Consew 30 SEWING MACHINE User Manual

0

RATING

INSTRUCTIONS,

PARTS

and

MAINTENANC

CONSEW

MOD

L

FOR

30

ROC

SEWING

DUR

MACHINE

CONSOLIDATED

New

SEWING

York

{California

MACHINE

- 1 -

SETTING

Carefully

small

Wipe

with

CAPACITY

Maximum

per

minute

its

thickness

To

assure

that

held

come

DIR~CTIO!Il

_

_...

______ ,

In

operation

operator.

do

not

~p

THE

unpack

parts

machine

a

good

AND

operatinr:;

depending,

durability

for

t,o

nroperly

the

not

turn

OF

__

To

and

grade

more

-=----'~

hand

V~CHINE

machine

accessories

clean

SPE~Q

of

of

sewing

speed

and

that

and

first

several

than

broken

in.

ROTATION

the

handwheel

avoid

tangled

wheel

.

from

protective

after

of

course,

of

trouble-free

2000

other~·Iise.

packing

are

machine

a

the

seams

weeks

RPM

of

the

threads

removed

grease

oil.

break-in

on

the

being

of

operation

in

order

machine

and

case

and

from

and

packing

lubricate

(see

period

type

of

crossed.

operation

to

allow

alwavs

jamming

make

Bel

miT)

is

material

it

the

maximum

the

turns

of

sure

that

material.

oil

holes

2000-2200

being

is

imperative

speed

parts

to

toward

the

sewing

all

stitches

sewn,

is

be-

the

hook,

OILING

.,_,....,..,.,

__

__

Do

not

operate

been

lowing

Oiling

tinuous

operating

prouerly

illustrations

must

operation

parts.

NOTE---During

more

....

_____

LUBRICATION

The

nance.

for

ing

the

fOINTS

frequently.

.._........___

..,

lubrication

The

normal

or

operating

damage

machine

OF

APP~IC~~TION

Lubrication

tion

the

chart,

points

of

surrounding

the

oiled

be done

to

the

break-in

,

__

...,..._. '

CHART

chart

service

to

the

is

an

all-temperature

points

which

is

lubrication

surfaces

machine,

at

every

indicate

at

least

assure

period

(see

fig.

interval

conditions.

machine.

are

readily

supplemented

(see

clean

before

even

if

spot

these

twice

free

runninf,

1)

specified

The

located

figs

only

for

requiring

spots.

daily

1.vhen

and

a new

machine

nrescribes

on t.he

Failure

lubricant

lubricante

by

with

..

2

individual

to

applying

testing,

lubrication.

the

durability

should

lubrication

lubrication

will

result

prescribed

reference

5).

Wipe

lubricant.

