Page 1

..................

.r.SmcefBDB

DNSEWe

CONSOLIDATED

L

INDUSTRIAL

OPERATING

CONSEW

INDUSTRIAL

SEWING

and

MACHINE

SEWING & CUTTING

INSTRUCTIONS

PARTS

for

MODELS

SEWING

LIST

18

CORP.

and

MACHINES

EQUIPMENT

118

IDA

TED

SEWING

MACHINE

Page 2

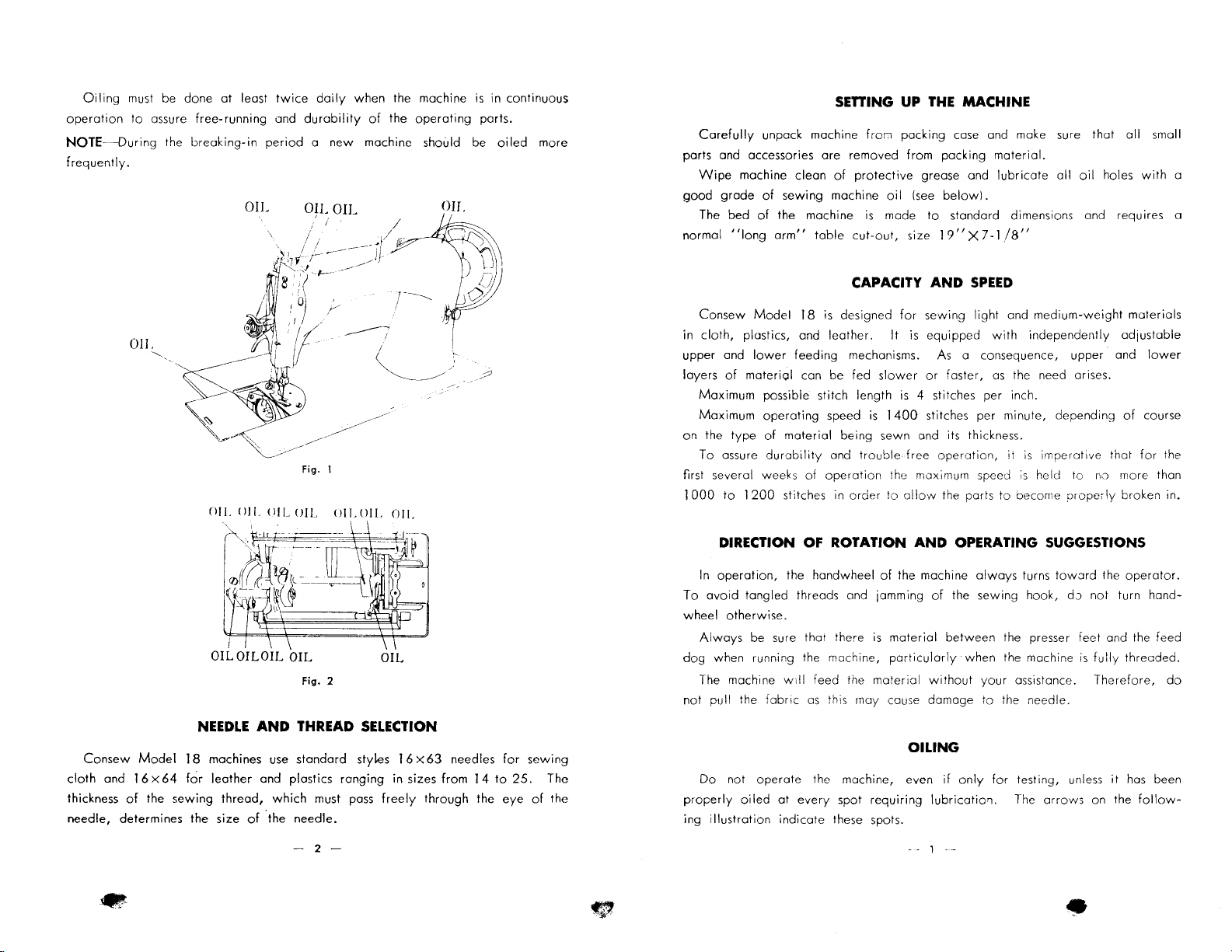

Oiling

must be done

operation

NOTE--During

frequently.

to

Oil

at

least

twice

daily

when

assure

free-running

the

breaking-in

and

durability

period a new

of

machine should be

OIL

O~I/

. /

\ I /

· hr

e

.

OIL

~----~~

;-~

'·.~'··I-·

·(

J

r·

- I I

~Jl

.-~..-'

;.

------------,.

