Page 1

2596061 EN 1905

IMPORTANT! Read and save these instructions. This manual to be left with the equipment.

INSTALLATION AND

OPERATION MANUAL

Adiabatic Humidification System

Condair MLP

US version

Humidication and Evaporative Cooling

Page 2

Thank you for choosing Condair

Installation date (DD/MM/YYYY):

Commissioning date (DD/MM/YYYY):

Site:

Model:

Serial number:

Contact

Condair Ltd.

2740 Fenton Road, Ottawa, Ontario K1T3T7

TEL: 1.866.667.8321, FAX: 613.822.7964

EMAIL: na.info@condair.com, WEBSITE: www.condair.com

Condair Inc.

2700 90th Street

Sturtevant, WI., USA 53177

TEL: 1.866.667.8321, FAX: 613.822.7964

EMAIL: na.info@condair.com, WEBSITE: www.condair.com

Proprietary Notice

This document and the information disclosed herein are proprietary data of Condair Ltd. Neither this document, nor

the information contained herein shall be reproduced, used, or disclosed to others without the written authorization

of Condair Ltd., except to the extent required for installation, operation or maintenance of the customer's equipment.

Liability Notice

Condair Ltd. does not accept any liability due to incorrect installation, maintenance or operation of the equipment,

or due to the use of parts/components/equipment that are not authorized by Condair Ltd.

Copyright Notice

© Condair Ltd., All rights reserved.

Technical modication rights reserved.

Page 3

Contents

1 Introduction 5

1.1 Before You Start! 5

1.2 General 5

2 For Your Safety 7

2.1 Safety 7

2.2 Health & Hygiene 8

3 Receiving and Storage 10

3.1 Inspection 10

3.2 Storage and Transportation 10

4 Site Planning 11

4.1 Prior to Starting 11

4.2 General Notes on Positioning 11

4.3 Experts on Site 12

5 Product overview 13

5.1 General description 13

5.2 Model Designation 14

5.3 MLP 100/300 Overview 16

5.4 MLP 500 Overview 17

5.5 MLP 2x800 overview 18

5.6 Principal installation diagram 19

5.7 Inlet water quality requirements 20

5.8 Optional equipment for MLP 20

5.9 MLP options list 21

5.10 MLP accessories list 22

6 Installation 23

6.1 General 23

6.2 Site Requirements and Sizing 24

6.3 Positioning the pump station 25

6.4 Water connection 26

6.5 Electrical installation 27

6.5.1 Power Supply Connection 28

7 Commissioning 29

7.1 Tools and materials for commissioning work 29

7.2 Inlet lter 30

7.3 Prepare for pump ush 31

7.4 Basic set-up of the controller 32

7.5 Pump ush procedure 37

3Contents

Page 4

8 Operation 38

8.1 Overview control unit 38

8.2 Equipment protection 39

8.3 Alarm messages 40

8.4 Controller menu 42

8.4.1 Alarms and user messages 43

8.4.2 Parameter change menu 44

8.4.3 Settings for section parameters 44

8.4.4 Pump 45

8.4.5 Conductivity monitoring, humidity logging and CIP (options) 46

8.5 Weekly inspection 47

9 Maintenance 48

9.1 Important notes on maintenance 48

9.2 Maintenance work 49

9.3 Preventive spare parts chart 50

9.4 Weekly check list 51

9.5 Troubleshooting 52

9.5.1 Malfunction with error indication 52

9.5.2 Resetting the error indication 53

9.5.3 Malfunction without error indication 54

10 Product data 55

11 Declaration of conformity 56

A Appendix 57

A.1 Siemens Scalence Router (option) 57

A.2 Optional Modbus TCP/IP 64

A.3 Setpoint 67

A.4 Temperature Sensor 69

A.5 Electrical Settings in the Humidity Regulator 70

A.6 Overview of calibration for conductivity sensors and converters (ampliers) 71

A.7 ML-system - Condair Ltd. 73

B Appendix 77

B.1 Installation Checklist 77

B.2 Commissioning Checklist 77

B.2.1 Pre-Start-Up Checklist 78

B.2.2 Performance Checklist 80

4 Contents

Page 5

1 Introduction

1.1 Before You Start!

Thank you for purchasing the Condair ML direct room high pressure adiabatic humidication system.

The Condair ML adiabatic humidier incorporates the latest technical advances and meets all recognized safety standards. Never-the-less, improper use of the Condair ML adiabatic humidier may result

in danger to the user or third parties, and/or damage to property.

To ensure safe, proper and economical operation of the Condair ML adiabatic humidier, observe and

comply with all information and safety instructions contained in this manual, as well as all relevant documentation of components of the installed humidication system.

If you have additional questions, contact your local Condair representative. They will be glad to assist you.

1.2 General

Limitations

The subject of this manual is the Condair ML direct room humidication pump stations and associated

equipment whether ancillary or supplementary. The various options and accessories may only be described

in-so-far as is necessary for proper installation and operation of the equipment. Additional information

on available options and accessories can be obtained in the instructions that are supplied with them.

This manual is restricted to the installation, operation, technical data and parts of the Condair ML direct

room humidication pump stations, and is intended for well trained personnel who are suitably qualied

for their respective tasks.

Symbols Used in This Manual

CAUTION!

The word "CAUTION" in conjunction with the general caution symbol is used to provide safety instructions that, if neglected, may cause damage and/or malfunction of the unit or damage to property.

WARNING!

The word "WARNING" in conjunction with the general warning symbol is used to provide safety instructions that, if neglected, may cause injury to personnel. Other specic warning symbols may also

be used in place of the general symbol.

Condair MLP

DANGER!

The word "DANGER" in conjunction with the general danger symbol is used to provide safety instructions that, if neglected, may cause severe injury to personnel or even death. Other specic danger

symbols may also be used in place of the general symbol.

XXXXXXX_EN_1905

5Introduction

Page 6

Other Related Publications

This manual is supplemented by other publications such as the ML Heads Installation Guide, which

are included in the delivery of the equipment. Where necessary, appropriate cross-references to these

publications have been added in this manual.

Storage of Manual

Keep this manual in a place where it is safe and readily accessible. If the equipment is moved to another

location, make sure that the manual is passed on to the new user.

If the manual is lost or misplaced, contact your Condair representative for a replacement copy.

Language Versions

This manual is also available in other languages – contact your Condair representative.

6 Introduction

XXXXXXX_EN_1905 Condair MLP

Page 7

2 For Your Safety

2.1 Safety

DANGER!

Always isolate all supplies to the system before commencing any maintenance or repair.

General

Every person who is tasked with the installation, operation or maintenance of the Condair ML adiabatic

humidier must read and understand this manual before performing any work. Knowing and understanding

the contents of the installation manual and the operation and maintenance manual is a basic requirement for protecting personnel against any kind of danger, preventing faulty operation, and operating the

unit safely and correctly.

All labels, signs and marking applied to the Condair ML adiabatic humidier must be observed and kept

in a readable state.

Personnel Qualications

All procedures described in this manual must only be performed by personnel who are adequately qualied, well trained and are authorized by the customer.

For safety and warranty reasons, any activity beyond the scope of this manual must only be performed

by qualied personnel authorized by Condair.

All personnel working with the Condair ML adiabatic humidier must be familiar with, and comply with

the appropriate regulations on workplace safety and prevention of accidents.

Intended Use

The Condair ML humidication heads are intended exclusively for adiabatic humidication and/or evaporative cooling using a RO water supplied (by others) Condair MLP high pressure pump station within

specied operating conditions (refer to the Condair MLP IOM for details). Any other type of application,

without the express written consent of Condair, is considered to be not conforming to its intended purpose, and may lead to dangerous operation and will void the warranty.

In order to operate the equipment in the intended manner all information contained in this manual, in

particular the safety instructions, must be observed closely.

Safe Operation

If it is suspected that safe operation has been compromised, the ML-System should immediately be shut

down and secured against accidental power-up.

Shut down the Condair ML Humidication System if:

Condair MLP

– Components are damaged, worn or very soiled

– Fans have stopped or are noisy

– Joints, pipes or hoses are leaking

– Unusual or very loud noise

No modications must be made on the ML-System without the manufacturer’s consent. All persons

working with the system must report to the owner if any alterations are detected.

Use only original accessories and spare parts available from your Condair representative.

XXXXXXX_EN_1905

7For Your Safety

Page 8

2.2 Health & Hygiene

DANGER!

Risk of infection or serious illness

The Condair ML System must be installed, operated and maintained in accordance with this manual.

Failure to do so could result in contamination that might cause Legionnaires’ disease, which can be fatal.

DANGER!

Risk of water contamination

To prevent water stagnation and microbial contamination, the systems power supply should be left

switched on. If the system is switched off for more than 48 hours, the pipework and system must be

disinfected as per the instructions, and a full risk assessment must be undertaken to ensure safe

operation.

Health Risks

Please observe the local health and safety codes, standards and technical guidance on the control of

Legionella in water systems.

The user is responsible for ensuring that the water system complies with local regulations, bye-laws and

guidelines (such as the HSE ACoP L8, VDI 6022, ISO 22000, HACCP or equivalent). If inadequately

maintained, water systems, of which any humidier is a part, can support the growth of microorganisms,

including the bacterium that causes Legionnaires’ disease.

Condair ML systems, products and components are produced according to the ISO 22000 standards,

which means that we have considered all aspects of this equipment to reduce the risk of Legionnaires’

disease and other similar conditions. However, the user is responsible for ensuring that the installation,

operation and maintenance work on the equipment is performed in a manner ensuring that the system

stays clean.

Any risks or hazards relating to the system, including during installation and maintenance, should be

identied by a competent health and safety representative who is responsible for introducing effective

control measures.

Water monitoring

The quality of water being used in the Condair ML Humidication System should be checked prior to

system commissioning and comply with the guidelines in the high pressure pump manual.

