Page 1

Mounting Instructions

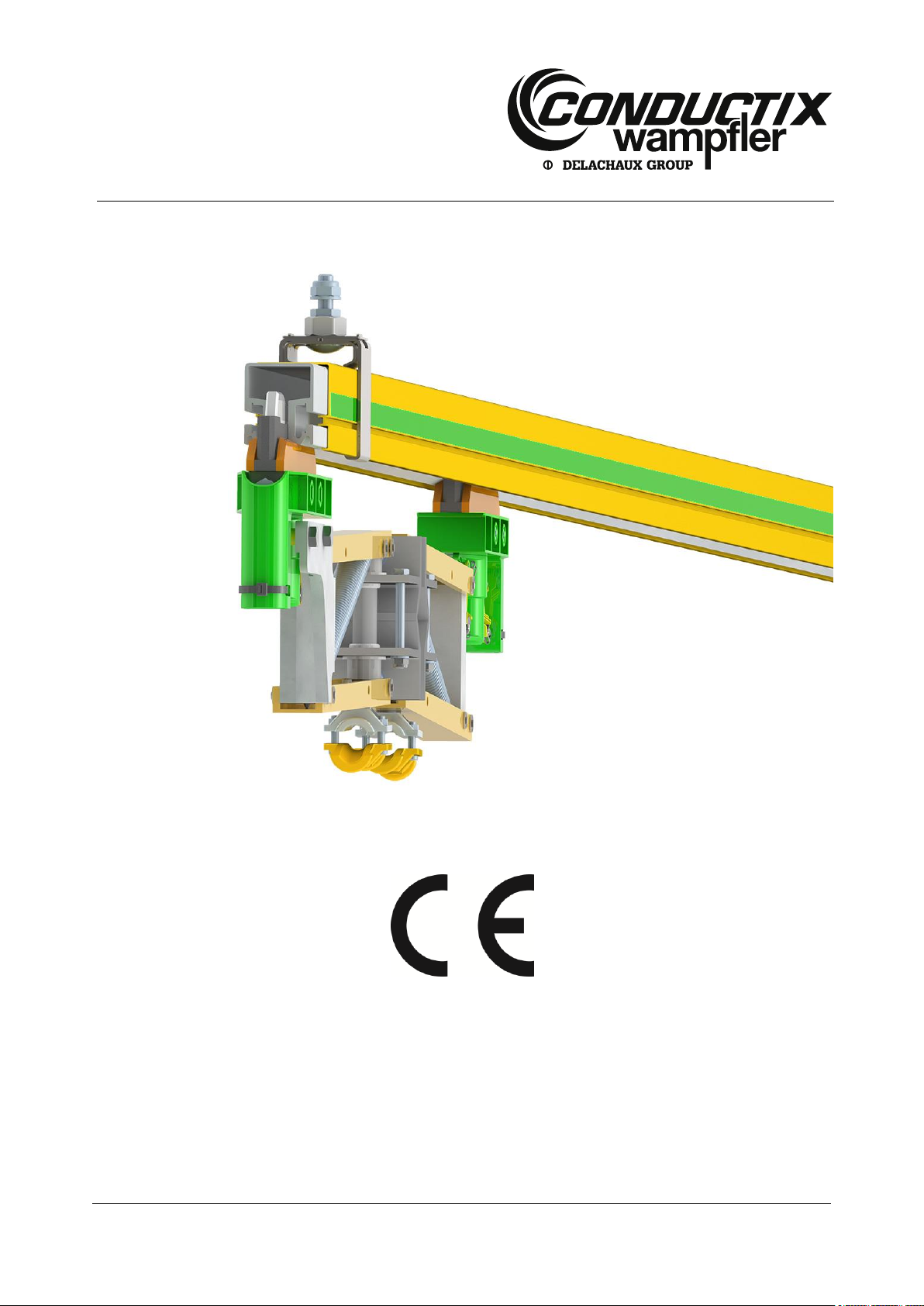

Programm 0514

ProfiDAT® Data Transmission System

MAL0514-0005b-EN

www.conductix.com translated document page 1 of 82

Page 2

Mounting Instructions

Programm 0514

ProfiDAT® Data Transmission System

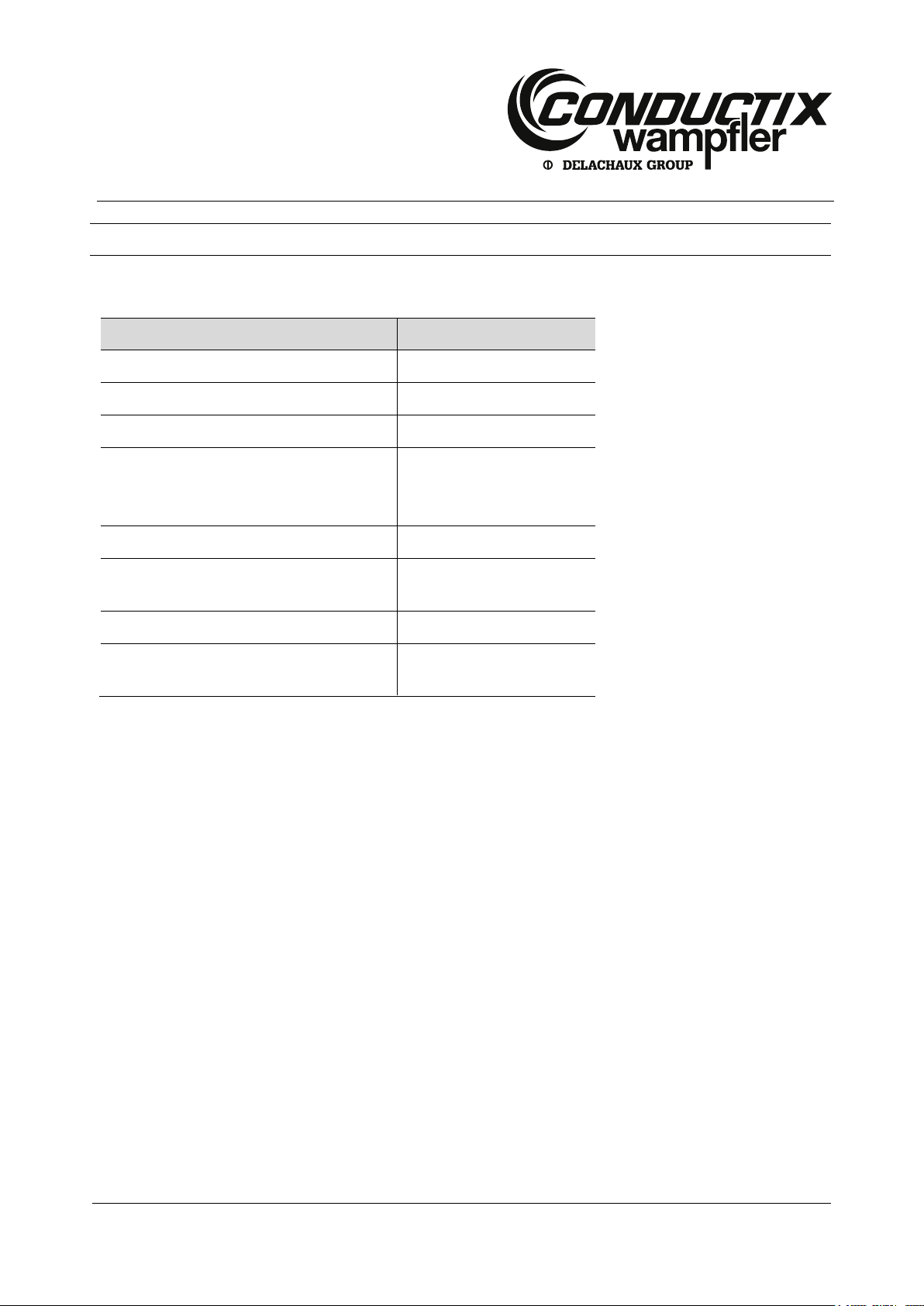

Contents

1 General Notes ............................................................................................................................................................................. 6

1.1 About this Document ................................................................................................................................................... 6

1.2 Limitation of Liability .................................................................................................................................................... 6

1.3 Copyright ..................................................................................................................................................................... 7

1.4 Spare Parts .................................................................................................................................................................. 7

1.5 Material defects ........................................................................................................................................................... 7

1.6 Technical support ........................................................................................................................................................ 7

2 Safety Instructions ...................................................................................................................................................................... 8

2.1 Explanation of Symbols ............................................................................................................................................... 8

2.2 Personnel Requirements ............................................................................................................................................. 9

2.2.1 Qualifications ............................................................................................................................................................... 9

2.2.2 Unauthorized Personnel .............................................................................................................................................. 9

2.2.3 Training ...................................................................................................................................................................... 10

2.3 Personal Protective Equipment ................................................................................................................................. 10

2.4 Intended Use ............................................................................................................................................................. 11

2.4.1 Improper use ............................................................................................................................................................. 11

2.5 Protective Measures to be taken by the Owner/Operator ......................................................................................... 12

2.6 Special Hazards ........................................................................................................................................................ 14

2.6.1 5 Protective Safety Rules when working on Electrical Systems ................................................................................ 14

2.6.2 Electrical Hazards and Sources of Danger ................................................................................................................ 15

2.6.3 Mechanical Hazards and Sources of Danger ............................................................................................................ 16

2.6.4 Danger due to Dust and Vapors ................................................................................................................................ 18

2.6.5 Danger related to the Place of Use ........................................................................................................................... 19

2.6.6 Unexpected Startup, unexpected Movement ............................................................................................................ 19

2.6.7 Emergency Stop ........................................................................................................................................................ 20

