Page 1

CONSOLIDATED SEWING MACHINE CORP.

I . .

INDUSTRIAL

SEWING

&

CUTTING

Model

106R

EQUIPMENT

INSTRUCTION

&

PARTS

BOOK

MANUAL

Page 2

Table

of

Contents

1. Introduction

2. Main specifications

................................................................................................................

........................................................................................................

3. Installation and preparation

Installation

1) Location

2) Installing

3) Mounting machine head

4) Mounting

5) Installing

6) Connecting

7) Installing

8) Installing

Preparation

1) Cleaning

2) Examination

3) Lubrication

4) Trial run

4. Operation

5. Adjusting

6. Adjustments

7. Cleaning

8.

Trouble

..............................................................................................................................

1) Selection

2) Coordinating between needle,

3) Installing

4) Winding

5)

Threading

6) Setting the bobbin

7) Installing

8) Setting stitch length

Presser

9)

10) Adjusting the pressure on

thread

1) Adjusting

2) Adjusting

3) Adjusting

1. Timing between needle

1) Adjusting position

2) Adjusting rotating hook timing with needle

3) Removing

2. Adjusting

1) Adjusting

2) Adjusting

3. Adjusting

.....................................................................................................................

1. Cleaning

2. Cleaning

shooting

..•.•...........................................................................•.......................................

of

the

machine

drip

pan

.........................................................................................................

rock

shaft

bracket

the

motor

........................................................................................................

the

clutch lever to the pedal.

the

bobbin

the

thread

.....................................................................................................................

the

machine

.................................................................................................................

..................................................................................................................

.....................................................................................................................

of

the

the

needle

the

bobbin

the

the

bobbin case

bar

height position

tension

the

thread

the

thread

the

tension

.............................................................................................................................

and

the

feed dog

the

height

the

position

the

tension release mechanism

the

feed dog

the

rotating hook

..............•.•.....................•..................................•.....•............•...............

winder

un-winder

.................................................................•....................................

thread

........................................................................................................

thread

needle

installing

thread

...........................................................................................................

and

............................................................................................................

take-up

guide

of

of

the

........................................................................................................

.............................•..............................................•..........................

.......................................................................................................

............................................................................................

...................•...................................•.........•.............•...................

..................................................................................................

knee lifter

.............................................................................................

.........................................................................................

.....................................................................................................

thread

...............................................................................................

and

..................................................................................................

reverse sewing

................................................................................................

the

presser

spring

................................................................................................

needle

and

the

......................................................................................................

thread

rotating hook

needle

bar

rotating hook

................................................................................................

...............................................................................

..............................................................................

and

sewing material.

drawing

....................................................................................

the

bobbin

................................................................................

foot

..........................................................................

....................................................................................

and

bobbin

.............................................................................

..........................................................................

............................................................................

..............................................................................

thread

.......................................................

thread

.....................................................

.........................................................

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Page 3

1.

Arm

and

Bed

..•.•••...•..•.....••••...•...•.......•......•.•..••...•.......•....•....••.•.............•...•.•..••.....•..•.......

2.

Needle

Arm

3.

4. Rotating

5. Stitch length Regulating

6. Feed dog lift mechanism

Presser

7.

Lubrication

8.

9. Knee lifter

10. Bobbin

11.

12. Accessories

shaft

Thread

arm

and

thread

and

vertical

hook

and

bar

and

drawing

..........•.............................................................................................................

....•....••.......•......•...•.......•...•.........••...•.......•.•....•..•..•.........••.........•..•....•....•.......•..

winder

un-winder

............................................................................•......................................

.......................................................................................................................

shaft

shaft

..•.•..•.....•.....•.........••.....••......•....................•................•..•..•...••...•.....•...••..

Parts

take-up

......................................................................................................

parts

.......................................................................................................

.............................................................................................

........................................................................•..........................

...............................................................................................

bar

.................................................................................................

catalogue

.

.

.

.

.

.

Page 4

Operating Instructions

Page 5

1.

Introduction

The

Consew

usage.

a

large

smooth

beautiful,

tarps,

pillows,

106R

It

is

engineered

rotating

and

even

even,

hook

flat

shoes

2. Specifications

1)

Max.

Sewing

2) Max. stitch length:

3)

Presser

4)

Max. thickness

5) Needle:

6)Hook:

7)

Motor:

foot lift:

speed:

sewing

feed

stitches

of

material to be sewn:

machine

with a needle

with a double

when

and

sewing a single

and

worker

is a

thread

is

widely

safety

single

bearing,

capacity.

layer

used

items.

needle,

thread

of

in

the

lockstitch

link

take-up,

It

has

all

fabric

or a lap

manufacture

designed

spiral

the

advantages

seam.

of

suitcases,

for

medium

bevel

gear

of a low

The

Consew

leather

2000

9mm

6.5

w/knee lifter

up to 8 layers

a thickness

DPx5,

Large

double

Yz

Motor

to

heavy

transmission

torque,

106R

goods,

spm

mm-13mm

of

of

8 mm each

#18~22

rotating hook with

HP,

thread

1PH,

capacity

llOV

duty

and

low noise,

produces,

handbags,

leather, with

Clutch

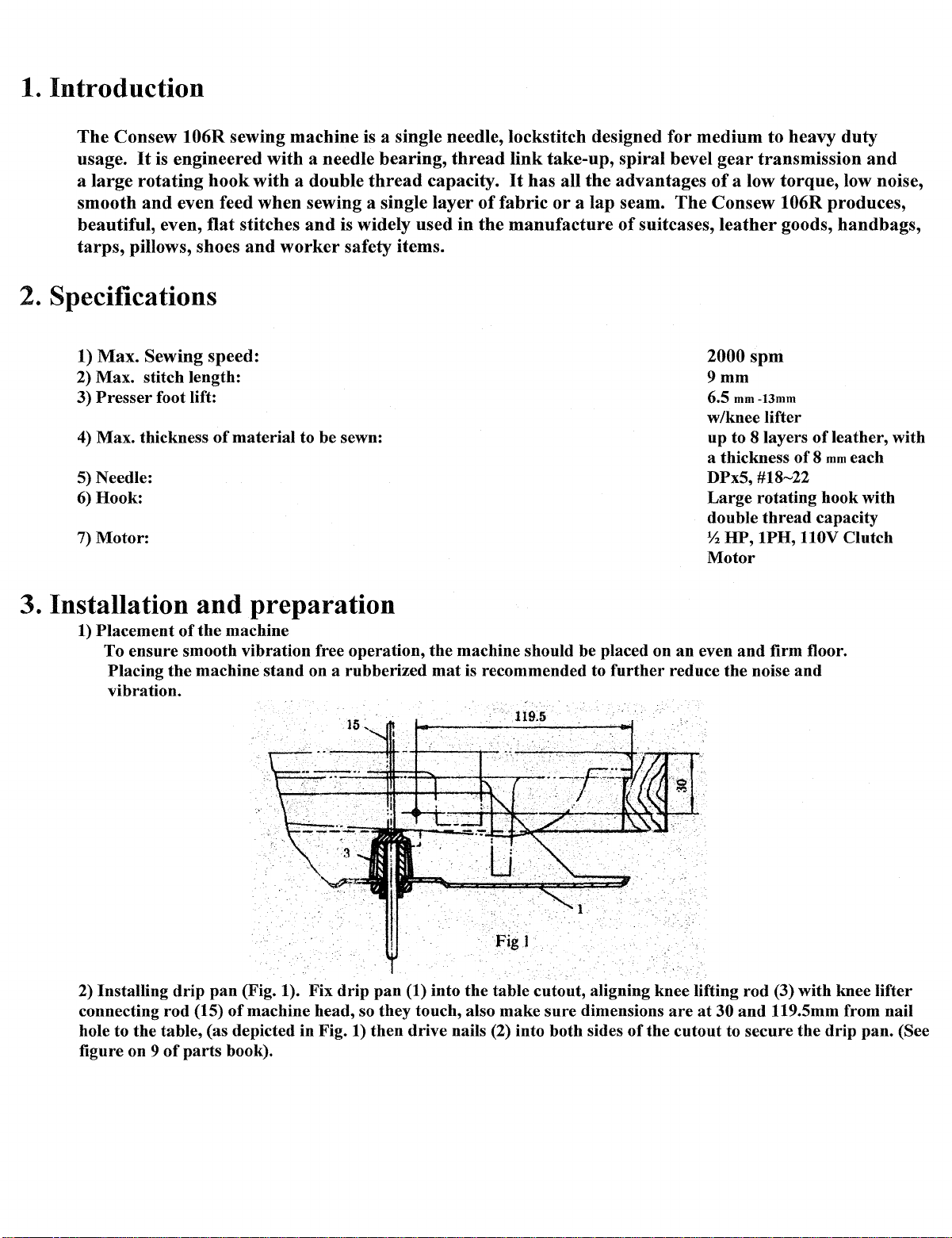

3. Installation

1)

Placement

To

ensure smooth vibration free operation, the machine should be placed on

Placing

vibration.

