CONSEW 255RB-3 Instruction Manual

Setting up the machine ......................................................................................

1

Oiling and it's adjustment .................................................................................

1

Oil adjuster ........................................................................................ ............

2

Needle and thread .........................................................................................

2/3

Inserting and removing bobbins ...............................................................

3

Winding bobbins and it's adjustment .............................................................

3

Threading the machine ................................................................................

4

Regulating the thread tension ...................................................................

5

Adjustment of the presser feet pressure ........................................................

5

Adjusting the stitch length and reverse stitch ....................................

6

Adjusting the left of the alternating presser feet ..........................................

6

How to reset the safety clutch mechanism .....................................................

7

INFORMATION FOR ADJUSTMENT

Replacement of the timing belt ...............................................................

7

Adjusting the height of the feed dog ..............................................................

8

Adjusting the timing of the needle plate, needle and feeder .......................

9

Adjusting the height of the needle bar ..................................................

10

Timing between the hook and needle .............................................................

10

Relative position between bobbin case and opener ....................................

11

Adjusting the height of the presser feet ..........................................................

11

Timing of the vibrating presser foot ......................................................

12

Adjusting the thread controller spring ............................................................

12

Fine adjusting of the lifting presser foot .........................................................

13

Changing the needle gauge ........................................................................

13

CONTENTS

Page

1

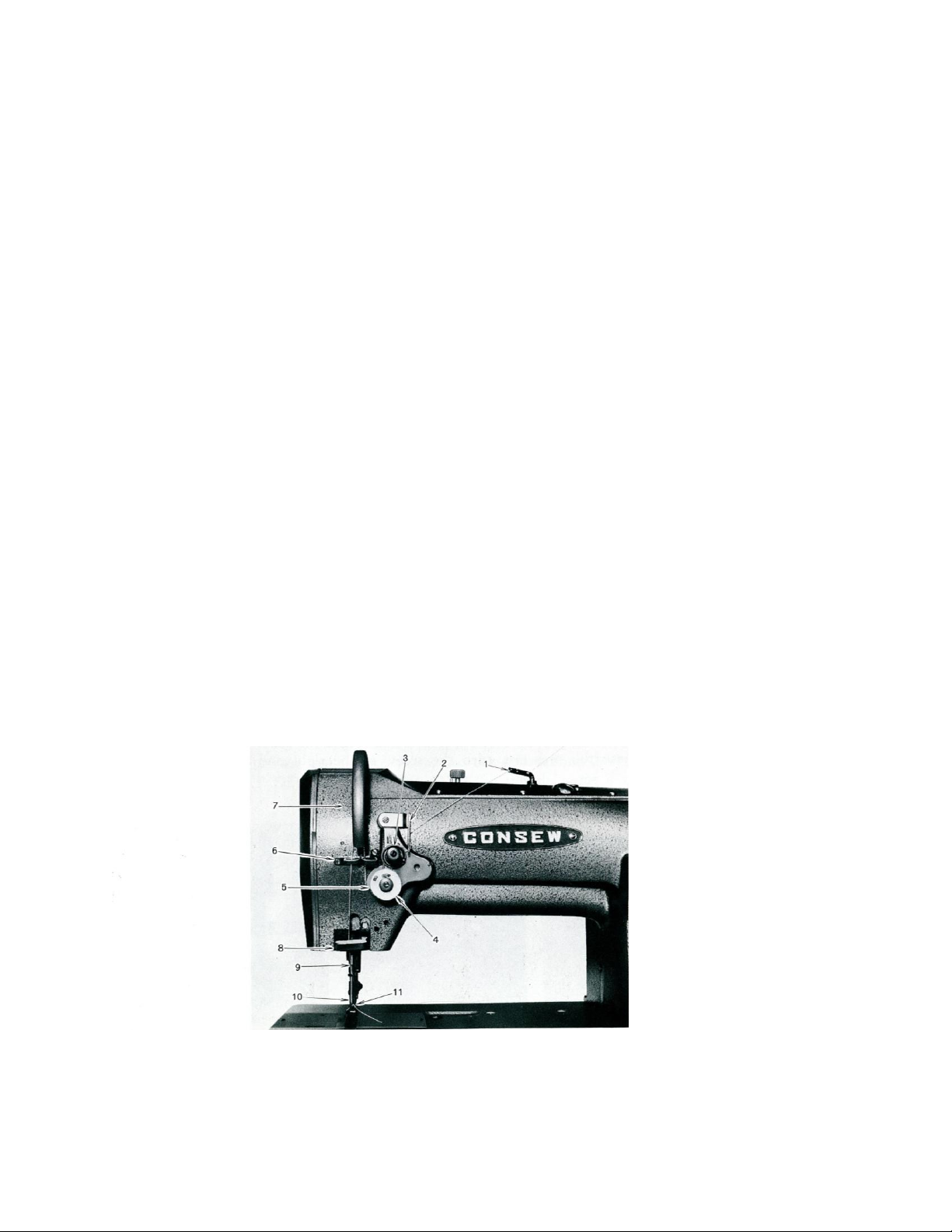

SETTING UP THE MACHINE

1.

