Conext XW+ 6848 NA, XW+ 5548 NA Owner's Manual

Conext

Conext XW+ 6848 NA

Conext XW+ 5548 NA

Owner’s Guide

975-0240-01-01 Revision H

November 2017

™

XW Inverter/Charger

http://solar.schneider-electric.com

Conext

Owner’s Guide

™

XW Inverter/Charger

http://solar.schneider-electric.com

Copyright and Contact

Copyright © 2007-2016 Schneider Electric. All Rights Reserved.

All trademarks are owned by Schneider Electric Industries SAS or its affiliated companies.

Exclusion for Documentation

U

NLESS SPECIFICALLY AGREED TO IN WRITING, SELLER

(A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER INFORMATION

PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION;

(

B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER SPECIAL, DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY

SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH STEPS HAVE BEEN TAKEN TO

MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED CONTENT IS

CONTAINED WITH THE ENGLISH LANGUAGE VERSION WHICH IS POSTED AT HTTP://SOLAR.SCHNEIDER-ELECTRIC.COM.

Date and Revision

November 2017 Revision H

Document Part Number

975-0240-01-01

Product Part Numbers

Product Part Numbers Related Product Part Numbers

865-6848-01 – Conext XW+ 6848 NA 865-1015-01 – Conext XW+ Power Distribution Panel

865-5548-01 – Conext XW+ 5548 NA 865-1025 – Conext XW+ Conduit Box

865-1020-02 – Conext XW+ Connection Kit for INV2 INV3 PDP

865-1030-1 – Conext MPPT 60 150 Solar Charge Controller

865-1032 – Conext MPPT 80 600 Solar Charge Controller

865-1050-01 – Conext System Control Panel

865-1060-01 – Conext Automatic Generator Start

865-1058 – Conext ComBox

865-1080-01 – Conext Battery Monitor

Contact Information

http://solar.schneider-electric.com

Please contact your local Schneider Electric Sales Representative or visit our website at:

http://solar.schneider-electric.com/tech-support/

Information About Your System

As soon as you open your product, record the following information and be sure to keep your proof of purchase.

Serial Number

Product Number

Purchased From

Purchase Date

_________________________________

_________________________________

_________________________________

_________________________________

About This Guide

Purpose

The purpose of this Owner’s Guide is to provide the information and procedures

necessary for configuring, operating, maintaining, and troubleshooting the

Schneider Electric Conext XW+ Inverter/Charger.

Scope

This Guide includes information about monitoring and configuring the Conext

XW+.

The Guide provides guidelines, detailed setup information, and information about

operating and troubleshooting the unit. It does not provide installation

procedures or details about particular brands of batteries, photoelectric cells, or

generators. Consult the equipment manufacturers for this information.

Audience

This Guide is intended for anyone who needs to operate, configure, and

troubleshoot the Conext XW+ Inverter/Charger. Certain configuration tasks

should only be performed by qualified personnel in consultation with your local

utility and/or an authorized dealer. Electrical equipment should be installed,

operated, serviced, and maintained only by qualified personnel. Keep

unqualified personnel away from batteries. Servicing of batteries must only be

performed or supervised by qualified personnel with knowledge of batteries and

their required precautions. Qualified personnel have training, knowledge, and

experience in:

• Installing electrical equipment

• Applying applicable installation codes

• Analyzing and reducing the hazards involved in performing electrical work

• Installing and configuring batteries

• Selecting and using Personal Protective Equipment (PPE)

No responsibility is assumed by Schneider Electric for any consequences arising

out of the use of this material.

975-0240-01-01 iii

About This Guide

Organization

This Guide is organized into four chapters and three appendices.

Chapter 1, “Introduction”, describes the operational features of the Conext XW+

Inverter/Charger.

Chapter 2, “Monitoring Operation”, contains information about monitoring Conext

XW+ Inverter/Charger operation using the inverter information panel or the

Conext System Control Panel.

Chapter 3, “Configuration” explains how to navigate through the Conext System

Control Panel menus and configure the Conext XW+ Inverter/Charger.

Chapter 4, “Troubleshooting”, contains information and procedures for identifying

and solving possible problems with the Conext XW+ Inverter/Charger.

Appendix A, “Specifications” provides the electrical and mechanical

specifications for the Conext XW+ Inverter/Charger.

Appendix B contains the default configuration settings and ranges for the Conext

XW+ Inverter/Charger. Configuration settings can be viewed and changed using

the Conext System Control Panel.

Abbreviations and Acronyms

CEC California Energy Commission

CSA Canadian Standards Association

GT Grid Tie

LCD Liquid Crystal Display

LED Light Emitting Diode

MPPT Maximum Power Point Tracking

NEC US National Electrical Code NFPA-70

PV Photovoltaic

PVGFP PV Ground Fault Protection

UL Underwriters Laboratories

VAC Volts AC

VDC Volts DC

Related Information

For information about installing the Conext XW+ Inverter/Charger, see the Conext

XW+ Inverter/Charger Installation Guide (975-0384-01-02).

You can find more information about Schneider Electric as well as its products

and services at http://solar.schneider-electric.com.

For available accessories, see “Available Conext XW+ Accessories” on page 1–

3.

iv 975-0240-01-01

Important Safety Instructions

DANGER

WARNING

CAUTION

NOTICE

READ AND SAVE THESE INSTRUCTIONS - DO NOT DISCARD

This guide contains important safety instructions for the Conext XW+ Inverter/

Charger that must be followed during operation and troubleshooting. Read and

keep this Owner’s Guide for future reference.

Read these instructions carefully and look at the equipment to become familiar

with the device before trying to install, operate, service or maintain it. The

following special messages may appear throughout this bulletin or on the

equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label

indicates that an electrical hazard exists which will result in personal

injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this signal word.

975-0240-01-01 v

Safety

Safety Information

1. Before using the inverter, read all instructions and cautionary

markings on the unit, the batteries, and all appropriate sections of

this manual.

2. Use of accessories not recommended or sold by the manufacturer may result

in a risk of fire, electric shock, or injury to persons.

3. The inverter is designed to be permanently connected to your AC and DC

electrical systems. The manufacturer recommends that all wiring be done by

a certified technician or electrician to ensure adherence to the local and

national electrical codes applicable in your jurisdiction.

4. To avoid a risk of fire and electric shock, make sure that existing wiring is in

good condition and that wire is not undersized. Do not operate the inverter

with damaged or substandard wiring.

5. Do not operate the inverter if it has been damaged in any way.

6. This unit does not have any user-serviceable parts. Do not disassemble the

inverter except where noted for connecting wiring and cabling. See your

warranty for instructions on obtaining service. Attempting to service the unit

yourself may result in a risk of electrical shock or fire. Internal capacitors

remain charged after all power is disconnected.

