Page 1

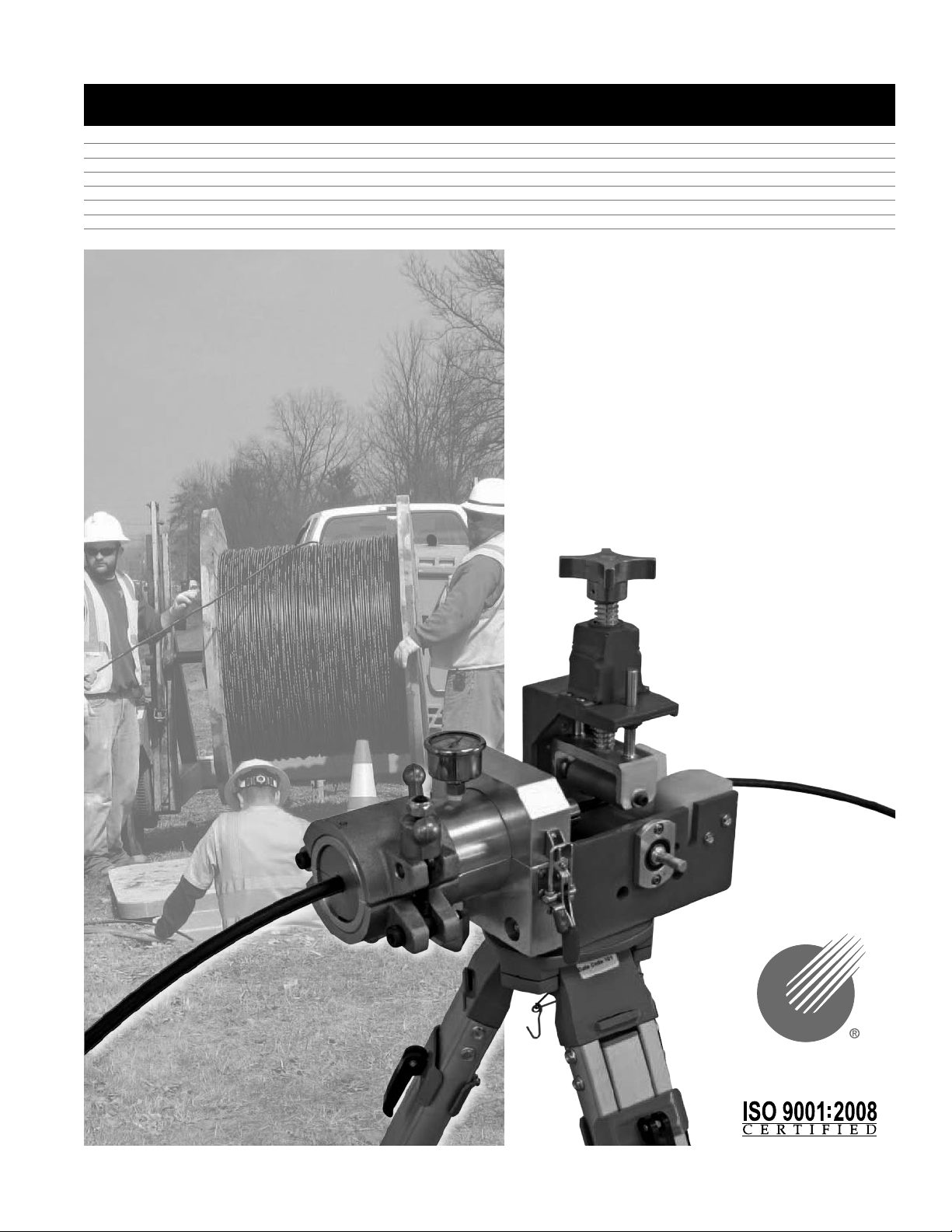

USER'S GUIDE & SAFETY MANUAL

Mini-Blower/Pusher

CONDUX

Page 2

Important Safety Notice

Read and understand all procedures and safety instructions before using the Mini-Blower/Pusher.

Observe all safety information on this page and note specific safety requirements as explained by

procedures in this manual. Failure to follow these instructions could result in serious personal injury

or death.

ADVERTENCIA:

Favor de leer y comprender todas las instucciones de operación y seguridad antes de usar la máquina. Si

Ud. no comprende las instrucciones favor de consultarle a su jefe.

READ MANUAL

FIRST

Save this user’s guide for future reference.

COMMUNICATIONS WITH THE MANUFACTURER

For any information related to the machine (use, maintenance, spare parts) always state Model, Serial

Number, Manufacturing Year and Order. This data can be found in the machine identification table.

Manufacturer:

Condux International Inc.