2)

Installing

connecting rod (15)

hole to the table, (as depicted in Fig. 1) then drive nails (2) into both sides

figure on 9

of

the

drip

of

parts

and

the

machine

preparation

machine

pan

(Fig. 1). Fix

of

machine head, so they touch, also make sure dimensions

book).

stand

on a rubberized

drip

pan

mat

(1) into

is recommended to

the

table cutout, aligning knee lifting

further

reduce the noise

are

of

the cutout to secure the

an

even

at

30

and

firm floor.

and

rod

(3) with knee lifter

and

119.5mm from nail

drip

pan. (See

Page 6

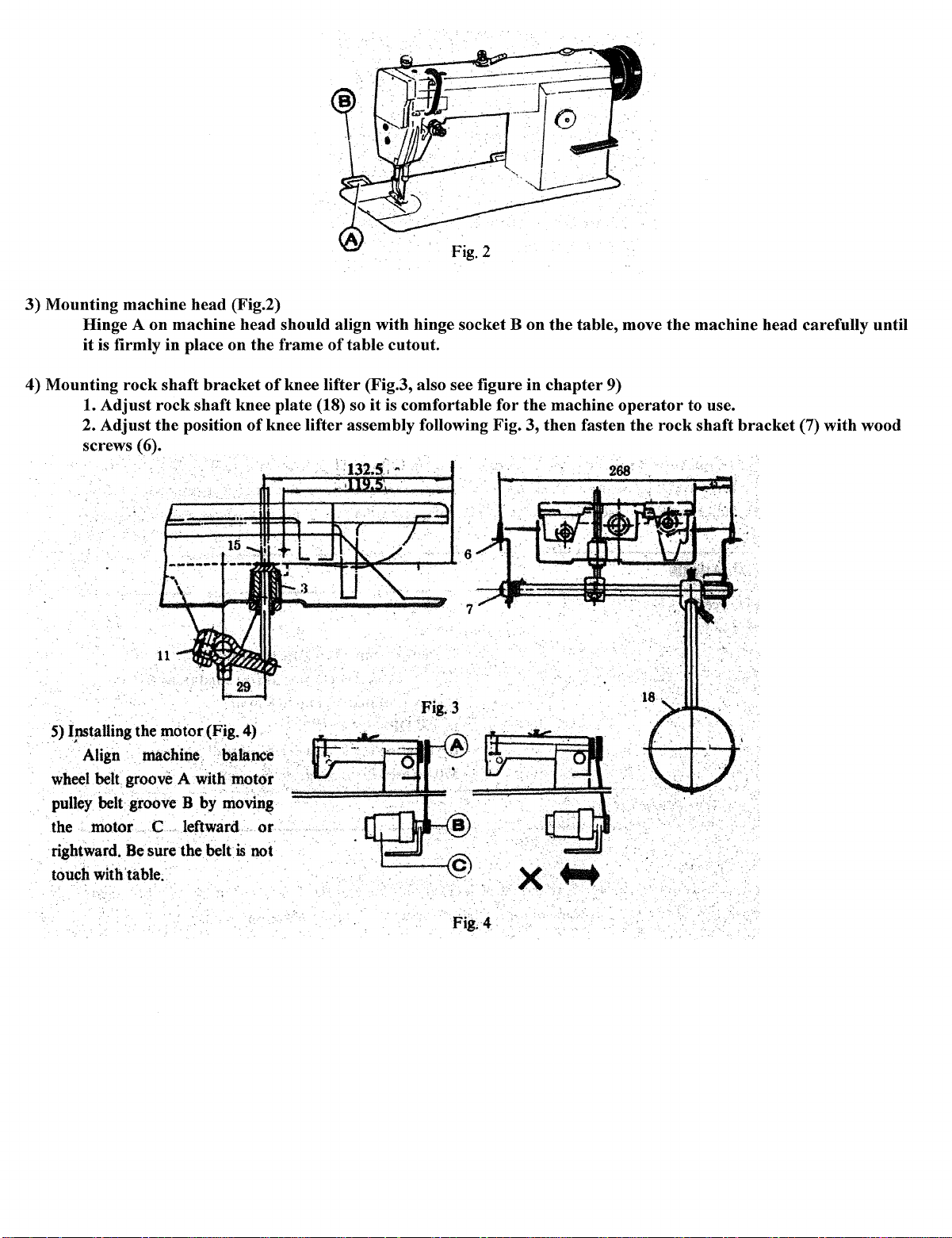

3)

Mounting machine head (Fig.2)

Hinge A on machine head should align with hinge socket B on

it

is firmly in place

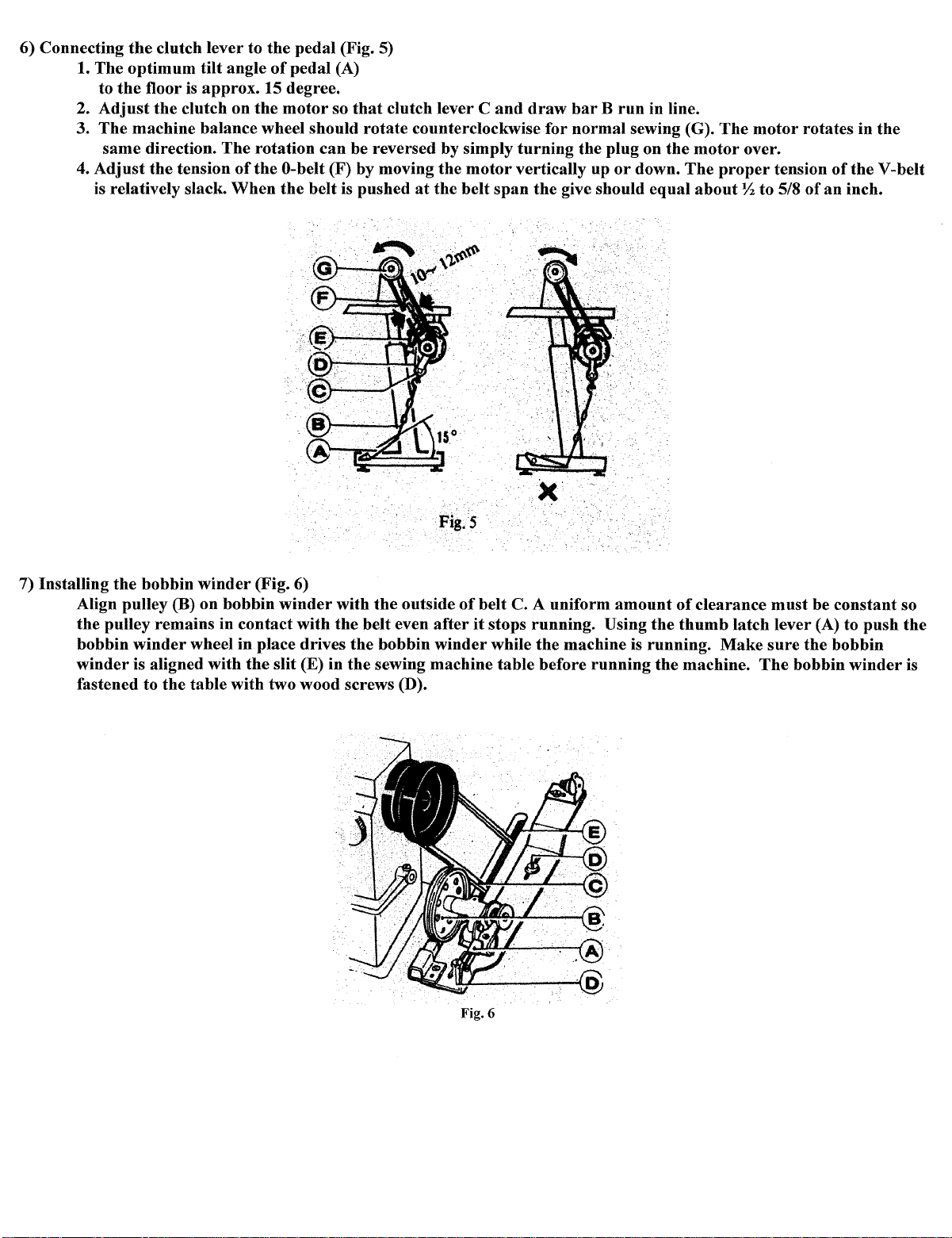

4) Mounting

1.

Adjust

Adjust

2.

screws (6).

rock

shaft

rock

the

on

bracket

shaft knee plate (18) so

position

Fig.2

the

table, move

the

frame

of

of

knee lifter assembly following Fig. 3, then fasten

of

table cutout.

knee lifter (Fig.3, also see figure in

it

is comfortable for

7

the

chapter

machine

9)

operator

the

the

machine head carefully until

to use.

rock

shaft

bracket

(7) with wood

5)

Installing the motor(Fig. 4)

' . .

Align machine.

wheel

belt

groove A with

pulley belt groove B by

the motor .

rightward. Be sure the

with'tilble.

touch

C.

leftward

belt

~lance

motor

mo~n$

...

or

is

not

~

Ernl.

·.·.·.···.···.··.··~.~

.

.··

...

·

..

......

x. · ....

FigA

Page 7

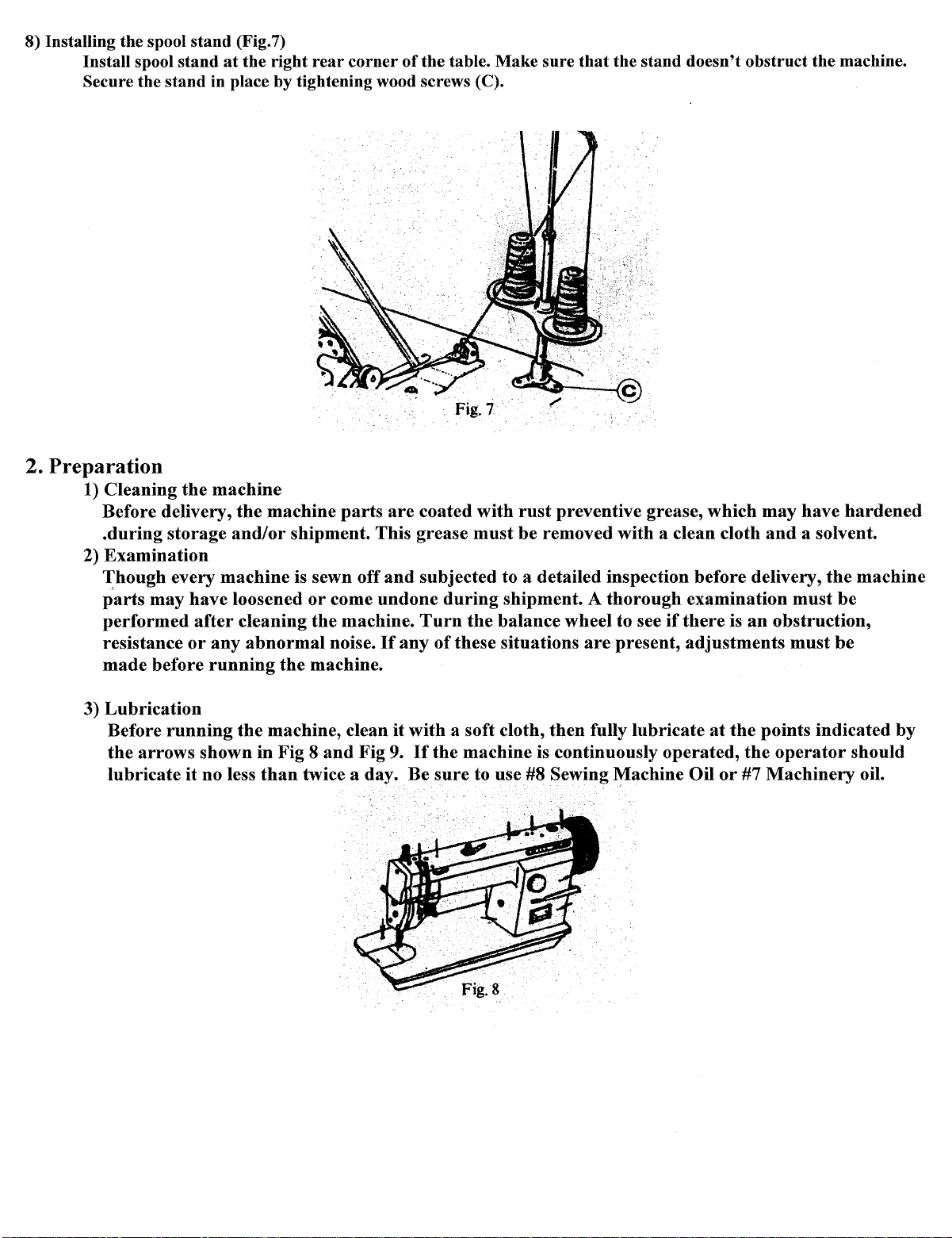

6) Connecting

The

1.

to

2.

