Consew 2206RB-14-7DD Instruction Manual

Model

2206RB-14-7DD

PARTS BOOK

AND

INSTRUCTION MANUAL

Revised 2020

CONSEW USA

© Consew USA - 2020

CONTENTS

)R

§

lYL~fm:fr-

L

±~ti#;r~~

2,

3Z*183:ffl:

3,

3Z*tJL~

4,

3Z*ll*t~9&.it

5,

i)ff]~fl*t~*jt

6,

7,

8,

9,

LUBRICATION

RUN-IN OPERATION

i~$

O'X

_,,,-,,_

iJlEJJJ

1fffl

BRIEF INTRODUCTION OF THE MACHINE

MAIN TECHNOLOGY SPECIFICATION

INSTALLATION OF THE OIL TRAY

INSTALLATION OF THE HEAD

INSTALLATION OF KNEE CONTROL DEVICE

ADJUST KNEE CONTROL DEVICE

······························

···

INSTALLATION OF THE NEEDLE

SETTING THE BOBBIN CASE···

WINDING THE BOBBIN THREAD

,~,~~-

BOTTOM THREAD

UPPER THREAD

ADJUSTING THE STITCH LENGTH

STITCHING AND REVERSE STITCHING

ADJUSTING THE THRESD TENSION

ADJUSTING THE PRESSURE OF THE PRESSER FOOT

ADJUSTING THE TAKE-UP SPRING

ADJUSTING THE PRESSER FOOT HEIGHT

··················································································

ADJUSTING THE LENGTH OF THE THREAD END

INSTRUCTION MANUAL

·····································································1

..............................

....................................

........................................................................

·····················

······

······

··················

···

···················································

......

...............................................................

··· ···

··· ···

··· ··· ··· ··· ··· ··· ···

••,•

··································································7

··········

............

·························································1

······

······

······--·······

·········

···

·······················

···

··· ···

······

......

··· ···

···

···

···

···

.........................................................

···························

..

············

········

...............

··················

···

···············

············

··· ··· ··· ···

···

··········

···················

···························

........................................

······

...............

···

···

.........................

················

············

···

······

···

··· ···

.....................

..........................

...........

············4

···

··················5

············5

··· ···

···

···

..............

...........

······

···5

···6

···

······9

10

1

2

2

3

3

6

7

g

8

9

ADJUSTING THE PRESSER FOOT HEIGHT · · · · · · · · · ·· · · · · ·· · ·· · ·· · · · ·

ADJUSTING THE DOG FEED HEIGHT

ADJUSTING THE DOG FEED ANGLE · · · · · · · · · ·· · · · · ·

t)ff]·tj·fi~t!'ii!H"J1Mt!

25,

26,

1

HOOK LUBRICATON ADJUSTMENT

::1;e;t;,;;·tts,,,r1

29,

_t;ziHMJ;J8{]t)ff]+~·

30,

13iMt[ljtx_f!:frtfLfz;JH"J'i)fi]1"j-

3L

tiB:]t!],

32,

-1g.

ADJUSTING THE OIL PUMP LUBRICATION

1j\[Js]i;J],\'~HU+:l:8{]1)fi]ff

1N::fs]t[]ltfrJ§}Tfwli'sJlt~B{]i)ff]ff

ADJUSTING THE THREAD TRIMMER DEVICE

CLEANING

...............

.....

· · · ·· · · · ·

... ·

···

···

······

············

······

···

······

ADJUSTING THE STITCH AND REVERSE STITCH LENGTH ERROR

ADJUSTING THE LOOSEN THREAD DEVICE OF THE TENSION DISCS

ADJUSTING SYNCHRONIZATION OF THE NEEDLE AND FEED DOG

······ ······

ADJUSTING SYNCHRONIZATION OF THE NEEDLE BAR HEIGHT AND

ADJUSTING THE TOP-FEEDING MACHNISM

ADJUSTING WALKING FOOT AND PRESSURE FOOT

ADJUSTING THE LIFTING AMOUT OF THE FOOT

ADJUSTING THE CLEARANCE BETWEEN THE FOOT

···············

············

······

...............

................................................

····························

·······················

······

············

······

······

· · · ·· · · · · · · · · · · · · · · · · · ·

·

..

······

·········

···

···············

.............

············ ············

······

···

DEVICE···

············

HOOK···l3

...........

...............

·· · · · ·

·········

·· · ·· ·

···

......

······11

···

......

······15

16~17

10

10

11

11

12

12

13

14

14

15

l8

§~CONTENTS

A.

:rJLnttlS5t

B.

t+f=f,

t3~~~-fffWt·/NEEDLE

..

J-"hl=l(A'-LI

C . . ,

D.

L*f4tt1H4

E.

Bs:.li!Pttl114

F.

J5JH1#[){L:j::

G.

H.

{!tilil11IJ11!'$14

1.

ff1jgj~fg:jr{q:

J.

{Wftt~14

K.

{fU§i#!H4

L.

~f~·f:j::

ACCESSORIES

~14-=f.:JID

MACHINE COVER ASM

BAR

FEED MECHANISM COMPONENTS

(9302

~ffl) /FEED MECHANISM(9302 SPECIAL-PURPOSE)

PRESSER FOOT ASM

ROTARY HOOK

THREAD

TRIMMER ASM

LUBRICATION

REVERSE

REVERSE

REVERSE

FEED

FEED

FEED

...

···

.........

MECHANISM

··································

AND

THREAD TAKE-UP MECHANISM

···

······

··· ···

...

···

· ··

···

....................................................................................

COMPONENTS ;;;

COMPONENTS

COMPONENTS

··· ··· ··· ··· ... ···

PARTS

..................................................................

·········

·············

· ·· · ·· ·· · · · · ·· · ·· · · ·· · ·· ·· · ·· · · ·· ·

······

···

···

BOOK

...............................................

.................................

·························

··· ··· ···

·····················

.....................................................

.....................

......................................................

···

···

···

···

··· ··· ··· ···

······

···

·········

···

···

···

···

··· ··· ··· ··· ··· ... ···

···

············

..

· · · · · · · · · · · · · ·· ·· · ·· · · ··

.........................

···

......

···

.........

··· ···

·········35

··· ···

··· ...

··· ···

···

··· ... ··· ··· ...

........

;;;;:45

···47

···47

19

23

27

31

37

·· ·39

43

49

m•*ffll

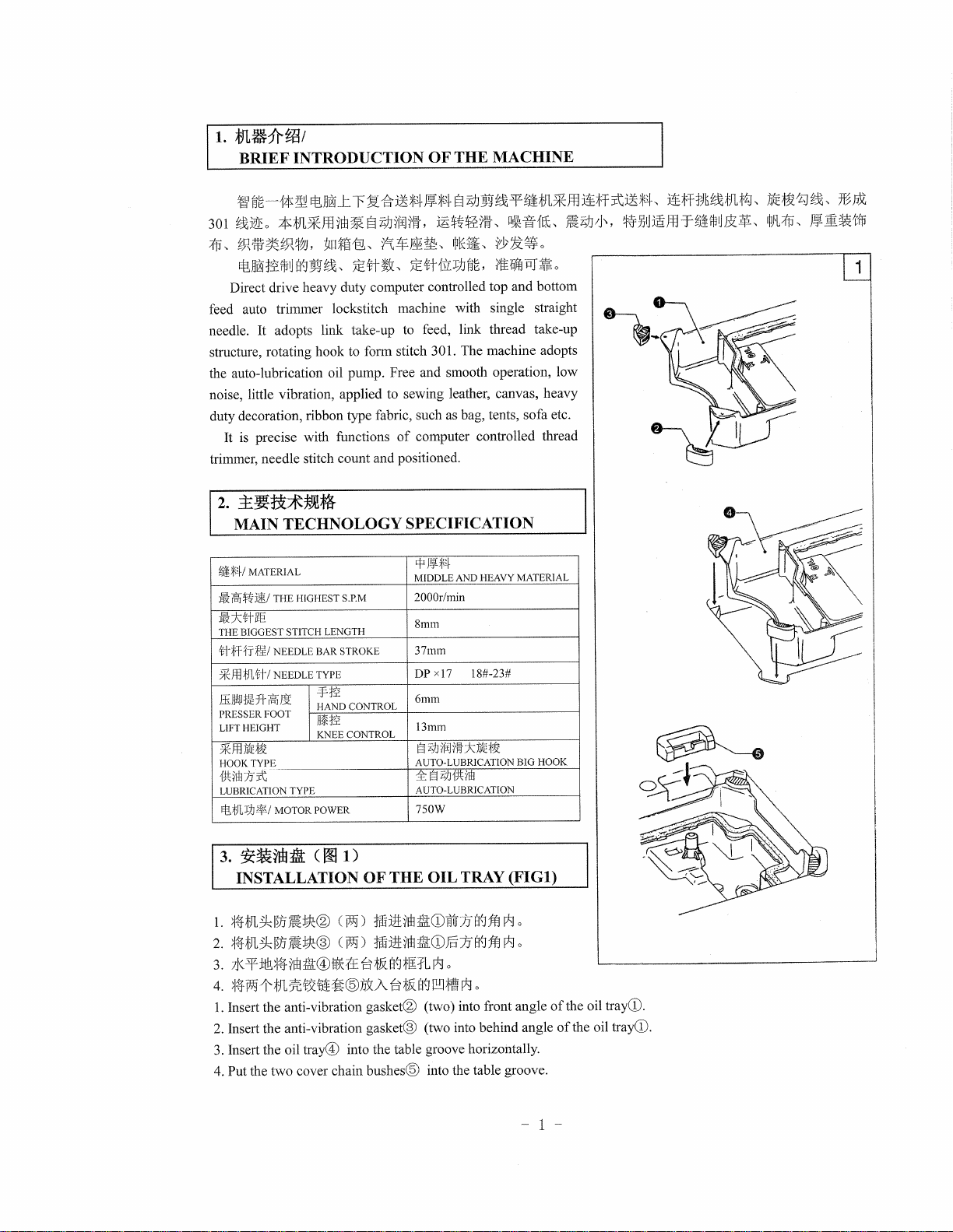

1.

