Page 1

Blue Heat/Net Sync

User Manual

Ethernet-to-Serial Synchronous Communications

Connect Tech Inc.

42 Arrow Road

Guelph, Ontario

N1K 1S6

Tel: 519-836-1291

Toll: 800-426-8979 (North America only)

Fax: 519-836-4878

Email: sales@connecttech.com

support@connecttech.com

Web: www.connecttech.com

CTIM-00044 Revision 0.03 , July 8, 2010

Page 2

Connect Tech Blue Heat/Net Sync User Manual

Limited Lifetime Warranty

Connect Tech Inc. provides a Lifetime Warranty for all Connect Tech Inc. products. Should this

product, in Connect Tech Inc.'s opinion, fail to be in good working order during the warranty

period, Connect Tech Inc. will, at its option, repair or replace this product at no charge, provided

that the product has not been subjected to abuse, misuse, accident, disaster or non Connect Tech

Inc. authorized modification or repair.

You may obtain warranty service by delivering this product to an authorized Connect Tech Inc.

business partner or to Connect Tech Inc. along with proof of purchase. Product returned to

Connect Tech Inc. must be pre-authorized by Connect Tech Inc. with an RMA (Return Material

Authorization) number marked on the outside of the package and sent prepaid, insured and

packaged for safe shipment. Connect Tech Inc. will return this product by prepaid shipment

service.

The Connect Tech Inc. lifetime warranty is defined as the serviceable life of the product. This is

defined as the period during which all components are available. Should the product prove to be

irreparable, Connect Tech Inc. reserves the right to substitute an equivalent product if available

or to retract lifetime warranty if no replacement is available.

The above warranty is the only warranty authorized by Connect Tech Inc. Under no

circumstances will Connect Tech Inc. be liable in any way for any damages, including any lost

profits, lost savings or other incidental or consequential damages arising out of the use of, or

inability to use, such product.

Copyright Notice

The information contained in this document is subject to change without notice. Connect Tech

Inc. shall not be liable for errors contained herein or for incidental consequential damages in

connection with the furnishing, performance, or use of this material. This document contains

proprietary information that is protected by copyright. All rights are reserved. No part of this

document may be photocopied, reproduced, or translated to another language without the prior

written consent of Connect Tech, Inc.

Copyright © 2010 by Connect Tech Inc.

Trademark Acknowledgment

Connect Tech Inc. acknowledges all trademarks, registered trademarks and/or copyrights

referred to in this document as the property of their respective owners.

Not listing all possible trademarks or copyright acknowledgments does not constitute a lack of

acknowledgment to the rightful owners of the trademarks and copyrights mentioned in this

document.

2 Revision 0.03

Page 3

Customer Support Overview

If you experience difficulties after reading the manual and/or using the product, contact the

Connect Tech reseller from which you purchased the product. In most cases the reseller can help

you with product installation and difficulties.

In the event that the reseller is unable to resolve your problem, our highly qualified support staff

can assist you. Our support section is available 24 hours a day, seven days a week on our

website at:

www.connecttech.com/sub/support/support.asp. See the contact information section below for

more information on how to contact us directly. Our technical support is always free.

Contact Information

We offer three ways for you to contact us:

Telephone/Facsimile

Technical Support representatives are ready to answer your call Monday through Friday, from

8:30 a.m. to 5:00 p.m. Eastern Standard Time. Our numbers for calls are:

Telephone: 800-426-8979 (North America only)

Telephone: 519-836-1291 (Live assistance available 8:30 a.m. to 5:00 p.m. EST, Monday to

Friday)

Facsimile: 519-836-4878 (online 24 hours)

Email/Internet

You may contact us through the Internet. Our email and URL addresses are:

sales@connecttech.com

support@connecttech.com

www.connecttech.com

Mail/Courier

You may contact us by letter and our mailing address for correspondence is:

Connect Tech Inc.

Technical Support

42 Arrow Road

Guelph, Ontario

Canada N1K 1S6

Connect Tech Blue Heat/Net Sync User Manual

Note:

Please go to the Download Zone or the Knowledge Database in the

Support Center on the Connect Tech website for product

manuals, installation guides, device driver software and

technical tips.

Submit your technical support questions to our customer support engineers via the Support

Center on the Connect Tech website.

Revision 0.03 3

Page 4

Connect Tech Blue Heat/Net Sync User Manual

EN 61000-4-2

EN 61000-4-4

EN 61000-4-6

EN 61000-3-2 Exempt

EN 61000-4-3

EN 61000-4-5

EN 61000-4-11

EN 61000-3-3 Pass

USA:

FCC – CFR47, Part 15, part 2

Canada:

ICES-003

Europe

EMC Directive

Japan:

VCCI

Australia/New Zealand:

AS/NZS

Certification Statements

Preliminary: Testing is still pending.

Class A Computing Device

Connect Tech Inc. declares that the product(s) covered by the contents of this manual have been

tested and found compliant with the below listed standards as required by the Electromagnetic

Compatibility (EMC) Directive for General Immunity Compliance.

EN 55022 Conducted and Radiated emissions

CISPR 22 Class A

EN 55024 Immunity to Disturbances

The above satisfy the requirements of:

Preliminary: Testing is still pending.

4 Revision 0.03

Page 5

Connect Tech Blue Heat/Net Sync User Manual

Table of Contents

Limited Lifetime Warranty ................................................................................................................... 2

Copyright Notice ................................................................................................................................ 2

Trademark Acknowledgment ................................................................................................................ 2

Customer Support Overview ................................................................................................................ 3

Contact Information............................................................................................................................ 3

Certification Statements ...................................................................................................................... 4

Table of Contents ............................................................................................................................... 5

List of Figures .................................................................................................................................... 7

List of Tables ..................................................................................................................................... 8

Introduction ....................................................................................................................................... 9

Features .................................................................................................................. 9

Understanding Virtual COM Ports ........................................................................... 10

Blue Heat/Net Sync Installation Overview ........................................................................................... 10

Hardware Installation ....................................................................................................................... 11

Connecting the Blue Heat/Net Sync to Your Network: ................................................. 11

Ethernet LEDs ............................................................................................... 11

Serial Port LEDs ............................................................................................ 12

Connecting Serial Devices ....................................................................................... 12

V.28 Connections: .......................................................................................... 12

Basic Async (V.28) RS-232 Null Modem Connection ................................. 12

Basic Sync (V.28) RS-232 Connection (Provides Clock) ............................ 12

Basic Sync (V.28) RS-232 Connection (Receives Clock) ............................. 12

RS-422/V.11 Connections ................................................................................ 13

Blue Heat/Net Synchronous Clocking ........................................................................ 13

Loopback Connectors .............................................................................................. 14

Connecting Power .................................................................................................. 15

DC Power Connector ............................................................................. 15

Phoenix Locking Screw Terminal Connector ............................................ 15

Activating the Special Operations Mode and Default Settings ...................................... 17

Using the Reset Button to Activate the Special Operations Mode ......................... 17

Selecting a Special Operation .......................................................................... 17

Power On Diagnostics: ........................................................................................... 18

LED Error Codes ........................................................................................... 18

SCM Cabling requirements ...................................................................................... 21

SCM: Serial Configuration Manager ................................................................ 21

Setting a Static or Dynamic IP Address ..................................................................... 21

Set the IP Address Using the Web Configuration Manager ................................. 22

Set the IP Address Using the Serial Configuration Manager ............................... 22

Blue Heat/Net Sync Configuration ...................................................................................................... 23

CDS (Configuration Data Space) ............................................................................. 24

Description .................................................................................................... 24

Access to CDS Parameters .............................................................................. 24

SCM (Serial Configuration Manager) ....................................................................... 25

Description .................................................................................................... 25

Getting Access to the SCM .............................................................................. 25

SCM Command Reference ............................................................................... 25

Brief Command List ............................................................................... 25

Command Details .................................................................................. 26

boot ............................................................................................. 26

cfg ............................................................................................... 26

exit .............................................................................................. 27

help ............................................................................................. 27

Revision 0.03 5

Page 6

Connect Tech Blue Heat/Net Sync User Manual

info .............................................................................................. 27

net ............................................................................................... 27

save ............................................................................................. 29

update .......................................................................................... 29

WCM (Web Configuration Manager) ........................................................................ 31

Signing In to the Web Configuration Manager .................................................. 31

Configure Advanced Serial Settings ......................................................... 33

Configure Blue Heat/Net Sync Settings .................................................... 33

Configure Firmware .............................................................................. 35

Restore Defaults .................................................................................... 35

Saving To Flash..................................................................................... 36

Monitoring Your Blue Heat/Net ....................................................................... 37

Monitor Serial Port Traffic ................................ ..................................... 37

Monitor Network Traffic ......................................................................... 38

Monitor TCP/IP Statistics ....................................................................... 38

My Blue Heat/Net Sync........................................................................... 38

Software Installation for Windows ...................................................................................................... 40

Installing the Blue Heat/Net Sync Configuration Manager .......................................... 40

Running the Configuration Manager ......................................................................... 44

Device Installation .................................................................................................. 44

Configure Default Blue Heat/Net Sync .............................................................. 45

Add New Blue Heat/Net Sync ........................................................................... 45

Auto Discover Blue Heat/Net Sync ................................................................... 46

Firmware Upgrades.......................................................................................................................... 47

Upgrade using WCM (Web Configuration Manager) .................................................. 47

Upgrade using SCM (Serial Configuration Manager) ................................................. 47

Software Development ...................................................................................................................... 48

Memory Map of IUSC and PLD Functions ........................................................ 50

ColdFire (5272) Bus: ............................................................................. 50

IUSC Access: ........................................................................................ 50

PLD Resource Access: ........................................................................... 51

PLD Memory Map Table................................................................................. 51

Port Settings, Clock Setup and General Settings......................................................... 59

IUSC Clocking Logic: ............................................................................................. 61

Appendix ......................................................................................................................................... 62

Blue Heat/Net Sync Specifications ............................................................................ 62

Operating Environment .................................................................................. 62

Communications ............................................................................................ 62

ESD Protection .............................................................................................. 62

Power ........................................................................................................... 62

Connectors .................................................................................................... 62

Dimensions .................................................................................................... 62

Cable and Power Supply Options ..................................................................... 62

Protocol Descriptions ..................................................................................... 63

Pinouts .................................................................................................................. 64

DB-25 Female Pinouts .................................................................................... 64

DB-9 Female Pinouts ..................................................................................... 65

Multi-drop Communications Using V.11 / RS422/RS485 Line Modes ................... 66

Rack Mount Option: ................................................................................................ 66

Default Settings ...................................................................................................... 67

Network Settings ............................................................................................ 67

Boot Settings .................................................................................................. 67

SCM Operation Settings .................................................................................. 67

Common Configuration Setups ................................................................................. 68

Static IP Setup ............................................................................................... 68

Using SCM ........................................................................................... 68

Using WCM .......................................................................................... 68

6 Revision 0.03

Page 7

Connect Tech Blue Heat/Net Sync User Manual

DHCP Setup .................................................................................................. 69

Using SCM ........................................................................................... 69

How the Blue Heat/Net Sync Boots Up ...................................................................... 69

Bootup Sequence ............................................................................................ 70

Flowchart of Special Operations Mode using the reset button ............................. 71

Asynchronous Communications Tutorial ........................................................... 71

Serial Line Interface Tutorial ................................................................................... 72

RS-232 Line Interface: .................................................................................... 72

Differential Line Interfaces: ............................................................................ 72

RS485/RS422/V.11 Details .............................................................................. 72

Basic 4-Wire, Full Duplex Communications: ............................................ 73

Multi-drop 4-Wire, Full Duplex Communications: .................................... 74

Basic - Wire, Half Duplex Multi-drop Connection: .................................... 74

Bus Contention on Differential Multi-drop Networks: ........................................ 75

Termination Resistors in Differential Networks ................................................. 76

Termination Resistors in Differential Networks:........................................ 76

List of Figures

Figure 1: LED Locations on Blue Heat/Net Sync.......................................................................... 11

Figure 2: Basic V.28 Asynchronous Connections ......................................................................... 12

Figure 3: Basic V.28 Synchronous Connections ........................................................................... 12

Figure 4: Basic V.28 Synchronous Connections ........................................................................... 12

Figure 5: Basic RS-422/V.11 Asynchronous Connections ............................................................ 13

Figure 6: Basic RS422/V.11 Synchronous Connections ................................................................ 13

Figure 7: Recommended Pinouts for V.28 (RS-232) Loopback Connector ................................... 14

Figure 8: Recommended Pinouts for a V.11 (RS422) Loopback Connector ................................. 14

Figure 9: DC Power Connector Illustration ................................................................................. 15

Figure 10: Phoenix Locking Screw Terminal Power Connector Illustration ................................ 15

Figure 11: LED Error Code Example ........................................................................................... 18

Figure 12: Blue Heat/Net Sync Serial Cable Connection Diagram .............................................. 21