2.6.8 Hazard Areas ............................................................................................................................................................. 20

2.7 Safety Devices ........................................................................................................................................................... 21

2.8 Conduct in the Event of Accidents and Malfunctions ................................................................................................ 22

3 Technical Specifications ........................................................................................................................................................... 23

3.1 General Information ................................................................................................................................................... 23

MAL0514-0005b-EN

www.conductix.com translated document page 2 of 82

Page 3

Mounting Instructions

Programm 0514

ProfiDAT® Data Transmission System

3.2 Interfaces ................................................................................................................................................................... 23

3.2.1 Electrical .................................................................................................................................................................... 23

3.2.2 Mechanical ................................................................................................................................................................ 24

3.3 Technical Data for the Transceiver ............................................................................................................................ 25

3.4 Technical Data for HF Cables ................................................................................................................................... 25

3.5 Operating Conditions ................................................................................................................................................. 26

4 Product Description and Mode of Operation ............................................................................................................................. 27

4.1 Overview .................................................................................................................................................................... 27

4.2 Brief Description ........................................................................................................................................................ 27

4.3 Description of Assemblies ......................................................................................................................................... 28

4.3.1 ProfiDAT® System ..................................................................................................................................................... 28

4.3.2 Electrical Components ............................................................................................................................................... 30

4.4 Modes of Operation ................................................................................................................................................... 32

4.4.1 Normal Operation ...................................................................................................................................................... 32

5 Transport, Packaging and Storage ........................................................................................................................................... 33

5.1 Shipment ................................................................................................................................................................... 33

5.1.1 Safety Instructions for Transport ............................................................................................................................... 33

5.1.2 Transporting packaged Parts .................................................................................................................................... 33

5.1.3 Transport Inspection .................................................................................................................................................. 34

5.2 Packaging .................................................................................................................................................................. 34

5.3 Storage of packaged Parts ........................................................................................................................................ 35

6 Installation and Commissioning ................................................................................................................................................ 36

6.1 Safety ........................................................................................................................................................................ 36

6.2 Preparations .............................................................................................................................................................. 37

6.3 Grounding .................................................................................................................................................................. 38

6.3.1 TN Network ................................................................................................................................................................ 38

6.3.2 Grounding Implementation Instructions ..................................................................................................................... 38

6.4 Mechanical Installation .............................................................................................................................................. 39

6.4.1 Installation of the Expansion Element ....................................................................................................................... 39

6.4.2 Mounting the ProfiDAT® Profile ................................................................................................................................. 41

6.4.3 Installing the PE rail connector .................................................................................................................................. 43

MAL0514-0005b-EN

www.conductix.com translated document page 3 of 82

Page 4

Mounting Instructions

Programm 0514

ProfiDAT® Data Transmission System

6.4.4 Installing the rail connector (without PE) ................................................................................................................... 44

6.4.5 Installing the Anchor Point ......................................................................................................................................... 44

6.4.6 Installing the Entry Funnel ......................................................................................................................................... 47

6.4.7 Adjusting the length of the ProfiDAT® Profile ............................................................................................................ 47

6.4.8 Installing the Infeed ................................................................................................................................................... 49

6.4.9 Connecting the ProfiDAT® Profile to the Entry Funnel .............................................................................................. 50

6.4.10 Installing the Terminating Unit ................................................................................................................................... 51

6.4.11 Installing the Current Collector .................................................................................................................................. 52

6.4.12 Installing the PE Cable on the ProfiDAT® Profile ....................................................................................................... 54

6.4.13 Use of the ProfiDAT® profile without PE function ...................................................................................................... 55

6.4.14 Installing Trace Heating (optional) ............................................................................................................................. 55

6.4.15 Mounting a Temperature Sensor (optional) ............................................................................................................... 56

6.4.16 Retrofitting of a PE Rail Connector (Ground) ............................................................................................................ 56

6.5 Electrical Installation .................................................................................................................................................. 59

6.5.1 Installing the ProfiDAT® Infeed Switching Cabinet .................................................................................................... 60

6.5.2 Installing a ProfiDAT® Transceiver on a Mobile System Component ........................................................................ 61

6.5.3 Installing the Connecting Cable (HF cable) on the Infeed Antenna ........................................................................... 62

6.5.4 Installing the Connection Cable (HS Cable) on the Transceiver ............................................................................... 62

6.6 Profile-heating (optional) ........................................................................................................................................... 63

6.6.1 Profile-heating Controller ........................................................................................................................................... 64

6.6.2 Profile-heating Components ...................................................................................................................................... 65

6.7 Checklist and Initial Commissioning .......................................................................................................................... 66

7 Operation .................................................................................................................................................................................. 69

7.1 Safety ........................................................................................................................................................................ 69

8 Maintenance and Servicing ....................................................................................................................................................... 70

8.1 Safety ........................................................................................................................................................................ 70

8.2 Maintenance Plan ...................................................................................................................................................... 71

8.2.1 Documentation .......................................................................................................................................................... 72

8.2.2 Replacement of the ProfiDAT® Antenna .................................................................................................................... 72

8.2.3 Maximum Wear of the Carbon Brushes .................................................................................................................... 74

8.2.4 Replacement of Carbon Brushes on the ProfiDAT® Current Collector ...................................................................... 75

MAL0514-0005b-EN

www.conductix.com translated document page 4 of 82

Page 5

Mounting Instructions

Programm 0514

ProfiDAT® Data Transmission System

9 Troubleshooting ........................................................................................................................................................................ 78

10 Dismantling and Disposal ......................................................................................................................................................... 79

10.1 Safety ........................................................................................................................................................................ 79

10.2 Dismantling ................................................................................................................................................................ 79

10.2.1 Dismantling the Assembly ......................................................................................................................................... 79

10.3 Disposal ..................................................................................................................................................................... 80

11 Additional Documents ............................................................................................................................................................... 81

11.1 Conformity Declaration .............................................................................................................................................. 81

11.2 Other applicable Documents ..................................................................................................................................... 81

12 Index ......................................................................................................................................................................................... 82

MAL0514-0005b-EN

www.conductix.com translated document page 5 of 82

Page 6

Mounting Instructions

Programm 0514

ProfiDAT® Data Transmission System

1 General Notes

1.1 About this Document

This document facilitates safe and efficient working with the Conductix-Wampfler ProfiDAT® data-transmission system. The datatransmission system consists of components integrated into a conductor rail system by the system engineer for the transmission of

data between a base unit and a mobile system component.

This document is a part of the data transmission system, and must be kept in its immediate vicinity and accessible to personnel at

all times. Personnel must read this document carefully and understand it before starting any work. Compliance with all safety and

handling instructions given in this document is a basic prerequisite for safe working.

Local accident-protection regulations and general safety guidelines for the area of use of the data-transmission system also apply.

Illustrations in this document are provided for basic understanding and may deviate from the actual versions of individual components.

In addition to these instructions, the instructions in the appendices for the individual installed components also apply.

1.2 Limitation of Liability

All data and information in this mounting instructions have been compiled in compliance with the applicable standards and regulations, best practice and our many years of experience and knowledge.

The manufacturer accepts no liability for damages resulting from:

Failure to comply with this document

Improper use

Use by untrained personnel

Unauthorized modifications

Technical changes

Use of unauthorized replacement parts and accessories

The actual scope of delivery may differ from the explanations and descriptions provided here if the model in question is a spe-

cial one, if additional equipped has been ordered or due to recent technical changes.

The obligations agreed upon in the delivery agreement and our General Terms and Conditions of business apply, as do the delivery

conditions of the manufacturer and the legal regulations applicable at the time the contract was concluded.

All products are subject to technical modifications in the context of improvement of function and further development.

MAL0514-0005b-EN

www.conductix.com translated document page 6 of 82

Page 7

Mounting Instructions

Programm 0514

WARNING!

Incorrect spare parts are a safety hazard!

Incorrect or faulty spare parts can impair safety as well as resulting in damage, malfunctions

or complete failure.

Always use original spare parts from the manufacturer!

ProfiDAT® Data Transmission System

1.3 Copyright

This document is subject to copyright, and is exclusively intended for internal use by customers.

Provision of the mounting instruction to third parties, reproduction in any form — even in part — as well as the reuse and/or disclosure

of its content are not permitted without the written approval of the manufacturer, except for the customer's internal use.

Infringements will result in liability for damages. Our right to further claims remains unaffected.

1.4 Spare Parts

Order spare parts from your contracted dealer or directly from the manufacturer.

Contact details: See the last page of this document.

Spare parts: see Section 11.2

1.5 Material defects

The regulations about material defects are listed in the general terms and conditions of business.

1.6 Technical support

For technical support please contact our staff from the Customer Support Department.

Contact details: See the last page of this document.

Our employees are also always interested in new information and experience from the field that can be valuable for the improvement

of our products.