BRIEF INTRODUCTION OF THE MACHINE

~~-~~~~~~~~~MWM§M~~f~m*ffl~ff~~M-~ffm~m~-~~~~-%~

*tJL*ffHlM1~§iJJifiJ1t,

ttnL

301

:;{ff,

~~~~ITT~~-~tt~-~tt~~~.

Direct drive heavy duty computer controlled top and bottom

feed auto trimmer lockstitch machine with single straight

adopts link take-up to feed, link thread take-up

needle.

structure, rotating hook to form stitch 301. The machine adopts

the auto-lubrication oil pump. Free and smooth operation, low

noise, little vibration, applied to sewing leather, canvas, heavy

duty decoration, ribbon type fabric, such as bag, tents, sofa etc.

trimmer, needle stitch count and positioned.

It

precise with functions

is

It

.±~tt*

2.

~n~t'i'§,,

;fit

~

1~$~~-

iEl!t~111·,

computer controlled thread

of

nt~1~-

iYbZ~o

~iJJ1J\,

t~3}1J~ffl-t-fft1JEl.i¥,

~if'L:;fff,

MAIN TECHNOLOGY SPECIFICATION

)IH,~

MATERIAL

iiU-'l-1

THE

~tlf:l£/

~

~:kHIBe

BIGGEST

THE

ti-fHrl~U

*J=!HJL4t/

LI~tfl1Jl1:H

PRESSER

LIFT

*fflm~

HOOK

NEEDLE

NEEDLE

~

FOOT

HEIGHT

TYPE

1;ltm37'J:rt

LUBRICATION

i=§.t)lJ)J.$/

HIGHEST

LENGTH

STITCH

sTRoKE

BAR

TYPE

+1~

fit

HAND

H~H~

KNEE

TYPE

MOTOR POWER

S.P.M

CONTROL

CONTROL

"t1

HEAVY

AND

MIDDLE

2000r/min

8111111

37mm

ffl

111]

i)J

§i)J1;ltmJ

18#-23#

j(jjJEf&

DP xJ7

6mm

13mm

§

AUTO-LUBRICATION

~

AUTO-LUBRICATION

750W

MATERIAL

HOOK

BIG

1

1)

rm

7E4t:'fi

tfl

c

tru:itt11Effi:CDfiJJ:fB{Jm

CWD

1ruill)mffi:CDJB1JITTm

CM°)

0

!S'fRB{JtlfJL

JJ>CA

:i:@

gasket®

gasket®

into the table groove horizontally.

bushes®

chain

pq

pq

ti

Qil

tliU'.1{]

IS'

(two) into front angle

(two into behind angle

into the table groove.

o

(FIGl)

0

pq

o

pq

*~¥lil~

3.

INSTALLATION OF THE OIL TRAY

itH:JL~~;lt~®

1.

i~t:JL~~n;lt~®

2.

;J(-Sf±ihi~Jmffl:®wd±

3.

1"

M

i~

4.

Insert the anti-vibration

1.

Insert the anti-vibration

2.

Insert the oil tray@

3.

4. Put the two cover

1

of

of

the oil

the oil

tray(D.

tray(D.

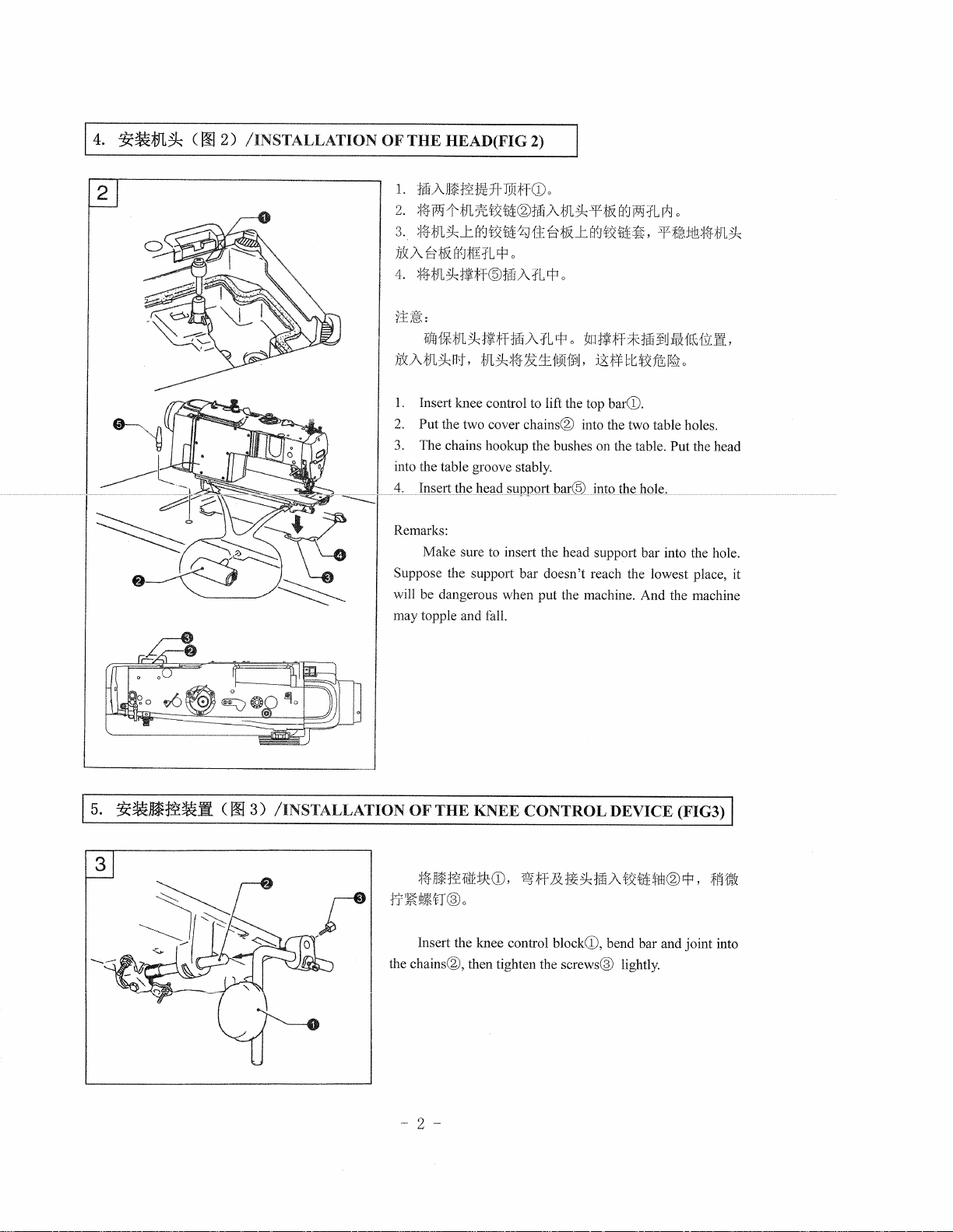

14.

1(~m~

(00

2)

/INSTALLATION

OF THE HEAD(FIG2)

2

1.

2.

itM1'ifLJ1Hxtr!®tffiAtfL!k:5ftJzs<J~HL1:fg

3.

iti:ll~J:R<Jtx:trJ!,1t-;:i{i

JJ:lA

EJ

fR

4.

1.

Insert knee control to lift the top

2.

Put the two cover

3.

The chains hookup the bushes on the table. Put the head

into the table groove stably.

InE>~rt:the

Remarks:

Make sure to insert the head support bar into the hole.

Suppose the support bar doesn't reach the lowest place, it

will be dangerous when put the machine. And the machine

may topple and fall.

s<rt[ffL

he<1d

1

=r

o

chains®

E>upport

barCD.

into the two table holes.

bgir@

...

intQthe

0

hole.

,

5.

*~~t£~.11.

C

00

3)

/INSTALLATION

OF

THE

KNEE

CONTROL

3

Insert the knee control

the

chains®,

-

2

then tighten the

