Page 1

Blue Heat/Net

Ethernet-to-Serial Communications

User Manual

Connect Tech Inc

42 Arrow Road

Guelph, Ontario

N1K 1S6

Tel: 519-836-1291

Toll: 800-426-8979 (North America only)

Fax: 519-836-4878

Email: sales@connecttech.com

support@connecttech.com

Web: www.connecttech.com

CTIM-00016 Revision 0.13, July 2006

Page 2

Limited Lifetime Warranty

Connect Tech Inc. provides a Lifetime Warranty for all Connect Tech Inc. products. Should this

product, in Connect Tech Inc.'s opinion, fail to be in good working order during the warranty

period, Connect Tech Inc. will, at its option, repair or replace this product at no charge, provided

that the product has not been subjected to abuse, misuse, accident, disaster or non Connect Tech

Inc. authorized modification or repair.

You may obtain warranty service by delivering this product to an authorized Connect Tech Inc.

business partner or to Connect Tech Inc. along with proof of purchase. Product returned to

Connect Tech Inc. must be pre-authorized by Connect Tech Inc. with an RMA (Return Material

Authorization) number marked on the outside of the package and sent prepaid, insured and

packaged for safe shipment. Connect Tech Inc. will return this product by prepaid ground

shipment service.

The Connect Tech Inc. Lifetime Warranty is defined as the serviceable life of the product. This

is defined as the period during which all components are available. Should the product prove to

be irreparable, Connect Tech Inc. reserves the right to substitute an equivalent product if

available or to retract Life Time Warranty if no replacement is available.

The above warranty is the only warranty authorized by Connect Tech Inc. Under no

circumstances will Connect Tech Inc. be liable in any way for any damages, including any lost

profits, lost savings or other incidental or consequential damages arising out of the use of, or

inability to use, such product.

Connect Tech Blue Heat/Net User’s Manual

Copyright Notice

The information contained in this document is subject to change without notice. Connect Tech

Inc. shall not be liable for errors contained herein or for incidental consequential damages in

connection with the furnishing, performance, or use of this material. This document contains

proprietary information that is protected by copyright. All rights are reserved. No part of this

document may be photocopied, reproduced, or translated to another language without the prior

written consent of Connect Tech, Inc.

Copyright 1997 - 2006 by Connect Tech, Inc.

Trademark Acknowledgment

Connect Tech, Inc. acknowledges all trademarks, registered trademarks and/or copyrights

referred to in this document as the property of their respective owners.

Not listing all possible trademarks or copyright acknowledgments does not constitute a lack of

acknowledgment to the rightful owners of the trademarks and copyrights mentioned in this

document.

Revision 0.13 9

Page 3

Connect Tech Blue Heat/Net User’s Manual

Certification Statements

Class A Computing Device

Blue Heat/Net

Connect Tech Inc. declares that the product(s) covered by the contents of this manual have been

tested and found compliant with the below listed standards as required by the Electromagnetic

Compatibility (EMC) Directive for General Immunity Compliance.

EN 55022 Conducted and Radiated emissions

CISPR 22 Class A

EN 55024 Immunity to Disturbances

EN 61000-4-2 EN 61000-4-4 EN 61000-4-6 EN 61000-3-2 Exempt

EN 61000-4-3 EN 61000-4-5 EN 61000-4-11 EN 61000-3-3 Pass

The above satisfy the requirements of:

USA: FCC – CFR47, Part 15, part 2

Canada: ICES-003

Europe EMC Directive

Japan: VCCI

Australia/New Zealand:

AS/NZS

10 Revision 0.13

Page 4

Connect Tech Blue Heat/Net User’s Manual

Table of Contents

Limited Lifetime Warranty..............................................................................................................................9

Copyright Notice..............................................................................................................................................9

Trademark Acknowledgment...........................................................................................................................9

Certification Statements.................................................................................................................................10

Table of Contents...........................................................................................................................................10

Table of Contents...........................................................................................................................................11

Introduction....................................................................................................................................................14

Features...............................................................................................................14

Understanding virtual COM ports.........................................................................15

Customer Support Overview................................................................................16

Contact Information..............................................................................................16

Blue Heat/Net Installation Overview.............................................................................................................17

Hardware Installation.....................................................................................................................................17

Connecting the Blue Heat/Net to your Network:...................................................17

Direct Connect .........................................................................................................17

Connecting to the Network.......................................................................................17

Ethernet LEDs..........................................................................................................18

Serial Port LEDs......................................................................................................19

Connecting Serial Devices...................................................................................19

RS-232 Connections: ...............................................................................................19

Connecting Power................................................................................................21

Activating the Special Operations Mode and Default Settings .............................21

Using the Reset Button to activate the Special Operations Mode............................21

Selecting a Special Operation..................................................................................22

Power On Diagnostics:.........................................................................................23

LED Error Codes .....................................................................................................23

Mounting Bracket .................................................................................................26

SCM and TCM Cabling requirements...................................................................27

SCM: Serial Configuration Manager.......................................................................27

TCM: Telnet Configuration Manager......................................................................27

Setting a Static or Dynamic IP Address................................................................28

Set the IP Address using the Web Configuration Manager......................................28

Set the IP Address using the Serial Configuration Manager....................................28

Blue Heat/Net Configuration ......................................................................................................................... 29

CDS (Configuration Data Space) .........................................................................30

Description...............................................................................................................30

Access to CDS Parameters.......................................................................................30

SCM (Serial Configuration Manager) ...................................................................31

Description...............................................................................................................31

Getting Access to the SCM.......................................................................................31

SCM Command Reference.......................................................................................31

TCM (Telnet Configuration Manager)...................................................................40

Description...............................................................................................................40

Getting Access to TCM............................................................................................40

TCM Command Reference.......................................................................................41

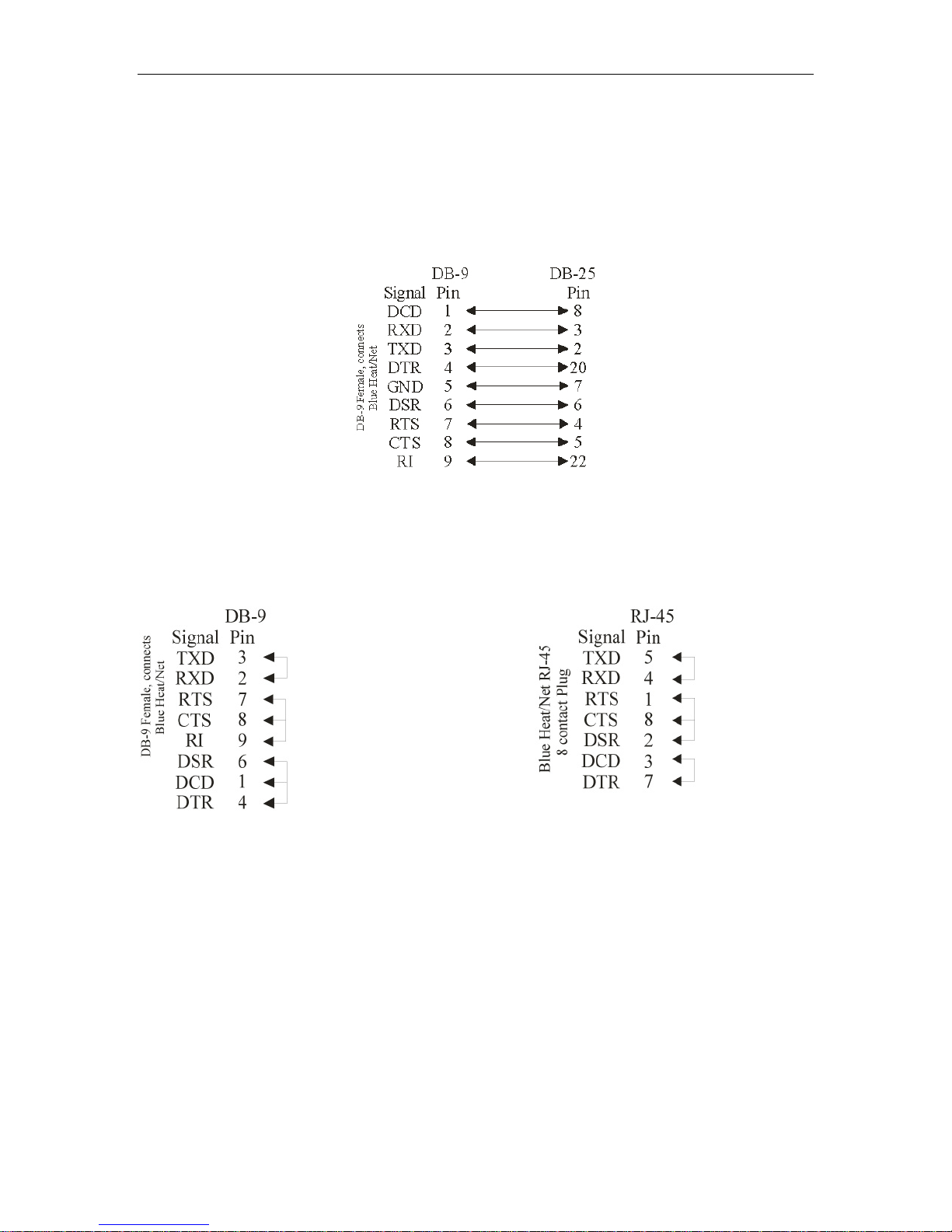

WCM (Web Configuration Manager).................................................................... 43

Signing In to the Web Configuration Manager........................................................43

Configuring Your Blue Heat/Net..............................................................................44

Monitoring Your Blue Heat/Net...............................................................................59

Field Server Protocols.............................................................................................62

Software Installation for Windows ................................................................................................................69

Installing the Blue Heat/Net Configuration Manager.............................................69

Running the Configuration Manager.....................................................................73

Device Installation................................................................................................73

Configure Default Blue Heat/Net.............................................................................73

Add New Blue Heat/Net...........................................................................................74

Auto Discover Blue Heat/Net...................................................................................74

Configuring the Blue Heat/Net..............................................................................75

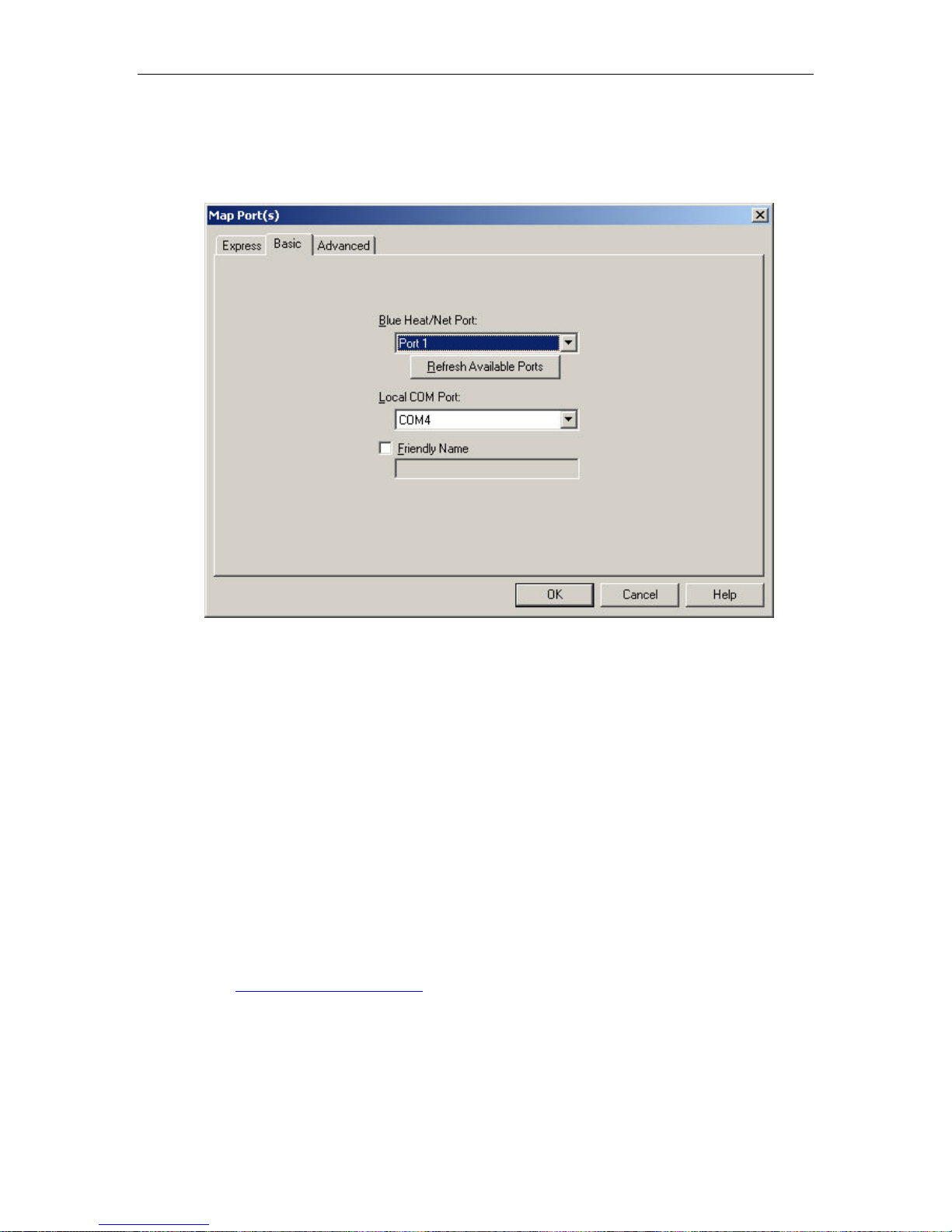

Port Mapping...........................................................................................................76

