Consilium Salwico CS3000 Service Manual

Fire Alarm System

Salwico CS3000

Service manual

Ver. 6

çConsilium

The contents of this document are subject to revision without notice due to continued progress in

methodology, design and manufacturing. Consilium assumes no legal responsibility for any error

or damage resulting from the usage of this document.

Edition 5, 09 1 E, August 2009.

Document no. S-4-007.875

Part no: 070073

© 2004-2009, Consilium Fire & Gas AB

Consilium Marine AB

P.O. Box 8763

SE-402 76 GÖTEBORG

SWEDEN

Tel: +46-31-710 77 00, Fax: +46-31-710 78 00

E-mail: cmab.got@consilium.se

Internet: www.consilium.se

Service Manual CS3000 Contents i

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 1995, Consilium Marine AB

Contents

About this manual..................................................................................................... ii

Chapter 1: Control unit

Service mode............................................................................. 1-1

Set address........................................................................ 1-1

Bypass built-in short circuit isolators................................... 1-1

Chapter 2: The circuit board of the control unit

Input/Output board IKK-4................................................. 2-1

Chapter 3: The circuit boards of the central unit

Loop processor board SPK-2............................................... 3-01

Alarm processor board LPK-2.............................................. 3-09

Relay board ARK-2.................................................................. 3-13

Input board INK-2..................................................................... 3-18

Output board UTK-2

................................................................ 3-22

Interface board GSK

-2.............................................................3-26

Interface board RS232K-2..................................................... 3-30

Interface board KPK-2............................................................ 3-34

Rack CSR-3200........................................................................ 3-38

Power unit CSS-3300............................................................. 3-40

Appendix A. DIP switch settings............................................................... A-1

Appendix B. Fault codes CS3000 version 4...................................... B-1

Appendix C. Fault codes CS3000 version 6..................................... C-1

Service Manual CS3000 Contents ii

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 1995, Consilium Marine AB

About this manual

This manual is intended to be used by personnel who maintain and perform

service on the CS3000 system.

Chapter Control Unit gives a general description on how the Control unit

works.

Chapter The Circuit Board of the Control Unit describes the functions of the

Control unit’s circuit board.

For information regarding the Central unit’s various circuit boards refer to The

Circuit Boards of the Central Unit chapter.

DIP switch settings for all different parts of the CS3000 system are listed in

the DIP Switch Settings appendix.

The fault codes for CS3000 version 4 and 6 are listed in the Fault Codes

CS3000 Version 4 and Fault Codes CS3000 Version 6 appendixes

respectively.

For a more detailed description of the system refer to the CS3000 Reference

Manual.

Service Manual CS3000 Chapter 1: Service mode 1-1

Control unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 1995, Consilium Marine AB

Chapter 1: Control unit

Service mode

The control unit includes a fourth access level to be used only by the service

engineer. There are two functions in the service mode: bypass the built-in short

circuit isolators and definition of control unit address.

Set address

(Access level 4)

Each control unit in the system must have a unique address in the interval 217

- 232. The control unit number must correspond with the number defined in

the Definition program. The control unit address must be set after the system

definition is downloaded and the system is restarted.

• Press F4 (MENU) until SERVICE is displayed on line 4.

• Press F1 (SERVICE).

• Press F1 (ADDRESS).

• Enter the address for the control unit. The address interval is 217 - 232.

Bypass built-in short circuit isolators

The built-in short circuit isolators, two on each loop, are bypassed when you

activate the SERVICE function. The short circuit isolators remain bypassed

until you activate them again.

• Press F4 (MENU) until SERVICE is displayed on line 4.

• Press F1 (SERVICE).

Service Manual CS3000 Chapter 2: Input/Output board IKK-4 2-1

The circuit board of the control unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 1995, Consilium Marine AB

