Page 1

INDUSTRIAL

ELECTRIC

STEAM

IRON

MODELS·

HOW

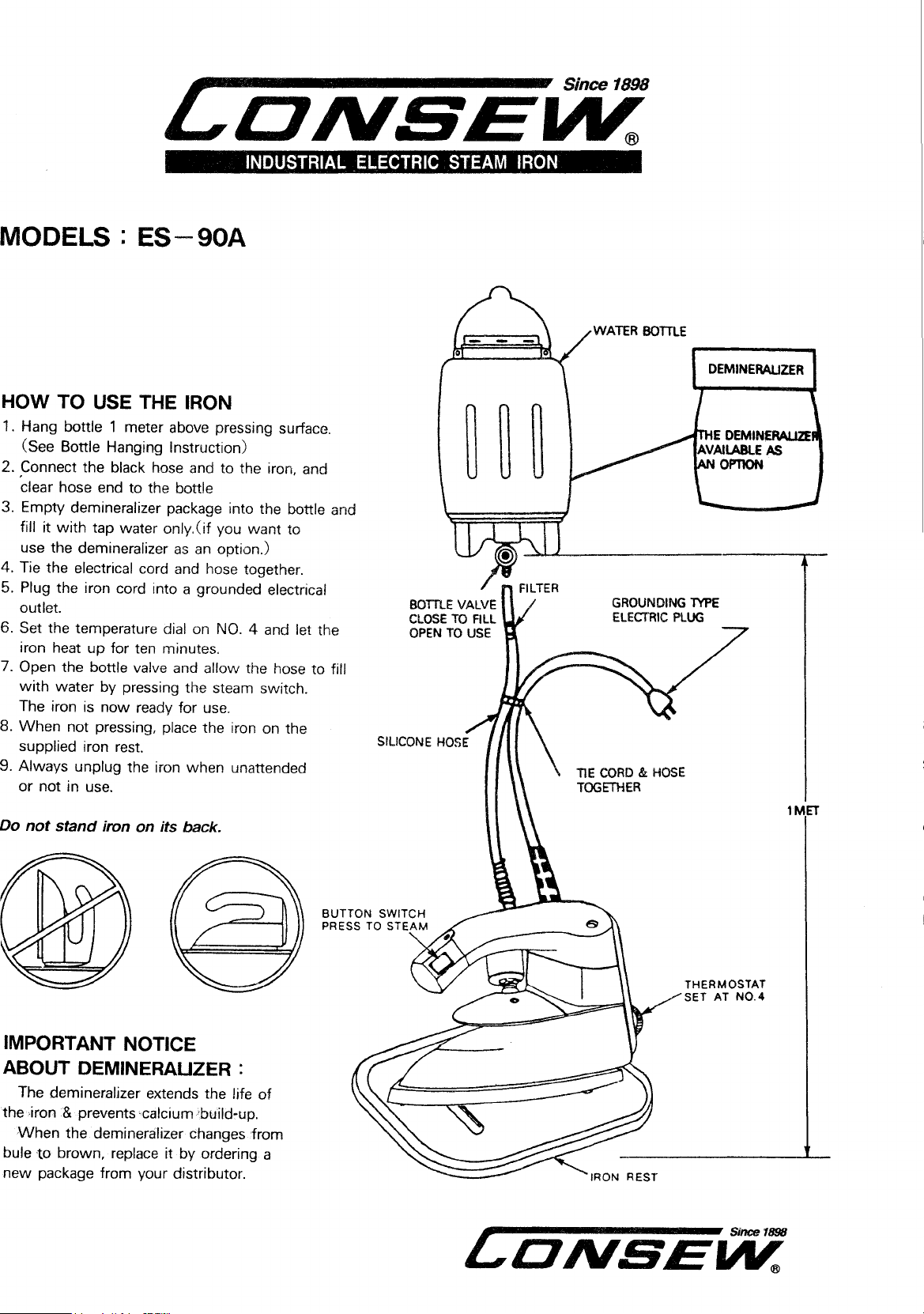

1. Hang bottle 1 meter above pressing surface.

2. Connect the black hose and to the iron, and

3. Empty demineralizer package into the bottle and

4. Tie the electrical cord and hose together.

5.

6.

7.

