Page 1

Xtreme/Multi-I/O

Users Guide

Connect Tech Inc.

42 Arrow Road

Guelph, ON CANADA

N1K 1S6

Tel: 519.836.1291

Toll Free: 800.426.8979 (North America Only)

Fax: 519.836.4878

Email: sales@connecttech.com

Web: www.connecttech.com

CTIM-00116 Revision: 0.02, Apr. 14, 2015

Page 2

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 2 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Table of Contents

Table of Contents ................................................................................................................................ 2

Customer Support Overview ............................................................................................................. 4

Contact Information ............................................................................................................................ 4

Limited Lifetime Warranty .................................................................................................................. 5

Copyright Notice ................................................................................................................................. 5

Trademark Acknowledgment ............................................................................................................. 5

Revision History .................................................................................................................................. 6

Introduction ......................................................................................................................................... 7

Configuration....................................................................................................................................... 8

USB Configuration File Method .................................................................................................................. 8

USB Virtual COM Port Configuration Method ........................................................................................ 11

Serial Port Configuration Method ............................................................................................................. 13

Configuration Commands ................................................................................................................ 14

Memory vs IO Spaces ................................................................................................................................ 14

Memory Space ................................................................................................................................. 14

I/O Space .......................................................................................................................................... 14

Board Address Decoding Capabilities ................................ .......................................................... 14

Command Groups ...................................................................................................................................... 14

Serial Ports (UARTS) ................................................................................................................................. 15

Serial Ports Enable / Disable .................................................................................................................... 16

Serial Port Clocking ................................ ................................ ................................................................ .... 16

Serial Port DTR DSR Wrapback .......................................................................................................... 16

RS422/485 (Port-5) Settings ..................................................................................................................... 17

CAN Ports (SJA1000) ................................................................................................................................ 18

CAN Port Clocking ...................................................................................................................................... 19

Board Configuration ................................................................................................................................... 19

J1708 Configuration ................................................................................................................................... 19

Misc Configuration ................................................................................................................................ ...... 20

IO Address Ranges set with IOD command ................................................................................ 20

Testing / Debugging ................................................................................................................................... 20

Operation ........................................................................................................................................... 21

MultiTech Modules ..................................................................................................................................... 21

Serial Ports (Uarts) ..................................................................................................................................... 22

Uart Registers ................................................................................................................................... 22

RS232 Serial Ports .......................................................................................................................... 23

RS422/RS485 Serial & J1708 Port ............................................................................................... 24

CAN Ports (SJA1000) ................................................................................................................................ 25

CAN Port Registers ......................................................................................................................... 26

LED Header ................................................................................................................................................. 27

Board Control/Status Registers ................................................................................................................ 28

INTR_STAT Register (Offset 0x00, read-only) ............................................................................ 28

RESET_CONT Register (Offset 0x00, write-only) ...................................................................... 28

PC104 Bus Test .............................................................................................................................................................. 28

LED_CONT Register (Offset 0x01, read-write) ........................................................................... 29

J1708 Bus Interface .......................................................................................................................... 30

Page 3

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 3 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Operation ..................................................................................................................................................... 30

Receiver ............................................................................................................................................ 30

Transmitter ........................................................................................................................................ 31

Detecting Transmission Errors or Potential Problems ............................................................................................... 31

Transmission Success ................................................................................................................................................... 31

J1708 Interrupts ............................................................................................................................... 32

Command, Control, Status Registers ...................................................................................................... 33

Command Register (Offset: 0x00) ................................................................................................. 33

Restart J1708 Bus SYNC .............................................................................................................................................. 33

Abort TX ........................................................................................................................................................................... 33

TX Kick ................................................................................................ ................................................................ ............. 33

Control Register (Offset: 0x01, Mem=0x04) ................................................................................ 34

Mask Reception of Good Transmitted Bytes .............................................................................................................. 34

TX Priority Register (Offset: 0x02) ................................................................................................................................ 34

TX Problem Limit Register (Offset: 0x03)..................................................................................... 34

J1708 Interrupt Status Register (Offset: 0x04) ............................................................................ 35

FIFO Status Register (Offset: 0x05) .............................................................................................. 35

RX EOM Level Register (Offset: 0x06) ......................................................................................... 36

RX Almost Full Level Register (Offset: 0x07) .............................................................................. 36

User-Ta Register (Offset: 0x08).................................................................................................... 37

Data FIFO’s ....................................................................................................................................... 37

J1708 IO ....................................................................................................................................................... 37

IO Connector & Jumper Locations ................................................................................................. 38

Serial Port-8 to Module GPIO Configuration .................................................................................. 39

Location of Resistors .................................................................................................................................. 39

FPGA Configuration Registers via SPI ........................................................................................... 40

Configuration Enhancements ................................................................................................................... 40

FPGA Configuration Registers ................................................................................................................. 41

PORT_CONFIG[N] (Reg 0 10) .................................................................................................. 43

IRQ_CONFIG[N] (Reg 12 16) ................................................................................................... 46

MEM_CONFIG (Reg 17)................................................................................................................. 47

MISC_CONFIG (Reg 18) ................................................................................................................ 49

FPGA_VERSION (Reg 19)............................................................................................................. 50

Page 4

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 4 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Customer Support Overview

If you experience difficulties after reading the manual and/or using the product, contact the Connect Tech

Inc. reseller from which you purchased the product. In most cases the reseller can help you with product

installation and difficulties.

In the event that the reseller is unable to resolve your problem, our highly qualified support staff can

assist you. Our support section is available 24 hours a day, 7 days a week on our website at:

www.connecttech.com/sub/support/support.asp. See the contact information section below for more

information on how to contact us directly. Our technical support is always free.

Contact Information

Mail/Courier

Connect Tech Inc.

Technical Support

42 Arrow Road, Guelph, ON

Canada N1K 1S6

Email/Internet

sales@connecttech.com

support@connecttech.com

www.connecttech.com

Note:

Please go to the Download Zone or the Knowledge Database in the Support Center on the Connect Tech

Inc. website for product manuals, installation guides, device driver software and technical tips.

Submit your technical support questions to our customer support engineers via the Support Center on the

Connect Tech Inc. website.

Telephone/Facsimile

Technical Support Representatives are ready to answer your call Monday through Friday, from 8:30 a.m.

to 5:00 p.m. Eastern Standard Time. Our numbers for calls are:

Toll Free: 800-426-8979 (North America only)

Telephone: 519-836-1291 (Live assistance available 8:30 a.m. to 5:00 p.m. EST, Monday to Friday)

Facsimile: 519-836-4878 (online 24 hours)

Page 5

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 5 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Limited Lifetime Warranty

Connect Tech Inc. provides a lifetime warranty for all of our products. Should this product, in Connect

Tech Inc.’s opinion, fail to be in good working order during the warranty period, Connect Tech Inc. will,

at our option, repair or replace this product at no charge, provided that the product has not been subjected

to abuse, misuse, accident, disaster or non Connect Tech Inc. authorized modification or repair.

You may obtain warranty service by delivering this product to an authorized Connect Tech Inc. business

partner or directly to Connect Tech Inc. along with proof of purchase. Product returned to Connect Tech

Inc. must be pre-authorized by Connect Tech Inc. with an RMA (Return Material Authorization) number

marked on the outside of the package and sent prepaid, insured and packaged for safe shipment. Connect

Tech Inc. will return this product by prepaid ground shipment service.

The Connect Tech Inc. lifetime warranty is defined as the serviceable life of the product. This is defined

as the period during which all components are available. Should the product prove to be irreparable,

Connect Tech Inc. reserves the right to substitute an equivalent product if available or to retract lifetime

warranty if no replacement is available.

The above warranty is the only warranty authorized by Connect Tech Inc. Under no circumstances will

Connect Tech Inc. be liable in any way for any damages, including any lost profits, lost savings or other

incidental or consequential damages arising out of the use of, or inability to use, such product.

Copyright Notice

The information contained in this document is subject to change without notice. Connect Tech Inc. shall

not be liable for errors contained herein or for incidental consequential damages in connection with the

furnishing, performance, or use of this material. This document contains proprietary information that is

protected by copyright. All rights are reserved. No part of this document may be photocopied,

reproduced, or translated to another language without the prior written consent of Connect Tech Inc.

Copyright 2013 by Connect Tech Inc.

Trademark Acknowledgment

Connect Tech Inc. acknowledges all trademarks, registered trademarks and/or copyrights referred to in

this document as the property of their respective owners.

Not listing all possible trademarks or copyright acknowledgments does not constitute a lack of

acknowledgment to the rightful owners of the trademarks and copyrights mentioned in this document.

Page 6

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 6 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Revsion

Date

Changes

0.01

June 11, 2013

Original

0.02

Apr. 14, 2015

Add/revise information in the “Configuration” section, to clarify some important

points.

