Page 1

CONDUX USER’S GUIDE & SAFETY MANUAL

WINCH LINE BLOWER SYSTEM

Page 2

IMPORTANT SAFETY NOTICE

Read and understand all procedures and safety instructions before using a Condux Winch Line Blower.

Observe all safety information on this page and note specific safety requirements as explained by procedures in

this manual. Failure to follow these instructions could result in serious personal injury or death.

ADVERTENCIA:

Favor de leer y comprender todas las instucciones de operación y seguridad antes de usar la máquina. Si Ud. no

comprende las instrucciones favor de consultarle a su jefe.

Save this user’s guide for future reference.

For any information related to the machine (use, maintenance, spare parts) always state Model, Serial Number,

Manufacturing Year and Order. This data can be found in the machine identification table.

Manufacturer:

Condux International Inc.

145 Kingswood Drive

Mankato, MN 56002-0247

1-507-387-6576

Fax 1-507-387-1442

Internet: http://www.condux.com

E-mail: cndxinfo@condux.com

Page 3

Table of Contents_________________________

1. GENERAL INFORMATION

Purpose of the Winchline Blower……………………….2

Technical Information…………………………………..2

Safe Operating Practices………………………………...3

Winch Line Blower Selection………..…………………..4

2. OPERATOR’S INSTRUCTION

Winch Line Blower Installation…………………………5

Winch Line Blowing Procedure…………………………11

Winch Line Blower Removal...………………………….12

3. WINCH LINE BLOWER ADAPTER

Purpose of the Winch Line Blower Adapter…………….15

Winch Line Blower Adapter Installation………………...15

Winch Line Blower Adapter Removal…………………...19

4. TROUBLESHOOTING

Solutions to possible problems………………………….21

5. APPENDIX

Winchline Blower Seal-Off Body Assembly……………..23

Condux Control Valve Assembly P/N 08209300……….25

Condux Air Hose Assembly P/N 08209310…………….26

Condux Conduit Missile Wear/Replacement Parts……...27

Winchline Blower Adapter Assembly…………………....28

Warranty Information…………………………………...29

Page 4

1. General Information

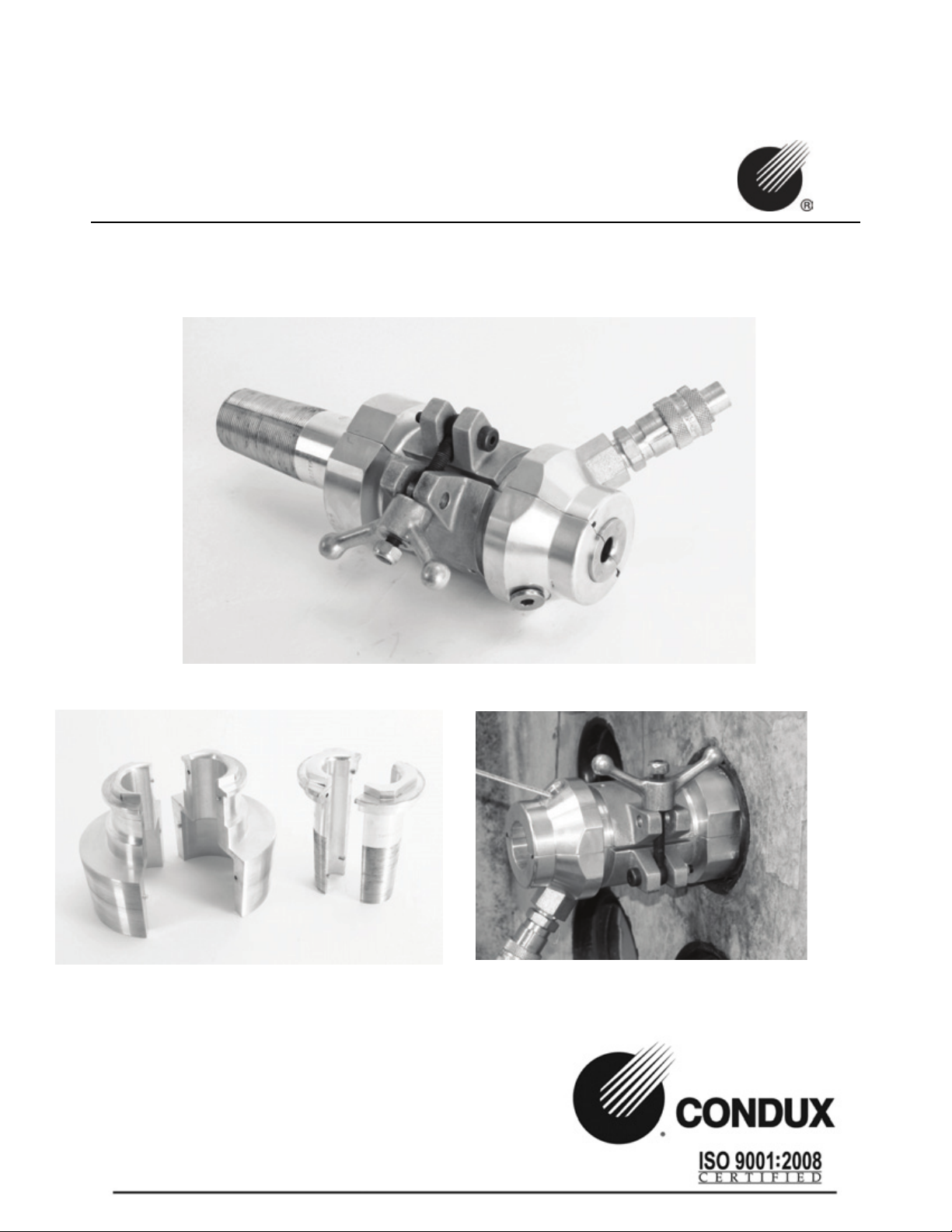

Purpose of the Winch Line Blower

The Condux Winch Line Blower is a unique device for inserting winch lines directly into

underground conduit before cable pulling or conduit proving operations. The winch line blower is

comprised of three main parts that, when used in conjunction with an air compressor and a cable

pulling winch mechanism (truck, trailer, or portable), will propel a standard steel winch cable into

an unobstructed, unoccupied, airtight, plastic conduit run at an average speed of 100 feet per

minute.

