Concordia Beverage Systems Xpress 6 User Manual

XPRESS

Technician’s Manual

Concordia Beverage Systems

1287 120th Avenue NE

Bellevue, WA 98005

(425) 453-2800

(800) 778-0990

(425) 453-2167 Fax

http://www.concordiacoffee.com/

Technical Writer and Editor: Shana McKibbin

Technical Support: Gary Williams, Gery Jaggars, Chris Collier, Dana

Klatt, Allen Moore, Dave Davis

Graphic Engineers: Dan Gilbert, Quan Nguyen

Edition: December, 2012

2900-300B

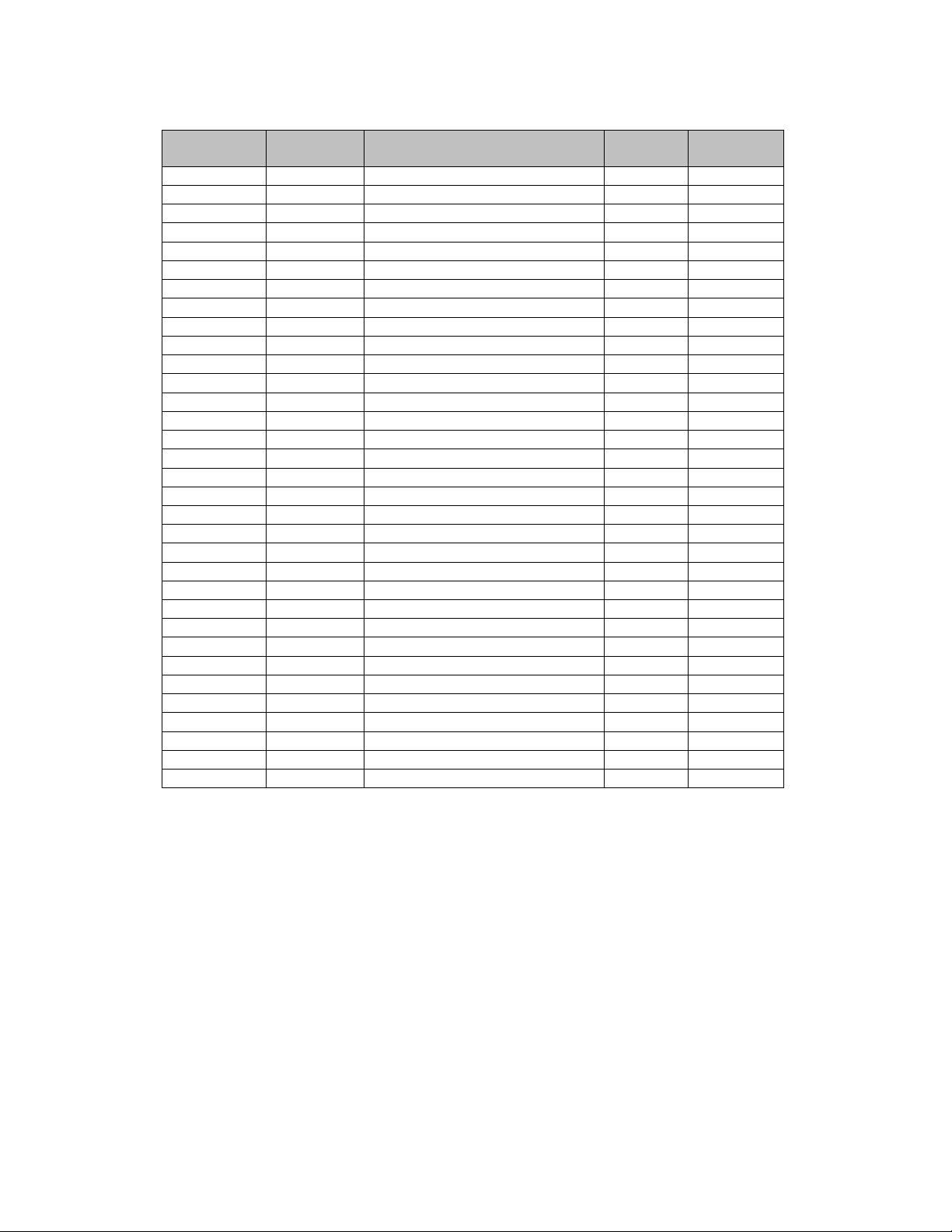

Revision Change Log

Replace

Old Section

With New

Section

Brief Description

Date

Revision

Number

All

All

Manual completely updated

1/28/13

2900-300B

Table of Contents

Section 1 :: Xpress Overview ......................................................................1-1

Xpress Overview ................................................................................................. 1-2

Xpress Components............................................................................................ 1-3

Flavor System Overview ..................................................................................... 1-4

Flavor System Components ................................................................................ 1-5

Section 2 :: Installation and Removal ....................................................... 2-1

Technical Specifications and Site Requirements ................................................ 2-2

Machine Dimensions ........................................................................................... 2-3

Installation ........................................................................................................... 2-4

Configuring the Machine for Supply Voltage ................................. 2-4

Espresso Machine Electrical Settings ........................................... 2-4

Setting the DC Jumper Plug .......................................................... 2-4

Configuring Transformer Auxiliary Connector #1 .......................... 2-5

Plumbing ............................................................................................................. 2-6

Connecting the External Drain ...................................................... 2-6

Water Supply ................................................................................. 2-6

Problems with Reverse Osmosis Water System ........................... 2-7

Flavor System ..................................................................................................... 2-7

Flavor System Installation ............................................................. 2-7

Prime the Flavor System ............................................................... 2-7

Chocolate Sauce ........................................................................... 2-7

Verify Flavor Pour Rate ................................................................. 2-7

Additional Tasks Required at Installation ............................................................ 2-8

Power Up the Machine .................................................................. 2-8

Install Bean Hoppers ..................................................................... 2-8

Install Cup Stand (Optional) .......................................................... 2-8

Operational Configuration ................................................................................... 2-8

Placing Milk in the Refrigeration Unit ............................................ 2-8

Machine Calibration ............................................................................................ 2-9

Customer Training ............................................................................................... 2-9

Installation Checklist ........................................................................................... 2-9

Removal Procedures........................................................................................... 2-9

Section 3 :: Electrical ................................................................................. 3-1

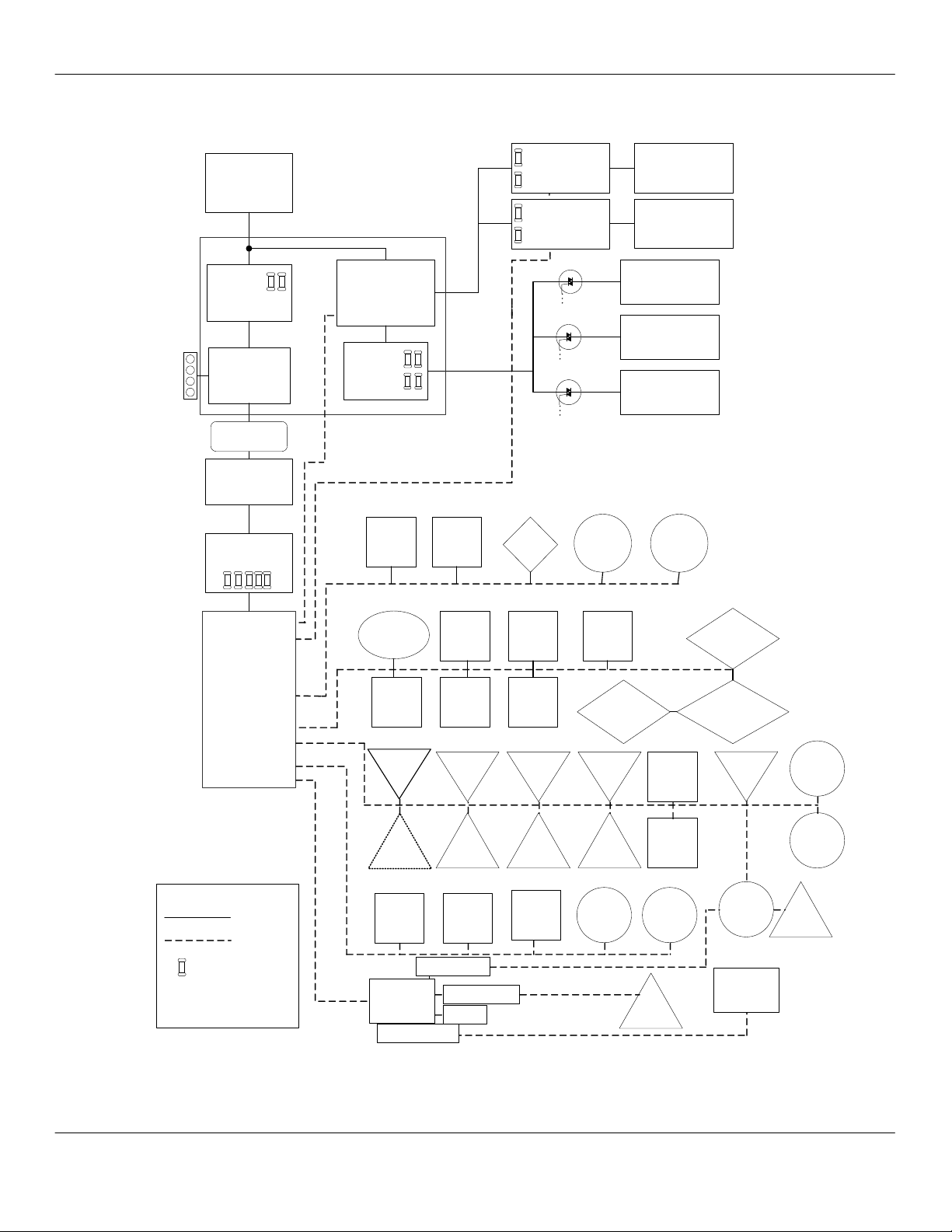

Electrical Block Diagram ..................................................................................... 3-2