MAL0514-0005b-EN

www.conductix.com translated document page 7 of 82

Page 8

Mounting Instructions

Programm 0514

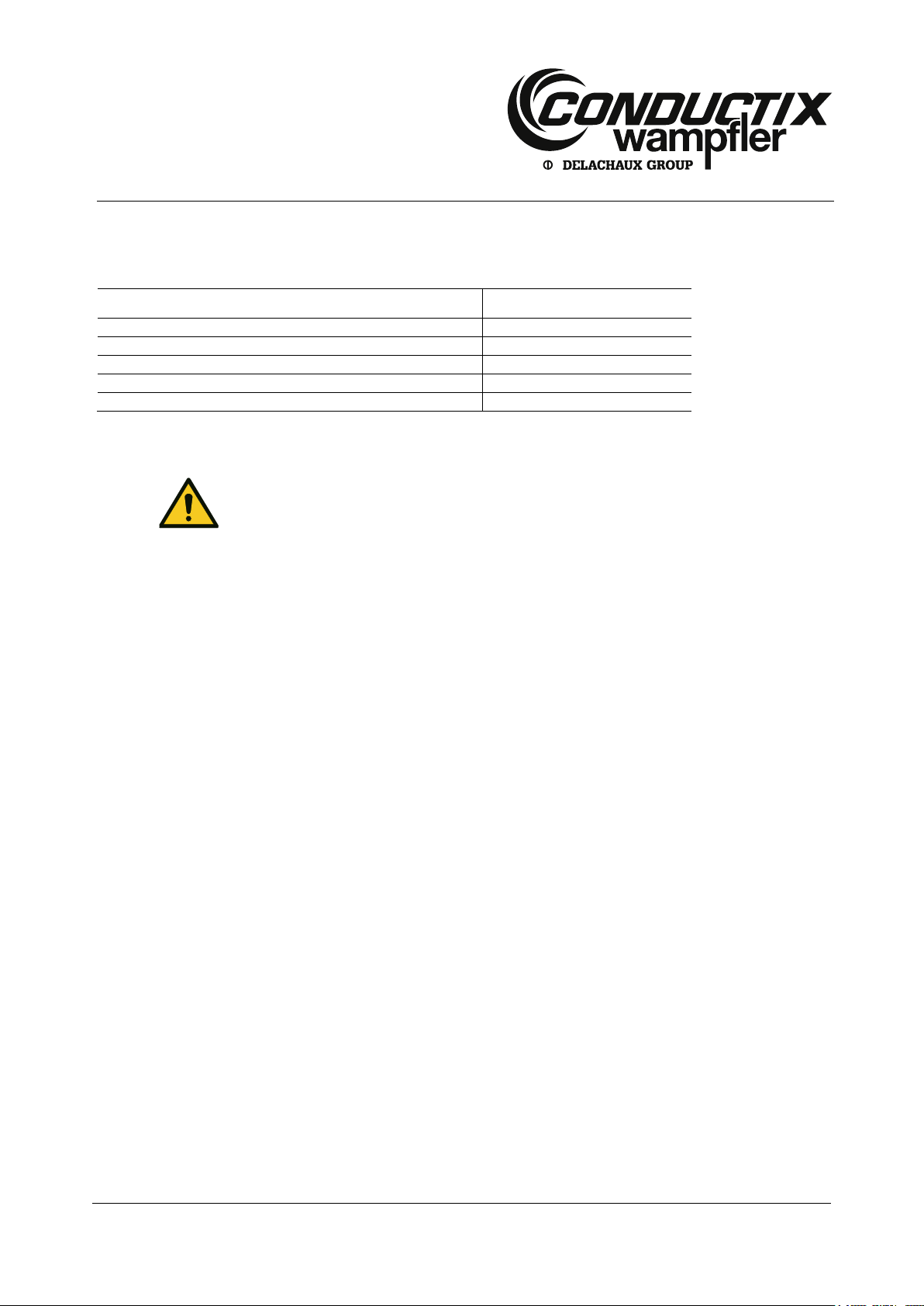

DANGER!

… indicates an immediately hazardous situation that will result in death or serious injury if not

avoided.

DANGER!

… indicates an immediately hazardous situation due to electricity that will result in death or se-

rious injury if not avoided.

WARNING!

… indicates a potentially hazardous situation that can result in death or serious injury if not

avoided.

WARNING!

… indicates a potentially hazardous situation due to electricity that can result in death or seri-

ous injury if not avoided.

CAUTION!

… indicates a potentially hazardous situation that can result in moderate or minor injury if not

avoided.

Tips and recommendations:

… highlights useful tips and information for efficient, problem-free operation.

CAUTION!

… indicates measures that will help you avoid material damage.

ProfiDAT® Data Transmission System

2 Safety Instructions

2.1 Explanation of Symbols

Safety and hazard information is identified by symbols in this mounting instruction. Safety instructions are introduced by signal words

that signal the scale of the hazard. Always observe safety and hazard instructions, and work carefully to avoid accidents, bodily injury

and damage to property!

MAL0514-0005b-EN

www.conductix.com translated document page 8 of 82

Page 9

Mounting Instructions

Programm 0514

WARNING!

Inadequately trained persons are at risk of injury!

Improper use can result in serious personal injury or material damage.

All activities must only be performed by qualified personnel.

WARNING!

Danger due to unauthorized personnel!

Unauthorized persons who do not meet the requirements described here are not acquainted

with the dangers in the working area.

Keep unauthorized personnel away from the working area.

In case of doubt, address the person and direct them away from the working area.

Stop working, as long as unauthorized persons are in the working area.

ProfiDAT® Data Transmission System

2.2 Personnel Requirements

2.2.1 Qualifications

Only persons who can be expected to perform their work reliably are acceptable personnel. People whose reactions are

impaired by drugs, alcohol or medications, for example, are not authorized.

When selecting personnel, follow all age- and occupation-specific guidelines applicable at the location of use.

The following qualifications are specified in the operating instructions for certain fields of activity.

Trained personnel and operators

have participated in a training session, given by the owner, on the tasks assigned to them and the potential hazards in case of

improper conduct.

The owner of the machine or system must document that the appropriate training has taken place.

Specialist personnel

consists of persons capable of performing assigned tasks and independently identifying and avoiding potential hazards based

on their specialist training, knowledge and experience as well as their knowledge of the applicable regulations.

Persons are deemed to be technically qualified if they have successfully completed training as a master electrician, apprentice

electrician, electrical engineer or electrical technician. Persons are also considered technically qualified if they have been employed in an appropriate capacity for several years, receiving theoretical and practical training in that time, and their

knowledge and skills have been tested by a specialist in the appropriate field of training.

The machine or system owner must document that the appropriate certificates or other proofs of qualification have been or are

being provided.

2.2.2 Unauthorized Personnel

MAL0514-0005b-EN

www.conductix.com translated document page 9 of 82

Page 10

Mounting Instructions

Programm 0514

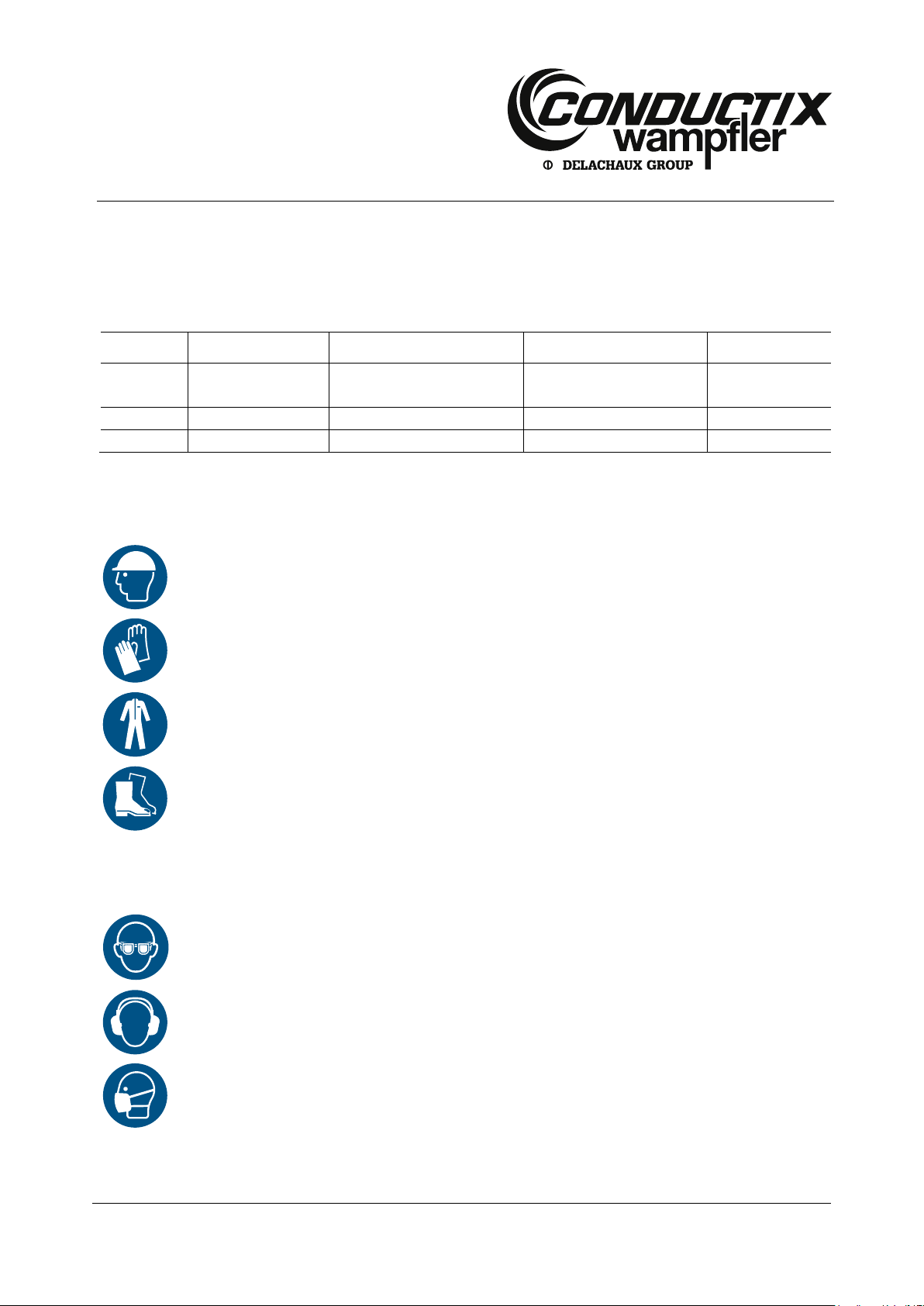

Date

Name

Type of training

Training given by

Signature

11/5/2009

John Doe

First safety training for

personnel

Dave Miller

Always use:

For all tasks:

Safety helmet

For protection against falling or flying parts and materials.