7. To reduce the risk of electrical shock, disconnect both AC and DC power

from the inverter before attempting any maintenance or cleaning or working

on any components connected to the inverter. Putting the unit in Standby

mode will not reduce this risk.

8. The inverter must be provided with an equipment-grounding conductor

connected to the AC input ground.

9. Do not expose this unit to rain, snow, or liquids of any type. This product is

designed for indoor use only. Damp environments will significantly shorten

the life of this product and corrosion caused by dampness will not be

covered by the product warranty.

10. To reduce the chance of short-circuits, always use insulated tools when

installing or working with this equipment.

11. Remove personal metal items such as rings, bracelets, necklaces, and

watches when working with electrical equipment.

vi 975-0240-01-01

Safety

DANGER

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E or CSA Z462.

• This equipment must only be installed and serviced by qualified electrical

personnel.

• Never operate energized with covers removed

• Energized from multiple sources. Before removing covers identify all

sources, de-energize, lock-out, and tag-out and wait 2 minutes for circuits

to discharge

• Always use a properly rated voltage sensing device to confirm all circuits

are de-energized.

Failure to follow these instructions will result in death or serious injury.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Disconnect negative and positive PV conductors before servicing. PV

conductors are to be treated as Hazardous Live and must be

disconnected.

• Normally GROUNDED conductors may be UNGROUNDED and

ENERGIZED when a GROUND FAULT is indicated on the front panel. Must

be serviced by qualified personnel.

Failure to follow these instructions will result in death or serious injury.

975-0240-01-01 vii

Safety

DANGER

DANGER

WARNING

Precautions When Working With Batteries

Note: Battery work and maintenance must be done by qualified personnel

knowledgeable about batteries to ensure compliance with battery handling and

maintenance safety precautions.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Remove watches, rings, or other metal objects.

• This equipment must only be installed and serviced by qualified electrical

personnel.

• Keep sparks and flames away from the batteries.

• Use tools with insulated handles.

• Wear protective glasses, gloves and boots.

• Do not lay tools or other metal parts on top of batteries.

Failure to follow these instructions will result in death or serious injury.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Battery Circuit Breakers must be installed according to the specifications

and requirements defined by Schneider Electric.s.

• Servicing of batteries must only be performed by qualified personnel

knowledgeable about batteries and the required precautions. Keep

unqualified personnel away from batteries.

• Disconnect the charging source prior to connecting or disconnecting

battery terminals.

Failure to follow these instructions will result in death or serious injury.

Limitations on Use

LIMITATIONS ON USE

The Conext XW+ Inverter/Charger is not intended for use in connection with

life support systems or other medical equipment or devices.

Failure to follow these instructions can result in death or serious injury.

viii 975-0240-01-01

Explosive Gas Precautions

WARNING

EXPLOSION HAZARD

This equipment is not ignition protected. To prevent fire or explosion, do not

install this product in locations that require ignition-protected equipment. This

includes any space containing gasoline-powered machinery, fuel tanks, as

well as joints, fittings, or other connections between components of the fuel

system.

Failure to follow these instructions can result in death or serious injury.

Working in the vicinity of lead acid batteries is dangerous. Batteries generate

explosive gases during normal operation. Therefore, you must read this Guide

and follow the instructions exactly before installing or using your inverter/charger.

To reduce the risk of battery explosion, follow these instructions and those

published by the battery manufacturer and the manufacturer of the equipment in

which the battery is installed.

Safety

FCC Information to the User

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment to a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

975-0240-01-01 ix

Safety

•THIS PAGE INTENTIONALLY BLANK•

x 975-0240-01-01

Contents

Important Safety Instructions

1 Introduction

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Performance Highlights - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Distinguishing Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Xanbus™ Network Communications Protocol - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Available Conext XW+ Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Bidirectional Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Surge Performance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Islanding Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

AC Coupling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Multi-unit Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Auxiliary Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Transfer Relay - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

K1 and K2 relay - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Monitoring the Conext XW+ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–11

Conext XW+ Information Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–11

Conext System Control Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

2 Monitoring Operation

Monitoring Operation with the Inverter Information Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Monitoring AC Input Status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Monitoring Conext XW+ Status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Monitoring Charger Status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Monitoring Events - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Equalizing Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Using Startup/Shutdown/Standby Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

Monitoring Battery Level - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Reading the Display Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Monitoring Operation with the Conext SCP - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Conext System Control Panel Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Using the Standby Button - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Conext System Control Panel Navigation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Viewing the Conext System Control Panel Home Screens - - - - - - - - - - - - - - - - - - - - - - 2–11

Viewing Other Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Reading the System Status Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Reading the Conext XW+ Home Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

975-0240-01-01 xi

Contents

Reading the Meters Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–18

3 Configuration

Using the Conext System Control Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Conext XW+ Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Setting the Time and Date - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Using the Setup Menus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Inverter Settings Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Using the Low Battery Cut Out and LBCO Delay Settings - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Using Search Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Charger Settings Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

Battery Charger Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12

Multi-Unit Charger Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12

Multi-Stage Charging Process - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–13

Equalize Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–18

Equalization Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–20

Custom and Lithium Ion Battery Settings Sub Menus - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–21

AC Input Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–24

Grid Support Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–26

Prioritizing and Managing Energy Sources with Advanced Features- - - - - - - - - - - - - - - - - - - - 3–29

Grid Support - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–29

Grid Support and Battery Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–30

Charger Block - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–32

Peak Load Shaving (PLS) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–32

Time-of-Use Metering - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–33

Self-Consumption - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–34

Generator Support Settings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–34

Auxiliary Output Settings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–37

Multi-Unit Config Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–39

Setting the Device Name - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–41

Setting the Device Number - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–42

Three-Phase Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–43

Connections Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–45

Copying Settings From Another Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–47

Resetting the Conext XW+ to Default Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–48

Using the Advanced Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–49

4 Troubleshooting

General Troubleshooting Guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Inverter Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Resistive Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Motor Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Problem Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Very Small Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

xii 975-0240-01-01

Fluorescent Lights and Power Supplies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Clocks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Searching - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Inverter Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Battery Charger Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–7

Faults and Warnings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–10

Warning Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–11

Warning Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–11

Fault Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–16

Fault Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–17

Inverter Operation After Faults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–17

A Specifications

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

Grid-tie Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3

Response to Abnormal Grid Conditions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

Conext XW+ Overload Capability - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Output Power Versus Ambient Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–8

Conext XW+ Efficiency - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–9

Inverting Efficiency (Typical) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–9

Charging Efficiency (Typical) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–10

Charging Efficiency Power Factor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–11

Mechanical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–12

Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–13

Contents

B Default Settings

Default Settings and Ranges - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–2

Inverter Settings Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–3

Charger Settings Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–3

Custom Settings Submenu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–3

LithiumIon Submenu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–4

AC Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–4

Grid Support Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–5

Gen Support Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–5

Aux Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–5

Connections Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–6

Advanced Features Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–6

975-0240-01-01 xiii

Contents

•THIS PAGE INTENTIONALLY BLANK•

xiv 975-0240-01-01

1 Introduction

Chapter 1, “Introduction”, describes the

operational features of the Conext XW+

Inverter/Charger.