Fuses .................................................................................................................. 3-3

Backplane ........................................................................................................... 3-4

AC Drawer Assembly .......................................................................................... 3-5

DC Board Assembly ............................................................................................ 3-6

CPU Board .......................................................................................................... 3-7

J4 ................................................................................................... 3-8

J2 ................................................................................................... 3-8

P3 .................................................................................................. 3-9

P4 .................................................................................................. 3-9

Peripheral Connections Configuration .............................................................. 3-10

Transformer ....................................................................................................... 3-11

Power Into the Machine .................................................................................... 3-15

DC Power Supply Board LEDs ......................................................................... 3-18

Heating Element Wiring Diagrams .................................................................... 3-20

Jumper Plug Connector Detail .......................................................................... 3-21

Section 4 :: Software .................................................................................. 4-1

Software Overview .............................................................................................. 4-2

Software Menu Informational Screens .......................................... 4-2

Categories ..................................................................................... 4-2

Service Switch ..................................................................................................... 4-3

Navigating the Software Menu ...................................................... 4-4

Accessing a Sub-Category ............................................................ 4-4

Exiting the Menu System ............................................................... 4-5

Accessing the Grand Total Drink Count ........................................ 4-5

Accessing Total Drink Count Statistics ......................................... 4-5

Accessing Daily Drink Count Statistics ......................................... 4-5

Software Quick Reference Table ........................................................................ 4-6

Calibration ......................................................................................................... 4-13

Calibrating Pump Pressure ......................................................... 4-14

Calibrating Espresso ................................................................... 4-14

Configuring the Bean Hoppers .................................................... 4-14

Espresso Extraction and Temperature Parameters .................... 4-15

Drink Temperatures ..................................................................... 4-15

Verifying Espresso Extraction ..................................................... 4-15

Calibrating Milk Timings .............................................................. 4-16

Calibrating Brewed Coffee .......................................................... 4-16

Calibrating Flavor Timings ........................................................... 4-17

Espresso Extraction Pre-Treatment Options .................................................... 4-17

Pre-Treatment Options ................................................................ 4-17

CPU Board ........................................................................................................ 4-19

Loading New Software to a Machine ................................................................ 4-20

Required Equipment .................................................................... 4-20

Configuring HyperTerminal ......................................................... 4-20

Connecting a Laptop to a Machine ............................................. 4-27

Updating Software for Customers with Custom Drink Recipes ... 4-30

Section 5 :: Plumbing ................................................................................ 5-1

The Water System .............................................................................................. 5-2

Line Pressure ................................................................................ 5-3

Check Valve .................................................................................. 5-3

Water Filtration System ................................................................. 5-3

Hot Water Tank ................................................................................................... 5-4

Temperature/Level Probe .............................................................. 5-5

Level Probe ................................................................................... 5-5

Temperature Probe ....................................................................... 5-6

Pressure Relief Valve .................................................................... 5-6

High Temperature Limit Switch ..................................................... 5-6

Water Inlet ..................................................................................... 5-6

Flowmeter ...................................................................................... 5-7

Heating Elements .......................................................................... 5-7

Brew Valve .................................................................................... 5-7

Hot Water Valve ............................................................................ 5-7

Draining the Hot Water Tank ......................................................... 5-8

Water Pump and Motor ....................................................................................... 5-8

Water Pressure Gauge .................................................................. 5-9

Setting Pump Pressure ................................................................. 5-9

Expansion Valve ............................................................................ 5-9

Check Water Flow Message ......................................................... 5-9

The Steam System............................................................................................ 5-10

Steam Tank – Front View ............................................................ 5-10

Steam Tank – Rear View ............................................................ 5-11

Steam Tank Fill Valve ................................................................. 5-12

Steam Tank ................................................................................. 5-12

Water Level Probes ..................................................................... 5-12

Pressure Gauge .......................................................................... 5-13

Heating Elements ........................................................................ 5-13

Pressure Relief Valve .................................................................. 5-13

High Temperature Limit Switch ................................................... 5-13

Steam Valves .............................................................................. 5-14

Left Steam Valve ......................................................................... 5-14

Center Steam Valve .................................................................... 5-15

Right Steam Valve ....................................................................... 5-15

Air Purge Process ....................................................................... 5-15

Captive Water Purge System ...................................................... 5-15

Draining the Steam Tank ............................................................. 5-15

Section 6 :: Coffee System ......................................................................... 6-1

The Coffee System ............................................................................................. 6-2

Espresso Path ............................................................................... 6-2

Grinders .............................................................................................................. 6-3

Double Grinder Assembly ............................................................. 6-3

Calibration: Espresso Grind .......................................................... 6-4

Grinder Adjustment Panel ............................................................. 6-4

Grinder Adjustment Diagram ......................................................... 6-5

Measuring the Coffee Powder Dose ............................................. 6-5

Coffee Powder Channel ................................................................ 6-6

Removing the Grinder ................................................................... 6-6

Replacing the Grinder Burrs/Blades .............................................. 6-7

Setting the Grinder Adjustment Indicator to Mid-Scale ................. 6-7

Bean Hoppers ..................................................................................................... 6-8

Filling a Bean Hopper .................................................................... 6-8

Inserting the Hopper Stopper ........................................................ 6-8

Removing a Bean Hopper ............................................................. 6-8

Brew Group ......................................................................................................... 6-9

Brew Group Initialization ............................................................. 6-10

Brew Group Components ................................................................................. 6-10

Hall-Effect Sensors ...................................................................... 6-11

Left Piston.................................................................................... 6-12

Right Piston ................................................................................. 6-12

Piston Movement ......................................................................... 6-12

Viewing the Left Piston Movement .............................................. 6-13

Removing the Left Piston ............................................................ 6-13

Removing the Right Piston .......................................................... 6-14

Gearbox Removal and Installation .................................................................... 6-15

Removing the Gearbox ............................................................... 6-15

Installing the Gearbox ................................................................. 6-16

Section 7 :: Milk System and Refrigeration Unit ...................................... 7-1

The Milk Delivery System ................................................................................... 7-2

Milk Delivery System Components ..................................................................... 7-2

Milk Pump Assembly ..................................................................... 7-2

Milk Pick-Up Tube ......................................................................... 7-2

Milk Pump ...................................................................................... 7-2

Milk System Theory of Operation ........................................................................ 7-3

Basic Terminology ......................................................................... 7-3

Initial Setup of the Milk System ..................................................... 7-4

Milk System Capabilities ............................................................... 7-5

A Common Milk Timing Mistake .................................................... 7-5

Air Gate Valve Assembly .................................................................................... 7-5

Air Gate Valves ............................................................................. 7-6

Air Purge Valves ............................................................................ 7-6

Air Vent Needles ........................................................................... 7-6

Connection of Milk Pump Assembly and Air Gate Valve Assembly 7-

6

Alt Milk Valve ....................................................................................................... 7-6

Steam Delivery Components .............................................................................. 7-7

Steam Valves ................................................................................ 7-7

Mixing TEE Assembly ................................................................... 7-7

Refrigeration Unit Overview ................................................................................ 7-8

Placing Milk in the Machine ........................................................... 7-9

Checking the Refrigeration Unit Temperature ............................... 7-9

Refrigeration Cooling Module Assembly ..................................... 7-10

Fan Control Board ....................................................................... 7-11

Cold Sink Deflector ...................................................................... 7-11

Interior Circulation Fan Assembly ............................................... 7-12

