F

E

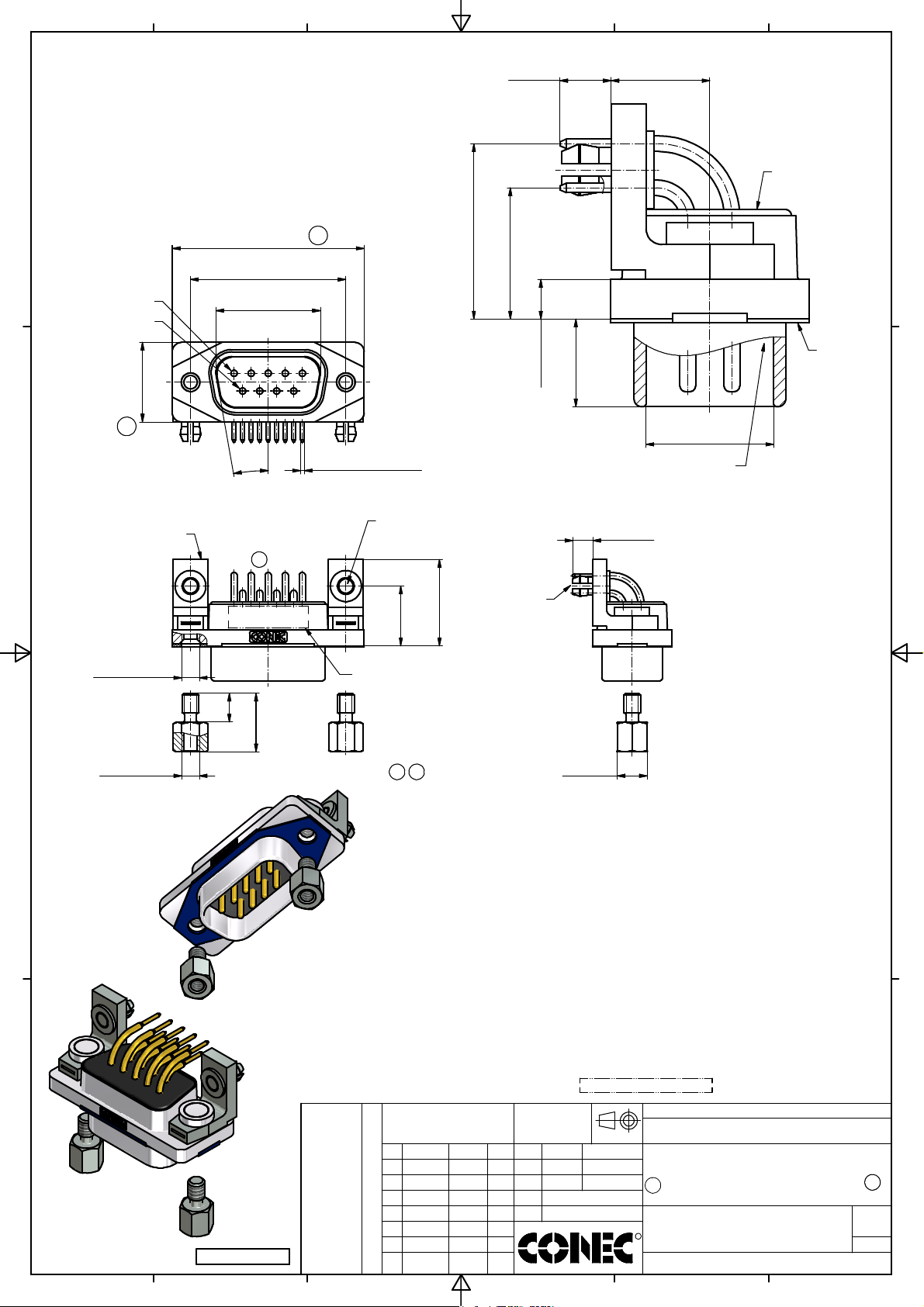

AT ALL TIMES WATER RESISTANT

CONNECTORS NOT IN USE SHOULD

BE COVERED WITH A CONEC WATER

RESISTANT CAP OR WATER TIGHT HOOD.

B

`

0,3

3,3

C

0,5

+

-

0,3

6,35

D

A

( 5 : 1 )

D D

3

4

,

,

0

0

-

0,3

+

POS. 1

30,88

25

16,81

+

-

-

0,12

0,13

0,23

+

-

0,02

0,15

c

POS. 6

5

1

3

,

,

0

0

-

+

8

,

2

1

c

`

0,05

0,6

°

0

1

C C

n

(9x)

+

3

4

8

,

,

2

0

0

,

-

+

1

4

1

4

,

8

5

2

8

2

,

1

1

0

0

,

,

-

+

0

0

-

+

5

4

5

,

6

,

2

5

0,25

+

8,23

-

0

RUBBER GASKET PLACED

ON TOP SURFACE OF MALE

SEALING

COMPOUND

SEALING

GASKET

INSULATOR

METAL BRACKET

b

15-00654o

CONEC ABC

PRESS FOR

FIXING ON PCB

3

4

,

,

0

0

-

+

3

4

,

,

0

0

-

+

6

,

9

5

8

,

3

1

PCB SNAP

3,2

`

0,2

4-40 UNC

4-40 UNC

6

,

4

4

,

9

SEE NOTE 17

d

b

4,8SW

NOTES:

B B

T

U

T

O

O

R

H

N

T

O

I

A A

RoHS compliant

F

E

Y

D

W

A

E

I

Y

M

P

T

D

R

O

N

A

C

P

A

E

,

B

D

Y

R

T

A

I

O

H

W

N

T

Y

Y

A

N

A

A

O

M

T

N

I

G

N

N

D

O

I

E

W

D

C

E

A

U

S

R

D

S

D

O

A

R

S

P

I

P

E

E

H

T

R

B

1. FOR WAVESOLDERING (SOLDER BATH TEMPERATURE 265°C FOR 8 SEC.

AND SOLDER PREHEAT 150°C FOR 180 SEC.)

