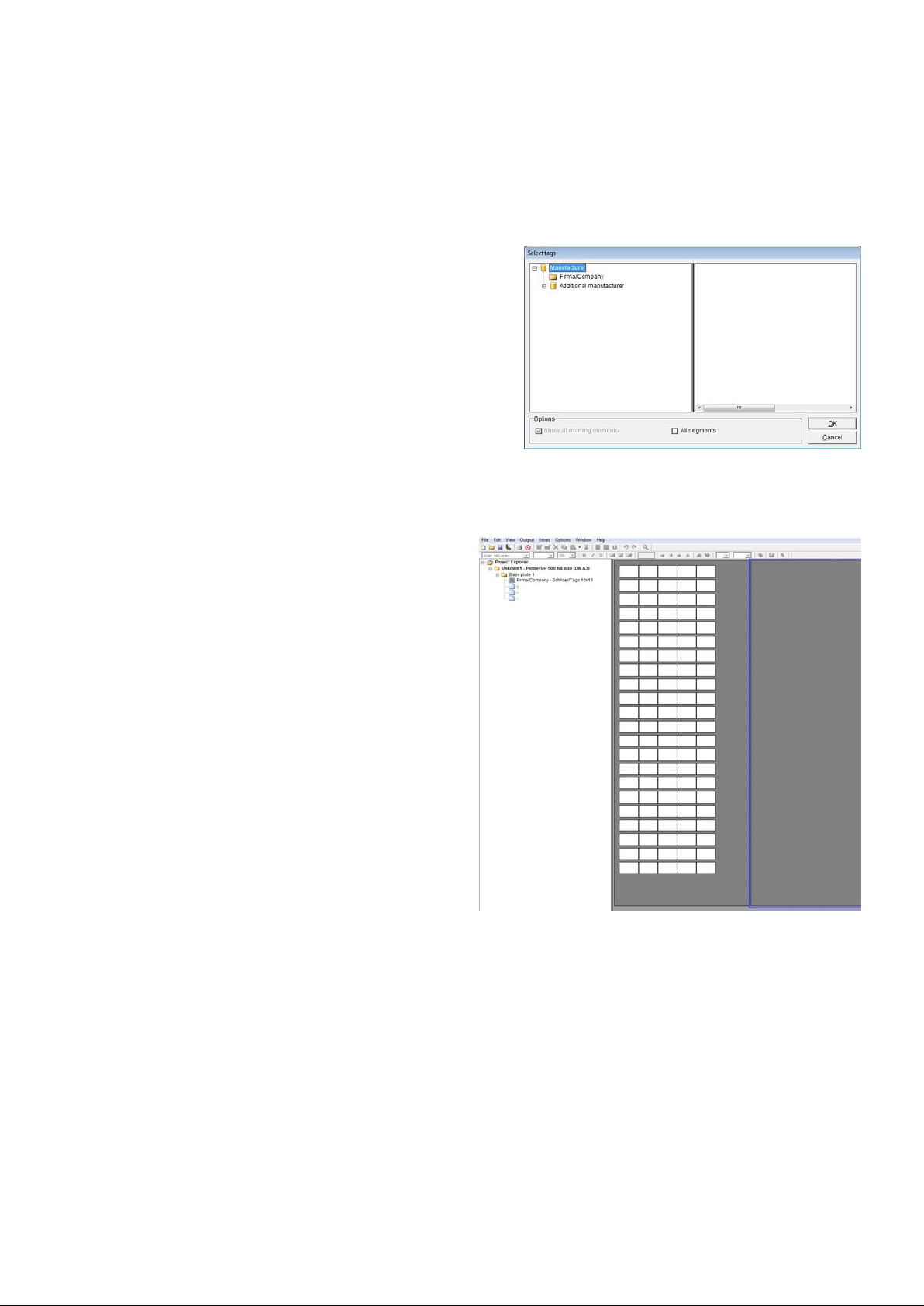

8.2 Select the labeling element

Click on the relevant manufacturer to select the labeling element required.

If you have switched on element recognition for the plotter or engraver, the individual

segments will be displayed on screen.

Double-click on the segment required. This

displays only the manufacturers of labeling

elements that can be used with the support

plates fitted.

Double-click to select the manufacturer and

then the element to be printed.

The relevant template appears on screen.

If you are not using the element recognition,

or using the VE 600, the labeling element will be shown on the screen by selecting

with a click.

There are different sizes, shapes and

material thicknesses available, in this

case tags with the size 10 x 15 mm

were selected.

If the labeling element, label sheet or endless labels are not available in the database,

you can use the designer variant to set these up at any time.

Page 13 of 67

Page 14

8.3 Labeling elements

You can choose from a variety of data input options to label tags or labels.

- Label straight onto the tag

Click on the tag to be labeled. The tag is selected and the toolbar shows the default

settings for selecting the font style, font size, etc.

You can change the settings and enter the labeling text directly. When you have

labeled individual tags, you can copy, insert, delete, cut or remove tags as well as add

new tags.

A more detailed instruction of how to select, copy, paste and delete tags you can find

within chapter 7.

Page 14 of 67

Page 15

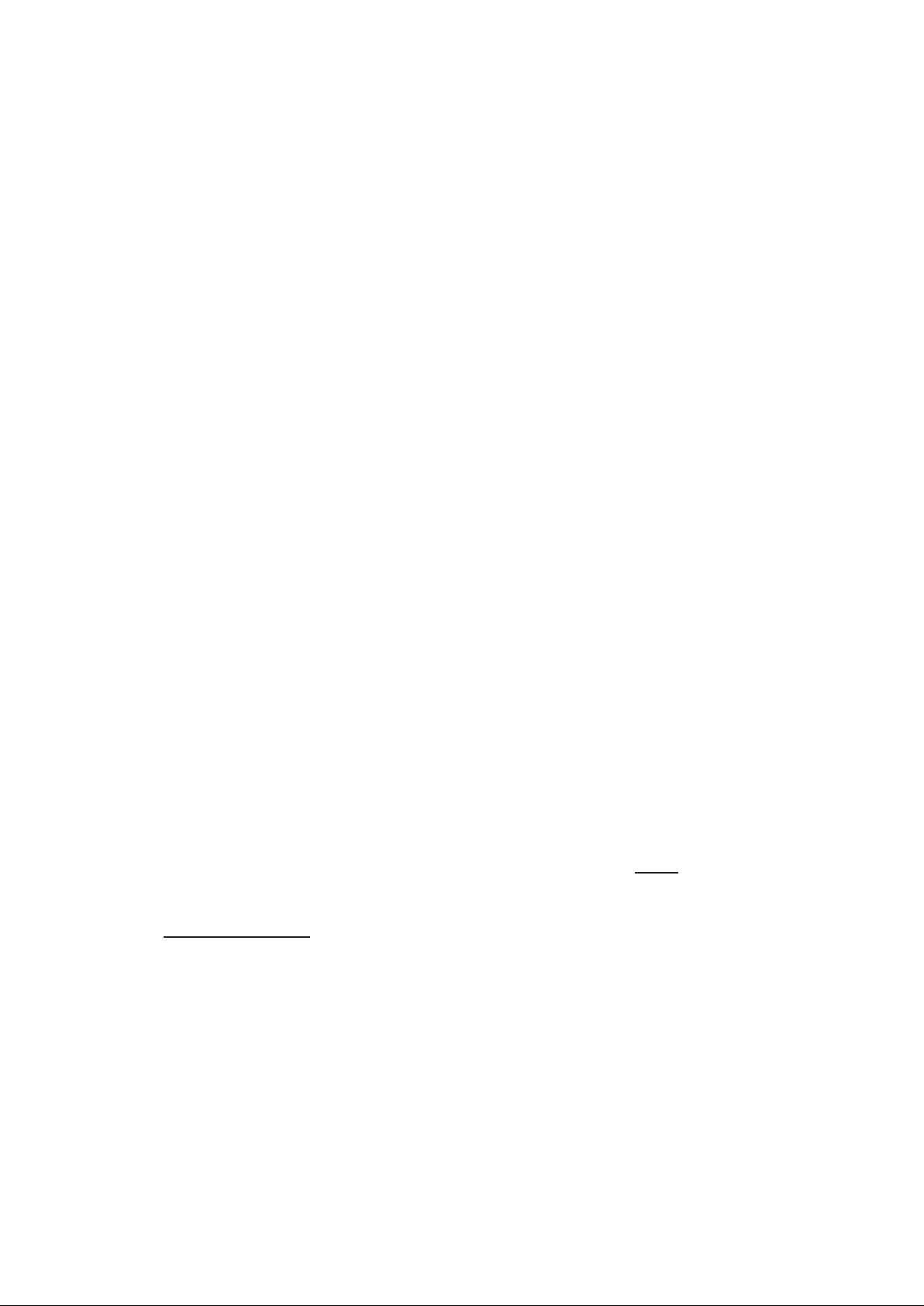

8.4 Extended input of labeling data

If you wish to set up multiple or consecutive labeling, or if you want to import data from

Excel or text files, double-click on the tag where labeling should begin. A window

subsequently opens enabling you to use the extended input options to create labeling

data.

