Page 1

EnergySmart

®

Dryer

W Series Models 600 through 5000 with TouchViewTMTechnology (Allen-Bradley)

Corporate Office: 724.584.5500 l Instant Access 24/7 (Parts and Service): 800.458.1960 l Parts and Service: 814.437.6861

U S E R G U I D E

UGD0 41-1212

www.conairgroup.com

Page 2

Conair recommends recording the model and serial number(s) of your equipment

and the date you received it in the User Guide. Our service department uses this

information, along with the manual number, to provide help for the specific equipment you installed.

Please keep this User Guide and all manuals, engineering prints and parts lists

together for documentation of your equipment.

Date:

Manual Number: UGD0041-1212

Serial Number(s):

Model Number(s):

Software Version(s):

Panelview Plus Operator Interface Terminal

Firmware Version Number:

Application File Name:

Programmable Logic Controller:

Firmware Version Number:

Application File Name:

Please record your equipment’s

model and serial number(s) and

the date you received it in the

spaces provided.

DISCLAIMER: Conair shall not be liable for errors contained in this User Guide or for incidental,

consequential damages in connection with the furnishing, performance or use of this information.

Conair makes no warranty of any kind with regard to this information, including, but not limited

to the implied warranties of merchantability and fitness for a particular purpose.

Co p yr ig ht 2 01 2 l C on ai r l A l l ri gh ts r es er ve d

NOTE: The software,

firmware and application

file information for your

specific EnergySmart

Dryer System is contained

on a serial tag that was

attached to the inside of

the EnergySmart Dryer’s

control panel during

assembly.

✐

Page 3

Table of Contents

1-1 Intr odu cti on

Purpose of the user guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

How the guide is organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Using the EnergySmart Dryer with your system . . . . . . . . . . . . . . . 1-3

Your responsibilities as a user. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

ATTENTION: Read this so no one gets hurt . . . . . . . . . . . . . . . . . . . 1-4

How to use the lockout device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2-1 Descrip tio n

What is the EnergySmart Dryer System? . . . . . . . . . . . . . . . . . . . . .2-2

Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

How the EnergySmart Dryer System works . . . . . . . . . . . . . . . . . . .2-3

Specifications: EnergySmart Carousel Plus W Series

Dehumidifying Dryers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Hopper Temperature Controller (HTC) . . . . . . . . . . . . . . . . . . . . . . . 2-5

GasTrac (CGT) Process Air Heater . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Dust Collectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Positive Displacement (PD) Pumps . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

CH Series Insulated Hoppers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Drying Monitor, DM-II Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

EnergySmart Dryer control options . . . . . . . . . . . . . . . . . . . . . . . . 2-13

3-1 Install a tio n

Installation - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Unpacking the EnergySmart Dryer System components . . . . . . . . . 3-6

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Ta bl e of Con te n ts l i

Page 4

Positioning the CH hopper floor stand . . . . . . . . . . . . . . . . . . . . . . . 3-8

Installation of the HTC control

(Models HTC 30, 60 and 90) . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

(Models HTC 120) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

(Models HTC 180 and 270) . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Location and mounting of the HTC heater assembly

(Models HTC 30, 60 and 90) . . . . . . . . . . . . . . . . . . . . . . . . 3-11

(Models HTC 120) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

(Models HTC 180 and 270) . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Installing the CH hopper cone section . . . . . . . . . . . . . . . . . . . . . . 3-12

Installing the CH hopper door, upper and lid sections . . . . . . . . . . 3-13

Installing the cyclone (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Installing the drying monitor probe . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Installing the receiver(s) (optional). . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Installing the purge valve(s) (optional) . . . . . . . . . . . . . . . . . . . . . . 3-25

Installing the modular distribution box(es) (optional) . . . . . . . . . . . 3-25

Securing the CH hopper to the floor . . . . . . . . . . . . . . . . . . . . . . . 3-26

Location and mounting of the GasTrac heater . . . . . . . . . . . . . . . . 3-27

Location and mounting of the dust collector (optional) . . . . . . . . . 3-28

Location and mounting of the vacuum pump(s)

and dust collector(s) (optional) . . . . . . . . . . . . . . . . . . . . . . 3-30

Positioning the dryer on the floor . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Removing the cable tie from the desiccant wheel

(W600-1000 models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Installing the regeneration exhaust cover . . . . . . . . . . . . . . . . . . . 3-31

Installing the return air inlet and air outlet adapters

(W1600-5000 models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Installing the overhead process air duct

(W3200-5000 models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

ii l Ta bl e of Co n te nt s

Page 5

Installation - Piping/Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Optional hard piping kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Connecting the heat sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Hopper Temperature Controller (HTC) as heat source . . . . . 3-37

GasTrac as heat source. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Connecting the dryer to the heat source . . . . . . . . . . . . . . . . . . . . 3-39

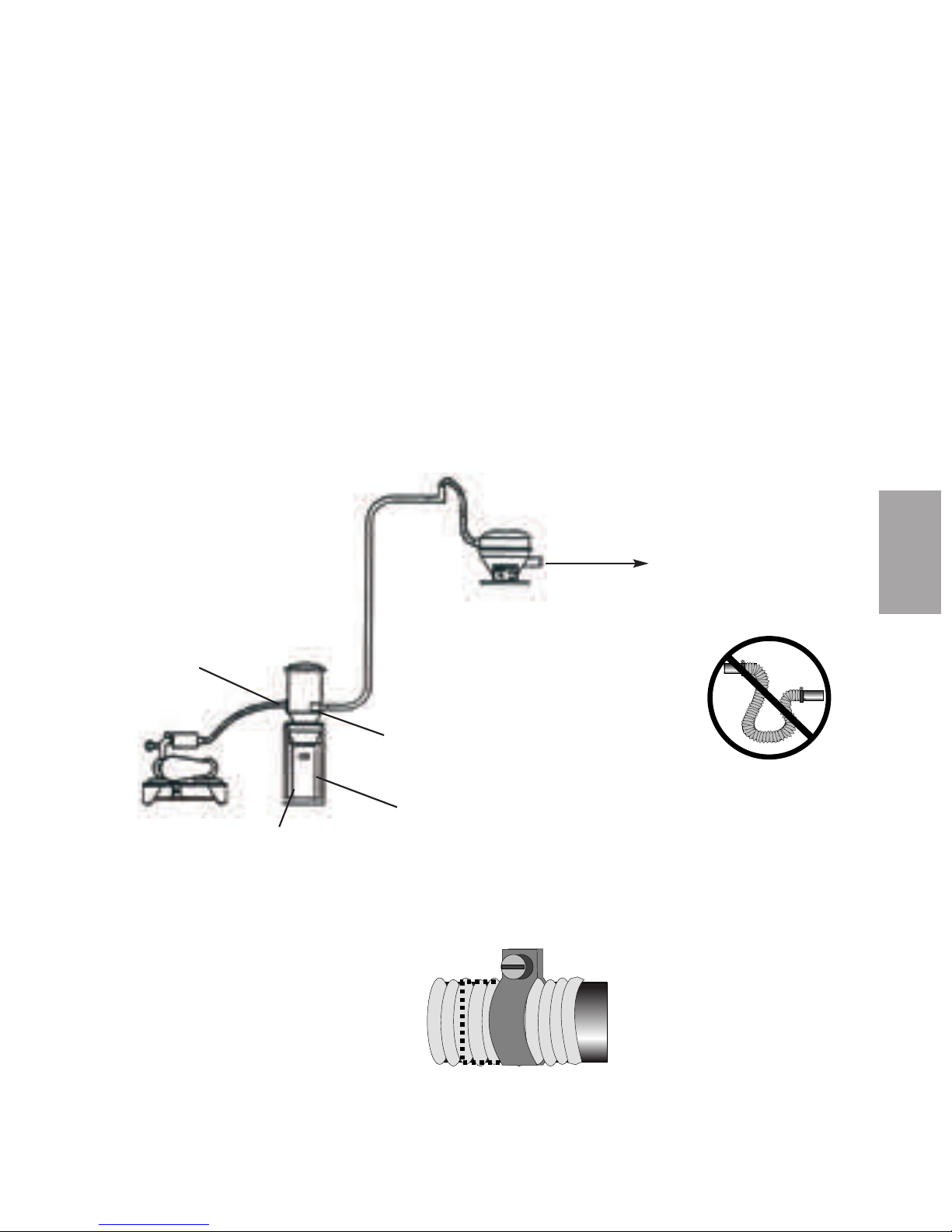

Connecting the dust collector (optional). . . . . . . . . . . . . . . . . . . . . 3-40

Connecting the cyclone separator (optional) . . . . . . . . . . . . . . . . . 3-41

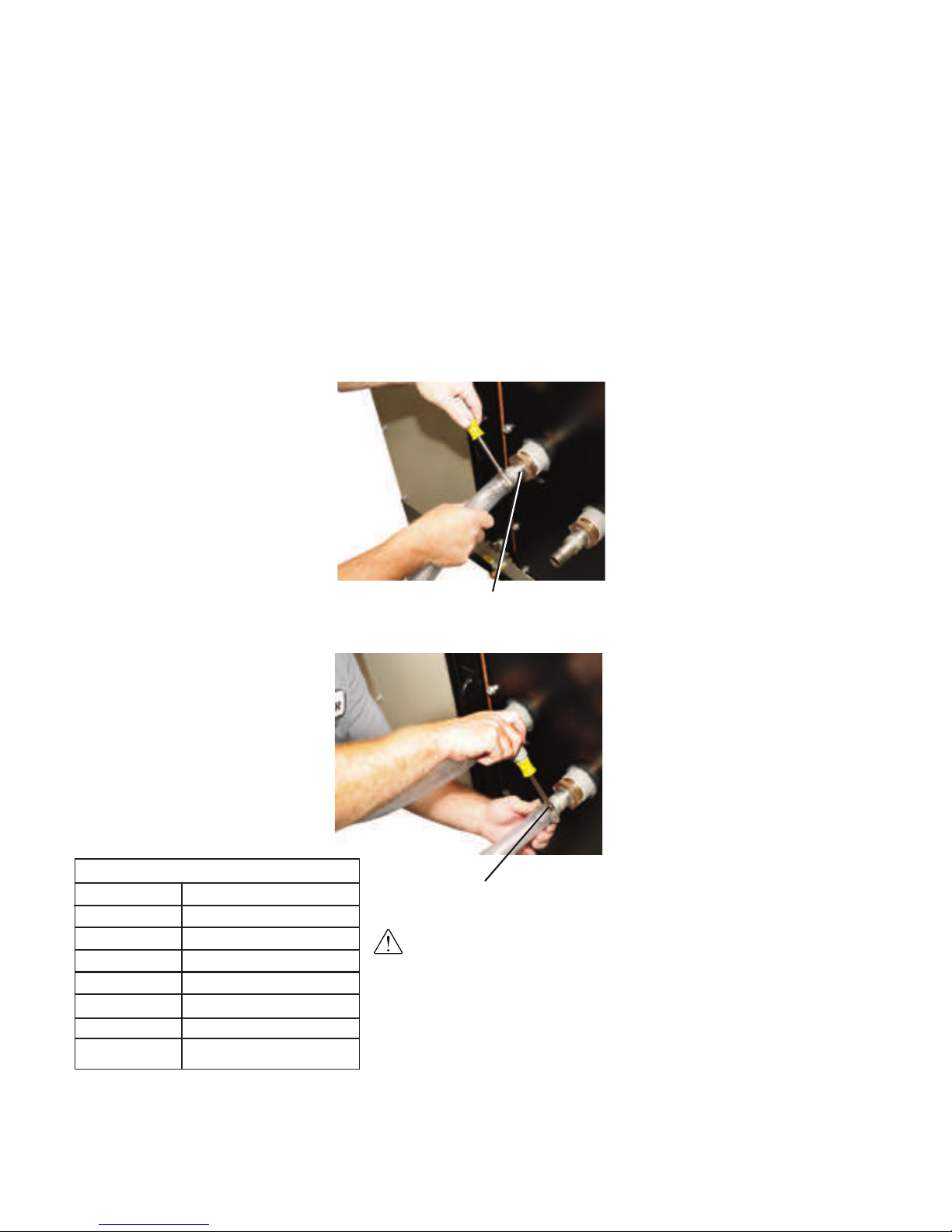

Installing the Dwyer 641 air velocity transmitter . . . . . . . . . . . . . . 3-42

Installing the level switch (optional). . . . . . . . . . . . . . . . . . . . . . . . 3-44

Adjusting the level sensor (optional) . . . . . . . . . . . . . . . . . . . . . . . 3-45

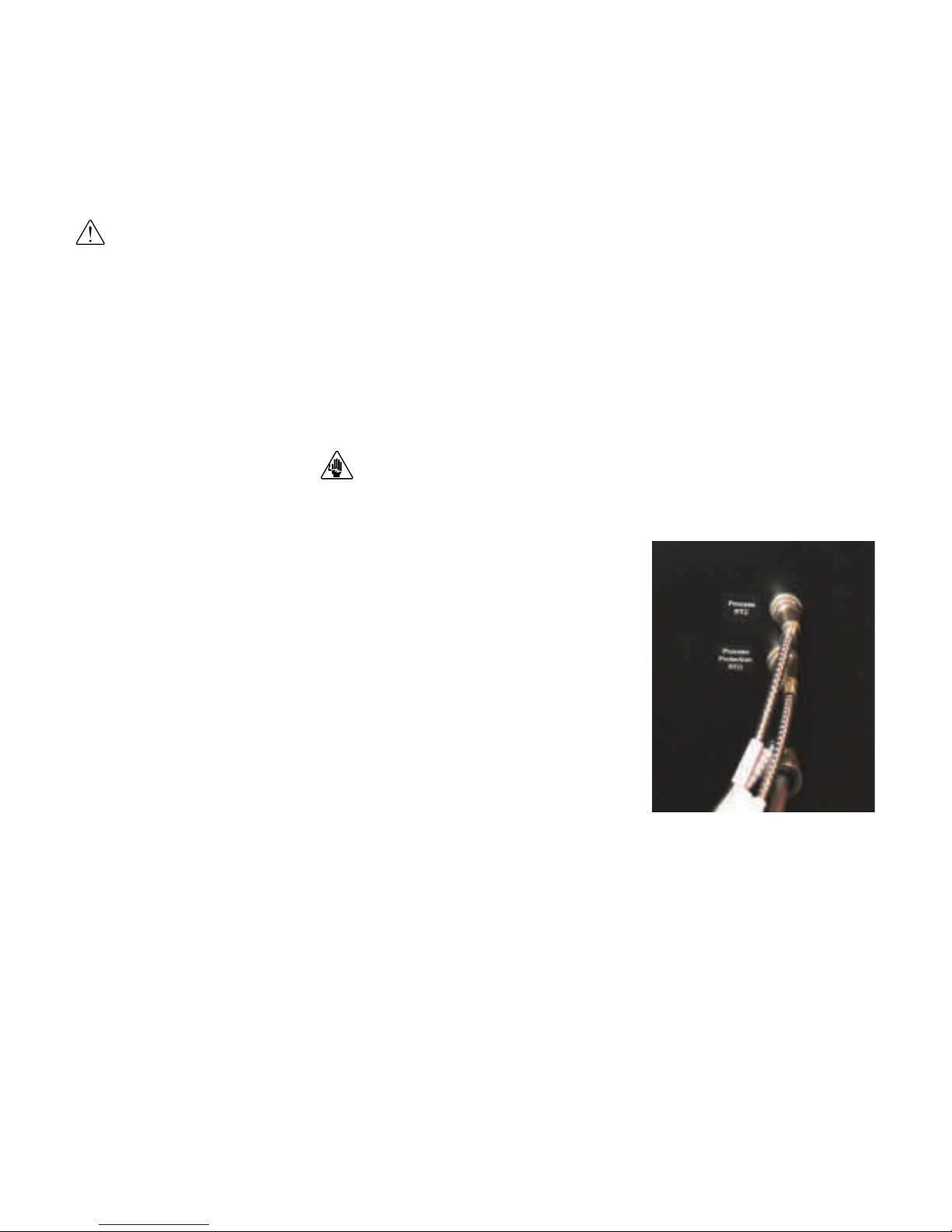

Installing the process protection RTD sensor. . . . . . . . . . . . . . . . . 3-46

Location of the process material temperature probe (RTD) . . . . . . 3-47

Installing the GasTrac RTD sensor . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

Installing the return air dew point line. . . . . . . . . . . . . . . . . . . . . . 3-49

Installation - Main Power Connections . . . . . . . . . . . . . . . . . . . 3-51

Connecting main power to the dryer . . . . . . . . . . . . . . . . . . . . . . . 3-52

Connecting main power to the HTC

(Models HTC 30, 60, 90 and 120) . . . . . . . . . . . . . . . . . . . . 3-53

(Models HTC 180 and 270) . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

Connecting main power to the GasTrac. . . . . . . . . . . . . . . . . . . . . 3-56

Connecting main power to the vacuum pump(s) (optional) . . . . . . 3-57

Connecting main power to the dust collector(s) (optional) . . . . . . . 3-57

Installation - Conveying Lines . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

Connecting the conveying lines to the receiver(s) (optional). . . . . . 3-60

Connecting the conveying lines to the purge valve(s) (optional) . . . 3-60

Connecting the conveying lines to the vacuum pump(s) and

dust collector(s) (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

Installation - Water Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

Typical water lines installation drawing. . . . . . . . . . . . . . . . . . . . . 3-64

Ta bl e of Con te n ts l iii

Page 6

Connecting the aftercooler/intercooler and optional

precooler (W600-1000) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

Connecting the aftercooler/intercooler and optional

precooler (W1600-5000) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

Installation - Control and Communications Wiring. . . . . . . . . . 3-67

Connecting the HTC to the HTC controller . . . . . . . . . . . . . . . . . . . 3-68

Connecting the RTD sensors (HTC only) . . . . . . . . . . . . . . . . . . . . 3-70

Connecting the GasTrac RTD sensors . . . . . . . . . . . . . . . . . . . . . . 3-72

Connecting the drying monitor probe to the dryer . . . . . . . . . . . . . 3-73

Connecting the receiver to the level switch (optional) . . . . . . . . . . 3-74

Connecting the EnergySmart Dryer control to system

components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-75

Installation - Compressed Air Lines . . . . . . . . . . . . . . . . . . . . . 3-85

Connecting the compressed air lines (optional) . . . . . . . . . . . . . . . 3-86

Installation - Gas Piping and Exhaust Flue . . . . . . . . . . . . . . . . 3-87

Typical gas line installation drawing . . . . . . . . . . . . . . . . . . . . . . . 3-88

Installing the Conair GasTrac. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-89

Connecting the gas and the exhaust flue to the GasTrac. . . . . . . . 3-92

Installation - Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-95

Checking for proper air flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-96

Testing the variable frequency drive (VFD). . . . . . . . . . . . . . . . . . . 3-99

Testing the installation of the HTC. . . . . . . . . . . . . . . . . . . . . . . . 3-100

Checking the gas and electrical systems of the GasTrac . . . . . . . 3-102

Testing the installation of the GasTrac. . . . . . . . . . . . . . . . . . . . . 3-103

Testing the primary receiver (optional) . . . . . . . . . . . . . . . . . . . . 3-105

Testing the secondary receiver (optional) . . . . . . . . . . . . . . . . . . 3-107

Configuring the Dwyer 641 air velocity transmitter . . . . . . . . . . . 3-109

Configuring the DM-II drying monitor . . . . . . . . . . . . . . . . . . . . . 3-110

Configuring the level switch (optional). . . . . . . . . . . . . . . . . . . . . 3-110

