Page 1

CONTA SIGN CS

Easy-Marking-System

©

Guide to Using

CONTA Sign CS 4.3 Labeling Software

Release: June 30,2007

Page 2

Guide to Using

CONTA Sign CS 4.3 Labeling Software

Content

1. System Requirements..................................................................................3

2. Software Installation .....................................................................................3

3. Selecting the Output Device and Changing Settings....................................3

4. Definitions.....................................................................................................4

5. Getting used to the Software........................................................................5

5.1 Create a new project..............................................................................5

5.2 Opening an existing project....................................................................5

5.3 Selecting tags / marking elements..........................................................5

5.4 Marking the selected tags / marking elements.......................................6

5.5 One-time, multiple and serial modes......................................................8

5.6 Importing files.........................................................................................9

5.7 Row labeling.........................................................................................10

5.8 Marking of endless strips......................................................................13

5.9 Copying functions.................................................................................14

5.10 Zoom function.....................................................................................15

5.11 Control print of the labeling data.........................................................16

5.12 Preferences........................................................................................16

5.13 No. of projects and base plates allowed.............................................16

5.14 Information menu > ?

.........................................................................16

6. Starting the Print Job with the Plotter.........................................................17

7. Scale Factor ...............................................................................................20

8. Designing new Tags...................................................................................21

8.1 Example for same sized tags for plotting and engraving......................22

8.2 Example for different sized tags for plotting and engraving .................25

8.3 Example for same sized labels for endless TT-Printer.........................27

8.4 Example for same sized labels for Office Printer .................................28

8.5 Example for different sized labels for Office Printer.............................29

8.6 Import / Export of User elements..........................................................30

1

Page 3

Guide to Using

CONTA Sign CS 4.3 Labeling Software

Content

9. Engraving Tags...........................................................................................31

9.1 Engraving with EMS-2 Engraver..........................................................31

9.2 Starting the Engraving..........................................................................33

10. Calibrating the Plotter...............................................................................37

11. Firmware update of the plotter..................................................................38

12. Printing on other output devices...............................................................39

12.1 Printing on endless TT-Printer............................................................39

12.2 Printing on standard Office Printer.....................................................40

2

Page 4

1. System Requirements

Pentium II PC (200 MHz or higher)

64 MB RAM

CD-ROM drive

VGA graphics adapter and monitor (256 colors, resolution 640 x 480)

Operating system: Windows 98, ME, NT, 2000, XP, Vista (32bit)

Mouse

2. Software Installation

First close all other applications. Insert the “CONTA Sign CS” CD into the CD-ROM

drive of your PC. Installation will start automatically. Please follow the on-screen

instructions. If the auto-start feature has been switched off on your PC, please start the

set-up program by double-clicking.

When the installation is complete, connect the plotter to the PC with the parallel

interface cable or USB -cable and switch the plotter on.

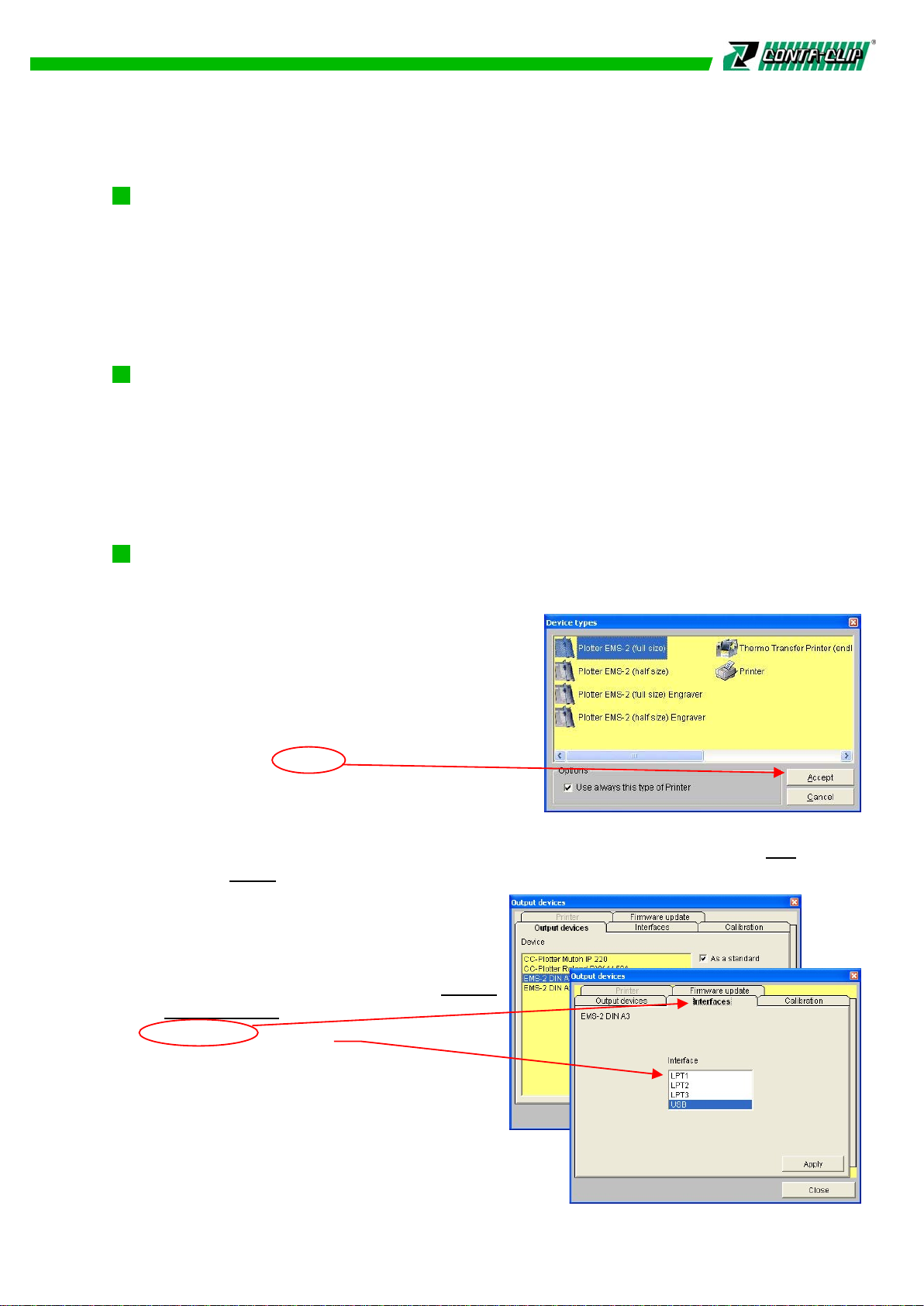

3. Selecting the Output Device and Changing Settings

Now start the CONTA Sign CS program by a double click on the symbol located on

the desktop. Before working with the software, you must first install the plotter you

intend to use. To do this, select the output

device in the window. As example, if you are

using the

EMS-2 select the output device and check the

clickbox as Use always this type of Printer.

You will not be asked any more in the future.

With the button Accept the setting will be

saved and the window be closed.

If you like to connect another output device in

the future, like the EMS-2 (half size) Engraver, endless Thermal-Transfer Printer or an

Office Printer, you can always get back to the window from the Menu bar > File

choose > New. The EMS-2 is default set as standard output device, connected

through the USB.

In addition, the EMS-2 has a parallel port,

to be used with the CONTA Sign CS. For

using you need to change the output to

parallel, go to the main menu bar > Output

> Output device and check the

Interface tab. Confirm LPT1 as the new

interface port and click on Apply.

Connect the parallel cable on both ends

and switch on the EMS-2, the software will

recognize the plotter accordingly.

and

3

Page 5

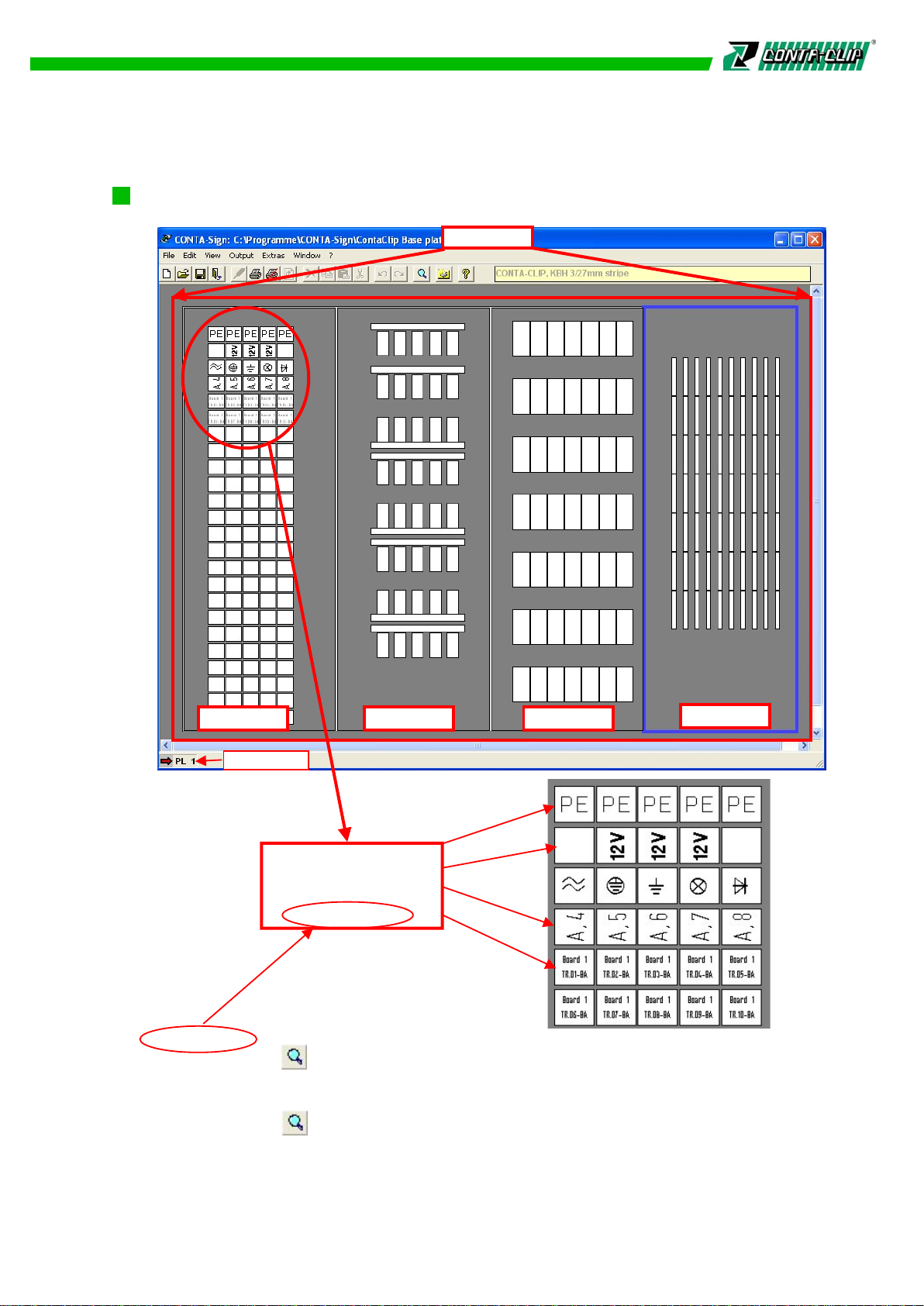

4. Definitions

Base Plate

Segment 1

Plate 1

Example of

Label Sequences

displayed with

Zoom Function

Zoom Function

click on Zoom Icon Zoom on

position the mouse and click the right mouse button Zoom in (enlarge)