145 Kingswood Drive

Mankato, MN 56002-0247

1-507-387-6576

Fax 1-507-387-1442

Internet: http://www.condux.com

E-mail: cndxinfo@condux.com

If you have questions on:

2

SAFETY - OPERATIONS - APPLICATIONS

CALL 1-800-533-2077

CONDUX

Page 3

Table of Contents

General Information .................................................4

1

Technical Specifications .............................................5

2

A. Air Compressor Requirements .................................. 5

B. Operational Capacities ........................................ 5

C. Physical Specifications ........................................ 5

Safe Operating Procedures ........................................... 6

3

A. Work Area Safety ............................................6

B. Pneumatic Devices ........................................... 6

Unpacking the Blower ...............................................6

4

A. Blower Components .......................................... 6

Set Up the Blower/Pusher ............................................ 7

5

A. Mounting the Blower/Pusher to Tripod ............................7

B. Configure the Blower/Pusher ...................................7

Blower/Pusher Operating Instructions ................................... 9

6

A. Final Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

B. Operations ................................................10

Appendixes ...................................................... 12

7

A. Charts .................................................... 12

B. Duct Rod Pusher ...........................................14

C. Blower/Pusher Assembly ..................................... 16

D. Mini-Blower Assembly ....................................... 17

E. Clamp Adjustment Screw ..................................... 18

F. Mount Clamp Assembly ...................................... 19

G. Clamp Roller Assembly ......................................19

3

Page 4

1.

General Information

The operating instructions contain a full description of the Condux Mini-Blower/

Pusher, which has been designed for the purpose of feeding fiber optic cable through

round conduits of uniform cross section. The conduit must previously have been

installed underground or overhead to receive the fiber optic cable and must be of

sufficient length on exit to be received by the machine. The conduit must be made of

material with sufficient compression strength for it to be adequately sealed in the exit

of a machine.

The fiber optic cable is continuously pushed into the conduit by a roller drive powered

by a cordless, corded or pneumatic drill. The exit of the machine consists of an air

box that is made in two halves that clamp together. The air box contains special

removable seals on entry and exit, which clamp around either the end of the conduit

or the fiber optic cable to be fed into the conduit. The seals can be changed to

accommodate different conduit and fiber optic cable sizes. The conduit is clamped

between a pair of seals at the entrance to the air block.

A clamp located in front of the entrance to the air block holds the conduit

mechanically to prevent it from moving axially. The fiber optic cable enters through

two seals located in an aluminum nozzle that splits in half. The aluminum nozzle is

located in the entrance to the air box and is shaped to ensure an airtight seal around

the fiber optic cable. When the two halves of the air box are closed, air pressure is

admitted into the space between the seals on entry and exit.

The use of the Mini-Blower/Pusher for operations different from those discussed in

this manual are considered extremely dangerous and thus forbidden. The non-respect

for the prescribed restraints of the machine causes a situation of improper use and

relieves the manufacturer from any responsibility, civil or penal. The manufacturer’s

responsibility declines even when one of the following happens:

a. The consequences caused by tampering and/or modifications carried out without

the manufacturer’s written acceptance.

b. The use of imitative spare parts.

c. Bad maintenance.

d. Use with disconnected safety devices.

e. The connection to machine and/or parts not produced and not directly authorized

by the manufacturer in a written acceptance.

The Condux Mini-Blower/Pusher is a unique device for inserting fiber optic cable

directly into conduit. The unit is comprised of an air block and a roller drive that,

when combined with an air compressor and a drill drive force, will propel fiber optic

cable measuring from .23" to .50" (5.8 mm to 12.7 mm) into an unobstructed,

unoccupied, airtight conduit.

GENERAL MACHINE USE

a. Only qualified operators should use the machine. The operator should only be the

person who received qualified training from the product owning company or trained

by the manufacturer.

b. Machine must only be used for the work it was designed for.

c. Machine is not to be used with unauthorized personnel on the job site.

d. Should there be any doubt concerning use, functioning, maintenance or

anything else, please contact the factory or factory representative.

4

Page 5

OPERATOR QUALIFICATIONS

a. Operator must know the required safety directives to run the machine that are

pertinent to the country where it is being used.

b. Operator in charge of the machine and installation project must be appropriately

dressed, avoiding large clothes, hanging jewelry or whatever might become

entangled in the moving parts.

c. Operator must also wear the necessary protective equipment such as gloves,

boots, helmet, etc.

d. Operator must carefully follow all advisements contained in the instruction

manual or on the machine.

e. Operator must have work area kept clean of obstacles that might inhibit a safe

working area.

MAINTENANCE QUALIFICATION

a. All of the machine maintenance must be carried out with the machine on a level

surface and not attached to any form of power source: electrical, or pneumatic.

b. Authorized and trained personnel must do all maintenance operations. Trained

personnel are defined as people who have received qualified training from the

using company or from the manufacturer.