Within the pre-view window the exact orientation and image of the text or graphic is

shown.

The top line of the window that has now opened next to pre-view provides you with

information about the tag or element as well as the number of tags available.

Underneath the line of information, a number of settings are available to change the

labeling data. Using the mouse, if you place the pointer on the relevant icon in the

toolbar, the respective function will be displayed.

Page 15 of 67

Page 16

You can change the following settings:

Font style, font size, bold, underline, left align, center, right align, rotate labeling by

90° at a time, number of lines, line spacing.

Changed settings can be saved as standard user settings by clicking on the Floppy

disc icon in the upper right tool bar.

Click on the Arrow icon at the end of the toolbar to restore all factory default settings.

Note:

The typeface selection in Bold or Italic is only available using the thermo transfer or

office printer.

If you have selected a plotter or an engraver as your device, you can modify specific

settings with reference to the relevant output device. The settings are displayed in the

lower part of the window.

The right section of the window provides you with special symbols and special

characters for the selected font type. Those could vary from type to type.

The extended character set provides country-specific characters and special symbols

for selection. This means that labels for other countries can be created without any

problem.

Country specific character sets such as Baltic, Greek, Turkish, Cyrillic etc. are

provided within the typeface ISO_3098_international or Block_Light_international

to be selected within the drop down menu.

In addition serif and ornamental typefaces can be chosen to be used spec. for

engraving.

Various Symbols and dedicated symbol fonts are available for selection, you can find

easily when checking the box Show symbol fonts only.

With the selection of the symbol font IEC 60414 you can find 11 sub folders within the

drop down menu to select symbols from. The font Symbol 1 and Symbol 2 are

showing additional technical symbols.

A detailed list of the available symbols you can find under > Help

from the main menu.

You can select the check box within the font selection in order to show

> Symbol fonts only

.

Page 16 of 67

Page 17

Note:

It is not possible to mix fonts and symbols per tag right away. If like to do so, please

create text boxes for the tag with the layout feature, as each box can be used with its

own font or symbol. Details you can find in chapter 10.

- Parameter settings

In the lower part of the window you can modify specific settings with reference to the

relevant output device.

For the plotter you can set plotter pen size and plotter pen speed, for the engraver you

can set tool size (see note), spindle revolution, engraving and penetration speed.

- Engraving tool size

The size of the engraving needle respective diameter of the cutter needle can be set

within the combo box.

Note:

Usually the tool size will be set according the font height using the formula 1/10 of the

height, e.g. 7 mm font height => .7mm tool size.

Click on the Arrow icon at the right side of the window to restore all factory default

settings. For the engraving the default values are well tested providing good results

from the beginning with the correct chosen material.

For the plotter the default values are set to provide a good quality plot versus speed.

All of the parameter settings can be changed before sending the data to the relevant

output device, details you can find in chapter 9.

- Mirror labeling

When checking the box Mirror labeling, the output on the engraver will be mirrored.

The respective tag will indicate the activated feature in a different color.

For this function specific reverse engraving material is needed, as engraved from the

back side and readable from the front side it is used for harsh environments, such as

food and oil industry.

In the middle of the window, you will see three tabs:

Multiple labeling – Consecutive labeling – Import labeling

Page 17 of 67

Page 18

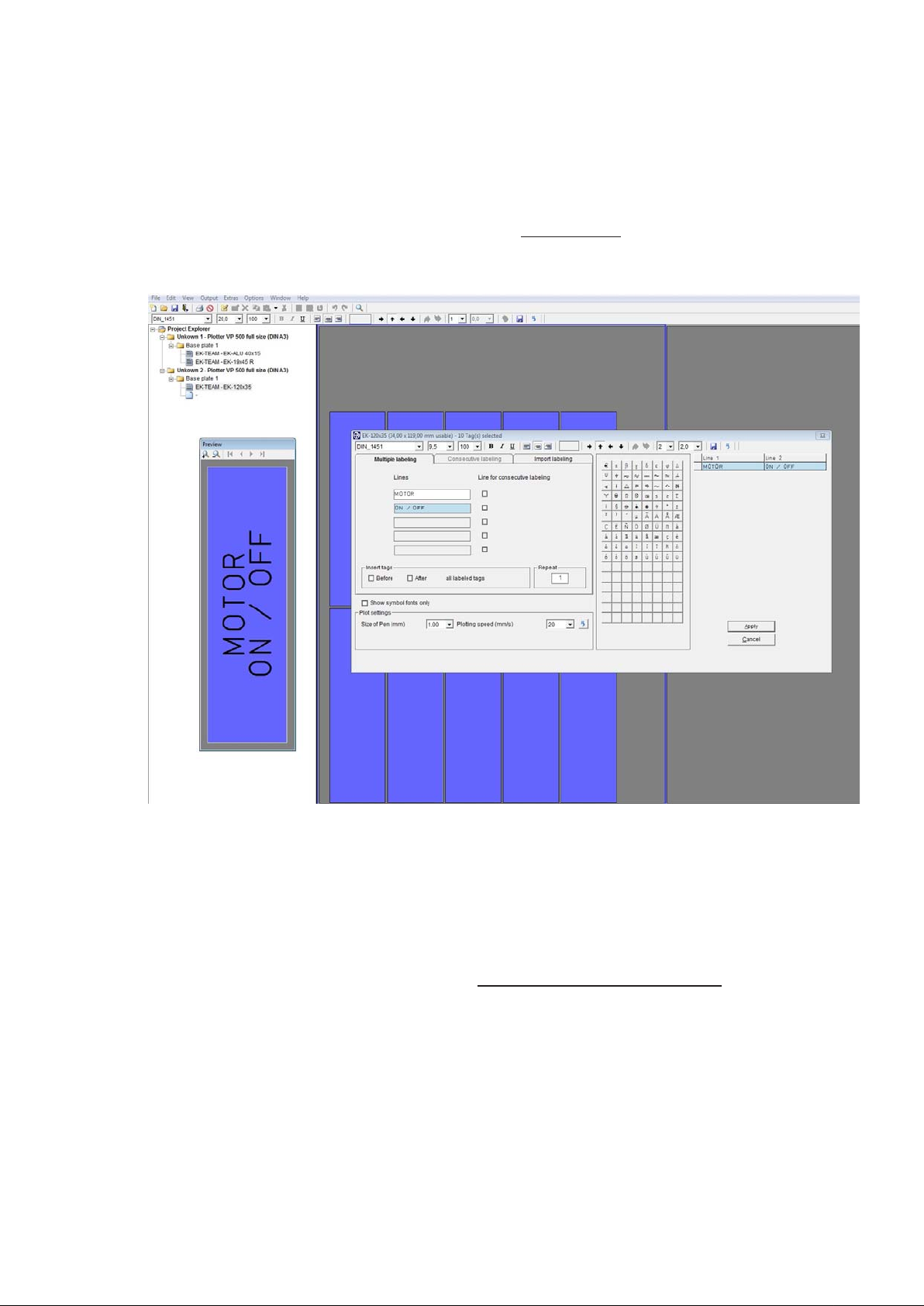

8.4.1 Multiple labeling

The relevant number of lines for editing will be opened according to the number of

lines set for each tag. You can now enter a suitable text and specify the number of

tags to be labeled with the same text in the > Repeat field. The entries are displayed in

the preview window. If required, you can also insert blank tags before or after the tags

you have labeled.