position the mouse and click the left mouse button Zoom out (reduce)

click on Zoom Icon Zoom off

Segment 2

Segment 3

Segment 4

4

Page 6

5. Getting Used to the Software

Our prime concern when developing this software was that users should be able to

carry out all labeling jobs quickly and easily.

For this reason, every task follows the same basic pattern:

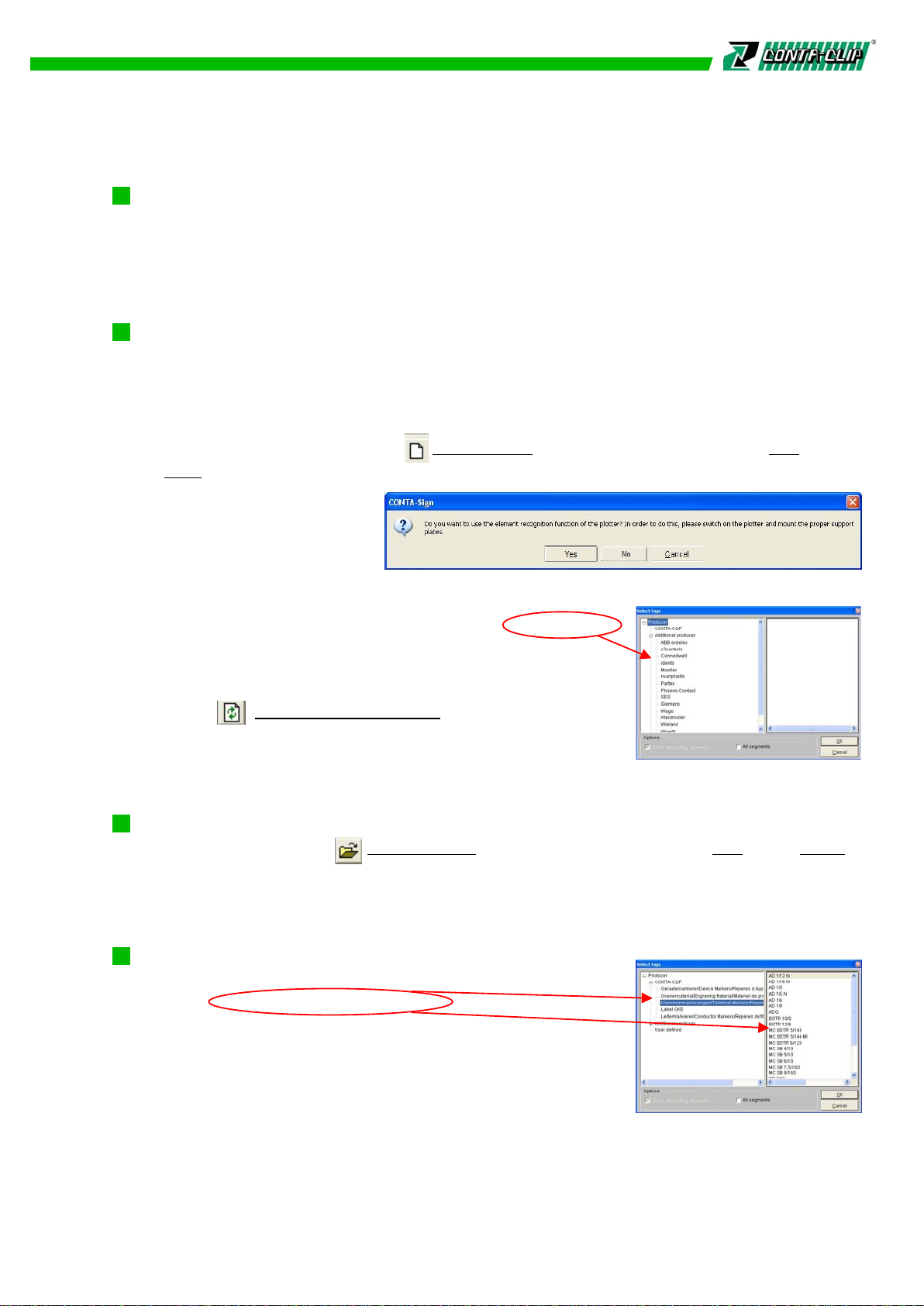

5.1 Create a new Project.

The EMS-2 has an integrated support plate recognition system included. The software

CONTA Sign CS reads the code of each field, starting with the left support plate.

Assuming the EMS-2 is turned on, the communication cable is connected and support

plates are placed on the plotter itself, the software pre-selects the marker cards

already. If you click on the icon New Project

> New from the main menu, the message comes up, if you like to use the recognition

system and read the

support plates.

After you confirm with Yes,

the support plates are

recognized and shown on

the screen together with the available marker cards. If you

confirm with No, all available elements and manufacturer

are presented in the list to be selected from.

After changing the support plate on the plotter or after

deleting a segment within the software, you could click on

the icon Rescan support plates

support plates.

and read the new

of the menu bar, or select > File and

5.2 Open an existing Project

If you click on the icon Open Project

from the main menu, existing projects could be loaded. You are able to work with

up to 10 different projects at the same time and could use all the Copy and Paste

functions between them.

5.3 Selecting tags / marking elements

After you double click on one of the segments on the

screen, a list of the available marker you can work with

and select from comes up. Just choose the type you have

placed on the support plate and the selection will be

presented on the screen.

If the no. of marker presented are not sufficient in order to

complete your job on one base plate (holding up to 4

support plates), new base plates with respective support plates could be added upon

your convenience.

of the menu bar, or select > File and > Open

5

Page 7

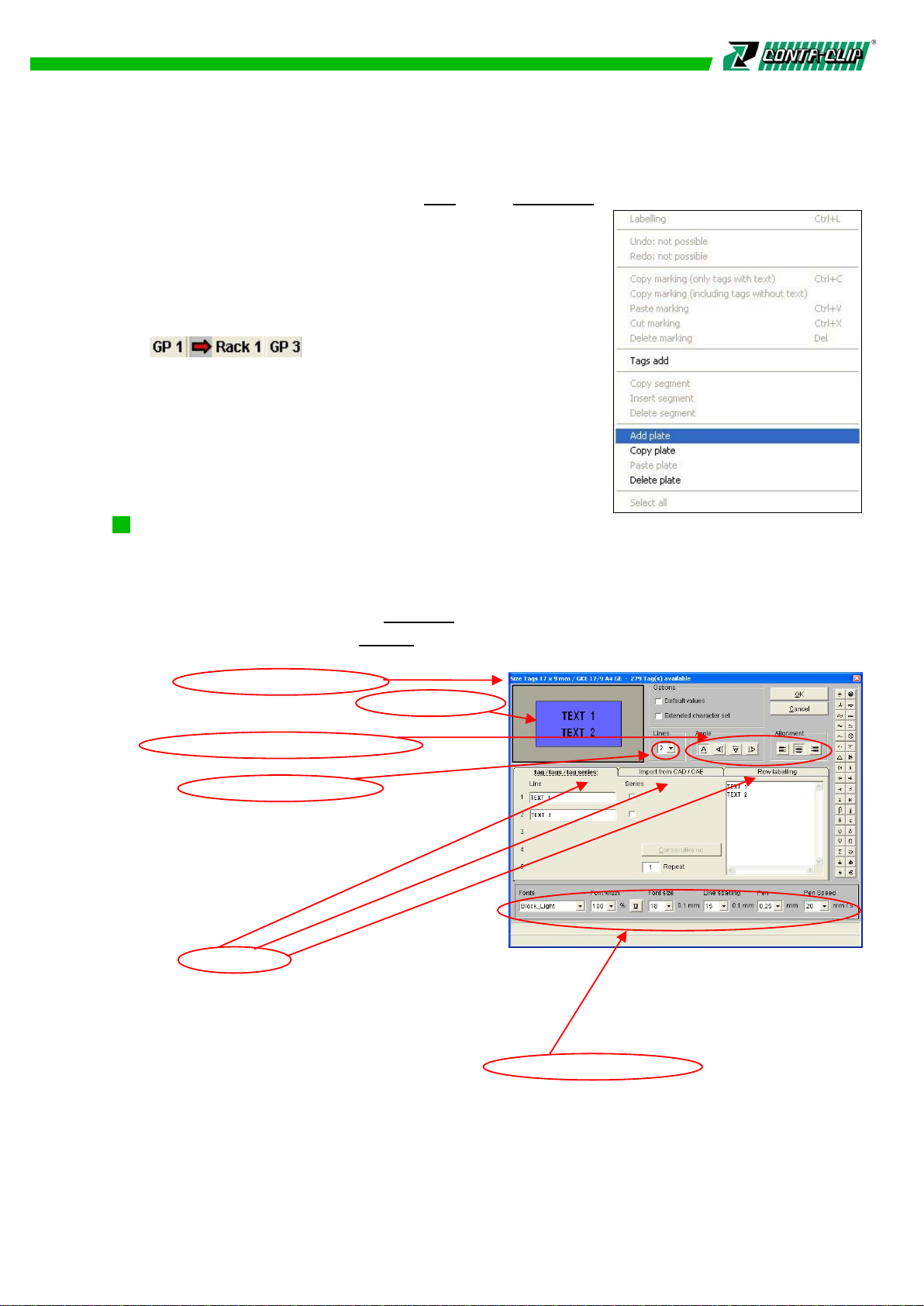

In order to do so, please select > Edit and > Add Plate from the main menu or use the

right mouse button.