Protective gloves

For the protection of hands against friction, scrapes, puncture or deeper wounds, as well as against

contact with hot surfaces.

Protective work clothing

Primarily for protection against entrapment by moving machine parts. Work clothing must be close fitting

with a low resistance to tearing; it must have close-fitting sleeves and no protruding parts.

Protective footwear

For protection against heavy falling parts and slipping on slippery floors.

Used for special

tasks:

Specific protective equipment is required when executing particular tasks. Separate reference to this is

made in the individual sections.

Safety eyewear

For eye protection against harmful influences such as strong light, chemicals, dust, splinters or weather

effects.

Hearing protection

For protection against loud noises and to prevent acoustic trauma.

Breathing mask (FFP-3 — according to country-specific requirements)

For protection against materials, particles, and organisms. In this case, for protection against the dust produced by the abrasion of carbon brushes and the PVC insulation of the conductor rail.

ProfiDAT® Data Transmission System

2.2.3 Training

Before commissioning the equipment, personnel must be trained by the owner. Log the implementation of training for better traceability.

Example of a training log:

2.3 Personal Protective Equipment

MAL0514-0005b-EN

www.conductix.com translated document page 10 of 82

Page 11

Mounting Instructions

Programm 0514

WARNING!

Hazard due to improper use!

Any application that deviates from or goes beyond the intended use of the devices can result

in hazardous situations.

Strict compliance with the specifications of this installation manual is required.

Refrain from improper use of the system.

Respect the instructions on improper use in chapter 2.4.1.

ProfiDAT® Data Transmission System

2.4 Intended Use

The data-transmission system is designed and built exclusively for the usage described here (intended use).

Intended use

The ProfiDAT® data-transmission system is used for data communication between a base unit and a mobile system component.

In addition to the capacity to transmit data, the ProfiDAT® profile can also be used as a ground conductor rail together with conductor

rails in product ranges 0813/0812 (max. 1000 V/max. 1000 A).

Transmission of electrical power is not permitted.

The system comprises at least one access point and one client transceiver, together with the corresponding infeed and consumer

antennas.

Compliance with these technical conditions is mandatory for the installation:

The maximum permitted traversing speed of the mobile transceiver is 5 m/s.

The profile may only be installed horizontally with the access aperture facing down.

Side access is also feasible after prior technical testing and approval by the manufacturer.

Electrical-engineering operating conditions:

The electrical system must be protected in accordance with local regulations and guidelines.

The system may only be installed on the PE profile (protective conductor, green/yellow).

2.4.1 Improper use

Claims of any kind due to damage incurred during use that deviates from the intended use described above ("use other than the

intended use") are excluded.

The owner bears sole liability for any damage resulting from improper use.

Improper use in particular includes the following forms of use:

Operation that does not comply with the specified operating conditions (see chapter 3.5)

Use of the ProfiDAT

Use where there is a risk of explosion (“Ex”-classified zones)

Use of the transceiver without the profile

Use of transceivers not supplied by Conductix-Wampfler

Use of the system parallel to a conductor rail system of a brand/type not approved by Conductix-Wampfler

Use of the system with accessories that are not approved and not authorized by the manufacturer

Use of the system by untrained personnel

MAL0514-0005b-EN

www.conductix.com translated document page 11 of 82

®

profile for the transmission of power

Page 12

Mounting Instructions

Programm 0514

ProfiDAT® Data Transmission System

Environmental conditions

The ProfiDAT® data transmission system may only be used under the ambient conditions described in chapter 3.

The ProfiDAT® data transmission system must not be used under the following ambient conditions:

Temperatures below -25°C or above +50°C

Wind speeds above 25 m/s (10 Bft) or 32.7 m/s (12 Bft) if the system is inactive.

Solar irradiance levels greater than 1120 W/m² (for components directly exposed to sunlight)

2.5 Protective Measures to be taken by the Owner/Operator

The data transmission system is used in an industrial setting. The owner of the data transmission system is therefore subject to the

legal obligations concerning workplace safety. In addition to the safety instructions in this document, all safety, accident-prevention

and environmental regulations that apply where the data transmission system is used must also be observed. In particular, pay

attention to the following:

Work on electrical components of the system may only be carried out when disconnected from the power supply.

The owner must become acquainted with the applicable occupational-safety regulations and perform a risk analysis to identify

additional hazards arising from the specific working conditions where the system is used. This knowledge must be

implemented in the form of operating instructions for the data transmission system.

For the entire time that the data transmission system is in use, the owner must check whether the operating instructions it has

produced correspond to the current regulatory situation and adjust them if necessary.

The owner must clearly regulate and define responsibilities for installation, operation, troubleshooting and maintenance.

The owner must ensure that all employees involved with the system have read and understood this installation manual. The

owner must also train the personnel at regular intervals and inform them of hazards.

The owner must provide personnel with the necessary protective equipment.

The owner must keep the keys for switching cabinets in a safe place. "Safe" means that only explicitly authorized personnel

may have access to the keys. The keys may only be issued to specialist personnel as described in chapter 2.2.1.

The owner must verify that the operating frequency of the data transmission system is permitted in the place of use.

MAL0514-0005b-EN

www.conductix.com translated document page 12 of 82

Page 13

Mounting Instructions

Programm 0514

EMC Directive 2014/30/EU, including

EMC Directive

EN 6100-6-2

Interference immunity in industrial areas

EN 61000-6-4

Interference emissions for industrial areas

EN 61000-3-2

Limit values for harmonic currents

EN 61000-3-3

Limitation of voltage changes, voltage fluctuations and flicker in public low-voltage power

supply networks for devices with a nominal current of 16 A per conductor that are not

subject to special connection requirements

EN 62311

Assessment of electrical and electronic equipment with respect to limiting exposure of

persons to electromagnetic fields (0 Hz – 300 GHz)

Radio Equipment Directive

2014/53/EC, including

Radio equipment

EN 301 489-1 V1.8.1

EN 301 489-17 V2.2.1

Protection requirements with regard to EMC

EN 300 328 V1.8.1

EN 301 893 V1.7.1

Use of the radio frequency spectrum

EN 300 440-1 V1.6.1

Air interface for radio equipment

2,4 – 2,4835 GHz; 5,15 – 6,35 GHz; 5,47 – 5,725 GHz

Low Voltage Directive 2014/35/EU,

including:

Low Voltage Directive

EN 60950-22

Information-technology equipment: Equipment to be installed outdoors

EN 60529

Protection classes due to housings (IP code)

ProfiDAT® Data Transmission System

The owner must observe the following standards, regulations and directives when operating the system:

The owner is also responsible for ensuring that the data transmission system is always in perfect working order. The following thus applies:

The operator must ensure that the service intervals described in this document are observed.

The owner must have all safety systems inspected for functionality and completeness on a regular basis (once yearly if

possible, but at least as often as required by applicable national regulations).

If components or the system have been modified, the safety systems must be re-inspected and adapted to the changed

circumstances such that the system is safe again.

MAL0514-0005b-EN

www.conductix.com translated document page 13 of 82

Page 14

Mounting Instructions

Programm 0514

ProfiDAT® Data Transmission System

2.6 Special Hazards

The following chapter lists residual risks determined on the basis of a risk assessment.

Follow the safety instructions and warnings in this installation manual to reduce health hazards and to avoid dangerous situa-

tions.

2.6.1 5 Protective Safety Rules when working on Electrical Systems

Work on electrical systems only when they are disconnected from the power supply. Follow the 5 safety rules (see DIN VDE

0150-100:2009-10/EN 50110-1:2004-11) before starting work:

1. disconnect the system from the power supply at the main switch,

2. secure the main switch against being switched on again,

3. verify disconnection from the power supply by measurements,

4. ground and short-circuit parts of the system to be worked on,

5. cover or block off adjacent energized parts.

Only electricians or personnel trained in electrical work may disconnect power or approve reconnection of power after work

carried out in the disconnected state!

MAL0514-0005b-EN

www.conductix.com translated document page 14 of 82

Page 15

Mounting Instructions

Programm 0514

Risk of death by

electrical shock!

Risk of injury from

falling or being thrown

across the room after an

electrical shock!

Burns due to arcing

caused by short circuit!

Contact with energized components can lead to death or severe injury by electrical shock. There is also a risk of injury from shock reactions, falling or being

thrown across the room as a result of an electrical shock.

Work on the following components is dangerous:

Main power supply

Electrically live components: Power feed, cables, connections, conductor rail,

connectors, current collectors, devices and connections within switching

cabinets, control systems, etc.

Parts that have become live due to a fault

Before working on the parts listed above:

Switch off the powers supply of the conductor rail system according

to the 5 safety rules and secure it against being switched on again.

For the 5 safety rules, see Section 2.6.1.

During work:

Use insulated tools

Before switching on:

Every time before the system is started, test the insulation resistance

according to locally applicable technical standards, directives and legal

regulations.

Carry out locally required electrical tests.

Maintain electrical safety:

Regularly test and maintain electrical equipment.

If dangerous deficiencies are identified, take measures to correct the

deficiencies without delay. Inform the system operator immediately.

If it is not possible to correct the dangerous deficiency, block off the

area involved or turn the equipment off and secure it against being

switched on again. Inform the system operator immediately.

Immediately secure loose cables and replace damaged cables.

Always replace blown fuses with fuses of the same rating.

DANGER!