Figure 13: Web Configuration Manager Sign In .......................................................................... 31

Figure 14: Blue Heat/Net Sync Settings ........................................................................................ 32

Figure 15: Configuring Blue Heat/Net Sync Settings .................................................................... 35

Figure 16: Firmware Upgrades/Downloads ................................................................................. 35

Figure 17: Restore Default Settings .............................................................................................. 36

Figure 18: Saving To Flash ........................................................................................................... 37

Figure 19: Monitoring Serial Port Activity ................................................................................... 37

Figure 20: Monitoring Network Traffic ........................................................................................ 38

Figure 21: Monitoring TCP/IP Statistics ...................................................................................... 38

Figure 22: My Blue Heat/Net Sync Hardware Details .................................................................. 39

Figure 23: My Blue Heat/Net Sync Software Details .................................................................... 39

Figure 24: Blue Heat/Net Sync Driver/Software Installation CD ................................................. 40

Figure 25: Blue Heat/Net Sync Software Installation Screen ....................................................... 41

Figure 26: My Blue Heat/Net Sync Places Screen ........................................................................ 44

Figure 27: Add or Auto Discover Blue Heat/Net Sync Menu Screen ............................................ 45

Figure 28: Add Blue Heat/Net Sync Screen .................................................................................. 45

Figure 29: Auto Discover Blue Heat/Net Sync Screen .................................................................. 46

Figure 46: Bootup Sequence ......................................................................................................... 70

Figure 47: Bootup Sequence via Reset Button .............................................................................. 71

Figure 48: Typical Asynchronous Date Frame ............................................................................. 72

Revision 0.03 7

Page 8

Connect Tech Blue Heat/Net Sync User Manual

List of Tables

Table 1: BlueHeat/Net Sync Power Connections and Current Specifications .............................. 16

Table 2: Connector Properties ...................................................................................................... 16

Table 3: Available Special Operations .......................................................................................... 18

Table 4: LED Error Codes for Blue Heat/Net Sync ...................................................................... 19

Table 5: Chip Selects .................................................................................................................... 48

Table 6: Interrupts ......................................................................................................................... 49

Table 7: ColdFire MCF5272 GPIO .............................................................................................. 49

Table 8: Base Address Map ........................................................................................................... 49

Table 9: DB-25 Female Pinouts .................................................................................................... 64

Table 10: DB-9 Female Pinouts .................................................................................................... 65

8 Revision 0.03

Page 9

Introduction

Connect Tech‟s Blue Heat/Net Sync allows remote access to synchronous/asynchronous serial

devices via an Ethernet LAN or the Internet. Blue Heat/Net Sync network-enables serial

communication devices that are designed to be connected to serial ports so that the devices no

longer need to be tied to a single computer.

The Blue Heat/Net Sync hardware is simple to install as it involves little more than plugging the

unit into the appropriate locations and performing the configuration steps outlined in this

manual.

Driver setup is made easy by Blue Heat/Net Sync‟s auto-detection feature. The software does the

work of locating the units, while the Configuration Manager leads you through the rest of the

installation.

Blue Heat/Net Sync‟s firmware is easily configured with a choice of methods: web browser,

Telnet, or direct serial connection with a terminal and/or terminal software. Once the Blue

Heat/Net Sync has been configured to your specifications, you will be able to remotely access

your devices immediately.

Features

● Four software selectable synchronous or asynchronous serial ports

● Software switchable; V.28, V.10, V.11, V.35, EIA-530, X.21 line modes

● Software switchable line modes and termination

● Supports NRZ, NRZB, NRZI-Mark, NRZI-Space, B-Phase-Space, B-Phase-Manchester,

Differential Bi-Phase encoding

● Transmission rates up to 9.216 Mbps (synchronous), 230.4 Kbps (asynchronous). 10 Mbps

communications possible with external clock.

● Bipolar clock input accepts sine/square wave signals up to 20 MHz +/- 10V.

● Includes synchronous protocols; SDLC, HDLC, MonoSync, BiSync, Transparent BiSync

● Software selectable internal and external clocking modes. External clocking is provided on

TXC and RXC pins

● Supports IP, TCP, UDP, ARP, RARP, TFTP, DHCP, BOOTP, HTTP, Telnet and DNS

● Use of TCP/IP means communications can be routed to support WANs, as well as LANs.

The Blue Heat/Net Sync does not need to be located at the same site as the controlling

computer

● Raw TCP server (HDLC and External Sync Line Modes only)

● Several levels of security are built into the Blue Heat/Net Sync that can limit connections

and help to ensure the privacy of data flow

● Memory: 8 MB flash, 16 MB SDRAM

● Includes an auto-MDIX 10Base-T, 100Base-TX LAN interface

● Network boot or booting from built-in flash memory

● Firmware upgrades are downloadable

● Customizable uClinux embedded operating system running on a ColdFire embedded

processor.

● Configuration can be done via Web Browser, Telnet or direct serial connection

● Front mounted diagnostic LEDs

● 5-28 VDC power input using either DC barrel or Phoenix screw terminal connector

Optional 5VDC power supply available

● 1U rack mount kit available

Connect Tech Blue Heat/Net Sync User Manual

Revision 0.03 9

Page 10

Connect Tech Blue Heat/Net Sync User Manual

Understanding Virtual COM Ports

In a typical serial port setup, the application communicates directly with the connected serial

port hardware.

Virtual COM ports differ in that the application communicates with a network protocol layer that

transfers the necessary information to and from the remote serial ports. The virtual ports appear

as standard serial ports to the application, but in reality the data is translated into a series of

Ethernet messages between the Blue Heat/Net Sync unit and the host computer. The serial port is

not physically connected to the host computer, but this is transparent to the application trying to

access it.

There are several advantages to using virtual COM ports, which include:

Distance – The serial ports can be a great distance away from the host computer. They are

not limited by the standard electrical characteristics of the RS-232 or RS-422 interface

because the primary data transfer is being done via Ethernet. Depending on the set up, these

serial ports can be at a different location and the Internet can act as the carrier of the serial

port traffic.

Speed – Short RS-232/422 cable lengths can be used with the primary distance relying on

the network connection. The capacitance of long lengths of serial cable does not limit data

speeds in these cases.

Cabling – Cost effective Ethernet cabling can be used for the transfer of information to the

Blue Heat/Net Sync and often this is part of the existing networking infrastructure.

Connecting serial ports in a remote location can be as easy as plugging in a Blue Heat/Net

Sync to the Ethernet network. This provides a simple, clean cabling arrangement.

Port Sharing – In some applications it is desirable to have a serial resource that is accessed

and shared by more than one host computer. Connect Tech‟s virtual serial port technology

allows this to be done easily.

Routing – Different ports on a Blue Heat/Net Sync can be connected to multiple host

computers.

Monitoring – Because the virtual serial ports are on the network, they can easily be

monitored to ensure everything is operating correctly.

Blue Heat/Net Sync Installation Overview

There are three main stages in the installation process for your Blue Heat/Net Sync.

1. Hardware Installation

This involves the physical connection of the Blue Heat/Net Sync hardware to your

network, and addresses issues such as cabling and power requirements.

2. Blue Heat/Net Sync Configuration

The first step in the configuration process is to set the IP Address. Then use one of three

available methods to configure the Blue Heat/Net Sync firmware settings for your

application. This can be done through the SCM (Serial Configuration Manager) or the

WCM (Web Configuration Manager), depending on circumstances and personal

preference.

3. Software Installation for Windows

This step installs and configures the Blue Heat/Net Sync drivers and ports for your host

Operating System and allows you to set parameters specific to your serial requirements.

This is done via the Blue Heat/Net Sync Configuration Manager.

NOTE: Software support for Windows and Linux is still in

development

10 Revision 0.03

Page 11

Connect Tech Blue Heat/Net Sync User Manual

Hardware Installation

Connecting the Blue Heat/Net Sync to Your Network:

Before you begin, take a minute to ensure that your package includes the required components

for your Blue Heat/Net Sync:

One Blue Heat/Net Sync unit

•

One power supply

•

One CD containing software and documentation

•

One Phoenix contact screw terminal plug PN: 1847055

•

One RJ-45 cable (optional)

•

If any of these components is missing, contact Connect Tech or your reseller.

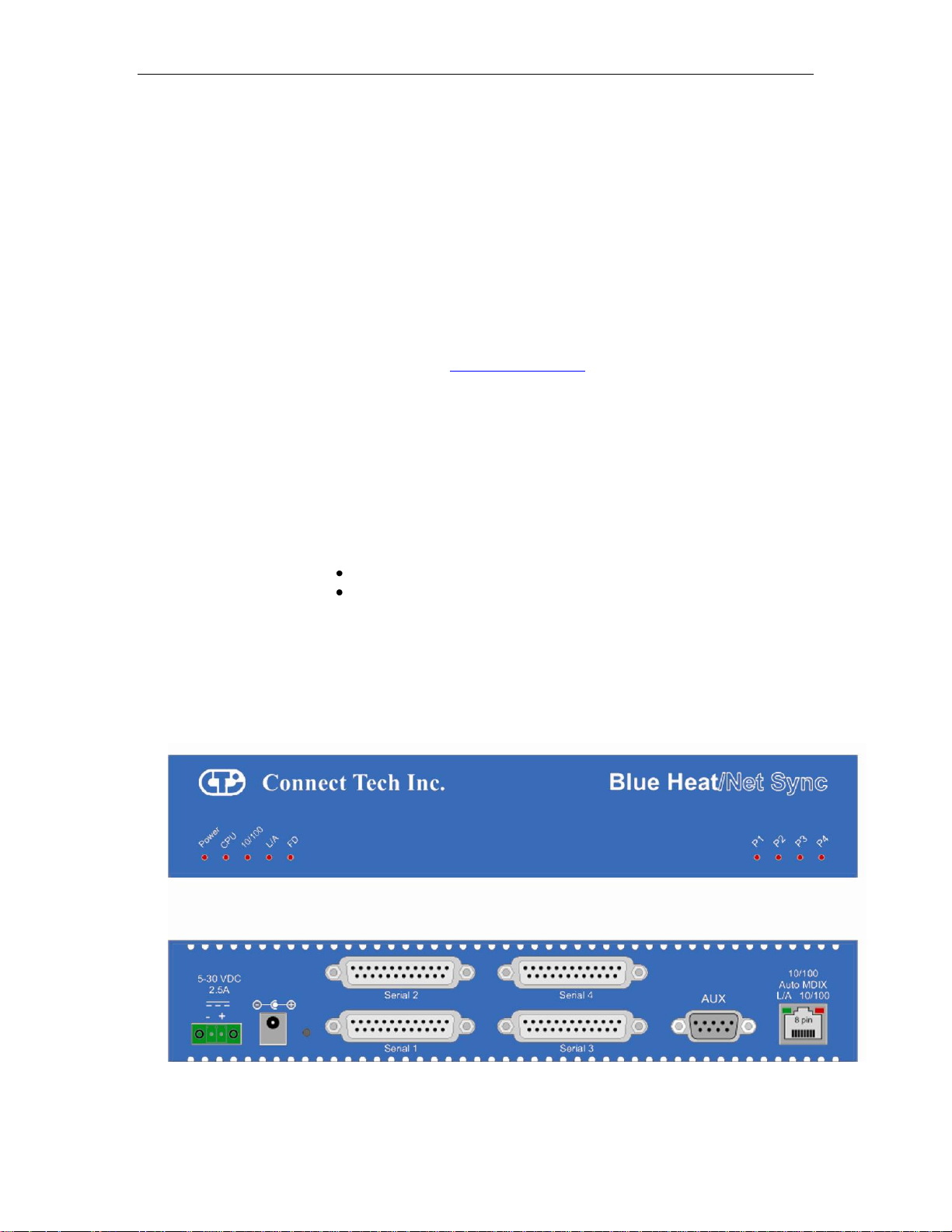

Ethernet LEDs

The front panel of the Blue Heat/Net Sync features Ethernet and serial port LEDs to monitor

activity.

Power: When this LED is on, the Blue Heat/Net Sync is receiving power.

CPU: Once the uClinux firmware is booted and running correctly, this LED lights up.

10/100: This LED represents the line rate at which the Blue Heat/Net Sync is connected

to your network.

LED on = a 100 megabit connection.

LED off = a 10 megabit connection.

(The Blue Heat/Net Sync automatically detects the line rate of your network).

L/A: This light illuminates when the connection to your network or computer is

achieved.

A blinking light indicates that Transmit (Tx) or Receive (Rx) activity is detected

on the Ethernet cable.