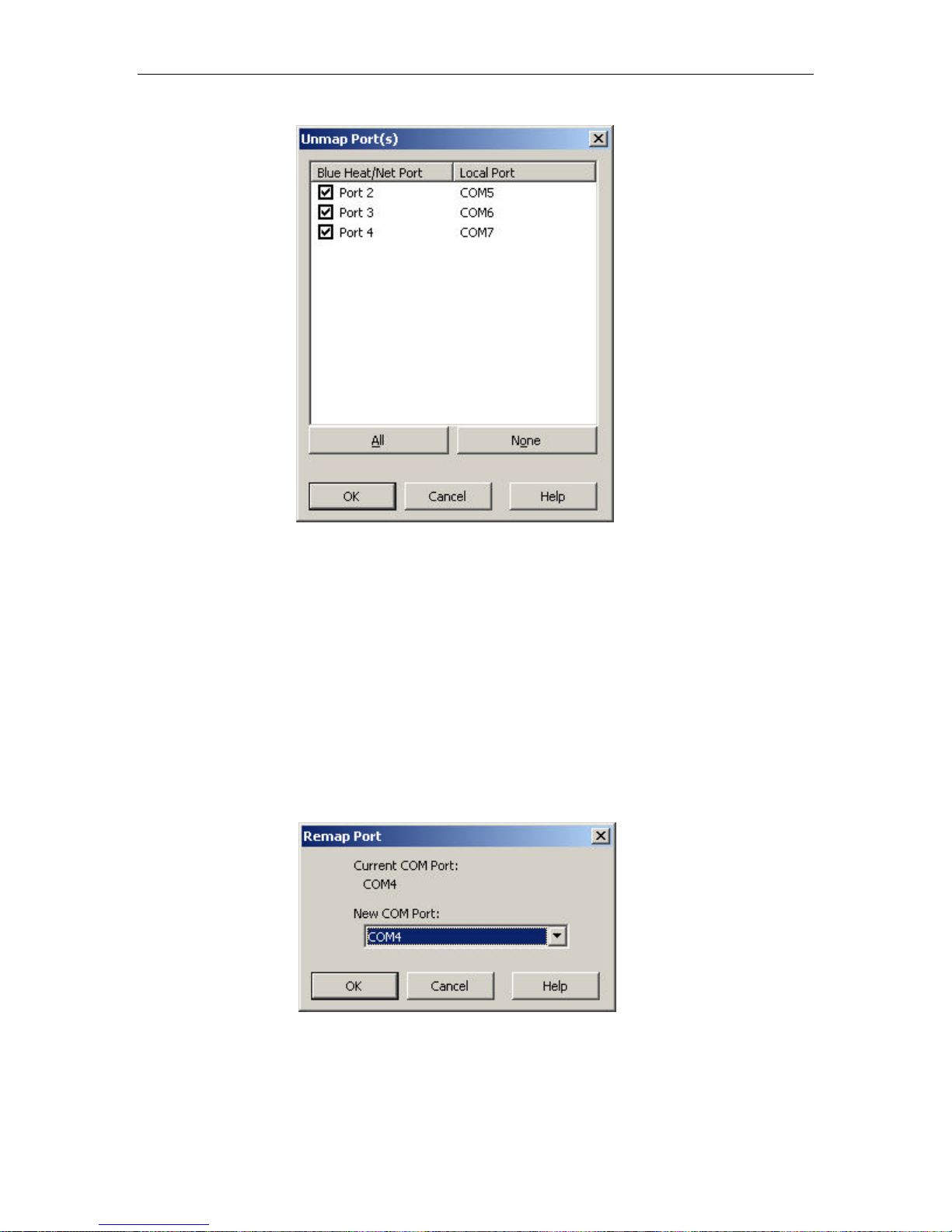

Unmap Port(s):........................................................................................................82

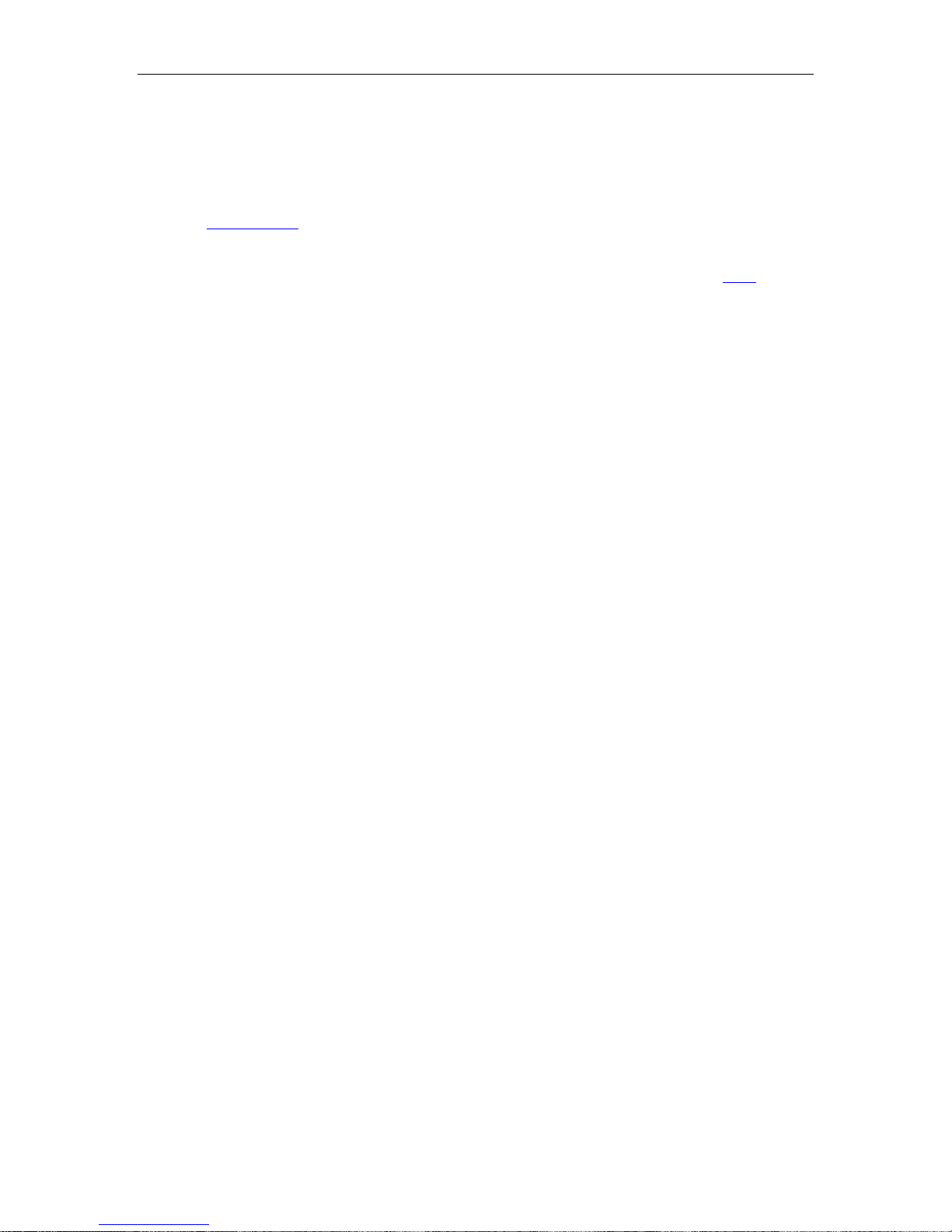

Remapping Ports......................................................................................................83

Revision 0.13 11

Page 5

Connect Tech Blue Heat/Net User’s Manual

Port Properties ........................................................................................................83

Advanced Settings ............................................................................................85

Special Options........................................................................................................85

RS-232......................................................................................................................86

RS-485 Options (on RS-422/485 ports)....................................................................86

Baud Rate Mapping .................................................................................................86

COM Port Number...................................................................................................86

Scan .........................................................................................................................87

Defaults Button........................................................................................................ 87

Export Settings .........................................................................................................87

Import Settings.........................................................................................................87

Replacing your Blue Heat/Net:................................................................................87

Removing your Blue Heat/Net:................................................................................88

Blue Heat/Net Properties:........................................................................................ 88

Driver Removal........................................................................................................88

Software Installation for Linux......................................................................................................................89

Installing the Linux host driver.............................................................................. 89

Linux host driver setup using auto discovery...........................................................89

Firmware Upgrades........................................................................................................................................90

Upgrade using WCM (Web Configuration Manager)..............................................90

Upgrade using TCM (Telnet Configuration Manager)............................................90

Upgrade using SCM (Serial Configuration Manager).............................................90

Appendix .......................................................................................................................................................91

Blue Heat/Net Specifications................................................................................91

Products...................................................................................................................92

Options.....................................................................................................................92

Protocol Descriptions ...........................................................................................93

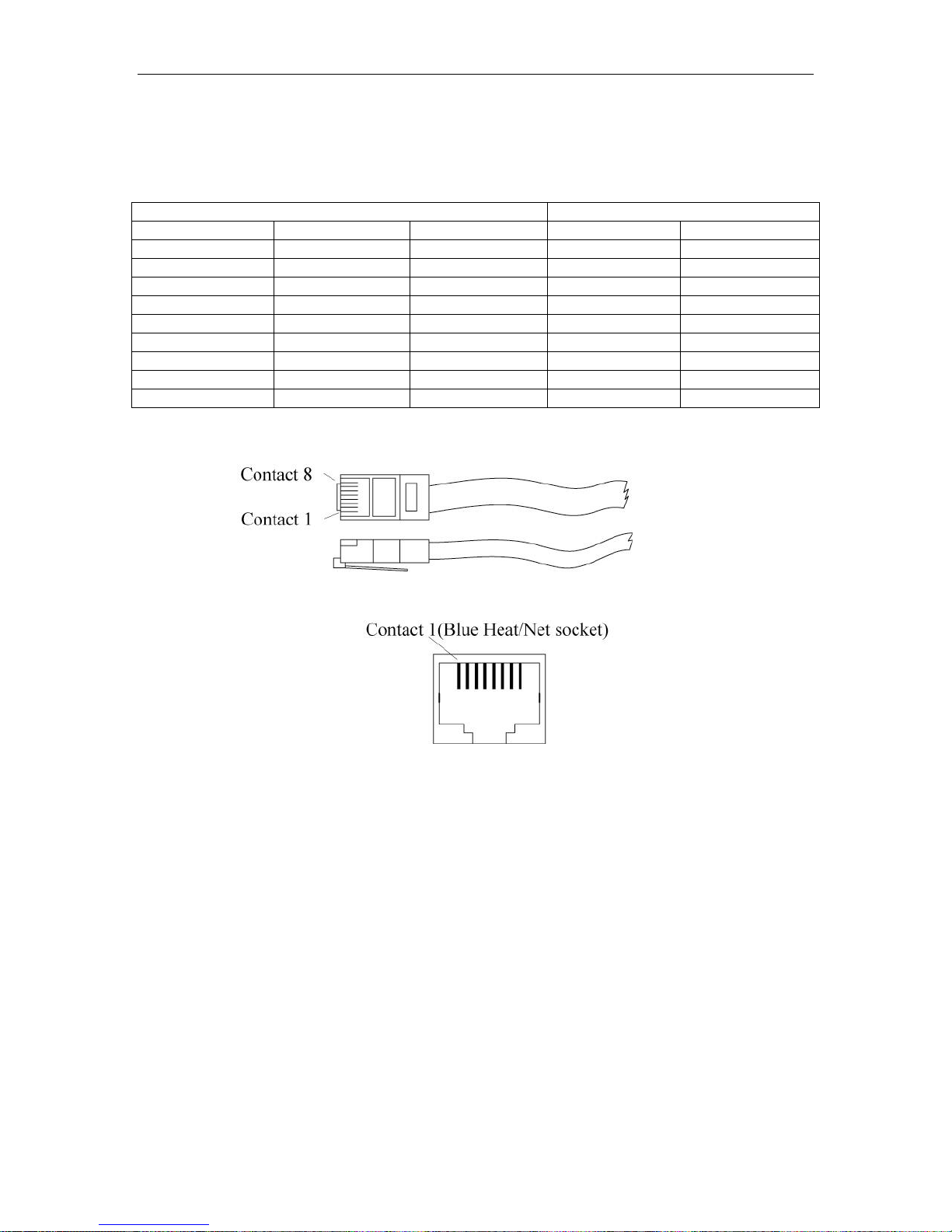

Pinouts.................................................................................................................94

