Page 1

CONSOLIDATED

l

__

INDUSTRIAL

SEWING

SEWING

MACHINE

&

CUTTING

CORP.

EQUIPMENT

I

I

CONSOLIDATED

l

__

400

INDUSTRIAL

VETERANS

SEWING

SEWING

BLVD,

I

MACHINE

&

CUTTING

CARLSTADT,

CORP.

EQUIPMENT

NJ

07072

Page 2

INDEX

1.

SPECIFICATIONS ................................. '"........ 1

2.

DESCRIPTION ................................................ 1

3.

SPEED

TO

4

5.

NEEDLES, NIPPLES

.............................................................. 1

OIL

THE MACHINE................................ 2

AND

THREAD

............ 3

TO REMOVE, REPLACE

6.

NEEDLE

7.

TO

THREAD

8.

LEARNING TO OPERATE THE MACHINE 9

9.

TO OPERATE THE

10. TO

11. TENSIONS ....................................................... 10

12. TO ADJUST THE LENGTH OF STITCH ....

13.

14. THE LOOPER .................................................. 12

REGULATE THE PRESSURE

PRESSER FOOT ............................................... 10

TO

REGULATE THE PRESSURE

THE NIPPLE ....................................................

AND

NIPPLE .................................. 4

THE

MACHINE

AND

MACHINE

SET

............ "........ 6

..................... 9

ON

THE

11

ON

11

15. TO SET THE LOOPER .................................. 13

16.

TO ADJUST THE NUMBER OF THE

BRAIDING

TO ADJUST THE TENSION OF THE

17.

BRAIDING

....................................................... 13

.......................................................

14

18. RAY STITCH .................................................. 14

19.

PILE

OR

MOSS

STITCH .................................... 15

Page 3

1.

SPECIFICATIONS

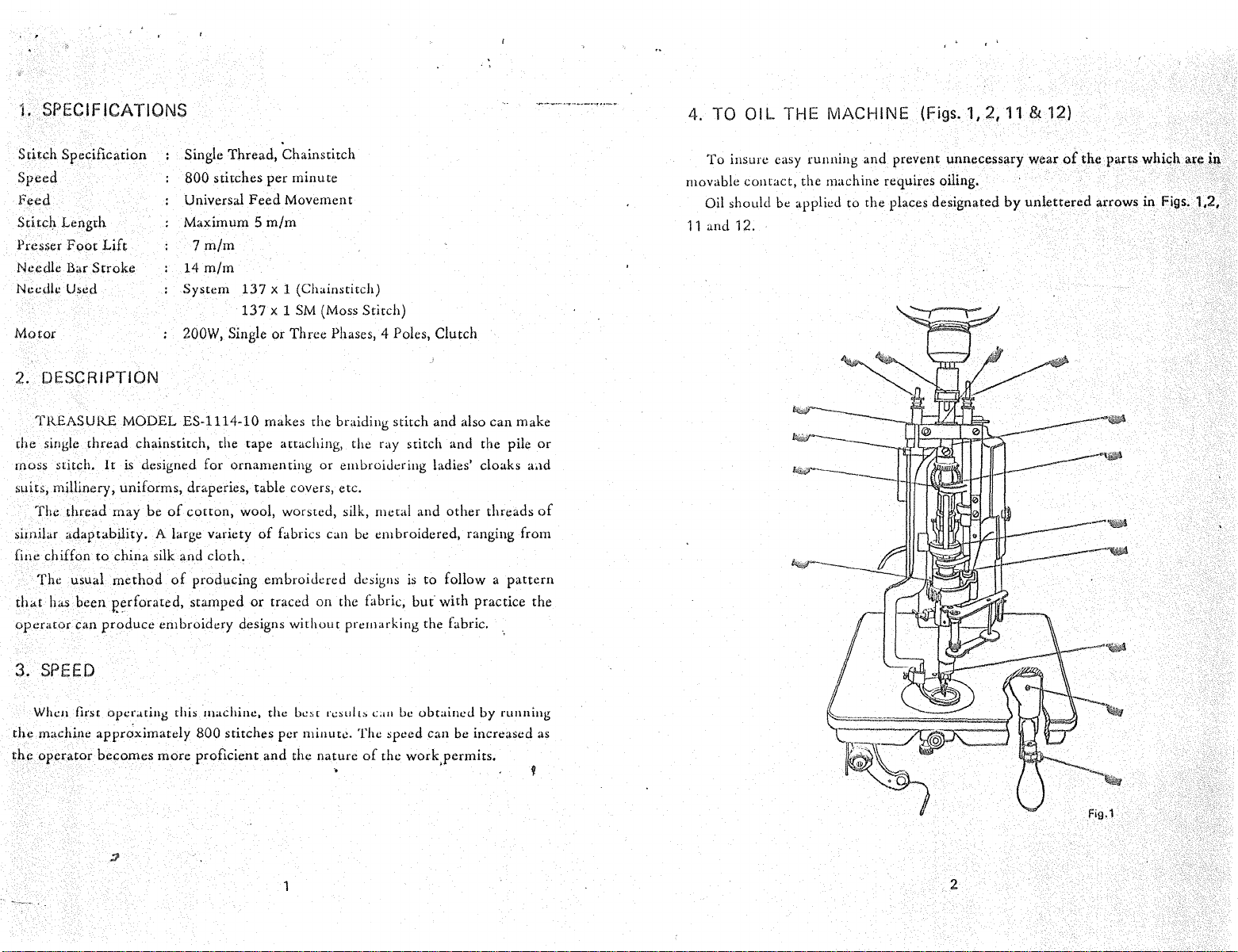

4. TO

OIL

THE MACHINE (Figs. 1, 2,

11

& 12)

Stitch

Specification

Speed

Feed

Stitc~

Length

Presser

Needle Bar

Needle

Motor

Foot

u~ed

Lift

Stroke

Single Thread, Chainscitch

800

stitches

Universal

Maximum 5

7m/m

14

m/m

System

200W,

per

Feed

Movement

m/m

137

x 1 (Chaimtitch)

137

x 1

Single

or

minute

SM

(Moss Stitch)

Three Phases, 4 Poles, Clutch

2. DESCRIPTION

TREASURE

rhe single thread chainstitch, the tape attaching, the ray stitch and the pile

moss stitch.

suits, millinery, uniforms, draperies, table covers, etc.

The thread

similar adaptability. A large variety

fint: chiffon

Tht: usual

th«t

has

operator

MODEL ES-1114-10 makes the braiding stitch and also

lr

may

to

china silk and

method

been

P.erforated,

can

produce

is designed for ornamenting

be

of

cotton,

of

stamped

embroidt:ry designs

wool, worsted, silk, metal and

of

cloth.

producing embroidered designs

or

traced on the fabric,

or

fabrics can

without

embroidering ladies' cloaks

be

embroidered, ranging from

premarking the fabric.

other

is

to

follow a

but

with practice the

can

make

threads

pattern

or

aad

of

To

insure easy running and prevent unnecessary wear

movable

11

contact,

the machine requires oiling.

Oil should be applied

and 12.

to

the places designated

by

unlettered

of

the parts which are

arrows

in

in

Figs. 1,2,

3.

SPEED

Whe11

first

the

the

machine

operator

operi!tiug

approximately

becomes more proficient and the nature

thi~

machine, the

800

bc:;r

rc:;uft, can

stitches per minute. The speed can be increased

be

obtained by running

of

the work,permits.

as

2

Page 4

' .