The Condair ML Humidication System must be monitored for hygiene as part of the maintenance program. Please refer to the maintenance section for further guidance.

8 For Your Safety

XXXXXXX_EN_1905 Condair MLP

Page 9

Guidelines for a Hygienic System

• Carry out a risk assessment of the water system using a competent person, and implement an appropriate monitoring and control program.

• Initiate procedures for changing lters, disinfection etc.

• Enter into a service contract that suits your company.

• Stop the system if polluted drinking water is found in your area.

• Avoid water temperatures between 77 °F (25°C) and 113 °F (45°C), which favour the growth of

Legionella.

• Do not stop the system unless it is faulty or leaking (avoid water stagnation).

• Refrain from closing nozzles or sections, unless there is leakage or a fault (avoid water stagnation).

• Disinfect the high-pressure system at least once a year and after every maintenance or repair. Always

carry out a complete system disinfection if it has been turned off for more than 48 hours.

• Have water samples taken and tested for harmful bacteria at least once a year.

• Conduct follow-up measurements until the system is clean if bacteria have been detected in the system.

Disinfection

Depending on the system hygiene, it is advised that preventative disinfection uid be added to the external RO water tank at an appropriate frequency, but at least once a year.

Condair Ltd. recommends using the disinfection uid HaloSpray or Sanosil S010 AG 5% (part number:

155404000) to the System via the high pressure pump, desired concentration 0.1%. HaloSpray or Sanosil

is safe, non-toxic and eco-friendly which provides a prophylactic, disinfection dose and is effective against

all types of microorganisms, including Legionella and E.coli.

Please read the pump manual for more information on disinfection.

If you are in any doubt about the suitability of water quality, please contact your Condair distributor who

will be happy to support you.

Condair MLP

XXXXXXX_EN_1905

9For Your Safety

Page 10

3 Receiving and Storage

3.1 Inspection

All Condair products are shipped F.O.B at the factory. All damage, breakage or loss claims are the responsibility of the shipping company. Upon receipt, remove the transit packaging and inspect the components

to ensure that no damage has occurred during transit. Inspect the goods as follows:

– Inspect the shipping boxes for damage. Report any shipping box damages to the shipping company

without delay.

– Check the goods against the packing slip to ensure that all items have been delivered. Report any

shortages to your Condair representative within 48 hours of receipt of the goods. Condair does not

assume responsibilities for any shortages beyond this period.

– Unpack the parts/components and check for any damage. If parts/components are damaged, notify

the shipping company immediately.

– Verify the model type on the specication label to ensure that it is suitable for your installation.

3.2 Storage and Transportation

Storage

Store the Condair ML adiabatic humidier in its original packaging inside a protected area that meets the

following requirements until it is installed. These requirements also apply if the unit needs to be stored

for an extended period of time. If put into storage prior to use, the components must be covered and

protected from physical damage, dust, frost and rain. Avoid below freezing temperatures as this can

degrade certain wet parts and components.

For storage Condair recommends:

– Room temperature: 41 to 104°F (5 to 40°C)

– Room humidity: 10 to 75% RH

Transportation

For optimum protection always transport the unit and components in their original packaging, and use

appropriate lifting/transporting devices.

Lifting or handling must only be carried out by trained and qualied personnel. Ensure that the lifting

operation has been properly planned and risk-assessed, and that all equipment has been checked by

a skilled and competent health and safety representative.

The customer is responsible for ensuring that operators are trained in handling heavy goods, and to

enforce the relevant lifting regulations. Refer to the weights and measures section for system weight.

Packaging

It is recommended that the components be kept in its transit packaging for as long as possible prior to

installation.

Keep the original packaging of the unit/components for later use. If the packaging needs to be disposed

of, observe local regulations on waste disposal. Recycle packaging where possible.

Disposal

You must observe local laws and regulations when disposing of your Condair ML system at the end of

its working life.

10 Receiving and Storage

XXXXXXX_EN_1905 Condair MLP

Page 11

4 Site Planning

4.1 Prior to Starting

The basic principles for planning described below are theoretical ones. In practice, the necessary humidication capacity is inuenced by parameters that cannot be covered by this documentation. For

this reason, the values that were determined in theory have to be complemented by practical values or

corrected in many cases. Condair’s technical service team will be pleased to assist you.

Notes on the planning of direct room air humidication systems in one or more zones.

Proceed as follows when selecting and/or dimensioning the air humidication system:

• Determine the volume of the room and the air changes

• Determine the set points (temperature and humidity/relative humidity)

• Determine the humidication areas

• Calculate the maximum humidication capacity

• Dene the device requirements

• Determine the placement of zone valves and hygrostats

4.2 General Notes on Positioning

The positioning of a system is always determined during planning and noted in the system documents.

Prior to mounting the ML Direct Room Humidication heads, ensure that all hose layouts, distances

between heads and atomization clearances have been considered and adhered to, as per the ML Heads

Installation Guide.

The recommended hose layouts, distances between humidication heads and atomization clearances,

are shown in the ML Heads Installation Guide. Consult local and national installation regulations. Condair

does not accept responsibility for violations of the installation codes.

The following general positioning notes, however, have to be read and complied with in any case:

• Make sure that the construction (rafter, beam, wall, pillar, ceiling construction, etc.) on which the

devices and/or system components will be mounted disposes of a sufcient load-carrying capacity

and is suitable for xing

• Position the Condair ML Direct Room Heads in such a way to enable the atomized mist to spread

freely. When the mist is prevented from spreading by obstacles (e.g. ceilings, beams, ventilation

ducts, airow, machinery, etc.), turbulences can build up and condensation may occur as a result.

• ML Heads Installation Guide shows the recommended clearances, of the expansion of the atomization stream, and the clearances that have to be maintained. These are ideal and recommended

maximum capacities using ML nozzles. Different weather, climate and indoor conditions can alter

the spread and distance of the mist.

Condair MLP

• As shown in ML Heads Installation Guide, when the nozzles and humidication heads are placed

one opposite the other, make sure that a minimum distances are adhered to. This will avoid the

streams to condensate each other.

• Pay close attention to the airow of the room. Do not install humidication heads or nozzles in the

immediate vicinity of a supply, return or exhaust system or of a cold-air inlet.

XXXXXXX_EN_1905

11Site Planning

Page 12

• Do not point humidication heads or their nozzles at cold parts of a building, e.g. outside walls,

windows, etc. (risk of condensation).

• Insulate cold-water pipes in the area of the atomizing stream (risk of condensation).

• The evaporation process absorbs heat from the ambient air. For this reason, make sure that the

atomized stream is not directed on persons or on places directly above workplaces.

• In order to guarantee optimum humidication, ensure that the atomizers are sensibly distributed in

the room.

• The system components have to be mounted in such a way to provide enough space for operation

and maintenance.

Please contact Condair’s Technical Service Team in case you have questions on positioning and clearances.

4.3 Experts on Site

Condair has expert technicians employed by Condair who can provide:

• Pre-site analysis

• Positioning and site assistance or recommendations

• Installation support

• Start-up and commissioning

• Bacteriological troubleshooting on site *

• Cleaning and disinfecting

• Preventive maintenance

• Repair and fault nding

• Training and guidance

*Condair uses an industry leading method for measuring bacterial activity in the water; the approved

and patented BactiQuant test. This, unique to Condair, eld test takes water samples from critical project

locations. Thereafter, the bacteriological quality of the water can be read within 30 minutes, and the

system can be disinfected if necessary.

Condair follows the guidelines in VDI 6022 for colony forming units (CFU) counts in humidiers. The

CFU count in the humidication water must not exceed 150 CFU/ml, corresponding to a maximum BQ

value of 52. Please contact your local Condair representative for further information about our services.

12 Site Planning

XXXXXXX_EN_1905 Condair MLP

Page 13

5 Product overview

5.1 General description

The MLP series is a high-pressure pump station for direct room humidication it’s developed by Condair

Group AG with focus on reliable and hygienic humidication solutions.

The MLP comes in ve basic models, MLP 100, 300, 500, 800 and 1000. The number indicates

the maximum continuous water outlet (high-pressure) at 943 psi (65 bar). If a larger capacity than

264 gal/hr (1000 l/h) is needed the MLP’s is made in versions with double or triple high pressure pumps

called e.g. MLP 2x800 or MLP 3x1000.

Important:

All components exposed to water are made of corrosion-resistant material. All hoses are steel-reinforced

and drinking water-approved.

The high-pressure pump is directly mounted on the electric motor. Power is supplied to the 3-phase

asynchronous motor via a magnet-operated protective motor switch. The high-pressure pump is protected against dry running by a pressure switch in the inlet manifold. A temperature sensor monitors the

temperature inside the pump and protects it from overheating.

The control unit consists of a touch display and a PLC mounted in the IP 65-rated electrical cabinet as

well as a power board for control of the high-pressure pump and connection terminals for power supply

(208...480 V/3N~/50-60 Hz).

From the touch screen, the operator can easily change humidity set point in each section, adjust alarm

limits and view hour counters, logged alarms, trend curves, etc.

The pump station is electrically wired at the factory. At the installation site, main power supply, humidity

signal, external safety chain, step valves and additional options must be electrically connected to the

control unit.

Condair MLP

XXXXXXX_EN_1905

13Product overview

Page 14

5.2 Model Designation

The specication label on the side of the Condair ML adiabatic humidier shows its model number, year

made, serial number, power supply and ratings. The breakdown of the model number is shown in Figure 1.

Product series:

Humidication Load (liters/hour):

100

300

500

800

Voltage and phase:

208V/3~

400V/3~

480V/3~

Figure 1: Model designation

Condair MLP 300 480V/3~

Electrical Schematics and Wiring Diagrams

A copy of the electrical schematics and wiring diagrams can be found on the inside panel of the control

panel.