Chapter 2: The circuit board of the control unit

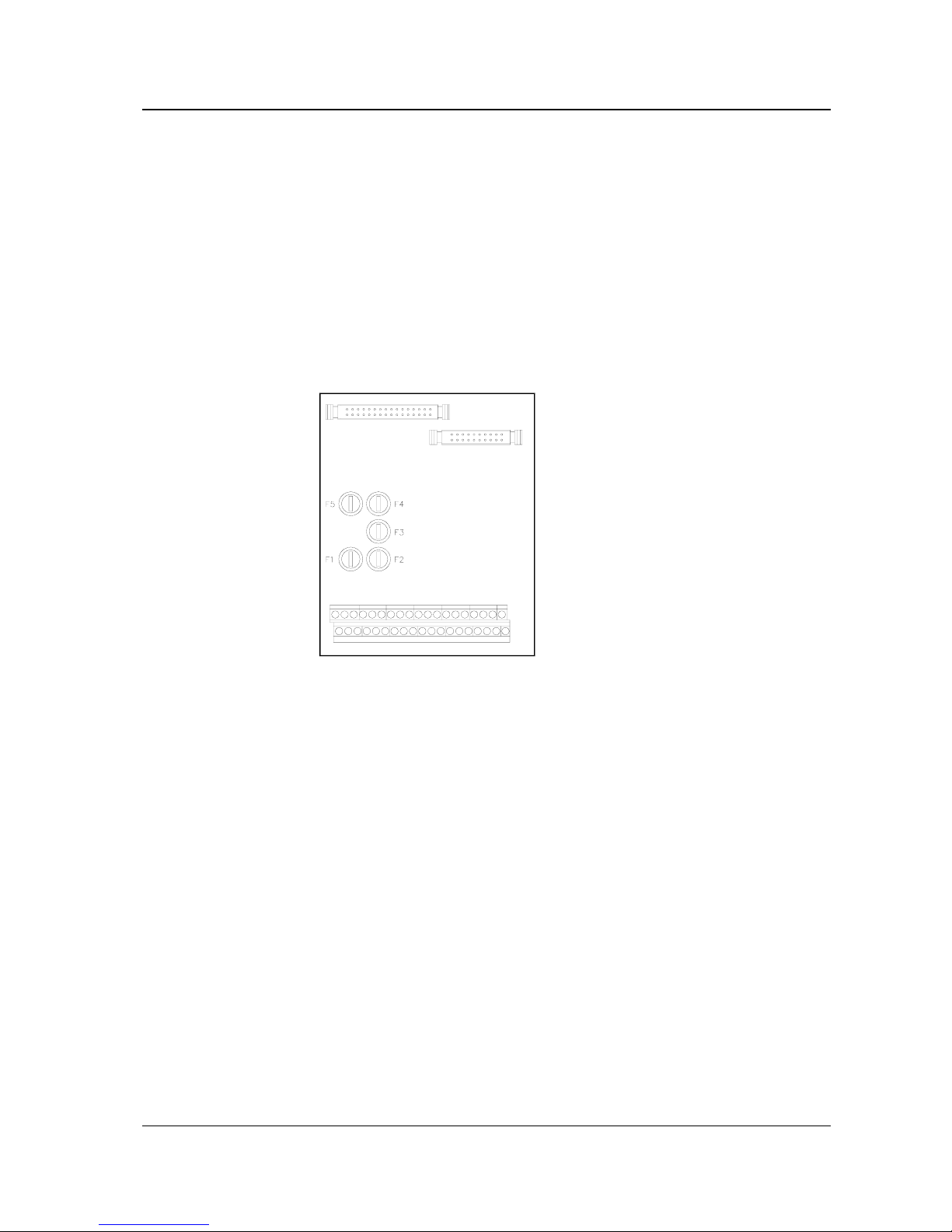

Input/Output board IKK-4

General

The Input/output board (IKK-4) interfaces the control unit processor board to

the system loop. The IKK-4 board also includes circuits for transient

suppression of all external signals. The IKK-4 board is controlled by the

control unit board, via the address and data busses.

Handling

Fuses

Fuse Fuse rating Fault code

F1: Control unit panel 500 mAT 5x20 mm Not supervised

F2: Main fuse 100 mAT 5x20 mm Not supervised

F3: Main fuse for F4-F5 500 mAT 5x20 mm Not supervised

F4: Power supply ext. device 315 mAT 5x20 mm Not supervised

F5: Power supply 315 mAT 5x20 mm Not supervised

Service Manual CS3000 Chapter 2: Input/Output board IKK-4 2-2

The circuit board of the control unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 1995, Consilium Marine AB