2. IP RATING: IP 67

3. SEALED TO WITHSTAND PRESSURE UP TO 1,45 PSI FOR 30 MINUTES

AFTER HIGH TEMPERATURE EXPOSURE

4. METALSHELL: ZINC DIE CAST; min. 50µin NICKEL PLATING over COPPER

5. INSULATORS: PBT GF UL 94 V-0; BLACK

6. SEALING GASKET: SILICONE; BLUE

7. RUBBER GASKET: TPE; BLACK

8. SEALING COMPOUND: EPOXY RESIN UL 94 V-0; BLACK

9. CONTACTS: COPPER ALLOY

PLATING (SEE PART NO.): o PLEASE ADD 1 for 30µin HARD GOLD over min. 50µin NICKEL

o PLEASE ADD 3 for GOLD FLASH over NICKEL

10. METAL BRACKETS: ZINC DIE CAST; 300µin COPPER/40-120µin NICKEL/120-200µin TIN

11. WASHERS: COPPER ALLOY; 80µin NICKEL

12. HEXLOCKING SCREWS: STAINLESS STEEL

13. PCB-SNAPS: COPPER ALLOY; min. 200µin TIN over 80µin NICKEL

PCB-HOLE: n3,1`0,1mm; PCB THICKNESS 1,6mm

14. P.C.B. HOLE DRILLINGS and RECOMMENDED PANEL CUT-OUT ON SHEET 2

15. RECOMMENDED TORQUE FOR MOUNTING SCREW 35Ncm (3.1 in.LB) / max. 67Ncm (6 in.LB)

16. CONNECTOR IS PART MARKED: 15-00654o CONEC ABC (see note 9)

H

D

b

N

m

A

G

H

C

E

Y

N

B

O

G

C

N

F

I

O

W

T

A

H

R

G

I

D

R

.

Y

D

N

P

2 x d

A

O

O

I

C

C

S

S

R

D

2 x c

I

E

N

M

A

T

R

L

P

E

3 x b

I

A

P

H

T

N

S

a Original

E

R

O

T

E

N

T

N

I

R

O

W

D

W

O

D

Ä5827

Ä5800

Ä5786

25.09.15 Unkrüer

04.09.15

28.08.15 HS

date

tolerance

dim. in mm

M.H.

drawn

appd.

norm

d-old

26.01.15

Lehmenkühler15.09.14

Fischer

namedescriptionrev.

C

scale:

material:

namedate

title:

D-SUB MALE 90°

9pos. SOLDER PIN ANGLED

d

with closed 4-40 UNC thread,metal bracket,snap

dwg no:

R

part no:

15K1A1551

15-00654

B

2:1 (5:1)

SEE NOTES

o

(see note 9)

b

DIN-

A3

1

sh:

A

F

E

P.C.B. HOLE DRILLINGS

(P.C.B. TOP SIDE)

D

C

B

A

D D

`

0,1

3,1

n

(2x)

1

5

7

,

6

6

,

9

2,74

1,37

0,12

+

25

-

0,13

`

0,1

5,49

0,1

+

1

n

`

0,1

`

0,1

`

0,1

4,11

(9x)

-

0

P.C.B. EDGE

1

,

0

1

,

`

0

`

4

8

9

,

5

2

,

5

FRONTPANEL

C C

RECOMMENDED PANEL CUT-OUT

`

0,1

0,26

i

A

B

B B

)

x

2

(

5

0

,

0

`

1

,

3

n

R

O

A A

F

E

D

E

I

P

O

C

E

B

T

O

N

Y

A

M

G

N

I

W

A

R

D

S

I

H

T

0

1

H

b

T

m

U

G

T

O

C

O

H

E

N

T

I

N

Y

O

W

A

C

Y

M

T

F

D

R

O

N

A

T

P

A

H

,

D

G

Y

I

R

A

I

R

.

H

Y

W

N

T

P

Y

O

O

A

I

N

C

S

A

O

S

D

T

I

N

I

N

M

N

A

R

D

O

P

E

E

I

P

D

C

H

E

U

N

S

S

D

E

R

S

T

O

E

A

T

R

N

I

P

P

R

W

E

E

R

W

O

B

20,5

°

1

`

°

`

0,1

25

D

N

A

H

Y

B

G

N

I

W

A

R

D

D

A

C

R

E

T

L

A

T

O

N

O

D

a Original

D

date

1

,

0

`

4

,

1

1

R

3

,

4

`

0

,

1

3

i

0,26

B

A

tolerance

dim. in mm

drawn

appd.

norm

d-old

26.09.15

Lehmenkühler15.09.14

Fischer

namedescriptionrev.

C

scale:

material:

namedate

title:

P.C.B. HOLE DRILLINGS

RECOMMENDED PANEL CUT-OUT

D-SUB Male 90° 9pos. Solder pin angled

dwg no:

R

part no:

15K1A1551

SEE SHEET 1

B

5:1

SEE SHEET 1

DIN-

A3

2

sh:

A

Loading...

Loading...