Revision History

Page 7

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 7 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

ESD Warning

Electronic components and circuits are sensitive to

ElectroStatic Discharge (ESD). When handling any circuit

board assemblies including Connect Tech COM Express

carrier assemblies, it is recommended that ESD safety

precautions be observed. ESD safe best practices include,

but are not limited to:

Leaving circuit boards in their antistatic packaging

until they are ready to be installed.

Using a grounded wrist strap when handling circuit

boards, at a minimum you should touch a grounded

metal object to dissipate any static charge that may

be present on you.

Only handling circuit boards in ESD safe areas,

which may include ESD floor and table mats, wrist

strap stations and ESD safe lab coats.

Avoiding handling circuit boards in carpeted areas.

Try to handle the board by the edges, avoiding

contact with components.

Introduction

Connect Tech’s Xtreme/Multi-I/O features dual SJA1000 CANbus controllers, isolated serial and CAN ports, and

two MultiTech Universal compatible sockets on a single PC/104 board design. This high density communication

board offers an all-in-one communication solution, optimizing Size, Weight, and Performance requirements. This

innovative product takes full advantage of the latest technologies in jumperless configuration, high voltage isolation

and advanced communication functionality.

Page 8

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 8 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Configuration

This product can be configured for operation by 3 different modes.

1. In or Out of the target system, via a USB connection, using a configuration file.

2. In or Out of the target system, via a USB connection, using the Virtual COM port interface.

3. In the target system using an on-board serial port (which is usually accessed from the target system by

a Serial Port Driver software).

When the board is not installed in the target system, and then plugged into a USB port, a portion of the board’s

circuits are powered from the USB port which causes a (very small) USB Mass Storage Device and a Virtual

COM port interface to be available to the computer.

It is highly recommended that the USB port be used for configuring the board due to its simplicity.

USB Configuration File Method

When connected to a Windows computer the USB Plug&Play mechanism will automatically detect the

Xtreme/Multi-I/O as a small Mass Storage Device. This allows the board’s settings to be defined by a file

which is “placed” onto the storage device implemented on the product. The storage space is very limited

(about 8K bytes) and is only intended for the files related to the board’s setup.

The product is shipped with a default CONFIG.TXT file which has been placed there when the unit was tested.

This file is a good starting point for any customer desired settings.

Copy this file to some other folder on your computer system.

Edit the copy, and save it.

Delete the CONFIG.TXT file from the folder on the Xtreme/Multi-I/O board.

Copy the file back to the folder on the Xtreme/Multi-I/O board.

This file is processed (and the settings stored in non-volatile memory) as the file is streamed to the

board from the USB interface. The file cannot be edited directly on the device.

Remember, to change the configuration file, first delete it from the Xtreme/Multi-I/O board , then

copy a new file to the folder on the board.

If the board is “in” the target system (powered by the target system), then that system must be reset

(shutdown and powered back up) so that all the configuration changes will take effect.

If the board is “out of” the target system, then the settings are just retained for use when the board is

installed in the target system.

On power-up the on-board FPGA applies defaults for all configuration settings, and then, within 500

mS, the PIC32 applies all the settings that have been stored.

Three files are used

CONFIG.TXT

o Is the file that contains the configuration commands (see sample on install disk).

o This file is processed as soon as the file is “placed” onto the USB drive, with results placed

into the ERRORS.TXT file.

ERRORS.TXT

o A file that shows results of processing the CONFIG.TXT file (after it has been read and

processed).

README.TXT

o A short reminder file about how to perform the configuration.

Page 9

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 9 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Page 10

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 10 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Typical CONFIG.TXT file:

U1P=0x300

U2P=0x320

U1I=10

U2I=10

RS1=E

RS2=E

RS3=E

RS4=E

RS5=E

RS6=E

RS7=E

RS8=E

UPD

Resulting ERRRORS.TXT file:

U1P = (IO) 0x0300

U2P = (IO) 0x0320

U1I interrupt set to 10

U2I interrupt set to 10

Page 11

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 11 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

USB Virtual COM Port Configuration Method

When the Xtreme/Multi-I/O USB port is connected to a Windows computer and combined with the supplied

inf file it will create a virtual serial port that can be accessed using a serial terminal program like putty,

realterm, or equivalent, to configure the port settings interactively.

This method is great for doing experiments with the board’s setup for your application. The final setting

choices could then the committed to a CONFIG.TXT file so that the settings can be applied to other boards

using the Configuration File Method (described above).

NOTE: Port settings like baud rate, bits etc. do not matter when configuring the board via the virtual serial

port

Setup commands are entered by typing them on the terminal application’s used interface, or by using the file

sending (or transfer) facility of that application.

Each command is processed upon pressing “ENTER” key (CR character) and feedback is given in an “OK” or

“ERROR” with details format.

IMPORTANT: In order to have the settings committed to Non Volatile memory the “UPD” command must be

the last command executed. Certain settings will take effect as soon as the UPD command is executed, but

some settings (which affect the PC/104 IO or Memory address settings or interrupt settings) will not take effect

until the board is reset (or powered down then up again).

Page 12

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 12 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Typical programming sequence:

CFG?

Xtreme/Multi-I/O Configuration

Firmware Version V1.00

FPGA Version A

Decode IO region is 10 bits

U1

U1P1 = (IO) 0x0300, 10

U1P2 = (IO) 0x0308, 10

U1P3 = (IO) 0x0310, 10

U1P4 = (IO) 0x0318, 10

U2

U2P1 = (IO) 0x0320, 10

U2P2 = (IO) 0x0328, 10

U2P3 = (IO) 0x0330, 10

U2P4 = (IO) 0x0338, 10

Uart Clock Setting = Mode 3 (1.8432MHz)

Uart 1 is ENABLED

Uart 2 is ENABLED

Uart 3 is ENABLED

Uart 4 is ENABLED

Uart 5 is ENABLED

Uart 6 is ENABLED

Uart 7 is ENABLED

Uart 8 is ENABLED

Port 5 termination enable/disable setting = T

Uart 1 DTR/DSR wrapback is CONNECTED

Uart 2 DTR/DSR wrapback is CONNECTED

Uart 3 DTR/DSR wrapback is CONNECTED

Uart 4 DTR/DSR wrapback is CONNECTED

Uart 5 DTR/DSR wrapback is CONNECTED

S1R?

Socket 1 RESET = NO

S2R?

Socket 2 RESET = NO

C1?

CAN1 = (IO) 0x0000, 255

CAN1 is DISABLED

C2?

CAN2 = (IO) 0x0000, 255

CAN2 is DISABLED

CM?

BASIC

Port 5 mode of operation set to J1708_MODE

Board base = (IO) 0x0ffe

CAN clock rate is currently set to 24MHz

J?

J1708 = (MEM) 0x00ff80, 255

Temperature is 301.65 K (28.50 C)

OK

DIS?

Invalid Command

RS8=D

OK

RS8?

Uart 8 is DISABLED

OK

SER?

SER

U1P1 = (IO) 0x0300, 10

U1P2 = (IO) 0x0308, 10

U1P3 = (IO) 0x0310, 10

U1P4 = (IO) 0x0318, 10

U2P1 = (IO) 0x0320, 10

U2P2 = (IO) 0x0328, 10

U2P3 = (IO) 0x0330, 10

U2P4 = (IO) 0x0338, 10

OK

UPD

OK

Page 13

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 13 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Serial Port Configuration Method

When the Xtreme/Multi-I/O is installed into a computer and Serial Port 8 is enabled, a terminal program can be

used to access the settings of the board much like the Virtual Serial Port method using the OS running on the

PC/104 stack. Use a terminal program like qtalk, minicom, realterm, etc to configure the port settings

interactively.

This method is also applicable to situations where the application needs to change certain settings dynamically

as part of the application’s operation. However, the primary PC/104 Bus settings (like IO/Memory addresses or

interrupts) would not be candidates for any dynamic operations.

NOTE: Because this method requires some settings to already be enabled, we do not recommend this as a

primary way to configure the board, but rather suggest using the USB port.

Each command is processed upon pressing “ENTER” key (CR character) and feedback is given in an “OK” or

“ERROR” with details format.