Topics in this chapter include:

• “Features” on page 1–2

• “Operation” on page 1–3

• “Monitoring the Conext XW+” on page 1–11

Introduction

Features

The Conext XW+ is a modular building block sine-wave inverter/charger that can

be used for residential and commercial battery based off-grid, grid backup, and

grid interactive applications.

The Conext XW+ is a self-contained DC to AC inverter, battery charger, and

integrated AC transfer switch. It is configurable in a hybrid system to operate with

generators and renewable energy sources. These configurations are capable of

extending battery based off-grid/backup autonomy.

Performance Highlights

• Excellent load starting with high 30-minute and 5-second power.

• Off-grid AC Coupling with PV inverters using frequency power curtailment

method.

• Operation in hot environments up to 70°C.

• Conversion of DC energy to AC energy for export to the utility grid.

• Power factor corrected charging minimizes AC current required for charging.

• True sine wave output.

Distinguishing Features

• Grid-interactive feature set enables time management and prioritization of

energy sources and power conversion to support advanced modes of

operation such as load shifting, self consumption and peak load shaving.

• Dual AC input connections with 60 A automatic transfer switch integrates

both utility grid and generator.

• Generator Support functionality assists small generators with heavy loads.

• Auxiliary port assist with relay switching of external devices such as battery

room fans, diversion loads and generators.

• Configurable battery parameters for customized battery charging.

• Field serviceable boards and components.

Xanbus™ Network Communications Protocol

The Conext XW+ uses Xanbus™, a network communications protocol developed

by Schneider to communicate with other Xanbus-enabled devices. You can

configure and monitor the Conext XW+ and other Xanbus-enabled devices in the

system using the Conext System Control Panel (part number 865-1050-01) or

Conext ComBox (part number 865-1058).

1–2 975-0240-01-01

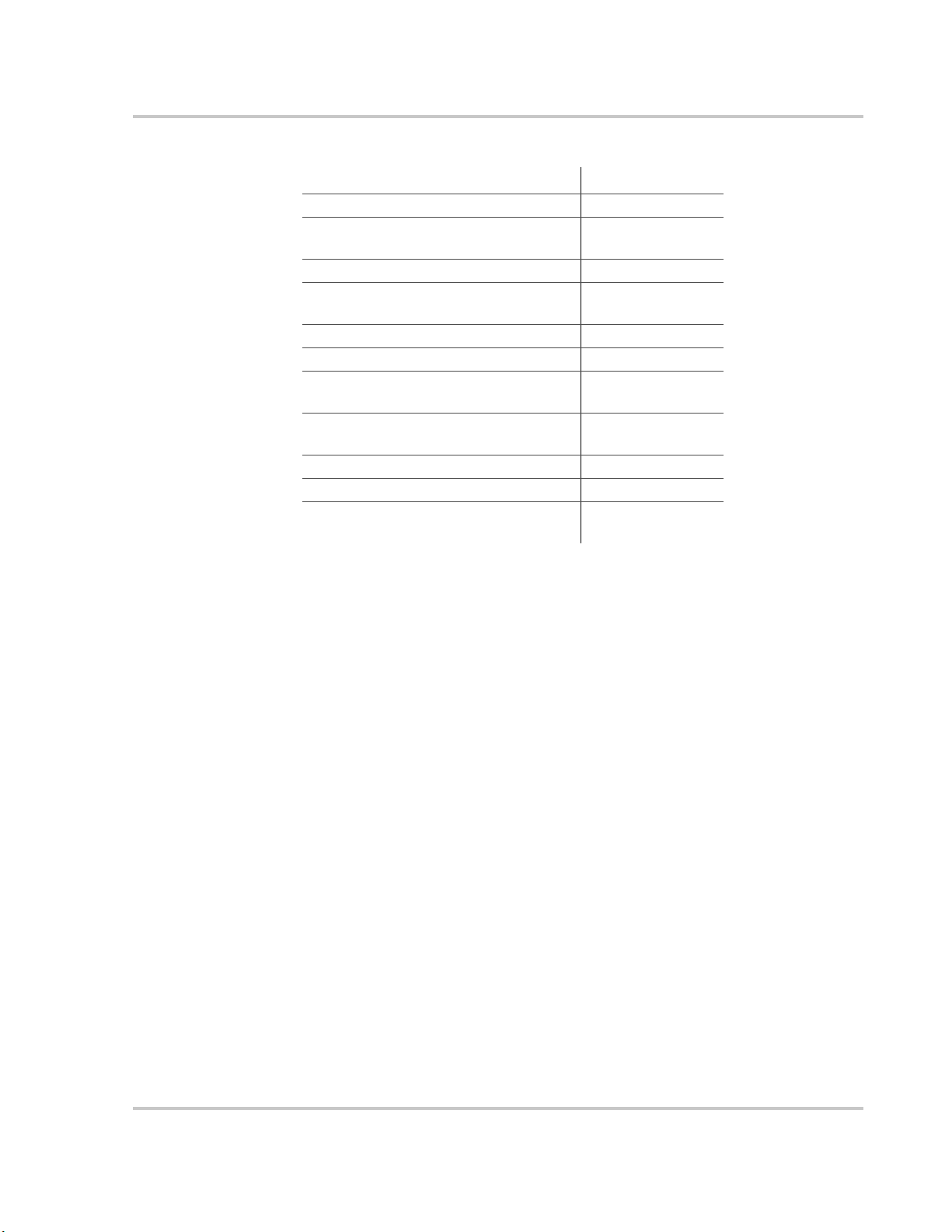

Available Conext XW+ Accessories

Accessory Part Number

Conext XW+ Power Distribution Panel 865-1015-01

Conext XW+ Power Distribution Panel

(Without AC Breakers)