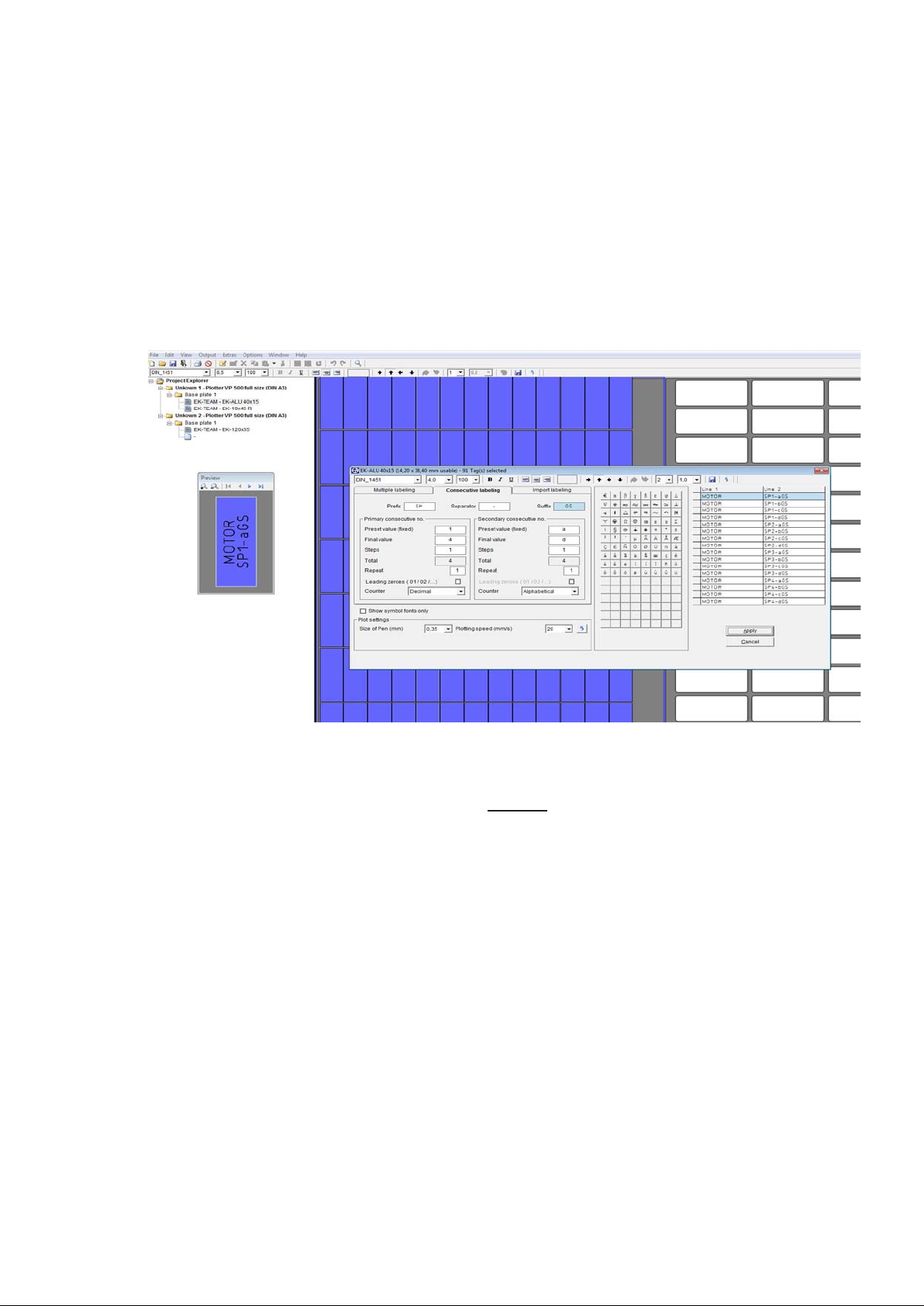

8.4.2 Consecutive labeling

If you need to number labels consecutively, you should first specify the number of lines

on the Consecutive labeling tab in which the consecutive numbering should be

inserted. To enable you to do this, the > Lines for consecutive labeling

field is activated

after the relevant lines.

After this, the program opens the consecutive labeling tab and the consecutive

labeling entries can then be added. You can enter the initial value, final value, text

prefix, text suffix, steps, counter and the number of repeats. You can opt for counting

to be ascending, i.e. the initial value is smaller than the final value, or descending,

i.e. the initial value is larger than the final value.

Page 18 of 67

Page 19

The window is split into two sections: primary consecutive number and secondary

consecutive number. This enables you to create two consecutive numbers that are

linked to one another. You can choose whatever you like as a separator.

The example shows the primary range TP 1 to 5 and the secondary

range 10 to 15-H, - has been selected as the separator, TP is thus the prefix text

and –H is the suffix text. The entries are displayed in the preview window.

When you click on the Apply button, the program takes you back to the previous tab.

If necessary, you can now add blank tags in front of each labeled tag. Likewise, you

can specify the number of series in the > Repeat

field in the Multiple labeling tab.