Exterior Cooling Module Fan Assembly ...................................... 7-12

Temperature Probe Assembly..................................................... 7-12

Milk Weight Trays ........................................................................ 7-13

Adjusting a Milk Weight Tray ....................................................... 7-15

Milk Level Sensors ...................................................................... 7-16

Auto Milk Select ........................................................................... 7-16

Section 8 :: Steam Wands ......................................................................... 8-1

Steam Wand Overview ....................................................................................... 8-2

Automatic Steam Wand ...................................................................................... 8-2

Automatic Steam Wand Theory of Operation ............................... 8-2

Automatic Steam Wand Selections ............................................... 8-3

Automatic Steam Wand Programming .......................................... 8-4

Air Pump ........................................................................................ 8-4

Steam and Vacuum Valve Assembly ............................................ 8-4

Automatic Steam Wand Wiring ........................................................................... 8-5

Replacing an Automatic Steam Wand ................................................................ 8-5

Manual Steam Wand........................................................................................... 8-6

Replacing a Manual Steam Wand ...................................................................... 8-6

Removing a Steam Wand ............................................................. 8-8

Installing a Steam Wand ..................................................................................... 8-8

Cleaning a Steam Wand ..................................................................................... 8-8

Section 9 :: Flavor System ......................................................................... 9-1

The Flavor System .............................................................................................. 9-2

Chocolate Sauce Delivery Path..................................................... 9-2

Syrup Delivery Path ....................................................................... 9-3

Flavor Tubes.................................................................................. 9-3

Flavor Storage Area ...................................................................... 9-4

Chocolate Sauce ........................................................................... 9-4

Chocolate Heater Assembly .......................................................... 9-4

Connecting Flavor Tubing ............................................................. 9-4

Changing the Flavor Pour Rate ..................................................... 9-5

Verifying Proper Syrup Flow .......................................................... 9-6

Changing Flavor Boxes ................................................................. 9-7

Peristaltic Pumps ................................................................................................ 9-8

Syrup Manifold .................................................................................................... 9-8

Chocolate Rinse Purge Valve ....................................................... 9-9

Milk Bowl ....................................................................................... 9-9

Removing the Syrup Manifold ....................................................... 9-9

Replacing the Syrup Manifold ..................................................... 9-10

Cleaning the Flavor Delivery System ................................................................ 9-10

Priming the Flavor Delivery System .................................................................. 9-12

Section 10 :: Vending ............................................................................... 10-1

Vending Overview ............................................................................................. 10-2

Vending Backpack ....................................................................... 10-2

Replacing a Card Reader ................................................................................. 10-2

Installing a Vending Unit ................................................................................... 10-3

Removing a Vending Unit ................................................................................. 10-3

Troubleshooting ................................................................................................ 10-3

Section 11 :: Cleaning and Maintenance .................................................. 11-1

Daily Maintenance............................................................................................. 11-2

Concordia Cleaning Products...................................................... 11-2

Cleaning Timers ................................................................................................ 11-3

Preventive Maintenance ................................................................................... 11-3

Section 12 :: Concordia Procedures ........................................................ 12-1

Service Call Process ......................................................................................... 12-2

Arrival to Site ............................................................................... 12-2

Machine Repair ........................................................................... 12-2

Hold for Parts Procedures ........................................................... 12-2

Departing from Site ..................................................................... 12-2

Required Immediately for Call Closeout ...................................... 12-3

Complete Call Protocol ..................................................................................... 12-3

Machine Appearance .................................................................. 12-3

Milk System ................................................................................. 12-3

Brew Group ................................................................................. 12-3

Water Tank .................................................................................. 12-3

Water Pump................................................................................. 12-3

Steam Tank ................................................................................. 12-3

Refrigeration Unit ........................................................................ 12-4

Espresso Extraction .................................................................... 12-4

Milk Pour ...................................................................................... 12-4

Service Call Checklist ....................................................................................... 12-5

Parts Return Policy ........................................................................................... 12-6

Non-Consignment Agents ........................................................... 12-6

Consignment Agents ................................................................... 12-6

Return Material Tag ..................................................................... 12-7

Parts Replenishment Form ............................................................................... 12-8

Section 13 :: Customer Service and Training .......................................... 13-1

Training the Customer....................................................................................... 13-2

User Guide .................................................................................. 13-2

Starting and Resetting the Machine ............................................ 13-2

Filling Machine with Beans and Milk ........................................... 13-2

Pouring Drinks and Cancelling Drinks ......................................... 13-2

Restocking and Changing Flavor Boxes ..................................... 13-2

Cleaning ...................................................................................... 13-3

Serial Number ............................................................................. 13-3

Accessing Software Menu ........................................................... 13-3

Troubleshooting Tips ................................................................... 13-3

Contacting Concordia for Assistance .......................................... 13-4

Concordia Beverage Systems’ Value-Added Service ....................................... 13-5

Value-Added Service ................................................................... 13-6

G.U.E.S.T. ......................................................................................................... 13-7

Greet the Customer ..................................................................... 13-7

Understand your Customer ......................................................... 13-8

Empathize with Your Customer ................................................... 13-9

Solve the Problem ..................................................................... 13-10

Train the Customer .................................................................... 13-10

Section 14 :: Messages ............................................................................. 14-1

Troubleshooting Display Messages .................................................................. 14-2

Section 15 :: Troubleshooting ................................................................... 15-1

Troubleshooting Quick Reference Guide .......................................................... 15-2

Machine Failure ........................................................................... 15-2

Coffee System ............................................................................. 15-3

Flavor System ............................................................................. 15-3

Milk System ................................................................................. 15-4

Troubleshooting Trees ...................................................................................... 15-5

Brew System: Right Drive Timeout ............................................. 15-6

Brew System: Invalid Stop L ....................................................... 15-7

Brew System: Invalid Stop R ....................................................... 15-9

Brew System: Left Drive Timeout .............................................. 15-11

Grinder System: Out of Beans .................................................. 15-13

Milk System: Overpouring Milk .................................................. 15-15

Milk System: Cold Milk Pour...................................................... 15-17

Milk System: No Milk Pour ........................................................ 15-19

Milk System: Short Milk Pour .................................................... 15-21

Refrigeration System: Temperature Above 40˚F ...................... 15-23

Steam System: Steam Temperature High ................................ 15-25

Steam System: Check Sensor Voltage ..................................... 15-26

Steam System: Check Steam Probes ....................................... 15-27

Steam System: Check Steam Tank .......................................... 15-28

Steam System: Steam Temperature Low ................................. 15-29

Water System: Water Temperature Too High ........................... 15-30

Water System: Water Temperature Too Low ............................ 15-31

Water System: Check Water Supply ......................................... 15-33

Water System: Water Tank Limit Switch Open ......................... 15-35

Flavor System: Cross-Contamination of Syrup Lines ............... 15-37

Flavor System: Too Much Flavor in Drink ................................. 15-38

Flavor System: Not Enough Flavor in Drink .............................. 15-39

Flavor System: No Flavor in Drink ............................................ 15-41

Electrical System: Check Analog Board .................................... 15-43

Electrical System: Incorrect Software for Touchpad ................. 15-44

Electrical System: Milk Pump Running Continuously ............... 15-45

Electrical System: Front Panel Failed ....................................... 15-46

Electrical System: Check Clock................................................. 15-47

Electrical System: Check Stats ................................................. 15-48

Electrical System: CPU Load Disp and Seq Error .................... 15-49

Electrical System: AC Voltage Error ......................................... 15-51

Electrical System: DC Voltage Failure ...................................... 15-53

Vending System: Card Swipe or Tap Not Authorized ............... 15-55

Vending System: Not Configured .............................................. 15-56

Vending System: No Display on Card Reader .......................... 15-57

Section 16 :: Parts Lists & Diagrams ....................................................... 16-1

Recommended Tools List ................................................................................. 16-2

Standard Tools ............................................................................ 16-2

Concordia Stocked Tools ............................................................ 16-2

Consumables .............................................................................. 16-2

Parts Lists and Diagrams .................................................................................. 16-3

Diagram 1: Machine Overview .................................................... 16-4

Diagram 1, Parts List: Machine Overview ................................... 16-5

Diagram 2: Grounds Bin Door, Refrigerator Door with Hot Water

Button Assembly ......................................................................... 16-6

Diagram 2, Parts List: Refrigerator Door with Hot Water Button

Assembly ..................................................................................... 16-7

Diagram 3: Refrigerator Door with Steam Wand Assembly ........ 16-8

Diagram 3, Parts List: Refrigerator Door with Steam Wand

Assembly ..................................................................................... 16-9

Diagram 4: Front Panel ............................................................. 16-10

Diagram 4, Parts List: Front Panel ............................................ 16-11

