Page 1

USER'S GUIDE & SAFETY MANUAL

Deluxe Blower

Patent # 6264171

Page 2

Important Safety Notice

Read and understand all procedures and safety instructions before using the Deluxe Blower. Observe all

safety information on this page and note specific safety requirements as explained by procedures in this

manual. Failure to follow these instructions could result in serious personal injury or death.

ADVERTENCIA:

Favor de leer y comprender todas las instucciones de operación y seguridad antes de usar la máquina. Si

Ud. no comprende las instrucciones favor de consultarle a su jefe.

READ MANUAL

FIRST

Save this user’s guide for future reference.

COMMUNICATIONS WITH THE MANUFACTURER

For any information related to the machine (use, maintenance, spare parts) always state Model, Serial

Number, Manufacturing Year and Order. This data can be found in the machine identification table.

Manufacturer:

Condux International Inc.

145 Kingswood Drive

Mankato, MN 56002-0247

1-507-387-6576

Fax 1-507-387-1442

Internet: http://www.condux.com

E-mail: cndxinfo@condux.com

If you have questions on:

SAFETY - OPERATIONS - APPLICATIONS

CALL 1-800-533-2077

2

Page 3

Table of Contents

General Information ..........................................................................4

1

Technical Specifications ......................................................................6

2

A. Hydraulic ..........................................................................6

B. Condition of Use ....................................................................6

C. Air Compression Requirements ........................................................6

D. Operational Capacities ...............................................................8

E. Electronic Control Box ...............................................................8

F. Physical Specifications ...............................................................8

G. Acoustic Emission ..................................................................8

H. Caterpillar Drive Specifications .........................................................8

I. Conduit Coupling Requirements ........................................................8

Safe Operating Procedures ....................................................................9

3

A. Work Area Safety ...................................................................9

B. Hydraulic Devices ...................................................................9

C. Pneumatic Devices ..................................................................9

D. Electric Devices ....................................................................10

Unpacking the Deluxe Blower .................................................................10

4

A. Blower Components ................................................................10

B. Tools and Materials .................................................................10

Set Up the Blower ..........................................................................11

5

A. Attach Blower to Job Box ............................................................11

6

Cable Crash Test ...........................................................................12

Pressure Test Conduit .......................................................................17

7

Prepare Conduit for Cable ....................................................................22

8

Prepare Cable .............................................................................25

9

Final Set-Up ..............................................................................27

10

11

12

13

14

15

16

A. Final Inspection ....................................................................28

Blower Operating Instructions .................................................................28

A. Observer at Exit Pit .................................................................28

B. Connect Hydraulic Systems ..........................................................28

C. Set up the Electronic Control Box ......................................................29

D. Panel Layout ......................................................................30

E. Traction Control .................................................................... 32

F. Operation .........................................................................32

Tear Down Procedures ......................................................................34

A. Remove Power from Unit ............................................................34

B. Remove Cable from Blower ..........................................................35

C. Separate Unit from Conduit ..........................................................35

Maintenance ..............................................................................36

A. Track Cleaning & Tightening ..........................................................36

B. Replacement of Drive Belt ...........................................................36

Troubleshooting Guide .......................................................................38

Appendices ...............................................................................39

A. Blower with Job Box ................................................................39

B. Upper Drive Shaft Replacement Kit ....................................................40

C. Lower Drive Shaft Replacement Kit ....................................................41

D. Hydraulic Motor Replacement Kit ......................................................42

E. Idler Bracket Bushing & Idler Bracket Screw Replacement Kits ...............................43

F. Air Block Assembly Replacement Kits ...................................................44

G. Counter Clamp Roller & Cable Guide Replacement Kits ....................................46

H. Timing & Takeup Roller & Idler Roller Replacement Kits ....................................47

I. Hydraulic Coupler (Male) Replacement Kit ...............................................48

J. Hydraulic Coupler (Female) Replacement Kit .............................................49

K. Clamp Adjustment Replacement Kit ....................................................50

L. Lower Counter Roller Replacement Kit ..................................................51

M. RH Cable Guide Roller Replacement Kit ................................................52

N. LH Cable Guide Roller Replacement Kit ................................................53

O. Counter Spring Replacement Kit ......................................................54

P. Base Mount ......................................................................55

Q. Pneumatic & Electrical Circuits .......................................................56

R. Hydraulic Circuit ...................................................................57

S. Hydraulic Flow Control Valve .........................................................58

T. Possible Wear & Replacement Parts & Accessories ........................................59

Warranty Information ........................................................................67

3

Page 4

1.

General Information

The operating instructions contain a full description of the Deluxe Blower, which has

been designed for the purpose of feeding fiber optic cable through round conduits of

uniform cross section. The conduit must previously have been installed underground

or overhead to receive the fiber optic cable and must be of sufficient length on exit to

be received by the machine. The conduit must be made of material with sufficient

compression strength for it to be adequately sealed in the exit of a machine. The

conduit must be airtight up to a pressure of 175 psi (12 bar). For this purpose,

connectors of screw, compression or fusion type must be used. Conduits from

(10 mm) to 1.97" (50.00 mm) and fiber optic cables from 1/4" (6 mm) to 1.13"

(28.7 mm) diameter can be accepted by the machine.

Fiber optic cable is fed into the conduit by combining pulling and pushing forces,

which draw the fiber optic cable through the conduit. The pulling force is achieved

by connecting the leading end of the fiber optic cable to a piston or carrier, which

fits exactly into the conduit to make an airtight seal. Air under pressure is fed in

behind the carrier causing it to be forced through the conduit. As the carrier moves

through the conduit, it pulls the fiber optic cable behind it. The fiber optic cable is

continuously pushed into the conduit by a tractor drive. This consists of two

caterpillar tracks, which grip the top and bottom of the fiber optic cable moving it into

the conduit. This ensures the fiber optic cable is always free as it moves into the

conduit and reduces the magnitude of the pulling forces needed to carry the leading

end through. Special lubricants are used to make it easier for the carrier to pass

through the conduit.

The exit of the machine consists of an air box that is made in two halves that clamp

together. The air box contains special removable seals on entry and exit, which

clamp around either the end of the conduit or the fiber optic cable to be fed into the

conduit. The seals can be changed to accommodate different conduit and fiber optic

cable sizes. The conduit is clamped between a pair of seals at the entrance to the

air block. A clamp located in front of the entrance to the air block holds the conduit

mechanically to prevent it from moving axially. The fiber optic cable enters through

two seals located in an aluminum nozzle that splits in half. The aluminum nozzle is

located in the entrance to the air box and is shaped to ensure an airtight seal around

the fiber optic cable. When the two halves of the air box are closed, air pressure is

admitted into the space between the seals on entry and exit.

The use of the Deluxe Blower for operations different from those discussed in this

manual are considered extremely dangerous and thus forbidden. The non-respect for

the

prescribed restraints of the machine causes a situation of improper use and relieves

the manufacturer from any responsibility, civil or penal. The manufacturer’s

responsibility declines even when one of the following happens:

a. The consequences caused by tampering and/or modifications carried out

without the manufacturer’s written acceptance.

b. The use of imitative spare parts.

c. Bad maintenance.

d. Use with disconnected safety devices.

e. The connection to machine and/or parts not produced and not directly

authorized by the manufacturer in a written acceptance.

The Deluxe Blower is a unique device for inserting fiber optic cable directly into

conduit. The Deluxe Blower is comprised of an air block and a tractor drive that,

4

when combined with an air compressor and a hydraulic power unit, will propel fiber

Page 5

optic cable measuring from 1⁄4" to 1.13" (6 mm to 28.7 mm) into an unobstructed,

unoccupied, airtight conduit run at speeds of 0 to 300 feet per minute (0-91 m/min).

A cable carrier must be placed at the front end of the cable.

The Deluxe Blower greatly reduces pulling stress on the cable. When equipped with

the electronic counter box, the tractor drive will automatically shut down if the cable

hits an obstruction or if it begins to slip on the tractor drive.

The blower comes standard with job box, hydraulic hoses with couplings, digital

LCD electronic counter box, and an adjustable control valve to the tractor drive for

speed adjustment.

GENERAL MACHINE USE

a. Only qualified operators should use the machine. The operator should only be

the person who received qualified training from the product owning company or

trained by the manufacturer.

b. Machine must only be used for the work it was designed for.

c. Machine is not to be used with unauthorized personnel on the job site.

d. Should there be any doubt concerning use, functioning, maintenance or

anything else, please contact the factory or factory representative.

OPERATOR QUALIFICATIONS

a. Operator must know the required safety directives to run the machine that are

pertinent to the country where it is being used.

b. Operator in charge of the machine and installation project must be appropriately

dressed, avoiding large clothes, hanging jewelry or whatever might become

entangled in the moving parts.

c. Operator must also wear the necessary protective equipment such as gloves,

boots, helmet, etc.

d. Operator must carefully follow all advisements contained in the instruction

manual or on the machine.

e. Operator must have work area kept clean of obstacles that might inhibit a safe

working area.

MAINTENANCE QUALIFICATION

a. All of the machine maintenance must be carried out with the machine on a level

surface and not attached to any form of power source: electrical, pneumatic, nor

hydraulic.

b. Authorized and trained personnel must do all maintenance operations. Trained

personnel are defined as people who have received qualified training from the

using company or from the manufacturer.

5

Page 6

2.

Technical Information

A. HYDRAULIC SYSTEM REQUIREMENTS

•HydraulicOperatingPressure:1500psi(103bar)maximum

•HydraulicFlow:6.8gpm(20.8l/m)maximum

•HydraulicCircuitType:OpenCenter

•5micronfiltration

•FittedwithBHTMAstandard1/2"flatfacedquickreleasecouplings

•Propersizedpowerunitshouldbeusedtoruntheblowermachineto

prevent overheating

IMPORTANT: Operators must take any precautions that may have been

recommended by the suppliers of lubricants or hydraulic fluids. This applies to

the use and disposal of lubricants and hydraulic fluids including the

lubricant used to ease the passage of fiber optic cables through conduits.

B. CONDITION OF USE

Temperature from 21° F ( -6° C) to 110° F (+43° C)

Humidity from 30% to 90% +/- 5%

Weather conditions relevant to working conditions

Natural and/or artificial lighting of the work site, minimum 200 lux

C. AIR COMPRESSOR REQUIREMENTS

•PneumaticPressure:175psi(12bar)Maximum

•RequiredFlowCapacity:375SCFM(11m3/min)Maximum

•ConduitSize:10mm-1.97"(50mm)OD

•Aircoolersarerecommendedforblowingfiber

•Compressorflowmayneedtobedoubledifblowingdistanceisgreaterthan

3,500 feet (1,067 meters)

•AirhosefittingsneedtobecompatiblewithDixon“AirKing”universal

couplings.

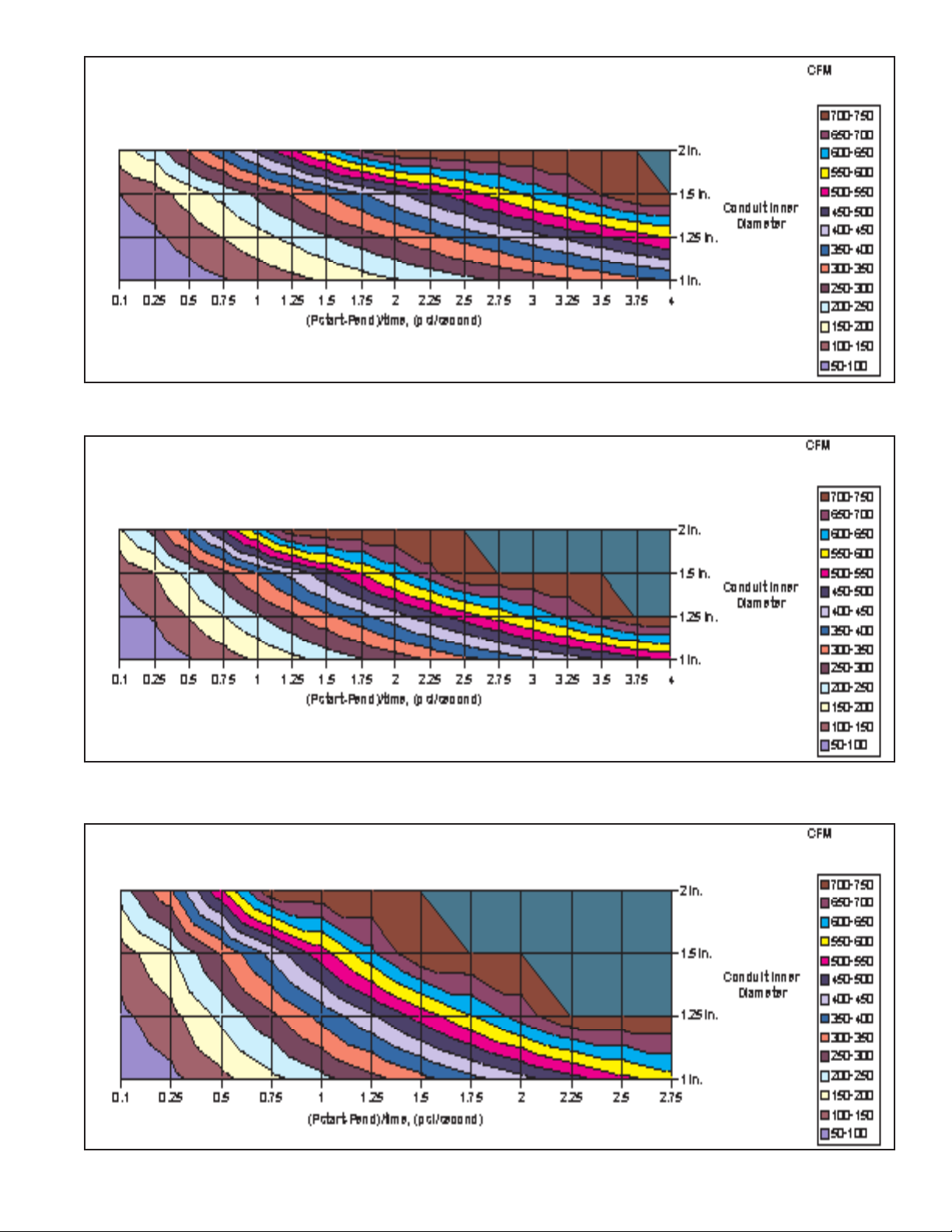

The following charts help to determine the compressor size requirement based on

testing the conduit system (Figures 1-3).