The Condux winch line blower will work with nearly all type of existing steel cable winches that

are currently being used for the installation of underground

utility cables.

Because of the unique design of the winch line blower, it will

operate in a wide range of conduit sizes, from 2to 6 inch duct,

and with various diameter winch lines up 7/8” (14mm)

without compromising efficiency.

The three main parts of the winch line blower are the

winchline blower body assembly, the missile and the control valve assembly. When each part of

the system is properly installed and maintained, this provides a means of using existing winch line

equipment to speed up cable installation procedures by as much as 1000 percent.

Technical Information

1. CONDITION OF USE

Temperature from 21° F (-6 C) to 110 F (+43 C)

Humidity from 30% to 90% +/- 5%

Weather conditions relevant to working conditions

Natural and/or artificial lighting of the worksite, minimum 200 lux

2. AIR COMPRESSOR REQUIREMENTS

Pneumatic Pressure: 175 psi (12 bar) Maximum

Required Flow Capacity: 375 SCFM (11 m3/min) Maximum

Control valve air hose fittings need to be compatible with Dixon “Air King”

universal couplings.

Safety Pop-off Valve on Control Assembly set for 90 psi.

CONDUX WINCH LINE BLOWER

2

Page 5

CONDUX WINCH LINE BLOWER

3

Safe Operating Practices

All tools, materials and equipment manufactured and supplied by Condux International are

designed to only be used by trained craft personnel. The information in this manual is essential for

the safe use of the Condux Winch Line Blower.

Operating procedures and guidelines must be read and understood by all personnel prior to using

any tools, materials, or equipment from Condux International.

OPERATOR QUALIFICATIONS

a) Operator in charge of the Winch Line Blower and installation project must be

appropriately dressed.

b) Operator must also wear the necessary protective equipment such as gloves, boots,

helmet, etc.

c) Operator must carefully follow all advisements contained in the instruction manual.

d) Operator must have work area kept clean of obstacles that might inhibit a safe working

area.

Condux will not be held liable for any injury or damage to either persons or property resulting

from the misuse of Condux equipment.

!WARNING: The Condux Winch Line Blower must be properly installed as

instructed. Failure to properly install the Winch Line Blower could result in severe

personal injury or damage to existing cables or conduit in the utility service

access vault.

!CAUTION: The Winch Line Blower is designed for use only in PVC and

polyethylene conduit. It will not operate properly and may cause personal injury

or physical damage if used in fiberglass, steel, concrete or other types of non-

plastic conduits.

This users guide and safety manual is intended to familiarize operators with the use and safety

procedures of the Condux Winch Line Blower.

This manual should be kept available to all operating personnel.

Page 6

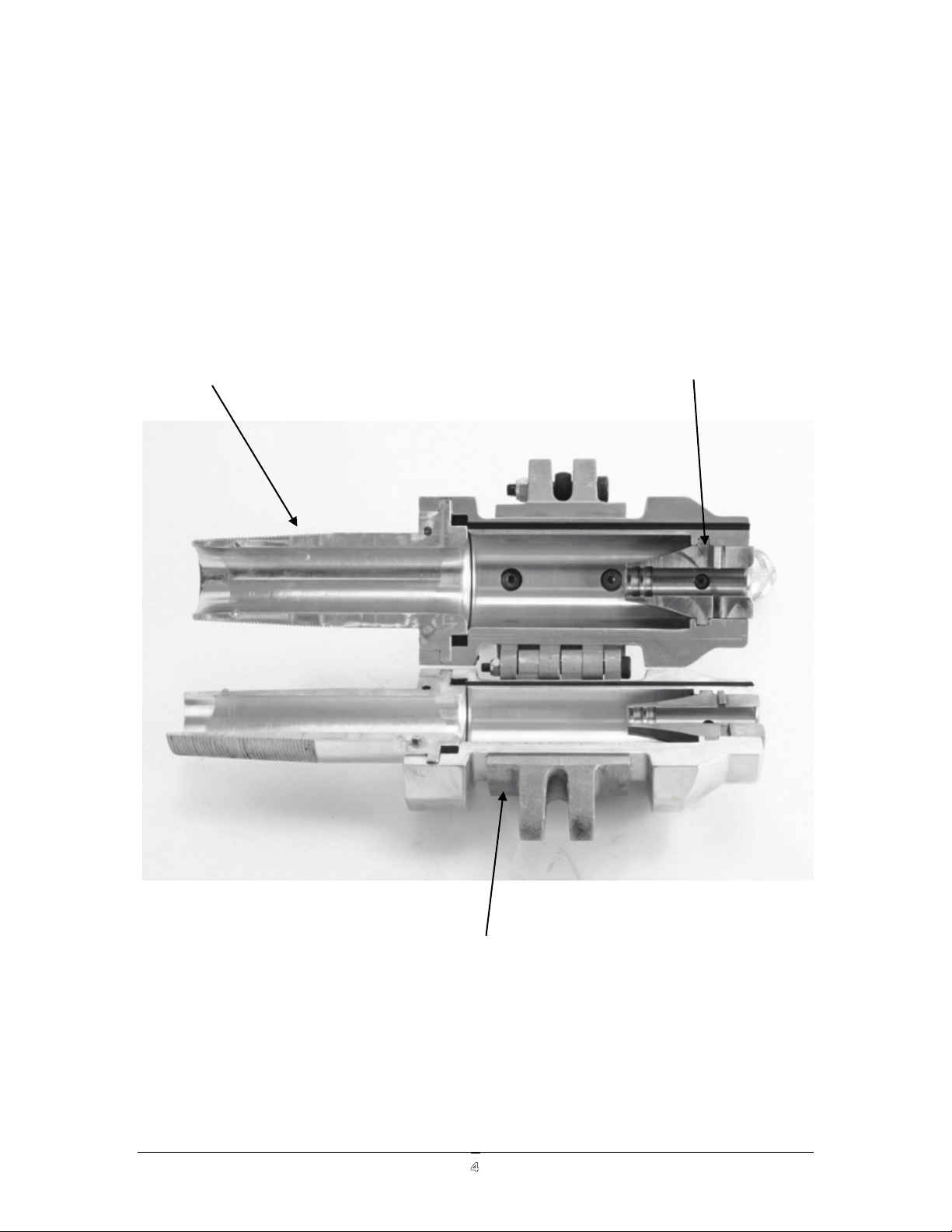

Winch Line Blower Seal-Off Selection

Threaded Adapter

Rope Venturi

Winchline Blower Body

1. Determine type(s) and diameter(s) of conduit in which the winch line will be inserted.

2. Select the correct threaded adpater to cover the range of conduit types and sizes

being used.

