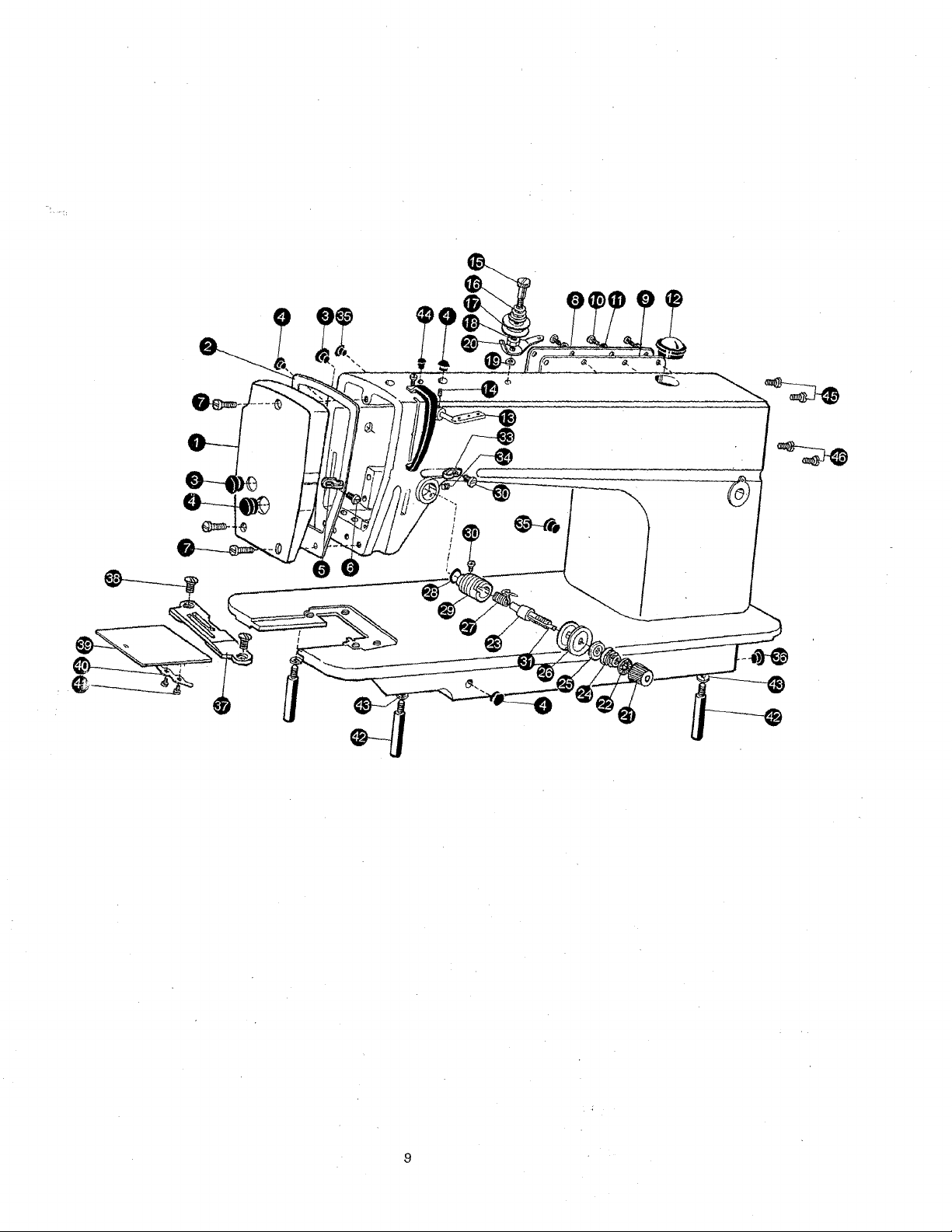

Consew 318RK-2 User Manual

DNSE

CONSOLIDATED SEWING MACHINE CORP.