FD: Indicates that your network is running in full duplex or half duplex mode:

ON = full duplex, OFF = half duplex

Figure 1: LED Locations on Blue Heat/Net Sync

Revision 0.03 11

Page 12

Connect Tech Blue Heat/Net Sync User Manual

2 - TX

3 - RX

15 - T/RXC

7 - SR

RX

TX

RXC

SR

Blue Heat/Net Sync

RS-232 Device

2 - TX

3 - RX

17 - T/RXC

7 - SR

RX

TX

RXC

SR

Blue Heat/Net Sync

RS-232 Device

2 - TX

3 - RX

7 - SR

RX

TX

SR

Blue Heat/Net Sync

RS-232 Device

Serial Port LEDs

The serial ports LEDs indicate serial activity for each port.

A flashing LED indicates that the port in question is receiving or transmitting data.

•

Connecting Serial Devices

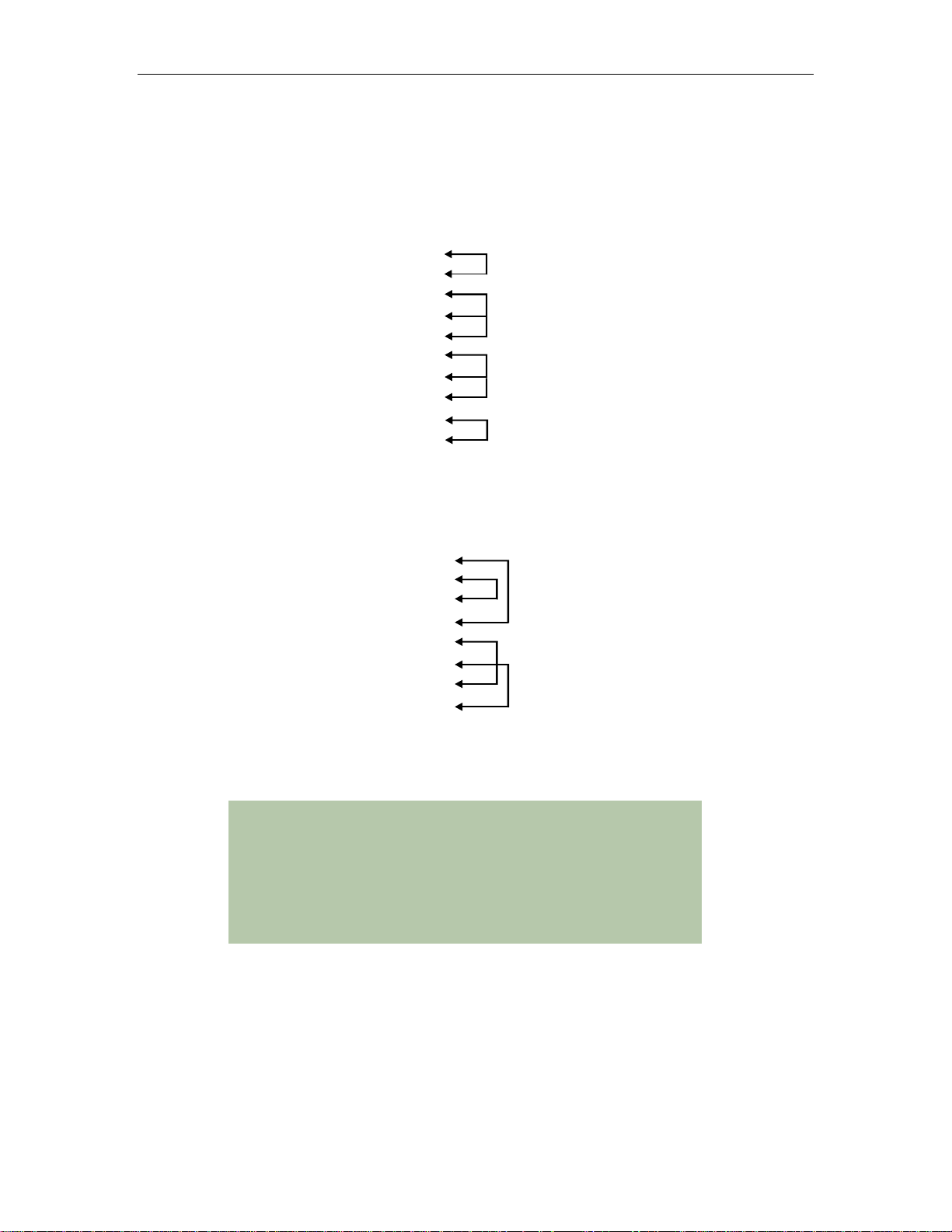

V.28 Connections:

V.28 has signaling levels the same EIA RS232.

Basic Async (V.28) RS-232 Null Modem Connection

This is the typical way to connect a Blue Heat/Net Sync to another serial device.

Figure 2: Basic V.28 Asynchronous Connections

Basic Sync (V.28) RS-232 Connection (Provides Clock)

Figure 3: Basic V.28 Synchronous Connections

Basic Sync (V.28) RS-232 Connection (Receives Clock)

Figure 4: Basic V.28 Synchronous Connections

NOTE: The Blue Heat/Net Sync clock signals are bidirectional.

See Blue Heat/Net Sync Clocking for more details.

12 Revision 0.03

Page 13

Connect Tech Blue Heat/Net Sync User Manual

2 - TX-

14 - TX+

16 - RX+

3 - RX-

9 - R/TXC+

17 - R/TXC-

7 - SR

RX-

RX+

TX+

TX-

RXC

RXC

SR

Blue Heat/Net Sync

RS-422/V.11 Device

2 - TX-

14 - TX+

16 - RX+

3 - RX-

7 - SR

RX-

RX+

TX+

TX-

SR

Blue Heat/Net Sync

RS-422/V.11 Device

RS-422/V.11 Connections

The following are basic connections that can be accomplished when the I/O levels are in V.11 (RS-

422) mode. V.11 mode signaling can be enabled with EIA-530, RS-449 or X.21 modes on your Blue

Heat/Net Sync.

Figure 5: Basic RS-422/V.11 Asynchronous Connections

Figure 6: Basic RS422/V.11 Synchronous Connections

NOTE: Blue Heat/Net Sync clock signals are bidirectional. The

Blue Heat/Net Sync can either source or receive a clock. See Blue

Heat/Net Sync Clocking for more details.

Blue Heat/Net Synchronous Clocking

The clocking circuits on the Blue Heat/Net Sync are very flexible. The Blue Heat/Net Sync DB-25 clock

pins are bi-directional. This means that the TXC or RXC pins can be inputs receiving a clock or outputs

driving a clock. Functionally the two pins are equal. For example, the following clocking combinations are

possible:

RXC as clock input and TXC as clock input.

RXC as clock output and TXC as clock output.

RXC as clock input and TXC as clock output.

RXC as clock output and TXC as clock input.

The Blue Heat/Net Sync receivers and transmitters can be clocked independently from any combination of

the above or from internal clock sources.

Clocking is also available from the EXT_REF_CLK input pin on the DB-9 female.

Revision 0.03 13

Page 14

Connect Tech Blue Heat/Net Sync User Manual

2 - TX-

14 - TX+

16 - RX+

3 - RX-

9 - RXC+

17 - RXC-

11 - TXC+

12 - TXC-

7 - SR

DB-25 Male

2 - TX

3 - RX

4 - RTS

5 - CTS

6 -DSR

8 - DCD

20 - DTR

22 - RI

15 - TXC

17 - RXC

DB-25 Male

Loopback Connectors

Loopback connectors are useful for performing diagnostics. The following figure illustrates the

recommended pinouts for creating loopback connectors for Blue Heat/Net Sync.

Figure 7: Recommended Pinouts for V.28 (RS-232) Loopback Connector

Figure 8: Recommended Pinouts for a V.11 (RS422) Loopback Connector

NOTES:

1. For an asynchronous loopback, omit the TXC and RXC pin.

2. When using clock signals, one signal must be configured as an

input, while the other must be configured as an output.

3. When using a DB-25 female loopback connector, solder cup

DB-25 connectors and 24 AWG solid core wire, such as wire

from a CAT5 cable is recommended.

14 Revision 0.03

Page 15

Connecting Power

The Blue Heat/Net Sync uses either a standard DC power jack or a Phoenix locking screw

terminal connector for power input. The Blue Heat/Net Sync can be safely connected or

disconnected at any time. The standard power supply requirements are as follows:

Model BMG006

5V (2.5A) power input using a DC barrel or Phoenix screw terminal connector. Rev A

models.

5V (2.5A) – 28 V DC (450mA) power input using a DC barrel or Phoenix screw terminal

connector. Rev B or greater models only.

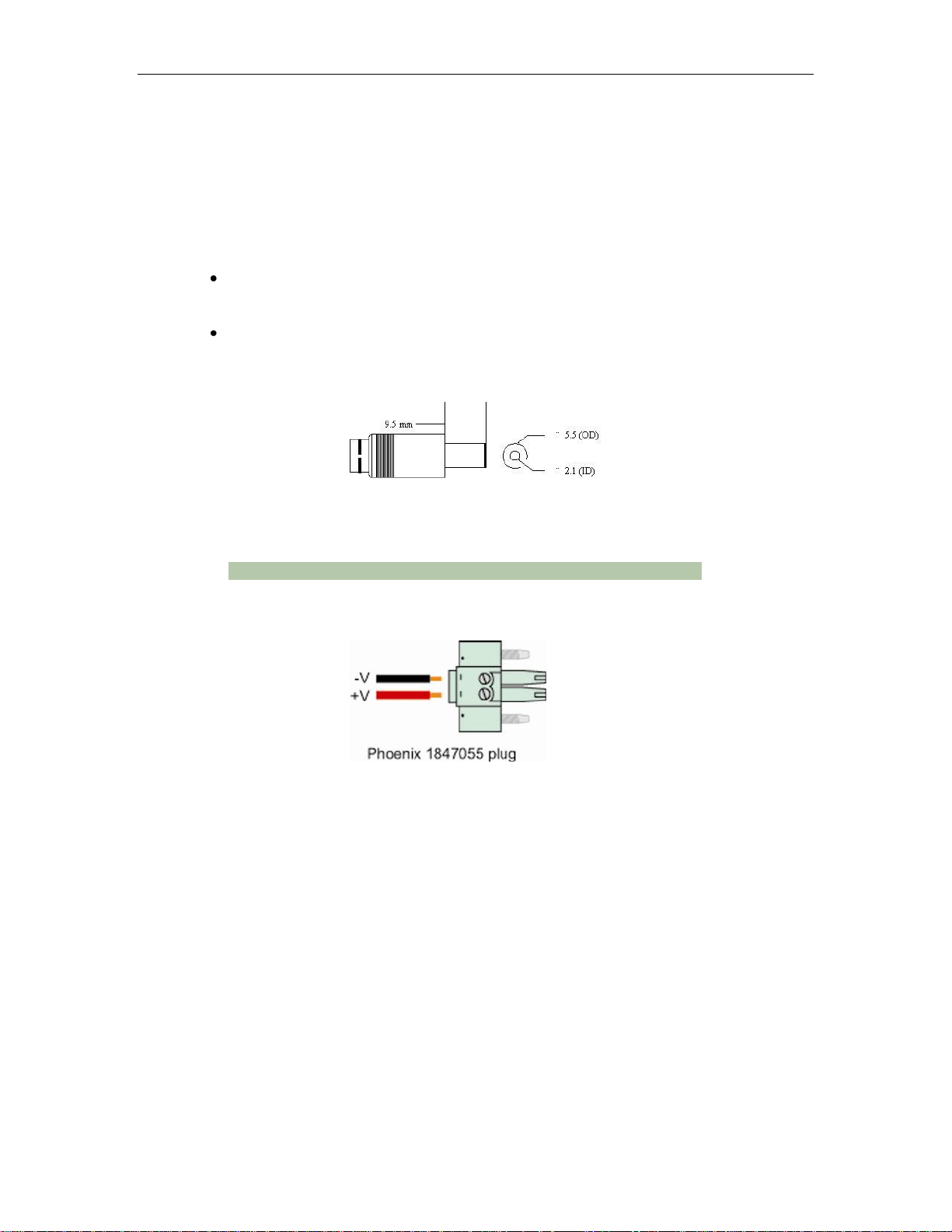

DC Power Connector

Connect Tech Blue Heat/Net Sync User Manual

Figure 9: DC Power Connector Illustration

NOTE: The center is positive, outside is ground (0V).

