Page 1

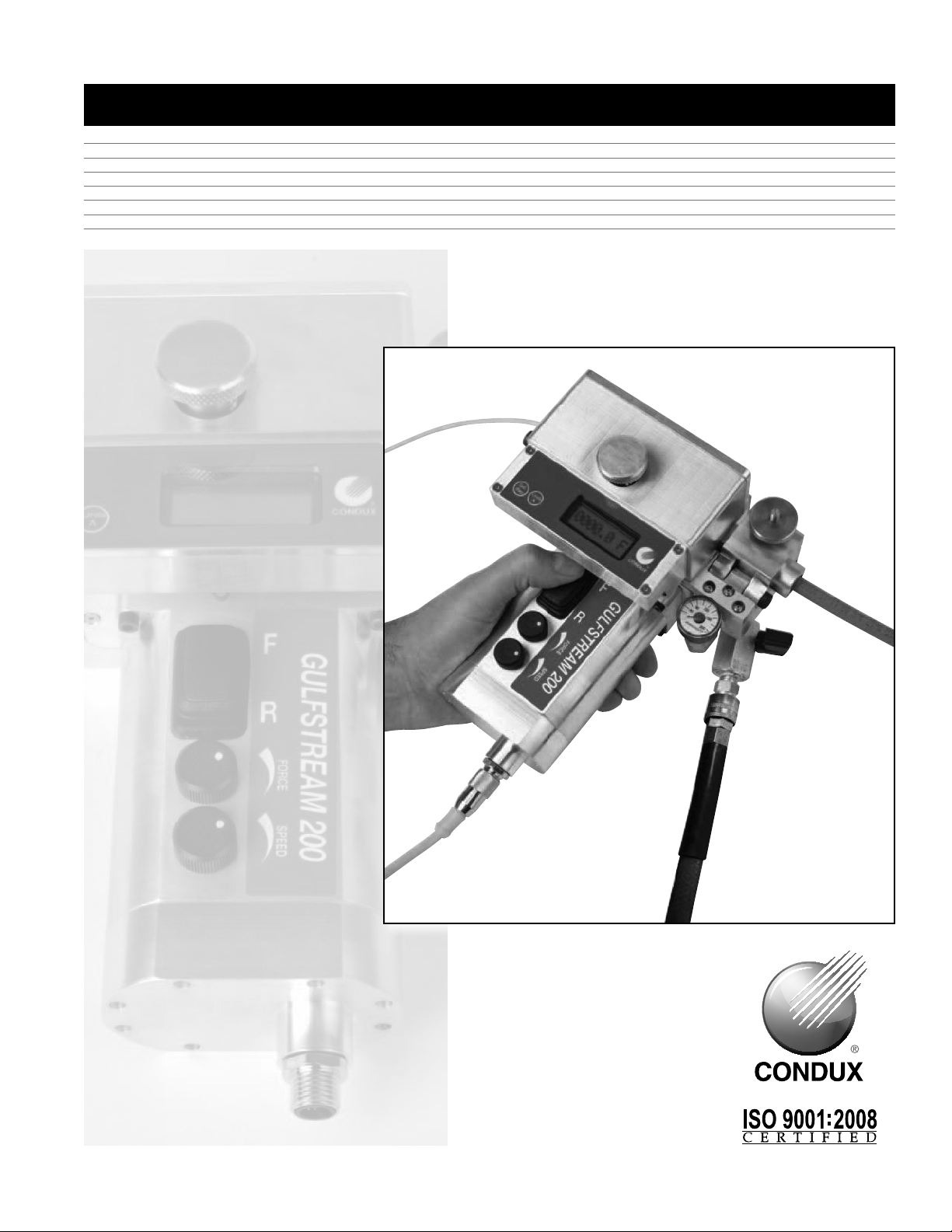

USER'S GUIDE & SAFETY MANUAL

Gulfstream™ 200 Micro Fiber Blower

Page 2

Important Safety Notice

Read and understand all procedures and safety instructions before using the Gulfstream™ 200 Micro

Fiber Blower. Observe all safety information on this page and note specific safety requirements as

explained by procedures in this manual. Failure to follow these instructions could result in serious

personal injury or death.

ADVERTENCIA:

Favor de leer y comprender todas las instucciones de operación y seguridad antes de usar la máquina. Si

Ud. no comprende las instrucciones favor de consultarle a su jefe.

READ MANUAL

FIRST

Save this user’s guide for future reference.

COMMUNICATIONS WITH THE MANUFACTURER

For any information related to the machine (use, maintenance, spare parts) always state Model, Serial

Number, Manufacturing Year and Order. This data can be found in the machine identification table.