1. Pressurize the conduit up to the maximum compressor pressure. That is the

Pstart - value.

2. Time for 10 seconds and record the ending pressure, Pend.

3. Subtract Pstart-Pend and divide by 10.

4. Find the appropriate x value and approximate length of conduit run then correlate

that information with the size of the conduit on the graph. The resulting zone is the

approximate compressor requirement.

6

Page 7

Figure 1. Compressor Sizing for 3,280 ft (1,000 m) of Conduit Run

OUT OF RANGE

Figure 2. Compressor Sizing for 4,921 ft (1,500 m) of Conduit Run

OUT OF RANGE

Figure 3. Compressor Sizing for 8,202 ft (2,500 m) of Conduit Run

7

Page 8

D. OPERATIONAL CAPACITIES

•PushingForce:175lbs(778N)maximum

•PushingSpeed:300ft/min(91m/min)maximum

•CableSizes:.25"to1.13"(6mmto28.7mm)

•ConduitSizes:1/2",3/4",1",1-1/4"TRUE,1-1/4",1-1/2"SDR11&13.5,

2" and metric O.D. conduit; 10 & 12 mm, 12.7 mm, 14 mm, 16 mm,

18 mm, 25 mm, 32 mm, 36 mm, 37 mm, 40 mm, 42 mm, 44 mm, 46 mm

and 50 mm

E. ELECTRONIC CONTROL BOX

•PowerRequirements:12voltsDC

•Powerconsumptionis24Watts

•Powerconnectionmustbetoautomotivepowerpointorpowerpoint

connection on Condux hydraulic power unit

•Fusedwitha2.5ampfuse,250volt-5x20mm-GMAtype

•Displays:TotalMachineDistance,DistanceofRun,OperationalSpeed,

Errors Descriptions

•AutomaticShutdownSpeeds:300ft/min(91m/min)maximum

F. P H YSICAL SPECIFICATIONS (DOES NOT INCLUDE LEGS OR JOB BOX)

•Height 16.5"(419mm)

•Length 30"(761mm)

•Width 14.8"(375mm)

•Weight 82lbs(37kg)

G. ACOUSTIC EMISSION

•Levelofmax.soundpressuretotheoperatorseat(ISO11202)Lep=85dB(A)

H. CATERPILLAR DRIVE SPECIFICATIONS

•Maximumpushingforce:175lbs(778N),dependingoncablediameter

•Maximumpushingspeed:300ft/min(91.5m/min)

•Maximumclampingforce:<114lbf/in(20N/mm)

•Independentpushingdrivebeltswithpolyurethanepadsprofiledforcable

0.23" (5.8 mm) to 1.13" (28.7 mm)

•Mechanicalgaschargedshockabsorberclamptopreventcablecrush.

•Side

guards.

I. CONDUIT COUPLING REQUIREMENTS

•Mustwithstandmaximumairpressureof175psi(12bar).

•Mustwithstandaxialloadingandvibration.

•Mustbescrewtype,compressiontype,orfusiontype.

•SightHolesmustbesealed.

•Mustfitsnugly.

•Conduitendsmustbecutoffsquarelyanddeburred.

•Conduitmustbefullyseatedintothecoupler.

•Couplersshouldbeinstalledinastraightsectionofconduit.

•Mustbesamesizeconduit.

8

Page 9

Safe Operating Practices

Read and understand all procedures and safety instructions before using the Deluxe

Blower. Observe all safety information on this page and note specific safety

requirements as explained by procedures called out in this manual. Failure to follow

these instructions could result in serious personal injury, property damage or death.

A. WORK AREA SAFETY

1. Wear personal protective equipment: hard hat, safety glasses, safety shoes, and

leather work gloves.

2. The safe operation of this equipment requires that the operators be on

stable footing.

3. Stay clear of cables or lines under tension.

4. Stay clear of pressurized line and conduit.

5. Stay out of manhole while blower is in use.

6. Use the blower only for its intended purpose. Do not use the tractor drive

without the air block to push or pull cable.

7. Do not place cable reel too close to unit. Place the reel far enough away from

the unit to ensure proper control.

8. Do not tamper with relief valves or pressure reducing valves.

9. Place cable grip on end of conduit to catch cable carrier and cable.

10. Keep hands away from tractor drive while blower is in operation.

B. HYDRAULIC DEVICES

Escaping fluids under pressure can penetrate the skin and cause serious personal

injury. Observe the following precautions to avoid hydraulic hazards:

1. Tighten all connections before applying pressure. Relieve pressure when

connecting or disconnecting hoses when servicing the unit.

3.

2. Check for leaks with a piece of cardboard. Do not use your hands!

3. Do not exceed working pressure of hydraulic hoses.

4. Visually inspect hoses regularly and replace if damaged.

C. PNEUMATIC DEVICES

The Deluxe Blower is a pneumatic device, using pressurized air to project cable at

high velocities. Please observe the following precautions when operating the blower:

1. Forced air creates flying debris. Always wear personal protective equipment.

Severe personal injury could result.

2. Ensure no personnel are in the destination access vault during the blowing

operation. Severe personal injury could result.

9

Page 10

4.

D. ELECTRIC DEVICES

The electronic counter box and power supply are electrical devices. Electric shock

hazards exist that could result in severe personal injury or death. Observe the

following precautions to avoid electrical hazards:

1. Do not operate in or near water. This includes setting the electronic counter box

or battery pack on a wet surface or exposing them to rain.

2. Do not remove cover of electronic counter box. There are no user-serviceable

parts inside. Refer servicing to qualified service personnel.

3. The electronic counter box power switch should be in the off position before

connecting or disconnecting any cords.

Unpacking the Blower

A. BLOWER COMPONENTS

Each Deluxe Blower Package contains the following items.

•Hydraulichosefromhydrauliccontrolassemblytohydraulicpowerunit

•Owner’sManual

•ShippingCrate

•Metric&StandardAllenWrenchSet

•

•

•VenturiAirPlug

•PlasticDividedCasew/PartsLabel

•PartsandUserManual

•1Qt.BlowingLubricant

•CapscrewSet(10)(M04-0.7’s)

•O-RingSealKit

3

⁄8" Drive Ratchet & 9⁄16" Deep Well Socket

5

⁄8" x 600 lb. Swivel

10

NOTE: If any parts are missing: please contact your Condux representative or call

Condux International at 1-800-533-2077 (USA or CANADA), or 1-507-387-6576.

B. TOOLS AND MATERIALS REQUIRED

The tools and materials are necessary to connect the Deluxe Blower to a hydraulic

power source, and to change the inserts:

1. Allen Wrench (

2. Allen Wrench (2.5 mm)

3. Allen Wrench (5 mm)

4. Screwdriver, Flat

5. Screwdriver, Phillips

6. 3⁄8" Drive Ratchet

7.

9

⁄16" Deep Well Socket

3

⁄32")

Page 11

Set Up the Blower

This manual contains setup and operating instructions for the Deluxe Blower with

job box.

IMPORTANT: The Deluxe Blower must not be located below overhead gantries,

power lines or walkways where there might be a risk of falling objects. The operator

must be wearing recommended protective gear before operating the blower.

Operating light levels should be at least 200 lux of light intensity.

A. ATTACH BLOWER TO JOB BOX

CAUTION: The machine should be removed with two people or lifted

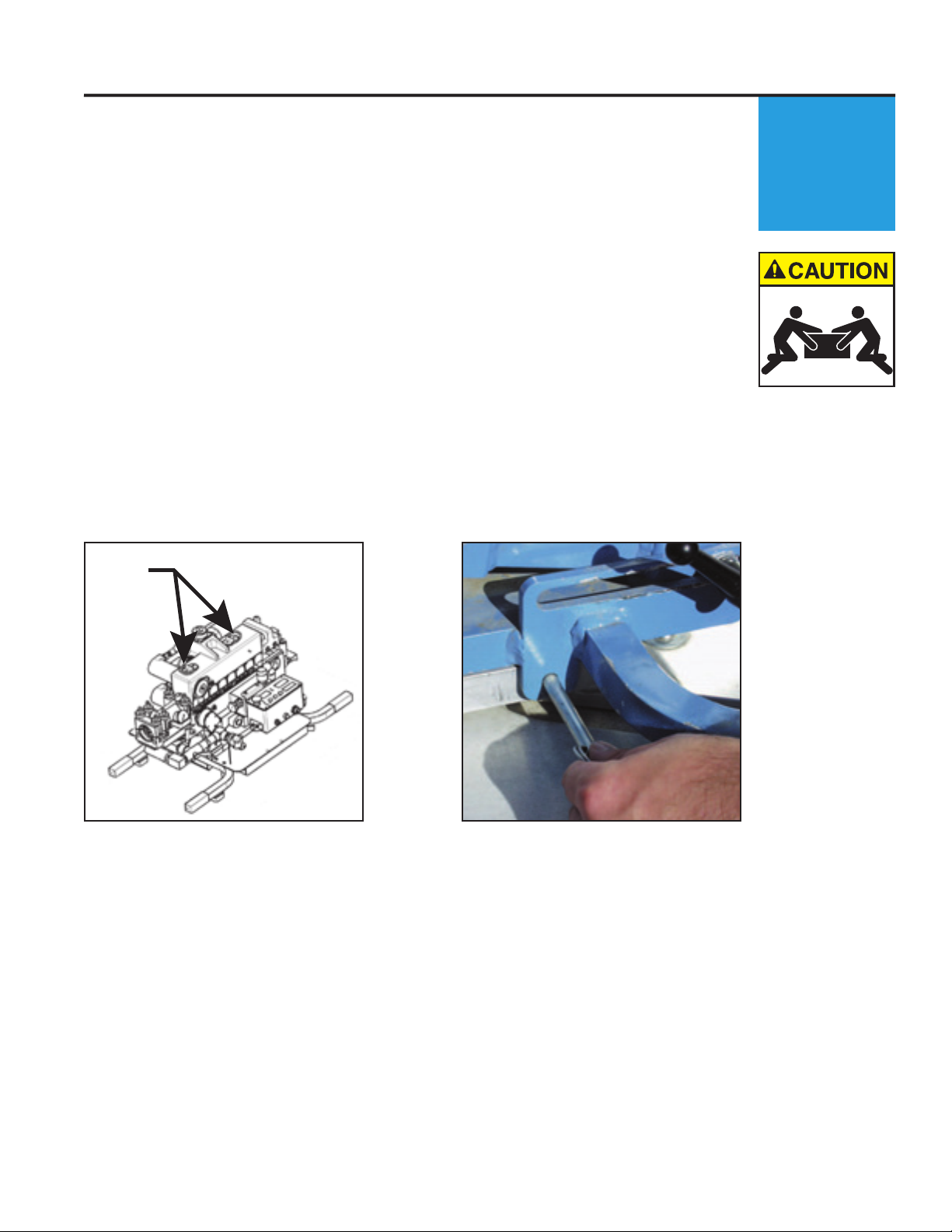

mechanically by the lift rings located on the top of the machine (Figure 4).

IMPORTANT: The Deluxe Blower should not be parked on a slope in excess of 13°.

It should not be parked on a side hill of more that 15°.