I INDUSTRIAL SEWING & CUTTING EQUIPMENT

OPERATING

INSTRUCTIONS

&

PARTS LIST

31SRK-2

'----

INDUSTRIAL

400 VETERANS BLVD, CARLSTADT,

SEWING

&

CUTTING

EQUIPMENT

NJ

07072

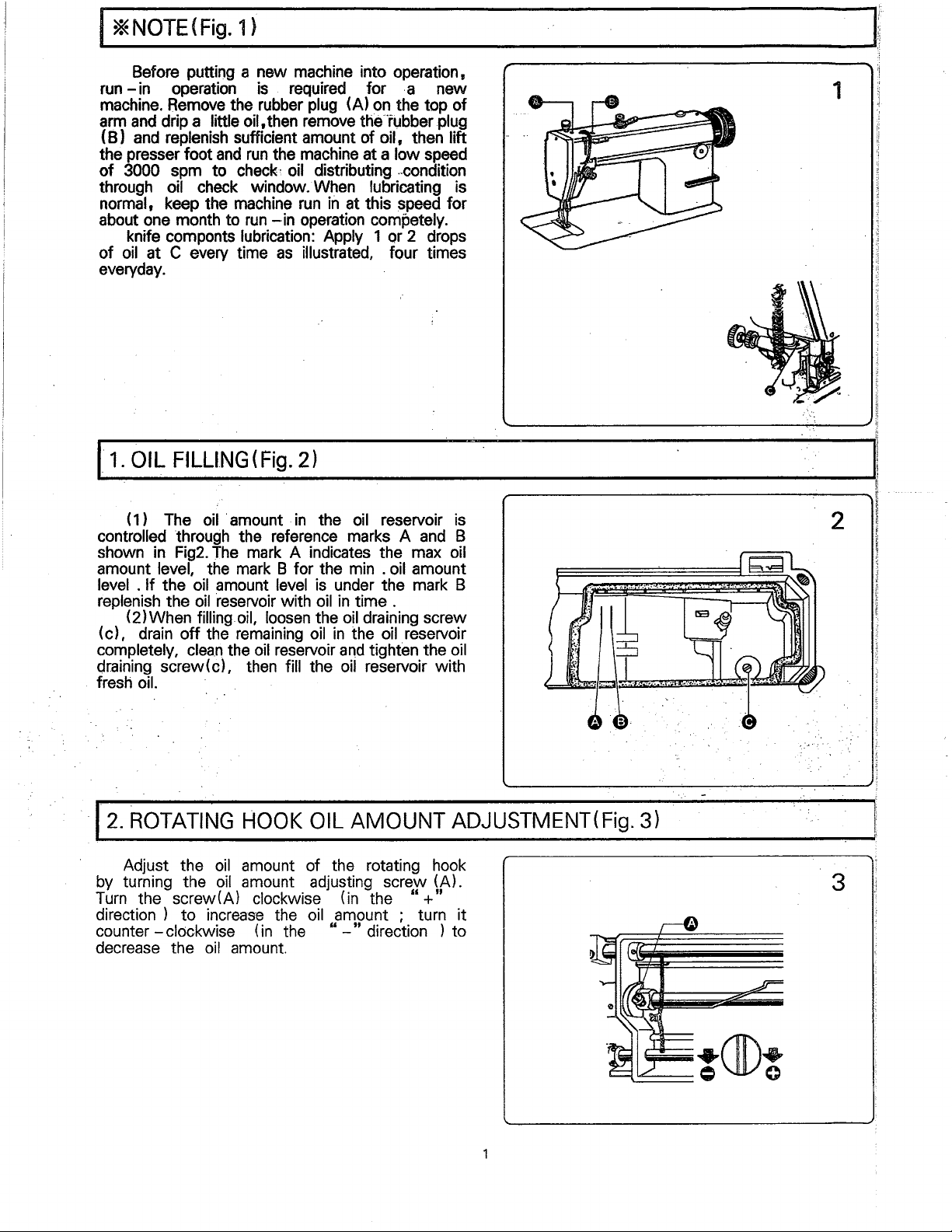

~'*_:·N_O_T_E_(F_ig_.1_)

Before putting a new machine into operation,

run

-in

operation

machine.

arm

(B)

the presser foot

of

through

normal, keep the machine

about one month to

of

everyday.

11.

controlled through the reference marks A

shown

amount level, the

level .

replenish the

(c), drain

completely,

draining screw(c), then fill the

. fresh oil.

Remove

and

drip a little oil,then remove the··rubber plug

and

replenish sufficient amount of oil, then lift

3000 spm to

oil check window. When lubricating is

knife componts lubrication: Apply 1 or 2 drops

oil

at C every time

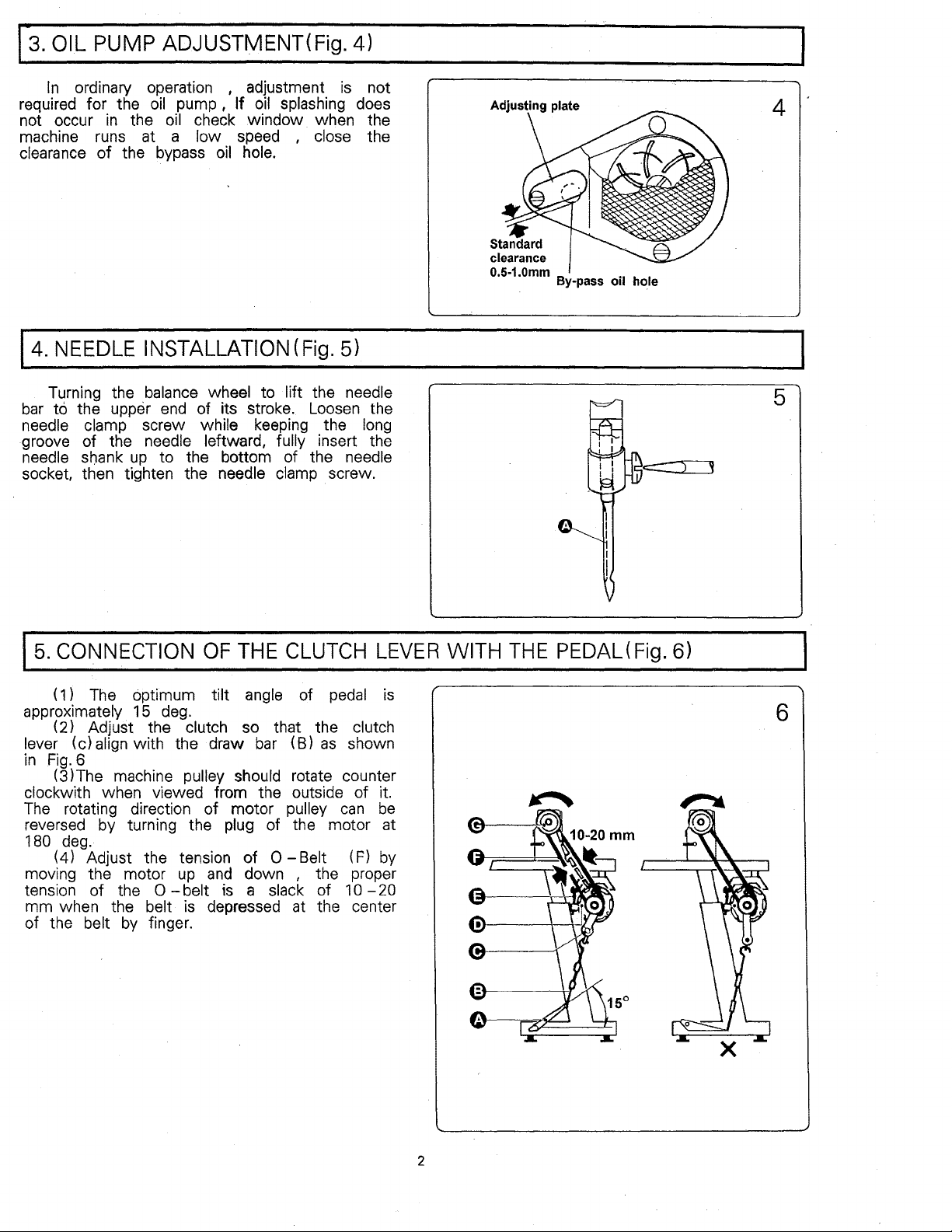

OIL

FILLING

( 1 ) The

in

If

(2)When filling.oil,

Fig2.

