Page 1

USER’S GUIDE & SAFETY MANUAL

Hand Held Micro Fiber Optic Blower

Page 2

Important Safety Notice

Read and understand all procedures and safety instructions before using a Condux

Handheld Micro Fiber Optic Blower. Observe all safety information on this page and note

specific safety requirements as explained by procedures in this manual. Failure to follow

these instructions could result in serious personal injury or death.

ADVERTENCIA

Favor de leer y comprender todas las instucciones de operaciÓn y seguridad antes de usar

la máquina. Si Ud. No comprende las instrucciones favor de consultarle a su jefe.

COMMUNICATIONS WITH THE MANUFACTURER

For an information related to the machine (use, maintenance, spare parts) always state model

number, manufacturing Year and Order. This date can be found on the parts identification

label

Manufacturer:

Condux International, Inc.

145 Kingswood Road

Mankato, MN 56002-0247

1-507-387-6576

Fax 1-507-387-1442

E-mail: cndxinfo@condux.com

Save this user’s guide for future reference

If you have questions on:

Safety – Operations – Applications

Call 1-800-533-2077

2

Page 3

1. General Information………………………………………… Page 4

2. Set up the Handheld Blower………………………………… Page 5

A. Pressure Test Conduit…………………………………… Page 5-8

3. Prepare Conduits for Cable…………………………………. Page 9&10

4. Prepare Cable/Micro Cable…………………………………. Page 11

A. Prepare Traditional Fiber Cable………………………… Page 11&12

B. Prepare Micro Fiber Cable……………………………… Page 12&13

5. Handheld Blower Operating Instructions…………………… Page 14&15

6. Handheld Blower Assembly………………………………… Page 16

Cable Pack & Duct Pack Selection Charts……………………… Page 17

Micro Duct Selection Chart & Micro Carrier Chart…………….. Page 18

Recommended Cable Lubricants………………………………… Page 19

Warranty Information……………………………………………. Page 20

Table of Contents

3

Page 4

General Information

General Product Use

a. Only qualified operators should use this product. The operator should only

be the person who received qualified training from the product owning

company or trained by the manufacturer.

b. Product must only be used for the work it was designed for.

c. Product is not to be used with unauthorized personnel on the job site

d. Should there be any doubt concerning use, functioning, maintenance or

anything else, please contact the factory or factory representative.

Operator Qualifications

a. Operator must know the required safety directives to run the product that

are pertinent to the country where it is being used.

b. Operator in charge of the product and installation project must be

appropriately dressed, avoiding large clothes, hanging jewelry or whatever

might become entangled in the moving parts

c. Operator must also wear the necessary protective equipment such as

gloves, boots, helmet, etc.

d. Operator must carefully follow all advisements contained in the instruction

manual or on the machine

e. Operator must have work area kept clean of obstacles that might inhibit a

safe working area.

Maintenance Qualification

a. Periodically inspect product for wear and tear.

b. Authorized and trained personnel must do all maintenance operations.

Trained personnel are defined as people who have received qualified

training from the using company or from the manufacturer

4

Page 5

Set Up the Handheld Blower

Pressure Test Conduit:

The conduit system must be able to withstand a maximum pressure of 175 psi, and

be free of leaks. Conduit may be tested for pressure using the Handheld cable

blower, follow the steps below.