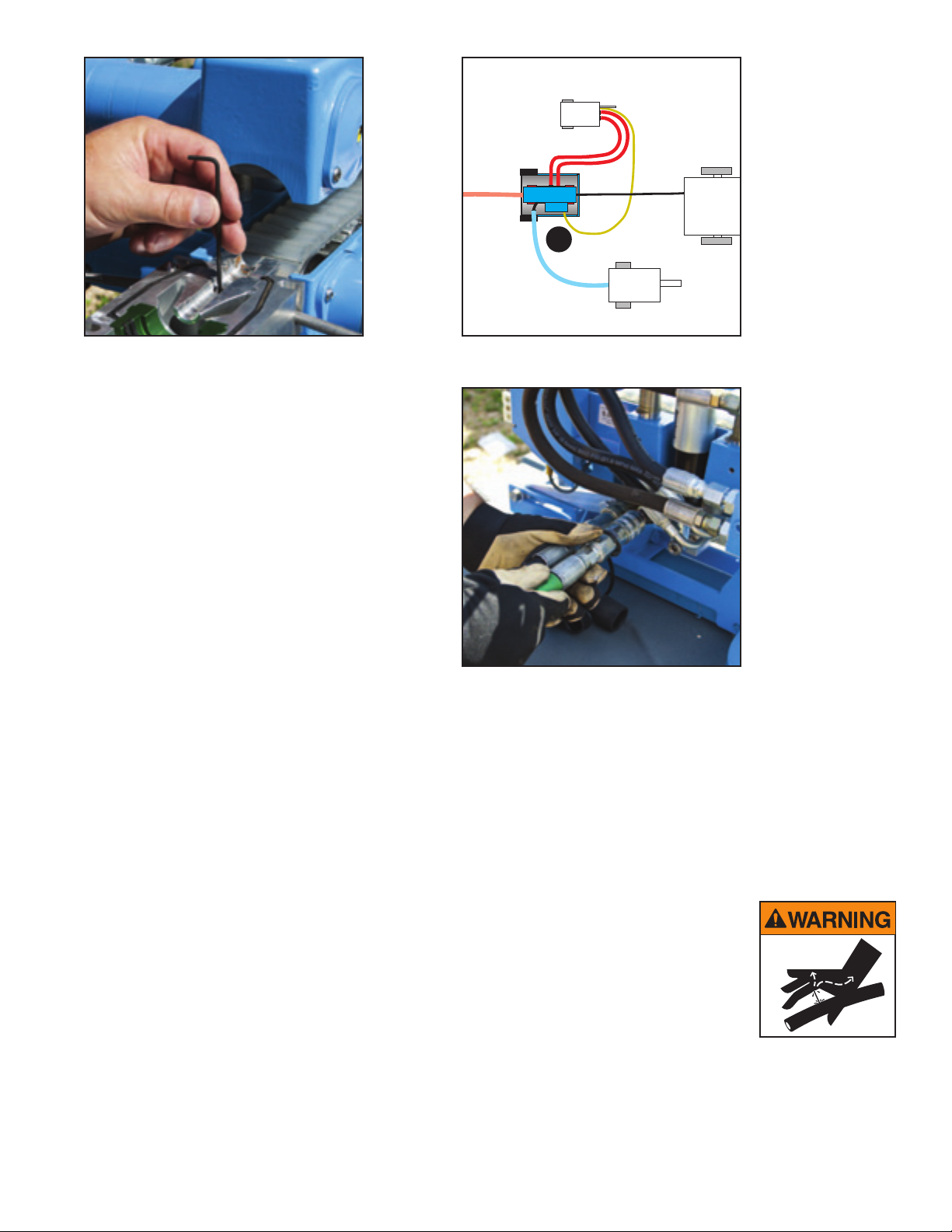

Remove the ball detent pin from the bottom of the blower. Attach the Deluxe Blower

to the job box by aligning the guide tracks on the bottom of the blower with the

channel on the top of the box. Holes in the box channel need to align with holes on

the blower guide track. Once aligned, replace ball detent pin so it locks the blower in

place (Figure 5).

5.

Lift

Rings

Figure 4. Lift out Blower with

Lift Rings

Figure 5. Replace Ball Detent Pin

11

Page 12

6.

Cable Crash Test

Cable Crash Testing is a very quick and easy step to be completed before attempting

the installation of cable with the Deluxe Blower. This test is necessary to set the

hydraulic motor pressure of the blower below the point that it may cause cable

damage as a result of over pushing or encountering an obstruction in the

sub-duct system.

Every cable has different pushing values and these values vary depending on

duct I.D. Example: A cable with a crash test value of 75 bar in 33 mm I.D. duct,

may have a crash value of only 60 bar in a 40 mm I.D. duct. This is because the

area of lateral movement is larger as the duct size increases.

!CAUTION: Always wear protective equipment: hard hat, safety glasses,

safety shoes and work gloves.

NOTE: The hydraulic motor pressure adjustment will have no effect on the

installation speed of the blowing unit. This is not a flow adjustment. This is a

pressure adjustment to prevent damage to the cable that can be caused by excessive

pushing force.

IMPORTANT: For the Crash Test to work properly use the same size cable and duct

that will be used for the job.

Set the hydraulic motor pressure on your Deluxe Blower using the following

procedure.