Conext XW+ Conduit Box 865-1025-01

Conext XW+ Connection Kit for INV2

INV3 PDP

Conext System Control Panel 865-1050-01

Conext Automatic Generator Start 865-1060-01

Conext MPPT 60 150 Solar Charge

Controller

Conext MPPT 80 600 Solar Charge

Controller

Conext ComBox 865-1058

Conext Battery Monitor 865-1080-01

Conext XW+ PDP 120/240V 60A

Breaker Kit

Operation

865-1014-01

865-1020-02

865-1030-1

865-1032

865-1215-01

Operation

Bidirectional Theory of Operation

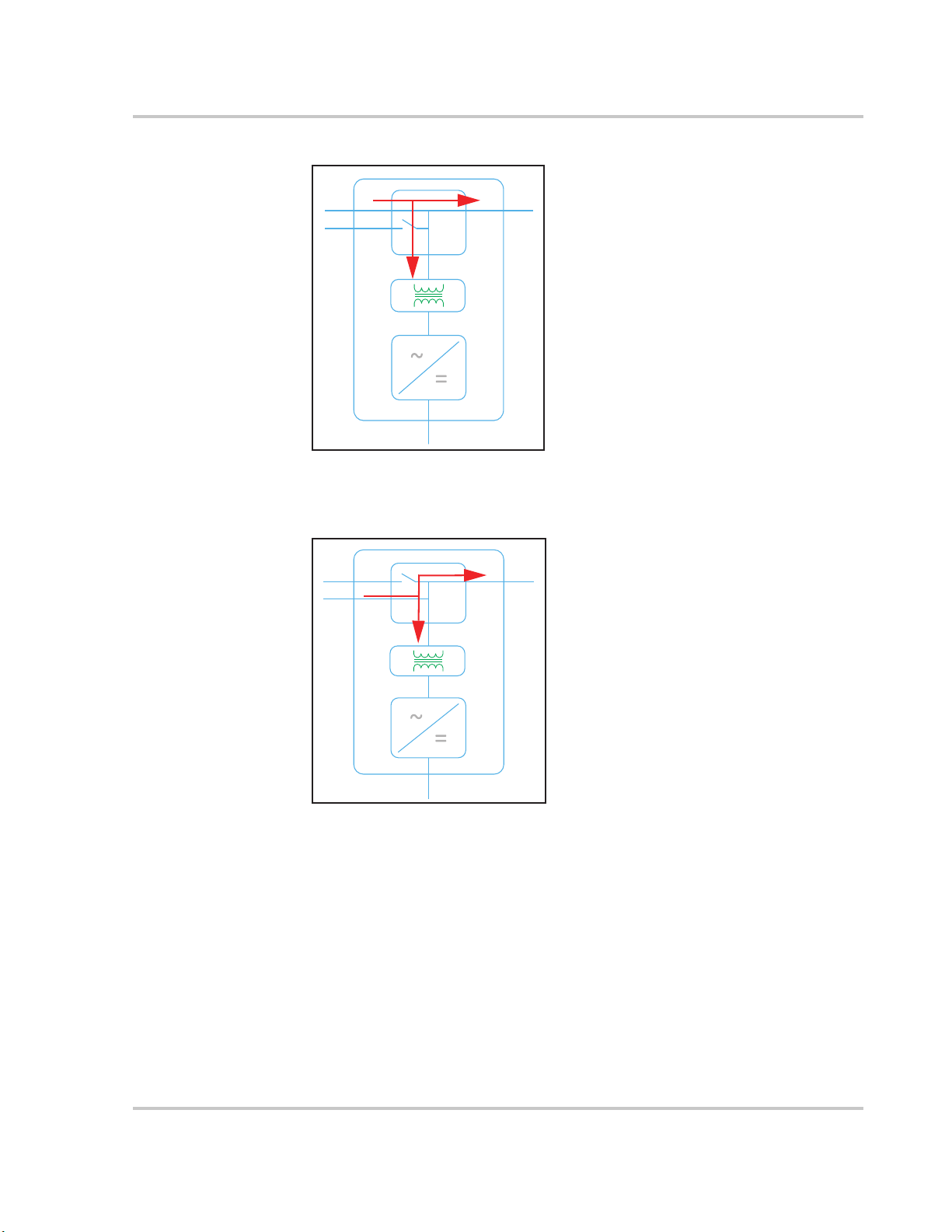

The Conext XW+ is a grid forming device consisting of a bidirectional inverter/

charger. It is capable of inverting DC power into AC power and controlling the

voltage and frequency of its inverter output. It will power external loads attached

to AC OUT (See Figure 1-2, “Inverting of DC to AC Connected to AC OUT” on

page 1–4).