8. When not pressing, place the iron

9. Always unplug the iron when unattended

Do not stand

TO

(See Bottle Hanging Instruction)

clear hose end to the bottle

fill it

with

use the demineralizer

Plug the iron cord into a grounded electrical

outlet.

Set the temperature dial

iron heat up for ten minutes.

Open the bottle valve

with

water by pressing the steam switch.

not in

is

use.

The iron

supplied iron

or

ES-90A

USE THE IRON

tap water only.(if you want to

as

an

option.)

on

NO.

4 and let the

and

allow the hose to fill

now ready for

rest.

iron

on its back.

use.

on

the

WATER

GROUNDING

ELECTRIC

TIE

CORD & HOSE

TOGETHER

BOffiE

DEMINERAUZER

1YPE

PLUG

1MET

IMPORTANT NOTICE

ABOUT DEMINERAUZER

The demineralizer extends the life

the iron & prevents ·calcium

When

bule

new package from your distributor.

the demineralizer changes from

to

brown, replace it by ordering a

:

of

'btJild~up.

LIDNSEMl

Page 2

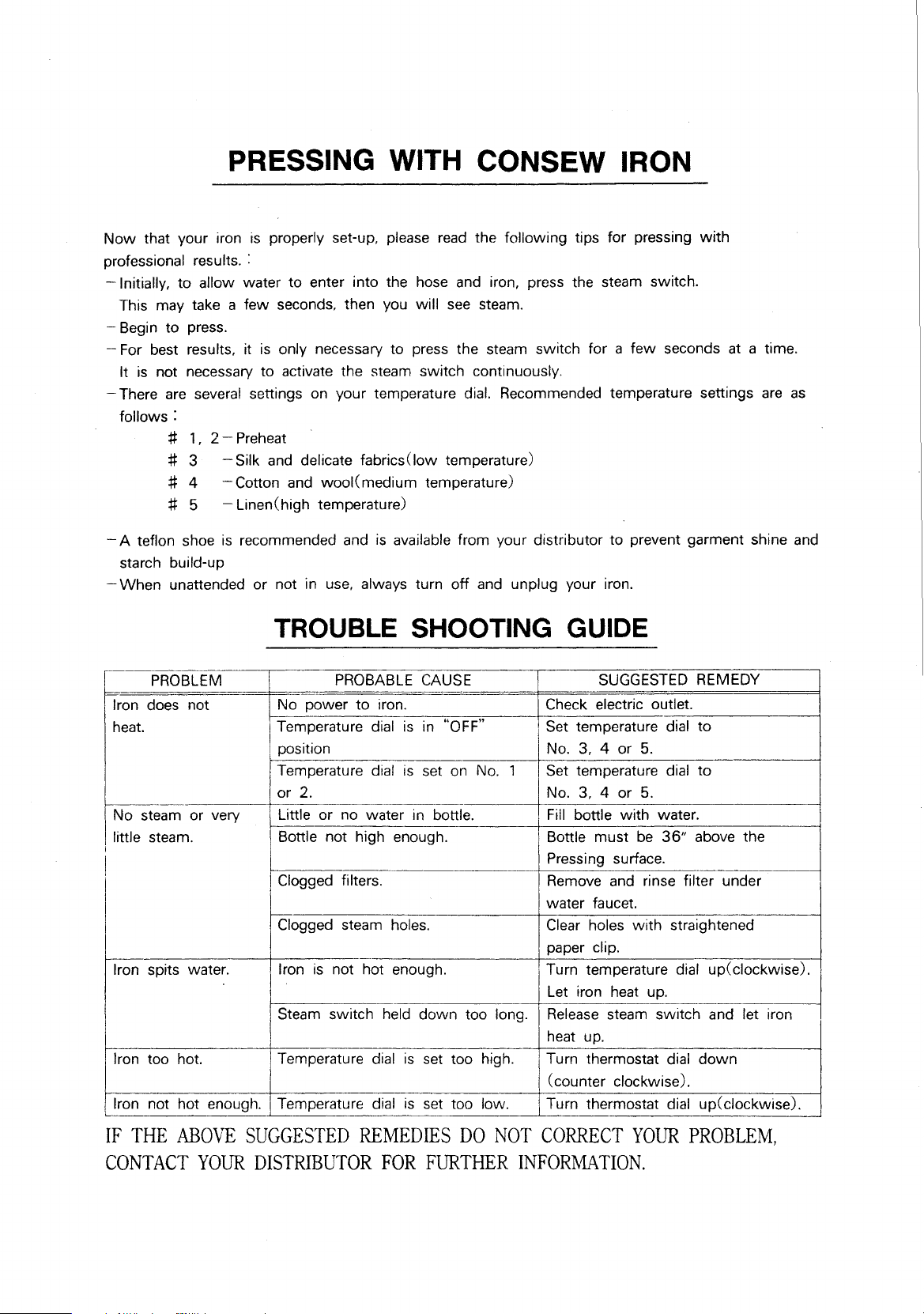

PRESSING WITH CONSEW IRON

Now

that your iron

professional results. :

-Initially,

This may take a

-Begin

--For

It

-There

follows:

-A

starch build-up

--When

to

allow water

to press.

best results, it

is

not necessary to activate the steam switch continuously.

are

several settings on your temperature dial. Recommended temperature settings

# 1 , 2 - Preheat

# 3

# 4

# 5

teflon shoe

unattended or not in

-Silk

-Cotton

- Linen(high temperature)

is

recommended and

is

properly set-up, please read the following tips for pressing

to

enter into the hose and iron, press the steam switch.

few

seconds, then you will see steam.

is

only necessary to press the steam switch for a

and delicate fabrics

and

wool(medium

use,

(low

temperature)

temperature)

is

available from your distributor to prevent garment shine and

always turn off and unplug your iron.

few

with