Page 14

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 14 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

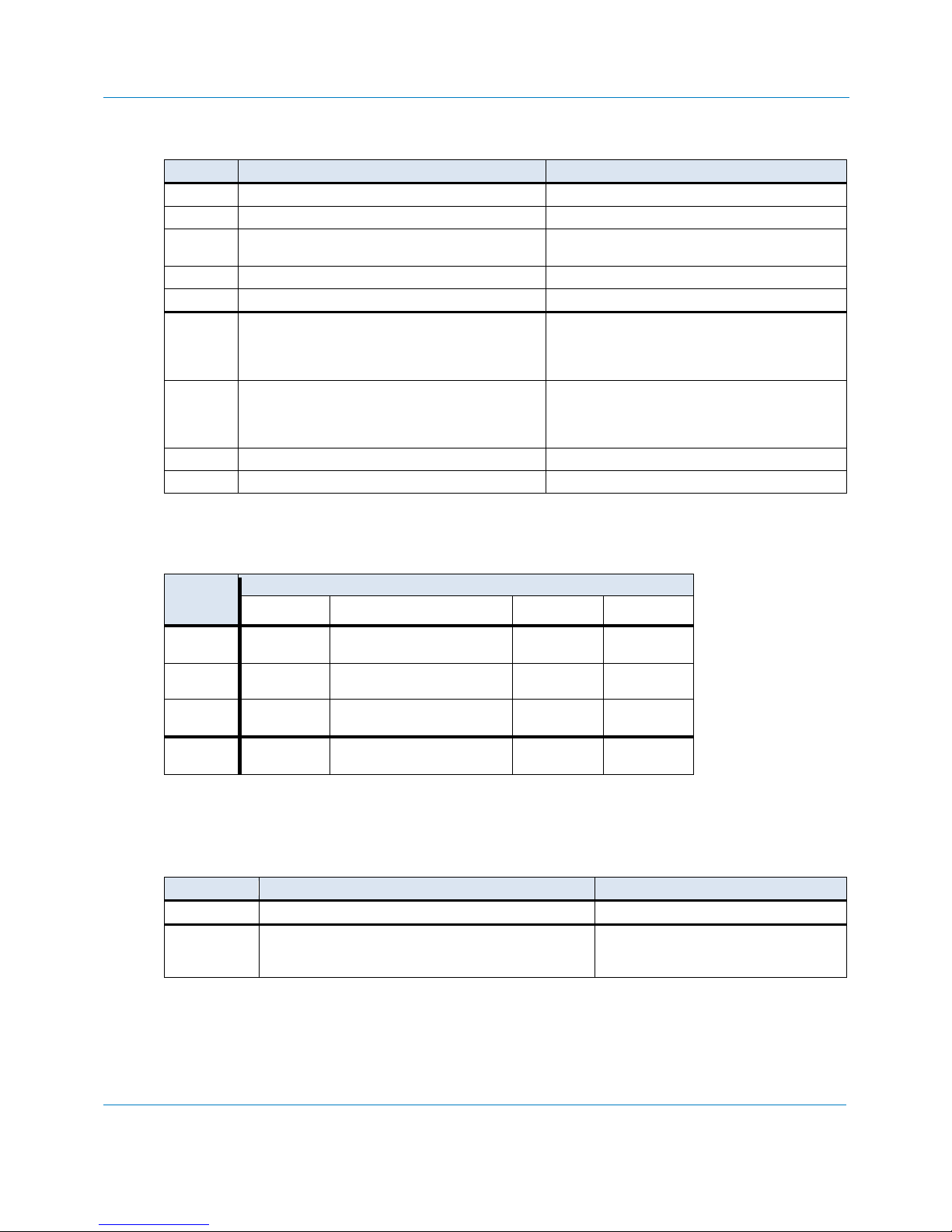

Group

Comment(s)

Serial Ports (UARTS)

Commands that set, or show, the Base Address (IO or Memory) or the IRQ assignments of

the UART Serial Ports.

Serial Ports Enable / Disable

Commands that allow individual serial ports to be Enabled or Disabled.

Serial Port Clocking

Commands that select, or show, a clock source for all Uart Serial Ports.

Serial Port DTR DSR

Wrapback

Commands that setup, or show the DTR to DSR wrapback on the chosen Port.

RS422/485 Port Settings

Commands that setup and show the RS422/485 Port settings.

CAN Ports (SJA1000)

Commands that set, or show, the Base Address (IO or Memory) or the IRQ assignments of

the CAN Ports.

CAN Ports Clocking

Commands that select, or show, a clock source for the CAN Ports.

Board Configuration

Commands to set, show the Base IO Address for the Board Control/Status Register.

J1708 Configuration

Commands to set, show the Base Address (IO or Memory) or the IRQ assignments of

J1708 Port.

Misc Configuration

Command to set, show a variety of miscellaneous settings.

Testing / Debugging

Commands that are used to test/debug the SPI interface between the PIC32 and FPGA.

Mainly used by software developers.

Configuration Commands

Memory vs IO Spaces

The first decision to make when configuring this board, is to determine whether the board will operate within

the Memory or I/O address Space of the computer system in which the board is installed. First, a quick

description of the two different Spaces.

Memory Space

Most (but not all) PC/104 CPU System board vendors provide one or more regions of Memory Addresses that

can be configured (or allocated) to the PC/104 Expansion bus connector(s) on CPU System board. This setup

may be performed via the BIOS setup or via jumpers or switches on the System board. This memory region is

usually located at addresses below the 1-Meg CPU memory address (commonly referred to as the Upper

Memory addresses), although some System boards allow the PC/104 Expansion Bus to be allocated to blocks of

addresses within the first 16-Meg of memory.

I/O Space

This region is supported by all PC/104 CPU System board vendors, and commonly consists of I/O Addresses

from 0x000 to 0x3FF, although some System boards support I/O addresses beyond 0x3FF, some even support

the full 16 bit IO range (0x0000 to 0xFFFF). (Note: Some I/O mapped PC/104 expansion boards only decode

the lowest 10 bits of the I/O address, therefore these boards restrict the usable I/O space to 0x3FF).

Board Address Decoding Capabilities

All the ports (Uart, CAN, J1708) of this board can be setup to reside in either IO or MEMORY space.

However, in most situations the Uart Serial Ports will be setup in IO space due to software limitations, and the

CAN Ports in MEMORY space because the SJA1000 devices have too many registers to fit easily in IO space.

The J1708 Port could be in either IO or MEMORY space as desired.

Command Groups

Page 15

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 15 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Command

Operation

Notes

SER?

Query all the Address and IRQ settings for

both Uarts (1 and 2), (Ports 1 through 8)

Un?

Query the Address and IRQ settings for a Port group

n = 1 for Ports 1 through 4

n = 2 for Ports 5 through 8

UnP?

Query the Address setting for a Port group

n = (as above)

UnPx?

Query the Address setting for a specific Port.

n = (as above)

x = 1,2,3,4 for a specific Port

UnI?

Query the IRQ setting for a Port group

n = (as above)

UnIx?

Query the IRQ setting for a specific Port

n and x = (as above)

UnP=v

Set the Address for a group of Ports.

See Note [1] below.

n = (as above)

v= Base Address value can be from:

See the IOD command for setting the IO decoding

width, and the resulting IO address range.

UnI=v

Set the IRQ for a group of Ports.

n = (as above)

v= one of these possible IRQ selections:

3,4,5,6,7,9,10,11,12,14,15

Serial Ports (UARTS)

These commands allow the 8 Uart Serial Ports to be configured with Address and IRQ assignments. The

assignments can also be queried.

Notes:

1. When the Address is entered as a single value (ie: U1P=0x300), then this is the Base Address for the group of Ports,

with each successive Port being set 0x08 bytes beyond the previous Port. (for this example: 0x300, 0x308, 0x310,

0x318). However, when the Addresses are entered as a comma separated list (ie: U2P=0x200,0x250,0x300,0x410),

then each Port is set to the Address value indicated.

2. Each enabled Port must have a unique Address which is at least 8 bytes away from any other Port’s Address.

3. All Uart Serial Ports can be set to the same IRQ number.

4. Ports are assumed to be IO Space if the address is entered as 3 or 4 HEX digits (ie: 0x300), otherwise Memory Space

if the address is longer (ie: 0xD0000).

5. The “0x” preceding an address value signifies HEX, otherwise decimal is assumed.

Page 16

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 16 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Command

Operation

Notes

RSn?

Query the Enable / Disable state of a Port.

n = 1 through 8

RSn=v

Set the Enable / Disable state of a Port.

n = (as above)

v = ‘E’ to enable the Port

‘D’ to disable the Port

‘C’ to connect port to PIC32 CPU (Port 8 only)

‘S’ to connect port to Module Socket-2 (Port 8 only)

note [2] below.

Command

Operation

Notes

UCD?

Query the Uart clock setting

UCD=v

Set the Uart clock setting

v = 0 (or ‘F’) for 14.7456 MHz

1 for 7.3728 MHz

2 for 3.6864 MHz

3 (or ‘S’) for 1.8432 MHz

Command

Operation

Notes

DSRn?

Query the DTR to DSR wrapback.

n = 1 through 5, Port number

DSRn=v

Set the DTR to DSR wrapback.

n = (as above)

v = ‘C’ = connected (enabled)

‘D’ = disconnected (disabled)

Serial Ports Enable / Disable

These commands allow the 8 Uart Serial Ports to be enabled or disabled. The assignments can also be queried.

When a port is disabled…

The respective Isolated Line Transceiver is turned-off, to reduce power consumption.

The decoding of the IO or Memory space is disabled.

The Port’s interrupt signal is disconnected (disabled) from asserting the IRQ.

Notes:

1. The LED Outputs obtain their isolated power from the Port-4 Isolated Line Transceiver, therefore

Port-4 must be Enabled to allow the LED outputs to operate properly.

2. The connections between Serial Port-8 and the GPIO pins of Module Socket-2 are implemented with

zero ohm resistors to select which GPIO pins to use (see the “Serial Port-8 to Module GPIO

Configuration”section for details).