Fire hazard due to overload or sparking!

Fire hazards occur due to overloaded cables, electrical arcs, short circuits or sparking. Sparking

can occur in poorly serviced, contaminated conductor rails or if installation does not comply with

the required tolerances.

Compliance with permissible current ratings is mandatory.

Tolerances must be observed during installation.

Install electrical protection as prescribed.

Check, service, and clean conductor rails regularly and as prescribed. See the

information in the documents for conductor rail range 0812/0813.

ProfiDAT® Data Transmission System

2.6.2 Electrical Hazards and Sources of Danger

MAL0514-0005b-EN

www.conductix.com translated document page 15 of 82

Page 16

Mounting Instructions

Programm 0514

Risk of crushing injury!

Risk of impact injury!

There is a risk of crushing of skin and limbs due to:

Current collectors (spring force) during installation, dismantling and

maintenance

Falling parts of the data transmission system in case of improper installation or

unsuitable operating conditions (in solvent-containing environments, for

example)

Moving parts (current collectors, mobile equipment) when the system is in op-

eration

Do not enter the hazardous area of the system when in operation, except

for repair and maintenance tasks.

Have installation done only by trained technicians.

Wear safety footwear, protective gloves and a safety helmet when

working on the data transmission system.

When replacing the carbon brushes, follow the instructions in chapter

8.2.4.

Only install the system where suitable operating conditions prevail. See

chapter 3.5

Risk of injury when

cutting and trimming!

The ends of profiles and connectors can have sharp edges, especially if they have

been trimmed at the construction site and have not been deburred.

Use protective gloves and safety footwear.

During installation: Deburr insulating profiles and power rails after sawing.

When dismantling: Handle cut, removed profiles with care and store them

properly (transport or other container).

Be on the lookout for sharp edges near the installation area and avoid

contact.

Danger of injury by

falling objects!

ProfiDAT® profiles, current collectors and other components (e.g., antennas) can

fall off during operation or during any other work on the system. This can cause

severe injuries or fatalities if they fall from great heights.

Wear a safety helmet.

During installation, commissioning, troubleshooting, maintenance: Block

off the entire danger zone.

During decommissioning, dismantling, disposal: Block off the entire

danger zone. Handle cut, removed profiles with care and store them

properly (transport or other container).

ProfiDAT® Data Transmission System

2.6.3 Mechanical Hazards and Sources of Danger

MAL0514-0005b-EN

www.conductix.com translated document page 16 of 82

Page 17

Mounting Instructions

Programm 0514

Danger of injury by

catching and

entanglement!

There is a danger of being entangled in moving parts when the system is in

operation during installation, commissioning, or service. Moving parts include, for

instance, the crane and the current collectors attached to it.

Do not enter the hazardous area of the system when in operation, except

for repair and maintenance tasks.

Traverse at reduced speed!

Before working on the system, switch off the power supply of the

system according to the 5 safety rules and secure it against being

switched on again. For the 5 safety rules, see chapter 2.6.1.

Wear closely fitting work clothing.

ProfiDAT® Data Transmission System

MAL0514-0005b-EN

www.conductix.com translated document page 17 of 82

Page 18

Mounting Instructions

Programm 0514

Danger of sensitization,

irritation of the mucous

membranes, and

respiratory diseases due

to dust!

Abrasion debris from the carbon brushes collects in the ProfiDAT® profiles and the

guide profile. This dust is very fine and is classified as harmful to health. Frequent

exposure can lead to sensitization. Persons who frequently spend longer periods

in a heavily used system without protective equipment must reckon with the following consequences:

Irritations of the mucous membranes

Respiratory diseases

Cancer

These consequences must also be reckoned with if there is a lack of caution in

handling accumulated dust (by blowing out the dust with compressed air, for example).

In workplaces with long-term exposure and heavily use systems, take

effective measures to protect employees from the dust.

Use personal protective equipment during all work performed on the data

transmission system where accumulated dust can be stirred up. Use

personal protective equipment particularly when cleaning the system.

Safety eyewear

Dust mask, class FFP3

Gloves

Disposable coverall

Clean the profiles as prescribed before starting work. There are special

instructions for this task; see chapter 11.

During cleaning operations, protect the surrounding area, for example by

covering or removing stored materials and blocking off areas in which

dust could fall onto people.

Do not blow out dust with compressed air. Instead, vacuum it up. The

vacuum cleaner must be equipped with a Class H fine filter.

Do not eat, do not drink, do not smoke during the work!

Poisonous gases in case

of fire!

In the case of a fire in the system, the plastic parts of the conductor rail system (PVC) will emit

toxic gases (HCl).

Leave the system immediately.

Notify the fire brigade.

ProfiDAT® Data Transmission System

2.6.4 Danger due to Dust and Vapors

MAL0514-0005b-EN

www.conductix.com translated document page 18 of 82

Page 19

Mounting Instructions

Programm 0514

Danger by slipping and

falling!

When entering the system, there is a danger of slipping and falling due to

environmental conditions such as moisture, snow, water, contamination and wind.

Wear personal protective equipment when entering the system and during

all work on the ProfiDAT® system.

Suspend work on the ProfiDAT

®

system in strong wind: Risk of falling!

Clean severely contaminated system parts before entering.

Failure/fault of the control system, software error!

Failure of the data transmission system or a software error can result in unexpected system

movements.

A plausibility check of signals must be carried out by the customer's higher-level control

system. We recommend the use of PROFIsafe controllers.

Complete the start-up checklist, see chapter 6.6

Restore the energy feed

after failure of the power

feed!

Failure of the power feed can lead to uncontrolled movements of the system.

Initialization of the RAM memory (carried out automatically).

External influences on

electrical equipment due

to external sources of interference!

External sources of interference, such as radio or radar, can cause malfunctions of the

components and the WiFi network.

Use only shielded aluminum profiles made by the manufacturer.

A plausibility check of signals must be carried out by the customer's higher-level control

system.

ProfiDAT® Data Transmission System

2.6.5 Danger related to the Place of Use

The following characteristics of the ProfiDAT® system can cause hazards when the ProfiDAT® system is installed in its

operational environment:

Electrical energy

Sparking

Dust caused by abrasion (of the carbon brushes)

Material composition of the insulating profiles, which releases toxic vapors if burned

The most important measure to provide protection from these dangers is to install the ProfiDAT® system only in locations where

suitable operating conditions prevail. See chapter 3.5

2.6.6 Unexpected Startup, unexpected Movement

MAL0514-0005b-EN

www.conductix.com translated document page 19 of 82

Page 20

Mounting Instructions

Programm 0514

WARNING!

Risk of injury due to moving components!

When the system is operating, severe injuries can result if persons or objects are within the

movement range (hazard area!).

Do not start the system if there are persons or objects within the movement range

(hazard area!).

Exception: Repair and maintenance work. Traversing is only permitted at

reduced speed.

Make sure that the system cannot start up in an uncontrolled manner.

Do not reach into moving parts.

Block off the hazard area around the entire system.

WARNING!

Risk of injury due to moving components!

Serious injuries may occur if the system is moved in an uncontrolled manner.

Block off working and hazard areas.

Do not reach into moving parts. The interfaces between current collectors and rail-

fastening equipment are particularly dangerous.

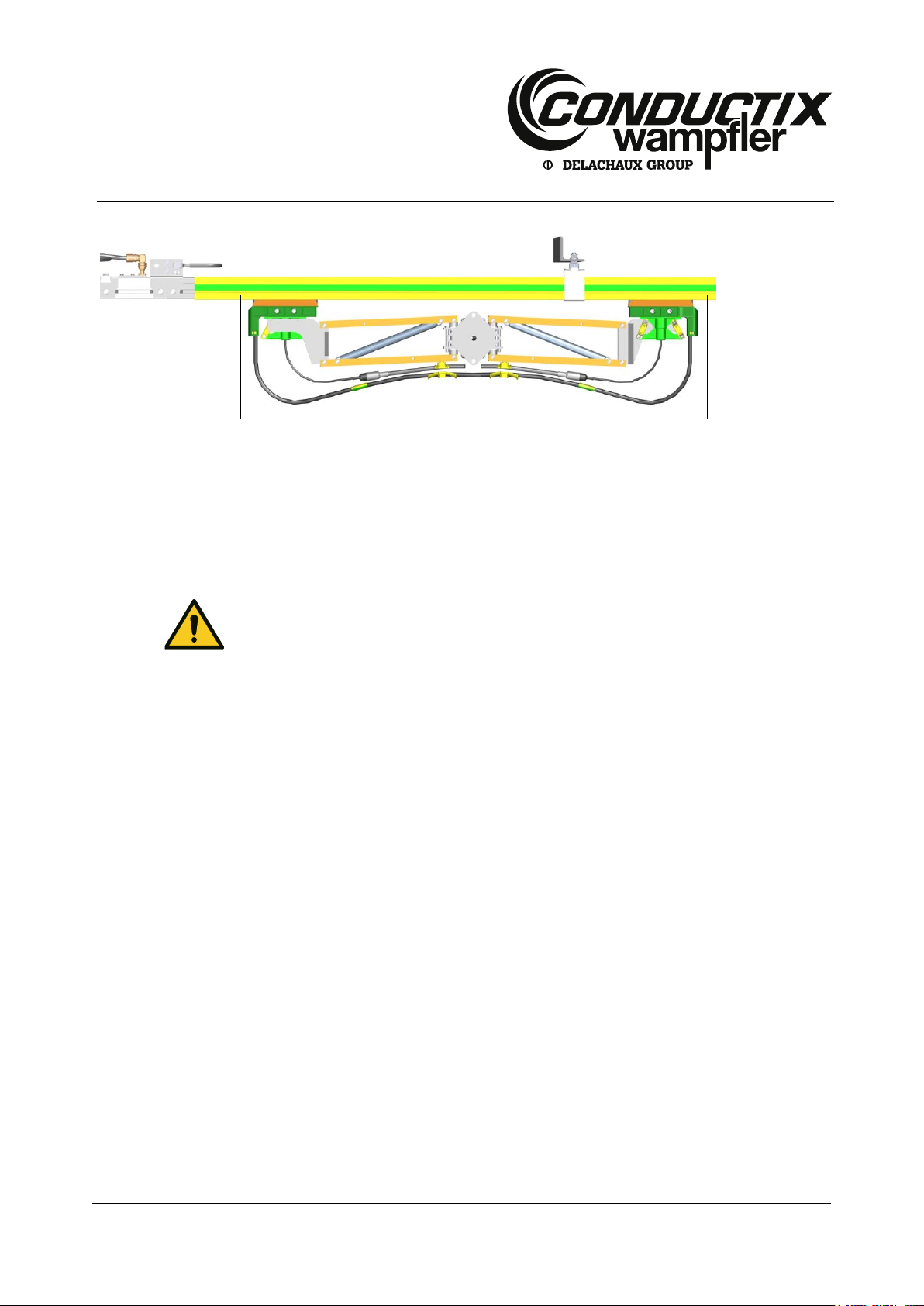

CAUTION!