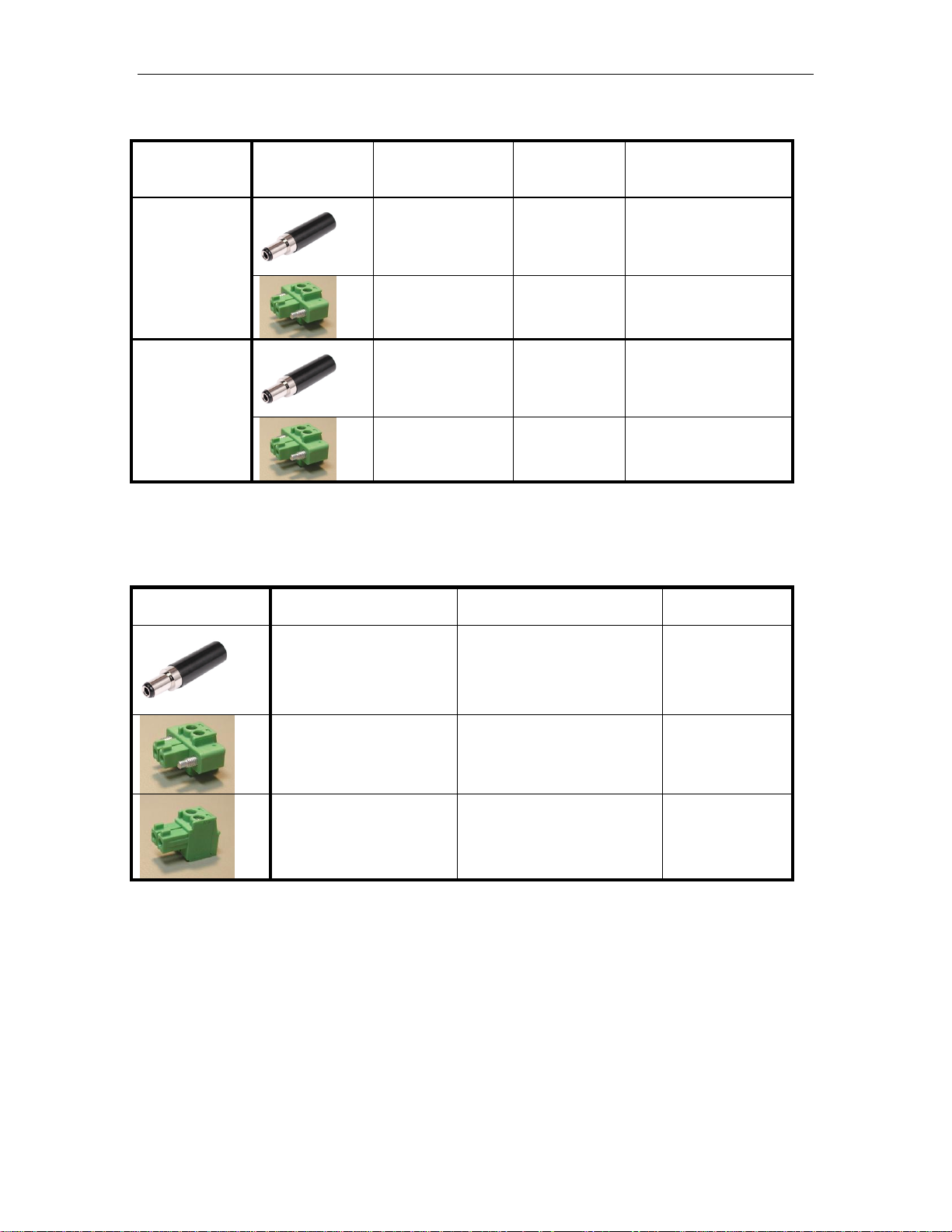

Phoenix Locking Screw Terminal Connector

Figure 10: Phoenix Locking Screw Terminal Power Connector Illustration

Revision 0.03 15

Page 16

Connect Tech Blue Heat/Net Sync User Manual

BlueHeat/Net

Description

Connector plug

type

Connector

Polarity

Voltage

Current

4 Port DB25

Synchronous /

Asynchronous

models (Rev A)

Centre Positive*

5VDC

875mA

Left Positive*

5-28VDC

@5V=2500mA

@28V=450mA

4 Port DB25

Synchronous /

Asynchronous

models (Rev B)

Centre Positive*

5-28VDC

@5V=2500mA

@28V=450mA

Left Positive*

5-28VDC

@5V=2500mA

@28V=450mA

Type

Details

Part Number

Typical Wire

Gauge

Standard DC Barrel

2.1mmID / 5.5mmOD

Digi-Key: CP3-1000-ND, or

equivalent

18-24 AWG

Stranded

Locking Screw Terminal,

3.3mm pitch

MC Series

Phoenix PN: 1847055, or

equivalent

16-28 AWG

Stranded

Screw Terminal,

3.5mm pitch

MC Series

Phoenix PN: 1840366, or

equivalent

16-28 AWG

Stranded

Table 1: BlueHeat/Net Sync Power Connections and Current Specifications

*

Note: The power input is protected by a series diode to prevent damage in the case of a reverse polarity

connection.

Table 2: Connector Properties

16 Revision 0.03

Page 17

Connect Tech Blue Heat/Net Sync User Manual

Activating the Special Operations Mode and Default Settings

Blue Heat/Net Sync includes a push button on the rear of the unit beside the DC power

connector. This push button can be used to perform special operations such as resetting the unit

to its default settings or forcing port scanning in situations where the SCM is not accessible.

Using the Reset Button to Activate the Special Operations Mode

To activate the Special Operations Mode, hold the reset button while the unit is powering up.

Hold the button until all the port LEDs blink rapidly and then release the reset button. The port

LEDs will continue to flash rapidly after the reset button is released to indicate the Special

Operations Mode is active.

Selecting a Special Operation

Once the Special Operations Mode has been activated, four operation options are available:

1. Abandon the Special Operations Mode

To abandon the Special Operations Mode without selecting a special operation, press

and hold the reset button for at least four seconds. While the button is pressed, the

rapid flashing of the port LEDs will stop. After four seconds, the rapid flashing will

resume and the reset button can be released. After the release of the reset button, the

port LEDs will turn off, indicating that the Special Operations Mode has terminated.

2. Cancel a Special Operation

If you need to cancel a special operation after it has been selected, repeatedly press the

reset button until all the port LEDs begin to flash rapidly. Then abandon the Special

Operations Mode by pressing the reset button for four seconds, as explained above.

3. Select a Special Operation

Operations are selected by repeated short presses of the reset button. Each time the

reset button is pressed it is counted and represented on the port LEDs as a binary

number with the port 1 LED as the least significant bit (see Table 1). Choose the

operation which you want to perform. If you miss the selection that you want, keep

pressing the button. The count starts over again once it reaches 7 (1111 binary).

4. Activate a Special Operation

To activate a selection, press and hold the reset button for at least four seconds. During

this time the rapid flashing of the port LEDs will stop. Once the rapid flashing resumes

you can release the reset button. The port LEDs will turn off indicating that the Special

Operations Mode has been activated.

Revision 0.03 17

Page 18

Connect Tech Blue Heat/Net Sync User Manual

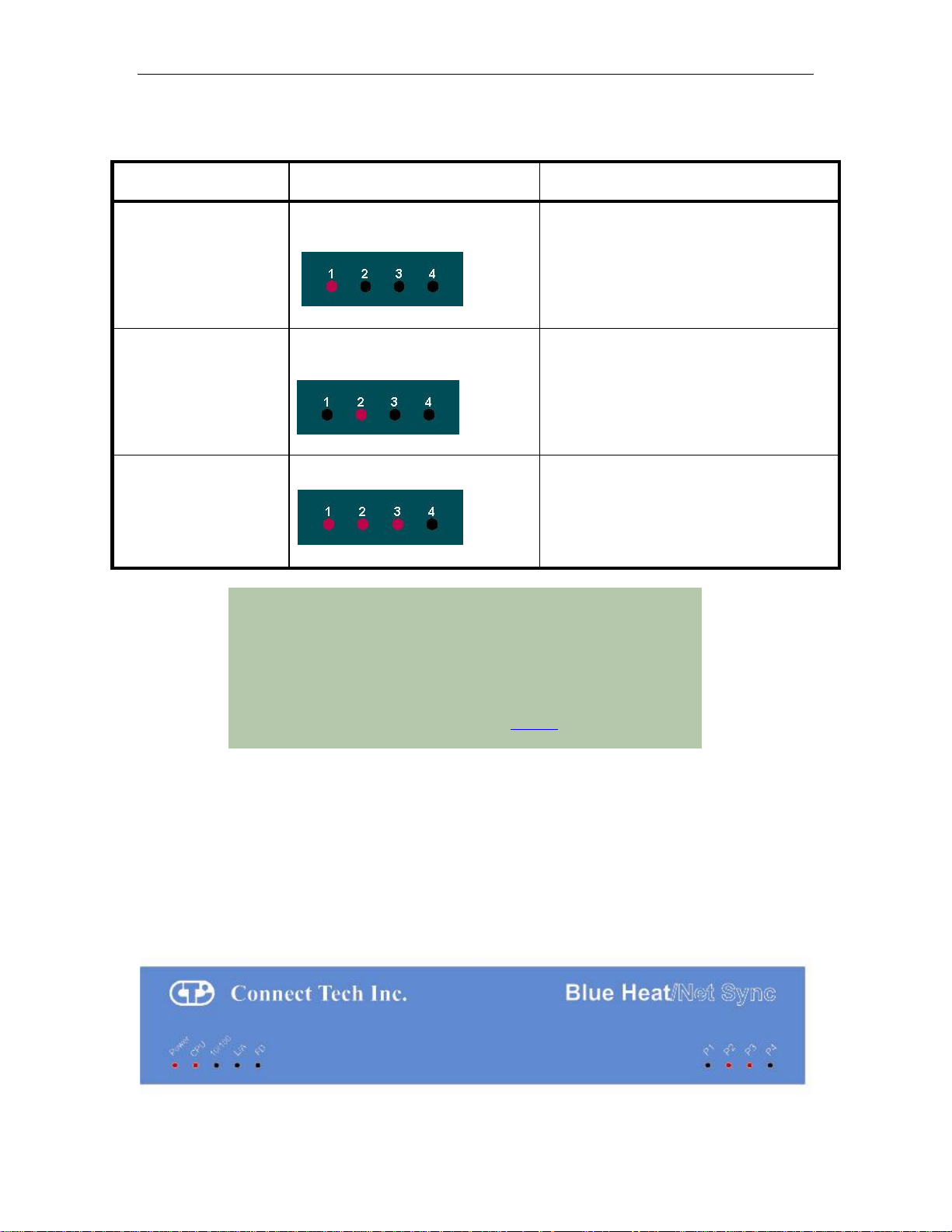

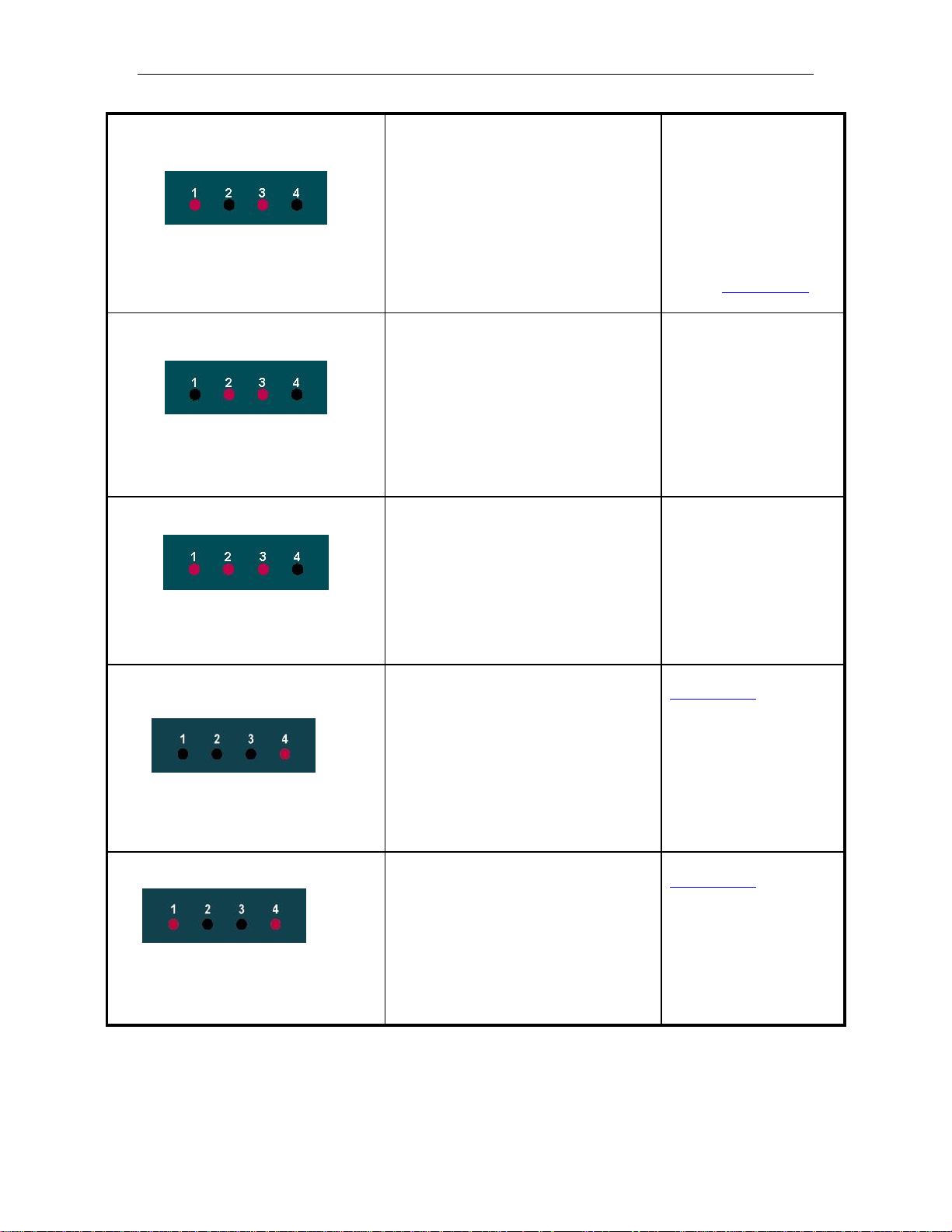

Special Operation

Number of presses (and binary

representation)

Usage

Force port scanning to

first two ports

(Scanning runs until

current scanning delay

setting times out. Default

is 30 seconds).