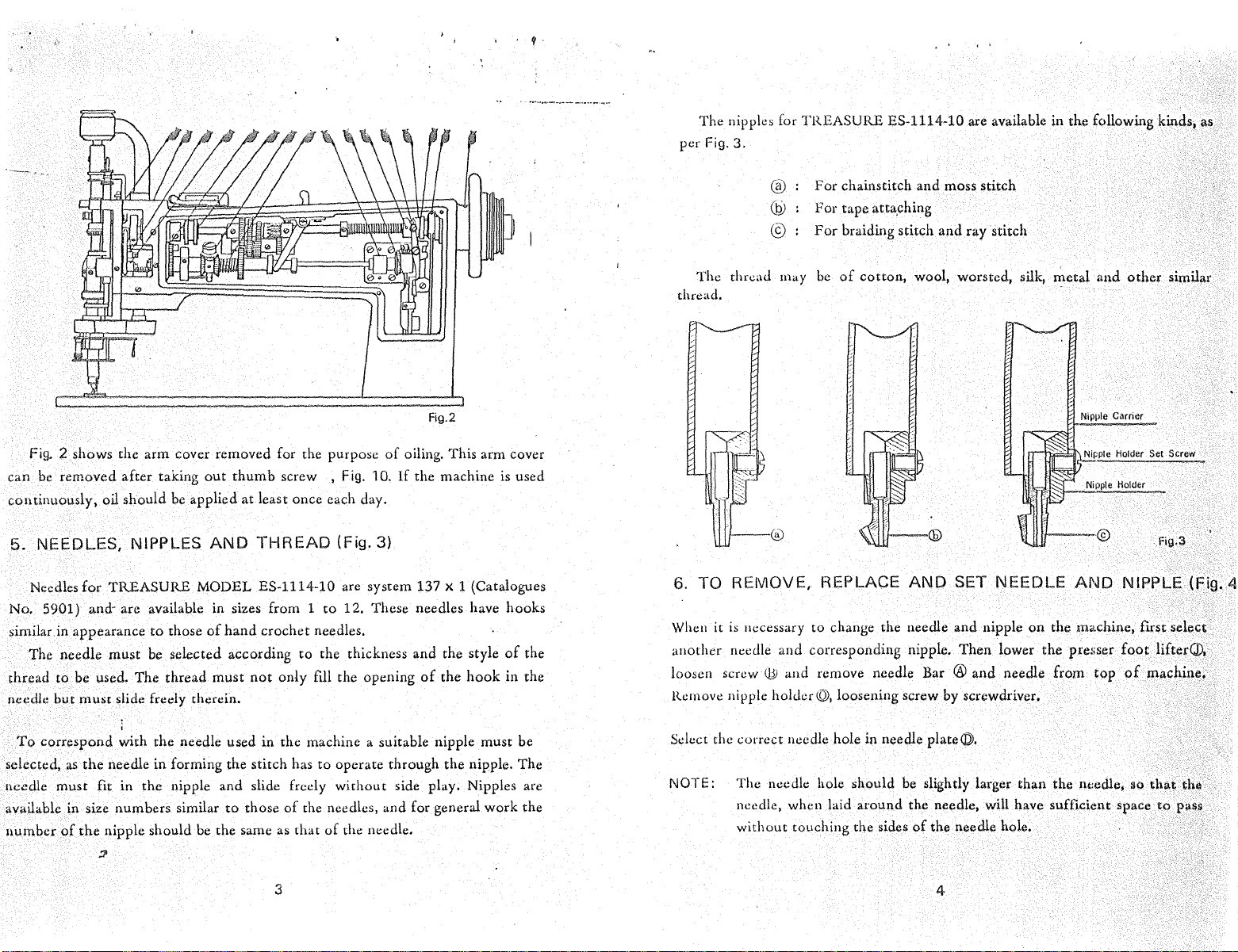

The nipples for TREASURE ES-1114-10 are available in the following kinds1 as

per

Fig.

3.

@

For

chainstitch and moss stitch

~

For tape atta.ching

©

For

braiding stitch

and

ray stitch

Fig.

2 shows the arm cover removed for the purpose

can

be

removed after taking

continuously, oil should

5.

NEEDLES, NIPPLES

Needles

No.

similarin

The

for

TREASURE MODEL ES-1114-10 are system 137 X 1 (Catalogues

5901) and- are available in sizes from 1

appearance

needle

must

to

be

thread to be used. The

needle

but

must

slide freely therein.

out

thumb

be applied

AND

those

of

hand

selected according

thread

must

screw , Fig. 1 0.

at

least once each day.

THREAD

(Fig. 3}

to

12. These needles have hooks

crochet needles.

to

the thickness and the style

not

only

fUl

the opening

Fig.2

of

oiling. This arm cover

If

the machine is used

of

the

hook

of

the

in the

The thread

may

be

of

cotton,

thread.

6. TO REMOVE, REPLACE

When

it

is

necessary to change the needle and nipple

another

loosen screw

Remove

needle

nipple

and

corresponding nipple. Then lower the presser

QJ!

and remove needle Bar ® and needle from top

holder©,

loosening screw by screwdriver.

wool, worsted, silk, metal

AND

SET NEEDLE

on

the machine, first select

and

other

Nipple Carrier

Nipple Holder Set Screw

Nipple

Holder

Fig.S

AND

NIPPLE (Fig; 4

foot

lifterQ).

of

machine,

similar

To

correspond with the needle used in the machine a suitable nipple must be

selected,

needle

available in size numbers similar

number

as

must

of

the

the

needle

in

forming the stitch has

fit

in

the

nipple and slide freely

to

those

nipple should be the same as that

::P

to

operate through the nipple. The

without

of

the needles, and for general work the

of

the needle.

side play. Nipples are

3

Select the correct needle hole in needle plate@,

NOTE: The needle hole should be slightly larger than the nt:edle

needle,

without

when laid around the needle, will have sufficient space

touching the sides

of

the needle hole.

4

ao

that

to

the

pass

1

Page 5

Loosen

needle,

Next, insert

then

thumb

tighten

the

screwQ)an.d

tighten screw securely

nipple

needle bar ®

- sleeve

un<kr the

needle faces the

NOTE: Do

carrier (Fig. 3)

and

adjust its height so

point

Be

sure

handle

screw

and

of

front.

not

tighten screw

is

operating

collar.

turn

thumb

screwQ).

selected nipple

with

the screwdriver. Insert the nipple

and

tighten screw securely. Screw selected needle

plate@

®into

until correct needle hole

the lower

part

of

nipple holder @

tighten with pliers provided. Replace needle

that

the fabric

to

be

embroidered. can

the needle.

®

is

as far

to

the

front

Then

tightened

collar

is

as possible and

tighten screw®, which also should face the front.

Q))

except

when needle bar

uansformed

when needle

(Y

is

not

and needle bar does

that

bar®

is in its place.