Using communications (optional). . . . . . . . . . . . . . . . . . . . . . . . . 3-113

iv l Ta bl e of Co n te nt s

Page 7

4-1 Op era tio n

The EnergySmart Dryer System control panel . . . . . . . . . . . . . . . . . 4-2

How to navigate the control screens . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Control function flow charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Login flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Operation flow chart 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Operation flow chart 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Operation flow chart 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Setup flow chart 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Equipment setup flow chart 1 . . . . . . . . . . . . . . . . . . . . . . . 4-11

Equipment setup flow chart 2 . . . . . . . . . . . . . . . . . . . . . . . 4-12

Communications setup flow chart . . . . . . . . . . . . . . . . . . . . 4-13

Example setpoint change . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Control function descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

EnergySmart Dryer System security levels . . . . . . . . . . . . . . . . . . 4-54

EnergySmart Dryer System Modbus communications . . . . . . . . . . 4-56

Starting the EnergySmart Dryer System

(Without OptiMizer™ mode) . . . . . . . . . . . . . . . . . . . . . . . . 4-58

Adjusting the EnergySmart Dryer System

(Without OptiMizer™ mode) . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Starting the EnergySmart Dryer System

(With OptiMizer™ mode). . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

Stopping the EnergySmart Dryer System. . . . . . . . . . . . . . . . . . . . 4-71

Using dryer recipes (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74

Copying files from the EnergySmart Dryer System . . . . . . . . . . . . 4-80

Using Dewpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-84

Using OptiMizer™. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

Ta bl e of Con te n ts l v

Page 8

5-1 Main ten anc e

Preventative maintenance checklist . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Inspecting the hoses, piping and gaskets . . . . . . . . . . . . . . . . . . . . 5-8

Cleaning the CH hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Maintaining the Dwyer 641 air velocity transmitter . . . . . . . . . . . . 5-10

Cleaning the combustion filter of the GasTrac . . . . . . . . . . . . . . . . 5-11

Cleaning the electrical enclosure filter of the GasTrac. . . . . . . . . . 5-12

Replacing the spark igniter of the GasTrac . . . . . . . . . . . . . . . . . . 5-13

Cleaning the ultraviolet flame detector of the GasTrac. . . . . . . . . . 5-15

Cleaning the process filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Cleaning the regeneration filter . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Cleaning the aftercooler/intercooler coils. . . . . . . . . . . . . . . . . . . . 5-19

Cleaning the volatile trap on the demister

(W600-1000). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Cleaning the volatile trap on the demister

(W1600-5000). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Cleaning the precooler coils (optional). . . . . . . . . . . . . . . . . . . . . . 5-23

Replacing the regeneration heater

(W600-1000). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

(W1600-2400). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

(W3200-5000). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Checking dew point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Cleaning the dust collector (optional). . . . . . . . . . . . . . . . . . . . . . . 5-32

Cleaning the cyclone separator (optional) . . . . . . . . . . . . . . . . . . . 5-32

6-1 Troub les hoo tin g

Before beginning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

A few words of caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

vi l Ta bl e of Co n te nt s

Page 9

DIAGNOSTICS

How to identify the cause of a problem . . . . . . . . . . . . . . . . . . . . . 6-4

Shutdown alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Passive alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Dew point troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Poor material drying troubleshooting. . . . . . . . . . . . . . . . . . . . . . . 6-29

REPAIR

Replacing fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Checking heater solid state relays. . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Checking or replacing temperature sensors . . . . . . . . . . . . . . . . . 6-36

Replacing the desiccant wheel assembly (W600-1000). . . . . . . . . 6-37

Replacing the desiccant wheel motor (W600-1000) . . . . . . . . . . . 6-39

Replacing the desiccant wheel motor (W600-1000) . . . . . . . . . . . 6-40

A Ap pen dix

We’re here to help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

How to contact customer service . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Before you call... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Equipment guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Performance warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Warranty limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Conair print numbers list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Ta bl e of Con te n ts l vii

Page 10

vi i i l Ta bl e of C on te nt s

Page 11

Introduction

Purpos e of the user guide . . . . . . . . . . . . . . 1- 2

How the guide is o rganiz e d . . . . . . . . . . . . . 1 - 2

Using the Energ y S mart Dry e r

with your system . . . . . . . . . . . . . . . . . 1- 3

Yo u r r e s ponsib i l i ties as a us e r . . . . . . . . . . . 1-3

ATTENT I O N:

Read this so n o o n e ge t s hu r t . . . . . . . . 1-4

How to u se t h e l o c kout device . . . . . . . . . . . 1-6

S E C T I O N

1

In t ro du ct io n l 1 -1

1

In t rod u ctio n

Page 12

✐

Purpose of the User Guide

This User Guide describes the Conair EnergySmart®Dryer System with

TouchViewTMTechnology and explains step-by-step how to install, operate, maintain and repair this equipment.

Before installing this product, please take a few moments to read the User

Guide and review the diagrams and safety information in the instruction

packet. You also should review manuals covering associated equipment in

your system. This review won’t take long, and it could save you valuable

installation and operating time later.

How the Guide is Organized

Symbols have been used to help organize the User Guide and call your

attention to important information regarding safe installation and operation.

Symbols within triangles warn of conditions that could be hazardous to users or

could damage equipment. Read and take precautions before proceeding.

Numbers indicate tasks or steps to be performed by the user.

A diamond indicates the equipment’s response to an action performed by the user.

An open box marks items in a checklist.

A circle marks items in a list.

Indicates a tip. A tip is used to provide you with a suggestion that will help you with

the maintenance and the operation of this equipment.

Indicates a note. A note is used to provide additional information about the steps

you are following throughout the manual.

1

◆

❒

•

✒

1- 2 l Int ro d uc ti on

Page 13

In t ro du ct io n l 1 -3

Using the EnergySmart Dryer with

Your System

The Conair EnergySmart®Dryer with TouchViewTMTechnology used within your

system is factory configured to be used as a central dryer only. Therefore, this

manual incorporates the information necessary to use these dryers for central

drying applications.

Your Responsibility as a User

You must be familiar with all safety procedures concerning installation, operation and maintenance of this equipment. Responsible safety procedures include:

• Thorough review of this User Guide, paying particular attention

to hazard warnings, appendices and related diagrams.

• Thorough review of the equipment itself, with careful attention

to voltage sources, intended use and warning labels.

• Thorough review of instruction manuals for associated equipment.

• Step-by-step adherence to instructions outlined in this User Guide.

1

In t rod u ctio n

NOTE: Dryers can be used for

various applications.

✐

Page 14

1- 4 l Int ro d uc ti on

ATTENTION:

Read this so no one gets h urt

We design equipment with the user’s safety in mind. You can avoid the potential

hazards identified within this system by following the procedures outlined below

and elsewhere in the User Guide.

WA RNING: Impro p e r i n s tallati o n , operat i o n o r

serv i c ing m ay r e sult in e quipmen t dam a g e o r

persona l inj u r y.

This equipment should be installed, adjusted and serviced by qualified

technicians who are familiar with the construction, operation and

potential hazards of this type of machinery.

All wiring, disconnects and fuses should be installed by qualified electrical technicians in accordance with electrical codes in your region.

Always maintain a safe ground. Do not operate the equipment at power

levels other than what is specified on the machine serial tag and data

plate.

WA RNING: Vo ltage hazard

This equipment is powered by three-phase alternating current,

as specified on the equipment’s serial tags and data plates. Reference

optional additional equipment’s manuals for their power requirements.

A properly-sized conductive ground wire from the incoming power

supply must be connected to the chassis ground terminal inside the

electrical enclosure. Improper grounding can result in severe personal

injury and erratic machine operation.

Always disconnect and lock out the incoming main power source before

opening the electrical enclosure or performing non-standard operating

procedures, such as routine maintenance. Only qualified personnel

should perform troubleshooting procedures that require access to the

electrical enclosure while power is on.

(continued)

Page 15

1

In t rod u ctio n

In t ro du ct io n l 1 -5

ATTENTION:

Read this so no one gets h urt

(c on ti nu ed )

We design equipment with the user’s safety in mind. You can avoid the potential

hazards identified within this system by following the procedures outlined below

and elsewhere in the User Guide.

CA UTION: Hot Surfaces.

Always protect yourself from hot surfaces inside the dryer and hopper.

Also exercise caution around exterior surfaces that may become hot

during use. These include the hopper door frame, the exterior of an

uninsulated hopper, the return air hose and the dryer’s process filter

housing and exhaust outlet and the Hopper Temperature Controller

(HTC) or GasTrac Dryer (CGT).

WA RNING: Do not p lace aerosol , c o mpresse d

gas o r f l a mmable mater i als o n o r nea r thi s

equipme n t .

The hot temperatures associated with the drying process may cause

aerosols or other flammable materials placed on the dryer or hopper to

explode.

Page 16

1- 6 l Int ro d uc ti on

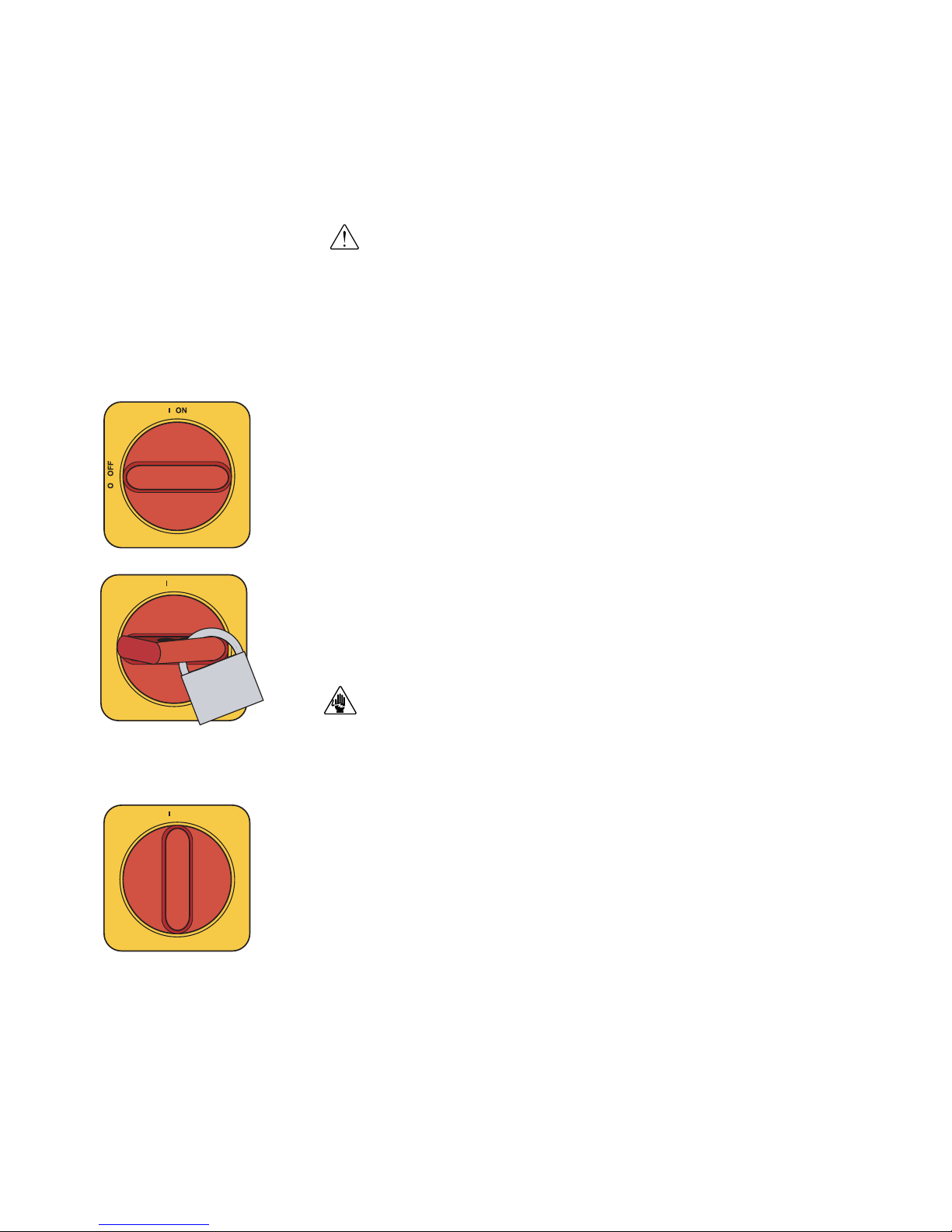

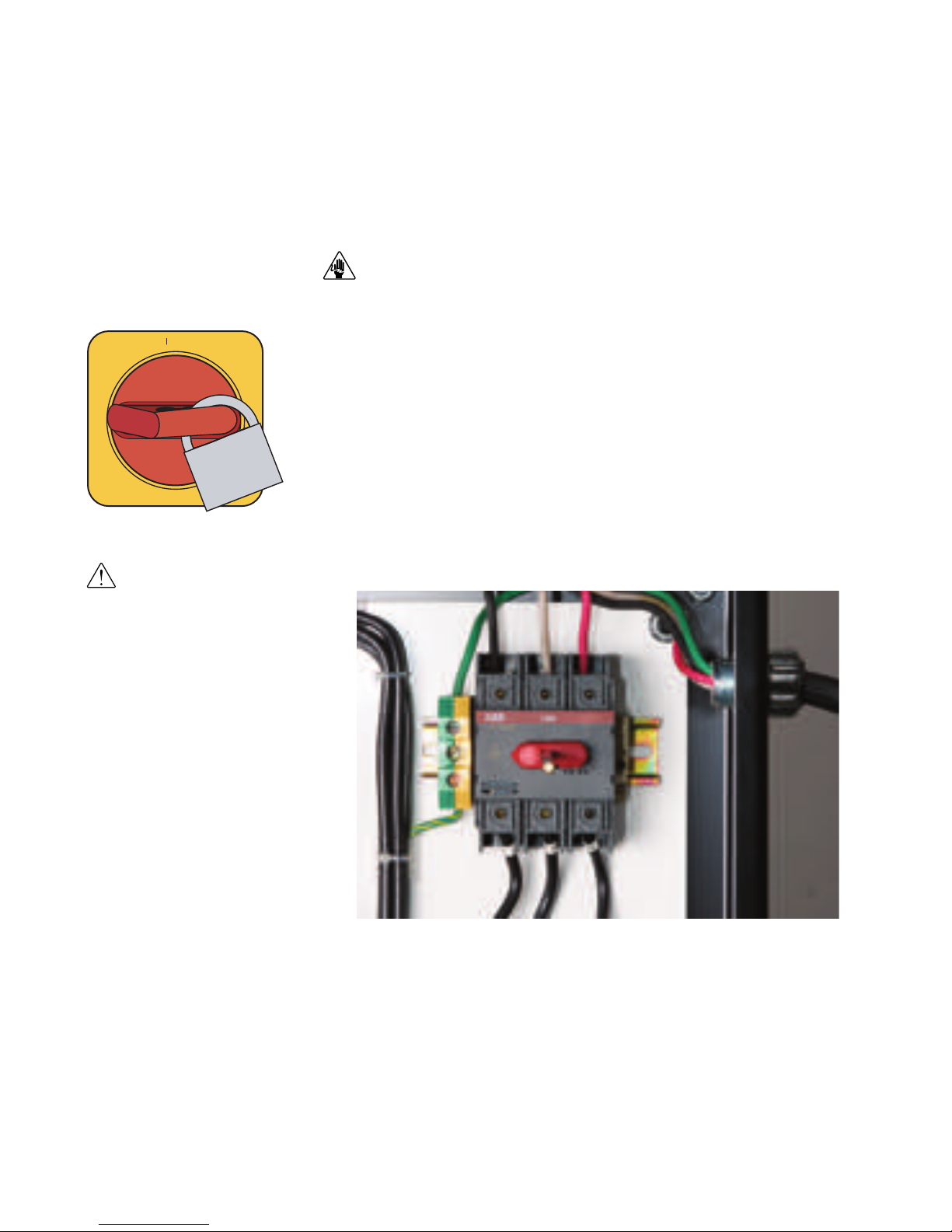

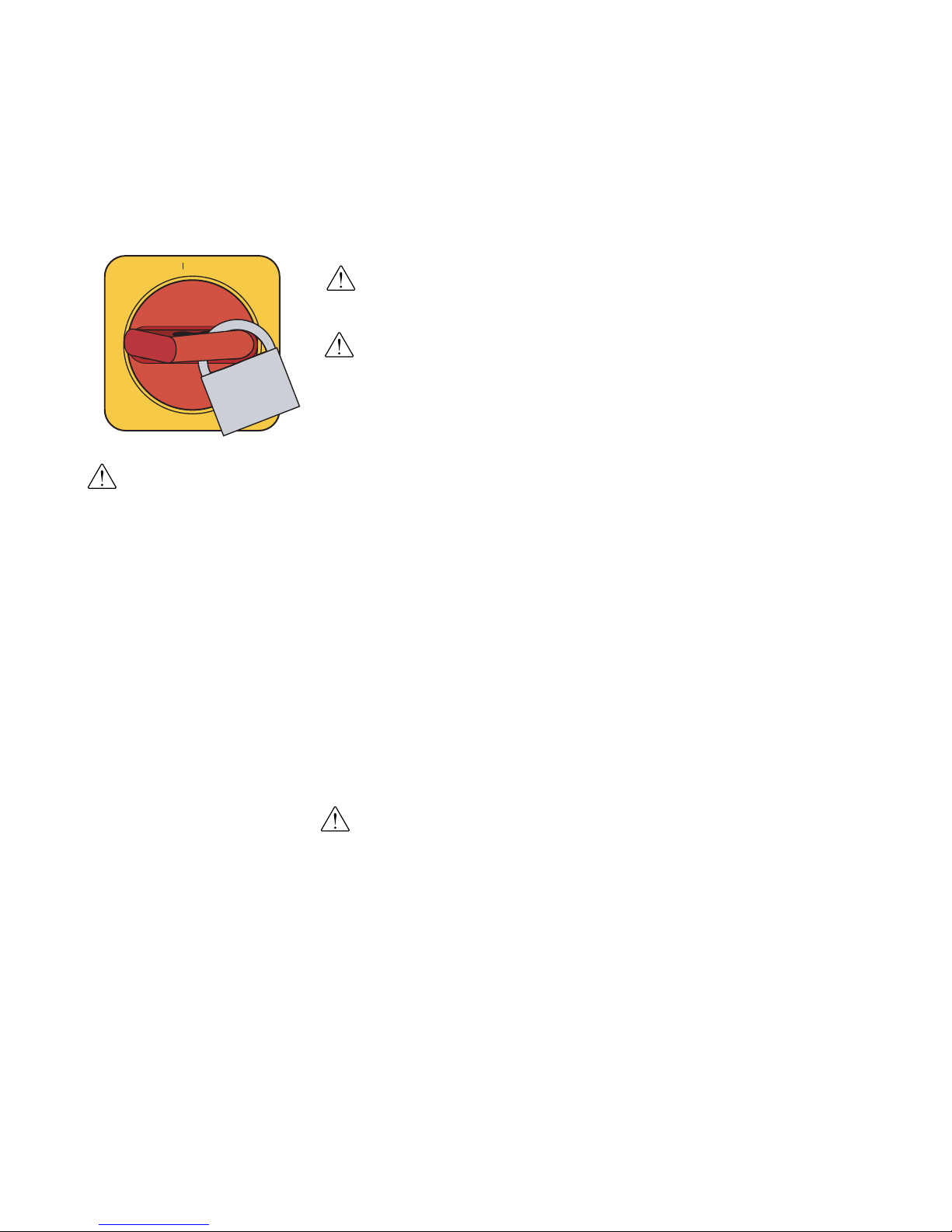

How to Use the Lockout Device

CAUTION: Before performing maintenance or repairs on this product, you should

disconnect and lockout electrical power sources to prevent injury from unexpected

energization or start-up. A lockable device has been provided to isolate this

product from potentially hazardous electricity.