3. Select the proper size rope venture. Comes standard with ½” – 9/16” venture.

4. Select the proper missile size for the conduit sizes that are going to be used.

CONDUX WINCH LINE BLOWER

4

Page 7

CONDUX WINCH LINE BLOWER

5

2. Operator’s Instructions

Winch Line Blower Installation Procedure

!WARNING: Do not use around live circuits. The Winch Line Blower is constructed

of steel and aluminum, as such is highly conductive. Electric shock may occur is

contact is made with live circuits. Always be certain that power has been

disconnected.

!CAUTION: Standard utility service access vault opening procedures must be

followed which include work area protection and gas detection. Hard hats, eye

and ear and foot protection, must be worn whenever working in utility service

access vaults.

1. Clean out the end of the conduit to remove any dirt or gravel that may get between

the conduit and the threaded adapter.

2. Place about ½ quart of cable pulling lubricant (such as Poly J) into the conduit.

While this is not required, it does help in installing the missile and helps to increase

the efficiency of the winch line blower.

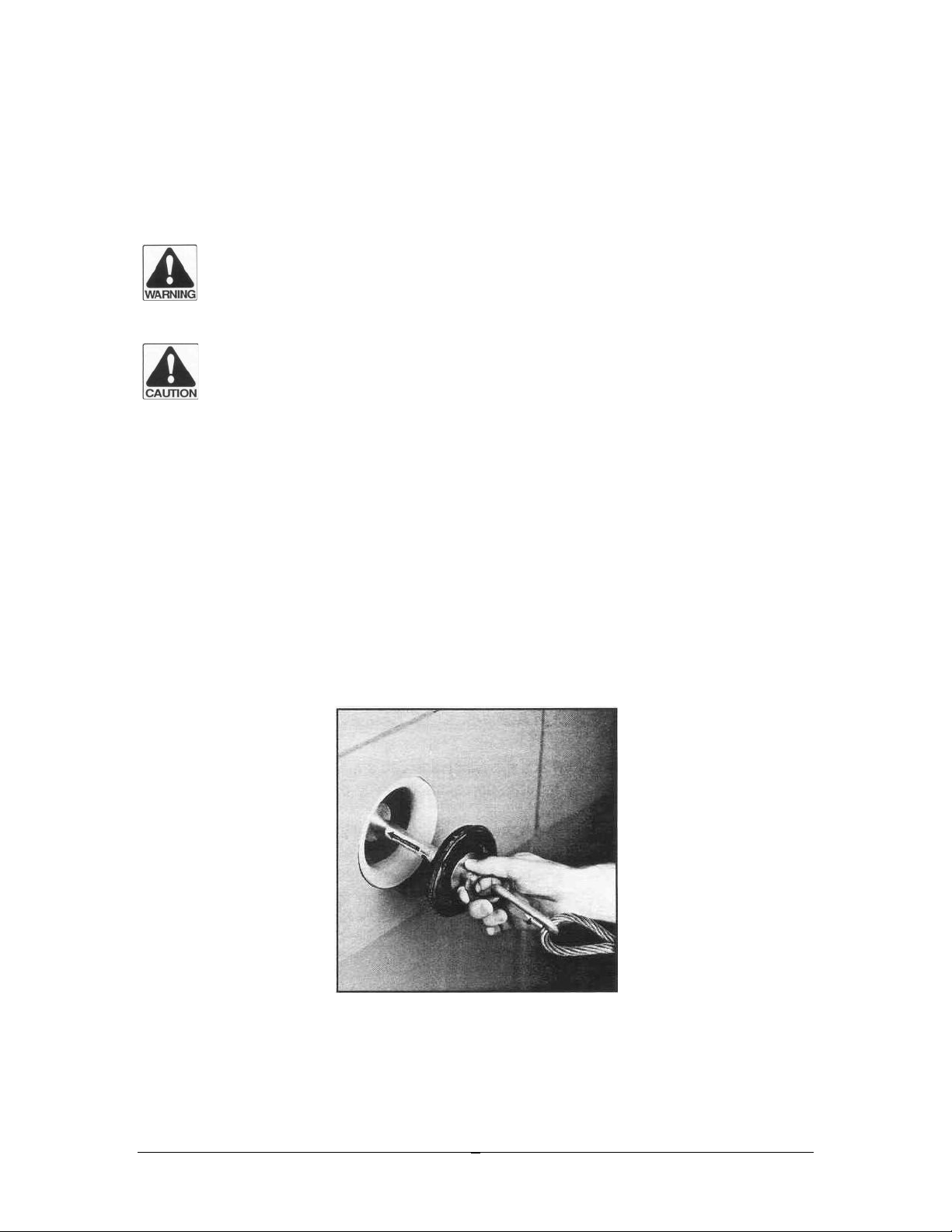

3. Attach the missile to the end of the winch line using the connector supplied with the

winch line blower. (See Fig. 1) The large metal disc must be forward in the direction

of winch line travel (as shown by the label on the missile).