RS-232 and RS-485..................................................................................................94

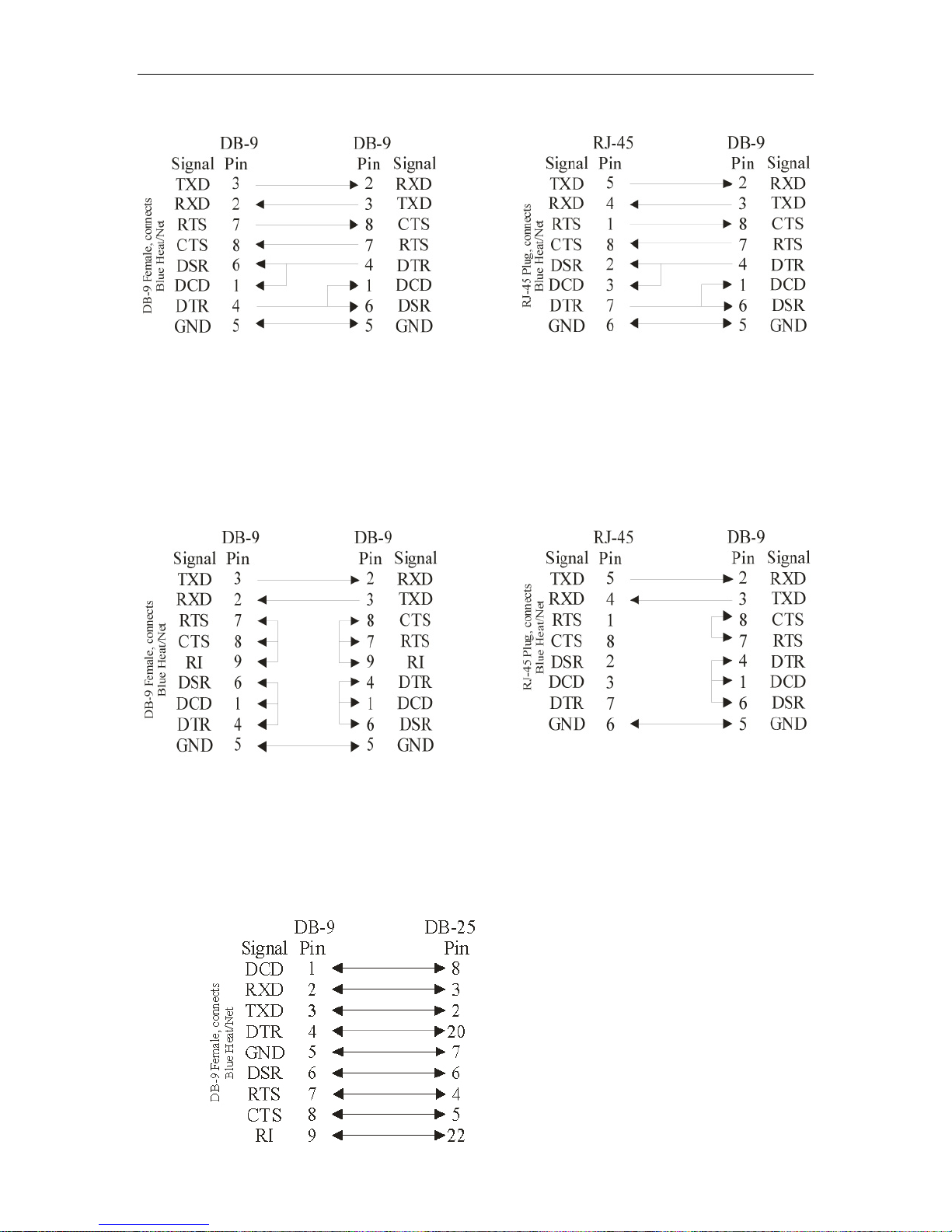

Cabling Examples: ...............................................................................................94

Typical RS-232 null modem connection:..................................................................94

Basic “3 wire” RS-232 null modem connection:.....................................................95

Connecting to DCE type devices:.............................................................................95

Loopback Connectors:.............................................................................................96

RS-422/485 Examples: ........................................................................................96

RS-422/485 Wiring Tips: .........................................................................................96

4-wire (full duplex, “RS-422 mode”) Wiring hardware flow control......................96

Four-wire (full duplex, “RS-422 mode”) Wiring without hardware flow control....97

Four-wire (full duplex multi-drop, “RS-485 mode”)...............................................97

Two-wire (1/2 duplex, “RS-485 mode”) Wiring ......................................................98

RS-485 Multi-drop Topology, Two-Wire and Four-Wire.........................................98

Default Settings....................................................................................................99

Network Settings......................................................................................................99

Boot Settings............................................................................................................99

SCM Operation Settings...........................................................................................99

CDS (Configuration Data Space) .........................................................................99

Common Configuration Setups..........................................................................100

Static IP Setup........................................................................................................100

DHCP Setup...........................................................................................................101

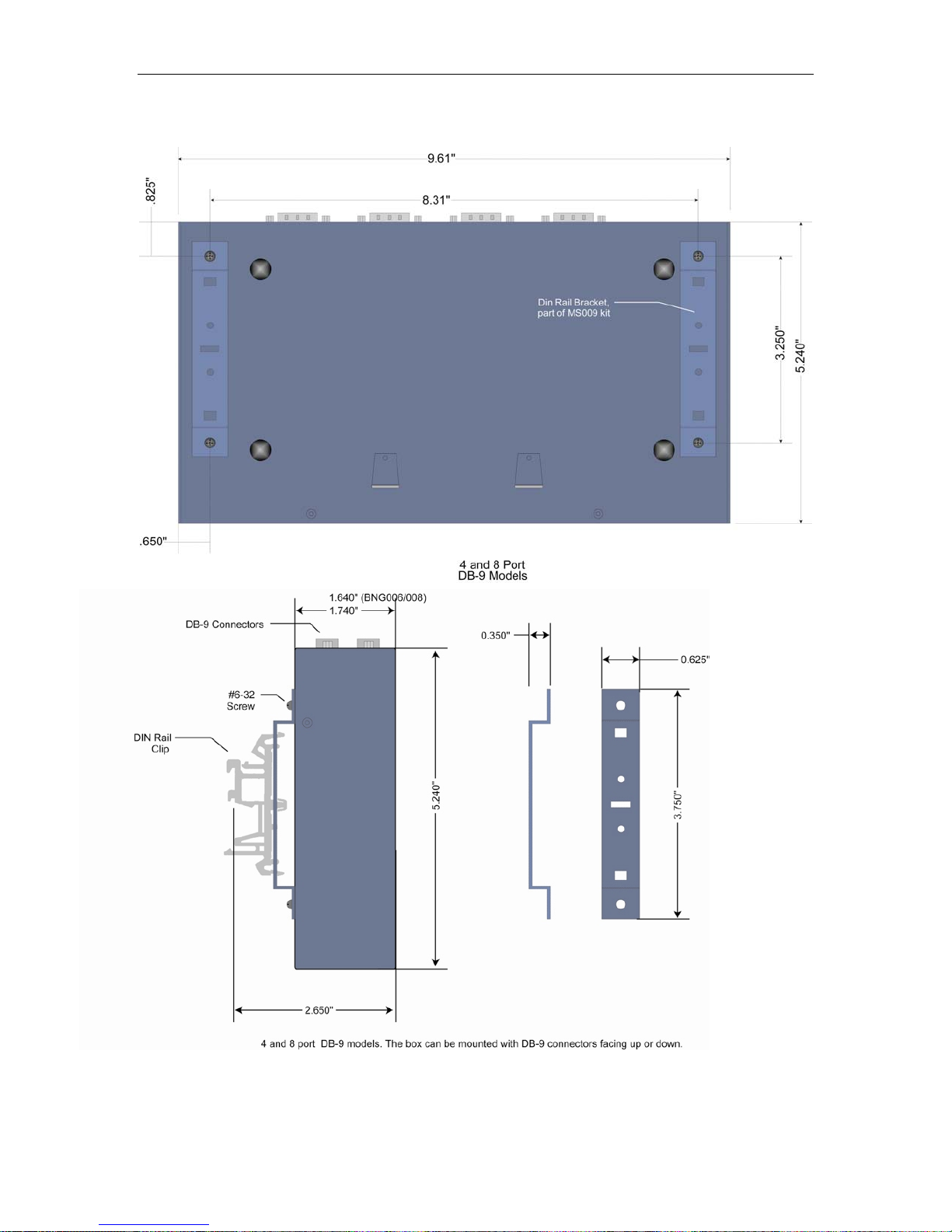

DIN Rail Mounting Option:..................................................................................102

How the Blue Heat/Net Boots Up.......................................................................104

Bootup Sequence....................................................................................................105

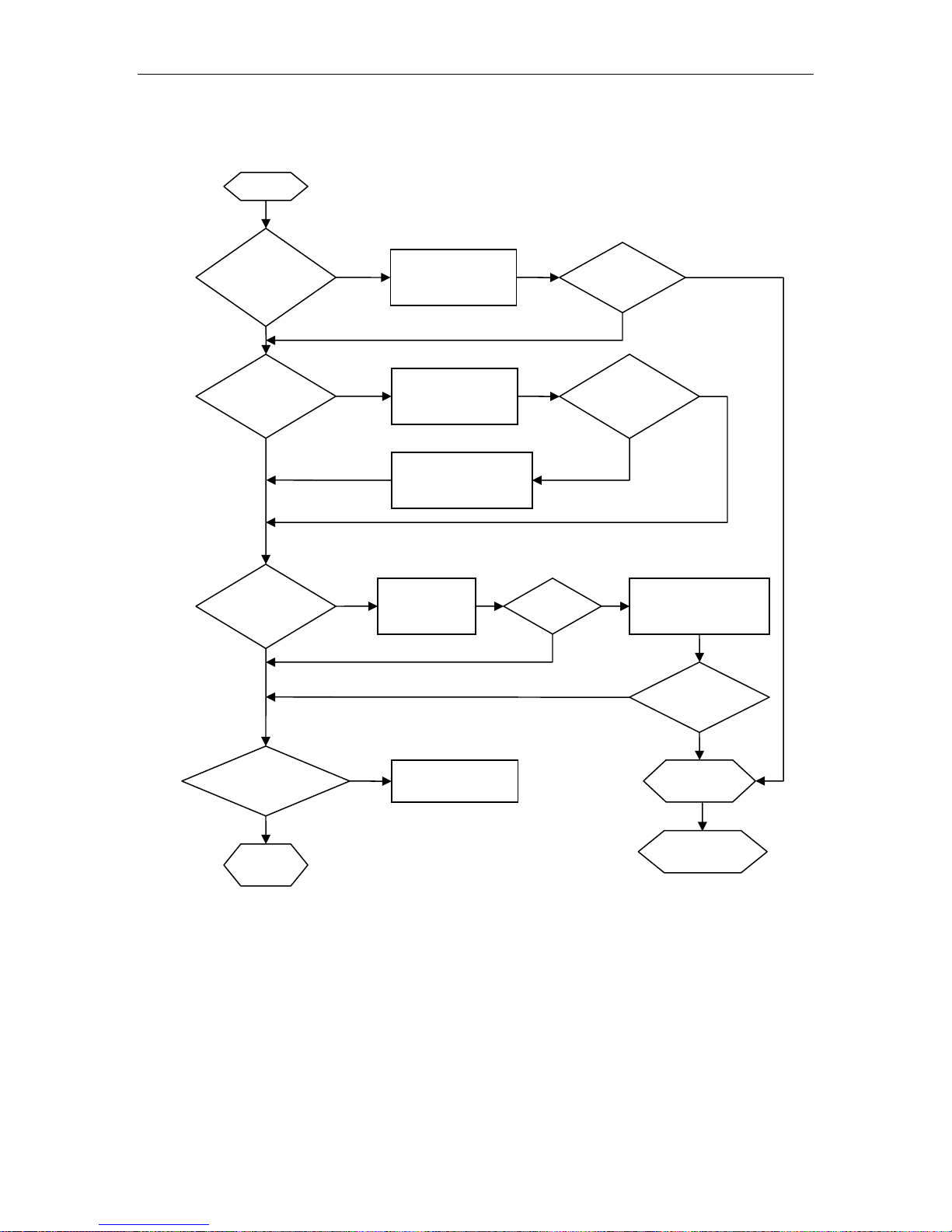

Flowchart of Special Operations Mode using the reset button..............................106

Asynchronous communications Tutorial................................................................106

Serial Line Interface Tutorial ..............................................................................107

RS-232 Line Interface:...........................................................................................107

RS-485 Line Interface:...........................................................................................107

Bus contention on RS-485 multi-drop networks:....................................................110

Bias and Termination Resistors in RS-485 networks:............................................111