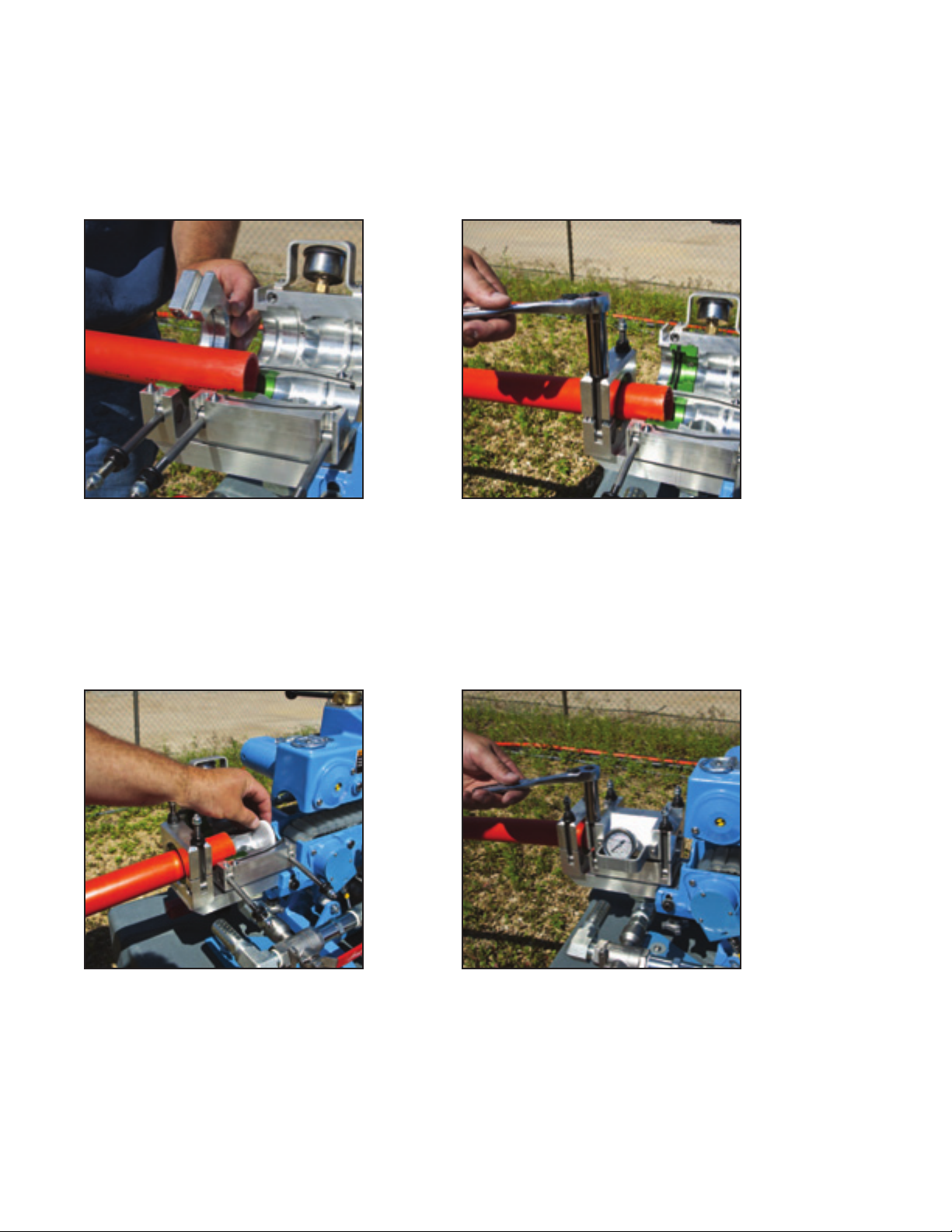

1. Attach 12' (4 m) of duct to the Deluxe Blower (Figure 6).

2. Install Conduit Pulling Eye on the receiving end of the duct (Figure 7).

Figure 6. Placement of Conduit in

Conduit Seal & Conduit Clamp

Figure 7. Installing Conduit

Pulling Eye

12

3. Cut a piece of fiber optic cable 15' (5 m) long. This is your test piece of cable.

4. Attach the correct size Venturi to fit the cable being installed (Figure 8).

Page 13

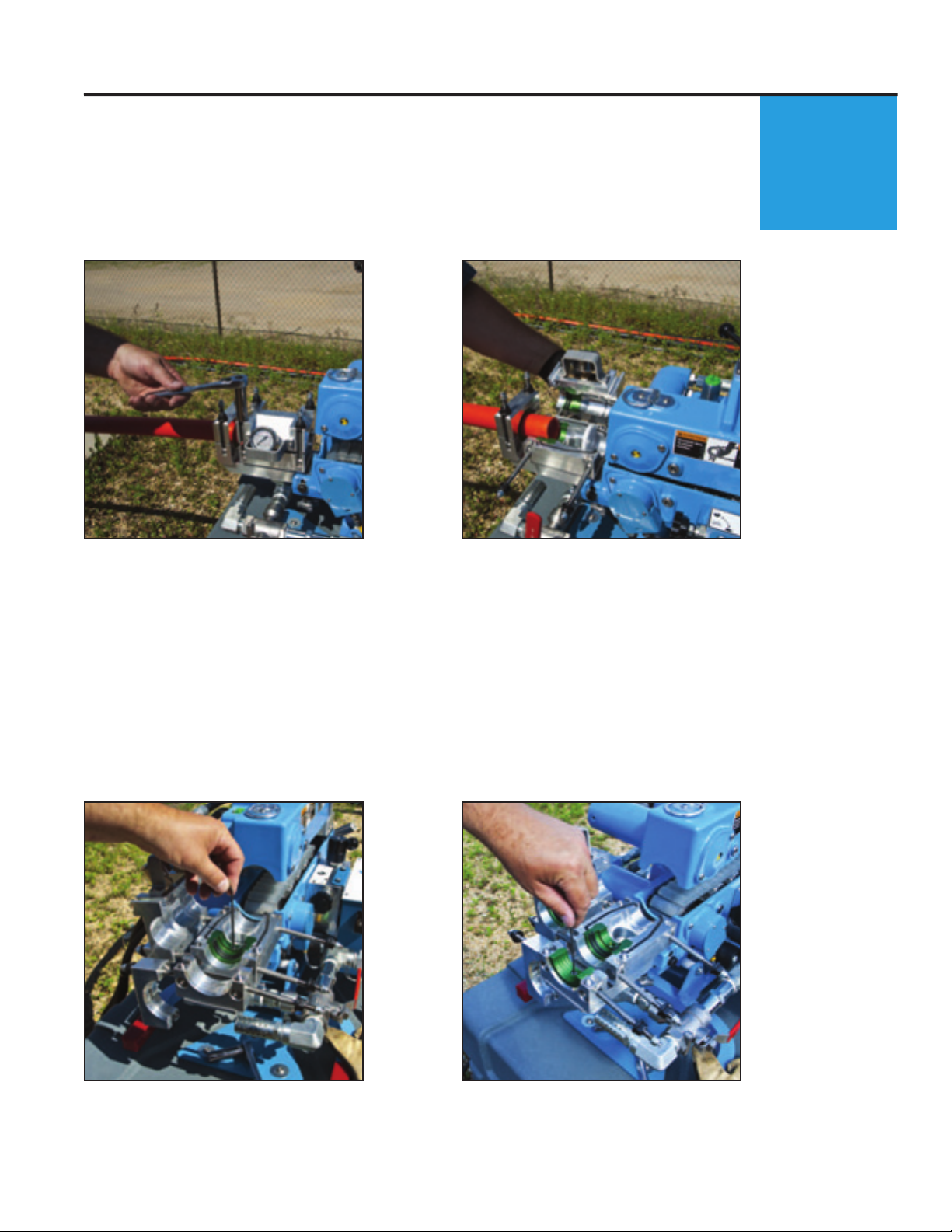

HYDRAULIC

POWER

SOURCE

HYDRAULIC

HOSES

ELECTRICAL HOOK UP

TO POWER SOURCE

Figure 8. Install Venturi

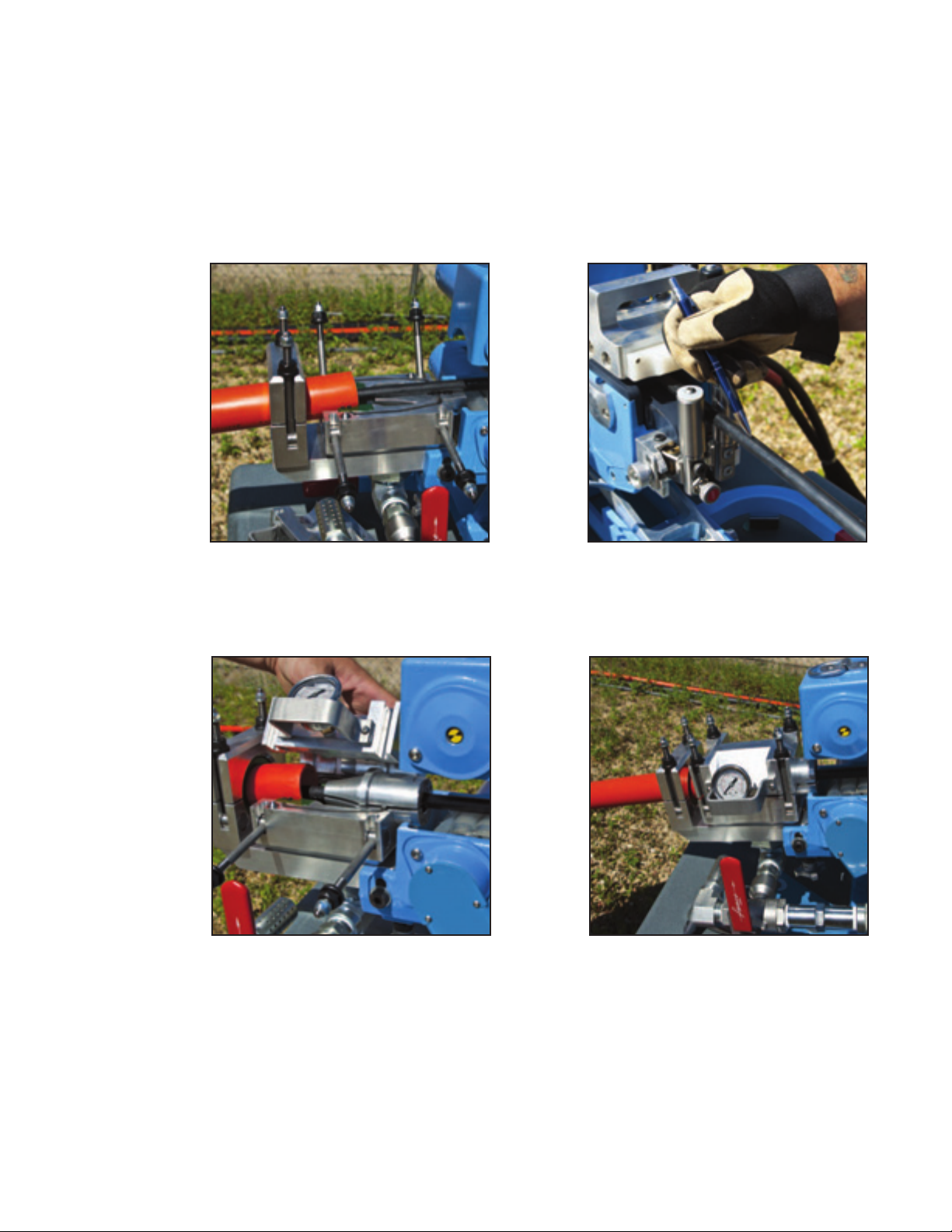

5. Attach Hydraulic Hoses (Figure 9).

The Deluxe Blower’s hydraulic system

uses quick-disconnect couplings.

Keep all connections clean to avoid

contamination and possible system

failure. Use hose end caps (supplied).

A contaminated hydraulic system will

effect the operation of the cable

blower and may invalidate your

product warranty. Take caution in

routing the hoses to prevent a tripping

hazard. Follow these steps to

connect the hydraulic components:

INNERDUCT

DELUXE LW

BLOWER

OPERATOR

AIR HOSE

COMPRESSOR

Figure 9. Typical Set-Up

FIBER

OPTIC CABLE

AIR

CABLE

REEL

A. Attach the quick-disconnect

couplings to the hydraulic power

Figure 10. Attach Hydraulic

Hoses

supply (Figure 10).

B. Start the hydraulic power unit and check all connections for leaks with a

piece of cardboard. In cold weather, run hydraulic power supply until

hydraulic oil warms up.

WARNING: Escaping fluids under pressure can penetrate the skin and

cause serious personal injury. Observe the following precautions to

avoid hydraulic hazards:

•Tightenallconnectionsbeforeapplyingpressure.Relievepressure

before connecting or disconnecting hoses.

•Checkforleakswithapieceofcardboard.Donotusehands!

•Donotexceedworkingpressureofhydraulichoses.Visually

inspect hoses regularly and replace if damaged.

C. Run the blower for approximately 1 minute to remove any trapped air and

then stop the blower and hydraulic power source.

B. ELECTRONIC CRASH TEST

To run the Crash Test utilizing the Electronic Control Boxes PRESSURE LIMIT

feature, follow Crash Test steps 1-5 to set up the blower.

13

Page 14

6. Press Touch Screen “LIMIT: XXXX” to open the Limit keypad.

7. Enter the desired pressure – suggested starting point is 800 PSI.

8. Place Cable in Blower from Rear Rollers through Tractor Drive. Push cable

through the duct until it stops against the Pulling Eye (Figure 13).

9. Place a mark on the Cable about 2" (51 mm) behind the Rear Rollers

(Figure 14).

Figure 13. Install Cable

Figure 14. Mark the Cable

10. Install top Venturi (Figure 15). Close Air Block and tighten (Figure 16).

Figure 15. Install Top Venturi

Figure 16. Close Air Block

and tighten

11. From the Rear Rollers, pull out approximately 8' (2.4 m) of cable from

the blower.

14

12. To avoid start up pressure spikes, which will register on the pressure

transducer and produce a false pressure error, set the Hydraulic Flow Control

to the lowest speed by rotating the flow control knob clockwise until it stops.

Page 15

13. Lower the Tractor Drive Cover, and tighten until the tracks make contact

with the cable. Give one additional turn to the clamp screw.

14. Turn on Hydraulic Power, and press the ECB DRIVE button ON.

15. Increase speed as quickly as possible by turning the Hydraulic Flow Control

counter-clockwise. The Cable should be pushed into the duct. Continue to

speed up the tracks until the cable stops and the ECB gives a

HI-PRESSURE ERROR screen.

16. If a HI-PRESSURE ERROR appears, follow the on-screen instructions to

reset the electronics and return to the Operations screen.

17. Raise Tractor Drive Cover. Pull out 8' (2.4m) of cable from the blower.

18. Lower and tighten Tractor Drive Cover. Repeat steps 6-7 to increase the

pressure by 50 PSI.

19. Repeat steps 12-16 until cable damage

is seen – either in the form of jacket

damage or bends in the cable, the

cable folds over, or you reach 1500 psi.

You will notice cable fold-over because

the line drawn on the cable will

disappear inside the machine or duct.

(Figure 17).

20. Repeat steps 6 and 7 to reduce the

PRESSURE LIMIT by 50 PSI.

21. Remove folded fiber and test again at

current PRESSURE LIMIT settings to

ensure no fiber fold over or

Figure 17. Cable folds over

damage occurs.

22. Remove test piece of fiber optic cable.

23. If the re-test is confirms no cable damage, Re-adjust Flow Control setting to

the slowest speed.

24. Remove test duct piece from the Deluxe Blower.

25. Crash test is complete.

15

Page 16

16

Page 17

Pressure Test Conduit

The conduit system must be able to withstand a maximum pressure of 175 psi, and

be free of leaks. A Conduit Pressure Test Kit, part number 08761457, is available to

perform this test. Conduit may also be tested for pressure using the Deluxe Blower,

follow the steps below.

1. Loosen the 6 nuts on the Air Block assembly (Figure 20). Open the Conduit

Clamp Cover and Air Block Cover (Figure 21).

Figure 20. Loosen Air

Block Assembly

2. Select the correct Conduit and Cable Components according to conduit and

cable size. Refer to the Conduit and Cable Pack selection charts

(Tables 1 and 2, page 18).

Figure 21. Open Conduit Clamp

Cover & Air Block Cover

7.

3. Choose the correct Conduit Seal and install both halves securely. (Figure 22).

4. Choose the correct Conduit Clamp and install both halves (same color as the

conduit seal). (Figure 23).

Figure 22. Install Conduit Seal

Figure 23. Install Conduit Clamp

17

Page 18

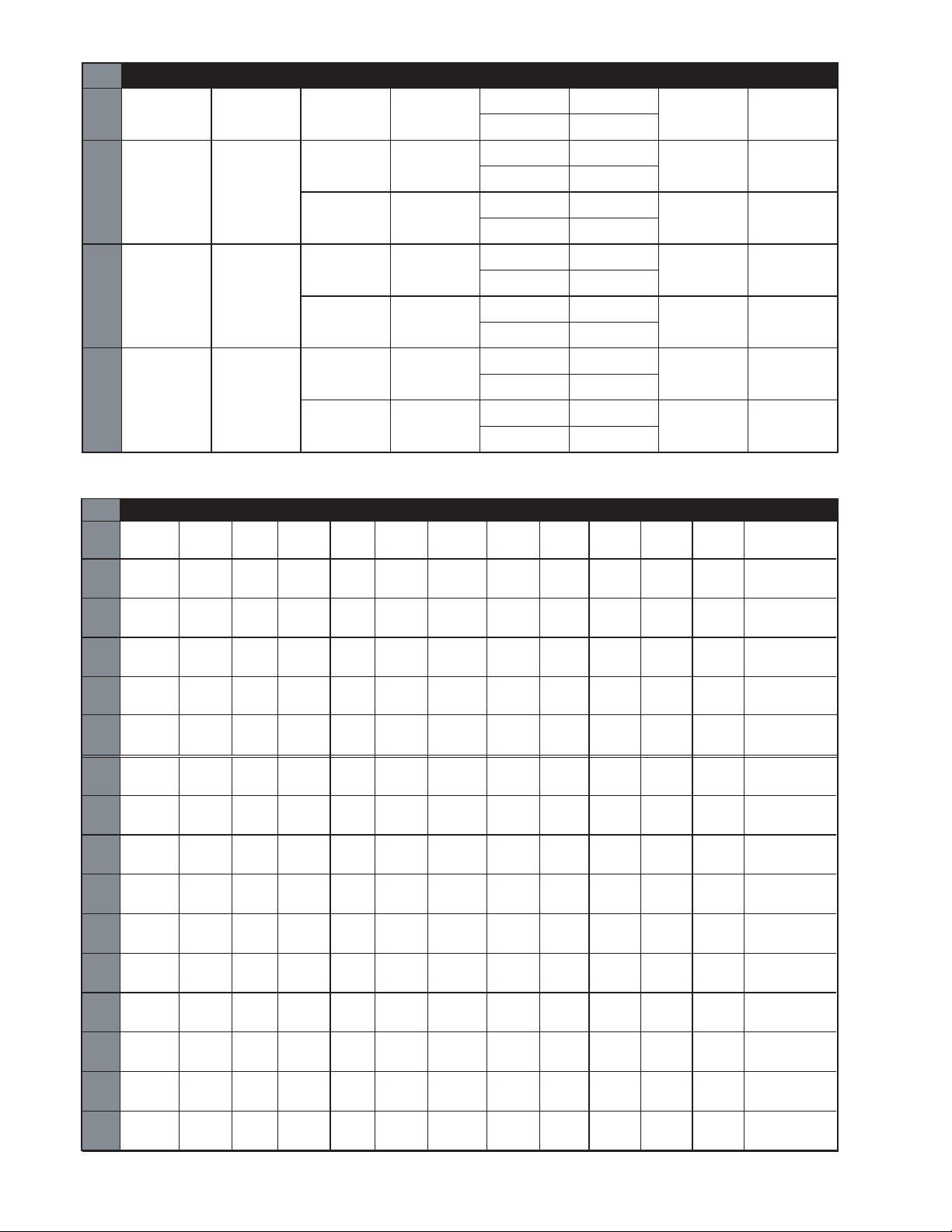

PACK

1

2

3

4

CABLE PACK VENTURI CABLE SEAL CABLE GRIP

Cable OD P/N Cable OD P/N Cable OD P/N Cable OD P/N

0.23-0.34 08780393 0.23-0.34

(5.8-8.8) Pack #1 (5.8-8.8) 0.29-0.34

08780281

(5.8-7.2) 0.21-0.35 08643754

(7.3-8.8)

0.35-0.42

0.23-0.28

0.35-0.48

(8.9-12.2) 0.43-0.48

08780282

(8.9-10.7) 0.32-0.48 08643755

0.35-0.60 08780394 (10.8-12.2)

(8.9-15.2) Pack #2 0.49-0.55

0.49-0.60

(12.3-15.2) 0.56-0.60

08780283

(12.3-14.0) 0.42-0.61 08643756

(14.1-15.2)

0.61-0.67

0.61-0.73

(15.3-18.5) 0.68-0.73

08780284

(15.3-17.0) 0.53-0.74 08643757

0.61-0.85 08780395 (17.1-18.5)