the

oil

oil

off

clean

oil

The

the

__________________________________

is

required for

the rubber plug (A)

and

run

the machine at a low speed

check~

·amount .

mark

amount level

·reservoir

remaining

the

oil distributing

run

in

run

-in

operation competely.

as

illustrated, four times

(Fig.

2)

in

the

mark

A indicates the max

B for the min . oil amount

is

with

oil

loosen

oil

the

oil

reservoir

at this speed for

oil

under the mark B

in

time .

oil

in

the oil reservoir

and

oil

.a

new

on

the top

..

condition

reservoir

draining screw

tighten the

reservoir with

and

of

1s

B

oil

oil

--------------~---[

~11

1

II

~

.

~

fl

2

f.

l

ij

~

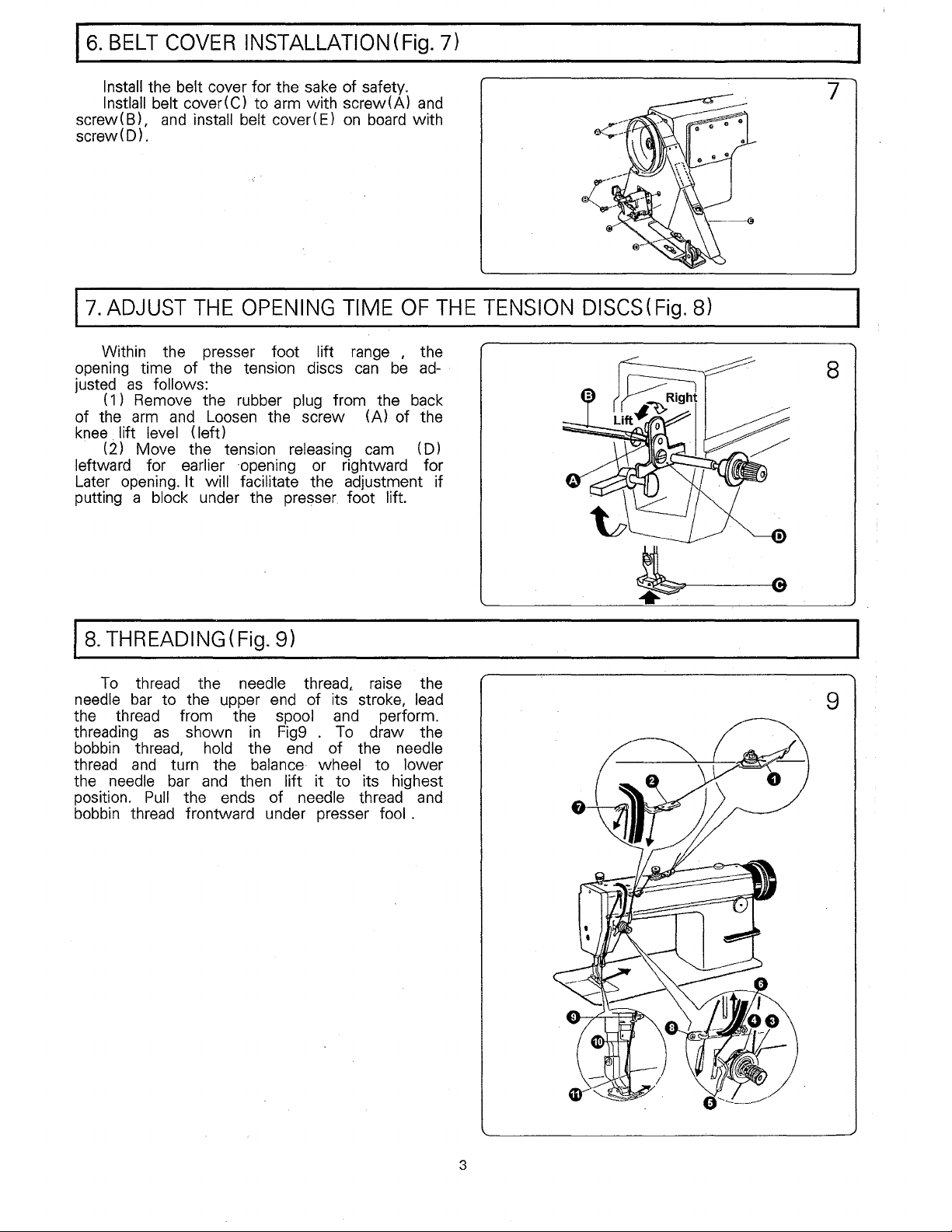

12.

ROTATING

Adjust the

by turning the

Turn

the screw(A) clockwise (in the

direction ) to

counter

decrease the

-clockwise (in the "

HOOK

oil

amount of the rotating hook

oil

amount adjusting screw (A).

increas·e

oil

the

amount.

OIL

AMOUNT

oil

amount ; turn it

-"

direction ) to

ADJUSTMENT(

"+"

Fig.

3)

-.:-···-:·

.

3

:.