Adjust

The

3.

same

Adjust

4.

is relatively slack.

the

clutch lever to

optimum

the

floor is approx. 15 degree.

the

clutch on

tilt angle

the

pedal (Fig. 5)

of

pedal (A)

the

motor

machine balance wheel should

direction.

the

The

tension

rotation

ofthe

When

can

0-belt (F) by moving

the

belt is pushed

so

that

clutch lever C

rotate

counterclockwise for

be reversed by simply

the

motor

at

the

belt

and

draw

turning

vertically up

span

the

barB

run

in line.

normal

the plug on

sewing {G).

the

or

down.

give should equal

motor

The

about

The

motor

over.

proper

Yz

to 5/8

rotates in

tension

of

of

an

the

inch.

the

V-belt

7) Installing

Align pulley

the pulley remains in contact with

bobbin

winder

fastened to

the

bobbin

(B) on bobbin

winder

wheel in place drives

is aligned with

the

table with two wood screws (D).

winder

(Fig. 6)

winder

the

slit (E) in

Fig.5

with

the

outside

the

belt even

the

bobbin

the

sewing machine table before

of

belt C. A uniform

after

it

stops running. Using

winder

while

amount

the

machine is running.

running

the

the

of

thumb

clearance

latch lever (A) to

Make

machine.

must

sure

The

be constant so

push

the

bobbin

bobbin

winder

the

is

Fig.6

Page 8

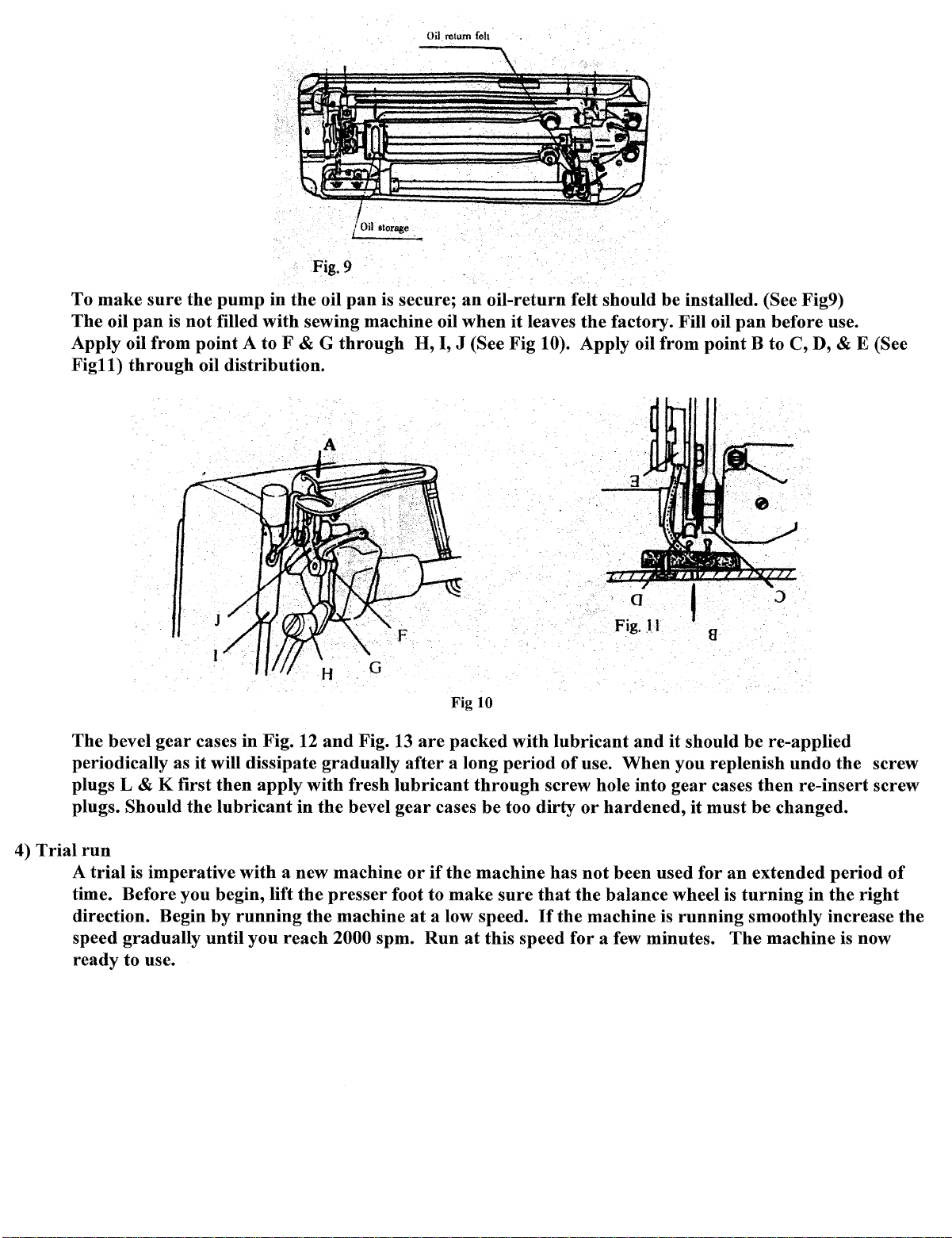

8) Installing

Install spool

Secure the

2.

Preparation

1) Cleaning

Before delivery,

.during

2) Examination

Though

p'arts may

performed

resistance

made

the

spool

stand

(Fig.7)

stand

at

the

right

rear

stand

in place by tightening wood screws (C).

the

machine

the

machine

storage

and/or

shipment. This grease

every machine is sewn off

have

after

or

before

loosened

cleaning

any

abnormal

running

or

the

the

machine.

corner

parts

come

undone

machine.

noise.

If

of

the

table.

Make

sure

that

the

stand

doesn't

are

coated

and

subjected to a detailed inspection before delivery,

Turn

any

with

rust

must

be removed

during

of

these situations

shipment. A

the

balance wheel to see

preventive grease, which

with

a clean cloth

thorough

are

present,

examination

if

there

is

adjustments

obstruct

may

have

and

a solvent.

must

an

obstruction,

must

the

machine.

hardened

the

be

be

machine

3)

Lubrication

Before

the

arrows

lubricate

running

shown

it

no less

the

machine, clean

in

Fig 8

than

twice a day. Be

and

it

Fig 9.

with

a soft cloth,

If

the

sure

then

fully lubricate

at

the

machine is continuously operated,

to use #8 Sewing Machine Oil

Fig.8

or

points indicated by

the

operator

#7

Machinery

should

oil.

Page 9

To

make

The

oil

sure

pan

is

the

not

pump

filled

in

with

Apply oil from point A to F

Figll)

through

oil distribution.

Fig.9

the

oil

pan

is

secure;

sewing machine oil

& G

through

H,

Oil return feb

an

oil-return felt should be installed. (See Fig9)

when

it

leaves

the

factory. Fill oil

pan

before use.

I, J (See Fig 10). Apply oil from point B to C, D, & E (See

4)

The

bevel

gear

cases

in

it

periodically as

plugs L

plugs. Should

Trial

run

A

trial

& K first

is imperative

will dissipate gradually

the

time. Before you begin, lift

direction. Begin by

Fig. 12

then

apply

lubricant

with

running

and

with

in

the

a new machine

the

presser

the

speed gradually until you reach 2000 spm.

ready

to use.

Fig. 13

fresh

bevel

lubricant

gear

foot to

machine

Fig 10

are

packed

after

a long period

through

cases be too

or

if

the machine has

make

at

a low speed.

Run

at

this speed for a few minutes.

with

lubricant

of

screw hole into

dirty

sure

that

If

the

Fig.ll

and

use.

When

or

hardened,

not

been used for

the

balance wheel is

machine is

it

should be re-applied

you replenish

gear

cases

it

must

an

turning

running

The

undo

then

re-insert screw

be

changed.

extended period

in

smoothly increase

machine

the

the

is

screw

of

right

the

now

Page 10

4.

Operation

1.