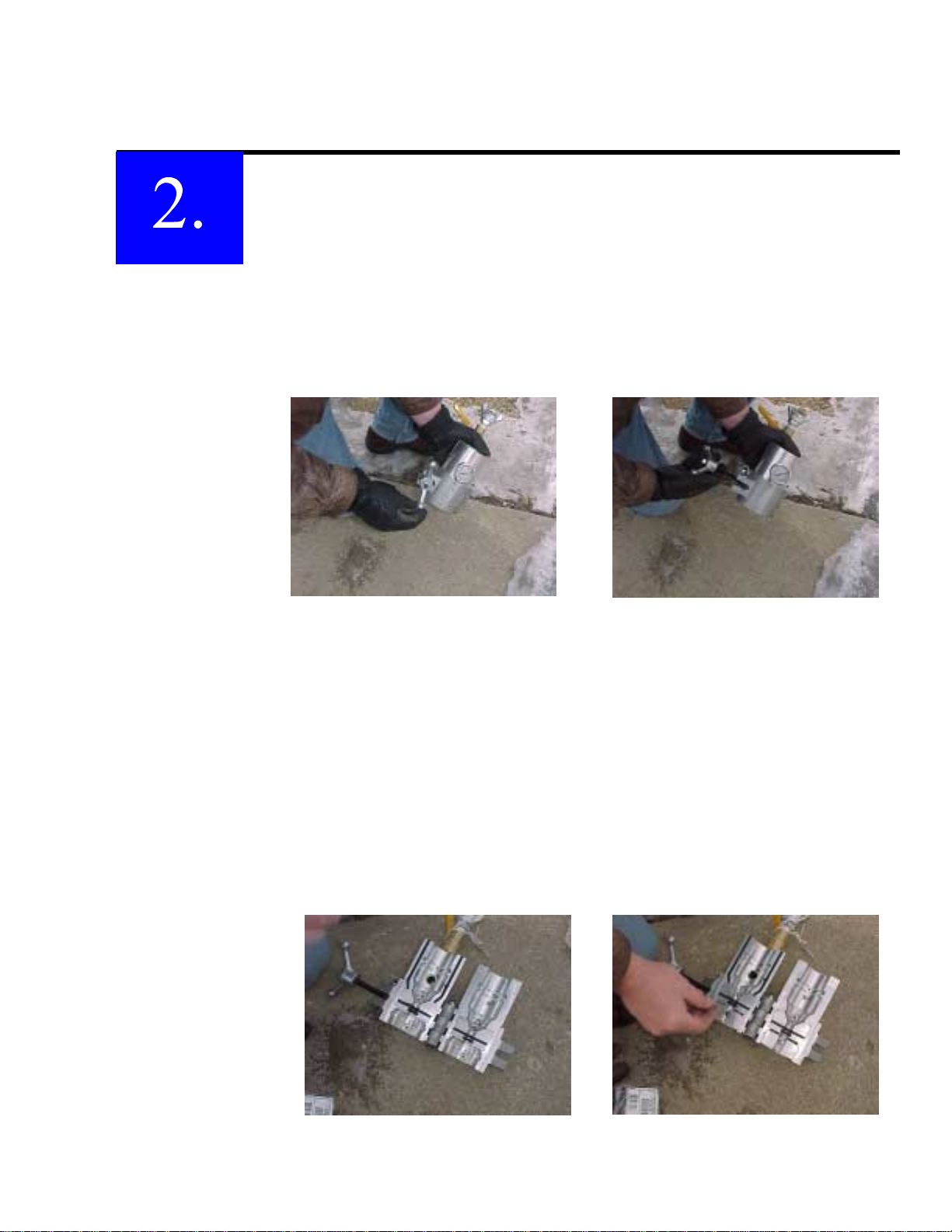

1. Loosen the speedball handle by turning it counter clockwise (Figure

1) until you are able to remove it from the bracket (Figure 2).

Figure 1 Loosen speedball handle

2. Select the correct Condux and Cable Components according to the

conduit and cable size. Refer to the Conduit and Cable Pack

selection charts (Table 1, 2, 3 & 4 on pages 17 & 18).

3. Choose the correct Conduit Seal and install both halves securely.

Use the provided 2.5 mm hex wrench (Figure 3).

4. Choose the correct Conduit Clamp and install both halves (same

color as the conduit seal). Used the provided 2.5 mm hex wrench

(Figure 4).

Figure 2 Remove speedball handle

from bracket

Figure 3 Install con d uit seal Figure 4 Install con d uit clamp

5

Page 6

5. Choose the correct Venturi to fit the cable being installed. Do not inst all at

this time!

6. Place the Seal Disk in Venturi Slot (See Figure 5).

7. Place conduit in the Conduit Seal and Conduit Clamp. Note placement up to

ridge on Conduit Seal (See Figure 6).

8. Close Handheld Blower and secure (See Figure 7). Tighten speedball handle

securely, but do not over tighten.