Lockout is the preferred method of isolating machines or equipment from energy

sources. Your Conair product is equipped with the lockout device pictured below.

To use the lockout device:

1

Stop or turn off the equipment.

2

Isolate the equipment from the electric power. Turn the rotary

disconnect switch to the OFF, or “O” position.

3

Secure the device with an assigned lock or tag. Insert a lock or tag

in the holes to prevent movement.

4

The equipment is now locked out.

WARNING: Before removing lockout devices and returning switches to the ON

position, make sure that all personnel are clear of the machine, tools have been

removed and all safety guards reinstalled.

To restore power, turn the rotary disconnect back to the ON position:

1

Remove the lock or tag.

2

Turn the rotary disconnect switch to the ON or “I” position.

ON

O OFF

ON

O OFF

Page 17

De s cr ip ti on l 2- 1

Description

What is the E nergy S m art D rye r Sys t e m ? . . . . 2-2

Typica l a p p l icat i o n s . . . . . . . . . . . . . . . . . . 2- 2

How the Energ y S mart Drye r Sy s t e m w o r ks . . . 2-3

Specif i c a tion s : E n ergyS m a rt C a rousel

Plus W Series Dehu m i d ifying Dr y ers . . . . 2-4

Hopper Temp e r a ture Cont r o l ler ( HTC) . . . 2-5

GasTrac (CGT) Proce s s A ir H e ater . . . . . . 2-6

Dust Collec t o r s . . . . . . . . . . . . . . . . . . 2- 7

Po sitive Displ a c ement (PD) Pumps . . . . . 2-8

CH S e ries Insula t ed H o ppers . . . . . . . . . 2 - 9

Dry i n g M o n i tor, DM-II Mode l . . . . . . . . 2-1 2

Energ y S mart Dry e r co n t r ol o p tions . . . . 2-13

S E C T I O N

2

2

De s cri p tion

Page 18

2- 2 l Des cr i pt io n

What is the EnergySmart®Dryer

System?

Energy efficient drying and superior end product are the results of having precise

control of your drying process. The EnergySmart Dryer System control allows

you to optimize your system settings to achieve consistent drying results that boost

your plant-wide efficiency and produce high quality final product. An OptiMizer™

Mode automatically adjusts the air flow and temperature of your process for maximum system efficiency.

The EnergySmart Dryer System could include:

• EnergySmart Dryer with TouchViewTMTechnology (Allen-Bradley control)

• CH Hopper with an integrated cyclone - optional

• Heater (gas or electric)

• Dust collector(s) - optional

• Patented DM-II drying monitor technology

• Receiver(s) - optional

• Vacuum pump(s) - optional

• Audible alarm

Typical Applications

1 Dryer on the floor, a single CH Hopper with a Hopper Temperature Controller

(HTC) or GasTrac Dryer (CGT) package on a floor stand.

The EnergySmart Dryer System can be used successfully in applications that

require:

• A contamination-free drying environment

• A constant flow of dehumidified air

• Throughput rates of 400 to 5,000 lbs {181 to 2,268 kg} per hour (some

materials can be run at higher rates).

• Dew points of -40°F {-40°C}.

NOTE: The EnergySmart

®

W600 - 5000 dryer provides

no heat to the process air. A

separate heat source is

required at the hopper inlet to

heat the air to the required

drying temperature.

✐

Page 19

De s cr ip ti on l 2- 3

2

De s cri p tion

How the EnergySmart Dr yer System

Works

The drying circuit is a traditional desiccant drying system. The dryer supplies low

dew point air that has passed through a heater (HTC or GasTrac) into the bottom

of a CH Hopper. The air moves up through the hopper picking up moisture from

the material as it transfers its heat into the material. Once the air is at the top of the

hopper, it returns to the dryer after passing through optional filtration to remove

fines. Once in the dryer, the air is cooled by passing through a cooling coil to

lower the temperature so that the air can be dried as it passes through the desiccant

where the moisture is absorbed.

Page 20

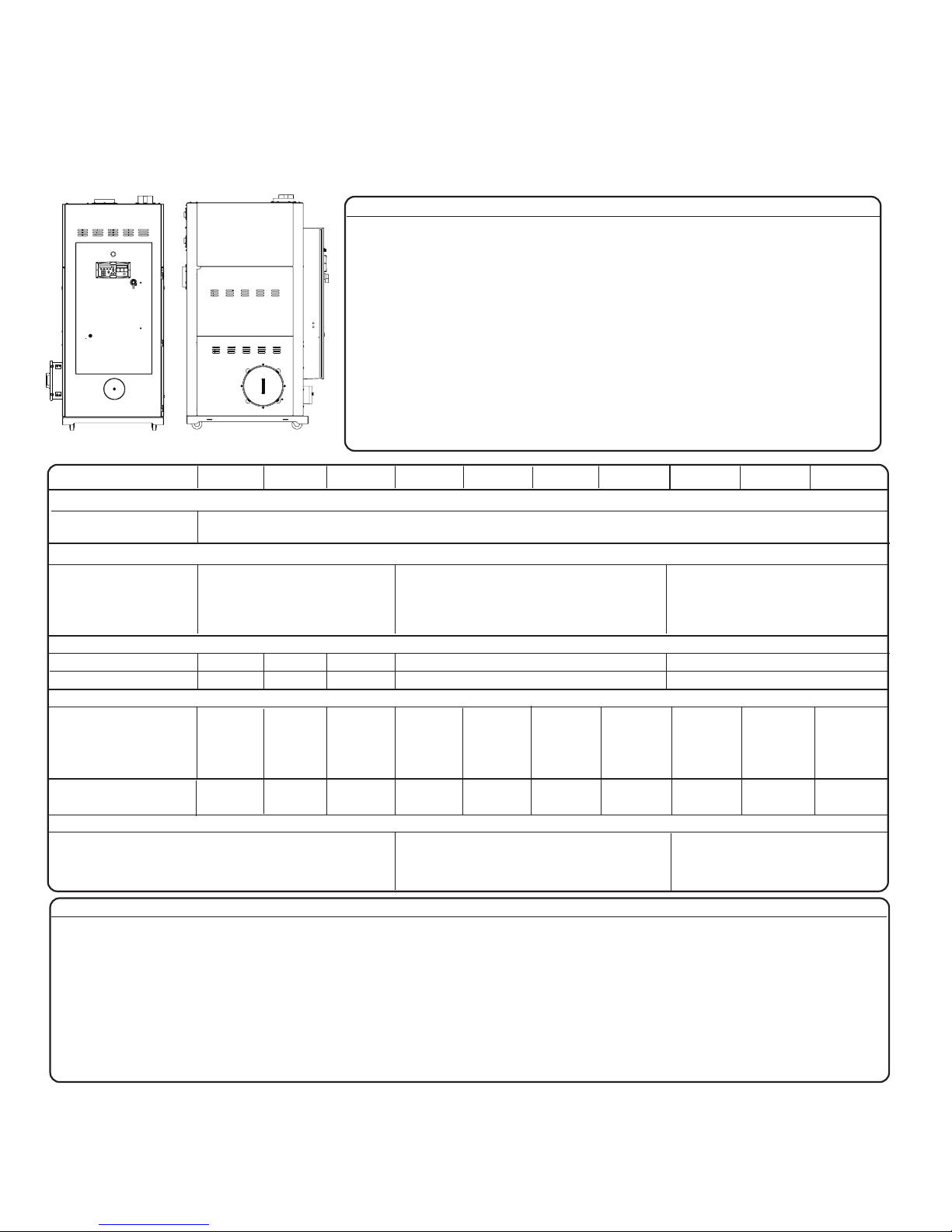

Specifications: EnergySmart Carousel

Plus W Series Dehumidifying Dryers

2- 4 l Des cr i pt io n

TPDX019-0712

SPECIFICATION NOTES:

*

Dryers W600-W5000 that are central dryers do not have process heaters. Hopper Temperature Controllers (HTC’s) or GasTrac Dryers (CGT’s) are used at the hopper for heating the process air. See the Hopper Temperature Controller (HTC) and GasTrac Dryer (CGT) specification sheets for further technical information.

†

Total amps listed apply to dryer only, see the Hopper Temperature Controller (HTC) or GasTrac (CGT) specification sheets for additional power requirements.

‡

Dryers running at 50 Hz will have 17% less airflow, and a 17% reduction in material throughput.

§

Total kW listed at a regeneration temperature of 350°F {177°C}. The total kW listed reflects the kW of the dryer only. It does not include any external heat source, for example

the Hopper Temperature Controller (HTC) or Gastrac Dryer (CGT).

** When drying below 150°F {66°C} a precooler is required.

††

Temperatures above or below the recommended levels may affect dryer performance. Tower, chiller or municipal water sources can be used.

‡‡

Not available in Allen Bradley models.

Specifications may change without notice. Consult a Conair sales representative for the most current information.

APPLICATION NOTES:

All dryers are supplied with an aftercooler/intercooler as standard. The aftercooler/intercooler reduces the temperature of the return air from the drying hopper, improving the efficiency of the desiccant. The

aftercooler/intercooler must be connected with the proper water flow rate and temperature to attain the rated

throughput.

When to use central models

Models W600 - W5000 of Carousel Plus dryers are all configured as central dryers. Central dryers do not

have process heaters. These models should be used when drying multiple materials that require different

drying temperatures. Central models dehumidify the process air, which is then heated to the correct setpoint by a Hopper Temperature Controller (HTC) or GasTrac Dryer (CGT).

When to use additional filtration

The standard return air cartridge filter is sized for the airflow of each dryer model and is suited for most

applications. You should consider adding an optional dust collector and/or volatile trap if:

●

The material contains excessive fines. An additional dust collector or cyclone will extend time between filter

cleaning.

●

The material produces volatiles during drying which condense into a waxy or oily residue. A volatile trap will

help to protect the desiccant.

MODELS W600

*

W800

*

W1000

*

W1300

*

W1600

*

W2000

*

W2400

*

W3200

*

W4000

*

W5000

*

Performance characteristics (with full hopper)

Drying temperature All models 100°- 375°F {38°- 191°C} with options

Dew point All models -40°F {-40°C}

Dimensions inches {cm}

A - Height 93.8 {238.3} 92.2 {134.2} 98.3 {249.7}

B - Width 49.3 {125.2} 53.9 {136.9} 58.2 {147.8}

C - Depth 72.4 {183.9} 106.6 {270.8} 123.6 {313.9}

Outlet/inlet hose diameter 8.0 {20.3} 12.0 {30.5} 12.0 {30.5}

Approximate weight lbs {kg}

Installed 1300 {590} 1300 {590} 1400 {636} 1600 {726} 2000 {907}

Shipping 1495 {678} 1495 {678} 1515 {687} 2620 {1188} 3385 {1535}

Voltage -

Standard/Central

Full load amps

†

400 V/3 phase/50 Hz

‡

89.2 / 34.3 89.2 / 34.3 116.6 / 34.2 152.7 / 42.9 159.4 / 49.6 194.1 / 56.8 221.7 / 57.0 282.7 / 90.5 317.0 / 97.7 371.9 / 97.4

460 V/3 phase/60 Hz 77.6 / 29.8 77.6 / 29.8 101.5 / 29.8 133.4 / 37.8 138.6 / 43.0 168.9 / 49.4 192.8 / 49.4 247.3 / 80.0 275.9 / 84.7 323.7 / 84.7

575 V/3 phase/60 Hz 62.1 / 23.9 62.1 / 23.9 81.1 / 23.8 106.6 / 30.2 110.8 / 34.4 135.1 /39.6 154.2 / 39.6 197.7 / 64.0 220.6 / 67.8 258.7 / 67.7

380 V/3 phase/60 Hz

‡‡

93.9 / 36.1 93.9 / 36.1 122.7 / 36.0 160.7 / 45.2 167.8 / 52.2 204.3 / 59.8 233.4 / 60.0 297.6 / 95.3 333.7 / 102.8 391.5 / 102.5

Total kilowatts§kW {BTU/min} 53 {3017} / 53 {3017} / 72 {4098} / 95 {5407} / 95 {5407} / 114 {6489} / 133 {7570} / 152 {8652} / 190 {10809} / 228 {12972} /

15 {854} 15 {854} 15 {584} 19 {1081} 19 {1081} 19 {1081} 19 {1081} 38 {2157} 38 {2157} 38 {2157}

Water requirements {for aftercooler/intercooler or optional precooler}

**

Recommended temperature

††

45°- 85°F {7° - 29°C} 45°- 85°F {7° - 29°C} 45°- 85°F {7° - 29°C}

Water flow gal./min. {liters/min.} 6 - 25 {22.7 - 94.6} 12 - 40 {45.4 - 151.4} 15 - 50 {56.8 - 189.3}

Water connections NPT 1 1/2 inch NPT 1 1/2 inch NPT 1 1/2 inch NPT

Page 21

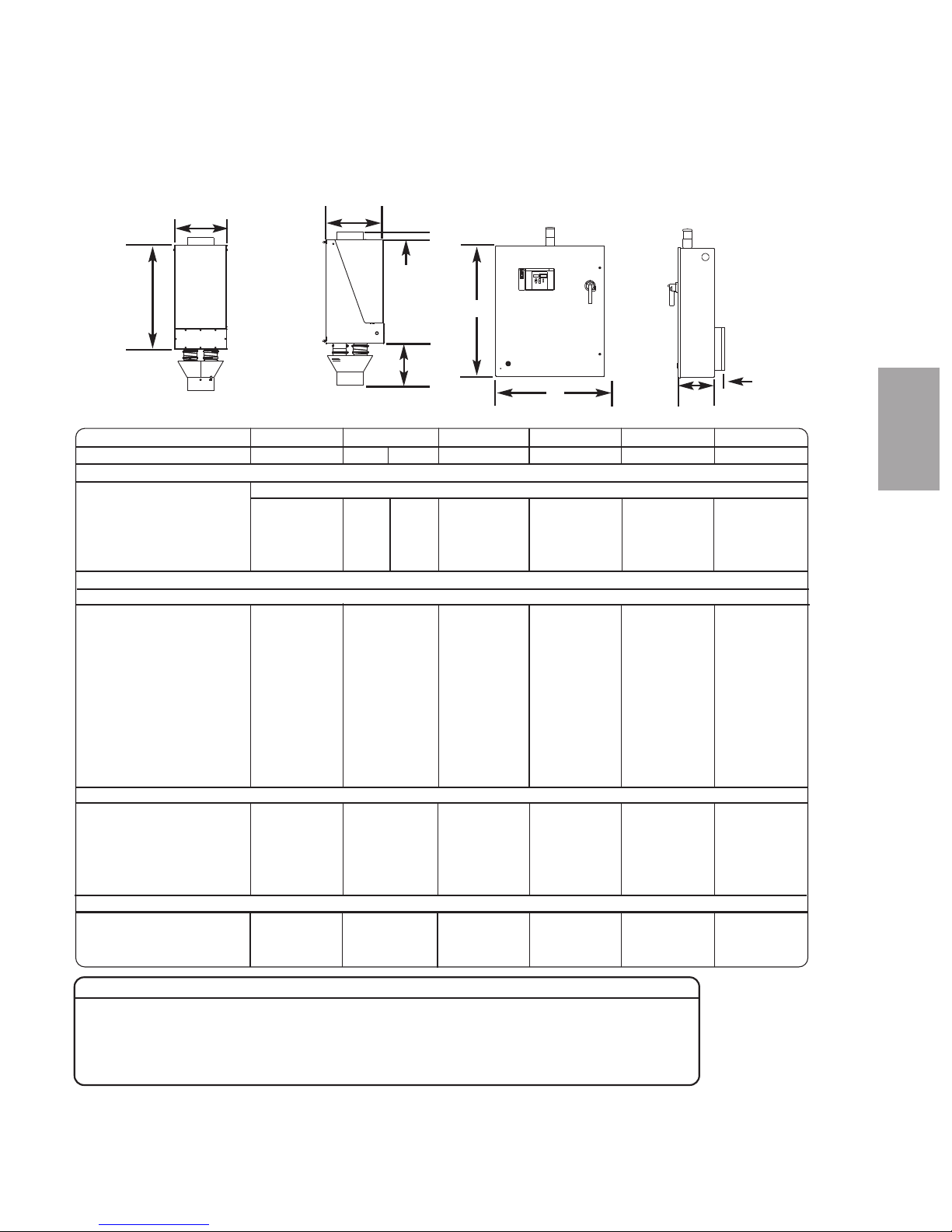

Specifications: Hopper Temper ature

Controller (HTC)

A

B

D

E

F

G

I

MODEL HTC HTC-30H* HTC-60H* HTC-90H* HTC-120H* HTC-180H* HTC-270H*

Carousel Plus dryer model W600 W800 W1000 W1600 W2400 W3200 W5000

Performance characteristics

Temperature range 150° - 375° F {66° - 191° C}

Flow rate cfm 300 400 500 800 1200 1600 2500

Pressure drop@flow rate

inches WC

†

3.0 1.8 2.3 4.0 3.8 5.9 6.4

{mm} WC

†

{76.2} {45.7} {58.4} {101.6} {96.5} {149.9} {162.6}

Dimensions inches {cm} and weight lb {kg}

Heater box dimensions

Inlet size (OD) 8812 12 12 12

Outlet size selection (OD) 8812 12 12 12

A - Height 31.4 {79.8} 27.5 {69.9} 27.0 {68.6} 31.0 {78.7} 34.0 {86.4} 36.4 {92.5}

B - Width 10.1 {25.7} 13.6 {34.5} 16.0 {40.6} 16.0 {40.6} 18.0 {45.7} 24.2 {61.5}

C - Depth 10.7 {27.2} 10.9 {27.7} 10.9 {27.7} 16.0 {40.6} 17.0 {43.2} 17.0 {43.2}

D - Height of discharge 1.75 1.5 2.0 1.0 2.0 1.0

nozzle above the heater box {4.4} {3.8} {5.1} {2.5} {5.1} {2.5}

E - Height of inlet nozzle 10.6 7.1 8.0 10.0 13.0 15.4

below the heater box {26.9} {18.0} {20.3} {25.4} {33.0} {39.1}

Installed weight lb {kg}

‡

38 {17} 37 {17} 78 {35} 93 {43} 102 {46} 131 {59}

Control center dimensions

Height - F 24.0 {61.0} 24.0 {61.0} 36.0 {91.4} 48.0 {122.0} 60.0 {152.4} 60.0 {152.4}

Width - G 24.0 {61.0} 24.0 {61.0} 30.0 {76.2} 36.0 {91.4} 42.0 {106.7} 42.0 {106.7}

Depth - H 10.0 {25.4} 10.0 {25.4} 10.0 {25.4} 10.0 {25.4} 12.0 {30.5} 12.0 {30.5}

Clearance for heat sink - I 3.0 {7.6} 3.0 {7.6} 3.0 {7.6} 3.0 {7.6} 3.0 {7.6} 3.0 {7.6}

Installed weight lb {kg} 150.0 {68.0} 150.0 {68.0} 180.0 {81.6} 250.0 {113.0} consult Conair consult Conair

Voltage full load amps

400 V/3 phase/50-60 Hz 44 87 131 175 261 381

480 V/3 phase/50-60 Hz 38 76 114 152 227 340

575 V/3 phase/50-60 Hz 30 61 91 122 182 272

SPECIFICATION NOTES:

* The HTC model number reflects the kilowatts of each unit. For example, HTC-60 has a 60 kilowatt heater.