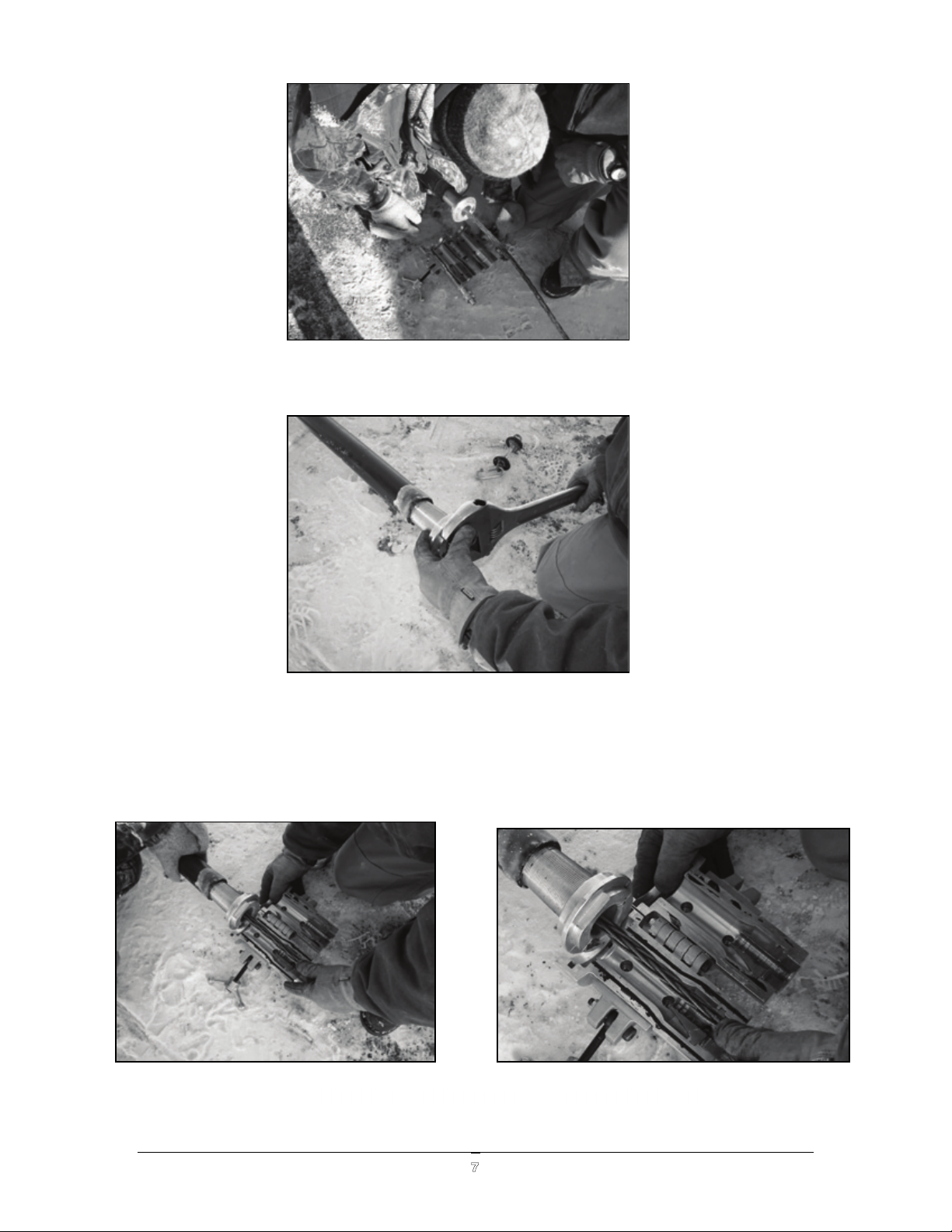

Figure 1: ATTACH THE MISSILE

Page 8

CONDUX WINCH LINE BLOWER

6

!CAUTION: Always know approximate length of the conduit runs and make

certain the winch drum contains enough winch line cable to reach the entire

distance before using the winch line blower.

!CAUTION: Inspect the winch line cable or know the condition of the cable before

using the winch line blower. Replace any cables that are kinked or have worn or

broken strands before using the winch line blower.

4. Insert the missile into the conduit and push into the conduit approximately one arms

length. (See Fig. 2)

FIGURE 2: INSERT MISSILE INTO CONDUIT

5. Place split-threaded adapter around winch line and screw threaded adapter into pipe

until tight by hand. Use adjustable wrench and screw threaded adapter one more full

turn. See Figure 3 & 4

!CAUTION: Before each use, visually inspect the Winchline Blower Body,

threaded adapters, and the missiles for signs of wear, fatigue, and/or breakage. If

any of these items show signs of wear, they should be replaced or system

function and efficiency will be affected (Reference Appendix).