ONE press

This forces the first two ports to RS-232

mode, causing the SCM to scan these ports

and thereby allowing access to the SCM (see

note below).

Force port scanning to all

ports.

(Scanning runs until the

SCM is entered or until

the unit is powered

down. There is no time

out).

TWO presses

This forces all ports to RS-232 mode,

therefore all ports are scanned for SCM use.

The Blue Heat/Net Sync will behave in the

same manner as an RS-232 only model (see

note below).

Restore factory default

settings

SEVEN presses

This restores the factory default settings for

ALL configuration parameters.

Table 3: Available Special Operations

NOTE: Why would I need to force port scanning?

Some line interface settings are inappropriate for SCM use.

During boot up, the SCM scans only those ports set for RS-232

mode. If all of the ports are configured for another mode, (1/2

Duplex or Multi-drop) SCM port scanning is bypassed, and the

SCM application cannot be accessed. Use of either of the “Force

Port Scanning” operations outlined in Table 1 will force port

scanning to occur so the SCM application can be accessed.

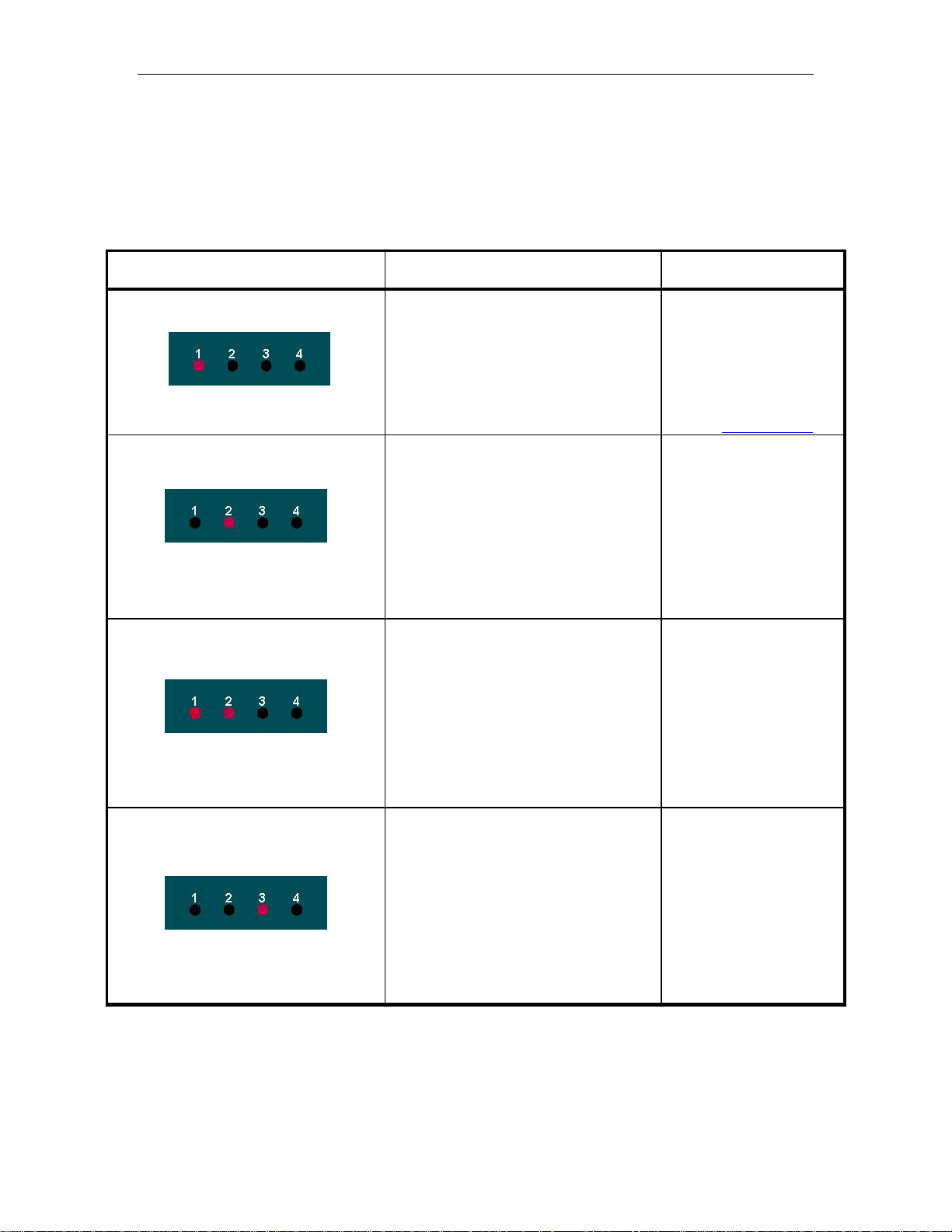

Power On Diagnostics:

LED Error Codes

If an error is detected during the bootup process, an error condition and code are displayed on

the LEDs on the face of the Blue Heat/Net Sync.

The error condition is signaled by a rapidly flashing CPU LED (about 10 to 20 per

•

second).

The error code is displayed on Port LEDs 1 to 4 as a binary number.

•

18 Revision 0.03

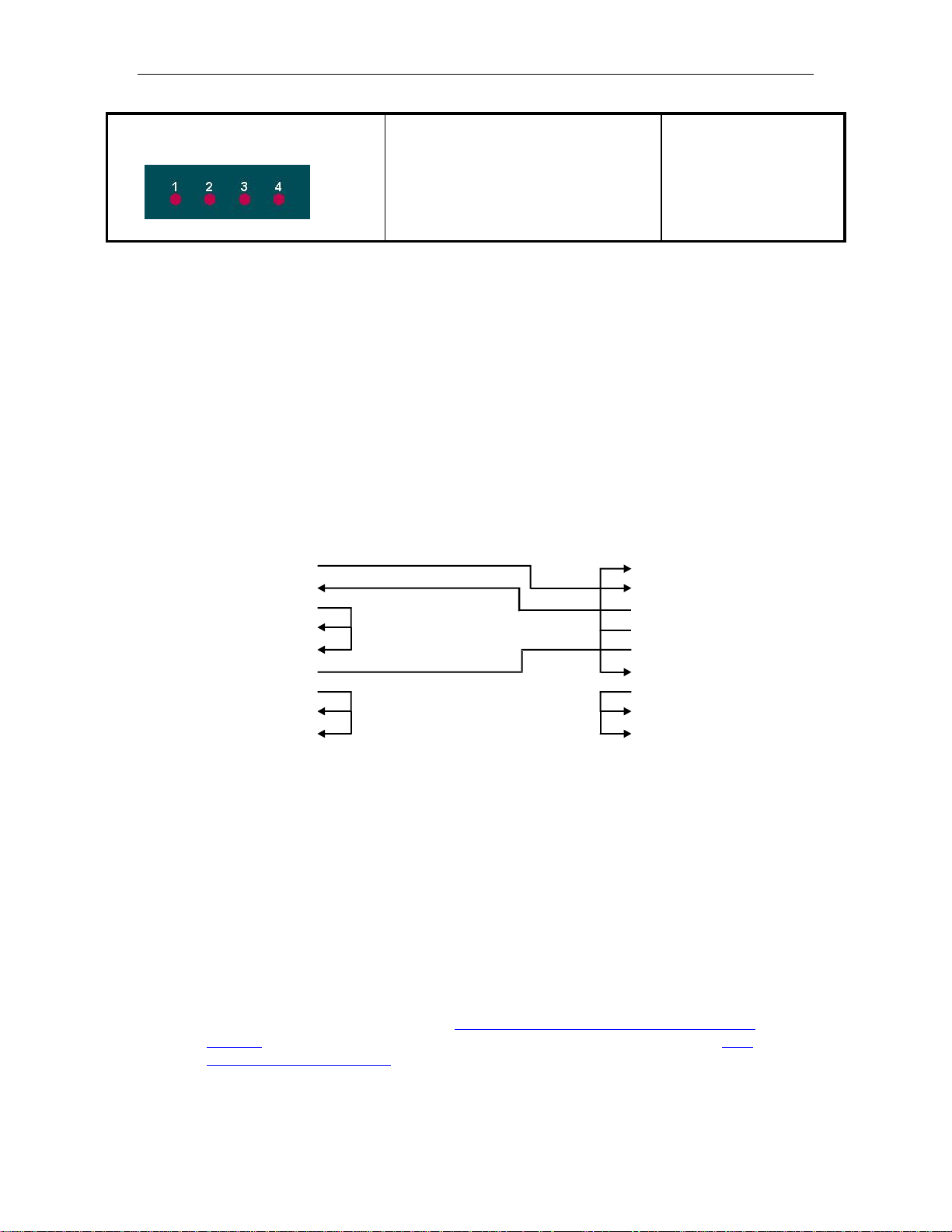

Figure 11: LED Error Code Example

Page 19

Connect Tech Blue Heat/Net Sync User Manual

Error Code and Event

Details

Suggested Corrective

Action

1. Loader code in flash is erased.

The regions of flash memory which hold

the loader code are both erased. (There

are two redundant loaders in flash that

can be run).

This may occur in when

there are ESD

disturbances or in

electrically noisy

environments. If this error

persists it may be a

hardware issue.

Contact Connect Tech.

2. Loader code in flash has a bad CRC.

The regions of flash memory which hold

the loader code both have CRC errors.

(There are two redundant loaders in flash

that can be run).

See corrective action for

error code 1.

3. RAM copy of loader code has a bad

CRC.

The loader code is copied to RAM

before execution. This error is shown if

the RAM copy has a CRC error.

See corrective action for

error code 1.

4. Configuration Data Space (CDS) areas

have corrupted data (CRC failure).

The CDS is copied from flash to RAM

during the beginning of the loader code.

If a CRC error is detected in the RAM

copy, this error is shown.

See corrective action for

error code 1.

In the above example, a rapidly flashing CPU LED during the boot up process signifies the Blue

Heat/Net Sync has experienced an error. Port LEDs 1 through 4 signify which error has

occurred. In this case, LED 2 and 3 are on, so the error code is 6. The chart below defines the

error details for each error code.

Table 4: LED Error Codes for Blue Heat/Net Sync

Revision 0.03 19

Page 20

Connect Tech Blue Heat/Net Sync User Manual

5. Cannot obtain an operating system

image (uClinux) to run.

This will occur when any of the enabled

boot sources (flash or BOOTP/TFTP or

TFTP) fail to obtain a valid compressed

operating system image to run.

Check network

connections, server

computer or your unit's

settings.

This error occurs if TFTP

booting is enabled and the

Blue Heat/Net Sync

cannot download the file

from the server.

Contact Connect Tech if it

persists.

6. Unexpected return from the uClinux

operating system.

This error occurs if the operating system

returns back to the loader.

See corrective action for

error code 1.

7. CDS re-programming failure.

Certain CDS items are updated during

the bootup. If a failure occurs during the

re-programming of the flash, this error

will occur.

See corrective action for

error code 1.

8. Boot count could not be incremented

in flash memory

This error is usually caused by a Flash

memory failure.

Contact

Connect Tech.

9. No ports found

This message usually indicates a UART

component failure.

Contact

Connect Tech.

20 Revision 0.03

Page 21

15. Mismatched CDS version number

uClinux checks the CDS version number

against its expected CDS version

number. If they are different, uClinux

does not continue its operation.

If you have updated the

uClinux code via SCM

and have not updated the

loader/SCM code, this

error appears on reboot.

Update companion loader

code and reboot.

