USER’S MANUAL

INDEX

1. MAIN COMPONENTS 1.1

2. SAFETY INSTRUCTIONS 2.1

3. CONTROL SWITCHES AND INDICATORS 3.1

4. SWITCH ON AND WORK 4.1

5. LOADING AND UNLOADING 5.1

6. SERVICE AND CARE 6.1

7. LONG WAREHOUSING 7.1

8. TECHNICAL SPECIFICATIONS 8.1

© 2004 CONHERSA

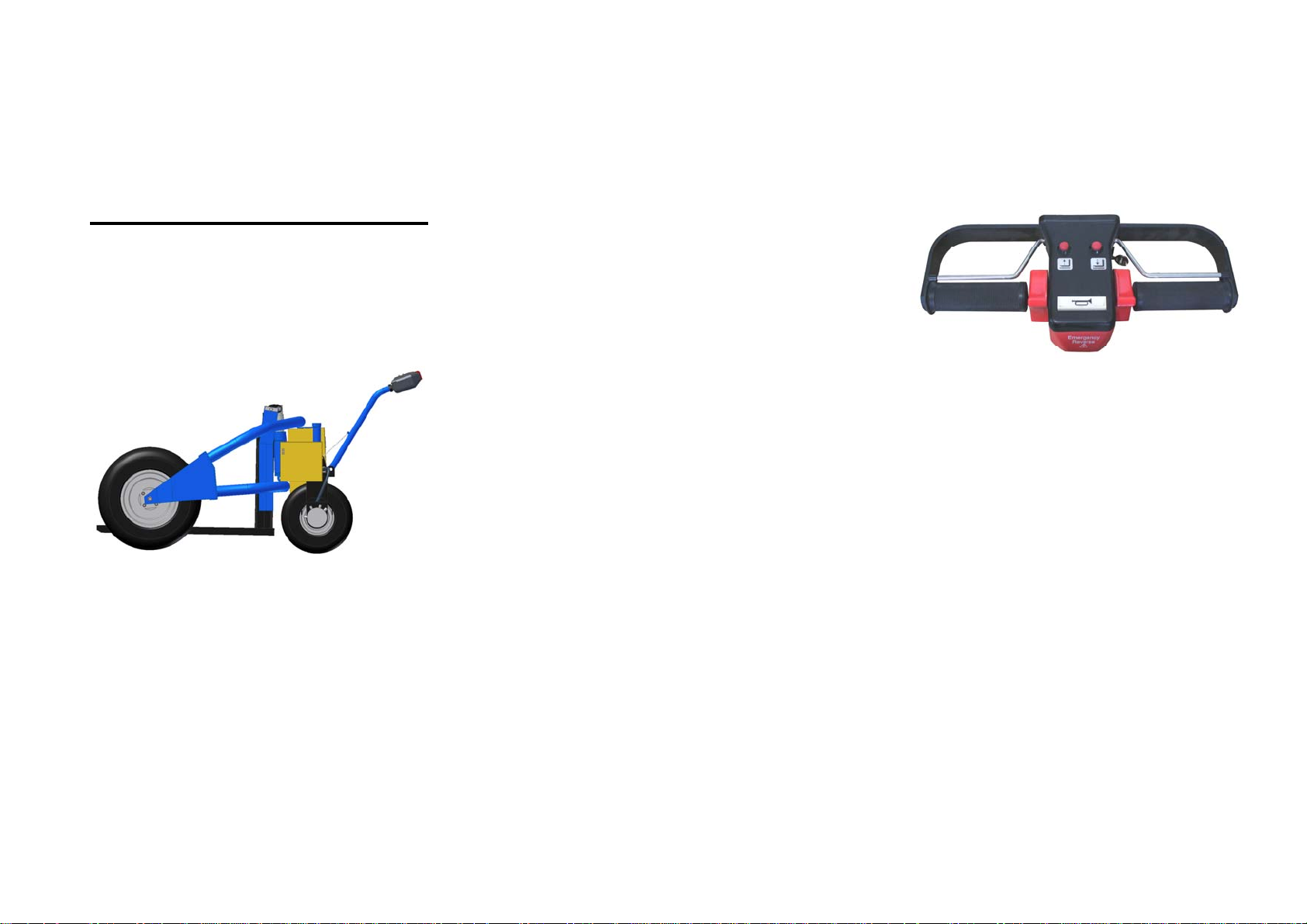

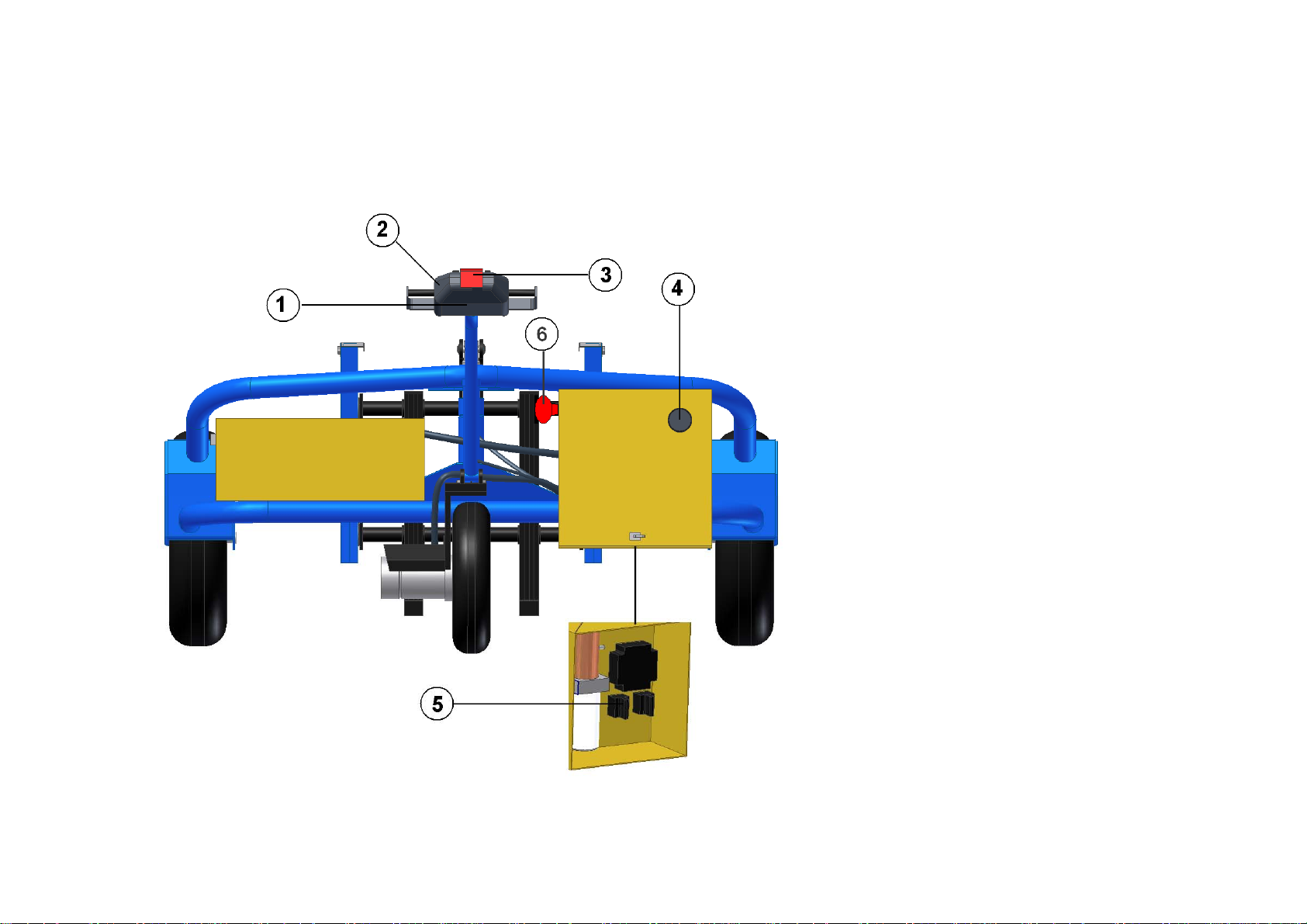

1. MAIN COMPONENTS

Chassis

c

d Front wheels

e Fork grouping

f Hydraulic cylinde r

g Handle

h Motor drive wheel

i Hydraulic motor pump

1.1

j Electronic controller

k Electric braking

l Batteries

11 Load indicator

12 Claxon

13 Emergency stop

c Chassis

d Front wheels

e Fork grouping

f Hydraulic cylinde r

g Handle

h Motor drive wheel

i Hydraulic motor pump

j Electronic controller

k Electric braking

l Batteries

11 Load indicator

12 Claxon

13 Emergency stop

1.2

2. SAFETY INSTRUCTIONS

Etiquettes 2.2

Hand pallet truck safety 2.4

Daily inspections 2.5

Hand pallet truck operator 2.9

Movement in ramps and special areas 2.10

Transport of the pallet truck 2.12

Testing 2.13

Noise level 2.13

Dangerous environment 2.13

2.1

ETIQUETTES

2.2

CAUTIONS WHILE LOADING

BATTERIES

1. Load batteries at an open-air

area, away from flames, fumes

and sparks. Battery’s gasses

may be explosives

2. Do not smoke around the

loading area.

3. Do not switch off during

loading: danger of sparks.