Serial Port Clocking

These commands allow 4 different clock choices for the Uart Serial Ports. Both Uart (all serial ports) are

clocked from the same source.

Serial Port DTR DSR Wrapback

These commands allow the DTR signal to be wrapped back (connected) to the DSR signal for the first 5 Uart

Serial Ports. When the wrapback is disable, the DSR signal is held at the inactive state.

Page 17

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 17 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Command

Operation

Notes

P5?

Query the Port-5 mode of operation

RSZ?

Query the Termination state of Port-5

P5=v

Set the Port-5 mode of operation

v = ‘F’ for Full Duplex

‘H’ for ½ Duplex

‘J’ for J1708 mode

RSZ=v

Set the Termination state of Port-5

v = ‘T’ to enable the Termination

‘O’ to disable the Termination

See note [1] below.

RS422/485 (Port-5) Settings

Page 18

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 18 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Command

Operation

Notes

CAN?

Query all the Address and IRQ settings for

both CAN (1 and 2) Ports

Cn?

Query the Address and IRQ settings for a CAN Port

n = 1 for CAN1

n = 2 for CAN2

CnP?

Query the Address setting for a CAN Port

n = (as above)

CI?

Query the IRQ setting for both CAN Ports

CnI?

Query the IRQ setting for a CAN Port

n = (as above)

CD?

Query the CAN Port IO or MEMORY region setting

CM?

Query the CAN decoding mode as BASIC or PELICAN

CSn?

Query the Enable or Disable state of a CAN Ports

n = 1 for CAN1

n = 2 for CAN2

CP=v

Set the Address for a CAN Port

See Note [1] below.

v= Base Address value

See Note [3] below.

CI=v

Set the IRQ for both CAN Ports.

See Note [2] below.

v= IRQ selections:

3,4,5,6,7,9,10,11,12,14,15

CnI=v

Set the IRQ for a specific CAN Port.

n = (as above)

v= IRQ selections:

3,4,5,6,7,9,10,11,12,14,15

CD=v

Set the CAN Port decoding region.

v = ‘P’ for IO region decoded

‘M’ for MEMORY region decoded

CM=v

Set the CAN Port Address decoding mode.

v = ‘B’ for “BASIC” mode (0x20 boundary)

‘P’ for “PeliCAN” mode (0x80 boundary)

See Note [4] below.

CSn=v

Set the Enable / Disable state of a CAN Port

v = ‘E’ to enable the Port

‘D’ to disable the Port

CAN Ports (SJA1000)

These commands allow the 2 CAN Ports to be configured with Address and IRQ assignments. The

assignments can also be queried.

Notes:

1. When the Address is entered as a single value (ie: CP=0x400), then this is the Base Address for the group of Ports,

with the next Port being set Base+0x80 bytes. However, when the Addresses are entered as a comma separated list (ie:

CP=0x400,0x500), then each Port is set to the Address value indicated.

Examples:

o With CM=B, CP=0x400

CAN Port-1 = 0x400, CAN Port-2 = 0x480 (decoding width = 0x20)

o With CM=P, CP=0x400

CAN Port-1 = 0x400, CAN Port-2 = 0x480 (decoding width = 0x80)

o With CP=0x0C0000 (the CM setting is ignored)

CAN Port-1 = 0x0C0000, CAN Port-2 = 0x0C0080 (decoding width = 0x80)

o With CP=0x0C0000,0x0C2000 (the CM setting is ignored)

CAN Port-1 = 0x0C0000, CAN Port-2 = 0x0C2000 (decoding width = 0x80)

2. When the IRQ is entered as a single value (ie: CI=5), then this IRQ number is applied to both CAN Ports. However,

when the IRQs are entered as a comma separated list (ie: CI=9,11) then each CAN Port is set to the IRQ value

indicated.

3. The value specified for the CP= command implies either IO or Memory Space. When the value for the CP command

is a 3 digit IO address in Hex (0x000 to 0xFE0 or 0xF80), the IO Space is implied. When the value for the CP

command is a 6 digit Hex value (0x000000 to 0xFFFFE0 or 0xFFFF80).

decoding width, and the resulting IO address range.

See the IOD command for setting the IO

4. The address decoding mode is used only when the CAN Ports are mapped into and IO region (with CD=P). The

SJA1000 must be set to operate in the mode that matches this address decoding mode (see the CLOCK DIVIDER

REGISTER in the SJA1000 data sheet for details).

Page 19

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 19 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Command

Operation

Notes

CC?

Query the CAN clocking selection.

CC=v

Set the CAN clock selection.

v = 16 or 24 (value indicates the frequency in MHz)

Command

Operation

Notes

BP?

Query the Board Base IO Address setting.

BP=v

Set the Board Base IO Address setting.

v= Base Address value can be from:

See the IOD command for setting the IO decoding

width, and the resulting IO address range.

Command

Operation

Notes

J?

Query the J1708 Base Address and IRQ settings

JP?

Query the J1708 Base Address setting

JI?

Query the J1708 IRQ setting

JS?

Query the Enable / Disable state of the J1708 Port.

JP=v

Set the J1708 Port Base Address.

v= Base Address value

See Note [1] below.

See the IOD command for setting the IO decoding

width, and the resulting IO address range.

JI=v

Set the J1708 Port IRQ.

v= IRQ selections:

3,4,5,6,7,9,10,11,12,14,15

JS=v

Set the Enable / Disable state of the J1708 Port.

v = ‘E’ to enable the Port

‘D’ to disable the Port

See note [2] below

CAN Port Clocking

The CAN controller (SJA1000) can be clocked by 2 different frequencies.

Board Configuration

This product contains a group of registers that are used at “run-time” to perform a variety of functions. This

Command sets or shows the Base IO Address setting for these registers.

J1708 Configuration

On this product the J1708 controller is implemented within the FPGA and is separate from the Uart Serial

Ports. These commands allow the J1708 Port to be configured with Address and IRQ assignments. The

assignments can also be queried.

Notes:

1. The value specified for the JP= command varies depending on whether the IO or MEMORY region is desired for the

J1708 Port. When IO region is desired, the value for the JP= command is a 3 digit IO address in Hex (000 to FE0 or

F80). When MEMORY region is desired, the value is a 6 digit Hex value (000000 to FFFFE0 or FFFF80).

2. When the J1708 Port is disabled…

The decoding of the IO or Memory space is disabled.

The Port’s interrupt signal is disconnected (disabled) from asserting the IRQ.

Page 20

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 20 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Command

Operation

Notes

TRD?

Query the board temperature.

Value return is degrees Kelvin

CFG?

Query all configuration settings.

VER?

Query the PIC32 and FPGA firmware version.

PIC32 firmware version appears as “Vx.y”

FPGA version appears as a letter “A”, “B”, “C”, etc.

IOD?

Query the IO Address decoding range (or width).

SnR?

Query the reset state of the Module Sockets

IOD=v

Set the IO Address decoding width.

v = 10, 11 or 12

=10 performs “10-bit” IO decoding.

=11 performs “11-bit” IO decoding.

=12 performs “12-bit” IO decoding.

