Page 1

Carousel Plus Dryer

W Series Models 600 through 5000 with DC-1 Controls

Corporate Office: 724.584.5500 l Instant Access 24/7 (Parts and Service): 800.458.1960 l Parts and Service: 814.437.6861

U S E R G U I D E

UGD035-1216

www.conairgroup.com

Page 2

Please record your equipment’s

model and serial number(s) and

the date you received it in the

spaces provided.

It’s a good idea to record the model and serial number(s) of your equipment and

the date you received it in the User Guide. Our service department uses this information, along with the manual number, to provide help for the specific equipment

you installed.

Please keep this User Guide and all manuals, engineering prints and parts lists

together for documentation of your equipment.

Date:

Manual Number: UGD035-1216

Serial Number(s):

Model Number(s):

See Screens 3 and 4 for Software Version

*Display Firmware Version:

*Control Firmware Version:

* NOTE: Displayed upon initialization, during power up, or on a data tag

inside the door.

DISCLAIMER: Conair shall not be liable for errors contained in this User Guide or for incidental,

consequential damages in connection with the furnishing, performance or use of this information.

Conair makes no warranty of any kind with regard to this information, including, but not limited

to the implied warranties of merchantability and fitness for a particular purpose.

Co p yr ig ht 2 01 6 l Co na ir l A ll r ig ht s re se rv ed

✐

Page 3

Table of Contents

1-1 I ntr odu cti on

Purpose of the user guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

How the guide is organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Using the Carousel Plus W Series as a central dryer . . . . . . . . . . . . 1-3

Your responsibilities as a user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

ATTENTION: Read this so no one gets hurt . . . . . . . . . . . . . . . . . . . 1-4

How to use the lockout device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2-1 D esc rip tio n

What is the Carousel Plus W Series Dryer? . . . . . . . . . . . . . . . . . . .2-2

Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

How it works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Specifications: Carousel Plus W Series Dehumidifying Dryer . . . . . . 2-7

Carousel Plus W Series Dehumidifying Dryer options . . . . . . . . . . . 2-8

3-1 I nst all ati on

Unpacking the boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Positioning the dryer on the floor . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Removing the cable tie from the desiccant wheel (W600-1000) . . . 3-4

Installing the regeneration exhaust cover . . . . . . . . . . . . . . . . . . . . 3-4

Installing the return air adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Installing the return air inlet and air outlet

adapters (W1600-5000) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Installing the overhead process air duct (W3200-5000) . . . . . . . . . 3-7

Connecting the main power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Ta bl e of C on te nt s l i

Page 4

Checking for proper air flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connecting the air hoses to a single hopper (W600-1000) . . . . . . 3-12

Connecting the air hoses to a single hopper (W1600-5000) . . . . . 3-13

Connecting the air hoses to a ResinWorks. . . . . . . . . . . . . . . . . . . 3-14

Connecting the dryer to the hopper . . . . . . . . . . . . . . . . . . . . . . . 3-15

Connecting the dryer to ResinWorks . . . . . . . . . . . . . . . . . . . . . . . 3-15

Connecting air hose adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Connecting the aftercooler and optional precooler (W600-1000). . 3-17

Connecting the intercooler and optional precooler (W1600-5000) . 3-18

Mounting a loader on the hopper . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Testing the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

4-1 O per ati on

Carousel Plus W Series Dryer: control panel DC-1. . . . . . . . . . . . . . 4-2

Carousel Plus W Series Dryer DC-1 control functions . . . . . . . . . . . 4-3

Control function flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Control function descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

To start drying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

To stop drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Using the auto start countdown function. . . . . . . . . . . . . . . . . . . . 4-17

How to disable the auto start on the DC-1 control. . . . . . . . . . . . . 4-17

Using the dewpoint monitor and dewpoint control. . . . . . . . . . . . . 4-18

5-1 M ain ten anc e

Preventative maintenance checklist . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Checking the dewpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Cleaning the hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

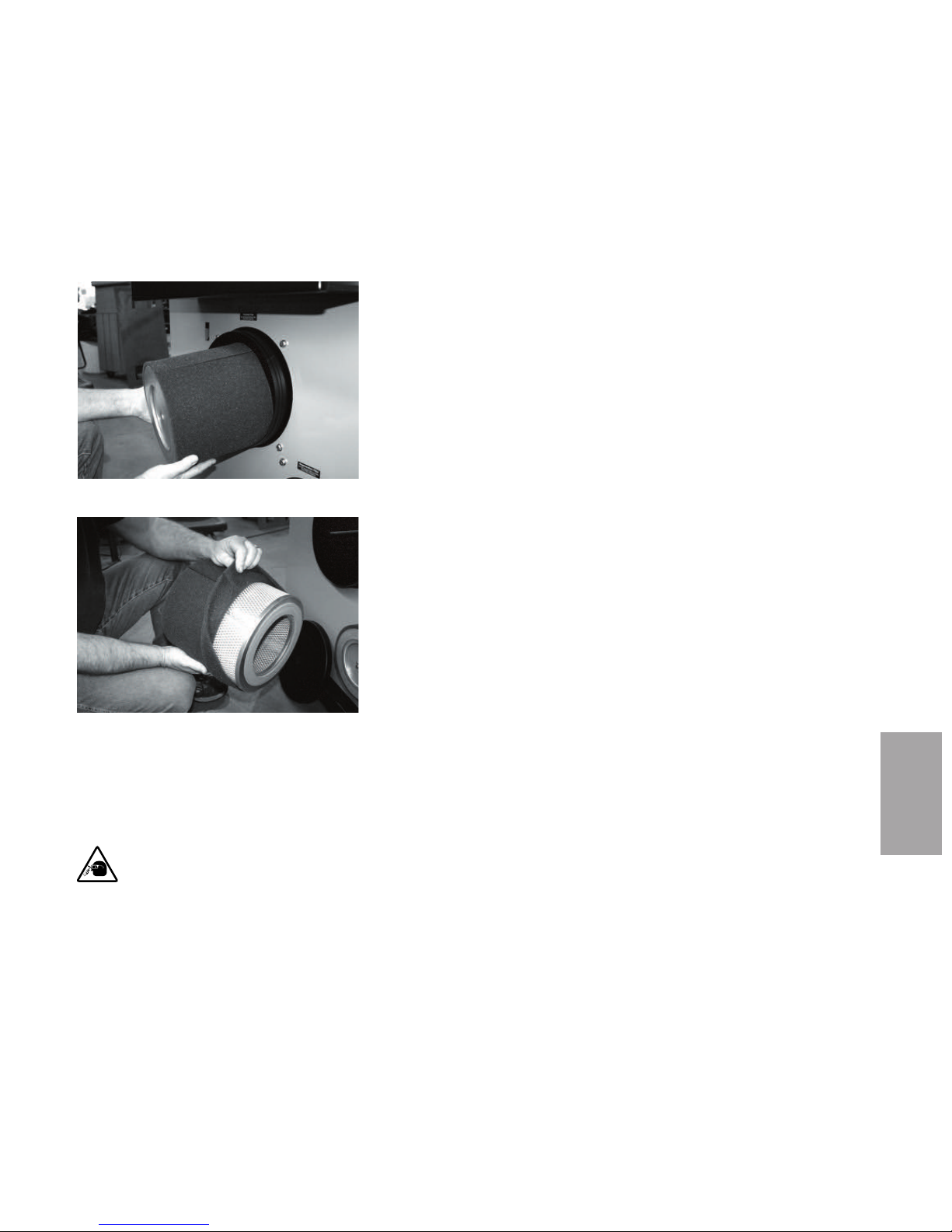

Cleaning the process filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

ii l Tab l e of Co nt en t s

Page 5

Cleaning the regeneration filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Cleaning the aftercooler/intercooler coils . . . . . . . . . . . . . . . . . . . . 5-9

Cleaning the precooler coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Cleaning the volatile trap on the demister . . . . . . . . . . . . . . . . . . . 5-11

Inspecting hoses and gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

6-1 Troubleshoo tin g

Before beginning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

A few words of caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

DIAGNOSTICS

How to identify the cause of a problem . . . . . . . . . . . . . . . . . . . . . 6-4

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Dewpoint troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Poor material drying troubleshooting. . . . . . . . . . . . . . . . . . . . . . . 6-18

REPAIR

Replacing fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Checking heater solid state relays. . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Checking or replacing temperature sensors . . . . . . . . . . . . . . . . . 6-25

Replacing the regeneration heater (W600-1000). . . . . . . . . . . . . . 6-26

Replacing the regeneration heater (W1600-2400). . . . . . . . . . . . . 6-28

Replacing the regeneration heater (W3200-5000). . . . . . . . . . . . . 6-30

Replacing the desiccant wheel assembly (W600-1000). . . . . . . . . 6-32

Replacing the desiccant wheel motor (W600-1000) . . . . . . . . . . . 6-34

Replacing the desiccant wheel motor (W1600-5000) . . . . . . . . . . 6-35

Ta bl e of C on te nt s l i ii

Page 6

iv l Tab l e of Co nt en t s

A App endix

We’re here to help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

How to contact customer service . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Before you call... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Equipment guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Performance warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Warranty limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

B Appendix

Cleaning the precooler coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

C A p pen dix

Cleaning the volatile trap on the demister (W600-1000) . . . . . . . . C-1

Cleaning the volatile trap on the demister (W1600-3200) . . . . . . . C-2

Page 7

Introduction

Purp o se o f t he u ser guid e . . . . . . . . . . . . . . 1-2

How the gu i de i s o rgani z ed . . . . . . . . . . . . . 1-2

Usin g th e C a rouse l P l us W Serie s

as a c entra l d r yer . . . . . . . . . . . . . . . . 1-3

Yo ur r espo n s ibil i ties as a u ser. . . . . . . . . . . 1 -3

ATTE N T ION:

Read th i s s o n o on e g e ts h urt . . . . . . . . 1-4

How to use th e lo c kout dev i ce . . . . . . . . . . . 1- 6

S E C T I O N

1

In t ro du ct io n l 1 -1

1

In t r odu c t ion

Page 8

✐

Purpose of the User Guide

This User Guide describes the Conair Carousel Plus W Series Dryer and

explains step-by-step how to install, operate, maintain, and repair this

equipment.

Before installing this product, please take a few moments to read the User

Guide and review the diagrams and safety information in the instruction

packet. You also should review manuals covering associated equipment

in your system. This review won’t take long, and it could save you valuable installation and operating time later.

How the Guide is Organized

Symbols have been used to help organize the User Guide and call your

attention to important information regarding safe installation and operation.

Symbols within triangles warn of conditions that could be hazardous to users or

could damage equipment. Read and take precautions before proceeding.

Numbers indicate tasks or steps to be performed by the user.

A diamond indicates the equipment’s response to an action performed by the user.

An open box marks items in a checklist.

A circle marks items in a list.

Indicates a tip. A tip is used to provide you with a suggestion that will help you with

the maintenance and the operation of this equipment.

Indicates a note. A note is used to provide additional information about the steps

you are following throughout the manual.

1

◆

❒

•

✒

1- 2 l I n tr od uc ti o n

Page 9

In t ro du ct io n l 1 -3

Using the Carousel Plus W Seri es

as a Central Dr yer

The Conair Carousel Plus W600-5000 Series Dryers are factory configured to

be used as central dryers only. Therefore, this manual incorporates the information necessary to use these dryers for central drying applications.

Your Responsibility a s a User

You must be familiar with all safety procedures concerning installation, operation and maintenance of this equipment. Responsible safety procedures include:

• Thorough review of this User Guide, paying particular attention

to hazard warnings, appendices and related diagrams.

• Thorough review of the equipment itself, with careful attention

to voltage sources, intended use and warning labels.

• Thorough review of instruction manuals for associated equipment.

• Step-by-step adherence to instructions outlined in this User Guide.

1

In t r odu c t ion

Page 10

ATTENTION:

Read this so no one gets hurt

We design equipment with the user’s safety in mind. You can avoid the potential

hazards identified on this machine by following the procedures outlined below and

elsewhere in the User Guide.

WA RNING : Impr o per inst a llati o n, oper ation , or

ser v icing ma y re sult in equi p ment dam a ge o r

perso n al injur y.

This equipment should be installed, adjusted, and serviced by qualified

technical personnel who are familiar with the construction, operation,

and potential hazards of this type of machine.