Technical Information

A. AIR COMPRESSOR REQUIREMENTS

Pneumatic Pressure: 40 PSI (12 BAR) MAXIMUM IN MICRODUCT

100 PSI in Traditional Duct

Required Flow Capacity: 185 SCFM (11 M3/MIN) MAXIMUM

Conduit Size: 10 MM – 1.50" OD

Air hose fittings need to be compatible with Dixon “Air King” universal couplings

B. OPERATIONAL CAPACITIES

• Cable sizes: .23" TO .50" (5.8 MM TO 12.7 MM)

• Conduit sizes:10-18MM, ½", ¾",1", 1-1/4" TRUE, 1-1/4", 1-½" SDR 11 & 13.5 AND

METRIC O.D. CONDUIT; 25 MM, 32 MM, 36 MM, 37 MM,

C. PHYSICAL SPECIFICATIONS (DOES NOT INCLUDE TRIPOD OR JOB BOX)

• Height 12"

• Length 14"

• Width 8"

• Weight 17 lbs

2.

5

Page 6

3.

Safe Operating Practices

Read and understand all procedures and safety instructions before using the Condux

Mini-Blower/Pusher. Observe all safety information on this page and note specific

safety requirements as explained by procedures called out in this manual. Failure to

follow these instructions could result in serious personal injury, property damage

or death.

A. WORK AREA SAFETY

1. Wear personal protective equipment: hard hat, safety glasses, safety shoes, and

leather work gloves.

2. The safe operation of this equipment requires that the operators be on stable

footing.

3. Stay clear of cables or lines under tension.

4. Stay clear of pressurized line and conduit.

5. Stay out of manhole while blower is in use.

6. Use the blower only for its intended purpose. Do not use the tractor drive

without the air block to push or pull cable.

7. Do not place cable reel too close to unit. Place the reel far enough away from the

unit to ensure proper control.

8. Do not tamper with relief valves or pressure reducing valves.

9. Place cable grip on end of conduit to catch cable carrier and cable.

10. Keep hands away from tractor drive while blower is in operation.

4.

B. PNEUMATIC DEVICES

The Condux Mini-Blower/Pusher is a pneumatic device, using pressurized air to

project cable at high velocities. Please observe the following precautions when

operating the blower:

1. Forced air creates flying debris. Always wear personal protective equipment.

Severe personal injury could result.

2. Ensure no personnel are in the destination access vault during the blowing

operation. Severe personal injury could result.

Unpacking the Blower

A. BLOWER COMPONENTS

Each Mini-Blower/Pusher Package contains the following items.

COMMON PARTS PACKAGE:

Part No Description

02290168 Hex key set metric and standard

08780126 Seal replacement kit

08780223 Venturi Plug

08780424 Capscrew set (m04-0.7 x 16)

6

Page 7

Actual parts:

08081315 – blower assy

08081301 – pusher assy

08764110 – 12 mm duct pack

08764150 – 12.7 mm duct pack

08780302 – .23-.34 cable pack

08780304 – .35-.48 cable pack

NOTE: If any parts are missing: please contact your Condux representative or

call Condux International at 1-800-533-2077 (USA or CANADA), or

1-507-387-6576.

Set Up the Blower/Pusher

A. MOUNTING THE BLOWER/PUSHER TO TRIPOD (OPTIONAL)

NOTE: The Mini-Blower/Pusher can be operated without optional surveyor’s

style tripod. If using the unit without the tripod, move to step B.

1. Loosen and remove tripod mounting nut. (See figure 1)

2. Place Mini-Blower Drive assembly on tripod so that the mounting bolt extends

through the receiving in the base of the unit. Orient assembly as necessary.

3. Secure drive assembly to tripod by replacing and tightening the mounting nut.

(See figure 2)

5.

Figure 1. Mount Unit on Tripod

B. CONFIGURE THE BLOWER/PUSHER

1. Attach the blower assembly into the drive assembly. Match up the ridge on the

blower assembly with the corresponding groove on the mounting block portion of

the drive assembly.

Figure 2. Mount Pusher Base

on Tripod

7

Page 8

2. Once in place, secure the Blower Assembly to Drive Assembly using

(2) #10-24 x 1 1/2" Capscrews. (See figure 3)

3. Select and install the appropriate sized Duct Clamp and Duct Seal to the Blower

Assembly using (1) M04-0.7 x 16mm Capscrew for each. (See figure 4)

Figure 3. Mount Blower

Figure 4. Select & Install

Duct Packs

4. Select and install the appropriate sized Venturi to the Blower Assembly using (1)

M04-0.7 x 16mm Capscrew. (See figure 5)

5. Install the duct. (See figure 6)

Figure 5. Select and Install

Figure 6. Install Duct

Bottom Venturi

8

Page 9

6. Load cable through drive assembly. Select and install the appropriate size cable

seals for the specific project. (See figure 7)

7. Install top venturi. (See figure 8)

Figure 7. Select & Install Seals

Figure 8. Install Top Venturi

Blower/Pusher Operating

Instructions

A. FINAL CONNECTIONS

1. Secure the blower assembly by closing the hinged top and tightening the blower

clamp. (See figure 9)

2. Secure drive assembly by closing and locking the back clamp with locking clip.

(See figure 10)

6.