1- DCD

2- RX

3- TX

4- DTR

5- GND

6- DSR

7- RTS

8- CTS

9- RI

TX 2

RX 3

RTS 4

CTS 5

DSR 6

SR 7

DCD 8

DTR 20

RI 22

DB-25 M

Connects to Blue Heat/Net Sync

DB-9 F

Connects to PC

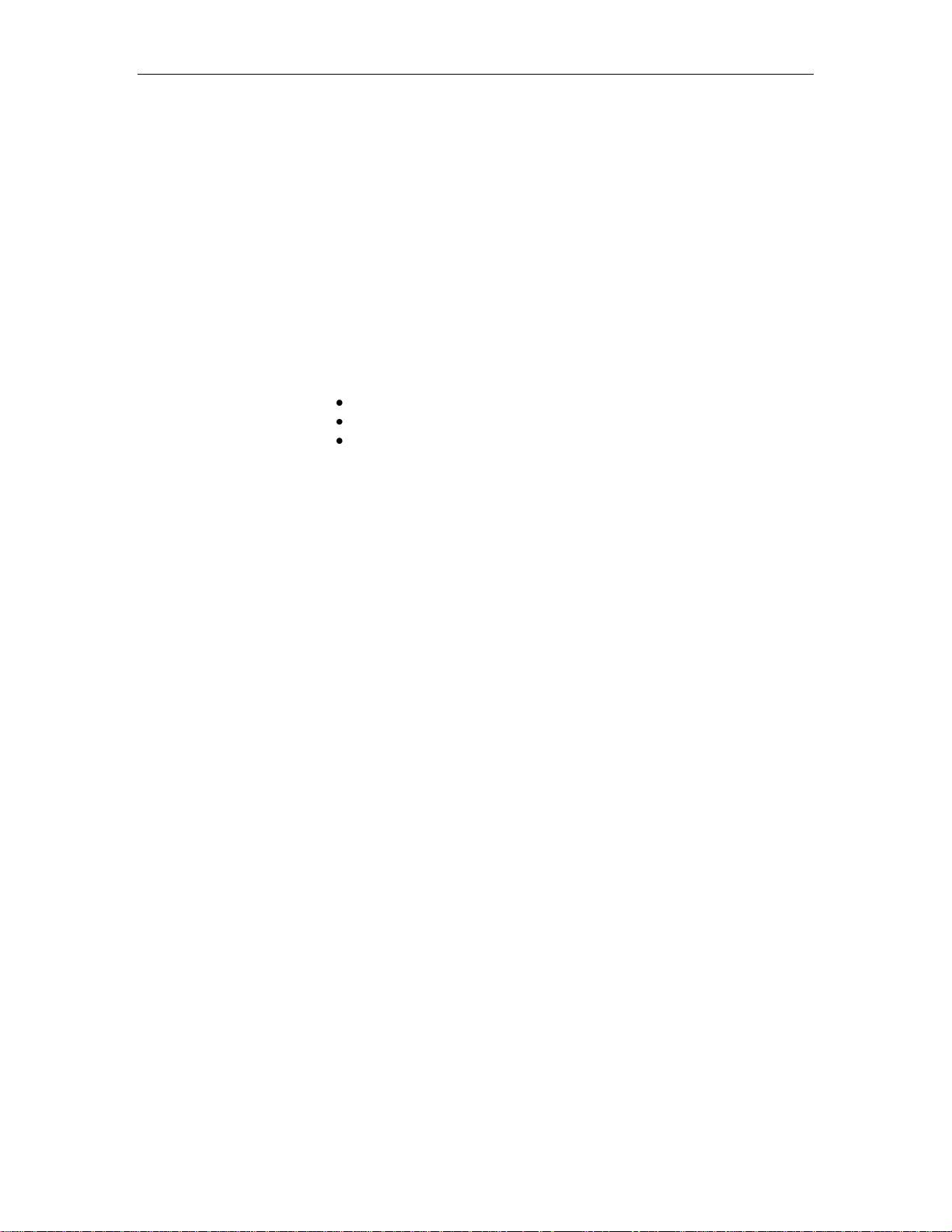

SCM Cabling requirements

SCM: Serial Configuration Manager

The Serial Configuration Manager is used to configure the Blue Heat/Net Sync via a serial port

and is discussed in greater detail later in this document. To access the Serial Configuration

Manager you will need to connect an RS-232 (V.28) serial cable from your standard computer

serial port to any RS-232 (V.28) port on the Blue Heat/Net Sync. The cabling required to

connect to the Blue Heat/Net Sync is as follows:

Connect Tech Blue Heat/Net Sync User Manual

The key signal connections are RX, TX and GND. The other signals may not be required in your

application. If you are assembling your own SCM cable, we recommend that all of the above

connections be made.

Setting a Static or Dynamic IP Address

Prior to configuring the Blue Heat/Net Sync, you must set a static or dynamic IP address. The

default IP address of a new Blue Heat/Net Sync is 192.168.42.1. If there is a possibility that this

has been changed, you will need to find the current IP address setting before you begin.

The easiest way to get the IP address of your Blue Heat/Net Sync is as follows:

Follow the steps outlined in the section Installing the Blue Heat/Net Sync Configuration

Manager and noting your Blue Heat/Net Sync‟s IP number (i.e. A.B.C.D) using the Auto

Discover Blue Heat/Net Sync feature.

Revision 0.03 21

Figure 12: Blue Heat/Net Sync Serial Cable Connection Diagram

Page 22

Connect Tech Blue Heat/Net Sync User Manual

Set the IP Address Using the Web Configuration Manager

NOTE: If you use the Windows Configuration Manager

and use Auto Discover to locate your Blue Heat/Net

Sync on the network, you can right-click and launch the

Web Configuration Manager from there.

You only need to use the route add command if you

choose not to use the Configuration Manager found on

the CD that accompanied your Blue Heat/Net Sync unit.

From the command prompt of your computer, run: route add A.B.C.0 mask 255.255.255.0 <current

IP of your host machine> Be sure to replace the .D from the Blue Heat/Net Sync‟s IP with a 0

(zero). Open your browser and put the Blue Heat/Net Sync‟s IP in the address bar (i.e. A.B.C.D)

This will open the WCM. Log in (default login is wcm and the default password is password)

and assign the static IP or change the IP to 0.0.0.0 if you are using a DHCP assigned IP.

Set the IP Address Using the Serial Configuration Manager

Insert your CD into the computer and complete the following steps:

1. Once your CD has been inserted, the Driver/Software Installation menu should appear. If it

doesn‟t, double-click on ctisetup.htm.

2. Click View in the Blue Heat/Net Sync Software section and then Connect in the Serial

Configuration Manager section. This will launch HyperTerminal that comes with Windows XP.

3. Unplug the power to the Blue Heat/Net Sync and plug it back in. Light indicators 1 to 4 will

blink sequentially. This sequential flashing will last for 30 seconds. You must log in during

this window.

4. During this sequential flashing, type the word password into the HyperTerminal window. Be

careful you do not miss the window of opportunity to enter the password.

5. You now have access to the Serial Configuration Manager (SCM). An scm> prompt is ready

to accept commands. If you do not see this prompt, unplug the power and repeat the steps above.

If you wish to set a dynamic IP address enter the following:

net dhcp=yes

save

exit

If you wish to set a static IP address, enter the following, substituting xxx.xxx.xxx.xxx with the

static IP you wish to assign:

net mip=xxx.xxx.xxx.xxx

save

exit

Close the HyperTerminal. You may now disconnect the DB-25 cable from your PC and connect

it to any serial device

.

22 Revision 0.03

Page 23

Connect Tech Blue Heat/Net Sync User Manual

Blue Heat/Net Sync Configuration

The Blue Heat/Net Sync comprises several software components, each of which manages

various functions of the Blue Heat/Net Sync. The following is a breakdown of these

components.

Operating System Software

o Host Operating System Driver

o Configuration Manager

o Web browser (Host Operating System supplied)

Blue Heat/Net Sync Software (Firmware)

o Embedded Operating System (uClinux)

Kernel

Drivers

Ethernet

Serial

Flash

Blue Heat/Net Sync Ethernet Protocol Converter application (Ctid)

Web server (Boa)

Web pages

Telnet services

o PPP Client and PPP Server

o Bootloader

o Serial Configuration Manager (SCM) Application

o Configuration Data Space (CDS)

The following section describes in brief what each main component controls.

Host Operating System Driver

The host operating system driver performs the translation from a standard serial COM port

interface to the Blue Heat/Net Sync protocol (which is then delivered to the LAN as described

above).

Configuration Manager

This software manages and configures the relationships between the Blue Heat/Net Sync serial

ports and the COM port assignments of the Host Operating System.

Web Browser

The host operating system supplies a Web Browser to support the Web Configuration Manager

(WCM) used to change the configuration settings of Blue Heat/Net Sync units.

Embedded Operating System

The embedded operating system is uClinux.

Bootloader

This code first starts up the embedded processor of the Blue Heat/Net Sync from a power-up or

software initiated reboot. It then obtains the embedded operating system image (file) from one of

several locations and runs the operating system.

Serial Configuration Manager (SCM) Application

This application is used to change the configuration settings of Blue Heat/Net Sync units by

connecting to a serial port on the Blue Heat/Net Sync from a terminal (or terminal emulation

Revision 0.03 23

Page 24

Connect Tech Blue Heat/Net Sync User Manual

program on a PC).

Configuration Data Space (CDS)

This is the area, in non-volatile (flash) memory, which stores the configuration parameters.

CDS (Configuration Data Space)

Description

The Blue Heat/Net Sync has a number of configuration parameters which are stored in a nonvolatile (flash memory) area. (See appendix for list of parameters).

The CDS area is stored redundantly in the flash memory along with a CRC-style checksum to

ensure data integrity.

Access to CDS Parameters

The parameters stored in the CDS can be changed through the use of the following configuration

tools:

SCM Serial Configuration Manager

WCM Web Configuration Manager

These three methods allow the user to change configuration parameters by the method that is

most convenient. In some cases several methods will be employed during different stages of the

setup of the Blue Heat/Net Sync. For example:

The SCM may be employed in the beginning when the unit is not connected to a network and

various networking parameters need to be set up prior to connection to a network.

WCM may be employed after the unit is connected to a network, possibly to modify other

settings related to serial ports, bootup settings or others.

More information about the operation of the SCM Command Reference and WCM (Web

Configuration Manager) follows.

NOTE: When CDS parameters are changed via the

SCM or WCM some settings will not take effect until the

Blue Heat/Net Sync is rebooted.

24 Revision 0.03

Page 25

SCM (Serial Configuration Manager)

Description

The Serial Configuration Manager is one of the applications you can use to access the

Configuration Data Space (CDS) settings of the Blue Heat/Net Sync. Since the CDS stores the

default serial port settings, it is important that the line mode is configured prior to first use.

Accessing the ports will not be possible otherwise.

Getting Access to the SCM

To access the SCM, simply connect a serial port terminal device (or a PC running a terminal

emulator program) to any of the serial ports on the Blue Heat/Net Sync and enter a correct

Password. A command prompt is then sent to the terminal and CDS parameters can be changed

using a command line style of entry.

Blue Heat/Net Sync has configurable line interfaces. Certain settings can affect access to the

SCM. The ports are scanned as follows:

The default line mode setting of all ports is Undefined. Under these conditions, the first two ports

are set to RS-232 mode during port scanning. Access to the SCM is available through these ports

only (you should set all ports to a known state prior to use).

When a port is set to something other than Undefined, any port with a setting of RS-232 or RS485 Full Duplex will be scanned. Otherwise, scanning is not performed and access to SCM is

not available.

NOTE: To access the Blue Heat/Net Sync via the SCM

your serial line interface settings must be at the default

values of 9600 baud, 8 data bits, no parity and 1 stop bit

(9600, 8, n, 1). No flow control is recommended.

In a situation where port scanning is not performed, you can still access the SCM using the push

button reset on the back of the unit. Follow the instructions in the section Activating the Special

Operations Mode and Default Settings to access the SCM in this situation

See the section which describes how the Blue Heat/Net Sync boots for a complete description of

the Bootup process of the Blue Heat/Net Sync and how to access the SCM.

Connect Tech Blue Heat/Net Sync User Manual

SCM Command Reference

SCM commands are entered as strings of ASCII characters with options separated by whitespace

characters. The entire command line is terminated by a CR character or CR/LF character pair.

Command lines can be entered manually (via a terminal or a PC with terminal emulator

program) or sent from an application program.

If an SCM command is entered with no options specified, the command shows the syntax of its

options and the current setting of those options.

Brief Command List

boot Bootup settings

cfg SCM operational settings

exit Exits the SCM application (and optionally reboots the Blue Heat/Net Sync)

help Brief list of available commands and their syntax

info Blue Heat/Net Sync general information and flash verification

net Network settings

Revision 0.03 25

Page 26

Connect Tech Blue Heat/Net Sync User Manual

save Save setting changes to non-volatile flash storage

update Download a new operating system via TFTP and flash,

(uClinux) and loader/SCM image.