Page 19 of 67

Page 20

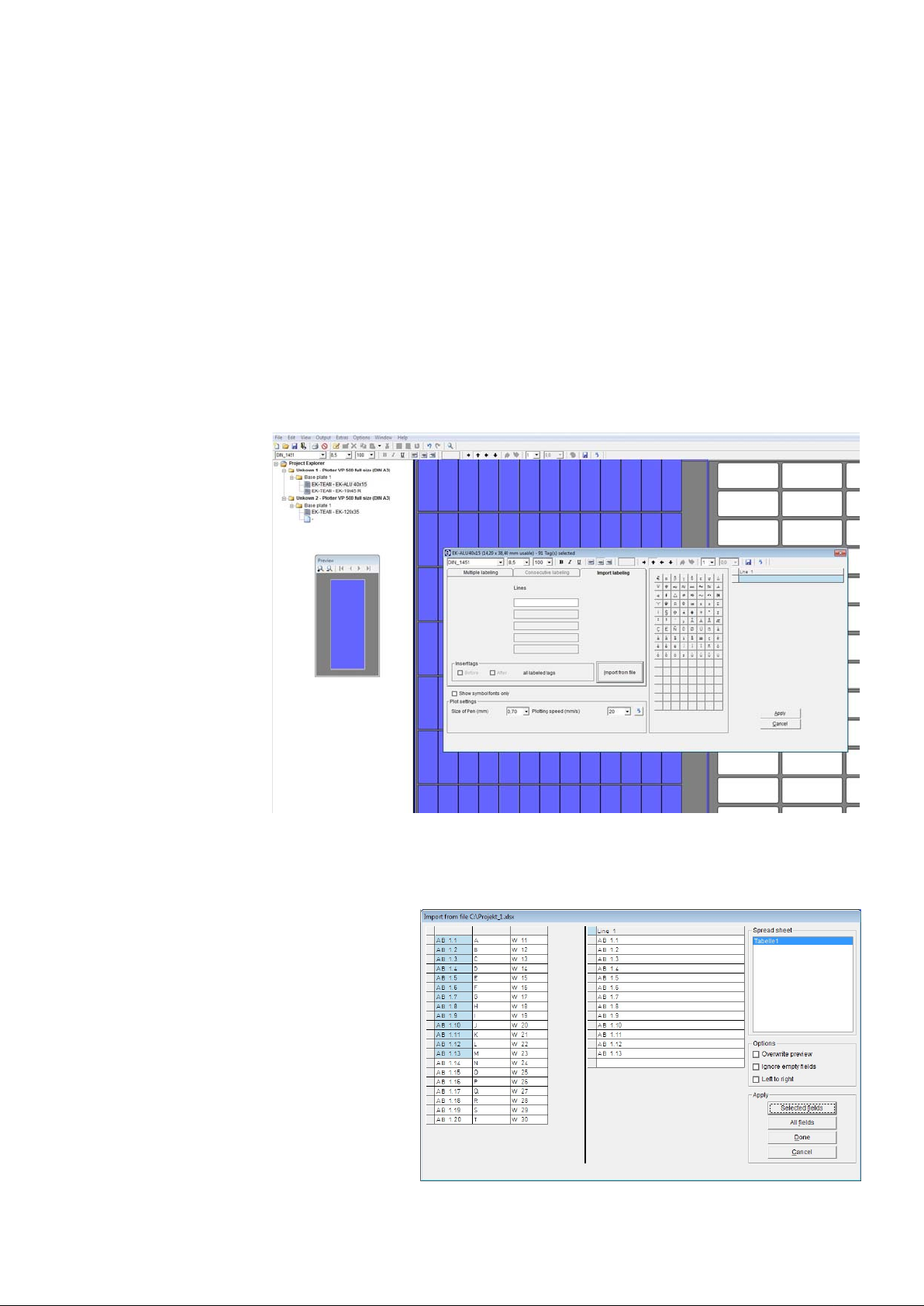

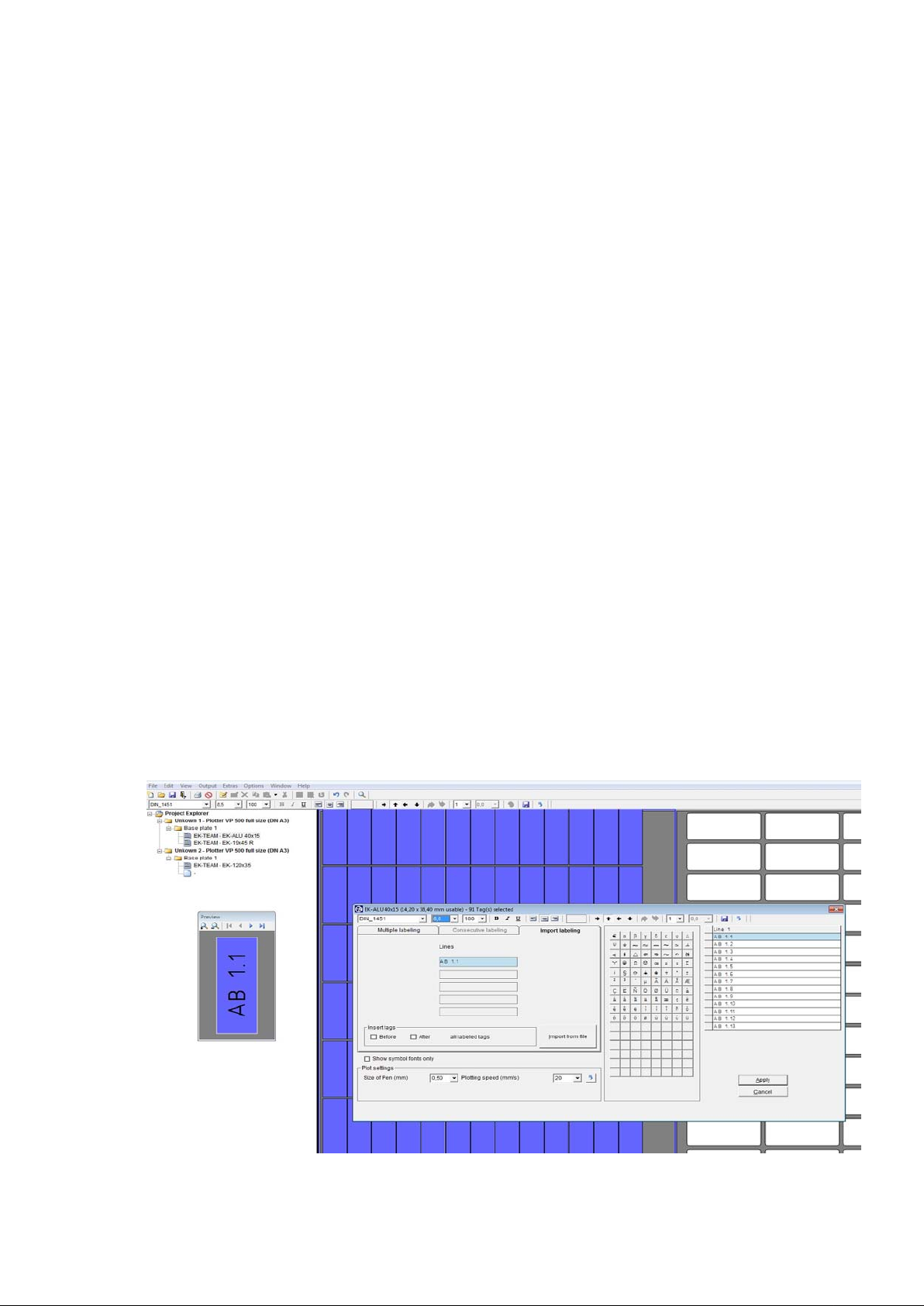

8.4.3 Importing labeling data from files

If you click on the Import labeling tab, you can import data from files.

You can copy data from programs such as E-plan, from text files or from

spreadsheet programs.

For a fast and easy way, you can copy and paste data through the clipboard.

A more efficient transfer help tool is available to do this, which enables you to extract

data from various file formats.

Click on the Import from file button to search for the file to be imported, then select it

by clicking on the file name and finally click Open to prepare the file for importing.

A window opens up and the file

to be imported is entered into a

table.

Page 20 of 67

Page 21

In this example, an Excel file was chosen. You can now select certain fields, sections

or individual cells and copy the selected data by clicking on the Selected fields

button. You can also copy all the data from the file by clicking on the All fields button.

Various options are available for importing:

- Overwrite preview

You have already imported data you do not want to use, just check the box

> Overwrite preview < and take the new selected data as new, this will overwrite the

existing data.

- Ignore empty fields

In case your spreadsheet file contains empty fields you do not want to import, just

check the box Ignore empty fields and they will be left out.

- Left to right

If you have selected 2 lines for the tag to be labeled, you can import the data e.g. from

Excel in a way that the orientation is correct from the beginning, in order to do so,

check the box > Left to right < and select two columns in the spreadsheet, when

importing.

When you have finished copying, click on the Apply button.

This will close the window and the data will be displayed in the previous window.

Page 21 of 67

Page 22

Note:

If you are importing data from text files, the data is not usually in a format available for

use. Various separators are available to enable you to separate the data properly.

You can use individual separators, or a combination of separators, such as Tab,

Space, Comma or Semicolon. You can also use other characters or letters. You can

activate this functionality by checking the < Other > box and then specifying your

requirement in the subsequent field, e.g. the letter B. Enter B in the empty field and

confirm your entry by clicking on OK.

Another option for separating when importing is to enter the number of characters.

Select < Fixed text length > and enter the number of characters after which a field

separation should be inserted, e.g. 4. Enter 4 in the empty field and confirm your entry

by clicking on OK.

If you want to import an Excel, Access or E-plan file, the program automatically

recognizes the type of file it is dealing with and provides the first table or worksheet

to be copied. You have the option of selecting additional worksheets or tables for this

file. The first worksheet or the first table are displayed by default.

Page 22 of 67

Page 23

8.5 Insert graphical elements or pictures

If you have selected an office printer or thermal transfer printer for printing the labels,

you can place as well graphics or pictures with the format JPEG, Bitmap or GIFF.

Highlight the label and select from the main menu > Edit

> Insert picture or click on the

icon insert graphic or picture.

Browse for the graphical element you want to insert and confirm with OPEN.

The element will be shown on all endless labels and on all labels of the sheets.

If you have used the layout function for dividing the label into text fields prior to placing

the graphical element, each text field can also hold a graphical element.

In addition the graphical element can be rotated in 90° steps.

To delete the graphic or picture click on the respective icon or go from the main menu

to > Edit

> Delete picture.

Page 23 of 67

Page 24

9. Output of labeling data

After entering all labeling data, the labeled tags can be printed or engraved. When you

began working, you selected the printing or engraving device you wanted to use.

If you click on the Print icon, the relevant printing output window opens for the output

device being used.

9.1 Output on plotter

The settings and information are entered or are displayed on the tabs.

Plot options – Support plates

Plot options tab

This tab enables you to set the following parameters:

- Only use pen inserted in pen holder

If you check this box, no pen is taken

out of the pen depot. Only the pen

inserted directly in the pen holder will be

used. This option is therefore always

required if you need to use pens that

are not suitable for the plotter’s pen

depot.

- Priming on pen change

If you select priming on pen change,

prior to labeling, the pen is taken to the

respective priming disk next to the pen

depot and is primed so that labeling is clear right from the first tag.

- Choose different pen in the pen depot

Two or more pens are displayed that should be used for this print instruction. If you

just want to use one plotter pen thickness, click on this option and choose the pen

to be used from the selection that subsequently appears.

- Choose plotting speed to be used

You can set different speeds for individual labeling sequences. If you just want to use

one speed, click on this option and set your required plotting speed from the selection

that subsequently appears.

Page 24 of 67

Page 25

- Pen size for graphic elements

You have the option of creating layouts on tags. These functions are detailed in the

section entitled > Create layouts on tags <. This enables you for example to create

text fields with frames, borders, etc. You can specify a particular pen for these graphic

elements.