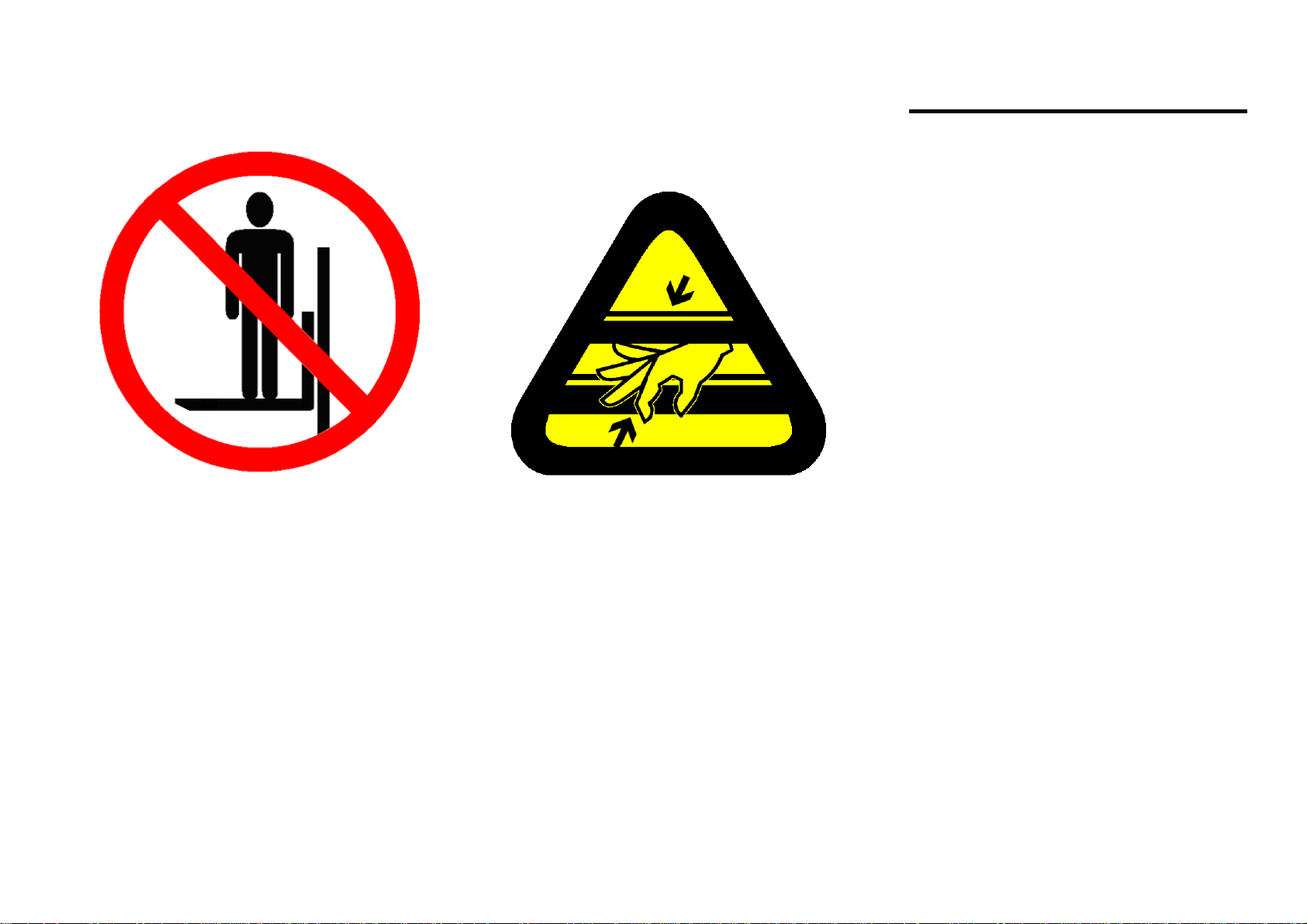

WARNING

Do not stand on the forks.

WARNING

Keep hands, feet and body

away from masts and forks.

Danger of trapping between fix

and mobile parts.

2.3

HAND PALLET TRUCK

SAFETY

USE UNDER INSTRUCTIONS

Hand pallet truck may only be

used under instructions included

in this manual.

WARNING

This hand pallet truck may only

be used to transport palletised

materials.

WARNING

Should you wish to use it for

different purposes, you may

ask for CONHERSA’S

agreement and, if necessary,

your local authorities in order

to avoid risks.

In case of handle malfunction,

press red button, switch off

and contact our technical

service.

WARNING

2.4

DAILY INSPECTIONS

Before using, following

inspections shall be followed:

1. Brake: When releasing handle,

make sure that hand pallet

truck is restrained and you can

not move it.

2. Forks: Visual inspection. Verify

correct lift and descent. No

damage in forks.

3. Hydraulic circuit: Verify possible

looses (leaks) in pipe and

cylinder.

4. Wheels: Verify tyres state.

Tighten bolts. Verify wheels

pressure.

5. Control instruments: Switch on

key. Verify battery’s light

indicators lights on.

6. Battery: Correct charge level

(20% at least).

7. Claxon: Verify well function.

8. Lifting: With forks unloaded,

verify correct lifting and

descent.

9. Connected: Pressing the deadman, verify correct forward and

reverse.

WARNING

In case of malfunction, switch

off, inform to whom it may

concern, and contact technical

service.

BRAKE

When releasing handle, verify

that speed controller returns to

neutral position and brake is

immediately blocked. (When

blocking, a sound must be

noticed).

Push the pallet truck to make

sure that it is well blocked and

you can not move it.

2.5

FORKS

Lift the fork by hand and place it

where needed.

Forks must be placed in

symmetry as per the axe.

The own friction of the for ks avoid

of not intended displacement.