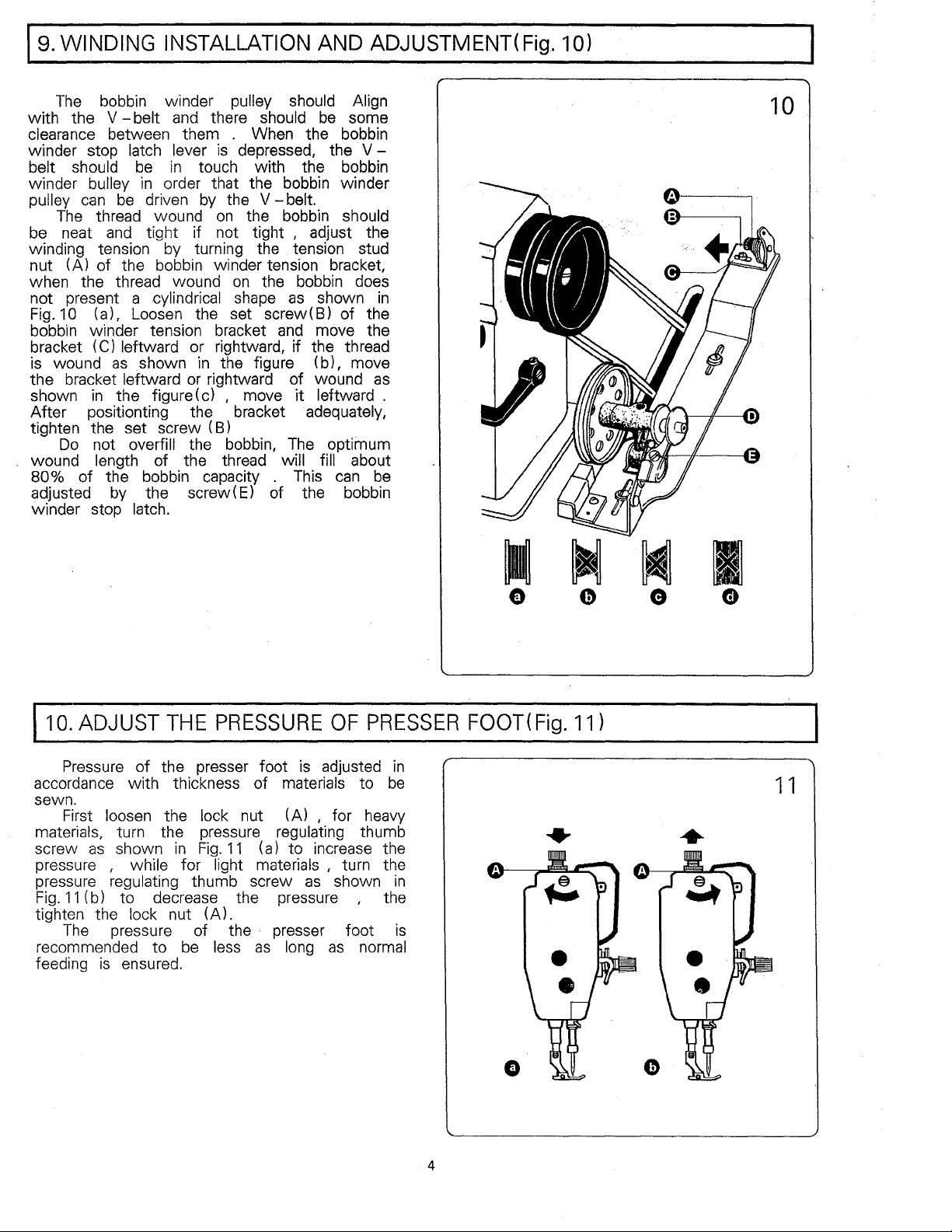

13.

OIL

PUMP

In

ordinary operation , adjustment

required for the

not occur

machine runs at a

clearance

14.

NEEDLE

in

of

ADJUSTMENT(

oil

the

oil

the bypass

INSTALLATION(Fig.

Fig.

is

pump,

If

oil

splashing does

check .window when the

low speed , close the

oil

hole.

5)

4)

not

Standard

clearance

0.5-1.0mm .

By-pass

011

4

ho.le

Turning the

bar

to the upper

needle clamp screw while keeping the long

groove of the needle leftward,

needle shank

socket, then tighten the needle clamp . screw.

15.

CONNECTION

( 1 )

The

approximately 15

(

2)

Adjust the clutch so that the clutch

lever (c)

in

Fig.

clockwith when viewed from the outside of

The

reversed by turning the plug of the motor at

180

moving the motor

tension of the

mm when the belt

of the belt

align

6

(3)The machine pulley should rotate counter

rotating direction of motor pulley

deg.

(4) Adjust the tension

balance

up

to the bottom of the needle

optimum tilt angle of

with the draw

0

by

finger.

wheel to lift the needle

end

of its stroke. Loosen the

fully insert the

OF

THE

deg.

up

and

-belt

is a slack of 1 0

is

depressed at the center

CLUTCH

bar

(B)

of

0-

Belt (F)

down , the proper

pedal

as

can

LEVER

shown

it.

be

by

-20

is

WITH

THE

PEDAL(

Fig.

5

) ,

6)

6

2

16.

BELT

COVER

INSTALLATION(Fig.

7)

Install the belt cover for the

lnstlall belt cover(C) to

screw( B),

screw(D).

17.

ADJUST

Within the presser foot lift

opening time of the tension discs

justed

( 1) Remove the rubber plug from the back

of the

knee

· (2) Move the tension releasing

leftward for earlier

Later opening.

putting a block under the presser foot lift.

and

install belt cover(

THE

as

follows:

arm

and

Loosen

lift level (left)

It will facilitate the adjustment if

OPENING

·opening or rightward for

sake

of safety.

arm

with screw(A)

E)

on

board

TIME

range

can

be

the screw (A) of the

cam

and

with

OF

, the

ad-

(D)

THE

TENSION

DISCS(Fig.

7

8)

8

Is.

THREADING

To

thread the needle

needle

the thread from the spool

threading

bobbin thread, hold the end of the needle

thread

the needle

position.

bobbin thread frontward under presser fool .

bar

to the upper

as

and

turn the

bar

Pull

(Fig.