unless

The

machine

of

be

is

the

oiled

mainte-

chart

in

malfunction-

for

to

the

lubrica-

photographs

lubricators

it

fol-

in

use

of

has

con-

is

on

and

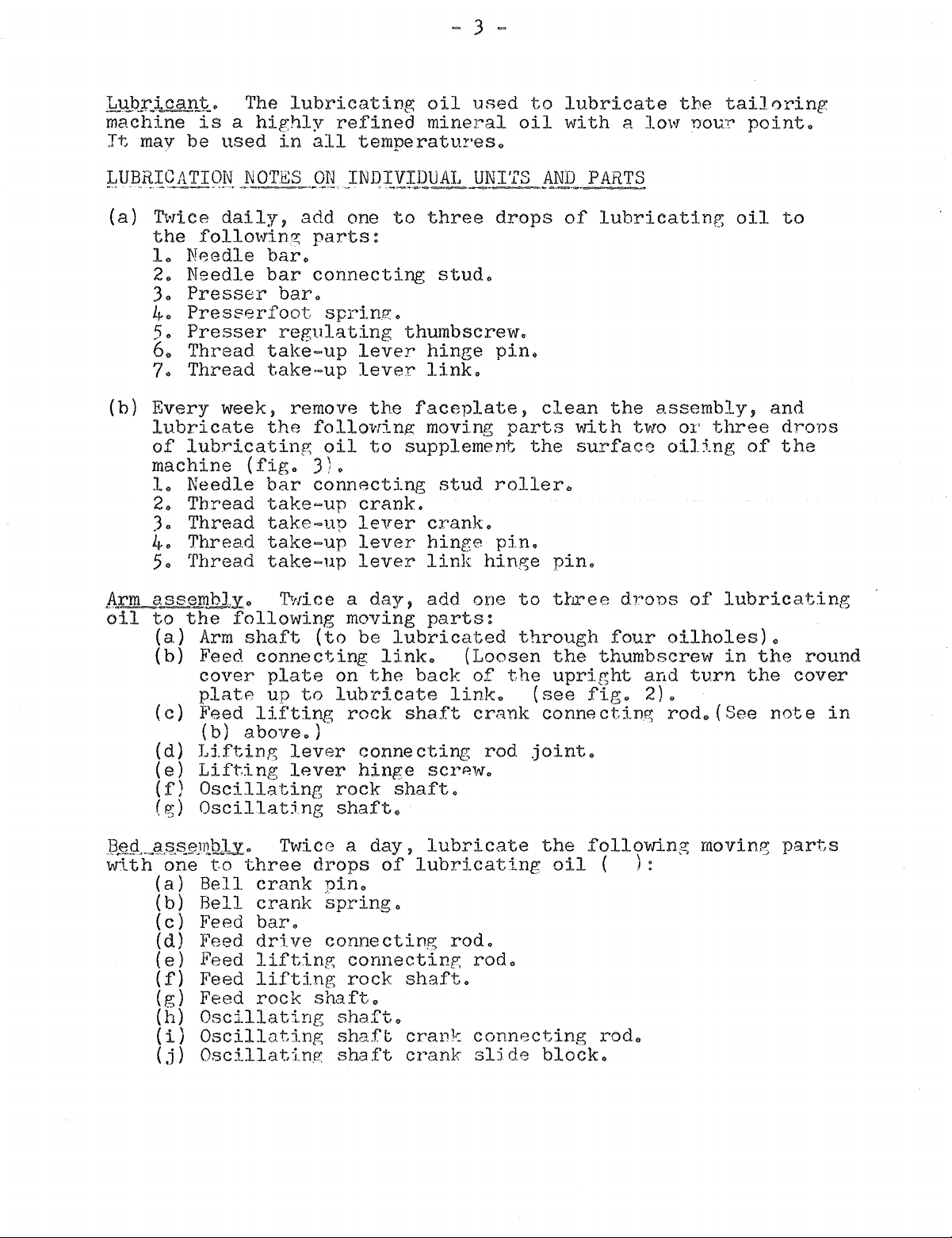

LUBRICATION

CHART

Arm

Shaft

Bobbin Winder Frame

Oil Well (See Note)

Lever

Rod

Frame--

Joint

Bobbin Winder

Hinge Pin (See Note)

Oscillating Drive Rock Shaft

Lifting

Connecting

CONSEW

Rebuilt

SEWING

.Also

SINGER

Class

MACHINE

Machine

31

15

MOD

•

Needle Bar

Presser Regulating

Thread

Take-up Lever Link

Presser

Foot

Presser Bar

Needle Bar Connecting

Lifting Lever Hinge Screw

Oscillating

Feed Lifting Rock

Connecting

Oscillating Shaft Crank

Connecting Rod

Spring

Shaft

Thumb

Rod

Screw

Stud

Shaft

The

machine should be oiled twice a day

drops

of

lubricating oil OJI to each

by

an

arrow.

Do

not

flood

four hour lubricating interval.

BOBBIN

WINDER-Every

well and bobbin winder frame hinge pin with one or two drops of

eating oil

!Jill).

FACE ASSEMBLY-Every week the face plate should

the

uncovered bearings and

lubricating oil fl'llilll).

these

day lubricate the bobbin winder frame oil

joints

by_

applying from one to three

of

the oil can points indicated

moving

parts

with ojl nor

lubricated

with

two

ignore

be

removed and

or three drops

-·NOTES-

above

the

lubri~

SHUTTLE

shuttle

three drops

of

week remove the sh\lttle body from the

cate

RACE-Twice

bearing in the

of

it.

oil

FiR:. J

over

every

shuttle

the

Oscillating Shaft

Slide Block

Feed Forked

Connecting

. Bell Crank Pin

Crank

Bell

day

apply lubricating oil fllllilll) to the

race,

at

the

same

surface

of

the

shuttle

shuttle

time

race itself.

race. clean

Rod

Spring

rubbing

and

Crank

two

Every

lubri·

or

k~~rjcaQt.

machine

Ti:.

mav

be

is

The

a

used

lubricating

highly

in

all

oil

refined

mineral

temperatu:r·eso

used

to

lubricate

oil

with a low

tbe

nour

tailoring

pointe

~UB~J.:.9JlTI9J'J

(a)

Ttvice

the

1

..