( ;

~~~--"'

·,

~

OIL

Oll

OIL OIL

~'

'

/~~~..-'---

~~

Fig.

1

OIL OIL

r~r~~~-w-~_

I

~~(r)~VJ~

!(

\C

__:]!it(~

'11.~.

I

OIL

OIL OIL

---~-

)\(~

OIL

Fig. 2

the machine

the

operating

~~OI~L

1/

:?: ,

,r---.......

is

in continuous

ports.

oiled

__.,

· ,

I

\WJ

I

_J1})o

'

(?

more

~.:;::1

OIL

OIL

Carefully

ports and accessories

Wipe

good

The bed

normal

Consew

in

cloth,

upper and

layers

Maximum

Maximum

on the

To

first several weeks

1

000

unpack machine

machine

grade

"long

plastics, and

of

materi<;~l

type

assure

to 1 200

clean

of

sewing

of

the machine

arm"

Model

lower

feeding

possible stitch length

operating

of

material

durability

stitches in

ore

table

18

is

can be fed

of

operation

DIRECTION OF ROTATION

In

operation,

To

avoid

wheel

otherwise.

Always

dog

when running the machine,

The machine

not

pull the

the handwheel

tangled

threads and jamming

be sure that there

will

feed

iabric

as

SEniNG

removed from packing

of

machine

cut-out,

CAPACITY

designed

leather.

mechanisms. As a consequence, upper and

speed

being

and

order

the

this rnay cause damage

UP

THE

MACHINE

fror:1

packing case and make sure that

material.

protective

is

is

troublefrce

is

material

grease and

oil

!see

below!.

made

to

standard dimensions and requires a

size

19"X7-1/8"

AND

for

sewing

It

is

equipped

slower

or

faster,

is

4 stitches per inch.

1400

stitches per minute, depending

sewn and its thickness.

operation,

the maxin1urn speeJ

to

allow

the parts

AND

of

the machine

of

material

particularly

between

without

lubricate

SPEED

light

and

with

as

it

to

OPERATING SUGGESTIONS

always

the sewing hook,

the presser feet and the feed

when the machine

your

to

the needle.

all

oil

medium-weight

independently

the need arises.

is

imperative

is

held to no more than

oecome

assistance.

turns

oropcr!y

toward

do

is

all

holes

materials

adjustable

of

that

broken in.

the

operator.

not turn

fully

threaded.

Therefore,

small

with

lower

course

for

the

hand-

a

do

Consew

cloth

and 1 6 X

thickness

needle,

NEEDLE

Model

of

determines the size

I 8 machines use

64

for

the

sewing

leather

thread,

AND

THREAD SELECTION

standard

and plastics

which

of

.the

needle.

-

styles I 6 X

ranging

must pass

2-

in sizes

freely

63

needles

from

through