Figure 5 Insert seal disk Figure 6 Insert duct

Figure 7 Close and tighten handle

9. Plug receiving end of Conduit with a properly sized Conduit Pulling Eye (See

Figure 8).

6

Figure 8 Insert innerdu ct eye

Page 7

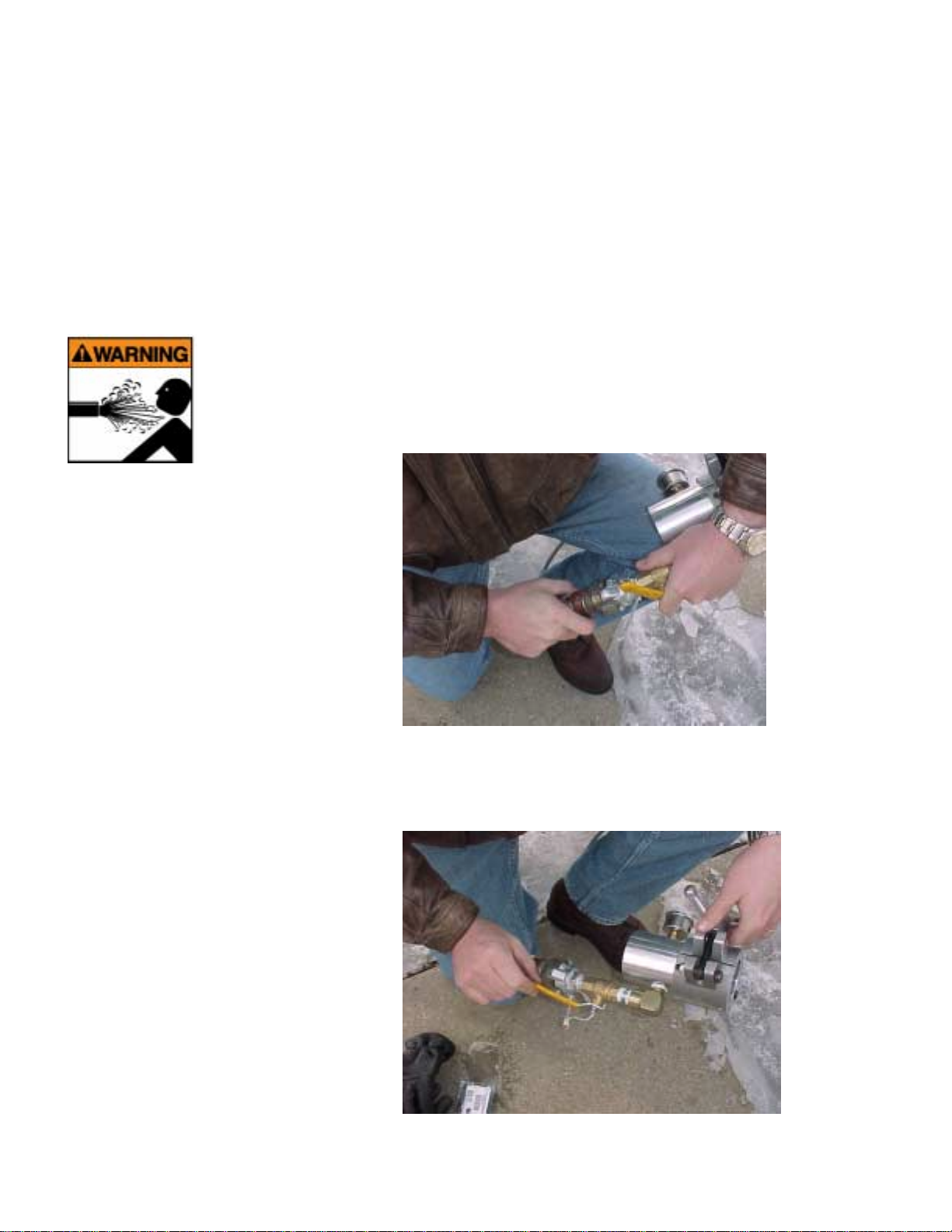

10. Connect the Air Compressor

11. Slowly open Air Control Valve by turning it to the 6 o’clock postion.

a. Ensure Air Valve is off before connecting air hose.

b. Attach the hose supplied with the air compressor to the air compressor

coupling. The Handheld blower is equipped with a claw type connector.