SnR=v

Set the reset state of the Module Sockets

v = ‘Y’ to Assert the reset

‘N’ to De-assert reset

n = 1 = Apply to Socket #1

2 = Apply to Socket #2

UPD

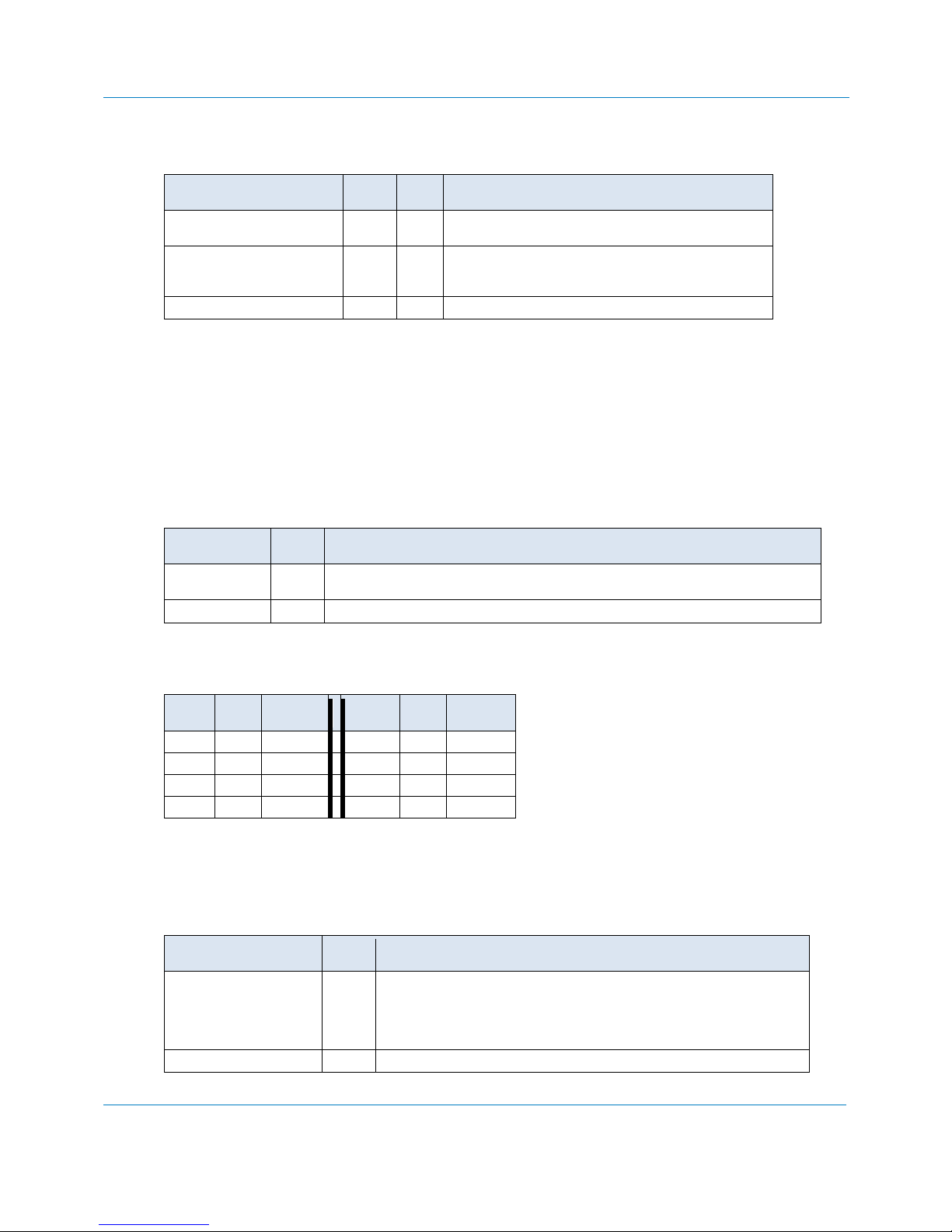

Write configuration changes to Non-Volatile storage

IO

Decode

Width

Base IO Address Range

Uart Ports

CAN Ports

J1708 Port

Board

10

0x000 to

0x3F8

0x000 to 0x3E0 (Basic mode)

0x000 to 0x380 (Pelican mode)

0x000 to

0x3E0

0x000 to

0x3FE

11

0x000 to

0x7F8

0x000 to 0x7E0 (Basic mode)

0x000 to 0x780 (Pelican mode)

0x000 to

0x7E0

0x000 to

0x7FE

12

0x000 to

0xFF8

0x000 to 0xFE0 (Basic mode)

0x000 to 0xF80 (Pelican mode)

0x000 to

0xFE0

0x000 to

0xFFE

Address

Boundaries

0x08

0x20 (Basic mode)

0x80 (Pelican mode)

0x20

0x02

Command

Operation

Notes

SPIR reg

Perform an SPI read operation from the indicated register.

reg is a decimal number 0 to N

SPIW reg value

Perform an SPI write operation to the indicated register.

reg is a decimal number 0 to N

value is a 16 bit HEX number as appropriate

for the register.

Misc Configuration

IO Address Ranges set with IOD command

The IO Address range depends on the IO Address decoding width.

Testing / Debugging

A couple of commands are available that directly write or read the FPGA registers that are accessed via an SPI

port between the PIC32 and the FPGA.

Page 21

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 21 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Operation

MultiTech Modules

Two Multitech wireless modules can be plugged into the top side of this board. Each communicates through a

serial port as described in the next section.

Refer to the “IO Connector & Jumper Locations”section for the locations of the Sockets.

Each module can be powered by either 5V or 3.3V by installing jumpers in the appropriate locations. Jumpers

are installed in pairs as shown below…

PCB Locations

Page 22

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 22 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Serial Ports (Uarts)

These serial ports are implemented with two, “554” style (quad) Uart devices, for a total of 8 serial ports.

These are used for various purposes on the board.

First Quad Uart

o Four isolated RS232 interface

o Port Order

1 = Header P1

2 = Header P2

3 = Header P3

4 = Header P4

Second Quad Uart

o One isolated RS422/RS485 Port

o Two ports connected to Module sockets P6 and P7

o One port connected to PIC32 (for Command line based configuration changes)

o Port Order

1 = RS422/RS485 to Header P5

2 = MultiTech module P6

3 = MultiTech module P7

4 = To PIC32

Uart Registers

Refer to the Exar ST16C554 data sheet for details of the Uart registers. A brief screenshot is shown here for

convenience.

Page 23

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 23 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Pin

Number

Signal

1

N/C 2 N/C

3

RxD

4

RTS 5 TxD

6

CTS

7

N/C 8 N/C

9

GND (Isolated)

10

+5V (Isolated), limited to 100 mA

RS232 Serial Ports

These 4 serial ports connect to Header group P1to P4 as indicated in the sketch below, as viewed from the edge

of the board. Each port can support bit rates up to 921.6K, and has xxxx V

from the main circuits.

[1]

of isolation, from each other and

N/C = Not Connected

Page 24

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 24 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Pin

Number

Signal

1

J1708+

2

J1708-

3

RX+ 4 TX+

5

TX-

6

RX-

7

Slow Slew Rate enable (strap to pin-9)

8

Termination Enable (strap to pin-10)

9

GND (Isolated)

10

+5V (Isolated), limited to 100 mA

RS422/RS485 Serial & J1708 Port

This serial port connects to Header P5 as indicated in the sketch below, as viewed from the edge of the board.

Each port can support bit rates up to 921.6K, and has xxxx V

[1]

of isolation, from each other and from the main

circuits.

When the J1708 Port is enabled (by the JS= command), this isolated interface circuit is re-commissioned for

the J1708 port. The IO header has special connection pins for the J1708 Port. Pins 3-4 and 5-6 must be

shorted so that the J1708 interface will operate properly.

Note: On the Rev.C version of the board, the Pins 3-4 and 5-6 connections are not required, instead a jumper

(J5) is provided to perform the signal shorting. Install 2, 50 mil jumpers on J5 as shown here…

Page 25

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 25 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Pin

Number

Signal

1

N/C

2

GND (Isolated)

3

CAN-

4

CAN+

5

GND (Isolated)

6

CAN+ (for termination strap)

7

CAN Bus Termination Resistor

(strap to pin-6)

8

+5V (Isolated), limited to 5 mA

9

N/C

10

N/C

CAN Ports (SJA1000)

These CAN Ports are implemented with industry standard SJA1000 devices. The CAN Bus interface circuits

are isolated from the other circuits on the board, and are connected to IO headers P9 and P10.

Each port can support bit rates up to 1M, and has xxxx V

circuits.

Both CAN controllers are clocked from the same source, which can be setup to be either 16 MHz or 24 MHz.

[1]

of isolation, from each other and from the main

Page 26

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 26 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

CAN Port Registers

Refer to the NXP SJA1000 data sheet for details of the CAN Controller registers. A brief screenshot is shown

here for convenience.

Page 27

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 27 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Pin

Number

Signal

Primary Function

Secondary Function

1

LED1-

Link-Activity from Module-1 (P6)

Software driven, from register in FPGA

2

LED1+

3

LED2+

Link-Activity from Module-2 (P7)

Software driven, from register in FPGA

4

LED2-

5

LED3+

From GPIO (pin-51) Module-2 (P7)

Software driven, from register in FPGA

6

LED3-

7

LED4+

Uart ports operating at highest

clock rate (14.7456 MHz)

Software driven, from register in FPGA

8

LED4-

9

LED5+

Software driven, from PIC32

Software driven, from PIC32

10

LED5-

LED Header

Five LED’s can be connected to the P11 header. The LED drive circuit is isolated from the other circuits on the

board, and gets its power from the P4 serial port isolator (U24). Port-4 must be enabled (see the “Serial Ports

Enable / Disable” section for details) so that power is available for the LED outputs.

Each LED is current limited on the board to approximately 6.5 mA.

Notes:

1. The software driven function of LED’s 1 through 4, is described in the “LED_CONT Register (Offset

0x01, read-write)” section.

