Consew 223, 223R, 227, 227R, 227B User Manual

...

OPERATING

INSTRUCTIONS

FOR

MODELS

CONSOLIDATED

227B,

SEWING

223,

227,

MACHINE

223R

227R

227BR

A

U.S.INDU»rfllB«

CyMl^ANV.

SPECIFICATIONS

SPEED

: Maximum 3000 r.p.m.

(With

reverse

stitch

with synchronized binder 2800 r.p.m.)

NEEDLE:

HOOK

STITCH

SIZE OF BED: 65^/>x269mm

MOTOR:

DIAMETER

135x17

: Rotating

LENGTH:Maximum5mm

250W,

OF MOTOR

2P,

hook

clutch

PULLEY

mechanism

motor

: 50 cycle 70 mm

60

cycle

or

60.mm

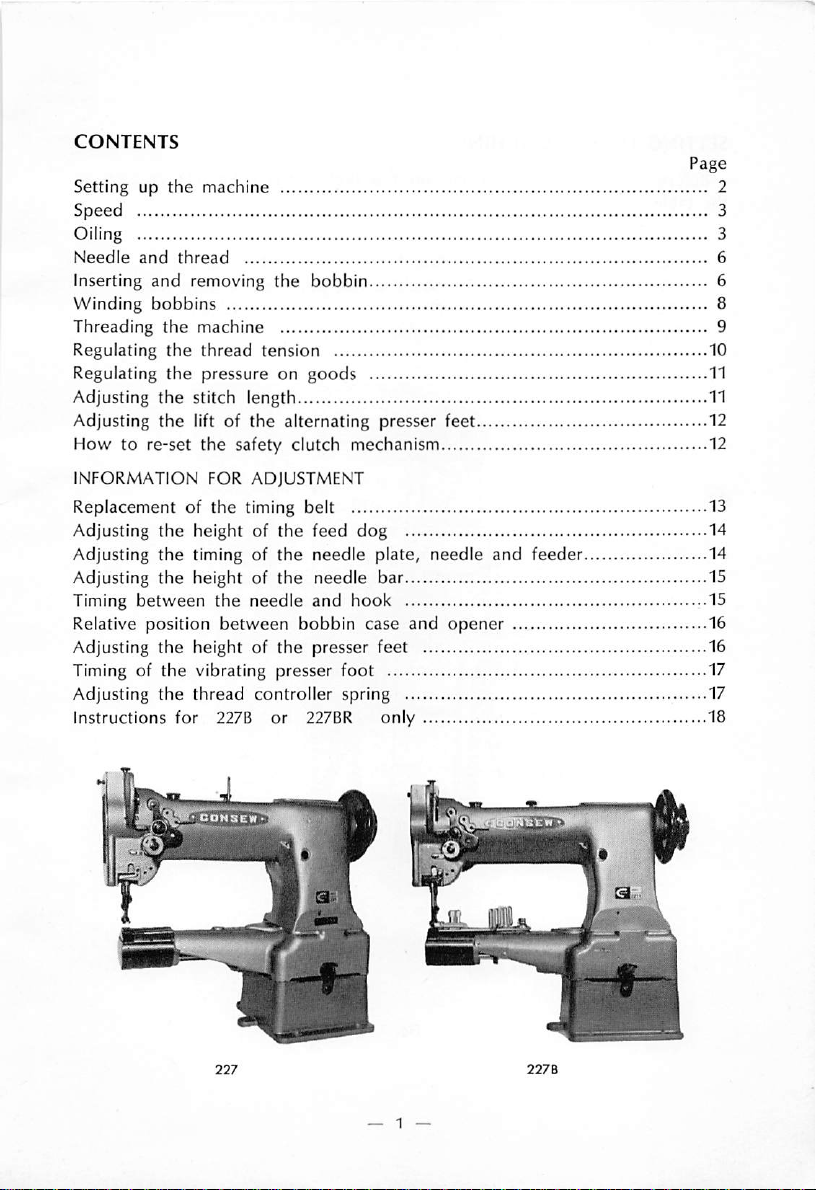

CONTENTS

Setting up

Speed

the

machine 2

Oiling 3

Needle

Inserting and removing

Winding

Threading

Regulating

Regulating

and

thread

the

bobbin 6

bobbins

the

machine 9

the

thread

the

pressure on

tension