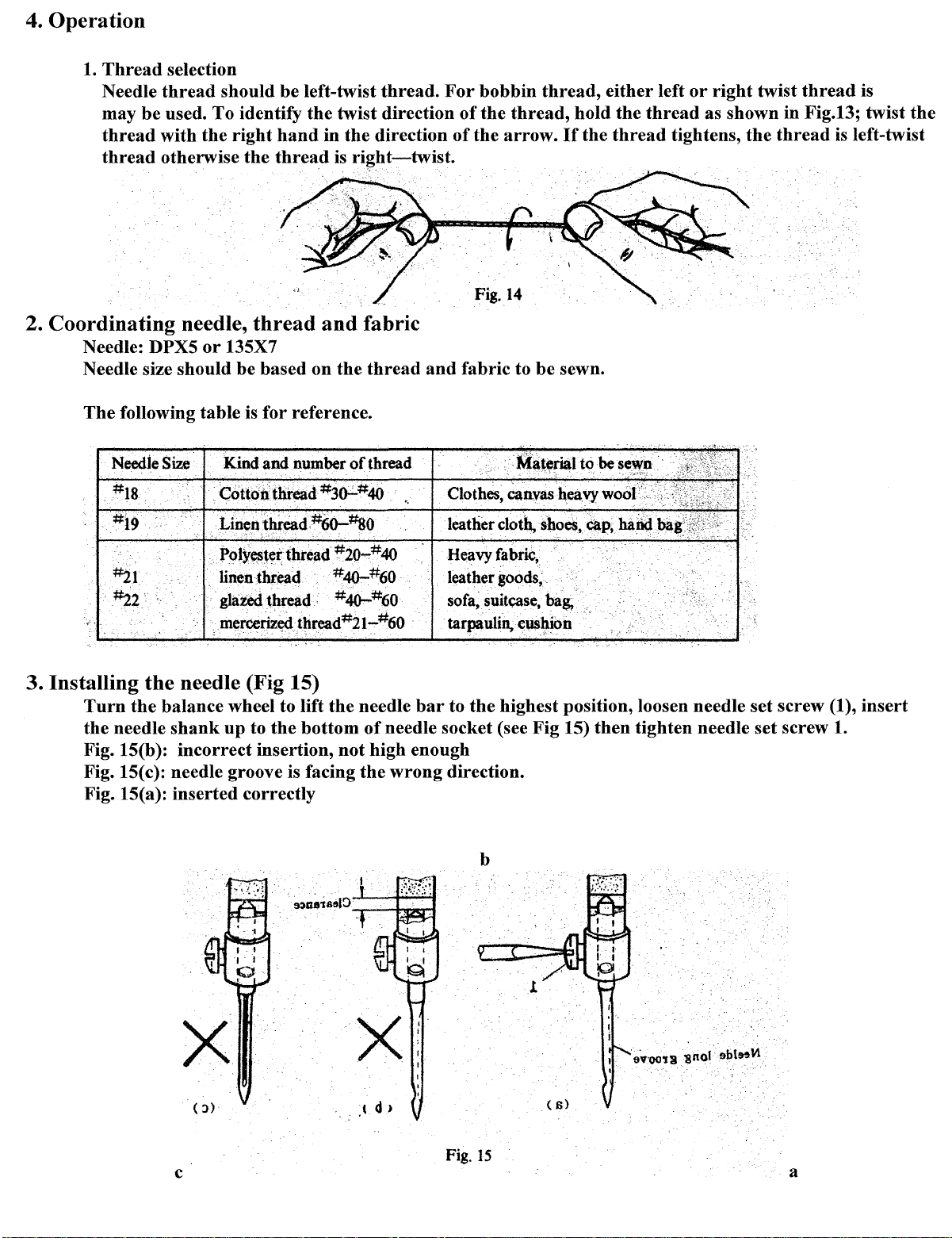

Thread

Needle

may

thread

thread

2.

Coordinating

Needle: DPX5

Needle size should be based

The

following table is for reference.

selection

thread

be

used.

with

otherwise

needle,

should be left-twist

To

the

or

identify

right

the

thread

135X7

the

hand

thread

on

in

and

thread.

twist direction

the

direction

is

ri~ht-twist.

For

of

of

bobbin

the

the

Fig. 14

fabric

the

thread

and

fabric to be sewn.

thread,

thread,

arrow.

hold

If

the

either

the

thread

thread

left

or

right

twist

thread

as shown in Fig.13; twist

tightens,

the

thread

is

is

left-twist

the

Needle

~1

·~2·

3. Installing

Turn

the

the

needle

Fig. 15(b ): incorrect insertion,

Fig. 15(c): needle groove is facing

Fig. 15(a): inserted correctly

Size

Kind and number

cottoxt'

)>oly~~er

. linen

thread

thread #2o-#40

thr~d

gtazedthread

.mercerlze,d

the

needle (Fig 15)

balance wheel to lift

shank

up

to

the

of

thread

~~#40

#40-:#60

#40-:#60

thread#2t-#60

the

needle

bottom

of

needle socket (see Fig 15)

not

high enough

the

wrong

..

Heavy

fabric,

leather

sofa~.suitcase,

tarpaulin,

bar

to

direction.

goods,

ba~

eu.sltion

the

highest position, loosen needle set screw (1),

b

··

then

tighten needle set screw 1.

insert

X

( :>)

Fig.

15

c

a

Page 11

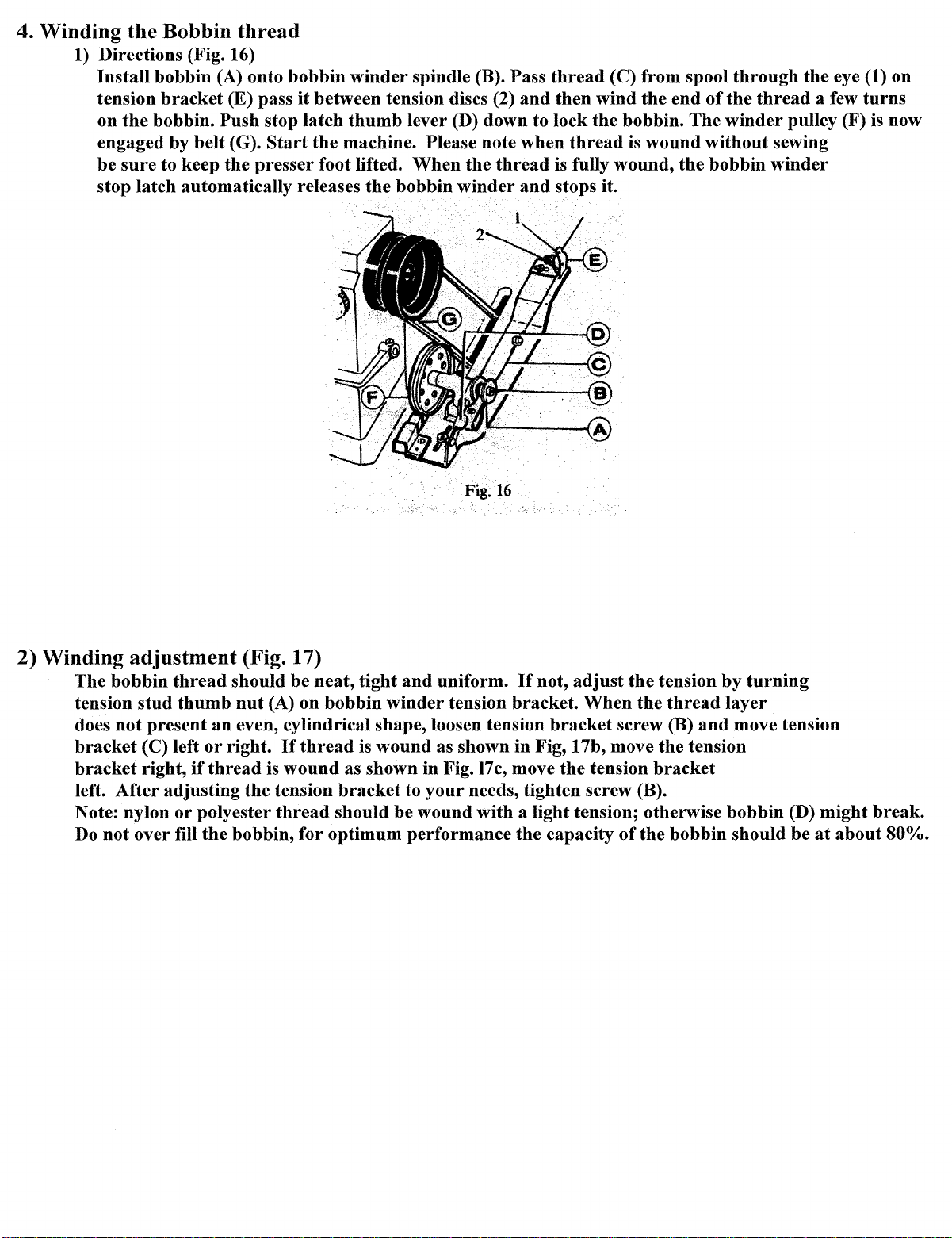

4. Winding

1)

Directions (Fig. 16)

Install

tension

on

engaged by

be

stop latch automatically releases

the

Bobbin

bobbin (A) onto

bracket

the

bobbin.

belt

sure

to keep

thread

(E) pass

Push

stop latch

(G).

Start

the

presser

bobbin

it

winder

between tension discs (2)

thumb

the

machine. Please note

foot lifted.

spindle (B). Pass

lever (D) down to lock

When

the

bobbin

the

thread

winder

Fig.

16

thread

and

then

when

is

and

stops it.

.

(C) from spool

wind the

the

bobbin.

thread

fully wound,

is

wound

end

The

the

through

of

the

thread

winder

without

bobbin

the

eye (1) on

a few

turns

pulley (F) is now

sewing

winder

2) Winding

The

bobbin

tension

does

not

bracket

bracket

left.

After

Note: nylon

Do

not

adjustment

thread

stud

thumb

present

(C) left

right,

over fill

an

or

right.

if

thread

adjusting

or

polyester

the

(Fig. 17)

should be

nut

even, cylindrical shape, loosen tension

the

bobbin,

(A) on

If

thread

is

wound

tension

thread

for

neat,

tight

and

uniform.

bobbin

bracket

should be wound with a light tension; otherwise

optimum performance

winder

is

wound

as shown

to

tension bracket.

as shown in Fig, 17b, move the tension

in

Fig.

your

needs, tighten screw (B).

17c,

If

move

the

not,

adjust

When

bracket

the

tension

capacity

the

tension

the

thread

screw (B)

bracket

of

the

bobbin

by

turning

layer

and

move tension

bobbin

should be

(D) might

at

about

break.

80%.