Page 9

Figure 5 7 6 Install Winchline Blower Body onto the Threaded Adapter

Figure 3 Place Threaded Adapter into Duct

Figure 4 Tighten Threaded Adapter Using a Wrench

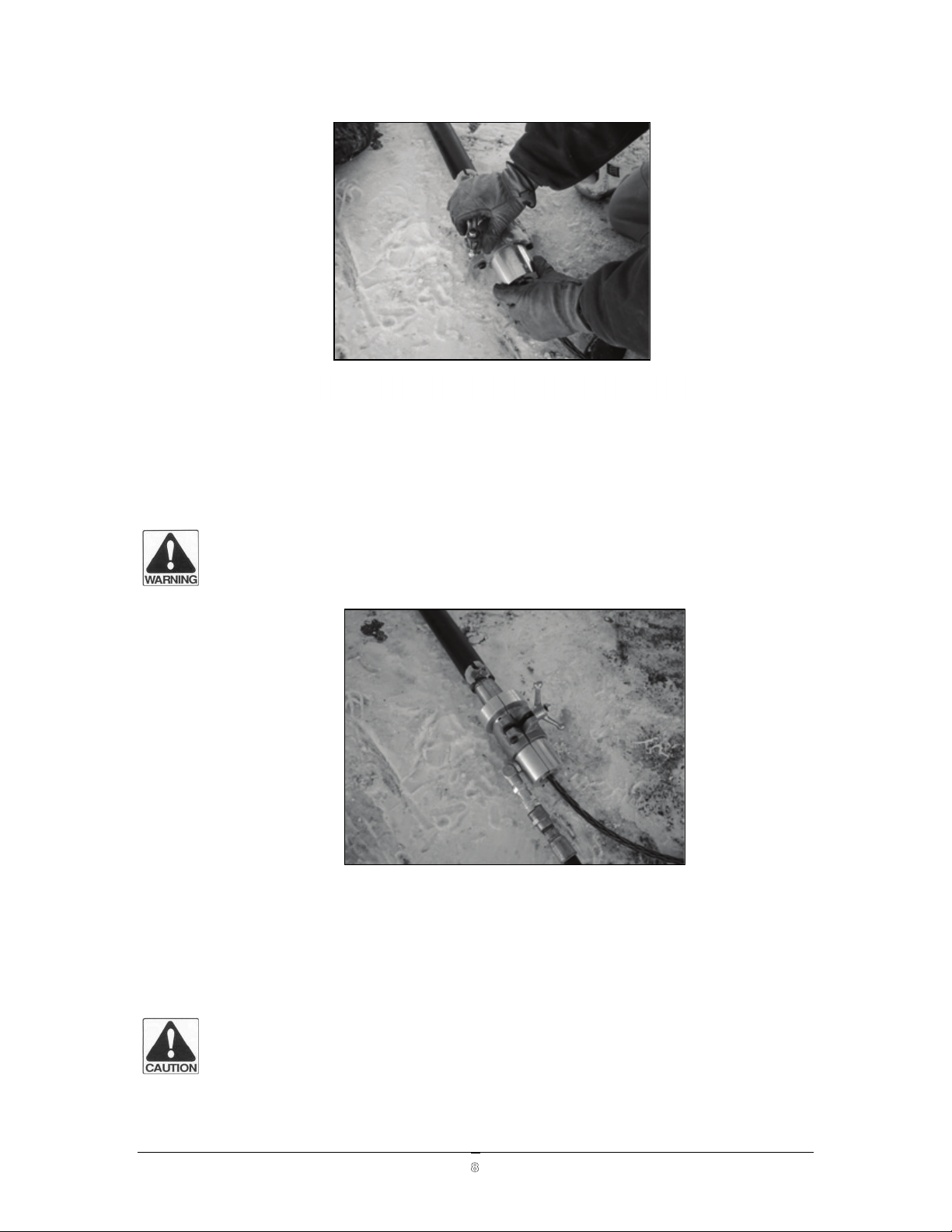

6. Install winchline blower body onto the threaded adapter by matching the threaded

adapter’s lip to the winchline blower body’s groove. See Figure 5 & 6

CONDUX WINCH LINE BLOWER

7

Page 10

7. Close winchline blower body and secure by tighten the speedball handle securely. do

Figure 7 Close and Secure Winchline Blower Body

not over tighten. See Figure 7

!WARNING: The Threaded Adapters should be screwed tight into the duct to

ensure that the Winchline blower does not blow out of the conduit and severely

injure persons or damage property.

Figure 8: Align The Winch Line

8. Ensure that winchline is entering in a straight line. Check the winch line alignment to

ensure that the winch line is not hung up or restricted and that it will feed through the

winchline blower smoothly. See Figure 8

!CAUTION: Always guide the winch line into the winchline blower parallel with

the center line of the conduit. Use additional sheaves or cable guides if

necessary.

CONDUX WINCH LINE BLOWER

8

Page 11

CONDUX WINCH LINE BLOWER

9

Figure 9: Attach Air Hose

9. Attach the air hose to the seal-off body assembly and tighten the locking ring on the

air connector. Rotate the 45° angle fitting away from the winch line channel and the

winch line to prevent tangling and wear of the air hose or connectors. See Figure 9

10. Run the air hose out of the utility service access vault, attach to the Control Valve

assembly, and tighten the locking ring on the air connector.

!DANGER: NEVER REMAIN IN EITHER START OR EXIT OF UTILITY SERVICE

ACCESS VAULTS DURING THE BLOWING PROCEDURE. SEVERE PERSONAL

INJURY OR DEATH COULD RESULT.

!WARNING: Do not attempt to operate the winch line blower with a different

control valve than what is supplied with the winch line blower kit. The seal-off

could blow out of the conduit or the conduit itself could rupture.

!WARNING: Check that all air hose connections are securely attached, and that

the locking ring is in place and tight.

11. Turn the control valve to the closed position (see Figure 10). In the closed position,

the valve handle will be turned perpendicular to the air flow through the fitting. Close

the outlet valve on the air compressor.

Page 12

CONDUX WINCH LINE BLOWER

10

Figure 10: Close Control Valve

12. Attach the compressor hose to the control valve assembly and insert the locking pin

the connector assembly.

13. Start the air compressor. The recommended air compressor size should be 75 to 185

CFM and 50 to 110 psi.

You are now ready to blow the winch line into the conduit.

Winch Line Blowing Procedure

!DANGER: ALL PERSONNEL MUST BE OUT OF THE START AND EXIT UTILITY

SERVICE ACCESS VAULTS DURING THE BLOWING PROCEDURE. SEVERE

PERSONAL INJURY OR DEATH COULD RESULT FROM FAILURE TO OBEY THESE

RULES.

1. Verify that all personnel are out of the start and exit utility service access vaults or

utility service access vaults.

2. Verify that the control valve is in the closed position.

!CAUTION: Keep the work area clean and free of debris. The work area should

provide good footing.

Page 13

CONDUX WINCH LINE BLOWER

11

Note: One person should be in charge of the control valve assembly and, if positioned properly,

should be able to view the winch line feeding off the winch drum, view the cable feeding down

into the utility service access vault around the sheave, blocks, etc., and monitor the condition of

the winch while it is being propelled. A second person should assist in monitoring the winch line

and keep in contract with the exit utility service access vault. Two-way radios are recommended

so the personnel at each end of the conduit run can be aware of the situation status immediately.

Figure 11: SLOWLY OPEN CONTROL VALVE

3. Open the outlet valve on the air compressor See Figure 11.

4. Slowly open the winch line blower control valve assembly. The control valve

assembly can be slowly opened by turning the valve handle in line with the air flow.

The missile will begin to move forward towards the exit utility service access vault,

pulling the winch line with it. Allow all slack to come out of the winch line before

opening the valve fully. Continue opening the control valve while constantly

monitoring the status of the winch line.