goods

10

11

Adjusting the stitch length 11

the

Adjusting the lift of

alternating presser feet 12

How to re-set the safety clutch mechanism 12

INFORMATION

Replacement of

Adjusting

Adjusting the timing of the needle plate, needle

Adjusting

Timing

between

Relative position

Adjusting

Timing of the vibrating presser

Adjusting

Instructions

FOR

ADJUSTMENT

the

timing belt 13

the

height of

the

height of

the

heightofthe

the

needle

between

the

feed

dog

the

needle

and

bar

hook

bobbin case and

presser

feet

opener

and

feeder 14

foot

the

thread controller spring 17

for 227B or 227BR

only

14

15

15

16

16

17

18

3

6

8

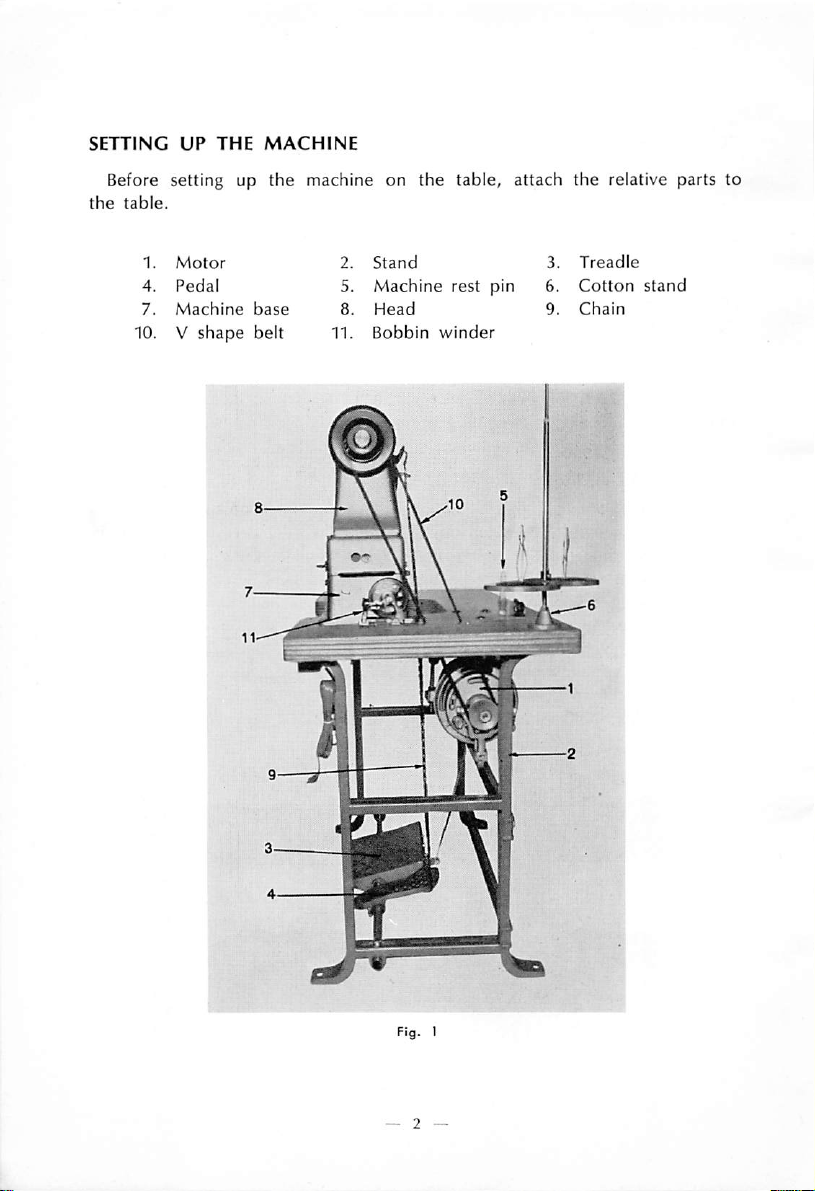

SETTING

UP

THE

MACHINE

Before setting up

the

table.