block.CD,

screws®

DEVICE (FIG3)

bend bar and joint into

lightly.

I

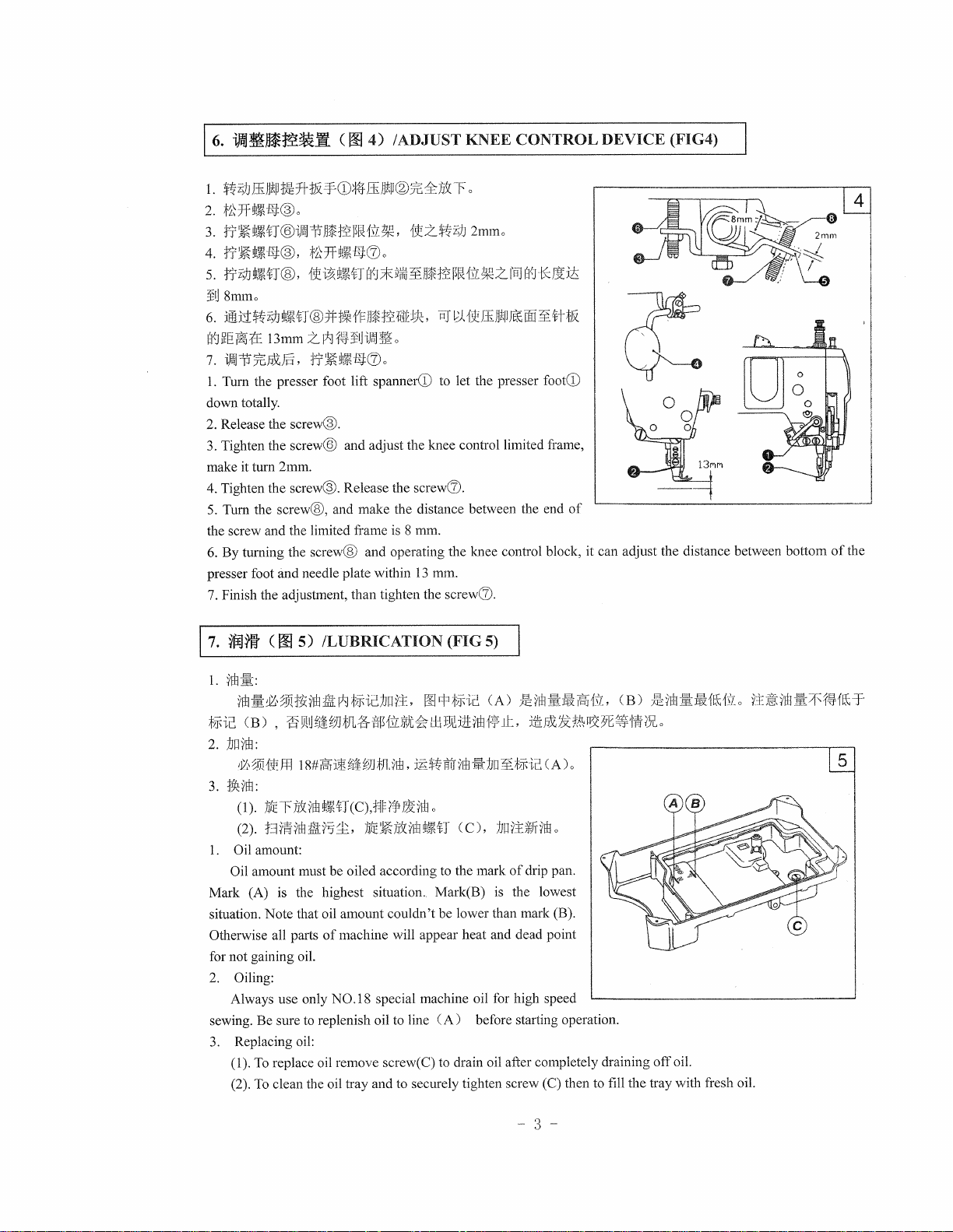

iJ.I!f}Jl~~J1.

6.

,

(00

/ADJUST KNEE

4)

CONTROL

DEVICE

(FIG4)

1.

ti~3HJ-&J:®o

2.

1rtJJtUT®,

5.

8mmo

iU

6.

iftilff%mJ0,

1.

Turn the presser foot lift

1.

down totally.

Release the screw®.

2.

3. Tighten the screw@ and adjust the knee control limited frame,

make it turn 2mm.

4. Tighten the screw®. Release the

Turn the screw@, and make the distance between the end

5.

the screw and the limited frame

By turning the screw@ and operating the knee control block, it can adjust the distance between bottom

6.

presser foot and

Finish the adjustment, than tighten the

7.

needle plate within

spannerCD

is

to let the presser

screw(7).

8 mm.

mm.

13

screw(7).

footCD

of

of

4

the

5)

J2f

line

18.l

(FIG

o

CC),

the mark

to

(A)

of

the lowest

is

before starting operation.

drip pan.

/LUBRICATION

5)

00

(

wJfit

11.

£,ivHse:m

t~1m:

3.

(1).

c2).

Oil amount:

1.

Oil amount must be oiled according

Mark (A)

situation. Note that oil amount couldn't be lower than mark (B).

Otherwise all parts

for not gaining oil.

Oiling:

2.

Always use only

sewing. Be sure

3. Replacing oil:

).

(1

(2).

1s#~J1fitm;um,

C)J4nJt

(

t~VH

1m

JJJ:

»JCF

1ai~1mffl:1'5~,

the highest situation. Mark(B)

is

machine will appear heat and dead point

of

special machine oil for high speed

N0.18

replenish oil

to

replace oil remove screw(C) to drain oil after completely draining off oil.

To

clean the oil tray and to securely tighten screw (C) then to fill the tray with fresh oil.

To

to

5

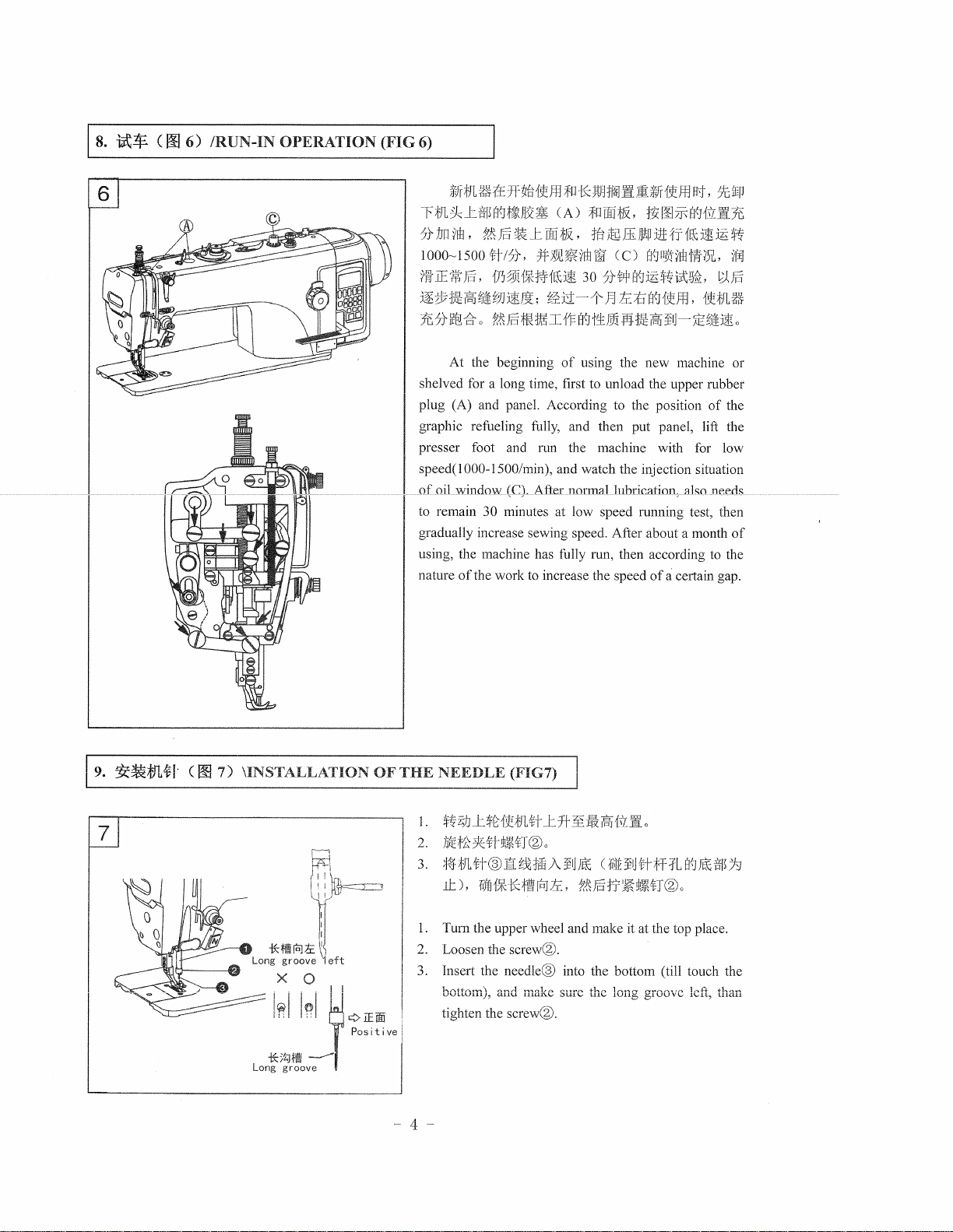

3 -

18.

6

Y-\$

(

00

6)

/RUN-IN OPERATION

(FIG

6)

At

the beginning

shelved for a long time, first to unload the upper rubber

plug

(A) and panel. According to the position

graphic refueling fully, and then put panel,

presser foot and run the machine with for low

speed(l

000-1500/min ), and watch the injection situation

of

oil

window

to remain 30 minutes at low speed running test, then

gradually increase sewing speed. After about a month

using, the machine has fully run, then according to the

nature

of

(C:).

the work to increase the speed

Afrer

of

using the

norm:il

new

luhrication,

of

machine

of

lift

ako

a

certain gap.

or

the

the

nf.f.ds

of

9.

*~;fntt

7

(

00

7)

\INSTALLATION

OF

¢

iErni

Positive

THE

NEEDLE

1.

2.

3.

1.

Turn the upper wheel and make it at the top place.

2. Loosen the

3. Insert the

botto1n),

tighten the

(FIG7)

screw®.

needle®

and

111ak.e

screw®.

4

into the bottom ( till touch the

sure

the

loi1g

groove

left,

tl1an

JJJEJi

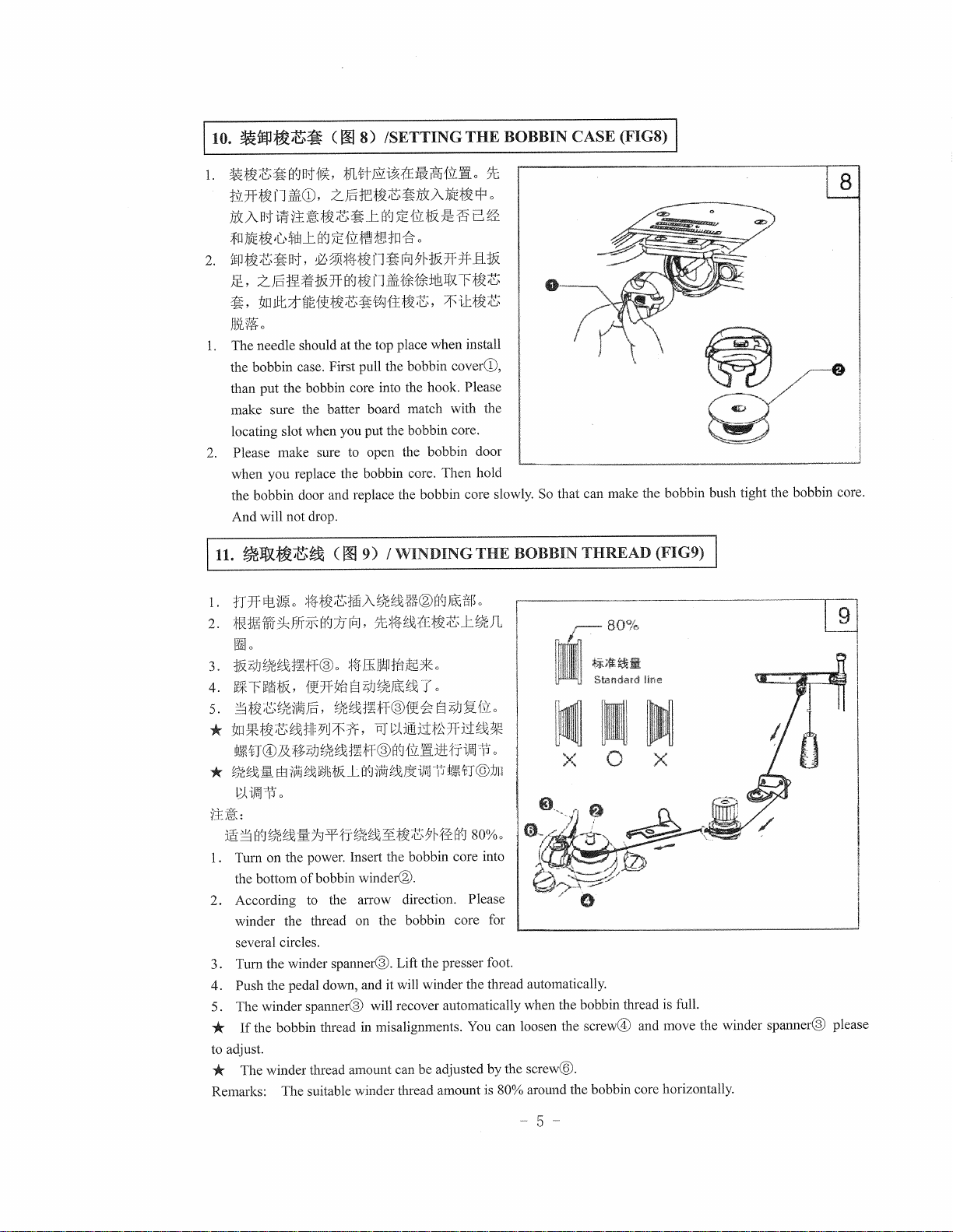

A

THE

T

~ifL~~~

110.