† The unit of measure WC is water column.

‡

Weights are approximate.

Specifications may change without notice. Consult a Conair representative for the most current information.

TPDS022-0808

C

De s cr ip ti on l 2- 5

2

De s cri p tion

H

Page 22

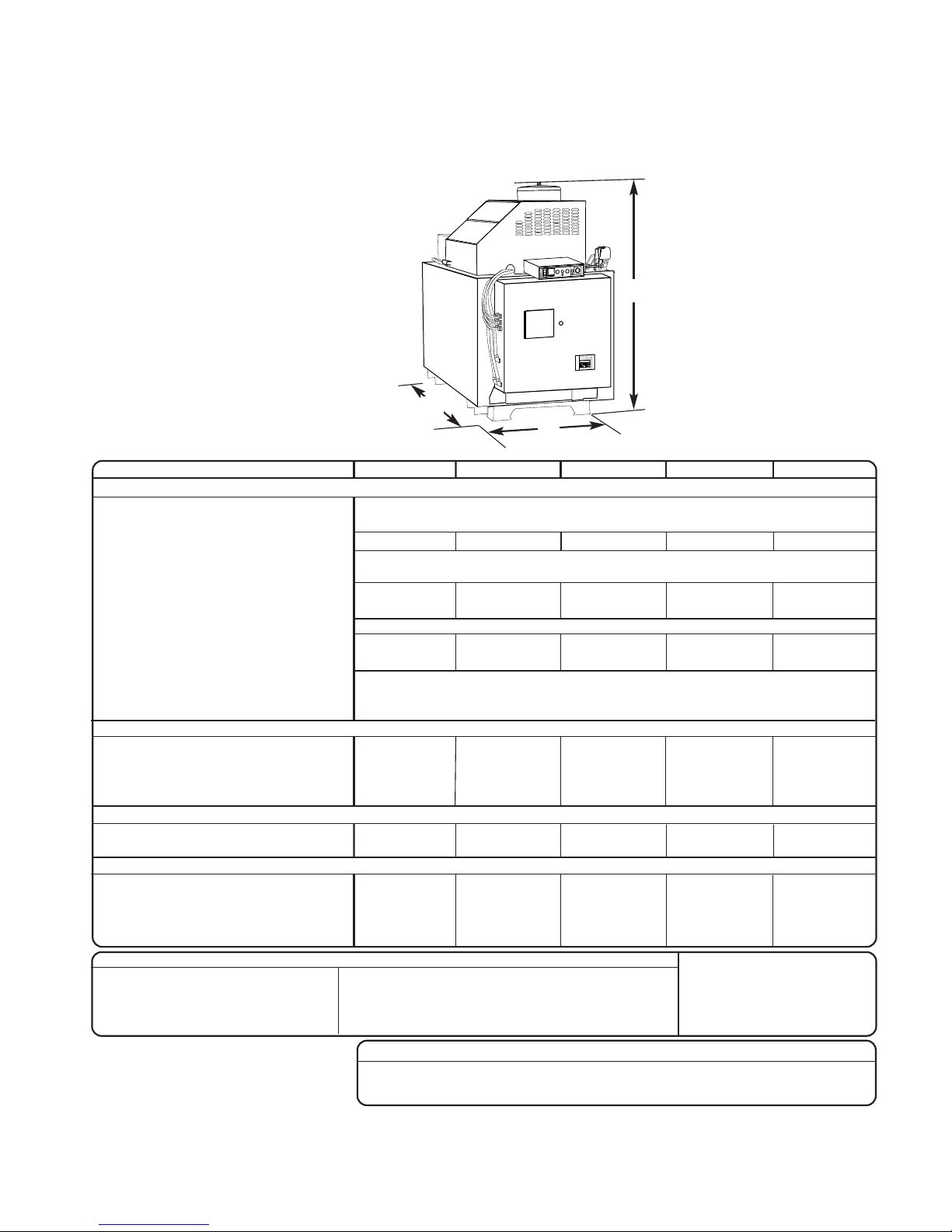

MODELS CGT150 CGT250 CGT350 CGT500 CGT700

Performance characteristics

Temperature range ºF {ºC} 250 - 350 {122 - 177}

Maximum flue temperature ºF {ºC} 750 {399}

Combustion blower 0.5 Hp peripheral 0.5 Hp peripheral 1 Hp peripheral 1 Hp peripheral 1 Hp peripheral

Ignition source Spark igniter, interrupted

Burner type Metal-ceramic

Minimum burner capacity BTU/hr 40,000 75,000 90,000 125,000 150,000

Maximum burner capacity BTU/hr 150,000 225,000 350,000 500,000 700,000

Gas consumption*

CFH @250ºF {L/hour} 50 {1416} 90 {2549} 105 {2973} 150 {4248} 230 {6513}

CFH @350ºF {L/hour} 140 {3964} 215 {6088} 325 {9203} 465 {13167} 675 {19114}

Gas pressure to regulator In. H2O {kPa} 10 - 20 {2.49 - 4.98}

Gas pressure from regulator In. H2O {kPa} 4 - 7 {0.99 - 1.74}

Gas heating rate BTU/ft

3

1000

Dimensions in. {mm}

A - Height 54 {1372} 61{1549} 61 {1549} 61 {1549} 61 {1549}

B - Width 29 {737} 37 {940} 37 {940} 37 {940} 37 {940}

C - Length 66 {1676} 64 {1626} 74 {1880} 74 {1880} 74 {1880}

Air inlet/outlet, OD 8 {203} 8 {203} 8 {203} 8 {203} 12 {300}

Approximate weight lb {kg}

Installed 600 {272} 600 {272} 600 {272} 600 {272} 600 {272}

Shipping 700 {317} 700 {317} 700 {317} 700 {317} 600 {272}

Voltage Total amps

380V/3 phase/50Hz 3.0 3.0 1.6 1.3 3.0

415V/3 phase/50Hz 3.0 2.7 1.5 1.2 3.0

240V/3 phase/60Hz 3.0 4.8 2.5 2.0 3.0

480V/3 phase/60Hz 3.0 2.4 1.3 1.0 3.0

Emissions

<10 ppm corrected to 3% O

2

<20 ppm corrected to 3% O

2

<10 ppm corrected to 3% O

2

Carbon Monoxide (CO)

NOX

Unburned hydrocarbons

10 - 30%

2 - 5%

9 - 10.5%

Primary excess air

Oxygen (O2) (ideal 3 - 4%)

Carbon Dioxide (CO

2)

All GasTrac components

meet:

UL372, UL795, FM, CGA, AGA,

NFPA 54, NFPA 79, NFPA 86

and IAS

A

B

C

Specifications: GasTrac (CGT) Process

Air Heater

SPECIFICATION NOTES:

*Designed for natural gas. For alternate fuel, contact your Conair representative.

Specifications may change without notice. Consult a Conair representative for the most current information.

2- 6 l Des cr i pt io n

TPDS009-0408

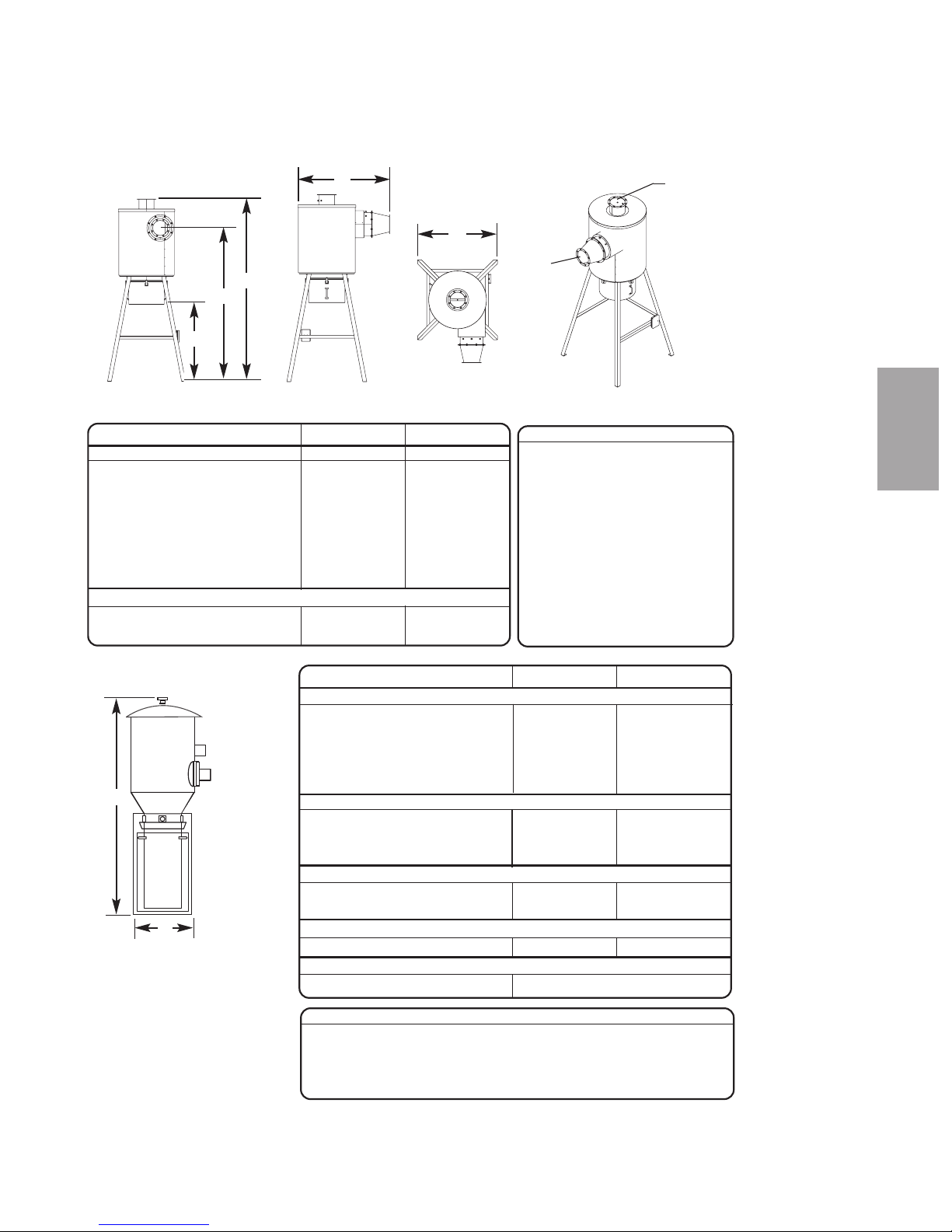

Page 23

MODELS 18087803 18087801

Uninsulated or Insulated Uninsulated Insulated

Dimensions inches {cm}

A - Height 96.5 {245} 96.5 {245}

B - Height to centerline 81.3 {207} 81.3 {207}

C - Clearance below canister 41.0 {104} 41.0 {104}

D - Depth 53.1 {135} 43.9 {112}

E - Width 42.2 {107} 42.2 {107}

Air inlet/outlet 8 12

Weight lb {kg}

Installed 150 {68} 160 {73}

Shipping 180 {82} 190 {86}

SPECIFICATION NOTES:

Specifications can change without

notice. Check with a Conair representative for the most current information.

Specifications: Dust Collectors

Air outlet

Air

inlet

A

B

C

D

E

De s cr ip ti on l 2- 7

2

De s cri p tion

MODELS DC1 DC2

Performance Characteristics

Pump size range Hp {kW} * 3-7.5 {2.2-5.6} 10-25 {7.5-18.7}

Vacuum line size OD in {mm} 1.5-2.5 {38.1-63.5} 2.25-4.0 {57.2-101.6}

Filter area ft2{M2} 42.8 {4.0} 100.3 {9.3}

Maximum collection capacity ft3{liters} 1.1 {31.1} 2.1{59.4}

Recommended dust collection ft3{liters} 0.75 {21.2} 1.0 {28.3}

Dimensions inches {cm}

A - Height 58.0 {147.3} 67.0 {170.1}

B - Width 15.0 {38.1} 19.0 {48.3}

Depth 20.0 {50.8} 19.0 {48.3}

Weight lb {kg}

Installed 110 {50} 150 {68}

Shipping 140 {64} 280 {127}

Voltage total amps

120V/1 phase/60Hz 1.0 1.0

Compressed air requirement

80-120 psi {5.5-8.3 bars}

SPECIFICATION NOTES:

* Model DC1 works with Conair pump models PSS3, PSS6, PD3, PD5, PD7.5.

Model DC2 works with PSS11, PD10, PD15, PD25.

Specifications can change without notice. Check with a Conair representative for

the most current information.

A

B

in

out

Model DC1 and DC2

TPCS012-0408

Page 24

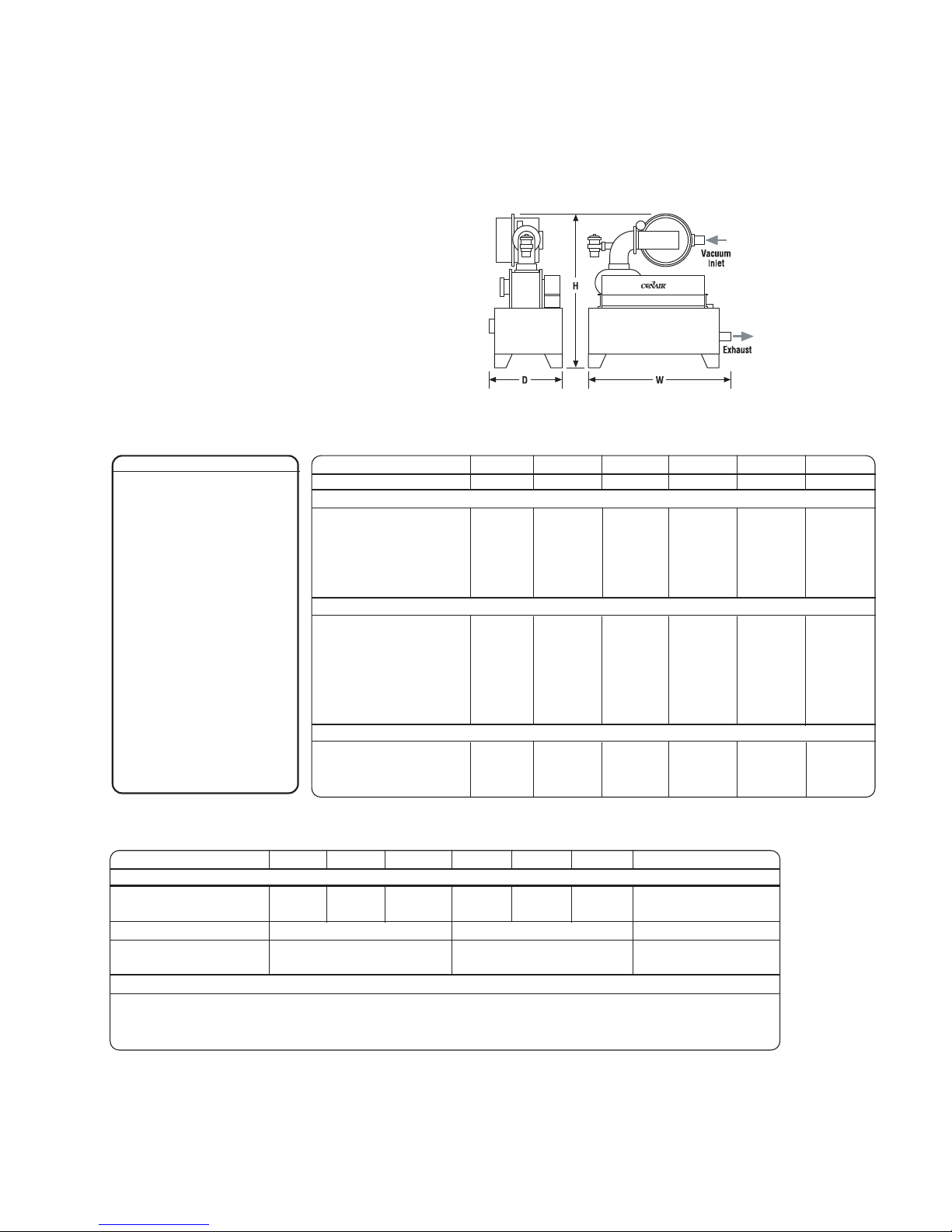

MODELS PD3 PD5 PD7.5 PD10 PD15 PD25

Motor Type* TEFC TEFC TEFC TEFC TEFC TEFC

Performance

Horsepower 357.5 10 15 25

Standard CFM at Material

Pickup Point @ 10" Hg 52.6 76.6 121.2 154.5 201.1 346.2

Average Sound Level (dbA)

@ 8", 10" and 12" Hg 86 86.3 86 85.8 88.8 93

Dimensions in. {mm}

Standard Inlet Size (OD) 1.5 {38} 1.75 {44} 2.25 {57} 2.5 {64} 3.0 {76} 4.0 {102}

Exhaust Line Size (OD) 2.5 {64} 2.5 {64} 2.5 {64} 4.0 {102} 4.0 {102} 4.0 {102}

Height (H) 37 {940} 37 {940} 41 {1041} 51 {1295} 51 {1295} 52 {1321}

Width (W) 35 {889} 35 {889} 35 {889} 39.5 {1003} 39.5 {1003} 39.5 {1003}

Depth (D) 27 {686} 27 {686} 27 {686} 33 {838} 33 {838} 34 {864}

Installed Weight / lb {kg} 325 {147} 325 {147} 370 {168} 625 {283} 640 {290} 960 {435}

Voltage Total Amps

240 7.6 12 18.8 28 39 59

480 3.8 6 9.4 14 19.5 29.5

575 2.9 4.8 7.5 10.7 16 27

* Energy-saving, high efficiency motors

are also available.

Specifications: Positive Di splacement

(PD) Pumps

MODELS PD3 PD5 PD7.5 PD10 PD15 PD25 SUPER (ANY MODEL)

Performance

Average Sound Level (dbA)

@ 8", 10" and 12" Hg

61.9 69.8 76.2 79.3 86.0 90.0 Under 60 dbA

Enclosure Construction Painted Steel Natural Aluminum Painted Steel

Allowance Space for

Service Access / in

48 (Opposite Vacuum Inlet) 36 (Opposite Vacuum Inlet) 36 (Front, Next to Filter)

Dimensions in. {mm}

Height (H) 49 {1245} 64 {1626} 96 {2438}

Width (W) 54 {1372} 55 {1397} 70 {1778}

Depth (D) 32 {813} 36 {914} 50 {1270}

SPECIFICATIONS FOR PUMPS WITH SOUND ENCLOSURES

Specifications not listed below are the same as those listed above. All Sound Enclosures include a cooling fan 115 VAC @ 2 amps.

SPECIFICATION NOTES:

Specifications can change with-

out notice. Check with a Conair

representative for the most current information.