A new blank base plate comes up to be used with more

segments. Up to 16 base plates could be used in one

project (max. 10 projects in one file).

To move from one base plate to the other just click on

their names in the lower left corner. Base plates could

also be renamed just with a double

click, or moved in the position to each other with drag

and drop.

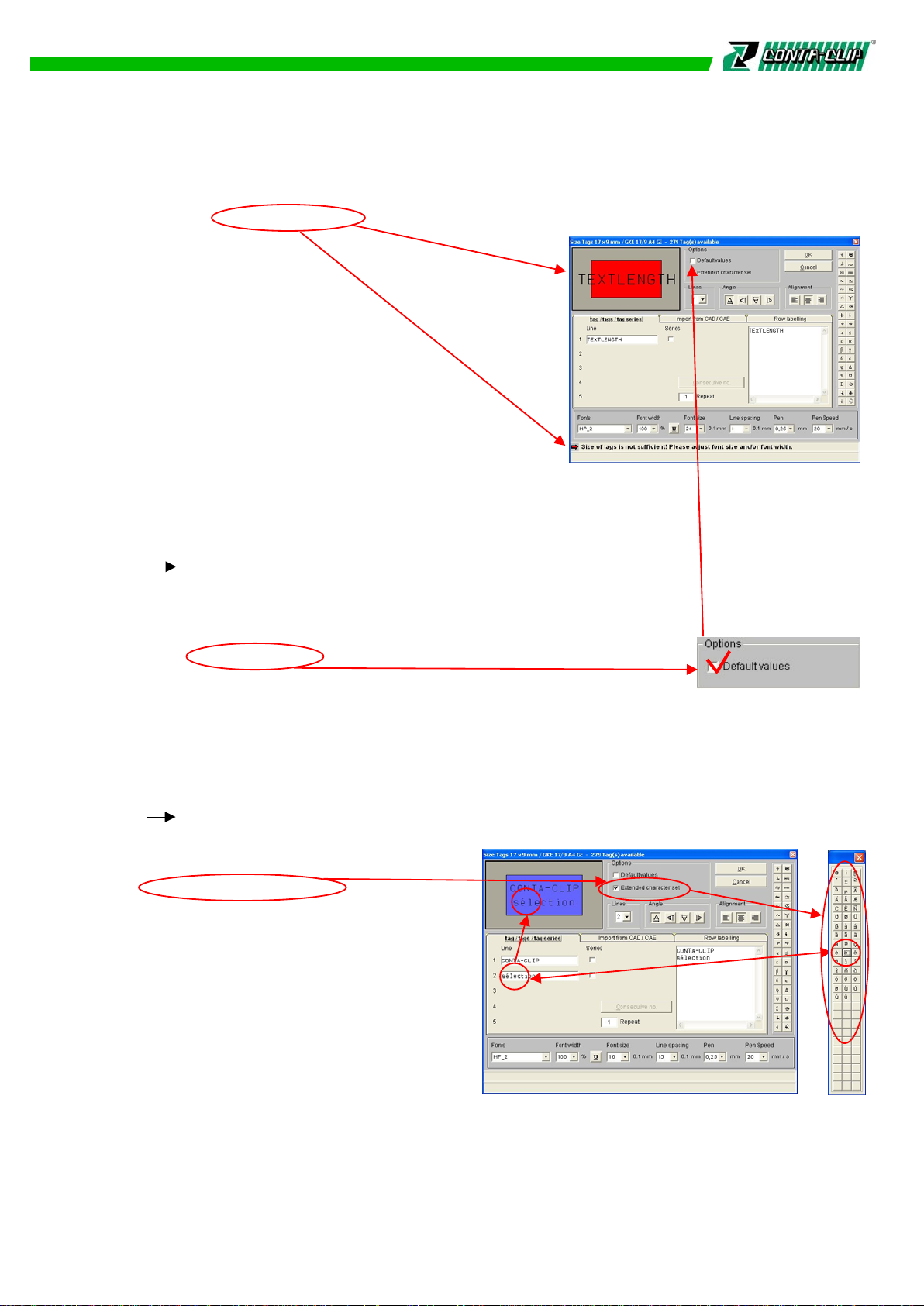

5.4 Marking the selected tags / marking elements

Double-click the tag or element where the labeling process is to begin.

This opens the labeling dialog box, which contains all the setting options. In order to

open the edit window, please click on the first tag to start with, use the right

mouse button and choose > Labeling

keyboard (check under > Option from the menu first). The exact description of the

selected tag and the number of tags available both appear in

the top line of the dialog box.

An outline of the selected marking element

is shown in the top third of the box.

Angle and text alignment options are found

next to this diagram.

The number of lines per tag can also be

specified here.

from the menu or start typing a character on the

Note that the program will only allow

options that are appropriate for the

selected element.

The various tabs for different methods of data input and import appear in the middle of

the box. This is where you can enter all the data and text for one-time, multiple, and

serial marking, and files to be imported from different programs, as well as text for

custom labeling (for example, row labeling).

The font, font width, font size, underline, line spacing, tip width of the plotter pen, and

plotting speed settings can be adjusted in the lower part of the box.

6

Page 8

The values match the chosen marking element, but can be altered within reasonable

limits. A warning message is displayed if text length exceeds the size of the tag.

This enables you to adjust the font, font size or

font width so that the text fits onto the tag

or element.

From a certain font height upward, only capital

letters and certain special characters are allowed

in order to make best use of the available labeling

area.

In such cases the following warning is displayed:

> Only upper case letters, special characters

and symbols are allowed <

Characters as "g, j, y, Ä, Ö, Ü" are not allowed in order to make best use of the

labeling area.

Restore Default values:

If you change parameters (font types, text height, line numbers etc.) for

each element the data will be stored in a separate file. If you choose the element

again, you will find the previously used parameter settings.

Click Default values , if you want to restore the original settings.

Note: After updating the software the user´s specific parameters

remain valid.

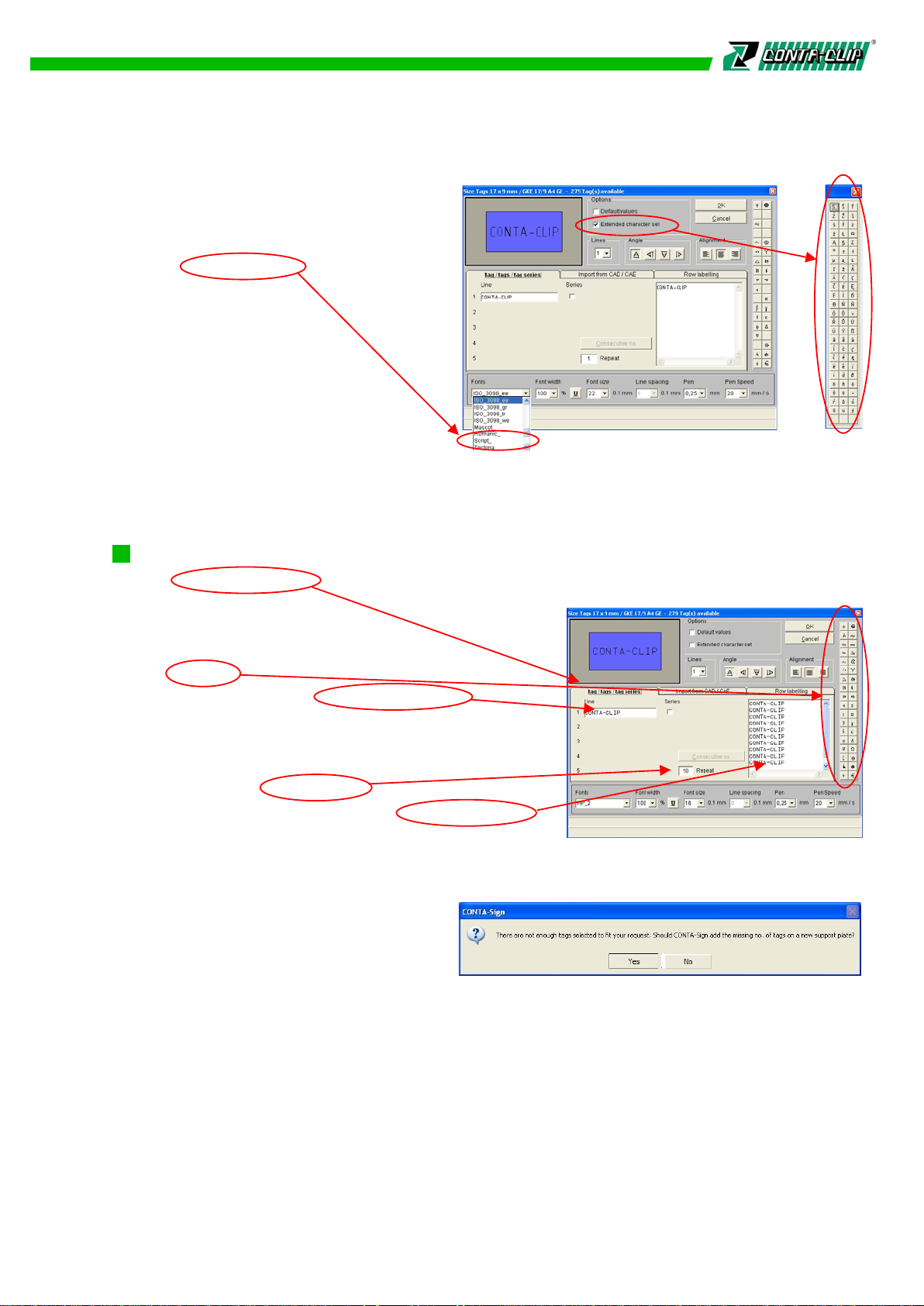

Extended character set

Country specific characters are directly

available by selecting

extended character set, the labeling

for other countries is easy to achieve.

Selecting the option, a new window

opens up at the right side with the

provided characters.

Without looking into the windows

character set for characters not

available through the keyboard directly,

country specific characters can be

selected with a click.