Figure 9. Tighten Blower Clamp

Figure 10. Install Back Clamp

9

Page 10

3. Adjust down pressure on cable by tightening the spring tensioned down pressure

adjustment to ensure positive contact with drive roller. (See figure 11)

4. Connect the air hose to the blower utilizing the universal claw type connector.

(See figure 12) Connect hose to air compressor follow specific manufacturer’s

instructions.

Figure 11. Adjust Pusher

Figure 12. Connect Air

Down Pressure

!WARNING: Forced air creates flying debris. Always wear personal protective

equipment. Severe personal injury could result.

!WARNING: Ensure no personnel are in the destination access vault during the

blowing operation. Severe personal injury could result.

B. OPERATIONS

1. Select the drive system and connect utilizing

the drive stem. (See figure 13)

Important: Make sure drive system is

oriented to turn the drive roller in the

proper direction.

Note: It is not recommended to run corded

or cordless drills in reverse for extend

periods of time.

10

Figure 13. Select Drive

Page 11

2. Open air control valve to engage air pressure. (See figure 14)

Important: Optimum air pressure not to exceed 40 PSI in microduct.

3. Engage drive system. Install fiber optic cable. (See figure 15)

Figure 14. Engage Air

Figure 15. Engage Drive

11

Page 12

A.

APPENDIX

4

Blower/Pusher Charts

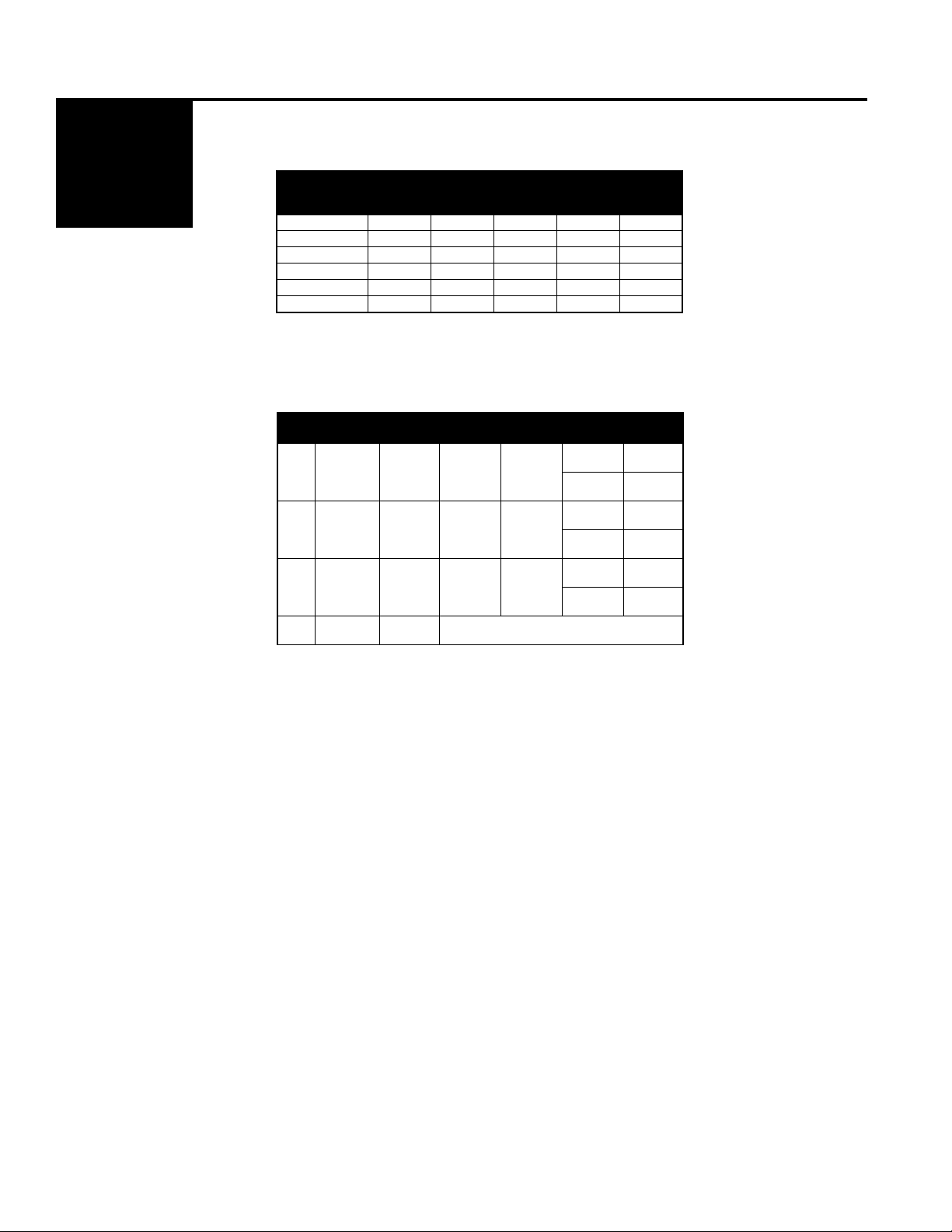

MICRO DUCT PACKS

Duct Size OD

(MM)