Diagram 5: Top Panel ............................................................... 16-12

Diagram 5, Parts List: Top Panel .............................................. 16-13

Diagram 6: Grinder Assembly ................................................... 16-14

Diagram 6, Parts List: Grinder Assembly .................................. 16-15

Diagram 7: Grinder Adjustment Assembly ................................ 16-16

Diagram 7, Parts List: Grinder Adjustment Assembly ............... 16-17

Diagram 8: Group Upper and Lower Piston Assembly ............. 16-18

Diagram 8, Parts List: Group Upper and Lower Piston Assembly 16-

19

Diagram 9: Group Drive System ............................................... 16-20

Diagram 9, Parts List: Group Drive System .............................. 16-21

Diagram 10: Milk Pump Assembly ............................................ 16-22

Diagram 10: Parts List, Milk Pump Assembly ........................... 16-23

Diagram 11: Product Delivery Assembly, Xpress 6 .................. 16-24

Diagram 11, Parts List: Product Delivery Assembly, Xpress 6 . 16-25

Diagram 12: Product Delivery Assembly, Xpress 0 .................. 16-26

Diagram 12, Parts List: Product Delivery Assembly, Xpress .... 16-27

Diagram 13: Refrigeration Unit Assembly ................................. 16-28

Diagram 13, Parts List: Refrigeration Unit Assembly ................ 16-29

Diagram 14: Chocolate Sauce Delivery System ....................... 16-30

Diagram 14, Parts List: Chocolate Sauce Delivery System ...... 16-31

Diagram 15: Syrup Delivery System ......................................... 16-32

Diagram 15, Parts List: Syrup Delivery System ........................ 16-33

Diagram 16: Refrigeration Unit Cooling Assembly .................... 16-34

Diagram 16, Parts List: Refrigeration Unit Cooling Assembly ... 16-35

Diagram 17: Steam Tank, Front ................................................ 16-36

Diagram 17, Parts List: Steam Tank, Front ............................... 16-37

Diagram 18: Steam Tank, Rear ................................................ 16-38

Diagram 18, Parts List: Steam Tank, Rear ............................... 16-39

Diagram 19: Water Pump and Motor ........................................ 16-40

Diagram 19, Parts List: Water Pump and Motor ....................... 16-41

Diagram 20: Hot Water Tank..................................................... 16-42

Diagram 20, Parts List: Hot Water Tank ................................... 16-43

Diagram 21: Water/Steam Gauge/ Air Valve Assembly ............ 16-44

Diagram 21: Parts List: Water/Steam Gauge/Air Valve Assembly 16-

45

Diagram 22, Parts List: Drain Valve Bridge Web Assembly ..... 16-46

Diagram 22, Parts List: Drain Valve Bridge Web Assembly ..... 16-47

Section 17 :: Index .................................................................................... 17-1

Section 18 :: Service Bulletins ................................................................. 18-1

Table of Contents – Service Bulletins ............................................................... 18-2

Service Bulletins .......................................................................... 18-3

Page Intentionally Left Blank

Page Intentionally Left Blank

T E C H N I C A L S U P P O R T

Section 1 :: Xpress

Overview

1. Xpress Overview

2. Xpress Components

3. Flavor System Overview

4. Flavor System Components

Section 1: Xpress Overview 3033-001B

Xpress Overview

1-2 Concordia Xpress Technical Support Manual

2900-300B

3033-001B Section 1: Xpress Overview

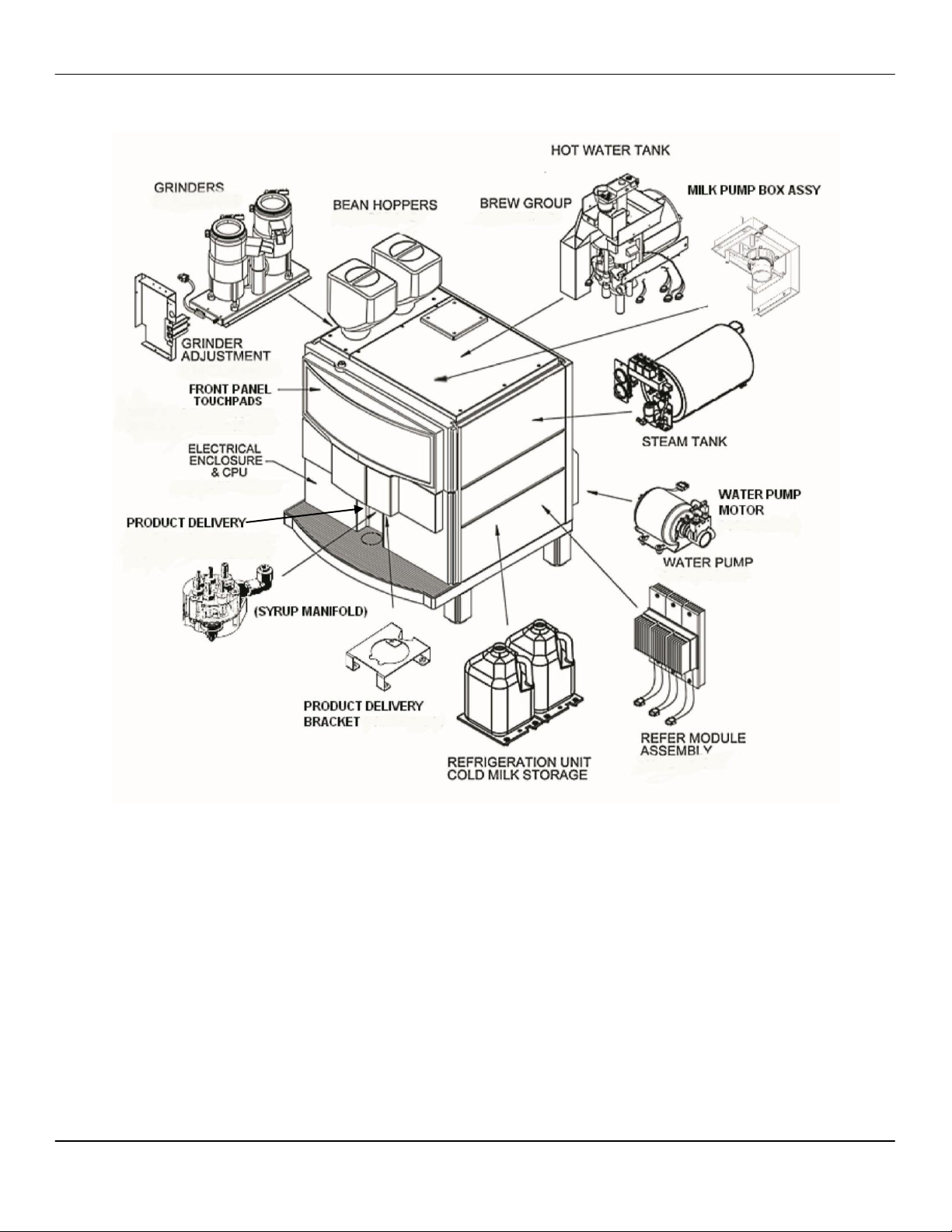

Xpress Components

Front Panel Touch Pad

The front panel touch pad provides a user interface for selecting and

pouring drinks.

Electrical Enclosure and CPU

The electrical enclosure houses the CPU, AC drawer, and DC board.

Bean Hoppers

Each bean hopper holds whole espresso roast beans and feeds the

beans to the grinders.

Water Pump and Motor

The water pump regulates the water pressure to 135-140psi during the

espresso extraction process. The motor supplies power to the pump.

Hot Water Tank

The hot water tank stores and heats the water used to brew espresso.

Brew Group

The brew group assembly brews espresso and automatically discards

the used coffee into the grounds bin.

Steam Tank

The steam tank provides steam used for steaming the milk.

Grinders and the Grinder Adjustment Assembly

The grinders are calibrated to grind espresso beans according to the

customer’s recipe. The grinder adjustment assembly changes the grind

of espresso beans.

Exhaust Fan

NOT SHOWN

The exhaust fan removes excess heat build-up from the machine interior.

Refrigeration Unit

The refrigeration unit stores the milk used for drinks.

Refrigeration Module Assembly

The refrigeration module assembly regulates the temperature inside the

refrigeration unit.

Milk Pump and Milk Pump Box Assembly

The milk pump assembly draws milk from the milk container.

Syrup Manifold

Xpress 6 only

Flavor is infused into drinks via the syrup manifold.

Product Delivery Bracket

The product delivery bracket holds the milk bowl (not shown) and the

syrup manifold.

Product Delivery Nozzle

The finished drink is poured through the product delivery nozzle and into

the customer’s cup.