- Plot speed for graphic elements

This enables you to select a particular plot speed for drawing graphic elements.

- Selected text will be printed

If you select this option, only the text you have previously selected will be printed.

- All selected tags will be printed

If you select this option, only the tags you have previously selected will be printed.

- All selected segments will be printed

With this option, only previously selected segments will be printed. You make your

selection by clicking on one or more segments on screen. You can select more than

one segment by holding down the Control key whilst clicking on the various

segments you wish to select.

Note:

If you are using the Plotter Basic half size (DIN A4) as the output device, some

options are not available for selection since this plotter has no pen depot and no

priming disk.

Support plates tab

This shows which labeling elements are being used and checks whether the

relevant support plate has been fitted

for the plotter. If a support plate is

missing or if the support plate is not

compatible with the labeling element,

the corresponding segment is

highlighted in red.

Note:

The Plotter Basic half size (DIN A4) has no support plate recognition and therefore

no check can be made to ensure the correct support plates have been fitted.

Page 25 of 67

Page 26

9.2 Output on engraver

The settings and information are entered or are displayed on the tabs.

Engraving options – Tag contours – Support plates

Engraving options tab

Within the upper part of the window under text and symbols you can enter couple of

settings.

When entering labeling data, various

engraving parameter will be pre-set

depending on the font size and

material. The labeling window displays

the depth of the engraving tool, the

engraving speed, the RPM for the

engraving spindle and penetration speed

used for each labeling task. If

necessary, you can change

the various settings as detailed below.

- Only one engraving tool and depth to be used

By entering the engraving data various engraving needle sizes will be assigned by the

program, depending on the font size. In the right side of the window the proposed

needle sizes are displayed. When executing the job, the system stops after the first

part with the first needle is finished, asking for exchanging the needle to the proposed

second size.

Click this option if you only want to use one tool size and depth of penetration.

- Only one engraving speed to be used

Different engraving speeds can be set for individual labeling tasks. If you just want to

use one speed, click on this option and set your required engraving speed from the

selection that subsequently appears.

- Choose RPM to be used

You can set different RPMs for the engraving spindle for individual labeling tasks. If

you just want to use one spindle speed, click on this option and set the spindle

speed required (RPM) from the selection that subsequently appears.

Page 26 of 67

Page 27

- Only one penetration speed to be used

You can set different speeds for individual labeling sequences. If you just want to use

one speed, click on this option and set your required penetration speed from the

selection that subsequently appears.

- Speed for graphic elements

You have the option of creating layouts on tags. These functions are detailed in the

section entitled > Create layouts on tags <. This enables you for example to create

text fields with frames, borders, etc. For these graphic elements, you can set the

parameters for the engraving speed, RPM for the engraving tool, and the penetration

speed for the engraving tool into the material being engraved.

The parameters are pre-set as factory default.

- Selected text will be engraved

If you select this option, only the text you have previously selected will be engraved.

- All selected tags will be engraved

If you select this option, only the tags you have previously selected will be engraved.

- All selected segments will be engraved

With this option, only previously selected segments will be engraved. You make your

selection by clicking on one or more segments on screen. You can select more than

one segment by holding down the Control key whilst clicking on the various

segments you wish to select..

- Engrave tag contour

If you check this box, the program automatically takes you to the Tag contours tab.

You can then use this tab to set

parameters according to whether you

wish to engrave tag contours, i.e.

outlines and any necessary holes. This

option is used if, for example, you are

using blank engraving plates or tags

that have not been prefabricated.

- Engrave contour around tags with lettering only

If you check this box, a frame will only be engraved around the tag if it contains

lettering.

- Engrave contours around all tags

If you select this option, a frame will be engraved around all tags.

Page 27 of 67

Page 28

- Round frame corners

If you select this option, a combo box appears in which you can set the radius to the

corners. You can set radii from 1 mm to 5 mm, graduated in steps of .5mm.

- Engrave holes on tags with lettering only

If you select this function, holes, if designed, will be engraved only on tags containing

lettering.

- Engrave holes on all tags

If you select this option, holes, if designed, will be engraved on all tags.

- Test plot

If you select this option you can test the engraving design using a pen before starting

the engraving job.

Note:

For making the test plot a special adapter, available as option, is needed in order to

hold the pen in place for plotting, inserted into the engraving head.

This feature is supported by the dedicated engraver only.

- Engrave tag contour only

Checking this box will enable you to just engrave the tag contours.

- Speed for tag contour

You can use this section to set the engraving speed, the revolution speed (RPM) of the

engraving spindle and the penetration speed for the engraving spindle for the material

being engraved. The parameters are pre-set as factory default

Note:

In principle, lettering is always engraved first, followed by the contours, as long as the

relevant parameters have been set.

- Setting the engraving material thickness

At the right side of the window you need to set the material thickness, if not already

displayed. Click on the combo box and select the material accordingly.

Note in general:

All in green indicated letterings and graphical elements such as holes, frames etc. will

be engraved according to your settings done.

Page 28 of 67

Page 29

Support plates tab

This shows which labeling elements are

being used and checks whether the

relevant support plate has been fitted

for the engraver. If a support plate is

missing or if the support plate is not

compatible with the labeling element,

the corresponding segment is

highlighted in red.

Note:

The Plotter Basic half size (DIN A4) with

engraving option and dedicated

Engraver series have no support plate

recognition and therefore no check can be made to ensure the correct support plates

have been fitted.

After all settings made the click on the OK button starts the engraving in general and

the following window opens:

The following sequence for engraving

will be done:

At the beginning all letterings, symbols then

after graphical elements followed by

contours will be engraved, if set

accordingly.

The top part of the window indicates the

respective engraving to be done,

letterings or symbols, graphical

elements, contours.

The right side the selected needle size is

indicated for you to follow or not.

The middle part provides information about the requested needle size and engraving

depth.

With a click on the Start button, the engraving will be started, right after three

additional buttons Repeat, Stop, Continue appear on the screen.

Page 29 of 67

Page 30

The button Stop will interrupt the engraving immediately and the engraving head

returns to the home position.

With the button Repeat the current engraving part can be restarted.

With the engraving part completed the button Continue takes you to the next step of

the engraving sequence, like graphical elements or contours if set up.

If no further steps are set the button

Continue is closing the engraving

window.

9.3 Printing on an office printer

The first time you send your data to be printed on an office printer, the following

message appears on screen:

When you confirm the message by clicking on OK, a window opens with the Printer

tab showing all printers available.

Page 30 of 67

Page 31

Now choose the printer you require and click on the button Test page.

A < Portrait test page > sheet is then printed on the relevant printer. Measure the top

and left margin with a ruler and enter the values in the respective boxes.

These entries are needed because all printers have different margin settings for text.

Click on OK to save these values. The program will then take you to the

< Print options > window, where you can set the following parameters for the printout:

- Specify the number of label sheets to be printed.

- Specify whether only the selected text or labels (tags) should be printed.

- Specify whether a frame should be printed around the lettering.

This function is useful if you want to cut out printed labels with scissors.

If you check this box, the program automatically takes you to the frame selection.

By clicking the relevant box, you can choose whether to plot a frame around labels

with lettering only or to plot a frame around all labels on the sheet.

If you select Plot frame only, only the frames will be printed, without any lettering.

Page 31 of 67

Page 32

9.4 Printing on a thermo transfer printer

The first time you send your data to be printed on a thermo transfer printer, the

following message appears on screen:

When you confirm the message by clicking on OK, a window opens with the Printer

tab showing all printers available.

Now select the TT printer required.

The < Increase size of tag> setting enables you to adjust lengths for unlimited strips

(Scale factor).

Page 32 of 67

Page 33

Click on OK to save these settings. The program will then take you to the

Print options window, where you can set the following parameters for the

printout:

- Enter the distance from left margin of the printing area.

- Specify whether only the selected text or labels (tags) should be printed.

By clicking on the tab Strip options you can modify the strip output.

- Increase size of tags to compensate width of terminal blocks

With the change of the value the width of the sections of the strip can be increased or

decreased to match the tag size.

- Raster mark showing as

Selecting, if raster mark should be printed, either All after each segment, Last only at

the end of last segment or None.

- Raster mark

- Selecting, if raster mark should be printed as Line or Dot.

- Specify whether only the selected text or labels (tags) should be printed.