2.6

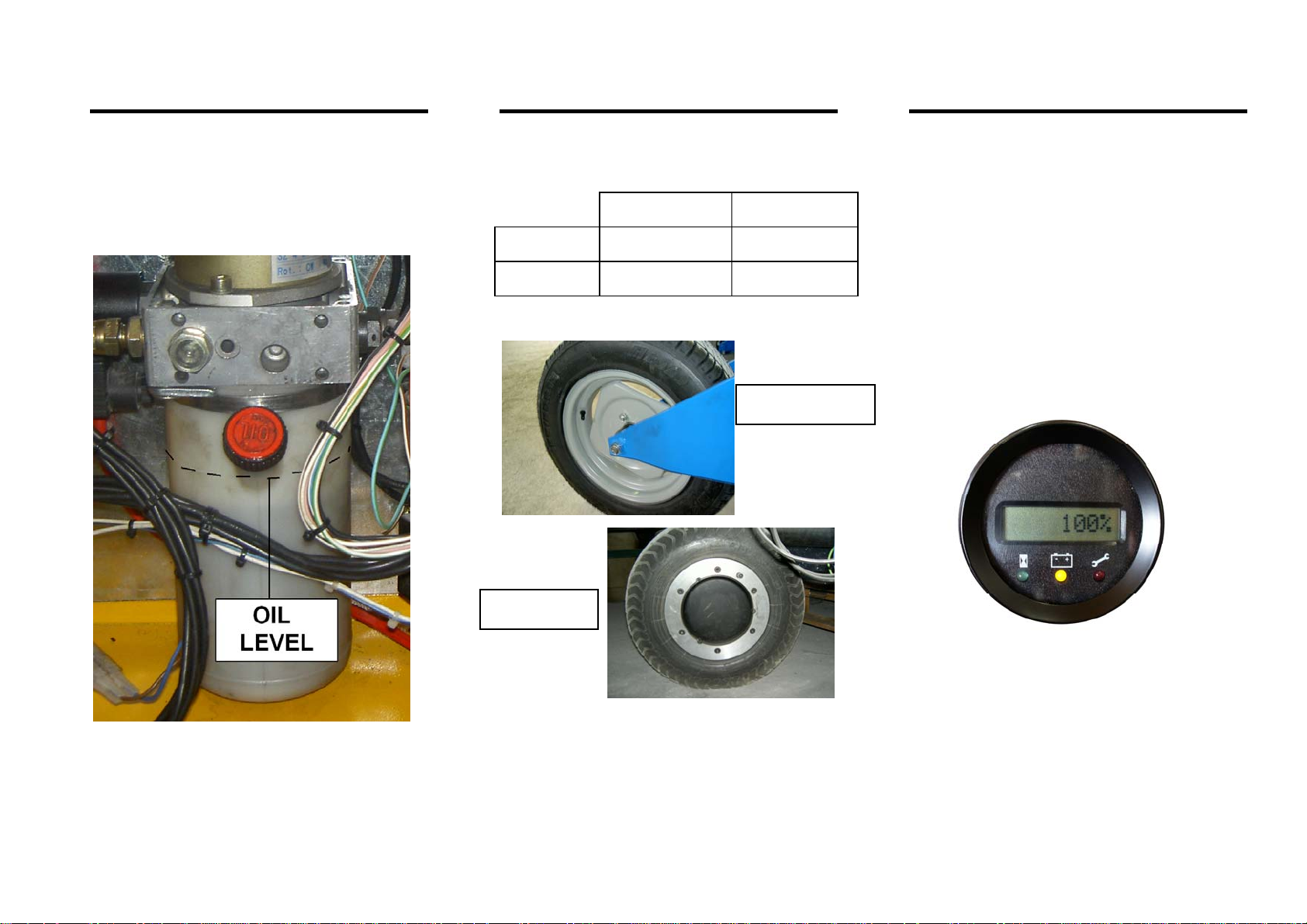

HYDRAULIC CIRCUIT

Verify oil level in the deposit.

Verify in case of possible oil

losses (leaks).

WHEELS

FRONT REAR

Measure 155R13” 4.00-8”

Pressure 2,7 bar Super elastic

front

BATTERY CHARGE LEVEL

Turn the key to ON position.

Verify charge level in the

indicator. If level is under 20%,

batteries must be charged.

Connect the charger for

approximately 10 hours (See

procedure on page 5.1).

rear

2.7

CONTROL INSTRUMENTS AND

CLAXON

Turn on the key. Verify battery

light indicator is on

Verify claxon by pressing the

claxon button.

HANDLE

Unloaded, press lifting and

descending buttons to verify that

forks go up and down correctly.

Press the dead-man function,

press smoothly the forwardreverse switch and verify that the

blocked brake is self-released (an

audible sound is heard), and the

truck commences to move gently.

Verify both, forward and reverse.

Contact key.

c

d Dead-man function

e

Forward-reverse throttle

f Claxon.

g Forks down button

h Forks up button

2.8

HAND PALLET TRUCK

OPERATOR

USER’S KNOWLEDGE

WARNING

While using, this manual’s

instructions shall be observed,

as well as local/national legal

dispositions.

SAFETY CLOTHING

Each site’s observations should

also be observed while using the

pallet truck.

For example:

Clothes should be tight enough

to avoid traps. If necessary in

the working site, user should

also wear protective glasses,

helmet, gloves, and whatever

required.

WARNING

For clothing, observation of the

national rules and obligations

is as must.

2.9

MOVEMENT IN RAMPS

AND SPECIAL AREAS

WARNING

Using the electric rough terrain

hand pallet truck for

transporting goods in ramps is

strictly forbidden.

Only permitted with the pallet

truck unloaded, if necessary.

WARNING

Do not turn in ramps.