Page 28

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 28 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

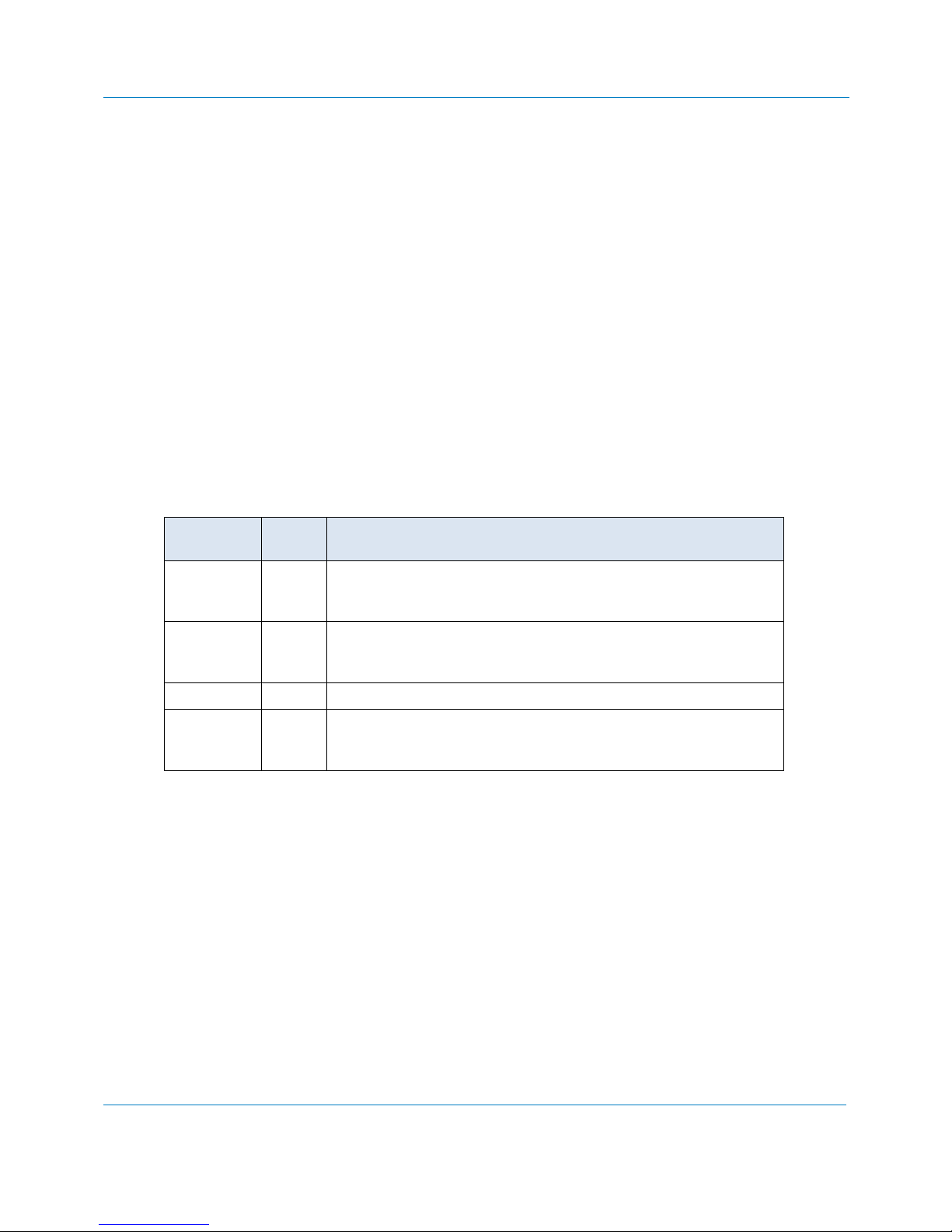

Register

Function

IO Offset

INTR_STAT

Interrupt Status

0x00 (read-only)

RESET_CONT

Reset Control

0x00 (write-only)

LED_CONT

LED Control

0x01 (write-read)

Control Item

Bit

Offset

Bit

Value

Comment(s)

Uart Group-1

0

0x1

Uart Ports 1 through 4 interrupt is active

Uart Group-2

1

0x2

Uart Ports 5 through 8 interrupt is active

CAN Port-1

2

0x4

CAN Port 1 interrupt is active

CAN Port-2

3

0x8

CAN Port 2 interrupt is active

J1708 Port

4

0x10

J1708 Port interrupt is active

Unused

5 7

Reserved for future use

Control Item

Bit

Offset

Bit

Value

Comment(s)

PIC32_RST

0

0x1

PIC32 Microcontroller Reset

Uart Group-1_RST

1

0x2

Uart Ports 1 through 4 reset

Uart Group-2_RST

2

0x4

Uart Ports 5 through 8 reset

CAN Port-1_RST

3

0x8

CAN Port 1 reset

CAN Port-1_RST

4

0x10

CAN Port 2 reset

Module-1_RST

5

0x20

MultiTech Module-1 reset

Module-2_RST

6

0x40

MultiTech Module-2 reset

BUS_TEST

7

0x80

PC104 Address Bus test mode enable

Board Control/Status Registers

Implemented in the FPGA is 2 registers which assist with the operation of the board. The Base PC/104

IO-Address for these registers is defined by the BP= command.

INTR_STAT Register (Offset 0x00, read-only)

Software can use the Interrupt Status register to determine which interrupts are active. All bits are

“active-high”.

RESET_CONT Register (Offset 0x00, write-only)

Software can use the Miscellaneous Control register to reset various circuits on the board. Writing a “1” to the

respective bit, will hold the reset on the respective circuit.

PC104 Bus Test

This bit enables a mode where the PC104 Address Bus signals can be confirmed as functioning. This bit

should be set to zero for normal operation of the board.

Page 29

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 29 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Control Item

Bit

Offset

Bit

Value

Comment(s)

LED1_STATE

0

0x1

=0, LED Off (after approximately 75 mS)

=1, LED On immediately

See Note [2] below

LED1_ENAB

1

0x2

=0, Primary LED function is active

=1, LED operation controlled by the LEDn_STATE bit.

See Note [1] below

LED2_STATE

2

0x4

Same as above for LED2

LED2_ENAB

3

0x8

Same as above for LED2

LED3_STATE

4

0x10

Same as above for LED3

LED3_ENAB

5

0x20

Same as above for LED3

LED4_STATE

6

0x40

Same as above for LED4

LED4_ENAB

7

0x80

Same as above for LED4

LED_CONT Register (Offset 0x01, read-write)

This register provides the secondary LED functions for the LED header (P11).

Notes:

1. The ENAB bit(s) allows software to take control the LED outputs (1 to 4). The primary function of the

LED is inhibited when the ENAB bit is On.

2. The LED output remains ON for as long as the STATE bit in ON (=1). When the STATE bit is turned

OFF, a timer in the FPGA hardware holds the LED output ON for 50 to 100 mS. This allows software to

“blink” an LED without needing to perform any timing.

Page 30

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 30 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

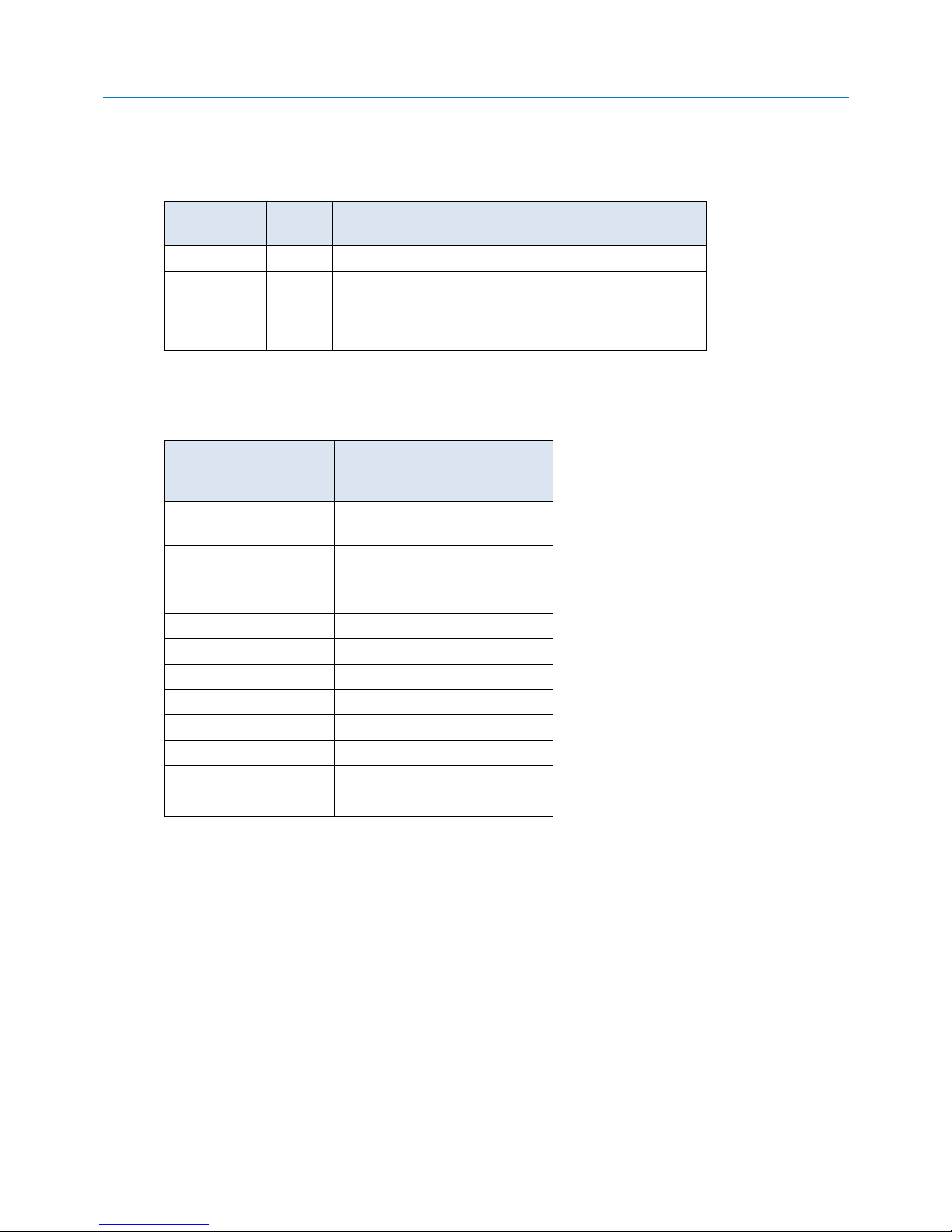

Control Item

Address Offset

Command, Control, Status Registers

0x00 0x0F

Data FIFO’s

0x10 0x1F

J1708 Bus Interface

Operation

The J1708 specification goes to significant detail about the requirements of the J1708 Bus interface, this

section elaborates on the specifics of this implementation of that interface. The J1708 specification should be

consulted to get a general sense of the nature of this communications protocol before continuing with the

description below.