Page 33 of 67

Page 34

10. Create layouts on tags

If you want to arrange text fields or graphic elements on tags, the program has a

user-friendly layout option that you can use for this purpose. This function is helpful

when you want to divide a tag into various fields. It gives you the opportunity to use

various font styles, font sizes and symbols in the individually created text fields. This

function is also useful if you want to create individual labeling fields on prefabricated

rating plates.

Call up the element for which you need to create a layout, select a tag and select

> Edit tag layout from the drop-down menu

.

Page 34 of 67

Page 35

After choosing the layout, the following window appears on screen.

The tag size is displayed in the top left field of the window.

Underneath that, you will see various components available that you can set up on the

tag.

For example, if you want to create a < text field with frame >, click on the

relevant component. You should then use the mouse to position the cursor in the

right-hand side of the window in the tag displayed there, click with the mouse to

specify where the text field should begin, and use the mouse to define the text field.

This will create your text field.

For other selections proceed the same way. You can also place circle / ellipse,

square / rectangle or separator lines on the tag.

Now you can click on the text field and move it to wherever you want it. You can also

enter the coordinates, such as the distance from the margin, height and width of tag,

directly into the relevant fields and confirm by pressing Enter. The entry is immediately

applied and the preview is updated.

Note:

It is easy to inadvertently move the graphic elements you have created when you

click on them with the mouse. In order to avoid moving the elements in error, you can

fix their positions by calling up the drop-down menu.

After fixing the position, you can still change the size and position of graphic elements

by entering the coordinates directly into the relevant fields.

Page 35 of 67

Page 36

If you are using a plotter or engraver as your output device, you can measure the text

fields with the plotter. To do this, click on the text field whose measurements you wish

to take and select >Take Measurement of text field function from the drop-down

menu.

The following window opens up:

Insert a pen directly into the

pen holder or take the spindle

out of the engraving head and

insert instead the optical

measurement tool, available as

option.

Then click on the left

Initial position button. The plotter

moves to upper left corner of the total

plot area. You can now go to the text

field in the top left-hand corner and

use the cursor keys to take the tip of

the pen or cross of the tool right to

the corner of the text field.

You can choose the step size for each click of the cursor button.

Once you have defined the upper left corner, go to the lower right corner of the text

field by clicking on the second Initial position button. Proceed as before. When you

click on Apply, the coordinates will be applied.

You can duplicate or delete components that have been created.

You also have options available for setting the alignment of text fields or graphic

elements that have been set up.

If, as shown in the example, you have used the mouse to click on the three

components whilst holding down the Control key and then clicked on the Vertical

alignment button, the elements created are aligned vertically. Other layout options are

available.

You can alter the size of the preview window to make it larger or smaller.

Page 36 of 67

Page 37

Once the layout is completely finished, there are two options available for you to apply

the layout:

Click on the Apply button to apply the layout to the previously selected tags. You can

now enter labeling data straight into the fields.

If you want to save this layout on the tags, click on the Save as button.

You then need to save this tag with the layout you have created with a new name.

When you want to use this labeling element with the layout at a later date, you can call

up the labeling element in the > User defined < folder.

Page 37 of 67

Page 38

11. Designer / Layouter

This is used for setting up your own marking elements, label sheets, endless labels or

endless strips, engraving tags or rating plates for engraving.

There are 4 different versions of the Designer/Layouter.

These can be selected on the menu by clicking on > Extras

> Tags and strips (Plotter)

> Tags (Engraver)

> Label sheets (Office printer)

> Endless labels and strips (Thermo transfer printer)

11.1 Setting up marking tags and strips for plotters

The Designer is called up using the following menu item:

> Extras > Designer/Layouter for > Tags and strips (Plotter).

> Designer / Layouter for

The following window opens up:

Here you can create a new

marking element by clicking

on the New button.

First enter the name of the

marking element you wish to

create in the left-hand window.

Next, you have to make the

following settings:

Use the plotter's support plate

recognition function.

If you have a plotter with support plate recognition, it is advisable to use this function

to make it easier later on to find the marking element that you have created. To do this,

the plotter must be switched on and the relevant support plate positioned on the

plotter.

If you do not want to use support plate recognition, or are using a plotter with no

support plate recognition function, click on Specify type of support plate.

Now you have to select the support plate on which you want to set up the tag or

element.

In the next stage you define the properties of the marking element.

Page 38 of 67

Page 39

Here you can choose between three options:

- Design tags within single group

The marking element has only one tag size.

- Design tags within multiple groups

The marking element has two or more tag sizes.

- Design strips

With this function you can create marking strips with the size needed, dividing them

into horizontal and vertical sections.

Selecting one of the dividing directions opens another window for entering the

additional strip parameter.

Page 39 of 67

Page 40

11.1.1 Design a marking element with one tag group

Enter the tag parameters for the marking element.

If you do not have the exact data to hand, it is easy to use the plotter to measure the

tags (recommended).

To measure using the plotter, all

you have to enter is the number

of tags along the X- and Y-axes.

All the other data can be easily

calculated using the program

and with the help of the plotter.

You can also specify the

sequence in which the tags will

be labeled. The sequence for

labeling can either be from

Upper left > to Upper right (line

by line), or from Upper left > to

Lower left (column by column).

Attention:

For processing to continue, it is essential that the plotter is switched on and the

marking element which is to be set up is positioned on the plotter, with the appropriate

support plate. Insert a pen directly into the plotter's pen holder. As an option, there is

also an optical measuring tool available which you can use to calculate and specify the

tag parameters. This tool is inserted like a pen directly into the plotter's pen holder.

When you have entered all or just some of the tag parameters, but at least the number

of tags along the X- and Y-axes, click on the Take measurements button and the

following window opens up:

To take measurements, proceed as follows:

First of all, specify the exact

position of the upper left corner

of the first tag in the matrix. To

do this, click on the

Initial position button left in the

first tag window. The plotter's

writing arm now moves to the

upper left corner of the plotter

field. You can use the relevant

cursor buttons as shown to

move to the exact position of the upper left corner of the first tag.

Page 40 of 67

Page 41

You can choose the step size for each click of the cursor at the top right of the

window. When you have moved to the position for the corner, you can use the

Pen Up/Down button to check that you have reached the exact position. The relevant

coordinates are displayed in mm, from the starting position of zero. Now specify the

exact position of the lower right corner for the first tag.

Do this following the same procedure as detailed above for locating the upper left

corner.

Now specify the upper left corner of the last tag in this matrix.

Go to the last tag bottom right and proceed just as before.

Specifying these three points completes all measurements for this marking element.

You can now save the values you have calculated by clicking on the Apply button.

The < Take measurements > window is closed and the program takes you back to

the previous page.

If you also click on the Apply button here, you will see the marking element that has

been set up. You can now check that all data have been correctly calculated. If any

error messages or notices are displayed, you should check your data again or allow

automatic correction.

Having completed the marking element, you now also have the option of positioning

text fields and graphic elements on the tags. Creating text fields like this is always

useful if you want to divide the tag up into different fields, so that you can later use

different text sizes, font types or symbols on the tag. See Section 10 of this manual for

information on how to set up a layout.

After you have specified the design and, if you wish, also the layout, click on Back to

close the Designer or Layouter.

The program takes you back to the main window, which you can then close by clicking

on the Close button.

You can select the labeling element you have created in the folder

>User defined

under > Manufacturer and call it up for lettering.

Page 41 of 67

Page 42

11.1.2 Design a marking element with more than one tag group

To set up groups of tags of different sizes, you proceed exactly as described in the

previous section.

In order to assign the tag groups, on the left of the window you must specify

appropriate names for the different tag groups. Once you have specified the name for

a tag group, you can then

enter the tag parameters

and measure the tags and

then create a layout if

required.

When you have finished

one tag group, you can set

up more tag groups.

11.1.3 Design marking strips

You have already specified the name for the marking strip, X-strip.

Page 42 of 67

Page 43

The next thing to do is to define the strip parameters:

First select the alignment of the strip. Lay the strip(s) vertically or horizontally on the

plotter.

Then enter the length and width of the strip, followed by the number of strips lying on

the plotter.

By using the Take measurements function, it is easy to calculate the start coordinates

and the strip spacing. Proceed exactly as described in the previous section.

After you have measured the strips and pressed Apply, you can specify a layout for

the strips in the right-hand section of the window.

You can subdivide the individual strips using horizontal and vertical scale factors.

First, if required, divide the strips into horizontal sections.