All wiring, disconnects, and fuses should be installed by qualified electrical technicians in accordance with electrical codes in your region.

Always maintain a safe ground. Do not operate the equipment at power

levels other than what is specified on the machine serial tag and data

plate.

WA RNING : Vo ltage ha z ard

This equipment is powered by three-phase alternating current,

as specified on the machine serial tag and data plate.

A properly sized conductive ground wire from the incoming power

supply must be connected to the chassis ground terminal inside the

electrical enclosure. Improper grounding can result in severe personal

injury and erratic machine operation.

Always disconnect and lock out the incoming main power source before

opening the electrical enclosure or performing non-standard operating

procedures, such as routine maintenance. Only qualified personnel

should perform troubleshooting procedures that require access to the

electrical enclosure while power is on.

1- 4 l I n tr od uc ti o n

(continued)

Page 11

1

In t r odu c t ion

In t ro du ct io n l 1 -5

ATTENTION:

Read this so no one gets hurt

(c on ti nue d)

We design equipment with the user’s safety in mind. You can avoid the potential

hazards identified on this machine by following the procedures outlined below and

elsewhere in the User Guide.

CA UTION : Hot Sur fa c es.

Always protect yourself from hot surfaces inside the dryer and hopper.

Also exercise caution around exterior surfaces that may become hot

during use. These include the hopper door frame, the exterior of an

uninsulated hopper, the return air hose and the dryer’s process filter

housing and moisture exhaust outlet.

WA RNING : Do not plac e a e rosol , compr e ssed

gas or flamm able mate r ials on or near th i s

equip m ent.

The hot temperatures associated with the drying process may cause

aerosols or other flammable materials placed on the dryer or hopper to

explode.

Page 12

1- 6 l I n tr od uc ti o n

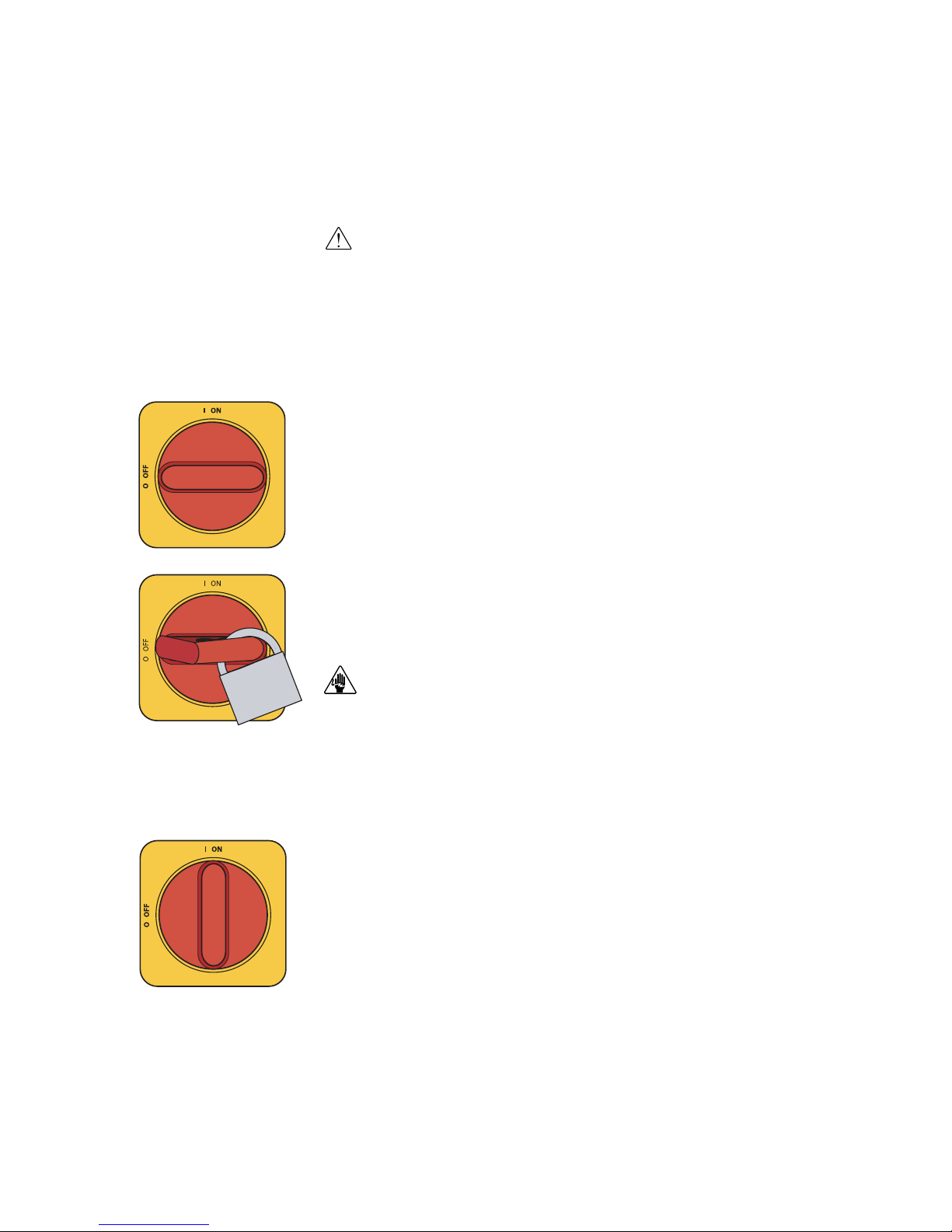

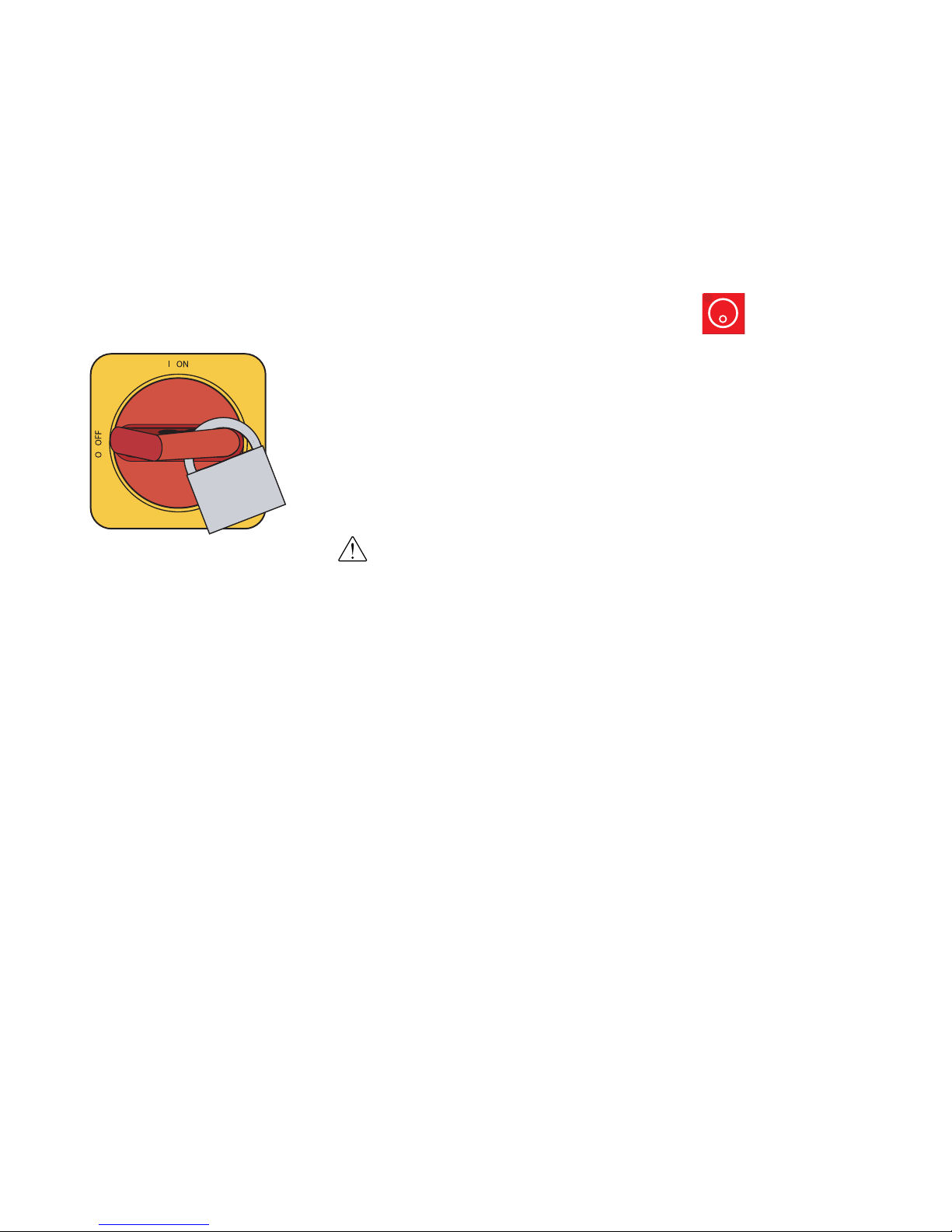

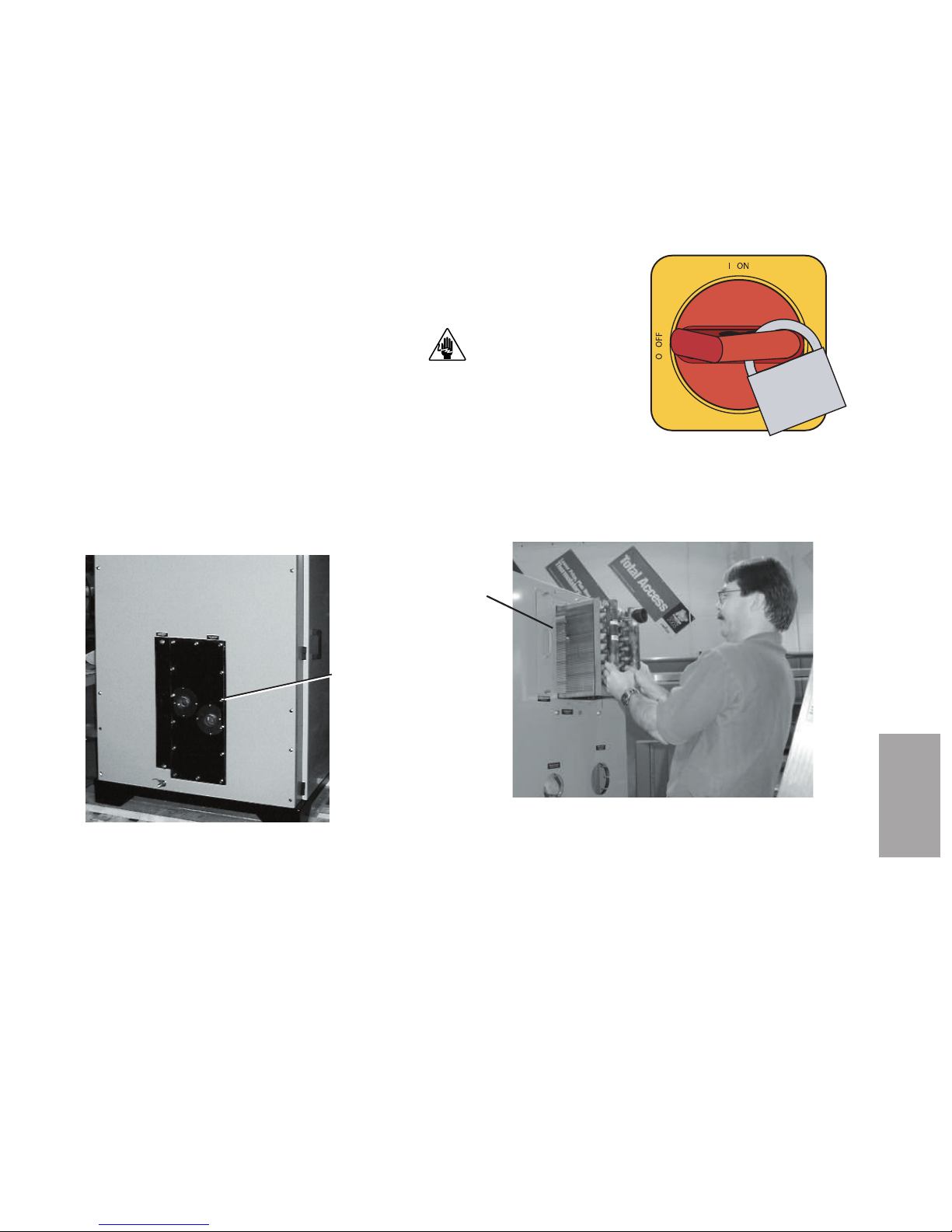

How to Use the Lockout Device

CAUTION: Before performing maintenance or repairs on this product, you should

disconnect and lockout electrical power sources to prevent injury from unexpected

energization or start-up. A lockable device has been provided to isolate this product from potentially hazardous electricity.