2- 8 l Des cr i pt io n

TPCS026-0408

Page 25

Specifications: CH Series Insulated

Hoppers

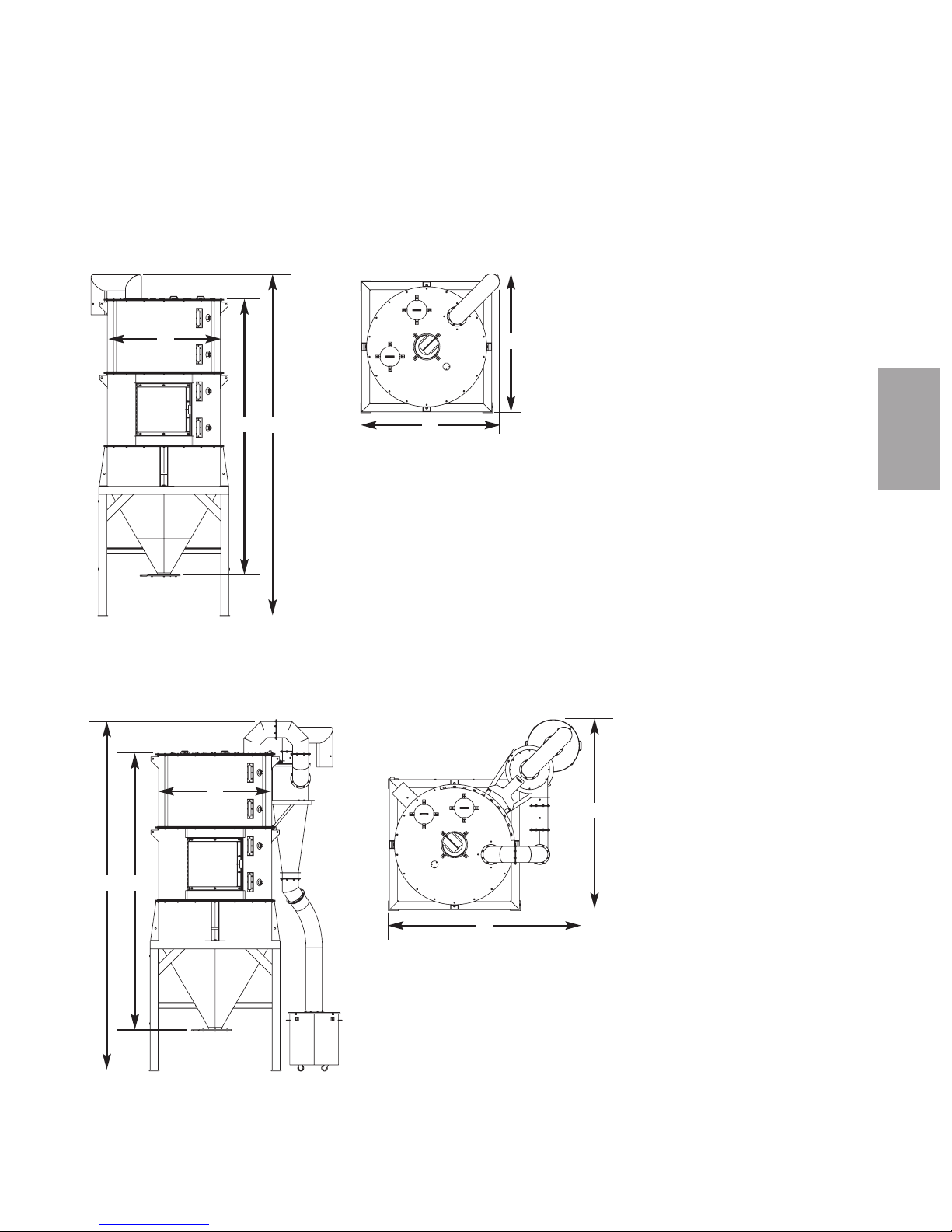

Without Integrated Cyclone (Fig. 1)

A

B

C

D

E

With Integrated Cyclone (Fig. 2)

A

BA

D

E

De s cr ip ti on l 2- 9

2

De s cri p tion

TPDS006-0408 REV

Page 26

Specifications: CH Series Insulated

Hoppers

MODEL CH54-70 CH54-85 CH54-99 CH54-114 CH54-129 CH64-158 CH64-187 CH64-215 CH64-248

FIGURE NUMBER Fig. 1 Fig. 1 Fig. 1 Fig. 1 Fig. 1 Fig. 1 Fig. 1 Fig. 1 Fig. 1

Performance characteristics

Capacity ft3{liter} 70 {1982} 85 {2407} 99 {2804} 114 {3228} 129 {3653} 158 {4475} 187 {5296} 215 {6089} 248 {7023}

Capacity @ 35 lb/ft

3

2450 2975 3465 3990 4515 5530 6545 7525 8680

Dimensions inches {cm}

A - Inside diameter 54 {137} 54 {137} 54 {137} 54 {137} 54 {137} 64 {163} 64 {162} 64 {162} 64 {163}

B - Hopper height 101.3 {257}120.1 {305} 132.1 {336} 138.1 {351} 150.1{381} 144.6

{367}

158.6 {403} 174.6 {443} 192.6 {489}

C - Overall height 136.8 {347}154.8 {393} 166.8 {424} 170.8 {434} 182.8 {464} 177.9 {452} 189.9 {482} 207.9 {528} 225.9 {574}

D - Width 69.4 {176} 69.4 {176} 69.4 {176} 69.4 {176} 69.4 {176} 76.0 {193} 76.0 {193} 76.0 {193} 76.0 {193}

E - Depth 69.4 {176} 69.4 {176} 69.4 {176} 69.4 {176} 69.4 {176} 76.0 {193} 76.0 {193} 76.0 {193} 76.0 {193}

Air inlet (OD) 8 {20.3} 8 {20.3}

Air outlet (OD) 8 {20.3} 8 {20.3}

Material discharge (ID) 6 {15.2} 6 {15.2}

Weights lb {kg}

Installed weight (hopper only) 1100 {499}1250 {567} 1450 {658} 1550 {703} 1650 {748} 1850 {839} 2050 {930} 2150 {975} 2250 {1021}

Mounting interfaces

Hopper loader (Top) IT07 IT07 IT07 IT07 IT07 IT07 IT07 IT07 IT07

Material discharge (Bottom) IB03 IB09 IB09 IB09 IB09 IB09 IB09 IB09 IB09

MODEL CH74-245 CH74-366 CH74-487 CH100-450 CH100-675 CH100-900

FIGURE NUMBER Fig. 1 Fig. 1 Fig. 1 Fig. 1 Fig. 1 Fig. 1

Performance characteristics

Capacity ft3{liter} 245 {6938} 366 {10365} 487 {13792} 450 {12743} 675 {19114} 900 {25485}

Capacity @ 35 lb/ft

3

8575 12810 17045 15750 23625 31500

Dimensions inches {cm}

A - Inside diameter 74 {188} 74 {188} 74 {188} 100 {254} 100 {254} 100 {254}

B - Hopper height 170.2 {432} 218.2 {554} 266.2 {676} 199 {505} 249 {632} 297 {754}

C - Overall height 193.7 {492} 241.7 {614} 289.7 {736} 219 {556} 269 {683} 317 {805}

D - Width 90.5 {229.9} 90.5 {229.9} 90.5 {229.9} 120.0 {305} 120.0 {305} 120.0 {305}

E - Depth 90.5 {229.9} 90.5 {229.9} 90.5 {229.9} 120.0 {305} 120.0 {305} 120.0 {305}

Air inlet (OD) 12 {30.5} 12 {30.5}

Air outlet (OD) 12 {30.5} 12 {30.5}

Material discharge (ID) 8 {20.3} 11.875 {30.2}

Approximate weight lb {kg}

Installed weight (hopper only) 3230 {1465} 3830 {1737} 5030 {2282} 9750 {4423} 10800 {4899} 11850 {5375}

Mounting interfaces

Hopper loader (Top) IT07 IT07 IT07 IT07 IT07 IT07

Material discharge (Bottom) IB09 IB09 IB09 IB09 IB09 IB09

Without Integrated Cyclone

Without Integrated Cyclone

SPECIFICATION NOTES:

Specifications can change without

notice. Check with a Conair representative for the most current

information.

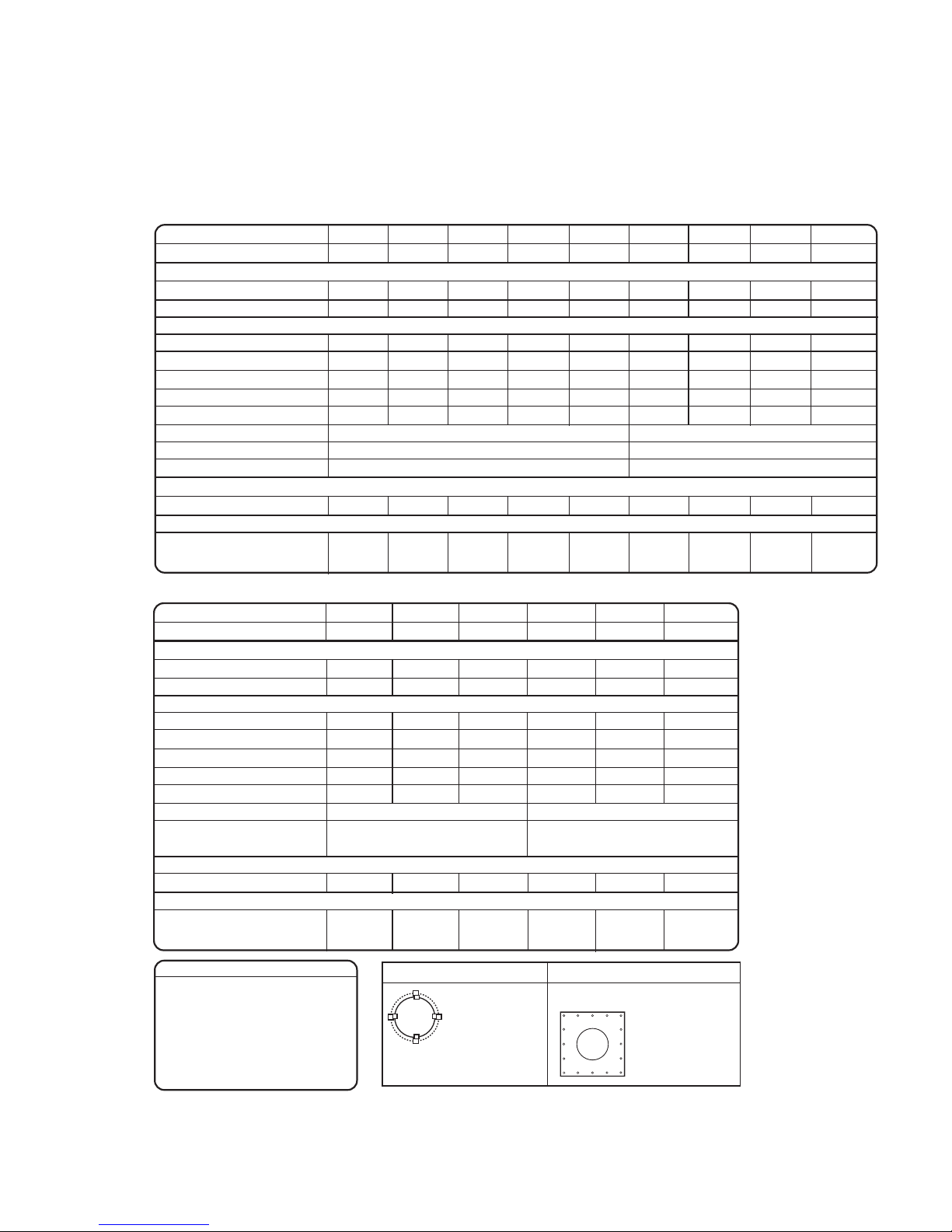

IT07

4 equally spaced

mounting clips on a

16.375 in. {416 mm}

diameter bolt circle

IB09

16 bolt holes, 7/16 in.

{11 mm}, on a 16.25 in.

{413 mm} square plate

Top for hopper loaders

Bottom at discharge

2- 1 0 l D es cr ip t io n

TPDS006-0408 REV

Page 27

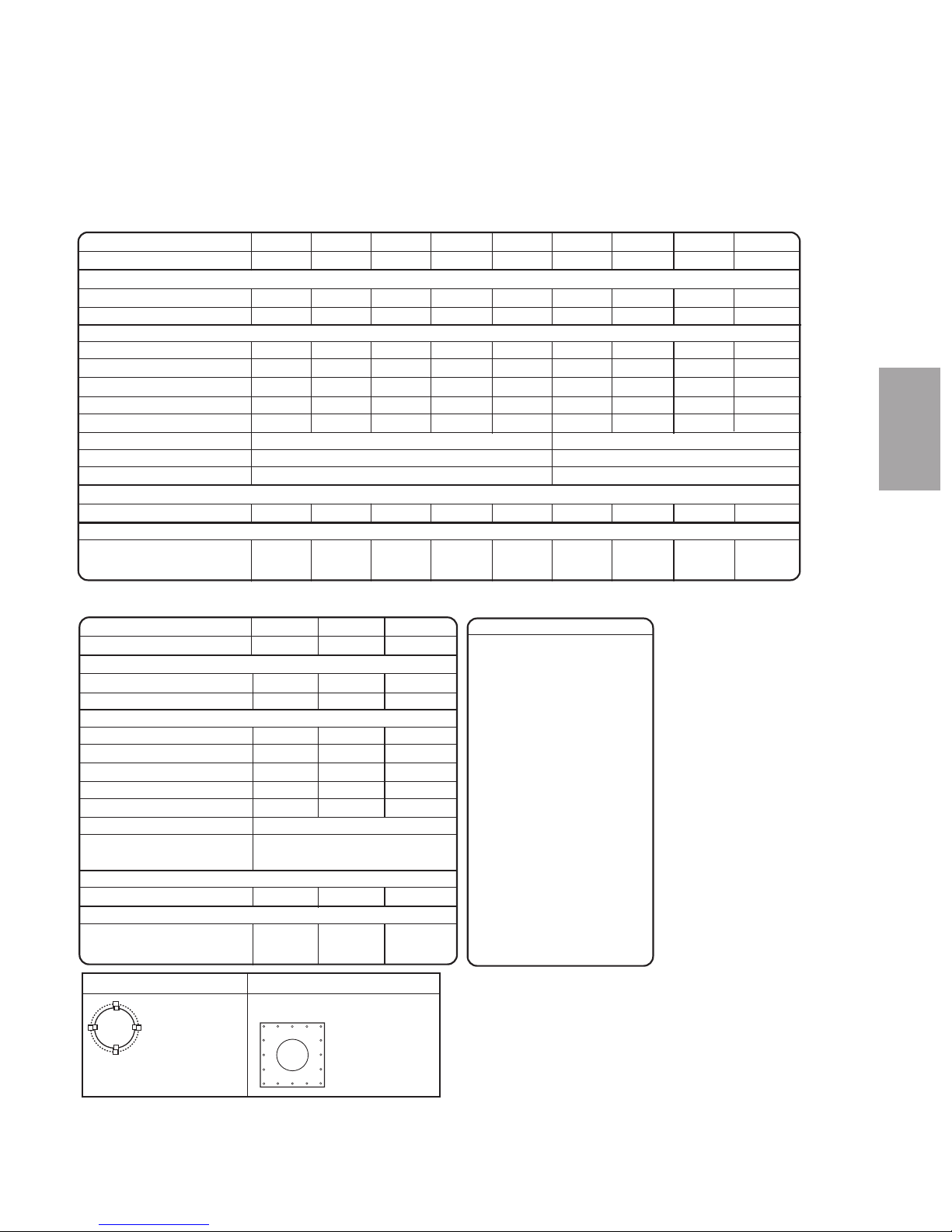

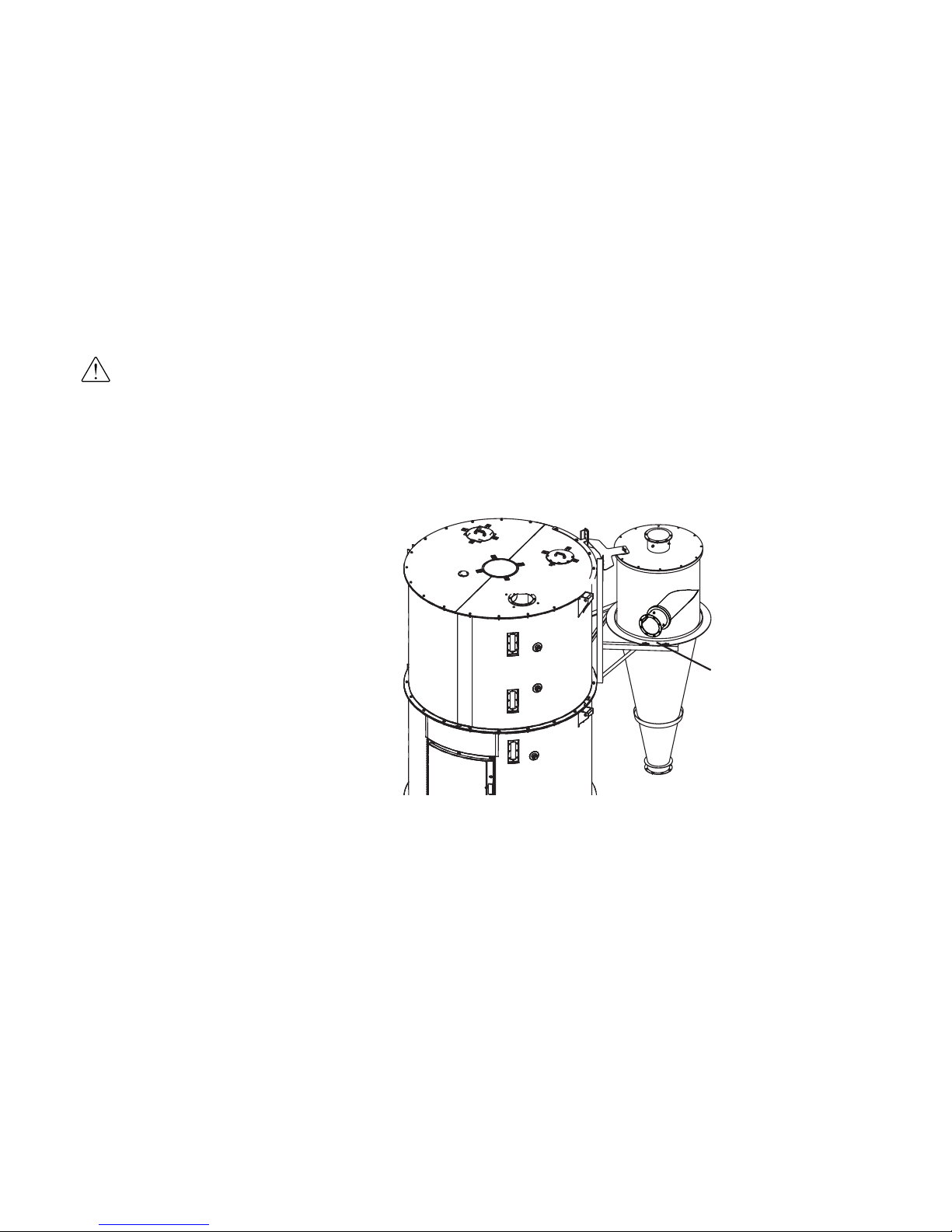

With Integrated Cyclone

With Integrated Cyclone

Specifications: CH Series Insulated

Hoppers

SPECIFICATION NOTES:

Specifications can change without notice. Check with a Conair

representative for the most

current information.

IT07

4 equally spaced

mounting clips on a

16.375 in. {416 mm}

diameter bolt circle

IB09

16 bolt holes, 7/16 in.

{11 mm}, on a 16.25 in.