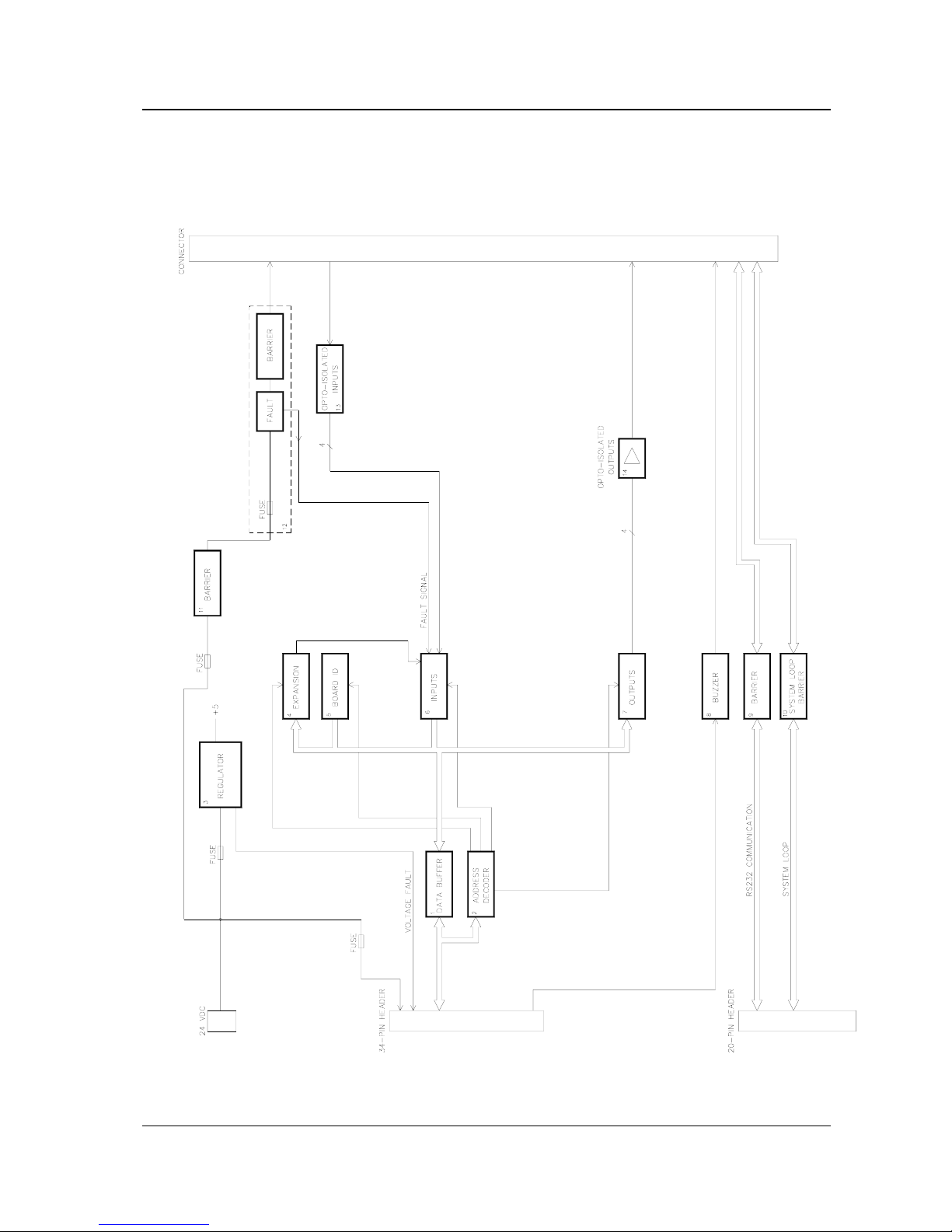

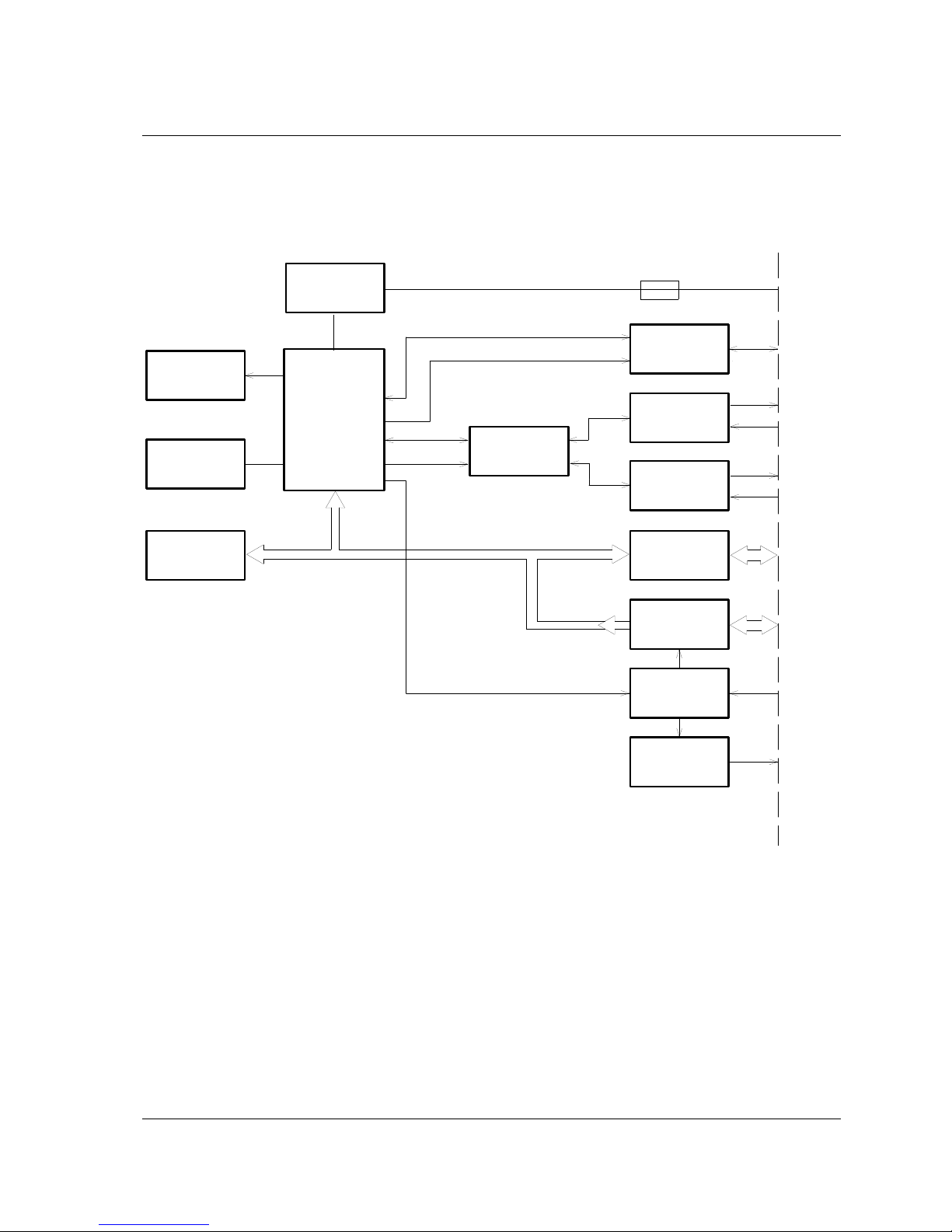

Function

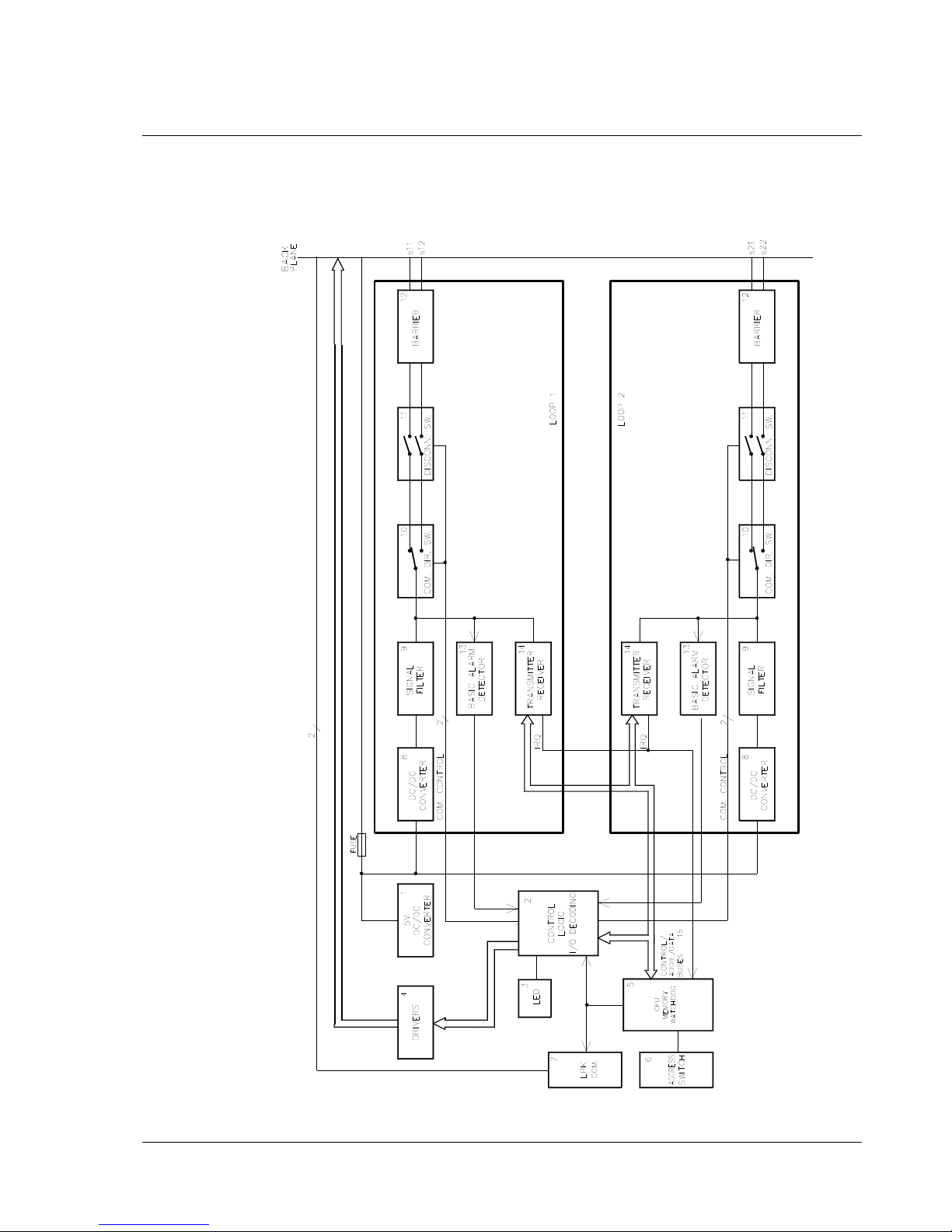

Block diagram

Service Manual CS3000 Chapter 2: Input/Output board IKK-4 2-3

The circuit board of the control unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 1995, Consilium Marine AB

1. Data buffer

The data bus is buffered before entering/leaving the board.

2. Address decoder

The address decoder selects the different blocks. The address decoder is

controlled by the control unit board.

3. Regulator

The regulator converts power voltage to 5 VDC.

4. Expansion

Future expansion possibilities. Not used.

5. Board ID

The control unit board reads the IKK-4 ID.

6. Inputs

Reads all external inputs.

7. Outputs

Controls the four transistor outputs.