2.

3o

4.

5.

6.

7.

(b)

Every

lubricate

of

machine

1

..

2.

)

..

4.

5

..

Arm

assei11J2lY.o

oil

to

(a)

(b)

(c)

(d)

(e)

(f)

(~)

..

.NOTES

daily,

followin~

Needle

Needle

Presser

bar.

bar

bar.

Preseerfoot

Presser

Thread

Thread

regulating

take-up

take-up

week, remove

the

lub:ricatinp:

(fig.

Needle

Thread

Thread

Thread

Thread

bar

take-up

take-up

take-up

take-up

T>trice a day,

the

following

Arm

shaft

Feed

cover

plate

Feed

(b)

Lifting

Lift.i

connecting

plate

up

lifting

above.}·

lever

ng

lever

Oscillating

Oscillating

gr~

JNPI..Y::tJLUJi.L

add

one

parts:

connecting

spring.

lever

lever

the

follo~rin.e:

oil

to

3}.

connecting

crank.

lever

lever

lever

moving

(to

be

on

the

to

lubricate

rock

connecting

hinge

rock

shafto

to

three

stud.

thumbscrew.

hinge

link.

faceplate,

moving

supplement

stud

crank.

hinge

link

add one

parts:

lubricated

link.

(Loosen

back

linko

shaft

screw.

shaft.

UNITS

drops

pin.

parts

roller.

pin.

hinge

of

the

crank

rod

AND

PARTS

of

clean

with

the

surface

pin.

to

three

through

the

upr:i.ght

{see

fig.

connecting

.jointo

lubricatinp;

the

assembly,

two

or

oiling

dJ~ons

four

of

oilholes).

thumbscrew

and

turn

2).

rod., (See

oil

to

and

three

of

drons

the

lubricating

in

the

the

cover

note

round

in

l3i!£LJ?)2.~?J1lhlY.

with

one

(a)

(b)

(c)

to

Bell

Bell

Feed

{d) Feed

(e)

Feed

(f)

Feed

(g) Feed

(h)

Oscillating

(i)

Oscillating

(.j)

Oscillating

Twice a

three

crank

crank

bar.

drive

lifting

lifting

rock

day,

drops

of

pine

springe

connecting

connecting:

rock

shafte

shafte

shaft

shaft

lubricate

lubricating

rod.

rod.,

shaft.

crank

crank

connecting

slj

de

the

block.

following

oil

(

rode

):

movinp;

parts

If

the

feed

needle,

structions

make

on

dog

the

page

stands

necessary

18.