1 4

the

to

for

25.

eye

sewing

of

•

The

the

~

Do

properly

ing

illustration

not

operate

oiled

the machine, even

at

every

spot

indicate

these spots.

OILING

requiring

if

only

for

testing, unless

lubricatio'1. The

1

--

arrows

•

it

on the

has been

follow-

Page 3

..

.,...,

Remember-uneven,

performance

Only

<=!

length

thread counterclockwise.

unravels,

The bobbin can be wound

of

your

left twist thread

of

thread between thumbs and index fingers

it

has

machine.

a right

knotted

is

If

twist.

to

it

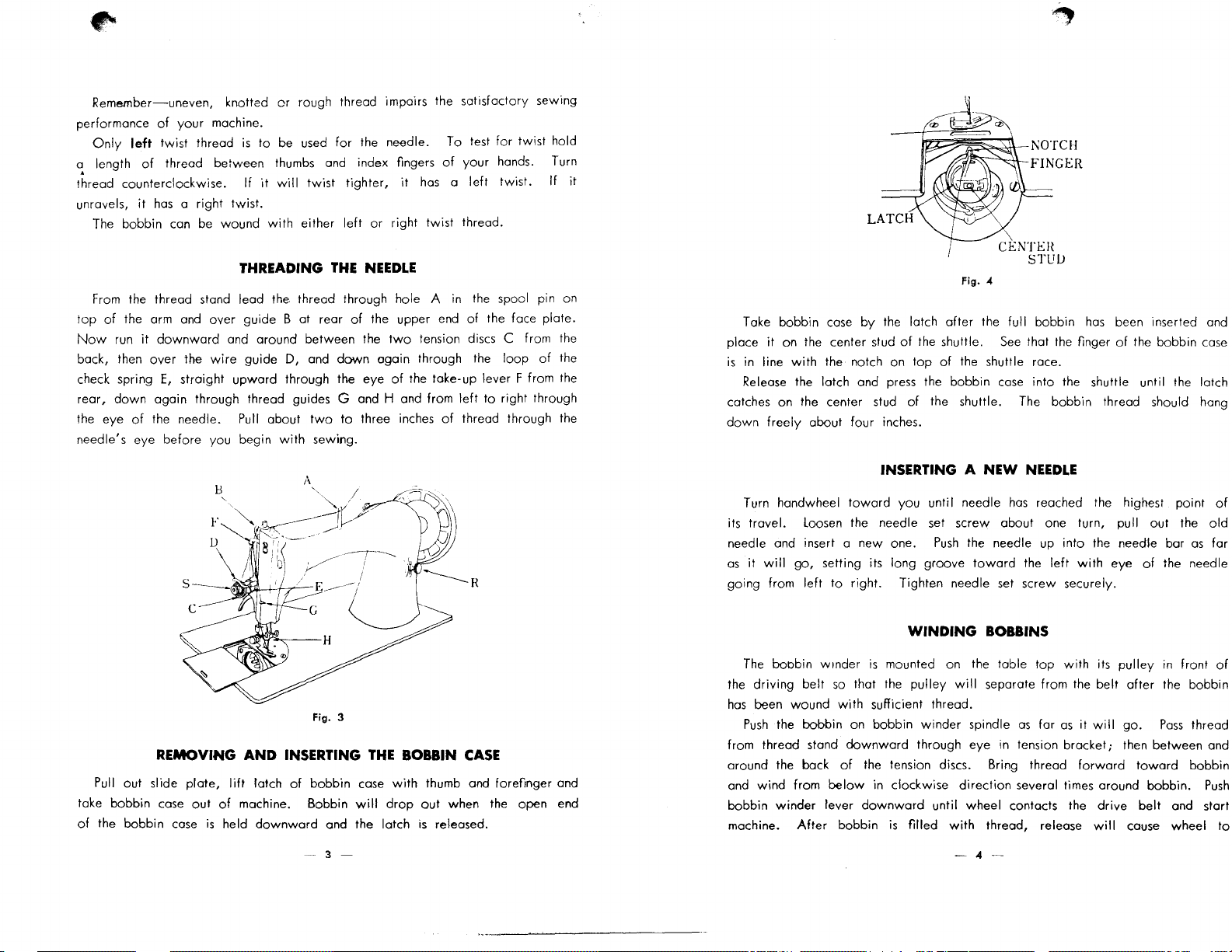

THREADING

From

the thread stand lead the thread through hole A in the spool pin on

top

of

the arm and

Now

run

it

downward

back, then

check spring

rear,

the eye

needle's eye before you begin

over

E,

down

again through thread guides G and H and from

of

the needle. Pull about

over

guide B at rear

and around between the

the

wire

guide

straight

upward

B

or

rough thread impairs the satisfactory sewing

be used

will

with

D,

through the eye

with

twist

either

and

two

sewing.

for

the needle. To test

tighter,

left

THE

of

down

to

it

has a left

or

right twist thread.

NEEDLE

the upper end

two

tension discs C from the

again through the

of

the take-up lever F from the

three inches

for

of

your

hands. Turn

twist.

of

the face plate.

loop

left

to

right through

of

thread through the

twist

of

hold

If

the

it

Fig. 4

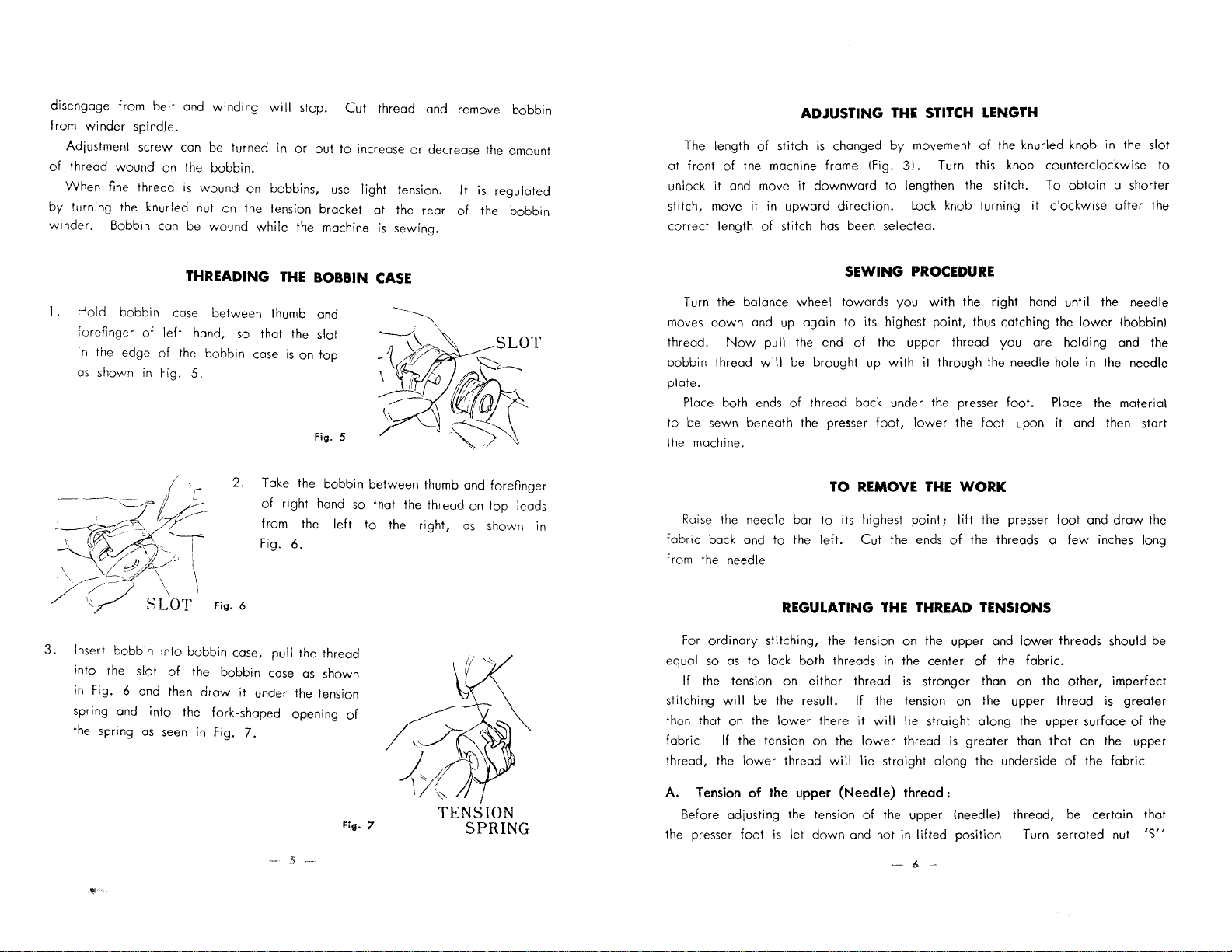

Take bobbin case

place

it

on the center stud

is

in line

with

Release the

catches on the center stud

down

freely

about four inches.

Turn handwheel

its travel. Loosen the needle set screw about one turn, pull

needle and insert a

as

it

will

go,

going from

left

by

the latch

the notch on

latch and press the bobbin case

INSERTING A NEW

toward

setting its long groove

to

right. Tighten needle set screw securely.

you until needle

new

one.

after

the full bobbin

of

the shuttle.

top

of

of

the shuttle. The bobbin thread should hang

See

that the finger

the shuttle race.

into

NEEDLE

has

reached the highest point

Push

the needle up

toward

the

has

been ·Inserted and

of

the bobbin case

the shuttle until the latch

out

the

into

left

with

the needle bar

eye

of

as

the needle

of

old

for

Fig. 3

REMOVING

Pull out slide

take bobbin case

of

the bobbin case

plate,

out