Use a safety clip on all pneumatic hose connections. (See Figure 9).

c. Observe all safety procedures.

d. Route all hoses properly to prevent tripping over them.

!WARNING: Forced air creates flying debris. Always wear personnel

protective equipment. Severe personnel injury could result.

!WARNING: Ensure no personnel are in the destination access vault

during the blowing operation. Severe personal injury could result.

Figure 9 Attach air hose

Pressurize conduit to 80 – 100 psi (5.5-6.9 bar) (See Figure 10).

Figure 10 Slowly open air control valve

7

Page 8

12. Prove conduit integrity.

a. Close Air Control Valve by turning it to the 3 o’clock position

13. Decompress the Handheld Blower by turning the air compressor air

valve off leaving the blower pressure valve on until the air pressure

gauge reads Zero. Disconnect air hose from handheld blower pressure

valve.

(See Figure 11)

b. Conduit must not lose more than 20 psi (1.38 bar) over a 2-

minute period.

c. After 2 minutes, turn air compressor valve off leaving the

blower pressure valve on until the air pressure gauge reads zero.

d. If conduit fails to hold required pressure, check entire conduit

run for leaks and repair them.

e. Repeat the pressure test until all leaks are found and repaired.

!WARNING: Handheld Blower contains compressed air when

blower is operated. Opening the Blower while under pressure

may cause serious personnel injury. Ensure blower is

depressurized before opening the Handheld blower and

removing the conduit pulling eye.

Figure 11 Close air control valve

8

Page 9

Prepare Conduit for Cable

1. Remove Conduit Pulling Eye from receiving end of Conduit.

2. Open Handheld Blower (See Figure 12)

Figure 12 Open handheld blower

3. Pour recommended (silicon-based) lubricant into Conduit opening before

Foam Carrier ¼ of the total recommend amount (See Figure 13) foam

carriers are not provided with the Handheld blower. (See Page 19 for

recommend amount of lubrication).

4. Insert foam into conduit (See Figure 14).

5. Insert Seal Disk in venturi slot if not already in place. (Figure 15).

Figure 13 Add

lubricant

Figure 14 Insert foam carri er

9

Figure 15 Insert seal disk

Page 10

6. Close the Handheld Blower and secure (See Figure 16) Tighten speedball

handle securely, but do not over tighten.

7. Prove Conduit integrity and spread lubricant through Conduit.

a. Re-connect the air hose to the Handheld Blower and attach all

safety clips.

b. Open the air compressor air control valve.

c. Slowly open Air Control Valve by turning to the 6 o’clock

position. (See Figure 17)

d. Blow foam through conduit to spread lubricant and check for

blockage. Follow all safety precautions.

e. After the foam exits, close Air Control Valve by turning it to the 3

o’clock position.

Note: Foam must exit in a reasonable time, allow approximately 10

seconds per 1,000 feet (300 m) or conduit may be contaminated or

blocked.

Figure 16 close and tigh te n handle

Figure 17 Slowly open the air

control valve

8. Ensure Handheld Blower is depressurized. Shut off the air from the

compressor, decompress the air in the hose and disconnect the hoses from

the handheld blower.

9. Remove Seal Disk and install Ventrui (See Figure 18). Use the provided

2.5 mm hex wrench.

Note: The venturi with the groove

goes into the bottom and gets

screwed into place while the top

half has the protrusion and sets

into the groove.

10

Figure 18 Insert ventrui

Page 11

Prepare Cable/Microcable

The Handheld Blower can be used to install traditional fiber cable or Micro Fiber

Cable. Follow the steps below for the type of cable you will be installing.

Prepare Traditional Fiber Cable:

1. Choose the correct Cable Grip and install on the fiber optic cable (See

Figure 19).

2. Install 5/8” (16 mm) Swivel on Cable Grip using a 3/32” hex wrench.

Grip must be firmly secured to cable (See Figure 20). The eye on the grip

can be compressed to fit smaller diameter conduits. The eye of a new grip

can be taped with electrical tape in order to make it narrower and travel

more easily through the conduit.