~~~ff~~~.m#@~a•~~~o~

1.

~A~~tt•~~ffL~~~~~~B~

{,,tril

:nJEti

□

l

iliPti~~ffn1,

2.

ZJ§

Jr:,

.~~~~~~~ff~tt~~.~il~~

(

Z

~

s{J

L

&,im~tt~nff

~1R7T

tffi

1E

J§

t!

1:v:

~

s{J

JJ,£

ff

ti~~

o

it

JJHi=i

r~1Hi3f#

1;1~1;1dili.Ifx

.ffir

!']

/SETTING

8)

00

fl5U1L

The needle should at the top place when install

1.

the bobbin case. First pull the bobbin

than put the bobbin core into the hook. Please

make sure the batter board match with the

locating slot when you put the bobbin core.

Please make sure to open the bobbin door

2.

when you replace the bobbin core. Then hold

the bobbin door and replace the bobbin core slowly.

And will not drop.

/WINDING

9)

~lf>ttt~~

111.

(00

coverCD,

BOBBIN CASE (FIGS)

o

r:p

1L1Jft.

ti~~

that can make the bobbin bush tight the bobbin core.

So

BOBBIN THREAD (FIG9)

THE

I

8

1.

2.

110

3.

4.

5.

*

*

1 . Turn on the power. Insert the bobbin core into

2. According to the arrow direction. Please

3. Turn the winder spanner®. Lift the presser foot.

4. Push the pedal down, and it will winder the thread automatically.

5. The winder spanner® will recover automatically when the bobbin thread

*

to adjust.

*

Remarks: The suitable winder thread amount is 80% around the bobbin core horizontally.

0

~-t)~"1fj

1

O

80%

_L..'l')Cjl'LJ\,-ll'A<-~·

~';[1-'"'1,c"-q.A~

of

;(,-

bobbin

winder®.

misalignments.

in

'Z-'43/:+C-•-,;:-J-'-fL.

Kl

the bottom

winder the thread on the bobbin core for

several circles.

the bobbin thread

If

The winder thread amount can be adjusted by the screw®.

1-1,

You

can loosen the

screw@

full.

is

and move the winder spanner® please

9

5 -

i

12.

!;3!~~

1.

$ti

rJJ

2.

~~itfizJ::11=ittt~,

1

3.

t

IPttt~11Jt

1:vAlU!Hn

1.

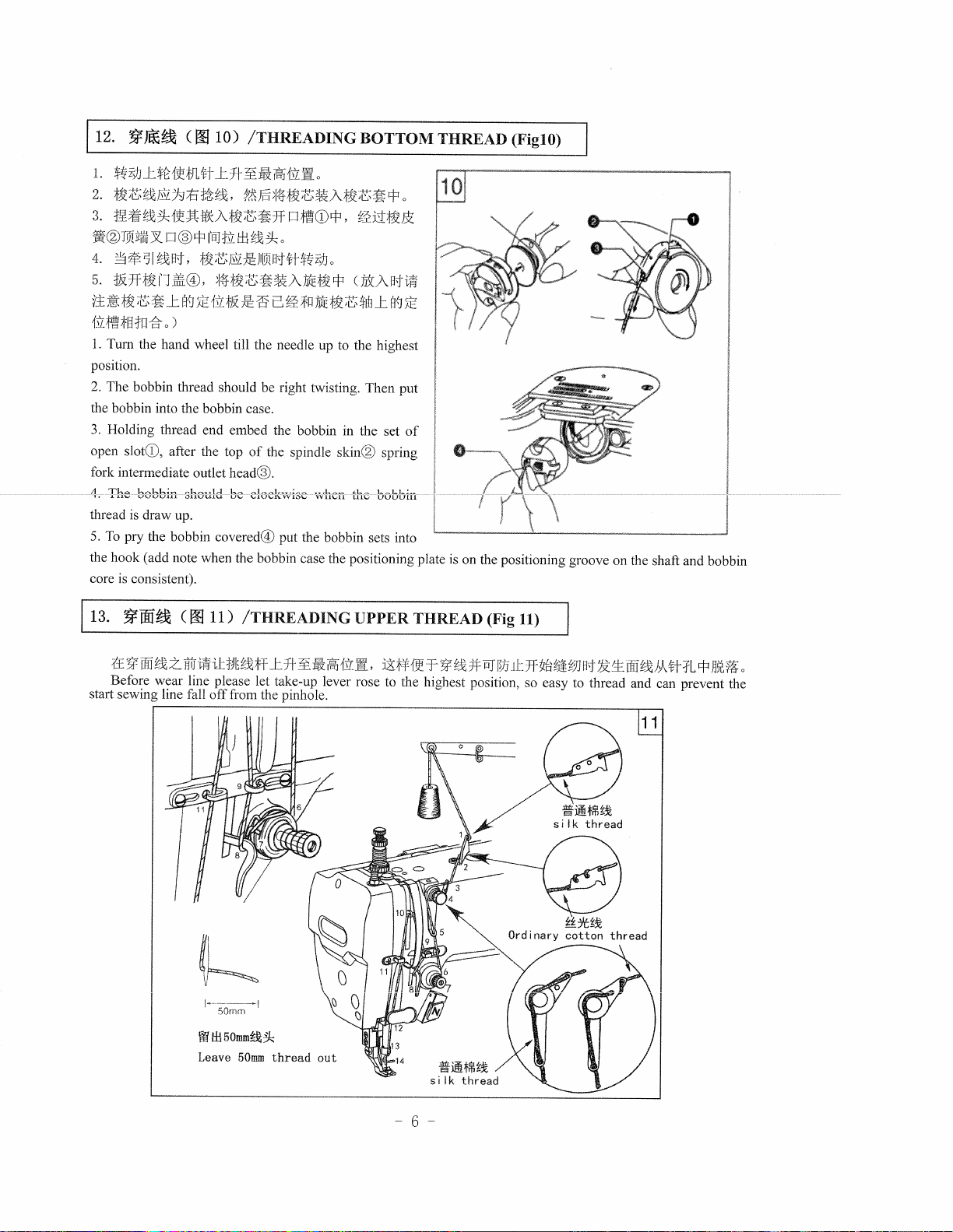

Turn the hand wheel till the needle up to the highest

position.

2. The bobbin thread should be right twisting. Then put

the bobbin into the bobbin case.

3. Holding thread end embed the bobbin

open

slotCD,

fork intermediate outlet

1

L

The

bobbh1

thread

is

5.

To

pry the bobbin covered@ put the bobbin sets into

the hook (add note when the bobbin case the positioning plate is on the positioning groove on the shaft and bobbin

core

is

consistent).

-1J~

11

17

@9=1j'§]

it

O )

after the top

draw up.

(0010)

;JJUt

/THREADINGBOTTOMTHREAD(FiglO)

-1~

fl-

wcAttrt~~3f

1ft

ili

~!

ti

~c'i~

J.5Y

fi!:

~~

1~

:t;~

of

head®.

should.

be

clock:vvisc

::k

0

J11Jn

n1·

H

$=!¥

~*A

nfE

i3

~

tP

the spindle

r)J

o

t~

r=p

JifE

t~

in

skin®

v\rl1cn

~c'i~

$1i1

the set

tl1c

J:.

of

spring

bob·bin

113.

!;j!ffi~

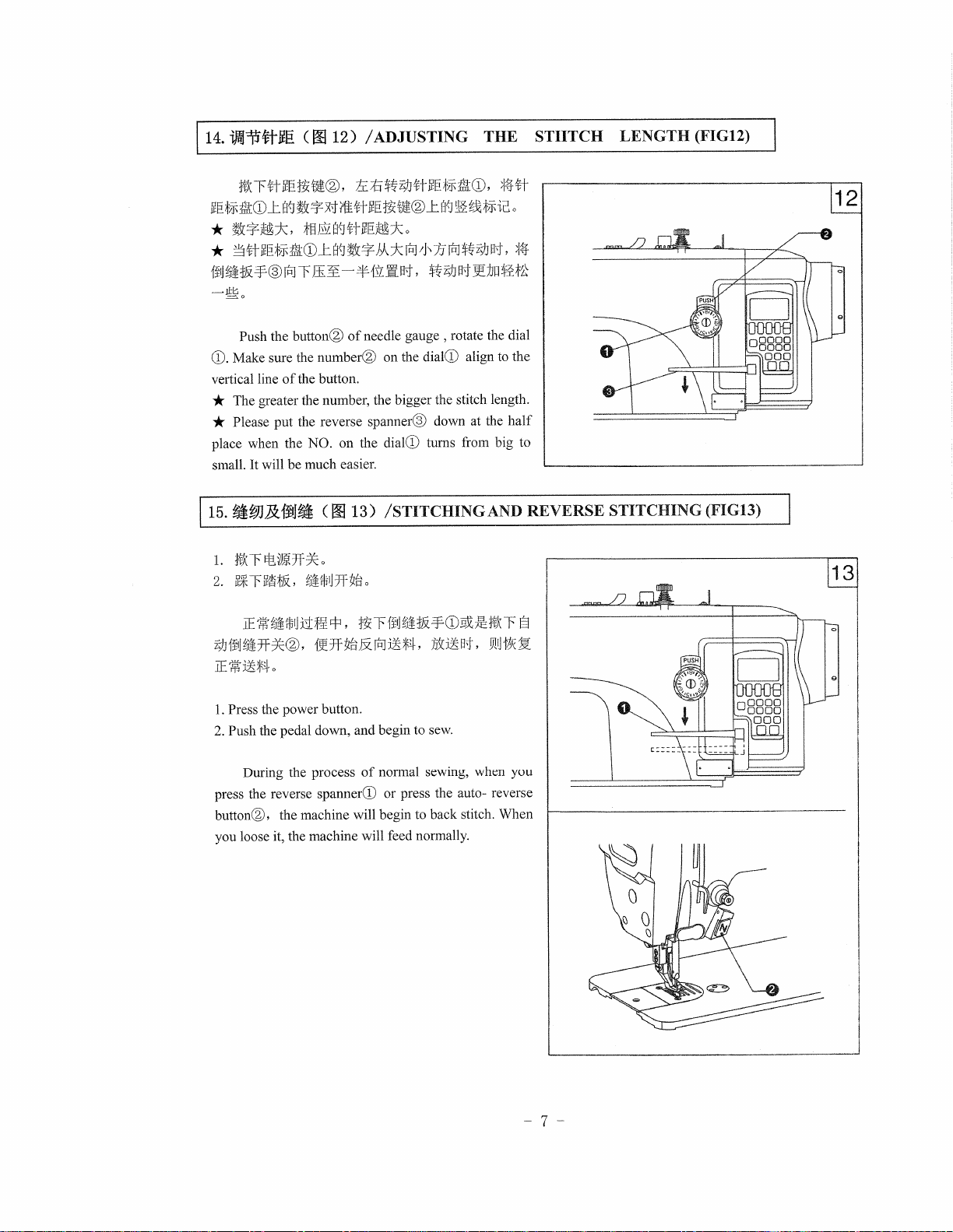

Before wear line please let take-up lever rose to the highest position, so easy to thread and can prevent the

start sewing line fall

(

00

11)

/THREADING UPPER THREAD (Fig

off

from the pinhole.