12 Revision 0.13

Page 6

Connect Tech Blue Heat/Net User’s Manual

List of Figures

Figure 1: LED locations on 2, 4 and 8 port Blue Heat/Net models ............................................................. 18

Figure 2: Typical RS-232 null modem connection....................................................................................... 19

Figure 3: Basic 3-wire RS-232 null modem connection............................................................................... 19

Figure 4: Recommended pinouts for loopback connectors. ......................................................................... 20

Figure 5: Power connector illustration........................................................................................................ 21

Figure 6: LED error code example.............................................................................................................. 23

Figure 7: Web Configuration Manager Sign In........................................................................................... 43

Figure 8: Configuring Basic Serial Port Settings (RJ-45 Models)............................................................... 44

Figure 9: Configuring Basic Serial Port Settings (DB-9 Models)................................................................ 45

Figure 10: PPP Call configuration.............................................................................................................. 47

Figure 11: PPP Answer Configuration........................................................................................................ 49

Figure 12: Raw TCP Server configuration .................................................................................................. 50

Figure 13: Raw TCP Client configuration................................................................................................... 51

Figure 14: Configuring Advanced Serial Port Properties ........................................................................... 54

Figure 15: Configuring Security Settings..................................................................................................... 55

Figure 16: Configuring Blue Heat/Net Settings........................................................................................... 56

Figure 17: Firmware Upgrades/Downloads................................................................................................ 57

Figure 18: Restore Default Settings............................................................................................................. 57

Figure 19: Saving To Flash.......................................................................................................................... 58

Figure 20: Monitoring Serial Port Activity.................................................................................................. 59

Figure 21: Monitoring Network Traffic ....................................................................................................... 60

Figure 22: Monitoring TCP/IP Statistics..................................................................................................... 60

Figure 23: My Blue Heat/Net Hardware Details......................................................................................... 61

Figure 24: My Blue Heat/Net Software Details............................................................................................ 61

Figure 25: WCM Basic Serial Screen.......................................................................................................... 62

Figure 26: WCM Protocol Map................................................................................................................... 67

Figure 27: Blue Heat/Net Driver/Software Installation CD......................................................................... 69

Figure 28: Blue Heat/Net Software Installation Screen............................................................................... 70

Figure 29: Blue Heat/Net Configuration Manager, Installation complete screen....................................... 72

Figure 30: My Blue Heat/Net Places screen................................................................................................ 73

Figure 31: Add or Auto Discover Blue Heat/Net menu screen .................................................................... 73

Figure 32: Add Blue Heat/Net screen.......................................................................................................... 74

Figure 33: Auto Discover Blue Heat/Net screen.......................................................................................... 75

Figure 34: Installed Blue Heat/Net screen................................................................................................... 75

Figure 35: Map Port(s) menu....................................................................................................................... 76

Figure 36: Map Port(s) Express method screen........................................................................................... 77

Figure 37: Found New Hardware Wizard.................................................................................................... 78

Figure 38: Configuration Manager Window after successfully mapping ports........................................... 79

Figure 39: Basic Port Mapping option........................................................................................................ 80

Figure 40: Advanced port mapping interface .............................................................................................. 81

Figure 41: Port action menu........................................................................................................................ 82

Figure 42: Unmap Port window................................................................................................................... 83

Figure 43: Remap Port window................................................................................................................... 83

Figure 44: Port Properties window.............................................................................................................. 84

Figure 45: Advanced settings window.......................................................................................................... 85

Figure 46: Baud Rate Mapping options....................................................................................................... 86

Figure 47: Replace Blue Heat/Net window .................................................................................................. 87

Figure 48: Blue Heat/Net properties............................................................................................................ 88

Figure 49: Remove Drivers window............................................................................................................. 88

Figure 50: DIN Rail mount option for Blue Heat/Net 2............................................................................. 102

Figure 51: DIN rail mount option for four and eight port DB-9 models.................................................... 103

Figure 52: Bootup sequence....................................................................................................................... 105

Figure 53: Bootup sequence via Reset Button............................................................................................ 106

Figure 54: Typical Asynchronous Date frame........................................................................................... 106

Figure 55: RS-232 signals.......................................................................................................................... 107

Revision 0.13 13

Page 7

Connect Tech Blue Heat/Net User’s Manual

Introduction

Connect Tech’s Blue Heat/Net enables you to remotely access your RS-232 and RS-422/485

serial devices via your Ethernet LAN or the Internet. Once installed, you can network-enable any

device that is designed to be connected to a serial port. Your industrial serial communication

devices will no longer be tied to a single computer. The Blue Heat/Net hardware is easy to

install, involving little more than plugging the unit into the appropriate locations and performing

some simple configuration steps, as outlined in this manual.

Driver setup is made easy by the Blue Heat/Net’s auto-detection feature. The software does the

work of locating the units, and the Configuration Manager leads you through the rest of the setup

process.

The Blue Heat/Net’s firmware is easily configured with a choice of methods: web browser,

Telnet, or direct serial connection with a terminal and/or terminal software. Once you’ve

configured the Blue Heat/Net to your specifications, you’ll be able to start remotely accessing

your devices immediately.

Features

●

Includes an auto-sensing 10Base-T, 100Base-TX LAN interface

●

Programmable uClinux embedded operating system running on a ColdFire embedded

processor

●

Power over Ethernet (PoE) option for 2 port models

●

Free Software Development Kit available

●

Serial ports on the unit can be linked to one or more remote computers via an Ethernet LAN

and accessed using standard serial applications

●

MDI/MDI-X

model (enables use of cross-over or straight through cable)

●

Serial ports can be run at speeds up to 460.8 Kbps on RS-422/485 ports (and RS-232 ports

on 2 port models) and 230.4 Kbps on RS-232 ports (4 and 8 port models)

●

Full modem control and hardware flow control pins on all ports

●

Supports IP, TCP, UDP, ARP, RARP, TFTP, DHCP, BOOTP, HTTP, PPP, Telnet and DNS

●

Use of TCP/IP means communications can be routed to support WANs as well as LANs.

The Blue Heat/Net does not have to be located in the same site as the controlling computer

●

Point-to-Point Protocol (PPP) client and server

●

Raw TCP client and server

●

Several levels of security are built into the Blue Heat/Net that can limit connections and

help ensure the privacy of data flow

●

Network boot or booting from built-in Flash Memory

●

Firmware upgrades are downloadable

●

Configuration of Blue Heat/Net units can be done via Web Browser, Telnet or direct serial

connection

●

Software switchable RS-232/422/485 with bias/termination models are available

●

Front mounted diagnostic LEDs

●

Wall mount bracket included

●

DIN Rail mount available on DB-9 models

●

1U rack mount available for BNG models

autodetect cabling feature prevents improper cabling connections on 2 port

14 Revision 0.13

Page 8

Understanding virtual COM ports

In a typical serial port setup, the application communicates directly with the connected serial

port hardware.

Virtual COM ports differ in that the application communicates with a network protocol layer that

transfers the necessary information to and from the remote serial ports. The virtual ports appear

as standard serial ports to the application, but in reality, the data is translated into a series of

Ethernet messages between the Blue Heat/Net unit and the host computer. The serial port is not

physically connected to the host computer, but this is transparent to the application trying to

access it.

There are several advantages to using virtual COM ports, which include:

Distance – The serial ports can be a very long distance away from the host computer. They

are not limited by the standard electrical characteristics of the RS-232 or RS-422 interface

because the primary data transfer is being done via Ethernet. Depending on the set up, these

serial ports can be at a different location and the Internet can act as the carrier of the serial

port traffic.

Speed – Short RS-232/422 cable lengths can be used with the primary distance relying on

the network connection. The capacitance of long lengths of serial cable does not limit data

speeds in these cases.

Cabling – Cost effective Ethernet cabling can be used for the transfer of information to the

Blue Heat/Net and often this is part of the existing networking infrastructure. Putting some

serial ports in a remote location can be as easy as plugging in a Blue Heat/Net to the

Ethernet Network. This provides a simple, clean cabling arrangement.

Port Sharing – In some applications, it is desirable to have a serial resource that is accessed

and shared by more than one host computer. Connect Tech’s Virtual Serial Port technology

allows this to be done easily.

Routing – Different ports on a Blue Heat/Net can be connected to multiple host computers.

Monitoring – The Virtual Serial Ports can easily be monitored to ensure everything is

working correctly because they are on the network.

Connect Tech Blue Heat/Net User’s Manual

Revision 0.13 15

Page 9

Connect Tech Blue Heat/Net User’s Manual

Customer Support Overview

If you experience difficulties after reading the manual and/or using the product, contact the

Connect Tech reseller from which you purchased the product. In most cases the reseller can help

you with product installation and difficulties.

In the event that the reseller is unable to resolve your problem, our highly qualified support staff

can assist you. Our support section is available 24 hours a day, seven days a week on our

website at:

www.connecttech.com/sub/support/support.asp

more information on how to contact us directly. Our technical support is always free.

Contact Information

We offer three ways for you to contact us:

Telephone/Facsimile

Technical Support representatives are ready to answer your call Monday through Friday, from

8:30 a.m. to 5:00 p.m. Eastern Standard Time. Our numbers for calls are:

Telephone: 800-426-8979 (North America only)

Telephone: 519-836-1291 (Live assistance available 8:30 a.m. to 5:00 p.m. EST, Monday to

Friday)

Facsimile: 519-836-4878 (on-line 24 hours)

Email/Internet

You may contact us through the Internet. Our email and URL addresses are:

sales@connecttech.com

support@connecttech.com

www.connecttech.com

Mail/Courier

You may contact us by letter and our mailing address for correspondence is:

Connect Tech Inc.

Technical Support

42 Arrow Road

Guelph, Ontario

Canada N1K 1S6

. See the contact information section below for

Note:

Please go to the

Support Center

manuals, installation guides, device driver software and

technical tips.

Submit your technical support questions to our customer

support engineers via the

website.

16 Revision 0.13

Download Zone

on the Connect Tech website for product

or the

Support Center

Knowledge Database

on the Connect Tech

in the

Page 10

Blue Heat/Net Installation Overview

There are three main stages in the installation process for your Blue Heat/Net.

1. Hardware Installation

This involves the physical connection of the Blue Heat/Net hardware to your network,

and addresses issues such as cabling and power requirements.

2. Blue Heat/Net Configuration

The first step in the configuration process is to set the IP Address. Then use one of three

available methods to configure the Blue Heat/Net firmware settings for your application.

This can be done through the Serial Configuration Manager, Telnet Configuration

Manager, or the Web Configuration Manager, depending on circumstances and personal

preference.

3. Software Installation and Configuration of Blue Heat/Net drivers

This step installs and configures the Blue Heat/Net drivers and ports for your host

Operating System, and allows you to set parameters specific to your serial requirements.

This is done via the Blue Heat/Net Configuration Manager.

Hardware Installation

Connect Tech Blue Heat/Net User’s Manual

Connecting the Blue Heat/Net to your Network

Before you begin, take a minute to ensure that your package includes the required components

that should have shipped with your Blue Heat/Net.

One Blue Heat/Net unit

•

One power supply

•

One CD containing software and documentation

•

One Quick Start Guide

•

One Pheonix contact screw terminal plug (2-port PoE models)

•

One RJ-45 cable (optional)

•

One DB-9 female to DB-9 female null modem cable (optional)

•

If any of these components is missing, contact Connect Tech

reseller.

NOTE: The Blue Heat/Net 2 port model features an MDI/MDI-X

Autodetect feature. The pinouts will adjust automatically to

accommodate the use of a null Ethernet cable or a straight

through cable.

Direct Connect

Direct connect is an Ethernet connection made directly from Blue Heat/Net to the Ethernet jack

on your computer.

This connection is achieved using a cross-wired Ethernet cable, also known as a null

Ethernet cable. These cables can be assembled yourself (see appendix

from any electronics or computer store.

:

(See Contact Details) or your

for pinouts) or purchased

Connecting to the Network

The most common method involves connecting your Blue Heat/Net to network hardware at the

facility where you are installing the Blue Heat/Net device. The hub or switch could be in a

network closet in your building, or locally on your desk or workbench. This connection is

achieved using a straight through Ethernet cable; a standard Ethernet cable readily available

from any electronics or computer store. (See appendix

Revision 0.13 17

for pinouts.)

Page 11

Connect Tech Blue Heat/Net User’s Manual

Note:

Connect Tech recommends you use quality Category 5 cables

or better when connecting to the Blue Heat/Net Ethernet jack.

Ethernet LEDs

On 4 and 8 port Blue Heat/Net models, the front panel features Ethernet and Serial Port LEDs to

monitor activity. The left front side of the box features five LEDs. (Two port models feature the

CPU LED on the face of the device between the two serial port LEDs. The 10/100 and

Link/Activity (L/A) indicators are located on the top). Their usage is as follows:

Power: When this LED is on, the Blue Heat/Net is receiving line power. (Some models

do not have this LED)

CPU: Once the uClinux firmware is booted and running correctly, this LED appears as

a continuous light.

10/100: This LED represents the speed at which the Blue Heat is connected to your

Network.