Concordia Xpress Technical Support Manual 1-3

2900-300B

Section 1: Xpress Overview 3033-001B

CHOCOLATE HEATER

ASSEMBLY

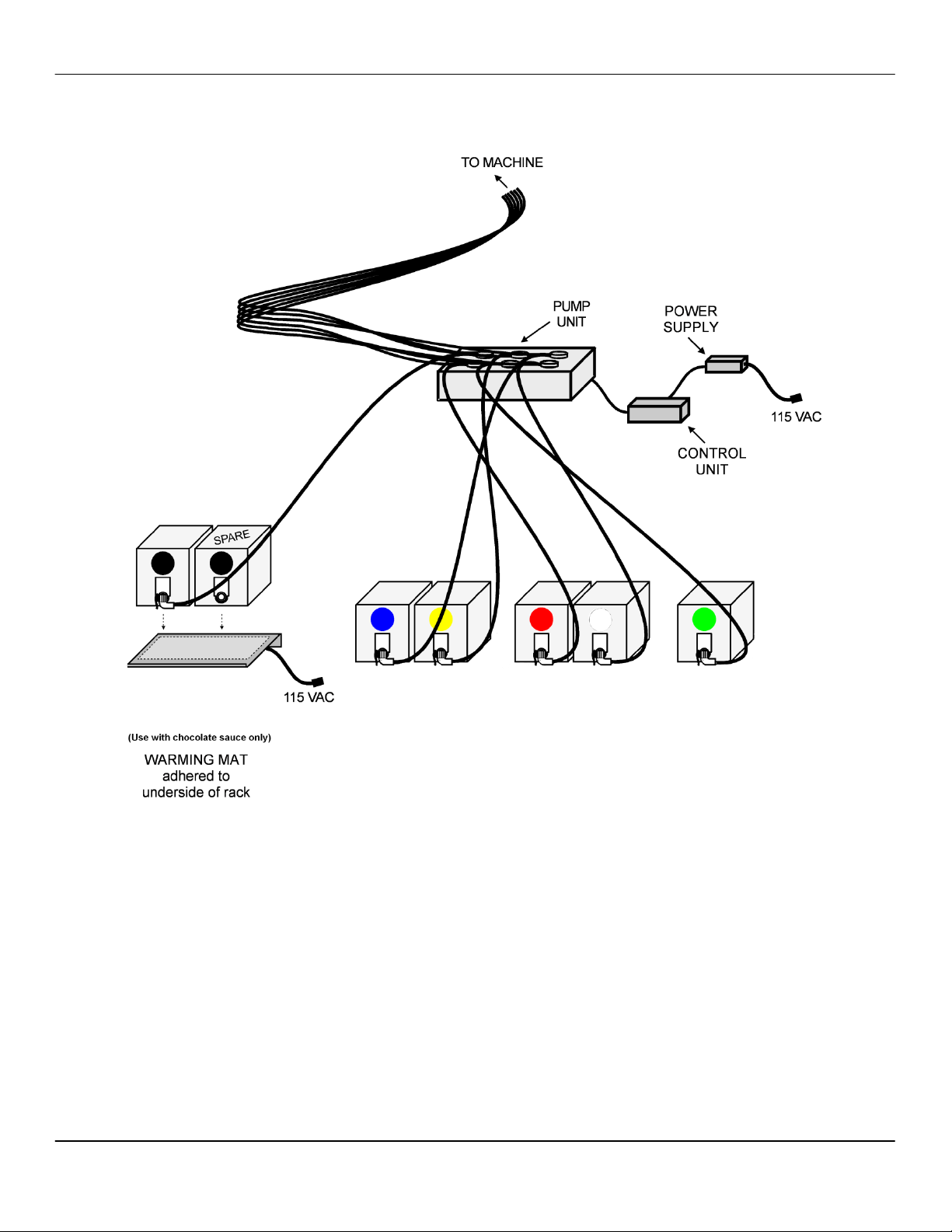

Flavor System Overview

1-4 Concordia Xpress Technical Support Manual

2900-300B

3033-001B Section 1: Xpress Overview

Flavor System Components

Xpress 6 only

Pump Unit

The pump unit contains the six peristaltic pump assemblies that move

the flavors from the boxes to the syrup manifold, and then to the product

delivery outlet.

Control Unit

The control unit houses the electronic board that controls the syrup

pumps.

Power Supply

The power supply provides 24Vdc power to the control unit.

Chocolate Heater Assembly

The chocolate heater assembly provides heat to the chocolate sauce, to

ensure a minimum temperature of 85°F (29.4°C) is maintained.

Concordia Xpress Technical Support Manual 1-5

2900-300B

Section 1: Xpress Overview 3033-001B

Page Intentionally Left Blank

1-6 Concordia Xpress Technical Support Manual

2900-300B

T E C H N I C A L S U P P O R T

Section 2 :: Installation

and Removal

1. Technical Specifications and Site

Requirements

2. Machine Dimensions

3. Installation

4. Plumbing

5. Flavor System

6. Additional Tasks Required at Installation

7. Operational Configuration

8. Machine Calibration

9. Customer Training

10. Installation Checklist

11. Removal Procedures

Section 2: Installation and Removal 3033-002B

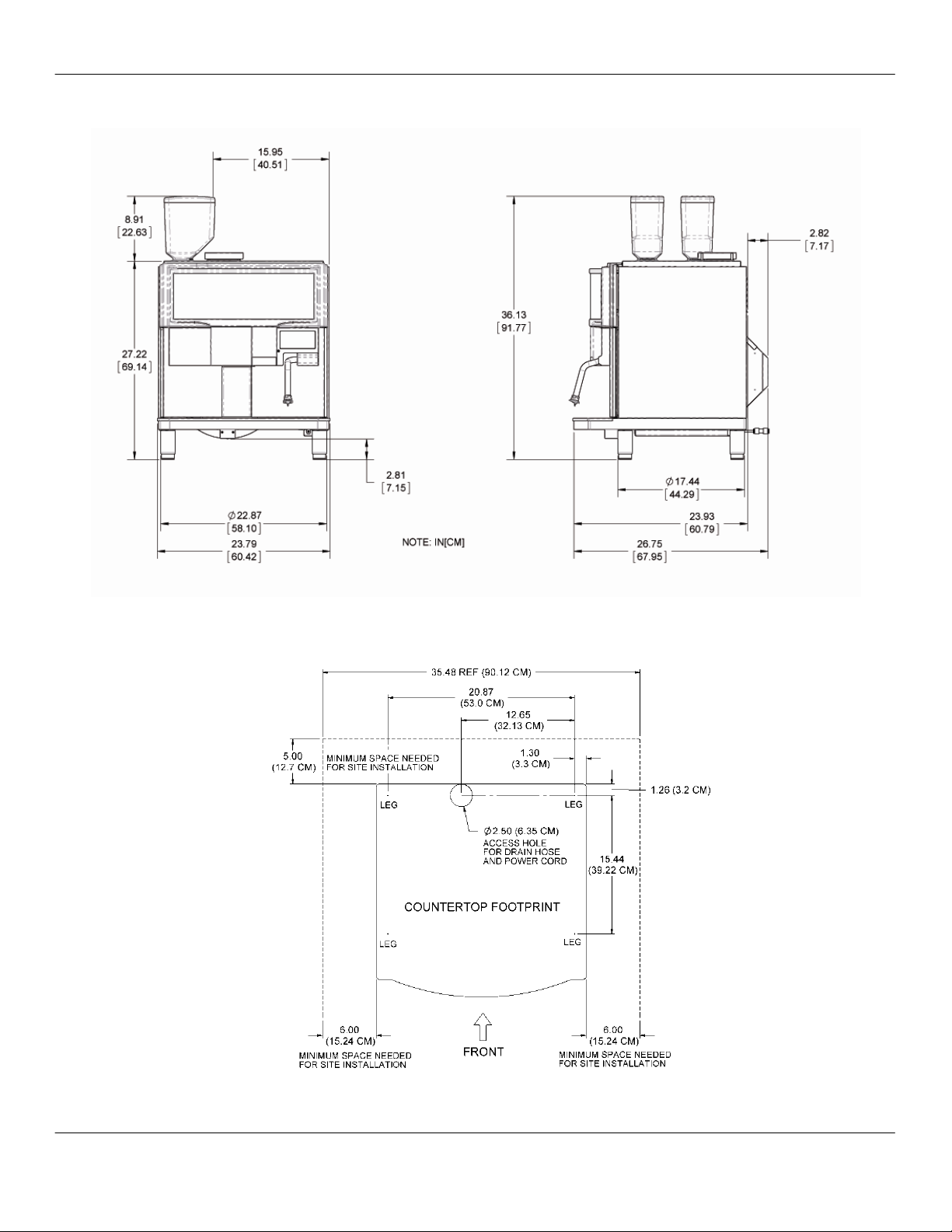

Technical Specifications

Weight: 300lbs/137kg

Operating Environment: 55°- 85°F (13°-29°C)

Power Consumption: 24 amps @ 208Vac max

8 amps @ 115Vac max

Compliance:

FCC: Part 15B, Class A, Part 68

UL Listed

NSF Certified

Power and Water Requirements

Power

Located within five feet (1.5 meters) of machine

Single Phase:

200-240Vac, 30amp dedicated circuit

NEMA L14-30 Receptacle

High Leg:

200-240Vac, 30amp, high leg dedicated circuit.