8. Buzzer

An external buzzer may be connected via a transient protected output. The

buzzer will be parallel connected to the fire alarm and the fault buzzer on the

control unit board.

9. Barrier

The RS 232 communication is protected against transients before entering the

control unit board.

10. System loop barrier

Transient barrier for the system loop.

11. Barrier

The power supply voltage output is protected against external transients.

12. Power supply output

A fused and fault supervised output for power supply to an external device.

13. Opto-isolated inputs

Four opto-isolated transient protected external inputs.

14. Opto-isolated outputs

Four transistor outputs. Deactivated at hang-ups in the programme execution.

Service Manual CS3000 Chapter 2: Input/Output board IKK-4 2-4

The circuit board of the control unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 1995, Consilium Marine AB

Technical data

Board size: 145 x 107 mm

Ambient temperature: -10°C - +70°C.

Ambient humidity: 96% Rh.

Input power: U

in

: 24 VDC (-20% - + 25%).

Current consumption: I

in nom

: 15 mA

I

in max

: 40 mA.

Outputs: 4 opto-isolated sourcing outputs

Inputs: 4 opto- isolated inputs, active high

Service manual CS3000 Chapter 3: Loop processor board SPK-2 3-1

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

Chapter 3: The circuit boards of the central unit

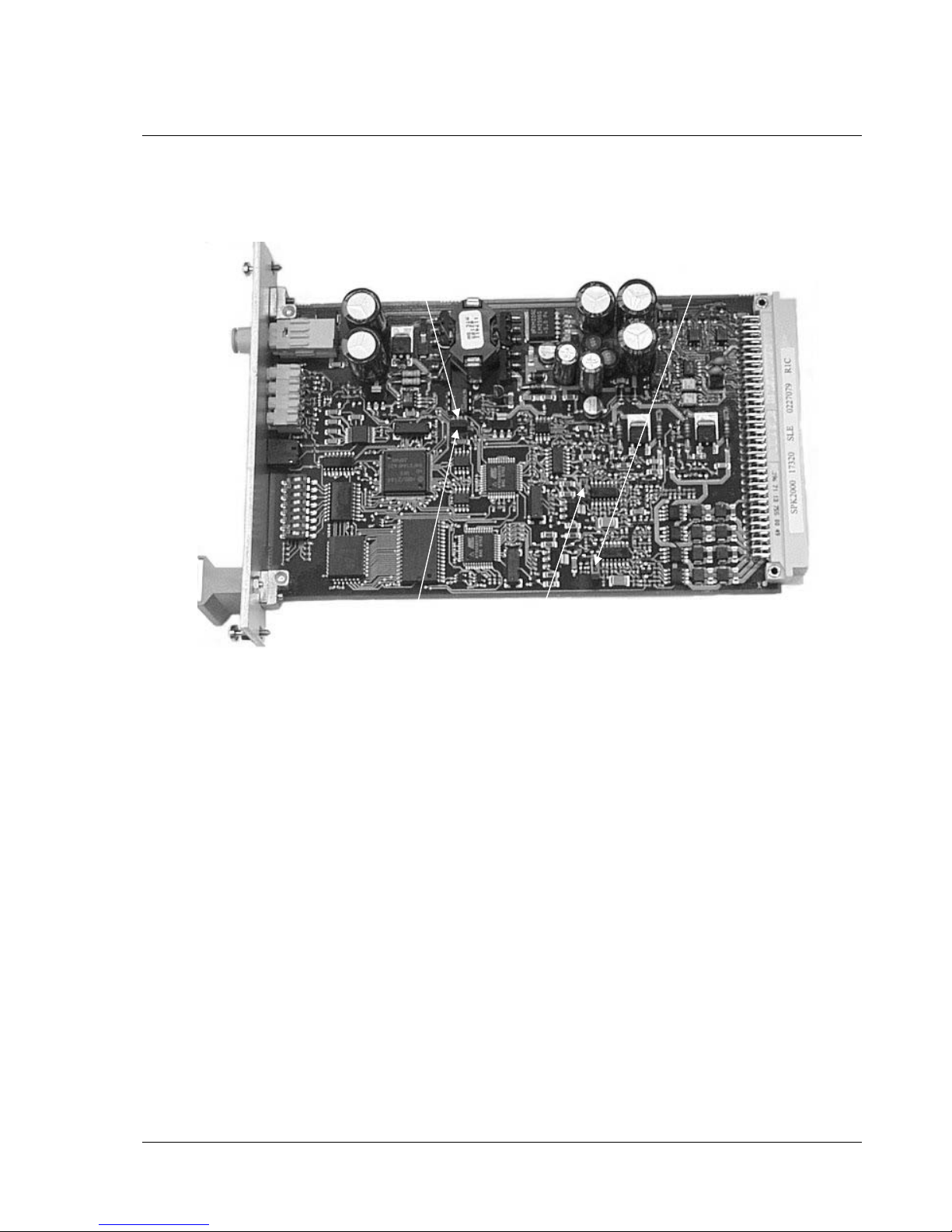

Loop processor board SPK-2

The loop processor boad SPK-2 exists in three different models. Model 1 and

model 2 differs only in the exterior of the front panel, whereas Model 3 has an own

block diagram.

General

The loop processor board SPK-2 controls and supervises two detector loops with

analogue and addressable detectors. The detectors are constantly polled in order to

detect faults or changes in alarm status. Detector-initiated alarms are also

recognised and verified. The events are reported to the LPK-2 and proper hardware

signals are then activated.

Handling

Indications

Model 1 There are nine LEDs on the front panel of the board.

No 1 (green) when lit: proper voltage supply.

No 2 (yellow) when lit: fault in loop #1.

No 3 (red) when lit: fire alarm in loop #1.

No 4 (yellow) when lit: fault in loop #2.

No 5 (red) when lit: fire alarm in loop #2.

No 6 (yellow) when lit: local processor failure

No 7 (in service mode) will flash synchronously with the central unit’s

communication with the loop-PCB.

No 8, 9 (in service mode) will flash synchronously with polling of the

loop-units

Model 2 & 3 There are eight LEDs on the front panel of the board.

No 1 (green) when lit: proper voltage supply.

No 2 (yellow) when lit: local processor failure.

No 3, 4 (green) (in service mode) will flash synchronously with polling of the

loop-units

No 5 (yellow) when lit: fault in loop #1.

No 6 (red) when lit: fire alarm in loop #1.

No 7 (yellow) when lit: fault in loop #2.

No 8 (red) when lit: fire alarm in loop #2.

Service manual CS3000 Chapter 3: Loop processor board SPK-2 3-2

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

Fuse

The battery voltage is fused. If the fuse is blown a signal is activated in the back

plane. The fuse is accessible on the front panel of the board, and can be used for

disconnecting the power.