Page 12

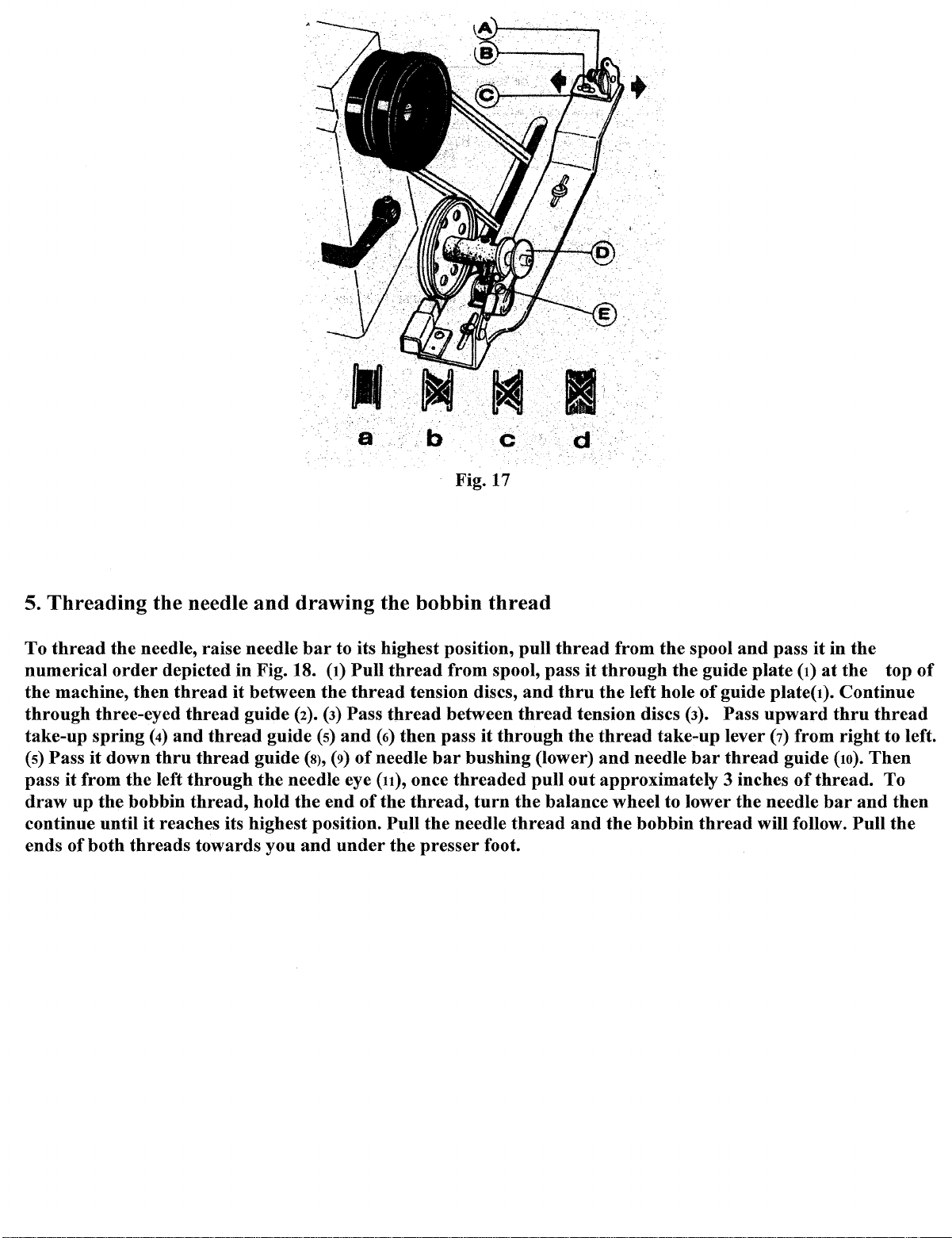

5.

Threading

To

thread

numerical

the

machine,

through

take-up

(s)

Pass

pass

draw

continue until

ends of

the

three-eyed

spring

it

down

it

from

up

the

both

order

the

bobbin

threads

the

needle

needle, raise needle

depicted in Fig. 18.

then

thread

thread

(4)

and

thru

thread

left

through

thread,

it

reaches its highest position.

towards you

and

it

between

guide

thread

hold

drawing

(2).

guide

guide

the

needle eye

the

bar

(s)

(s),

and

b c

Fig. 17

the

bobbin

to its highest position, pull

(1)

Pull

thread

the

(3)

Pass

and

(9)

end

under

thread

of

of

tension discs,

thread

(6)

then

pass

needle

(11),

the

once

thread,

Pull

the

bar

the

presser

thread

from spool, pass

between

it

through

bushing

threaded

turn

needle

thread

foot.

d

thread

and

thru

thread

(lower)

pull

the

balance wheel to lower

from

the

it

through

the

left hole

tension discs

the

thread

and

out

approximately 3 inches

and

the

take-up

needle

bobbin

spool

the

(3).

and

pass

it

in

guide

of

bar

thread

plate

(1)

at

the

guide plate( I). Continue

Pass

upward

lever

(7)

thread

the

needle

will follow.

guide

from

of

thread.

bar

thru

right

(10).

the

thread

Then

and

Pull

top

of

to left.

To

then

the

Page 13

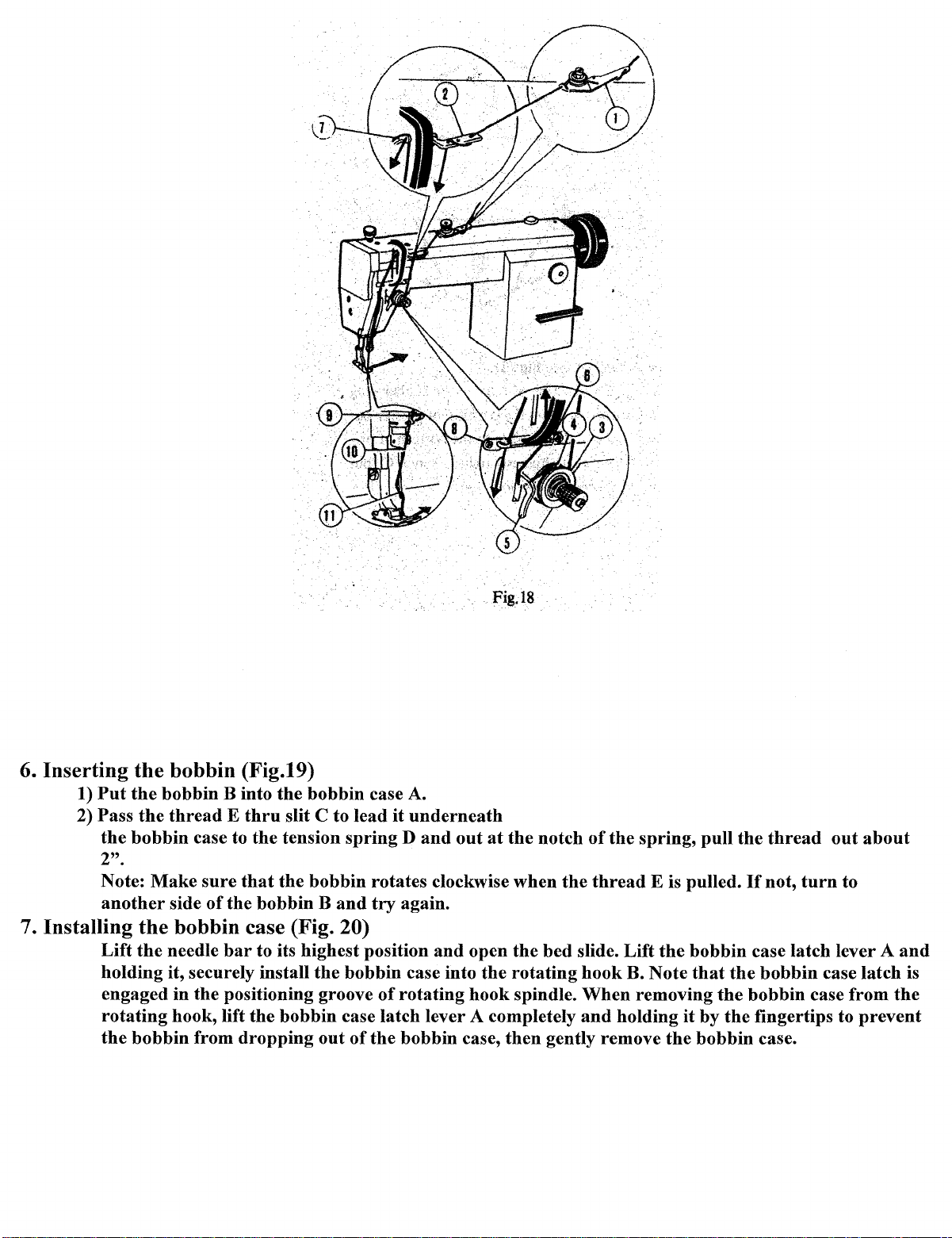

6.

Inserting

1)

Put

2) Pass

the

2".