in its place, needle bar

is

holder@

bar

® down

the

not

enter

in line

just

hook

into

of

If

into

with

and

the

into

into

pass

the

the

the

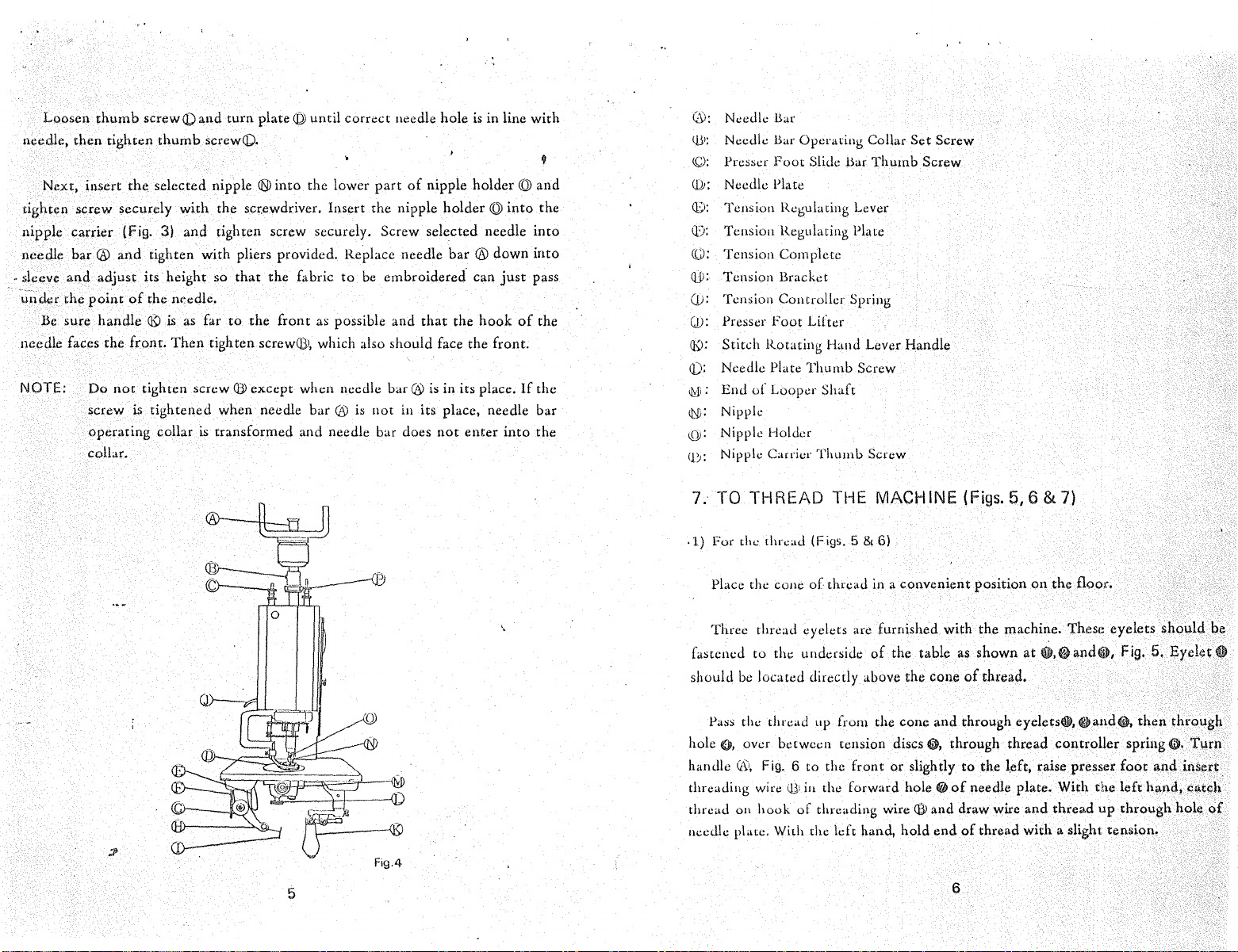

@:

Needle liar

(1}>:

Needle liar Operaring Collar

<Q:

Pres5er

Q)J;

Needle Plate

())·

Tension Regulating Lever

(1): Tension Regulating Plate

((;);

Tension Complete

Qj): Tension Bracket

(j):

Tension Controller Spring

(]): Presser

qy;

Stitch Rotating Hand Lever Handle

Q):

Needle Plate Thurnb Screw

<l:Ji;

End

Q{i: Nipple

I.QJ:

Nipple Holder

(!J;

Nipple Carrier

Foot

Slide liar

Foot

Litter

of

Looper Shaft

Thumb

Thumb

Screw

Set

Screw

Screw

5

7. TO THREAD THE MACHINE (Figs.

·1) For the tl1read (Figs.

Place the cone

thread eyelets are furnished with the machine. These eyelets

Three

fastened

to

the underside

should be located directly above the cone

Pass

th<.:

thread up from the cone

hole

0.

over between tension discs

handle

Qv,

Fig. 6 to

threading wire ll): in the forward

thread

011

hook

of

needle plate.

Wilh

5&6)

of

thread in a convenient position

of

the table as shown

of

thread.

and

through eyeletsO, @and(U.

0,

through thread

the

front

or

slightly

hole@

threading

wire®

tlu: left hand, hold

to

the l.eft, raise presser

of

needle plate. With

and draw wire

end

of

thread

6

5,6 & 7)

on

the floor.

at

0.@

controller

and

thread

with

a slight tension.

and

Vi),

Fig. 5. Eyelet 0

then

spring (i).

foot

and

the

left

hand,

up

through

should

through

'turn

insert

catc;h

hole

be

of

Page 6

With the right hand,

machine, quickly bear

thread

(6;, draw thread directly

after

2)

for

one

stitch. Keep

it

comes up through needle hole.

For

the

cord

(Fig. 7)

turn

down

hindle@

toward

handle @ straight to the left, having

and up

on

handle®

in

same position and with the threading wire

you, laying

so the needle will pick up the

end

of

thread loosely

started

on

needle plate

the

Fig.6

0

r

l

Wind the

pulley.

barO

6,

then through

3)

For

Wind the

pulley.

guide

4D

the

hole

braid leader guide.

Now

cord

0 on the

Place

it

on

the

cord

spool bracket@. Insert the cord

with

th.~.threading

to

the braid (Fig. 7)

brai~

Gil

Place

it

on

of

the

bracket

4»

of

the

the

mi>Chine

wire (large) 0 and pass it below the

the hole

on the braid spool G), U$ing the spool winder spindle

the braid spool bracket till. Pass the braid through the braid

br~id

is

of

(1il

and through the hole (f)

leader bracket, then through the forward hole (I)

ready for operation.

cord

spool

the nipple€#.

e,

using the spool winder spindle

into

the

end

of

of

the braid leader

7

on

top

of

needle

nipple

carr~er

on

rod

of

the

the

and

the

1

J

8

Page 7

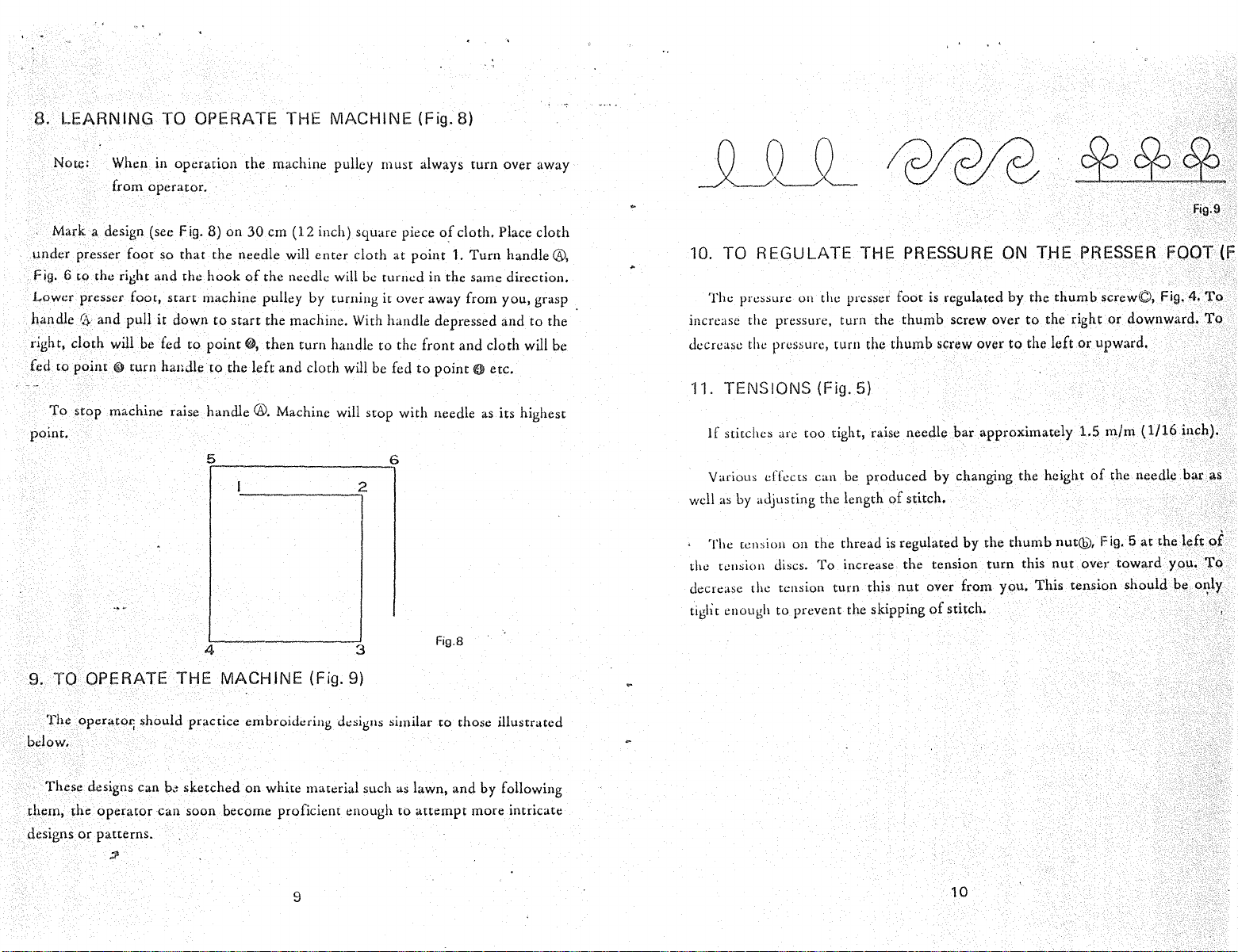

8.