7

Page 9

Country specific characters will be

provided according to the selected

typeface, e.g. if you choose the

font ISO_3098_ee, characters for

eastern European countries are

available.

Additional character sets such as

Cyrillic, Baltic, Turkey, Greek, will be

available by selecting the spec. font

under ISO_3089.

Also ornate fonts can be selected,

specifically to be used for engraving.

5.5 One-time, multiple and serial modes

By choosing the tab for one-time, multiple, and serial modes, corresponding

sequences of text, numbers, characters and

symbols can be entered. At the right-hand corner

of the marking window you will find a large choice

of symbols which can be selected by a click.

The number of lines opened for editing

corresponds to the number of lines set per tag.

Text can now be entered. The number of tags to

be labeled with the same text should be

entered in the Repeat field.

The data input is shown in the preview window.

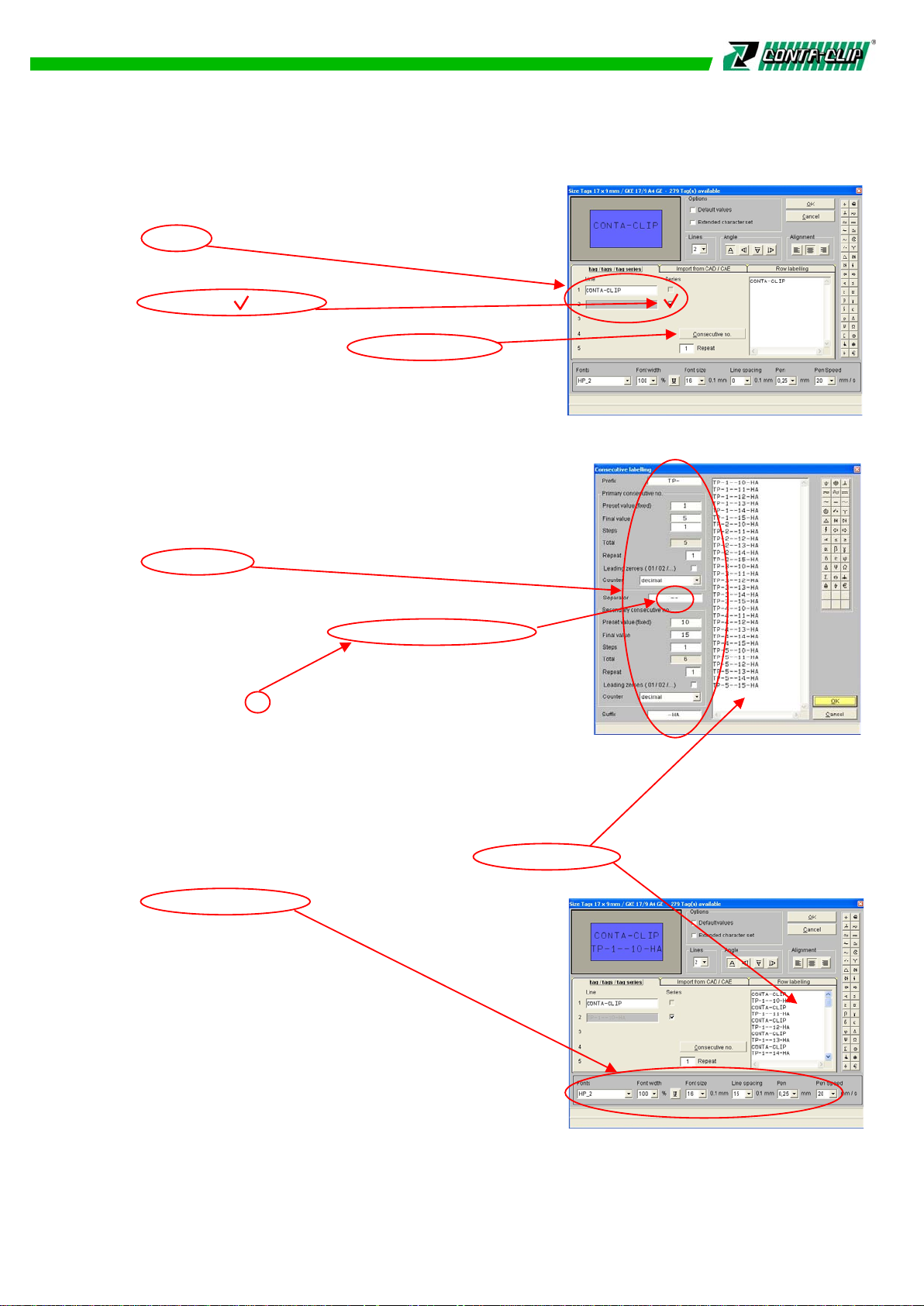

If the number of repetitions exceeds the number of tags available, the following

warning is displayed: > Not enough tags selected to fit your request <,

and the number of repetitions must

either be corrected or more tags

must be provided for labeling by

confirming with Yes.

Clicking OK transfers the labeling to the tags.

8

Page 10

If sequential numbering is to be carried out, after

selecting the number of lines you must specify

the line in which the sequential numbering is to

appear. To allow this, the Series check box to the

right of the line is activated.

Checking this box then activates the

consecutive no. button and prevents input in the

editing field. Clicking the Consecutive no. button

opens a further window, allowing serial marking to

be entered.

Here the start value, final value, preceding text

(prefix), following text (suffix), step size, counting method, and number of repetitions

can be entered, the counting method can be chosen

to be in ascending order.

The count could be chosen in decreasing nos. (start

value higher than final value) or increasing nos. (start

value lower than final value).

The left part of the window is separated in two parts,

primary serial number and secondary serial number,

in order to create two interlinked consecutive numberings, with free chosen character for separation. The

example shows as primary series TP-1 to 5 and the

secondary series 10 to 15 –HA, with a separation

character of --, TP- is the preceding text (prefix) and

–HA the following text (suffix).

If the series labeling job specified exceeds the number of tags available, the following

warning is displayed: > Not enough tags marked for labeling <.

The number of tags must either be reduced for example, by changing the final value or

more tags must be provided for labeling.

The sequences entered are listed in the preview window.

Clicking OK returns you to the previous window, and any necessary

parameter changes can be made there.

Clicking OK again transfers the labeling to the

tags. You can edit the data in the preview window.

It is possible to delete texts, insert empty rows and

special symbols or other texts.

Note: If you want to insert more data in series,

sequences cannot be shown and edited in the

series modus.

9

Page 11

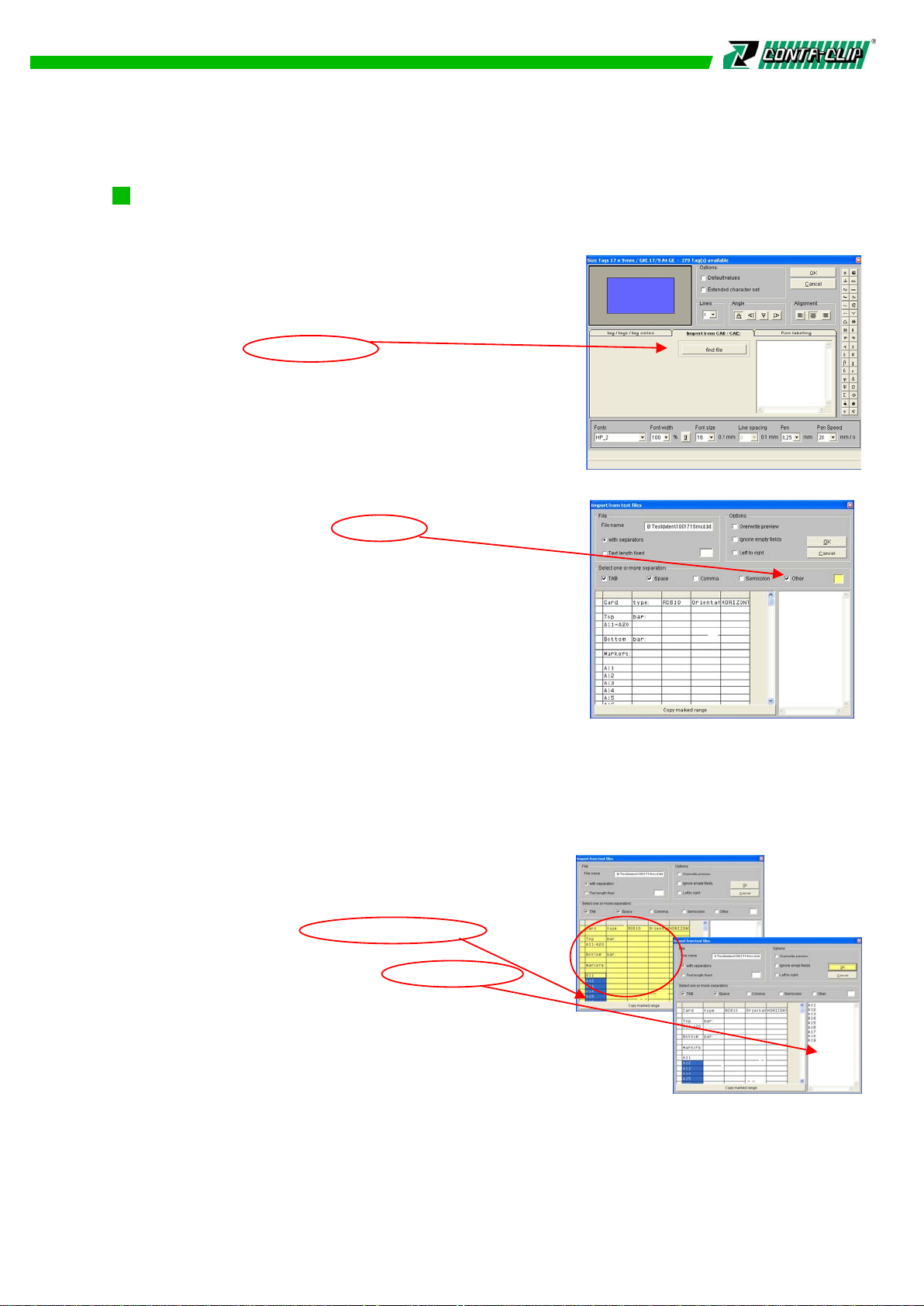

5.6 Importing files

After choosing the Import file tab, data can be imported from other files.

Data can be imported from other CAD/CAE programs, text files,

or spreadsheet programs.

An efficient import function is available to allow

extraction of the required data from a range of file

formats.