Note:

another

7. Installing

Lift

holding it, securely install

engaged in

rotating

the

the

bobbin

the

bobbin B into

the

thread E thru

bobbin

the

the

bobbin

case to

Make

side

bobbin

needle

the

hook, lift

from

sure

(Fig.19)

the

bobbin case A.

slit C to lead

the

tension

that

the

bobbin rotates clockwise when

of

the

bobbin B

case (Fig. 20)

bar

to its highest position

the

positioning groove

the

bobbin

dropping

out

Fig.l8

it

underneath

spring D and

and

try

again.

bobbin case into

of

rotating

case latch lever A completely

of

the

bobbin case,

out

and

at

open

the

hook

the

notch

the

bed

rotating

spindle.

then

gently remove

of

the

the

thread

slide. Lift

hook

When

and

holding

spring, pull

E is pulled.

the

bobbin

B. Note

removing

that

it

by

the

bobbin case.

the

thread

If

not,

turn

case latch lever A

the

bobbin

the

bobbin case from

the

fingertips to

out

about

to

and

case latch is

the

prevent

Page 14

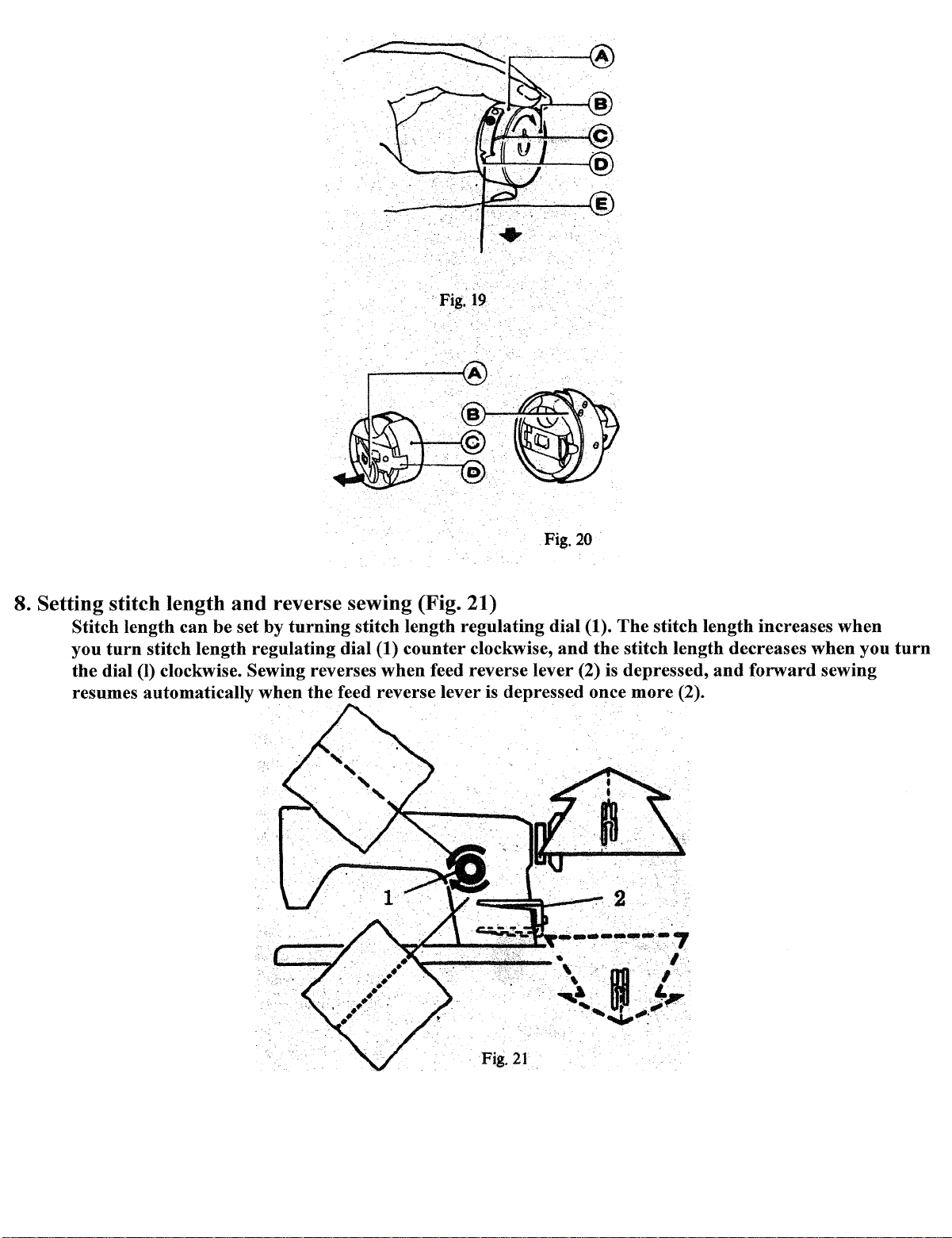

·Fig.

'.

19

Fig. 20

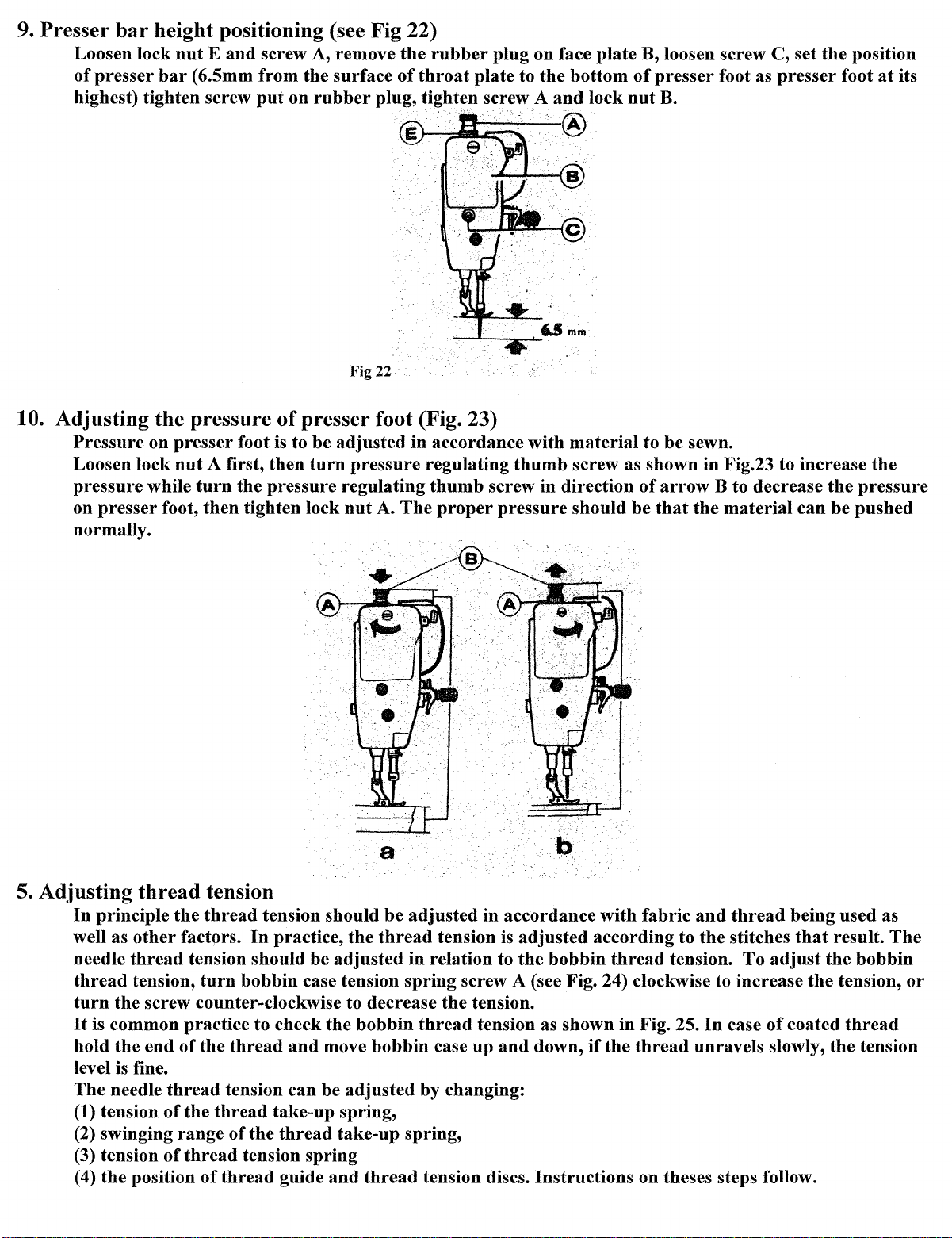

8. Setting stitch length

Stitch length can be set by

you

turn

stitch length regulating dial (1)

the

dial

(I)

clockwise. Sewing reverses

resumes automatically

and

reverse sewing (Fig. 21)

turning

stitch length regulating dial (1).

counter

when

when

the

feed reverse lever

The

stitch length increases

clockwise,

and

the

stitch length decreases

feed reverse lever (2) is depressed,

is

depressed once

more

(2).

2

Fig.

21

.

and

forward

when

when

sewing

you

turn

Page 15

9.

Presser

bar

height positioning (see Fig 22)

Loosen lock

of

presser

highest) tighten screw

nut E and

bar

( 6.5mm

screw A, remove

from

the

surface

put

on

rubber

plug, tighten screw A

Fig22

the

of

rubber

throat

plug

plate to

on face

the

bottom

and

plate

lock

1=1-'-...........__,®

B, loosen screw C, set

of

nut

presser

B.

foot as

presser

the

foot

position

at

its

10. Adjusting

Pressure

Loosen lock

pressure

on

presser

normally.

the

on

presser

nut

while

foot,

pressure

foot is to

A first,

turn

the

then

tighten lock

of

presser

be

then

turn

pressure

foot (Fig. 23)

adjusted

pressure

regulating

nut

A.

The

in accordance

regulating

thumb

proper

thumb

screw in direction

pressure

with

material

screw as shown

should

to

of

be

be

sewn.

arrow

that

in

Fig.23 to increase

B to decrease

the

material

can

the

pressure

be

pushed

the

5. Adjusting

In

well as

needle

thread

turn

It

hold

level is fine.

The

(1) tension

(2) swinging

(3) tension

(4)

thread

principle

other

thread

tension,

the

screw counter-clockwise to decrease

is common practice to check

the

end

needle

the

position

tension

the

thread

factors.

tension should

turn

bobbin

of

the

thread

thread

of

of

the

thread

range

thread

of

tension

of

tension

thread

tension should

In

practice,

be

case tension

and

can

take-up

the

thread

spring

guide

the

adjusted

the

bobbin

move

be

bobbin

adjusted

spring,

take-up

and

thread

be

adjusted

thread

in

relation to

spring

thread

by

spring,

tension discs.

in accordance

tension is

screw A (see Fig. 24) clockwise to increase

the

case

changing:

adjusted

the

tension.

tension as shown

up

and

down,

Instructions

according

bobbin

if

with

fabric

thread

in

Fig. 25.

the

thread

on theses steps follow.

and

to

the

tension.

In

case

unravels slowly,

thread

stitches

To

adjust

of

being used as

that

result.

the

bobbin

the

tension,

coated

thread

the

tension

The

or

Page 16

Fig. 24

Strong

1.

Adjusting

The

thread

spring

spring

(1) Adjusting

the

thread

normal

Loosen tension

the

tension

take-up

tension

tension

the

tension

take-up

of

the

spring

and

and

stud

is

widen

shorten

thread

stud

set screw A,

counter-clockwise to decrease

spring

thread

5-Smm.

the

range

the

range

take-up

take-up

For

spring

tighten tension stud set screw A.