Hinge

2.

Motor

3.

Oil pan

4.

Oil bottle

5.

Knee lifter

6.

Stand

7.

Treadle

8.

Machine rest pin

9.

Cotton stand

10.

Cushion rubber

11.

Head of machine

12.

V belt

13.

Bobbin winder

Before setting up the machine on the table, attach the relative parts to the table.

OILING AND IT'S ADJUSTMENT

Do not operate the machine, even if for testing, unless it has been properly oiled.

(1) To fill the oil reservoir on top of the machine, pour oil through the oil filler hole (A),

until oil level reaches to the upper reference line.

Oiling is automatically made by the vibration of the machine while sewing operation

through the oiling wicks in the machine, and Oil flow stops automatically when the

operation of the machine ends.

2

(2) The hook mechanism should receive careful attention when lubricating the machine.

Push open the slide plate in the bed (the right and left plates in case of two needle

machine) and pull out the oil gauge (C). Fill oil in the resorvior for the rotating hook

mechanism up to the level marked on the oil gauge.

Care must be taken that oil flow stops when oil level falls to the bottom.

(3) Oiling adjustment to the hook mechanism.

The maximum oil flow is made when the reference line on the oil adjusting knob (2) is in a

line with the point (1), and it stops when the reference line is upright.

To adjust this, loosen the pinch screw (3) and turn the oil adjusting knob, then tighten

the pinch screw.

OIL ADJUSTER

Oiling to inside of arm top cover is automatically made by the vibration of the

machine while sewing operation.

Stop oiling temporarily by the following method at your option in case of long

sewing operation.

When point of the dial enters into point of arm bed cover after turning the dial, the

dial goes down and oiling stops completely.

NEEDLE

The size of the needle to be used should be determined by the size of the thread,

which must pass freely through the eye of the needle.

To insert the needle, turn the machine pulley Over toward you until the needle bar

(1) moves up to it's highest point, loosen the needle set screw (2) and put the needle up

into the needle bar as far as it will go, with the long groove of the needle toward the left

(but, toward inside direction in case of two needle machine), and tighten the needle set

screw securely.

3

THREAD

Cotton, synthetic or silk thread can be used according to your purpose, the thickness of

thread is up to # 8.

Left twist thread should be used in the needle, but either right or left twist thread can be

used in the bobbin.

In case of two needle machine, use right twist thread in the left needle for perfect

stitching.

INSERTING AND REMOVING BOBBINS

Push open the slide plate (1), (in case of two needle machine, left-hand and right-hand

plates). Pull up the latch (2) of the bobbin case and lift the bobbin (3) out of the bobbin

case.

To insert a full bobbin in the bobbin case, hold it between thumb and index finger of

your right hand. Place the bobbin on the center post of the bobbin case and push down the

latch (2).

Be sure that the thread draws out from the bobbin from left to right. Pull the thread into

the slot (4) and between the bobbin case opener (5) and the projection (6) and under the

tension spring (7).

Draw out about 5 mm of the thread on the needle plate and close the slide plate leaving

a sufficient space for passage of the thread.

WINDING BOBBINS AND ITS ADJUSTMENT

Push a bobbin on the bobbin winder spindle ( 1 ) as far as it ‘vill go. Pass the thread

from the thread stand downward through the eye (7) in the tension bracket, then between

and around the back of the tension disc, bring the thread forward toward the bobbin and

wind from below in clockwise direction several times around the bobbin.

Push bobbin winder lever (3) downward until the wheel (2) contacts the drive belt and

then start the machine.

4

After the bobbin is filled with thread, release will cause wheel to disengage from the belt

•

and winding will stop.

Cut the thread and remove the bobbin from the spindle.

Adjustment screw (5) can be turned in or out to increase or decrease the amount of

thread wound on the bobbin.

When fine thread is wound on bobbins, use light tension.

It is regulated by turning the knurled nut (6) on the tension bracket at the rear of the

bobbin winder.

Bobbin can be wound while the machine is sewing.

If the thread does not wind evenly on the bobbin, loosen the screw (4) in the tension

bracket and move the bracket to the right or left as may be required, then tighten the screw.

THREADING THE MACHINE

Raise the needle bar to its highest point.

From the thread stand, lead the thread to the thread guide (1) on top of the machine

arm, down to the upper guide hole of the thread guide (2) from right to left. Pass the thread

in weaving fashion through the other two holes in (2) and from right to left over and

between the tension discs (3). Now pull the thread downward from right to left beneath and

around thread controller (4), continue to pull the thread upward through the fork in the

thread controller and against the pressure of the check spring (5) and through the thread

guide (6), pull the thread upward through the eye in the take-up lever (7) down through the

thread guide (6) again and then through the thread guide (8) and (9) and from left to right

through the eye of the needle.

(In case of the two needle machine, pass the thread through the eye of the needle from

inside to outside).

5

Loading...

Loading...