Clicking the Browse button makes it possible to

locate the file to be imported. Click to

select the file name, and then click Open to

access the file for importing.

A window will now open displaying the data for

importing, in table format.

You can choose the separator to be “tab”, “space”, “comma” or “semicolon” as single

or in combination. In addition further character can be

defined by clicking the box Other and entered in the

next field, e.g. “B”, enter “B” in the field and confirm

with OK.

Another possibility for separating imported files is

the no. of character.

Select the click box Text length fixed and enter the

no. of character in the empty field, clicking OK

activates the new separator.

If you want to import Conta Sign, Excel, Access or E-Plan files, the program will

automatically recognize the format and open the first worksheet for importing.

This is the default setting. You can also select other sheets from the file.

You can now copy either part or the entire table and use it for marking.

Please follow these steps:

Use the mouse to select individual or multiple cells,

individual or multiple columns, individual or multiple

rows, and click the Copy marked range button.

The data will be inserted into the editing field, and

you can check whether the copied data is correct.

It is possible to edit the data in this window, like

input of new data, delete data, correct data and copy data.

10

Page 12

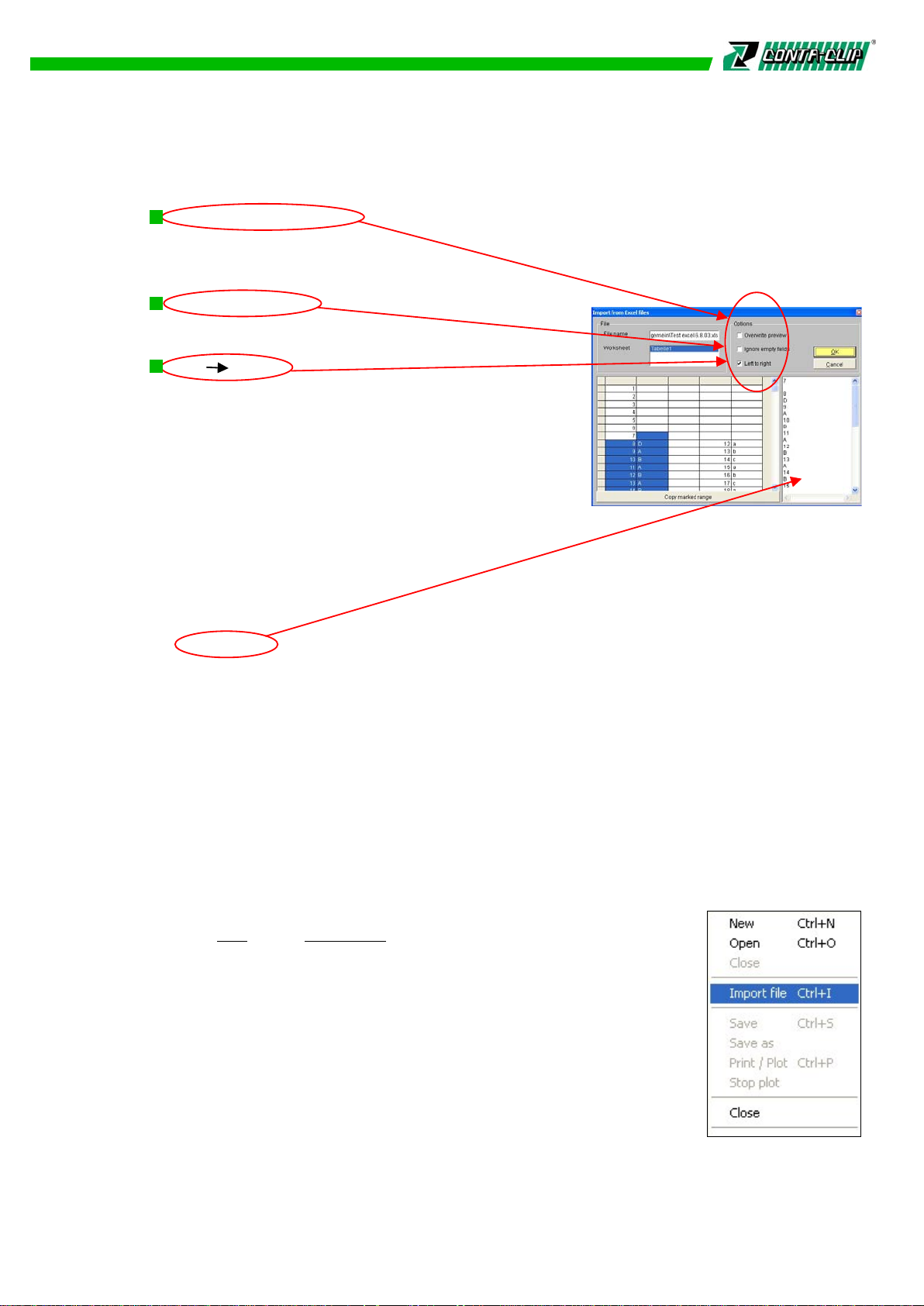

The following functions exist to aid data import:

Overwrite existing data

If you enable this function, newly copied data will automatically overwrite previously

copied data. If this function has not been enabled, the data will be appended to the

existing data.

Ignore null values

If this function is enabled, cells containing no data

will not be imported.

Left Right

This function allows the import sequence to be

changed. In the default setting, the data is transferred

by column from top to bottom. If the left-to-right

function is enabled, the data is transferred by row

from left to right.

Data can also be easily imported from files using Copy and Paste and the Windows

Clipboard.

To do this, open the relevant file and copy the data to the Clipboard.

When the original file has been closed, the data on the Clipboard can be pasted into

the editing field on the right-hand side of the import box either by pressing the

Ctrl V keys or by using the shortcut menu which pops up after clicking

the right mouse button.

After the data has been transferred to the preview window, it can be modified as

required. Available functions include deleting data, inserting data, etc.

Clicking OK transfers the labeling to the tags.

If the number of requested tags exceeds the number of tags available, the following

warning is displayed: > Not enough tags selected to fit your request <,

and the number of imported tags must either be corrected or more tags must be

provided for labeling.

Another direct import function is available from the main menu,

select

The import filter is specially designed for the import of files created

by former software programs, supporting a direct import of a

complete marker card.

There is no “select from” available, the file is recognized and

opened in the background upon importing the data. The software

opens the dedicated segment on a new base plate and transfers

the labeling to the tags accordingly. Post import of the data, all edit

functions can be used as previously described.

Special import formats are available at sales support.

> File and > Import file.

11

Page 13

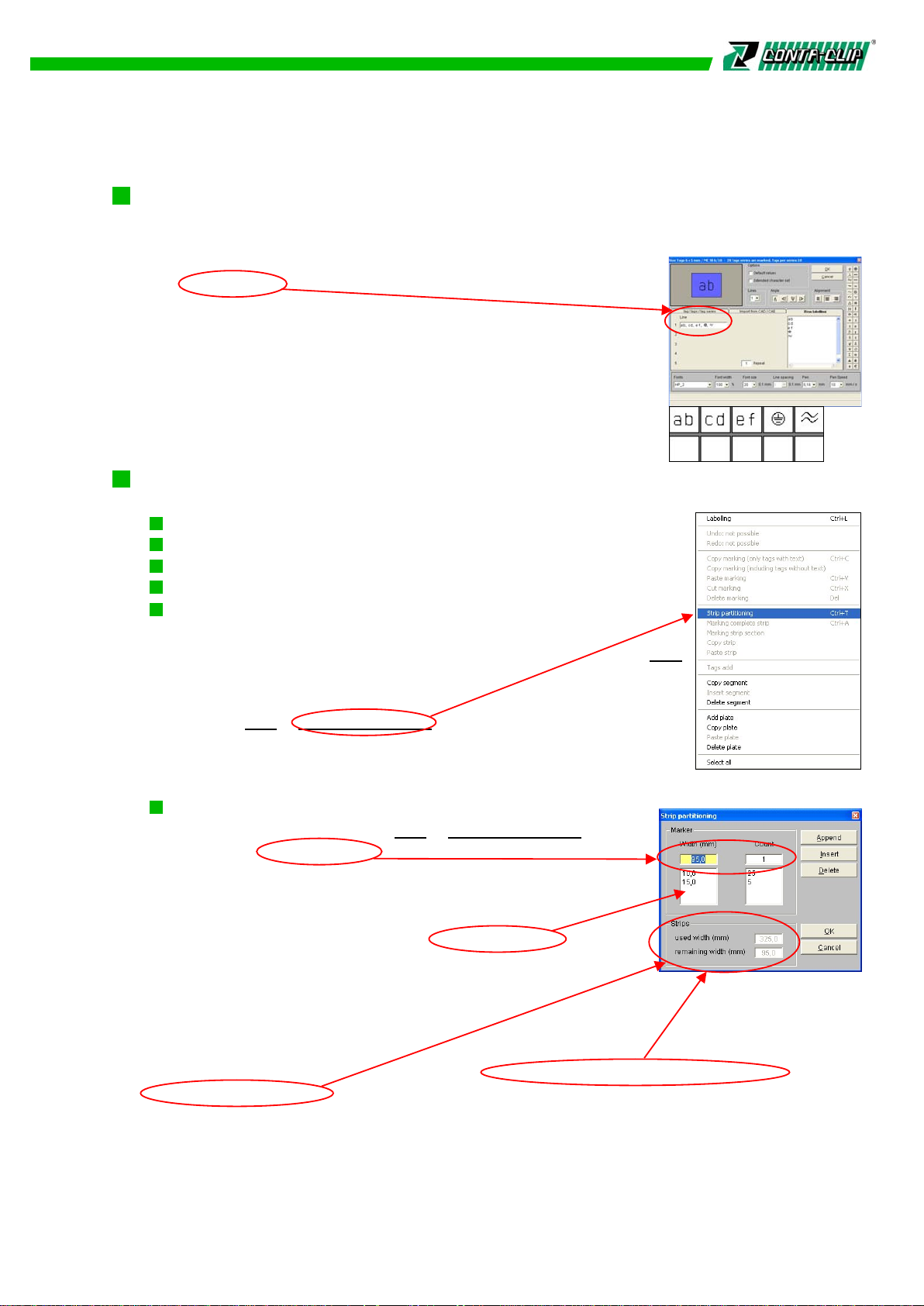

5.7 Row labeling

After choosing the row labeling tab, marking can be easily carried out on individual

row. Please ensure that you have selected complete row, since otherwise proper

labeling will not be possible.