(15.3-21.6) Pack #3 0.74-0.79

0.74-0.85

(18.6-21.6) 0.80-0.85

08780285

(18.6-20.1) 0.64-0.87 08643758

(20.2-21.6)

0.86-0.92

0.86-0.97

(21.7-24.6) 0.93-0.97

08780286

(21.7-23.4) 0.75-1.00 08643759

0.86-1.13 08780396 (23.5-24.6)

(21.7-28.7) Pack #4 0.98-1.04

0.98-1.13

(24.7-28.7) 1.05-1.13

08780446

(24.7-26.4) 1.00-1.24 08643137

(26.5-28.7)

08780406

08780407

08761424

08761425

08761426

08761427

08761428

08761429

08761430

08761431

08761432

08761433

08761434

08761435

(5.3-8.9) 033-29-1194

(8.1-12.2) 033-29-1195

(10.7-15.5) 033-29-1196

(13.5-18.8) 033-29-1197

(16.3-22.1) 033-29-1198

(19.1-25.4) 033-29-1199

(25.4-31.5) 033-03-013

Table 1. Cable Packs

PACK

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

DUCT PACK DUCT CLAMP DUCT SEAL CARRIER FOAM CARRIER CABLE GRIP INNERDUCT EYE

Duct Size P/N Duct OD P/N Duct OD P/N Carrier P/N Carrier OD P/N Duct OD P/N P/N and ID Range

1/2" 08780795 0.84

SDR 11-13.5 Pack #1 (21.30) (21.30) (17.50) (19.0) (19-25) 033-03-012

3/4" 08780680 1.050

SDR 11-13.5 Pack #2 (26.6) (26.6) (19.0) (19.0) (25.4-31.5) 033-03-013

1" 08780386 1.315

SDR 11/13.5 Pack #3 (33.4) (33.4) (28.5) (31.8) (25.4-31.5) 033-03-013

1.25" 08780392 1.660

SDR 11/13.5 Pack #4 (42.2) (42.2) (35.9) (38.1) (38.1-50.5) 033-03-016

1.5" 08780397 1.900

SDR 11/13.5 Pack #5 (48.3) (48.3) (41.1) (44.5) (38.1-50.5) 033-03-016

2" 08780930 2.023

SDR 11/13.5 Pack #6 (51.4) (50.8) (50.8-63.2)

25 mm

32 mm

36 mm

37 mm

1.25" TRUE

40 mm

42 mm

44 mm

46 mm

50 mm

08780240 0.984

08780385 1.260

08780387 1.417

08780388 1.457

08780389 1.500

08780390 1.575

Pack #12 (40.0) (40.0) (33.0) (38.1) (38.1-50.5) 033-03-016

08780391 1.653

Pack #13 (42.0) (42.0) (35.0) (38.1) (38.1-50.5) 033-03-016

08780545 1.732

Pack #14 (44.0) (44.0) (38.0) (38.1) (38.1-50.5) 033-03-016

08780460 1.811

Pack #15 (46.0) (46.0) (33.0) (38.1) (38.1-50.5) 033-03-016

08780575 1.969

Pack #16 (50.0) (50.0) (40.0) (50.8) (38.1-50.5) 033-03-016

_______ _______ _______ _______

Pack #7 (25.0) (25.0) (20.0) (31.8) (25.4-31.5) 033-03-013

Pack #8 (32.0) (32.0) (27.0) (31.8) (31.8-37.8) 033-03-015

Pack #9 (36.0) (36.0) 1.220 (31.0) 08761555 (31.8) (31.8-37.8) 033-03-015

Pack #10 (37.0) (37.0) (31.0) (31.8) (31.8-37.8) 033-03-015

Pack #11 (38.1) (38.1) (31.7) (38.1) (31.8-37.8) 033-03-015

08780791

08780682

08780369

08780375

08780404

08780099

08780368

08780370

08780371

08780372

08780373

08780374

08780546

08780466

08780435

0.84

1.050

1.315

1.660

1.900

0.984

1.260

1.417

1.457

1.500

1.575

1.653

1.732

1.811

1.969

08780786

08780685

08780307

08780051

08780398

08780134

08780306

08780308

08780309

08780333

08780334

08780335

08780547

08780461

08780431

0.688

0.75

1.121

1.414

1.618

0.787

1.063

1.181 (30.0) 08761643 1.25

1.220

1.250

1.299

1.378

1.496

1.299

1.606

08780793

08780690

08761250

08761255

08761260

08761265

08780230

08761560

08761555

08761670

08761579

08761660

08761786

08761579

08761579

0.75

0.75

1.25

1.50

1.75

2.00

1.25

1.25

1.25

1.50

1.50

1.50

1.50

1.50

2.00

08078300

08078300

08761439

08761440

08761441

08761442

08761439

08761439

08761439

08761439

08761440

08761440

08761440

08761440

08761440

08761442

.75-.99 08643131

1.00-1.24 08643137

1.00-1.24 08643137

1.50-1.99 08643149

1.50-1.99 08643149

2.00-2.49 08643155

1.00-1.24 08643137

1.25-1.49 08643143

1.25-1.49 08643143

1.25-1.49 08643143

1.25-1.49 08643143

1.50-1.99 08643149

1.50-1.99 08643149

1.50-1.99 08643149

1.50-1.99 08643149

1.50-1.99 08643149

033-03-017

08761840

.78-.87

(20-22)

08761840

.71-.89

(18-22)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761844

1.37-1.68

(35-43)

08761844

1.37-1.68

(35-43)

08761840

.71-.89

(18-22)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761842

1.06-1.43

(27-37)

08761844

1.37-1.68

(35-43)

18

Table 2. Conduit Packs

Page 19

5. Choose the correct Venturi to fit the cable being installed. Do not install at

this time!

6. Place conduit in the Conduit Seal and Conduit Clamp. Note placement up to

ridge on Conduit Seal (Figure 24).

7. Clamp conduit in place (Figure 25).

Figure 24. Placement of Conduit

in Conduit Seal & Conduit Clamp

Figure 25. Clamp Conduit

in Place

8. Place Seal Disk in Venturi slot. (Figure 26).

9. Close Air Block Cover and secure (Figure 27). Tighten nuts securely, but do

not over tighten. Use a cross-tightening procedure.

Figure 26. Installing Seal Disk

Figure 27. Tighten Air Block

Cover

19

Page 20

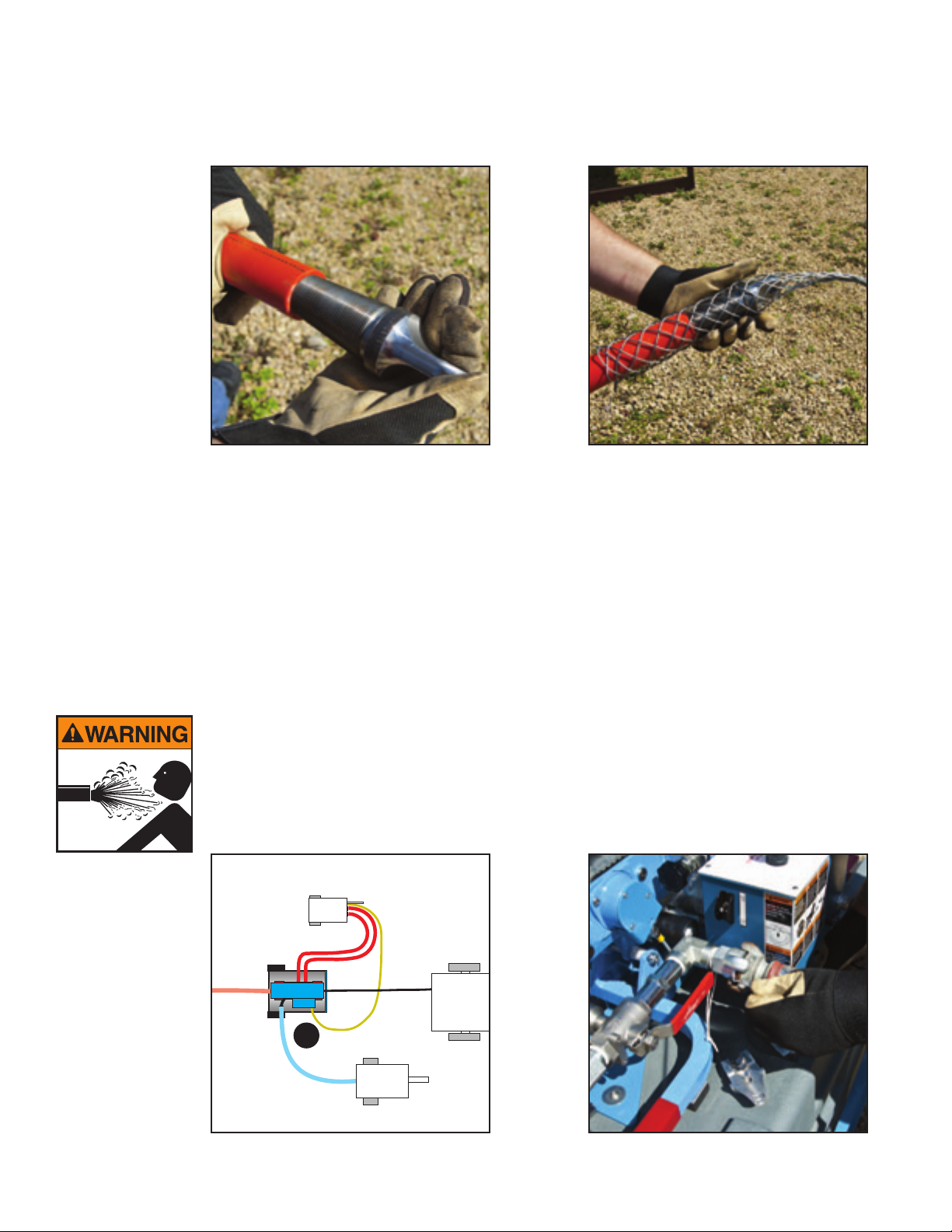

10. Plug receiving end of Conduit with a properly sized Conduit Pulling Eye

(Figure 28) (Appendix R pg. 62).

11. Choose the correct Pulling Grip & install on receiving end of Conduit

(Figure 29).

Figure 28. Installing Conduit

Figure 29. Installing Pulling Grip

Pulling Eye

12. Connect the Air Compressor (Figure 30).

a. Ensure Air Valve is off before connecting air hose.

b. Attach the hose supplied with the air compressor to the air compressor

coupling. The blower air valve assembly is equipped with a claw type

connector. Use safety clips on all pneumatic hose connections (Figure 31).

c. Observe all safety procedures.

d. Route all hoses properly to prevent tripping over them.

!WARNING: Forced air creates flying debris. Always wear personal

protective equipment. Severe personal injury could result.

!WARNING: Ensure no personnel are in the destination access vault

during the blowing operation. Severe personal injury could result.

HYDRAULIC

POWER

SOURCE

HYDRAULIC

HOSES

ELECTRICAL HOOK UP

TO POWER SOURCE

20

INNERDUCT

DELUXE LW

BLOWER

OPERATOR

AIR HOSE

OPTIC CABLE

AIR

COMPRESSOR

FIBER

Figure 30. Typical Connections

CABLE

REEL

Figure 31. Installing Air Hose with

Safety Clips

Page 21

13. Slowly open Air Control Valve. Pressurize conduit to 80-100 psi (5.5-6.9 bar)

(Figure 32).

Figure 32. Open Air Control Valve

Figure 33. Close Air Control Valve

14. Prove conduit integrity.

a. Close Air Control Valve (Figure 33).

b. Conduit must not lose more than 20 psi (1.38 bar) over a 2-minute period.

c. After 2 minutes, relieve air pressure. Open air pressure relief valve by

moving the blower pressure valve handle counter clockwise to the 9 o’clock

position (Figure 34).

d. If conduit fails to hold required pressure, check entire conduit run for leaks

and repair them.

e. Repeat the pressure test until all leaks are found and repaired.

!WARNING: Air Block Assembly contains compressed air when blower is

operated. Opening Air Block while under pressure may cause serious

personal injury. Ensure blower is depressurized before removing Air

Block cover, or removing conduit pulling eye.

15. Decompress the Air Block by

turning the Air Valve to the 9 o’clock

position. Shut off the air at the

compressor, decompress the air

hose and disconnect the air hose

from the fiber blower.

Figure 34. Decompress Air Block

21

Page 22

Prepare Conduit for Cable

1. Remove Conduit Pulling Eye and Pulling Grip from receiving end of Conduit.

After removing pulling eye, re-install pulling grip in order to catch Foam Carrier

during conduit lubrication (Figure 35).

8.

2. Open the Air Block Cover (Figure 36).

Figure 35. Install Pulling Grip on

Conduit

3. Tilt Blower forward (Figure 37).

4. Pour recommended (silicon-based) lubricant into Conduit opening before

Foam Carrier: 1 quart/6000 feet (1 liter/2 km) (Figure 38)

(See Appendix T for lubricant ordering information).