AND

lift

latch

of

machine. Bobbin

is

held

downward

INSERTING

of

bobbin

and the latch

3 -

THE

case

will

BOBBIN

with

drop

CASE

thumb and forefinger and

out

when the open end

is

released.

The

boobin w1nder

the

driving

has

been

Push

from thread stand

around the bock

and

bobbin

machine.

belt

wound

the bobbin on bobbin

wind

from

winder

lever

After

WINDING

is

mounted on the table top

so

that the

with

downward

of

below

downward

bobbin

pulley

sufficient thread.

winder

through eye in tension

the tension discs. Bring thread

in clockwise

until wheel contacts the

is

filled

BOBBINS

will

separate from the

spindle

direction

with

thread, release

-4-

with

its

pulley

in

front

belt

after

the bobbin

as

far

as

it

will

go.

Pass

bracket;

several times around bobbin.

then between and

forward

drive

will

cause wheel

toward

belt

and start

of

thread

bobbin

Push

to

Page 4

disengage from

from

winder

Adjustment screw can be turned in

of

thread

When

by

turning the knurled nut on the tension bracket

winder.

belt

and

spindle.

wound

on the

fine thread

Bobbin can be

is

winding

bobbin.

wound

wound

on

while

will

stop.

or

bobbins,

the machine

out

Cut

thread and remove bobbin

to

use

increase

light

at

is

or

decrease the amount

tension.

the rear

sewing.

It

of

is

regulated

the

bobbin

The length

at

front

unlock

stitch, move it in

correct length

of

of

the machine frame

it

and move

of

ADJUSTING

stitch

is

it

downward

upward

stitch

has

THE

changed

direction.

by

(fig.

to lengthen the stitch. To

been selected.

STITCH

movement

31. Turn this knob

Lock knob turning

LENGTH

of

the knurled knob in the slot

counterclockwise

obtain

it

clockwise

to

a shorter

after

the

THREADING

1.

Hold

bobbin case

forefinger

in

as

--

~~'--~

-~

I,

.

-"---(

of

left

hand,

the edge

shown in Fig.

~--~-

t

~~}!~"-'

of

the bobbin case

5.

'--~

" I

\

·~-/

\

\

\ )cL:;,;:; \ \

)/

/-/

./

\r

3.

Insert bobbin into bobbin case,

into

in Fig. 6 and then

spring and

the spring

s .

the slot

as

'LOT

of

the

draw

into

the fork-shaped opening

seen in Fig.

between

so

that the slot

2.

Take the bobbin

of

from the

Fig.

Fig. 6

bobbin

it

under the tension

7.

THE

BOBBIN

thumb and

is

on

top

Fig. 5

right hand

6.

pull

the thread

case

as

left

shown

of