The editing field is used to enter the text to be printed on the

row. The characters for each tag must be separated by

commas for example, “ab, cd, ef, symbol, symbol” means print

“ab” on the first tag, “cd” on the second tag , “ef” on the third

tag, "symbol" on the forth tag and "symbol" on the fifth tag .

Clicking OK transfers the labeling to the tags.

5.8 Marking of endless strips

This software has special features for marking of endless strips:

Strip partitioning

Marking complete strip

Marking strip section

Copy a strip

Insert a strip

If you choose strip-material, the above mentioned functions for

sectioning and marking of strips are available on the menu > Edit

By clicking you can select the strip you wish to mark.

Note: In order to mark a section of strip you have to prepare it first

via menu > Edit > Strip partitioning.

.

Strip partitioning

You can open a window via > Edit

allows you to divide the strip into various sections.

First put in the width of the strip and then the amount of

elements required in that width and confirm by pressing the

button Append .

Thereafter you can select and add further sections with

different widths.

If you wish to insert a section between other sections you have to mark-out the

section before which you want to insert.

Then press the button Insert to start the process.

You can delete sections by marking-out the section and pressing the Delete button.

At the bottom part of the window you can check strip-length already occupied and the

remaining strip-length.

After completion of sectioning press OK button and the strip will show up with the

corresponding divisions.

> Strip partitioning which

12

Page 14

Marking complete strip

Mark-out the required strip by clicking.

Via the menu > Edit

can get to the labeling window in which

you can select the type of marking. This

function allows you to carry out marking

in multiple and serial mode in various

element-widths.

Note: The space available for marking is

calculated on the lowest element-width. Should you request

an individual marking on the various element-widths, please choose this

marking possibility over the menu by selecting > Edit

Marking strip section

Mark-out the strip section you want to work on by clicking.

Via menu > Edit

window and can select the print. This function

allows you to completely utilize the available element-width.

> Marking complete strip you

> Marking strip section

> Marking strip section you can open the labeling

Note: Cut markings can be added to the print output. The settings

are made in the print output menu (see chapter “Printing Tags”).

Copy strip / Insert strip

Mark-out the strip you wish to copy by clicking.

Via menu > Edit

Now click to the strip onto which you want the data to be

inserted. Via menu > Edit > Paste strip the data will be inserted.

> Copy strip you can prepare the copy process.

13

Page 15

5.9 Copying functions

To avoid having to repeatedly enter the same or similar sequences, the program

provides a multiple number of copying functions:

5.9.1. Copying a marking sequence

Select a sequence by clicking it with the left mouse button. Now click the right mouse

button and choose > Copy marking (only tags with text)

shortcut menu.

Then use the left mouse button to select the element where the

copied sequence is to be inserted.

Open the shortcut menu by right-clicking and choose

> Paste marking

The copy/paste functions can also be accessed via the

icons / on the toolbar or by choosing > Edit from the

menu bar.

5.9.2. Copying several marking sequences

To copy several sequences, you can use the Shift - key to extend and select the area

to be copied. Copy and paste as described above.

Note: Simultaneous copying of multiple sequences to other types of tags

is not possible.

. If desired, the sequence can be altered.

from the

5.9.3. Copying parts of marking sequences

To copy individual markings from within sequences follow these steps:

Hold down the Ctrl - key and select all the labels you wish to copy by clicking them

with the left mouse button. Copy and paste as described above.

Note: Simultaneous copying of partial marking from multiple sequences to

other types of tags is not possible.

5.9.4. Copying of marking with empty signs

If you want to copy a range of tags, including non marked tags, mark these

and click the right mouse button, select in the menu

> Copy marking (including signs without text)

Copy and paste as described above.

.

14

Page 16

5.9.5. Copying a complete segment with tags

Choose the segment with a mouse

click. Press the right mouse button,

select in the menu > Copy segment

and activate it. Go to the destination

segment and click the mouse to

activate it. Press the right mouse

button and select in the

menu > Paste segment

Using the menu bar > Edit and sub

menus copy and paste works in the same way as described above.

5.9.6. Copying an entire base plate

Choose > Edit from the menu bar,

followed by > Copy Plate.

Choose again > Edit from the menu

bar, followed by > Paste Plate.

The whole plate will be copied

automatically.

5.9.7 Copying of texts onto other tag sizes

In some cases, the copying function of text to other tag sizes is disabled. It is only

allowed to copy in a common sense. The preview of the print must fit on the tag, like

writing angle and text size.

In general only one sequence can be copied at a time.

Note: All copy functions described can also be used between projects.

5.10. Zoom function

In order to activate or deactivate the zoom function, choose > View

from the menu bar or click on the icon.

Click on the icon once and move the mouse to the position on the base plate you like

view differently. With the left mouse click the position will be taken as new screen

center and enlarged. A new click on the icon will deactivate the function, continuing

to work with the current zoom.

The click with the right mouse button reduces the screen by a given zoom factor.

> Zoom function

15

Page 17

5.11 Control print of the labeling data

You can send the print data to a standard printer by selecting

> Extras from the main menu.

Print all segments:

The printer prints two quarter size segments per page, a two page

printout from the EMS-2 full size

Print selected segments only:

The printer prints one page with the selected segment.

5.12 Preferences

Choose > Extras

To select the language please check the next window coming up.

Before the plot starts a message comes

up, reminding you how to treat the

plotter pens. If you don´t like to have it

come up please check the mark. If you select a tag ready for labeling, you can just start to enter the character on the keyboard as

first character accepted, the labeling window opens and the character is

placed on the selected tag. If you don´t like to have it in place please

check the mark.

5.13 No. of projects and base plates allowed

Choose > Windows

overview of your actual project no. and base plates activated.

In total you can have up to 10 different projects and up to 16 base plates from each

project open and work with.

> Options from the menu bar for opening the window to select form.

from the menu bar in order to receive the

5.14 Information menu > ?

Choose > ? from the menu bar to receive further information about the system.

If you select Support plates, a window with different lists comes up,

showing the actual available support plates, the description and part no.

If you select Online-help, a description of general features of the software

is available. You can click within the software at any time on the icon

or open the help file from the menu bar > ?

The information window opens from the

menu bar > ?

about the software version, the release of the database

and the firmware of the EMS-2. To close the window

click on the OK button.

> Information with important information

> Online-Help.

16

Page 18

6. Starting the Print Job with the EMS-2

Once all the data for printing the job are entered the tags can be plotted.

In the upper left corner of the screen you will find the

information. In order to start printing, the plotter needs to be switched on

and connected with the respective data cable.

Click on the printer icon in the main menu bar. Prior

to starting, the software verifies if the plotter runs in the

plotting mode. If you are using the engraving option for

this plotter also, the plotter could be in the engraving

mode. If that is the case, you will find some instructions

on the screen how to switch the plotter into the plotting

mode. After confirming the message the

status will be re-checked.

Now the software verifies if the selected

support plates are identical with the ones

placed on the plotter, if not, a warning message comes up on the screen you need to

confirm.

Following new information are displayed and adjustments could be selected from:

In the top part of the window the selected

plotter and interface are indicated.

The next click box you can

check to activate or deactivate priming the

plotter pen on one of the fields left or right of

the Pen Station.

The next field of the window indicates the

recognized support plates, placed on the

plotter. Are those different from the ones

chosen for this project, the necessary support

plate for this job is indicated in red.

The right side of the window is used to show the different plotter pens to be used for

this job, also with a color indication according to the standard color coding of the

EK-TEAM Plotter Pens.

If the tip of the pen used is larger than .5 mm a message comes up, telling that the

standard pen sizes (.18 mm to .5 mm) for

this job will be different.

17

Page 19

Different print options could be set up in the lower part of the window:

Use one Plotter Pen Size only

In order to execute this job, two or more pens

to be used might be indicated. If you

like to use one tip size, please check this box

and select the respective Pen.

Use Pen inserted in Pen Holder

Once checked this box, no Pen will be picked

up from the Pen Station. The pen directly

inserted into the Pen Holder will be used. This

option could be used, if pens

used are different from the EK-Team Pens, although they might have a HP compatible

outside dimension, but will not fit into the Pen Station of the plotter.

Use one Plotter Speed only

In order to execute this job, different speeds (10 to 40 mm per second) could be

selected from the data entry. In order to work with one speed selection only, please

check this box and select the respective speed.

Print selected tags only

If you check this box, only the tags marked before are subject to be printed.

Select a sequence

Just click in the edit window on the sequence once and it is marked.

Select multiple sequences

Just click in the edit window on the first sequence once, hold down the

Shift Button and click on the next sequence ones etc. and all are marked.

Select single tags

Hold down the Ctrl Button and just click in the edit window on the single

tag or multiple tags once and they are marked.

Print selected segments only

If you check this box, only the segments marked before are subject to be printed.

Just click in the edit window on the segment once and it is marked. In order to mark

two or more segments, hold down the Ctrl Button and click on each segment once.

18

Page 20

If you print on endless strips, additional adjustments are subject to be

checked.

Insert a cutting line

No

no cutting line is printed

Yes

cutting lines are printed after each tag length

Final

cutting line is printed after the last tag of the

whole strip length

The print job starts with a click on the OK Button.

The software checks again if the selected support plates are placed on the plotter.

If not, a warning message comes up to be

confirmed, either continue or cancel.

In case the already started job should be stopped, please click on the

icon Stop Plot in the menu bar. The printout will be interrupted, the data

(if any left) in the print spooler of the PC and the EMS-2 will be deleted.

The EMS-2 will re-align and move back to the origin, waiting for the new job.

Alternative the power of the EMS-2 can be re-cycled by pressing the OFF and ON

button. All existing data will be deleted and the zero position re-aligned.

Other plotter connected might be different in the operation, please refer to the

instruction manual.

19

Page 21

7. Scale factor

The data created from each individual tag for the database was carefully investigated,

although they are not frequently checked. There could be a chance for the printable

tags to receive by the time a slight mechanical deviation, spec. in the scale factor,

means the distance from one tag to the next in both of the directions x and y.

Temperature and humidity at the work bench could influence the distance as well as

new production series and different production techniques during the process like

material and temperature changes. Covering the complete x and y dimension of the

marker card, deviations of > 1 mm are noticeable. In order to be able to correct the

settings a special function is provided under menu > Extras

> Elements> Scale factor.