Figure 36. Open Air Block Cover

22

Figure 37. Loosen Handle to Tilt

Blower

5. Insert Foam Carrier (selected according to conduit size) into Conduit

(Figure 39) (See Table 2 on page 18).

6. Insert Seal Disk in venturi slot if not already in place. (Figure 40).

Figure 38. Pour Lube into Conduit

Page 23

Figure 39. Insert Foam Carrier

Figure 40. Insert Seal Disk

7. Close the Air Block Cover. Tighten spanner nuts securely, but do not over

tighten (Figure 41). Use cross tightening procedure with the spanner wrench to

secure completely.

Figure 41. Tighten Air Block

Figure 42. Close Air Control Valve

Cover

8. Prove conduit integrity and spread lubricant through Conduit.

a. Re-connect the air hose to the fiber blower and attach all safety clips.

b. Turn the Air Control Valve handle to the 12 o’clock position and turn on the

air from the compressor (Figure 42).

c. Slowly open Air Control Valve by turning to the 3 o’clock position.

d. Blow Foam Carrier through conduit to spread lubricant and check for

blockage. Follow all safety precautions.

e. After the Foam Carrier exits, close Air Control Valve.

NOTE: Foam Carrier must exit in a reasonable time, allow for approximately

10 seconds per 1,000 feet (300 m) or conduit may be contaminated or blocked.

23

Page 24

9. Ensure Air Block is depressurized. Open air pressure relief valve by moving

the blower pressure valve handle counter clockwise to the 9 o’clock position

(Figure 43). Shut off the air from the compressor, decompress the air in the

hose and disconnect the hose from the blower.

10. Remove Seal Disk and install Venturi (Figure 44).

Figure 43. Decompress Air Block

NOTE: The venturi with the groove

goes into the bottom and gets

screwed into place while the top half

has the protrusions and sets into the

groove (Figure 45).

Figure 44. Install Venturi

Figure 45. Install Venturi Bottom

and Attach with Screw

24

Page 25

Prepare Cable

The Deluxe Blower is designed so cable may be installed from the side. Follow these

steps so cable is properly positioned to begin operation.

1. Choose the correct Cable Grip and install on fiber optic cable (Figure 46)

(See Tables 1 & 2, on page 18).

2. Install 5/8" (16 mm) Swivel on Cable Grip. Grip must be firmly secured to

cable (Figure 47). The eye on the grip can be compressed to fit smaller

diameter conduits. The eye of a new grip can be taped with electrical tape in

order to make it narrower and travel more easily through the conduit.

9.

Figure 46. Install Cable Grip on

Fiber Optic Cable

3. Choose the correct Carrier and install on Swivel (Figure 48).

4. Raise upper Tractor Drive Cover with turn crank (Figure 49). Open the rear

cable guide roller by pulling out spring plunger and rotating the roller out

(Figure 50).

Figure 47. Install Swivel on

Cable Grip

Figure 48. Install Carrier

5. Tilt Blower forward (Figure 51).

Figure 49. Raise Tractor Drive

with Turn Crank

25

Page 26

Figure 50. Open Rollers

Figure 51. Tilt Blower

6. Add lubricant to Conduit before Carrier: 1/2 quart/6000 feet (.5 liter/2 km)

(Figure 52).

7. Feed Cable Assembly through the counter rollers by lifting the Counter Roller

Bracket. Lock the Rear Cable Guide Roller into place, and feed the cable

through the Tractor Feed. (Figure 53).

26

Figure 52. Add Lubricant before

Cable Assembly

8. Push Cable Assembly, including entire

Cable Grip, into Conduit.

9. Add lubricant to Conduit behind Cable

Assembly: 1/2 quart/3000 feet

(.5 liter/1 km) (Figure 54).

Figure 53. Feed Cable Assembly

Through Blower

Figure 54. Add Lubricant Behind

Cable Assembly

Page 27

10. Choose the correct Cable Seals and install on cable. Grooved side of Cable

Seal faces conduit. Place Cable Seals into Venturi, split side down

(Figure 55).

11. Close Air Block Cover (Figure 56). Tighten nuts securely, but do not over

tighten. Use cross tightening procedure to completely secure.

Figure 55. Install Cable Seals

Figure 56. Close Air Block Cover

Final Set-Up

1. Lower Tractor Drive Cover with turn crank until the cover reaches the stopper-

bushing. The stopper-bushing will prevent the tractor cover from being clamped

too tightly on the cable (Figure 57).

2. Level the height of Air Block’s Venturi Tube with Tractor Drive and the

approximate center line of the cable (Figure 58). Tighten slide cap screws after

adjustments are made.

11.

10.

Figure 57. Lower Tractor Drive

Cover With Turn Crank

3. Notify crew that preparations are complete and cable blowing is to begin.

Figure 58. Level Air Block With

Tractor Drive

27

Page 28

IMPORTANT: It is recommended that if a reel-tensioning unit is not being used,

the cable reel should then be kept under control by a second operator who is

required to wear proper safety equipment and maintain a proper distance from

the cable.

A. FINAL INSPECTION

!CAUTION: Before placing the blower into operation, always perform a

final inspection of all components used.

1. Check that the Cable Grip is attached to conduit on receiving end.

2. Notify crew that preparations are complete and cable blowing is to begin.

Blower Operating Instructions

A. OBSERVER AT EXIT PIT

Station an observer with a 2-way communication device, at the far end of the Conduit,

where the Cable carrier will exit.

11.

B. CONNECT THE HYDRAULIC SYSTEMS (Figure 59)

The Deluxe Blower’s hydraulic system uses quick-disconnect couplings. Keep all

connections clean to avoid contamination and possible system failure. Use hose end

caps (supplied). A contaminated hydraulic system will effect the operation of the

cable blower and may invalidate your product warranty. Take caution in routing the

hoses to prevent a tripping hazard. Follow these steps to connect the hydraulic

components:

1. Attach the quick-disconnect couplings to the hydraulic power supply (Figure 60).

HYDRAULIC

POWER

INNERDUCT

DELUXE LW

BLOWER

SOURCE

OPERATOR

AIR HOSE

HYDRAULIC

HOSES

ELECTRICAL HOOK UP

TO POWER SOURCE

OPTIC CABLE

AIR

COMPRESSOR

FIBER

CABLE

REEL

28

Figure 59. Typical Set-Up

Figure 60. Attach Hydraulic

Hoses

2. Start the hydraulic power unit and check all connections for leaks with a piece

of cardboard. In cold weather, run hydraulic power supply until hydraulic oil

warms up.

Page 29

WARNING: Escaping fluids under pressure can penetrate the skin and

cause serious personal injury. Observe the following precautions to

avoid hydraulic hazards:

•Tightenallconnectionsbeforeapplyingpressure.Relievepressure

before connecting or disconnecting hoses.

•Checkforleakswithapieceofcardboard.Donotusehands!

•Donotexceedworkingpressureofhydraulichoses.Visuallyinspect

hoses regularly and replace if damaged.

3. Run the blower for approximately 1 minute to remove any trapped air and then

stop the blower and hydraulic power source.

C. SET UP THE ELECTRONIC CONTROL BOX

1. Install Electronic Control Box on blower and secure with 1/4 turn fasteners

(Figure 61).

2. Attach Power Cord and plug into 12 volt power supply (Figure 62). Take

caution in routing the electrical cord to prevent a tripping hazard.

Figure 61. Install Electronic

Control Box

3. Attach solenoid valve, front tractor sensor,

rear counter sensor, and transducer plugs

(Figure 63).

4. Turn on control box power (Figure 64).

Select the Traction Control required.

Press the Traction Control button ON to

activate. This stops the blower's tractor

drive if the slippage or speed parameters

are exceeded. Press OFF to disable this

function.

Figure 62. Attach Power Cord

Figure 63. Attach Sensor Plugs

29

Page 30

D. PANEL LAYOUT

The Deluxe Blower Electronic Control Box

uses a touch screen controller with four

function buttons.

Figure 64. Turn on Control

Box Power

30

Figure 65. Control Panel

DRIVE:

OFF/F1: Disengages Hydraulics from the Blower. The OFF touch screen button

will be highlighted when the unit is stopped. The operator can use either the

touch screen button of the Function button.

ON/F2: Engages Hydraulics to the Blower. The ON touch screen button will be

highlighted when the unit is running. The operator can use either the touch

screen button of the Function button.

CAUTION! Make sure the Hydraulic Flow Control Knob is turned all the way in

before switching electronics to ON. Failure to do so could damage the cable.

TRACTION CONTROL (TRAC CTRL):

OFF/F3: Turns Traction Control feature OFF. The OFF touch screen button will be

highlighted when the Traction Control feature is turned OFF. The operator can

use either the touch screen button of the Function button.

ON/F4: Turns Traction Control feature ON. The ON touch screen button will be

highlighted when the Traction Control feature is turned ON. The operator can

use either the touch screen button of the Function button.

Page 31

SCALE: Touching the touch screen on any of the Units (FPM/MPM, FT/M,

PSI/BAR) will open a UNITS screen. Select from Metric or Imperial units, and

press ENTER.

SPEED: Displays cable speed in Feet/Min or Meters/Min

DIST: Displays distance of current installation in Feet or Meters – Resettable

RESET: Touch Screen button that will reset DIST to 0

TOTAL: Displays lifetime distance on the machine in Feet or Meters –

Non Resettable.

PRSSR: Displays hydraulic working pressure in PSI or BAR. This pressure should

match the pressure shown on the analog pressure gauge.

LIMIT: Displays the pressure limit set point in PSI or BAR. When the PRSSR value

exceeds this set limit, the tractor drive will be stopped. This feature is NOT

dependent on having the TRACTION CONTROL system turned ON. To change

the LIMIT value, touch the screen in the LIMIT: XXXX area, and a keypad will

appear. Enter the desired limit value and press ENTER to save the new value.

Press ESC to exit screen without saving the new value.

When the pressure LIMIT is exceeded, the display will show:

HI-PRESSURE ERROR – follow on-screen instructions and press RESET at

bottom of screen to return to operation (Figure 66).

EMERGENCY STOP BUTTON: Press the Emergency Stop button at any time to

immediately stop the tractor drive. When the Emergency Stop button is pressed,

the display will show:

!!EMERGENCY STOP!! – follow on-screen instructions and press RESET at

bottom of screen to return to operation. The EMERGENCY STOP screen will not

clear until the Emergency Stop button is pulled up (Figure 66A).

Figure 66A. Emergency StopFigure 66. Hi-Pressure Error

31

Page 32

E. TRACTION CONTROL

Once activated, the traction control will stop the blower’s tractor drive if track speed

goes above the maximum speed setting of 300 ft/min. (91 m/min.), or if the

slippage allowance is exceeded. Slippage is measured by comparing the speed of

the tracks with the speed of the cable being installed.

If slippage or speed parameters are exceeded, the display will show one of the

following screeens:

SLIP ERROR – follow on-screen instructions and press RESET at bottom of screen

to return to operation (Figure 66B).

HI-SPEED ERROR – follow on-screen instructions and press RESET at bottom of

screen to return to operation (Figure 66C).

Figure 66C. Hi-Speed ErrorFigure 66B. Slip Error

DRIVE will be in OFF position after RESET. Press ON/F2 to resume cable

installation.

F. O PERATION

1. Re-connect hose from air compressor and attach all safety clips. Start the Air

Compressor and Hydraulic Power Supply. Refer to respective manufacturers

operating instructions for these units.

2. Make sure Electronics DRIVE is switched to ON. ON will be highlighted.

Introduce a small amount of air to the system in order to straighten out the

cablecarrierinsidetheconduit.Tur n thehydraulicstothe“on”position

(Figure 67). Slowly rotate the flow control knob, counterclockwise to engage

tractor drive and increase speed (Figure 68). Push cable 50 to 100 feet

(15 to 30 m) into Conduit.

3. Slowly open the Air Control Valve to allow air flow to the Air Block by turning

flow control handle clockwise to the 3 o’clock position so it is in line with the air

compressor hose (Figure 69).

4. Maintain control of cable reel to ensure smooth, stable flow. Failure to do so

may cause cable to unwind too quickly. Continue to control cable speed with

the flow control knob.

32

Page 33

Figure 67. Turn on Hydraulics

Figure 68. Rotate Hydraulic Flow

Control Knob

Figure 69. Turn On Air

Figure 70. Turn Off Air at the

Air Block

!WARNING: Never wrap line around your hand, arm, foot, or leg. Severe

personal injury or death could result from entanglement.

!CAUTION: Always wear protective equipment: hard hat, safety glasses,

safety shoes and work gloves.

5. Turn Tractor Drive off immediately when the observer indicates the Cable

Carrier has exited the Conduit (air pressure will decrease sharply).

•TheTractor Drive will continue to travel unless the track speed exceeds the

slippage allowance, or the maximum speed of 300 ft/min. (91 m/min.) is

exceeded for more than 2 seconds. The OFF/F1 button will also stop the

tractor drive.

•PressstarttoallowTractor Drive to resume.

NOTE: If the TRACTION CONTROL (TRAC CTRL) is set to OFF, the Tractor

Drive will continue to operate regardless of the slippage and speed parameters.