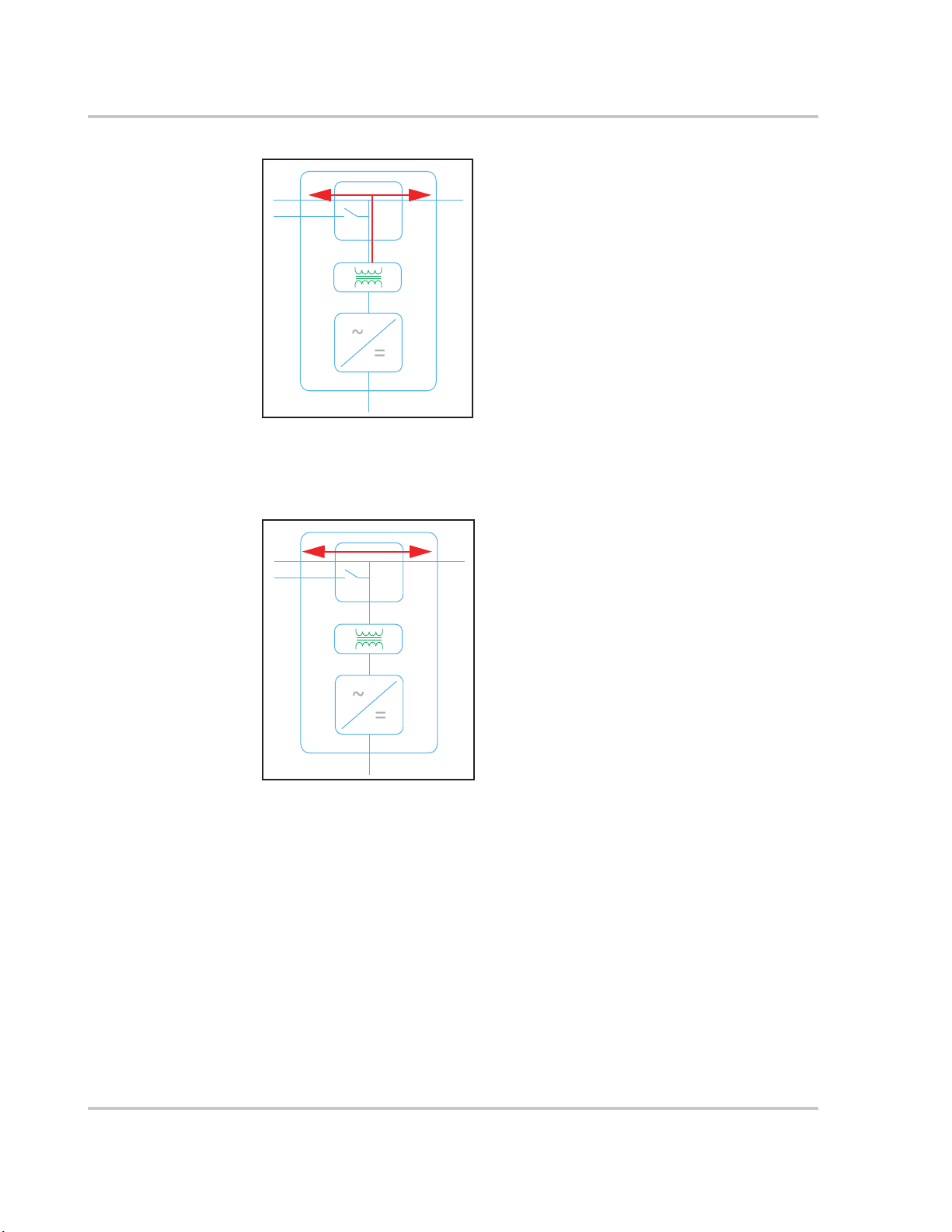

The Conext XW+ is also capable of charging external batteries by converting AC

power into DC power (See Figure 1-3, “Charging External Batteries and

Supplying AC Out with AC Passthrough from AC1 Grid ” on page 1–5). The

Conext XW+ accepts AC power through connection AC2 for charging batteries,

usually from a generator (See Figure 1-4, “Charging External Batteries and

Supplying AC Out with AC Passthrough from AC2 Generator” on page 1–5).

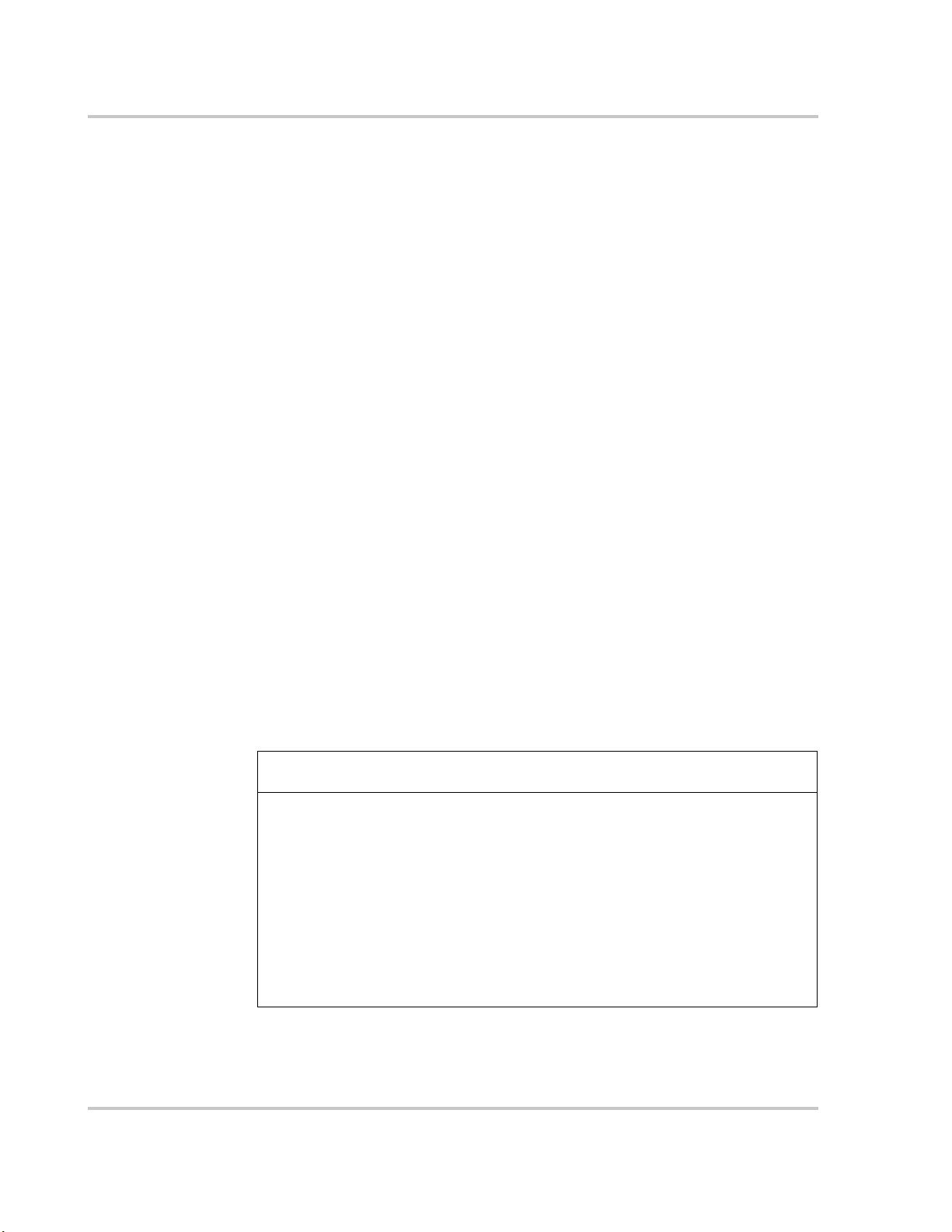

The Conext XW+ will convert externally sourced DC power into AC power for

export to the utility grid attached to its AC1 connection (See Figure 1-5,

“Converting Excess Available DC power for Export to Utility Grid (AC1) and AC

Out” on page 1–6).

The Conext XW+ has an internal automatic transfer switch (K1, K2) which allows

either AC1 or AC2 to be connected to the inverter input, but not both at the same

time (See Figure 1-1, “Connection Points and Major Power Conversion

Components of Conext XW+ ” on page 1–4). This allows shared AC energy

during charging or to directly passthrough from AC1, or AC2, to AC Out.