Crushing hazard due to stored energy!

When working on the current collector, there is the risk of crushing extremities due to

uncontrolled movements as a result of the energy stored in the spring.

The spring force must be taken into consideration, during all works on the current

collector. Do not reach between profiles and current collectors (see Fig. 1).

During installation, maintenance and repair works: Check the spring force with

caution.

ProfiDAT® Data Transmission System

2.6.7 Emergency Stop

The ProfiDAT® data transmission system is used for transparent transmission of safety-relevant signals. These signals must be

generated by a higher-level component. Suitable safety components must be used to guarantee the emergency-stop function. The

emergency stop must be implemented using safety equipment provided by the customer and depends on the nature of the power

supply.

We recommend the use of a PROFIsafe system.

2.6.8 Hazard Areas

MAL0514-0005b-EN

www.conductix.com translated document page 20 of 82

Page 21

Mounting Instructions

Programm 0514

Fig. 1: Sketch of the hazard area at the current collector

WARNING!

Risk of death due to inoperative safety devices!

Safety is only guaranteed if the safety devices are intact.

Before starting work, check that the safety systems are serviceable and properly

installed.

Never disable or deactivate safety systems.

Danger area

ProfiDAT® Data Transmission System

2.7 Safety Devices

The data transmission system has no safety devices. The system is always operated in conjunction with the plant in which the data

transmission system is installed. Therefore pay attention to the safety equipment of the plant!

MAL0514-0005b-EN

www.conductix.com translated document page 21 of 82

Page 22

Mounting Instructions

Programm 0514

Conductix-Wampfler GmbH

Rheinstrasse 27 + 33

79576 Weil am Rhein – Märkt

Germany

Phone: +49 (0) 7621 662-0

Fax: +49 (0) 7621 662-144

info.de@conductix.com

www.conductix.com

ProfiDAT® Data Transmission System

2.8 Conduct in the Event of Accidents and Malfunctions

Measures to take in the event of accidents:

Shut down the system and secure it against unauthorized, unintentional and/or erroneous activation.

Secure the danger zone

Remove persons from the danger zone.

Initiate first-aid measures

Alert the rescue services

Inform responsible parties at the operating site

Clear access routes for emergency vehicles

Measures to take in the event of malfunction:

Shut down the system and secure it against unauthorized, unintentional and/or erroneous reactivation.

Secure the work area against entry

Consult qualified personnel when analyzing the fault

Involve authorized personnel for maintenance and repair

Check for disconnection from power

Remove the component and replace with a new component

Determine the cause of the fault and repair the component

Conductix-Wampfler must be informed immediately if personal injury or material damage can occur during breakdowns.

MAL0514-0005b-EN

www.conductix.com translated document page 22 of 82

Page 23

Mounting Instructions

Programm 0514

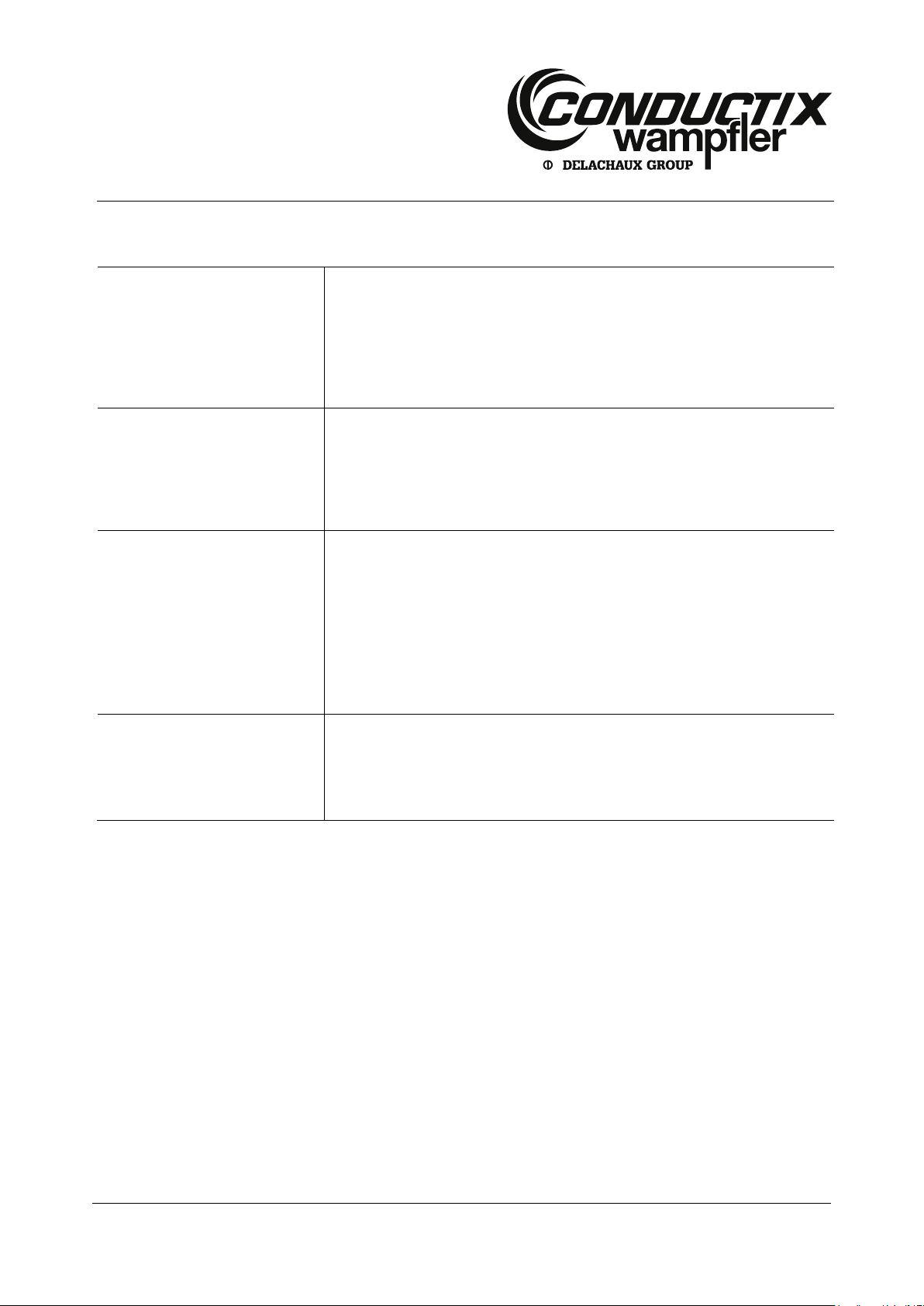

Designation

Value, unit

System length (without segmentation)

500 m

Profile length

5000 mm

External profile dimensions (width x height)

50 mm x 56 mm

Power supply:

ProfiDAT® transceiver

ProfiDAT® infeed cabinet

24 V DC*

120–500 V AC / 50–60 Hz

Maximum data transmission rate

100 Mbit/s

Maximum travel speed of the mobile transceiver

(connection trolley)

5 m/s

Interface

Ethernet (RJ45 as standard)

System service life (except wear parts and

electrical components)

10 years

ProfiDAT® Data Transmission System

3 Technical Specifications

3.1 General Information

* Deviations may occur, see the manufacturer’s documentation (chapter 11.2 “Other applicable Documents”)

3.2 Interfaces

3.2.1 Electrical

The interfaces to the customer system are:

Data interface

Power supply/control voltage

PE

Data interface: ProfiDAT Ethernet, RJ45 connection.

The customer has to connect the ProfiDAT® system with its own system at both ends of the ProfiDAT® system with a RJ45 connector

or an optional LC (fiber-optic) connector. The interface is located on both the mobile and the stationary transceivers.

The customer system must provide the data using the Ethernet protocol. If the customer control system is not Ethernet capable, the

appropriate conversions must be made.

PE interface:

The interface for the customer's grounding cable is located at the PE rail connector (see chapter 4.3.1). At the flap (M10 drilled hole),

the PE cable must be connected according to the applicable standards.

MAL0514-0005b-EN

www.conductix.com translated document page 23 of 82

Page 24

Mounting Instructions

Programm 0514

Description

Voltage/frequency

AC power supply

Infeed switching cabinet

120–500 V, 50/60 Hz

DC control voltage

Transceiver

24 V DC*

WARNING!

Danger of injury by current collector!