10 08764140 08764142 08764143 5-9 mm 08913547

12 08764110 08764112 08764113 10-12 mm 08913545

12.7 08764150 08764151 08764153 10-12 mm 08913545

14 08764120 08764122 08764123 10-12 mm 08913545

16 08764130 08764132 08764133 10-12 mm 08913545

18 08781110 08781106 08781101 13-15 mm 08913538

Part

Number

Duct

Clamp

Duct

Seal

MINI-BLOWER/PUSHER CABLE PACKS

Pack Cable OD P/N Cable OD P/N Cable OD P/N

1

2

3

4 (10-12.7)

CABLE PACK VENTURI CABLE SEAL

0.23-0.34

(5.8-8.8)

0.35-0.48

(8.9-12.2)

0.49-0.60

(12.3-15.2)

08780802

Pack #1

08780804

Pack #2

08780806

Pack #3

08780755

Pack #4

0.23-0.34

(5.8-8.8)

0.35-0.48

(8.9-12.2)

0.49-0.60

(12.3-15.2)

08780803

08780805

08780807

Nylatron Venturi for Flat Fiber Optic Cables

INNERDUCT EYE

ID

Range

0.23-0.28

(5.8-7.2)

0.29-0.34

(7.3-8.8)

0.35-0.42

(8.9-10.7)

0.43-0.48

(10.8-12.2)

0.49-0.55

(12.3-14.0)

0.56-0.60

(14.1-15.2)