Page 14

CONDUX WINCH LINE BLOWER

12

Figure 12: MONITOR STATUS

5. Continue monitoring the winch line status and the pressure gauge on the control

valve assembly, Figure 12. Average pressure reading during normal missile blowing

operations should be approximately 70 – 90 psi.

!DANGER: DO NOT ATTEMPT TO GRAB ONTO THE WINCH LINE TO ASSIST ITS

TRAVEL OR SLOW IT DOWN. SERIOUS PERSONAL INJURY OR DEATH MAY

RESULT FROM FAILURE TO OBEY THESE RULES.

!DANGER: DO NOT LEAVE THE MOVING WINCH LINE UNATTENDED. PERSONNEL

OR EQUIPMENT COULD BECOME ENTANGLED, RESULTING IN SERIOUS

PERSONAL INJURY OR DEATH.

!CAUTION: Do not tamper with or remove the pressure relief valve. Pressure must

be limited to 90 psi. If the pressure exceeds 90 psi., immediately shut the control

valve and check the pressure gauge and the pressure relief valve for proper

operation. If no faults can be found, return the control valve assembly to Condux

International Inc. for repair or replacement (see Appendix for return instructions).

NOTE: Starting and stopping of the winch line blower repeatedly during one conduit run may

put undue stress on missile and winch line connections and/or winch line drum. Once the missile

and winch line are moving forward, keep air pressure and flow constant to propel the winch line

at an average rate of 100 feet per minute.

6. While monitoring the winch line blowing procedure, use care to prevent the winch

line and missile from “out running” the air compressor. This is characterized by the

winch line jumping, flapping or surging (shooting into the conduit very quickly, then

stopping, and shooting quickly into the conduit again). If this begins to occur, slow

down the air flow by partially closing the control valve until the winch line feeds off

the drum SMOOTHLY and CONSISTENTLY.

Page 15

CONDUX WINCH LINE BLOWER

13

!WARNING: Winch line cable must be kept tight and must not be allowed to jump,

flap, surge, or become slack. Damage to utility service access vault equipment

may result.

7. If the winch line is proceeding smoothly and consistently, listen for the exit end

personnel to relay that missile and winch line have arrived. If the winch line does not

proceed smoothly or stops before reaching the exit, follow the troubleshooting

guide in the following section.

!DANGER: READ AND UNDERSTAND THE TROUBLESHOOTING INSTRUCTIONS

BEFORE USING THE WINCH LINE BLOWER SYSTEM. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

Winch Line Blower Seal-off Body Removal

Figure 13: MISSILE ARRIVES

1. Once the missile arrives in the exit utility service access vault, close the control valve

on the control valve assembly. See Figure 13

2. Close the outlet valve on the air compressor and shut off the compressor.

3. Remove the air hose from the control valve assembly to assure all air pressure is

removed from the system and cannot be accidentally applied while in the access vault.

!CAUTION: ALLOW THE EXCESS AIR TO BLEED OFF FROM THE CONTROL VALVE

ASSEMBLY AND THE SEAL-OFF BODY ASSEMBLY PRIOR TO ENTERING THE

UTILITY SERVICE ACCESS VAULT.

4. Disconnect the air hose from the seal-off body assembly and pull the air hose out of

the utility service access vault and out of the way.

Page 16

CONDUX WINCH LINE BLOWER

14

5. Remove the winchline blower assembly from the conduit by turning the winchline

blower body counter-clockwise until the unit can be removed from the duct.

6. Set the winchline blower off to one side and out of the way.

7. The missile and connector must be removed from the winch line at the exit utility

service access vault. The winch line can then be prepared to pull in the cable

assemblies or a mandrel, depending on job requirements.

!WARNING: Never attempt to pull back mandrels or cable with the winchline

blower assembly still installed in the conduit. Damage to the seal-off body

assembly or the conduit will result.

!CAUTION: Keep all components of the Winch Line Blower Kit clean and free of

all foreign materials.

Page 17

3. Installing Measuring Tape

Installation Procedures

1. Clean out the end of the conduit to remove any dirt or gravel that may get between the

conduit and the Threaded Adapter. Apply a ¼” cup of lubricant into the duct system.

2. Remove rope venture if installed See Figure 1

Figure 1 Remove Rope Venturi

3. Insert the seal disk plug into rope venturi slot See Figure 2

Figure 2 Insert Seal Disk Plug

CONDUX WINCH LINE BLOWER

15

Page 18

4. Remove Hex plug using a 5/16” hex wrench and install 3/8” rope adapter see Figure 3

and Figure 4.

Figure 3 Remove Hex Plug

Figure 4 Insert 3/8” Rope Adapter

!CAUTION: Always know approximate length of the conduit runs and make

certain the measuring tape reel contains enough measuring tape to reach the

entire distance before using the winch line blower blower.

CONDUX WINCH LINE BLOWER

16

Page 19

5. Insert measuring tape through the 3/8” rope adapter See Figure 5

Figure 5 Insert Measuring Tape through 3/8” Rope Adapter

6. Attach measuring tape to carrier and install carrier into the duct See Figure 6

Figure 6 Attach Measuring Tape to Carrier and Insert into Duct

!CAUTION: Before each use, visually inspect the winchline blower body assembly,

threaded adapters and missiles for signs of wear, fatigue, and/or breakage. If any of

these items show signs of wear, they should be replaced, or system function and

efficiency will affected (Reference Appendix)

CONDUX WINCH LINE BLOWER

17

Page 20

7. Screw threaded adapter into pipe until tight by hand. Use adjustable wrench and screw

threaded adapter one more full turn See Figure 7 & 8

Fig. 7 Insert Threaded Adapter into Duct

Fig. 8 Insert Threaded Adapter into Duct

8. Install winchline blower body onto the threaded adapter. Close winchline blower body

and secure by tighting the speedball handle securely, do not over tighten See Figure 9 and

Figure 10.