- 5 =

too

high,

adjustments

or

if

it

is

in

accordance

out

of

time

with

with

in-

the

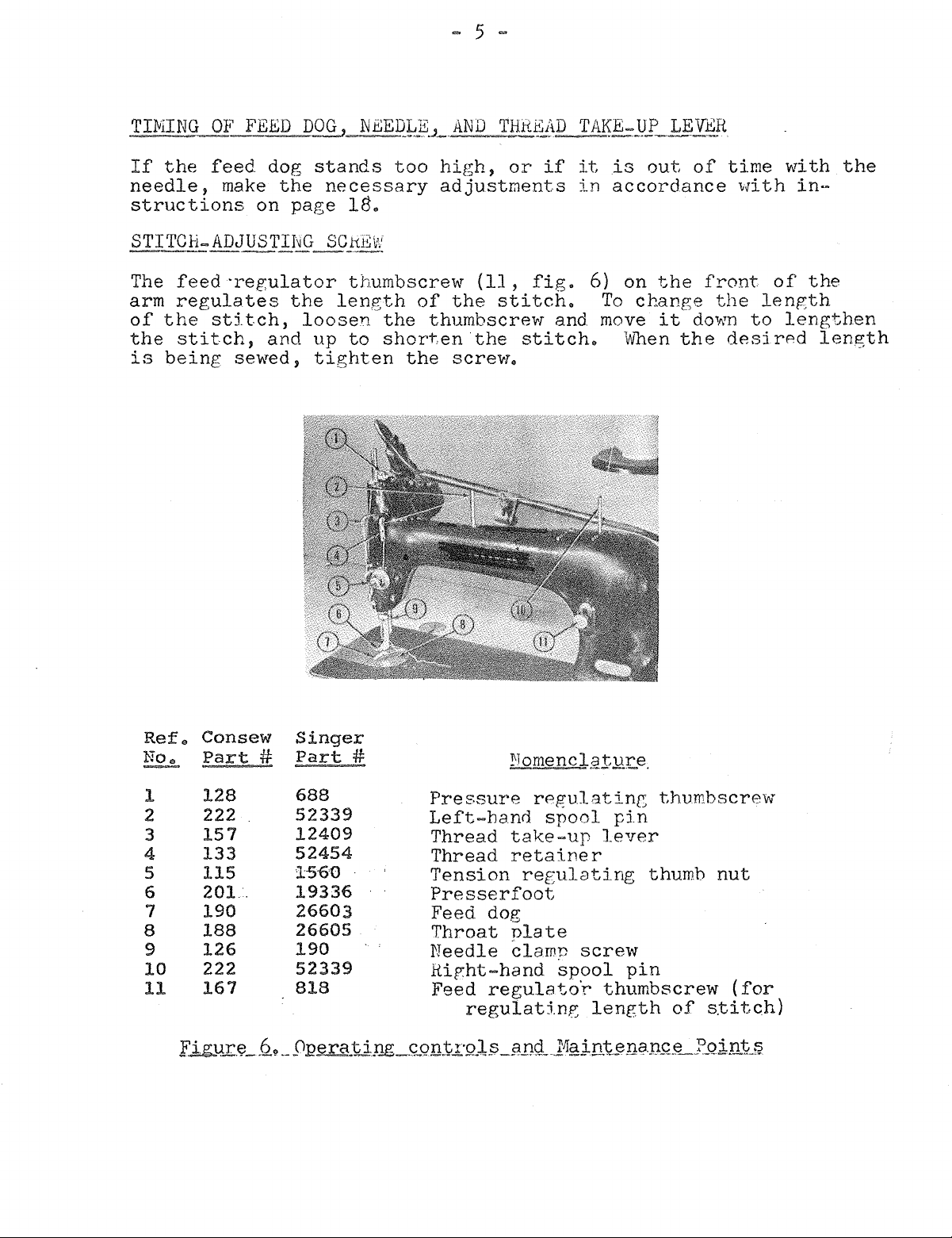

STITCH-ADJUSTING

The

arm

of

the

is

-------'~

feed

regulates

the

stitch,

stitch,

being

-regulator

the

loosen

and

sewed,

SCrtEW

thumbscrew

length

the

up

to

short,en

tighten

of

(11,

the

fig.

stitch.

thumbscrev-r and move

the

stitch.

the

screv-r.

6)

To

on

the

change

it

Wben

front

do1rm

the

the

desi

of

length

to

lengthen

rPd

the

length

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

Consew

Part

128

222

157

133

115

201.

190

188

126

222

167

#

Singer

Part

688

52339

12409

52454

156'0

19336

26603

26605

190

52339

818

#

~Tomencl.SJtllr.e.

Pressure

Left-hand

Thread

Thread

Tension

rPgulatinc

spool

take-up

retainer

regulating

Presserfoot

Feed dog

Throat

Needle

nlate

6lamn

Rir,ht-hand

Feed

regulato'r

regulatin~

pin

lever

screw

spool

thumbscrew

length

thumbscrew

thumb

pin

of

nut

(for

s.titch)