Part

Number

08780406

08780407

08761424

08761425

08761426

08761427

12

Page 13

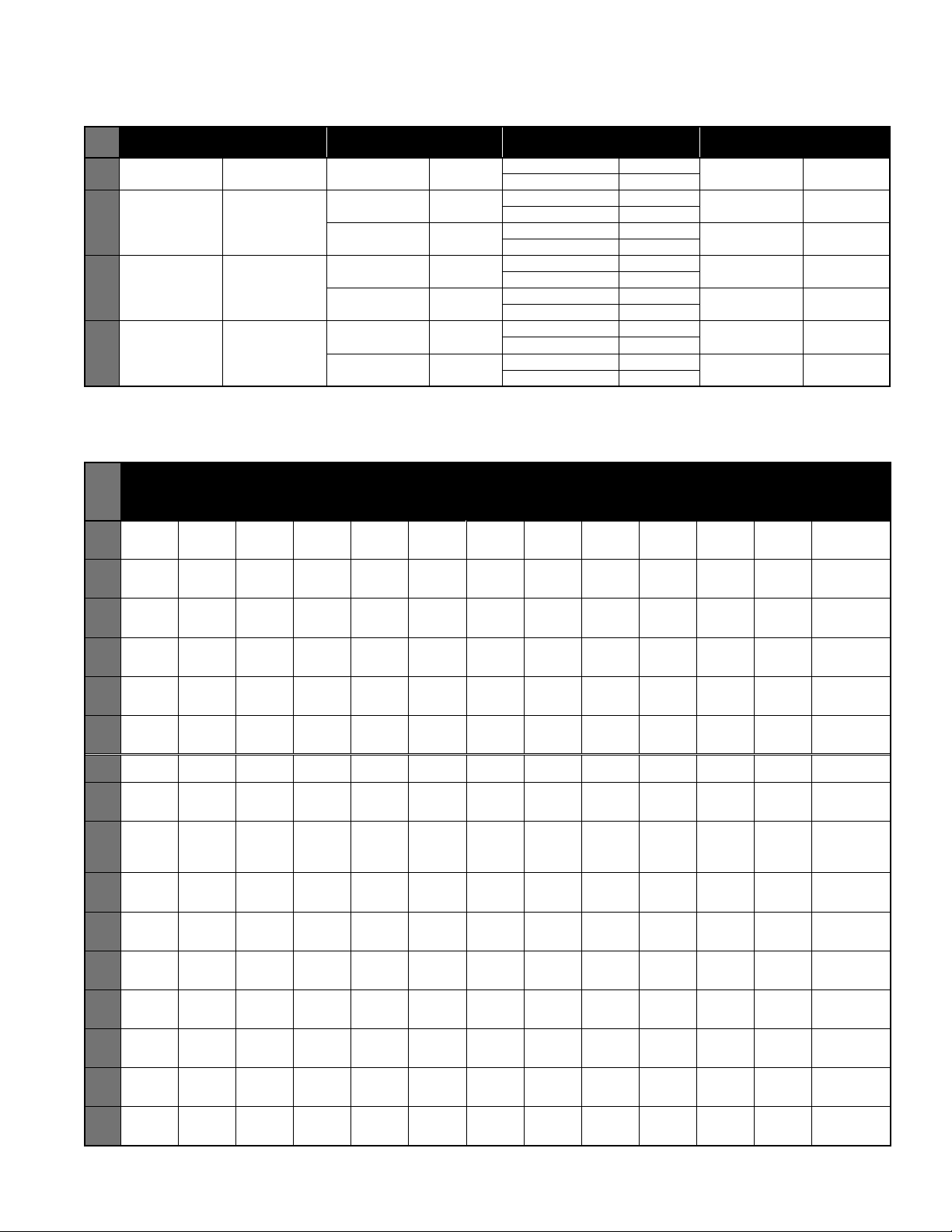

2

PACK

0.23-0.34 (5.8-8.8)

1

3

0.35-0.60 (8.9-15.2)

2

0.61-0.85 (15.3-21.6)

3

0.86-1.13 (21.7-28.7)

4

CABLE PACK VENTURI CABLE SEAL CABLE GRIP

Cable OD P/N Cable OD P/N Cable OD P/N Cable OD P/N

08780393 Pack #1

08780394 Pack #2

08780395 Pack #3

08780396 Pack #4

REPLACEMENT CABLE PACKS

0.23-0.34 (5.8-8.8)

0.35-0.48 (8.9-12.2)

0.49-0.60 (12.3-15.2)

0.61-0.73 (15.3-18.5)

0.74-0.85 (18.6-21.6)

0.86-0.97 (21.7-24.6)

0.98-1.13 (24.7-28.7)

08780281

08780282

08780283

08780284

08780285

08780286

08780446

REPLACEMENT DUCT PACKS

PACK

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

DUCT PACK DUCT CLAMP DUCT SEAL CARRIER FOAM CARRIER CABLE GRIP

Duct Size P/N Duct OD P/N Duct OD P/N Carrier P/N

1/2"

SDR 11-

13.5

3/4"

SDR 11-

13.5

1"

SDR

11/13.5

1.25"

SDR

11/13.5

1.5"

SDR

11/13.5

2"

SDR

11/13.5

25 mm

32 mm

36 mm

37 mm

1.25"

TRUE

40 mm

42 mm

44 mm

46 mm

50 mm

08780795

Pack #1

08780680

Pack #2

08780386

Pack #3

08780392

Pack #4

08780397

Pack #5

08780930

Pack #6

08780240

Pack #7

08780385

Pack #8

08780387

Pack #9

08780388

Pack #10

08780389

Pack #11

08780390

Pack #12

08780391

Pack #13

08780545

Pack #14

08780460

Pack #15

08780575

Pack #16

0.84

(21.30)

1.050

(26.6)

1.315

(33.4)

1.660

(42.2)

1.900

(48.3)

0.984

(25.0)

1.260

(32.0)

1.417

(36.0)

1.457

(37.0)

1.500

(38.1)

1.575

(40.0)

1.653

(42.0)

1.732

(44.0)

1.811

(46.0)

1.969

(50.0)

08780791

08780682

08780369

08780375

08780404

—— —— —— ——

08780099

08780368

08780370

08780371

08780372

08780373

08780374

08780546

08780466

08780435

0.84

(21.30)

1.050

(26.6)

1.315

(33.4)

1.660

(42.2)

1.900

(48.3)

0.984

(25.0)

1.260

(32.0)

1.417

(36.0)

1.457

(37.0)

1.500

(38.1)

1.575

(40.0)

1.653

(42.0)

1.732

(44.0)

1.811

(46.0)

1.969

(50.0)

08780786

08780685 0.75 (19.0) 08780690 0.75 (19.0) 08078300

08780307

08780051

08780398

08780134

08780306

08780308

08780309

08780333

08780334

08780335

08780547

08780461

08780431

0.23-0.28 (5.8-7.2) 08780406

0.29-0.34 (7.3-8.8) 08780407

0.35-0.42 (8.9-10.7) 08761424

0.43-0.48 (10.8-12.2) 08761425

0.49-0.55 (12.3-14.0) 08761426

0.56-0.60 (14.1-15.2) 08761427

0.61-0.67 (15.3-17.0) 08761428

0.68-0.73 (17.1-18.5) 08761429

0.74-0.79 (18.6-20.1) 08761430

0.80-0.85 (20.2-21.6) 08761431

0.86-0.92 (21.7-23.4) 08761432

0.93-0.97 (23.5-24.6) 08761433

0.98-1.04 (24.7-26.4) 08761434

1.05-1.13 (26.5-28.7) 08761435

Carrier

0.688

(17.50)

1.121

(28.5)

1.414

(35.9)

1.618

(41.1)

2.023

(51.4)

0.787

(20.0)

1.063

(27.0)

1.181

(30.0)