Movement in ramps is delicate:

pay maximum attention and

care.

WARNING

Caution when moving on a

truck surface. Please make

sure that the truck is stopped.

The ramp used to place the

hand pallet truck onto the truck

must be resistant enough to

bear the hand pallet truck.

Ramp should be firmly placed

on the ground in order to avoid

unexpected movements.

Pay maximum attention during

the loading and unloading of

the hand pallet truck on the

truck.

2.10

ENTRY IN SERVICE LIFTS

Elevation of the pallet trucks in

service lifts should only occur

when the service lift has enough

power and has been designed for

this purpose.

WARNING

Make sure that the service lift

is powerful enough –see the

service lift weight capacity- to

load the pallet truck.

Do not operate nor work with

the pallet truck inside the

service lift.

MOVEMENT

Visibility

Do not drive forward when the

load does not permit complete

visibility. In that case, drive

backward, except when driving

into a service lift, where entering

backwards is forbidden.

If visibility difficulties remain,

another operator should indicate

the correct direction. In this case,

drive slowly and handle with care.

Verify that working area is

lightened enough.

Make sure that the pallet truck

does not touch the sides of the

service lift, and that it is well

placed in order to avoid

unexpected movements.

Operators should never get into

the service lift before the pallet

truck. Get out of the lift always

before the pallet truck.

2.11

TRANSPORT OF THE

PALLET TRUCK

WARNING

1. Unloaded, put forks in the

upper position.

2. Confirm that in and out

angles do not interfere with

the ground or transport

platform. (see picture)

3. When using a wooden made

bridge between platform and

dock, make sure that the

planks can bear the pallet

truck.

4. Use only the lifting hangers

to lift the pallet truck. (see

picture)

6.Switch off and release

contact key.

2.12

TESTING

2.3. Descending speed test.

NOISE LEVEL

After transport or a long

warehousing period, functional

testing is necessary.

Three tests:

1. Daily inspection test. (See page

2.5), to be made by users.

2. Dynamic tests, to be made by

the technical service.

2.1. Movement test.

Confirm that the pallet truck

moves towards the correct

forward-reverse switch, and

confirm that the blocking

brake works properly.

Confirm that descending

speed is not more than 0.6

m/s.

3. Hold load test.

With the machine off, fully loaded

with the forks up, confirm that the

forks don’t move down at all, or

they move down but not faster

than 10mm/min.

NOISE LEVEL

Less than 70 dB (A)

DANGEROUS

ENVIRONMENT

WARNING

Use of pallet truck in

dangerous environment is

strictly forbidden.

With the pallet truck loaded,

press up and down buttons to

make sure of correct work.

2.2. Piling test.

Lift completely and descent

the load at maximum speed

several times.

A dangerous environment may

cause fire or explosions

because of dust, fumes or

gasses.