seconds at a time.

are

as

TROUBLE SHOOTING GUIDE

PROBLEM

ron does not

~

eat.

I

==c=

~~wer

I Temperature dial

,

pos1t1on

!Temperature dial IS set on No. 1 Set temperature dial

PROBABLE CAUSE I SUGGESTED REMEDY

to

1ro_n-:-.

-,-----,

~=;-----4-

7

is

in

"OFF" . Set temperature dial

~heck

No. 3, 4 or

electric outlet.

5.

h I or 2. No. 3, 4 or 5.

No steam- or very

I

, little steam. 1 Bottle not high enough. Bottle must

' I Pressing surface.

Iron spits water.

Iron too hot. Temperature dial

Iron not hot enough. Temperature dial

L-------~-L-~--------

IF

THE

ABOVE

~Little

~ogged

SUGGESTED

or no water in bottle. I Fill bottle with water.

be

Clogged filters. Remove and rinse filter under

water faucet.

steam holes.

Iron

is

not hot enough. Turn temperature dial up(clockwise).

Steam switch held down too long. Release steam switch and let

is

set too high. Turn thermostat dial

is

set too low. Turn thermostat dial up(clockwise).

REMEDIES

-

DO

NOT

Clear holes

paper clip.

Let iron heat up.

heat up.

(counter clockwise).

--

·-------------;-----~--1

CORRECT

with

YOUR

to

to

36"

above the

straightened

down

PROBLEM,

--

1ron

CONTACT

YOlJR

DISTRIBUTOR

FOR

FURTHER

INFORMATION.

Page 3

.-----·-

-----

---

---

• I

' 0 i '

-------;

~

~?-_

j_

______

- -

: -- I

---

----f?1:;

'f

I

~1

..

c~.

!£=

<~-~~::;~~-~-

I :

:~~

"J

'tl ' I

-·---

_ - - l I

;·-

:

t-

'-="-

, I

I · I

i

\:2_1>

~-

.

L._

-·-

' I

:®""'

-

---(?_~

i L - -

--@

~Xi

~-,_'Y9;,n:

I • •

'!"!'

'~

: .

:----

.

I \

. I

'

...

I

--~

---"

~iJ

~:_

~

'-

'--.

9-"):

<NO);

"-----

""'-:

~:

--·-

~

\~ff

. . -- !

(_-

itt)

i~

,'!)

: j

' ! 1 I

~I

~!)

/ ®

\_._-~,-

. . . .

9

/-~_

--;,3

---

0)

·-~--------

·-

.

I o

0-~-

-·--r

- '

j

Exploded View

~t----(;_0)

'

-----~)

-----<~

i I

---

I

i1

-~

~~

~

I.