Lockout is the preferred method of isolating machines or equipment from energy

sources. Your Conair product is equipped with the lockout device pictured below.

To use the lockout device:

1

Stop or turn off the equipment.

2

Isolate the equipment from the electric power. Turn the rotary

disconnect switch to the OFF, or “O” position.

3

Secure the device with an assigned lock or tag. Insert a lock or tag

in the holes to prevent movement.

4

The equipment is now locked out.

WARNING: Before removing lockout devices and returning switches to the ON

position, make sure that all personnel are clear of the machine, tools have been

removed, and all safety guards reinstalled.

To restore power to the dryer, turn the rotary disconnect back to the ON position:

1

Remove the lock or tag.

2

Turn the rotary disconnect switch to the ON or “I” position.

Page 13

De s cr ip ti on l 2- 1

Description

Wha t is th e C a r ouse l Pl u s W S erie s D r yer ? . . 2-2

Typi c a l a ppli c ati o n s . . . . . . . . . . . . . . . . . . 2- 2

How it wor k s . . . . . . . . . . . . . . . . . . . . . . 2-4

Spec i fica t ions: C arous e l P l us W Seri e s

Dehu m idify i ng Dry e r. . . . . . . . . . . . . . . 2- 7

Caro u sel Plus W Se r ies Dehu m idify i ng

Dr y er o ptio n s . . . . . . . . . . . . . . . . . . . 2-8

S E C T I O N

2

2

De s c rip t i on

Page 14

What is the Carousel Plus W Series

Dryer?

The Carousel Plus W Series dehumidifying dryer produces low-dewpoint air that

removes moisture from hygroscopic plastics. The dryer pulls moist air from a

drying hopper and circulates it through a dehumidifying desiccant wheel. The

dryer then circulates the air through the material in the hopper.

The dryer’s closed-loop design ensures a continuous supply of dehumidified air

while preventing contamination from moisture in the plant.

Typical Applications

1 Dryer on the floor, single hopper (with HTC Hopper Temperature Control

package) on a floor stand.

2 Dryer on the floor, multiple hoppers in central configuration (ResinWorks) with

separate heat source for each hopper.

The Carousel Plus W Series Dryer can be used successfully in applications that

require:

• A contamination-free drying environment.

• A constant flow of dehumidified air.

2- 2 l D e sc ri pt io n

NOTE: The W600 - 5000 pro-

vides no heat to the process

air. A separate heat source is

required at the hopper(s) inlet

to heat the air to the desired

drying temperature.

✐

(continued)

Page 15

De s cr ip ti on l 2- 3

2

De s c rip t i on

Typical Applications ( co nt inu ed )

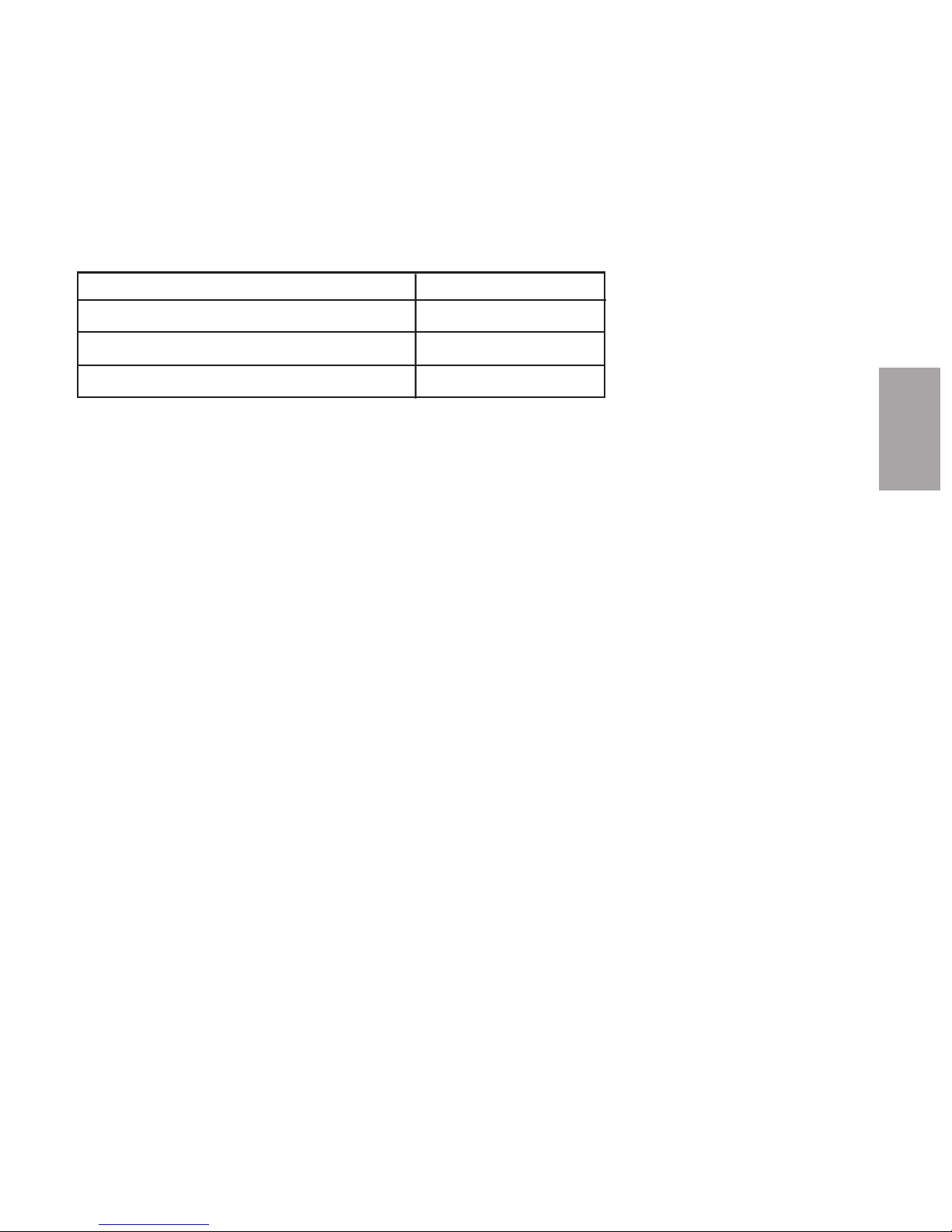

Model Drying Temperature Range

Low temperature (with precooler)* 100° - 150°F {38° - 66°C}

Standard 150° - 240°F {66° - 116°C}

High heat (with aftercooler/intercooler)* 150° - 375°F {66° - 191°C}

Low-high (with aftercooler/intercooler & precooler)* 100° - 375°F {38° - 191°C}

* See page 3-17, 3-18 and Appendix B

• Throughput rates of 600 to 5000 lbs {271 to 454 kg} per hour (some

materials can be ran at a higher rate).

• Dewpoints of -40°F {-40°C}.

Use the aftercooler/intercooler when:

• You are drying at temperatures over 240°F {116°C}.

• Throughput rates are less than 50% of the dryer’s rated capacity.

• You are pre-drying material at temperatures over 150°F {66°C}

• The return air is 120°F {49°C} or above.

Dryer Options

• Dewpoint monitor/dewpoint control

• Audible and visual alarm

NOTE: Temperature setback is only available in conjunction with the Hopper Temperature

Controller (HTC) or ResinWorks systems.

✐

NOTE: The aftercooler/intercooler reduces the temperature of air returning from the drying hopper, improving the efficiency of the desiccant.

✐

NOTE: Carousel Plus W Series 600-1000 Dryers use an aftercooler located before the the process

blower. Carousel Plus W Series 1600-5000 uses an intercooler located after the process blower.