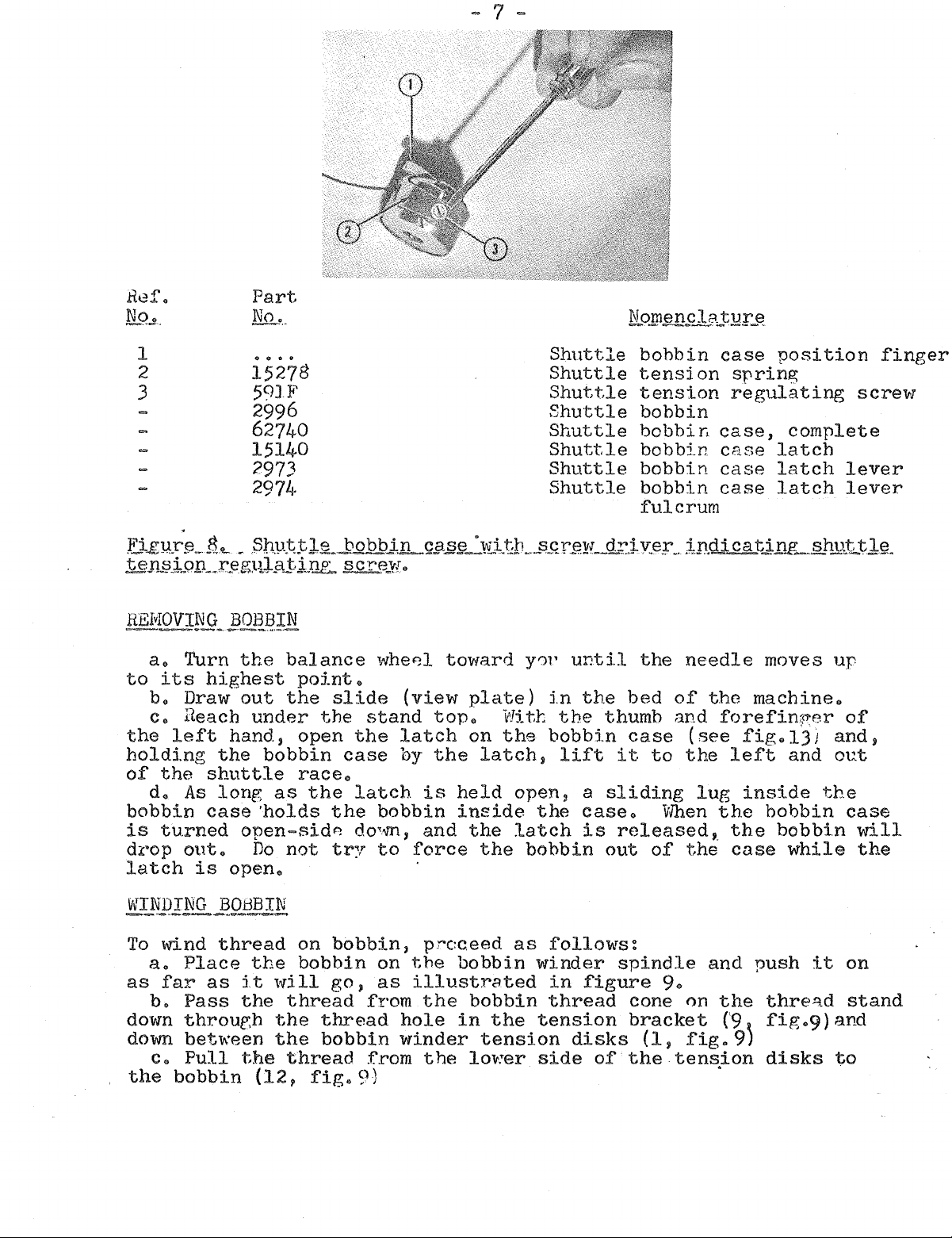

- 7 -

Refo

Nq.!

1

2

3

Part

No

•.~

0 0 & 0

15278

50lF

2996

62740

15140

2973

2974

'

E,.i.gg~r~-

tepJ?_j._qp _

REMOVING

-~'~>-""""""""------·"''-·--

a., Turn

to

b.,

c.,

the

holding

of

d

bobbin

is

drop

latch

~ll.-

_r_egnJ-fl!,}_n_p:..

its

highest

Draw

Heach

left

the

shuttle

..

As

case

turned

out,.

is

~

Shvt~lf?.~

bo

bbl!LQP-.§~_:vt.i.tb~.-s.~

.§Ql:e_r!o

BOBBIN

the

balance

out

the

under

hand.,

the

bobbin

long

as

'holds

open-sidP.