LED on = a 100 megabit connection.

LED off = a 10 megabit connection.

(The Blue Heat/Net automatically senses the speed.)

L/A: (2 port models only). This light is on when a link or connection to a network or

computer is achieved. A blinking light indicates that Transmit (Tx) or Receive

(Rx) activity is detected on the Ethernet cable.

Link: (4 and 8 port models) The Link light is on when a connection to a network or

computer is achieved.

Act. (4 and 8 port models) This LED indicates that Transmit (TX) or Receive (RX)

activity is detected on the Ethernet cable.

Figure 1: LED locations on 2, 4 and 8 port Blue Heat/Net models

18 Revision 0.13

Page 12

Serial Port LEDs

The serial ports LEDs (two, four or eight, depending on your model) indicate serial activity for

each port.

A flashing LED indicates that the port in question is receiving or transmitting data.

•

BN001-004 models: If the LED is on, there is an RS-232 connection detected on the

•

RS-232 serial port.

Connecting Serial Devices

RS-232 Connections:

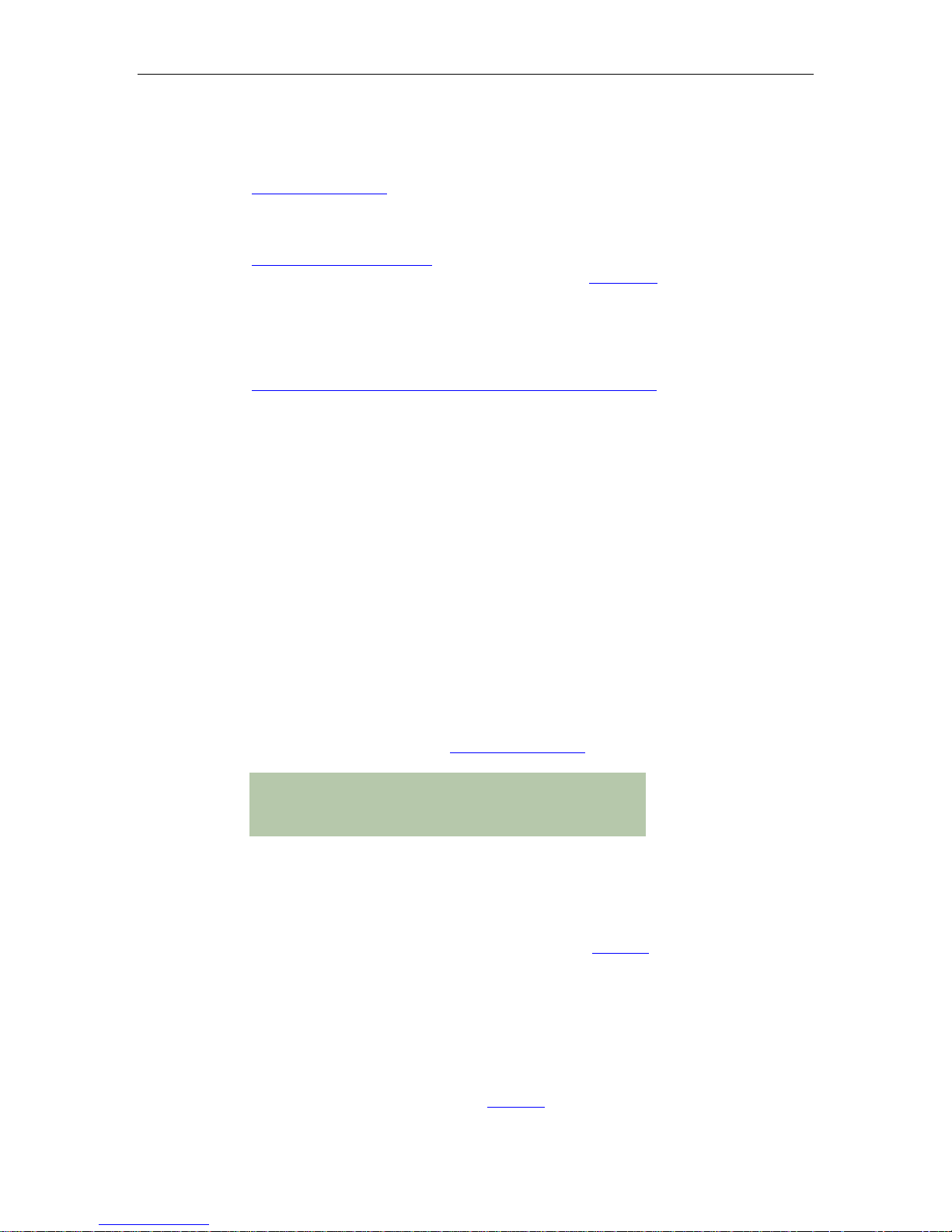

Typical RS-232 null modem connection

This is the typical way to connect to DTE type devices, such as the Blue Heat/Net. It is used

when hardware RTS-to-CTS flow control is required. The cable required is called a cross-over

Connect Tech Blue Heat/Net User’s Manual

or null modem cable, and is readily available at any electronics retailer/distributor.

Figure 2: Typical RS-232 null modem connection

Basic 3 wire RS-232 null modem connection:

Used to connect to DTE type devices like the Blue Heat/Net, this connection is used when

hardware RTS-to-CTS flow control is NOT required. The cable is called a cross-over cable, and

is readily available at any electronics retailer/distributor.

Figure 3: Basic 3-wire RS-232 null modem connection.

Revision 0.13 19

Page 13

Connect Tech Blue Heat/Net User’s Manual

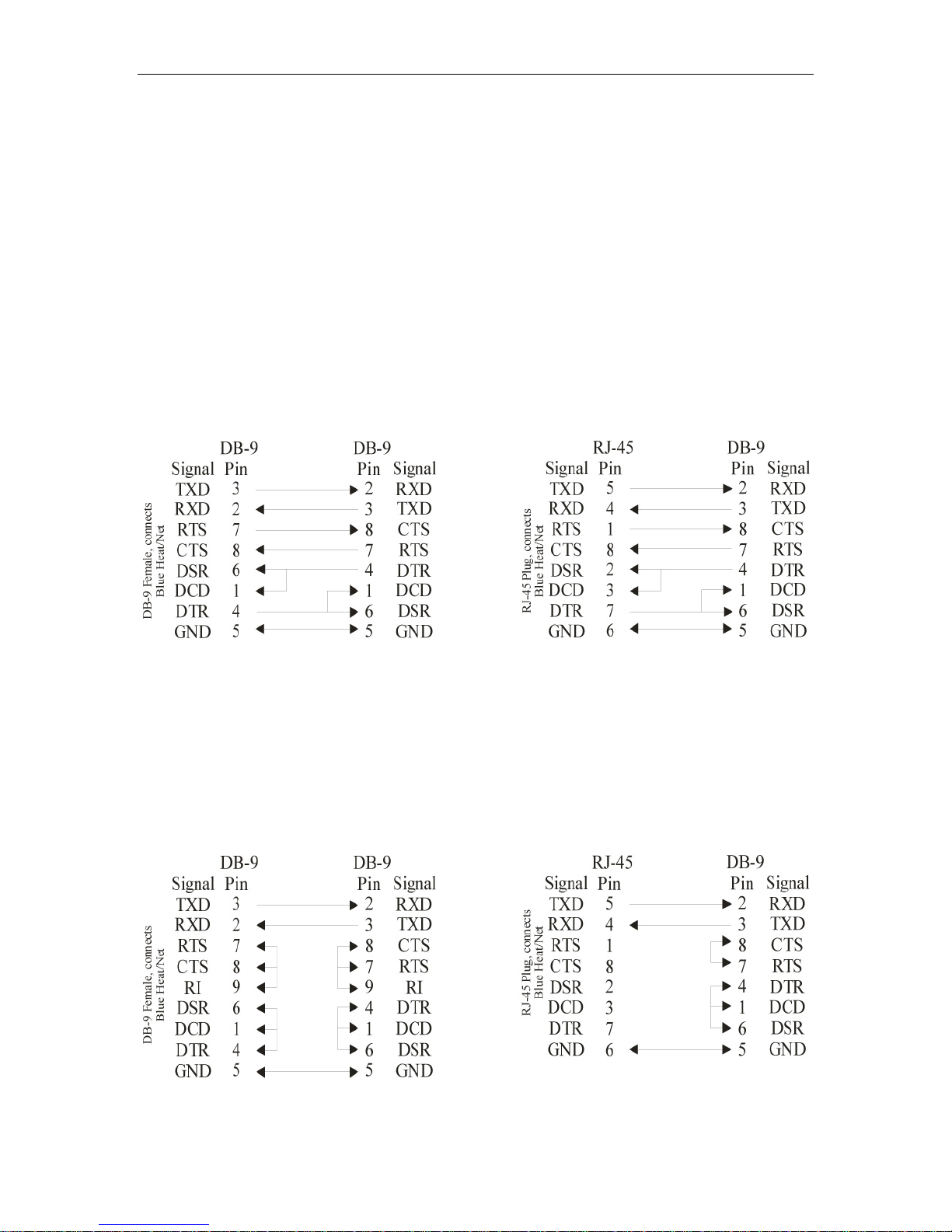

Connecting to DCE type devices:

DCE type devices do not require a null modem cable; instead, they require a straight through

cable. Straight through cables, both DB-9 to DB-9 and DB-9 to DB-25, are commonly available.

The following is an example of a DB-9 female cable to a DB-25 male cable to connect to a

modem.

Figure 4: DB-9 female to DB-25 male for modem connection.

Loopback Connectors:

Loopback connectors are useful for performing diagnostics. The following are the recommended

pinouts for creating loopback connectors for your Blue Heat/Net products.

Figure 4: Recommended pinouts for loopback connectors.

DB-9: For DB-9 female loopback connectors we recommend solder cup DB-9 connectors and

28 AWG solid core wire.

RJ-45: For RJ-45 loopback connectors, we recommend 8 pin RJ-45 connectors and about 2

inches of CAT 5 cable. You will have to crimp the wires from the CAT 5 cable into the RJ-45

plug, then strip and solder the wires to match the above loopback pinout.

20 Revision 0.13

Page 14

Connecting Power

The Blue Heat/Net uses a standard DC power jack for power input. The Blue Heat/Net can be

safely connected or disconnected at any time. New BNG (RoHS compliant) models include the

additional option for 9 to 30V DC power input using a Phoenix locking screw terminal

connector. The standard power supply requirements are as follows:

Two port models

Models BN009, BN010, BN018

0.75A DC, 5 to 30 Volts unregulated.

Model BN009/10 with Power over Ethernet (PoE) and Screw terminal power

PoE: To use Power over Ethernet, the Blue Heat/Net must be connected to an IEEE 802.3af

compliant “PSE” Power Sourcing Equipment, such as a PSE Hub or PSE Switch

Screw Terminal Power: Use the provided Phoenix screw terminal connector Phoenix SMSTB

2,5/2-ST-5.08 to power 36-56V DC. The power input is polarity independent. The acceptable

wire size is 14-24 AWG, 2.08-0.20 mm².

Four and Eight port models

Models BN001 to BN004

1A DC, 5 to 6 Volts unregulated.

Models BN005 to BN008

2A DC, 5 Volts regulated.

Model BNG008

2A DC, 5 Volts regulated.

Screw Terminal Power: Use the provided Phoenix screw terminal connector Phoenix MC

1,5/2-STF-3,5 to power 9-30V DC. The power input is polarity independent.

Connect Tech Blue Heat/Net User’s Manual

Power Connector:

Figure 5: Power connector illustration.

Note:

The center is positive, outside is ground (0V).

Activating the Special Operations Mode and Default Settings

On Blue Heat/Net models with software selectable line interfaces, there is a small reset button

located on the rear surface. On two port models, it is located between the DB-9 connectors. This

push button can be used to perform special operations, such as resetting the unit to its default

settings, or to force port scanning in situations where the SCM is not accessible.

Using the Reset Button to activate the Special Operations Mode

Revision 0.13 21

Page 15

Connect Tech Blue Heat/Net User’s Manual

To activate the Special Operations Mode, hold the reset button while the unit is powering up.

Hold the button until all the port LEDs blink rapidly. Release the reset button. The port LEDs

will continue to flash rapidly after the reset button is released to indicate the Special Operations

Mode is active.

Selecting a Special Operation

After the Special Operations Mode has been activated (see instructions

as described below:

1.

Abandon the Special Operations Mode

To abandon this mode without selecting a special operation, press and hold the reset

button for at least four seconds. While the button is pressed, the rapid flashing of the

port LEDs will stop. After four seconds, the rapid flashing will resume, you can now

release the reset button. After you release the button, the port LEDs will all be off,

indicating that the Special Operations Mode has terminated.

2.

Cancel a Special Operation

If you need to cancel a special operation after it has been selected, repeatedly press the

reset button until all the port LEDs begin to flash rapidly. Then abandon the Special

Operations Mode by pressing the reset button for four seconds, as explained above.

3.