The rating plate is placed in the upper left corner on the side of the control unit (when facing the front).

Figure 2: Rating plate

14 Product overview

XXXXXXX_EN_1905 Condair MLP

Page 15

A label with the internal order number and electrical schematic diagram number is placed on the inside

of the left-hand cabinet hatch (when facing the front) on the control unit.

Figure 3: Label with the internal order number and electrical schematic diagram number

Condair MLP

XXXXXXX_EN_1905

15Product overview

Page 16

5.3 MLP 100/300 Overview

Figure 4: MLP 100/300 Overview

Figure 5: Hydraulic diagram MLP 100/300

F Filter 10", 1 µm

FR Water meter

G1 Pressure gauge, 0-145 psi (0-10 bar)

G2 Pressure gauge, 0-145 psi (0-10 bar)

G3 Pressure gauge,

high-pressure 0-2321 psi (0-160 bar)

K1 Check valve

K2 Check valve

M1 Motor, high pressure pump

MV1 ON/OFF valve 1/2" 0-145 psi (0-10 bar)

P1 PAH high-pressure pump 1015 psi (70 bar)

PS Pressure switch

PT Pressure transmitter (Option)

R Pressure reduction

T Thermostat

UV UV system

V1 Test water tap

Table 1: Legend MLP 100/300 Overview

16 Product overview

XXXXXXX_EN_1905 Condair MLP

Page 17

5.4 MLP 500 Overview

Figure 6: MLP 500 Overview

Figure 7: Hydraulic diagram MLP 500

F

FR

G1

G2

G3

K1

K2

M1

Filter 10", 1 µm

Water meter

Pressure gauge, 0-145 psi (0-10 bar)

Pressure gauge, 0-145 psi (0-10 bar)

Pressure gauge,

high-pressure 0-2321 psi (0-160 bar)

Check valve

Check valve

Motor, high pressure pump

MV1

P1

PS

PT

R

T

UV

V1

ON/OFF valve 1/2" 0-145 psi (0-10 bar)

PAH high-pressure pump 1015 psi (70 bar)

Pressure switch

Pressure transmitter (Option)

Pressure reduction

Thermostat

UV system

Test water tap

Condair MLP

Table 2: Legend MLP 500 Overview

XXXXXXX_EN_1905

17Product overview

Page 18

5.5 MLP 2x800 overview

Figure 8: MLP 2x800 Overview

Figure 9: Hydraulic diagram MLP 2x800

F1 Filter 10", 1 µm

FR1 Water meter

G1 Pressure gauge, 0-145 psi (0-10 bar)

G2 Pressure gauge, 0-145 psi (0-10 bar)

G3 Pressure gauge,

high-pressure 0-2321 psi (0-160 bar)

K1+K2 Check valve

Table 3: Legend MLP 2x800 Overview

K3+K4 Check valve

P1+P2 PAH high-pressure pump 1015 psi (70 bar)

PS Pressure switch

R1+R2 Pressure reduction

T1+T2 Thermostat

UV1 UV system

V1 Test water tap

18 Product overview

XXXXXXX_EN_1905 Condair MLP

Page 19

5.6 Principal installation diagram

sensor

valve

sensor

valve

sensor

valve

modules

Reverse

Osmosis

Ion exchange

Power

Supply

ML Princess

Solenoid

Humididity

Humidication zone

Power

Supply

ML Solo modules

Humidication zone

Drain

Humididity

Solenoid

ML Flex Line system

Humidication zone

Drain

Humididity

Solenoid

Drain

Drain

filtration

treatment:

ML Pump station and water treatment

Power

Supply

treatment:

Optionalwater

Optional water

Water

Supply

Safety pre-

Carbonfilter

Carbon lter

Reverse osmosis

Softening

Softening

Safety preltration

Figure 10: Principal installation diagram

Condair MLP

XXXXXXX_EN_1905

19Product overview

Page 20

5.7 Inlet water quality requirements

The quality of water being used in the MLP system should be checked prior to system commissioning.

Condair A/S recommends that the MLP system be connected to a RO or DI mains water supply.

Table 4: Inlet water quality requirements

Water supply Reverse osmosis or demineralized water

Conductivity 5-50 µS/cm

TDS max 35 ppm

KMnO4 max 10 ppm

NTU max 1.0

Temperature max 59°F (15°C)

Fe max 0.2 ppm

Mn max 0.05 ppm

Max hardness max 1º dH

free chlorine max 0.1 ppm

5.8 Optional equipment for MLP

Choosing the right water treatment is essential for successful humidication. In the ML-System programme,

there is a large variety of water treatment and optional equipment to choose from. The ML-System is

designed to be customised to meet the specications, be it essential water treatment or features. It is

possible to combine ML Systems, water treatment and optional equipment in numerous combinations

and it is thus impossible to describe all of them here. In the following, the most commonly used ancillary

and optional equipment for the MLP system is listed.

Optional and ancillary equipment can be divided into the three following main groups:

MLP options: Added features which are intergraded into the controller of the MLP or placed on its frame,

e.g. conductivity and hardness alarm, BAS integration, ultra-pure water (mixed bed), CIP system, CO

adding, damping water outlet, holding tanks (RTN). Options cannot be retrotted and must therefore be

listed when ordering

Water treatment: Stand-alone systems for improving the water quality in order to meet the inlet water

quality requirements for the MLP, e.g. booster pump, non-return valve, silt/pre-lter, carbon lter and

softener. See separate Water treatment / RO manual for further information.

High-pressure building installation: Added features and optional equipment – e.g. fan speed controller,

ow monitor, temperature read-out. Options for the high-pressure building installation will be described

in the I/O manual for the high-pressure building installation. See separate High-pressure equipment

manual for further information.

2

20 Product overview

XXXXXXX_EN_1905 Condair MLP

Page 21

5.9 MLP options list

Options cannot be retrotted and must therefore be listed in connection with order placement.

Table 5: MLP options list

Fan control (Prepare of the control board)

Fan control box (1-4 zones) Start/stop fans in each zone between humidication cycles.

Overheating protection of the

high-pressure pump (ow/

temp-dependent)

PLC webserver access Access to the PLC's homepage from a standard browser.

Humidity logger Logs the humidity in each zone every 15 minutes (1 year back).

BAS/BMS integration Modbus

TCP/IP

Backup high-pressure pump The pump station is tted with an extra high-pressure pump for

Status relay Potential-free relays for (ready, running, warning, error).

Pulse generator for water meter The water meter is equipped with a pulse emitter which can be

Prepares the control board with terminals I/O for connecting a

fan control box.

Only possible if the control board has been prepared for the

accessory.

Dumps excess water via a solenoid valve if the temperature or

ow through the pump comes outside the permissible limit.

Displays the operating status and humidity for each zone.

Data is stored in a .csv comma-separated values le, which can

be accessed on a SD card or the PLC's webserver.

Displays the operating humidity and alarm status of the system

via a TPC/IP protocol.

redundancy, automatic changeover.

linked to tele-reading systems, the PLC and to M-Bus networks.

Condair MLP

XXXXXXX_EN_1905

21Product overview

Page 22

5.10 MLP accessories list

Accessories can be retrotted.

Table 6: MLP accessories list

Pulse generator for water meter,

retrot kit

ML control box for induct system ML satellite unit for connecting and controlling an induct system

Satellite box (4 zones) Ads 4 additional zones (humidity I/O and zone valve terminals) to

Satellite box (8 zones) Ads 8 additional zones (humidity I/O and zone valve terminals) to

Humidity logger retrot kit Logs the humidity in each zone every 15th minute one year

Alarm lamp Alarm ash which can be placed up to 328 ft (100 m) from the

Modbus TCP/IP Gateway IP

translator

Remote alarm SMS Sends a SMS via a prepay SIM-card if the system goes in alarm

Remote alarm email Sends an email if an alarm is triggered in the system and when

BAS/BMS integration Modbus

TCP/IP, retrot kit

The water meter is equipped with a pulse emitter which can be

linked to tele-reading systems, the PLC and to M-Bus networks.

from an MLP or an MLP pump station.

an existing ML-System.

an existing ML-System.

back. Data is stored in a .csv comma-separated values le.

pump, connects to an alarm output.

Easy setup op Modbus TCP/IP communication to BAS as IP addresses can be chosen by the costumer on site.

and when the alarm is cancelled.

the alarm is cancelled. Up to 25 recipients.

Displays the operating humidity and alarm status of the system

via a TPC/IP protocol.

22 Product overview

XXXXXXX_EN_1905 Condair MLP

Page 23

6 Installation

6.1 General

Strictly observe and perform all installation tasks including the mounting of the unit and connection of the

water and power supplies as described in this manual. Observe and comply with all local and national

codes dealing with water and electrical installations.

Condair does not accept any liability for installation of humidication equipment by unqualied personnel,

or the use of equipment/parts that are not authorized by Condair.

Personnel Qualications

All installation work must be performed only by persons familiar with the ML-System pump station and

sufciently qualied for such work. All work on electric installations must only be performed by adequately

qualied electricians.

Safety

The pump station and any control units may only be connected to the mains after all installation work

has been completed. All statements relating to correct positioning and installation must be followed and

complied with. When installing components of the MLP, use the materials and hoses supplied with the

unit. In case of doubt, please contact your Condair supplier.

Observe the following safety precautions:

WARNING!

Risk of injury and risk of damage to equipment

Do not retighten/unscrew hoses while the system is pressurized!

CAUTION!

Risk of breeding ground for bacteria

Do not use oil, grease, glue, Teon, silicon, O-ring lubrication, etc. when assembling pipes or

hose connections.

All of the above products can act as food for bacteria and therefore may pose a health risks.