Do

not

open,.

point

open

race.

the

slide

the

case

the

tr:r

..

stand

the

latch

do'm,

~rhe0l

bobbin

to

(view

tope

latch

by

the

is

and

force

toward

plate)

W:i.tt

on

the

latch,

held

ineide

the

the

Shuttle

Shuttle

Shuttle

Shuttle

Shuttle

Shuttle

Shuttle

Shuttle

bobbin

tension

tension

bobbin

bobbifi

bobbin

bobbin

bobbin

fulcrum

rf.!:l!!_d~J

y0P

unt:i.l

in

the

the

bobbin

lift

open,

latch

the

a

case..

is

bobbin

v:e~-·

.tndi

the

needle

bed

of

thumb and forefin(<'l'er

case

it

to

(see

the

sliding

When

released,.

out

of

the

case

spring

regulating

case,

case

case

case

ca

the

fig

left

lug

inside

the

the

case

position

finger

screw

complete

latch

latch

latch

lever

lever

tjN:;._.shvJ'-tlS1.

moves

ur

machine.

of

..

lj)

and,

and

out

the

bobbin

bobbin

while

case

will

the

.!f~Nj)JNG

To

wind

a.

as

far

b,.

dovm

down

c

..

the

,EO®JN

thread

Place

as

Pass

throue:h

between

Pull

bobbin

the

it

the

the

(12,

on

bobbin

\'fill

thread

the

the

thread

f'ig

bobbin,

on

go,

as

from

thread

bobbin

from

..

9)

prcc.eed

the

bobbin

illustrated

the

bobbin

hole

in

winder

the

loV<;er

as

winder

the

tension

tension

side

follows:

spindle

in

figure

thread

disks

of

9.,

cone

~'m

bracket

(1,

fige9J

the

tension

and

the

C9

•

push

thre.qd

~

fig.9)

disks

it

on

stand

and

to

- 9 -

Figure

a.,

bobbin,

The

thread

to

right

and

just

10

shovrs

thread

should

before

the

when

draw

the

relative

the

over

babbin

bobbin

the

top

is

positions

is

put

of

the

slinped

of

into

bobbin

into

the

the

the

bobbin

bobbin

and

from

case.,

case,

case.,

left

b.,

in

A,

the

bobbin

bobbin

c.

figure

and

into

C,

figure

To

thread

figure

and

Pull

11,

in

away

the

draw

the

11.

the

11,

the

the

case

from

thread

the

delivery

bobbin

slot

so

you.,

into

thread

eye

case,

in

the

that

the

down

at

the

hold

edge

the

thread

bobbin

under

end

it

being

case

the

of

the

in

the

nulls

thread

bobbin

left

near

tension

the

over

slot,

case

hand,

top,

the

top

as

tension

sprine,

as

and

in

as

c

shov-m

place

of

the

B,

spring

in

-

11

-

Remember--uneven,

sewing

Only

tNist

of

tighter,

The

performance

left.

hold

your

hands.

bobbin

twist

a

length

it

has a left

c2n

be wound

Needle

SETTING

a.

Never

Set

b.

needle

c.

the

long

rectly

d.,

the

NEEDLE

·----#--

Select

use

the

needle

To

set

bar

Loosen

needle

groove

in

Tighten

needle

a good

a

bent

\vith

the

moves up

the

up

into

of

the

line

with

the

will

knotted

of

thread

of

Turn

thread

NEEDLE

Size

11

14

16

1e

20

22

needle

needle

the

needle,

to

needle

the

needle

the

needle

turn

or

your

is

thread

twist.

with

or

long

turn

its

clamp

clamp

arm

clamp

slir.

or

rough

thread

machine.

to

be

used

between

for

thumbs

counterclockwise.

If

it

unravels,

either

AND

THfi.EAD

of

the

one

vri

groove

the

highest

screw

as

so

thRt

of

the

scr·e'."~•

left

proper

th

the

to

balance

uoint.

(9,

far

as

it

l1k1.chine.

CHART

faces

If

imnairs

the

or

Thread

60-70

40-60

30-40

16-24

size

point

the

left.

wheel

fig.

it

6),

will

to

the

needle.,

and

index

If

it

right

Size

80-100

24-30

as

explained

blunted

toward

put

go,

the

screw

the

satisfactory

To

test

fingers

it

will

tlvist

has a right

t1.vist

thread.