975-0240-01-01 1–3

Introduction

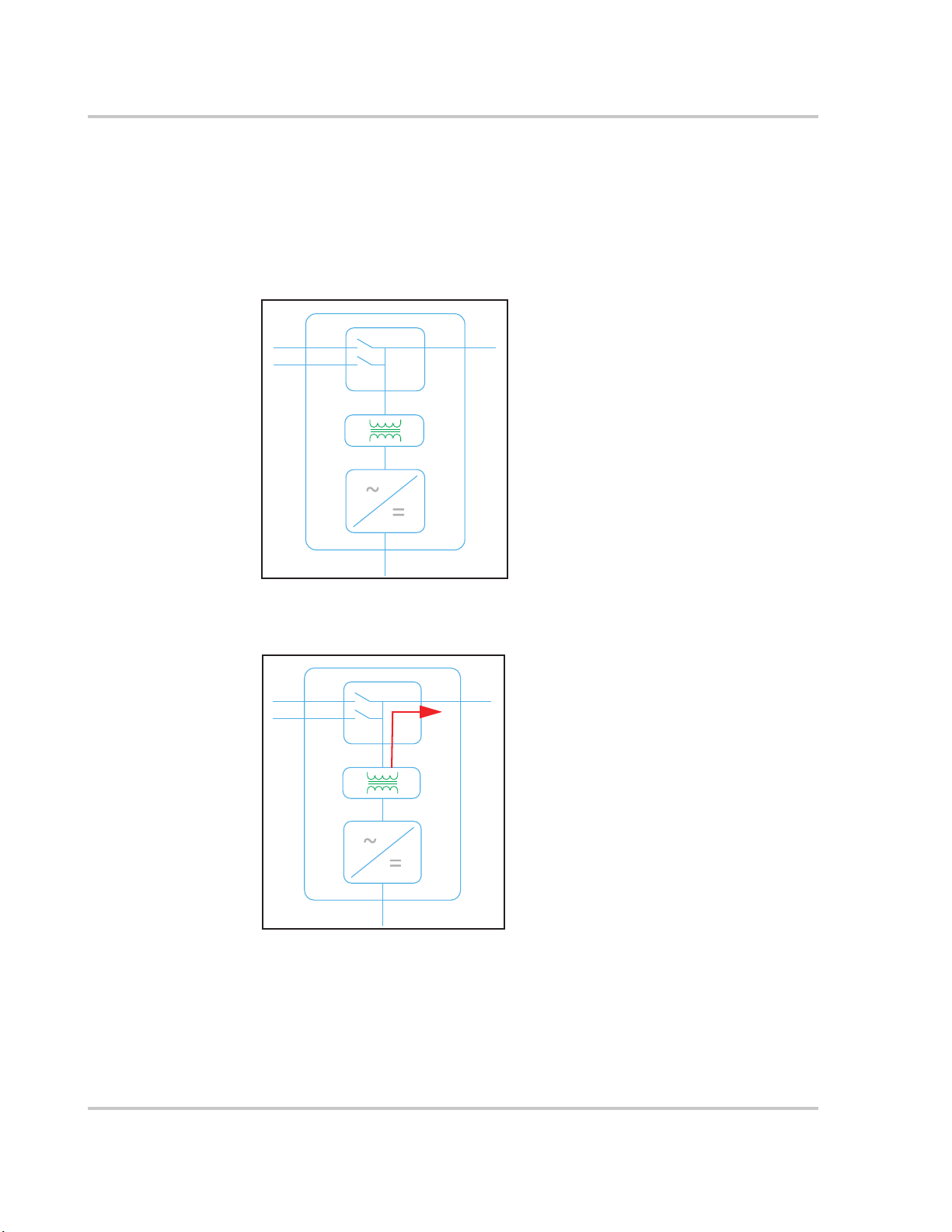

K

2

K

1

AC Transformer

Bidirectional AC/DC

power block

AC Interface Board

AC

1

AC

2

AC

OUT

Through firmware control over power conversion and the management of K1 and

K2, Conext XW+ can facilitate advanced interaction with the utility grid to

optimize the utilization of renewable and non-renewable energy sources.

Because the Conext XW+ is a device capable of forming an AC grid signal (AC

voltage and frequency) it is also ideal for use off-grid.

The red arrows in the diagrams below represent the direction of power flow in the

respective modes of operation. These modes and other special functions will be

explained throughout this manual.

Figure 1-1 Connection Points and Major Power Conversion Components of

Conext XW+

AC

AC

1

2

AC

OUT

Figure 1-2 Inverting of DC to AC Connected to AC OUT

1–4 975-0240-01-01

Figure 1-3 Charging External Batteries and Supplying AC Out with AC

AC

1

AC

2

AC

OUT

AC

1

AC

2

AC

OUT

Passthrough from AC1 Grid

Operation

Figure 1-4 Charging External Batteries and Supplying AC Out with AC

Passthrough from AC2 Generator

975-0240-01-01 1–5

Introduction

AC

1

AC

2

AC

OUT

AC

1

AC

2

AC

OUT

Figure 1-5 Converting Excess Available DC power for Export to Utility Grid (AC1)

and AC Out

Figure 1-6 AC Passthrough

1–6 975-0240-01-01

Surge Performance

Unlike many other inverters, the Conext XW+ helps stop voltage from sagging

dramatically during surge conditions. The Conext XW+ handles surges of over

twice its rated output power with only a minimal drop in output voltage for limited

periods of time.

Islanding Protection

Islanding protection is an essential safety feature that helps reduce harm to those

working on the utility grid from a distributed energy source such as the Conext

XW+. Islanding protection also helps to prevent loads connected to the Conext

XW+ from being damaged by a fluctuating utility grid input. The Conext XW+

uses proprietary positive feedback control to achieve anti-islanding operation

while maintaining low total harmonic distortion at the grid connection. Default

software settings are programmed into each Conext XW+ at the factory so that

they comply with applicable safety regulations (such as IEEE 1547 and UL 1741

in North America).

In some instances it may be desirable from both a utility and a customer point of

view to adjust the default anti-islanding settings. For example, the Conext XW+

may experience “nuisance trips” if the grid is weak and the voltage falls outside

the allowable range specified by regulations. It may be difficult for a utility to

adjust the grid to stop this problem. With permission from the utility, the factory

settings may be changed to allow the Conext XW+ to operate over a wider grid

voltage range. These settings must only be changed by qualified service

personnel using a special software application (Conext Configuration Tool, Order

# 865-1155-01) provided by the manufacturer.

Operation

While exporting energy, the Conext XW+ continuously monitors the utility grid

voltage and frequency. If the grid voltage or frequency move beyond the Conext

XW+ default ranges (for example, during a power surge or outage) the Conext

XW+ stops exporting energy through AC1 and disconnects from the utility. If

disconnected due to a grid voltage disturbance, five minutes is the nonadjustable minimum reconnect time during which the Conext XW+ does not

export energy through AC1 to the grid. The Fault light on the Conext XW+

information panel will indicate a utility fault. No fault code appears on the threecharacter display because the fault is with the utility grid, not with the Conext

XW+.

In addition to the information panel, the Conext System Control Panel indicates a

utility fault with the Fault light and also displays a fault message on screen (faults

F23 to F40 are utility faults—see Figure 4-6, “Fault Messages” on page 4–19).

The fault cannot be manually cleared. Utility faults will clear automatically when

the utility grid voltage and frequency return to within the ranges programmed into

the Conext XW+. If grid support is enabled and the utility voltage and frequency

come back within tolerance, the Conext XW+ information panel displays a

countdown timer for five minutes until the Conext XW+ can start interacting with

the grid again.

975-0240-01-01 1–7

Introduction

NOTICE

AC Coupling

Off-grid AC Coupled system architecture is often used to create a stand-alone

grid. Commonly this means that PV inverters are connected to the output of a

battery-based inverter/charger putting both on the same AC bus along with the

AC loads. In this scenario, the battery powered inverter charger provides the

necessary frequency and voltage to enable the PV inverter to produce power.