Once a segment with a marker card is placed on

scale in x-direction

the EMS-2 the first upper left tag should be checked,

if the print is centered in both directions

(see also item 10 Calibration). There after the last tag

scale in

y- direction

at the lower right corner needs to be printed in the same

manner. If not printed exactly the same, the

scale factor for this particular card is

not perfectly correct.

In order to correct the scale factor select one tag on the segment and choose > Extras

> Elements and > Scale factor from the menu.

The tags are changing into red and the EMS-2

moves with the inserted pen or magnifying tool

to the lower right corner to the point of the

beginning of the last tag.

With the button Pen Up /Down the plotter pen

or magnifying tool can be lowered in order to

find exactly the correct spot of the beginning of

the last tag at the lower right corner.

You can move the arm of the plotter with the four cursor buttons in

the pre-selected steps from 0.025 mm up to 10 mm, the default value is 0.1 mm.

After completion you must press the button Accept in order to save the changes to the

user file within the database, the general database is always kept original.

Closing the window moves the plotter arm back to the previous position.

The next start of the software will take the changed information from the user database. You can return to the original values by clicking the Reset button.

The complete dimension in x and y direction can be changed with the correction of the

scale factor. Re-check the result of the print again by printing the last tag at the lower

right corner, centered in both directions.

20

Page 22

8. Designing new Tags

This part of the program allows you to design own tags and elements or labels.

In order to open the program, choose > Extras and > Elements from the main menu.

To open the designer for labels for the endless

TT-Printer and Office Printer choose > Extras and

> Labels from the main menu.

There are two versions available designing new tags:

Design tags with same size

Design tags with different sizes

If you like to design e.g. a label sheet with same sized labels in a matrix, use

> Design tags with same size. If you like to design e.g. a serial no. plate with different

sized label areas, use > Design tags with different sizes.

Note: Designing tags is only possible with a plotter as output device selected. If you

are working with the engraving feature, the software

suggests to use either the half (DIN A4) or full size

(DIN A3) plotter.

The use of the design program is described below,

after saving, the designed elements are available for

labeling in the folder > User defined

(manufacturer) after selecting the correct output

device.

under > Producer

21

Page 23

8.1 Example for designing a label sheet (matrix) with same sized labels for plotting and engraving

Open the designer from the main menu with > Extras > Elements

> Design tags with same size as described above.

The following window appears:

With a click on the button New a new element can be named in the window under

<Untitled>. It is useful to work with the element recognition system of the plotter in

order to find the element more easy later on.

For the element you want to design, enter a

new name in the window <Untitled>.

If you don´t want to use the element

recognition system or you are working offline

(without being connected to the EMS-2),

select the type of support plate for the sheet.

You can select between a quarter size, half

size or full size support plate.

You can always assign the support plate to

the project later on. As soon as you are connected back to the plotter place

the support plate and click on the button Assign support plate identification.

Pre-selected is the plate for sheets (half size plate).

Further you can select in the lower left part of the window, if the new designed material

is for plotting only or plotting and engraving. The buttons are only active once the

support plate is recognized or assigned to the project.

Once selected, click on the Edit button.

Note: Engraving is only possible on dedicated support plates.

22

Page 24

A new window opens up,

where you can enter the data

of the tag (size of the label),

if known.

You can always take the

measurements using the

plotter system, if the data is

not available.

You need only to enter the

nos. of tags in x and y

direction.

All other data necessary for the program, can be taken with the plotter system.

Please enter the no. of tags in x and y direction as shown in the window.

If available enter also the size of the tag (label) and the distance to the next tag. You

can always correct the data later on, if the exact nos. are not present at the moment.

Always take the start position of the first tag with the plotter system!

Further on, you can decide on the labeling direction of the tags.

For the sequence for plotting or engraving you can choose between upper left to upper

right (by row) or upper left and lower left (by column).

Attention: It is essential for continuing the design to switch on the plotter and have the

support plate with the label sheet placed on.

Insert a plotter pen directly into the pen holder of the plotter.

If you have entered minimum the no. tags (label) in each direction, please click on the

Take measurements button.

A new window opens up, providing

buttons and entry windows, in order

to take all relevant measurements

for the new element.

23

Page 25

Please follow the steps for taking measurements:

Determine the exact position of the

first tag on the label sheet. In order to

do so, please click on the most left

button Initial position of the window.

The arm of the plotter moves to its upper left corner limit (zero position). From there

you can move the arm with the pen inserted to the upper left corner of the first tag with

the cursor buttons. You can select the size per step in mm in the upper right area of

the window.

Please check with the Pen Up/Down button the correct position after you moved the

pen to the initial point of the tag. The respective co-ordinates are shown in real nos. in

the x- and y- window based on the zero position.

Determine now the exact position

at the lower right corner of the first

tag. Just repeat the steps as for the

upper left corner, described above.

As next step, determine now the

exact position of the upper left corner

of the last tag (size of matrix).

Take the initial position in the same

manner as described above.

After completion of the three steps all measurements are taken for the element.

In order to save the data for the new element, please click on Accept.

The window "Take corner measurements of tags" will be closed and you are back to

the previous window.

24

Page 26

Please click on the button Accept in the window and the new designed

element will be shown.

Now you can check, if all

the data where taken

correctly . Any up-coming

error or warning message

at this point means,

please re-check the data

manually or allow the

automatic correction by the program.

Click on the button Close in order to

terminate the designer program.

You can find the new element for

labeling in the folder > User defined

under > Producer.

Example

Note: All new elements in the folder User defined will continue

to be available after program updates.

8.2 Example for designing a serial no. plate with different sized label areas for

plotting and engraving

Open the designer from the main menu with > Extras > Elements > Design tags with

different sizes.

The same window appears, as described before for designing

tags with the same size. All adjustments will be done in the same

manner. After clicking on the button Edit a similar window

appears, extended by additional functions.

Now you have the ability to implement different sized

labeling areas. Each new area or field needs to have an own name.

Taking the measurements is now similar to the

previous sample of the label sheet matrix.

25

Page 27

In case you like to copy the labeling field and place it at a different y-position,

click on the Button Duplicate. Please enter the new position in the new

upcoming window and confirm the entry by clicking on Accept.

Note: The new labeling areas could be part of a label sheet (matrix) as well as a

single area.

Please click on the button Close in the previous window and the new

designed element will be shown.

Now you can check, if all the data were taken

correctly.

Click on the button Close in order to terminate

the designer program. You can find the new

element for labeling in the folder

> User defined

In case the labeling is not exactly centered, you are allowed to edit the new designed

elements at any time. Open the designer program again, choose the element or part

of the element you want to change and click on the button Edit for making the

adjustments.

under > Producer.

Note: All new elements in the folder User defined

program updates.

will continue to be available after

26

Page 28

8.3 Example for designing same sized labels for endless TT-Printer

Open the designer from the main menu with > Extras > Labels

> Designer endless labels

The following window appears:

With a click on the button New a new element can be named in the window

under <Untitled>.

Confirm the new name by clicking on Edit

and the new window for entering the data of

the label will open up.

Take the measurements of the label and the distance between two labels.

Enter the data into each field incl. the no. of labels in x-direction,

confirm the entry with Accept and the labels will be shown as designed.

as described above.

Please check if all measurements were taken

correctly. With Close the designer will be

terminated.

After selecting from the main menu > New

correct output device, the designed labels are

available for labeling in the folder

> User defined under > Producer (manufacturer).

the

27

Page 29

8.4 Example for designing same sized labels for Office Printer

Open the designer from the main menu with > Extras > Labels

> Design label sheets with same size as described above.

The following window appears:

With a click on the button New a new

element can be named in the window under

<Untitled>.

Confirm the new name by clicking on Edit

and the new window for entering the data of

the label will open up.

Take the measurements of the label, the distance between two labels and the start

point from the left and upper side. Enter the data into each field incl. the no. of labels

in x- and y-direction, confirm the entry with Accept and the labels will be shown

as designed.

Please check if all measurements were taken

correctly.

With Close the designer will be terminated. After

selecting from the main menu > New

output device, the designed labels are available

for labeling in the folder

> User defined

under > Producer (manufacturer).

the correct

28

Page 30

8.5 Example for designing different sized labels for Office Printer

Open the designer from the main menu with > Extras > Labels

> Design label sheets with different sizes

The same window appears, as described

before for designing label with the same

size. All adjustments will be done in the

same manner.

After clicking on the button Edit a similar

window appears, extended by additional

functions.

Now you have the ability to implement different sized labeling areas. Each new area or

field needs to have an own name.

Taking the measurements is now similar to

the previous sample of the label sheet

matrix.

In case you like to copy the labeling field and

place it at a different y-position, click on the

Button Duplicate.

Please enter the new position in the new upcoming window and confirm the entry by

clicking on Accept.

as described above.

Note: The new labeling areas could

be part of a label sheet (matrix) as

well as a single area.

29

Page 31

8.6 Import / Export of User elements

You can import or export user designed elements and exchange with other

users (created as described in chapter 8.1 and 8.2).

To export an user designed element, click on the

button Export and select the folder saving the .txt-file.

The file name is suggested as the element name.

Exported files can be imported at another work

stations.

To import an user designed element, click on the

button Import and select the file to be imported. You can

find the new element in the User defined

overwrite an already existing name for an

element.

folder. You can

30

Page 32

9. Engraving Tags

Please select the output device first in order to start engraving with the

EMS-2 Engraver (see also chapter 3 page 3). In the upper left corner of the screen

you will find the information.

Connect the engraving unit according to the manual and switch on the Controller

first, followed by the plotter EMS-2.

The steps getting used to the software, starting at chapter 5, are not changed using

the engraver. Just where the functions are different or additional a new description is

implemented into the manual as described in the following.

9.1 Engraving with the EMS-2 Engraver

Double-click the tag or element where the engraving process is to begin.

This opens the labeling dialog box, which contains all the setting options. In order to

open the edit window, please click on the first tag to start with, use the right

mouse button and choose > Labeling

start typing a character on the keyboard (check under > Extras> Option from the menu

first).

Further adjustments using the engraving tool

are available by clicking on the button

Adjustments Engraving Tool

from the menu (see also item 5.4 page 7) or

31

Page 33

Following adjustments for the engraving unit could be made and selected from.

Size of tool

Engraving needle in the size of .2 mm up

to 1 mm could be selected from.