The J1708 controller is implemented entirely in the FPGA. It consists of three (3) tightly coupled control

blocks; the Transmitter, Receiver and Interrupt Generator. The Transmitter and Receiver blocks share a

common Data Bit PLL clocking mechanism which clocks data bits at 9600 bps.

By its nature, the J1708 Bus is a ½ Duplex Bus, which causes any transmitted bits to also be received. It is this

behaviour that allows transmitted bytes to be checked for collisions with other bits being transmitted by other

device(s) on the J1708 Bus.

Receiver

The Receiver consists of a PLL clock recovery block, a control state machine, data bit shifting block and

controlling registers. The clock recovery block finds falling edges within the receive data stream and uses them

the align the phase of the data clock, in order to properly receive the data bits. This clock is also used by the

Transmitter.

Upon power up (or when the Restart J1708 Bus SYNC command is issued) the Receiver will begin hunting for

19 consecutive Bus Idle periods. During this time both the Receiver and Transmitter will not receive/send any

data bits. Once 19 Idles are found the Receiver and Transmitter become operational.

Data bytes are framed in the usual asynchronous fashion, ie: 1-START bit, 8 data bits, 1-STOP bit.

When a legal START bit is detected, the following data bits are shifted into the Receiver data shift register

(only 8 bits are collected). The following bit is considered to be the STOP bit, and if it is legal (=1) the data

byte is placed into the FIFO.

Note: Because the J1708 Bus is ½ duplex, any transmitted bits are also received. This implementation

can either store the transmitted bytes into the Receiver FIFO, or can mask (prevent) them from being

stored. This feature is controlled by the Mask Reception of Good Transmitted Bytes control bit. Refer to

the Control Register section below for more details. Even with this feature enabled, the Receiver

always receives the transmitted bits, so that error conditions in the Transmitter can be detected.

Messages are groups of one or more data bytes that can be considered to belong together. Since there are no

delineating features in the data bytes themselves, the only feasible way to delineate (separate) received

messages is by determining when the J1708 Bus has gone Idle for a certain amount of time. The RX EOM Level

register allows the host software to be notified when the desired Bus Idle interval has been reached (via and

interrupt), so that data can be retrieved from the Receiver FIFO.

Various Receiver conditions cause an interrupt to be generated. The situations/conditions that generate

interrupts are covered in more detail later in the J1708 Interrupts section, but are listed here for reference…

Receiver EOM (End of Message)

Page 31

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 31 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Receiver FIFO Almost Full

Receiver FIFO Full

Transmitter

The Transmitter consists of a control state machine block, data bit shifting block, and controlling registers. It is

clocked by the Data Clock that is recovered by the Receiver. In this way the starting of a transmitted message

can be accurately timed from the end of the last message “seen” on the J1708 Bus. This accurate timing is the

essence of J1708 Bus messaging.

Transmission starts as soon as data byte(s) are written to the Transmitter FIFO, however the actual bit

transmission is delayed until after the J1708 Bus has been Idle for a certain amount of time. This time is

measured in Bit intervals from the end of the last message “seen” on the J1708 Bus. The duration of the delay

is controlled by the TX Priority register setting, and by a collision and re-transmission algorithm (which delays a

random number of Bus Idle periods). In special circumstances a user controlled delay can be setup (with the

User-Ta register setting).

Software Implementation Note:

An alternate method to “kick off” Transmitter activity, is by using the TX Kick command, which causes the

TX FIFO Empty interrupt to occur. In response to this interrupt, software can load data into the TX FIFO,

which causes the transmission to begin.

Transmission continues until one of 3 situations occur.

The Transmitter FIFO becomes empty.

An error is detected in the data bytes sent.

The software issues an Abort TX command.

Detecting Transmission Errors or Potential Problems

Since multiple devices can begin their bit transmissions at the same (or nearly same) point in time, there is a

variety of transmission issues that are detected and acted upon by the this J1708 controller. The detection is

possible because all transmitted bits are also received. At each byte boundary the byte sent is compared to the

byte received.

1. In circumstances where there is heavy data traffic on the Bus, there may be situations where the

transmission of a message cannot begin because there is never a sufficiently long enough Idle period

on the bus. Each time a transmission is refused (preempted) by another transmission on the bus, this

condition is counted in a “TX Problem” counter. Also, if a collision occurs while the first byte of the

message is being transmitted, then again, this problem counter is incremented. This problem counter

value is compared against the TX Problem Limit register value. If the limit is reached an interrupt is

generated to the software. With the collision scenario, the Transmitter will again delay for the

required amount of Idle periods and attempt to re-send the message. This process repeats (forever)

until the transmission start is successful or software takes some action (in response to the problem

interrupt).

2. In rare circumstances there may be a collision on the Bus after the first byte is successfully sent. In

this case the Transmitter self aborts as soon as the current byte is finished, the Transmitter FIFO is

flushed (emptied) and the TX Abort interrupt occurs.

This TX Problem counter is reset (to zero) when the first byte of a new/next message (packet) is

loaded from the FIFO into the TX data shift register.

Transmission Success

In the absence of any errors or commanded aborts, the Transmitter will continue sending data bytes until the

data FIFO is empty. When the last bit of the last byte is sent, this is the moment in time where the transmission

Page 32

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 32 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

of a “message” is deemed to have finished, any further data placed into the FIFO is treated as the “next”

message and will wait for the appropriate J1708 Bus Idle interval. The application software is notified by the

generation of the TX Success interrupt. This interrupt occurs just after the last bit of the last byte is sent (during

the STOP bit).

J1708 Interrupts

A variety of events are detected during the operation of the J1708 controller. These events are reported to the

software via interrupts. These interrupts are…

TX Success

TX Aborted

TX Problem

TX FIFO Almost Empty

TX FIFO Empty

RX FIFO Almost Full

RX FIFO Full

RX EOM

Details of these interrupts can be found in the section for the J1708 Interrupt Status Register.

Page 33

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 33 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Register Name

IO

Address

Offset

MEM

Address

Offset

Access Comments

Command

0x00

0x00

R/W(1)

Control

0x01

0x04

R/W

TX Priority

0x02

0x08

R/W

TX Problem Limit

0x03

0x0C

R/W

J1708 Interrupt Status

0x04

0x10

R/W(1)

FIFO Status

0x05

0x14

RO

RX EOM Level

0x06

0x18

R/W

RX Afull Level

0x07

0x1C

R/W

User-Ta

0x08

0x20

R/W

Control Item

Bit

Offset

Bit

Value

Comment(s)

Restart J1708 Bus SYNC

0

0x1

Bit clears when the Receiver enters the SYNC state

Abort TX

1

0x2

Bit clears when Abort is completed

TX Kick

2

0x4

Force the generation of the TX FIFO Empty interrupt

Unused

3 31

Not used

Command, Control, Status Registers

These registers provide the complete control and operation of the J1708 port.

R/W Read or Write, unused bits are ignored on write, and return zero’s on read.

RO Read only, unused bits return zero’s

R/W(1) Read or Write, Writing a zero (0) has no effect. Unused bits are ignored on write, and return

zero’s on read.

Command Register (Offset: 0x00)

This register is setup so that it’s control bits operate independently. Only when a one (1) is written to the

appropriate bit, does the indicated action take place. Writing a zero(0) to a bit has NO effect. All bits in this

register will self-clear when the operation takes place.

Restart J1708 Bus SYNC

This bit will restart the J1708 Bus re-synchroniation process. See the above Operation section for details.

Abort TX

This bit causes the Transmitter to abort sending bytes as soon as the current byte has been completely sent. The

Transmitter FIFO is also flushed (emptied) by this command.