1.220

(31.0)

1.220

(31.0)

1.250

(31.7)

1.299

(33.0)

1.378

(35.0)

1.496

(38.0)

1.299

(33.0)

1.606

(40.0)

08780793 0.75 (19.0) 08078300

08761250 1.25 (31.8) 08761439

08761255 1.50 (38.1) 08761440

08761260 1.75 (44.5) 08761441

08761265 2.00 (50.8) 08761442

08780230 1.25 (31.8) 08761439

08761560 1.25 (31.8) 08761439

08761643

08761555

08761555 1.25 (31.8) 08761439

08761670 1.50 (38.1) 08761440

08761579 1.50 (38.1) 08761440

08761660 1.50 (38.1) 08761440

08761786 1.50 (38.1) 08761440

08761579 1.50 (38.1) 08761440

08761579 2.00 (50.8) 08761442

1.25 (31.8) 08761439

OD

0.21-0.35 (5.3-8.9)

0.32-0.48 (8.1-12.2)

0.42-0.61 (10.7-15.5)

0.53-0.74 (13.5-18.8)

0.64-0.87 (16.3-22.1)

0.75-1.00 (19.1-25.4)

1.00-1.24 (25.4-31.5)

P/N Duct OD P/N

.75-.99

(19-25)

1.00-1.24

(25.4-31.5)

1.00-1.24

(25.4-31.5)

1.50-1.99

(38.1-50.5)

1.50-1.99

(38.1-50.5)

2.00-2.49

(50.8-63.2)

1.00-1.24

(25.4-31.5)

1.25-1.49

(31.8-37.8)

1.25-1.49

(31.8-37.8)

1.25-1.49

(31.8-37.8)

1.25-1.49

(31.8-37.8)

1.50-1.99

(38.1-50.5)

1.50-1.99

(38.1-50.5)

1.50-1.99

(38.1-50.5)

1.50-1.99

(38.1-50.5)

1.50-1.99

(38.1-50.5)

08643131

033-03-012

08643137

033-03-013

08643137

033-03-013

08643149

033-03-016

08643149

033-03-016

08643155

033-03-017

08643137

033-03-013

08643143

033-03-015

08643143

033-03-015

08643143

033-03-015

08643143

033-03-015

08643149

033-03-016

08643149

033-03-016

08643149

033-03-016

08643149

033-03-016

08643149

033-03-016

08643754

033-29-1194

08643755

033-29-1195

08643756

033-29-1196

08643757

033-29-1197

08643758

033-29-1198

08643759

033-29-1199

08643137

033-03-013

INNERDUCT

EYE

P/N and ID

Range

08761840

.78-.87 (20-22)

08761840

.71-.89 (18-22)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761844

1.37-1.68

(35-43)

08761844

1.37-1.68

(35-43)

08761840

.71-.89 (18-22)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761844

1.37-1.68

(35-43)

13

Page 14

B.

APPENDIX

Duct Rod Pusher

14

Page 15

DUCT ROD PUSHER (08081301)

ITEM PART NUMBER DESCRIPTION QTY

1 02021400 CAPSCREW, HEX HEAD 1/4-20 X 0.75LG GR5 CZ 2

2 02102001 FLATWASHER, 1/4 TYPE A NARROW CZ 7

3 02240800 CAPSCREW, BUTTON HEAD #10-24 X 0.50LG SS 4

4 02269675 CAPSCREW, BUTTON HEAD #08-32 X 0.38LG SS 16

5 02269678 SPRING,COMPRESSION 1.095OD x 0.105WD x 1.00LG 1

6 02269687 BEARING,BALL W/SEALS 15MM ID X 28MM OD 2

7 02287830 SETSCREW, HEX SOCKET #10-24 X 0.25LG W/NYL TIP 2

8 02288425 CAPSCREW,HEX HEAD 1/4-20 X 1.75LG GR5 CZ 2

9 02288443 SCREW,TAPPING #10 X 1.00LG TYPE AB HEX HEAD CZ 4

10 02290269 CLAMP,TOGGLE 360LB PULL ACTION 2

11 08081302 BLOCK,GUIDE-NYLON 1

12 08081305 ROLLER,CENTER DRIVE 1

13

14 08081308 BLOCK,LOWER CLAMP 1

15 08081309 BLOCK,UPPER CLAMP 1

16 08081310 SHAFT,DRIVE-CENTER ROLLER 2

17 08761033 SCREW,CLAMP ADJUSTMENT - ASSEMBLY 1

18 08761034 BODY,COUNTER-MACHINED 1

19 08761036 INSERT,CLAMP ROLLER ADJUSTMENT 1

20 08761045 HOUSING,BEARING-DRIVE SHAFT 2

21 08761510 MOUNT,CLAMP ROLLER 1

22 08761516 MOUNT,CLAMP ADJUSTMENT SCREW 1

23 12013700 NUT, LOCK NUT 1/4-20 GR5 - NYLOC 2

24 21032451 KEY,DRIVE SHAFT 3/16 SQ X 0.50LG 2

080

81319

SLEEVE,DRIVE ROLLER

1

15

Page 16

C.