Select a Special Operation

Operations are selected by repeated short presses of the reset button. Each time the

reset button is pressed; it is counted and represented on the port LEDs as a binary

number, with the port 1 LED the least significant bit. (see Table 1.) Choose the

operation which you want to perform. If you miss the selection which you want (press

the button too many times), keep pressing the button, the count starts over again once it

reaches 7 (1111 binary).

4.

Activate a Special Operation

To activate a selection, press and hold the reset button for at least four seconds. During

this time, the rapid flashing of the port LEDs will stop. When the rapid flashing

resumes, you can release the reset button. The port LEDs will turn off, indicating that

the Special Operations Mode has been activated.

Table 1: Special Operations Available

), there are four options

Special Operation

Force port scanning to

first two ports

(Scanning runs until

current scanning delay

setting times out. Default

is 30 seconds.)

Force port scanning to all

ports.

(Scanning runs until the

SCM is entered or until

the unit is powered

down. There is no time

out.):

22 Revision 0.13

Number of presses (and binary

Usage

representation)

ONE press This forces the first two ports to

RS-232 mode, causing the SCM to

scan these ports and thereby

allowing access to the SCM. (see

note below)

TWO presses This forces all ports to RS-232

mode, therefore all ports are

scanned for SCM use. The Blue

Heat/Net will behave in the same

manner as an RS-232 only model.

(see note below)

Page 16

Connect Tech Blue Heat/Net User’s Manual

Restore factory default

settings

NOTE: Why would I need to force port scanning?

Some line interface settings are inappropriate for SCM use.

During boot up, the SCM scans only those ports set for RS-232

or RS-485 Full-Duplex mode. If all of the ports are configured for

another mode, (1/2 Duplex or Multi-drop) SCM port scanning is

bypassed, and the SCM application cannot be accessed. Use of

either of the “Force Port Scanning” operations outlined in Table 1

will force port scanning to occur so the SCM application can be

accessed.

SEVEN presses This restores the factory default

Power On Diagnostics:

LED Error Codes

If an error is detected during the bootup process, an error condition and code are displayed on

the LEDs on the face of the Blue Heat/Net.

The error condition is signaled by a rapidly flashing CPU LED (about 10 to 20 per

•

second).

The error code is displayed on Port LEDs 1 to 4 as a binary number on four and eight

•

port models, and is represented in two port models by the behavior of the Serial 1 and

Serial 2 LEDs (see chart below).

settings for ALL configuration

parameters.

In the above example, a rapidly flashing CPU LED during the boot up process signifies the Blue

Heat/Net has experienced an error. The port LEDs 1 through 4 signify which error has occurred;

in this case, LED 2 and 3 are on, so the error code is 6. The chart below defines the error details

for each error code.

Revision 0.13 23

Figure 6: LED error code example.

Page 17

Connect Tech Blue Heat/Net User’s Manual

Table 2: LED error codes for Blue Heat/Net

2 port LED key:

CPU rapid error flash Slow flash Fast flash

(50 ms on/off) (1 s on/off) (.25 s on/off)

Error Code and Event

1.

Loader code in Flash is erased.

2.

Loader code in Flash has a bad

CRC.

Details Suggested

The regions of Flash memory which hold the

Loader code are both erased. (There are 2

redundant Loaders in Flash which can be

run).

The regions of Flash memory which hold the

Loader code both have CRC errors. (There

are 2 redundant Loaders in Flash which can

be run).

Corrective

Action

This may occur in

electrically noisy

environments or if

there are ESD

disturbances. If

this error persists,

it may be a

hardware issue.

Contact Connect

Tech.

See corrective

action for error

code 1

3.

RAM copy of Loader code has a

bad CRC.

4.

Configuration Data Space (CDS)

areas have corrupted data (CRC

failure).

24 Revision 0.13

The Loader code is copied to RAM before

execution. This error is shown if the RAM

copy has a CRC error.

The CDS is copied from Flash to RAM

during the beginning of the Loader code. If a

CRC error is detected in the RAM copy, this

error is shown.

See corrective

action for error

code 1

See corrective

action for error

code 1

Page 18

Connect Tech Blue Heat/Net User’s Manual

5.

Can’t obtain an Operating System

image (uClinux) to run.

6.

Unexpected return from the

uClinux Operating System.

7

. CDS (re)programming failure.

This will occur when any of the enabled

boot sources (Flash or BOOTP/TFTP or

TFTP) fail to obtain a valid compressed

Operating System image to run.

This error occurs if the Operating System

returns back to the Loader which is NOT

supposed to occur.

Certain CDS items are updated during the

bootup. If a failure occurs during the reprogramming of this region of Flash, this

error will occur.

Check network

connections,

server

computer or your

unit's settings.

This error occurs

if TFTP booting

is enabled, and the

BH/Net can't

download the file

from the server.

Contact Connect

Tech if it persists.

See corrective

action for error

code 1

See corrective

action for error

code 1

8.

Boot Count could not be

incremented in Flash memory

Revision 0.13 25

This error is usually caused by a Flash

memory failure.

Contact

Connect Tech

Page 19

Connect Tech Blue Heat/Net User’s Manual

9

. No ports found

(NOTE: Error displays on LEDs 5-8

on 8 port models, 1-4 on 4 ports)

15.

Mismatched CDS version

number

This message usually indicates a UART

component failure.

uClinux checks the CDS version number

against its expected CDS version number, if

they are different uClinux does not continue

its operation.

Contact

Connect Tech

If you have

updated the

uClinux

code via SCM and

haven't updated

the Loader/SCM

code, this error

appears on reboot.

Update companion Loader

code and reboot.

Mounting Bracket

The 4 and 8 port Blue Heat/Nets feature a simple vertical mounting bracket. First fasten the

mounting bracket to the vertical surface, and then slide the Blue Heat/Net onto the bracket. The

bracket is designed so that the serial port connectors face down.

A DIN Rail Mount option, sold separately as part number MS009 consists of two brackets with

DIN rail mount clips. (See appendix for more information about DIN rail mounting

The 2 port Blue Heat/Net has built-in wall mount flanges that accept a number of connection

options. DIN rail mount clips are available as part number MS010.

.)

26 Revision 0.13

Page 20

SCM and TCM Cabling requirements

SCM: Serial Configuration Manager

The Serial Configuration Manager is used to configure the Blue Heat/Net via a serial port. The

Serial Configuration Manager is discussed in greater detail later in this document. To access the

Serial Configuration Manager you will need to connect an RS-232 serial cable from your

standard computer serial port to any RS-232 port on the Blue Heat/Net. The cabling required to

connect to the Blue Heat/Net is as follows:

Blue Heat/Net products with RJ-45 connectors:

These models ship with optional DB-9 female to RJ-45 Jack adapters (PN: CB005) and a

straight through Ethernet cable, 2 meters (6.5 ft) in length (PN: CB006). Follow the steps below:

1. Plug the CB005 adapter into your PC serial port.

2. Plug either end of the CB006 cable into the CB005 adapter.

3. Plug the other end of the CB006 cable into any RS-232 RJ-45 serial port on the Blue

Heat/Net.

If you don’t have a CB006 cable and CB005 adapter, you can make your own SCM cable from a

DB-9 female, some length of CAT 5 cable and a RJ-45 plug. See the “Typical Null Modem

Cabling” section in the Connecting Serial Devices Section.

Blue Heat/Net product with DB-9 male connectors

Any null modem serial cable with DB-9 female connectors will work. Simply connect your null

modem serial cable from the PC serial port to any RS-232 port on your Blue Heat/Net.

Connect Tech Blue Heat/Net User’s Manual

:

TCM: Telnet Configuration Manager

The Telnet Configuration Manager is used to configure the Blue Heat/Net in much the same way

as the Serial Configuration Manager. You will need to connect your Blue Heat/Net to your

network through a hub or switch or through a direct connection to your computer.

Network Connection

Connect the Blue Heat/Net to your network hardware using a standard straight through CAT 5

network patch cable. A patch cable is optionally available with the Blue Heat/Net, part number:

CB006.

Direct Connect

You can connect your Blue Heat/Net directly to a computer without a hub or switch. You will

need standard cross-wired CAT 5 network patch cable.

Revision 0.13 27

Page 21

Connect Tech Blue Heat/Net User’s Manual

Setting a Static or Dynamic IP Address

Prior to configuring your Blue Heat/Net, you must set a static or dynamic IP address. The default

IP address of a new Blue Heat/Net is 192.168.42.1. If there is a possibility that this has been

changed, you will need to find the current IP address setting before you begin.

The easiest way to get the IP address of your Blue Heat/Net is as follows:

Follow the steps outlined in the section Installing the Blue Heat/Net Configuration Manager

noting your Blue Heat/Net’s IP number (i.e. A.B.C.D) using the Auto Discover Blue Heat/Net

feature.

Set the IP Address using the Web Configuration Manager

Note: If you use the Windows Configuration Manager

and use Auto Discover to locate your Blue Heat/Net on

the network, you can right-click and launch the Web

Configuration Manager from there.

You only need to use the route add command if you

choose not to use the Configuration Manager found on

the CD that accompanied your Blue Heat/Net.

From the command prompt of your computer, run: route

IP of your host machine>

Open your browser and put the Blue Heat/Net’s IP in the address bar (i.e. A.B.C.D) This will

open the WCM.

Log in (default login is wcm and the default password is password) and assign the static IP or

change the IP to 0.0.0.0 if you are using a DHCP assigned IP.

Be sure to replace the .D from the Blue Heat/Net’s IP with a 0 (zero).

add A.B.C.0 mask 255.255.255.0 <current

,

Set the IP Address using the Serial Configuration Manager

Insert your CD into the computer. The Driver/Software Installation menu should appear. If it

doesn’t, double-click on ctisetup.htm.

Click View in the Blue Heat/Net Software section and then Connect in the Serial Configuration

Manager section. This will launch HyperTerminal that comes with Windows XP.

Unplug the power to the Blue Heat/Net and plug it back in. Light indicators 1 to 8 (or 1 to 4)

will blink sequentially. This sequential flashing will last for 30 seconds. You must log in during

this window.

During this sequential flashing, type the word password into the HyperTerminal window. Be

careful you don’t miss the window of opportunity to enter the password.

You now have access to the Serial Configuration Manager (SCM). An scm> prompt is ready to

accept commands. If you do not see this prompt, unplug the power and repeat the steps above.

If you wish to set a dynamic IP address enter the following:

net dhcp=yes

save

exit

If you wish to set a static IP address, enter the following, substituting xxx.xxx.xxx.xxx

static IP you wish to assign:

net mip=xxx.xxx.xxx.xxx

save

exit

Close the HyperTerminal. You may now disconnect the RJ-45 cable from your PC and connect

it to any serial device.

with the

28 Revision 0.13

Page 22

Blue Heat/Net Configuration

The Blue Heat/Net comprises several software components, each of which manages various

functions of the Blue Heat/Net. The following is a breakdown of these components.

Operating System Software

o Host Operating System Driver

o Configuration Manager

o Web browser (Host Operating System supplied)

Blue Heat/Net Software (Firmware)

o Embedded Operating System (uClinux)

Kernel

Drivers

Ethernet

Serial

Flash

Blue Heat/Net Ethernet Protocol Converter application (Ctid)

Web server (Boa)

Web pages

Telnet services

o PPP Client and PPP Server

o Bootloader

o Serial Configuration Manager (SCM) Application

o Configuration Data Space (CDS)

The following section describes in brief what each main component controls.

Host Operating System Driver

The Host Operating System driver performs the translation from a standard Serial COM port

interface to the Blue Heat/Net protocol (which is then delivered to the LAN as described above).

Configuration Manager

This software manages and configures the relationships between the Blue Heat/Net serial ports

and the COM port assignments of the Host Operating System.

Web Browser

The Host Operating System supplies a Web Browser to support the Web Configuration Manager

(WCM) used to change the configuration settings of Blue Heat/Net units.

Embedded Operating System

The embedded Operating System is uClinux.

PPP Client and PPP Server

A Blue Heat/Net port can behave as a PPP connection, enabling you to run network protocols

over a serial link. PPP connections are often used in applications that require remote monitoring.

You can set the Blue Heat/Net to behave as either the dial out or “client” side (PPP Originate) or

the answering or “server” side (PPP Answer).

Bootloader

This code first starts up the embedded processor of the Blue Heat/Net from a power-up or

software initiated reboot. It then obtains the Embedded Operating System image (file) from one

of several locations and runs the Operating System.

Serial Configuration Manager (SCM) Application

Connect Tech Blue Heat/Net User’s Manual

Revision 0.13 29

Page 23

Connect Tech Blue Heat/Net User’s Manual

This application is used to change the configuration settings of Blue Heat/Net units by

connecting to a serial port on the Blue Heat/Net from a terminal (or terminal emulation program

on a PC).

Configuration Data Space (CDS)

This is the area, in non-volatile (Flash) memory, which stores the configuration parameters.