✐

Page 16

How It Works

2- 4 l D e sc ri pt io n

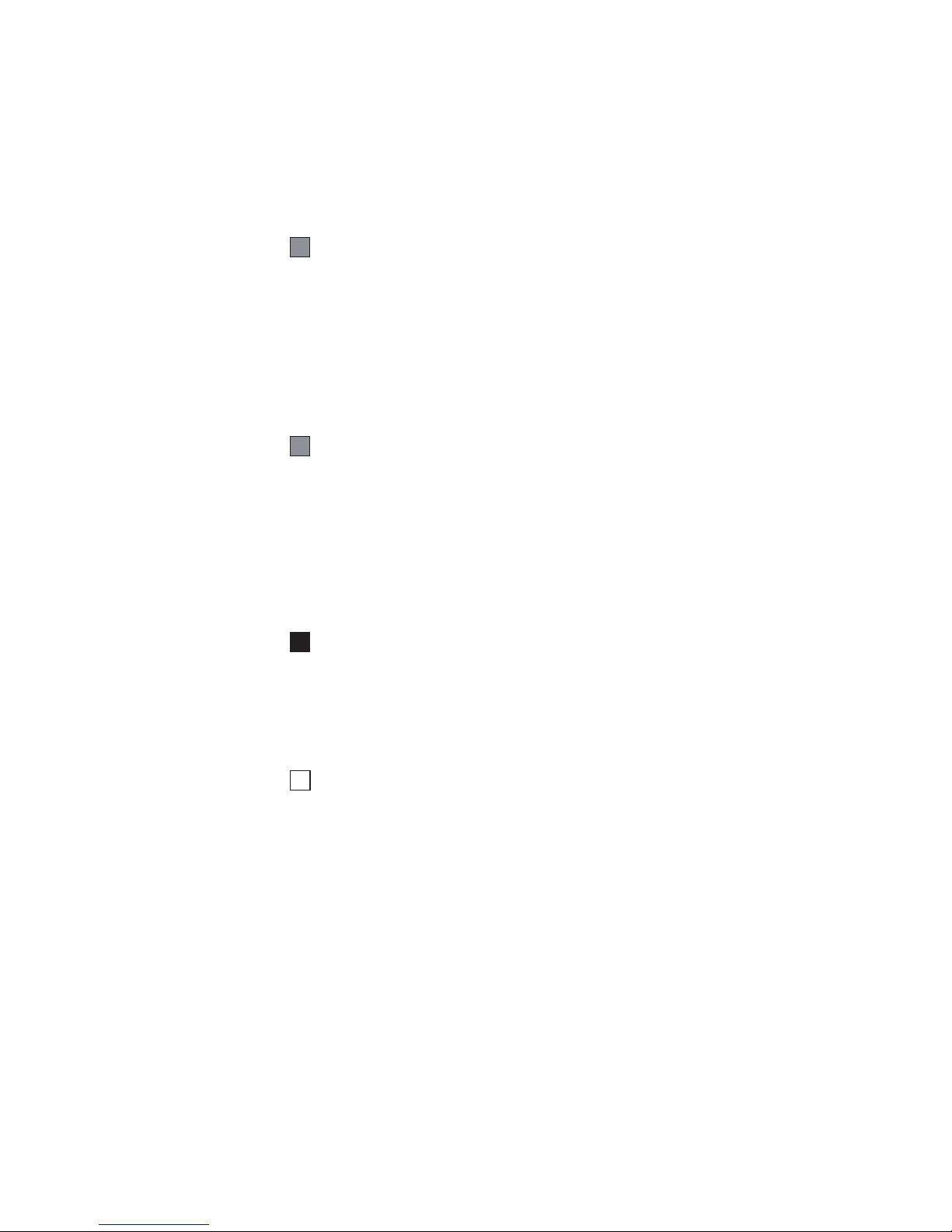

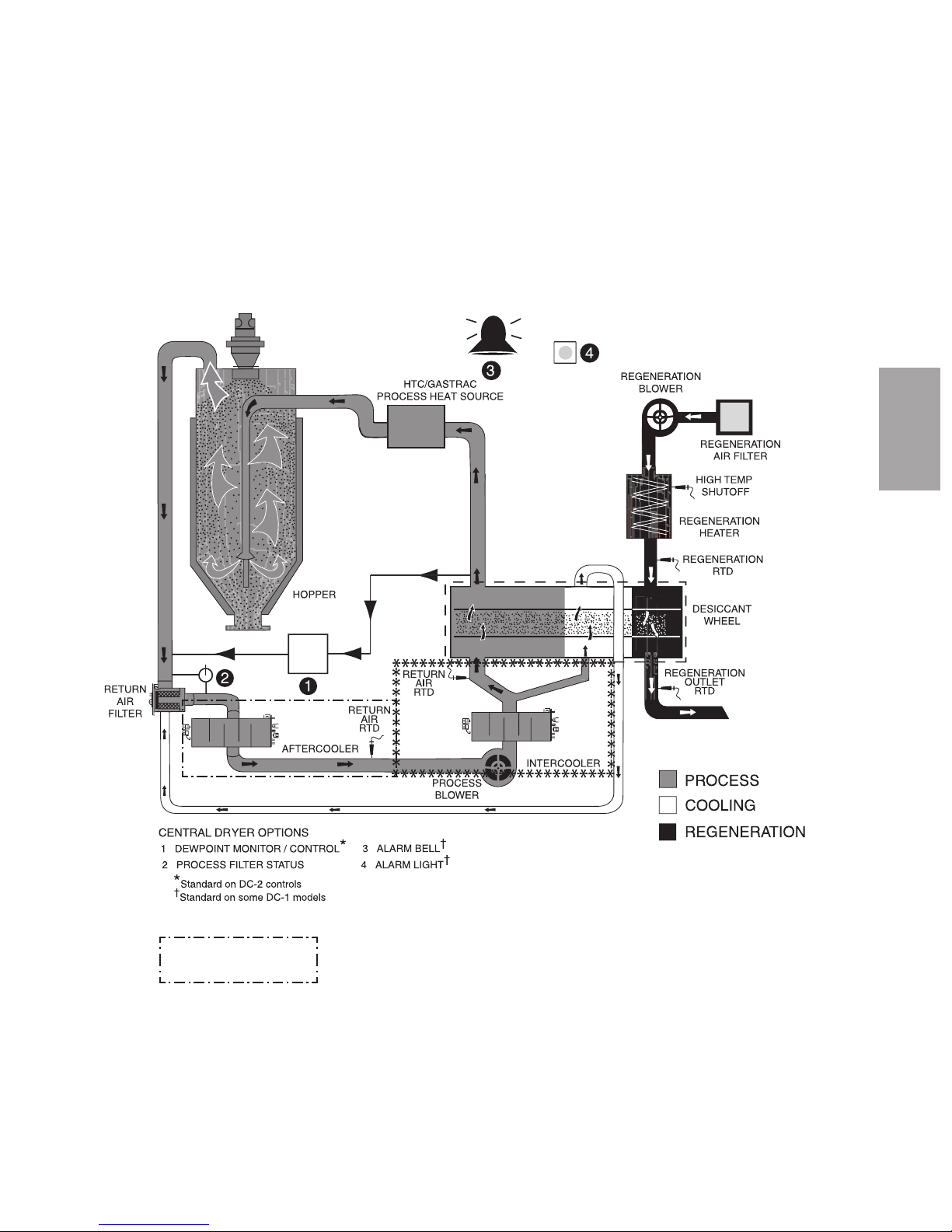

The Process (Drying) Cycle (W1600 - 5000)

Process air from the hopper is pulled into the dryer, through the process filter and

then into the process blower inlet. Air exits the process blower and then enters the

intercooler, then passes through the desiccant wheel, where moisture is removed.

The air exits the dryer and passes through the precooler (if installed), then into the

process heat source (HTC or CGT Gas Unit). After the air exits the process heat

source it then goes into the hopper inlet through internal piping, then to the spreader cone, which evenly distributes the air through the material.

The Cooling Cycle (All models except W2400 and 5000)

Regenerated desiccant must be cooled before it rotates back into the process cycle.

The process blower pushes the process air through the desiccant wheel. A small

amount of the process air is diverted through a small section of the desiccant wheel

to cool the air. The cooling air then returns back to the process air stream at the

start of the process cycle.

The Regeneration Cycle

The regeneration blower pulls air through the regeneration filter into the dryer’s

regeneration heater. The air is heated to 350°F {177°C} before it is pushed into the

“wet” section of the desiccant wheel. The hot air purges moisture from the

desiccant. The moist air is blown out the moisture exhaust at the top of the dryer.

The Process (Drying) Cycle (W600 - 1000)

Process air from the hopper is pulled into the dryer, through the process filter and

then into the process blower inlet. Air exits the process blower and then enters the

aftercooler, then passes through the desiccant wheel, where moisture is removed.

The air exits the dryer and passes through the precooler (if installed), then into the

process heat source (HTC or CGT Gas Unit). After the air exits the process heat

source it then goes into the hopper inlet, then to the spreader cone, which evenly

distributes the air through the material.

Page 17

2

De s c rip t i on

How It Works (c on tin ued )

(W600 - 1 6 0 0 and 3 2 0 0 )

De s cr ip ti on l 2- 5

W-series 1600-5000

intercooler location only.

W-series 600-1000

aftercooler location.

NOTE: Earlier W1600-5000 dryers will have their intercoolers in the W6001000 location.

✐

NOTE: Carousel Plus W Series 600-1000 Dryers use an aftercooler located

before the the process blower. Carousel Plus W Series 1600-5000 dryers

use an intercooler located after the process blower.

✐

**********************

**********************

******

******

Page 18

2- 6 l D e sc ri pt io n

How It Works (c on tin ued )

(W2400 and 5 0 0 0 )

Protected under

United States Patent

No. 7,101,414 and

other US and Foreign

Patents Pending.

.

NOTE: Carousel Plus W Series 600-1000 Dryers use an

aftercooler located before the the process blower. Carousel

Plus W Series 1600-5000 dryers use an intercooler located

after the process blower.

✐

Power Purge

W 2400 and 5000 models have a Power Purge (cooling fan)

feature integral to the desiccant wheel assembly.

Page 19

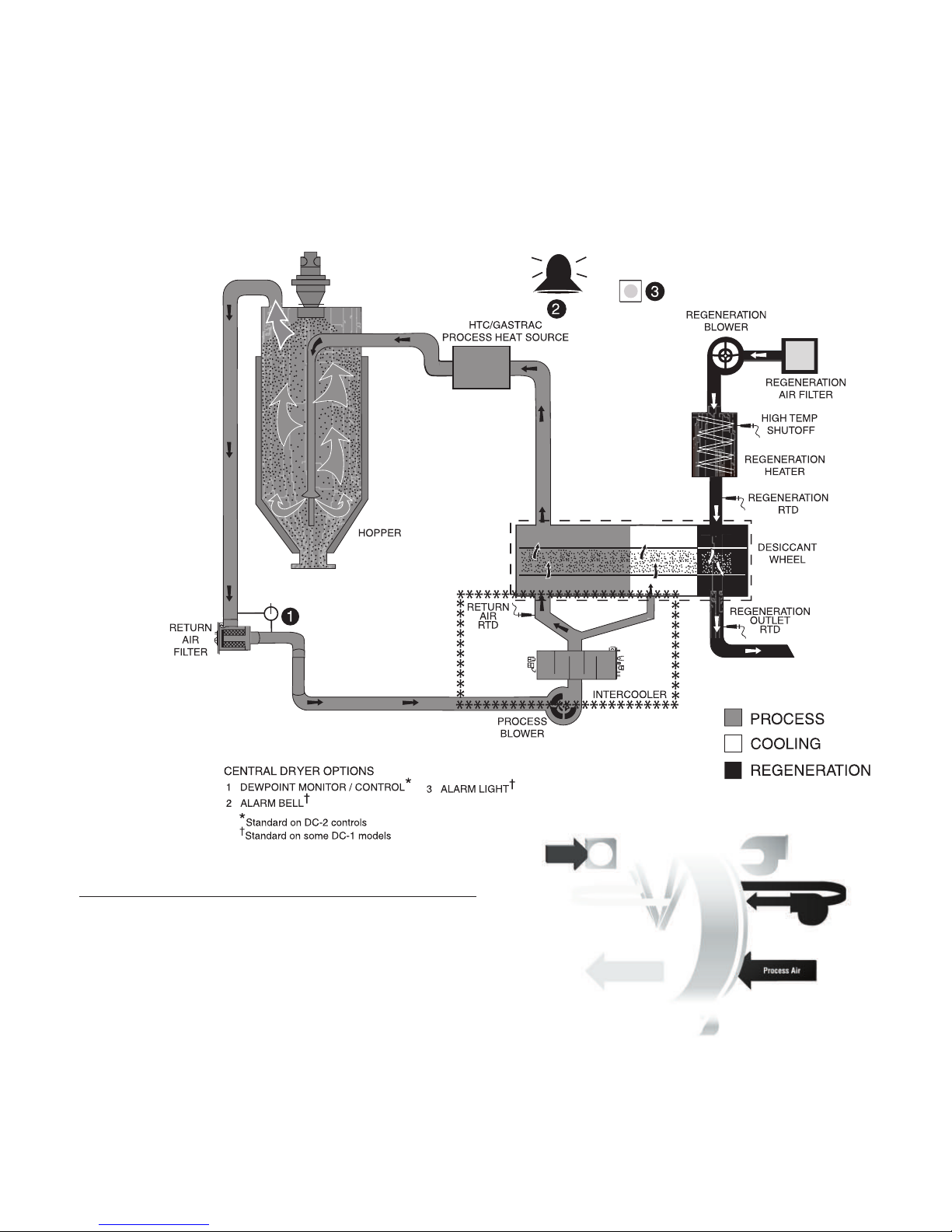

Specifications: Carousel Plus W

Series Dehumidifying Dryers

C

A

B

De s cr ip ti on l 2- 7

2

De s c rip t i on

TPDS019-0311-REV

MODELS W600* W800* W1000

*

W1600

*††

W2400

*††

W3200

*††

W5000

*

††

Performance characteristics (with full hopper)

Drying temperature All models 100 - 375°F {38 - 191°C} with options

Dewpoint All models -40°F {-40°C}

Dimensions inches {cm}

A - Height 92.6 {235.2} 95.5 {242.6} 102.8 {261.1}

B - Width 43.3 {109.9} 48.3 {122.7} 48.9 {124.2}

C - Depth 57.6 {146.3} 86.2 {218.9} 112.0 {284.5}

Outlet/inlet hose diameter 8 {20.3} 12 {30.5} 12 {30.5}

Approximate weight lbs {kg}

Installed 1300 {590} 1300 {590} 1400 {636} 1600 {726} 1600 {726} 2000 {907} 2000 {907}

Shipping 1495 {678} 1515 {687} 1515 {687} 2100 {953} 2620 {1188} 3385 {1535} 3385 {1535}

Voltage - Full load amps

400 V/3 phase/50 Hz† 37.2 37.2 37.5 64.7 73.7 122.3 128.0

460 V/3 phase/60 Hz 32.0 32.0 32.2 56.3 63.1 106.6 111.0

575 V/3 phase/60 Hz 25.6 25.6 25.7 45.0 50.5 85.3 89.1

Water requirements {for aftercooler/intercooler or optional precooler}

§

Recommended temperature

**

45°- 85°F {7- 29}

Water flow gal./min. {liters/min.} 6-25 {22.7-94.6} 12-40 {45.4-151.4} 15-50 {56.8-189.3}

Water connections NPT 1 1/2 in. NPT

SPECIFICATION NOTES:

* Dryers W600-W5000 are central dryers and do not have process heaters. Hopper Temperature Controllers (HTC’s) or ResinWorks systems are used at the

hopper for heating the process air. See the Hopper Temperature Controller (HTC) specification sheet for additional information.

†

Dryers running at 50 Hz will have 17% less airflow, and a 17% reduction in material throughput.

‡ Total kW listed at a regeneration temperature of 350°F {177°C}.

§ When drying below 150 °F {66°C} a precooler is required. When drying above 180°F {82°C} an aftercooler/intercooler and insulated drying hose is

required.