25

Fig.

spring

is approx. 25-35g.

The

sewing light weight materials (with a

of

the

of

spring.

the

spring.

For

sewing heavier weight materials,

tension (Fig. 26)

turn

tension

stud

B clockwise to increase

the

spring

tension.

After

normal

short

the

the

swing

range

of

the

stitch length), lessen

strengthen

spring

adjustment,

tension,

be

sure

or

the

the

turn

to

Fig. 26

Page 17

(2)

Adjusting

The

thread

stud B counter

take-up

spring

clockwise to release

B counter-clockwise until

regulator,

then

turn

tension

set screw A.

the

swing

Loosen set screw B,

clockwise to decrease

Re-adjustment

range

of

turn

the

is needed only in

tension is

spring C just

stud

about

the

30g.

tension

of

comes into

B clockwise by

To

attain

thread

contact

another

this, loosen set screw A first,

take-up

with

the

1 /2

turn.

Fig.27

thread

take-up

spring

(Fig. 27).

tension complete C clockwise to increase

swing range. Before delivery,

the

case

of

sewing special

thread

materials

take-up

spring

stopper

After

the

swing

or

C to zero.

on

thread

adjustment,

range

spring

with

is

special

then

Turn

tension

take-up

tighten tension

or

turn

properly

thread.

turn

tension

stud

spring

it

counter-

adjusted.

stud

2. Adjusting

The

position

materials

guide

Thread

Position

Material

and

guide

weight

the

thread

of

the

being sewn

the

materials to

guide

thread

and

guide affects

the

sewing conditions.

be

sewn is

•••

illustrated

·.I

Left

sewing quality

The

normal

in

the

following table.

•.

Center

·~

MediUB1

and

must

be

adjusted

relationship between

3

Ri$ht

r~•

,~.

I

.-

__

,,__.,._._

Light.

r

according

the

position

to

of

the

the

thread

Page 18

3. Adjusting the tension

Fig. 28 shows

When

adjusted

1)

If

the

nut

counterclockwise to decrease

increase

If

the

2)

clockwise to increase

clockwise to decrease

If

the

3)

stitches

needle

the

bobbin

needle

stitches

the

various types

are

puckered, loose,

accordingly.

thread

thread

appear

tension

thread

tension is too low

the

needle

the

bobbin

as shown in Fig. 28( d), (e),

of

needle

is

too high

the

tension (see Fig. 29).

thread

thread

thread

of

stitch

or

the

or

bobbin

needle

thread

or

bobbin

tension

tension (see Fig. 30).

and

bobbin

patterns.

thread

thread

tension

thread

or

turn

the

adjustments

thread

Normal stitches should

breaks,

the

tension

of

needle

appear

and

as shown

b

.C

d

e

tension is too low,

or

tighten

is

too high,

bobbin case tension regulating screw

can

be

the

turn

made

turn

the

bobbin

the

case tension regulating screw to

tension regulating

by following

tension regulating

bobbin

counter-

the

above steps.

in

Fig. 28(a).

thread

thumb

must

thumb

nut

be

Page 19

Fig.

29

6. Machine

Timing between needle

1) Adjusting

Turn

the face plate,

bring

clamping screw B

Adjustment

and

the

needle

the

balance wheel to position

A.

Loosen needle

the

center

of

bar

needle eye, D

and

replace

rotating

hook

motion

position (Fig. 31)

the

needle

bar

C connecting

match

rubber

up

plug.

with

Fig. 30

bar, C at

stud

the

inside surface

its lowest position. Remove

the

clamping screw B. Move needle

of

rotating

hook

E.

rubber

bar

C vertically to

Then

tighten

plug

from

Fig. 31

Fig.32

Page 20

2) Adjusting

Turn

the

balance wheel to position

lifted again

center line C,

rotating

at

2.5

mm

and

hook

hook

point

timing with needle (fig. 33)

the

needle

from its lowest position,

point

D should be 1.2mm above

bar

the

Fig.33

at

its lowest position,

rotating

the

hook

point D should coincide with needle

upper

edge E

and

when

of

needle eye.

the

needle

bar

is

When

of

3) Removing

Lift

the

Loosen

the

two set screws D on

from

colliding

slowly.

To

adjusting

needle D

and

needle

rotating

with

install

the

rotating

and

hook

point C must

installing

bar

to its highest position. Remove

hook

the

bobbin case

rotating

the

feed dog

the

rotating

hook

hook

rotating

holder

hook.

support

follow

hook

At

point timing also note

be

constant

at

approximately 0.05mm (see Fig. 34).

Fig. 34

(Fig. 35)

the

position

bracket

this point, the

since

the

feed dog

the

above sequence

throat

plate

screw C

hook

support

that

will

in

reverse.

the

clearance between

and

take

out

and

take

down position

turn

freely on its shaft,

is

at

its highest. Remove

the

needle

the

and

the

bracket

and

it

the

notched

bobbin

A. Loosen

can

be

rotating

bottom

case.

kept

hook

Fig.

35

Page 21

2.

Adjusting

1) Adjusting

the

feed dog

the

height

Turn

teeth should be

above

balance wheel to raise

the

throat

of

the

feed dog

0.8-lmm

plate surfaces

above the

the

feed dog to its highest position,

it

throat

is

the

plate surface.

ideal height for sewing heavy material.

If

the

at

that

height

position,

of

the

the

height

feed dog teeth

of

feed dog

islmm

When

lifting

clamping screw A.

2) Adjusting

the

throat

plate

. . . . . . .

~'~ffl!l.t

adjusting, loosen feed lifting

rock

shaft

the

position

slit end to

crank

B till

the

of

feed dog (Fig. 37)

the

front

end

rock

proper

The

of

the

~

f

0.8mm-Imm

shaft

crank

height

Fig. 36

standard

fully advanced feed dog

clamping screw A (Fig. 36) slightly,

of

the

feed dog teeth is achieved,

position

of

feed dog A is

is

1.5 mm.

after

that

then

adjustment,

the

clearance

turn

from

feed

tighten

2)Max the feed dog to

ping

screws. Move feed dog

ment, tighten clamping screw.

the

3 Adjusting

The

tension discs should be pushed

tension discs can

lever (left).

open earlier

tension release mechanism (Fig. 38)

Then

when

the

position

support

be

adjusted. Remove

the

tension releasing cam can be moved left

the cam

is

where

to

adjust

apart

the

moved left.

Fig. 37

the feed dog fully advances. Loosen two feed

the

to open

rubber

clearance between

when

plug

the

at

the

presser

rear

or

the

feed dog

foot

is

lifted.

of

arm

and

right, open

and

But

loosen screw A

later

when

rock

shaft

throat

the

open timing

the

cam

crank

plate. After

of

the

is moved right,

clam

of

the

knee lifting

adjust-

Fig.38

Page 22

7. Cleaning

1) Cleaning

Remove

2) Cleaning

Brush

the

the

the

feed dog (Fig. 39)

throat

the

hook

rotating

plate

and

wipe

Fig. 39 Fig. 40

and

hook

the

clean off all the

dust

and

(Fig. 40)

bobbin case with a soft cloth.

lint on

the

feed dog

with a brush.

Page 23

8.

Trouble

shooting

Trouble

Needle

breaking

Stitches skip

Needle thread

Breaking

Possible causes

1. Needle

2.

Needle

Operator

3.

the material.

4.

The weight

1.

2. Needle set incorrectly.

1. Needle threaded incorrectly.

2.

Tension too high.

3. Poor quality

4.

Needle too thin

is

too thin

is

set incorrectly.

pushes

being sewn

Needle

number

weight

is

of

bent

is

or

bent.

or

pulls

of

the material

is

too heavy.

or

the needle

not correct for the

the fabric.

thread

or

too rough.

. Remedy

Change the needle.

Refer to Fig. 15

Do

not push

Do not exceed the technical

Specs

Change the needle.

Refer to Fig. 15

Refer to Fig. 18

Refer to Fig. 29

Change the thread

Change the needle

or

of

the machine

pull the fabric.

Bobbin thread

breaking

Loose

stitches

Puckering

1. The bobbin

tension

2.

Thread

is

loose and uneven.

3. Needle hole on

is

rough

1.

Incorrect tension level on thread

and bobbin

2. Tension too low on thread tension

spring

1. The weight

is

too light, the stitch length

too long

2.

The tension on the needle

and bobbin

thread

is

too high

on bobbin

throat

or

worn.

of

the fabric

is

too high

plate

Lessen the bobbin thread tension

Re-wind the bobbin

throat

plate

or

Change

needle hole with emery cloth

Re-adjust tensions

Adjust the tension on

take-up spring-Fig. 26

Adjust accordingly

Adjust tension regulating

thread take-up spring and bobbin case

tension spring screw.

polish

thread

thumb

nut,

3. Pressure on presser foot too high

Loosen pressure regulating

thumb

screw.

Page 24

Parts

Catalogue

Page 25

1.

11

~

..

:

~······.

:.~

42

. '

' I

46'1):

. r

..

?·

.

f

f.,

f

I

I

I

I

I

I

I

I

Page 26

1.

Arm

and

Bed

Item

1.

2.

3.

4.

5.

6.

7.

8.

9.

10. Face plate 1

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44. Spring 1

45.

46.

47. Position finger for oil wick

48.

49. Cover 1

50.

51.

Description

Machine Bed 1

Machine

Screw 2

Screw 1

Screw

Pin

Name plate 1

Trade

Nail

Rubber

Rubber

Rubber

Rubber

Rubber

Thread

Screw

Screw 1

Screw 3

Rear

Screw

Washer

Screw 1

Spring

Thread

Shim 1

Split stop ring

Thread

three-eye

Screw 1

Oil pipe 1

Nut

Stop plate 1

Spring

Thread

Pin

Discs 2

Screw 1

Thread

Thread

Screw 1

0-type ring

Set screw 1

Thread

Throat

Screw 2

Slide plate 1

Screw 2

Oil plug

Seal ring 1

Press plate 1

Screw

Arm

mark

plug (M9) 1

plug (N9

plug 2

plug 1

plug 1

Finger 1

cover

tension discs 2

guide plate 1

thread

tension releasing plate 1

take--up

tension adjusting

finger 1

plate

finger 1

spring

bracket

#of

Pieces

1

1

2

1

4

1

1

1

6

6

1

1

1

1

1

1

1

1

1

2

1

4

Page 27

2.

e-2.2

I

'

26

27

28

. I

.:

..