3. Chose the correct Carrier and install on Swivel (See Figure 21)

4. Add lubricant to Conduit before Carrier: ¼ of the recommended

5. Push Cable Assembly, including entire cable grip, into conduit.

6. Add the rest of the lubricant to the Conduit behind the Cable Assembly.

Figure 19 Installing Cable Grip Figure 20 Installing Swivel

amount.

11

Figure 21 Install carrier

Page 12

7. Choose the correct Cable Seals and install on cable. Grooved side of

Cable Seal faces the conduit. Place Cable Seals into the Venturi, split

side down

8. Close the handheld blower and secure, Tighten speedball handle

securely, but do not over tighten.

Prepare Micro Fiber Cable

The carriers are designed to attach to the central strength member (CSM) of the

cable. The seals are sized to accommodate the proper ID duct size for

maximization of blowing distances and create and air tight seal in the duct. A

caliper has been included into the, Micro Duct Carrier Kit (not included), for

proper sizing of the correct Push Retainers. A bottle of adhesive is added to

reinforce the attachment of the push retainers.

1. Strip the fiber cable down to the CSM, approximately 5/8” (16 mm) form

the end (See Figure 22).

Figure 22: Strip of the CSM to length of

approximately 5/8” (16 mm)

2. Select proper carrier seals for the duct inside diameter (ID) (See Table 1)

Duct ID (mm) Condux Carrier Seal P/N

8 08764118

10 08764128

12 08764138

14 08764148

3. Select the proper Push Retainers based on the CSM diameter

measurement taken with the included calipers (See Table 2).

Central Strength Member (CSM)

Condux Push Retainer P/N

Dia. (mm)

1.5 02289350

2.0 02289351

2.5 02289352

3.0 02289353

12

Page 13

4. Slide two (2) Carrier Seals onto the CSM followed by two (2) Push

Retainers. The seals should be relatively loose on the fiber but retained

on the CSM with the Push Retainers.

Note: Notice the direction of how the Push Retainers need to be assembled

to the fiber. The cone portion of the retainer faces the end of the CSM. They

should fit very tight onto the fiber.

5. Apply a tug on the Carrier Seals toward the end of the fiber to ensure the

Push Retainers do not come off.

6. Apply adhesive to the front of the retainers where they interface with the

fiber. Allow for the adhesive to setup (See Figure 23)

Figure 23: Assembly of Carriers onto the CSM of Micro Fiber Optic

Cable.

7. Check that Microcable slides smoothly in the Microduct.

8. The Microcable CSM may be trimmed back and/or wrapped with tape to

create a “bullet” configuration to prevent any jamming in the duct.

9. Push the Cable Assembly, into the conduit.

10. Add the rest of the lubricant to Conduit behind the Cable Assembly.

11. Choose the correct cable seals and install on cable. Grooved side of

Cable Seal faces conduit. Place Cable Seals into Ventrui, Split side down

12. Close handheld blower and secure, tighten speedball handle securely, but

do not over tighten.

13

Page 14

Handheld Blower Operating Instructions

14

1. Station an observer with a 2-way communication device, at the far

end of the Conduit, where the cable carrier will exit.

2. Re-connect hose from air compressor and attach all safety clips. Start

the air compressor. Refer to respective manufacturers operating

instructions for these units.

3. Slowly open the Air Control Valve to allow airflow to the Handheld

Blower by turning the flow control valve hand to the 6 o’clock

position.

4. Maintain control of the cable reel to ensure smooth, stable flow.

Failure to do so may cause cable to unwind to quickly. Continue to

control cable speed with the flow control knob.

!WARNING: Never wrap line around your hand, arm, foot or leg.

Severe personal injury or death could result from entanglement.

!CAUTION: Always wear protective equipment: hard hat, safety

glasses, safety shoes and work gloves.

5. Turn off the Air Control Valve immediately when the observer

indicates the cable carrier has exited the Conduit (air pressure will

decrease sharply).

6. Turn off compressed air by closing the Air Control Valve at the

Handheld Blower (See Figure 24). Shut off air at the compressor and

decompress air hose. Depressurize the Handheld Blower by turning

the air control handle on. Remove air hose when system is relieved

of pressure.