11)

11

50mm

ffl

ltl50mm~:¼

Leave

50mm

thread

out

~imt*ii

s

i

I k

thread

- 6

114.

~~ttffi

(

III

ADJUSTING THE

/

12)

STIITCH

LENGTH

(FIG12)

~Ttt~~•®·

~~AQ)L~~*~mtt~~-®L~~~~fil◊

tB

~*,

i!t=r:

*

3ttieiiAWL

*

{futJiiJf¥®itu

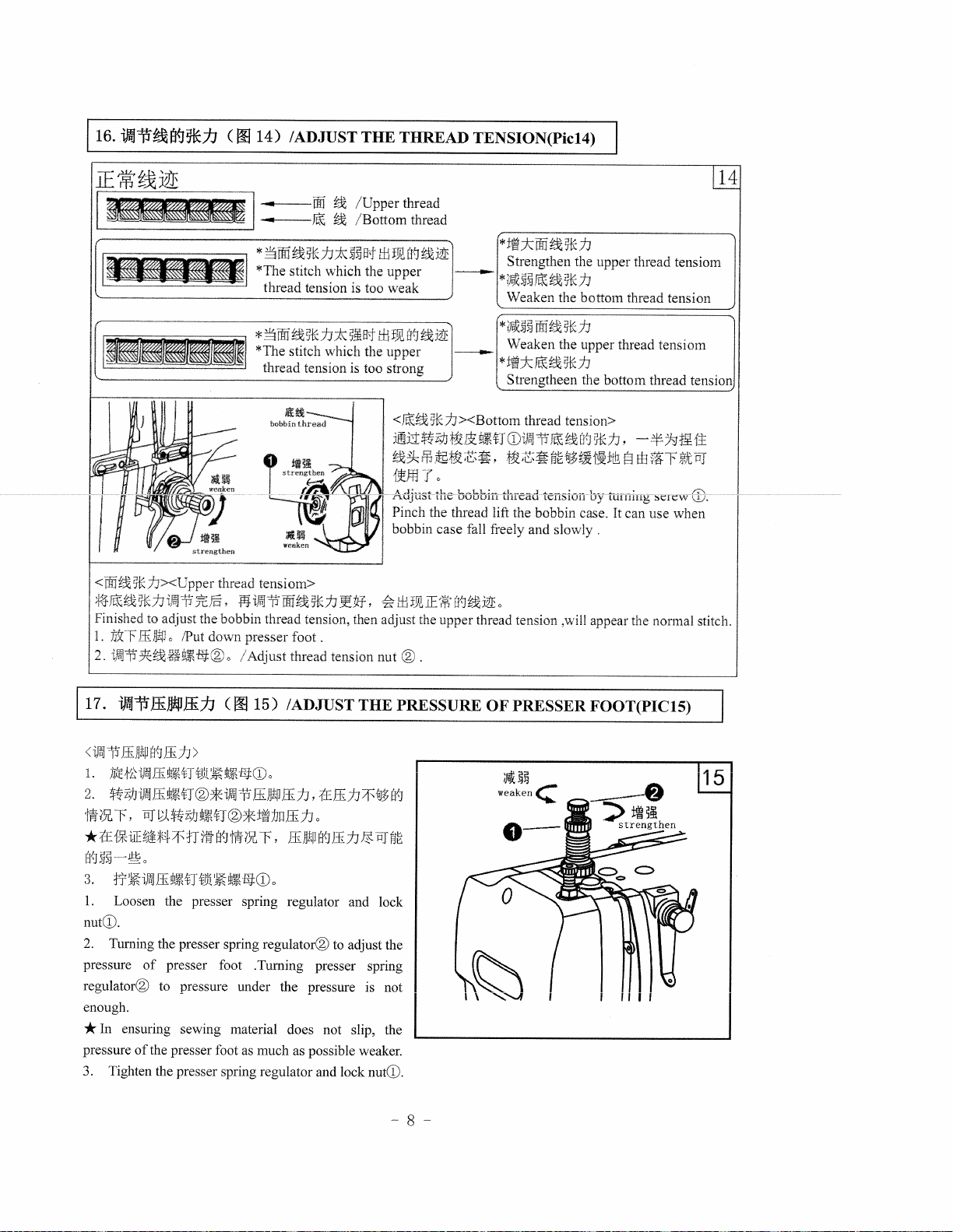

Push the

Make sure the

Q).

vertical line

The greater the number, the bigger the stitch length.

*

Please put the reverse spanner® down at the

*

place when the NO. on the

small.

~mBdJIJ~

15.

j

~r

i.

R*T&{Mlz,

2.

rr$-~tt~~,

iJ1fWi7f*®·

rr$~)f~-◊

button®

the button.

of

will be much easier.

It

fjif#IJ3ltzt

~~~~tt~~AQ),

tt!fe~:k

<J

□

J§Z

Mt*J,A:k1tJ

□

of

number®

13)

III

(

o

1

J\1JitD$tfJJa~·'

l{i)Ja1J~JP$H~

,

needle gauge , rotate the dial

on the diaIQ)

turns from big to

dialQ)

/STITCHING

0

~Tffl-~¥Q)~~~T~

1JJHEI&itD~f~·,

ffitt

~~

the

to

align

half

AND REVERSE STITCHING (FIG13)

!TIH~~

,

12

13

Press the power button.

1.

Push the pedal down, and begin to

2.

normal sewing, when you

During the process

press the reverse

button®,

you loose it, the machine

the machine will begin to back stitch. When

of

spannerQ) or press the auto- reverse

will

sew.

feed normally.

- 7 -

j

16.

iJ~fi!f~1¥HlUJ

(

00

14)

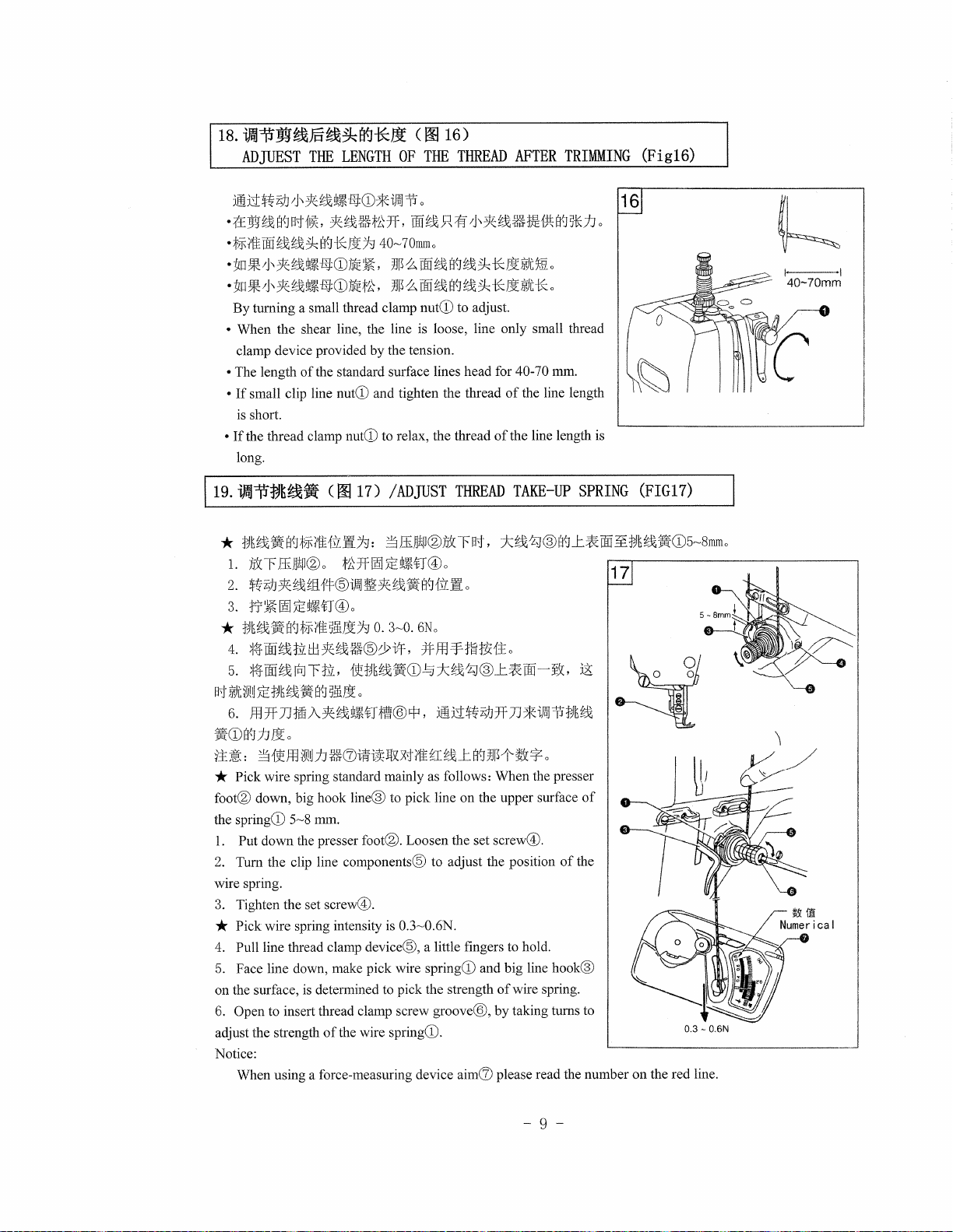

/ADJUST THE THREAD TENSION(Pic14)

/Upper

/Bottom

thread

thread

14

Finished to adjust

I

.

2.

117.

iffiJT-f

thread

the

bobbin

o

/Put

dmvn

&J14J£KiJ

(

*The

stitch

\vhich

the

thread

tension

is too

tensiom>

thread tension, then adjust the

presser

/Adjust

00

foot

.

thread

tension

15)

/ADJUST THE PRESSURE OF PRESSER FOOT(PIC15)

'-z:;:

nut

A

a{Jf~j:21

upper

strong

<~~

Pinch

bobbin

5-K

the

case

upper

---

7J

thread

Strengthen

><Bottom

lift

the

fall freely

thread tension

thread

bobbin

and

the

tension>

case. It

slowly

,1,:vill

upper

thread

can

.

appear the

tensiom

use

when

nonnal

stitch.

<

ift-0

·,ri

lli

flt/J

B<J

J±

;J

>

1.

»JE

tt

ift-0

lli

tUT

i1t~

tJ

BJ:CD

o

2.

tti)JiJ~llimlH®*i?i-OTf

m~T,

~~~~•n®*~~lliJJo

*~~fil~~~nm~m~T,

lj<J

~~

·-··

lfJ2

o

3.

rr

~i~

lli

ti

1n~tJ~JJ

I . Loosen the presser spring regulator and lock

nutCD.