.a--

21.

I

I

I'

I

I

I

'

I

I

I

I

I

I

:

.24

I

J.

I

I

:

23

I

I

l

l .

...

-----

20

.l.

...

.~25

.J

29

19

3.

g;(

.

·.1

.

~.

1;

\1\.·t

·~··

...

··•·

..

··

··~·

...•.

8-~.-

......

~"".

-_

' ·

.··

..........

_>···. J

l7,

.

16

/

.

Page 28

2.

Needle

Bar

and

Thread

Take-up

Item

I.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

Description

Thread

Thread

Thread

Thread

Thread

Thread

Thread

Needle

Needle

Needle

Needle

Needle

Thread

Thread

Needle

Needle

Thread

Thread

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle set screw

Needle

Needle

Needle

take-up

take-up

take-up

take-up

take-up

take-up

take-up

bearing

bar

connecting

bar

connecting link

bar

connecting stud

bar

connecting

take-up

take-up

bar

crank

bar

crank

take-up

take-up

bar

crank

bar

bushing

bar

bushing

bar

bushing

bar

bushing (lower)

bar

bushing (lower) set screw

bar

bushing (lower)

bar

bar

thread

bar

connecting stud slide block guide-way

bar

connecting

bar

connecting

crank

lever

lever eyelet bushing

lever link

lever link oil wick

lever

link

hinge pin

lever

link

hinge pin set screw

link

cap

screw

stud

clamping screw

lever

guard

lever

guard

screw

set screw

crank

clamping screw:

crank

position screw

position screw

(upper)

(upper)

(upper)

guide

set screw

rubber

thread

stud

slide block

stud

slide block guide-way screw

guard

plug

#of

Pieces

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

l

1

l

l

1

1

1

1

1

1

1

1

1

Page 29

3.

' '

'

:

10

I

,

' .

I I

\21'f?!

. .

' '

'

23\.\

~-~··.,.

fQbP

' I

12'

..

·(}.

..

~

.

..,_12

' : :

L.!3

'

c4f.

22

f '

f

... :

25

I

I

Page 30

3.

Arm

Shaft

and

Vertical

Shaft

Item

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

Description

Arm

shaft

Arm

shaft

flanged

Arm

shaft

bushing

Arm

shaft

bushing

Arm

shaft

bushing

Arm

shaft

collar 1

Arm

shaft

collar set screw 2

Feed dog

Feed

Screw 2

Arm

Bevel

Bevel

Arm

Arm

Balance wheel 1

Balance wheel set screw 2

Arm

Vertical

Vertical

Vertical

Vertical

Rotating

Bevel

Vertical

fork

cam

shaft

bevel

gear

set

gear

case

shaft

bushing

shaft

bushing

shaft

screw 1

shaft

shaft

shaft

shaft

hook

gear

case (lower) assembly 1

shaft

bushing

oil

set screw 5

(middle) 1

sliding block complete 1

gear

screw 8

(upper)

(rear)

(rear)

bevel

gear

bushing

bushing

bevel

gear

shaft

bevel

(front) 1

pad

(felt) 3

complete 1

oil sea1asembly 1

(upper)

(upper)

(lower) 1

(lower) 1

gear

#of

Pieces

1

1

1

1

1

1

1

1

Page 31

4.

·~.

I

14_j

Page 32

4. Rotating

Hook

and

Shaft

Item

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Description

Hook

Collar

Screw

Rear

Felt

Screw

Front

Felt

Hook

Screw

Bobbin

Bobbin

Position finger

Screw

shaft

complete

for

hook

bushing

bushing

complete

case, complete

shaft

#of

pieces

1

1

2

1

1

1

1

1

1

3

1

1

1

1

Page 33

5.

Page 34

5. Stitch Length Regulating

Item

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

Description

Stitch length dial

Stitch length

Screw

Rubber

Stop

pin

Spring

0-type

Stitch length adjusting swing

Set screw

Hinge

pin

Screw

Stitch

length

Pin

Set screw

Reverse feed swing lever, complete

Screw

Shaft

for feed lever

Screw

Reverse feed lever

Set screw

Set screw

Reset lever

Screw

Coil spring

Set

hook

Screw

plug

ring

for

adjusting

link

spring

screw

bar

bar

#of

pieces

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

Page 35

6.

17

. '

'

•

. '

r·..,~--..

..

.,

'

~

I J '

, . .

t • t

I '

I

~

29.

Page 36

6. Bottom Feed

Item

Mechanism

Description

#of

pieces

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19. Collar

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

Feed cam

Screw

Fork

slide block, complete 1

Fork

crank

Feed

Screw

Pin

Set screw

Feed shaft

Front

Rear

Screw

Collar

Screw

Stop

ring

Stop

ring

Front

Feed dog

Screw

Feed dog

Screw

Feed dog

Screw

Link

Screw

Nut

Shaft

Oil wick

Feed dog lift

Screw 1

Nut

bushing

bushing

for

arm

shaft

crank

for feed dog lift 1

for feed

shaft

support

crank,

complete 1

1

2

1

1

1

1

2

1

1

1

2

1

2

1

1

1

1

1

2

1

2

1

2

1

1

1

2

1

Page 37

7.

8

~-,

..

9

lo .

~

Page 38

7.

Presser

Bar

Item

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

Description

Presser

Presser

Presser

bar

lifter

bar

lifter position screw

bar

lifting

cam

Knee lifter lever (left)

Tension releasing

Knee

lifter lever (left) screw

Knee

lifter

link

Knee

lifter

link

Tension releasing

Tension releasing

Knee

lifter lever (left) (right)

Knee

lifter lever (left) (right)

Knee

lifter lever (left) (right) hinge screw

Knee lifter lifting

Knee

lifter bell

Presser

Presser

Presser

bar

bar

bar

bushing

bushing

cam

hinge screw

cam

hinge screw

rod

rod

crank

(right)

set screw

Screw

Presser

Presser

Thread

bar

guide

bar

guide

finger

bracket

bracket

set screw

Screw

Reel

for

spring

Presser

Pressure

Pressure

bar

spring

regulating

regulating

thumb

thumb

screw

screw lock

Screw

spring

spring

connecting

nut

#of

pin

pieces

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 39

8.

7~

. I

IO

I

I

I

I

I

Page 40

8.

Lubrication

Item

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Description

Oil

wick

fixing

Oil

wick

fixing

Oil

wick

fixing

Oil wick fixing

Wick

Small oil

Small oil

Small oil

Long

Long

Long

Long

for

oil

reservoir

reservoir

reservoir

oil

wick

oil

wick

oil

wick

oil

wick

wick

plate

plate

hook

hook

fixing

screw

oil

fixing

fixing

clamp

assembly

screw

screw

plate

pad

hook

hook

screw

#of

pieces

1

2

1

1

1

1

1

1

1

2

1

1

Page 41

9.

Page 42

9.

Drip

Pan

and

Knee

Lifter

Item

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

Description

Drip

pan

Nails

Knee lift

Knee lifter

Hexagon

Round

Knee lifter

Knee lifter

Knee lifter

Knee lifter

Knee lifter lifting

Knee lifter bell

Knee lifter bell

Knee lifter

Knee lifter

Knee lifter knee plate assembly

Knee lifter knee plate set screw

pushing

pushing

nut

head

rock

rock

rock

rock

rock

rod

rod

rod

wood screw

shaft

bracket

shaft

spring

shift

spring

shaft

crank

crank

crank

shaft

joint

joint

stop dog

guide

pin

set screw

bushing

#of

Pieces

1

6

1

1

1

4

2

1

1

1

1

4

1

1

1

1

1

Page 43

10.

••

IJ-25

, I

I

18

Page 44

10. Bobbin

Winder

Item

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

Description #

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

VVasher 1

Bobbin

Bobbin

Bobbin

VVasher 2

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

winder

base 1

frame

frame

spring

spring

spindle 1

brake

frame

frame

pulley 1

stop latch

stop latch

rivet 2

stop latch

stop latch 1

brake

brake

tension

tension

tension disc 2

tension

tension

tension

pulley set screw 1

stop latch screw 1

wood screw 2

hinge

stripe

oil

oil

stripe

stripe

pin

plunger

clamping screw 1

wick

wick

thumb

trip

trip

clamp 1

bracket

stud

spring

stud

thumb

bracket

cap 1

lever 1

lever 1

lever hinge screw 1

nut

screw 1

of

pieces

1

1

1

1

1

1

1

1

1

1

Page 45

11.

. I

. I

'I

I · I

I I

,

_____

.

_J

r-----

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I.

l

I

I

1

I

I

-----1

19~

7

f-19

17-~~~-~---

.--I lS.

-t-

~---·

Page 46

11. Spool

Stand

Item

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

Description

Wing

Spring

Thread

Thread

Thread

Thread

Spool

Spool

Spool

Thread

Spool

Spool

Felt

Spool

Spool

Spool

Spool

Spool

Spool

nut

washer

guide position

guide

guide

guide

rest

rest

rest

guide position plate

pin

stand

pad

pin

washer

pin

lock

pin

nut

stand

rest

rod

stand

rod

rod

nut

rod

rod

sleeve

rod

sleeve set screw

washer

nut

wood screw

cup

#of

pieces

1

1

1

2

1

1

1

1

1

1

2

2

2

2

2

2

1

1

3

Page 47

12.

--·~.-<

..

~·

....

' ' .

. . .

•'

-'-"'"' : '

··2

,3

4

I

I

I

8

Page 48

12. Accessories

Item

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Description

Arm

Arm

table connecting

Accessory box

Oil

Needle

Triangle

Arm

Bobbin

Screw

Screw

Screw

table connecting

hook

can

belt

vibration

driver

driver

driver

proof

(small)

(middle)

(big)

hook

vibration

washer

block

protection tool

#of

pieces

2

2

1

1

1

1

2

5

1

1

1

Loading...

Loading...