** Temperatures above or below the recommended levels may affect dryer performance. Tower, chiller or municipal water sources can be used.

††

Models W1600-5000 do not have casters.

Specifications may change without notice. Consult a Conair representative for the most current information

.

Page 20

2- 8 l D e sc ri pt io n

Carousel Plus W Series

Dehumidifying Dr yer Options

• Volatile trap (only in conjunction with aftercooler/intercooler) - The volatile

trap is recommended if drying materials that produce volitales that condense

into a waxy or oily residue and/or if the material contains excessive fines.

• Precooler - The precooler reduces the temperature of air after the desiccant

wheel and before the process heater, which enables the dryer to control

temperatures at low setpoints, (100º - 150ºF {38º - 66ºC})

• Filter check - The filter check sensor will activate a passive alarm when the

process filter is clogged or needs to be replaced.

NOTE: Temperature setback is only available in conjunction with the Hopper Temperature

Controller (HTC) or the ResinWorks system.

✐

Page 21

In s ta ll at io n l 3 -1

Installation

Unpa c king the box e s . . . . . . . . . . . . . . . . . 3-2

Prep a ring for ins t alla t ion . . . . . . . . . . . . . . 3-3

Po siti o n ing the dr y er on the floo r . . . . . . . . . 3-4

Remo v ing the cabl e t i e f r om the

desi c cant whe e l ( W 600- 1 0 00) . . . . . . . . 3-4

Inst a lling th e re g enera tion exh a ust cove r . . . 3 -4

Inst a lling th e re t urn air ada p ter . . . . . . . . . . 3-5

Inst a lling th e re t urn air inl e t a n d a ir o utle t

ada p ters (W1 6 00-50 0 0) . . . . . . . . . . . . 3-6

Inst a lling th e Ov e rhead Pr o cess A i r D u ct

(W32 0 0-500 0 ) . . . . . . . . . . . . . . . . . . . 3-7

Conn e cting th e ma i n p ower . . . . . . . . . . . . . 3-8

Chec k ing for prop e r a ir f low . . . . . . . . . . . . 3 -9

Conn e cting th e ai r h o ses to a s i ngle

hopp e r ( W 600- 1 000) . . . . . . . . . . . . . . 3-12

Conn e cting th e ai r h o ses to a s i ngle

hopp e r ( W 1600 - 5000) . . . . . . . . . . . . . 3-13

Conn e cting th e ai r h o ses to a

Resi n Wo r ks . . . . . . . . . . . . . . . . . . . . 3-14

Conn e cting th e dr yer to the hop p er . . . . . . 3 -15

Conn e cting th e dr yer to Resi n Wo rks . . . . . . 3-15

Conn e cting ai r ho s e a dapt e rs . . . . . . . . . . 3 -16

Conn e cting th e af t erco o l er and opti o nal

prec o oler (W6 0 0-100 0 ) . . . . . . . . . . . . 3 - 17

Conn e cting th e in t erco o l er and opti o nal

prec o oler (W1 6 00-50 0 0) . . . . . . . . . . . 3 - 1 8

Moun t ing a l oader on th e ho p per . . . . . . . . 3- 1 9

Te sting th e in s tall a tion . . . . . . . . . . . . . . . 3- 1 9

S E C T I O N

3

3

In s t all a t i on

Page 22

3- 2 l I n st al la ti on

Unpacking the Boxes

The Carousel Plus W Series Dryer comes in one to four boxes, depending on the

model and options ordered. The box(es) could include (depending on the options

selected):

• Carousel Plus W Series Dryer

• Delivery air hose

• Return air hose

• User Guide

1 Carefully remove the dryer and components from their shipping

container(s). Note that the dryer is secured to its shipping container with metal

bands that pass through the bottom of the dryer frame.

2 Unbolt any additional items secured to the shipping pallet, such as the

regeneration exhaust cover and return air adapter. (Carousel Plus W Series

1600-2400 Dryers will have a dry air delivery adapter. Carousel Plus W Series

3200-5000 Dryers will have a dry air delivery adapter and an overhead process

air duct.)

3 Remove all packing material, protective paper, tape, and plastic.

4 Cut and remove the desiccant wheel tie securing the wheel assembly.

(W600-1000)✎

5 Carefully inspect all components to make sure no damage occurred during

shipping, and that you have all the necessary hardware.

Page 23

In s ta ll at io n l 3 -3

Unpacking the Boxes ( co nti nue d)

6 Take a moment to record serial numbers and electrical power specifications

in the blanks provided on the back of the User Guide’s title page. The

information will be helpful if you ever need service or parts.

7 You are now ready to begin installation.

Follow the preparation steps on the next page, then choose one of the two

mounting options:

• Dryer on the floor, single hopper (with HTC Hopper Temperature Control

package) on a floor stand.

• Dryer on the floor, multiple hoppers in central configuration (ResinWorks)

with separate heat source for each hopper.

3

In s t all a t i on

NOTE: The W600 - 5000 provides no heat to the process air. A separate heat source is

required at the hopper(s) inlet to heat the air to the desired drying temperature.

✐

Preparing for Instal lation

The Carousel Plus W Series Dryer is easy to install if you plan the location and

prepare the mounting area properly.

1 Make sure the mounting area provides:

❒

A grounded power source supplying the voltage and correct current

for your dryer model. Check the dryer’s serial tag (on the control box) for

the correct amps, voltage, phase, and cycles. Field wiring should be completed by a qualified personnel to the planned location for the dryer. All

electrical wiring should comply with your region’s electrical codes.

❒

A source of water, when using the aftercooler/intercooler and/or pre-

cooler. The W Dryer’s aftercooler/intercooler and precooler require

tower, city, or chiller water at temperatures of 45° to 85°F {7° to 29°C}.

Refer to the Specifications Sheet (page 2-7) for flow rate for your unit.

Piping should be ran to the planned dryer location. Use flexible hose to

connect the water pipes to the aftercooler/intercooler and/or optional precooler.

❒

Minimum clearance for safe operation and maintenance. You should

maintain 24 in. {61 cm} clearance on all sides of the dryer.

Material and conveying lines

installed. If you plan to use

vacuum or compressed air

loaders to fill the hopper,

install conveying lines to the

drying hopper location.

✒

NOTE: The aftercooler/intercooler reduces the temperature

of air returning from the drying

hopper, improving the efficiency of the desiccant.

✐

Page 24

3- 4 l I n st al la ti on

Posit ioning the Dr yer on the Floor

1 Lift the dryer from the shipping container using a fork truck.

2 Position the dryer on the floor near the hopper or ResinWorks sled. Make

sure the location allows for the connection of all hoses, keeping hose lengths as

short as possible.

Removing the Cable Tie from the

Desiccant Wheel (W600-1000)

1 Open the dryer side panels and remove the cable tie securing the desiccant

wheel, if it was not done while unpacking the dryer.