~-

---1

0

----

I .

I

j

~

\\

~

l

~~-

t

-~

----\_ij)

__....o

___

./~

---

-·-

-tf\~~

- - - -OfJ

Ci_l)

----

J;~!-

~-----(ijl

®

,·/~.~~

I \ \

I

i

f'•./

(}-:;--·-c?J

·,:J----

'

·.

\ n

\\\

\

f

~-<_§),

__

../_-~

.(;.'-

\.._

__

I

~):

NO

PART

NO

19047

! 1

531100/531300

I 2

59010

3

4

51003

5

511102

5

511101

7

52001

21059

8

551200

18~1

541100/541200

9·1

14005

9-2

14002

14004

9·3

14007

9·4

14101

9·5

14011

9·5

9-7

14102

54001

9·8

9·9

14039

9-10

14501/14502

14038

9·11

14019

9·12

51009

10

11

511100

12

52103

13

58901158902

13·1

21070

14

161000

14·1

16009

16102

14-2

14·3

16010

14-4

16107

15

16108

15·1

16018

15·2

16031

15·3

16003

---·---

SILICONE

IRON

BASE

ASSY(

12CN/22fN)

COVER

THERMO

SHIELD

HANDLE

BASE

HANDLE

BACK

CCNER

THERMOSTAT

THERMOSTAT

SOLENOID

HOSE

HOSE

VALVE

RUBBER

VALVE

VALVE

VALVE

VALVE

VALVE

VALVE

COIL

LOCKING

SOCKET

HANDLE

LAMPASSY

LINE

CORD

WATER

HANGER

FILTER

WATER

WATER

SILICONE

FILTER

SILICONE

SiliCONE

'-

KNOB

VALVE

BARB

NUT

BARS

SOLENOID

D-RING

PACKING

PIN

SPRING

BODY

NAME

PLATE

COIL

CCNER

COIL(

12fN/22fN)

COVER

WASHER

NUT

HEAD

CAP

SET

CORD(

12fNI22M

PROTECTOR

BOmE

BOmE

BOTTLE

VALVE

HOSE

HOSE

HOSE

DESCRIPTION

REST

ASSY

ASSY(

12fN/22CN)

BOLT(M5X65)

ASSY

ASSY

SET

SPRING

'i/E!

90A~tl

90A1Jtll

ii'!I,;IE!

mt~SET

;J;I-'f.SET

~1Jtll

A90~~PI

UPil:-SET

'II"!SET

~~?,jLig

l"!if,;l

lit:<£~

~~PIIit.:il!f

'II!:!E!

~~~

'II!:!~

'II!:!~E!

i!~~llj

~~~~

~llj2jAI

'iJLig

\!JI!fg

Al-'f.l!SET

IESET

~f!.l!E.tlSET

fl

HSET

H.:ili!l

tiEl

H

~35fT

~i!I~~ET

IIEI

~i!li!!!t:

~i!lf!!!AAilfj

Page 4

CEILING HOOK INSTALLATION INSTRUCTIONS

IMPORTANT:

OVER

CAUTION

hardware is

that

HOOK.

are

SLIDE CHAIN LINK ONLY

-Injury

pulled from the ceiling. To avoid such injury,

structurally sound.

CAUTION-DO

to persons or damage to the ceiling may result if the bottle or mounting

NOT SLIDE ELECTRICAL WIRE

OVER

HOOK.

mount

only to ceiling members

OH

WATER

FOR HOLLOW CEILINGS :

1)

Drill

5/8"'

diameter hole in the ceiling at desired hook loca-

tion.

2\

Assemble toggle bolt by screw1ng bolt

3 I Insert flaps and bolt assembly(

with

the

bolt(A)

turning hook(C1 clockwise until firmly seated.

protruding through ceiling. Lock assembly

A/B)

(AI

into toggle

hinge up into ceding hole

HOSE

..

B;

by

FOR

Screw hook clockwise into ceiling until! firmly seated.

WOOD

BEAM

CEILINGS

FOR EITHER METHOD

Hang the bottle assembly by a chain from the hook so that the bot-

is

tom of the bottle

the iron.

1 METER( 1 Yardstick) from the water inlet on

LDNSEJiil

Loading...

Loading...