9l

thread,.

end

of its stroke,

shown

and

the ends of needle thread

in

Fig9 . To

balance·

then lift it to its highest

wheel to lower

and

raise

perform.

draw the

the

lead

and

9

3

19.

WINDING

The

bobbin winder pulley should Align

with the V

clearance between them . When the bobbin

winder stop latch lever

belt should

winder

pulley

be

winding tension

nut (A) of the bobbin winder tension bracket,

when the thread wound

not present a cylindrical

Fig.

bobbin winder tension bracket

bracket

is

the bracket leftward

shown

After positionting the bracket adequately,

tighten the set screw (B)

wound length of the thread

80% of the bobbin capacity .

adjusted

winder stop latch.

bulley

can

be

The

thread wound

neat

and

10

(a), Loosen the set screw(

(C) leftward or rightward, if the thread

wound

Do

as

in

the figure (c) , move it leftward .

not overfill the bobbin,

by

INSTALLATION

-belt

and

there should

is

depressed, the V -

be

in

touch with the bobbin

in

order that the bobbin winder

driven

tight if not tight , adjust the

shown

the screw(E) of the bobbin

by

the V

on

the bobbin should

by

turning the tension stud

on

the bobbin does

shape

in

the figure (b), move

or

rightward of wound

AND ADJUSTMENT(

be

-belt.

as

shown

B)

and

move the

The

optimum

will

fin

This

can

some

of the

about

in

as

be

Fig.

10)

10

110.

ADJUST

Pressure of the presser foot

accordance with thickness of materials to

sewn.

First loosen the lock nut (A) , for

materials, turn the pressure regulating thumb

as

screw

pressure

pressure regulating thumb screw

Fig.

11

tighten the

The

recommended to

feeding

shown

, while for light materials , turn the

(b) to decrease the pressure , the

pressure of the · presser foot

is

THE

in

Fig.

lock nut (A).

be

ensured.

PRESSURE

is

11

(a) to increase the

as

less

as

long

OF

PRESSER

adjusted

heavy

shown

as

normal

be

in

in

is

FOOT(

Fig.

11

I

CD

l

1 1

4

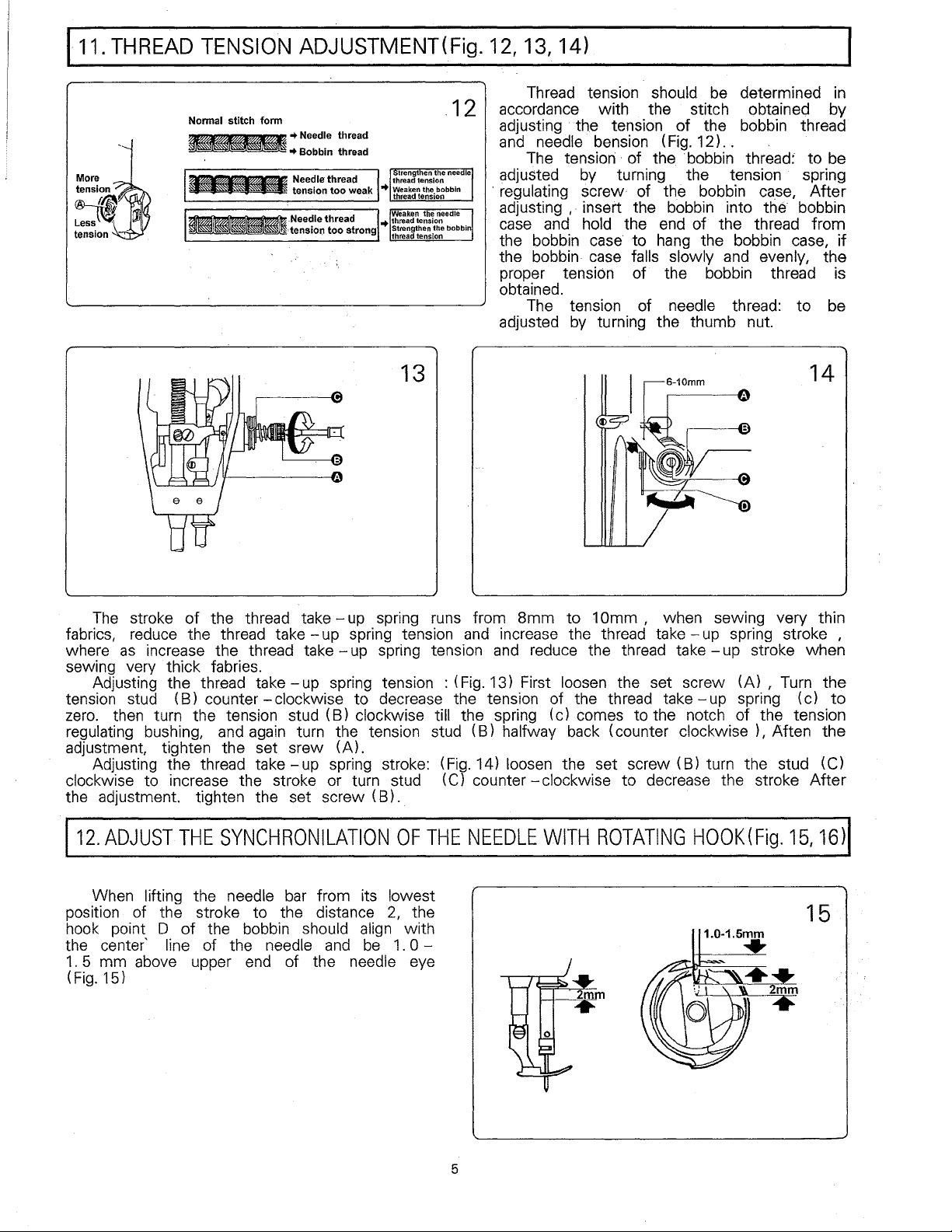

!11.