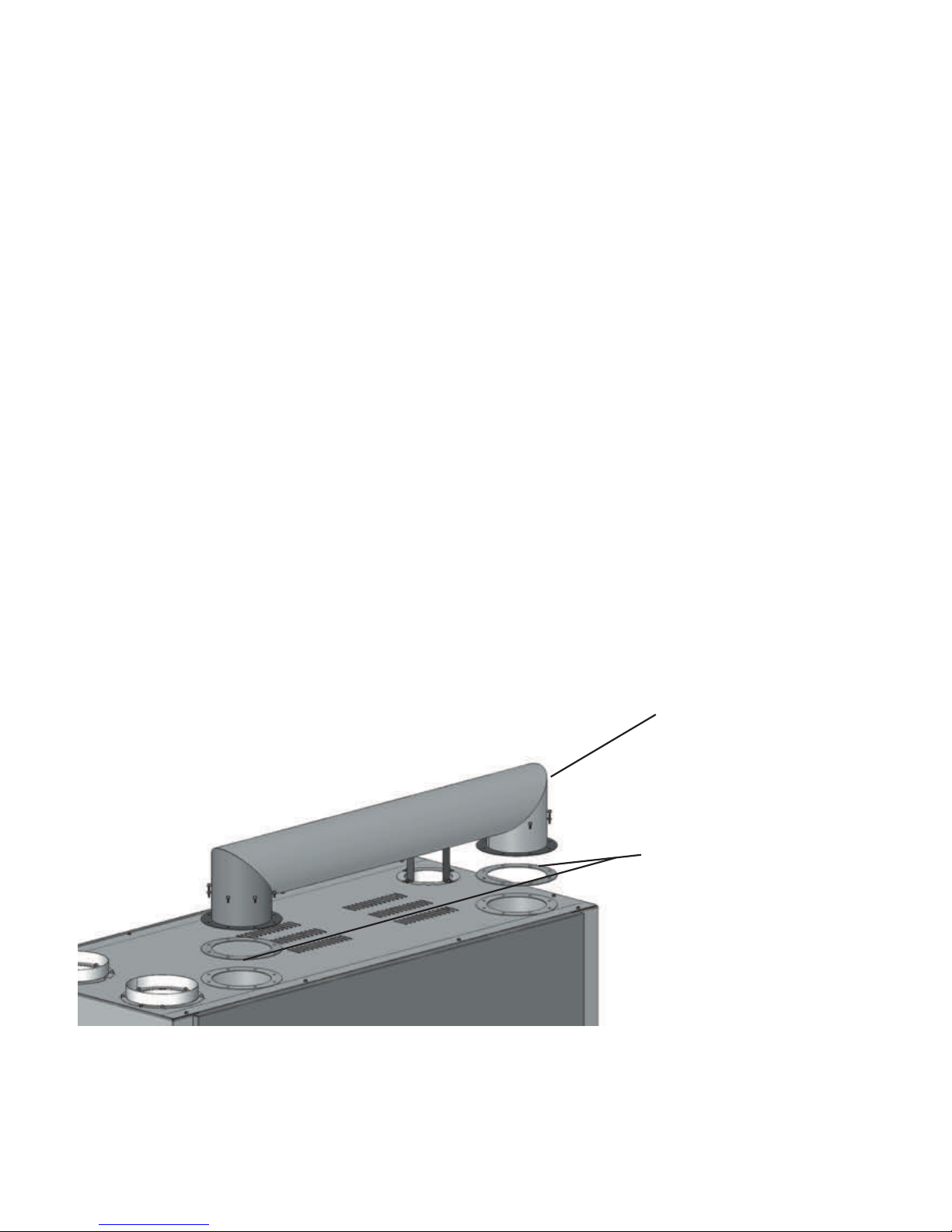

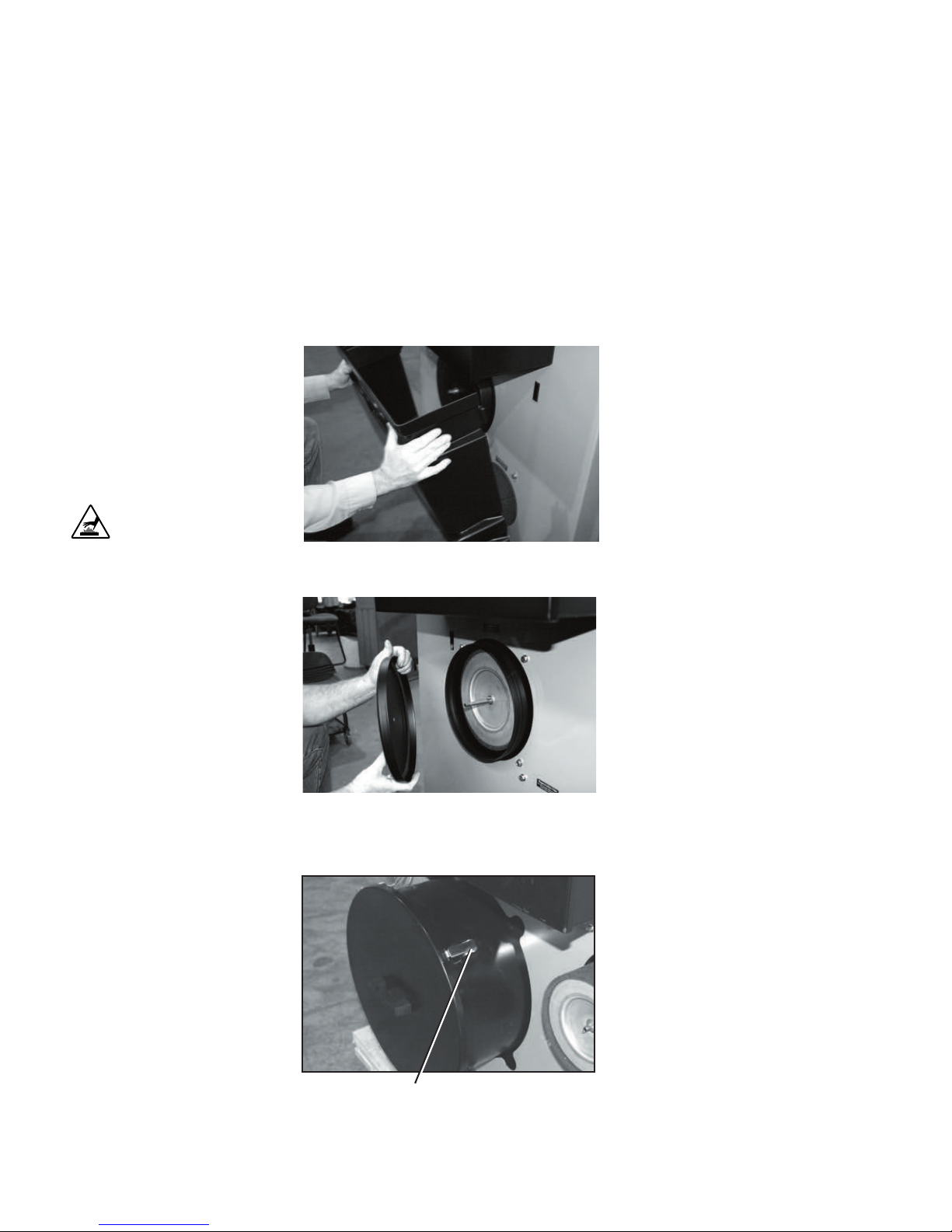

Installing the Regen eration

Exhaust Cover

The Carousel Plus W Series Dryer’s regeneration exhaust cover must be installed.

To install the regeneration exhaust cover:

1 Remove the exhaust cover that is attached to the dryer’s shipping pallet.

2 Locate the bolt pattern at the top of the dryer, on top of the regeneration

exhaust outlet.

3 Position the regeneration exhaust cover on top of the regeneration exhaust

outlet, aligning both bolt patterns.

4 Secure the regeneration exhaust cover with supplied hardware, using an

appropriately sized wrench.

Desiccant Cable Tie

Regeneration

Exhaust Cover

Page 25

3

In s t all a t i on

In s ta ll at io n l 3 -5

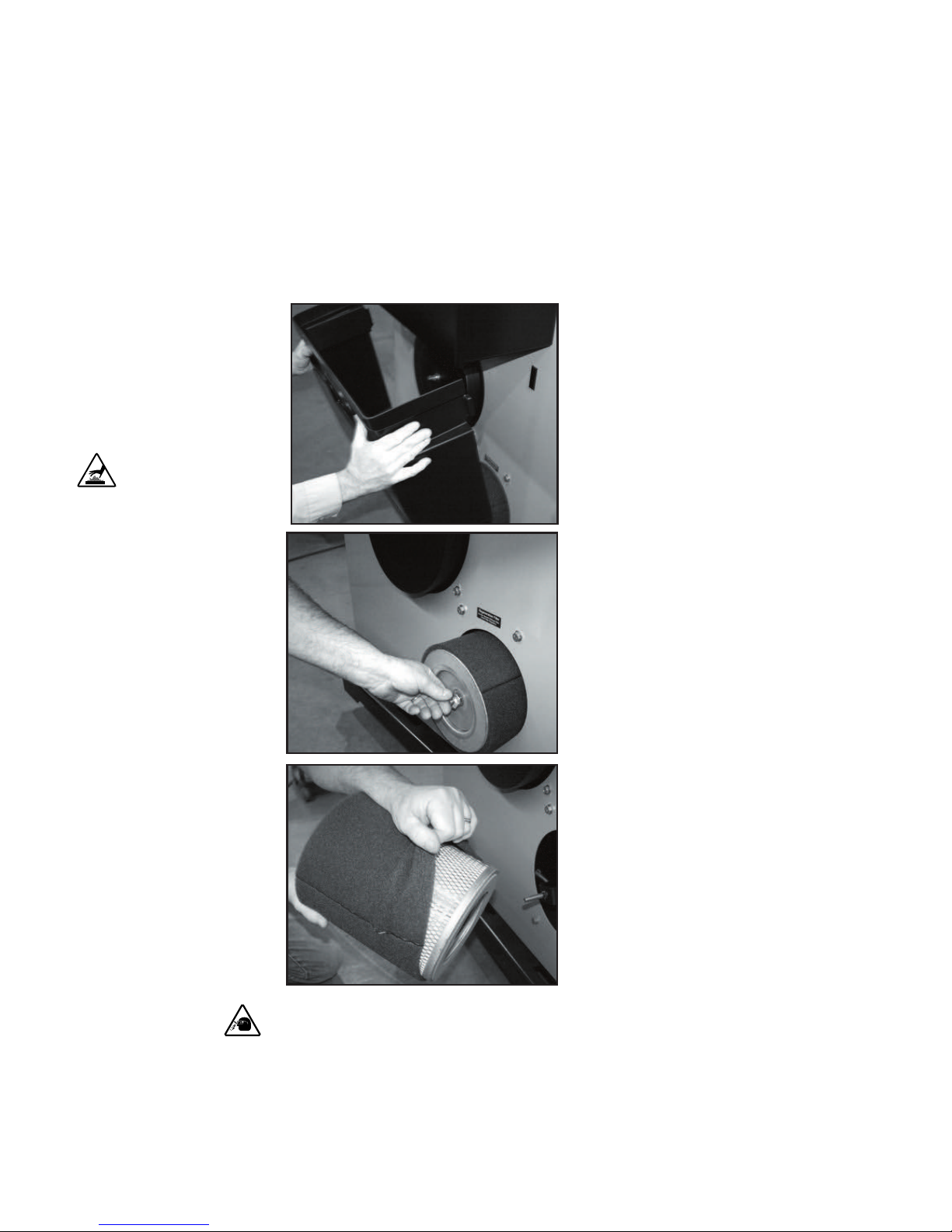

Installing the Retur n Air Adapter

(W600 - 1 0 0 0 )

The Carousel Plus W Series Dryer’s return air adapter must be installed.

To install the return air adapter:

1 Remove the return air adapter that is attached to the dryer’s shipping

pallet.

2 Locate the bolt pattern on the top of the dryer, on top of the return air inlet.

3 Position the return air adapter on top of the return air inlet, aligning both

bolt patterns.

4 Secure the return air adapter with supplied hardware, using an appropriate-

ly sized wrench.

Return Air

Inlet Adapter

Page 26

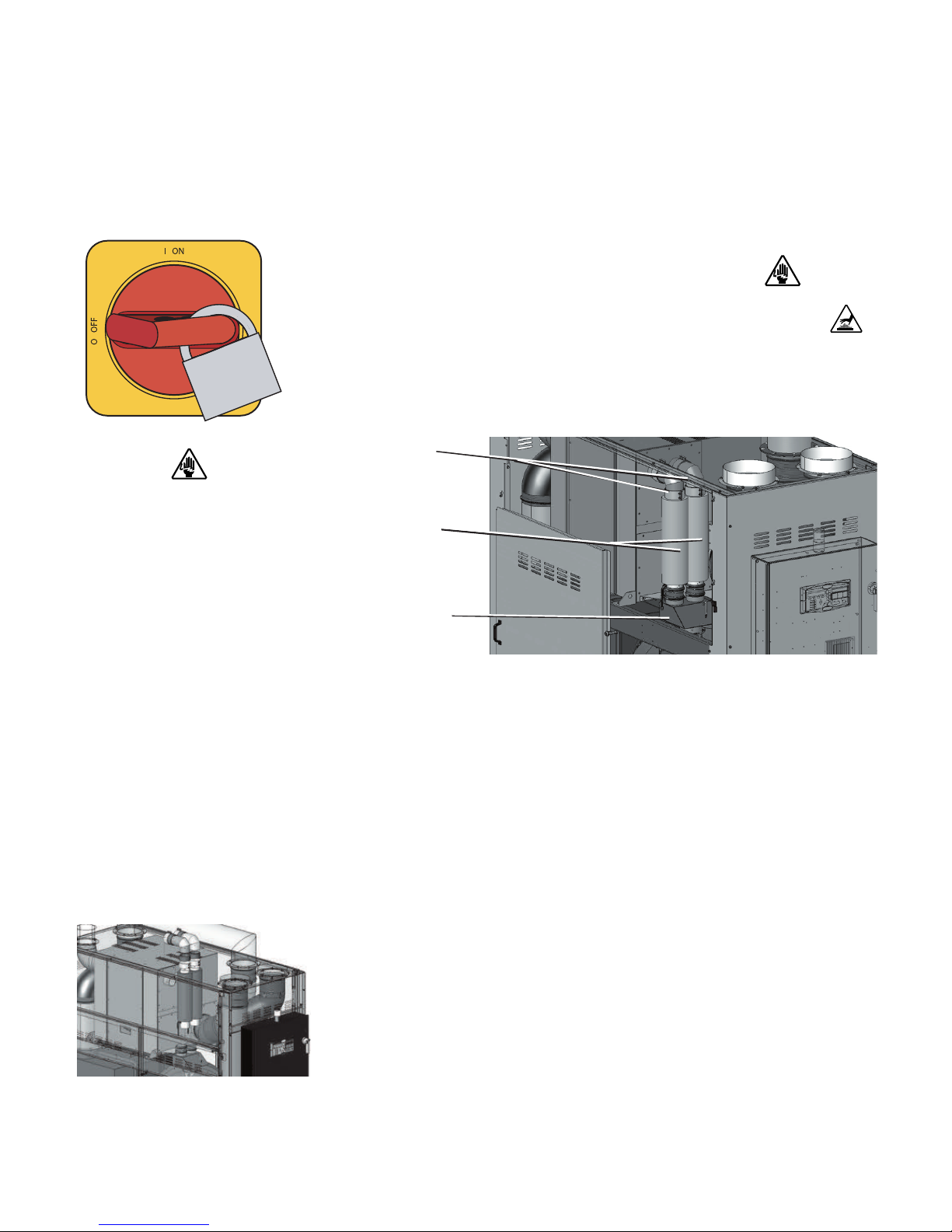

Installing the Retur n Air Inlet and

Air Outlet Adapters (W1600 - 5000)

The Carousel Plus W Series Dryer’s return air inlet and air outlet adapters will be

removed when the dryer is shipped

To install the return air inlet and air outlet adapters:

1 Remove the return air inlet and air outlet adapters that are attached to the

dryer’s shipping pallet.

2 Locate the bolt patterns on the top of the dryer, on top of the return air inlet

and air out outlet.

3 Position the return air adapter on top of the return air inlet, aligning both

bolt patterns.

4 Secure the return air adapter with supplied hardware, using an appropriate-

ly sized wrench.

5 Position the air inlet adapter on top of the inlet air inlet, aligning both bolt

patterns.

6 Secure the air inlet adapter with supplied hardware, using an appropriately

sized wrench.

3- 6 l I n st al la ti on

Dry Air

Outlet

Adapter

Return Air

Inlet Adapter

Page 27

Installing the Overh ead Process Air

Duct (W3200 - 5000)

The Carousel Plus W Series Dryer’s overhead process air duct will be removed

when the dryer is shipped.

To install the overhead process air duct:

1 Remove the overhead process air duct that is attached to the dryer’s ship-

ping pallet. The piping will be shipped as one unit with included gaskets (2).

2 Locate the bolt patterns on the top of the dryer, over top of the overhead

process air duct inlet and outlet.

3 Position the overhead process air duct on top of the overhead process air

duct inlet and outlet making sure to place supplied gaskets between the

overhead process air duct and the inlet and outlet of the dryer, align all bolt

patterns.

4 Secure the piping with supplied hardware, using an appropriately sized

wrench.