Fuse ratings:

Model 1 & 2: 1 AT 5x20 mm

Model 3: 1.6 AT 5x20 mm

Setting the address

The address of loop #1 of the board is set with a DIP-switch (SW1), with 8

switches. Bit #1 is set with SW1-1, and bit #8 with SW1-8. The address of loop #2

is automatically set by the system to the next consecutive value.

Set the address of each SPK-2 according to the definition in the Definition

program.

Restarting the board

Remove the fuse from the board to disconnect the power. When the fuse is put back

on, the board is restarted.

Replacing the board

To replace the SPK-2 follow these steps:

1. Disconnect the power by removing the fuse.

WARNING!

The power must be disconnected before the board is removed.

2. Remove the board and replace it with the new board.

Service manual CS3000 Chapter 3: Loop processor board SPK-2 3-3

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

Function

Block diagram Model 1 & Model 2

NB! In the diagram blocks 8 - 14 are doubled, one set for each detector loop.

Service manual CS3000 Chapter 3: Loop processor board SPK-2 3-4

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

1. Power supply

Power supply for processor, memory and logic of the loop processor board.

2. Control logic

Control logic for activation and blocking of hardware signals to the back plane.

LEDs for indication of status and communication are also controlled in this block.

3. LED indications

LEDs for indicating status of fire, fault, communication and voltage.

4. Drivers

Drivers for adapting hardware signal to the back plane.

5. CPU/Memory/watchdog

This is the main block of the SPK-2 board. The CPU controls both of the detector

loops and the communication with the LPK-2. The memory circuits contain the

programme code, default data for the detectors and status information. The

watchdog supervises the processor and checks for hang-ups in the programme

execution.

6. Address switch

The 8-bit address of the SPK-2, i.e. the loop number, is set with the DIP switch.

7. LPK communication

Interface for back plane communication.

8. DC/DC converter

The DC/DC-converter converts the battery voltage from the back plane to 30 VDC,

for the detector loops.

9. Signal filter

Signal filter for the communication signals.

10. Communication direction switch

For closed loops the choice of direction for the communication is made with this

switch.

11. Disconnection switch

With this switch the entire detector loop may be disconnected.

12. Barrier

Barrier for protecting the loops against incoming transients.

13. Basic-Alarm detection

Circuit for the detection of a basic-alarm.

14. Transmitter/receiver

Transmitter, receiver and interface for the processor bus.

15. Buses

The control signal bus contains signals to control the reading and writing of devices

connected to the address bus and the data bus.

Service manual CS3000 Chapter 3: Loop processor board SPK-2 3-5

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

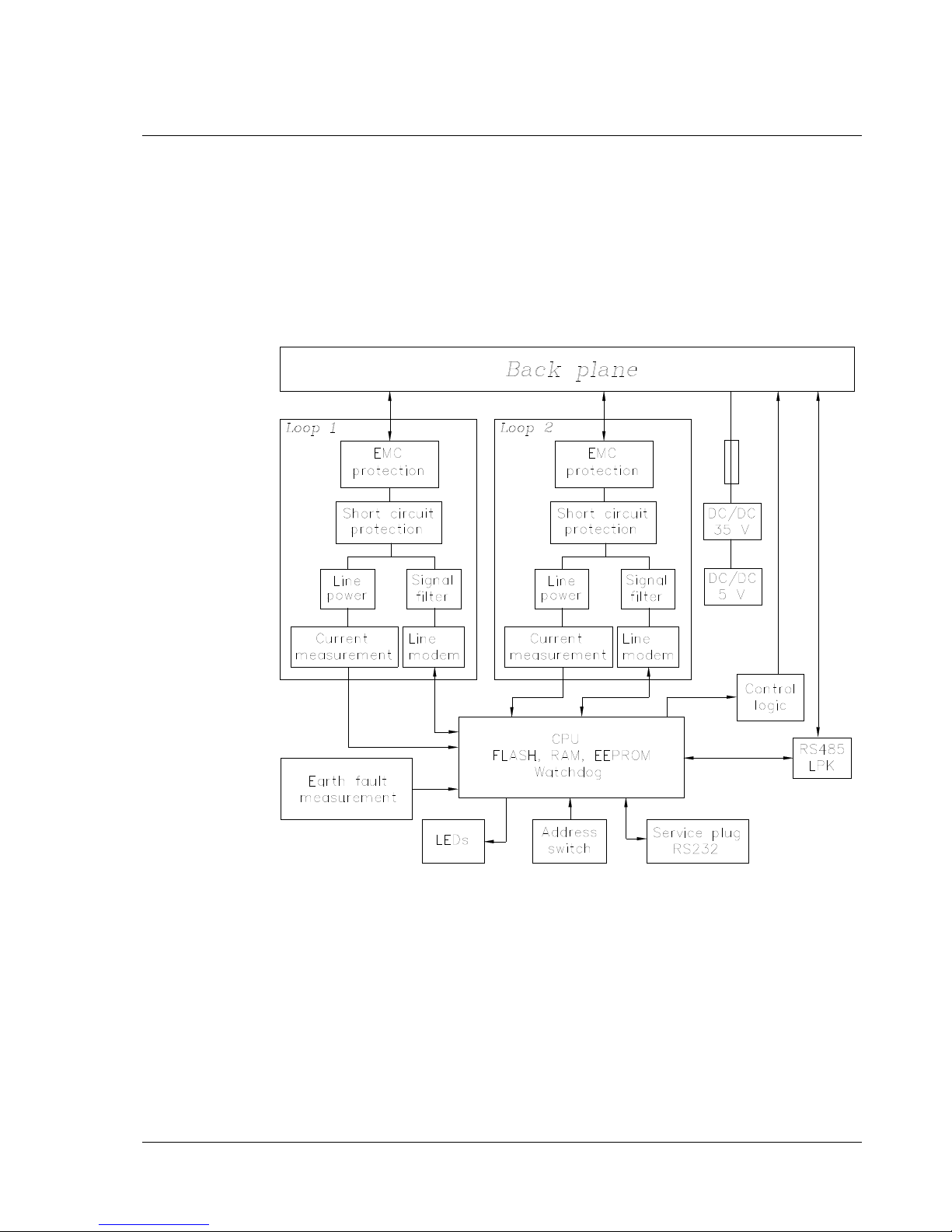

Block diagram Model 3

SPK-2 Model 3 can be split into three functions: Power supply, loop and processor

with memory. The power supply provides the board with loop power and power for

the logic and the processors. The loop part contains electronics for two loops and

handles power supply for the loop and sending/transmitting of IDA and NOSE

messages. The processor controls the loops and communicates with the LPK via the

RS485 channel of the back plane.

The whole board is galvanically isolated from the CS3000 rack.