First define the height of the first section, by entering the height in mm in the

> Partition 1

field. The remaining height is then transferred into > Partition 2. In this

way, you can subdivide the strips into a maximum of 5 sections. When you have

finished dividing them up into sections, first click on the Apply button. This completes

the horizontal subdivision.

Next, you can make a vertical subdivision for each section. Click on Crosswise for the

relevant strip.

Then the following window opens up:

To enter the required subdivision of the strip, proceed as

follows:

First enter the width and then the number of tags.

By clicking on the Add button, the data are transferred to the

field below. If the strip is not yet fully divided up, you will be

shown the length of strip that is still available. Now you can

specify other tag widths.

When you click on Apply, the program takes you back to the

previous window and displays the subdivision that you have

specified.

In this way you can subdivide the individual sections using

different tag widths in succession as required.

Page 43 of 67

Page 44

When you have finished all the subdivisions, close the Designer.

You can select the labeling element you have created in the folder

> User defined

under > Manufacturer and call it up for labeling.

Note:

If you have created the labeling data for a strip and are producing the plotting data on

the plotter, there is the opportunity to define various options for plotting.

On the tab Strip options, you can determine whether cutting marks as

separating lines or dots should also be plotted.

Page 44 of 67

Page 45

11.2 Setting up engraving tags for engraving units

Call up the Designer under > Extras > Designer/Layouter for > Tags (Engraver).

The following window opens up:

Here you can create a new

engraving element (individual

tags or tag groups) by clicking

on the New button.

First enter the name of the

engraving element you wish

to create in the left-hand

window.

Then you can define whether

you want to use the plotter`s

support plate recognition

function.

Use the plotter`s support plate recognition function.

If you have a plotter unit with support plate recognition, it is advisable to use this

function to make it easier later on to find the engraving element that you have created.

To do this, the plotter must be switched on and the relevant support plate positioned

on the plotter.

If you do not want to use support plate recognition, or are using a plotter with no

support plate recognition function, click on < Specify type of support plate >.

Pre-select is the DIN A4 support plate, select another type on which you want to set up

the element if required.

If none of the suggested support plates are required, click on

< Use complete labeling area >, also needed with the use of custom made support

plates.

Then you define the engraving material and enter the thickness of the material in the

box at the bottom of the window.

Page 45 of 67

Page 46

In the next stage you define the properties of the marking element.

Here you can choose between three options:

- Design tags within single group

The engraving element has only one tag size.

- Design tags within multiple groups

The engraving element has two or more tag sizes.

- Design strips

With this function you can create marking strips with the size needed, dividing them

into horizontal and vertical sections.

Selecting one of the three options opens another

window for entering the additional parameter.

Page 46 of 67

Page 47

11.2.1 Design tags within single group

Now there are various ways you can create your engraving tags.

- You want to create prefabricated sign / rating plate

First define the shape of the tag, square/rectangle or circle/ellipse.

Then enter the required tag size.

When you click on the Apply button, the tag you have created will be displayed.

If you like to create single text fields e.g. on a rating plate, click on the button

Create layout for text and graphic.

Details you can find in section 10.

With a click on the button Back takes you back to the previous window where you can

add additional tags or the button Close will exit the designer.

You can select the labeling element you have created for engraving in the folder

> User defined

under > Manufacturer and call it up for labeling.

Page 47 of 67

Page 48

- You want to create your tags on a blank plate.

First define the shape of the tag, square/rectangle, circle/ellipse, push button.

Then enter the required tag size and the number of tags in X and Y direction, or

click on < Automatic tag partitioning >.

When you click on the Apply button, the tags you have created will be displayed.

The program calculates the possible number of tags to be created on the selected

field. In case you enter the number of tags in X and Y direction manually and click the

Apply button, the tags will be displayed as well, any error will be indicated for you in

order to reduce the number of tags if the number in either direction do not match.

IN addition you can enter the start position and the distance between the tags,

You can also specify the sequence in which the tags will be labeled. The sequence for

labeling can be either from upper left > to upper right (line by line), or from upper left

> to lower left (column by column).

Having completed the engraving tags, you now also have the option of positioning

text fields and graphic elements on the tags. Creating text fields like this is always

useful if you want to divide the tag up into different fields, so that you can later produce

different text sizes, font types or symbols on the tag.

To do this, click on the Layout for text and graphics button.

See section 10 of this manual for a description of how to set up a layout.

If you now want to make holes or cutouts in the tags you have created, or round off the

corners, click on the Holes, cut-outs, frame corners button see below details.

You want to enter the data for an existing tag plate, please proceed as described

above. The exact position you can define using the take measurement function.

When you have entered all or just some of the tag parameters, but at least the number

of tags along the X and Y axes, click on the Take measurements button and the

following window opens up:

Page 48 of 67

Page 49

Attention:

For processing to continue, it is essential that the engraver is switched on and the

engraving element which is to be set up is positioned on the engraver, with the

appropriate support plate. First take the engraving spindle out of the engraving head

and then insert the optical measuring tool into the engraving head, available as an

option.

To take measurements, proceed as follows:

First of all, specify the exact position of the upper left corner of the first tag in the

matrix. To do this, click on the Initial position button left in the first tag window.

The engraver's engraving arm now moves to the upper left corner of the engraving

field. You can use the relevant cursor buttons as shown to move to the exact position

of the upper left corner for the first tag.

You can choose the step size for each click of the cursor at the top right of the

window. Go to the exact position of the top corner. The relevant coordinates are

displayed in mm, from the starting position of zero. Now specify the exact position of

the lower right corner for the first tag.

Now specify the upper left corner of the last tag in this matrix. Go to the last tag bottom

right and proceed just as before.

Specifying these three points completes all measurements for this engraving element.

You can now save the values you have calculated by clicking on the Apply button.

The < Take measurements > window is closed and the program takes you back to

the previous page.

If you also click on the Apply button here, you will see the engraving element that has

been set up.

You can now check that all data have been correctly calculated. If any error messages

or notices are displayed, you should check your data again or allow automatic

correction. Now the engraving element is created.

After you have specified the design click on Back to close the window, in the main

window you can design additional tags or you can close by clicking on the Close

button.

You can select the engraving element you have created in the folder

> User defined under > Manufacturer and call it up for engraving.

Page 49 of 67

Page 50

- Holes, cut-outs, frame corners

If you now want to make holes or cut-outs in the tags you have created, or round off

the corners, click on the Holes, cut-outs, frame corners button.

The following window then opens up:

Here you can round off the corners by clicking on the > Round frame corners

field and selecting the radius.

You also have the option of making holes or cut outs in the tag.

You can choose from the following:

- holes in a circle or ellipse

- cut-outs rectangle or in a square

- holes with tabs or notches

- elongated holes

After selecting, go to the tag with the mouse and draw a circle or a cut-out.

When selecting holes with tabs or notches you can choose the number of tabs or

notches, used for switches, push-buttons etc.

Later you can use the coordinates to define the position and size of the circle or

cut-out exactly.

There are a number of alignment functions available.

Use the Apply button to save the data and close the window.

Page 50 of 67

Page 51

Having completed the engraving tags, you now also have the option of positioning text

fields and graphic elements on the tags. Creating text fields like this is always useful if

you want to divide the tag up into different fields, so that you can later produce

different text sizes, font types or symbols on the tag.

To do this, click on the Layout for text and graphics button.

See Section 10 of this manual for a description of how to set up a layout.

After you have specified the design and, if you wish, also the layout, click on Back to

close the Designer or Layouter.

The program takes you back to the main window, which you can then close by clicking

on the Close button.

You can select the engraving element you have created in the folder

> User defined under > Manufacturer and call it up for engraving

11.2.2 Design tags within multiple groups

To set up groups of tags of different sizes, you proceed exactly as described in the

previous section.

In order to assign the tag groups, on the left of the window you must specify

appropriate names for the different tag groups. Once you have specified the name for

a tag group, you can then enter the tag parameters and measure the tags and then, if

you wish, add holes, cut-outs and radii.

Then a layout can be created.

When you have finished one tag group, you can set up

more tag groups.

Page 51 of 67

Page 52

11.2.3 Design marking strips

You have already specified the name for the marking strip, “X-strip”.

The next thing to do is to define the strip parameters:

First select the alignment of the

strip,lay the strip(s) vertically or

horizontally on the engraver.

Then enter the length and width

of the strip, followed by the

number of strips lying on the

engraver.

By using the < Take measurements > function, it is easy to calculate the start

coordinates and the strip spacing.

Proceed exactly as described in the previous section.