Prevention: Wash your hands before or wear clean gloves while assembling parts in direct

contact with water. Keep dust covers on pipes and hoses until just before assembly. Only approved lubricant is dish soap

CAUTION!

Do not fasten the pump station or hoses/pipes to vibrating installations.

Condair MLP

CAUTION!

Risk of damage to internal components from electrostatic discharge (ESD)

The electronic components inside the humidier are sensitive to electrostatic discharge (ESD).

Prevention: Take appropriate and special measures to protect the electronic components inside the

unit against damage caused by ESD.

XXXXXXX_EN_1905

23Installation

Page 24

WARNING!

Heavy object - risk of injury!

The pump station or pump skid are extremely heavy. Smaller models can weigh 275 lb (125 kg)

while the bigger units can weigh in excess of 550 lb (250 kg).

Prevention: Always use appropriate lifting device(s), and proper assistance, safety equipment, har-

ness prior to lifting or moving any Condair ML equipment.

Recommended Tools

Condair recommends the following tools for unpacking, measuring, connecting and tightening all things

regarding installation.

• Screwdriver set

• Spirit level

• Polygrip pliers

• Wire cutters

• Spanner set

• Tape measure

• Marker

• Box cutter

6.2 Site Requirements and Sizing

Please observe the following regarding positioning and installation:

• The pump station must be installed only in a location with a drain in the oor.

• The site must be freely accessible with sufcient space for convenient operation and maintenance.

• Minimum recommended clearance and free space around pump station: 20 inches (0.5 m) side to

side, and 32 inches (0.8 m) front and back.

• The pump station is designed for operation in a frost-free and dry environment, never outdoors.

• Do not install the pump station in exposed locations or locations with heavy dust loads.

• The pump station is designed for installation on a load-bearing oor.

24 Installation

XXXXXXX_EN_1905 Condair MLP

Page 25

6.3 Positioning the pump station

Please observe the following on positioning and installation:

• The pump station must be installed only in a location with a drain in the oor.

• The site must be freely accessible with sufcient space for convenient operation and maintenance

(min. free space around pump station: laterally 19.7" (0.5 m), 31.5" (0.8 m) front / back).

• The pump station is designed for operation in a frost-free and dry environment, never outdoors.

• Do not install the pump station in exposed locations or locations with heavy dust loads.

• The pump station is designed for installation on a load-bearing oor.

Before installing the MLP it is important to consider placement of additional water treatment equipment

in the room ( e.g. Carbon lter, softener, RO). Please note that the combination/size of water treatment

systems will vary from one installation to the next due as a result of water quality and regulatory

requirements in the given location.

Start by examining the types of water treatment systems to be installed and read their installation

instructions as regards location and any requirements for supply and drainage.

Mark the location of the different systems in the room and note any missing supply or drains for the

systems. Make sure you have the necessary xing equipment available: cable ties, cable trays, screws

and wall anchors.

Adjust the screws under each leg on the

frame so that the pump station and the

RO tank (if relevant) can be levelled. Use

a bubble level to ensure that the pump

station is perfectly level.

Figure 11: Adjusting the pump station

Condair MLP

XXXXXXX_EN_1905

25Installation

Page 26

6.4 Water connection

WARNING!

Do not open and ll hoses, pumps, lters or tanks with water if the system is not to be started

immediately after installation (48 hours). Stagnant water acts as a breeding ground for potentially

dangerous micro-organisms.

Before connecting the MLP to the water supply it must be ensured that the incoming water is as clean

as possible. These is done by running a hose from the supply to the drain and open the shut-off valve

completely. Let the water run to drain for at least ten minutes. Shut off the water again and connect MLP to

the water supply with the supplied hose (3/4"/59.1" (3/4"/1.5 m)). Condair recommends that the in coming

water is tested for bacterial contamination please contact Condair for further information on the subject.

1: ¾" RG male inlet connection

2: Gasket

3: Steel braided hose

26 Installation

Figure 12: Water connection

XXXXXXX_EN_1905 Condair MLP

Page 27

6.5 Electrical installation

DANGER!

Danger of electric shock!

Installations and electrical connection must only be done by trained technicians and according

to local standards

High voltages, danger of electric shock! Touching live parts may cause severe injury or death.

All connections must be made according to the electrical documentation which is found inside the control

unit of the electrical cabinet / main box.

Notes on electrical installation

– Installation must be carried out according to local rules and regulations

– The electrical installation (power supply, humidity control) must be carried out according to the wir-

ing diagram supplied with the unit and the applicable local regulations. All information given in the

wiring diagrams must be followed and observed.

– All cables must be run into the control unit via the cable openings and the use of cable glands.

– Make sure the cables do not rub against vibrating parts.

– The supply voltage must comply with the voltage in the wiring diagram.

– Study the system set-up part to get an overview.

– The pump station comes with a 3 m rubber coated power cable.

– Power consumption and size of pre-fuse can be found chapter with product data

Condair MLP

XXXXXXX_EN_1905

27Installation

Page 28

6.5.1 Power Supply Connection

• Make sure that electrical supply corresponds to the specications on the humidication system rating plate.

• Unlock the control panel enclosure door with the provided panel key.

• Insert the power supply cable through a suitable free cable gland and lead the cable to the eld

terminal block, as shown on the picture of the enclosure below.

• Follow the appropriate electrical wiring diagram for the actual humidication system and connect the

power supply leads to the eld terminal block accordingly.

28 Installation

XXXXXXX_EN_1905 Condair MLP

Page 29

7 Commissioning

WARNING!

The system start-up must be carried out or monitored by persons approved and trained by

Condair. Errors in the start-up phase may ultimately result in illness, injury and death of humans..

CAUTION!

When tting water lters, RO membranes, hoses and other components in direct contact with

water please, wear sterile gloves or touch only the packing paper to keep the lter bacteria-free.

Remember to wash your hands!

CAUTION!

Commissioning of the pump should be the last thing performed at an installation site. When

the pump has run with water and the preservation uid (windscreen wash) has been ushed

out, it should always be kept on (summer and winter) in order to keep the system hygienically

clean by allowing it to run its automatic ushing and UV routine.

7.1 Tools and materials for commissioning work

– Screwdriver set (remember small screwdriver for terminals)

– Polygrip pliers

– Spanner set

– Conductivity Meter

– BQ water analyses set ML part: 155600010

– Multi-meter (Volt, Amp)

Condair MLP

XXXXXXX_EN_1905

29Commissioning

Page 30

7.2 Inlet lter

Insert lter:

• Unscrew the lter housing [1] using a lter

wrench.

• Insert the lter [2], and make sure that it is

centered on the guide knob at the bottom of

the lter housing.

• Tighten the lter as much as possible by hand

and then use the lter wrench to tighten approx.

1/4 turn.

• Slowly open the water supply

• If the lter housing is hard to tighten or leaks,

unscrew it and check that the lter is centered,

the O-ring is undamaged and the sealing surface is smooth and free of dirt.

Figure 13: Inlet lter housing and lter

Figure 14: Air-vent screw, inlet lter

Note: Do not touch the lter with your bare hands

(slide it out of the packing directly into the lter

housing).

Airing lter:

• Slowly open the water supply (tap) to the MLP

• Bleed the lter by loosening the air-vent screw

[1] on the lter top until water leaks continuously.

• Retighten the air-vent screw.

30 Commissioning

XXXXXXX_EN_1905 Condair MLP

Page 31

7.3 Prepare for pump ush

CAUTION!

The rst time a new pump and/or RO membrane is to be used, it is important to ush out any

preservation uids so that they do not end up in the high-pressure system.

• Remove plugs and strips from the highpressure

hose and lead it to a drain or a bucket.

Figure 15: Flushing the pump

Before the pump is started for the rst time, the controller must be set up.

Condair MLP

XXXXXXX_EN_1905

31Commissioning

Page 32

7.4 Basic set-up of the controller

Figure 16: Control unit

1: Touch Screen (D2)

2: Humidication On/Off (S1)

3: Reset/Start (S2/P1)

4: Keyhole, open cabinet

5: Main power switch (S3)

• Put S1 in OFF position

• Start the controller by turning the power switch

S3 in ON position

• The display lights up the start center → ►START

1.1.1

Every time the system is switched on after a power

break, you will see a screen that tells you to control

the pump rotation.

Verify that the pump rotation is correct.

A push on the Test rotation starts the high-pressure

pump for 5 seconds, so that the rotation can be

observed according to the arrows on the pump.

When the rotation control has passed it is possible

(by customer’s responsibility) to skip this screen

in the future (It can be deselected in screen 1.6).

Upon completion of rotation control, press Rotation

ok.

A technician pin will be required; 197

32 Commissioning

XXXXXXX_EN_1905 Condair MLP

Page 33

1.1

Select language by pressing the ag.

Select the units to use in the screens.

• Litre/hour

• Lb/hour

• Celsius

• Fahrenheit

Press the right arrow (F4) to continue.

1.0

The Basic setup page provides access to pages

and selectable functions:

1.1-Choice of language

1.2-Calibration of screen

1.3-Set time and date

1.4-Selection of active sections

1.5-Selection of names for the sections

1.6-General selections (settings)

1.7-Membrane ush

1.8- Version and change passwords (factory

settings)

1.9-ML-System (factory settings)

Once you have made your selection(s), press Home

(F1) to continue.

1.2

Calibrate Screen: Adjusts the viewing angle, so

you can stand upright and operate the screen.

When calibrating, do not lean forward in order to

get a better view. You will not get the desired effect.