1.

Motor

4.

Pedal

7.

Machine

10. V

shape

the

base

belt

machine on

2.

Stand

the

table,

5. Machine rest pin 6.

8.

Head

11.

Bobbin

winder

attach

3.

9.

the

relative parts to

Treadle

Cotton

Chain

stand

SPEED

Maximum operating

speed

after a break-in period is 3000 stitches per minute

depending, of course, on the type of material being sewn, its thickness and

that of seams being crossed. (In case of the machine with reverse lever or

synchronized

To assure durability

the

first several weeks of operation the maximum speed is held to not more

binder

2800

and

r.p.m.)

trouble-free

operation,

it is

recommended

that

for

than 2400 RPM in order to allow the parts to become properly broken in.

in

operation

operator.

OILING

Do not

properly oiled at every

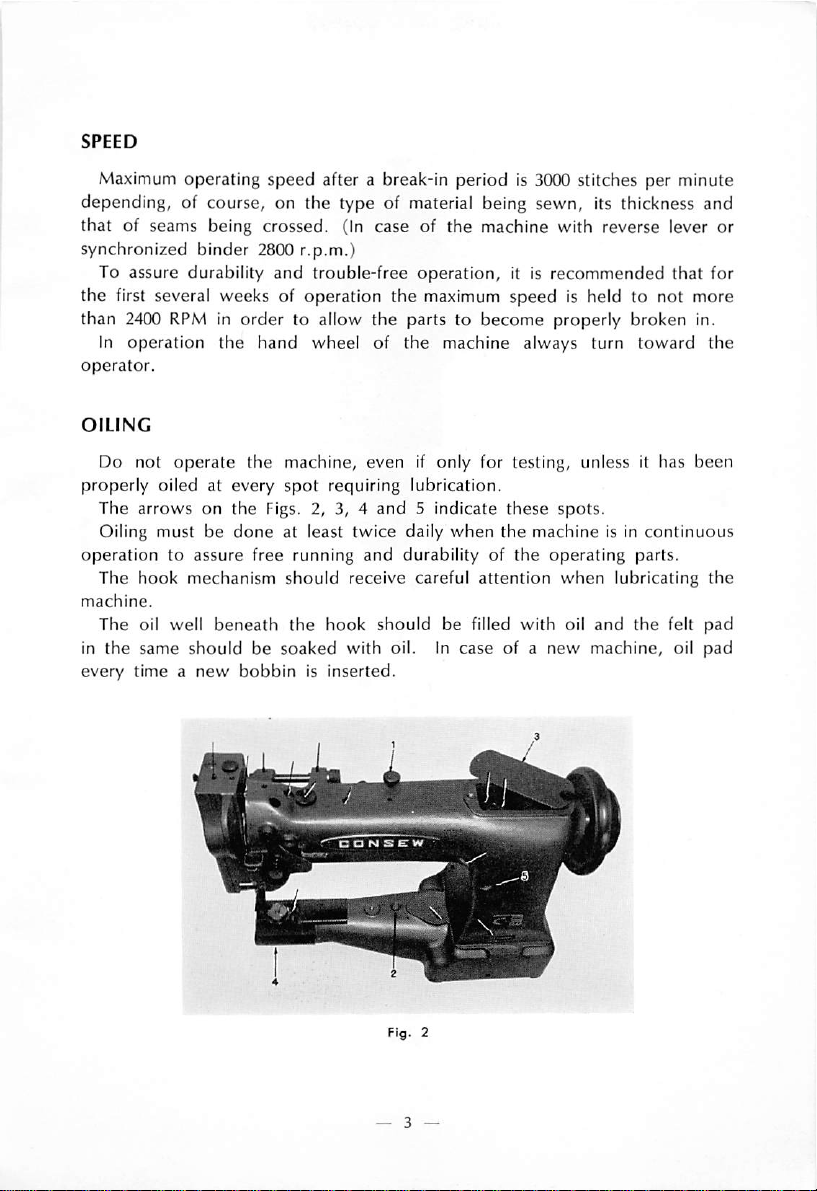

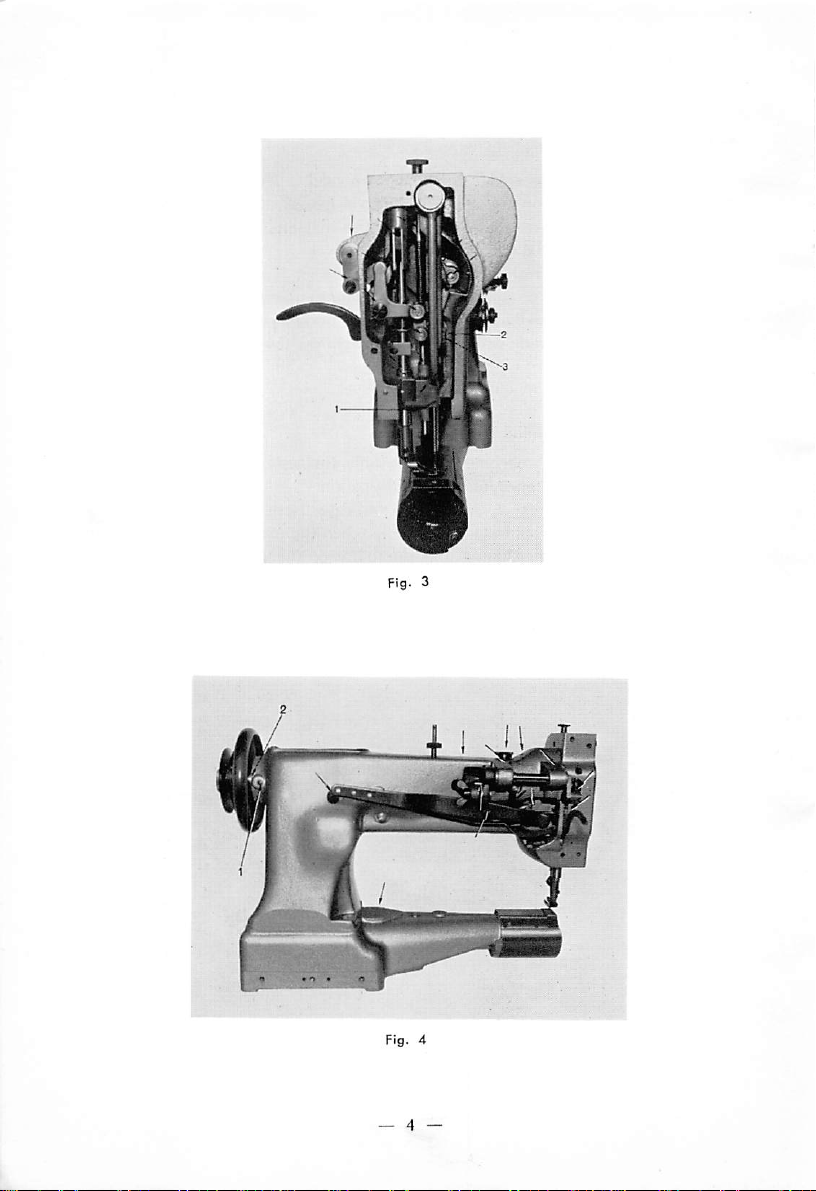

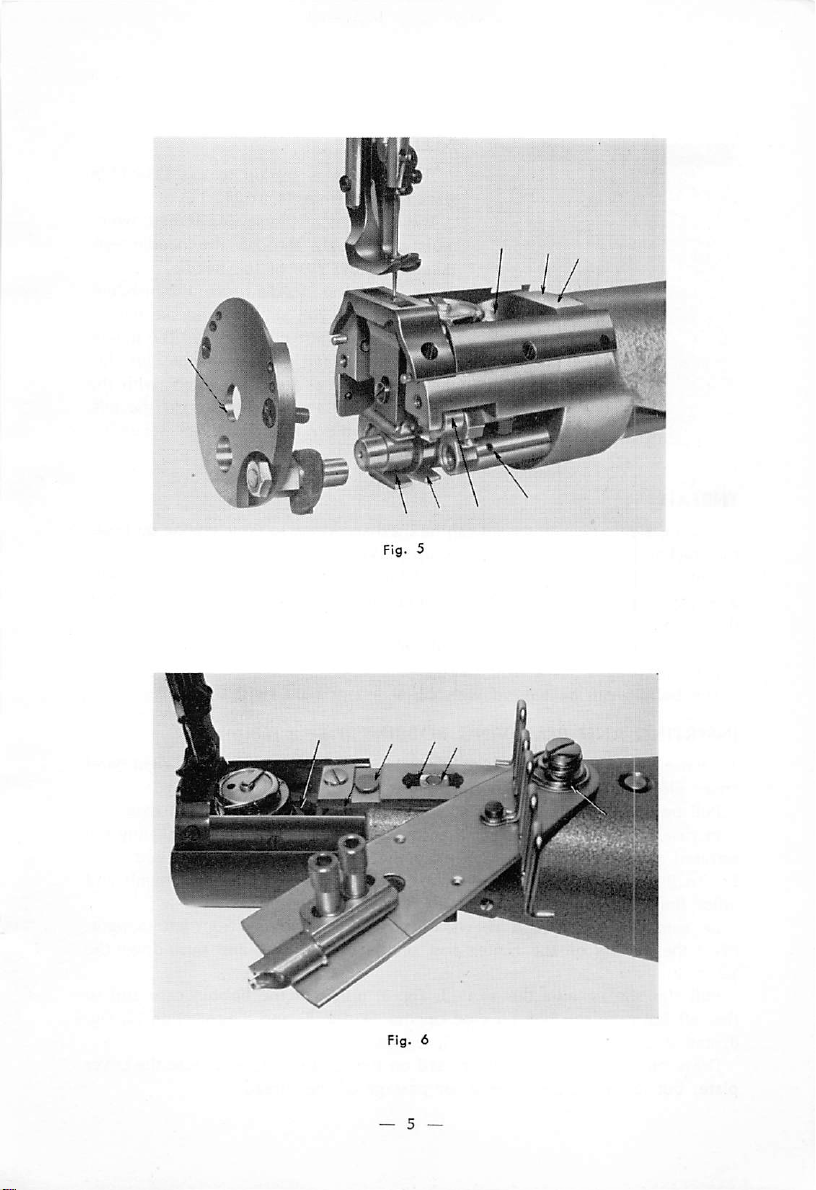

The

arrows

Oiling must be

operation

The

hook

machine.

The oil well

in

the

same

every

time a

the

hand

wheel

operate

the machine, even if only for testing, unless it has been

spot

on the Figs. 2, 3, 4

done

at least

to assure free running

of

the

requiring lubrication.

and

twice

daily

and

durability of

mechanism should receive careful

beneath

shouldbesoaked

new

bobbin

the

hook

should

with oil. in case of a

is inserted.

machine always turn

5 indicate

when

these

the

machine is in

the

operating

attention

be filled with oil

new

spots.

when

and

machine, oil

toward

continuous

parts.

lubricating

the

felt

the

the

pad

pad

1

fl

iv

i\

:/

-

Loading...

Loading...