Manufacturer:

Condux International Inc.

145 Kingswood Drive

Mankato, MN 56002-0247

1-507-387-6576

Fax 1-507-387-1442

Internet: http://www.condux.com

E-mail: cndxinfo@condux.com

If you have questions on:

SAFETY - OPERATIONS - APPLICATIONS

CALL 1-800-533-2077

2

Page 3

Table of Contents

1

General Information .................................................4

Technical Specifications ............................................. 5

2

A. Condition of Use ............................................. 5

B. Air Compressor Requirements .................................. 5

C. Operational Capacities ........................................ 5

D. Electrical Requirements .......................................5

E. Physical Specifications ........................................ 5

F. Caterpillar Drive Specifications .................................. 5

G. Conduit Coupling Requirements ................................ 5

3

Safe Operating Procedures ........................................... 6

A. Work Area Safety ............................................ 6

B. Pneumatic Devices ........................................... 6

C. Electrical Devices ............................................ 6

4

Unpacking the Blower ...............................................7

A. Blower Components .......................................... 7

Set Up the Blower ..................................................8

5

A. Determine Fiber Size .........................................8

B. Select Cable Seal & Duct Pack .................................8

C. Install Cable Seal & Micro Fiber in Duct Pack ......................9

D. Install Micro Duct ............................................9

E. Install Duct & Fiber in Blower .................................. 10

F. Install Fiber in Tractor Drive & Tighten ...........................10

G. Connect Battery Pack to Blower ...............................11

H. Panel Layout ..............................................11

I. Connect Air Compressor ......................................12

6

Crash Test ....................................................... 13

7

Blower Opterations ................................................14

A. Engage Air ................................................ 14

B. Verify Adjustable Push Force ..................................14

C. Engage Tractor Drive ........................................ 14

D. Adjust Speed ..............................................14

E. Install Fiber ................................................ 14

8

Tear Down Procedures ............................................. 15

A. Remove Power from Unit .....................................15

B. Remove Fiber from Blower .................................... 15

9

Maintenance ..................................................... 16

A. Track Cleaning & Tightening ...................................16

B. Replacement of Drive Belt ....................................16

10

Troubleshooting Guide .............................................. 18

11

Replacement Parts ................................................19

A

Appendices ...................................................... 20

3

Page 4

1.

General Information

The Gulfstream™ 200 is a unique device for inserting fiber optic cable directly into

conduit. The Gulfstream 200 is comprised of an air block and a tractor drive that,

when combined with an air compressor and a battery pack, will propel fiber optic

cable measuring 0.8mm to 5.5mm into an unobstructed, unoccupied, airtight conduit

run at speeds of 0 to 165 ft/min (0-55 m/min). A cable carrier may be placed at the

front end of the cable.

The Gulfstream 200 greatly reduces pulling stress on the cable. The adjustable push

force of the tractor drive will stall the motor if the cable hits an obstruction.

The Gulfstream 200 comes standard with a digital LCD cable meter display, 2 battery

packs, battery charger, duct packs, seal kits and duct lube, all packaged in a foam

filled carrying case.

These operating instructions contain a full description of the Gulfstream 200, which

has been designed for the purpose of feeding fiber cable through conduits of uniform

cross section. The conduit must previously been installed underground or overhead to

receive the fiber optic cable and must be of sufficient length on exit to be received by

the machine. The conduit must be of material with sufficient compression strength for

it to be adequately sealed in the duct clamps of the machine. The conduit must be

airtight up to a pressure of 175psi (12bar). For this purpose, connections of screw,

compression or fusion type must be used. Conduits from 5mm to 12.7mm and fiber

optic cable from 0.8mm to 5.5mm can be accepted by the machine.

The Gulfstream 200 consists of an air block that is made in two halves that clamp

together around the duct clamps. The duct clamps hold a seal that the fiber optic

cable is fed through before entering the duct. The duct clamps and cable seals can be

interchanged to accommodate different conduit and cable sizes. The conduit is

mechanically clamped between the duct clamps at the exit of the air block, preventing

movement in any direction. Built in seals conform around the conduit when clamped.

The fiber cable is fed through the duct by a combined pulling/pushing force. The

pulling force is achieved when pressurized air is fed into the air block and forced into

the duct, generating drag on the fiber cable from airflow passing over it. The pushing

force is created by engaging the tractor drive system. As the tractor drive feeds more

and more fiber cable into the duct, more and more drag force is created by the airflow.