Condair MLP

XXXXXXX_EN_1905

33Commissioning

Page 34

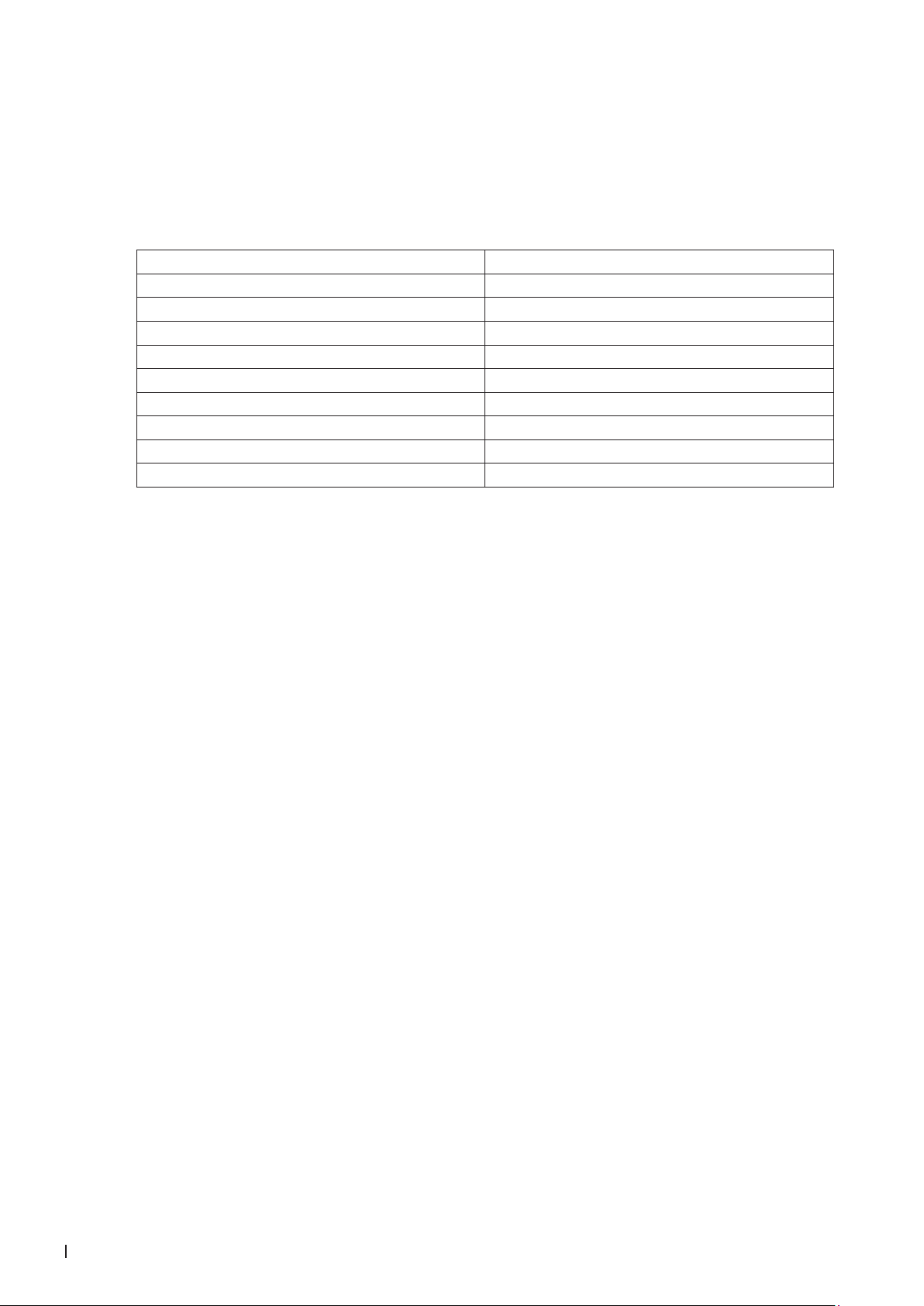

1.3

Time/date can be set (stored in the screen only).

Note: Remember to press F3 to set the PLC clock

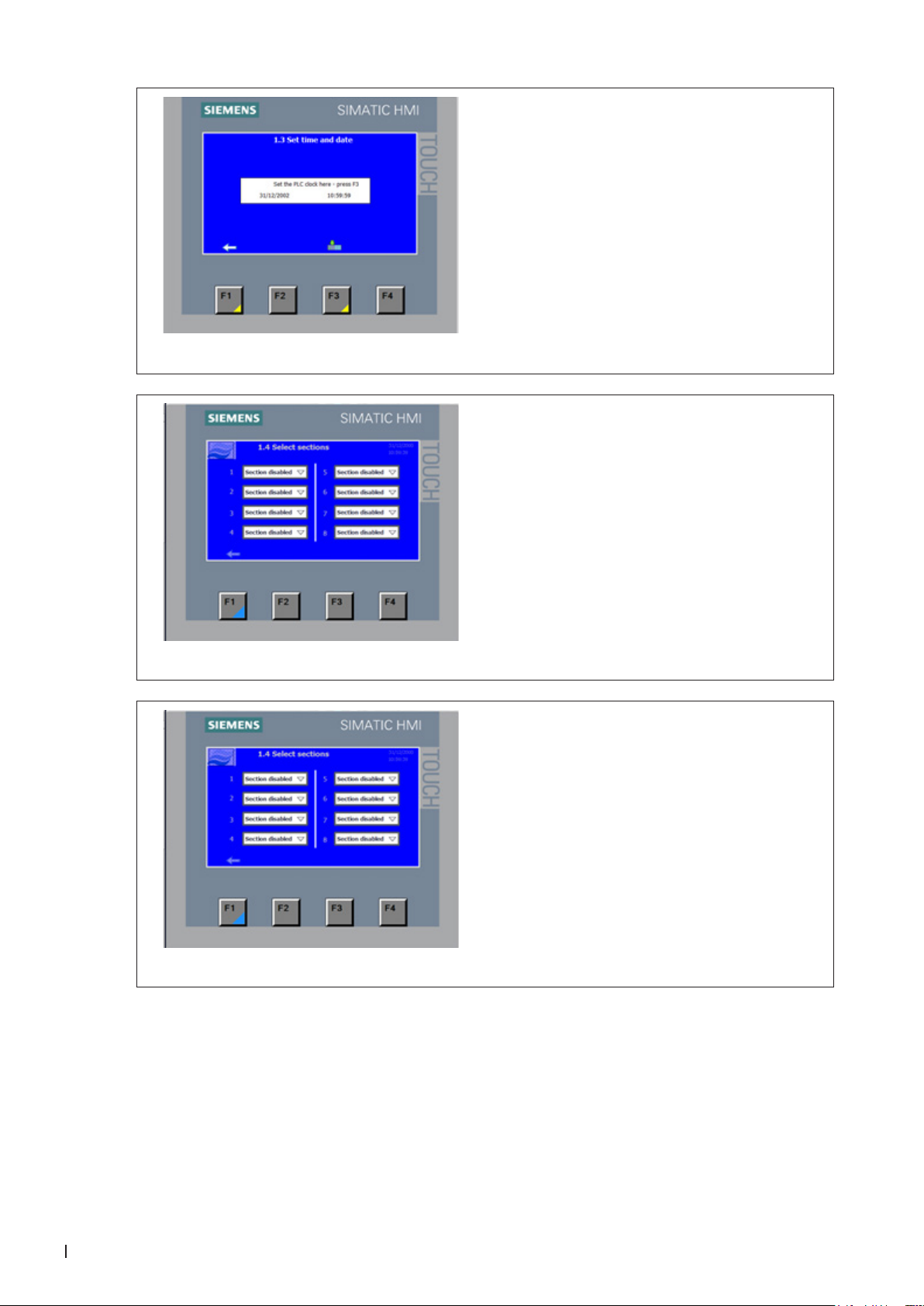

1.4

Select which section (zones) is active.

A section is dened as a humidity sensor and a

valve set connected to the controller

• Section disabled

• Section enabled

1.5

Selection of user-dened section names.

You can use up to 8 characters to dene each

section.

Default is 1-2-3…11-12

34 Commissioning

XXXXXXX_EN_1905 Condair MLP

Page 35

1.6

General selection between options and setups for

the general pump station. Please note that some of

the options require hardware that has to be ordered

together with the pump.

Master pin will be required; 8599

Standard setting is the top choice in the drop-down

menus.

Here also shown in bold:

• No CIP function

• CIP function

• No fan control

• Aut fan control

• Constant fan control

• No EC monitoring

• EC monitoring

• EC monitoring +RV/CO2

• EC monitoring +MB+CO2

• No pressostat 3

• Pressostat 3

• Aut reset disabled (inlet water low pressure)

• Aut reset enabled (inlet water low pressure)

• 1 section – valve set

• 1 section – no valve set

• Humidity controlled (20-80% RH)

• Direct controlled (0-10 V)

• % controlled (0-100%

• No Logging

• Logging selected

• Rotation check enabled (1.1.1)

• Rotation check disabled (1.1.1)

Condair MLP

XXXXXXX_EN_1905

35Commissioning

Page 36

1.7

Select MLP size and select 1-4 or 1-8 sections.

This selection is pre-set from factory according to

the controller hardware.

Changing password is only possible with the master

password.

36 Commissioning

XXXXXXX_EN_1905 Condair MLP

Page 37

7.5 Pump ush procedure

Venting and ushing the high-pressure pump:

Force the HP pump to run by adjusting the set point

in a section to 75%.

Let the HP pump ush for 10 minutes.

Turn S1 (on/off switch) to off position, and connect

the HP discharge hose to the high-pressure

manifold.

Note: It is important to use two wrenches, otherwise

there is a danger of the glue breaks and highpressure manifold leaks.

Figure 17: Connecting HP discharge hose

Leave the main switch turned on and the S1 (on/off switch) in off position. This way the system will perform a ush routine that together with the UV lamp will help keeping the system clean.

Condair MLP

XXXXXXX_EN_1905

37Commissioning

Page 38

8 Operation

Every person operating the MLP's controller must have read and understood this manual.