2.13

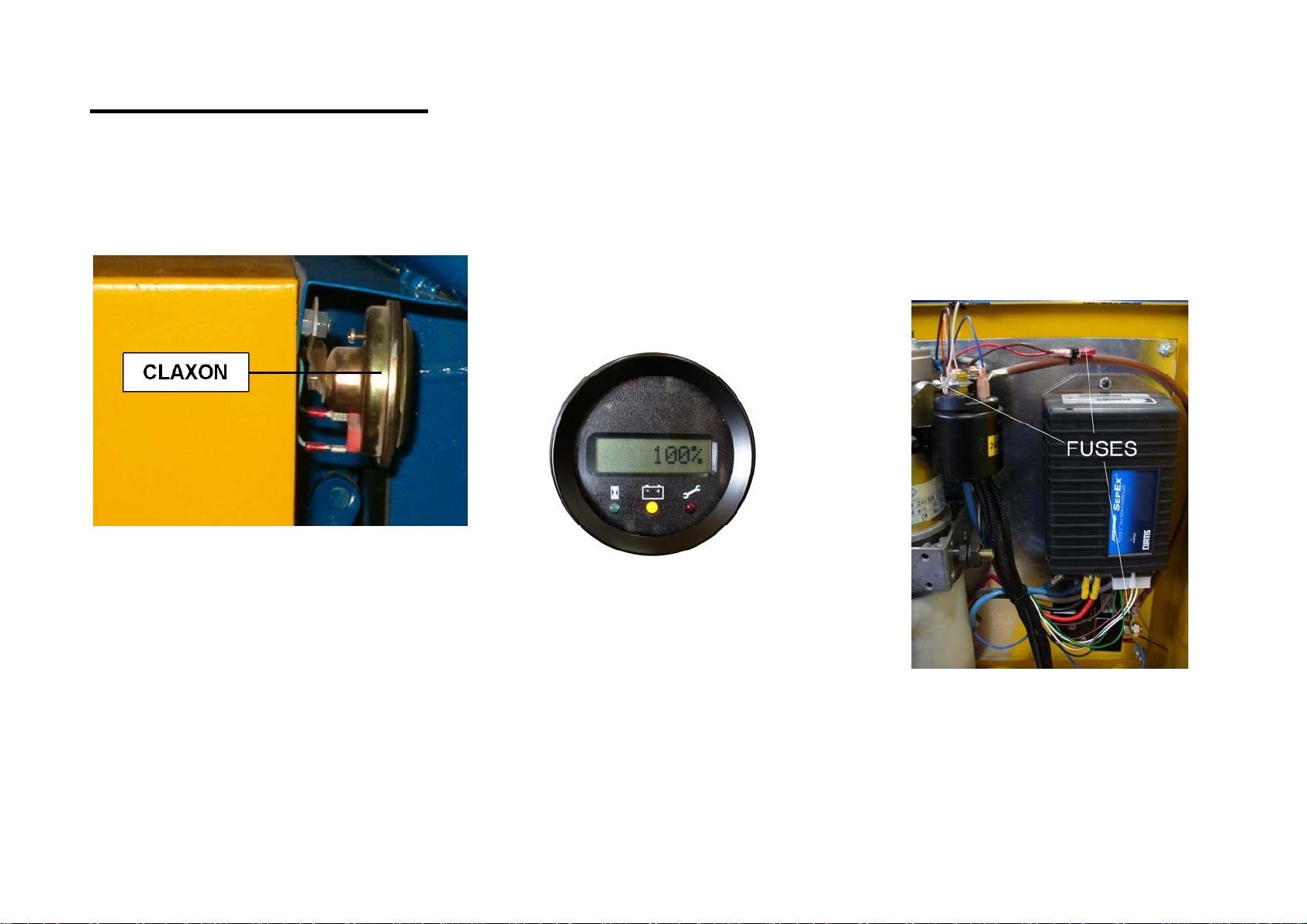

3. CONTROL SWITCHES AND INDICATORS

c Contact key.

d Handle.

e Security button.

f Battery charge indicator.

g Fuses

h Emergency stop

3.1

HANDLE SWITCHES

Contact key

Contact key is located at the

lower part of the handle.

It has two positions:

- Connected

- Disconnected

When connected, the batteries

light indicator will turn on.

When disconnected, all circuits

are off.

Forward-reverse swit ch.

It is the red switch. It may be

pressed either with the left or the

right hand.

When releasing, it comes back to

the neutral position.

Buttons for lifting and descending

the forks.

They are located at the centre of

the handle.

When pressing, the forks start to

move, and they stop just when

buttons are released.

c Contact key

d Dead-man function

e

Forward-reverse throttle

f Claxon

g Forks down button

Dead-man function

Placed at both sides of the

handle. Must be pressed to allow

the machine moving forwardreverse.

3.2

h Forks up button

CONTROL INDICATORS

WARNING

Claxon

The claxon is located next to the

up and down buttons.

Battery charge level indicator

It has a display, showing the %

battery level.

Two things to know:

1. When turning the key on, the

display indicates the battery

level..

2. Shows the error code in case of

electronic fault.

Fuses

The fuses are located in the

electronic controller.

The fuses may only be

changed by the specialized

personnel.

Replace the fuses by others

with similar characteristics.

WARNING

When the pallet truck is not

being used, make sure to turn it

off.

3.3

4. SWITCH ON AND WORK

c Contact key

Dead-man function

d

e forward-reverse throttle

f Claxon

g Forks down button

h Forks up button

4.1

SWITCH ON AND WORK

WARNING

Before using the pallet truck,

please read carefully all the

security instructions of this

user’s manual, pages 2.2 to

2.13 of this manual.

1. Confirm that the blocking brake

is on by pushing the pallet

truck: you should not be able to

move it.

2. Disconnect the emergency

stop

3. Turn on the key without

pressing the throttle.

WARNING

If the blocking brake does not

work, do not turn on the key.

4. Make sure that there is enough

battery charge by checking the

indicator.

5. Confirm that your way is clear,

and press the dead-man

function, and the forwardreverse throttle smoothly

towards the required way.

Movement

While moving, the forks must be

at their top position.

Turn

The closer you turn, the slowest

the speed should be, in order to

avoid unexpected load

movements.

WARNING

When leaving the pallet truck,

put down the forks and remove

the contact key.

If error “CODE 23” appears,

two causes:

1. Forward-reverse throttle has

been pressed without using the

dead-man function, or

2. the temperature thermal switch

of the motor has reached and

excessive heating, due to an

intensive work. Turning off the

machine during 20 minutes

should be enough to cool the

machine.

4.2

Movement on slopes (ramps)

Movement on slopes with the

machine loaded is strictly

forbidden.

5. LOADING AND UNLOADING

LOADING

Adjust the forks in symmetry as

per the pallet truck axe. The more

separated the forks are, the more

stability there is.

Face the load frontally and stop

just before. Adjust forks height to

enter into the pallet to be loaded

correctly.

Move forward smoothl y under the

pallet, and when stopping, make

sure that the blocking brake is

automatically activated (blocking

sound should be noticed)

Lift the load. Make sure it remains

stable. Press forward or reverse

and move slowly.

TRANSPORT

Moving with the pallet truck

loaded should be made with

special care and attention. If the

load height does not allow proper

visibility, the pallet truck must be

driven forward, except when

entering into the service lifts,

where it is strictly forbidden.

UNLOADING

Move towards the un loading area

slowly.

Verify that, when stopping, the

automatic blocking brake is on

(blocking soun d).

Put down the forks to unload.

Move reverse to get away from

the pallet.

When restarting again, make sure

that the forks are in the top

position to avoid any obstacle

while moving.