Failure to comply with the prescribed supply voltages for the controller can cause a controller

failure and electrical components may be destroyed. As a result, the current collector may run

jerkily and hit persons or objects.

Observe and comply with the prescribed supply voltages.

Keep persons and objects out of the hazard area (see chapter 2.6.6).

ProfiDAT® Data Transmission System

Power supply/control voltage:

The controller of the ProfiDAT® data transmission system requires the following power supply:

* Deviations may occur, see the manufacturer’s documentation (chapter 11.2 “Other applicable Documents”)

On commissioning of the transceiver devices, please observe that the cycle periods for the ProfiDAT® communication distances must

be adapted.

The cycle period must be at least 32 ms (but can differ depending on the application) and must be adjusted accordingly in the superior

control assembly group.

3.2.2 Mechanical

The interface between the data transmission system and the system is:

Current collector

The current collector on the ProfiDAT® profile performs a dual function. Two divided carbon brushes guide the current collector on

the ProfiDAT® profile. The carbon brushes secure the connection to the ground conductor rail (ProfiDAT® profile) while data

transmission occurs via the two built-in antennas. The antennas are inserted into the slot in the ProfiDAT® profile and are electrically

isolated from the carbon brushes.

MAL0514-0005b-EN

www.conductix.com translated document page 24 of 82

Page 25

Mounting Instructions

Programm 0514

Designation

Value, unit

Ethernet

1 x 100 Mbit/s RJ45*

Supply voltage:

24 V DC*

Data rate

up to 100 Mbit/sec

Operating frequency

4.9–5.8 GHz**

Energy consumption

See the data sheet for the transceiver

Temperature range

See the data sheet for the transceiver

Dimensions (width x height x depth)

See the data sheet for the transceiver

Weight

See the data sheet for the transceiver

Designation

Value, unit

Temperature range

-25°C to +50°C

Min. bending radius

40 mm

Tension force

50 N

Recommended coupling torques:

N connector

SMA/R-SMA

4–6 Nm

79–113 Ncm

CAUTION!

The HF cables may not be squeezed (for instance through firm pulling at the cable binder).

Observe the bending radius of the HF cables.

Maintain the recommended coupling torque.

ProfiDAT® Data Transmission System

3.3 Technical Data for the Transceiver

* Deviations may occur, see the manufacturer’s documentation (chapter 11.2 “Other applicable Documents”)

** Country-specific deviations may occur

Please note the information in the documentation of the transceiver, see chapter 11.2. “Other applicable documents”.

3.4 Technical Data for HF Cables

The following values must not be exceeded:

MAL0514-0005b-EN

www.conductix.com translated document page 25 of 82

Page 26

Mounting Instructions

Programm 0514

Designation

Value

Notes

Minimum

Maximum

Conditions

Ambient temperature

-25°C

+50 °C

At a relative humidity of

[100% at +20°C]

Wind speed in operation

25 m/sec (10 Bft)

Wind speed when not in operation

32.7 m/sec (12

Bft)

CAUTION!

Faults due to incorrect operating conditions!

Operating conditions outside the specified range can lead to malfunctions due to short circuits,

premature aging, and damage to electrical and mechanical components.

Important parameters are:

Dust and deposits

Humidity/condensation

Cold/hot temperatures

Corrosion

ProfiDAT® Data Transmission System

3.5 Operating Conditions

MAL0514-0005b-EN

www.conductix.com translated document page 26 of 82

Page 27

Mounting Instructions

Programm 0514

Fig. 2: Overview

ProfiDAT® Data Transmission System

4 Product Description and Mode of Operation

4.1 Overview

4.2 Brief Description

The ProfiDAT® data transmission system provides a means of communication between the base station and the mobile system

component. The ProfiDAT® system is installed parallel to the electrification system.

In addition to data transmission, the ProfiDAT® profile can simultaneously be used as a ground conductor rail. The system has a

variable length. It consists of at least one fixed and one mobile transceiver, the infeed antenna and the consumer antenna. Hanger

clamps are used to fasten the profiles to the steel construction, which is provided by the customer. The profiles are mechanically

attached using connectors that ensure the stability and secure connection of the profiles. Data is fed into and received from the

profile by means of an infeed antenna attached at the end of the system (end infeed) or within the system (central infeed/section

infeed). The mobile consumer antenna can continuously receive and transmit data.

Examples of applications are:

High-performance crane systems

Rope-drawn STS crane-trolley systems

People movers/passenger transportation systems

Portable electrical consumers

MAL0514-0005b-EN

www.conductix.com translated document page 27 of 82

Page 28

Mounting Instructions

Programm 0514

Fig. 3: Profile

Profile (slotted wave guide)

The profiles are used as a data channel. They are electrically conductive

and are simultaneously used as a protective conductor (PE).

The standard length of a profile is 5000 mm. The outer dimensions are

50 x 56 mm (width x height). The conductor cross-section is at least

585 mm².

Fig. 4: Hanger clamp

Hanger clamp

The rail clamps are attached to the supporting construction with nuts and

bolts, which are provided by the customer.

The hanger clamps are pushed onto the profiles. Two hanger clamps are

installed for each profile. The spacing between hanger clamps is

2500 mm.

Fig. 5: Hanger clamp for installation on a C-rail

Hanger clamp for installation on a 40 x 40-mm C-rail

Fig. 6: Anchor point

Anchor point

The anchor point is fixed to the hanger clamp and the PE rail connector

and is used to create a fixed point.

Fig. 7: Rail connector

Fig. 8: PE rail connector

Rail connector

The rail connector connects two profiles together and is screwed onto

the profile.

There are two types of connectors:

Connector, simple

PE connector, with connection for a grounding cable

The ground cable is attached to the lug (PE rail connector).

There must be a PE connector every five profiles (every 25 m) and at

each expansion element.

ProfiDAT® Data Transmission System

4.3 Description of Assemblies

4.3.1 ProfiDAT

®

System

MAL0514-0005b-EN

www.conductix.com translated document page 28 of 82

Page 29

Mounting Instructions

Programm 0514

Fig. 9: Infeed antenna

Fig. 10: Infeed antenna for funnel

Infeed antenna (infeed unit) with cable

The feed-in antenna is installed at the end of the system (end infeed). It

is used to feed data signals in and out.

System lengths up to 250 m are possible with end infeed.

There are two types of antennas:

Antenna screwed to the profile

Antenna for funnels, attached to the profile with a connector

At the end of the ProfiDAT® section, there is a terminating element with a

terminating resistance that attenuates the signal to the point that no

interference emissions are produced for other equipment in the vicinity of

the data transmission system.

Fig. 11: Expansion element

Expansion element

The expansion element connects two ProfiDAT® profiles together,

compensating for changes in the length of profiles due to temperature

fluctuations.

The expansion element is fastened to the ProfiDAT® profile using PE rail

connectors as well as by screws to the load-bearing profile. A flexible

cable transmits the data signal between the two antennas.

The expansion element can also be used as a section infeed. This allows system lengths of 500 m to be achieved. Segmentation makes the

system expandable (see chapter 6.4.8.2).

Fig. 12: Entry funnel

Entry funnel

The entry funnel is installed at the drive-in zone. The entry funnel guides

the current collector onto the conductor rail.

The entry funnel can only be used in systems with the slot facing down.

ProfiDAT® Data Transmission System

MAL0514-0005b-EN

www.conductix.com translated document page 29 of 82

Page 30

Mounting Instructions

Programm 0514

Fig. 13: Current collector (dual collector)

Fig. 14: Current collector (single collector)

Current collector

Two divided carbon brushes guide the current collector on the ProfiDAT® profile. The antennas are inserted into the slot in the ProfiDAT®

profile and are electrically isolated from the carbon brushes.

Use of the single collector:

If there are no transitions in the traversing range

If there are no expansion joints in the system

With end infeed

Fig. 15: Overview and arrangement of the electrical components

1

ProfiDAT® adapter cable

10

ProfiDAT® transceiver with 24 V power supply line

2

Infeed connection

11

R-SMA plug, terminating resistor 50 Ohm / 6 GHz / 1 W

3

Antenna adapter cable

12

N-connector terminating resistor, 50 Ohm / 6 GHz / 1 W

4

Antenna connection

A

Infeed switching cabinet

B

Current collector

C

Moving system part

D

ProfiDAT® profile

E

Expansion element (optional, depending on system type)

ProfiDAT® Data Transmission System

4.3.2 Electrical Components

MAL0514-0005b-EN

www.conductix.com translated document page 30 of 82

Page 31

Mounting Instructions

Programm 0514

© Siemens AG 2017. All rights reserved

Fig. 16: Transceiver (sample photo)

The transceiver is a PROFINET/PROFIsafe-compatible communication device

based on the IEEE 802.11n standard. Communication with PROFINET-IO uses

a Layer 2 Tunneling Protocol (L2TP).

Installation can be on a wall, profile, or DIN rail.

The figure shows an example, because various transceiver types are available.

See the manufacturer’s documentation for a detailed description of the

transceiver (chapter 11.2 “Other applicable Documents”).

Fig. 17: Infeed switching cabinet

The power feed cabinet contains the component needed to mount a ProfiDAT®

transceiver on the system. From the switching cabinet, the antenna connection

of the ProfiDAT® transceiver is connected to the infeed antenna on the

ProfiDAT® profile.

The ProfiDAT® transceiver is mounted on the DIN rail.