CONDUX WINCH LINE BLOWER

18

Page 21

Figure 9 Install Winchline Blower Body

Figure 10 Secure Speed Ball Handle

CONDUX WINCH LINE BLOWER

19

Page 22

9. You are now ready to install your measuring tape

10. For Winch Line installation procedures refer back to Section 2 of this manual.

CONDUX WINCH LINE BLOWER

20

Page 23

CONDUX WINCH LINE BLOWER

21

4. Troubleshooting

Solutions to possible problems

!WARNING: DO NOT ENTER THE UTILITY SERVICE ACCESS VAULT TO CHECK

THE MISSILE OR SEAL-OFF WHILE THE SYSTEM IS UNDER PRESSURE. SHUT OFF

THE AIR SUPPLY AND DUMP THE RELIEF VALVE PRIOR TO ENTERING THE

UTILITY SERVICE ACCESS VAULT.

PROBLEM

SOLUTION

THREADED ADAPTER DOES NOT FIT

INOT THE CONDUIT.

1. Wrong size threaded adapter was

selected

MISSILE GOES INTO CONDUIT A

DISTANCE BUT WILL NOT EXIT AT

OTHER END.

1. If air is escaping at the exit end, the

air is bypassing the missile. The

missile is either worn out or is the

wrong size for the conduit in

which it is being used. The missile

will have to be pulled back out of

the conduit and replaced. Follow

the removal process for the seal-off

body assembly as listed in the

previous section and use the winch

truck to pull back the missile.

2. If no losses are found at either end

of the conduit run, the missile may

have stopped due to a conduit

obstruction or due to an unsealed

conduit run. In the latter case, the

Condux Winch Line Blower will

not properly function. In this

instance, the seal-off body

assembly must be removed from

the conduit as described in the

previous section, the missile must

be pulled back out of the conduit

by the winch line, and another

method of inserting the winch line

into the conduit must be used.

MISSILE GOES INTO CONDUIT A

DISTANCE BUT WILL NOT EXIT AT

OTHER END DUE TO A CONDUIT

1. The Condux Winch Line Blower

will push water, sand, and small

gravel in front of the missile and

Page 24

CONDUX WINCH LINE BLOWER

22

OBSTRUCTION.

will clear the conduit of light

obstructions. The missile is also

able to maneuver through most

areas where the conduit may be

deformed and flattened. If the

missile is not able to pass through

the conduit, the conduit is fully

plugged or has a major conduit

obstruction.

MISSILE GOES INTO CONDUIT A

DISTANCE BUT WILL NOT EXIT AT

OTHER END DUE TO TOO MUCH

BACK FORCE ON THE MISSILE.

1. The winch line is exerting too great

of a back force on the missile to

propel the missile and cable any

further. This may be due to too

many bends in the run, the distance

of the conduit run being too great,

or the tension on the winch line

being too large.

SEAL OFF ASSEMBLY SLIPS OUT OF

THE PIPE

1. Using an adjustable wrench screw

the threaded adapter into the duct

tighter.

2. Check the threads for wear.

Page 25

CONDUX WINCH LINE BLOWER

23

5. Appendix

Winch Line Blower Body Assembly

Page 26

CONDUX WINCH LINE BLOWER

24

Winchline(Blower(Body(Assembly!

ITEM

PART(

NUMBER

DESCRIPTION

QTY

"

#$%$#"&'

()*++!,-!./0123456!!748

"

&

#&&$$###

90:;!:<,7456!,</=:;3!2!">&5=829

" ( #&&$$*?'

,0=-,3;@A,2-457!!9#B2#)%!C!"'99!"$2$--!

& B #&&$$''*

5/8A5D:<,!!9#'2")##!,E

" * #&&$$'?B

5/8A5D:<,!!9#$2")&*!,E

" ' #&&$$%$%

F;G!134H;3!2!&)*99

" % #&&$?&?(

-@456!I<:8!!9"#2")*#!C!"&*99

" $ #&&$?&?B

-F</:1;3!-,3;@!!9"#!C!B#99!J9#$2")&*!8F3;01-K

" ? #&&$?&?*

-F</:1;3!-,3;@!!9#$!C!%#99!J9#'2")##!8F3;01-K

"

"#

#&&$?&?%

,0=-,3;@A,2-457!!9#'2")#!C!"&99!"$2$--!

B

""

#&&$?($&

5/8A5D:<,!8F45!!!9"#2")*#!,E

"

"&

#&&?##&#

(>B<23456!90:;!F;G!=:/6!L488456

"

"(

#&&?##&"

(>B<23456!90:;!C!">&5=82L!L488456

"

"B

#$&#"#$"

I<1D!45-;38!2!@:I

&

"*

#$&#"#$'

@45,F:45;!H;58/34!-;8!J">&!!2!?>"'K!45,:/1;1

"

"*

#$&#"#$?

@45,F:45;!H;58/34!-;8!J">B!!2!(>$K!0H04:0I:;

!

"*

#$&#"#?#

@45,F:45;!H;58/34!-;8!J%>$K!0H04:0I:;

!

"'

#$%'B##"

I<1D!,</=:456!

&

"%!

#$%'B##'!

-=;;1!I0::!F051:;!J9"#2")*#!8F3;01-K!

"!

Page 27

CONDUX WINCH LINE BLOWER

25

Condux Control Valve Assembly P/N 08209300

ITEM(

PART(NUMBER(

DESCRIPTION(

QTY(

"!

#&#B%$##!

(>B5=82L!?#1;6!;:I<@!L488456!

&!

&!

#&"&?%"#!

-0L;8D!,:4=!

"!

(!

#&&&&"##!

(>B5=829!C!(>B5=829!=4=;!54==:;!L4884562"!">&:6!

"!

B!

#&&&&&##!

(>B5=829!C!(>B5=829!=4=;!54==:;!L4884562&!">&:6!

&!

*!

#&&&&(##!

(>B5=82L!,3<--!L488456!

"!

'!

#&&&&B##!

(>B5=829!C!">&5=82L!3;1/,;3!I/-F456!L488456!

"!

%!

#&&&&*##!

(>B5=829!C!">B5=82L!3;1/,;3!I/-F456!L488456!

"!

$!

#&&&&%##!

"'#=-4!60/6;!2!">B5=829!I<88<9!9</58!

"!

?!

#&&$$$%'!

:05D0312-0L;8D!,:4=!!

"!

"#!

#&&$?&%$!

,:0@!,</=:456!(>B5=82L!