TX Kick

This bit causes the TX FIFO Empty interrupt to occur, but only if the TX FIFO is actually empty at the time

when the TX Kick command is issued. If the TX FIFO is not empty, then this command is ignored, and the TX

FIFO Empty interrupt will occur when the TX FIFO gets to the empty point (or some other TX event occurs,

which terminates the transmission).

Page 34

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 34 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Control Item

Bit

Offset

Bit

Value

Comment(s)

Mask Reception

of Good Transmitted Bytes

0

0x1

Bytes that are transmitted without error are not placed into

the receiver FIFO.

Port Enable

1

0x2

1=Enable the J1708 port

0=Port disabled… Interrupts won’t occur, RX is inhibited,

and TX will consume any data placed into the TX Fifo.

Unused

2 7

Not used

Control Item

Bit

Offset

Comment(s)

TX Priority Value

0 2

Values of 0 to 7 represent the 8 priority levels, with “0” being the highest priority.

Default value is “7” (lowest priority).

Unused

3 7

Not used

Spec

Priority

Reg

Value

Bus

Idles

Spec

Priority

Reg

Value

Bus

Idles

“1” 0 12 “5” 4 20

“2” 1 14 “6” 5 22

“3” 2 16 “7” 6 24

“4” 3 18 “8” 7 26

Control Item

Bit

Offset

Comment(s)

TX Problem Limit Value

0 7

Values of 2 to 254 (even numbers only) represent the limit point at which the

number of TX problems will cause an interrupt.

Non even numbers written will be rounded down to the next lowest even

number. A value written less than 2 will be set to 2.

Default value is 10.

Control Register (Offset: 0x01, Mem=0x04)

This register has bits the influence the operation of the J1708 interface.

Mask Reception of Good Transmitted Bytes

Because the J1708 Bus is ½ duplex, any transmitted bits are also received. When this bit is set (=1), bytes that

are transmitted without error, are NOT placed into the Receiver FIFO. This reduces the data processing burden

on the host CPU.

TX Priority Register (Offset: 0x02)

This register sets the priority for all transmitted messages. (see the J1708 specification for details about the

meaning of “Priority”). This setting controls how long the J1708 Bus must be Idle before a transmitted

message can begin. This Idle period is measured in Bit Intervals.

Each priority value translates into a number of Bus Idle periods as follows (see J1708 specification for more

details)…

TX Problem Limit Register (Offset: 0x03)

This register is used to set the threshold for Transmitter problems that will cause an interrupt. See the above

Detecting Transmission Errors or Potential Problems section for more information about Transmitter

problems.

Page 35

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 35 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Control Item

Bit

Offset

Bit

Value

Comment(s)

TX Success

0

0x1

A transmitted message has completed successfully.

TX Aborted

1

0x2

A transmission error was detected, and transmission was aborted.

TX Problem

2

0x4

“N” transmission problems have been counted.

“N” is set by the TX Problem Limit register

TX FIFO Almost Empty

3

0x8

Transmitter FIFO has reached the Almost empty point

Occurs when less than 4 bytes remain in the Transmitter FIFO

TX FIFO Empty

4

0x10

Transmitter FIFO has been emptied.

This interrupt can also be initiated by the TX Kick command.

RX FIFO Almost Full

5

0x20

Receiver FIFO has reached the “Almost Full” level as defined by the

RX Almost Full Level Register.

Remaining FIFO space is 512-N, where N is defined by the RX Almost Full

Level Register.

RX FIFO Full

6

0x40

Receiver FIFO is Full (not a desirable situation)

RX EOM

7

0x80

Receiver EOM detected.

Control Item

Bit

Offset

Bit

Value

Comment(s)

TX FIFO Empty

0

0x1

Outgoing message FIFO is empty

TX FIFO Almost Empty

1

0x2

Outgoing message FIFO is almost empty

Occurs when less than 4 bytes remain in the Transmitter FIFO

TX FIFO Almost Full

2

0x4

Outgoing message FIFO is almost full

Remaining FIFO space is 512-16 = 496 bytes

TX FIFO Full

3

0x8

Outgoing message FIFO is full (NO space)

RX FIFO Empty

4

0x10

Incoming message FIFO is empty

RX FIFO Almost Empty

5

0x20

Incoming message FIFO is almost empty

Occurs when less than 4 bytes remain in the Receiver FIFO

RX FIFO Almost Full

6

0x40

Incoming message FIFO is almost full

Remaining FIFO space is 512-N, where N is defined by the RX Almost Full

Level Register.

RX FIFO Full

7

0x80

Incoming message FIFO is full (NO space)

J1708 Interrupt Status Register (Offset: 0x04)

This register is used as both an indication of which J1708 interrupts are active, and as a method of clearing

selected interrupts. An interrupt is cleared by writing a “1” to its bit (writing a zero has no effect). Reading this

register clears the J1708 interrupt signal that is routed to the PC/104 Interrupt.

FIFO Status Register (Offset: 0x05)

The Transmitter and Receiver FIFO’s have signals that indicate the state of the respective FIFO, these can be

accessed through this (read-only) register. These signals are useful for software operations that read or write to

the data FIFO’s. The state transitions of some of these signals are used to generate interrupts (see above).

Page 36

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 36 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Control Item

Bit

Offset

Comment(s)

RX EOM Level value

0 3

Values of 0 to 15, although a value lower that 3 would probably give false EOM

interrupts.

Default value is 6.

Unused

4 7

Not used

Control Item

Bit

Offset

Comment(s)

RX Almost Full Level value

0 4

Values of 1 to 31.

Writing a value of zero will be ignored, and the current value will be retained.

Default value is 16.

Unused

5 7

Not used

RX EOM Level Register (Offset: 0x06)

As described in the Receiver section above, this register sets the number of Bus Idle intervals that are desired

to cause an RX EOM interrupt.

RX Almost Full Level Register (Offset: 0x07)

As bytes enter the Receiver FIFO they are counted. When the count reaches the threshold set in this register,

the RX FIFO Almost Full interrupt is generated. This allows software to empty the data FIFO periodically during

the reception of a message.

Software Implementation Notes:

The range of values for this register seems a little low, considering that the FIFO is 512 bytes deep. But it’s

been setup this way because most J1708 messages are relatively short. This value should be set to

correspond to the typical (or average) received message length.

Using the RX FIFO Almost Full interrupt is somewhat optional, the RX EOM interrupt could be used

exclusively in many applications.

Page 37

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 37 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

Control Item

Bit

Offset

Bit

Value

Comment(s)

User-Ta value

0 4

---

R/W

Values of 0 to 31.

User Ta in effect

5

0x20

RO

0= Priority derived Bus access.

1= User specified Bus access (User-Ta value is

in effect).

Ignore Ta in effect

6

0x40

RO

0= Some Bus access delay is being used.

1= No access delay will be used (data collisions

can occur).

Unused

7

---

Not used

Register Name

Address

Offset

Access Comments

TX FIFO (512 bytes)

0x10 0x1F

Write accesses

RX FIFO (512 bytes)

0x10 0x1F

Read accesses

User-Ta Register (Offset: 0x08)

Normally the transmission of bytes does not begin until a specific number of J1708 Bus Idle periods have

occurred (controlled by the TX Priority register setting). Under special circumstances it may be appropriate to

use this register to override the normal “priority/random” Bus access mechanisms.

Values 1 to 31 cause the transmitter to wait the specified number of Bus Idles before transmitting. Values

below 12 and above 26 (and odd values between 13 and 25) are outside the range specified by J1708 and must

be used with caution/wisdom.

Setting this register to zero has special meaning. It causes the transmitter to begin transmission immediately

(as soon as data is placed in the data FIFO), which can cause a collision with data being transmitted by some

other device. This feature is mainly useful for testing scenarios. When this condition exists, the Ignore Ta bit

in the Control register will read as a one (1).

To place the transmitter back into its normal “priority” derived delay mode, the TX Priority register value must

be written with an appropriate value. (ie: the current value could be read and written back to the register).

Data FIFO’s

The data FIFO’s for the J1708 controller are 512 bytes in length. There is one FIFO for the Receiver and one

for the Transmitter.

Although the FIFO’s are addressed over a range of offsets, there is no requirement to write/read from

consecutive offsets, however the FIFO’s can be addressed as consecutive locations, if that is more convenient

for software. Writes (or reads) from any offset in the range will cause bytes to be placed into (or removed

from) the FIFO’s.

J1708 IO

The J1708 Port shares the isolated IO circuits with the RS422/RS485 Port. When the J1708 port is enabled (by

the JS= command), the P5 connector becomes the J1708 port connection point. See the “RS422/RS485 Serial

& J1708 Port” section for details of the electrical connections and jumpering.

Page 38

Connect Tech - Xtreme/Multi-I/O - Users Guide

Document: CTIM-00116

Revision: 0.02 0.02

Page 38 of 50

Connect Tech Inc. Proprietary Information

Date: Apr. 14, 2015

IO Connector & Jumper Locations

Page 39

Connect Tech - Xtreme/Multi-I/O - Users Guide