{413 mm} square plate

Top for hopper loaders

Bottom at discharge

MODEL CH54-70 CH54-85 CH54-99 CH54-114 CH54-129 CH64-158 CH64-187 CH64-215 CH64-248

FIGURE NUMBER Fig. 2 Fig. 2 Fig. 2 Fig. 2 Fig. 2 Fig. 2 Fig. 2 Fig. 2 Fig. 2

Performance characteristics

C

apacity ft3{liter} 70 {1982} 85 {2407} 99 {2804} 114 {3228} 129 {3653} 158 {4475} 187 {5296} 215 {6089} 248 {7023}

Capacity @ 35 lb/ft

3

2450 2975 3465 3990 4515 5530 6545 7525 8680

D

imensions inches {cm}

A - Inside diameter 54 {137} 54 {137} 54 {137} 54 {137} 54 {137} 64 {163} 64 {162} 64 {162} 64 {163}

B

- Hopper height 101.3 {257}120.1 {305} 132.1 {336} 138.1 {351} 150.1{381} 144.6

{367}

158.6 {403} 174.6 {443} 192.6 {489}

C

- Overall height 140.6 {357}157.6 {400} 169.6 {431} 175.6 {446} 187.6 {477} 182.4 {463} 194.4 {494} 212.4 {539} 230.4 {585}

D - Width 96.4 {245} 96.4 {245} 96.4 {245} 96.4 {245} 96.4 {245} 101.8 {259} 101.8 {259} 101.8 {259} 101.8 {259}

E - Depth 96.4 {245} 96.4 {245} 96.4 {245} 96.4 {245} 96.4 {245} 101.8 {259} 101.8 {259} 101.8 {259} 101.8 {259}

Air inlet (OD) 8 {20.3} 8 {20.3}

Air outlet (OD) 8 {20.3} 8 {20.3}

Material discharge (ID) 6 {15.2} 6 {15.2}

Approximate weight lb {kg}

Installed weight

(hopper and cyclone) 1650 {748}1800 {816} 2000 {907} 2100 {953} 2200 {998} 2400 {1089} 2600 {1179} 2700 {1225} 2800 {1270}

Mounting interfaces

Hopper loader (Top) IT07 IT07 IT07 IT07 IT07 IT07 IT07 IT07 IT07

Material discharge (Bottom) IB03 IB09 IB09 IB09 IB09 IB09 IB09 IB09 IB09

MODEL CH74-245 CH74-366 CH74-487

FIGURE NUMBER Fig. 2 Fig. 2 Fig. 2

Performance characteristics

Capacity ft3{liter} 245 {6938} 366 {10365} 487 {13792}

Capacity @ 35 lb/ft

3

8575 12810 17045

Dimensions inches {cm}

A - Inside diameter 74 {188} 74 {188} 74 {188}

B - Hopper height 170.2 {432} 218.2 {554} 266.2 {676}

C - Overall height 263.5 {669} 311.5 {791} 479.5 {1218}

D - Width 118.6 {301} 118.6 {301} 118.6 {301}

E - Depth 118.6 {301} 118.6 {301} 118.6 {301}

Air inlet (OD) 12 {30.5}

Air outlet (OD) 12 {30.5}

Material discharge (ID) 8 {20.3}

Approximate weight lb {kg}

Installed weight (hopper and cyclone) 3780 {1715} 4380 {1987} 5580 {2531}

Mounting interfaces

Hopper loader (Top) IT07 IT07 IT07

Material discharge (Bottom) IB09 IB09 IB09

De s cr ip ti on l 2- 11

2

De s cri p tion

TPDS006-0408 REV

Page 28

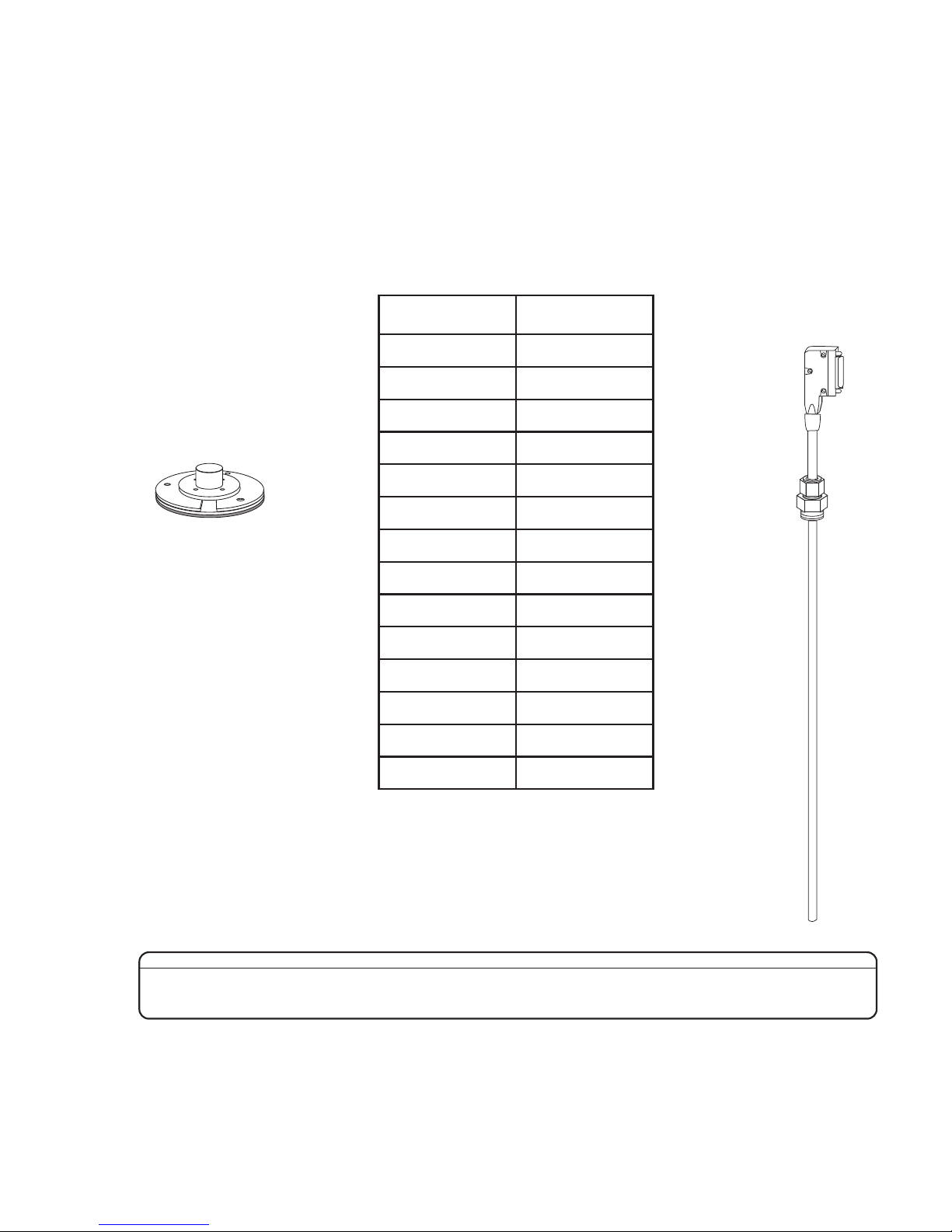

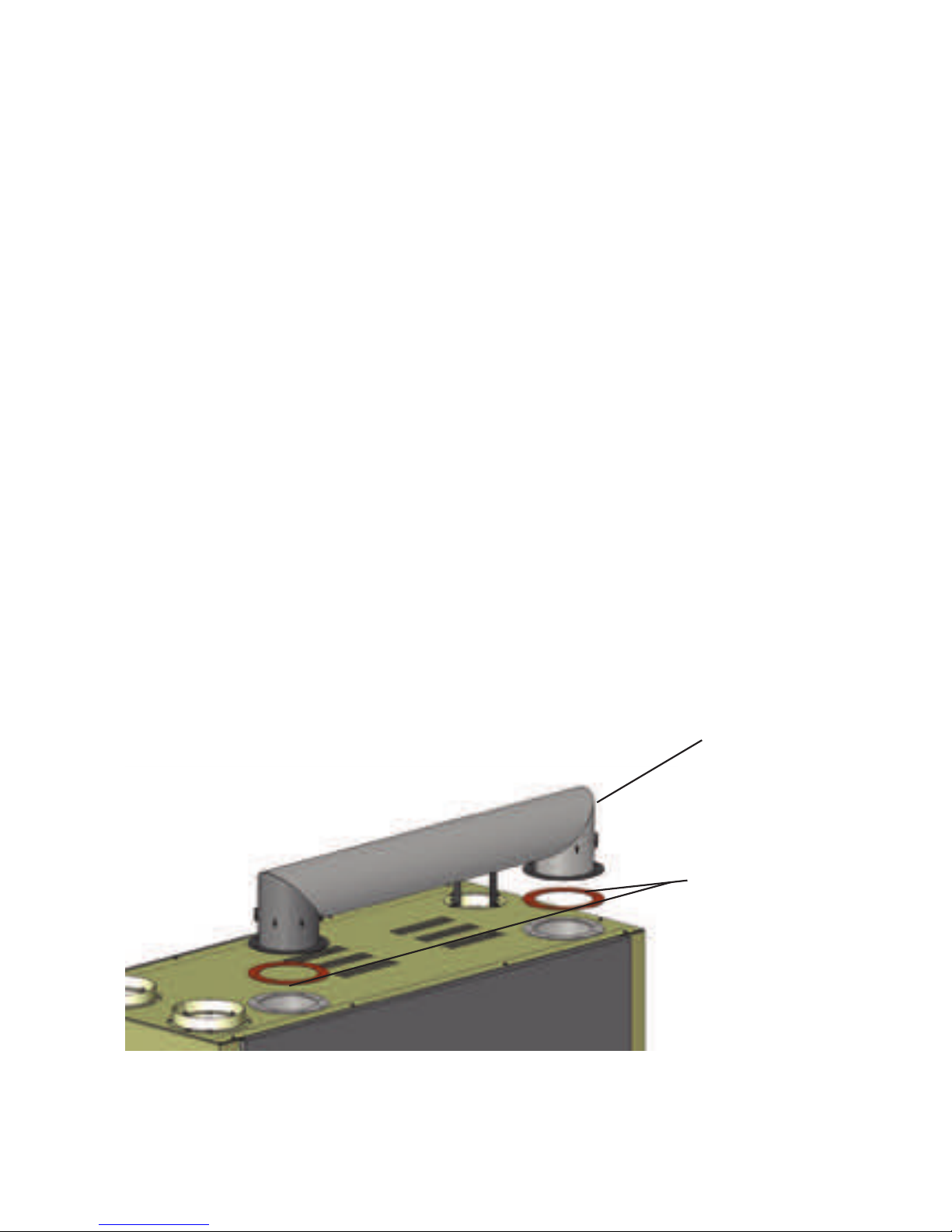

Angled Probe

Allows the DM-II to be used on

hoppers that have insufficient

clearance for correctly mounting

the probe around loading devices.

Probe Mounting

Adapter Kit

(Includes half coupling,

two mounting plates,

screws and gasket)

NOTE: The mounting adapter

kit will only be included if the

DM-II was ordered as a retrofit kit. Otherwise, the adapter

plate will already be in place

on the hopper.

The DM-II package includes:

●

Drying monitoring probe

●

Connecting cable

●

Pre-wired dryer panel

●

Light tower

Specifications: Dr ying Monitor, DM-II

Model

✐

SPECIFICATION NOTES:

Specifications can change without notice. Check with a Conair representative for the most current information.

Drying Hopper # Conair Part #

CH 54-70 1819080140

CH 54-85 1819080141

CH 54-99 1819080142

CH 54-114 1819080123

CH 54-129 1819080143

CH 64-158 1819080125

CH 64-187 1819080126

CH 64-215 1819080127

CH 64-248 1819080144

CH 74-245 1819080126

CH 74-366 1819080145

CH 100-450 1819080132

CH 100-675 1819080133

CH 100-900 1819080134

2- 1 2 l D es cr ip t io n

Page 29

Energ ySmart Dryer Control Options

• Visual alarms - The visual alarm is a blinking red alarm light that alerts the user to

any shut down alarm.

• Trending screens - The trending screens display temperature, air flow, dew point and

differential pressure of the EnergySmart Dryer System. Each can be used to graph

real-time data of a running dryer system.

• Recipe storage screen - The recipe storage screen is used to store and instantly recall

specific dryer parameters that are used with different types of material. Up to 99 dryer

recipes can be saved within the control.

• Loading control screens - Dedicated screens control the function and activation of up

to two (2) optional receivers. Loading, dump and purge times can be individually

altered for each receiver.

• Communications - Allows the dryer to be networked to industrial control systems.

De s cr ip ti on l 2- 13

2

De s cri p tion

Page 30

2- 1 4 l D es cr ip t io n

Page 31

In s ta ll at io n l 3 -1

Installation

Ins t a l l a tion - G e n e r a l . . . . . . . . . . . . . . . . . . . . . 3-5

Unpacking the EnergySmart™ Dryer System

components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . 3-7

Positioning the CH hopper floor stand . . . . . . . . . . . . . . 3-8

Installation of the HTC control

(Models HTC 30, 60 and 90) . . . . . . . . . . . . . . . . . 3-9

(Models HTC 120) . . . . . . . . . . . . . . . . . . . . . . . . 3-10

(Models HTC 180 and 270) . . . . . . . . . . . . . . . . . 3-10

Location and mounting of the HTC heater assembly

(Models HTC 30, 60 and 90) . . . . . . . . . . . . . . . . 3-11

(Models HTC 120) . . . . . . . . . . . . . . . . . . . . . . . . 3-11

(Models HTC 180 and 270) . . . . . . . . . . . . . . . . . 3-11

Installing the CH hopper cone section . . . . . . . . . . . . . 3-12

Installing the CH hopper door, upper and lid sections . . 3-13

Installing the cyclone (optional) . . . . . . . . . . . . . . . . . . 3-17

Installing the drying monitor probe . . . . . . . . . . . . . . . 3-22

Installing the receiver(s) (optional). . . . . . . . . . . . . . . . 3-25

Installing the purge valve(s) (optional) . . . . . . . . . . . . . 3-25

Installing the modular distribution box(s) (optional) . . . . 3-25

Securing the CH hopper to the floor . . . . . . . . . . . . . . . 3-26

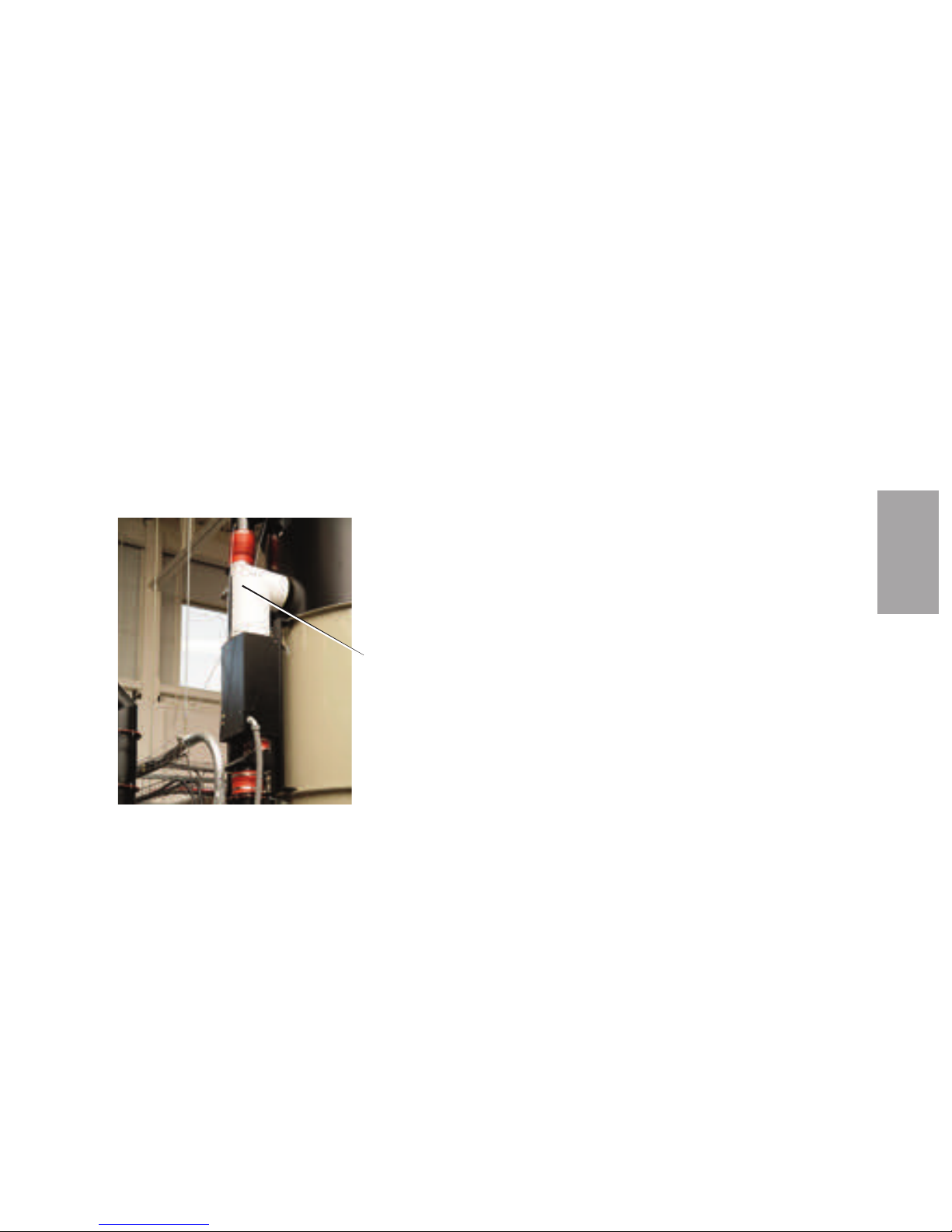

Location and mounting of the GasTrac heater . . . . . . . . 3-27

Location and mounting of the dust collector (optional). . 3-28

Location and mounting of the vacuum pump(s)

and dust collector(s) (optional) . . . . . . . . . . . . . . . 3-30

Po s i t ioning the d r y e r o n the floor . . . . . . . . . . . 3 - 3 1

Rem o v i n g t h e cab l e tie from the d esiccant

whe e l (W60 0 - 1 0 0 0 m o d e l s ) . . . . . . . . . . . . 3-3 1

S E C T I O N

3

3

In s tal l a tio n

Page 32

Installation ( con t inu e d)

Ins t a l l i n g t h e r e g e n e r a t i on e x h aust c over . . . . . 3 -31

Ins t a l l i n g t h e r e t u r n a i r ada pte r . . . . . . . . . . . . 3- 3 2

Ins t a l l i n g t h e r e t u r n a i r inl e t and air outlet

ada pte r s (W16 0 0 - 5 0 0 0 m o d e l s) . . . . . . . . . 3-33

Ins t a l l i n g t h e o v e r h e a d p r o c ess a i r

duc t (W320 0 - 5 0 0 0 m o d e l s ) . . . . . . . . . . . . 3 - 3 4

Ins t a l l a tion - P i p i n g /Hoses . . . . . . . . . . . . . . . . . 3-35

Opt i o n a l h a r d pip i n g kit s . . . . . . . . . . . . . . . . . 3-36

Con n e c t i n g t h e h e a t sourc e s . . . . . . . . . . . . . . 3-37

Hop p e r tem p e r a t u r e c o n t r o ller ( H TC) a s

hea t source . . . . . . . . . . . . . . . . . . . 3-37

Gas Tr a c a s he a t source . . . . . . . . . . . . . . 3 - 3 8

Con n e c t i n g t h e d r yer to the h e a t s o u r c e . . . . . . 3 - 3 9

Con n e c t i n g t h e d u s t col l e c t o r ( o p t i onal) . . . . . . 3-40

Con n e c t i n g t h e c y clone separ a tor (opti o n a l ) . . . . 3 - 4 1

Ins t a l l i n g t h e D w y e r 6 4 1 air velocit y

tra n s m i t t er . . . . . . . . . . . . . . . . . . . . . . . 3 - 4 2

Ins t a l l i n g t h e l e v e l s wit c h (opt i o n a l ) . . . . . . . . . 3- 4 4