"!

""!

#&&?##&&!

?#=-4!=<=2<LL!H0:H;!2!">&5=829!

"!

"&!

#&&?##(#!

(>B5=829!C!(>B5=829!=4=;!54==:;!L4884562B!:6!

"!

"(!

#%##?%##!

I0::!H0:H;!(>B5=82L!

"!

"B!

#%#&&###!

90:;!:<,7456!,</=:;3!2!(>B5=829!

"!

Page 28

CONDUX WINCH LINE BLOWER

26

Condux Air Hose Assembly P/N 08209310

ITEM

PART(NUMBER

DESCRIPTION

"

#%#&&"##

L;90:;!:<,7456!,</=:;3!2!(>B5=82L

&

#$&#?(""

(##=-4!043!F<-;!C!&*L8!2!(>B5=829!I<8F!;51-

Page 29

CONDUX WINCH LINE BLOWER

27

Condux Conduit Missile Wear/Replacement Parts

Conduit

Missile

Conduit

Range

In (mm)

Replacement

Item A

Wear Item B

Wear Item C

08203920

3.83(97)-

4.17(106)

08581237

08209128

08209108

08204020

4.03(102)-

4.32(110)

08581237

08209129

08209109

08204920

4.81(122)-

5.05(128)

08581237

08209130

08209110

08205020

5.05(128)-

5.34(141)

08581237

08209131

08209111

08205920

5.76(146)-

6.07(154)

08581237

08209132

08209112

08206020

6.07(154)-

6.36(161)

08581237

08209133

08209113

Page 30

CONDUX WINCH LINE BLOWER

28

Accessories

Threaded Adapters

PART(NUMBER

DESCRIPTION

#$&#""#$

@45,F:45;!1/,8!010=8;3!2!(>B45

#$&#"""#

@45,F:45;!1/,8!010=8;3!2!"45

#$&#"""&

@45,F:45;!1/,8!010=8;3!2!"!">B45

#$&#"""*

@45,F:45;!1/,8!010=8;3!2!"!">&45

#$&#"#&#

@45,F:45;!1/,8!010=8;3!2!&45

#$&#"#&*

@45,F:45;!1/,8!010=8;3!2!&!">&45

#$&#"#(#

@45,F:45;!1/,8!010=8;3!2!(45

#$&#"#(*

@45,F:45;!1/,8!010=8;3!2!(!">&45

#$&#"#B"

@45,F:45;A1/,8!010=8;3!2!B45

#$&#"#*"

@45,F:45;A1/,8!010=8;3!2!*45

#$&#"#'"!

@45,F:45;A1/,8!010=8;3!2!'45!

Rope Venturi’s

PART(NO.(

DESCRIPTION(

#$&#"#$'

@45,F:45;!H;58/34!-;8!J">&!!2!?>"'K!45,:/1;1

#$&#"#$?

@45,F:45;!H;58/34!-;8!J">B!!2!(>$K!0H04:0I:;

#$&#"#?#

@45,F:45;!H;58/34!-;8!J%>$K!0H04:0I:;

Page 31

CONDUX WINCH LINE BLOWER

29

NOTES:

Page 32

CONDUX WINCH LINE BLOWER

30

NOTES:

Page 33

CONDUX WINCH LINE BLOWER

31

Warranty Information

A. FACTORY ASSISTANCE

Condux International Inc. can provide further advice regarding any problems with the installation,

service, assembly, or disassembly of the Winch Line Blower. Call toll free at 1-800-533-2077 (USA

and Canada) or 1-507-387-6576 and ask for assistance. The Winch Line Blower can be returned

to the factory at any time for service or repair; however, a Return Material Authorization (RMA)

must be obtained from Condux before shipping. Condux will not accept returned items without

an RMA.

B. LIMITED WARRANTY

Condux International Inc. extends the following warranty to the original purchaser of these goods

for use, subject to the qualifications indicated: Condux International Inc. warrants to the original

purchaser for the use that the goods or any component thereof manufactured by Condux

International Inc. will be free from defects in workmanship for the period of one year from the

date of purchase. Provided such goods are installed, maintained, and used in accordance with

Condux’s written instructions.

Lack of routine maintenance as specified in the maintenance sections of the User’s Guide

will void the warranty.

Components not manufactured by Condux International Inc. but used within the assembly

provided by Condux International Inc. are subject to the warranty period as specified by the

individual manufacturer of said component, provided such goods are installed, maintained, and

used in accordance with Condux’s and the original manufacturer’s written instructions.

Listed wear parts as called out in the User’s Guide are not covered under the warranty.

Condux’s sole liability and the purchaser’s sole remedy for a failure of goods under this limited

warranty, and for any and all claims arising from the purchase and use of the goods, shall be

limited to the repair and replacement of the goods that do not conform to this warranty.

To obtain repair or replacement service under the limited warranty, the purchaser must contact

the factory for a Return Material Authorization (RMA). Once obtained, send the RMA along with

the defective part or goods, transportation prepaid, to:

Condux International Inc.

145 Kingswood Drive

Mankato, MN 56001 USA

THERE ARE NO EXPRESS WARRANTIES CONVERING THESE GOODS OTHER THAN AS SET

FORTH ABOVE. THE IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS FOR

PARTICULAR PURPOSE ARE LIMITED IN DURATION TO ONE YEAR FROM DATE OF

PURCHASE.

CONDUX ASSUMES NO LIABILITY IN CONNECTION WITH THE INSTALLATION OR USE OF

THIS PRODUCT, EXCEPT AS STATED IN THISE LIMITED WARRANTY. CONDUX WILL IN NO

EVENT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Page 34

CONDUX WINCH LINE BLOWER

32

CONDUX INTERNATIONAL, INC.

P.O. Box 247 • 145 Kingswood Drive, Mankato, MN 56002-0247 USA

1-507-387-6576 • 1-800-533-2077 • FAX 1-507-387-1442

Internet: http://www.condux.com • e-mail: cndxinfo@condux.com

© Copyright 2012, Condux International, Inc.

Printed in USA

Literature Part Number: 08201098

Revision Number: 1.1

Loading...

Loading...