International machines are shipped without a power plug. A

plug must be attached at the time of installation and meet

with all local electrical codes.

Flavor Delivery System

Domestic

Chocolate Heater Assembly

115Vac, 15amp

NEMA 5-15P

Control Unit

115Vac, 15amp

NEMA 5-15P

International

Chocolate Heater Assembly

230Vac

Control Unit

90-260Vac

Water

Cold water source with a 1/4” or 3/8” tube fitting with a

shut-off valve, located within five feet (1.5 meters) of

machine

Pressure

Minimum: 30psi; Maximum: 100psi (min: 2 bar, max 7 bar)

25 gallons per hour (95 liters per hour)

A fresh water bypass is required for sites with a reverse

osmosis filter system

Scalex Water Treatment System

Included with the unit: two cartridges (one carbon, one

softener)

25”H x 11”W x 5.25”D

63.5cmHx28cmWx13.34cmD

Location Requirements

Locate indoors only

Overall Space

23.79”W x 26.75”D x 36.13”H

59.64cm x 67.49cm x 91.44cm

Machine Counter Space

36”W x 29”D x 42”H

91.44cm x 73.66cm x 106.68cm

Flavor Delivery System

30”W x 30”D x 27”H

76.2cmWx76.2Dx68.6H

Drain

Connection for ¾”/1.9cm drain dose

Indirect drain required

Located within five feet/1.5 meters of machine

Technical Specifications and Site

Requirements

To ensure the site is ready, the customer is required to complete and

return a pre-installation checklist. The customer is required to have

electrical, water, and a drain located within a specified distance from the

machine.

2-2 Concordia Xpress Technical Support Manual

2900-300B

3033-002B Section 2: Installation and Removal

Machine Dimensions

Concordia Xpress Technical Support Manual 2-3

2900-300B

Section 2: Installation and Removal 3033-002B

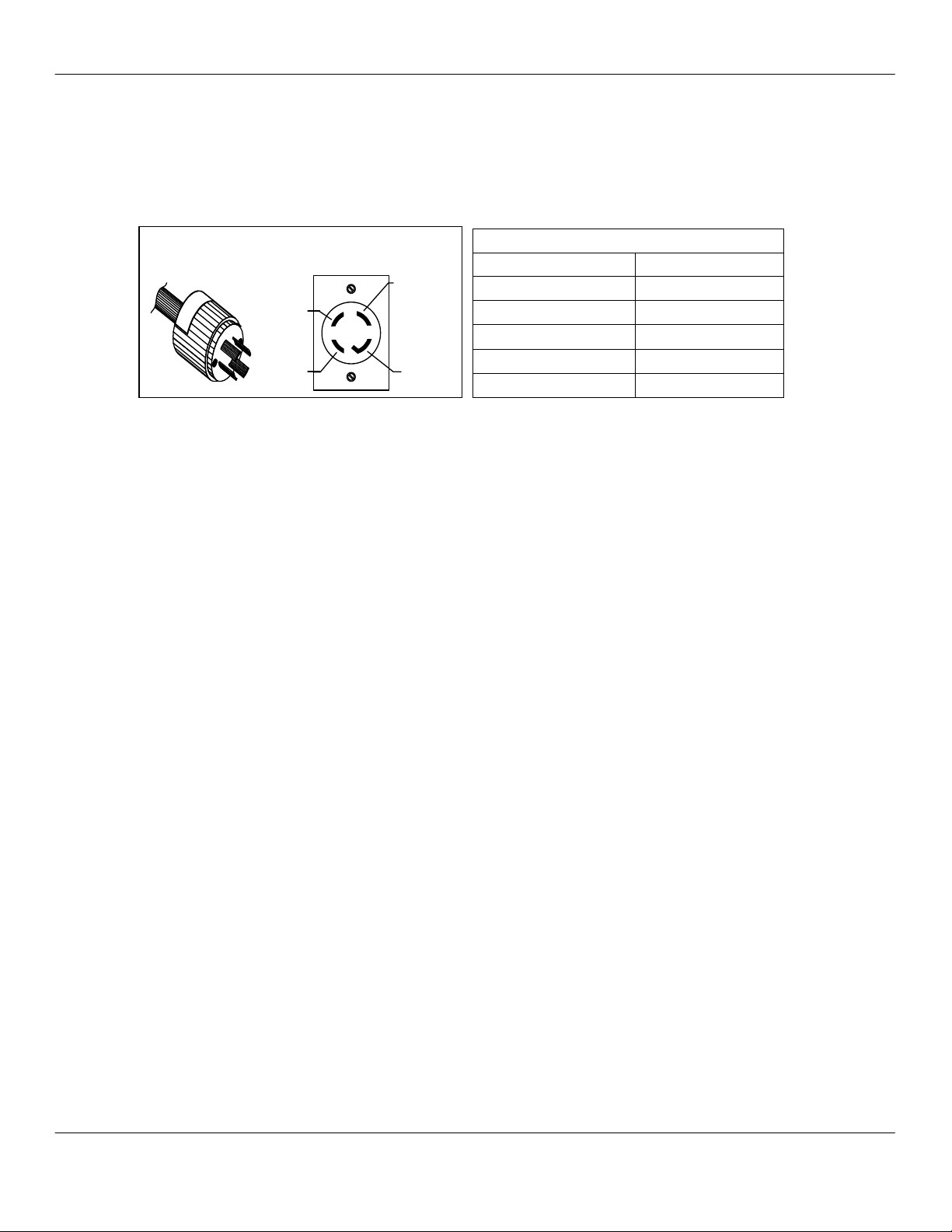

IBS6+ Equipped with 4 prong 208 volt plug

L1 120VAC

TO NEUTRAL

NEMA

L1430-R

L2 120VAC

GROUND

NEUTRAL

TO NEUTRAL

Connections

Voltage

L1 to Ground

110Vac – 120Vac

L2 to Ground

110Vac – 120Vac

L1 to Neutral

110Vac – 120Vac

L2 to Neutral

110Vac – 120Vac

L1 to L2

200Vac – 240Vac

Ground to Neutral

0Vac

Confirming Receptacle Voltages

Plug and Receptacle – US only

Xpress equipped with 4 prong 208 volt plug

Installation

Configuring the Machine for Supply Voltage

Before connecting machine to the electrical supply, check and verify

incoming power supply. The following chart displays the required

voltages.

Espresso Machine Electrical Settings

Prior to connecting the machine to the power source, verify the electrical

settings are correct. The DC jumper plug and transformer must be

properly configured.

WARNING: Failure to properly set the DC jumper plug and the

transformer connector can result in machine malfunction, short circuit,

blown fuses, overheating, or damage to circuit boards.

Setting the DC Jumper Plug

1. Measure the source voltage at the NEMA L1430-R receptacle

(refer to the chart above). Record the value in the electrical

section of the installation checklist.

2. Remove the electrical enclosure cover to access the DC power

supply board.

CAUTION: ESD protection required.

3. Remove the DC power supply board using the white ejector

lever.

4. Use the diagram on the next page to configure the DC jumper

plug to the measured source voltage.

5. Insert the free end of the yellow wire into the correct pinhole.

6. Insert the jumper plug into connector J1 located on the DC

power supply board.

7. Re-install the DC power supply board. Ensure the board is fully

seated by firmly pressing the board into connector on the

backplane connector.

8. Re-install the electrical enclosure cover and verify the display

cable is not stressed, pinched, or cut when front panel is

lowered.