2. Turning the presser spring

pressure

regulator©

enough.

*

pressure

3. Tighten the presser spring regulator and lock

of

presser foot . Turning presser spring

to pressure

In ensuring sewing material does not slip, the

of

the presser foot as

llifl!PlliJJ,

£J:CD

o

regulator©

under

much

1£lli;J~ttB<J

rr~~ffnff~~

to adjust the

the

pressure is not

as possible weaker.

nutCD.

15

.~

8 -

-ij~f:W~~JR~~l¥1*1t

18.

LENGTH

ADJUEST

THE

C

OF

16)

00

THREAD

THE

AFTER

TRIMMING

(Figl6)

~Mtt~~~~--HJ:CD*~~

<:1s~·11j,

•1£J~tl(

•

•

•

• When the shear line, the line is loose, line only small thread

• The length

•

•

19.

I

*

1.

2.

3.

*

4.

5.

mt

s·,J

6.

➔

ti

ffi

It

TJF

~tUJ-HJ:G)JJJE~,

5JVJ\

~□

~tliliJ

:ll!H\

□

-ti

turning a small thread clamp

By

clamp device provided by the tension.

small clip line

If

short.

is

the thread clamp

If

long.

~-=p~~~-

1JEt~JfB11jftl1:frI75J:

EsJtll®o

n5CF

tt~~~ffl#®~-~~-B<J&Io

rr~~JE~IH®o

1M~JfB<JTJF1UJi£751

~[fi~~~~~fl:@~~'

~oo~~~~.

t:J~t~

;E

iY1~

mffnffiA~~•nM®~,

~ttfl:Kff,

751

fi

81-Lt

tlt~k

JJJEH;,

£JG)

the standard surface lines head for

of

nutG)

nutCD

17)

00

(

flff~JEiliJH®o

~m~•CD~:k~¼J®J:*OO-~.

o

sliJt

s<J

•

0

1

ffi~U~f=f

0mm

7

40~

ffi

¾

]~

ffi

¾

]~

nutCD

and tighten the thread

to relax, the thread

/ADJUST

J\~t~~1Rd~B151UJ

o

s<J~l~KJ!tmt~fl

t~

~

~~

$l~

tl

to adjust.

THREAD

i3£Ulll®Ji!CFBJ,

6No

3~0.

o.

#ffl~ffi~fto

~tttt~Hn*~~m~

KJ!tmt-lL

70 mm.

40-

the line length

of

the line length is

of

TAKE-UP

:ki~¼J@8<JJ:*ffiIHJEt~•G)5~8mmo

•G)s{])JJ!to

~CT)ifif

fJ

i~~

i31tffl

=

Pick wire spring standard mainly as follows: When the presser

*

down, big hook line@ to pick line on the upper surface

foot®

springG)

the

Put down the presser

1.

2. Tum the clip line components® to adjust the position

wire spring.

3. Tighten the set

Pick wire spring intensity is 0.3~0.6N.

*

Pull line thread clamp

4.

Face line down, make pick wire spring(])

5.

on the surface, is determined to pick the strength

6. Open to insert thread clamp screw

adjust the strength

Notice:

When using a force-measuring device

5~8 mm.

screw®.

of

the wire

If>lx~·

foot®.

device®,

spring(]).

Loosen the set

a little fingers to hold.

groove®,

screw@.

and big line hook@

of

by

please read the number on the red line.

aim(I)

JJ~1-lY:¥

s1

trt~J:

;it

o

wire spring.

taking

o

SPRING

~

the

of

turns

of

to

o

16

17

(FIGl

7)

0.3

~

0.6N

1+----1

- 40~70mm

-

9

I

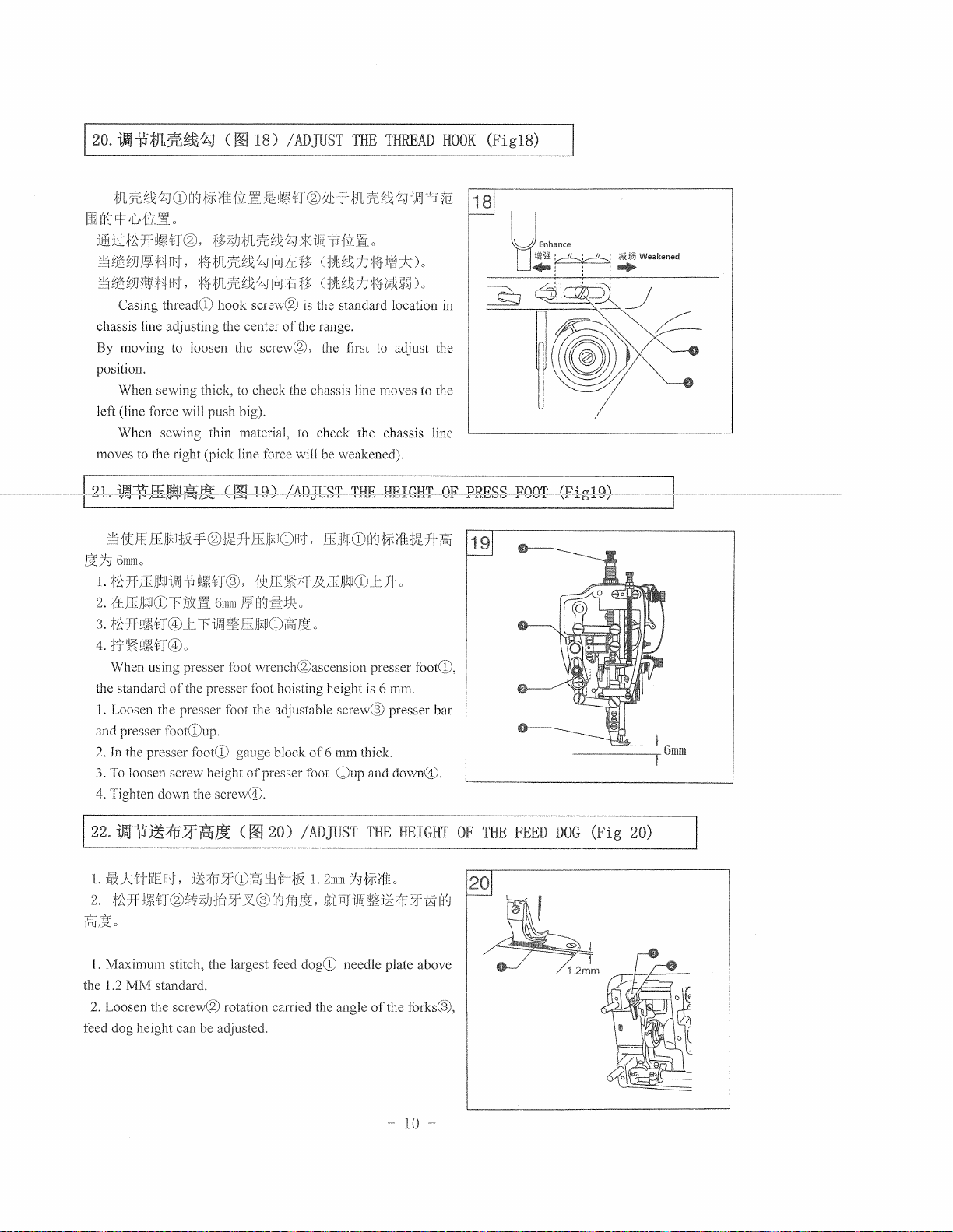

20.

iJ.J"'Tf:tf1'.Jt~'4J

a::i1Lt~~tm2:

to loosen

position.

When

6rnrno

1.

2.

3.

4.

the standard

1.

and

2. In the

3. To loosen

4.

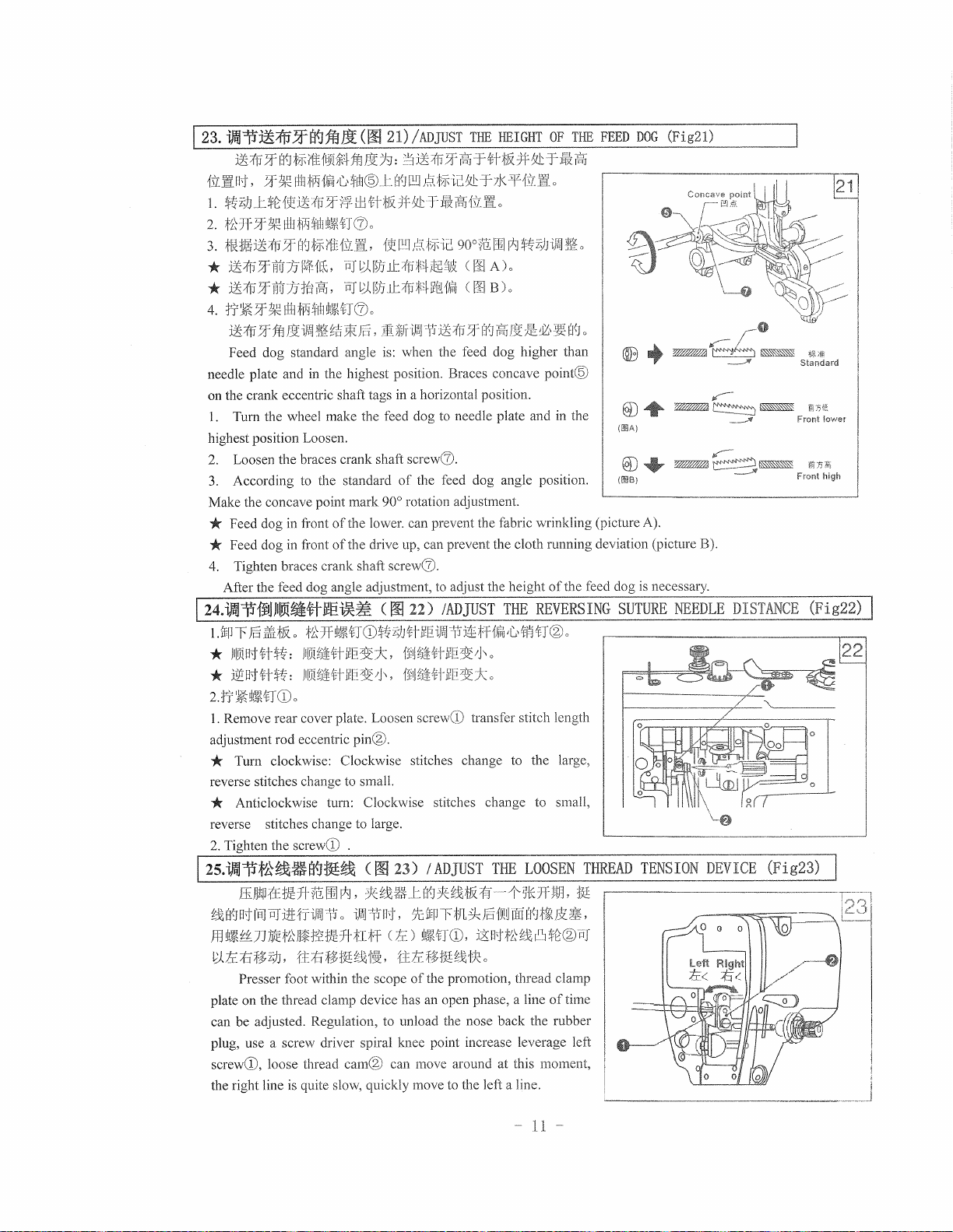

1

/r'1.'·/l·IJl~

'!'