The fiber cable floats in the conduit, minimizing any resistance to being pushed in by

the tractor drive.

The use of the Gulfstream 200 for operations other than those described in this

manual are considered dangerous and are discouraged. Use of this machine for work

other then what is intended, relieves the manufacture from any responsibility, civil or

penal. The manufactures responsibility ceases even when one of the following occurs:

a. Tampering and/or modifications carried out without written approval of

the manufacture.

b. Not using original manufactured replacement parts.

c. Poor maintenance.

d. Not using supplied safety devices or equipment.

e. Connection of this unit to machines and/or parts not produced or

authorized in writing by the manufacture.

4

Page 5

Technical Information

A. CONDITION OF USE:

Temperature from 21° F (-6° C) to 110° F (+43° C) Humidity from 30% to 90% +/- 5%,

Weather conditions relevant to working conditions, Natural and/or artificial lighting of

the work site, minimum 200 lux.

B. AIR COMPRESSOR REQUIREMENTS

1. Pneumatic Pressure: 175 psi (12 bar) Maximum

2. Required Air Flow: 5 - 15 CFM (.14 - .42 m3/min)

3. Conduit Size: 5mm – .50" (12.7mm) OD

4. Air hose fittings: ¼" Quick Connect

C. OPERATIONAL CAPACITIES

1. Pushing Force: 10lbs (45N) Max Push Force

2. Pushing Speed: 165 ft/min (50 m/min) Maximum

3. Cable Sizes: 0.8mm to 5.5mm

4. Conduit Sizes: 5mm, 7mm, 8.5mm, 10mm, 12mm, 12.7mm (

D. ELECTRICAL REQUIREMENTS:

1. Power Requirements: 12Volt (10.8V) DC @ 5Amp Max

2. Power Consumption: 60 Watts Maximum

3. Power Connection: Supplied Battery Pack (includes battery charger)

E. PHYSICAL SPECIFICATIONS

1. Height 4.6" (117 mm)

2. Length 7.5" (190 mm)

3. Width 6.0" (152 mm)

4. Weight 5.7 lbs (2.6 Kg)

F. CATERPILLAR DRIVE SPECIFICATIONS

1. Pushing Force: 10lbs (45N) Max Push Force

2. Pushing Speed: 165 ft/min (50 m/min) Maximum

3. Maximum clamping force: <12 lbf/in (2.1 N/mm)

4. Constant cable centerline design

5. Forward and reverse

6. Independent pushing drive belts with molded urethane cover profiled

for cable 0.8mm to 5.5mm

7. Slide guards

1

⁄2")

2.

G. CONDUIT COUPLING REQUIREMENTS

1. Must withstand maximum air pressure of 175 psi (12 bar)

2. Must withstand axial loading and vibration

3. Must be screw type, compression type, or fusion type

4. Sight holes must be sealed

5. Must fit snugly

6. Conduit ends must be cut off squarely and deburred

7. Conduit must be fully seated into the coupler

8. Couplers should be installed in a straight section of conduit

9. Must be same size conduit

5

Page 6

3.

Safe Operating Practices

Read and understand all procedures and safety instructions before using the

Gulfstream 200. Observe all safety information on this page and note specific safety

requirements as explained by procedures called out in this manual. Failure to follow

these instructions could result in serious personal injury, property damage or death.

A. WORK AREA SAFETY

1. Wear personal protective equipment: hard hat, safety glasses, safety shoes,

and leather work gloves.

2. The safe operation of this equipment requires that the operators be on

stable footing.

3. Stay clear of cables or lines under tension.

4. Stay clear of pressurized line and conduit.

5. Use the blower only for its intended purpose.

6. Do not place cable reel too close to unit. Place the reel far enough away from

the unit to ensure proper control.

7. Place cable grip on end of conduit to catch cable carrier and cable.

8. Keep hands away from tractor drive while blower is in operation.

B. PNEUMATIC DEVICES

The Gulfstream 200 is a pneumatic device, using pressurized air to project cable at

high velocities. Please observe the following precautions when operating the blower:

1. Forced air creates flying debris. Always wear personal protective equipment.

Severe personal injury could result.

2. Ensure no personnel are in the destination access vault during the blowing

operation. Severe personal injury could result.

C. ELECTRICAL DEVICES

The motor, controller, and digital display are electrical devices. Electrical shock

hazards exist that could result in severe personal injury or death. Observe the

following precautions to avoid electrical hazards:

1. Do not operate in or near water. This includes setting the unit on a wet surface

or exposing to rain.

2. Do not remove the digital display cover. There are no user-serviceable parts

inside. Refer servicing to qualified service personnel.