Knowing and understanding the contents of the manuals is a basic requirement for protecting the personnel against any kind of danger, to prevent faulty operation and to operate the unit safely and correctly.

All safety notes in the installation and operation manual for the MLP must be observed and adhered to.

All work described in this controller manual may only be carried out by properly trained personnel which

is authorised by the customer.

If you have questions after reading this documentation, please contact your Condair representative who

will be happy to assist you.

8.1 Overview control unit

1: Touch Screen (D2)

2: Humidication On/Off (S1)

3: Reset/Start (S2/P1)

4: Keyhole, open cabinet

5: Main power switch (S3)

Figure 18: Control unit

38 Operation

XXXXXXX_EN_1905 Condair MLP

Page 39

8.2 Equipment protection

Pressure switch (inlet water)

The MLP has a pressure switch which monitors the inlet water pressure.

If the inlet water pressure drops, the controller will stop the pump, thus protecting it against dry running.

If the water pressure drops, the screen will display ‘PM Water pressure too low’.

Max. hygrostat to protect against excessive humidication

A max. hygrostat can be connected to the control unit. If humidity levels rise to a value that exceeds

the value set on the max. hygrostat, the system stops and the alarm lamp ashes. The system will not

restart until the alarm is acknowledged by pressing ‘Alarm reset’.

Temperature switch

The high-pressure pump is protected against overheating by a temperature circuit that measures the

current temperature in the pump. The temperature limits can be set individually.

If the temperature exceeds 122°F (50ºC), the pump will stop immediately and must be reactivated via

the reset button once the temperature has dropped again.

Description of touch screen

The screen has four F keys. Each of the keys is used to navigate between the different screen images.

When these are used, the individual key function is indicated in the description directly above the key.

The actual touch screen can be operated by gently tapping the relevant screen ‘buttons’ with your nger.

If you want to change a numerical value, press the relevant number key. This will make a numerical

keyboard appear on which the new value can be entered. Remember to enter any comma that may be

needed.

Any incorrect entry can be deleted using the Backspace button. Once a new value has been entered,

press Enter at the bottom right of the image using the numerical keyboard.

Condair MLP

XXXXXXX_EN_1905

39Operation

Page 40

Protection against unwanted changes

On the display, the control unit settings are password-protected against unwanted changes. The different

user groups have different passwords and different rights.

User (no password) can read operational information and alarms.

User 1 (password 1234) as above + changes of set points.

Technician (password 197) as above + changes of operational parameters and choice of membrane rinse.

Master (password 8599) as above + selectable options, reset to factory settings.

Technician xxxx, as above + factory / service menu.

Additionally, there are areas of the screen that are protected by extra passwords, to which only the ML

System has access.

When a password is required in order to change parameters, a screen will appear where the password

can be entered. Once the password has been entered, the system is unlocked for ve minutes.

8.3 Alarm messages

This page shows alarms and operational messages. The alarm display contains information about when

an alarm was triggered and when it was reset. The page shows active alarms and previous alarms.

Please note that the system does not have a backup memory, which means that previous alarms will

be lost in case of power failure.

Max.Hygrostat Sect. 1…12

Max. hygrostat in the current section has dropped out due to excessive humidity. The system has stopped

and must be restarted once the humidity level has dropped.

Water pressure too low

The water pressure on the water inlet to the pump station is too low.

Sensor error Section 1…12

The signal from one of the humidity sensors is outside the expected interval of 20 to 80% RH. In order

to ensure that it will be possible to start up the system in very dry conditions, the 20% limit is reduced to

5% RH for the rst 10 minutes after the system is switched on. If an alarm is triggered, only the affected

sections will be stopped.

Pump too hot

The water is too hot – above 122°F (50ºC). The system has stopped and must be restarted once the

temperature has dropped.

Thermal relay error

The protective motor switch for the high-pressure pump is disengaged. Engage the relay and try restarting.

40 Operation

XXXXXXX_EN_1905 Condair MLP

Page 41

UV lamp error

There is an error on the UV lamp

CIP dosing time alarm (option)

The CIP weight has not given a signal within the expected time

CIP weight error (option)

The CIP weight gives an incorrect signal

CIP overdosing last day (option)

The CIP self-monitoring system is defect due to possible overdosing. Please call for service

Operational message display

The pump will start automatically after delay.

The pump has been paused, e.g. after disinfection. The pump will start automatically after the expiry of

the set time.

Service

The pre-set service interval has been reached. The system must be serviced!

UV lamp error

The UV bulb or ballast is broken.

UV lamp soon to be changed

Warning 3 weeks prior to UV lamp change / service.

UV lamp error too old

Replace UV lamp and reset service interval.

Condair MLP

XXXXXXX_EN_1905

41Operation

Page 42

8.4 Controller menu

2.0

Normal operation page

Shows up to four sections at a time. The names of

the section changes colour according to the current status.

• White – normal inactive

• Green – active section – humidication is on

• Yellow ash – humidity out of range

• Red ashing – alarm on the section

Humidity, set point and load for each section.

Just tap the set point to go to the set point adjust

screen.

If an alarm or message is triggered, a bar will appear

across the screen, showing the message.

Access to the menu page – the alarm page – the page

for other displays and to the page for section 5-8.

2.2

Changes of set points for the individual section.

42 Operation

XXXXXXX_EN_1905 Condair MLP

Page 43

2.3

Shows the pump temperature and the actual ow –

calculated after the setting for each section.

If the EC option is selected, lines for the actual EC

monitoring will also be displayed.

Hour counter – select between pumps and each

section.

Access to the Trend curve for each section.

2.3.1

Graphic display of humidity development in the

relevant section for the last hour.

Please note that this function will be reset when

the power to the screen is cut.

8.4.1 Alarms and user messages

4.0

All alarms and operational messages are shown,

showing the time at which they occurred and the

time when the alarm stopped.

Please note that the alarm log will be reset after

a power cut.

Condair MLP

XXXXXXX_EN_1905

43Operation

Page 44

8.4.2 Parameter change menu

8.4.3 Settings for section parameters

3.0

Menu for the pages where the different parameters

can be changed.

3.1

Section parameters for sensor scaling and regulator settings

These values should be changed by Condair’s

technicians only.

Hum.Alarm

Set the HI and LO. The alarm appears if the humidity

becomes lower than the pre-set value in HI or lower

than the pre-set value in LO.

44 Operation

XXXXXXX_EN_1905 Condair MLP

Page 45

8.4.4 Pump

3.9

Pump alarm settings

These values should be changed by Condair's

technicians only.

Condair MLP

XXXXXXX_EN_1905

45Operation

Page 46

8.4.5 Conductivity monitoring, humidity logging and CIP (options)

3.10

EC controller set point

These values should be changed by Condair's

technicians only.

3.10.1

Scaling EC sensors

These values should be changed by Condair’s

technicians only.

3.11

For detailed description in the logging option, read

Condair document TI086.

46 Operation

XXXXXXX_EN_1905 Condair MLP

Page 47

3.11.1

Build a log le

3.12

Select the days you want to run a CIP function –

CIP on days (one or two days each week)

Select the CIP start time.

Select the dosing amount (can only be selected in

intervals of 5 ml per 50 litres of water)

8.5 Weekly inspection

During operation, the MLP and the humidication system have to be inspected weekly. On this occasion,

check the following:

• Entire humidication system for leakage

• Electric installation for damage

• Operating display for warning or error messages

• UV lters

• Pressure drop over lters

• Water treatment systems such as carbon lter, softener, RO

If the inspection reveals any irregularities (e.g. leakage, error indication) or any damaged components

take the MLP out of operation. Have a qualied specialist or Condair service technician correct the

damage or malfunction.

Fill in the ‘Service form for weekly monitoring of humidifying systems’ provided in the appendix of this

manual. Failing to do so could affect your warranty

Condair MLP

XXXXXXX_EN_1905

47Operation

Page 48

9 Maintenance

9.1 Important notes on maintenance

Qualication of personnel

All maintenance work must be carried out only by well-qualied and trained personnel authorised by

the owner.

Maintenance and repair of the electrical installation of the Condair MLP must be carried out only by

qualied personnel (e.g. electrician) who are aware of possible dangers and implications.

It is the owner’s responsibility to verify proper qualications of the personnel.

General note

The instructions and details for maintenance work must be followed and upheld.

Only the maintenance work described in this documentation may be carried out.

Only use original ML-System spare parts to maintain the warranty on the system.

Safety

Before maintenance is initiated, the MLP must be taken out of operation in accordance with instructions

in section "Taking the MLP out of operation" and protect against unintentional switching on.

The MLP must be cleaned and disinfected at the intervals described in this manual and the cleaning

work has to be carried out correctly by trained and instructed personal.

WARNING!

Poorly maintained humidication systems may endanger health. Therefore it is mandatory to observe

the specied maintenance intervals and to carry out maintenance work in strict accordance with the

instructions.