(Cotton)

abovee

or

turned.

you

until

tbe

shank

and

left

is

turn

and

too

loose,

the

is

for

twist.

the

of

di-

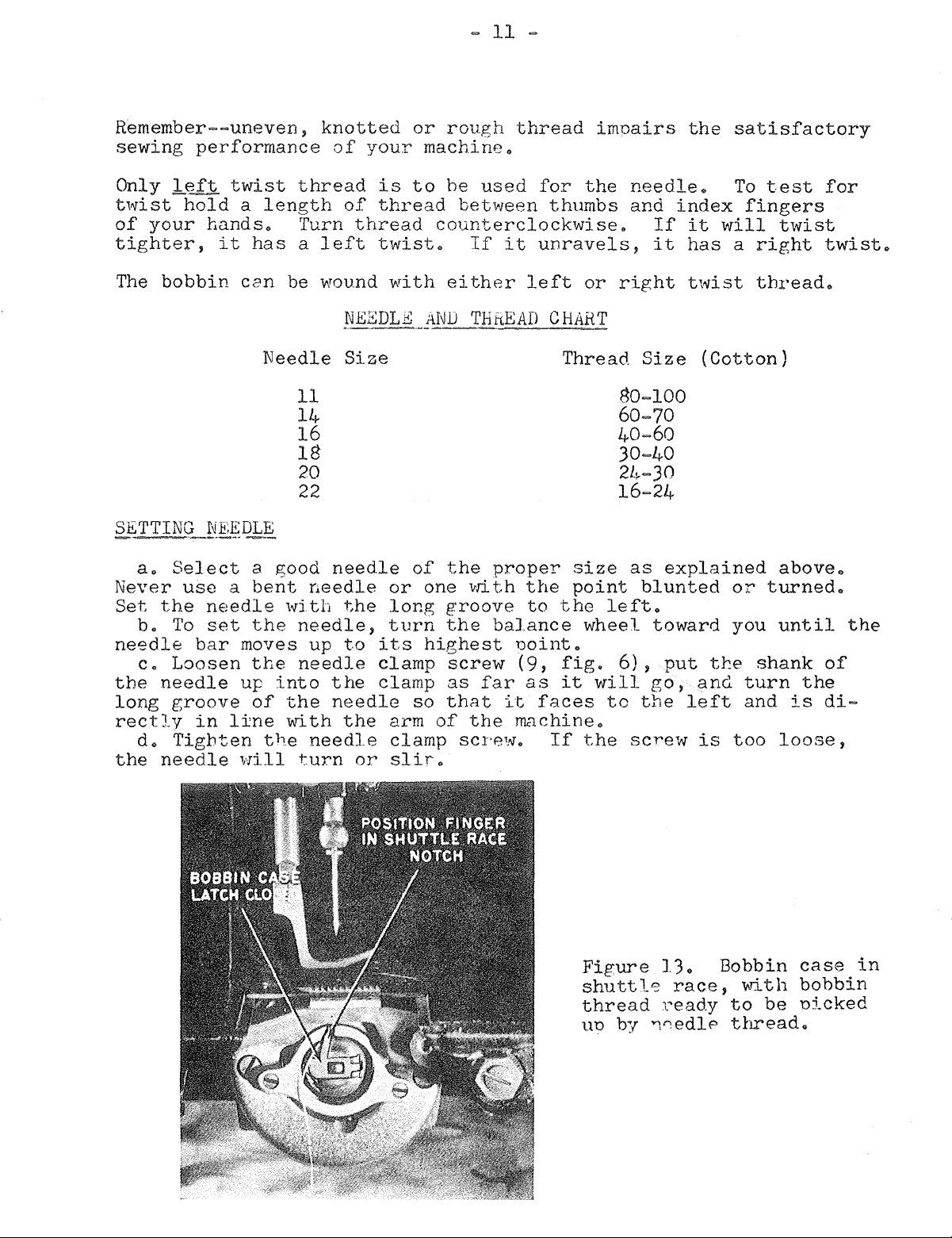

Figure

shuttls

thread

uu

by

13.,

Bobbin

race,

ready

~0edlP

to

tl~ead.

with

be

case

bobbin

nicked

in

Loading...

Loading...