Command Details

boot

Syntax: boot [mode=] [file=] [delay=]

Description: This command establishes the Blue Heat/Net Sync boot-up mode. For a detailed

description of the boot-up process of the Blue Heat/Net Sync, see How the Blue

Heat/Net Sync Boots Up in the Appendix.

Options: mode=

A comma-separated list of the following sub-options. Each sub-option is

preceded by either a + or a – to indicate if the sub-option is enabled or disabled.

±flash Enables or disables the ability to boot from the flash memory.

±bootp Enables or disables the ability to obtain the boot-up information from a

Server.

±tftp Enables or disables the ability to download and boot from a file located on

a Server.

file=

This option specifies the default file name used for the boot-up (if TFTP boot is

enabled) and also the default file name when using the flos command.

This can be any sequence of characters up to 128 characters in length. (The

default is BHNuClinux_vvv.gz, where vvv is the current version number of the

“Operating System image”).

delay=

This sets the time duration for accessing the SCM application. It can be set from

2 to 30 seconds, the default is 30. (See the section How the Blue Heat/Net Sync

Boots Up for more information).

cfg

Syntax: cfg [port=] [timeout=] [password=] [prompt=] [file=]

Description: Establishes the settings used by the SCM application to

modify its behavior.

Options: port=

Specifies the port number to scan for a password to gain entry in the SCM.

N = Scan just port N (N=1 to the number of ports on the unit).

255 = Scan all ports on the unit (default unless unit has programmable line

interfaces).

timeout=

Specifies the time duration allowed for a TCM (via telnet) session to be idle (no

activity) before the session is terminated.

0 to 1092 minutes

(default = 5)

Note: A setting of zero allows infinite timeout.

NOTE: The TCM function is currently not available with this

product.

26 Revision 0.03

Page 27

Connect Tech Blue Heat/Net Sync User Manual

password=

This sets the password phrase, which is used to gain access to the SCM and

WCM modes of configuring the Blue Heat/Net. The default is “password”.

prompt=

This setting controls whether a password prompt (and other password entry

status information) is presented to the terminal. This prompting is helpful for

new users of the product but may present a problem when other devices are

connected to the serial port.

yes enables the password prompting (default)

no disables the password prompting

file=

This sets the file name used as a default when using the flldr command.

It can be any sequence of characters up to 128 characters in length. (The default

is “BHNloader_vvv.gz”, where vvv is the current version number of the

“Loader”).

exit

Syntax: exit [-nosave] [-no_reset][-login]

Description: This command is to exit the SCM and reboot the Blue Heat/Net Sync. If CDS

changes have been made a warning message is issued and the SCM will not exit.

Options: -nosave

Exit without saving changes (abandon changes).

-no_reset

Exit SCM without rebooting, maintaining the changes to settings for this session

only. (Booting is continued after the SCM is exited.)

-login

Exit without saving changes, and restart the SCM login process.

help

Syntax: help

Description: Displays a brief list of all the commands.

Options: There are no options for the help command. Please note that specific help for the

options of each command can be obtained by entering any command with a

single “?” argument. An example would be net ?

info

Syntax: info [-v]

Description: This command is used to show basic information about the Blue Heat/Net Sync

unit, like Serial Number and Version Numbers, and performs a confidence

(CRC and Decompression verification) test of the contents of the flash memory.

Options: -v

This option disables the confidence tests.

net

Syntax: net [network= | net=]

Revision 0.03 27

Page 28

Connect Tech Blue Heat/Net Sync User Manual

[my_ip= | mip=]

[server_ip= | sip=]

[gateway_ip= | gip=]

[subnetmask= | snm=]

[broadcast_ip= | bcip=]

[dns_ip=]

[domain=]

[host name=1 host=]

[tcp=]

[mac=]

[dhcp=]

Description: Establishes the network settings.

Options: network= | net=

Sets the “network” portion of the IP address into my_ip, server_ip and

gateway_ip. The address entered is masked by the subnet mask setting before

being applied. This command is a shortcut for quickly setting all the IP

addresses of the unit. See note below.

my_ip= | mip=

This sets the IP address of the Blue Heat/Net Sync unit (default is 192.168.42.1).

See note below.

server_ip= | sip=

This sets the Server IP address. This address determines the address of the

Server to use when the Bootp and tftp mode is enabled (see boot command), and

also as the default Server address to use for the update commands (default is

0.0.0.0). See note below.

gateway_ip= | gip=

This sets the Gateway IP address. This address is used when the Bootp mode is

enabled, default is 0.0.0.0. See note below.

subnetmask= | snm=

This sets the Subnet mask IP address. (The default is 255.255.255.0) See note 1.

broadcast_ip= | bcip=

This sets the Broadcast IP address. This is used when the Bootp mode is

enabled. (The default 255.255.255.255). See note below.

dns_ip=

This sets the IP of Domain Name Server. (The default is 0.0.0.0). This must be

set to update the Blue Heat/Net Sync firmware automatically from Connect

Tech‟s anonymous ftp server.

domain=

This sets the Domain name of the unit. (The default is blueheat.net)

Host name=1 host =

This sets the Host name of the Blue Heat/Net Sync unit. (The default is

BHNssssssss, where “ssssssss” is the serial number of the unit).

tcp=

This sets the base TCP port number used for Host TCP/IP and UDP/IP

communications. The default is 49152 (0xC000)

28 Revision 0.03

Page 29

Connect Tech Blue Heat/Net Sync User Manual

mac=

This displays the MAC address of the unit. (The default is 00:0C:8B:SS:SS:SS,

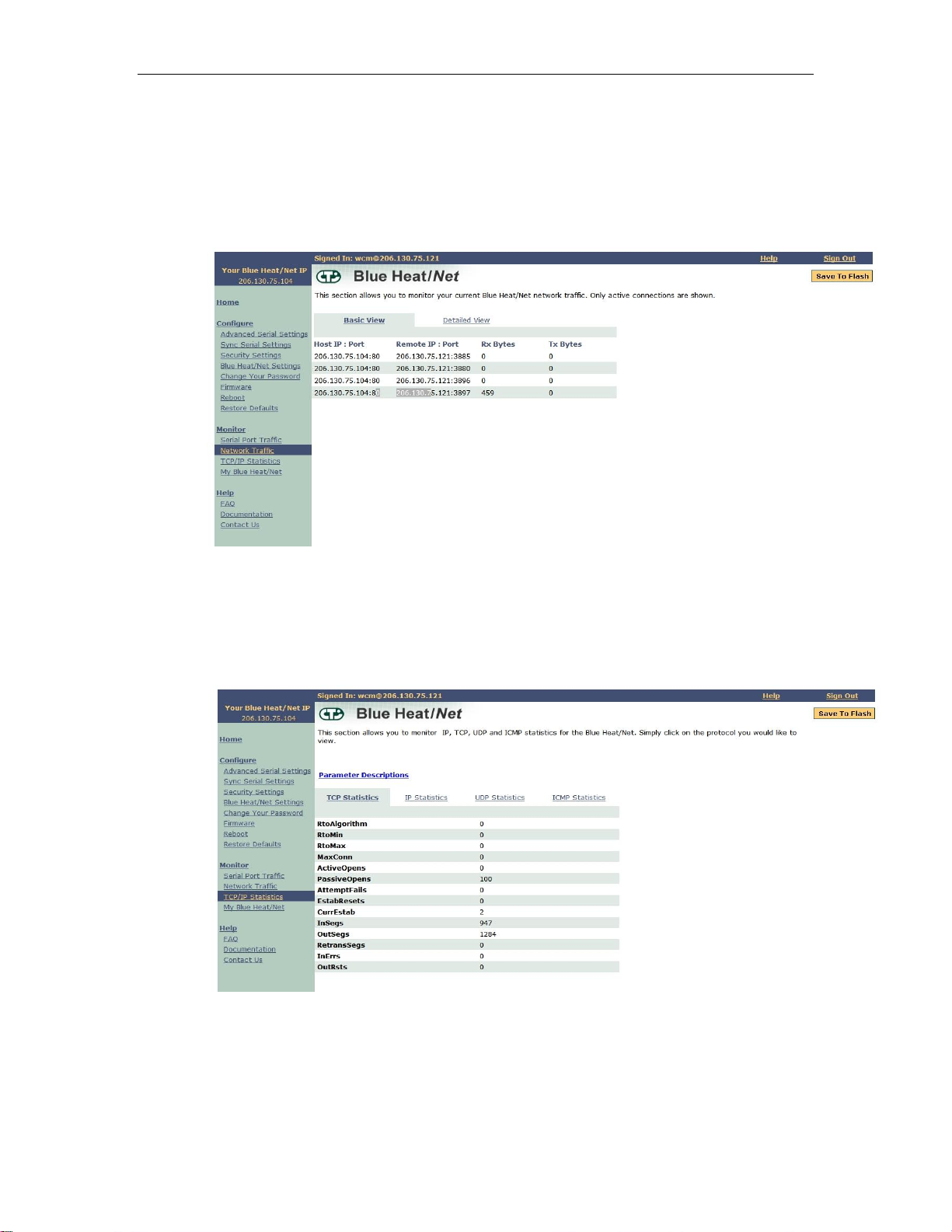

where SS:SS:SS is the hex value of the serial number of the unit). Note: The

MAC address cannot be changed, it can only be displayed.

dhcp=

This enables or disables DHCP support.

yes enables

no disables (default)

NOTES:

All IP addresses are entered in common IP address

notation: ddd.ddd.ddd.ddd where ddd is a decimal number

from 0 to 255.

IP address “my_ip, server_ip, gateway_ip and dns_ip” can

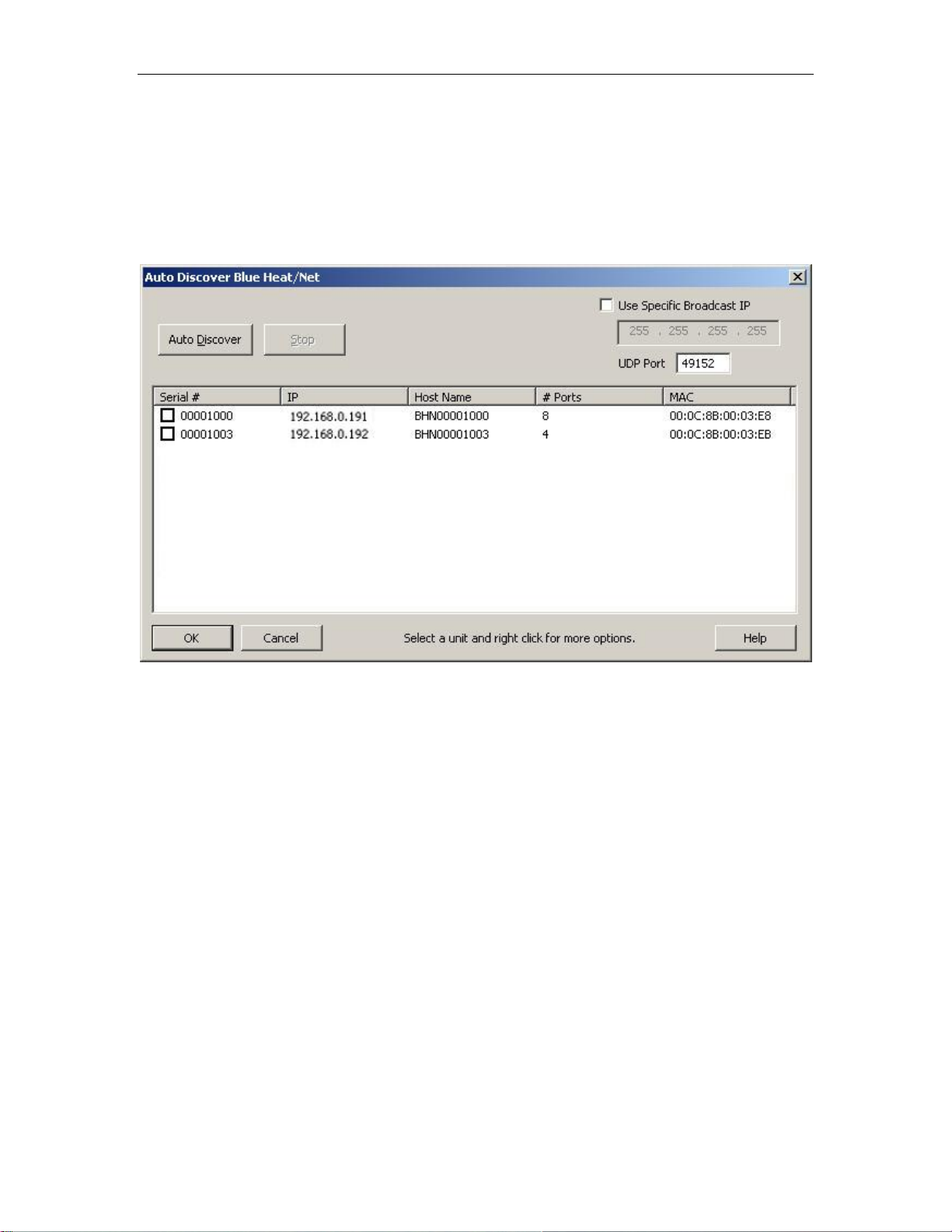

be entered right justified, meaning that the address

entered will be applied to the specified address starting

from the least significant digit, masked by the subnet

mask. For example:

If the subnet mask is set to 255.255.255.0, and the

following command is entered:

net net=12.23.34.00 mip=45 sip=56 gip=67 dns_ip=89

The following IP addresses result:

the Blue Heat/Net Sync unit will be

12.23.34.45

the Server will be 12.23.34.56

the Gateway will be 12.23.34.67

and the DNS IP will be 12.23.34.89

save

update

Syntax: save

Description: This command saves the setting changes into the CDS in the non-volatile (flash)

memory.