In s ta ll at io n l 3 -7

Overhead Process Air

Duct

Gaskets (2)

Page 28

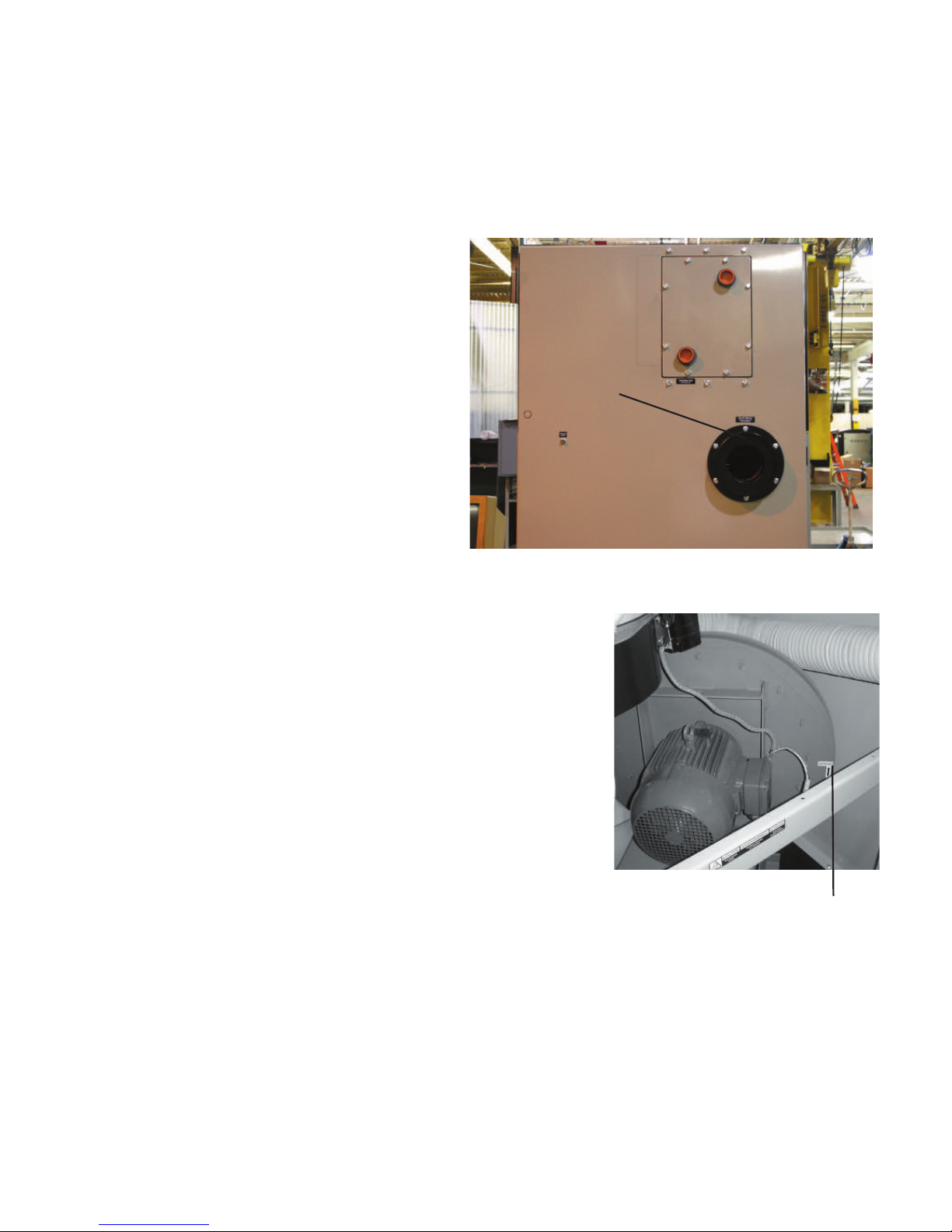

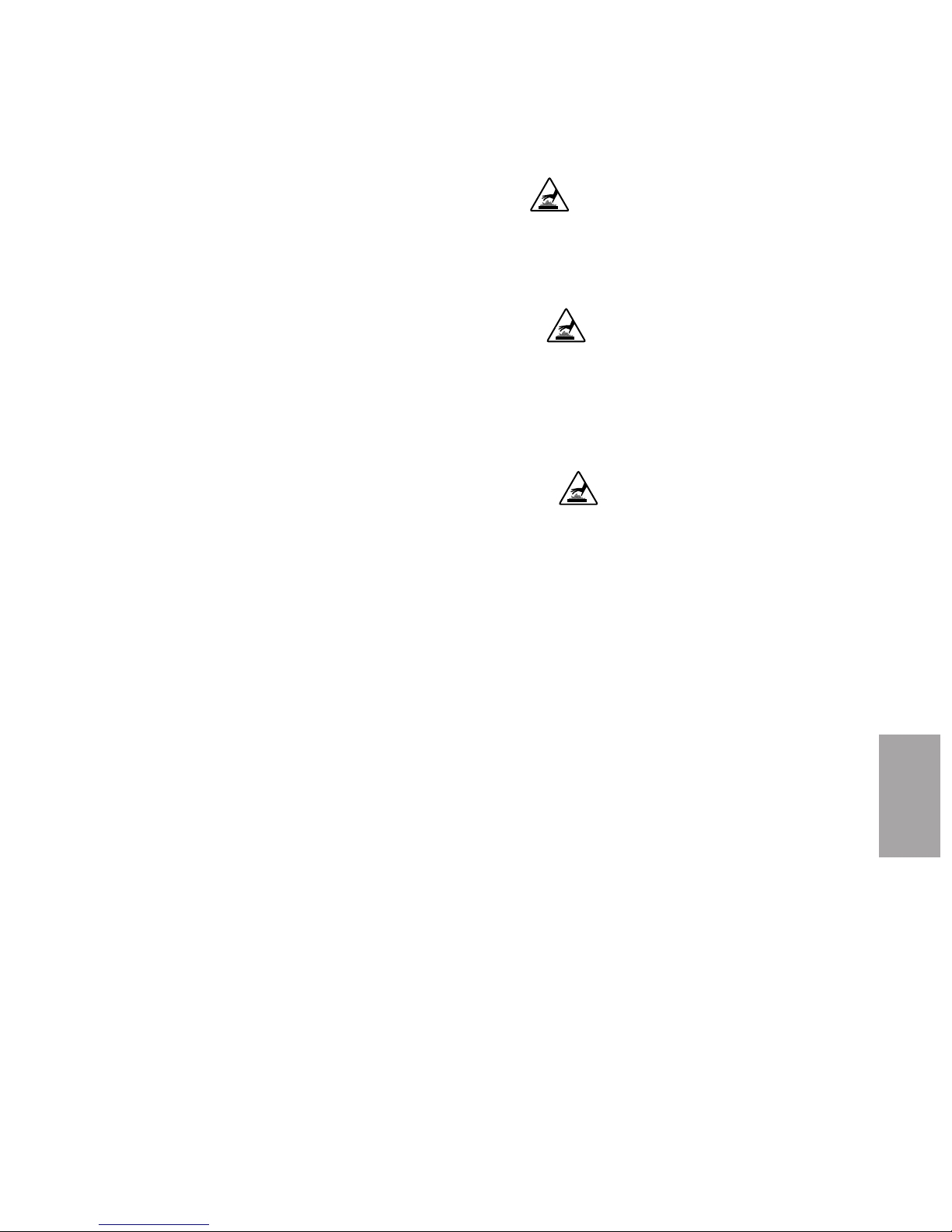

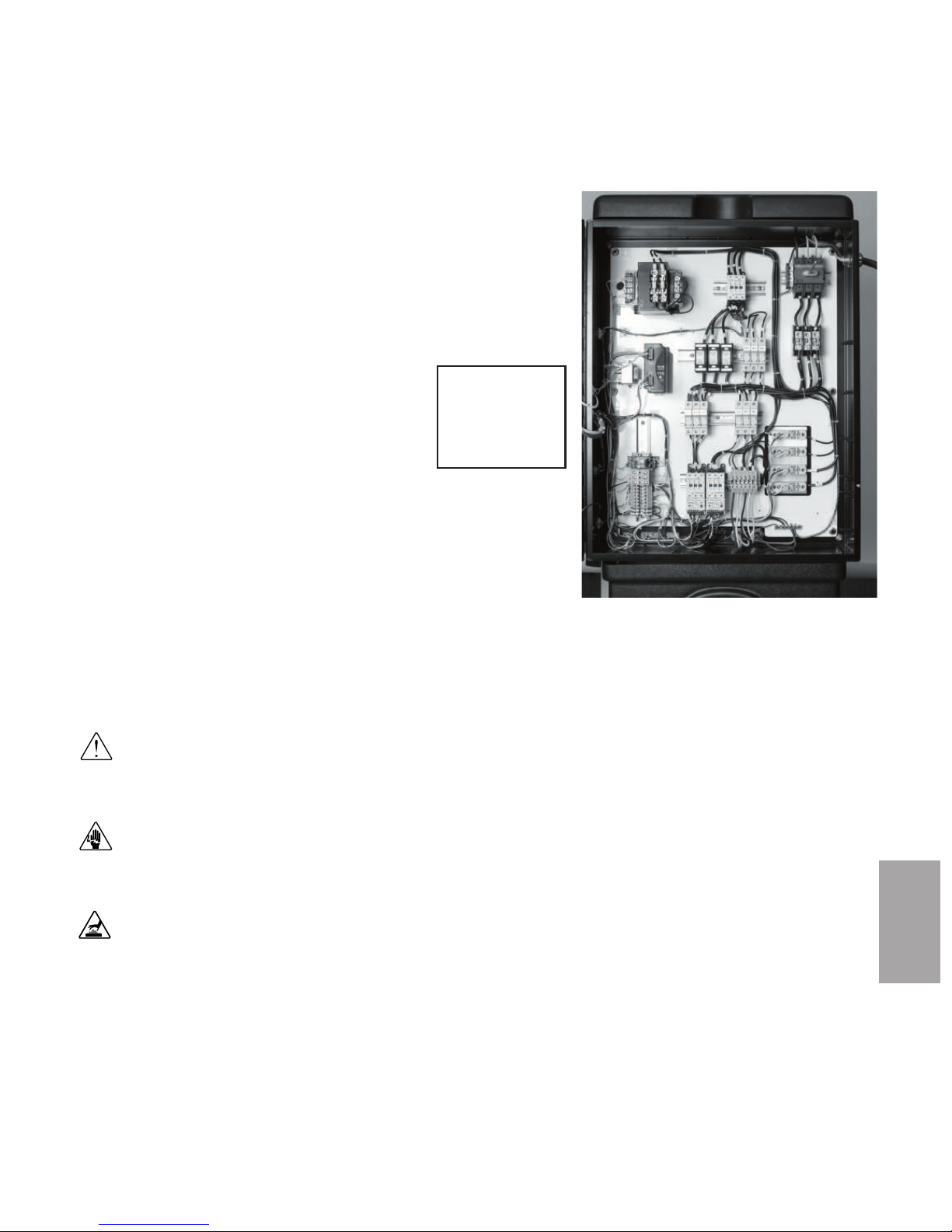

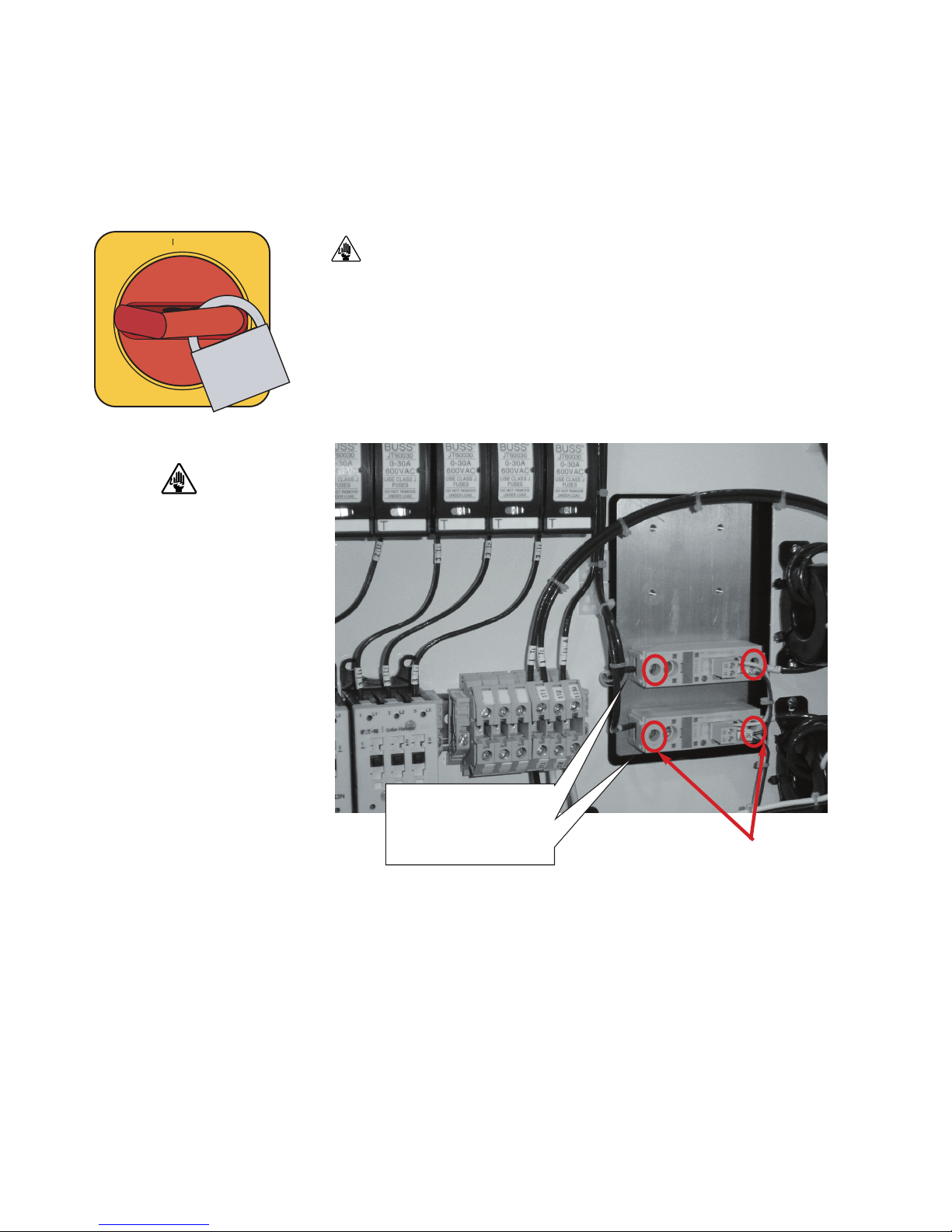

Connecting the Main Power

CAUTION: Always disconnect and lock out the main power sources before mak-

ing electrical connections. Electrical connections should be made only by qualified

personnel.

1 Open the dryer’s electrical enclosure. Turn

the disconnect dial on the dryer door to the Off

or “O” position. Lock out the main power (see

Page 1-6 for complete lock out information).

Turn the captive screw, and swing the door

open.

2

Insert the main power

wire through the knock-

out in the side of the enclosure or the rear of the dryer. (the dryer’s electrical

wire connection location was a factory option and may be connected through

the front or the rear of the dryer.) Secure the wire with an appropriate compression fitting or strain relief.

3- 8 l I n st al la ti on

IMPORTANT: Always refer to the

wiring diagrams that came with

your dryer before making electrical

connections.

3

Connect the power wires

to the three terminals at the top of the power

disconnect holder.

4 Connect the ground wire to the ground lug as shown in the photo.

Page 29

Auto Start

Dryer Status

Process Blower Regen. Blower

Regen. Heater

Set Point Actual

1 Process Temp.

2 Regen. Temp.

3 Return Air Temp.

4 Auto Start

5 Load Time (MDC)

6 Activate Setback Temp.

7 Setback Temp.(Process)

8 Dewpoint

Shutdown Alarms

A1 Process High Temp

A2 Process Loop Break

A3 Process Heater High Temp

A4 Regen Heater High Temp

A7 Return Air High Temp

A49 Process Protection High Temp

A53 Process Blower Overload

A55 Wheel Rotation Failure

Passive Alarms

P1 Process Temp Deviation

P3 Regen Temp Deviation

P5 Return Air Mid High Temp

P17 MDC Conveying Demand

1000

Opening the Dryer Doors

(W1600 - 5 0 0 0 )

Carousel Plus W Series 1600-5000 Dryers designed after August 2007 will

have locking side panel door bolts.

To unlock the side panel door bolts:

1 Rotate the two (2) locking door bolts on the dryer door counterclockwise

with a regular screw driver.

2 Close the dryer doors and rotate the two (2) locking door bolts clockwise

to resecure the dryer doors.

Checking for Proper Air Flow

This procedure is needed on W600-5000 models if the phase detection option

was not ordered with the dryer.

CAUTION: If the air flow direction is incorrect due to improper phase connection, material from the hopper can be pulled back into the dryer, causing permanent damage to this equipment.

1 Turn on the main power to the dryer. Make sure the dryer’s discon-

nect dial is in the ON position. This powers up the control and the display

lights will illuminate.

2 Press the START button then the STOP button.

(continued)

Start and Stop Buttons

Stop

Start

In s ta ll at io n l 3 -9

3

In s t all a t i on

IMPORTANT: This procedure must be performed before the dryer’s air hoses are

connected to the hopper or before loading material into the hopper.

Dryer Door

Locking Bolts (2)

(W1600-5000)

Page 30

3- 1 0 l I ns ta ll at io n

Checking for Proper Air Flow ( co nti nue d)

3 Visually verify the blower motor is

moving in the correct direction indicated by the arrow on the blower

housing. The W series 600-5000 dryers