THREAD

Nonnal stitch fonn

~1\1~~

=~

TENSION

==~==~=~=

~--~Needle

~

ADJUSTMENT(

•

Need~e

• Bobbm thread

·tension too strong

thread

thread

Fig.

12, 13, 14)

Thread tension should be determined in

. 1 2 accordance with the stitch obtained by

adjusting

and

adjusted by turning the tension spring

· regulating screw of the bobbin

adjusting ,

case and

the bobbin case to hang the bobbin case,

the bobbin· case falls slowly and evenly, the

proper

obtained.

adjusted by turning the thumb nut.

· the tension

needle· bension (Fig.

The tension· ·

· insert the bobbin into the bobbin

tension

The tension of

of

the ·bobbin thread:

hold the end

of

of

the bobbin thread

12)..

to

be

ca,se,

of

the thread from

the bobbin thread is

needle thread:

After

to

be

if

13

The stroke

fabrics, reduce the thread take

where

sewing very thick fabries.

tension stud

zero. then turn the tension stud (B) clockwise till the spring (c) comes to the notch of the tension

regulating bushing, and again turn the tension stud (B)

adjustment, tighten the set srew

clockwise

the adjustment. tighten the set screw

as

Adjusting the thread take

Adjusting the thread take

of

the thread take

increase the thread take

(B)

counter

to increase the stroke or turn stud (C) counter

-clockwise

-up

spring runs from

-up

spring tension and increase the thread take

-up

spring tension and reduce the thread take

-up

spring tension : (Fig. 13) First loosen the set screw (A) , Turn the

to decrease the tension of the thread take

halfway back (counter clockwise ) , Aften

(A).

-up

spring stroke: (Fig. 14) loosen the set screw (B) turn the stud (C)

(B).

8mm

to 1

-clockwise

Omm

, when sewing very thin

-up

spring stroke ,

-up

-up

spring (c)

to decrease the stroke

stroke when

14

to

the

After

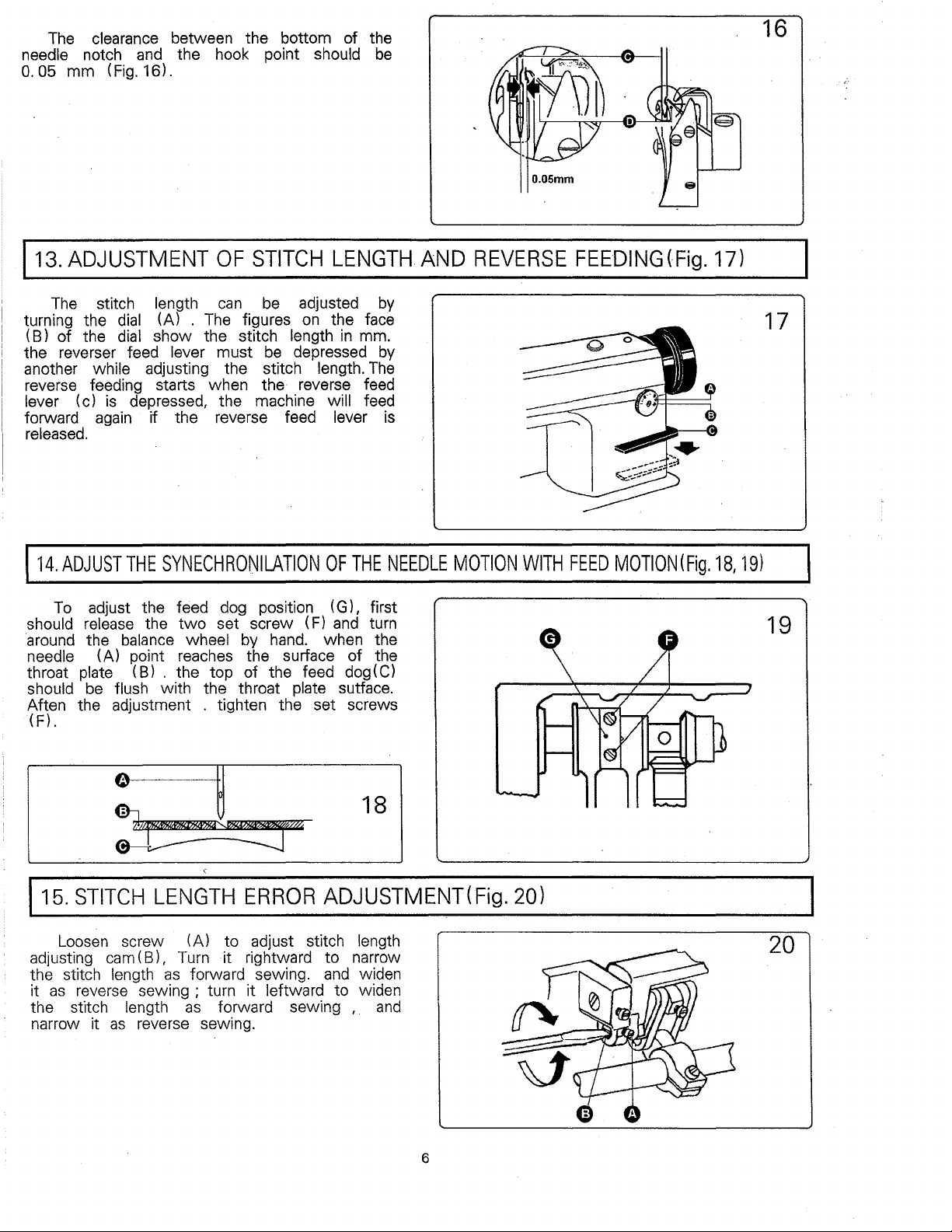

112.

ADJUST

When lifting the needle bar from its lowest

position of the stroke

hook point

the center'

1.