3. The drive switch should be in the neutral "center" position before connecting

or disconnecting any cords.

6

Page 7

Unpacking the Blower

A. BLOWER COMPONENTS

Each Gulfstream 200 STD Kit contains the following items:

GS200 Micro Fiber Blower

Battery Pack W/Cord

Rechargeable Battery (2)

Battery Charger

Duct Clamp Insert Assemblies (5-7mm; 8.5-10mm; 12-12.7mm)

Bottle of Lubricant

Common Parts Kit

(Includes: Cable Seals (1.5; 2.0; 2.5; 3.0; 3.5; 4.0; 4.5; 5.0; 5.5 mm)

Blank Seal; O-Ring Kit; Seal Kit; Flat Belt; Hex Key Set; Plastic Case)

NOTE: If any parts are missing: please contact your Condux representative

or call Condux International at 1-800-533-2077 (USA or CANADA), or

1-507-387-6576.

4.

7

Page 8

5.

Set Up the Blower

This manual contains setup and operating instructions for the Gulfstream 200 micro

fiber blower.

A. DETERMINE FIBER SIZE

Determine size of fiber to be installed. To provide optimal traction and grip, if fiber

diameter is 1.5mm or less, the top belt of blower must be changed to a flat belt which

is included in the common parts kit. This flat belt is to be used in combination with the

bottom grooved belt, so that adequate contact and proper push force can be applied

to the fiber. Refer to Section 9 for belt replacement instructions.