!WARNING: Handheld Blower contains compressed air when

Handheld Blower is operated. Opening the Handheld Blower while

under pressure may cause serious personal injury. Ensure Handheld

Blower is depressurized before opening the Handheld Blower.

Figure 24 Close control valve

Page 15

7. Open Handheld Blower and remove cable seals (See Figure 25).

8. Pull Conduit and Cable out of the Handheld Blower

Figure 25 Open Handheld Blower and Remove Cable

and Duct

15

Page 16

Handheld Blower Assembly

Item No. Part_Number Dwg_Description Quantity

1 00263400 QUAD-RING, 3.5MM-CS CORD 3.53" 2

2 02020000 FTG,HYD 08-NPT_M ;08-NPT_M 1

3 02129700 UNIVERSAL CPLG, 1/2 MALE 1

4 02272600 FTG,HYD 08 O-RING;08-JIC 90 1

5 02288582 GAUGE,PRESS 0-200 1.50 BACK MT 1

6 02288665 NUT M06-1.00 NYLOC ST GR2 CZ 1

7 02288694 NUT M08-1.25 NYLOC ST GR2 CZ 1

8 02289293 BOLT,SWING M10-1.5 X 100 ST 1

9 02289294 SCREW,SHOULDER M10 DIA-40MM 1

10 02289295 SCREW,SHOULDER M08 DIA-70MM 1

11 02289297 CAPSRW M06-1.0X 12 CSSS 18-8 4

12 02289382 NUT M10-1.50 NYLOC STGR2 THNCZ 1

13 08764001 COUPLING,LOWER HALF BLOWER 2

14 08764003 INSERT,LOWER INTERFACE BLOWER 1

15 08764004 INSERT,UPPER INTERFACE BLOWER 1

16 08764006 HANDLE,BALL 4.50 OD-M10 THRDS 1

17 11274400 VALVE,BALL- .50 IN 1

16

Page 17

Duct Pack Duct Clamp Duct Seal Carrier Foam C arrier Cable Grip

Duct Size P/N Duct OD P/N D uct OD P/N Duct ID P/N Carrier OD P/N Duct OD P/N

1" 08780386 1.315 08780369 1.315 08780307 1.121 08761811 1.25 08761439 1.00-1.24 08643137

SDR 11/13.5 Pack #1 (33.4) Blue (33.4) Blue (28.5) (31.8) (25.4-31.5) 033-03-013

1.25" 08780392 1.660 08780375 1.660 08780051 1.414 08761817 1.50 08761440 1.50-1.99 08643149

SDR 11/13.5 Pack #2 (42.2) G reen (42.2) Green (35.9) (38.1) (38.1-50.5) 033-03-016

1.5" 08780397 1.900 08780404 1.900 08780398 1.618 08761819 1.75 08761441 1.50-1.99 08643149

SDR 11/13.5 Pack #3 (48.3) Red (48.3) Red (41.1) (44.5) (38.1-50.5) 033-03-016

25 mm 08780240 0.984 08780099 0.984 08780134 0.787 08780230 1.25 08761439 1.00-1.24 08643137

(25.0) Orange (25.0) Orange (20.0) (31.8) (25.4-31.5) 033-03-013

32 mm 08780385 1.260 08780368 1.260 08780306 1.063 08761810 1.25 08761439 1.25-1.49 08643143

(32.0) Gold (32.0) Gold (27.0) (31.8) (31.8-37.8) 033-03-015

36 mm 08780387 1.417 08780370 1.417 08780308 1.181 (30.0) 08761812 1.25 08761439 1.25-1.49 08643143

(36.0) R ed (36.0) Red 1.220 (31.0) 08761813 (31.8) (31.8-37.8) 033-03-015

37 mm 08780388 1.457 08780371 1.457 08780309 1.220 08761813 1.25 08761439 1.25-1.49 08643143

(37.0) Blue-Gray (37.0) Blue-Gray (31.0) (31.8) (31.8-37.8) 033-03-015

1.25" TRU E 08780389 1.500 08780372 1.500 08780333 1.250 08761814 1.50 08761440 1.25-1.49 08643143

(38.1) Clear Alum. (38.1) Clear Alum. (31.7) (38.1) (31.8-37.8) 033-03-015

40 mm 08780390 1.575 08780373 1.575 08780334 1.299 08761815 1.50 08761440 1.50-1.99 08643149