5.1

6. SERVICE AND CARE

Classification of maintenance works 6.2

Maintenance to be made by the technical service 6.2

Maintenance to be made by users 6.3

6.1

CLASSIFICATION OF

MAINTENANCE WORKS

There are two types of

maintenance works:

1. Technical service: Only to be

made by the technical service.

2. User: To be made by the pallet

truck users (qualified worker)

WARNING

User should not make any

reparations nor maintenance

when technical service is

required.

Some operations may be

dangerous and should only be

made by the technical service.

MAINTENANCE TO BE

MADE BY THE TECHNICAL

SERVICE

The following operations should

only be made by our technical

service:

1. Batteries condition control.

2. Change batteries.

3. Change hydraulic oil.

4. Adjust motor pump.

5. Maintenance of the electronic

control.

6. Change fuses.

MAINTENANCE TO BE

MADE BY THE USER

As well as the daily inspections

(see page 2.5), the worker must

carry on with the following:

1. Tyres air-pressure control.

2. Change the front tyres.

3. Charge batteries.

4. Batteries electrolyte level

control.

5. Pallet truck cleaning.

6. Emergency forks descent.

6.2

MAINTENANCE TO BE

MADE BY THE USER

WARNING

Before making any

maintenance, turn off the key.

Confirm that the automatic

blocking brake is on.

TYRES AIR-PRESSURE

CONTROL

From time to time, the airpressure control should be made

to confirm that it is correct.

Front tyres

1. Release valve screw-top.

2. Connect a manometer.

3. Correct pressure is 2,7 bar. If

it is less, add air with the

pump.

Pressure (bar)

Front 2,7

Rear Super elastic

CHANGE FRONT TYRES

Front tyres

1. Put a wooden chock under the

pallet truck to separate it from

the floor. Verify that pallet truck

remains stable.

2. Fasten the bolt with a wrench.

With the other hand, loosen the

nut with an 18 wrench, just up

to when there are only few

turns of the nut left.

6.3

NOTE: Do not tight the nut too

much: some pieces could be

damaged and turning the pallet

truck would be impossible.

3. With a nylon hammer or

wooden chock, hit the nut in

order to take it out.

4. Unscrew completely the nut

and release the bolt by hand.

5. Take out the wheel.

6. Once the wheels is taken out,

repair the puncture, change the

tyre, etc.

7. Assembling procedure should

be done all the way round.

Make sure not to damage the

nut when inserting.

6.4

BATTERY CHARGE

WARNING

3. Connect the prov ided cabl e to the

pallet truck and an electric socket

(220 V).

1. Charge the batteries in a well

ventilated area, away from

heating points and sparks.

(Gases of batteries may be

explosives)

2. Do not smoke in the charging

area.

3. Do not disconnect the

connector during the charging

process: risk of sparks.

Suggestions for the battery charge

1. For a longer battery life, it should

be discharged at least 35% before

charging.

2. To avoid deep discharge that

could cause lifeless, when ar riving

to a 20% of battery charge, the

machine slows its speed

drastically.

Charging process

1. Move pallet truck close to an

electric socket (220 V).

2. Turn off the contact key.

4. Verify that the red light is on.

5. Batteries are completely charged

when the green light is

permanent.

6. Disconnect the cable, wind it and

keep it safe. .

7. Turn the contact key on and

confirm that all the battery charge

level is at 100%.