5 mm above upper end of the needle eye

(Fig. 15)

THE

SYNCHRONILATION

to

the distance

0

of

the bobbin should align with

line of the needle

and

be

OF

2,

1.

THE

the

0 -

NEEDLE

5

WITH

ROTATING

HOOK(Fig.

15,

15

16)1

The

clearance between the bottom of the

needle notch

0.

05

mm (Fig. 16).

and

the hook point should

16

be

113.ADJUSTMENT

The

stitch length

turning the

(B) of the

the reverser feed

another while adjusting the stitch length.

reverse feeding starts when the reverse feed

lever (c)

forward

released.

114.

ADJUST

To

should release the

·around

needle (A) point reaches the surface of the

throat

should

Aften the adjustment . tighten the set screws

(F).

dial

(A) .

dial

show the stitch length

is

depressed, the machine will feed

again

adjust the feed dog position (G), first

the

plate (B) . the top of the feed

be

if the reverse feed lever

THE

SYNECHRONILATION

balance

flush with the throat plate sutface.

OF

can

The

figures

lever must

two

set screw (F)

wheel

by

STITCH

be

adjusted

on

be

depressed

hand.

LENGTH

by

the face

in

mm.

The

OF

THE

and

turn

when the

dog

(C)

AND

by

is

NEEDLE

REVERSE

MOTION

WITH

FEEDING(Fig.

FEED

MOTION(Fig.

17)

18,

17

191

19

18

115.

STITCH

Loosen

adjusting

the stitch

as

reverse sewing ; turn it leftward to widen

it

the stitch

narrow it

cam

LENGTH

screw (A) to adjust stitch length

(B),

Turn

length

as

as

forward sewing.

length

reverse sewing.

as

ERROR

it rightward to narrow

forward sewing , .

ADJUSTMENT(

and

widen

and

Fig.

201

6

20

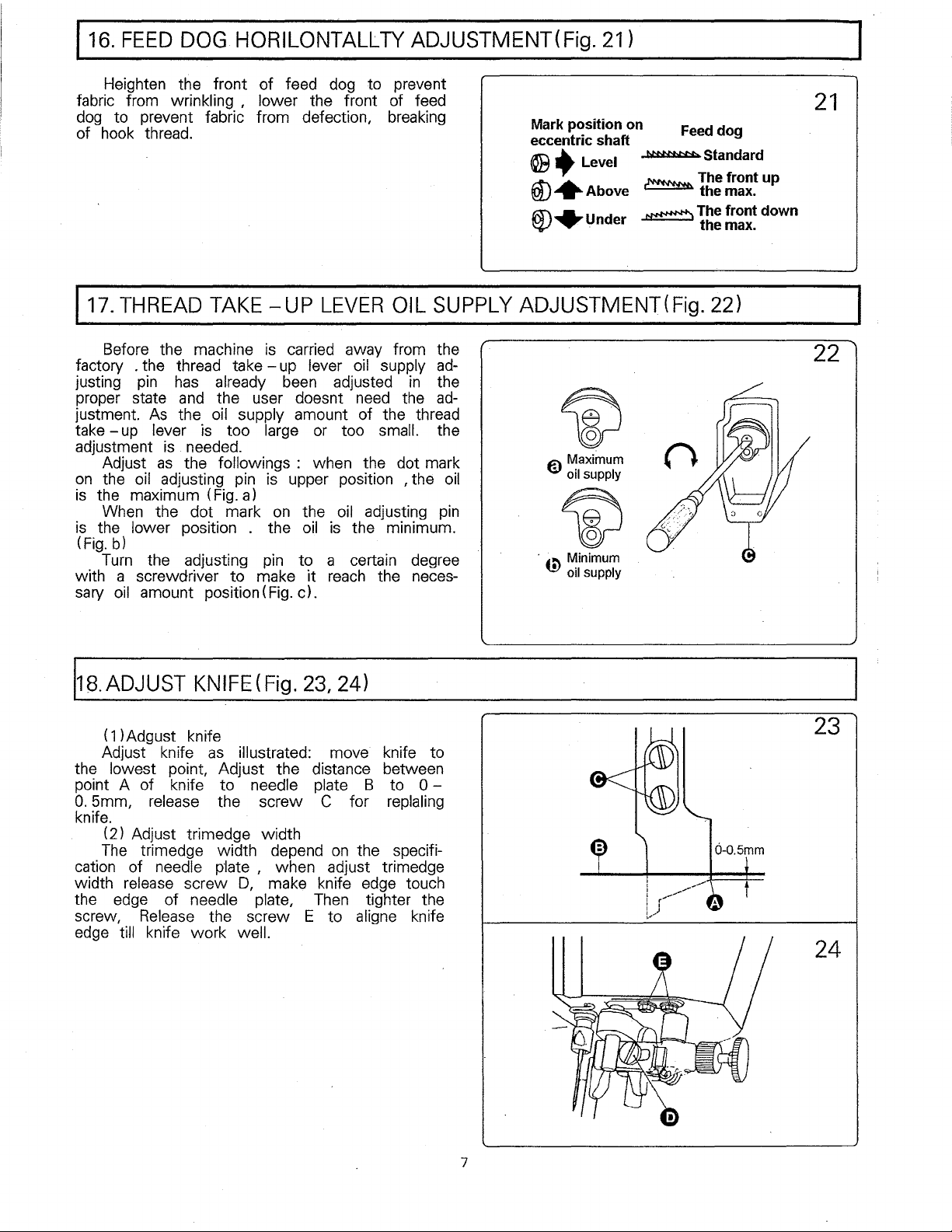

116.

117.

FEED

Heighten the front of feed dog to prevent

fabric from wrinkling , lower the front of feed

dog

to prevent fabric from defection,

of

hook

THREAD

DOG

thread.