CDS (Configuration Data Space)

Description

The Blue Heat/Net has a number of configuration parameters which are stored in a Non-Volatile

(Flash memory) area. (See appendix for list of parameters)

The CDS area is stored redundantly in the Flash memory along with a CRC-style checksum to

ensure data integrity.

Access to CDS Parameters

The parameters stored in the CDS can be changed through the use of the following configuration

tools:

SCM Serial Configuration Manager

TCM Telnet Configuration Manager

WCM Web Configuration Manager

These three methods allow the user to change Configuration Parameters by whichever method is

most convenient. In some cases several methods will be employed during different stages of the

setup of the Blue Heat/Net, for example:

The SCM may be employed in the beginning when the unit is not connected to a network and

various networking parameters need to be set up prior to connection to a network.

TCM or WCM may be employed after the unit is connected to a network, possibly to modify

other settings related to Serial Ports, Bootup settings or others.

More information about the operation of the SCM

Note:

When CDS Parameters are changed via the SCM, TCM

or WCM, some settings will not take effect until the Blue

Heat/Net is next rebooted or powered up.

, TCM and WCM follows.

30 Revision 0.13

Page 24

SCM (Serial Configuration Manager)

Description

The Serial Configuration Manager is one of the applications you can use to access the

Configuration Data Space (CDS) settings of the Blue Heat/Net. Since the CDS stores the default

serial port settings, it is important that the line mode is configured prior to first use. Otherwise,

you’ll not be able to access the ports.

Getting Access to the SCM

To access the SCM, you simply connect a serial port terminal device (or a PC running a terminal

emulator program) to any of the serial ports on the Blue Heat/Net, and enter a correct Password.

A command prompt is then sent to the terminal and CDS Parameters can be changed using a

command line style of entry.

Note:

For RJ-45 models, the Blue Heat/Net ships with the unit

configured to scan all serial ports on the unit for entry of

the Password. This behavior can be changed by

alteration of one of the CDS parameters.

If your Blue Heat/Net model has configurable line interfaces (DB-9 models), certain settings

can affect access to the SCM. The ports are scanned as follows:

The default Line mode setting of all ports is Undefined. Under these conditions, the first two

ports are set to RS-232 mode during port scanning. Access to the SCM is available through these

ports only. (You should set all ports to a known state prior to use.)

When a port is set to something other than Undefined, any port with a setting of RS-232 or RS-

485-Full Duplex will be scanned. Otherwise, scanning is not performed, and access to SCM is

not available.

Note:

To access the Blue Heat/Net via the SCM your serial line

interface settings must be at the default values of 9600

baud, 8 data bits, no parity and 1 stop bit (9600, 8, n, 1).

No flow control is recommended.

In a situation where port scanning is not performed, you can still access the SCM using the push

button reset on the back of the unit. Follow the instructions in the section Activating the Special

Operations Mode and Default Settings to access the SCM in this situation

See the section which describes How the Blue Heat/Net Boots for a complete description of the

Bootup process of the Blue Heat/Net and how to access the SCM.

Connect Tech Blue Heat/Net User’s Manual

SCM Command Reference

SCM commands are entered as strings of ASCII characters with options separated by whitespace

characters. The entire command line is terminated by a CR character or CR/LF character pair.

Command lines can be entered manually (via a terminal or a PC with terminal emulator

program) or sent from an application program. There is no character-to-character minimum

timing restriction. The command line buffer is limited to the size of the FIFO on the serial port,

which is 64 characters for the RJ-45 model and 128 for the DB-9 model of the Blue Heat/Net.

If an SCM command is entered with no options specified, the command shows the syntax of its

options and the current setting of those options.

Revision 0.13 31

Page 25

Connect Tech Blue Heat/Net User’s Manual

Brief Command List

boot Bootup settings

cfg SCM operational settings

exit Exits the SCM application (and optionally reboots the Blue Heat/Net)

help Brief list of available commands and their syntax

info Blue Heat/Net general information and Flash verification

net Network settings

port Serial port settings, line interface settings and UART information

pson Personality settings

save Save setting changes to Non-volatile (Flash) storage

update Download (via TFTP) and Flash a new Operating System

(uClinux) and Loader/SCM image.

Command Details

boot

Syntax: boot [mode=] [file=] [delay=]

Description: This command establishes the Blue Heat/Net boot-up mode. For a detailed

description of the boot-up process of the Blue Heat/Net, see How the Blue

Heat/Net Boots up in the Appendix.

Options: mode=

A comma-separated list of the following sub-options. Each sub-option is

preceded by either a + or a – to indicate if the sub-option is enabled or disabled.

±flash Enables or disables the ability to boot from the Flash memory.

±bootp Enables or disables the ability to obtain the boot-up information from a

Server.

±tftp Enables or disables the ability to download and boot from a file located on

a Server.

file=

This option specifies the default file name used for the boot-up (if TFTP boot is

enabled) and also the default file name when using the flos command.

This can be any sequence of characters up to 128 characters in length. (The

default is BHNuClinux_vvv.gz, where vvv is the current version number of the

“Operating System image”).

delay=

This sets the time duration for accessing the SCM application. It can be set from

2 to 30 seconds, the default is 30. (See the section How the Blue Heat/Net

Boots up for more information).

32 Revision 0.13

Page 26

Connect Tech Blue Heat/Net User’s Manual

cfg

Syntax: cfg [port=] [timeout=] [password=] [prompt=] [file=]

Description: Establishes the settings used by the SCM application to

modify its behavior.

Options: port=

Specifies the port number to scan for a password to gain entry in the SCM.

N = Scan just port N (N=1 to the number of ports on the unit).

255 = Scan all ports on the unit (default unless unit has programmable line

interfaces).

timeout=

Specifies the time duration allowed for a TCM (via telnet) session to be idle (no

activity) before the session is terminated.

0 to 1092 minutes

(default = 5)

Note: A setting of zero allows infinite timeout.

password=

This sets the password phrase, which is used to gain access to the SCM, TCM

and WCM modes of configuring the Blue Heat/Net. The default is “password”.

prompt=

This setting controls whether a password prompt (and other password entry

status information) is presented to the terminal. This prompting is helpful for

new users of the product but may present a problem when other devices are

connected to the serial port.

yes enables the password prompting (default)

no disables the password prompting

file=

This sets the file name used as a default when using the flldr command.

It can be any sequence of characters up to 128 characters in length. (The default

is “BHNloader_vvv.gz”, where vvv is the current version number of the

“Loader”).

exit

Syntax: exit [-nosave] [-no_reset][-login]

Description: This command is to exit the SCM and reboot the Blue Heat/Net. If CDS changes

have been made a warning message is issued and the SCM will not exit.

Options: -nosave

Exit without saving changes (abandon changes).

-no_reset

Exit SCM without rebooting, maintaining the changes to settings for this session

only. (Booting is continued after the SCM is exited.)

-login

Exit without saving changes, and restart the SCM login process.

Revision 0.13 33

Page 27

Connect Tech Blue Heat/Net User’s Manual

help

Syntax: help

Description: Displays a brief list of all the commands.

Options: There are no options for the help command. Please note that specific help for the

options of each command can be obtained by entering any command with a

single “?” argument. An example would be net ?

info

Syntax: info [-v]

Description: This command is used to show basic information about the Blue Heat/Net unit,

like Serial Number and Version Numbers, and performs a confidence (CRC and

Decompression verification) test of the contents of the Flash memory.

Options: -v

This option disables the confidence tests.

net

Syntax: net [network= | net=]

[my_ip= | mip=]

[server_ip= | sip=]

[gateway_ip= | gip=]

[subnetmask= | snm=]

[broadcast_ip= | bcip=]

[dns_ip=]

[domain=]

[host name=1 host=]

[tcp=]

[mac=]

[dhcp=]

Description: Establishes the network settings.

Options: network= | net=

Sets the “network” portion of the IP address into my_ip, server_ip and

gateway_ip. The address entered is masked by the subnet mask setting before

being applied. This command is a shortcut for quickly setting all the IP

addresses of the unit. See note below.

my_ip= | mip=

This sets the IP address of the Blue Heat/Net unit (default is 192.168.42.1). See

note below.

server_ip= | sip=

This sets the Server IP address. This address determines the address of the

Server to use when the Bootp and tftp mode is enabled (see boot command), and

also as the default Server address to use for the update commands (default is

0.0.0.0). See note below.

gateway_ip= | gip=

This sets the Gateway IP address. This address is used when the Bootp mode is

enabled, default is 0.0.0.0. See note below.

34 Revision 0.13

Page 28

Connect Tech Blue Heat/Net User’s Manual

subnetmask= | snm=

This sets the Subnet mask IP address. (The default is 255.255.255.0) See note 1.

broadcast_ip= | bcip=

This sets the Broadcast IP address. This is used when the Bootp mode is

enabled. (The default 255.255.255.255). See note below.

dns_ip=

This sets the IP of Domain Name Server. (The default is 0.0.0.0). This must be

set to update the Blue Heat/Net firmware automatically from Connect Tech’s

anonymous ftp server.

domain=

This sets the Domain name of the unit. (The default is blueheat.net)

Host name=1 host =

This sets the Host name of the Blue Heat/Net unit. (The default is BHNssssssss,

where “ssssssss” is the serial number of the unit).

tcp=

This sets the base TCP port number used for Host TCP/IP and UDP/IP

communications. The default is 49152 (0xC000)

mac=

This displays the MAC address of the unit. (The default is 00:0C:8B:SS:SS:SS,

where SS:SS:SS is the hex value of the serial number of the unit). Note: The

MAC address cannot be changed, it can only be displayed.

dhcp=

This enables or disables DHCP support.

yes enables

no disables (default)

Notes:

All IP addresses are entered in common IP address

notation: ddd.ddd.ddd.ddd where ddd is a decimal number

from 0 to 255.

IP address “my_ip, server_ip, gateway_ip and dns_ip” can

be entered right justified, meaning that the address

entered will be applied to the specified address starting

from the least significant digit, masked by the subnet

mask. For example:

If the subnet mask is set to 255.255.255.0, and the

following command is entered:

net net=12.23.34.00 mip=45 sip=56 gip=67 dns_ip=89

The following IP addresses result:

the Blue Heat/Net unit will be 12.23.34.45

the Server will be 12.23.34.56

the Gateway will be 12.23.34.67

and the DNS IP will be 12.23.34.89

port

Revision 0.13 35

Page 29

Connect Tech Blue Heat/Net User’s Manual

Syntax: port [port#]

[line_mode= | lmode=]

[baudrate= | baud=]

[data_bits= | bits=]

[parity= | par=]

[stop_bits= | stop=]

[software_flow= | sflow=]

[xoff=]

[xon=]

[hardware_flow= | hflow=]

[local_loopback= | llb=]

[special_char_mode= | scm=]

[error_char= | errch=]

[break_char= | brkch=]

[event_char= | evtch=]

[use_xoff_xon_limits= | xlim=]

[xofflim=]

[xonlim=]

[escape_char= | esc=]

[fifos=]

[txload=]

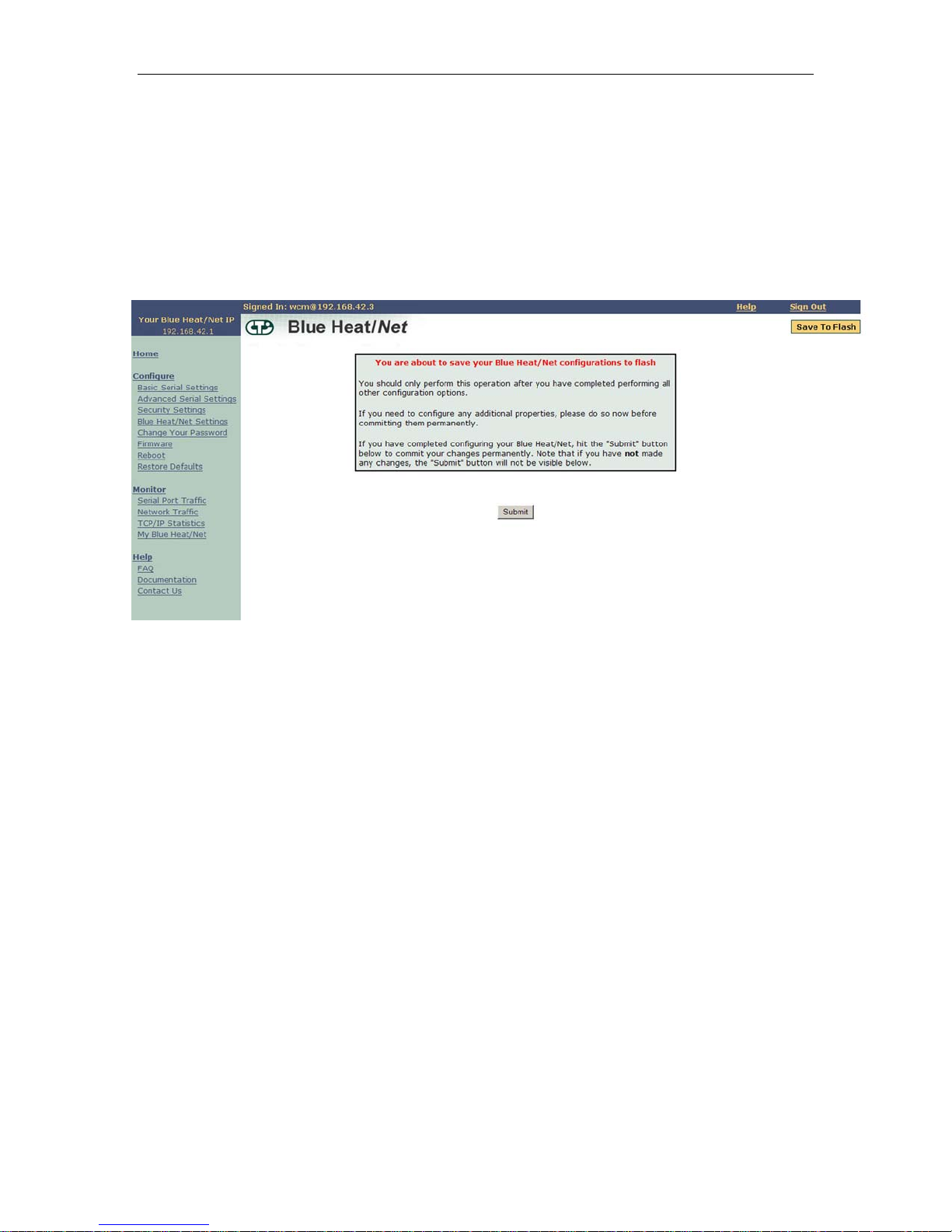

Description: This command establishes the initial settings of the serial ports when the Blue

Heat/Net is powered up.