LEARNING

TO OPERATE THE MACHINE (Fig. 8)

Note: When in

from operator.

Mark a design (see Fig. 8)

under

presser foot so

Fig. 6

to

the right and the

Lower

presser foot,

handle

right,

fed

~·and

pull it

doth

will

be

fed

to

point

li) turn handle

To

stop machine raise handle

point.

operation

that

start

down

to

the

machine pulley

on

30

em

the needle will

hook

of

the needle will be turned in the same direction.

(12

inch) square piece

enter

cloth

must

at

always

point

turn

of

cloth. Place

1.

Turn

machine pulley by turning it over away from you, grasp

to

start

the machine. With handle depressed

point@,

to

5

the

then

turn

handle

left

and

cloth

®.

Machine will stop with needle

to

the

will be fed

6

to

front

and

point 0 etc.

cloth

as

2

over away

cloth

handle®,

and

to

the

will be

its highest

10. TO REGULATE THE PRESSURE ON THE

The pressure

increase the pressure, turn the

decrease the pressure, turn the

11. TENSIONS {Fig.

If

stitches are too tight, raise needle

Various effects can be

well

as

by

The

tension

the tension discs.

decrease the tension turn this

tigll t enough

Oil

the presser foot

5)

produced

adjusting the length

on

the thread is regulated by the

To

increase the tension

to

prevent the skipping

is

thumb

thumb

regulated by the

screw over

screw over

bar

approximately 1.5

to

to

the right

the

left

thumb

by changing the height

of

stitch.

thumb

turn

nut

over from you. This tension should be

of

stitch.

nut@, Fig. 5

this

nut

PRESSER

screw©, Fig. 4,

or

downward.

or

upward.

m/m

( 1/16 inch).

of

the needle

at

over

toward

Fig.9

FOOT (Fi!

To

To

bar

as

the

left

of

you.

To

ox:ly

4

9. TO OPERATE THE MACHINE (Fig.

The

operator; should practice embroidering d.:signs similar

3

9)

Fig.8

to

those illustrated

below.

These designs can

them,

the

operator

designs

or

patterns.

;P

sketched on white material such as lawn,

can

soon become proficient enough

9

to

and

attempt

by following

more intricate

b,~

10

Page 8

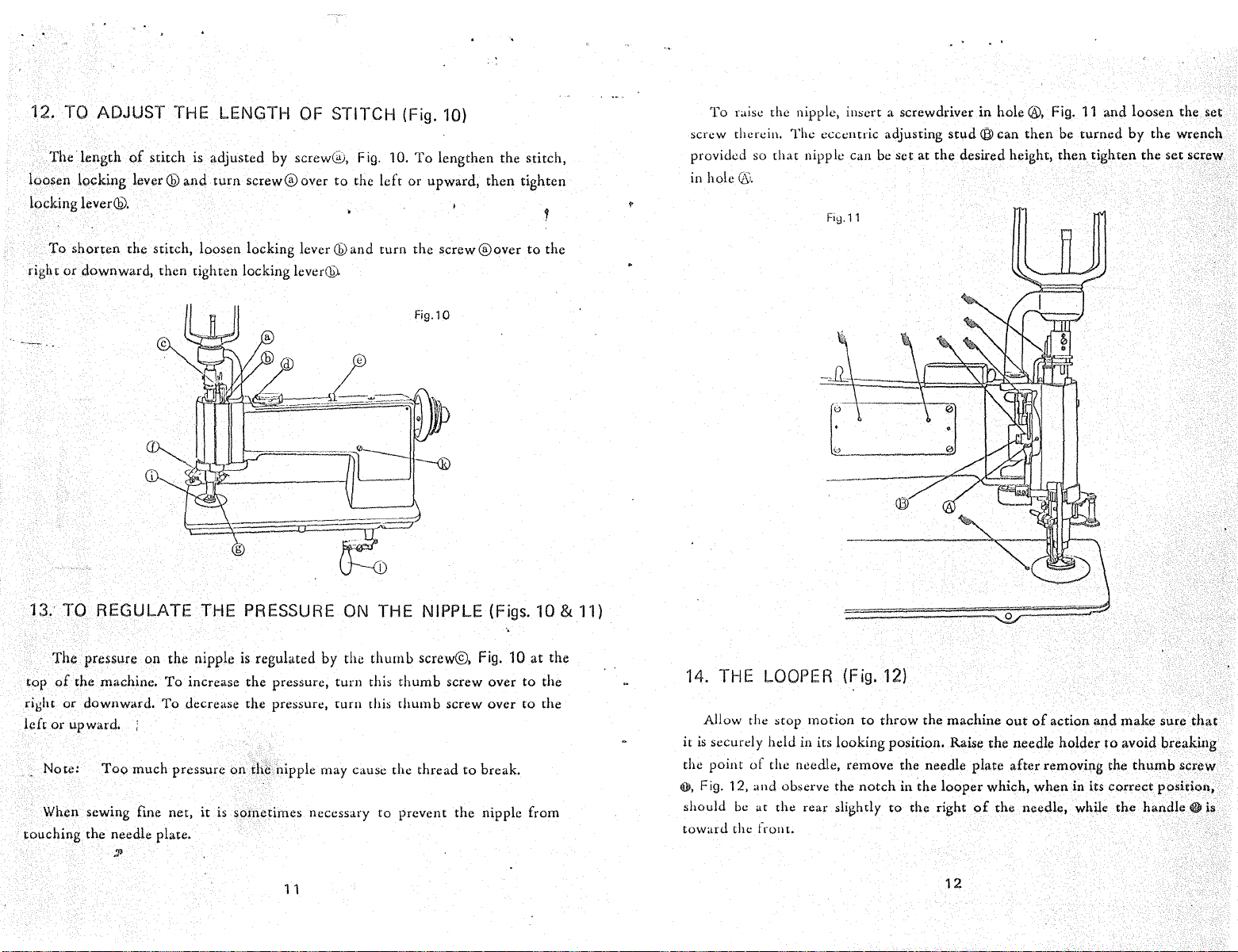

12. TO ADJUST THE LENGTH

The

length

loosen locking

locking

right

lever@.

To

shonen

or

downward, then tighten locking

of

stitch

is adjusted by screw@, Fig.

lever®

the stitch, loosen locking

and

turn

screw®

OF

STITCH (Fig.

over

to

lever®

lever®

and turn the screw

the

10.

left

10)

To

lengthen the stitch,

or

upward,

then

®over

tighten

to

the

To

raisl! the nipple,

screw therein. The eccentric adjusting

provided so

in

hole®.

that

in~ert

a screwd1·iver in

nipple can be set at

Fiy.11

the

hole®.

stud®

can

desired height,

then

Fig.

11

and loosen the set

be

turned

then

by

tighten the set screw

the wrench

13. TO REGULATE THE PRESSURE

The

pressure

top

of

the machine.

right

or

downward.

left

or

upward. ;

Note:

When sewing fine net,

touching

the needle plate.

on

Too

much pressure

:J'

the nipple is regulated by the

To

increase the pressure,

To

decrease the pressure,

on

the nipple may cause the thread

it

is sometimes necessary

11

ON

THE NIPPLE (Figs. 10 & 11)

turn

turn

thumb

this

this

screw@,

thumb

thumb

to

prevent the nipple from

Fig.

screw over

screw over

to

break.

10

to

to

at

the

the

the

14. THE LOOPER (Fig.

Allow the stop motion

it

is

securely held in

point

the

0,

Fig. 12, and observe the

should

toward

of

be

at the rear slightly

the front.

its

looking position. Raise the needle holder

the needle, remove the needle plate after removing the

12)

to

throw

notch

the machine

in the

to

the right

out

of

action

and

to

looper

which, when in its correct position,

of

the needle, while

12

make sure

avoid breaking

thumb

the

handle~

that

screw

is

Page 9

15.

TO

SET

Turn

the machine

Fig. 4

to

the

front.

turn

the gear slightly,

instructed

shaft~,

above.

tighten the set screw@. .

THE

LOOPER (Figs. 4 & 12)

back

on

its hinges

Loosen

After

set

until

the

having set

screw(!), Fig. 12

notch

the

and

turn handle

of

in the

worm

looper

gear flush with th\!

t),

Fig. 12

the operating

is

in its

worm

correct

end

and

gearO,

position

of

the

screw®,

and

as

looper

Note: Do

17.

TO

It

is

brackdr;

To

adjll~~

it docs

and

from you.

over

bracket\f;by the left hand

!lOt

turn

To

increase the tension

toward

lf

the geMs do

not

change the lever while

cause the machine

ADJUST

the best for

Fig.

a:; above, bring the handleQ)to front,

turn

the

braid spool bracket(Oto the above position.

To

decrease the tension

you.

THE

the

10

is

set in the left while

round, then press the gear changing lever@, Fig. 10

not

engage

the

clutch is engaging.

to

damage.

TENSION OF

normal braiding embroidery works

of

the

braiding,

of

the braiding,

after

the

and

turn

the pulley by the right

THE

BRAIDING

the

handle

CD

is

hold

turn

the

braid

turn

above adjustment,

at

the

the

the

hand.

If

do

so, it

may

(Fig. 10)

that

the braid spool

front.

handle

by

the knee as

to

the right

spool bracketCDover

braid

spool bracketeD.

. ~ f

('•

h?ld

the braid spool

16.

TO

The

number

located

engage and

ing

embroidery.

ln

ca~c

of

In

ca~c

of

In

case

of

In

case

of

The

bigger

Therefore,

ADJUST

on

the

the

the

number

the

n~mber

the

number

the

number

the

set

the number 1 for normal braiding stitch.

:I'

THE

NUMBER

of

the

braiding can be adjusted

top

of

the machine frame.

machine will be

1, one braiding (roll) per one stitch

2,

3,

4,

1/4

number

operated

1/2

braiding (roll) per one stitch

1/3

braiding (roll) per one stitch

braiding (roll) per one stitch

is

set, the coarser the internal

OF

as chainstitch, moss

13

THE

At

BRAIDING

by

the lever@, Fig. 10, which

the

number

of

the braiding will be.

0,

the

stitch

(Fig. 10)

gears do

or tape attach-

is

not

Note:

·The

""·

Fig.

18.

The

tensions

(1)

For

loosen the screwll},

Do

do so,

additional

7 and the braid leader guidajp,

RAY

STITCH (Figs. 4 &

r:•y

stitch

of

the cord and the braid slightly tight as

loosening thread (fig. 4)

not

prc~s

the gear changing lever

it may cause the machine

adjustment

will be made

7)

Citll

be

done

by

adjusting the tensions

Fig.

4 and lift the needle

Fig.

14

to

damage.

by

the braid

10.

®while

you

like.

bar®

the

spool

of

so

that

clutch

adjusting

the

thread

th,e

thread

is

engaging.

thumb

loos.:,

loosens.

If

nut

the

'

Page 10

' '

(2)

For

tightening

cord

(Fig. 7)

tighten the screw {lil, Fig. 7 so

slow.

(3) For tightening braid (Fig. 7)

· tighten the

nut

~.

Fig. 7 so

slow.

Then,

set

the

lever

@)

, Fig.

that

that

10

to

the number 1.

the rotation

the

rotation

of

the cord

of

the braid spool

spool~

becomes

0becomes

19. PILE

OR

MOSS

The raised pile or moss stitch

the

will drop

handle®,

the

hook

the

screw

knurled

stitches in loose loops on the materials.

Fig. 4 w the front, loosen the

of

the needle will

$.

Reach

end

0,

Fig. 12

left and while holding it

then release the knurled

The

looper-

will

then be set in the opposite direction

for the chain stitch,

-~hile

handle(!), Fig.

10

(spur).

By

operating

circles

of

The higher the

thickness

the machine and

dropp~d

stitch loops laid one on the other, raised pile. work

needle

of

the

material used will have

machine for pile stitching.

STITCH (Figs. 4,

is

produced by adjusting the machine so

point

directly

under

the bed

of

the operating worm ·gear 0 draw

turn

end

of

or

with

is

at

the

is

set the longer the loop will be. The size

of

the machine with the left hand, grasp the

handle

~around

the gear.

the

notch

front. Change the pn:sser

turn

handle(l)rapidly, so

10

& 12)

screw<.IY

to

the back

and

turn

of

to the right directly

of

the looper

to

be considered when adjusting the

To

accomplish this,

the needle

the machine,

th;

worm gear

to

that

which is required

at

the front

footCDto

the presser

as

to

make very small

of

bar®

of

the

then

to

is

thread

that

turn

so

that

tighten

t&

the

the back,

~.he

needle

foot

produced.

and

it

<"

I

15

Page 11

Machine Frame & Covers Components

Ref. No.

1

2

3

4

5

6

7

8

9

lO

11

12

PMtS

No.

AJ\11114·10

ol81

8470

5227

8466-A

4015

8434

8150

8483

S-8445

8172

8146

Description

Machine

Arm

Arm

Arm

Spool Can:iex

Spool Canier

Arm

Arm

Arm

Cord Spool Bracket Supporting Ann with

Cord

Cord Spool Bracket Supporting

Top

Head

Head

Side

Side

Side

Spool

Frame

Screw

Cover

Cover

Cover

Cover

Cover

Brackllt

Thumb

Driving

Driving

Position

Thumb

Scxew

Gear Cover

Gear

Cove.r

Pin

Screw

SupportiJli

Sll~

Ann

Arm

·Scxew

Clamp

Position

Needle

Scxew

l)in

Bea{ing

7

-11

rr:-12

9

'

TK-111-10

Page 12

I'

•

7

9·'------~--------------~

ll

16

I

18

;_

20

.

19

I

~13

·

.

~13

®1)~

\

17

17

221i

~

~

12

21

23

3

Page 13

Arm Head Part5 Component:)

\No.1)

14

27

Ref. No. Parts No.

64 72 Arm Head

1

8020

2

8021 Arm Head Screw

3

4

8022

5 815 0 Arm Head Position

9

6 8145 Arm Head Position Pin

S-8462

7

8

11152

9

4031

10· 84

11

12

13

14

15

16

17

18 8463 Spool Carrlllr ldlllr Gear Supporting Block ·

19

20

21

22

23 8335 Nipple Set Scn;w ·

24

25

26

27

28 84

29

30

31

32

33

34

35 8311 Feed Sliae Block

36

3 7 8 314

39

40

41

42

43

74 Spool Carrier Driving Gear Cover Bracket

4 015 Spool Carrier Driving Gear Cover Bracket

8452-A

8465 Nipple Carrier Sleeve

8464 Spool Carrier

8461

8475-C

2553-A

113-A

8320-A

8339

8498-A-3

8510-AA

8027-3

8449

831 Needle Bar Guide Block & Collar

77

84 76 Needle Bar Guide Block

8308

5176-A

8030

129-B

S~8456

8312

ll;\ 1 "\

124

8335 Feed Lever Bracket

8037

8036

8038

Arm

H11ad

Arm Head Screw (lower)

Spool Carrier Driving Gear Guide with Ref.

SpoQl Carrier Driving Gear Guide Screw

Spool Carrier Driving Gear Guide

Nipple Carrier Sleeve with Screws

Spool

Carrier

Spool Carrier Driving Idler Gear

Spool Carrier Driving Idler Gear

Spool Carrier Idler Gear Supporting

Nipple Holder · · · ·

Nipple Holder Set Screw

Nipple (for Braiding)

Needle Bar

Needle

(137xl

Arm Head Sleeve

Needle Bar Guide Block Set Scfew (Large) ·

Arm Head Sleeve Cap ·

Arm Head Sleeve Cap Screw

Arm Head Sleeve Gear

Arm Head Sleeve Gear Set Screw

Feed Rotating Shaft & Gear

Feed Lever

Feed

Lever Hinge Pin

Ft>ed

Lever Bracket

Feed Lever Bracket Set Screw

Feed Recovering

Feed

Recovering Spring (Left)

Feed Recovering

Description·

Screw (upper)

(upper)

Pin

Buiihit13

Driving

G6ar

Driving

Idler

#3)

Set

Spt1113

Spril13

(lon~)

(shQtt)

Gear

Stud

Stud

Set

Sc~ew

Screw

(RI&bt)

Screw

Set

Screw

Set

Block

..

with

(Small)

No.8

Set

Screw

'·

Screw

Set Sctew

·· .·

Ref; Nos. 28

....

2~

'\

Page 14

Arm

Huad Parts Componant$ (No. 2)

Parts

1:1067

8161

8065

8139

8138

8064

8140

8069-A

IH!!8

8070-A

S-8453

8072

8481-A

8454-A

8073-D

8315

8316

8136

8310-A

8428

4173

8317

8051

8055

8182

8054

8160

8052

~IJSl

8041

8048

No.

-A

l're5ser

Presser

Presser

Presser

Presser

Press~r

Presser

Presser

Presser

Presser

Presser

Presser

Presser

P(esser

...

Presser

Presser

Presser

Pn:sser

Feed

Feed

Feed

Feed

Feed

Fee<!

Nipple

Nipple

Nipple

Nipple

Nipple

Nipple

~ip\)1$

Feed

Fee<!

Ref.

No.

2

3

4 8066

5 8322

6

7 8063

8

9

10

11

12

13

14

.,

'

15

16

17

7

32

18

19

20

21

\

8

22

23

24

25

26

27

[~

10

I

15

28

29

30

31

ll

33

34

Description

Foot

SW1o

Foot

Slide

Foot

Slide

Foot

Slide

Foot

Slide

Foot

Slide

Foot

Slide

Foot

Slide

Foot

Slide

Foot

Slide

Foot

Lever

Foot

Lever

Fuot

Levex

Foot

Lever

Foot

Clamp

Foot

Clamp

Foot

Foot

Shoe

Lever

Bracket

Lever

Bracket

Leve.r

Bracket

Slide

Bar

Slide

Bar

Block

Slido

Bar

Block

Curies

Carrier

Guide

Caxdw

Gui<!e

Carrier Thumb

Carrier Thumb

Casrt.r

Spdlli

Canw

Extt>m\Qn

Reg~

tin& Sctew

Regulating

Bar

Thllrnb

Bar

Thumb,Scxew

Bar

Spxin&

Bar

Sprini

Bar

Bar

Adjustina

Bar

Guide

Bu

Guide

Bu

Spdng Stop

Bat

Spdlli Stop

Swivel

Swivel

Swivel

Thumb

(Rubber)

Guide

Guide

G\lide

Sot

Screw

Screw

SCA:eW

Screw

Lock

SlllOW

Nu.t

PlUilil:lf

SCA:ew

Set

Screw

Scxew

Stop

SCA:lJW

Hingt~

Screw

Sclew

.

I

Cap

Cap

Scn>w.

SCA:QW

N1,1t.

Levlj)tN~t

· ·

1

Page 15

7

~

5

/9

I

~

Description

Crank

Cmier

Bell

Crank

Foot

Slide Bell Crl4lk

Foot

Slide Bell Crank Hinge

Foot

Slide Bell Crank

Foot

Lifter

Foot

Lifter Hinge Screw

Thumb

Screw

Stud

Stud

Hin;:e

with

Set

S!f!eW

Sttu1

Stud

H.inge

Ref. No$.

Set

Stud

Stul!

17-18

Sc&ew

Set

Se~ew

10

11

12

13

14

15

16

17

18

19

20

21

22

No.

2

3

4

5

6

7

8

9

Parts No.

8042

8044

8045

8046

8043

5225-C

8057

8455

5225-C

1>059

3455

5225-C

8060-A

3061

1)304

1>27

827-1

411>5

84()4

1>26

124

8467

Feed Bell Cranl';

Feed Bell Crank RoUer

Feed Bell Crank Roller Scxew •

Feed Bell Crank Spring

Filed Bell Crank Hinge

Feed Bell Crank Hinge

Nipple CMrier Bell

Nipple

Nipple CMrier Bell Crank Hinge

Presser

Prllm:r

Presser

Presser

Presser

Needle Bar Operating Slide

Braid Leader Assembly

Braid Leader Guide

Braid Leader Guide Set Screw

Braid L.:ader

Spool Carlier Assembly

Spool Carrier Set Qcrew

Braid Spool (Metal)

Ref.

15

6

16

~

1\:l

"

-

20

9

21

~

22

Page 16

Gear Change Lever, Spool Carrier

Components

DisenQ<!Qing

Lever~

~24

~-23

Ref. No.

2

3

4

5

6

7

8

10

11

12

13

14

15

16

1

16

17

Hl

19

20

21

22

23

2-lc

Parts

8439

8440

8441

8435

113-ll

8437-1

8437-2

8437-3

8438

.;,,

84;,:,

8491

8489

5207

8514

8416

129-B

S-84t

129-A

8415

8414

114-B

81-lc6

'JQ

No.

7

Description

Gear

Change

Gear

Change

Gear

Change

Gear

Change

Gear

Change

Gear

.change

Gear

Change

Gear

Change

Gear

Change

Spool Carrier

Spool Carrier

B

Spool Carrier

Spool Cauier

')1

Canier

Carrier

Spo,,

rier

lntennL

lmermed,..:.

lntermedi;ue

Intermediate

Intermediate

Intermediate

lntermediat~:

lmermediate

Lever

Cover

Levex

Cover

Graduated

Lever

Base

Lever

Base

Lever

Lever

Spring

L.evo::r

Ball

Lever

Set Saew

Disengasing

Disengaging

Dist:ngagiog

Disengaging

Disengaging

Disengaging

Disengagillg

Gear

(No.1)

·H

Set

•

Assembly

Gc~l

" t

Gear

Gear

B,~,,;

Gear

Br<~~·

Gear

Brack<;.

Set

Screw

Plat~!

Set

Screw

Lever

Leves

Sprin&

Lever

Spring

Lever

Bracke$

L~ver

Stt+d

L.ev~rr

Stud.

L.everCover

Screw

(No.

Screw

Scfew

Nut

2~4)

22

19

•'

Page 17

feed

Rotating Gear &

Stop

Bracket Pa.ru Componentli

/24

~

lO

:at)

11

16-....

i

'-1

17

~

22

Ref.

No.

2

3

4

5

6

7

8

9

10

11

12

13

14 8081

15

16

17

18

19

20

21

22

23

24

25

26

Parts No.

3424

113-A

8146

8423-A

8142

8420

8422-A

8142

8112-B

821

8442

ts079

8486

121

8443

8083

124

8084

8077

8078

8075

8076

8473

8172

8159

Do5Crlp,tion

Feed Rotating Shaft

Feed Rotating Shaft

Feed Rotating Shaft Brackllt:Posjtion

Filed Rotating

Feed Rotating Gear Set Screw

Stitch Rotating Shaft

Stitch Rotating Gear (Upper)

Stitch Rotating Gear Set Screw

Stitch Rotating Gear (Lower)

Stop Bracket Assembly (Ref. Nos.

Stop Bracket

Stop Brackl':tlnteilocking Rod

Stop Bracket Interlocking Rod Spring

Stop Bracket lnterlockinl) Stop Block

Stop Bracket Interlocking Stop Block Screw

Starting Trip Lever Slide

Starting Trip Lever Slide

Starting Trip Lever Sli\le Cap Screw

Starting Trip Lever Sli\le Spring

Stop

Cam

Roller

Stop

Cam Roller Screw

Stop

Cam Rocking Lever

Stop

Cam

Rocking Lever Hinge

Stop Bracket Set

Stop Bracket Set Screw (Short)

Stop Bracket Position Pin

Geu

SCiew

B&a~et

Bra~et

Set

(Rear)

Cap,,

Stu\1

(Long)

SCiew

:Pin

11-23)

SCiew

l

I

S:~l

13

. '

Page 18

Foed Rotating

Shaft

Mechanism Compononu

Pans

Ref. No,

1

2

3

4

5

I'

•

6

7

8

9

10

11

12 8142

13

14

15

16 8146

17

18

19

20 8504

21

22

23

24

25

26

27

28

29

30

No.