6. Turn off compressed air flow to the Air Block (Figure 70).

33

Page 34

!WARNING: Air Block Assembly contains compressed air when blower

is operated. Opening Air Block while under pressure may cause serious

personal injury. Ensure blower is depressurized before removing Air

Block cover.

7. Remove Cable Grip from receiving end of Conduit.

8. If electronics stop blower before Cable Carrier exits, restart blower, making sure

speed is within minimum and maximum allowance. Also see Troubleshooting

Guide.

Tear Down Procedures

!WARNING: Air Block Assembly contains compressed air when blower is

operated. Opening Air Block while under pressure may cause serious personal

injury. Ensure blower is depressurized before removing Air Block cover.

12.

A. REMOVE POWER FROM UNIT.

1. Turn off compressed air by closing the Air Control Valve at the blower

(Figure 71). Shut off air at the compressor and decompress air hose.

Depressurize the air block by turning the air control valve to the 9 o’clock

position (Figure 72). Remove air hose when system is relieved of pressure.

Figure 71. Turn Off Air at the

Air Block

Figure 72. Decompress Air Block

34

2. Raise Tractor Drive Cover with turn crank (Figure 73).

3. Turn off Hydraulic Power Supply and disconnect hydraulic hoses (Figure 74).

Keep all connections free of dirt and particles. Use hose end caps (supplied).

4. Disconnect electronic cords.

!WARNING: Escaping fluids under pressure can penetrate the skin and

cause serious personal injury. Release pressure before disconnecting

hoses.

Page 35

Figure 73. Raise Tractor Drive

Cover

Figure 74. Turn Off Hydraulic

Power

B. REMOVE CABLE FROM BLOWER.

1. Open Air Block Cover and remove Cable Seals (Figure 75).

2. Pull the Guide Roller Knob and move Rear Guide Roller into open position.

Lift Counter Roller Knobs so rollers are clear of cable (Figure 76). Pull cable

out from side of unit.

Figure 75. Remove Cable Seals

Figure 76. Open Rollers To

Remove Cable

C. SEPARATE UNIT FROM CONDUIT.

1. Open Conduit Clamp.

2. Pull unit away from Conduit.

3. If repositioning the machine, the Deluxe Blower should not be parked on a slope

in excess of 13°. It should not be parked on a side hill of more that 15°.

35

Page 36

13.

Maintenance

Figure 77. Maintenance Schedule

CAUTION: Operators are not permitted to perform maintenance tasks

unless Condux personnel or representatives have appropriately trained

them. Disconnect the machine from its electrical, pneumatic, and

hydraulic power sources before servicing.

A. TRACK CLEANING AND TIGHTENING

1. Inspect track before and after each use.

2. Clean after each use, or when necessary. Remove the top assembly to clean

thoroughly by:

•Removetopcapscrewwitha3mmallenwrenchandtheflatwasheron

clamp adjustment screw. This will allow for the top track assembly to be

unscrewed off the blower with the clamp adjustment (Reference Appendix K).

•Pressurewashifnecessary

3. To compensate for normal belt stretching, there is a rubber dampening bushing

part number 08780028, which is lobed larger on one side than the other,

located at the pivot position of the idler skid part number 08780105. It is in the

smaller lobe position when it leaves the factory. If a tighter belt is needed,

rotate the bushing so the skid presses against the larger lobe. Be sure to have

both bushings in the same configuration before locking the skid back into

position. If this is not enough, then new tracks must be purchased (Reference

Appendix B & C).

B. REPLACEMENT OF THE DRIVE BELT

The drive belt needs to be replaced when the machine is unable to tractor drive the

specified range of cable diameters. Only genuine spares should be used otherwise

the machine may be unsafe and void warranty (Reference Appendix B & C).

36

1. Remove the 2 capscrews which hold the sled in place with a 3 mm T-handled

allen wrench. This should allow the sled to rotate up.

Page 37

2. Remove the pivot shaft with an 8 mm allen wrench.

3. On the bottom drive, remove the 3 capscrews from the prox cover with a 2 mm

allen wrench.

4. The bearing cap can be removed from both the top and bottom assembly using

a 5 mm allen wrench.

5. At this point, the drive pulley can be removed straight out the same hole as the

bearing cap and the belt can be removed. This sequence is reversed for the

reassembly of the new belt with a key note, the dampening bushing must be

rotated back to the smaller lobe position on the pivot shaft.

NOTE: Become familiar with the Replacement and Wear Parts associated with

the LW Blower, they are listed in Appendix T pg. 59.

Figure 78. Torque Specifications for Steel into Steel

Figure 79. Torque Specifications for Steel Capscrew into Aluminum

37

Page 38

Troubleshooting Guide

Problem Solution

14.

Cable becomes jammed in the conduit

system.

Tractor Feed does not pull the cable off

the reel.

Blower cuts out with electronic error or

highspeed error.

1. Inform the people at the other end of

the conduit that a problem has been

experienced and the operator is going to

shut down the system.

2. Shut off the hydraulic valve at the blower.

3. Shut off the pneumatic air supply with the

Air Control Valve turning it to the 9 o’clock

position, allowing the air pressure to be

depressurized from the conduit and the air

block.

3. Using the counter or the measurement on

the cable, determine where the

blockage might be located.

5. Notify supervisor about problem and

determine a solution accordingly.

Assist the reel by pushing it, and/or by pulling

the cable off the reel.

Blower has exceeded the maximum speed

allowance. Adjust speed accordingly, or wipe

cable clean from mud and dirt.

It is difficult to keep the cable moving

near the end of the conduit run.

The cable run is hard to restart after

having stopped.

Tractor feed doesn’t start.

Assist the blower by manually pushing the

cable into the conduit.

Do not bend or crimp the cable.

Put air to the system with the track down. The

tractor feed can be restarted after the air

pressure has increased and stabilized.

1. Hydraulic flow control is at the lowest

speed-increase flow speed slowly.

2.Hydraulic“on”/”off”isinthe“off”

position-rotatehandletothe“on”

position.

3.Electronicsisinthe“stop”position-pushthe

“start”button.

4.“E-stop”isstillintheactivemode-rotate

clockwise to allow the button to reset.

5.Hydraulicpowerpackisinthe“off”

position-turnittothe“on”position.

38

6. Check that the hydraulic hoses are

connected correctly.

Page 39

Blower with Job Box

A.

APPENDIX

Blower with Job Box

ITEM PART NO DESCRIPTION QTY

1 02288701 Pin, Hitch Cotterless 3/8 x 4.50 1

2 08780195 Cart, Job Box LW FO Blower-Assy 1

3 08782000 Blower, LW Fiber Optic-Deluxe 1

ITEMS 1, 2 ARE NOT INCLUDED WITH 08782000

Parts List, Blower with Job Box

39

Page 40

B.

APPENDIX

Upper Drive Shaft Kit

Upper Drive Shaft Repair Kit

08780625

REQUIRED

ITEM PART NO DESCRIPTION

1 02288583 Capsrw M06-1.0 X 10 BHSS 18-8 2 2

2 02288656 Ring, Retaining 28MM Ext (3100) 1 1

3 08780010 Cap, Bearing Assy-Upper Drvshft 1 1

4 08780011 Shaft, Upper Drive-Upr Drv Assy 1 1

5 08780642 Bushing, Dampening (Kit includes 2) 1 NA

6 08780029 Shaft, Pivot-Idler Assy 1 NA

7 08780105 Bracket, Idler Roller Mnt Assy 1 NA

8 08780181 Key, Drive Shaft 7mm-8mm-19.5mm 1 1

9 08780664 Pulley, Timing Drv-Assy 1 1

10 08780904 Belt, Cable 50mm x 260mm Center 1 NA

08780625 KIT INCLUDES ITEMS: 1, 2, 3, 4, 8 & 9

Parts List, Upper Drive Shaft Repair Kit

08780625

40

QTY

KIT

QTY

Page 41

Lower Drive Shaft Kit

C.

APPENDIX

Lower Drive Shaft Replacement Kit

08780626

REQUIRED

ITEM PART NO DESCRIPTION

1 02288583 Capsrw M06-1.0 X 10 GHSS 18-8 2 2

2 02288656 Ring, Retaining 28MM Ext (3100) 1 1

3 08780642 Bushing, Dampening-(Kit includes 2) 1 NA

4 08780029 Shaft, Pivot-Idler Assy 1 NA

5 08780105 Bracket, Idler Roller Mnt Assy 1 NA

6 08780181 Key, Drive Shaft 7mm-8mm-19.5mm 1 1

7 08780277 Shaft, Lower Drive-Lwr Drv Assy 1 1

8 08780278 Cap, Bearing Assy-Lower Drvshft 1 1

9 08780664 Pulley, Timing Drv-Assy 1 1

10 08780904 Belt, Cable 50mm x 260mm Center 1 NA

08780626 KIT INCLUDES ITEMS: 1, 2, 6, 7, 8 & 9

Parts List, Lower Drive Shaft Replacement Kit

08780626

QTY

KIT

QTY

41

Page 42

D.

APPENDIX

Hydraulic Motor Kit

Hydraulic Motor Replacement Kit

ITEM PART NO DESCRIPTION

1 02269664 CAPSRW 0.25-20X0.62 CSSTALY PL 3 3

2 02269694 FTG,HYD 06 O-RING;06-JIC 2 2

3 08780940 MOTOR,HYD 5/8 SHAFT-PAINTED 1 1

Parts List, Hydraulic Motor Replacement Kit

42

08780636

08780636

REQUIRED

QTY

KIT

QTY

Page 43

Idler Bracket Bushing & Screw Kits

E.

APPENDIX

Idler Bracket Bushing Replacement Kit

08780642

Idler Bracket Screw Replacement Kit

08780643

REQUIRED

ITEM PART NO DESCRIPTION

1 08780028 Bushing, Dampening-Polyurethane 2 2

Parts List, Idler Bracket Bushing Replacement Kit

08780642

ITEM PART NO DESCRIPTION

1 02290189 Screw, Shoulder M05 Dia-8mm Lg 2 2

Parts List, Idler Bracket Screw Replacement Kit

08780643

QTY

REQUIRED

QTY

KIT

QTY

KIT

QTY

43

Page 44

F.

APPENDIX

Air Block Assembly Kits

Airblock Bracket Replacement Kit

08780629

Airblock Clamp Assembly

Replacement Kit

08780942

44

Airblock Assembly Replacement Kit

08780935

Page 45

REQUIRED

ITEM PART NO DESCRIPTION

1 02129701 Coupling, Universal 3/4 Male 1 NA

2 02288573 Capsrw M05-0.8 X 16 CSSS 18-8 8 8

3 02288605 Screw, Shoulder M10 Dia-16mm Lg 2 2

4 02288606 Flatwasher M10-Narr St Cz 2 2

5 02288671 Muffler, Pneumatic Exhaust 12MP 1 NA

6 08780159 Mount, Airblock (W/Insert) LW FO Blwr 1 1

7 08780258 Pad, Guide-LW Airblock Mount 2 2

8 08780935 AIRBLOCK, LW BLOWER ASSEM - NEW 1 NA

9 08780942 BLOCK, CLAMP(ASSY) SWINGBOLT 1 NA

08780629 KIT INCLUDES ITEMS: 2, 3, 4, 6 & 7

QTY

Parts List, Airblock Bracket Replacement Kit - 08780629

KIT

QTY

REQUIRED

ITEM PART NO DESCRIPTION

1 02288416 1/4-20 THIN NYLOC NUT (CLEAR ZINC) 2 1

2 02289401 5/16 DIA X 5/8 SHOULDER SCREW (1/4-20 THRDS) 2 1

3 02290167 5/16-18 SWIVEL FLANGE HEX NUT 2 1

4 NA LOCATOR PIN NA NA

5 NA LOCATOR BUSHING NA NA

6 NA LOWER SWING BOLT CLAMP BODY NA NA

7 NA UPPER SWING BOLT CLAMP BODY NA NA

8 08782314 SWING BOLT-MACHINED 4 1

08782321 CLAMP BODY (INCLUDES 4, 5, 6 & 7) 1 NA

08782322 SWING BOLT KIT(INCLUDES 1ea 1, 2, 3 & 8) 2 NA

QTY

Parts List, Airblock Clamp Assembly Replacement Kit - 08780942

REQUIRED

ITEM PART NO DESCRIPTION

1 08780126 QUAD-RING, 3.5MM-KIT 1 NA

2 02288416 NUT 0.25-20 NYLOC STGR2 THN CZ 4 1

3 02288571 CAPSRW M04-0.7X 12 BHSS 18-8 2 NA

4 02288582 GAUGE, PRESS 0- 200 1.50 BCK MT 1 NA

5 02289401 SCREW, SHOULDER 0.312 DIA-0.625 4 1

6 02290167 NUT 0.31-18 HEX SWIVEL FLANGE 4 1

7 08780937 AIRBLOCK, UPPER MACH - LW 1 NA

8 08780938 GUARD, GAUGE-MACH- LW FOB 1 NA

9 08780941 AIRBLOCK, LOWER MACH-SWINGBOLT 1 NA

10 08782314 BOLT, SWING-MODIFIED-DLX BLOWER 4 1

08782322 SWING BOLT KIT (INCLUDES 1ea - 2, 5, 6 &10) 4 NA

QTY

KIT

QTY

KIT

QTY

Parts List, Airblock Assembly Replacement Kit - 08780935

45

Page 46

Counter Clamp Roller & Cable Guide Kits

G.