Options: port#

This specifies the port number to change or query. If the port number is omitted,

the command returns a summary of all the ports on the Blue Heat/Net.

N where N is 1 to the number of ports on the unit.

line_mode= | lmode=

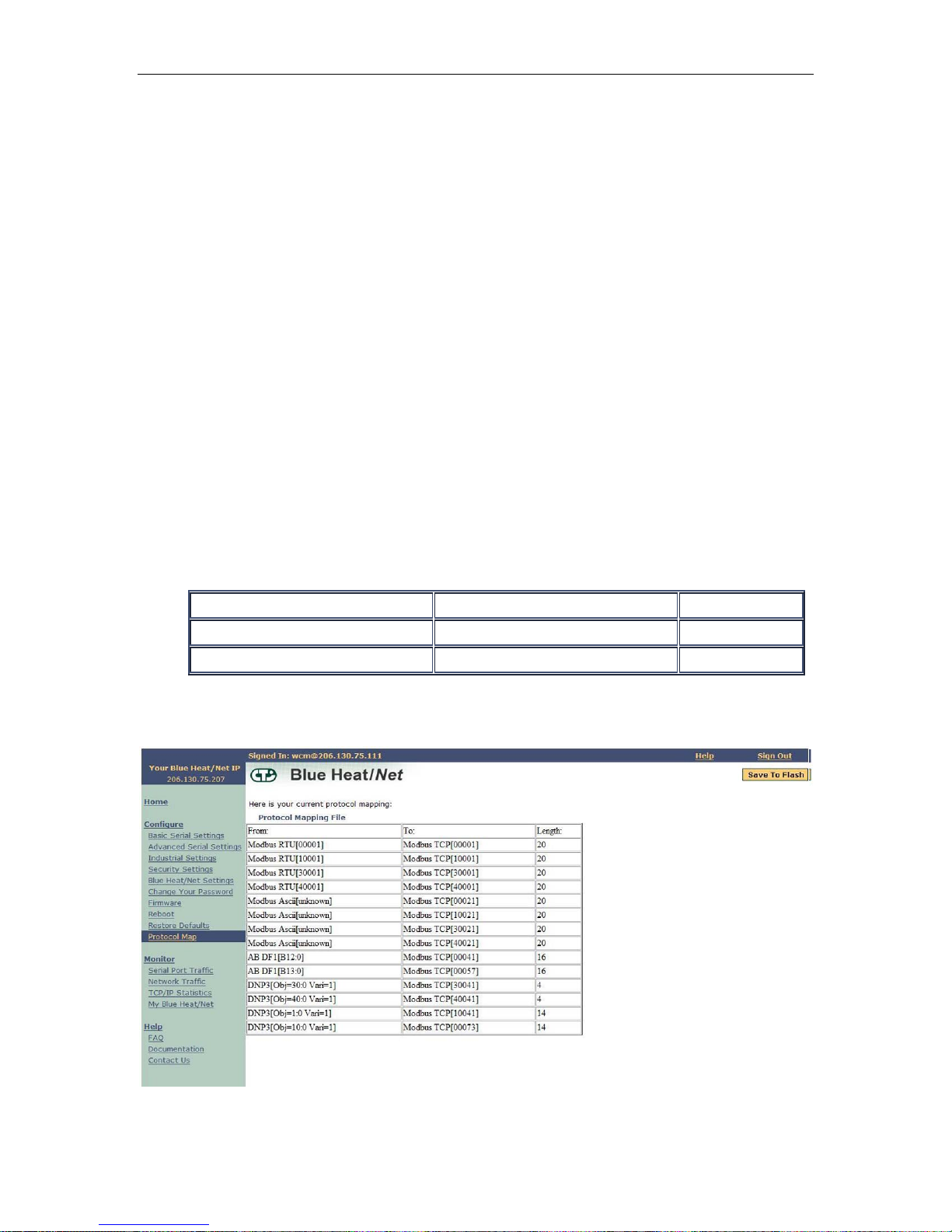

This is used to change the Line Interface Mode settings on units supporting this

feature.

232 Sets RS-232 mode

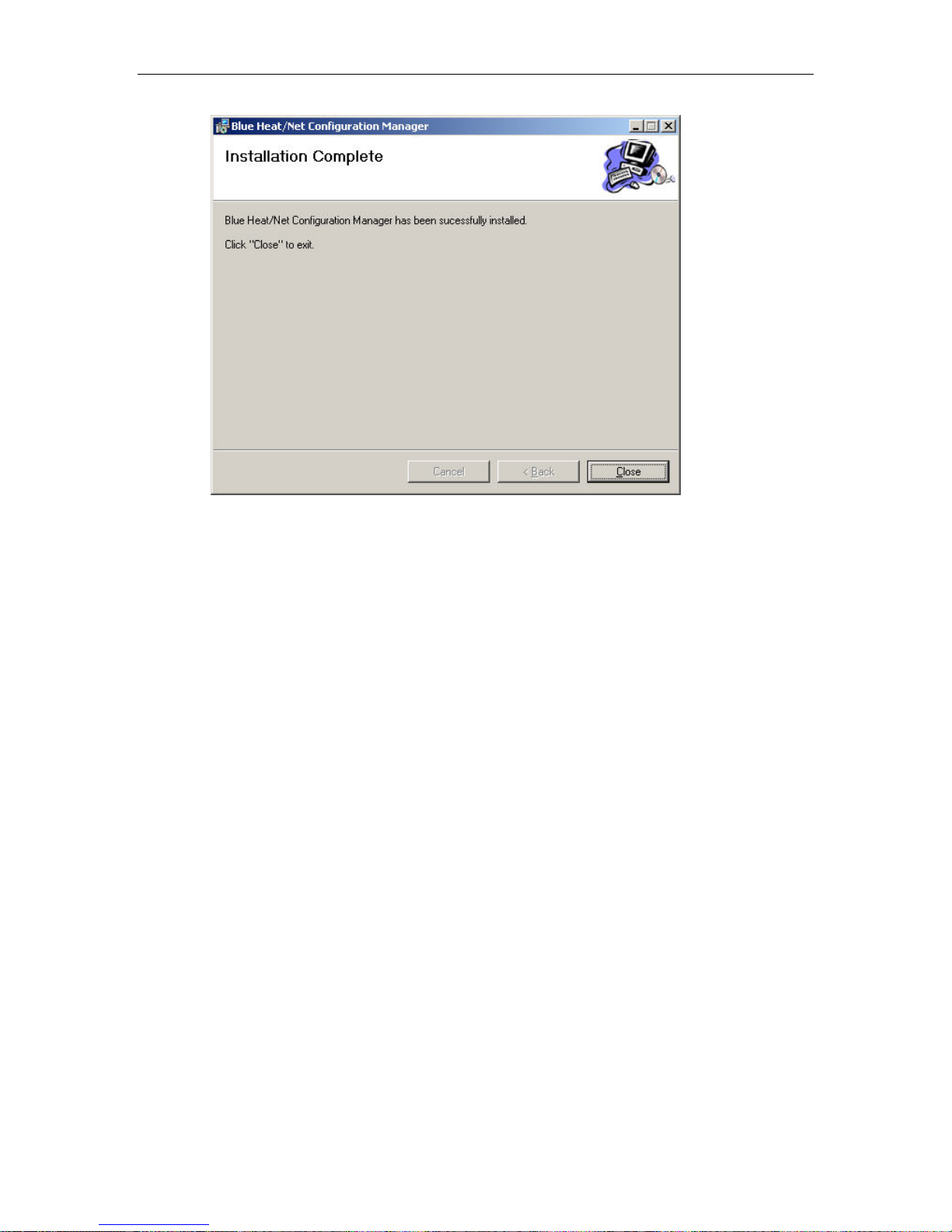

full Sets RS-422/485 Full-Duplex mode

4wire Sets RS-422/485 4-Wire Multi-drop mode

2wire Sets RS-422/485 2-wire Multi-drop mode (½ Duplex)

±tri Enables or disables line driver Tri-State at power-up. (Valid

only with RS-422/485 Full Duplex mode.)

±bt Enables or disables Line Bias and Termination on RS-485

ports

baudrate= | baud=

This sets the baud rate.

50 to 460800 (default 9600, maximum 230400 baud on RJ-45 models )

data_bits= | bits=

This sets the number of data bits in each character (byte).

5, 6, 7 or 8 (default)

parity= | par=

This sets the parity mode

n no parity (default)

e even

o odd

0 force 0 (space parity)

1 force 1 (mark parity)

36 Revision 0.13

Page 30

Connect Tech Blue Heat/Net User’s Manual

stop_bits= | stop=

This sets the number of stop bits

1 (default)

1.5

2

software_flow= | sflow=

This sets the software (xon/xoff) flow control mode.

n none (default)

r receive (xoff is transmitted when the FIFO buffer fills, xon is

transmitted when FIFO buffer is emptied)

t transmit (transmit will stop when xoff is received, and resume when

xon is received)

b both receive and transmit

xoff=

This sets the xoff character (entered as a HEX value).

0 to FF (default is 13)

xon=

This sets the xon character (entered as a HEX value).

0 to FF (default is 11)

hardware_flow= | hflow=

This sets the hardware (RTS/CTS) flow control mode, using a comma-separated

list of the following sub-options. Each sub-option is preceded by either a + or a

– to indicate if the sub-option is enabled or disabled.

±cts

When enabled, the transmission will stop when the CTS signal goes off, and will

resume when CTS goes on.

±rts

When enabled, RTS will go off when the FIFO buffer fills, and will go on again

when the receiver buffer empties.

±dsr

When enabled, the transmission will stop when the DSR signal goes off, and

will resume when DSR goes on. (Currently not supported.)

±dtr

When enabled, DTR will go off when the FIFO buffer fills, and will go on again

when the FIFO buffer empties. (Currently not supported.)

±rts_toggle | ±rtog

This establishes the toggle mode of the RTS signal. In this mode the RTS signal

goes on before a block of transmit characters and goes off at the end of the

block. (Currently not supported.)

Example: hflow=+cts,-rts

The default for hflow is all flags disabled.

fifos=

This enables or disables the use of the FIFOs on the UART channel.

yes enabled

no disabled

The default is yes.

txload=

This sets the maximum number of bytes to load into the transmitter FIFO.

Revision 0.13 37

Page 31

Connect Tech Blue Heat/Net User’s Manual

1 to the FIFO size of the UART (default is FIFO size)

The following options are not implemented

[local_loopback= | llb=]

[special_char_mode= | scm=]

[error_char= | errch=]

[break_char= | brkch=]

[event_char= | evtch=]

[use_xoff_xon_limits= | xlim=]

[xofflim=]

38 Revision 0.13

Page 32

pson

Connect Tech Blue Heat/Net User’s Manual

[xonlim=]

[escape_char= | esc=]

Syntax: pson [port#][p=][flags=][+d]

Description: This command sets the Personality or profile of a port. It establishes the

application that will use the port.

Options: port#

This specifies the port number. This number can be any valid port number

starting at 1 to the number of ports available on the particular Blue Heat/Net

unit. If the port number is omitted, the command returns the personality of all

ports on the Blue Heat/Net.

p=

This sets the personality string to the value supplied (up to 32 characters).

Default is ctid_portd.

flags=

This sets the personality flags to the value supplied (entered as a HEX value).

0 to 0xFFFF. Default is 0x0001 (RE_SPAWN)

+d

This sets the personality flags to the default values.

Note: