Connerton A-4F User Manual

Installation,

Operation &

Maintenance

Fine Cooking Equipment For Over 70 Years

MODEL A-4F OVER/UNDER BROILER

For Your Safety

Do NOT store or use gasoline or

other flammable vapors and liquids

in the vicinity of this, or any other

appliance.

After installation of your broiler, immediately contact your local gas supplier to obtain

information in the event the user of your equipment smells gas. This information must be

posted in a prominent location.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death.

Read the installation, operation and maintenance

instructions thoroughly before installing or servicing this

equipment.

To Purchaser

To User

Instructions

Warning!

RETAIN THIS MANUAL FOR FUTURE USE

Upon receipt of this broiler, inspect it thoroughly for any damage which may have occurred during

shipment. If damage is observed, contact the delivery agency immediately.

1. Preparation For Installation:

upon it’s proper installation. It should be installed in accordance with the National Fuel Gas Code

Z223.1

Installation must be made by a licensed plumber.

Initial setup must be made by a licensed service company.

A gas pressure regulator is supplied with your broiler. The regulator must be installed before connecting

broiler to gas supply line.

Install regulator in a drip-free area.

The broiler and it’s individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPa).

, these instructions, and applicable State and Local Codes.

Safe and satisfactory operation of the broiler depends, to a great extent,

Please note: air vent can plug with grease, thereby shutting gas supply off.

The Connerton Company

1131 E. Wakeham Avenue, Santa Ana, CA 92705-4145

Telephone: (714) 547-9218 Fax: (714) 547-1969

www.connertoncompany.com

Ceramic radiants are boxed and placed in grease pan for shipment. Remove top griddle plate and

carefully place them over top burners like a saddle.

2. Clearances And Ventilation:

adjacent to combustible walls. Minimum clearance from combustible construction; 6 inches from side

and 6 inches from back. 0 inch clearance sides and back for non-combustable locations.

Keep broiler area free and clear from combustibles.

The area in front of, and above the broiler must be clear to avoid obstruction of flow of combustion and

ventilation air. Means must be provided for adequate air supply and adequate clearance for air openings

into the combustion chamber.

Adequate clearances must be provided in front and sides of the broiler for servicing and proper

operation.

It is important that the broiler be installed under an exhaust hood which is adequate to remove the

products of combustion and cooking vapors. Sufficient make-up air must also be provided to the space

where the broiler is located to replace air removed through the exhaust hood.

3. Gas Piping:

arrow pointing toward the broiler. Connect outlet side of regulator to broiler. The regulator is set at 4 inch

w.c. on natural gas and 11 inch w.c. on propane gas. A 1/8” pressure tap is provided on the gas

manifold at the front of the broiler for checking the gas pressure.

plug with grease, thereby shutting gas supply off. Install regulator in drip-free area.

Connect broiler to the gas supply line. Under no circumstances should the gas supply line be smaller

than the inlet pipe on the broiler. A gas shutoff valve must be installed in the gas supply line upstream of

the broiler for complete shutdown and service. Use pipe sealant on all pipe joints. Sealant must be

resistant to the action of L.P. gasses.

Make sure the gas pressure regulator supplied with the broiler is installed correctly, with the

This appliance is design certified for installation on combustible floors and

Please note: air vent on regulator can

For proper performance, the broiler must be level. Adjusting feet are provided at the bottom of the legs.

Carefully level the broiler using “bubble” type level on top plate.

If the broiler is supplied with casters, the installation must be made with a connector that complies with

the Standard for Connectors For Moveable Gas Appliances ANSI Z21.69, and a quick-disconnect device

that complies with the Standard For Quick-Disconnect Devices For Use With Gas Fuel ANSI Z21.41.

Adequate means must be provided to limit the movement of the broiler without depending on the

connector and the quick-disconnect device or it’s associated piping to limit the broiler movement.

Restraining device should be connected to legs or back of body.

IMPORTANT: Check all gas connections for leaks, using a soap and water solution.

DO NOT USE AN OPEN FLAME FOR CHECKING PURPOSES

4. Lighting And Relighting Of Broiler:

A.

Turn gas valve and thermostat knob(s) located at the front of the broiler to “OFF”. Wait 5 minutes.

B.

Turn valve knobs marked lower to “ON”. Note: thermostat remains “OFF”.

C.

Turn pilot lighter valve adjusting screw(s) counterclockwise and light pilots. Adjust flame height to

approximately ¼”.

D.

To light top burners, turn valve knobs marked upper to “ON”. To light bottom burners, turn

thermostats to desired temperature.

E.

For complete shutdown, turn all gas valve knob(s) to “OFF” and turn pilot adjustment screw(s)

clockwise to shut off all gas supply to pilot light(s).

F.

To relight, repeat above procedures.

5. Care And Maintenance:

Contact Factory, factory representative, or a local service company to perform maintenance and repairs.

Please Note: Contact Factory before any warranty repairs are made.

Operator Notes:

1. Flexible Gas Line:

while installing same. Carefully follow instructions, using two wrenches. Also, do not operate broiler with

the inner track pulled out, as this will cause excessive wear and breakage of the flexible gas line.

2. Roller Bearings:

should be disassembled and all bushings be cleaned and re-greased.

3. Thermostat:

surface thermometer.

4. Pressure Regulator:

plugged. (Refer to section on preventative maintenance.) If this does not free the diaphragm and allow

the gas to flow through, the pressure regulator must be replaced.

5. Cleaning:

(See section on preventative maintenance for detailed cleaning procedures.)

A. To clean griddle plates, place a small amount of water on griddle while hot with long-handled

pot brush. ( .)

B. Remove stainless steel liners for cleaning.

C. Lift out grease chute from inside to clean.

D. Periodically (but not sooner than every 3 months) clean broiler burner ports and orifices. (

Make sure equipment is cold before removing.

E. Empty grease pan and clean broiler drawer. Follow these instructions to remove broiler drawer.

1.

Disconnect flexible gas connector from thermostat. Carefully hold inside hex nut with

wrench to avoid any bending or torquing of flexible line.

2.

Remove front bolt from bar on inner track that assembly rolls on.

3.

Pull inner track out to rear stop bolt.

4.

Lift off broiling griddle from drawer.

5.

Lift out broiler drawer through slots cut in inner track.

6.

Clean and replace in reverse order. Grease track with high-temp grease.

To prolong the life, it is important that the flexible gas line is not twisted or bent

Lubricate rollers every other day. To prolong life, once a year the entire mechanism

The thermostats can go out of calibration and should be checked periodically with a

If there is no gas, the pressure regulator is possibly frozen closed, or the vent is

DO NOT USE ICE

Note:

)

6. Cooking:

1. This is a broiler/griddle combination unit. The heat from the bottom broiler burners combined with

the radiated heat from the top burners cook the product simultaneously from the top and bottom

while the broiler drawer is in the “up-and-in” position for red meat, lower for chicken, fish and pork.

2. The broiler griddle/drawer moves in and out easily on heavy duty roller bearings for loading and

unloading. It is spring balanced for easy movement up and down; automatically stays in chosen

position

3. For optimal griddle operation, turn on griddle 30 minutes prior to use.

4. Set the top burner flame at 1/2 throttle using both the left and right side manual control knobs. Set

higher if radiants do not glow red.

5. Ensure that the flames are blue in color. (Slight orange flickering is normal, but yellow flame

indicates improper gas combustion. Yellow tips on blue flames are considered acceptable.)

6. Put the bottom grill plate in the down-and-in position, and set the thermostat control knob to 350º.

7. When not cooking, the drawers must be kept in the down position. It is very important to keep the

temperature of the bottom grill plate below 450º. If the drawer is in the up-and-in position while idle,

the grill surface can reach 650º, creating hot spots as well as producing a tough meat product.

8. When turning the bottom grills on or off, use the thermostat control knob. The lower control valves

are used only for complete gas shut-off. The top burner heat temperature is controlled by the left

and right control valve knobs.