Options: (none)

Syntax: update <-os | -loader | -jffs> [server_ip= | sip=] [file=]

Description: Download and store (in flash memory) a new uClinux Operating System image

or a new Loader/SCM image. The download is conducted by a TFTP download

from a Server. After download the image file is checked as being a valid gzip

file (file is decompressed to validate its contents), and then the file is stored in

flash memory. The OS file is stored in flash in its compressed form, but the

Loader is stored uncompressed.

Options: -os | -loader | -jffs

Use -os to update the uClinux OS.

Use –loader to update the loader/SCM.

Use –jffs to update the JFFS system (Journaling Flash File System).

Revision 0.03 29

Page 30

Connect Tech Blue Heat/Net Sync User Manual

server_ip= | sip=

Specify the Server IP address from which the file is to be downloaded.

file=

Specify the file name to download. If the –jffs option is chosen, then the file=

option is mandatory.

NOTE: After downloading, the image is checked to

ensure the file is correctly formatted. If the file is bad the

command exits. The version is checked against your

current version. If they match, you will be prompted to

choose if you wish to program the flash. Enter “y” to

continue. If the version is different, the new version

needs to be saved with the save command when the

update is finished.

When the JFFS is updated, all previous contents are

destroyed. Only use this option when updating to a Blue

Heat/Net Sync that supports Personality settings.

30 Revision 0.03

Page 31

Connect Tech Blue Heat/Net Sync User Manual

WCM (Web Configuration Manager)

Signing In to the Web Configuration Manager

You will need to know the IP address of your Blue Heat/Net Sync unit before you use the Web

Configuration Manager. Use the Serial Configuration Manager to assign the Blue Heat/Net Sync

a valid IP address, or tell the Blue Heat/Net Sync to use DHCP to automatically obtain an IP

address. Please refer to the SCM Command Reference documentation for information on how to

do this.

Once you know your IP address, open your web browser and go to: http://_your_ip_address_/ or

http://www.hostname.com/

You will arrive at the Blue Heat/Net Sync Web Configuration Manager Sign In page. The

default username is wcm. Leave this name as is. The default password is password. Use this

username/password combination and click the Sign In button to log on to the Web Configuration

Manager.

Figure 13: Web Configuration Manager Sign In

Once you have signed in, you should immediately

change the default password.

At this point you should be directed to the Web Configuration Manager homepage.

To sign out of the Web Configuration Manager, just click on the Sign Out link on the upper

right hand side of the Web Configuration Manager.

Revision 0.03 31

Page 32

Connect Tech Blue Heat/Net Sync User Manual

Figure 14: Blue Heat/Net Sync Settings

32 Revision 0.03

Page 33

Connect Tech Blue Heat/Net Sync User Manual

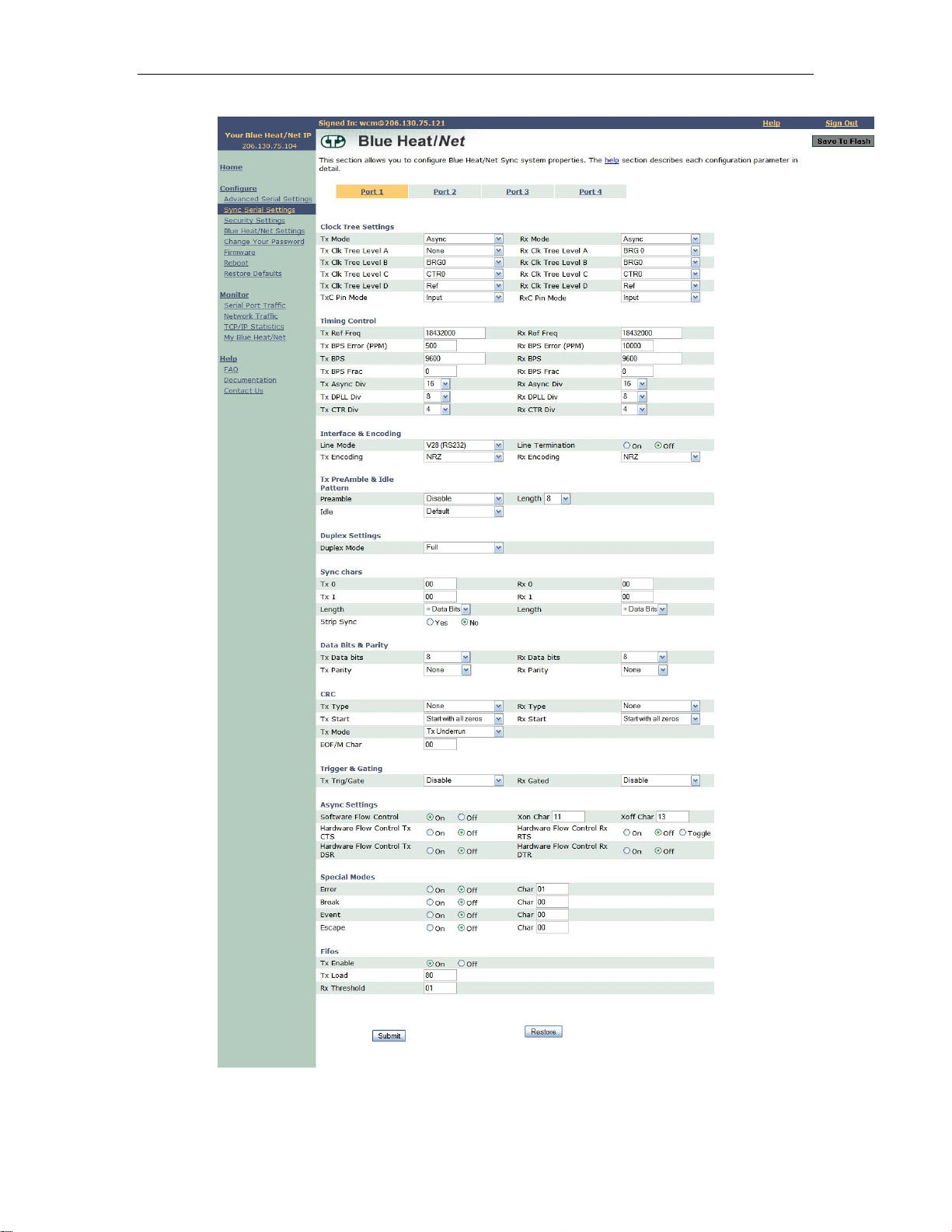

Configure Advanced Serial Settings

The Web Configuration Manager also allows you to configure more advanced serial port

properties. These advanced properties will allow you to configure the XOn Character, XOff

Character, Break Character, Escape Character, Error Character and Event Character, and

Transmit Load Setting for each serial port.

Further, you will be able to specify whether you want to enable Null Stripping or RTS Toggle

for a particular port as well as the option to enable or disable the Break, Event and Error

characters.

By default, all advanced serial properties are disabled. You should only use these advanced

properties if you require them.

You are required to use the ASCII representation of characters using the respective hexidecimal

values. For example, if you wanted your XOn character to be capital 'A', you would specify a

hex value of 41.

We have provided you with an ASCII table on the Advanced Serial Port Properties page for your

convenience. Click on the ASCII Table link, and an ASCII table will open in a new window.

Each serial port parameter has been abbreviated due to space constraints. We have provided

another link which describes the abbreviated parameter descriptions. Click on the Parameter

Descriptions link, and a new window will open which contains a description of each parameter.

Configure Blue Heat/Net Sync Settings

This section provides various Blue Heat/Net Sync Configuration options, and shows you the

saved versus current settings. The details for each configuration option are provided below:

Flash Enabled: This option enables or disables the ability of the Blue Heat/Net Sync to

•

boot-up from flash memory.

Bootp Enabled: This option enables or disables the Blue Heat/Net‟s ability to obtain

•

boot-up information from the server (see "Server IP Address" below).

TFTP Enabled: This option enables or disables the ability to download and boot from a

•

file located on a server (see "Server IP Address" below).

DHCP Enabled: This option enables or disables the use of DHCP. If DHCP is enabled,

•

the Blue Heat/Net Sync will attempt to automatically obtain an IP address. If DHCP is

disabled, you must manually specify an IP address for the Blue Heat/Net.

Configuration Port: This option sets the port to scan for the password to gain entry into

•

the Serial Configuration Manager. You can specify a particular port, or specify the Scan

All Ports option. In this case the Blue Heat/Net Sync will scan all ports for the password

when the Blue Heat/Net Sync is booting. The default setting is Scan All Ports.

Session Timeout: This option specifies the time allowed between web page navigation.

•

The default session timeout is 5 minutes. This means if the Web Configuration Manager

has not received any requests for more than 5 minutes, you will be automatically logged

out. You can set the timeout from 1 minute to 2 hours, or disable the session timeout all

together by selecting the Disable Timeout option.

Boot Delay: This option specifies time allowed for gaining access to the Serial

•

Configuration Manager while the Blue Heat/Net Sync is booting. The time ranges from

2 seconds to 30 seconds. The default setting is 30 seconds.

Revision 0.03 33

Page 34

Connect Tech Blue Heat/Net Sync User Manual

Server IP Address: This option sets the server IP address. This is used as the Server

•

address to use when bootp mode or TFTP mode is enabled. The default Server IP

address is 0.0.0.0

Blue Heat/Net Sync IP Address: This option sets the IP address of your Blue Heat/Net.

•

The default IP address for your Blue Heat/Net Sync is 192.168.42.1

Domain Name: This option sets the domain name of your Blue Heat/Net. The default

•

domain name is blueheat.net.

Host Name: This option sets the hostname of your Blue Heat/Net. The default hostname

•

is BHNssssss, where ssssss is your Blue Heat/Net Sync serial number.

Gateway IP Address: This option sets the Gateway IP address for your Blue Heat/Net.

•

The default Gateway IP address is 0.0.0.0

Broadcast IP Address: This option sets the Broadcast IP address. The default Broadcast

•

IP address is 255.255.255.255.

Subnet Mask: This option sets the Subnet mask IP address. The default Subnet mask IP

•

address is 255.255.255.0.

Bootfile Name: This option specifies the default file name which will be used for Blue

•

Heat/Net Sync boot-up, if TFTP is enabled. If TFTP is enabled, the Blue Heat/Net Sync

will attempt to download the bootfile you specify from a Server IP address you specify

(see "Server IP Address" above). The bootfile name should reference a valid uClinux

kernel image. If TFTP is enabled, the Blue Heat/Net Sync unit will attempt to download

this image, and will also attempt to decompress the image and run it.

TCP Port: This option allows you to change the starting local TCP port that is used to

•

service clients connecting to the Blue Heat/Net Sync unit. The default TCP port is

49152. When altering the TCP port on the Blue Heat/Net Sync unit, you must also alter

it on the user‟s side.

Domain Server IP Address: This option sets the Domain Name Server IP address. The

•

default DNS IP address is 0.0.0.0.

After you've made any necessary configuration changes, click the Submit button at the bottom of

the page. A confirmation page will show up confirming the Blue Heat/Net Sync changes.

34 Revision 0.03

Page 35

Connect Tech Blue Heat/Net Sync User Manual

Figure 15: Configuring Blue Heat/Net Sync Settings

Configure Firmware

This section enables you to download new firmware to the Blue Heat/Net Sync unit. Select a

download source and a specific firmware file path, if applicable, and then submit the download

request. This section also provides a link to reboot your Blue Heat/Net. This is standard

procedure after installing new firmware.

Figure 16: Firmware Upgrades/Downloads

Restore Defaults

The Restore Defaults page enables you to quickly reset all or some of the default basic,

advanced, security, Blue Heat/Net Sync or system settings of your Blue Heat/Net Sync.

Revision 0.03 35

Page 36

Connect Tech Blue Heat/Net Sync User Manual

NOTE: This function is not currently operational.

Figure 17: Restore Default Settings

Saving To Flash

When you make configuration changes, the changes are stored temporarily in memory. If you

reboot your Blue Heat/Net Sync at this point, any configuration changes you made will be lost.