6.5

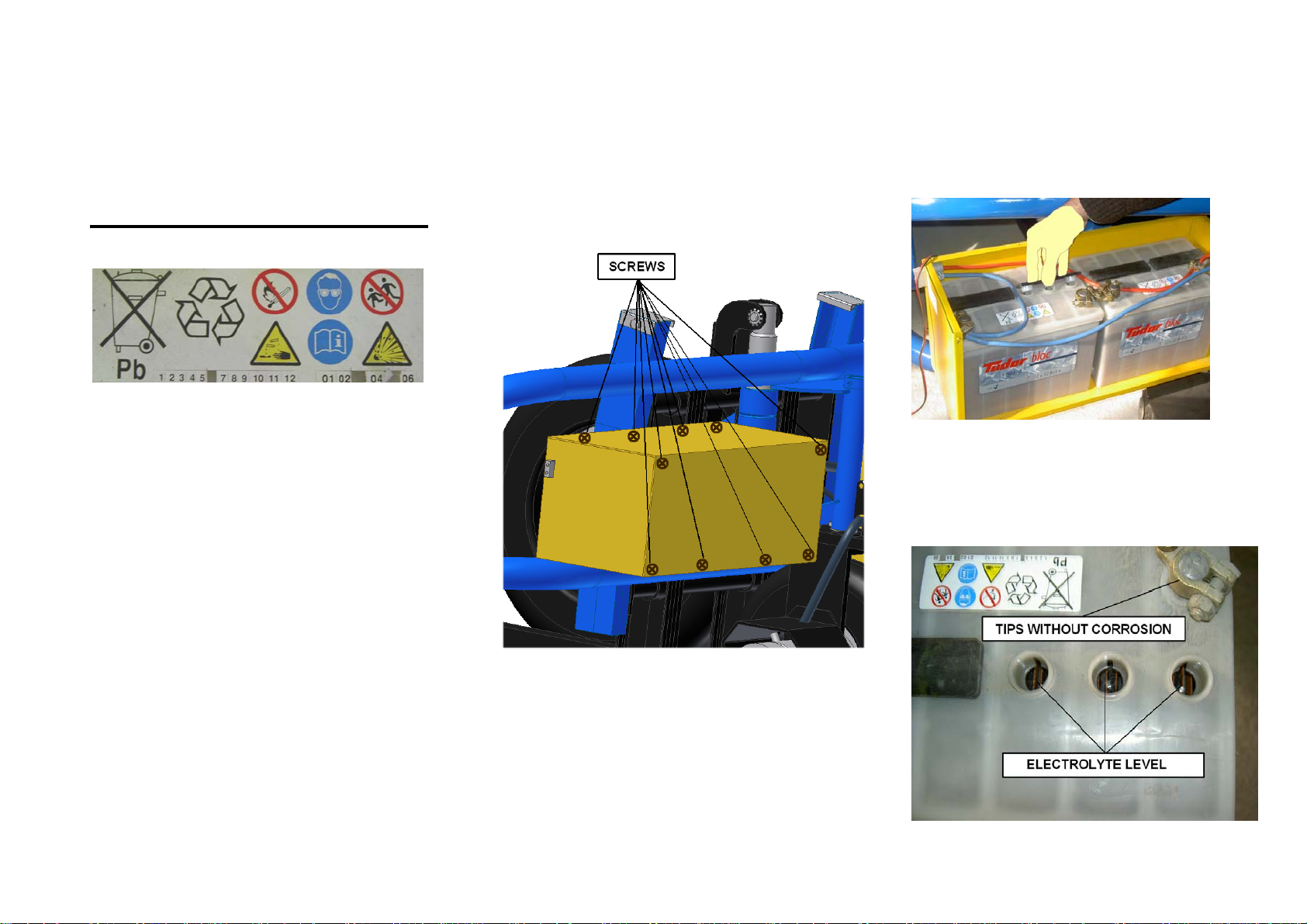

BATTERIES MAINTENANCE

1. Loosen with a screwdriver the

10 screws of the batteries

yellow metal box.

4. Put aside the top of the battery

glasses carefully, without

touching the connecting tips.

WARNING

1. Batteries maintenance must

be made by authorized

personnel.

2. Always use gloves and

protective glasses.

3. Smoking in the area is

forbidden.

Maintenance frequency.

Must be done at least twice a

year (if possible, before and after

summer).

5. Verify that the electrolyte level

is correct. If necessary, fill in

with distilled water up to the

nets.

2. Take out the top and front part

of the metal box.

3. Confirm that there are no

electrolyte leaks and no

corrosion on the tips.

6.6

CLEANING THE PALLET TRUCK

WARNING

Before cleaning, turn off the

key.

Verify that the blocking brake

is on.

Cleaning the handle.

Cleaning the motor chassis

Clean the dust with a brush.

Do not use water.

Finish with a dry cloth.

Cleaning the forks grouping

guides.

Clean the dust with a brush.

Do not use water.

Clean the dust with a brush.

Do not use water.

Finish with a dry cloth.

Finish with a dry cloth .

6.7

EMERGENCY DESCENT OF

THE FORKS

If the forks are suddenly blocked

in the top position, there is a way

of putting them down:

1. Turn off the key.

2. Open the right hand side box,

where the motor pump is

located.

3. Verify that there are no

obstacles under the forks.

4. Press the red button to make

the forks go down.

6.8

7. LONG WAREHOUSING

LONG TIME WAREHOUSING

When the pallet truck is not going

to be used for a long time, keep it

in a dry and clean place, and

follow the following instructions:

1. Clean the pallet truck as

explained before.

2. Charge the batteries

completely.

3. Place the pallet truck in a

horizontal position.

4. Dissemble the batteries and put

them in a dry and fresh place.

5. Put the pallet truck on wooden

sticks in order to avoid damages

and deformations of the tyres.

WARNING

When there is no inside area

available, place the pallet truck

in a horizontal area and cover it

completely with a waterproof

plastic cover.

For warehousing for a longer

period, please contact

technical service.

WARNING

Don not use a waterproof cover

made of vinyl: it may cause

static electricity and

subsequently produce flames

with the batteries gasses.

7.1

SERVICE DURING THE

WAREHOUSING

1. Charge batteries every two

months.

2. Make visual inspections to

verify that there is no corrosion.

3. Clean the dirty areas and apply

anticorrosion if needed.

POST-WAREHOUSING

SERVICES

1. Remove the grease of the

exposed areas of the hydraulic

cylinders.

2. Charge the batteries

completely.

3. Turn on the key to confirm

batteries are completely

charged

4. Go ahead with the tests of page

2.13

7.2

8. TECHNICAL SPECIFICATIONS

In this plaque, located at the right hand side, following

information should be seen: Serial number, traction

motor, elevation motor, tyres pressure, etc.

MAIN PARAMETERS

MAXIMUM FORWARD-REVERSE

SPEED

MAXIMUM LOAD PERMITTED 1.200 kg

MAXIMUM FORKS ELEVATION 200 mm

WARNING

Do not overload the pallet truck.

Do not try to exceed the above parameters.

< 0,6 m/s

8.1

Loading...

Loading...