CASE

---·----......,,

between

so

that the thread on

to

thumb and forefinger

the

right,

as

shown in

top

leads

Turn the balance

moves

down

thread.

bobbin thread

plate.

to

the machine.

fabric

from the needle

Now

Place both ends

be sewn beneath the presser

Raise

the needle

back and

wheel

and up again

pull the end

will

be

brought

of

thread back under the presser

bar

to

the

REGULATING

For

ordinary

so

equal

If

the tension on

stitching

than that on the

fabric

thread, the

stitching, the tension on the upper and

as

to

lock both threads in the center

either

will

be the result.

lower

If the tension on the

lower

thread

SEWING

towards

to

of

TO REMOVE

to

its highest

left.

Cut

thread is stronger than on the

If

there

it

lower

will

lie

PROCEDURE

you

with

the

its highest

the upper thread

up

foot,

THE

the tension on the upper thread is

will

straight

point,

thus catching the

with

it

through the needle hole in the needle

lower

the

foot

THE

WORK

point;

the ends

lift

the presser

of

the threads a

THREAD TENSIONS

of

lie

straight

thread

is

along

greater

along

the underside

right

hand

until

the needle

lower

you

are

holding and the

foot.

Place the material

upon

it

and then start

foot

and

few

inches long

lower

threads should be

the

fabric.

other,

the upper surface

than that on the upper

of

the

(bobbin)

draw

the

imperfect

greater

of

the

fabric

Fig.

7

-- 'i

..

A.

Tension

Before adjusting the tension

the presser

of the upper

foot

is

let

down

(Needle)

and not in

thread:

of

the upper (needle) thread, be certain that

lifted

position Turn serrated nut

- 6 -

'S"

Page 5

•

ACCESSORIES

BOBBIN

KNEE

PRESSER

PARTS

WINDER

LIFTER

FOOT AND

FOR

WIPER

Tne

word

No.

means a

INDEX

••• , ...

, . .

.....

...... ......

• · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2

................................................

UPPER

FEED

SEAM

C stem ped

.. ·

complete

......

at

DOG

· ·

the side

set

......

······ ......

..

.. .. .. · .. · 7

.... · ......

of

of

the porto,

· · · .. 7

ports

PAGE

8

J/7

on tension

to

decrease

B.

Once

it

is

require

outside

Turn this screw

and counterclockwise

device

Tension

the tension

rarely

regulation,

of

the bobbin case shell on

//

to

it.

of

the

necessary

do

clockwise

l\/

'\~i

~"0··;

N~.~·

\ I .