HORILONTALLTY

TAKE

-UP

LEVER

ADJUSTMENT(Fig. 21)

breaking

OIL

SUPPLY

Mark

position

eccentric shaft

@.Level

@+Above

®+under

on

N:Mr:N:N:.

~

~The

ADJUSTMENT(

Feed

The

Fig.

dog

Standard

front

the

max.

front down

the

max.

22)

21

up

Before the machine

factory . the thread

justing

proper state

justment.

take

adjustment

on

is

is

(Fig.

with a screwdriver to make it

sary

118.

the lowest point, Adjust the distance between

point A of knife to needle plate B to

0.

knife.

cation of needle

width

the edge of needle plate,

screw,

edge

pin

has

already

and

the user doesnt

As

the

oil

-up

lever

Adjust

the

oil

the maximum (Fig.a)

When

the lower position . the

b)

Turn

the adjusting

oil

amount position(

ADJUST

(

1)

Adgust knife

Adjust knife

5mm, release the screw C for replaling

(2) Adjust trimedge width

The

trimedge width depend

release

Release

till knife work well.

is

is

. needed.

as

the followings : when the dot mark

adjusting

the dot mark

KNIFE

as

p·late

screw

the screw E to

is

carried away from the

take-

too large

up

lever

oil

supply

been

supply amount of the thread

pin

is

on

pin

Fig.

(Fig.

illustrated: move knife to

, when adjust trimedge

D,

make knife

adjusted

need

or

too

upper position , the

the

oil

oil

is

the minimum.

to a certain degree

reach

c).

23,

24)

on

the specifi-

edge

Then

aligne

in

the

small.

adjusting

the neces-

0-

touch

tighter the

knife

adthe

ad-

the

oil

pin

~

€)

Maximum

• oil supply

~

·

6)

Minimum

• oil supply

22

23

24

7

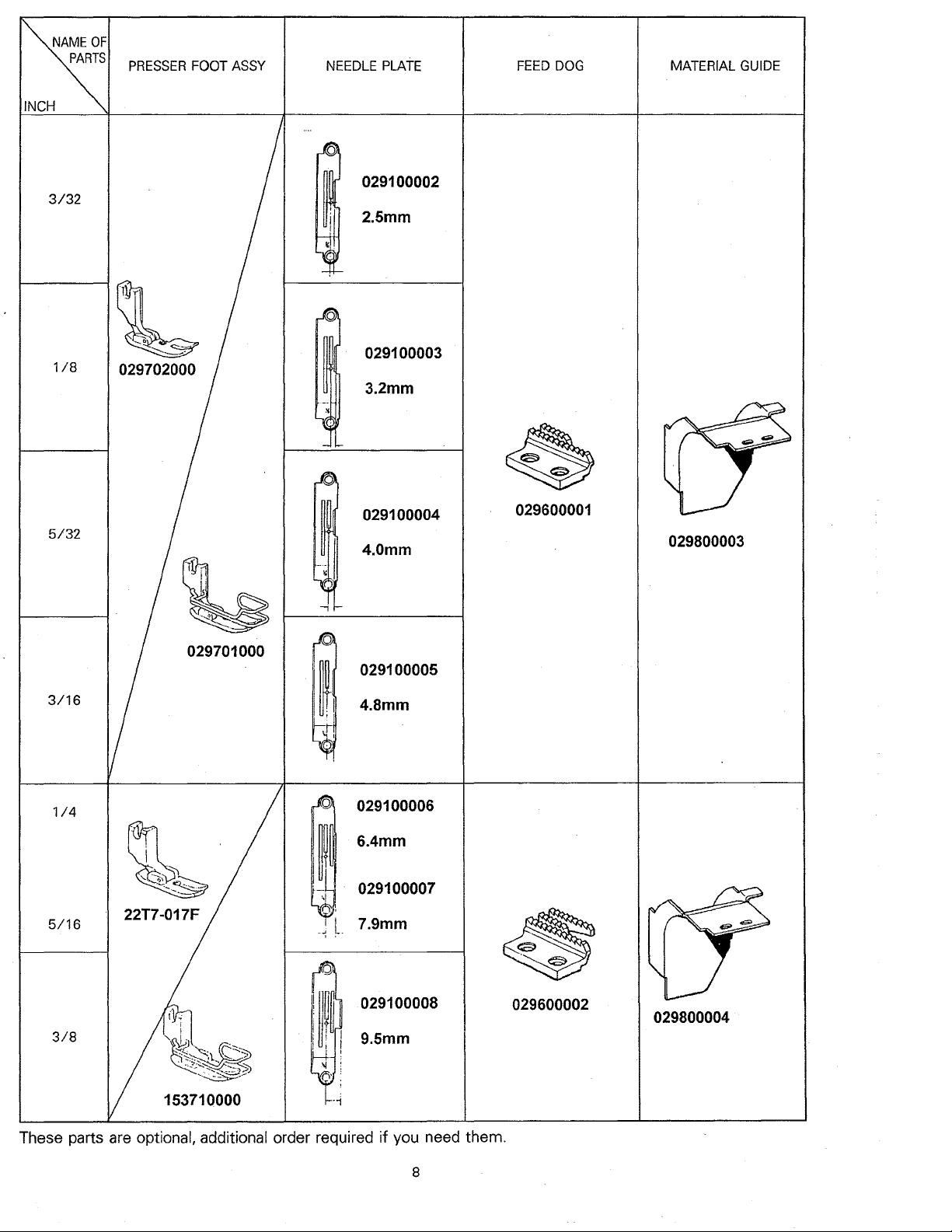

3/32

PRESSER

FOOT

ASSY

NEEDLE

029100002

2.5mm

PLATE

FEED

DOG

MATERIAL

GUIDE

1/4

5/16

3/8

'

'

~

~

029100006

6.4mm

029100007

7.9mm

029100008

9.5mm

029600002

153710000

These parts

are

optional, additional order required if you need them.

8

029800004

9

Loading...

Loading...