When

Loosen the

presser

presser

of

presser

,_,~.,v./,,,,

screw

presser

the

presser

footG-)

(

00

18) /

the center

the

to

check

foot

"·--e1-1e:n''\.

foot

foot

the

gauge

ADJUST

is the standard location in

of

the range.

the chassis line

to

'L'.,J,1sc1ens1on

uu1u.~,.«u,..,

block

THE

the first to adjust the

moves

check

the

chassis line

presser

...,,-rP"'1'·''

of 6 mm

foot

thick.

and

THREAD

to the

fi.)ot0),

presser bar

down@.

HOOK

(Figl8)

__

L6

mm

THE

1.

Maximum

the 1.2

2. Loosen

feed

dog

MM

standard.

the

can

feed

rotation carried the

be

ad1usted.

needle

of

HEIGHT

the

forks@,

above

OF

THE

FEED

10

DOG

HEIGHT

iJJl'l~;fff;fe<JjgJl

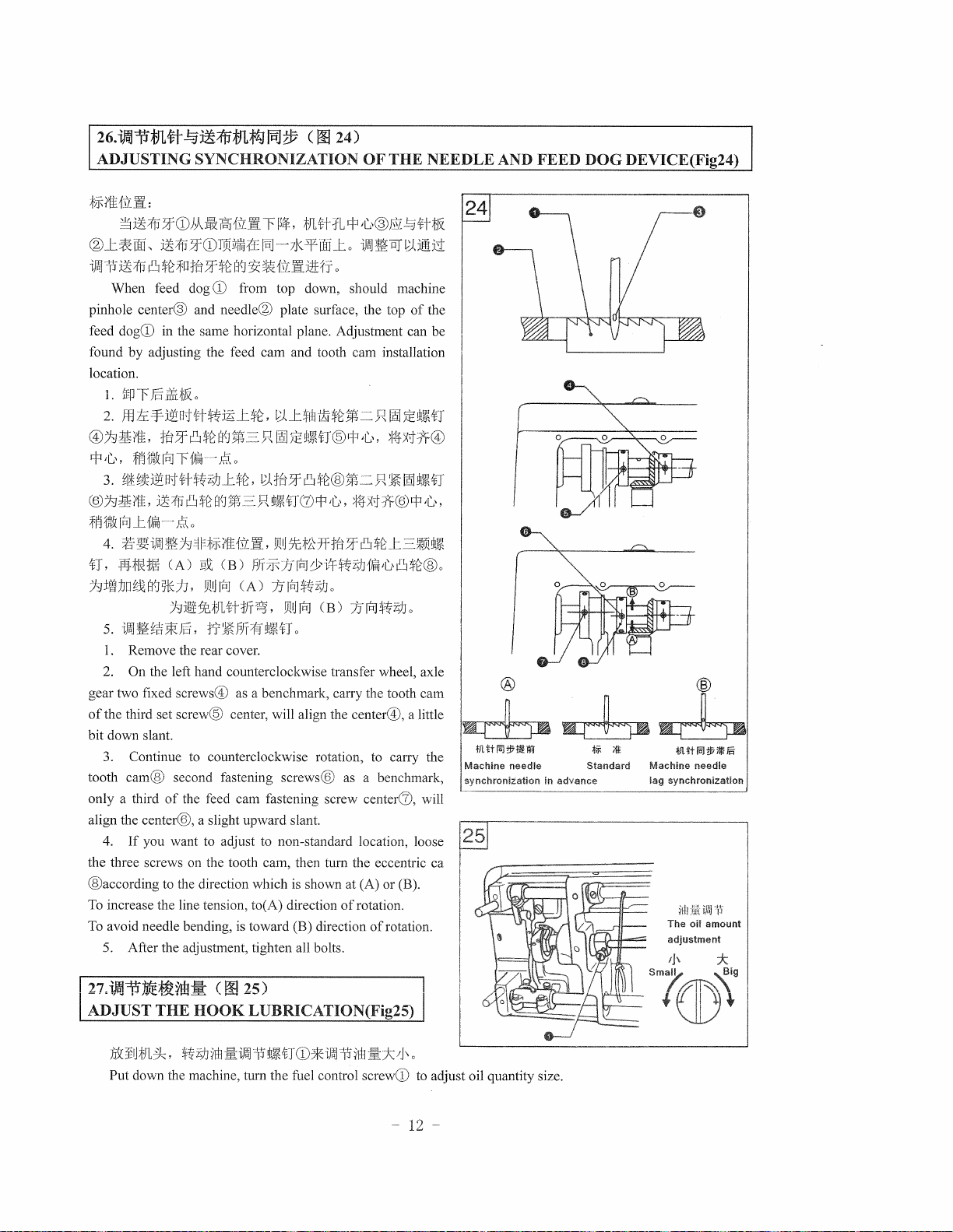

23.

j

4.

Feed dog standard angle is: when the feed dog higher than

in

in

in

to

front

front

needle plate and

on the crank eccentric shaft tags

Turn the wheel make the feed dog

1.

highest position Loosen.

Loosen the braces crank shaft

2.

According

3.

Make the concave point mark 90° rotation adjustment.

Feed dog

*

Feed dog

*

Tighten braces crank shaft

4.

After the feed dog angle adjustment,

(00

the highest position. Braces concave

a horizontal position.

in

screw(J).

the feed dog angle position.

the standard

the lower. can prevent the fabric wrinkling

of

the drive up, can prevent the cloth running deviation

of

of

ADJUST

21) /

THE

needle plate and

to

adjust the height

to

THE

OF

point@

the

in

the feed dog

of

FEED

(Fig21)

DOG

necessary.

is

Remove rear cover plate. Loosen

1.

adjustment rod eccentric

Turn clockwise: Clockwise stitches change to the large,

*

reverse stitches change to small.

Anticlockwise turn: Clockwise stitches change to small,

*

reverse stitches change to large.

Tighten the

2.

Presser foot within the scope

plate on the thread clamp device has an open a line

can be adjusted. Regulation, to unload the nose back the rubber

plug, use a screw driver spiral knee point increase left

screwCD,

the right line

screwCD

loose thread can move around at this moment,

quite slow, move

is

pin@.

.

of

transfer stitch

the promotion, thread clamp

time

of

the left a line.

to

-

11

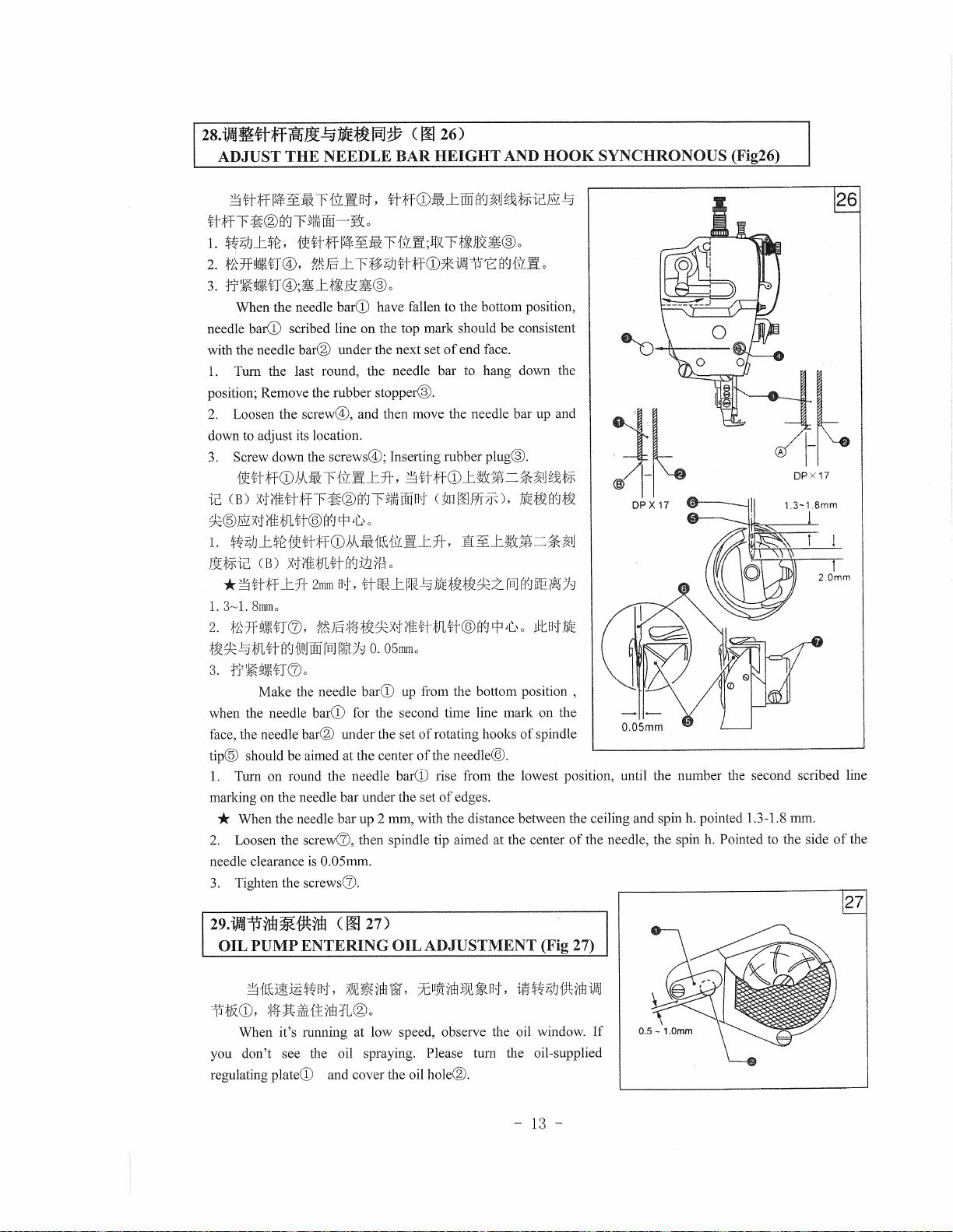

26.iffl11mtt

ADJUSTING

~~;;{ffmfij!AJzv

coo

SYNCHRONIZATION

24)

OF THE NEEDLE AND FEED DOG DEVICE(Fig24)

24

When feed dog

pinhole

feed

found by adjusting the feed cam and tooth cam installation

location.

center®

dog(D

in the same horizontal plane. Adjustment can be

;g±~h~tU<JsKJJ,

5.