48 Maintenance

XXXXXXX_EN_1905 Condair MLP

Page 49

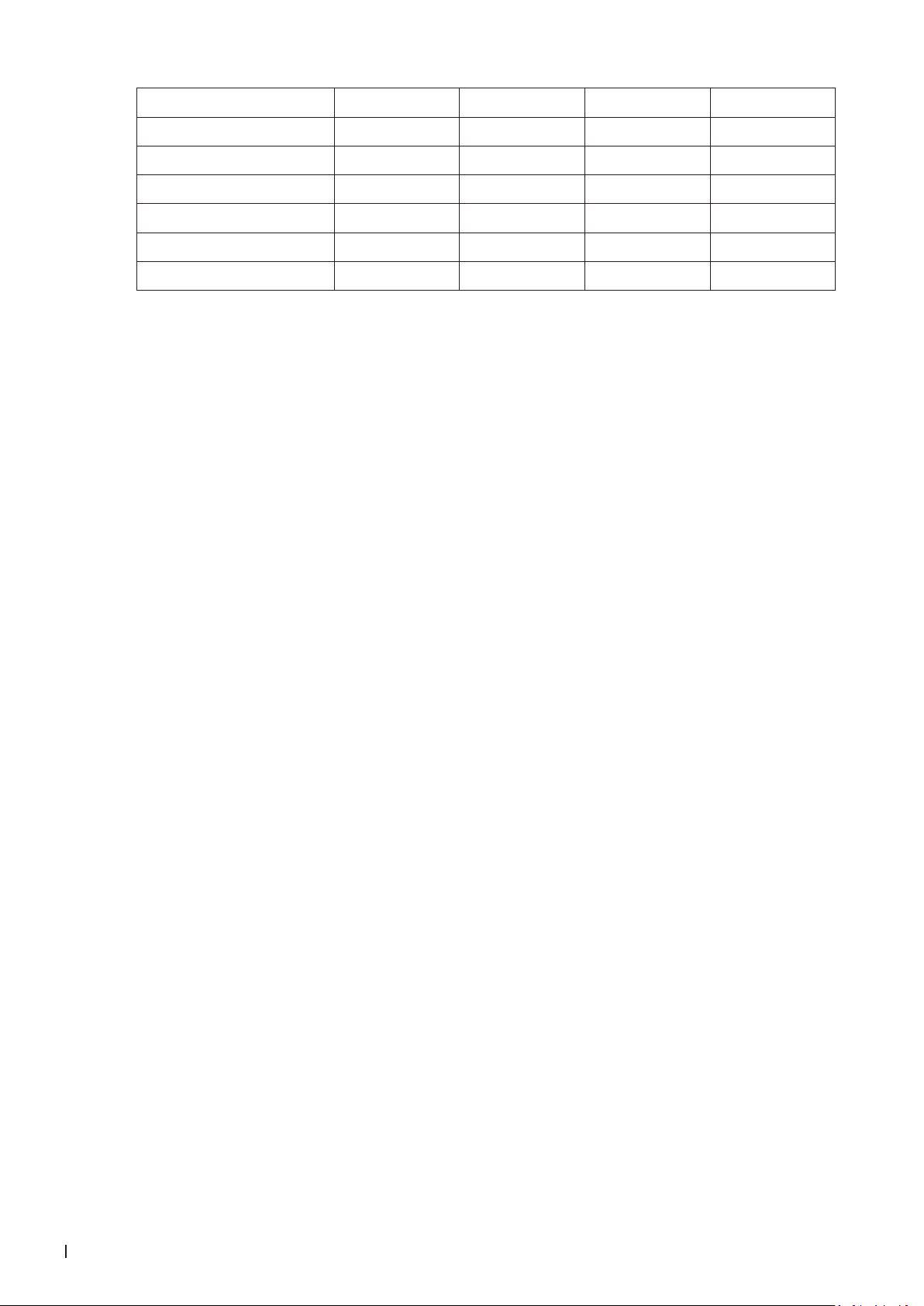

9.2 Maintenance work

To ensure safe, hygienic and economic operation of the MLP, vital components must be checked and

maintained periodically according to the table below. The maintenance intervals and maintenance work

stated below are guideline values. Local conditions, quality of the water, etc. could inuence the maintenance intervals. After having carried out the maintenance work, ll in the maintenance checklist, sign it

and reset possible maintenance indications. The relevant personnel are fully liable for any maintenance

work not carried out.

Service, to be carried out Half

Review of the system

Testing of the system's overall function X X X X

Meter reading of water consumption (if present) X X X X

Reading of pump running hours X X X X

Logbook registration X X X X

Control weekly monitoring checklist X X X X

Water treatment system / incoming water

Analysis of water hardness (in case of water softening) X X X X

Pump unit

Replacement of lters X X X X

Check the condition of the pump (pressure & noise) X X X X

Testing of solenoid valves and replacement if necessary X X X X

Change gasket kit in high pressure relive X X X

Functional testing of max hygrostat circuit X X X X

Functional testing of high pressure gauge X X X X

Functional testing of pressure switch (pressostat) X X X X

Service inspection of PAHT pump (age 2 years or 8000 running hours) X X

Testing of ON/OFF valve and replacement if necessary X X X X

UV system

Functional testing of UV systems X X X X

Cleaning of quartz glass on UV systems X X X

Replacement of UV-lamp X X X

Replacement of quartz glass X

Humidity sensors

Testing and adjusting of humidity sensors. Replaced if +/- 10% deviation X X X X

Checking of max humidity controller (max hygrostat) X X X X

Control units

Analysis and testing of programming X X X X

Transfer relay replacement X X X

Testing of contact K1 and replacement if necessary X X X

Hygiene

Extraction of water sample from pump (Bacterie test) X X X X

Desinfection of the system

year

X X X X

Each

year

Every 2

years

Every 4

years

Condair MLP

XXXXXXX_EN_1905

49Maintenance

Page 50

9.3 Preventive spare parts chart

100 300 2x300 500 2x500 800 2x800 1000 2x1000

Part Description P/N

208V

480V

208V

480V

208V

480V

208V

480V

208V

480V

208V

480V

208V

480V

208V

480V

Water Filters

20" 1-Micron sediment lter 2300218 0 0 1 1 1 1 1 1 1 3 mo.

10" 1-Micron sediment lter 2300213 1 1 0 0 0 0 0 0 0 3 mo.

O-ring for lterhouse 430020050 1 1 1 1 1 1 1 1 1 12 mo.

UV Lamps

8400900 UV lamp for .5 GPM Unit - SQ-PA 2300239 1 0 0 0 0 0 0 0 0 12 mo.

8400902 UV lamp for 2GPM Unit - S2Q-PA 2300241 0 1 1 1 1 0 0 0 0 12 mo.

8400903 UV lamp for 5GPM - S5Q-PA 2300243 0 0 0 0 0 1 1 1 1 12 mo.

Quartz Sleeves

Quartz sleeve (QS-212) for SQ-PA 2300235 1 0 0 0 0 0 0 0 0 24 mo.

Quartz Sleeve (QS-330) for S2Q-PA 2300236 0 1 1 1 1 0 0 0 0 24 mo.

Quartz Sleeve (QS-463) for S5Q-PA UV 2300237 0 0 0

Electrical Control System

Thermal relay 2.8-4.8 A 349010202 0 0 0 0 0 0 0 1 0 2 0 0 0 0 0 0 0 0 36 mo.

Thermal relay 4.5-6.3 A 349010203 0 0 1 0 2 0 0 0 0 0 0 1 0 2 0 0 0 0 36 mo.

Thermal relay 1.1-1.6 A 349010208 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 36 mo.

Thermal relay 2.2-3.2 A 349010209 1 0 0 1 0 2 0 0 0 0 0 0 0 0 0 0 0 0 36 mo.

Thermal relay 5.5-8.0 A 349010212 0 0 0 0 0 0 1 0 2 0 0 0 0 0 0 1 0 2 36 mo.

Thermal relay 11.0-16.0 A 349010067 0 0 0 0 0 0 0 0 0 0 1 0 2 0 1 0 2 0 36 mo.

Siemens Contactor 24VDC 9A 349010218 1 1 1 1 2 2 1 1 2 2 0 1 0 2 0 1 0 2 36 mo.

Siemens Contactor 24VDC 12A 2585530 0 0 0 0 0 0 0 0 0 0 1 0 2 0 1 0 2 0 36 mo.

Relay, Print frame relay 680010177 6 6 6 6 6 6 6 6 6 12 mo.

High Pressure Pumps

Service kit PAHT 2 104466001 1 0 0 0 0 0 0 0 0 24 mo./8K hr.

Service kit PAHT 4/6.3 104466002 0 1 2 1 2 0 0 0 0 24 mo./8K hr.

Service kit PAHT 10/12.5 104466003 0 0 0 0 0 1 2 1 2 24 mo./8K hr.

Pressure Regulator

Service kit pressure regulator 104481000 1 1 2 1 2 1 2 1 2 12 mo.

Gasket 1/2" connection hose 705020042 2 2 4 2 4 2 4 2 4 12 mo.

Gasket 3/4" connection hose 705020043 2 2 4 2 4 2 4 2 4 12 mo.

Check Valves

Check valve 1/4" high pressure 510020000 1 1 2

Nipple 3/8" hose x 1/4" 730020279 1 1 2 0 0 0 0 0 0 24 mo.

1/4" or 1/8" hose extension tting 108301000 1 1 2 0 0 0 0 0 0 24 mo.

Check valve 3/8" high pressure 510020005 0 0 0 1 2 1 2 1 2 24 mo.

3/8" x M20 nipple w/cone 730020278 0 0 0 1 2 1 2 1 2 24 mo.

Brystnippel 3/8”, 100 bar 721000002 0 0 0 1 2 1 2 1 2 24 mo.

Nozzles

Nozzle Complete stainless 2,5 l/h. 103160000 5% 5% 5% 5% 5% 5% 5% 5% 5% 12 mo.

Nozzle Complete stainless 4,5 l/h. 103150000 5% 5% 5% 5% 5% 5% 5% 5% 5% 12 mo.

Disinfection

Disinfection, Sanosil HM10 Ag 5% - quart 2300001 1 1 1 2 2 0 0 0 0 12 mo.

Disinfection, Sanosil HM10 Ag 5% - Gallon 2587665 0 0 0 0 0 2 2 2 2 12 mo.

Test Strips

HACH Test Strips 5-in-1 50 strips 2300144 1 1 1 1 1 1 1 1 1 12 mo.

Bacteria Testing

BAQ Water Testing Kit 155605000 2

2 2 2 2 2 2 2 2 12 mo.

0 0 1 1 1 1 24 mo.

0 0 0 0 0 0 24 mo.