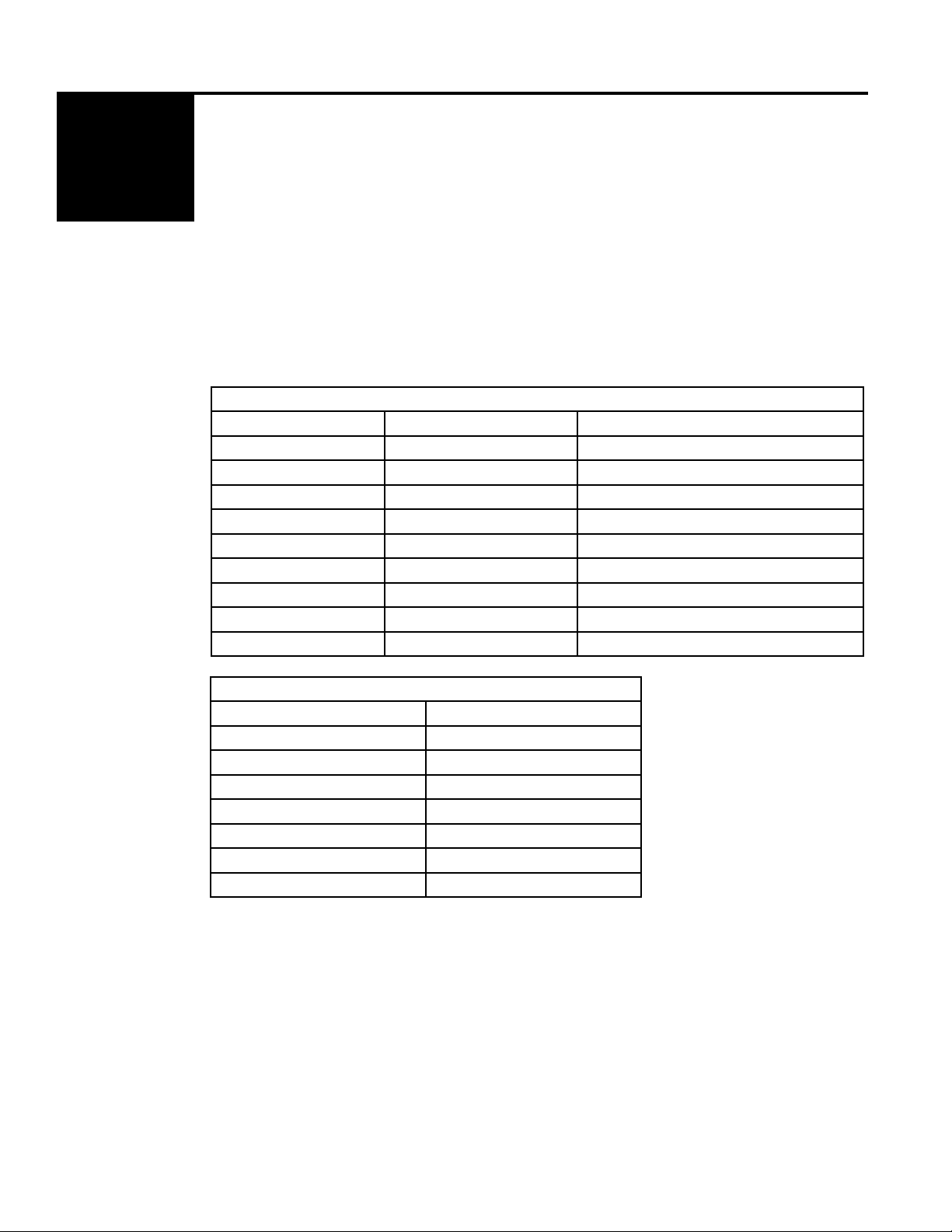

B. SELECT CABLE SEAL & DUCT PACK

Choose the correct cable seal and duct pack for the particular application according to

duct and cable size. Refer to Cable Seal and Duct Pack selection charts.

CABLE SEAL SELECTION

CABLE OD (mm) CABLE SEAL KIT PN DUCT PACK PN

0.8-1.5 08783074 08783051; 08783052; 08783053

1.5-2.0 08783057 08783051; 08783052; 08783053

2.0-2.5 08783058 08783051; 08783052; 08783053

2.5-3.0 08783064 08783051; 08783052; 08783053

3.0-3.5 08783059 08783051; 08783052; 08783053

3.5-4.0 08783060 08783052; 08783053

4.0-4.5 08783061 08783052; 08783053

4.5-5.0 08783062 08783052; 08783053

5.0-5.5 08783063 08783052; 08783053

DUCT PACK SELECTION

DUCT OD (mm) DUCT PACK PN

5.0mm 08783051

7.0mm 08783051

8.0mm 08783052

8.5mm 08783052

10.0mm 08783052

12.0mm 08783053

12.7mm 08783053

8

Page 9

C. INSTALL CABLE SEAL & MICRO FIBER IN DUCT PACK

Install the appropriate cable seal on the micro fiber. Make sure orientation of seal on

fiber is correct so that it will seat in the duct pack properly. (See figure 1).

Once the cable seal is positioned properly on the micro fiber, install the cable seal in

the bottom half of the appropriate duct pack. (See figure 2).

Figure 1. Install Micro Fiber in

Cable Seal

Figure 1. Install Cable Seal in

Bottom Half of Duct Pack

Note: The bottom half of the duct pack is designated by a small hole on the

outside of the unit.

D. INSTALL MICRO DUCT

After the cable seal and micro fiber are in place, position the micro duct properly in

the bottom half of the duct pack. (See figure 3).

Once the micro duct is in place, secure the configuration by installing the top half of

the duct pack and pressing firmly together. (See figure 4).

Figure 3. Position Micro Duct

Properly in Duct Pack

Figure 4. Install Top Half of Duct

Pack and Press Together

9

Page 10

E. INSTALL DUCT & FIBER IN BLOWER

Loosen the knob on the Air Block assembly. Open the air block cover. Insert the duct

pack assembly into the air block as shown. (See figure 5). Close air block cover and

hand tighten knob to secure. (See figure 6).

Figure 5. Insert Duct Pack

Figure 6. Tighten Knob

Assembly into Air Block

F. INSTALL FIBER IN TRACTOR DRIVE AND TIGHTEN

Feed the micro fiber between tractor drive and through the rear fiber guide.

(See figure 7). Tighten tractor drive using the down screw to ensure even pressure on

the micro fiber. (See figure 8). Do not over tighten.

10

Figure 7. Feed Micro Fiber

Between Tractor Drive and

Rear Fiber Guide

Figure 8. Tighten Tractor Drive

Down Screw

Page 11

G. CONNECT BATTERY PACK TO BLOWER

Attach power supply cable to blower unit and battery pack, tighten connections.

(See figure 9). Once you have the supply cable connected, install the battery in

battery pack as shown. (See figure 10).

Figure 9. Attach Battery Pack

Figure 10. Install Battery

Cable to Blower Unit

H. PANEL LAYOUT

A description of each of the buttons and displays for the Gulfstream 200 micro fiber

blower control box appears below. (See figure 11).

Figure 11. Panel Layout

Sel/Res:

1. Push Sel/Res to toggle between distance, rate, and total

2. Hold sel/Res to reset the distance

Units:

1. Toggles between US and Metric units for all modes

11

Page 12

I. CONNECT AIR COMPRESSOR

NOTE: Ensure the air control valve is off before connecting the air hose.

Attach the air compressor hose to the air compressor if necessary. Then

connect the compressor hose to the blower unit. (See figure 12). The unit uses a

standard quick connect air compressor coupling.