This type of system must be able to maintain power generation in balance with

power consumption at all times. If there is more power being generated than can

be consumed by the loads, power will flow to the inverter/charger and be

converted to DC power which flows into the battery. Once the battery reaches

capacity, power generation by the PV inverter must be curtailed to maintain the

balance between generation and consumption. As the battery bank reaches

capacity, Conext XW+ curtails PV inverter generation by raising the AC line

frequency causing compatible PV inverters to reduce their power output in an

orderly manner. This is called Active Frequency Shift Power Curtailment.

During a grid outage even a home with a grid-tie PV inverter system will be

without power because PV inverters cannot produce power without the presence

of a reference voltage and frequency. To enable the PV inverter to provide power

during a grid outage the Conext XW+ is retrofitted in front of the PV inverter. The

PV inverter is rewired from the grid connection to a critical load (sub) panel and

the AC Couple is on the Conext XW+ AC Output port. When the grid is present,

PV inverter power feeds the loads and any excess is exported by Conext XW+ to

the grid using AC1 (where permitted by the local utility). During a grid outage,

Conext XW+ anti-islanding protection prevents power from being exported to

grid on AC1. Conext XW+ then uses Active Frequency Shift Power Curtailment to

reduce the power output of compatible PV inverters, maintaining the balance of

generation and consumption.

Consult the manufacturer's specifications to determine if your PV inverter is

compatible with Active Frequency Shift Power Curtailment. Conext XW+ AC

coupling function is enabled by default (Advanced Features Menu).

AC COUPLED PV INVERTER COMPATIBILITY

AC power generated by AC coupling PV inverters with Conext XW+ must be

consumed by AC loads or used to charge batteries. As an alternative, the

excess power produced from a PV inverter can be routed to dump loads. Do

not AC couple PV inverters with the Conext XW+ that are unable to reduce,

derate or cease the excess PV inverter power in response to the changes in

AC line frequency controlled by the Conext XW+. Consult the manufacturer's

specifications of your PV inverter and confirm compatibility.

Failure to follow these instructions can result in equipment damage.

The AC coupling advanced setting should remain enabled except in cases when

the DC voltage level is allowed to have large variations and the line frequency

needs to remain constant.

1–8 975-0240-01-01

Further details about AC Coupling can be found in the document AC Coupling of

Inverters Solutions Guide (975-0240-01-01) available at http://solar.schneider-

electric.com.

Multi-unit Operation

Up to three Conext XW+ units can be installed together in a single phase configuration

with the Conext PDP (Power Distribution Panel). A maximum of four Conext XW+ units

can be installed together in a single phase configuration with the addition of a second

PDP. The PDP is an ideal optional companion for managing AC connections and

integrating a battery bank and other DC connections. Regardless of how it is installed,

the maximum number of Conext XW+ in a single phase or split phase configuration is

four.

Three Conext XW+ units can also be configured in a cluster for three-phase operation

using a single PDP (PDP is optional). Up to three clusters of three Conext XW+ units

can be installed in a three-phase configuration when using an external AC contactor.

Multiple Conext XW+ units and other Xanbus devices with common connections to

battery banks, PV arrays, the utility grid or a generator require programming during

commissioning to enable correct operation.

Inverting

Operation

For multiple units, the master Conext XW+ synchronizes operation of other connected

units using the same Xanbus network. When AC loads are present, all units produce

power, effectively sharing the load. Multiple units do not produce power together when

Search mode is enabled. See “Using Search Mode” on page 3–9.

Parallel Charging

Multiple Conext XW+ units on the same Xanbus network synchronize their charging

stages to help provide efficient charging of the battery bank. When a single unit

transitions from bulk to absorption, so do all other units. In absorption, all units must

complete the absorption stage before any of them transition to the next stage. Note that

units stop sharing charge current just before completing the bulk stage and only share

charging load during the bulk stage.

Each Conext XW+ unit provides a maximum charging current set by the Max Charge

Rate setting. The maximum current may be decreased, subject to the internal operating

temperature.

When one or more Conext Solar Charge Controllers are installed and operating in the

system, Conext XW+ units synchronize only their bulk charging stage with the charge

controllers.

Note: Equalization is device specific. Only the device(s) on which equalization was

initiated will perform the equalization. Other devices will stay in float or no-float

depending on their settings.

975-0240-01-01 1–9

Introduction

AC Transfer

Multiple Conext XW+ units monitor each other to determine the quality of AC input. If AC

input is deemed to be bad by any of the paralleled units, no transfer to AC Out occurs

and the AC LED continues to flash on each unit’s information panel until the AC is

qualified by all. If the system was in passthrough and AC fails on any unit, all units

transfer to invert simultaneously.

Faults

When the Conext XW+ detects a fault condition, the fault is displayed on the Conext

XW+. The Conext XW+ also turns on the Fault light on the Conext XW+ and inverter

information panel. A fault affects the operation of the unit. See “Fault Types” on page 4–

14 for an explanation of the different fault types.

• When a single Conext XW+ slave unit in a multi-unit system has a fault, only the

affected device shuts down.

• When a master unit has an invert mode fault that causes it to stop inverting, it is

considered a system-wide fault and all units shut down. Invert mode faults on slave

units only shut down the affected slave unit.

• All units shut down when there is a battery-related fault such as battery overtemperature or over-voltage.

Independent Operation of Features Each Conext XW+ grid-interactive feature (e.g.

enhanced grid support, grid sell, load shave and generator support) operates

independently. This enables Conext XW+ units in a multi-unit system to be configured to

perform multiple functions independently and allows greater flexibility in operating the

entire system.

Auxiliary Output

Each Conext XW+ has one programmable 12 V, 0.25 A auxiliary output that is able to

run a small fan or operate an external relay to perform other functions. Examples

include remotely starting a two-wire start generator in cases where the Xanbus-enabled

Conext AGS is not used, disconnecting external non-critical loads, or turning on a

diversion load for battery voltage regulation. See “Auxiliary Output Settings” on page 3–

37 for programme parameters.

Transfer Relay

The built-in transfer relay is rated for 60 amps. When an external AC source is detected

and qualified on either of the AC1 or AC2 inputs, the relay transfers loads from the

Conext XW+ to the external power source, and then activates the battery charger. Multiunit systems of three or more require the use of an external AC contactor to manage the

AC bus.

K1 and K2 relay

The Conext XW+ design does not allow the K1 and K2 relays to close simultaneously.

This design helps stop the generator input (AC2) from back feeding to the utility grid

(AC1).

1–10 975-0240-01-01

Monitoring the Conext XW+

AC1

AC2

Event

Equalize

kW

A

Charging

!