~~~~,;

1\\~_.V

I

J8:f·

~-.

the right

lower (Bobbin) thread:

of

the

to

so

to

\·

•'

to

increase tension and

lower

!bobbin) thread

adjust

it

ever

again.

by

carefully

no more than 1

loosen

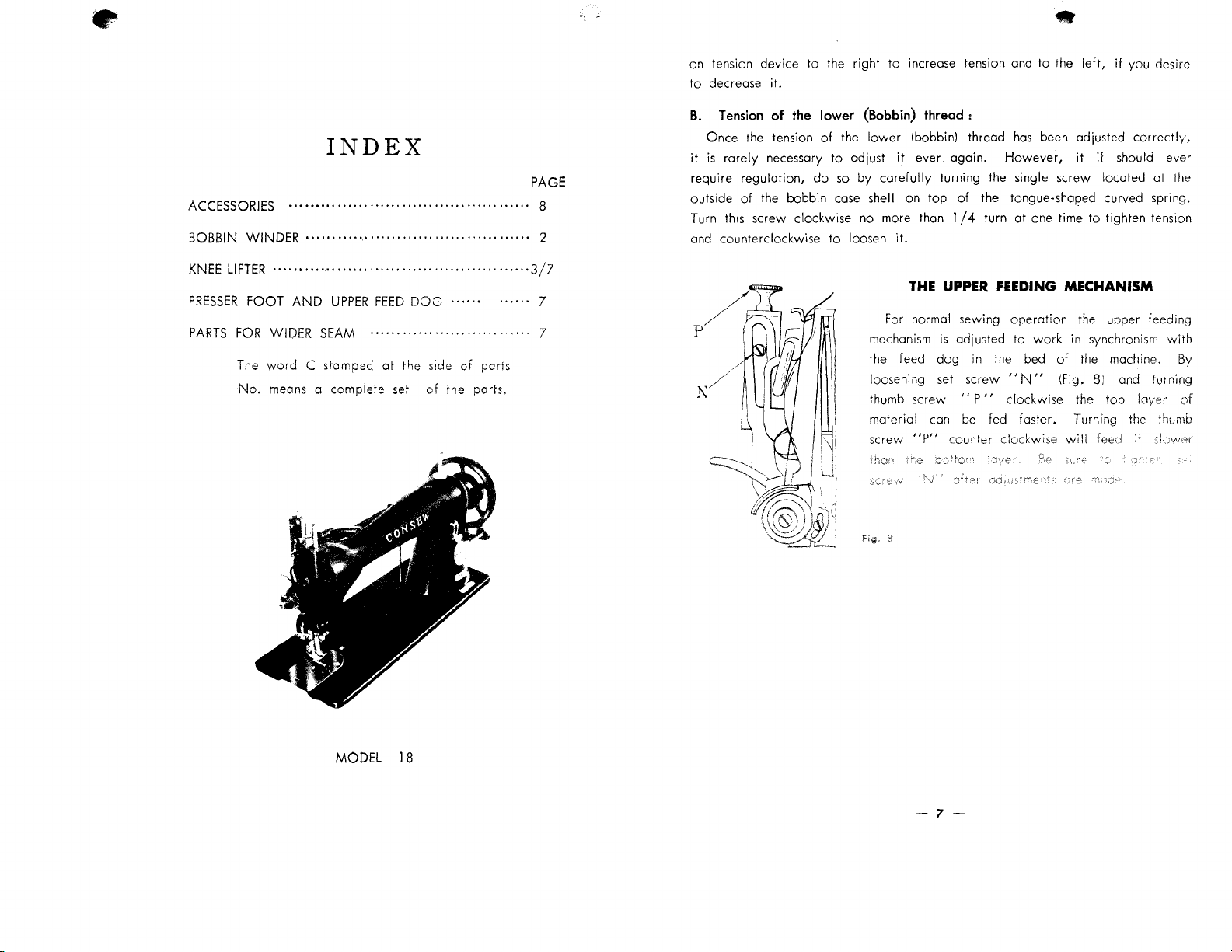

For normal sewing

mechanism

the feed

loosening set screw

thumb screw

material con be fed foster. Turning the thumb

screw

fig.

turning the single screw

top

of

/4

it.

THE

UPPER

is

odju3ted to

dog

"

"P"

cou'1ter

•

to

the

left,

if

you desire

has

been adjusted

However,

the tongue-shaped curved spring .

turn

at

FEEDING

operation

in the bed

"N"

P"

clockwise

clockwise

it if

one time

MECHANISM

the upper feeding

work

in synchronism

of

the machine.

(fig.

the

will

correctly,

should ever

located

to

tighten tension

8) and turning

top

feed

at

Ioyer

the

with

By

of

MODEL

18

-7-

Page 6

PARTS

NO.

6004

6005

6006

6007

6008

6009

6010

6010

6011

6012

6013

6014

6015

6016

6017

6018

6019

6020

6021

6022

6023

6024

6025

6026

6027

6027

6027

6028

6029

6029

6030

PAGE

101

103

104

104

105

103

106

106

106

106

106

106

106

106

106

110

105

103

101

105

103

103

103

101

103

103

103

101

101

109

106

NAME

Oscillating rock shaft crank

!I

Lower

II

Lower

shaft crank

shaft

II

11

slide block

11

Shuttle driver

Shuttle race body

shuttle race complete

Shuttle race back

II

11

II

II

II

II

II

II

II

11

body

spring

II

II

cap sprjng

II

screw

screw

Bobbin case

Bobbin

Feed

rock

shaft rocker

Feed

driven rock shaft crank

Feed

ba.se

Feed

lifting rock shaft

II

II

II

II

II

II

Feed base center screw

Feed

rock shaft center screw

Feed

lifting rock shaft center screw

Center screw with

bar

crank

II

II

with

nut(8013)

Feed dog

11

set screw

Upper feed rod

pin

set screw

Needle plate

shaft screw pipe

roller

set screw

nut

complete

PARTS

NO.

6031

6033

6034

6035

6050

c

6051 c

6052

c

6053

6054

6055

6056

6057

6058

6059

6060

6061

6062

6063

6064

6065

6066

6067

6068

6069

6070

6071

6073

6074

6075

6076

6077

PAGE

106

106

106

106

109

109

109

109

109

109

109

109

109

109

109

109

109

109

109

109

109

109

109

109

109

110

110

110

110

111

111

NAME

Needle plate set screw

Slide plate

Oscillating hook slide friction spring

Slide plate spring screw

Bobbin winder complete(6051 C

&

Bobbin winder

Bobbin winder spool stand complete

II

II

II

If

II

II

II

II

II

II

II

!I

II

II

Bobbin winder tension

II II

II II

II

base

pulley

spindle

frame

stop latch

frame hinge screw

II

" spring

stop latch hinge screw

pulley set screw

spool stand

11

pin

tension screw stud

disc

II

spring

regulating thumb nut

II

II

thread guide

II

screw

11

Wrench

Scale

11

Machine rest

set screw

pin(

wood)

Machine hinge plate

Machine hinge connection

6052

nut

C)

-1-

•

-2-

.,

•

Page 7

•

~

•

PARTS

NO.