Service manual CS3000 Chapter 3: Loop processor board SPK-2 3-6

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

DC/DC converter

Power is taken from the back plane and converted via a galvanically isolated

DC/DC converter into 35V. The 35V is used to power feed the loops and is also

converted to 5V for the logic. The voltage feed is fused.

Control logic

Signals in the back plane for fuse fault, voltage fault and prim-alarm. All signals

are galvanically isolated between SPK-2 and the back plane.

LEDs

Indicating status of the system. Some LEDs are active only in service mode.

CPU, memory and watchdog

The CPU controls and supervises the communication on both loops and also

communicates with the LPK. The memory contains program code with initial

values for the loop units and also gives status information. The watchdog

supervises the CPU and activates a reset signal to the CPU in case of malfunction.

Address switch

An 8-pole DIP-switch deciding the physical address of the board.

RS485 LPK communication

One asyncronous channel of the processor is used for communication with the

LPK. These signals are adapted to the RS485 levels and are galvanically separated

from the back plane.

Service plug

RS232 channel used for service, debugging and downloading of code.

Earth fault measurement

Measuring positive and negative earth faults. Since the board is galvanically

separated from the rest of the system, the measurement is a local indication of earth

faults from the loops. Earth fault is not measured when the board is used for

connection of GSK.

Loop : EMC protection

Protecting the electronics from various EMC disturbances.

Loop: Short circuit protection

Contains two parts, one part automatically disconnecting the loop power when the

current consumption exceeds allowed limit and one part which is used to control

the power feed to the primary and/or secondary side of the loop.

Loop: Line power

Feeding the loop with correct DC voltage and current and adapting the loop to the

signalling used on IDA and NOSE loops.

Loop: Current measurement

Measuring the DC current which is fed to the loop.

Loop: Signal filter

Separating and filtering out IDA/NOSE communication from the DC supply

voltage on the loop.

Loop: Line modem

Sending and receiving IDA/NOSE communication. Communication with the

processor via serial channel.

Service manual CS3000 Chapter 3: Loop processor board SPK-2 3-7

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

Jumpers Model 3

JP1 Must always be strapped in normal operation. The strap enables the

watchdog.

JP2 Never strapped during normal operation.

JP1 and JP2 are only strapped differently during production when the card is

programmed the first time.

JP3 Normally strapped.

JP4 Normally strapped.

JP3 and JP4 can be used to enhance reception of loop communication in case of

loops with communication problems.

JP1

JP3

JP4

JP2

Service manual CS3000 Chapter 3: Loop processor board SPK-2 3-8

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

Technical data Model 1 & 2

Board size: Single Europe board, 100 x 160 mm

Front panel: Anodised aluminium, width 6 TE(30.1 mm)

Ambient temperature: -10°C to +70°C

Ambient humidity: 96% Rh

Input power: U

in

: 24 VDC (-20% - + 25%)

Current consumption: I

in nom

: 90 mA

I

in max

: 160 mA

Output voltage: U

ut

: 30 VDC (+/- 5%)

Output current: I

ut nom

: 45 mA

I

ut max

: 125 mA

Model 3

Board size: Single Europe board, 100 x 160 mm

Front panel: Anodised aluminium, width 6 TE(30.1 mm)

Ambient temperature: -10°C to +70°C

Ambient humidity: 96% Rh

Input power: U

in

: 24 VDC (-20% - + 25%)

Current consumption: I

in nom

: 120 mA (no loop units connected)