APPENDIX

Counter Clamp Roller Replacement Kit

08780630

REQUIRED

ITEM PART NO DESCRIPTION

1 08780091 Roller, Cable Clamp-Assy 1 1

2 08780094 Shaft, Cable Clamp Roller 1 1

3 08780095 Spacer, 10mm-14mm-21.5mm Nylon 1 1

4 08780096 Spacer, 10mm-14mm-1.5mm Nylon 1 1

Parts List, Counter Clamp Roller Replacement Kit

08780630

QTY

KIT

QTY

Counter Cable Guide Replacement Kit

ITEM PART NO DESCRIPTION

1 02288649 Capsrw M03-0.5 X 12 SHAA 18-8 2 2

2 08780266 Guide, Cable-Upper Entrance 1 1

Parts List, Counter Cable Guide Replacement Kit

46

08780631

08780631

REQUIRED

QTY

KIT

QTY

Page 47

Timing & Takeup Roller & Idler Roller Kits

H.

APPENDIX

Timing & Takeup Roller

Replacement Kit

08780632

REQUIRED

ITEM PART NO DESCRIPTION

1 02288573 Capsrw M05-0.8 X 16 CSSS 18-8 4 1

2 08780006 Shaft, Idler Pulley-BT Blower 4 1

3 08780037 Retainer, Idler Plly-12mm Shaft 4 1

4 08780663 Pulley,Timing Idler-Assy 1 1

Parts List, Timing & Takeup Roller Replacement Kit

08780632

QTY

KIT

QTY

Idler Roller Replacement Kit

08780633

REQUIRED

ITEM PART NO DESCRIPTION

1 02288573 Capsrw M05-0.8 X 16 CSSS 18-8 3 1

2 08780007 Shaft, Idler Roller-LW Blower 3 1

3 08780031 Retainer, Idler Roll-10mm Shaft 3 1

4 08780250 Pulley, Idler Assy-54mm 3 1

Parts List, Idler Roller Replacement Kit

08780633

QTY

KIT

QTY

47

Page 48

I.

APPENDIX

Hydraulic Coupler (Male) Kit

ITEM PART NO DESCRIPTION

1 02260200 Cap, Dust (Male Flat Face Cplrs) 1 1

2 02286710 Hose 06 x 22.0-06sw 1

3 02288620 Coupler, Male-Flat Face Metric 1 1

4 02288643 Hose 06 x 21.0-06sw 1

5 02288643 Hose 06 x 21.0-06sw 1 1

6 02288703 Ftg, Hyd 18mm-Thread Bond Seal 1

ITEMS 2, 4, 5 ARE NOT INCLUDED IN KIT 08780634

Parts List, Hydraulic Coupler (Male) Replacement Kit

Hydraulic Coupler (Male)

Replacement Kit

08780634

08780634

REQUIRED

QTY

KIT

QTY

48

Page 49

Hydraulic Coupler (Female) Kit

J.

APPENDIX

Hydraulic Coupler (Female)

Replacement Kit

08780635

REQUIRED

ITEM PART NO DESCRIPTION

1 02260201 Cap, Dust (Fem Flat Face Cplrs) 1 1

2 02286710 Hose 06 x 22.0-06sw 1

3 02288619 Coupler, Female-Flt Face Metric 1 1

4 02288643 Hose 06 x 21.0-06sw 1

5 02288643 Hose 06 x 21.0-06sw 1

6 02288703 Ftg, Hyd 18mm-Thread Bond Seal 1 1

ITEMS 2, 4, 5 ARE NOT INCLUDED IN KIT 08780634

Parts List, Hydraulic Coupler (Female) Replacement Kit

08780635

QTY

KIT

QTY

49

Page 50

K.

APPENDIX

Clamp Adjustment Kit

Clamp Adjustment Replacement Kit

ITEM PART NO DESCRIPTION

1 02240800 Capsrw, #10-24 x 0.50 BHSS 18-8 1 1

2 02288610 Cylinder, Lift-Pnuematic Chrgd 1

3 02288644 Lever, Ball Knob 10mm 08mm Thr 2 2

4 02288646 Zerk, Grease, 6mm-1.0 Straight 1 1

5 02289031 Bearing , Thr 1.265-2.0-0.062 1 1

6 02290172 Washer, Fender #10-1.00-.113 1 1

7 08780081 Shaft, Tension Adjustment 1 1

8 08780106 Body, Handle-Clamp Cylinder 1 1

9 08780661 Bushing, Clamp Stopper 1 1

ITEM 2 IS NOT INCLUDED IN KIT 08780637

Parts List, Clamp Adjustment Replacement Kit

50

08780637

08780637

REQUIRED

QTY

KIT

QTY

Page 51

Lower Counter Roller Kit

L.

APPENDIX

Lower Counter Roller Replacement Kit

08780638

REQUIRED

ITEM PART NO DESCRIPTION

1 02288574 Capsrw, M05-0.8 x 12 BHSS 18-8 4 4

2 08780022 Shaft, Counter (Assy) LW FO Blwr 1 1

3 08780257 Housing, Brg Assy - (Front) 1 1

4 08780260 Housing, Brg Assy - Cntr Rllr 1 1

Parts List, Lower Counter Roller Replacement Kit

08780638

QTY

KIT

QTY

51

Page 52

M.

APPENDIX

RH Cable Guide Roller Kit &

Adjustable Rear Cable Guide Kit

REQUIRED

ITEM PART NO DESCRIPTION

1 02186901 Nut, #10-24 Nyloc St GR2 CZ 1 1

2 02288574 Capsrw M05-0.8 x 12 BHSS 18-8 6 1

3 02288584 Capsrw M06-1.0 x 20 CSSS 18-8 5 2 3

4 02288925 Screw, Shoulder M06 Dia-35mm Lg 2 2

5 02288926 Capsrw M04-0.7 x 10 CSSS 18-8 4 4

6 02288989 Flatwasher M06-Fender SS 18-8 2 1

7 02289053 Setscrew M04-0.7 x 10 HXSO NTST 2 2

8 02290177 Knob, Hand-Knurled .75 Dia SS 1 1

9 08780133 Roller, Rear Entry (Assy) 2 1

10 08780135 Pad, Guide-Rear Cable Entry 1 1

11 08780252 Shaft, Vert Guide Roller 1 1

12 08780473 Arm, Pivot RH-Adj Cbl Guide 1 1

13 08780474 Arm, Pivot LH-Adj Cbl Guide 1 1

14 08780475 Shaft, Adjustment-ADJ CBL Guide 1 1

15 08780476 Pin, Pivot RH-ADJ CBL Guide 1 1

QTY

KIT

QTY

KIT

QTY

16 08780477 Pin, Pivot LH-ADJ CBL Guide 1 1

17 08780479 Plate, Bearing Mnt Assy 2 2

18 08780481 Block, Pivot Mount Assy 1 1

ITEMS 2, 3, 6, 9, 11 COME IN KIT 08780639

ITEMS 1, 3, 4, 5, 7, 8, 10, 12, 13, 14, 15, 16, 17, 18 COME IN KIT 08780482

Parts List, RH Cable Guide Roller Replacement Kit

52

08780639

Page 53

LH Cable Guide Roller Kit

N.

APPENDIX

LH Cable Guide Roller Replacement Kit

08780640

REQUIRED

ITEM PART NO DESCRIPTION

1 02288574 Capsrw M05-0.8 x 12 BHSS 18-8 6 1

2 02288579 Plunger, Spring-M10x1.5 SS 1 1

3 02288585 Screw, Shoulder M08 Dia-16mm LG 1 1

4 02288989 Flatwasher M06-Fender SS 18-8 2 1

5 08780059 Shaft, Pivot Guide Roller 1 1

6 08780133 Roller, Rear Entry (Assy) 2 1

Parts List, LH Cable Guide Roller Replacement Kit

08780640

QTY

KIT

QTY

53

Page 54

O.

APPENDIX

Counter Spring Kit

Counter Spring Replacement Kit

08780641

REQUIRED

ITEM PART NO DESCRIPTION

1 02288583 Capsrw M06-1.0x 10 BHSS 18-8 2 1

2 02288588 Flatwshr M06-Narr ST CZ 2 1

3 02288639 Cap, Vinyl .75id-.88od-1.00 Blk 2 1

4 02288677 Sensor, Pickup-Turck Picoprox 1

5 02288721 Spring, Comprss .063-0.600-2.50 2 1

6 02288727 Shaft, Counter (assy) LW FO Blwr 1

7 02290215 Clamp, Cable Counter-Assy 1

8 08780022 Retainer, Spring-Cable Clamp 1 1

9 08780090 Pad, Guide-Rear Cable Entry 1

10 08780097 Cordset Assy 2pin W/Connectors 2

11 08780135 Panel, Control-Touch LW Blower 1

12 08780193 Cordset, Rear Sensor LW Blower 1

13 08781011 Cordset, Front Sensor LW Blower 1

QTY

KIT

QTY

14 08781026 Cordset, Transducer LW Blower 1

ITEMS 4, 6, 7, 9, 10, 11, 12, 13, 14 ARE NOT INCLUDED IN KIT 08780641

Parts List, Counter Spring Replacement Kit

54

08780641

Page 55

Base Mount

P.

APPENDIX

ITEM PART NO DESCRIPTION QTY

1 02288654 Handle, Adjustable Clamping 1

2 02288701 Pin, Hitch Cotterless 3/8 x 4.50 1

3 08780160 Base, Adjustable Assy-LW FO Blowr 1

ITEMS 1 AND 2 INCLUDED WITH ITEM 3

Base Mount Individual Replacement Parts

55

Page 56

Q.

APPENDIX

Pneumatic & Electrical Circuits

Pneumatic Circuit

08780994

56

Electrical Circuit

08780996

Page 57

Hydraulic Circuit

R.

APPENDIX

Hydraulic Circuit

08780997

57

Page 58

Hydraulic Flow Control Valve

S.

APPENDIX

Parts List, Hydraulic Control Flow Valve

Replacement Kit

08780945

ITEM PART NO DESCRIPTION QTY

1 02260200 Cap, Dust (male Flat Face Cplrs) 1

2 02260201 Cap, Dust (fem Flat Face Cplrs) 1

3 02269708 Valve, Cartridge-Direc. Control 1

4 02288589 Valve, Cartridge-Flow Control 1

5 02288590 Knob, Cartridge Valve Flow Ctrl 1

6 02288619 Coupler, Female-Flt Face Metric 1

7 02288620 Coupler, Male-Flat Face Metric 1

58

8 02288637 Gauge, Press 0-2000 1.50 Bck Mt 1

9 02288638 Ftg, Hyd 06-jic, M14 O-Ring 2

10 02288641 Lever, Ball Handle 2 Pos Detent 1

11 02288703 Ftg, Hyd 18mm-Thread Bond Seal 2

12 02288859 Valve, Cartridge-Solenoid 12vlt 1

13 02290614 Valve, Cartridge-Hex Adj Relief 1

14 02290766 Transducer, Prsr 2000psi-4/20ma 1

15 02290768 Ftg, Hyd 04 O-Ring_m;04 Npt_f 1

16 02290769 Ftg, Hyd 04 Npt_m;04 Npt_f Tee 1

17 02290770 Ftg, Hyd 04 Npt_m;02 Npt_f 1

ECB Upgrade Kit - 08781022

PART NO DESCRIPTION QTY

08781020 Panel, Control-Touch LW Blower 1

08781023 Kit, Pressure Transducer-LWB 1

BREAKDOWN of 08781023 Kit

PART NO DESCRIPTION QTY

02289187 Bag, 8.00-11.50 Plastic Bubble 1

02290766 Transducer, Prsr 2000psi-4/20ma 1

02290768 Ftg, Hyd 04 O-Ring_M;04 Npt_f 1

02290769 Ftg, Hyd 04 Npt_M;04 Npt_f Tee 1

02290770 Ftg, Hyd 04 Npt_M;02 Npt_f 1

08781026 Cordset, Transducer LW Blower 1

Page 59

Possible Wear & Replacement Parts

For replacement parts please contact the factory or Condux representative.

List of possible wear items:

Part Number Description

08780904 Belt, Cable 50MM X 260MM Center

See Table 1, pg 18 for

correct cable seal size

08780126 Kit, Seal Replacement-LW Blower

08780424 Machine Screws,M04-0.7X16 (10)

08780135 Pad, Guide-Rear Cable Entry

08780266 Guide, Cable-Upper Entrance

08780133 Rear Entry Rollers

08780091 Upper Counter Roller

08780022 Lower Counter Roller

See Table 2, pg 18 for

correct carrier size

OTHER WEAR OR REPLACEMENT PARTS