Adj u s t i n g t h e lev e l sens o r (opt i o n a l ) . . . . . . . . . 3-45

Ins t a l l i n g t h e p r o c e s s p r o t e ction RTD sensor . . . 3 - 4 6

Loc a ti o n of the process material temperature

pro b e (RT D ) . . . . . . . . . . . . . . . . . . . . . . 3 - 4 7

Ins t a l l i n g t h e G a s Trac RTD sensor . . . . . . . . . . 3 - 4 8

Ins t a l l i n g t h e r e t u r n a i r dew point line . . . . . . . 3 - 4 9

Ins t a l l a tion - M a i n Po wer C o nnections . . . . . . 3-51

Connecting main power to the dryer . . . . . . . . . . . . . . 3-52

Connecting main power to the HTC

(Models HTC 30, 60, 90 and 120) . . . . . . . . . . . . . 3-53

3- 2 l Ins ta l la ti on

Page 33

Installation ( con t inu e d)

(Models HTC 180 and 270) . . . . . . . . . . . . . . . . . 3-54

Connecting main power to the GasTrac . . . . . . . . . . . . 3-56

Connecting main power to the vacuum pump(s)

(optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

Connecting main power to the dust collector(s)

(optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

Ins t a l l a tion - C o n v e y ing L i n es . . . . . . . . . . . . . . 3-59

Con n e c t i n g t h e c o n v e y i ng l i n es t o t h e

rec e i v e r ( s) ( o p t ional) . . . . . . . . . . . . . . . . 3-60

Con n e c t i n g t h e c o n v e y i ng l i n es t o t h e purg e

val v e s (op t i o n a l ) . . . . . . . . . . . . . . . . . . . 3 - 60

Con n e c t i n g t h e c o n v e y i ng l i n es t o t h e vacu u m

pum p ( s ) an d dust collect o r ( s ) ( o p t i o n al) . . . 3 - 61

Ins t a l l a tion - W ater L i nes . . . . . . . . . . . . . . . . . 3- 6 3

Typic a l water lines installa tio n drawing . . . . . . . 3-64

Con n e c t i n g t h e a f t e r c o oler/inter c o o l e r

and option a l prec o o l e r ( W 6 0 0 - 1 000) . . . . . . 3 - 6 5

Con n e c t i n g t h e a f t e r c o oler/inter c o o l e r

and option a l prec o o l e r ( W 1 6 0 0 - 5000) . . . . . 3-66

Ins t a l l a tion - C o n t r o l a n d Com m u n i c ations

Wir i n g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-67

Con n e c t i n g t h e H T C to the HTC c o ntroller . . . . . 3-68

Con n e c t i n g t h e R T D s e n s o rs ( H T C o n l y ) . . . . . . . 3 -70

Con n e c t i n g t h e G a s Trac RTD sensors . . . . . . . . . 3 - 7 2

Con n e c t i n g t h e d r ying monito r probe to

the dryer . . . . . . . . . . . . . . . . . . . . . . . . 3-73

Con n e c t i n g t h e r e c e i v e r t o t h e leve l

switch (optio n a l ) . . . . . . . . . . . . . . . . . . . 3 -74

In s ta ll at io n l 3 -3

3

In s tal l a tio n

Page 34

3- 4 l Ins ta l la ti on

Installation ( con t inu e d)

Con n e c t i n g t h e E n e r g y S m a r t D r y e r con t r o l

to system compone n t s . . . . . . . . . . . . . . . 3 - 7 5

Ins t a l l a tion - C o m p r e ssed A ir L i n e s . . . . . . . . . . . 3-85

Con n e c t i n g t h e c o m p r e s sed a i r l i n e s

(op t i o n a l ) . . . . . . . . . . . . . . . . . . . . . . . . 3-86

Ins t a l l a tion - G a s Pipi n g and Exhaust Flue . . . . . . 3-87

Typic a l gas line installa tio n drawing . . . . . . . . . 3-88

Ins t a l l i n g t h e C o n a i r G a s Trac . . . . . . . . . . . . . . 3-89

Con n e c t i n g t h e g a s and the exhaust flue to

the GasTr a c . . . . . . . . . . . . . . . . . . . . . . 3 - 9 2

Ins t a l l a tion - Te s ting . . . . . . . . . . . . . . . . . . . . . 3 - 95

Che c k i n g f o r prop e r air flow . . . . . . . . . . . . . . 3-96

Te s t i ng t h e v a r i a b le f r e quency drive (VFD) . . . . . 3 - 9 9

Te s t i ng t h e i n s t a l la tion o f t h e H T C . . . . . . . . . 3- 1 00

Che c k i n g t h e gas and electrica l syste m s

of the GasTr a c . . . . . . . . . . . . . . . . . . . . 3 - 1 02

Te s t i ng t h e i n s t a l la tion o f t h e G a s Trac . . . . . . . 3-103

Te s t i ng t h e p r i m a r y rec e i v e r ( o p t i o n al) . . . . . . 3-1 0 5

Te s t i ng t h e s e c o n d ar y r e c e i v e r ( o p t ional) . . . . . 3 - 107

Con f i g u r i ng t h e D w y e r 6 4 1 air veloci t y

tra n s m i t t er . . . . . . . . . . . . . . . . . . . . . . 3-109

Con f i g u r i ng t h e D M - I I d r ying

mon i t o r . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1 10

Con f i g u r i ng t h e l e v e l s wi t c h (op t i o n a l ) . . . . . . . 3-110

Usi n g comm u n i c a t i o n s ( o p t ional) . . . . . . . . . . 3 - 1 1 3

Page 35

Installation - General

In s ta ll at io n - Ge ne ra l l 3 -5

3

In s tal l a tio n

Page 36

Unpacking the EnergySmart™

Dryer System Components

Because of their size and shape and the multiple sizes in which the hopper is

available, the components of the EnergySmart Dryer System come packaged for

shipping in the best available manner. The EnergySmart System components

include, depending on the model and options ordered:

! EnergySmart Dryer with TouchView Technology - Allen-Bradley control

! CH Hopper - with or without integrated cyclone - optional

! Heater (HTC or GasTrac)

! Dust Collector(s) - optional

! DM-II Drying Monitor

! Receiver(s) - up to two (2) - optional

! Vacuum pump - up to two (2) - optional

! Hard piping kit - optional

1 For the EnergySmart Dryer System components that are mounted to

pallets, remove the hardware securing each component to its pallet, then

remove the component from the pallet. With a forklift, hoist or crane carefully

move the components to their approximate installation locations.

2 Remove all packing material, protective paper, tape and plastic, including any

inserted inside the components.

3 Carefully inspect all components to ensure no damage occurred during ship-

ping, and that you have all the necessary hardware. If any damage is found,

notify the shipping agent immediately.

4 Take a moment to record serial numbers and electrical power specifications

in the blanks provided on the back of the User Guide's title page. This information will be helpful if you ever need service or parts.

5 You are now ready to begin installation. Follow the preparation steps in the

next section.

6 Determine if your application is electric or gas. Disregard installation

steps for options not used.

3- 6 l Ins ta l la ti on - G en er al

NOTE: Some components may

be strapped to their shipping

pallet, remove as necessary.

✐

Page 37

3

In s tal l a tio n

In s ta ll at io n - Ge ne ra l l 3 -7

Preparing for Installation

The EnergySmart Dryer System is easy to install if you plan the location and

prepare the installation area properly.

1 Make sure the installation area provides:

❒

Grounded power sources supplying the correct voltages and currents for your system components. Check each component's serial

tag for the correct amps, voltage, phase and cycles. Field wiring to

each component should be completed by qualified electrical personnel.

All electrical wiring should comply with your region's electrical codes.

❒

Minimum clearance above and around each component for safe

operation and maintenance. Refer to the component manuals sup-

plied with your EnergySmart Dryer System to determine minimum

clearances needed for each component.

❒

A mounting area that will support the weight of the fully loaded CH

Hopper, floor stand and the other system components. Refer to the

specifications supplied with your EnergySmart Dryer System for the

weights of each component.

❒

A source of water for the aftercooler/intercooler or optional precooler of the dryer. The water source must be tower, city or chiller

water at temperatures of 45° to 85°F {7° to 29°C}. Refer to the specifications supplied with your system for the flow rate. Piping should be

installed to the dryer location. Flexible hose can be used to connect

the water pipes to the aftercooler/intercooler or optional precooler.

❒

If the heat source supplied with your EnergySmart Dryer System is

a GasTrac (CGT), the installation location must provide for an

exhaust flue and gas lines that meet all applicable local, regional

and national codes. Conair recommends that the GasTrac should have

a dedicated vertical stack that exits the building through a rain-protected

roof penetration. See Installation section entitled, Connecting the Gas

and the Exhaust Flue to the GasTrac.

❒

Material and conveying lines installed. If you plan to use optional

vacuum receivers to fill the CH Hopper, install conveying lines to the

hopper location as well as to the optional vacuum pump(s) and its associated dust collector(s) used within your EnergySmart Dryer System.

Page 38

3- 8 l Ins ta l la ti on - G en er al

Positioning the CH Hopper Floor

Stand

WARNING: You are responsible for the structural integrity of this installation.

CAUTION: Care should be taken while moving the main CH Hopper floor stand and

sections to ensure that no damage occurs during assembly.

IMPORTANT: You will need to consider the installation of your entire dryer system

before permanently placing any system component, see Installation - Piping and

Hoses for reference.

Due to the varying size of Conair CH Hoppers, Conair recommends:

• Following all applicable local building and safety codes

1 Make sure the installation location for the CH Hopper meets all provisions for

clearances, will support the weight of the fully loaded hopper and provides

space for the installation of the other system components, such as optional

receivers. See the specifications and drawings supplied with your system for

details.

2 Using a forklift, hoist or crane, move the floor stand to its installation location.

NOTE: For EnergySmart Dryer

Systems supplied with "small"

hoppers, the floor stand and cone

section may be pre-assembled

from Conair.

✐

Page 39

3

In s tal l a tio n

In s ta ll at io n - Ge ne ra l l 3 -9

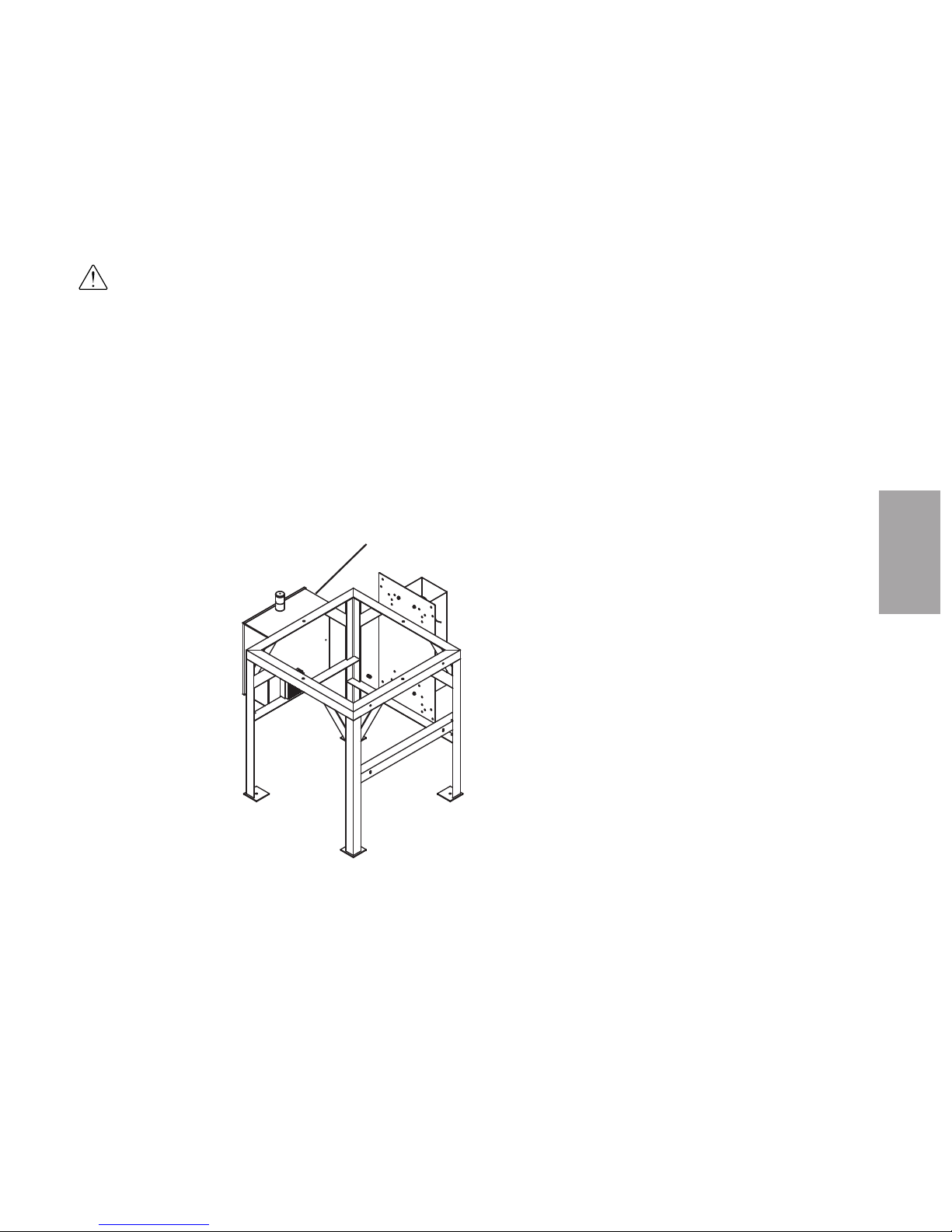

Installation of the HTC Control

(Mode ls HT C 30, 60 , a nd 90 )

CAUTION: You are responsible for the structural integrity of this installation.

NOTE: The HTC control is shipped mounted on the left side of the CH Hopper floor stand

on models 30, 60 and 90.

NOTE: If, by using your own provisions, you change the mounting arrangement of the

control center to a wall mount unit, it must be mounted 6 inches {152.4 mm} off of the

wall to provide clearance for the heat sink.

✐

✐

HTC Control

Center

(continued)

NOTE: If using a GasTrac for the

drying system heat source, see

Installation section entitled,

Installing the CH Hopper Cone

Section.

✐

Page 40

Installation of the HTC Control

(c on ti nu ed ) (Mod el HT C 120)

CAUTION: You are responsible for the structural integrity of this

installation.

1 Securely bolt the HTC control to the left side of the floor stand. Use the

supplied locking fasteners to securely mount the HTC control center to the floor

stand to prevent vibration-induced loosening.

NOTE: If, by using your own provisions, you change the mounting arrangement of the control center to a wall mount unit, it must be mounted 6 inches {152.4 mm} off of the wall to

provide clearance for the heat sink.

Installation of the HTC Control

(c on ti nu ed ) ( Mo de ls HTC 180 and 27 0)

CAUTION: You are responsible for the structural integrity of this installation.

1 Move the control center into

its final location for operation

(see figure to the right). The

control center must be positioned close enough to the

hopper to allow connection of

the RTD temperature probe.

The control center can be

mounted to a wall, the hopper

frame or a floor stand with

customer supplied provisions.

NOTE: If, by using your own provisions, you change the mounting arrangement of the control center to a wall mount unit, it must be mounted 6 inches {152.4 mm} off of the wall to

provide clearance for the heat sink.

✐

HTC Control Center

(Free-Standing)

✐

HTC Control

Center

✐

NOTE: If the lengths of the process

and process protection RTD wiring

are too short for your installation,

contact Conair Parts Department

(800.458.1960) to purchase

extension cables. From outside the

United States, call 814.437.6861.

(continued)

3- 1 0 l I ns ta ll a ti on - Ge ne r al

NOTE: If using a GasTrac for the

drying system heat source,

see

Installation section entitled,

Installing the CH Hopper Cone

Section.