After you have measured the strips and clicked on Apply, you can specify a layout for

the strips in the right-hand section of the window.

You can subdivide the individual strips using horizontal and vertical scale factors.

First, if required, divide the strips into horizontal sections.

First define the height of the first section, by entering the height in mm in the

> Partition 1

field. The remaining height is then transferred into > Partition 2. In this

way, you can subdivide the strips into a maximum of 5 sections.

When you have finished dividing them up into sections, first click on the Apply button.

This completes the horizontal subdivision.

Next, you can make a vertical subdivision for each section. Click on Crosswise for the

relevant strip.

Page 52 of 67

Page 53

Then the following window opens up:

To enter the required subdivision of the strip, proceed as

follows:

First enter the width and then the number of tags.

By clicking on the Add button, the data are transferred to the

field below. If the strip is not yet fully divided up, you will be

shown the length of strip that is still available. Now you can

specify other tag widths.

When you click on Apply, the program takes you back to the

previous window and displays the subdivision that you have

specified.

In this way you can subdivide the individual sections using

different tag widths in succession as required.

When you have finished all the subdivisions, close the

Designer.

You can select the labeling element you have created in the

folder

> User defined under > Manufacturer and call it up for labeling.

Note:

If you have created the labeling data for a strip and are producing the engraving data

on the engraver, the horizontal and vertical separating lines will be engraved.

Page 53 of 67

Page 54

11.3 Setting up label sheets for office printers

Call up the Designer under > Extras > Designer / Layouter for > Label sheets

(Office printer).

The following window opens up:

Here you can create a new label sheet by

clicking on the New button. First enter the

name of the label sheet you want to create in

the window.

Then click on Edit and another window opens:

Now you have to enter the appropriate tag

parameters for your label sheet here. If you

do not have the data directly to hand, then

you must enter the width and height of the

tag, the distance from the top left-hand

corner of the first tag (start coordinates) and

the tag spacing along the X- and Y-axes,

using a ruler. You also have to enter the

number of tags along the X- and Y-axes.

You can also specify the sequence in which

the tags are printed.

Page 54 of 67

Page 55

The sequence for labeling can be either from upper left > to upper right (line by line),

or from upper left > to lower left (column by column).

When you click on the Apply button, the tags you have created are displayed on the

screen.

Having completed the labels, you now also have the option of positioning text fields

and graphic elements on the labels. Creating text fields like this is always useful if you

want to divide the label up into different fields, so that you can later use different text

sizes, font types or symbols on the label.

To do this, click on the Create layout for text and graphic button.

See Section 10 of this manual for a description of how to set up a layout.

After you have specified the layout if you wish, click on Back to close the Layouter.

The program takes you back to the main window, which you can then close by clicking

on the Close button.

You can select the labeling element you have created in the folder

< User defined under > Manufacturer and call it up for printing.

11.4 Setting up endless labels and strips for thermo transfer printers

Call up the Designer under > Extras

> Designer for > Endless labels and strips

(Thermo transfer printer).

The following window opens up:

You can now create new endless labels or

endless strips here by clicking on the New

button.

First enter the name of the label or strip that you

want to create in the window.

Now you have to specify whether you want to

create an endless label or an endless strip.

Click on either Label or Strips.

After you click on one of those options, the

relevant window opens.

Page 55 of 67

Page 56

11.4.1 Design an endless label

Enter the width and height of the tag here.

If, on your endless roll, you have more than

one label side by side, enter the number of

labels in the appropriate field.

You must also enter the tag distance in X and Y.

Page 56 of 67

Page 57

Note:

When the labels are subsequently printed out on a thermo transfer printer, the tag

spacing along the Y-axis is detected by a light barrier. The entry on the tab only serves

to ensure that it displays correctly on the screen.

When you click on the Apply button, the tags you have created are displayed on the

screen.

Having completed the labels, you now also have the option of positioning text fields

and graphic elements on the labels. Creating text fields like this is always useful if you

want to divide the label up into different fields, so that you can later use different text

sizes, font types or symbols on the label.

To do this, click on the Create layout for text and graphic button.

See Section 10 of this manual for a description of how to set up a layout.

After you have specified the layout if you wish, click on Back to close the Layouter.

The program takes you back to the main window, which you can then close by clicking

on the Back button.

Click on Close to close the Designer.

You can select the labeling element you have created in the folder

< User defined under > Manufacturer and call it up for printing.

11.4.2 Design an endless strip

First decide on the size of the strip and enter its length and width.

Then you can divide up the strip using horizontal

and vertical scale factors.

If required, divide the strip into horizontal

sections.

First of all, specify the height of the first partition,

by entering the height in mm in the > Partition 1

field. The remaining height is then transferred into

> Partition 2. In this way you can subdivide the

strip into a maximum of 5 partitions.

Page 57 of 67

Page 58

When you have finished dividing the strip into partitions, you first click on the Apply

button. This completes the horizontal division.

After that, you can make a vertical division for each partition. Click on Crosswise for

the relevant strip.

Then the following window opens up:

To enter the required subdivision of the strip,

proceed as follows:

First enter the tag width and then the number of

tags.

By clicking on the Add button, the data is

transferred to the field below. If the strip is not yet

fully divided up, you will be shown the length of strip

that is still available. Now you can specify other tag

widths.

When you click on Apply, the program takes you

back to the previous window and displays the

subdivision that you have specified.

In this way you can subdivide the individual

partitions using different tag widths in succession

as required. When you have finished all the

subdivisions, close the Designer.

You can select the labeling element you have

created in the folder < User defined under >

Manufacturer and call it up for printing.

Note:

If you have created the labeling data for a strip and are printing out the print data on a

thermo transfer printer, there is the opportunity to define various options for printing.

You can determine whether dividing marks as separating lines or dots should also be

printed.

Page 58 of 67

Page 59

12. Import/Export of labeling elements and labels created with

various designer versions

Elements created by the user, as detailed in the preceding sections, can be imported

and exported. This provides an opportunity to swap elements that you have defined

yourself. To export a marking element, click on the Export button and then

select the location where the txt file should be saved. You are advised to use the

name of the element as the file name.

Exported files can be imported to another

workstation. To import, click on the

Import button and select the file to be

imported.

The new element appears in the list of

marking elements in the > User defined

folder.

If the database already contains an

element with the same name, the

element that already exists can be

overwritten.

13. Special functions using plotter and engraving versions

13.1 Access of graphic files for plotting or engraving

Graphic files, designed and created by e.g. CorelDraw, can be sent to the plotter or

engraver, assuming the files are saved as .plt file extension (HPGL).

If you like to send the file, please go to > Extras

menu.

The following window appears:

Clicking on Search you can browse through the folders selecting the file to be plotted.

Further settings can be changed:

- Priming on pen change, check click box

- Plotting speed, range 5 to 40 mm/sec

The file will be sent to the plotter by

confirming the selection with OK.

> Send HPGL file from the main

Page 59 of 67

Page 60

If you like to send the file to the engraver the following window appears:

Clicking on Search you can browse through the folders selecting the file to be

engraved.

Further settings can be changed:

- Engraving speed, range 2 to 20 mm/sec

- Revolution (RPM) spindle, range 5000 to 50000 RPM

- Penetration speed, range 2 to 6.5 mm/sec

The file will be sent to the engraver by confirming the selection with OK.

13.2 Scale factor

The data in the database have been carefully entered and checked. However, they are

not subject to regular checking. Thus over time, the tags to be printed could have their

mechanical measurements altered, particularly the scale, i.e. the distances of the

markers from one another in both the x- and y-directions.

Possible influences include workstation temperature and humidity.

However, production influences, such as materials and temperatures when making the

tags, could also have an impact such that there could be deviations from the original

values set. Deviations > 1 mm are quite possible across the entire length and width as

well as a shift in the start point.

In order to make any correction to possible deviations, select from the main menu

> Extras

> Shift of start point and correction of scale factor.

If you notice the output on the tag is not centered, you can change the start point and

the scale factor in x- and y-direction accordingly.

Page 60 of 67

Page 61

To make a correction, proceed as follows:

Turn on the plotter and select a tag on the segment and then follow the menu path

> Extras > Shift of start point and correction of scale factor.

The tags are now all colored red and the following window appears:

Insert a plotter pen into the pen holder or the optical measurement tool with hairline

cross into the engraving head (spindle location) and click on the button

Initial Position in the far left field.

The plotter moves to the upper left corner of the first tag. The peak of the