APPENDIX

Blower/Pusher Assembly

16

BLOWER/PUSHER ASSEMBLY (08780800)

ITEM PART NUMBER DESCRIPTION QTY

1 02288338 CAPSCREW, #10-24 x 1.50LG COUNTERSUNK 2

2 08081301 DUCTROD PUSHER ASSEMBLY 1

3 08081315 MINI-BLOWER ASSEMBLY 1

Page 17

Mini-Blower Assembly

D.

APPENDIX

MINI-BLOWER ASSEMBLY (08081315)

ITEM PART NUMBER DESCRIPTION QTY

1 00263400 CORD,QUAD-RING 3.5MM CS X 3.75LG 2

2 02020000 FITTING,HYD 1/2IN MALE NIPPLE 1

3 02129700 COUPLING,UNIVERSAL 1/2IN MALE 1

4 02272600 FITTING,HYD ELBOW 1/2IN (M) O-RING/ 1/2IN (M) JIC 1

5 02288582 GAUGE,PRESSURE 1 1/2IN DIA BACK MNT 0-200 PSI 1

6 02288665 NUT,HEX LOCK M06-1.00 NYLOC 1

7 02288694 NUT,HEX LOCK M08-1.25 NYLOC 1

8 02289293 BOLT,SWING M10-1.50 X 100MM LG 2

9 02289294 SCREW,SHOULDER M10 DIA X 40MM LG 1

10 02289295 SCREW,SHOULDER M08 DIA X 70MM LG 1

11 02289297 CAPSCREW,COUNTERSUNK M06-1.00 X 12MM LG SS 4

12 02289382 NUT,HEX LOCK M10-1.50 NYLOC THIN 1

13 08081316 ADAPTER,LOWER INSERT - MB 1

14 08081317 ADAPTER,UPPER INSERT - MB 1

15 08764001 COUPLING,BODY - HAND HELD BLOWER 2

16 08764006 HANDLE,SPEED-BALL - M10 THREADS 1

17 08780223 PLUG,VENTURI AIR 1

18 11274400 VALVE,BALL 1/2IN 1

17

Page 18

E.

APPENDIX

Clamp Adjustment Screw

18

CLAMP ADJUSTMENT SCREW

ITEM PART NUMBER DESCRIPTION QTY

1 02102001 FLATWASHER, 1/4 TYPE A NARROW CZ 1

2 02287600 FLATWASHER, 1/4 NYLON 2

3 02288555 CAPSCREW, BUTTON HEAD 1/4-28 X 0.75LG SS 4

4 08761033 SCREW,CLAMP ADJUSTMENT - ASSEMBLY 1

5 08761510 MOUNT,CLAMP ROLLER 1

Page 19

Mount Clamp Assembly

MOUNT CLAMP ASSY

ITEM PART NUMBER DESCRIPTION QTY

F.

APPENDIX

1 02102001 FLATWASHER, 1/4 TYPE A NARROW CZ 1

2 02290268 SCREW,SHOULDER 1/4 DIA X 3.25LG 1

3 08081311 ROLLER,CLAMP ASSEMBLY 1

4 08761510 MOUNT,CLAMP ROLLER 1

Clamp Roller Assembly

G.

APPENDIX

CLAMP ROLLER ASSEMBLY (08081311)

ITEM PART NUMBER DESCRIPTION QTY

1 02290379 RING,RETAINING 5/8 EXT (1000 SERIES) 2

2 08081313 SLEEVE,CLAMP ROLLER-PU 1

19

Page 20

Available Options

HEAVY DUTY TRIPOD

The Mini-Blower/Pusher mounts easily to the surveyor style

tripod, which adds stability and versatility to fiber optic cable

installations.

PNEUMATIC DRILL DRIVE “Y” CONNECTOR

A "Y" Connector air hose option allows for the use of a

pneumatic drill drive configuration. Unit also comes with

variable pressure control.

Heavy Duty Tripod

Part # 08780850

"Y" Connector Air Hose

Part # 08780855

MINI-BLOWER/PUSHER JOB BOX

The Mini-Blower/Pusher is easy to handle and

transport. The blower and all accessories including

cable and conduit packs and seal kits conveniently

fit into the lightweight job box.

Job Box with Kit

Part # 08780801

Condux International, Inc.

P.O. Box 247 • 145 Kingswood Drive, Mankato, MN 56002-0247 USA

1-507-387-6576 • 1-800-533-2077 • FAX 1-507-387-1442

www.condux.com • e-mail: cndxinfo@condux.com

© Copyright 2011, Condux International, Inc.

Printed

Literature Part Number: 08780899

Revision Number: 1.1

in USA

Loading...

Loading...