8110-A

8142

8458

8459

4078

8460

129-A

8097-A

129-B

8457

8097

Spool Cauier

Spool Carrier

Spool Carrier

Spool Canicr

Spool

Spool Carrier

Spool'Can:ier

Spool Carrier

Spool Carrier

Spool Carrier

Spool Carrier

Spool Carrier

8427

8496

8429

Spool

· Spool Carder

Spool

Spool

8495

S-8425

8492-T

Spool

Spool Carder

Spool Carrier

Spool Carrier

8433

129-B

8432

8431

Feed Rotating Shaft

Feed Rotatins Shaft

Feed Rotating Shaft

Feed Rotating Shaft

8479 Feed Rotating Shaft

8430 Feed Rotating Shaft

5262

Feed Rotating Shaft

10017-A Feed Rotating Shaft

8142

8421

Feed Rotating Shaft

Feed Rotating Shaft

0&$cription

Ca.rde•

Caxrier

Ca.rriex

Caxrier

Carrier

Gear

Driving

Gear

Drivinz

Gear

Driving

Gear

Drivin~

Gear

Driving

Gear

Driving

Gear

Driving

Gear

Driving

Gear

Driving

Gear

Driving

Gear

Driving

Gear

Driving

Geax

Driving

Gear

Driving

Gear

Driving

Gear

Dr

Gear

Driving

Gear

Driving

Gear

Driving

Gear

Driving

Gear

Gear

Gear

Block

Block

Block

Block

CoUax

Collar

Bevel

Gc:ar

Bevel

Gear.

Gea,t

Shaft

Gear

Slu!it

Gear

Shaft

Gear

Gear

Set

Bevel

Gear

Bevel

Gear

Bevel

Ge-ar

Bevel

Gear

Bevel

Gear

Bevel

Geill'

Bevel

<;lear

Bevel

Gear

ivins

Bevel

Gear

Bevel

Gear

Sle~ve

Gear Assembly

Sleeve

Gear

Sleeve

Gear

(Small)

Set

SCLeW

{Lax$e)

Set

SCLew

Pin

Pin

Se'

Set

SCLew

Set Screw

Bushing

:Bushing

Screw

Set

S.;:rew

Sleev~

Set

Scxew

Set

S(:lew

Btacket

B&a~et

Blacl\.et

Sprl,ng

'Thrt!st

·

SCLe.w

Set Screw

Taper

Pi~

Washer

Beaxins

30

15

,·

Page 19

'

I

14

~~13

8

'

16

n

17

~

I

I

18

'

Looper

Ref.

No.

1

2

3

4

5

6

7

8

9

HJ

ll

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

"'

~~

Operating

Pam

No.

1!106

8107

805

8104

8105

8102

8103

806

8100-A

8101

124

8099

8152

129-B

8158

8150

822

S-8444

8174

8175

8176

8177

8178

8179

5207

8089-A

8092

8093

8090

8091

8088

8143

8149

8094

8097·~A

1;142

Muchaoism

Needle Plate

Needle Plate Clamping Thumb

Looper

Looper Operating Collar

Looper Operating Collar Set

Looper

Looper Operating

Looper Bracket

Looper

Looper Position Plate

Looper Position Plate

Looper Bracket

Looper

Looper

Looper Bracket Set

Looper Bracket Position

Looper Operating Connection

Looper Operating Connection , ,

Looper Operating Connection Joint Pitman

Looper Operating Connection Joint Pitman Nut (Upper).

Looper

Looper Operating Connection

Looper Operating Connection Joint

Looper Operating Connection Joint

Looper Operating

Looper Operating

Looper Operating

Looper Operating

Looper Operating

Looper Operating

Looper Operating

Looper Operating

Looper Operating

Looper Operating

Looper

ComponenU

Screw

Operatin&

Oper;>ting

Collar

Collar

Operating Connection Joint

Opera

Gear

Gear

Gear

Assembly

Set

Screw

Connection

Bell

Bell

Bell

Bell

Bell

Bell

Bell

Bell

Shaft

tin&

Sbaft

Assembly

Scu~w

(Spiral)

Spring

(Ref.

No$.

Screw

Sci:ew

Pin

Assembly

Joint , ,

Joint

Crank

Crank

Hinge

Crank

Hinge

Crank

Hinge

Crank

Hinge

Crank

Bracket

Crank Bracket Set

Crank Bracket

,

Bevel

GtJJ

(Ret'.

NO$.

9-

14)

(Ref.

PHman

Hinge

Stud

Hinge

Stud

Hin&e

StMd

Block

Block Screw

Screw

Screw Nut

Screw

Position

{l,dl)

4 -· 7)

NoJ,lS

Nl.lt

(Lowef)

Sprin&Wa~er

Nut

·

Pin

- 28)

·

11

Page 20

19

2~,"

'

·"

·~·~

..

;4~5

<

33

~35

3~<

36

~

I

;j]

34

39

Rut.

No.

"'

9

1()

1 t

12

13

l4

15

16

17 5107

lll

19 8117

20

21 lH42

22

23

24 8142

25 8113

26 8143

27 8149

28 8122

29 !H23

30

31

32 8119

33

34 8120

35 8121

36

S-8115-A

37

38

39 8116

40

41

f'afl>

No.

~ill

ol21

lil:~JJ

4HIJ-A

l:ll

liW

til

5267-A

.HSH)·-A

8164

1.\143

8110-A

·

8114-A

8096-A

8124

!lOS

8045

5176-A

8118

5070

8141

Ot>${;fipdOfl

Tcm.i.:w

T .:n>l.:.n .i'i4te

Tlln.lou

'l'tnlion Still!

Ten:>ion

Ten~on

Stitch

Stitd1 Rotatin&

Stiteh

Stitch

Stitch

Utat::k.£1

Du.:

Stud Nnt

lhac~t

Rat<Ltin&

Rotat~

R<Hating

RoJating

Stitch Rotating

Stitch Rotating

Stitch Rotating

Stitch

Rotating

Starting

Tdp

Lever

Startil~

Trip

Lever

Starlin&

Trip

Lever

Stitch Rotatlni

StaniJ~

Trip

Starting Trip

Starting Trip

Statting Trip

Lever

bver

Lever

Lever

Stitch Rotating

Stitch Rotating

Stitch Rotating

Stitch Rotating

Stitch Rotatmg

Stiteh Rotatillg

Al>~<iillbly

Set

Stxew

Gear

Rxl!.l:kllt

Geilt

~tacket

Hand

Lever

Hand.Levet

Hand

Gear

llrackot

Gear

Bracket

Gear

llKacket

Rod

(Intermediate)

Hinse

Han«

Hinge

Block

Block

Hand

Hand

Hand

Hand

Hand

Hand

(RiiJ'.

Not.

Shaft

Stu.ft

Lever

Shaft

&It

Po~tiQn

Screw

Lever

liand!e

Screw

· ·

Screw

Stlui

Lever

with fin&,

Lever

Set

Sccew

Lever

Hancih!

Lever

Handle

Lever

Hilncile

Leverlb,ndle

2

Ceaz

·

Ctar

~~

&;le\\1

Sl:HlW

·

Ptn

As.wmbl¥

Screvr

· · · ·

Sleev.,

SletW;J

Wilmer

Sl~;~ve

S1:1ew

(RI)f;

Page 21

----

Cord Spool &

Belt

Cover Compommts "

3

"@

I

{

I

\

5"

k

10

~

~

11

Description

Spool

Spool

Spindle

Spool Spindle Washer

Spool Spindle

Spool Bracket

Spool

friction

Spool

Friction

Spool

Friction

Spool

Bracket Sleeve with Screws

Spool Bracket Sleeve

Spool Bracket Sleeve

Cover

(Left)

Set

Screw

EXTRA

ACCESSORIES

Thumb

Nut

Sprin~

Spring Screw

Spring Adjusting Scxew

Set

Screw

Thrust

Bearing

12-

19)

.,

10

ll

"'12

'"13

"14

"15

"16

*17

*18

"'19

"20

l

2

3

4

5

6

7

8

9

Parts No.