Engraving speed

Adjustments of 2 mm/s up to 20 mm/s

could be selected from

Revolution per minute (RPM)

Adjustments of 5,000 up to 50,000 RPM

for the engraving spindle could be selected from

Penetration speed

Adjustments of 0.1 mm/s up to 1 mm/s could be selected from in steps of .1 mm/s

The type of the tool and the penetration depth will be suggested according to the

selected engraving material.

Restore Default values:

If you change the above parameters for each element the data will be stored in a

separate file. If you choose the element again, you will find the previously used

parameter settings.

Click Default values , if you want to restore the original settings.

Note: After updating the software the user´s specific parameters remain valid.

32

Page 34

9.2 Starting the Engraving

Once all the data for engraving the job are entered the tags can be engraved. In the

upper left corner of the screen you will find the information.

In order to start engraving, the engraving unit needs to be installed and

connected according to the manual. There after switch on the engraving

controller EMS-2 first followed by the plotter EMS-2.

Click on the printer icon in the main menu bar.

Prior to starting, the software verifies if the plotter

runs in the engraving mode. If the plotting mode is

detected, you will find some instructions on the

screen how to switch the plotter into the engraving

mode.

After confirming the message the status will be

re-checked.

Now the software verifies if the selected support plates are identical with the ones

placed on the plotter. If not, a

warning message comes up on the screen

you need to confirm.

Following new information are displayed and

adjustments could be selected from:

In the top part of the window the

selected plotter and the used interface is

indicated.

The field below in the window indicates the

recognized support plates, placed on the

plotter. Are those different from the ones

chosen for this project, the necessary

support plate for this job is indicated in red.

The right side of the window is used to show

the different engraving needles to be used for

this job, also with a color indication.

33

Page 35

Various engraving options could be set in the middle part of the window:

Only one engraving tool and depth to be used

In order to execute this job, two or more

engraving needles to be used might be indicated. If you like to use one needle size and

penetration depth only, please check this box.

Only one engraving speed to be used

In order to execute this job, different engraving

speeds (2 to 20 mm per second) could be

selected from the data entry. In order to work

with one speed selection only, please check

this box and select the respective engraving

speed.

Only one revolution speed (RPM) to be used

In order to execute this job, different revolution speeds (5000 to 50000 RPM) for the

engraving spindle could be selected from the data entry. In order to work with one

selection only, please check this box and select the respective revolution speed.

Only one penetration speed to be used

In order to execute this job, different penetration speeds (0.5 mm to 5 mm per second)

for the engraving needle could be selected from the data entry. In order to work with

one selection only, please check this box and select the respective penetration speed.

All selected tags will be engraved

If you check this box, only the tags marked before are subject to be engraved.

Select a sequence

Just click in the edit window on the sequence once and it is marked.

Select multiple sequences

Just click in the edit window on the first sequence once, hold down the

Shift Button and click on the next sequence ones etc. and all are marked.

Select single tags

Hold down the Control Button and just click in the edit window on the single

tag or multiple tags once and they are marked.

All selected segments will be engraved

If you check this box, only the segments marked before are subject to be engraved.

Just click in the edit window on the segment once and it is marked. In order to mark

two or more segments, hold down the Control Button and click on each segment

once.

34

Page 36

Various options for the frame are available in the lower part of the window:

Reverse labeling

With this option selected, the lettering will be reverse engraved. You will have a clean

surface at the front, engraved from the back side. Useful for engraving letterings used

in harsh environments, no particle could stick

in the engraved groves making the lettering

unreadable (specific material required).

Engrave frame around lettering

With this option selected, a frame will be

engraved around the lettering. First the

lettering will be engraved. Thereafter the

engraving process stops asking you in a

message box to change the engraving needle

or to alter the engraving depth.

If no tag is selected, all frames around the

tags will be engraved, even if they don’t carry

any lettering.

Engrave frame only

With this option selected, the frame will be engraved only without the lettering.

This selection is useful engraving multiple depths on thicker material. Using first a

lower penetration depth and for the second run the final setting.

Round frame corners

With this option selected, you can select in a combo box various

radius settings for the corner engraving of the frame. Possible settings for the radius

are between 1 mm and 5 mm in .5 mm steps.

35

Page 37

The engraving job starts with a click on the OK Button.

The software checks again if the selected support plates are placed on the plotter.

If not, a warning message comes up to be

confirmed, either continue or cancel.

There after the software reminds you by a

message to verify, if the selected engraving needle is inserted into the spindle.

This message needs to be confirmed with a click on the

OK Button and the engraving job starts.

In case the already started engraving job should be stopped, please click on the

icon Stop Plot in the menu bar. The engraving will be interrupted, the data

(if any left) in the print spooler of the PC and the EMS-2 Engraver will be deleted.

The EMS-2 Engraver will move back to the origin, waiting for the new job.

Alternative the power of the EMS-2 can be re-cycled by pressing the OFF and ON

button. All existing data will be deleted and the zero position re-aligned.

For further information, please refer to the operating instructions of the

Plotter EMS-2.

36

Page 38

10. Calibrating the Plotter

The EMS-2 is calibrated during the production. In case of small deviations, like the

printout is not correctly in the center of the marker, the plotter could be calibrated

manually.

In order to do so, please make sure there are no parts on the plot field, like ball

pen, not proper mounted support plates etc., then go to the

menu > Output

The arm moves into the center position.

In the window on the screen you have 4 cursor buttons in order to move the setting in

either direction, in steps .025 mm up to 10 mm, the default setting is .1 mm.

Each click in the button will move the Pen holder

connected to the arm into the desired direction. After

the changes made, hit the CCCCaaaalllliiiibbbbrrrraaaatttteeee button and the

new settings are stored in the software.

Please check again during the next print, if necessary

use the calibration function again until the output

performance is satisfied.

Use always the first tag at the upper left corner of the

segment (see also item 7 Scale factor).

The RRRReeeesssseeeetttt button takes you back to the original setting.

> Output device and choose > Calibration.

Although the other output devices you might want to use are pre-calibrated, because

of the different starting point, the calibration procedure as described is essential with

those other devices.

37

Page 39

11. Firmware update of the plotter

11. Firmware update of the plotter11. Firmwareupdate des Plotters

With this option you are able to update the existing firmware of the plotter.

It is necessary e.g. if you are using a EMS-2 plotter already, purchased in 2005

or earlier and now wanted to use the engraving feature.

In order to download a new version, please follow the steps as described:

Start the program CONTA Sign CS and switch on the plotter. Make sure the plotter is

connected with the interface cable to the PC and the interface is selected correctly

(see point 3).

Choose from the main menu > Output

The upcoming window shows the actual firmware in

nos. A later version of the firmware is shown in the

field below with a higher no.

Now you can update to the next level of the firmware.

If the later version is not in the pre-selected folder,

please use the find file button to search for in

another folder.

With a click on the button Update a new message window opens up.

You are asked to switch the plotter into the download mode.

In order to do so, turn off the

plotter, hold down the button

Clear buffer and the button STOP together and press ON again.

The control LEDs STOP and Clear buffer are on.

> Output devices the tab > Firmware update.

Confirm the setting with the OK button and the update process

starts. A new message opens up telling you the plotter will turn off

automatically after completion. Confirm with the OK button.

In order to check if the new firmware is stored correctly in the plotter,

turn on the plotter again and choose from the main menu > Output

the tab > Firmware update. In the field “Actual firmware version” should now be the no.

of the latest version.

> Output devices

38

Page 40

12. Printing on other output devices

11. Firmware update of the plotter11. Firmwareupdate des Plotters

With the connection of other output devices, labeling data could be printed on

Thermal-Transfer Printer (TT-Printer) as well as standard Office Printer.

As described in chapter 8 the labels need to be designed first.

12.1 Printing on endless TT-Printer

Please select first the output device from the main menu > File

In the upper left corner of the screen you will find the information

> New.

The designed labels are available for labeling in the folder > User defined

> Producer (manufacturer).

Enter the labeling data in the editing window as

usual. The data can be changed and modified as

described in chapter 5.4 to 5.6.

By selecting a margin, a fixed distance within the

label can be set, making sure the print is always

within the label area.

In addition the text can be manipulated for printing

in Bold, Italic, Underline, clicking OK transfers the

data to the label.

After all entries are completed,

click on the icon Print / Plot / Engrave.

A message window opens up with the information to

select first a system printer, clicking OK opens the

window with the available printer list, please select

the TT-Printer.

If necessary you can change the size of the label just

to perform a final correction of the total length

by entering a factor.

under

Clicking on Apply, opens the print window with the

possibility of entering the margin to the left border of

the endless labels.

Please confirm with OK and the printout will be

started.

Please check the print on the label regarding

the position, if necessary change the entry of

the left border margin or go back to the

designer and make the corrections in view of

size and distance of the label.

39

Page 41

12.2 Printing on standard Office Printer

11. Firmware update of the plotter11. Firmwareupdate des Plotters

Please select first the output device from the main menu > File > New.

In the upper left corner of the screen you will find the information.

The designed labels are available for labeling in the folder > User defined

> Producer (manufacturer).

Enter the labeling data in the editing window as

usual. The data can be changed and modified as

described in chapter 5.4 to 5.6.

By selecting a margin, a fixed distance within the

label can be set, making sure the print is always

within the label area.

In addition the text can be manipulated for printing

in Bold, Italic, Underline, clicking OK transfers the

data to the label.

After all entries are completed,

click on the icon Print / Plot / Engrave.

A message window opens up with the information to

select first a system printer, clicking OK opens the

window with the available printer list.

Please select the Office Printer you like to use for the

printout.

In addition you need to enter the data of the

non printable areas from the top and left in both of the

formats, portrait and landscape.

under

Click on Test page in order to print the two pages

for you to take the measurements from the

top and left side, enter the data and click on Apply.

The data are stored for the selected printer and the

print window opens accordingly.

40

Page 42

In the top part of the window you enter the no. of copies, in the lower part you have

11. Firmware update of the plotter11. Firmwareupdate des Plotters

the following choices to select from:

Print frame around lettering

With this option selected, a frame will be

printed around the lettering.

Print frame only

With this option selected, the frame will be

printed only without the lettering.

All selected tags will be printed

If you check this box, only the labels marked before are subject to be printed.

Please confirm with OK and the printout will be started. Check the print on the

label regarding the position, if necessary change the entry of the upper and left

border margin or go back to the designer and make the corrections in view of size

and distance of the label.

41

Loading...

Loading...