The infeed cabinet contains:

1) Transceiver (access point)

2) Thermostat/hygrostat

3) DIN rail (35 x 15 mm)

4) LED display/indicator light (optional)

5) Heating element (mounted in the side wall)

6) Connector terminals

7) Line circuit breaker

8) Power supply

Dimensions: 380 x 600 x 210 mm (width x height x depth)

ProfiDAT® Data Transmission System

Transceiver

ProfiDAT® power feed cabinet

Connectors:

Power supply (screw connection): 120–500 V AC / 50–60 Hz

Ethernet cable (screw connection):

N connector

Ground cable

MAL0514-0005b-EN

www.conductix.com translated document page 31 of 82

Page 32

Mounting Instructions

Programm 0514

“24V OK” indicator lamp

(in the door):

Lit: ProfiDAT® transceiver power supply is active.

ProfiDAT® Data Transmission System

Display:

HF cables

HF cables are used for connector cables and adapter cables for the transmission of data between the transceiver and antennas (see

Fig. 15).

4.4 Modes of Operation

The ProfiDAT® data transmission system is used in the “normal operation” mode.

4.4.1 Normal Operation

During normal operation, the operator controls the system. No person may be present in the working area during normal operation

to monitor the working process. Traversing commands are given exclusively by the operator.

MAL0514-0005b-EN

www.conductix.com translated document page 32 of 82

Page 33

Mounting Instructions

Programm 0514

WARNING!

Risk of death due to suspended loads!

When lifting loads, there is a risk of death from falling parts or parts swinging out of control.

Never walk under suspended loads.

Follow the specifications provided for the attachment points.

Do not lash to protruding machine parts or eyelets on attached components. Be sure

the lashing elements are firmly seated.

Use only authorized lifting gear and lashing components with sufficient load capacity.

Do not use torn or worn ropes or straps.

Do not attach ropes or straps at sharp corners and edges, and do not knot or twist

them.

Damage due to improper

transport!

Damage due to improper transport!

Improper transport can result in substantial property damage.

Unload packaged parts upon delivery and during internal transport with care, and ob-

serve the symbols and the hazard information on the packaging.

Use only the provided lashing points.

Wait until just before installation, for removing packaging material.

ProfiDAT® Data Transmission System

5 Transport, Packaging and Storage

5.1 Shipment

5.1.1 Safety Instructions for Transport

5.1.2 Transporting packaged Parts

Transport packed parts under the following conditions:

Dry and free of dust.

Do not expose to aggressive media.

Protect from direct sunlight.

Avoid mechanical vibrations.

Transport temperature: -25 to +50 °C.

Relative humidity max. 60 %

MAL0514-0005b-EN

www.conductix.com translated document page 33 of 82

Page 34

Mounting Instructions

Programm 0514

CAUTION!

File a complaint on every defect, as soon as it is detected. Damage compensation claims may

only be made within the applicable claim periods.

WARNING!

Environmental damage due to improper disposal!

Packaging materials are valuable resources and can often be reused or usefully processed

or recycled.

Dispose of packaging materials in an environmentally appropriate manner.

Comply with locally applicable disposal guidelines; if necessary, engage a specialist

company to handle the disposal.

ProfiDAT® Data Transmission System

5.1.3 Transport Inspection

Check the delivery for completeness and transport damage immediately upon receipt.

If transport damage is externally visible, proceed as follows:

Do not accept delivery, or accept it only with reservations.

Note the scope of damage on the transport documents or on the transporter's delivery note.

Submit a complaint.

5.2 Packaging

The individually packaged parts are packed in accordance with the anticipated transport conditions. Only environmentally friendly

materials have been used for packaging.

The packaging is designed to protect the individual components from transport damage, corrosion and other damage until installation.

As a result, do not destroy the packaging and remove it only shortly before installation.

Handling packaging materials:

Dispose of packaging material according to valid legal regulations and local guidelines.

MAL0514-0005b-EN

www.conductix.com translated document page 34 of 82

Page 35

Mounting Instructions

Programm 0514

CAUTION!

In some cases, there may be instructions for storage on the packed parts that go beyond the

requirements listed here. Comply with them accordingly.

ProfiDAT® Data Transmission System

5.3 Storage of packaged Parts

Store packaged parts under the following conditions:

Do not store outdoors.

Store in a dry, dust-free place.

Do not expose to aggressive media.

Protect from direct sunlight.

Avoid mechanical vibrations.

Storage temperature: 15 to 35 °C

Relative humidity: max. 60%

When storing for more than 3 months, check the general condition of all parts and the packaging at regular intervals. If

necessary, refresh or replace the preservative

MAL0514-0005b-EN

www.conductix.com translated document page 35 of 82

Page 36

Mounting Instructions

Programm 0514

WARNING!

Risk of death due to suspended loads!

Falling loads can cause serious injuries or even death.

Never walk under suspended loads.

Only move loads under supervision.

Set down the load before leaving the workplace

Injury due to improper installation and initial commissioning!

Improper installation and commissioning can result in serious personal injury and/or material

damage.

Before starting work, ensure sufficient space for assembly.

Handle open, sharp-edged components with care.

Make sure the installation area is tidy and clean! Loosely stacked or scattered

components and tools are sources of hazards.

Install components properly. Comply with specified screw tightening torques.

ProfiDAT® Data Transmission System

6 Installation and Commissioning

6.1 Safety

Personnel:

Installation and commissioning may only be carried out by specially trained technicians!

Use the following personal protective equipment for all installation and commissioning work:

Protective work clothing

Safety helmet

Protective footwear

Protective gloves

MAL0514-0005b-EN

www.conductix.com translated document page 36 of 82

Page 37

Mounting Instructions

Programm 0514

ProfiDAT® Data Transmission System

6.2 Preparations

Required tools:

Open-ended spanner, SW10

Open-ended spanner, SW17

Open-ended spanner, SW24

Set of Allen keys, SW3

Allen key, SW5

Phillips screwdriver

Torque wrench

Lubricant

Hot air blower

Chop saw

Required material:

Cable ties

Shrink sleeve

Conductive paste 080021

Lubricant for stainless-steel screws, recommended: Klüber 46 MR 401 paste

Klüber Lubrication München KG

Geisenhausenerstr. 7

D-81379 Munich

Screw tightening torques:

M6 screw (SW10 open-ended spanner): 8 Nm

M10 screw (SW17 open-ended spanner): 40 Nm

MAL0514-0005b-EN

www.conductix.com translated document page 37 of 82

Page 38

Mounting Instructions

Programm 0514

DANGER!

Risk of death by electrical shock!

The steel structure may be at high voltage if it is not properly grounded.

Contact with the steel structure can lead to death or severe injury. There is also a high risk of

injury from overreaction caused by electrical shock.

Read and follow the locally applicable and international guidelines for proper ground

installation and lightning protection.

Provide the grounding installation that is appropriate to the architecture of the power

grid at the place of installation of the system (TT network or TN network).

Connect the steel structure to the grounding installation.

Install a conductive connection between all parts of the steel structure. Use toothed

washers for screw connections or other suitable components to establish a conductive

connection between coated components

Regularly check the proper grounding of the steel structure.

ProfiDAT® Data Transmission System

6.3 Grounding

The system operator must ensure sufficient grounding of the steel structure, especially the painted components. Safety regulations

and country-specific directives for the grounding of electrical equipment (e.g. VDE/UVV/VBG4) must be followed.

The grounding of the steel structure must be taken into consideration for different application cases:

Protection against electrical shock

Lightning protection

6.3.1 TN Network

In a TN network, the ProfiDAT

power supply transformer.

The total impedance between phase conductor and PE conductor must not exceed 0.16 Ω.

®

profile (ground conductor rail) is connected by a cable directly to the grounded star point of the

6.3.2 Grounding Implementation Instructions

The ProfiDAT

every fifth conductor rail joint. The cross-section of the connector cable must be at least 16 mm².

Locally applicable standards or regulations may require different (lower) grounding impedance values. The system operator

must check the locally applicable standards or regulations and implement the grounding system accordingly.

The grounding impedance must be measured during installation and a test report prepared with the following content:

MAL0514-0005b-EN

www.conductix.com translated document page 38 of 82

Condition of the grounding unit,

Extent of corrosion and corrosion protection,

Fastenings of the cables and components,

Measurement of grounding impedance,

Documentation of modifications and extensions.

®

profile (ground conductor rail) must be connected to the load-bearing profile at the start and end, as well as at

Page 39

Mounting Instructions

Programm 0514

The following describes the installation of the data transmission system step by step in a logical

sequence. Some steps may be carried out in parallel on site.

The hanger clamps are designed as sliding suspension devices so that profiles can expand or

contract as the temperature changes. To this end, it is necessary to install defined anchor points

and expansion points. The expansion element performs the functions of both the anchor point

and the expansion point.

The anchor point of the expansion element points toward the left-hand end of the system.

Fig. 18: Installation of the ProfiDAT® expansion element (shown without connecting cable)

1

2

ProfiDAT® Data Transmission System

6.4 Mechanical Installation

Personnel:

Installation by technical personnel only

At least two people

6.4.1 Installation of the Expansion Element

Depending on the system type, the installation of one or more expansion elements is necessary. The air gap in the expansion element

must be adjusted depending on the ambient temperature during installation. Both expansion joints of the expansion element must

have the same air gap.

Starting from the left-hand end of the system, the first expansion element for the ProfiDAT® profile is installed. All other expansion

elements are mounted at intervals of at most 50 m. The exact positions of the expansion elements can be found in the system layout.

Work steps:

Fix the expansion element (1) to the support structure using two fastening screws (2).

Read the air gap "s" from the table in Fig. 19 and adjust it.

MAL0514-0005b-EN

www.conductix.com translated document page 39 of 82

Page 40

Mounting Instructions

Programm 0514

Fig. 19: Determining the air gap for the expansion element

Ensure that the air gaps on the expansion elements are not displaced during the further

installation of the profiles!

-10

-20

-30

+10

0