NOTE: Route all hoses properly to prevent tripping over them. (See figure 12A).

Figure 12. Connect Air

Compressor Hose

Figure 12A. Typical Setup

12

Page 13

Crash Test

Cable Crash Testing is a very quick and easy step to be completed before attempting

the installation of cable with the Gulfstream 200. This test is necessary to set the

electronic push force control of the motor below the point that it may cause cable

damage as a result of over pushing or encountering an obstruction in the

sub-duct system.

Every cable has different pushing values and these values vary depending on

duct I.D. Example: A cable with a crash test value of 75 bar in 33 mm I.D. duct,

may have a crash value of only 60 bar in a 40 mm I.D. duct. This is because the

area of lateral movement is larger as the duct size increases.

!CAUTION: Always wear protective equipment: hard hat, safety glasses, safety

shoes and work gloves.

NOTE: The electronic push force adjustment will have little effect on the installation

speed of the blowing unit. This is an adjustment to prevent damage to the cable that

can be caused by excessive pushing force.

IMPORTANT: For the Crash Test to work properly use the same size cable and duct

that will be used for the job.

6.

Set the electronic push force adjustment on the Gulfstream 200 using the following

procedure:

a. Attach 12' (4 m) of duct to the Gulfstream 200 with 15' (5 m) of fiber optic cable

(See figures 3-8) using the appropriate duct pack and cable seal.

b. Set the adjustable push force to about half way of the maximum.

c. Install Conduit Pulling Eye or place your thumb or finger over the receiving end

of the duct.

d. Push cable through the duct until it stops against the Pulling Eye

e. Place a mark on the Cable about 1" (25 mm) behind the Rear Guide

f. From the Rear Guide, pull out approximately 8' (2.4 m) of cable from the blower

g. Lower the Tractor Drive

h. Turn on the tractor drive and allow cable to move until it stops. Note the push

force setting.

i. Increase push force slightly

j. Repeat steps f through i until the cable folds over or you reach maximum push

force setting. If the tractor drive belt is slipping on the cable, tighten the tractor

drive down screw and repeat steps f through i. You will notice cable fold-over

because the line drawn on the cable will disappear inside the machine or duct

k. Reduce push force slightly if cable fold-over has occurred and test once more

to ensure no fiber fold-over or damage occurs at this setting. This will be

maximum push force setting for this application

l. Reset the speed to the minimum and remove test fiber and duct

m. Test complete

13

Page 14

Blower Operations

A. ENGAGE AIR

Start compressor. Slowly open the air control valve to allow air flow to the air block by

turning the control valve knob clockwise.

7.

IMPORTANT: Do not exceed 175 PSI when operating the unit.

!WARNING: Forced air creates flying debris. Always wear personal

protective equipment.

B. VERIFY ADJUSTABLE PUSH FORCE

Verify adjustable push force is set to the established crash test value and the speed is

at minimum.

C. ENGAGE TRACTOR DRIVE

The tractor drive can be operated in forward and reverse. For installation, engage the

tractor drive in forward by depressing the tractor drive control switch to the “F” position

as shown. (See figure 13).

D. ADJUST SPEED

Use the Speed control knob to adjust the tractor drive speed to ensure smooth

installation and match the amount of air pressure being used so that the forces are

working together, not against one another. (See figure 14). Counterclockwise

increases speed and clockwise decreases speed.

E. INSTALL FIBER

14

Figure 13. Tractor Drive Forward

Figure 14. Adjust Speed Control

Page 15

Tear Down Procedures

!WARNING: Air Block Assembly contains compressed air when blower is

operated. Opening Air Block while under pressure may cause serious

personal injury. Ensure blower is depressurized before removing Air

Block cover.

A. REMOVE POWER FROM UNIT

1. Turn off compressed air by closing the Air Control Valve at the blower.

(See figure 15). Shut off air at the compressor and decompress air hose.

Depressurize the air block by turning the air control valve counterclockwise.

(See figure 16). Remove air hose when system is relieved of pressure.

8.

Figure 15. Turn Off Air

2. Raise Tractor Drive by turning down screw counterclockwise. (See figure 17).

3. Disconnect battery cable

B. REMOVE FIBER FROM BLOWER

1. Loosen the knob on the Air Block assembly and open the air block.

(See figure 18).

Figure 16. Depressurize Air Block

Figure 17. Raise Tractor Drive

2. Remove duct pack assembly.

3. Open duct pack assembly and remove the conduit.

Figure 18. Loosen Knob

15

Page 16

9.