✐

Page 41

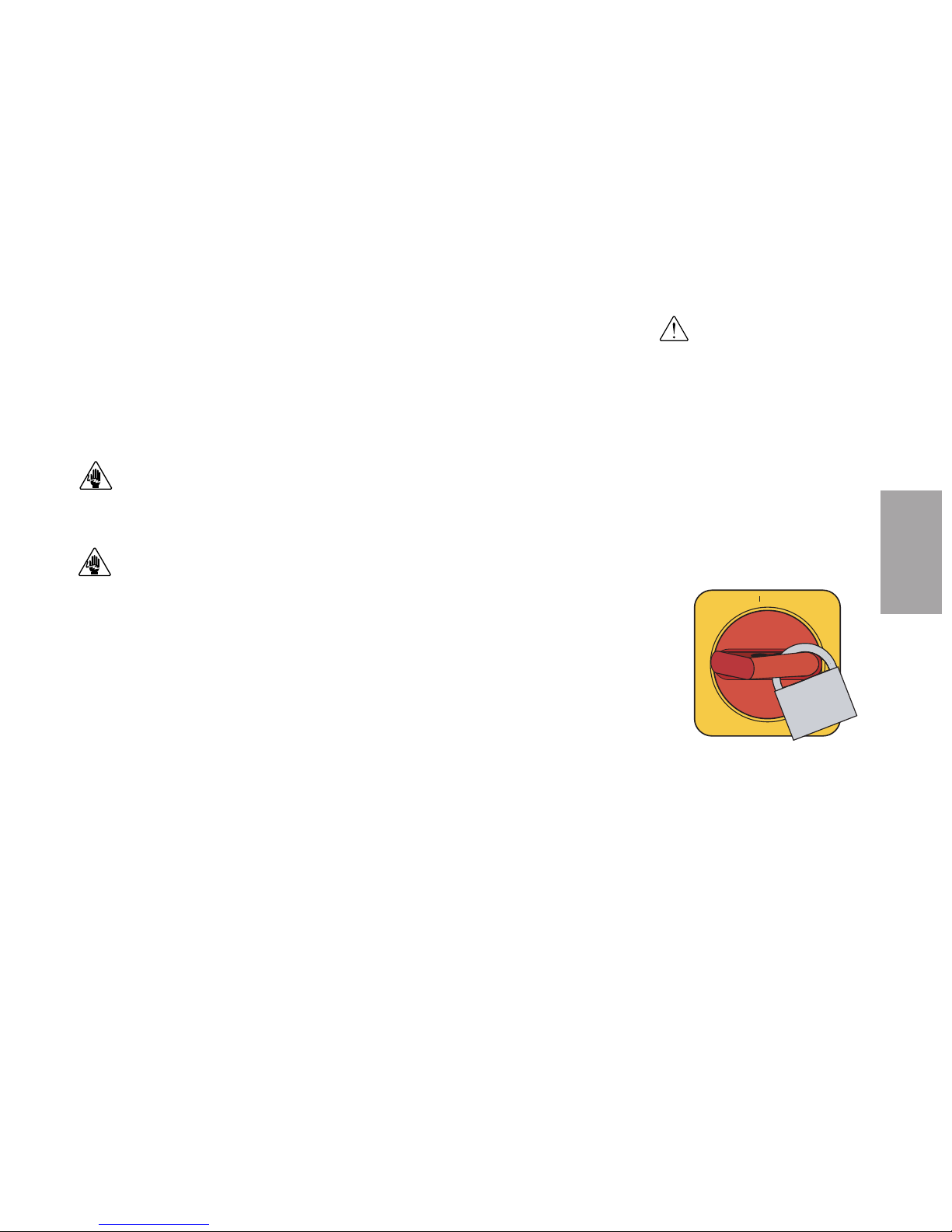

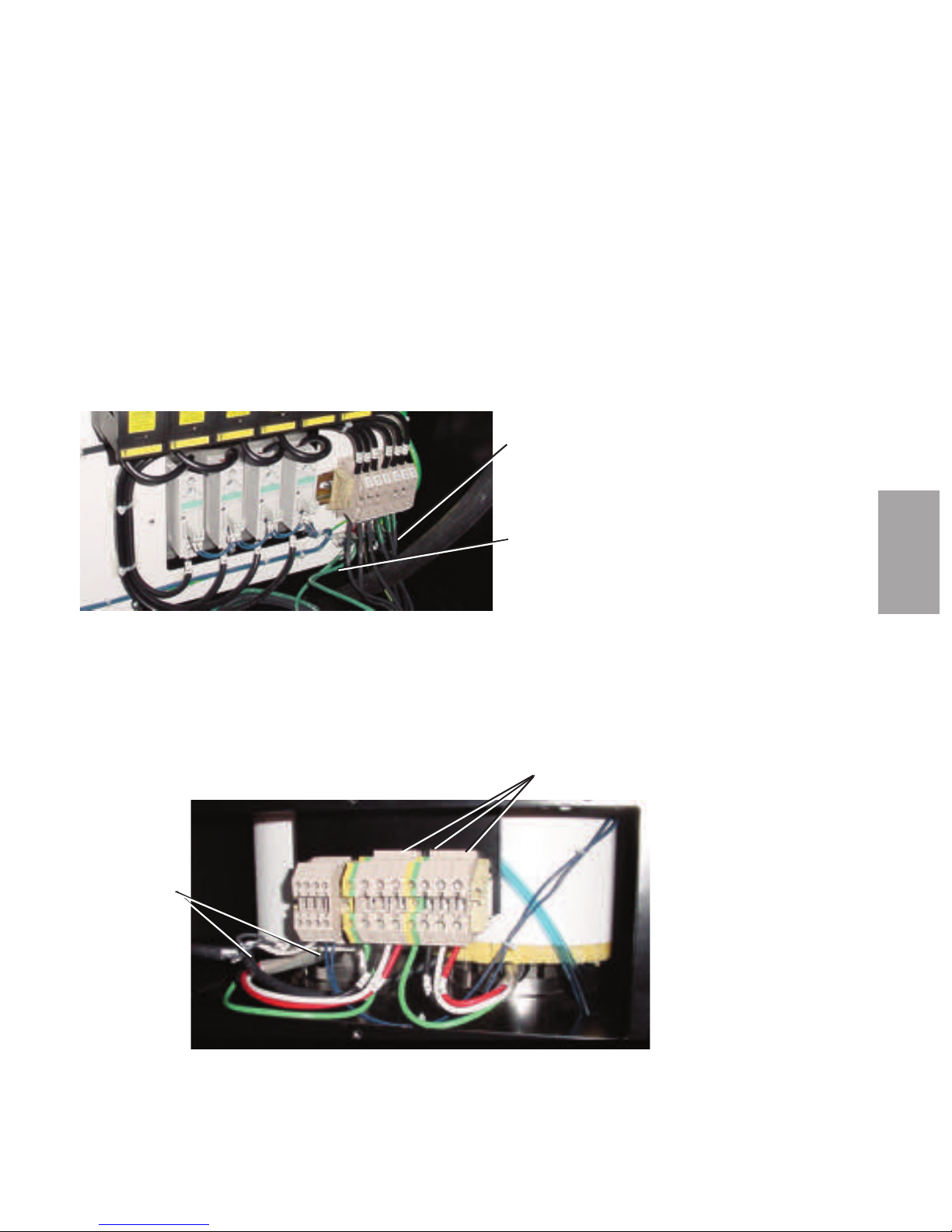

CAUTION: Always disconnect

and lock out the main power

sources before making electrical connections. Electrical

connections should be made

only by qualified personnel.

CAUTION: Check the disconnect with a volt meter to

ensure that the power is off.

Location and Mounting of the HTC

Heater Assembly

(Mode ls HT C 30, 60 and 90)

CAUTION: You are responsible for the structural integrity of this installation.

NOTE: The HTC heater assembly is shipped mounted to the back of the floor stand on

Models 30, 60 and 90 (see figure to the right).

NOTE: The heater is prewired to the control box on HTC Model 30, 60 and 90.

Location and Mounting of the HTC

Heater Assembly (M od el HTC 120)

CAUTION: You are responsible for the structural integrity of this installation.

1 Securely bolt the HTC heater assembly to the back of the floor stand (see

figure to the right). Use the locking fasteners provided to securely mount the

heater assembly to the floor stand to prevent vibration-induced loosening.

NOTE: The heater is prewired to the control box on HTC Model 120.

Location and Mounting of the HTC

Heater Assembly

(Mode ls HT C 180 and 270)

CAUTION: You are responsible for the structural integrity of this installation.

1 Securely bolt the HTC heater assembly to the back of the floor stand (see

figure to the right). Use the locking fasteners provided to securely mount the

heater assembly to the floor stand to prevent vibration-induced loosening.

2 Refer to the wiring diagram to make the wiring connections for the heater

and control box. Only a qualified electrician should make the wiring connections between the control and the heater. The customer must supply the appropriately-sized wire and conduit to make connections.

✐

HTC Heater

HTC Heater

IMPORTANT: Always refer

to the wiring diagrams that

came with your HTC before

making electrical connections.

✐

In s ta ll at io n - Ge ne ra l l 3 -1 1

3

In s tal l a tio n

✐

Page 42

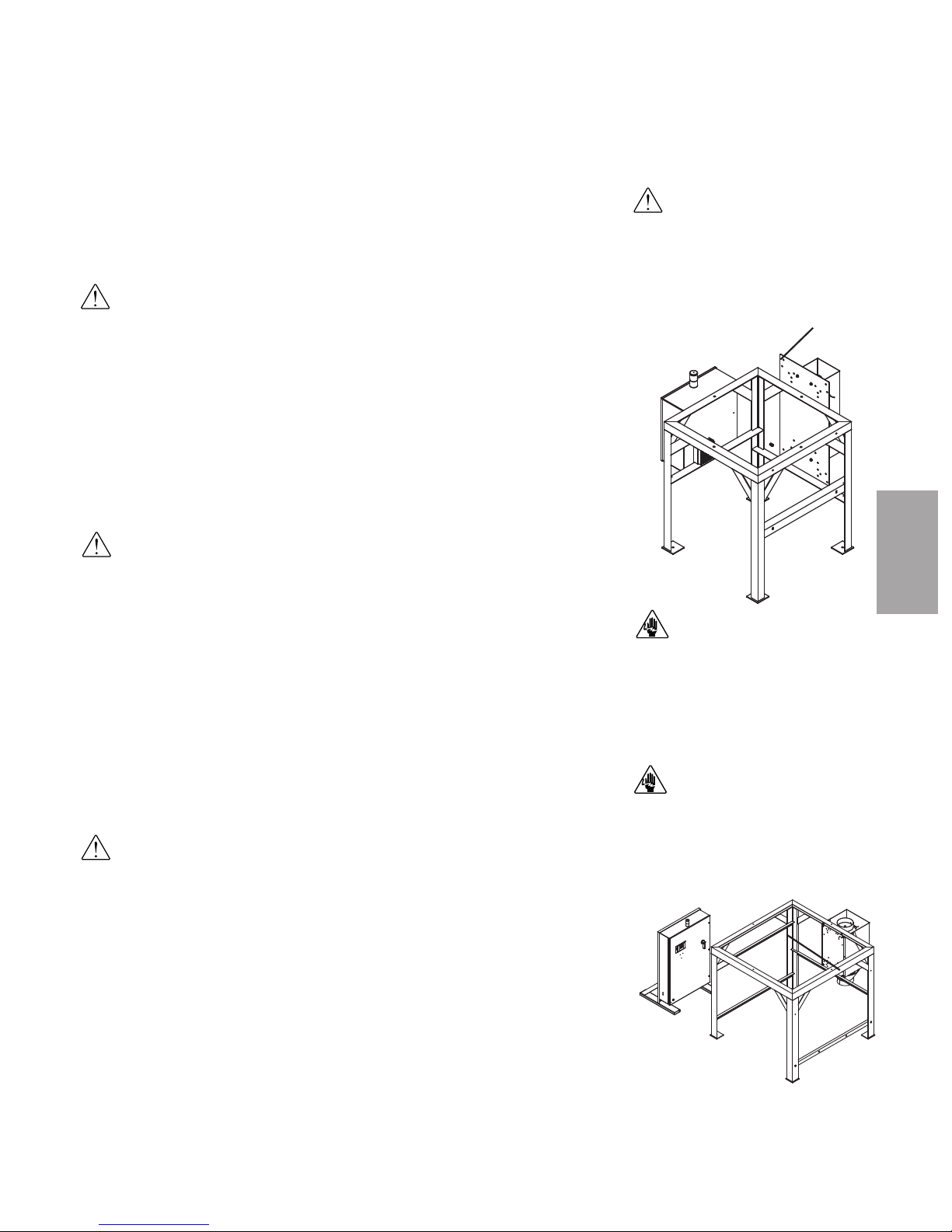

Installing the CH Hopper Cone

Section

Install the hopper cone section on the floor stand using the following steps.

IMPORTANT: You will need to consider the location of the CH Hopper’s delivery air inlet in relation to the dryer installation location for proper setup.

IMPORTANT: You will need to consider the location of the HTC heater outlet

in relation to the CH Hopper air inlet location for proper setup.

1 If any hoses, wires, etc. were attached to the floor stand and cone

section (for shipping purposes), make sure they are positioned away

from the mating surfaces of the assemblies so they will not be damaged

during this procedure.

2 Using a forklift, hoist or crane, lift the cone section assembly above

the floor stand.

CAUTION: To prevent accident and injury, lift the cone and hopper sections

onto the floor stand assembly using a forklift, hoist or crane.

3 Set the cone section on the floor stand as shown. Make sure the holes

in the cone section mounting lugs align with the holes in the top of the

floor stand assembly.

4 Secure the cone section to the floor stand assembly using the supplied

hardware.

NOTE: For EnergySmart Dryer

Systems supplied with "small"

hoppers, the floor stand and cone

section may be pre-assembled at

the factory. If your floor stand

and cone section are pre-assembled and you have secured the

floor stand to the floor,

see

Installation section entitled,

Installing the CH Hopper Door,

Upper and Lid Sections.

✐

3- 1 2 l I ns ta ll a ti on - Ge ne r al

NOTE: If using carbon steel hop-

pers, be sure to clean out the

hopper prior to use. Conair

applies a rust inhibitor that must

be removed several hours before

using the hopper.

✐

Page 43

Installing the CH Hopper Door,

Upper and Lid Sections

IMPORTANT: Before installing the hopper door, upper (if applicable), and

lid sections of the CH Hopper, careful consideration should be given to

the following:

• When installing the hopper door section, make sure the hopper door is posi-

tioned to allow easy access into the hopper to aid in installation and to facilitate

hopper cleaning and maintenance in the future.

• When installing the hopper lid section, make sure to identify the location of the

hopper’s return air outlet. The lid section has multiple piping options that can be

connected to an optional cyclone or traditional CH Hopper outlet, then to an

optional dust collector and finally to the dryer’s return air inlet. Consider all piping/hosing possibilities when installing the dryer, heater (gas or electric), optional

dust collector and optional cyclone before making the installation permanent.

Hoppe r D oo r Section

To install the hopper door section of the CH Hopper:

1 Apply sealer around the lip on the top of the cone section.

2 Using a forklift, hoist or crane, lift the hopper door section assembly above

the cone section.

CAUTION: To prevent accident and injury, lift the hopper door section onto the

cone section using a forklift, hoist or crane.

NOTE: When applying the sealer,

do not cover the holes in the cone

section lip. Apply the sealer

around the holes so you will have

a good seal but not interfere with

the mounting hardware that will

be used to secure the hopper

door section to the cone section.

✐

✒

TIP: Conair recommends applying

strip and stick sealer 1/8 inches

{3.2 mm} from the inside to the

edge of the CH Hopper.

NOTE: When installing the hopper

door section, make sure the hopper door is positioned to allow

easy access into the hopper to

aid in the continuing installation

and to facilitate hopper cleaning

and maintenance in the future.

✐

In s ta ll at io n - Ge ne ra l l 3 -1 3

3

In s tal l a tio n

(continued)

Page 44

Installing the CH Hopper Door,

Upper and Lid Sections (c on tin ue d)

Hoppe r D oo r Section ( co nt in ued )

3 Set the hopper door section on the cone section as shown. As the hopper

door section is positioned on the cone section, make sure the holes in the hopper

door section align with the holes in the cone section.

4 Secure the hopper door section to the cone section using the supplied

hardware.

3- 1 4 l I ns ta ll a ti on - Ge ne r al

(continued)

Page 45

Installing the CH Hopper Door,

Upper and Lid Sections (continued)

Hoppe r U pp er Section(s ) ( I f App l ica b le)

To install the hopper upper section(s) of the CH Hopper:

1 Apply sealer around the lip on the top of the hopper door section.

2 Using a forklift, hoist or crane, lift the hopper upper section assembly

above the hopper door section.

CAUTION: To prevent accident and injury, lift the hopper upper section onto the

hopper door section using a forklift, hoist or crane.

IMPORTANT: Line up the sight glasses of the hopper upper section(s) with the sight

glasses of the hopper door section.

3 Set the hopper upper section on the hopper door section. As the hopper

upper section is positioned on the hopper door section, make sure the holes in

the upper section align with the holes in the door section.

4 Secure the hopper upper section to the hopper door section using the

supplied hardware.

NOTE: If more than one (1) hopper upper section is to be installed, repeat the steps

detailed in this section for each hopper upper section.

✐

NOTE: When applying the sealer,

do not cover the holes in the hopper door section lip. Apply the

sealer around the holes so you will

have a good seal but not interfere

with the mounting hardware that

will be used to secure the hopper

upper section to the hopper door

section.

✐

✒

TIP: Conair recommends applying

strip and stick sealer 1/8 inches

{3.2 mm} from the inside to the

edge of the CH Hopper.

In s ta ll at io n - Ge ne ra l l 3 -1 5

3

In s tal l a tio n

(continued)

Page 46

Installing the CH Hopper Door,

Upper and Lid Sections (continued)

Hoppe r L id Section

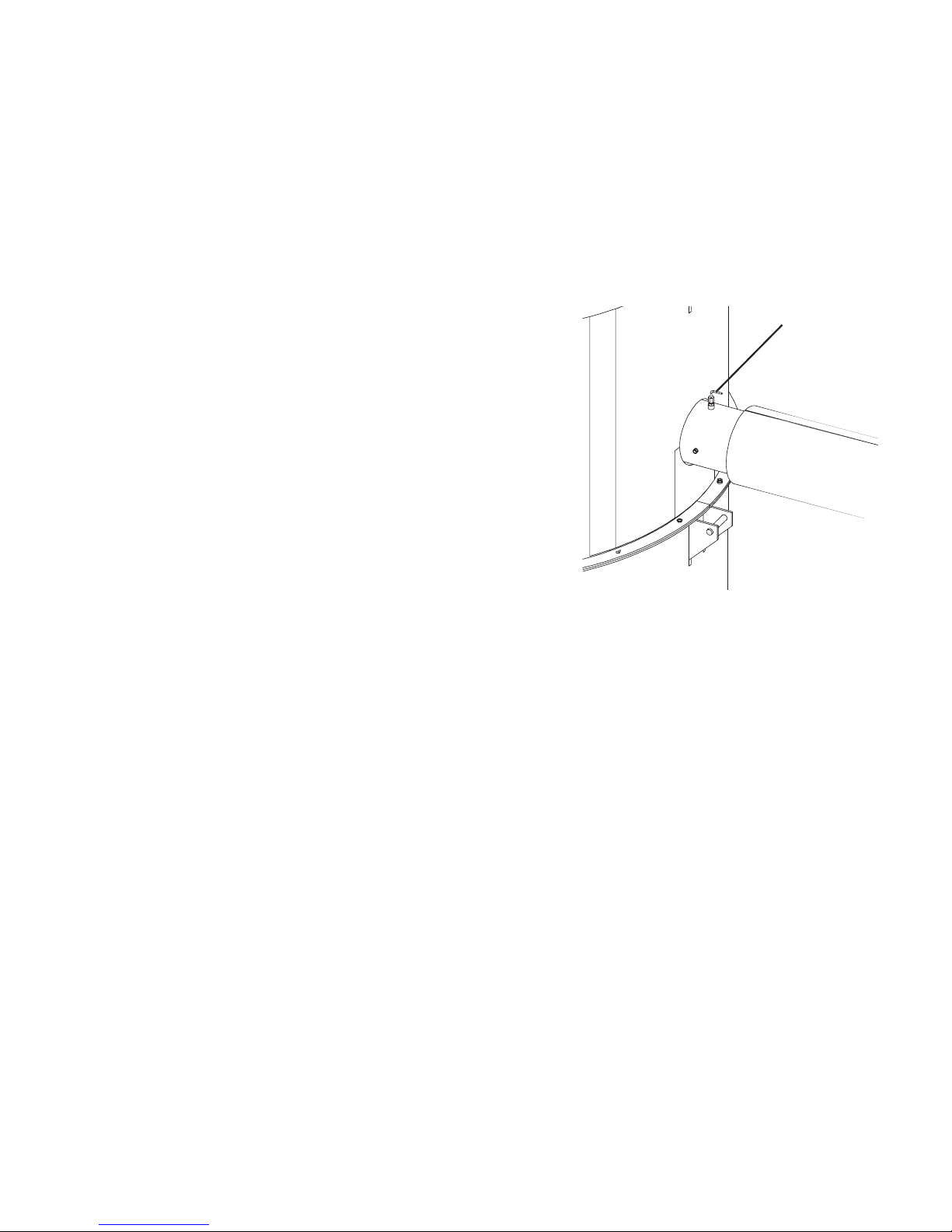

IMPORTANT: Improper mounting of the hopper lid will cause interference when

installing the DM-II monitor probe and optional integrated cyclone. See the illustration below for recommended hopper lid mounting locations.

To install the hopper lid section of the CH Hopper:

1 Apply sealer around the lip on the top of the hopper door or hopper upper

section, if applicable.

2 Using a forklift, hoist or crane, lift the hopper lid section assembly above

the hopper door or hopper upper section.

3 Set the hopper lid section on the hopper door or hopper upper section as

shown below. As the hopper lid section is positioned on the hopper door or

hopper upper section, make sure the holes in the hopper lid section align with

the holes in the hopper door or hopper upper section.

4 Secure the hopper lid section to the hopper door or hopper upper section

using the supplied hardware.

CAUTION: To prevent accident and injury, lift the hopper lid section onto the hopper

door or hopper upper sections using a forklift, hoist or crane.

NOTE: When applying the sealer,

do not cover the holes in the

upper section lip. Apply the sealer

around the holes so you will have

a good seal but not interfere with

the mounting hardware that will

be used to secure the hopper lid

section to the hopper upper

section.

✐

✒

TIP: Conair recommends applying

strip and stick sealer 1/8 inches