1.

Remove the rear cover.

2.

On the left hand counterclockwise transfer wheel, axle

gear two fixed

of

the third set screw@

bit down slant.

3. Continue

tooth

cam@

only a third

align the center®, a slight upward slant.

4.

the three screws on the tooth cam, then turn the eccentric ca

@according to the direction which

To

increase the line tension, to(A) direction

To

avoid needle bending,

5.

of

If

you want to adjust to non-standard location, loose

After

the adjustment, tighten all bolts.

CD

from top down, should machine

and

needle@ plate surface, the top

CB)

J3/r~}iftrJd>ilttz;JJ1ffiH,,8$2@o

v1urtu

CA)

scn~w1,~'±J

to

second fastening screws@ as a benchmark,

the feed cam fastening screw

as a benchmark, carry the tooth cam

center, will align the

counterclockwise rotation,

is

shown at (A) or (B).

is

toward (B) direction

center®,

centerC:V,

of

rotation.

to

carry the

of

rotation.

of

the

a little

will

fJl

H

FaJ

:!fH,li!litJ

Machine needle

synchro11iiatio11 in advance

ti;

il

f}Htfaltirr.fila

Machine needle

synchronization

i1I11,.:;

u~

oil

-ri

amount

The

12

7.

i/1!1

l'f

MEi'&

11!!

it

(

00

25

ADJUST

THE

HOOK

)

LUBRICATION(Fig25)

I

!iUUifL:'k,

Put down the machine, turn the fuel control

screwCD

to

adjust oil quantity size.

12

2s.iMJtEttffiWill!§J1E~raJzv

ADJUST THE NEEDLE

coo

BAR

26)

HEIGHT AND

HOOK

SYNCHRONOUS (Fig26)

i:\HtH~$~:i:-F 1iIIBt,

OO-Jt

r!!fm

RS

~®

r

tHf

ni}Jl:.~t,

1.

tlff~JH®,

2.

rr~~JH@;£J::.ttEl£®o

3.

When

barG)

needle

with the needle

Tum

1.

position; Remove the rubber

Loosen the

2.

down to adjust its location.

3. Screw

1ftHH$~:ii:r1iII;l+xrtifl1£®o

J::.

PtJB

barG)

needle

the

scribed line

under the next set

bar®

the last round, the needle

screw®,

screws®;

the

down

ttHG)JiJ::.ffis<Jt1JtUiid$J=j

0

rlii,MHfG)*i%JfS't1j<J1irlio

have fallen to the bottom position,

the top mark should be consistent

on

face.

end

of

to hang down the

bar

stopper®.

and then move the needle bar up and

Inserting rubber plug@.

~

8:1

I~

®1-

CB)

·i2

o

,C,,

r:p

liS

tt®

;R:@$xt

1.

mrn~·ic,

1.

2.

t~;R:

3.

when the needle

face, the needle

tip@

1.

marking on

*

2.

needle clearance

3.

29.iMJilab~t#~ab

OIL

11.LtJL

0

Y!HMH{]

xt

(B)

J::.f+

3tfff

*

Smmo

3~1.

CT),

3HUJ

ti~

ITiH§J

19W

Jj{]

tMt

_Lj

Make the needle

bar®

should be aimed at the center

Tum on round the needle

needle bar under the set

the

When the needle bar up 2 mm, with the distance between the ceiling and spin h. pointed 1.3-1.8 mm.

Loosen the

Tighten the

PUMP

screw(]),

is

screws(]).

ENTERING

:iiJ}f\-

IN,

2mm

1JLH@8{]

1fHi·

t~;R:x~·

izJ·

J§

Pt

o

5mm

o

o.

J9

!rrlt

up from the bottom position ,

barG)

for the second time line mark on the

barG)

rotating hooks

under the set

then spindle tip aimed at the center

0.05mm.

27)

00

(

of

needle®.

the

of

rise from the lowest position, until the number the second scribed line

barG)

edges.

of

ADJUSTMENT

OIL

r:p

,G,

o

spindle

of

the needle, the spin h. Pointed to the side

of

27)

(Fig

DPX

0.05mm

17

A

1-~

DP><

26

17

1

2.0mm

of

the

27

frtRG),

When it's running at low speed, observe the oil window.

see the oil spraying. Please turn the oil-supplied

don't

you

regulating

plate(])

and cover the oil

hole®.

13

-

If

-

I

30.1:~~-kfJL~

1¥Ji)Wj-='p

(

00

28)

/ Adjusting the top-feeding machnism (

Fig.28)

28

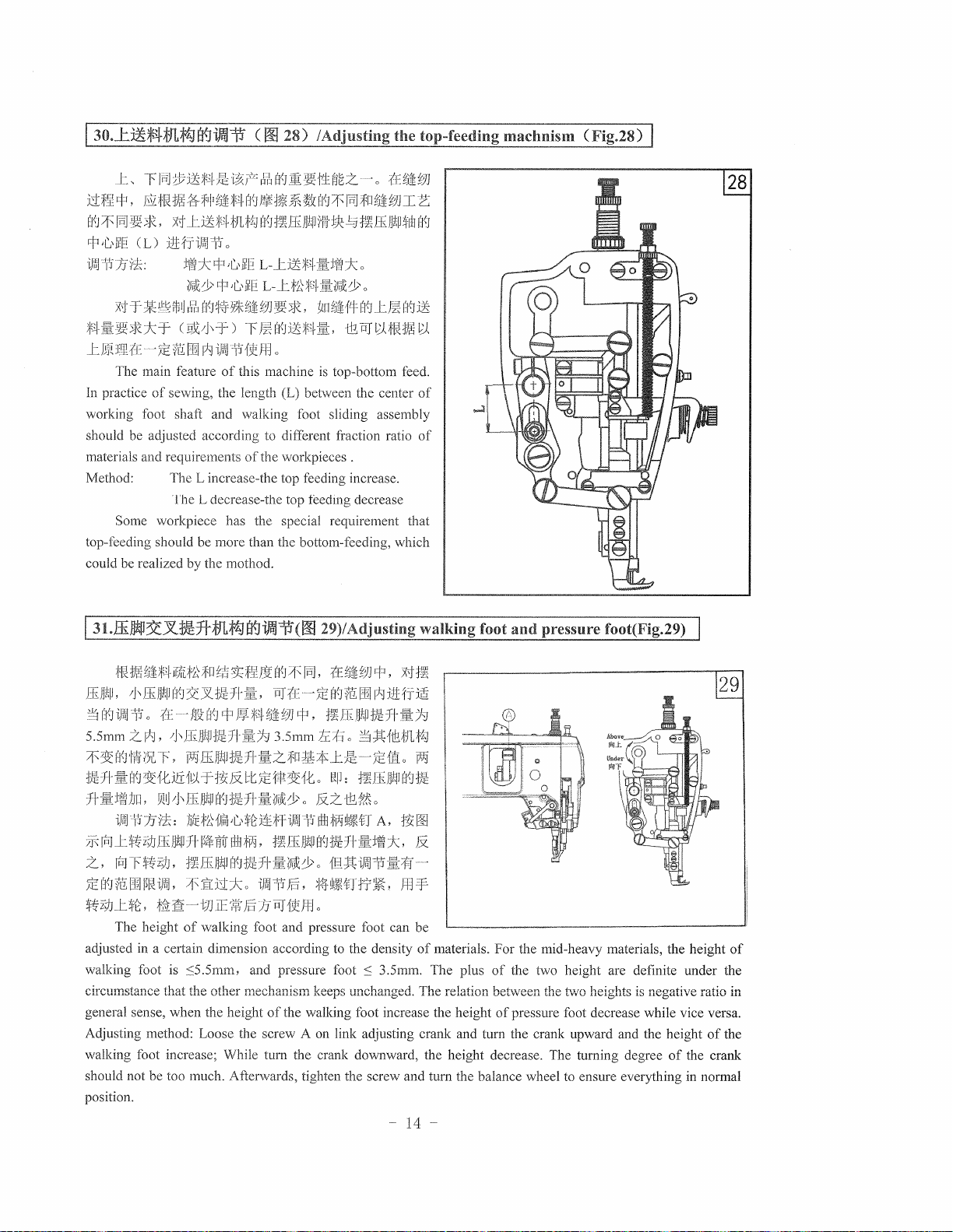

The main feature

In

working foot foot sliding assembly

should be

Method: The L increase-the top feeding increase.

top-feeding should be more than the bottom-feeding, which

could be realized by the mothod.

I

3LffJJ!J3'l:Xt%3ttJ1~1¥Ji)Wj-='µ(00

Some

of

act11ustt;(1

The L decrease-the top decrease

wo,rkf)Ie(~e

of

this machine

the between the center

a,:::ccirct1111g

to different fraction ratio

has the requirement that

is

top-bottom feed.

29)/Adjusting walking foot

of

of

and

pressure

foot(Fig.29)

29

The height

adjusted

walking foot is

circu1nstance

general sense, when the height

Adjusting method: Loose the screw A on link adjusting crank and turn the crank upward and the height

walking foot

should not be too much. Afterwards, tighten the screw and turn the balance wheel to ensure everything

position.

of

walking foot and pressure foot can be

in

a certain dimension according to the density

:S5.5mm,

that

the

'"'".,.,~,,c•p•

and pressure foot

other

1necha11is1n

of

the walking foot increase the height

While turn the crank downward, the height decrease. The turning degree

:S

uncha11ged.

of

materials. For the mid-heavy materials, the height

3.5mm. The plus

The

relation

of

the two height are definite under the

betv·veen

of

pressure foot decrease while vice versa.

14

the

tv10

l1eigl1ts

is

negative

of

the crank

in

of

ratio

of

the

normal

in

Loading...

Loading...