6321

6322

6323

6324

6325

6326

6327

6328

6329

6330

6331

6332

6332

6333

6334

6335

6336

6337

6338

6339

6340

6341

6342

6343

6344

6345

6346

6347

6348

6349

PAGE

106

106

106

102

102

102

106

106

103

103

103

104

104

l 04

102

102

102

102

102

102

102

102

102

102

102

102

102

102

102

103

NAME

Thread take

II

II

II II

II

II

Needle

II II

up

cam

II

II

II

II

bar

crank pipe

11

II

II

II

crank

connecting stud

screw

roller stud

II

pin

Needle bar

Needle clamp

Needle bar thread guide

Thread take

Thread take

II

up

up

II

lever complete

lever

11

set screw

Upright bracket plate

Upper feed dog set plate

II

II

II

II

II

II

II

II

II

11

base

II

II

pin

II

bracket

II

II

screw

Presser bar guide bracket

II

II

II

1.'

II

II

set screw

roller

II

II

Presser bar attaching bracket

11

Presser bar lifter

11

11

set screw

& knee lifter connecting rod conne-

ctor

II II

II

II

Upper feed dog set plate connecting plate

11

11

double binding screw

Middle presser foot

-4-

PARTS

NO.

6078

6079

6080

6081

6082

6083

6084

6085

6086

6087

6088

6088

6088

6088

6090

6303

6304

6305

6306

6307

6308

6309

6310

6311

6313

6314

11

pin

6315

6316

6317

6318

6320

PAGE

111

111

111

111

111

111

111

111

1,11

111

111

111

111

111

112

103

104

101

102

102

108

102

102

102

102

101

l

09

NAME

Machine hinge plate set screw

Knee

lifter complete

Rock

shaft for 6079

II

11

hanger

II

11

knee arm

II

II

II

II

11

n

11

11

11 11

Drip

II II

II

II

II

11

11

11

" lifting bracket set screw with hook

pan

pJate

11

arm hub

lifting bracket

II

hook

II

stop dog

knee arm set screw

11

plate screw

stop

dog

set screw

Upper feeding rock shaft front metal

II

II

II

Upper feeding rock shaft

"

II

"

1/

II

II

11

rear metal

bme

Feed cam

Upper feed forked connection

11

11

regulator box

II

II

II

slide stud

Balance wheel

Upper feed regulator thumb screw

11

11

II

II II II

II

II

11

screw

II II

(long)

rece1ver

II

Upper feed rod

II II

set pin

set screw

set screw

-3-

Page 8

PARTS

NO.

6350

6351

6352

6353

6353

6354

6355

6356

6356

6357

6358

6359

636Q

6361

6363

6365

6366

6367

6368

6369

6270

6371

6372

7020

7023

7025

7026

7027

7028

7029

7030

PAGE

103

103

109

107

107

108

108

109

109

108

103

109

109

109

109

105

106

104

104

104

104

104

107

107

107

107

] 07

107

107

NAME

Upper feed dog

Presser bar lifting lever

II

II

set screw

Face plate

Face plate complete

Knee

lifter lifting lever

II

Lifting

lever connecting bar

Lifting

lever connecting bar complete

Arm

side cover

II

hook

Presser bar thumb screw nut

Lifting

lever connecting bar joint

II

II

II

II

11

11

Upper shaft screw

Upper shaft

Needle bar crank set screw

Knee

lifter bell crnak body

II

it

"

II

II II

II

II

11

11

" spring

set screw

Upper feed rod base

II

II

set screw

Feed regulator body

Tension spring receiver

Tension thread guide

11

11

11

11

(big)

(middle)

(small)

Thread take up spring

Tension releasing

/I

II

pin

nut

joint set screw

pin

PARTS

NO.

8007

8007

8008

8009

8009

8010

8012

8013

8013

8013

8013

8014

8014

8014

8020

8020

8023

8031

8031

8031

8035

8036

8037

8039

8040

8042

8053

8054

8056

8057

PAGE

1

04

1

04

104

104

108

101

101

1

01

103

103

103

101

101

101

103

103

106

107

107

103

104

103

103

103

103

104

101

104

104

104

NAME

Feed cam set screw

Balance wheel screw

Rear bush

II

Knee

lifter lifting lever hook screw

screw

Crank connecHng rod

Oscillating rock shaft crank shaft

II

If

If

nut

Feed rock shaft center screw nut

Oscillating rock shaft crank shaft screw pipe nut

Feed lifting rock shaft center screw

Forked rod screw

Connecting rod screw

Feed regulator connecting rod screw

Lower shaft crank

pin

Shuttle driver pin

Thread take

Upper feeding rock shaft

up

cam

pin

pin

Tension spring receiver set screw

Tension thread guide set screw

Needle bar thread guide set screw

Thread take

up

lever roller with nut

Presser regulating thumb screw

Presser bar spring

Presser bar

Upper feed dog screw

Lower

shaft crank set screw

Forked rod

Feed regulator connecting rod

Feed regulator set screw

11

thumb srew

·---

!::'

--.

.....

--6-

-

Page 9

..

·•

..