8336

8331

70l2·A

8332

8487

8329

8140

4356

8448

98

8446

830

8503-1

8503-2

5276

8185

11554

5233

11557

8184

Cord

Cord

Cord

Cord

Cord

Cord.

Cord

Cord

Cord

Cord

Cord

Belt Cover Assembly (Ref. Nos,

Ddt

Bult Cover (Right)

Belt Cover

Belt Cover Washer

!ielt Cover Bracket

Belt Cover Bracket Set Screw

Belt Cover Bracket Wood Sctew

Belt Cover Wood Screw

"'

Ref. No.

8

-

fl

13

12

21

Page 22

Standard Accassories

3

~----~

6

-

~

Ref. No.

Pans

No.

AC~Ol

l

2

AC-02

AC-03

3

4

AC-04A

5

AC-05

6

AC-08

7

8166

8 8157

9

8165

8493

10

11

8126

8171 Plieu

12

13

8168

14

8170

8169

15

8499

16

17 8156

18

8497

19

5249

20

8073-B

8027-3

21

22

8501-4

23

8321-4

24 8505 Presser

25

8467 . Braid Spool (Metai)

26

8502

AC~~06

27

Description

Screw Driver (Large)

Screw Driver (Medium)

Sw1w Driver (Small)

Oller

ou

Acce~sory

Screw

Bed Clamping Thumb Screw

Machine Hinge Connection

Tool (for Adjustinz Hinge Stud #84SS)

Spool Screw Stud

Thread Knife

Twee1.er&

Machine Rest Pin (Wood)

Cleaning

Threader

Spool Winder Spindle

Spool Winder Spindle Washer

Presser

Needle

Nipple (for Chainstitching)

Nipple (for Tape·Attaching)

Spool

Wrench

Box

Eye

Wife

Wife

Foot

(l37xl

Foot

(Woo<!)

(3

mm)

J.~

Shoe (Rubber)

#3)

(Spur)

{fl

~

"'

. ,

~27

23

Page 23

f\iumerical Parts· List

Part$ No.

AC-01

AC.Q2

AC-03

AC-04A

AC.Q5

-

AC-n8

81 19

!=c.

98

c

•••

..

113-A

ll3·B

114-B

121

124

129·A

l29·B

131 3

132

805

806

808

810

811

821 13

822

!

__

824 3

826

827,827-1

.

830

~

831 . 5

At.Hll4-10

2SS3·A

4015

4031

4105

Parts

Pat:e

23

23

23

No.

4140-A

4173

4185 9

23 4356

23

23

21

.

5,13 5190·A

11 5207 11,19

11

13,19

5,9,13,17 5233 21

11,15

5,11,15,17 5262

..

3

17

17

19

19

19

17

9

9

21

1

5

1,5

5

-

11

5070 19

5162·B

5176·A

5176-A

5225-C

5227

5249

5266 3

5267·A 19

5276

8005-A

8006 3

8008 3

8009·A 3

8010 3

8012

8013 3

8014 3

8015 3

8017-B

8018 3

8020 5

8021

8Q22

8027

8030

Page

.

23

15

21

5,23

19

7

21

11-

5

19

19

9

1

3

3

3

5

5

5

Parts

No.

8036

8037.

8038

8042

8043

8044

8045

8046

8047 7

8048

8051

8052

8053

8054

8057 9

8059 9

806Q.A

8061 9

8063 7

8064 7

8065

8066

8067

8069·A 7

8070 7

8072 7

8073·B

·8075

8076

8077

8078

8079

8081

8083

Page

9,19

7,23

13

13

13

13

13

13

13

Parts

5

5

5.,

9

9

9

9

7

7

7

7

7

r-------~--~-+--------r-~~~-------+--~~1

8084

8088

8089-A

8090

• 8091

8092 17 8128 19 8175

8093

8094 · 17 8130-A 19 8117 11 I

8095-B

8096-A 17,19 8!32·A 19 8!79 = --··_._1_1._,.,.j

8097

8097·A 15,17 8136 7

~--------,_-------+----------r-~~--+---------+-----~~1

8098-B

8099

8100-A

8101

No.

9

7

7

7

8102

8103

8104

~---s_1o_s

r----s_I~o6

r---------1--------+---------~------~------·~~------~

t--~----;......-----

~---81_2_o

__ ~ _____

__

_,

8107 17 8150 1,5,17

8110·A 15,19 8152

8112-B

8113 19 8157

8114-A

S-8115-A 19

8116

8117 19

8118

8119

__

,_

8121 19 8166

8122 19 8168

Page

__

~_1_7

19

19

19

19

____

l9

Parts

13

17

17

17

No.

8123

8124

8125 19 · 8171 23 .

8126 23 8172 1,13

Page

19

19

l~h

No.

8169 23

8170 23

f~~

>

I.

17---~---8-l-27--~----l-9--+----8-l7-4---r~-ml~1-4.

17

17

15

17

17

17

17

17

17

17

l_7

13

__

__

__

+-

----------~~--~~

8129-A

8131 19 8178

8133·A

8138 7 8184

8139 7

8140 . 7,21 8304 . 9 I

8141

8142 13,15,17,19 8310.A 7

8143 17,19 8311

8145 s 8312 s

r-

___

8_1_46

__

~r-1~,1_1~,1_3,~l_sr-

+-

___

s_l_4_9

__

-r

8156

8158

8159

816o 1 8322·A 1 < r

8161 7 8329

8164 19

___

s_l_65~-+~--2_3~r----83

19

19

8!76

81tH

8!82

818:5

19

__

1_7~,1~9~+----8·~314~~----~s~

17

23

23

17

13

8308 s

___

s

__

31~3--~~~~s~

831.5

8316 · 1

831'7

8320.A S

8321-4 23

._:_-+---..--~

8332

__

3s

__

~----··S_

23

23

8336

.,

8339 s

..

.:. . . •.•

.. · ·.

21

a!'

21

17

11

11.

21

21

·.

..

1

1

s

7

1'

,-;

..

;

..

<

..

•••

...

···

.·

I

1

.

I·

I

· '

......

25

Page 24

·-

..

'

Parts No.

8403

8404

8405

1)406

~-

.

l

'~~-

!

.

r

;

8407

8408

~

8410

·:.8411'

~8412

.

8414

8415

8416

S·8417

.

.I!•UO

8421

8421·A

8423·A

8424

S·842.S

8421

8428

8429

8430

8431

8432

8433

8434

8435

13>417·1

8437·2

8437·3

S438

8439

---

Page

11

11

11

11

13

15

13

13

13

15

15

3

3

3

3

3

3

3

3

3

..

3

Parts

I

S-8444

$-8445

S·ll453 7

S·8456 5

'•

S·8462

8463 5 8504

1

15

15

15

15 8470

15

1

11

u.

u

11

11

11

8465

8466·A

8467

8472

8473

8474

i41S.C

8476

No.

8440

8441

8442

8443

8446

8448

8449

8452·.-1.

8454·A

8455 9

8457

8458

8459

8460

8461

8464

8477

8479

8480.A

Page Parts No.

11

-

11

13

13

17

11

11 8490

'5

15

15

15

15

9,23 10017-A

5

13

5

5

15

848l·A

8483

8484

8486

8487

1 8488

8489

8491

5

7 8495

5

5

5

5

1

1

5 •

5

3

8492-T

8493

8496

8497 13

8498·A s

8499

8501~4

8502

8503-1

8503-2

8505

8510.,AA

8514

11152

11554

11557

.

..

•

.

.

.

98·A

l3l.C

8188

8055

4078

7012·A

AC·06

F

,/

Page··

7

1

9

13

11

.11

11

11

uf

15

13

15

15

23

23

23

21

21

15

23

5

11

IS

5

21

21

3

l

7

7

15

21

23

J.

Loading...

Loading...