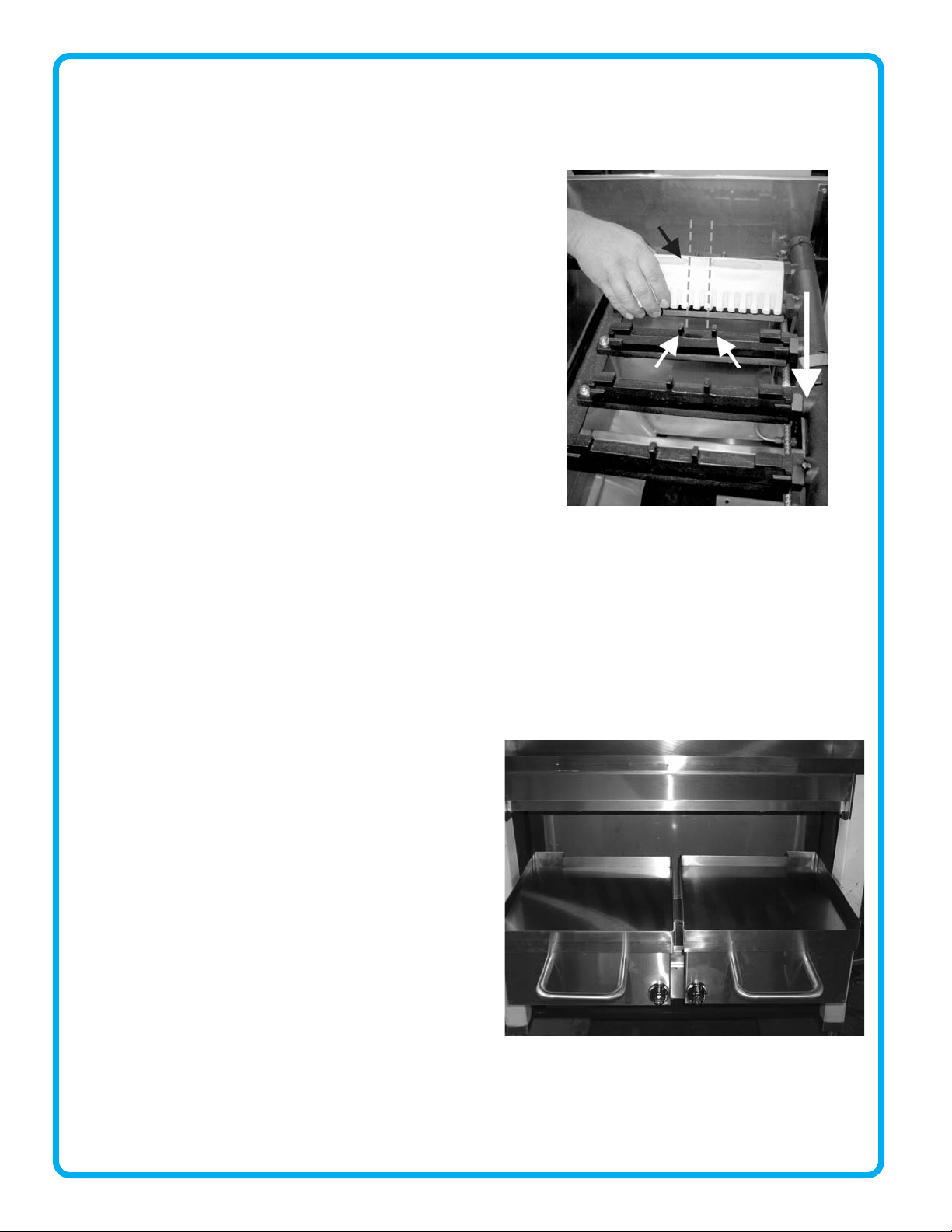

Installing Radiants:

Carefully remove radiant from it’s shipping

1.

container.

material and are easily chipped or broken.

2.

Position radiant over top burner, lower radiant onto

burner, aligning holes in the top of the radiant with

the tabs extending from the burner.

3.

Check radiant to make sure that it is centered and

resting on top of the burner, held in position by the

tabs on the burner.

Radiants are made from ceramic

NOTE:

DO NOT FORCE RADIANT ONTO BURNER.

This will cause the radiant to break. If the radiant

does NOT fit gently onto burner, contact the

Factory or your factory representative.

Installing Bottom Griddle Plate:

1. Position bottom griddle plate onto drawer frame

with grease chute facing rear of broiler.

Loading...

Loading...