Inverting

Operation of the Conext XW+ can be monitored using the factory-installed inverter

information panel or the optional Conext System Control Panel and ComBox. To

configure the Conext XW+, the Conext System Control Panel or ComBox must be used.

Conext XW+ Information Panel

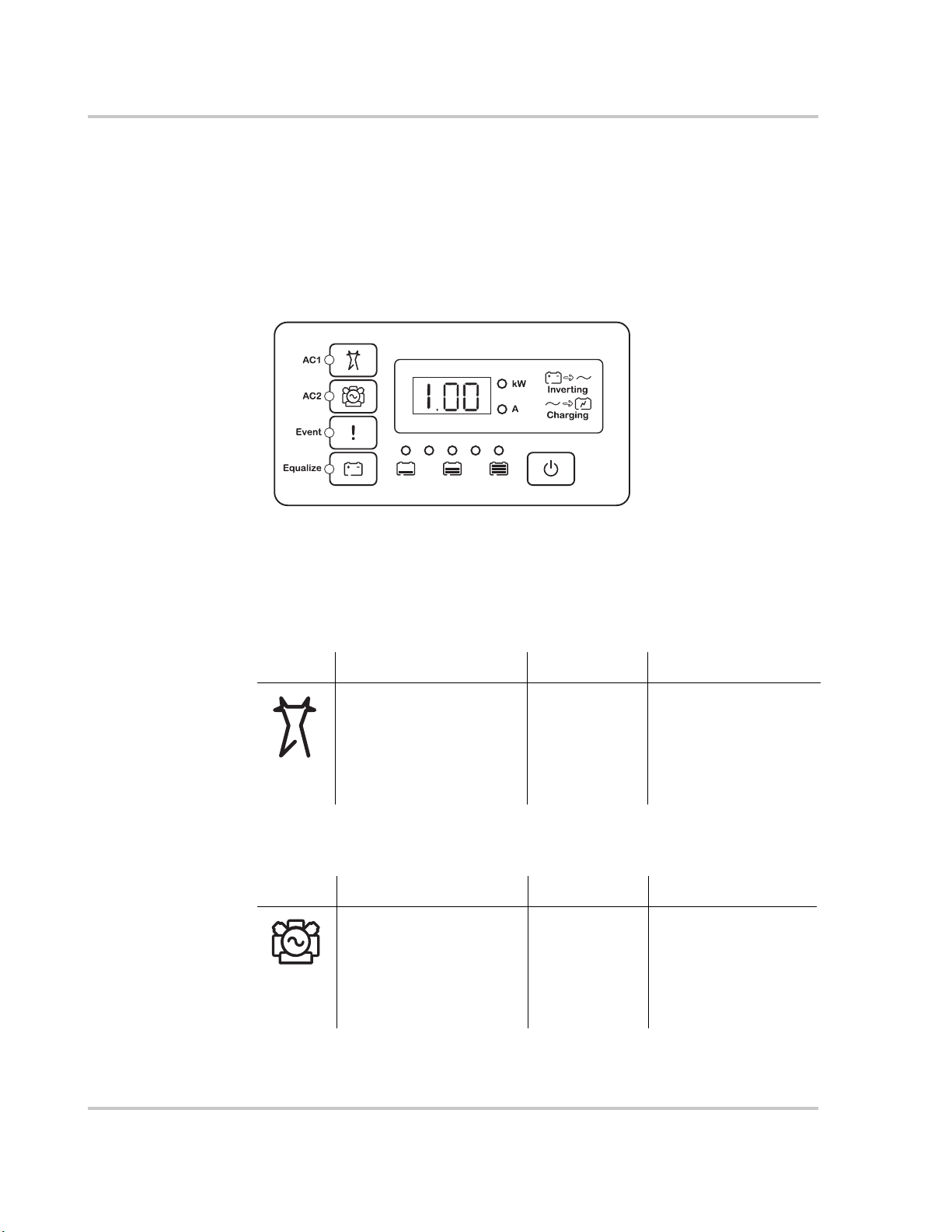

The Conext XW+ information panel features:

• Buttons for Conext XW+ Startup/Shutdown/Standby control, clearing faults and

warnings, and battery equalization.

• A three-character display to indicate power output, charge current, anti-islanding

countdown or troubleshooting information.

• LEDs to indicate AC input status, output status, battery condition, and system

warnings/faults.

Monitoring the Conext XW+

Figure 1-7 Conext XW+ Information Panel

975-0240-01-01 1–11

Introduction

Standby

Event/Warning

Conext SCP

Conext System Control Panel

The Conext System Control Panel (Conext SCP) or Conext ComBox is required for

configuring the Conext XW+ and other Xanbus-enabled system components.

The Conext SCP features:

• A liquid crystal display which provides graphics and text describing real time

operation and status information.

• LED event and warning indicator.

• Internal clock which is used to control time-dependent Conext XW+ functions.

• Buttons to select configuration menus, customize Conext XW+ functions and clear

faults and warnings.

Figure 1-8 Conext System Control Panel

1–12 975-0240-01-01

2 Monitoring

Operation

Chapter 2, “Monitoring Operation”, contains

information about monitoring Conext XW+

Inverter/Charger operation using the inverter

information panel or the Conext System Control

Panel.

The topics in this chapter include:

• “Monitoring Operation with the Inverter

Information Panel” on page 2–2

• “Monitoring Operation with the Conext SCP”

on page 2–10

Monitoring Operation

Monitoring Operation with the Inverter Information Panel

The inverter information panel on each Conext XW+ monitors a single Conext

XW+. The Conext XW+ information panel displays basic information and

performs start up, shut down, equalization and standby functions. LEDs on the

information panel indicate AC input status, Conext XW+ status, battery condition,

and charging and equalization status. The Conext XW+ LEDs and threecharacter display screen indicate warning and event conditions.

Figure 2-1 Inverter Information Panel

Monitoring AC Input Status

Grid (AC1) The green Grid (AC1) LED indicates the presence and status of the

AC source connected to the AC1 input.

Symbol LED On LED Flashing LED Off

AC input is present and

qualified. The Conext

XW+ is ready to charge

batteries, pass AC

through to the loads, or

interact with the grid.

Gen (AC2) The green Gen (AC2) LED indicates the presence and status of a

generator or other auxiliary AC source on the AC2 input.

Symbol LED On LED Flashing LED Off

The AC source is present

and AC input is qualified.

The Conext XW+ is ready

to charge batteries and

pass power through to

the loads.

AC input is

present and is

being qualified.

AC input is

present and is

being qualified.

The Conext XW+ is not

connected to the grid.

AC input is not

present, or AC input is

present but not within

qualifying range.

AC input is not

present, or AC input is

present but not within

qualifying range.

2–2 975-0240-01-01

Loading...

Loading...