Maintenance

Procedure Daily Weekly Monthly 60 Days 90 Days

Clean all assemblies and

components thoroughly

Inspect fasteners and screws X X X X X

Check Belt Tension. Replace if

excess wear has occured

A. TRACK CLEANING AND TIGHTENING

1. Inspect track before and after each use.

2. Clean after each use, or when necessary. Remove the top assembly to clean

thoroughly by:

•Unscrewingtractordownscrewalltheway

•Separatingthetwohalves–notepartsbeingdisassembledtoease

reassembly

B. REPLACEMENT OF THE DRIVE BELT

The drive belts need to be replaced when the machine is unable to tractor drive the

specified range of cable diameters. Only genuine spares should be used otherwise the

machine may be unsafe and void warranty.

X X X X X

X X X X X

1. Remove front cover plate and plastic guard from top half assembly

(See figure 19).

Figure 19. Remove Front Cover Plate

16

Page 17

2. Loosen tension screw on side of top assembly with allen wrench until the pulley

can slide enough to free the belt (See figure 20).

Figure 20. Loosen Tension Screw

3. Remove the belt (See figure 21).

Figure 21. Remove the Belt

4. Install new belt.

5. Tighten tension screw on side of top assembly to 40 in-oz.

6. Repeat steps for bottom assembly (if required).

17

Page 18

Troubleshooting Guide

Problem Solution

10.

Cable becomes jammed in the conduit

system.

Tractor Feed does not pull the cable off

the reel.

Blower cuts out with electronic error of

minspeed or highspeed error.

1. Inform the people at the other end of

the conduit that a problem has been

experienced and the operator is going to

shut down the system.

2. Shut off the pneumatic air supply with the

Air Control Valve turning it to the 9 o’clock

position, allowing the air pressure to be

depressurized from the conduit and the

air block.

3. Using the counter or the measurement on

the cable, determine where the

blockage might be located.

4. Notify supervisor about problem and

determine a solution accordingly.

Assist the reel by pushing it, and/or by pulling

the cable off the reel.

Blower has exceeded the minimum or

maximum speed allowance. Adjust speed

accordingly, or wipe cable clean from mud

and dirt.

The cable run is hard to restart after

having stopped.

Tractor feed doesn’t start.

Put air to the system with the track down. The

tractor feed can be restarted after the air

pressure has increased and stabilized.

Tractor Drive switch is in the neutral "center"

position. Select forward or reverse.

18

Page 19

Gulfstream 200 Replacement Parts

02290722

02290724

02290725

02290727

02290834

08230675

08783026

08783065

08783070

08783075

08783051

08783052

08783053

KNURLED THUMB KNOB(BRASS)-BELT CLAMP FORCE

MINI-GAUGE - 200PSI

MINI BALL VALVE 1/8NPT

3PIN CORDSET

KNURLED THUMB KNOB-DUCT CLAMP

POLY LUBRICANT 6PAC - 8OZ BOTTLE

BATTERY CLIP ASSEMBLY

KIT, BELT V-GROOVE GS200 (2 Belts)

KIT, BELT SMALL FIBER GS200 (1 Flat/1 V-Groove)

KIT, BELT FLAT GS200 (2 Belts)

DUCT CLAMP INSERT ASSY 5.0-7.0MM

DUCT CLAMP INSERT ASSY 8.5-10.0MM

DUCT CLAMP INSERT ASSY 12.0-12.7MM

Battery & Charger Replacement Parts

US

(08783050)

INTERNATIONAL

(08783050-EU)

08783055 BATTERY, DEwALT 12V LI-ION

08783056 CHARGER, BATTERY DEwALT 12V LI

02290858 BATTERY, DEwALT 10.8V EURO

02290859 CHARGER, BATTERY DEwALT 10.8V EURO

11.

Common Parts Kit

08783072 COMMON PARTS KIT (INCLUDES THE FOLLOwING)

08783054 1 PLASTIC CASE

02290837 1 HEx KEY SET

08783074 1 1.5MM CABLE SEAL KIT (5 PCS)

08783057 1 2.0MM CABLE SEAL KIT (5 PCS)

08783058 1 2.5MM CABLE SEAL KIT (5 PCS)

08783064 1 3.0MM CABLE SEAL KIT (5 PCS)

08783059 1 3.5MM CABLE SEAL KIT (5 PCS)

08783060 1 4.0MM CABLE SEAL KIT (5 PCS)

08783061 1 4.5MM CABLE SEAL KIT (5 PCS)

08783062 1 5.0MM CABLE SEAL KIT (5 PCS)

08783063 1 5.5MM CABLE SEAL KIT (5 PCS)

08783071 1 BLANK CABLE SEAL KIT (5 PCS)

08783076 1 SEAL KIT (INCLUDES ADHESIVE)

08783077 1 O-RING KIT (5 PCS)

SEE BELT KITS 1 FLAT BELT

19

Page 20

A.