2-4 Concordia Xpress Technical Support Manual

2900-300B

3033-002B Section 2: Installation and Removal

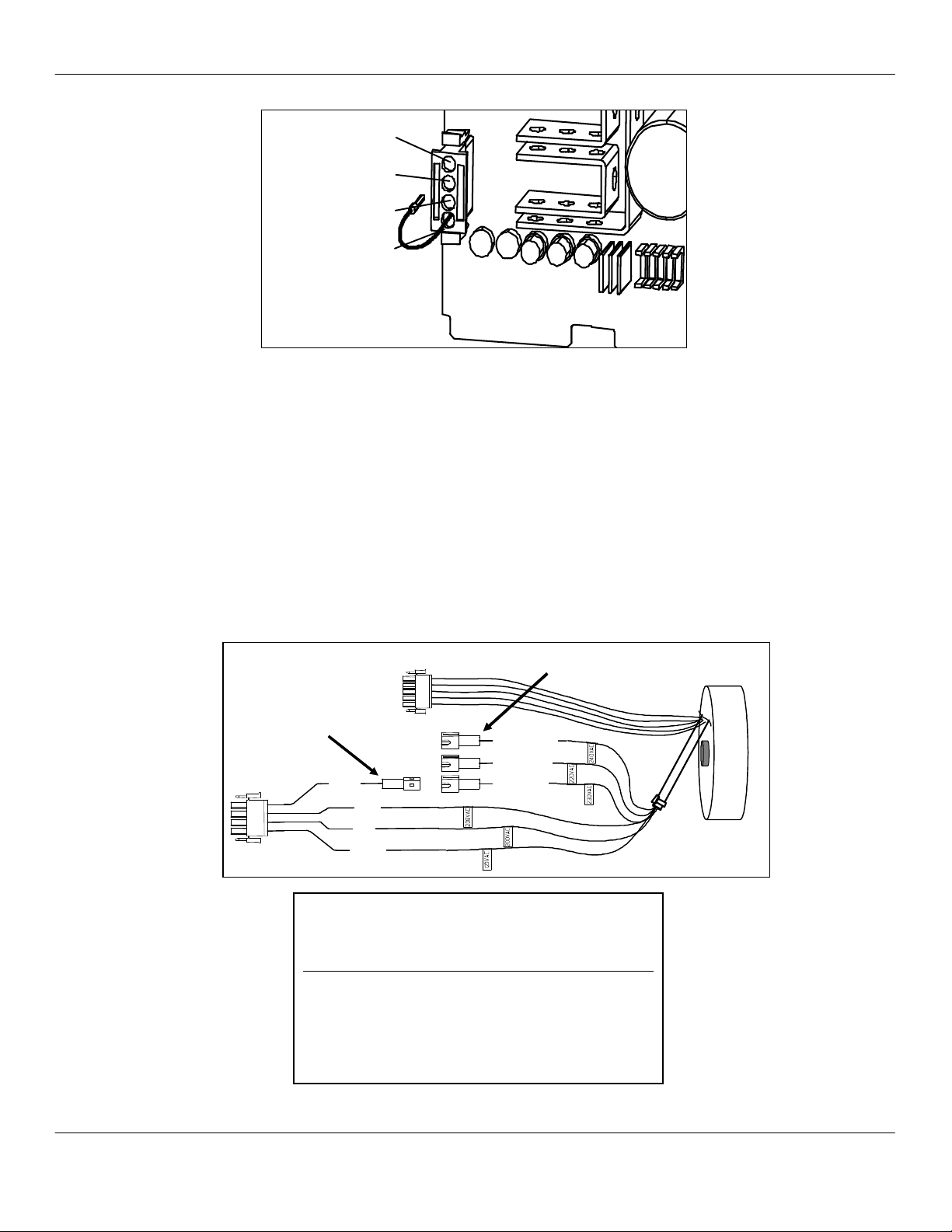

VOLTAGE TABLE

MEASURED SOURCE AUX

CONNECTOR CONNECTOR

VOLTAGE RANGE #1 SETTING

200 – 205 200 NO ADJUSTMENT

206 – 215 208 NO ADJUSTMENT

216 – 225 220-240 #3 GREEN WIRE

226 – 235 220-240 #4 WHITE WIRE

236 – 245 220-240 #2 ORANGE WIRE

AUXILIARY

CONNECTOR #1

TRANSFORMER

CONNECTORS #2, #3, #4

BROWN

RED

BLUE

WHITE

WHITE 230V

GREEN 220V

ORANGE 240V

1 2 3

4

Transformer Auxiliary Connector Configuration

Configuring the DC Jumper Plug

50-60Hz

200 VAC

208 VAC

220-240 VAC

L2

200 VAC

208 VAC

220-240 VAC

L2

Configuring Transformer Auxiliary Connector

#1

It may be necessary to configure the auxiliary connector at the

transformer, depending on the measured supply voltage.

1. Remove the machine back panel.

2. Locate the transformer and connectors.

3. Using the voltage table, connect the transformer auxiliary

connector #1 to the appropriate connector labeled 220Vac,

230Vac, or 240Vac.

4. Reinstall the back panel and proceed with machine installation.

Concordia Xpress Technical Support Manual 2-5

2900-300B

Section 2: Installation and Removal 3033-002B

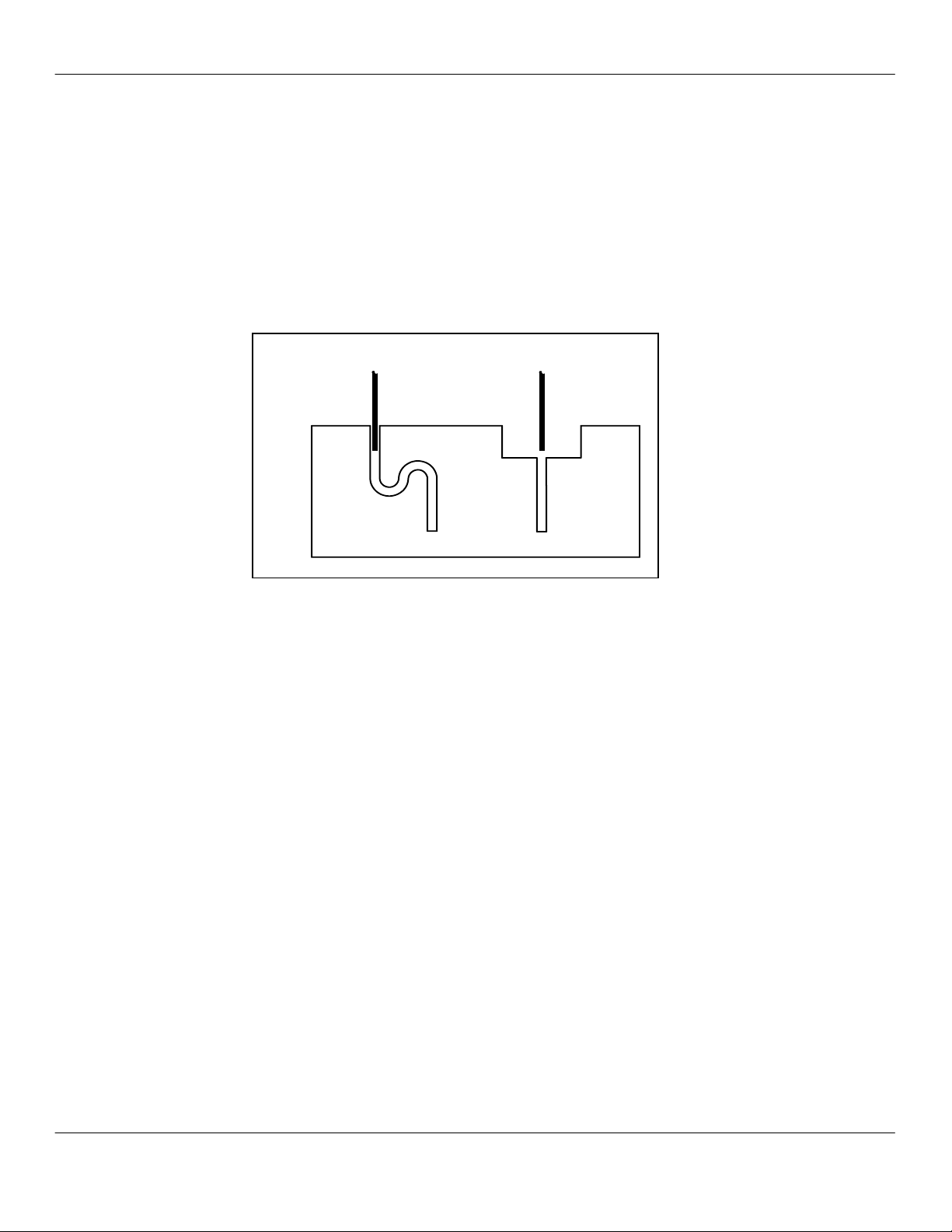

INDIRECT

DRAIN

FLOOR SINK

DRAIN

DRAIN HOSE

FROM MACHINE

DRAIN HOSE

FROM MACHINE

Approved Drain Configurations

Plumbing

Connecting the External Drain

Only a qualified plumber complying with all local codes and requirements

can install the drain at the site. You are responsible for connecting the

machine to the drain.