(40.0) Black (40.0) B lack (33.0) (38.1) (38.1-50.5) 033-03-016

42 mm 08780391 1.653 08780374 1.653 08780335 1.378 08761816 1.50 08761440 1.50-1.99 08643149

(42.0) Blue-Gray (42.0) Blue-Gray (35.0) (38.1) (38.1-50.5) 033-03-016

44 mm 08780545 1.732 08780546 1.732 08780547 1.496 08761786 1.50 08761440 1.50-1.99 08643149

(44.0) Gold (44.0) Gold (38.0) (38.1) (38.1-50.5) 033-03-016

50 mm 08780575 1.969 08780435 1.969 08780431 1.606 08761818 2.00 08761442 1.50-1.99 08643149

(50.0) B lue (50.0) Blue (40.0) (50.8) (38.1-50.5) 033-03-016

Table 1 Conduit Packs

Page 18

Page 19

Cable Pack Ve nturi Cable Seal Cable Grip

C a b le O D P /N C ab le O D P /N C ab le O D P/N C a b le O D P /N

0.23-0.34

(5.8-8.8) Pac k #1 (5.8-8.8) Purple 0.29-0.34 0 8780407 (5.3-8.9) 033-29-1194

08780393

0.23-0.34

08780281

0.35-0.60

(8.9-15.2) Pack #2 0.49-0.55 08761426

08780394

0.35-0.48

(8.9-12.2) Blue 0.43-0.48 08761425 (8.1-12.2) 033-29-1195

0.49-0.60

(12.3-15.2) Green 0.56-0.60 08761427 (10.7-15.5) 033-29-1196

08780282

08780283

0.61-0.85

(15.3-21.6) Pack #3 0.74-0.79 08761430

08780395

0.86-1.13

(21.7-28.7) Pack #4 0.98-1.04 08761434

08780396

0.61-0.73

(15.3-18.5) Red 0.68-0.73 08761429 (13.5-18.8) 033-29-1197

0.74-0.85

(18.6-21.6) Gold 0.80-0.85 08761431 (16.3-22.1) 033-29-1198

0.86-0.97

(21.7-24.6) Clear A lum. 0.93-0.97 08761433 (19.1-25.4) 033-29-1199

0.98-1.13

(24.7-28.7) Black 1..05-1.13 08761435 (25.4-31.5) 033-03-013

08780284

08780285

08780286

08780446

0.23-0.28 08780406

(5.8-7.2) 0.21-0.35 08643754

(7.3-8.8)

0.35-0.42 08761424

(8.9-10.7) 0.32-0.48 08643755

(10.8-12.2)

(12.3-14.0) 0.42-0.61 08643756

(14.1-15.2)

0.61-0.67 08761428

(15.3-17.0) 0.53-0.74 08643757

(17.1-18.5)

(18.6-20.1) 0.64-0.87 08643758

(20.2-21.6)

0.86-0.92 08761432

(21.7-23.4) 0.75-1.00 08643759

(23.5-24.6)

(24.7-26.4) 1.00-1.24 08643137

(26.5-28.7)

Table 2. Cable Packs

MICRO DUCT PACKS Innerduct Eye

Duct Size OD (MM) Part Number Duct Clamp Duct Seal ID Range P/N

10 08764140

12 08764110

14 08764120

16 08764130

08764142 08764143

08764112 08764113 10-12 mm 08913545

08764122 08764123 10-12 mm 08913545

08764132 08764133 10-12 mm 08913545

Table 3. Micro Duct Packs

Carrier Kit - Micro Fiber (P/N 08764090)

Kit Includes:

P/N Description Qty

02289350 RETAINER,PUSHON QCKLCK 1.5MM 20

02289351 RETAINER,PUSHON QCKLCK 2.0MM 20

02289352 RETAINER,PUSHON QCKLCK 2.5MM 20

02289353 RETAINER,PUSHON QCKLCK 3.0MM 20

08764118 DISC,CARRIER - 08MM ID DUCT 10

08764128 DISC,CARRIER - 10MM ID DUCT 10

08764138 DISC,CARRIER - 12MM ID DUCT 10

08764148 DISC,CARRIER - 14MM ID DUCT 10

02284200 ADHESIVE,LOCTITE 38004 3GM TBE 1

02288875 CALIPER,CABLE DIAMETER 1

Page 20

r

®

t

d

V

Recommended Blowing Lubricants

Polywater® Prelube 2000™

Specially formulated for use with fiber optic cable blowing systems, Polywate

field proven with the Deluxe LW Blower. This lubricant is a special lubricant used to prelubricate the condui

system before installing the cable. Prelube 2000™ is compatible with all types of cable jackets an

conduit types.

Part Number Description Qty

08230600 1 Quart (.9 liter) Squeeze Bottle 12/case

08230601 1 Gallon (3.8 liter) Jug 4/case

08230900 1 Quart (.9 liter) Squeeze Bottle Winter Grade 12/case

08230901 1 Gallon (3.8 liter) Jug Winter Grade 4/case

Polywater® Prelube 2000™ recommended usage quantity

Duct Size Per 1,000 Feet Per Kilometer

1 inch 3 fl. oz. 300 ml

1.25 inch 4 fl. oz. 400 ml

1.5 inch 5 fl. oz. 500 ml

2 inch 6 fl. oz. 600 ml

Lubricant Quantity

Prelube 2000™has been

Std

Pkg

Polywater Prelube 5000™

Polywater® Prelube 5000™ is more concentrated than the Prelube 2000™. It is intended for

blowing microcable into small diameter microtubes. The improved chemistry allows this product

to spread further and lower friction low coasting levels. The lower viscosity allows practical

application into the microtubes.

20

Part Number Descript ion Std Pkg Qt y

08230675 8 ft.oz squeeze bottle 6/case

Polywater® Prelube 5000™ recommended usage quantity

Lubricant Quantity

Tube Size (OD/ID)

14/12 0.30 fl. Oz. (9 ml) 3 in. (8 cm)

12/10 0.25 fl. Oz. (7 ml) 4 in. (10 cm)

10/8 0.20 fl. Oz (6 ml) 5 in. (12 cm)

olume Required Fill Length of Microtube

Page 21

WARRANTY INFORMATION

Condux International, Incorporated extends the following warranty to the original purchaser of these goods for use,

subject to the qualifications indicated:

Condux International, Incorporated warrants to the original purchaser for use that the goods or any component thereof

manufactured by Condux International will be free from defects in workmanship for a period of 1 year form the date of

purchase, provided such goods are installed, maintained, and used in accordance with Condux’s written instructions.

Components not manufactured by Condux International but used within the assembly provided by Condux International

are subject to the warranty period as specified by the individual manufacturer of said component, provided such goods

are installed, maintained, and used in accordance with Condux’s and the original manufactures written instructio ns.

Condux’s sole liability and the purchaser’s sole remedy for a failure of goods under this limited warranty, and for any

and all claims arising out of the purchase and use of goods, shall be limited to the repair or replacement of the goods

that do not conform to this warranty.

To obtain repair of replacement service under the limited warranty, the purchaser must contact the factory for a Return

Material Authorization (RMA), Once obtained, send the RMA along with the defective part or goods, transportation

prepaid, to:

Condux International, Inc.

145 Kingswood Road

Mankato, MN 56001 USA

THERE ARE NO EXPRESS WARRANTIES COVERING THESE GOODS OTHER THAN

AS SET FORTH ABOVE. THE IMPLIED WARRANTIES OR MERCHANTABILITY AND

FITNESS FOR PARTICULAR PURPOSE ARE LIMITED IN DURATION TO ONE YEAR

FROM DATE OF PURCHASE

CONDUX ASSSUMES NO LIABILITY IN CONNECTION

WITH THE INSTALLATION OR USE OF THIS PRODUCT,

EXCEPT AS STATED IN THIS LIMITED WARRANTY,

CONDUX WILL IN NO EVENT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES

©Copyright 2005 , Condux International, Inc.

Printed in USA

Literature Part Number 08764010

21

Revision Number 1.0

Loading...

Loading...