APPENDIX

Gulfstream 200 Charts & Drawings

ITEM PART NO DESCRIPTION QTY

1 02290727 CORDSET, 3 PIN, IM, FS TO MS 1

2 08783026 CLIP, BELT-BATTERY GULFSTREAM 200 1

20

Page 21

ITEM PART NO DESCRIPTION QTY

1 02288203 CAPSCREW, #6-32X0.50 SHSTALY PL 4

2 02288240 CAPSCREW, #6-32X0.37 BHSS 18-8 3

3 02288636 FITTING, HYD 02-NPT_M; 02-NPT_F 90 2

4 02290723 PLUNGER, SPRING #4-48 .1-.5# 2

5 02290724 GAUGE, MINI 1/8 NPT 200 PSI 1

6 02290725 VALVE, MINI 1/8 NPT BALL WEDGE 1

7 02290726 COUPLING, QC 1/8 NPT 1/4 CPLG 1

8 02290739 SCREW, SHOULDER .250 DIA-.875 1

9 02290740 SCREW, SHOULDER .188 DIA-.500 1

10 02290749 SCREW, SHOULDER .125 #4-40 2

11 02290834 NUT, KNURLED THUMB 10-32 THREADS 1

12 08783020 CLAMP, AIRBLOCK GULFSTREAM 200 1

13 08783025 BLOCK, MANIFOLD GULFSTREAM 200 1

14 08783032 BOLT, SWING #10-32 X 2.0" SS 1

15 08783034 GUARD, FRONT GULFSTREAM 200 2

16 08783035 GUARD, WINDOW GULFSTREAM 200 1

21

Page 22

4

10

15

5

13

2

17

21

9

20

11

3

6

8

14

16

10

19

15

9

20

11

7

1

18

3

12

5

22

22

Page 23

ITEM PART NO DESCRIPTION QTY

1 02152600 CAPSCREW, #2-56X0.50 SHSTALY PL 2

2 02269674 RING, RETAINING 0.250 EXTERNAL A/R

3 02288269 CAPSCREW, 0.25-20X1.25 SHSTALY PL 2

4 02290722 KNOB, BRASS KNURLED, 1/4" SHAFT 1

5 02290728 SPRING, COMPRESS .062-.500-.500 2

6 02290729 SPRING, COMPRESS .041-.360-.750 4

7 02290738 SPRING, COMPRESS .016-.125-.500 2

8 02290742 SETSCREW, .138-32 X .37 HXSO SS 2

9 02290743 CAPSCREW, #2-56X0.188 CSSS 18-8 6

10 08783065 KIT, BELT V-GROOVE (2BELTS) GS200 1

08783070 KIT, BELT V-GROOVE/FLAT (1EA) GS200 OPT

08783075 KIT, BELT FLAT (2BELTS) GS200 OPT

11 08783081 KIT, TAKE-UP SHAFT ASSY - GS200 2

12 08783004 BLOCK, LOWER GULFSTREAM 200 1

13 08783082 BLOCK, UPPER (ASSY)-GS200 (INCLUDES BEARINGS) 1

14 08783006 PLATE, FRAME GULFSTREAM 200 1

15 08783008 PULLEY, T5 25T, GULFSTREAM 200 4

16 08783009 FLANGE, GUIDE GULFSTREAM 200 1

17 08783010 SHAFT, TENSION ADJUSTMENT GS200 1

18 08783011 SHAFT, GUIDE 1/4" FLAT GS200 2

19 08783018 SLEEVE, BUSHING, 3/8" GULFSTREAM 200 1

20 08783030 PLATE, COVER BELT TENSION GULFSTREAM 200 2

21 08783079 SHAFT, SENSOR (ASSY) GS200 1

22 12001302 NUT, 0.37-16 HEX ST GR5 CZ 1

23

Page 24

Condux International, Inc.

P.O.Box247•145KingswoodDrive,Mankato,MN56002-0247USA

1-507-387-6576•1-800-533-2077•FAX1-507-387-1442

www.condux.com•e-mail:cndxinfo@condux.com

© Copyright 2013, Condux International, Inc.

Printed in USA

Literature Part Number: 08783049

Revision Number: 1.1

Loading...

Loading...