208V

Service Cycle

480V

50 Maintenance

XXXXXXX_EN_1905 Condair MLP

Page 51

9.4 Weekly check list

Service form for weekly monitoring of MLP

Date

Initial

Reading of water meter

in m³

Reading of hour meter

in hours

Reading of conductivity

in µS/cm

Testing UV light

Manometer 1 (G1)

Manometer 2 (G2)

Difference G1 - G2

Condair MLP

XXXXXXX_EN_1905

51Maintenance

Page 52

9.5 Troubleshooting

Qualication of personnel

Have faults eliminated by qualied and trained personnel only. Malfunctions caused by the electrical

installation must only be repaired by authorised personnel (e.g. electrician).

Repair work on the high-pressure pump may only be carried out by your Condair representative’s service

technician.

Safety

When eliminating faults, the MLP must be taken out of operation and prevented from further inadvertent

operation.

Make sure the power supply to the MLP is disconnected (test with a voltage tester) and that the stop

valve in the water supply line is closed.

9.5.1 Malfunction with error indication

Error message Cause Remedy

Max.

humidistat

Inlet water

pressure too

low

Sensor error Humidity sensor missing or defect Install humidity sensor

Max. humidistat has been tripped, due

to high humidity

Max. humidistat defect or incorrectly set Change max. humidistat

Max. humidistat circuit damaged or not

installed correctly

The inlet water pressure is too low Check the inlet pressure at maximum ow

The Inlet water pressure is too low for

short periods (if inlet pressure and ow

seems ok when measured)

Defect Inlet pressure switch [PS] Replace pressure switch

Wiring to humidity sensor damaged or

incorrectly installed

Check that ventilation is on

Set point is correct

Incoming set point signal OK

Set correct rel. humidity, e.g. 85% RH

Check circuit for faults

Check settings for max. humidistat in

controller are correct

If no max. humidistat, a jumper must be

installed over terminals (4 & 4+)

for pump station according to product data

Check the water installation for periodically high consumption e.g. cleaning, tank

lling and maintenance work

Replace wiring according to electrical

diagram

52 Maintenance

Humidity outside range (below 20% RH

or above 80% RH)

Sensor scaling is wrong Scale the sensor correctly in the controller

XXXXXXX_EN_1905 Condair MLP

Check the humidity at sensor and reset

if below 20% RH

Page 53

Error message Cause Remedy

Stop - Pump

too hot

Water ow through high-pressure pump

too low

Ambient temperature too high at pump

location (max. 77°F (25ºC))

Incoming water to warm Lower inlet water temperature (max.

Inlet pressure / ow missing Defect inlet valve [MV1]

Damaged thermostat or cable [T] Change thermostat and cable

High-pressure pump defect Locate cause of failure, e.g. running

9.5.2 Resetting the error indication

Press the reset button underneath the touch screen.

Check ush valve MV5 at step valve block

opens and nozzle are not clogged

Lower ambient temperature in pump room

(max. 77°F (25ºC))

59°F (15ºC))

Water supply blocked / closed

hours exceeded 8,000, particles / dirt in

system, missing water pressure, defect

inlet valve.

Change pump when cause of failure

has been established and corrected

Note: If the fault has not been eliminated, the error indication reappears after a short while.

Condair MLP

XXXXXXX_EN_1905

53Maintenance

Page 54

9.5.3 Malfunction without error indication

The following table provides malfunctions that do not issue messages, notes on the cause of malfunction

and information on how to eliminate the source of trouble.

Malfunction Cause Remedy

Water's dripping from

modules/ex/

nozzles

Condair MLP

humidies

permanently.

Maximum

humidication

capacity not

reached.

Defect / clogged nozzles Replace nozzles

Zone valves defect / leaking Repair valves

Air in system Air the entire system

Pressure to low Check / repair PAHT pump

Water below 5 µS/cm Adjust RO

Nominal humidity value too high. Reduce nominal humidity value.

Ambient humidity very low. No measures to be taken, just wait.

The internal controller is activated,

although an external controller is

connected

Air change to high Contact your Condair supplier.

Defective zone valves Check the function of valves

Hygrostat defect Check calibration and function

Spray nozzles clogged. Remove nozzles and replace them

Hoses to nozzle pipes are leaking

or disconnected, or nozzle pipes are

leaking.

Deactivate internal controller.

Check hoses/nozzle pipes and seal, as

required

Control unit is

switched on

but the display

of the control

unit does not

show anything.

Service switch in power supply line is

off.

Fuses of the power supply line blown Have an electrician replace fuses of the

Fuse of control unit blown Have an electrician replace fuse of the

Display or control board defective Have a Condair service technician re-

Set service switch in power supply line

to On position.

power supply line.

control unit.

place the display or the control board.

54 Maintenance

XXXXXXX_EN_1905 Condair MLP

Page 55

10 Product data

(180-200)

(108-3600)

396.8-440.9

238.1-7936.6

(72-2844)

(175-190)

385.8-418.9

158.7-6269.9

(160-175)

(108-2400)

352.7-385.8

238.1-5291.1

(72-1896)

(155-170)

341.7-374.8

158.7-4180.0

(85-100)

(108-1200)

187.4-220.5

238.1-2645.5

(75-95)

(72-948)

165.3-209.4

1164.0-2090.0

(1....4)

14.5...58.0

55.1x27.6x63.0

(1400x700x1600)

(1....4)

14.5...58.0

55.1x27.6x63.0

(1400x700x1600)

(1....4)

14.5...58.0

32.3x27.6x63.0

(820x700x1600)

(1....4)

14.5...58.0

32.3x27.6x63.0

(820x700x1600)

(1....4)

14.5...58.0

26.0x19.7x51.2

(660x500x1300)

(1....4)

14.5...58.0

26.0x19.7x51.2

(660x500x1300)

32 A 32 A 50 A 50 A

92.6-

79.4-701.1

MLP100 MLP300 MLP500 MLP800 MLP1000 MLP 2X800 MLP 2X1000 MLP 3X800 MLP 3X1000

Capacity = water consumpt. [lb/h (kg/h)], 60 Hz 26.5-264.6

(42-528)

143.3-176.4

(36-318)

121.3-154.3

(12-120)

Weight [lb (kg)] 110.2-143.3

(65-80)

26.0x19.7x51.2

(660x500x1300)

(55-70)

26.0x19.7x51.2

(660x500x1300)

(50-65)

(660x500x1300)

Dimension w x d x h [inches (mm)] 26.0x19.7x51.2

(1....4)

14.5...58.0

(1....4)

14.5...58.0

(1....4)

Water supply dynamic pressure [psi (bar)] 14.5...58.0

Pipe inlet "RG 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 2x3/4" 2x3/4"

Pipe outlet "RG 1/4" 1/4" 3/8" 3/8" 3/8" 2x3/8" 2x3/8" 4x3/8" 4x3/8"

Sound level [dB(A)] <75 <80 <80 <80 <80 <80 <80 <80 <80

60Hz

Electrical conn. 3-phased Un = 208-277 V

Absorbed Power [kW] 1.1 1.8 2.3 4.0 4.0 7.4 7.4 11.2 11.2

Pre fuse 16 A 16 A 16 A 16 A 20 A

Electrical conn. 3-phased Un = 400-480 V

Absorbed Power [kW] 1.4 2.1 2.6 3.6 4.4 6.8 8.4 9.7 12.5

Pre fuse 16 A 16 A 16 A 16 A 16 A 20 A 20 A 25 A 25 A

Condair MLP

XXXXXXX_EN_1905

55Product data

Page 56

11 Declaration of conformity

56 Declaration of conformity

XXXXXXX_EN_1905 Condair MLP

Page 57

A Appendix

A.1 Siemens Scalence Router (option)

This describes how to set up the Siemens Scalance S615, in

order to create a connection between PLC and external communication (e.g. BMS system).

It is assumed, that the Siemens Scalance S615 is properly connected to the mains supply and the patch cables are connected

to the PLC and to the HMI (if applicable).

The PLC should be connected in port P2-P4.

2589380

Gateway IP Translator, Separate

box, Y17 incl. PIN code

2589381

Gateway IP Translator, Built-in, Y17

incl. PIN code

Connect a PC with a patch cable to port P1 on the Siemens

Scalance S615. (Not the BMS PC)

Change your PC’s IP address to:

IP address: 192.168.1.20

Subnet mask: 255.255.255.0

The image shows the procedure in Windows 10.

If you are using another version of windows or a MAC, you will

nd a lot of instructions on the internet. Search for: Change IP

address windows xx or MAC...

Open the "Network and Sharing Center" (1) in the control panel

and click the "Connections" link (2).

A new window will open, showing the details about your internet connection. Click the "Properties" button (3).

The default settings of a PC is to "Obtain the IP address automatically". However, you can change it, if required.

Condair MLP

Select "Use the following IP address" and ll in (8):

IP address: 192.168.1.20

Subnet mask: 255.255.255.0

Click "OK" and it‘s done.

Don‘t forget to check the box "Validate settings upon exit". Your

PC will automatically run the network diagnostic and verify the

connection.

If your computer is used on more than one network (most likely

not), enter the details like subnet mask, default gateway, preferred DNS server, alternate DNS server, etc (9).

The IP setting is nished now and the communication with the

Siemens Scalance S615 should work.

Switch back to "Obtain an IP address automatically", after the

settings of the Siemens Scalance S615 are done.

XXXXXXX_EN_1905

57Appendix-A

Page 58

Open a browser, enter the IP address 192.168.1.1 in the

address bar and press "Enter".

This warning (or similar) will appear. To proceed click: "Continue to this website (not recommended)".

The login screen for the conguration of the router appears.

At the rst login:

Enter "admin" for both Name and Password.

If the Router is accessed the rst time you are prompted to

change the password.

Select "OK”. The "Account Passwords" window appears.