PARTS

NO.

8060

8060

8076

8077

8078

8079

8086

8091

8093

8102

8104

8115

8116

8119

6349

6350

6349

6350

6349

6350

6349

6350

6349

63130

PAGE

107

107

107

107

107

107

109

106

109

109

104

110

110

110

113

113

113

113

113

113

113

113

113

113

NAME

Tension thread guide set screw(middle)

Face plate set screw

Tension screw

Tension disc wheel

Tension spring

Tension stud nut

Knee

lifter lifting lever hinge screw

Shuttle race set screw

Arm

side cover set screw

Spool

pin

Feed regulator screw washer

Screw driver

11

Oil can

PRESSER

FOOT

Middle presser foot

Upper feed dog (

Middle presser foot

Upper feed dog

Middle presser foot

Upper feed dog

Middle presser foot

Upper feeb dog

Middle prsser foot

Upper feed dog

stud.

(big)

(small)

AND

FEED

DOG (Different size)

(standard)

11

(bottom

( II

( II

( II

( II

( II

( II

( II

)

1

/8"

II

3/16"

II

1/4"

II

5/16"

II

grooved)

II )

II )

II )

II )

II )

II )

II )

PARTS

NO.

6312

6319

6362

6364

6071

6073

6074

8115

8116

8119

PAGE

PARTS

Upper feed regulator box (instead of

Upper feed rod (instead of

Upper feed regulator thumb screw(instead of

Feed regulator body (instead of

CONTENTS OF

110

110

110

110

110

110

Wrench

Scale

Screw driver

Oil can

Oil

Needle 3 pes.

Bobbin 3 pes.

FOR

11

WIDER

ACCESSORIES

set screw

11

NAME

SEAM

(big)

(small)

6318)

BOX

7020)

631

0)

6314)

-7-

-8-

Page 10

6335

6326

....

6325

0

6324

If

~

6334

6318

6309

8010

8053

6348

6345

6347

11

6346

H

6343

6344

<':

...

6337

~

6336

6311

~

-102-

6314

T

6315

"""""""

6340

6341

ceQ

6316

5

6317

6310

I

f

~

8014

0~

8014

o:=

6029

6021

4

0

6004

g

6028

6026

....

6026

41111

-101-

8012

0

8013

~

•

~

Page 11

..

.(lilt:,

-

630?

t))Q5

0

8013

1§1

8036

n

6358

r()

6023

6020

~

8031

'i"

6009

j319

6329

~

6024

~

·-

6025

...e

8020

~

II

6330

~

6331

\)

6027

8

39

. -

II

cl040

i1

6350

~

8037

I!

7020

~

8056

p:

8104

0

8057

~

8054

'"L~

8042

6006

•

8008

.

6308

=

8009

8007

-

8035

9.

6367

6369

6007

a

=

~

6332

6332

63:;t-

•

6368

~

6027

-103-

I

L

La_

a

-104-

Page 12

0..

·-·

0

'()

e

N

N

I

0

'{)

.:(

::

::: : : : :

L

:;;;

:::

::

:

::::~

m:;;

::y

:::!

:J

·==r~

L!".)

0

....

e

M

<')

'"

'()

N

C'J

'0

"-

0

'()

u

0

0

'-()

M

N

0

00

~

<f)

0

'()

'1"

0

'()

('<

I

N

M

'{)

'()

0

'()

0

0

'()

'

'{)

'{)

M

'{)

"-

N

M

'()

Ctm

a

0..

0

00

I

'

7

M

M

0

-.o

0

("')

0

'()

M

0

'{)

<f)

M

0

'{)

••

••

M

0

~

-.o

<.0

0

......

M

0

'{)

1.0

00

N

M

'()

A

0

'()

0J

0

-.o

f.

Page 13

f'

Ll")

Ll")

M

'()

r

M

M

'<)

0')

~/)

C')

··O

co

('J

0

"

Ll")

N

~

!"'-

o-

0

0

co

J

•

'<)

N

0

~'

<>

('.,

0

CD

~::p

r

~

•.

\.."'·~

0

"7

Ll")

M

'<)

0

(")

0

"

(")

0

00

0

'()

0

w

()<. 0

C"-j

:::.-::)

,,

,..-'

--

•

...

ex,

0

-

t-

0

......

('..

''

...

{=)

co

'.(;

f·,

0

co

~

C'J

.:.._·:.

co

!'.

0

CD

•

Page 14

co

c

)

0

"'

co

a-.

0

Page 15

c:.~

m

0

c:=

'D

ro

ro

0

'D

'0

ro

ro

0

'D

I

""

C)

""

'D

t

'-C

"-

0

"-'

Page 16

6350

6349

l

••••••••••••••••••••••••••

PARTS FOR 118

REVERSE

FEED

~,,I

•

6350

•

6350--;£

6350

-~

-}f(,

6349--

6349-M,

~

r

6616;:

8105 8014

6623

1

6617

••••••••••••••••••••••••••

:~

Loading...

Loading...