I

in max

: 1300 mA

Output voltage: U

ut

: 32 - 34 VDC

Output current: I

ut max

: 300 mA/loop

Service manual CS3000 Chapter 3: Alarm processor board LPK-2 3-9

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

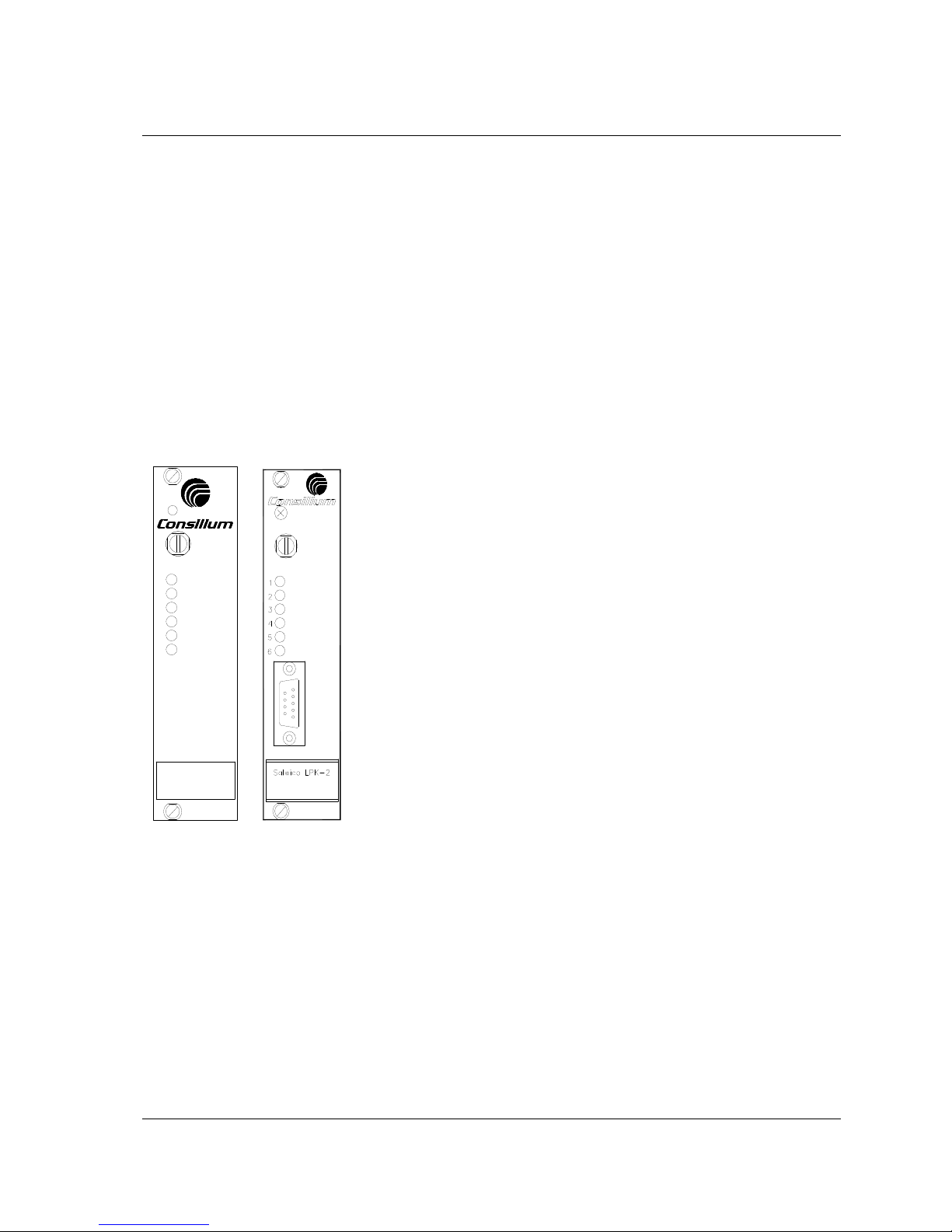

Alarm processor board LPK-2

General

The alarm processor board LPK-2 controls and supervises the external alarm

devices. The board also controls external functions such as fans, fire doors and

release of fire extinguishing agents through relay outputs. The LPK-2 also

monitors all communication within its own central with all loop processor

boards. The LPK-2 that is situated in the main central unit also monitors all

communication on the system loop with control units and with external

computers, printers, etc.

The alarm processor board exists in two different models, which differ only in

the exterior of the front panel. Model 2 has an additional connector for

downloading data from a computer.

Handling

1

2

3

4

5

6

Salwico LPK-2

Model 1 Model 2

Indications

There are six LEDs on the front panel of the board.

No 1 (green) when lit: proper voltage supply.

No 2 (red) when lit: fire alarm has been given on the fire

brigade relay output.

No 3 (yellow) when lit: fault has been detected.

No 4 (yellow) when lit: local system failure

No 5 (green) (in service mode) will flash synchronously with the

central unit’s communication with the

loop-PCB.

No 6 (green) (in service mode) will flash synchronously with the

communication on the system loop.

Fuse

The battery voltage is fused. If the fuse is blown a signal is activated in

the back plane. The fuse is accessible on the front panel of the board,

and can be used for disconnecting the power.

Fuse rating: 1 A 5x20 mm

Setting the address

The address of the board is set with a DIP-switch (SW1), with 8 switches.

• Sw 6 (when set) activates the service mode.

• Sw 7 (when set) allows communication only on loop 1 (the primary loop).

• Sw 8 (when set) allows communication only on loop 2 (the secondary loop).

• Sw 6, 7, 8 (when set together) forces downloading of definition data.

The address interval is 1 - 16. The LPK-2 board controlling and supervising the

main central unit is always set to one. The addresses of the other LPK-2, if

installed in the system, are set according to the definition in the Definition

program.

Service manual CS3000 Chapter 3: Alarm processor board LPK-2 3-10

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

Restarting the board

Remove the fuse from the board to disconnect the power. When the fuse is put

back on, the board is restarted.

Replacing the board

To replace the LPK-2 follow these steps:

1. Disconnect the power by removing the fuse.

2. To avoid activation of Bells, remove fuses F5-F10 on ARK-2.

WARNING!

The power must be disconnected before the board is removed.

3. Remove the board and replace it with the new board.

Service manual CS3000 Chapter 3: Alarm processor board LPK-2 3-11

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

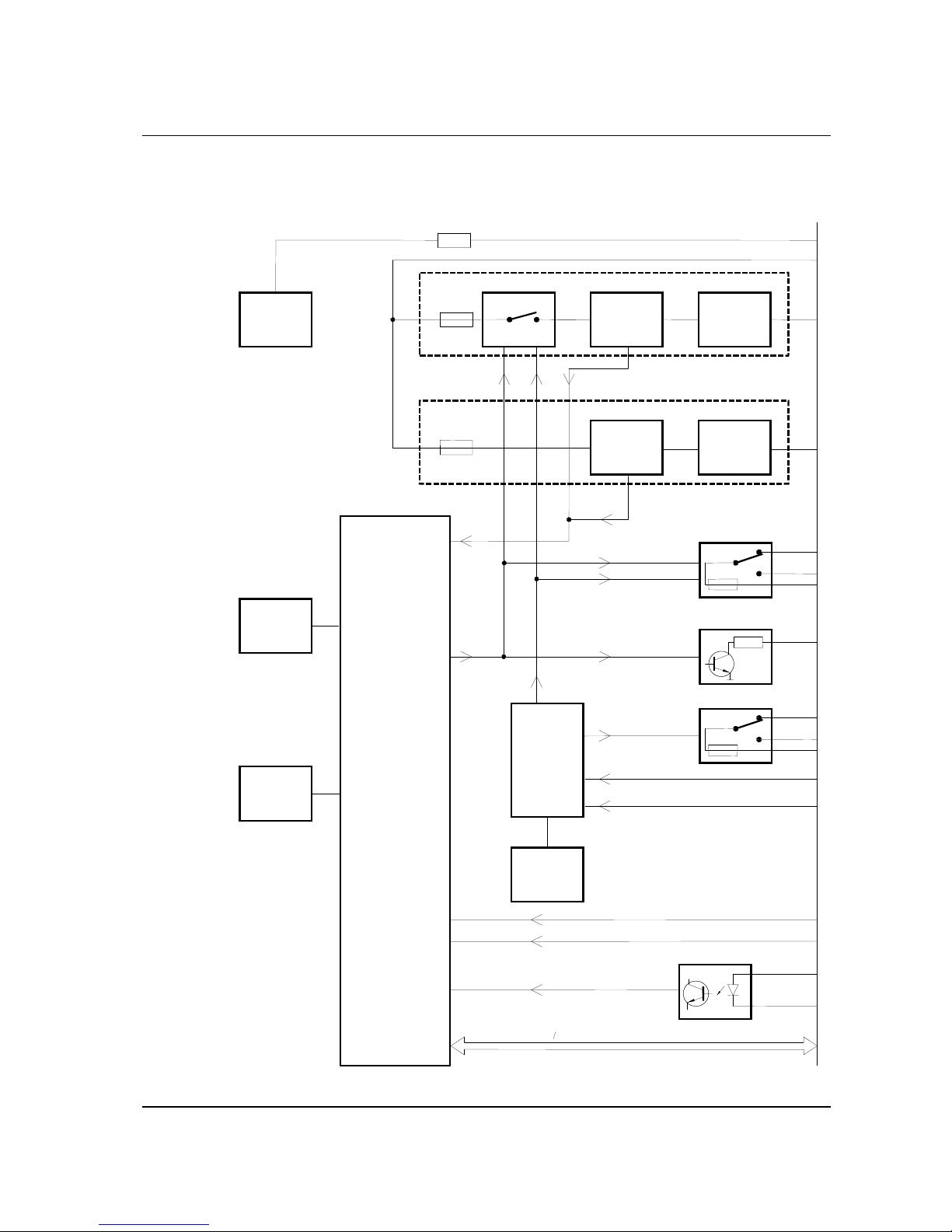

Function

Block diagram

OUTPUTS

RELAY

SYSTEM

COM. LOOP

(CSM/LPK)

(CSM/LPK)

COM. LOOP

SYSTEM

SYSTEM

SYSTEM

BUFFERS

DATA/ADDRESS

COM. CONTR.