The following requirements must be met:

Drain accommodating a 3/4” (1.9cm) ID drain hose

Drain must be located within five feet (1.5 meters) of machine

The minimum rate of fall required is one inch (2.54cm) per foot, and the

drain hose must have a continuous rate of fall. Ensure the drain hose is

connected to the machine drain port.

If the drain has any low spots or any horizontal runs as it travels from the

machine to the drain, water and other waste from the machine will back

up and cause the drain hose and/or the drain tray to clog.

NOTE: When water and drain lines are connected, check for leaks.

Water Supply

To ensure proper operation of the machine, the following requirements

must be met:

Cold water source with a shut-off valve and 1/4" or 3/8” tube

fitting

Water pressure: minimum 30psi; maximum 100psi

Water source must be located within five feet (1.5 meters) of

machine

All machines ship with a Scalex water treatment system

Prior to connecting the water filter to the machine, flush the water

filtration system with 2 gallons (8 liters) of water.

2-6 Concordia Xpress Technical Support Manual

2900-300B

3033-002B Section 2: Installation and Removal

Problems with Reverse Osmosis Water System

A fresh water bypass is required for sites with a reverse osmosis filter

system. The machine water level sensors are inoperative when used

with this system.

Flavor System

Flavor System Installation

The flavor boxes and the flavor tubes are color-coded. It is important to

verify the colors are correctly matched, to ensure customers receive the

desired drink and that cross-contamination of flavors does not occur.

Flavor boxes containing one gallon of syrup can be stacked. Boxes of

chocolate sauce should not be stacked, as the chocolate sauce box must

be on the chocolate heater assembly to ensure it maintains the correct

temperature.

Prime the Flavor System

Once the flavor boxes are positioned and connected, the flavor system

must be primed. Please see the Priming the Flavor Delivery Tubes topic

in Section 9: Flavor System.

WARNING: The machine MUST be fully warmed up before priming

the flavor system, or a false head of steam may occur in the steam tank.

Chocolate Sauce

It is necessary to pre-warm the chocolate sauce to 85°F (29.4°C) before

use; otherwise, it will not flow properly.

WARNING: If chocolate sauce is not heated to the required

temperature, there is a high risk of the chocolate sauce flavor tubing

exploding. This is due to the viscosity of cold chocolate sauce.

NOTE: Installation cannot be completed until the chocolate sauce is at

the proper temperature.

Verify Flavor Pour Rate

It is important to verify flavor volume and ensure it meets the

requirements and preferences of the customer.

Please see the Changing the Flavor Pour Rate topic in Section 9: Flavor

System, for information and directions for adjusting the time and volume

of flavor pours.

Concordia Xpress Technical Support Manual 2-7

2900-300B

Section 2: Installation and Removal 3033-002B

Additional Tasks Required at Installation

Power Up the Machine

1. Close both tank drain valves

2. Ensure the electrical cord is plugged in and twist-locked

3. Ensure water is supplied to unit

4. Ensure a drain is connected to the unit

5. Start the unit by turning on the main power switch located behind

the grounds bin door

6. Warm-up will take 10-15 minutes

NOTE: The grounds bin must be in place and all doors must be

closed.

Install Bean Hoppers

1. Install the bean hoppers.

2. Fill the bean hoppers with fresh, whole, espresso roast beans.

For information on the bean hoppers, please see Section 6:

Coffee System.

IMPORTANT: Ensure the hopper stoppers are removed, so that the

beans can be delivered to the grinder.

Install Cup Stand (Optional)

Install the cup stand beneath the product outlet.

Operational Configuration

The Xpress is configured with a default recipe. However, it may still be

necessary to make minor adjustments to the grinder settings or milk

levels, depending on an existing customer recipe or customer

preference. For instructions on calibrating the grinder, please see

Section 6: Coffee System, and for instructions on adjusting the milk

levels, please see the Calibration topic in Section 4: Software. For

instructions on adjusting flavor timings, please see Section 9: Flavor

System.

At this time, set the time and date, using the software menu in the

machine. Please see Section 4: Software for detailed instructions on

accessing and using the TIME & DATE menu.

Placing Milk in the Refrigeration Unit

Place two gallons of milk in the upper refrigeration unit. Non-fat milk is

placed in the rear position and regular milk (whole or 2%) in the front.

2-8 Concordia Xpress Technical Support Manual

2900-300B

3033-002B Section 2: Installation and Removal

Machine Calibration

The calibration process is the same regardless if the setup includes the

default recipe, or if it includes a customer-specific recipe.

To ensure the machine is properly calibrated, verify the following:

1. Water Pump Pressure

2. Espresso Extraction Times

3. Drink Temperatures

4. Drink Levels

5. Syrup Volumes

6. Taste Profile

If necessary, adjust the bean grind to achieve the appropriate extraction

times.

Customer Training

Complete customer training is required at the time of installation. Refer to

Section 12: Concordia Procedures, for complete instructions.

Customer Training Includes:

How to turn machine on/off

How to refill milk supply, bean hoppers, consumables

How to select drinks and drink options

Show location of serial number

How to clean the machine (including cleaning cards)

How to change flavor boxes

How to empty the grounds bin

Installation Checklist

The installation checklist (PN 6000-075) must be completed and faxed to

Concordia within 24 hours of installation.

Removal Procedures

Prepare and package machine and components following the procedure

described in the Concordia Shipping Kit (PN 2900-142).

1. Record the drink GRAND TOTAL on the service invoice.

2. Record the machine serial number.

3. Clean the grinders.

4. Clean the brew group.

5. Run the daily clean cycle (brew group and milk system clean

processes).

6. Clean the refrigeration unit.

7. Clean the flavor delivery system.

Concordia Xpress Technical Support Manual 2-9

2900-300B

Section 2: Installation and Removal 3033-002B

8. Clean all interior and exterior surfaces (drain tray and grate,

grounds bin, cup holder).

9. Drain and disconnect the water supply, and drain the water and

steam tanks.

10. Prepare the machine and components for shipping.

11. If Demo Machine: remove, clean, and pack water filtration

system.

12. Ensure the User Guide and cleaning cards are included with the

unit.

13. Coil the power cord, water supply line, and drain hose and

secure with a Ty-Wrap®.

2-10 Concordia Xpress Technical Support Manual

2900-300B

T E C H N I C A L S U P P O R T

Section 3 :: Electrical

1. Electrical Block Diagram

2. Fuses

3. Backplane

4. AC Drawer Assembly

5. DC Power Supply Board

6. CPU Board

7. Peripheral Connections Configuration

8. Transformer

9. Power Into the Machine

10. DC Power Supply Board LEDs

11. Heater Element Wiring Diagrams

12. Jumper Plug Connector Detail

Section 3: Electrical 3033-003B

Power In

Fuses

Power Switch

Main Power

Relay/Contactor

Relay for Water

Tank Heating

Elements

Relay for Steam

Tank Heating

Elements

Water Pump

Transformer

DC Power Supply

Display

Heating Elements

Heating Elements

Rear Grinder

Front Grinder

Backplane

Left

Piston

Hall

Right

Piston

Hall

Flow

meter

Coffee

Piston

Left-Motor

Hall

Brew

Piston

Right-

Motor Hall

Transducer

Refer

Temp

Steam

Level

Grounds Bin

Mag Switch

Grounds Bin

Door Mag Switch

JP8

Front Panel

Mag Switch

Milk

Level

Sensor

Water

Temp

Water

Tank

Level

Post

Steam

Capp

Purge

Valve

Latte

Steam

Fill

Alt

Milk

optional

Switched

Fans

Un-

Switched

Fans

Water

Element

Cutoff

Steam

Element

Cutoff

Refer

Chip #2

Refer

Chip #1

Refer

Chip #1

Refer

Chip #3

Right

Group

Motor

Right

Group

Motor

JP2

JP7

JP3

Brew

Water

Hot

Water

CPU

Board

P1

AC Drawer

J1

JP9

J2

Fuses

Ground

L1

L2

Neutral

JP5

DC Voltage

AC Voltage

JP10 Control Voltage

F19F19

F18

F18

F18

F18

F18 F18

F18

F18

F18

F18

F16

F15

F16

F16 F17

F16F16F16

Fuse # on DC Board

F18

J3

KEY

F18

F18

J3

Jumper Plug on Back

Plane

JP

Fuse

J1 Adjustable

Jumper Plug

CPU/DC

Controlled Triac

CPU/DC

Controlled Triac

CPU/DC

Controlled Triac

JP3

Air

Vent

Valve

P4

Steam

Level

Safety

Syrup

Control Box

Milk

Pump

Latte

Air Valve

Capp Air

Valve

F18

Mini Backplane

Speed Cntrl

Expansion PCA

Electrical Block Diagram

3-2 Concordia Xpress Technical Support Manual

2900-300B

Loading...

Loading...