INT.COM.

BASIC

1

12

10

9

8

8

6

7

2

5

4

3

BLOCK

24 VDC

LOOP 2

LOOP 1

ADDRESS/DATA/CONTROL

TX/RX

TX/RX

TX/RX

RX

TX

RX

TX

TX/RX

DIR

TX/RX

FUSE

SWITCH

LOOP

CONVERTER

11

BACK PLANE

LOOP (SPK)

ALARM

SIGNALS

BACK PLANE

WATCH-DOG

MEMORY

CPU

INDICATIONS

LED-

DC/DC

SWITCH

ADDRESS

CLOCK

REAL TIME

Service manual CS3000 Chapter 3: Alarm processor board LPK-2 3-12

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

1. DC/DC converter

The DC/DC circuit converts the battery voltage of the back plane to 5 VDC,

which is supplied to all logical circuits on the board.

2. CPU/Memory/Watchdog

This is the main block of the LPK-board. The CPU uses the memory circuits for

executing the programme code. There is also a non-erasable memory containing

the system configuration and the external controls. The watchdog supervises the

processor and checks that there are no hang-ups in the programme execution.

3. LED indications

One green LED indicates that the board is power supplied. If the watchdog is

activated (possible fault in the board), a yellow LED is lit, indicating system

fault. Furthermore there are two LEDs (one yellow and one red) indicating fault

and alarm in the central unit. Finally there are two green LEDs that are used for

service purposes.

4. Address switch

With the DIP switch the 8-bit address of the LPK is set.

5. Real time clock

The real time clock is keeping track of the time in the system. The clock has

built-in registers for seconds, minutes, hours, days, week-day, month and year

(including leap-years). The real time clock is reset from the control panel.

6. Internal communication loop (RS485)

The internal communication loop is connected to all SPKs in the same rack

system. All SPKs are polled and supervised via this loop.

7. Loop switch

The loop switch changes the communication channel from one external loop to

the other.

8. System communication loop (RS422)

This block contains the communication with control units and other central

units.

9. Data/address buffers

All bus connections going from the back plane are buffered in special buffer

circuits.

10. Back plane signals

Certain hardware signals in the back plane are read by the LPK after a voltage

conversion.

11. Basic-alarm

The basic-alarm function is activated if a SPK or the LPK is faulty and therefore

incapable of transmitting an alarm. This board will block the basic-alarm

function if the processor is in proper working order.

12. Fire brigade output

Two relay outputs for connection to the fire brigade. The alarm relay is

programmable and the other relay is activated when there are not muted faults in

the system.

Service manual CS3000 Chapter 3: Alarm processor board LPK-2 3-13

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

Technical data

Board size: Single Europe board, 100 x 160 mm.

Front panel: Anodised aluminium, width 6 TE (30.1 mm).

Ambient temperature: -10°C to +70°C.

Ambient humidity: 96% Rh.

Input power: U

in

: 24 VDC (-20% - + 25%).

Current consumption: I

in nom

: 80 mA

I

in max

: 120 mA.

Outputs: 2 relays, 480 mA, 125 V

Service manual CS3000 Chapter 3: Relay board ARK-2 3-14

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

Relay board ARK-2

General

Orders to the alarm devices and controls issued by the LPK is executed by the

relay board. The alarm device outputs can also be activated by a basic-alarm

via the back plane. Furthermore the relay board may be used for monitoring

external signals and for supervision of power supply to external units.

Handling

Indications

The LED on the front panel of the board is lit every time the board is polled.

Fuses

There are 14 fuses on the front panel..

F1 Output 24 VDC 1+ F2 Output 24 VDC 1F3 Output 24 VDC 2+ F4 Output 24 VDC 2F5 Alarm bell output 1+ F6 Alarm bell output 1F7 Alarm bell output 2+ F8 Alarm bell output 2F9 Alarm bell output 3+ F10 Alarm bell output 3F11 Relay output RL1 F12 Relay output RL2

F13 Relay output RL3 F14 GA-output

Fuse rating: 2 AT 5x20 mm

Salwico ARK-2

F13

F11

F9

F7

F5

F3

F1 F2

F4

F6

F8

F10

F12

F14

Service manual CS3000 Chapter 3: Relay board ARK-2 3-15

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

Jumper "PLUS"

With this jumper the pulse type can be altered. In the left position the pulse is

internally generated, in the right position the pulse comes from an external

source.

Switch S9

This switch is found on the front panel and is used for resetting the basicalarm.

Switch SW1

SW1-1, SW1-2, SW1-3 (B1, B2, B3)

"ON" : Steady signal to corresponding alarm bell output.

"OFF": Pulsed signal to corresponding alarm bell output.

SW1-4, SW1-5, SW1-6 (R1, R2, R3)

"ON" : Steady signal to the outputs of relays RL1-RL3.

"OFF": Pulsed signal to the outputs of relays RL1-RL3.

SW1-7 (GA)

"ON" : Signal in step with the signal on the GA-input.

"OFF": Pulsing signal

Replacing the board

To replace the ARK-2 follow these steps:

1. Shut down the central by removing the fuses F3-F6 on the KE-2 rectifier.

WARNING!

The power must be disconnected before the board is removed.

2. Remove the board and replace it with the new board.

3. Start up the central by inserting F3+F4 and F5+F6 in that order.

Service manual CS3000 Chapter 3: Relay board ARK-2 3-16

The circuit boards of the central unit

Document no.: S-4-007.875/E

Prepared: 1995-03-17 Fia

Revision: R4 2004-03-15 BM

© 2002, Consilium Marine AB

Function

Block diagram

IN PUT

SIG NALS

CONTROL

BASIC ALAR

M

LED

PA NEL

SW ITCH

DIP

PTC

BARRIERFA ULT

BACK PLANE

PTC

uP BUS

OP TO I S OL.

EXT. FUSE FAULT

SW ITCH

PA NEL

15

14

13

12

17

16

11

10

9

8

7

EPLD/ PI

1

4

3

6

5

2

LOG IC

GA

GA INTERM. INPU

T

GA INPUT

OUTPUT

GA - RELA

Y

OUTPUT

FIRE/ FAUL

T

RELAY OUTPU

T

POWER SUP PL Y

ALARM DEVI CE

DET.

FA ULT

BARRIERFA ULT

FUSE

FUSE

CONVERTE

R

DC/ DC

Loading...

Loading...