are equipped with centrifugal process

blowers.

Dry Delivery

Air

Direction

Indication

Arrow

✐

NOTE: Models W600-1000

dryer aftercooler and dry

air delivery configuration

shown. Location on larger

models are different.

Refer to the labeling on

your dryer. See

Installation section entitled, Installing the

Return/Delivery Air

Adapters, for proper air

line connections.

Page 31

In s ta ll at io n l 3 -1 1

3

In s t all a t i on

Checking for Proper Air Flow ( co nti nue d)

4 If air flow is incorrect disconnect power, follow proper lockout procedures and

swap any 2 of the 3 main power wires.

If the air flow is reversed, the process blower is turning in the wrong

direction. Turn off and lock out the main power source. Open the electrical

enclosure and reverse any two leads connecting the main power supply to

the dryer.

WARNING: All wiring, disconnects, and fuses should be installed by qualified electrical technicians in accordance with electrical codes in your

region. Always maintain a safe ground. Do not operate the equipment at

power levels other than what is specified on the the machine serial tag

and data plate.

LEADS

WARNING: All wiring, disconnects, and fuses should be installed by

qualified electrical technicians in accordance with electrical codes in your

region. Always maintain a safe ground. Do not operate the equipment at

power levels other than what is specified on the the machine serial tag

and data plate.

Page 32

3- 1 2 l I ns ta ll at io n

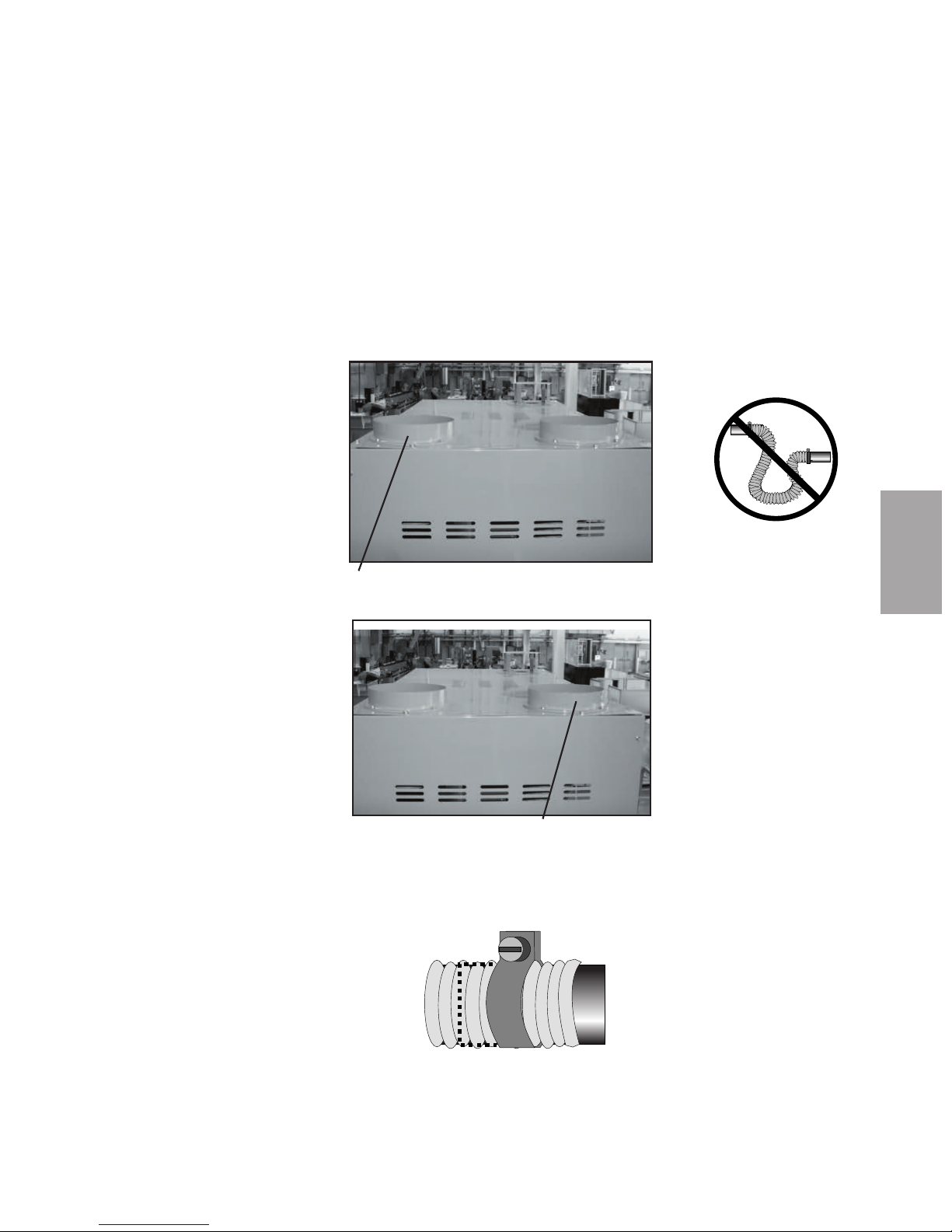

Connecting the Air Hoses to a

Single Hopper ( W 6 0 0 - 1 0 0 0 )

Using the two flexible hoses provided, connect the inlet of the HTC and outlet

of the drying hopper to the dryer. Make sure the dryer is located as close as

possible to the hopper (10 ft {3.05 m} of hose supplied).

1 Attach one hose from the return

air inlet, located on top of the

dryer, to the outlet of the hopper.

2 Attach one hose from the delivery

air outlet to the inlet of the HTC.

3 Secure hoses with clamps. The hose clamp

should be secured at least 1/4 in. {0.64 cm}

from the end of the inlet or outlet tube.

NOTE: Do not allow the

flexible hoses to kink or

crimp.

✐

Return

Air Inlet

Dry Delivery Air

✐

NOTE: Models W600-1000

dryer aftercooler and dry

air delivery configuration

shown. Location on larger

models are different.

Refer to the labeling on

your dryer.

✐

NOTE: All air hose connections will be appropriately

labeled.

Page 33

In s ta ll at io n l 3 -1 3

3

In s t all a t i on

Connecting the Air Hoses to a

Single Hopper ( W 1 6 0 0 - 5 0 0 0 )

Using the two flexible hoses provided, connect the inlet of the HTC and outlet

of the drying hopper to the dryer. Make sure the dryer is located as close as

possible to the hopper (10 ft {3.05 m} of hose supplied).

1 Attach one hose from the return

air inlet, located on top of the

dryer, to the outlet of the hopper.

2 Attach one hose from the delivery

air outlet, located on top of the

dryer, to the inlet of the HTC.

3 Secure hoses with clamps. The hose clamp should be secured

at least 1/4 in. {0.64 cm} from the end of the inlet or outlet tube.

NOTE: Do not allow the

flexible hoses to kink or

crimp.

✐

Return Air

Inlet

Delivery Air

Outlet

Page 34

3- 1 4 l I ns ta ll at io n

NOTE: Do not allow the

flexible hoses to kink or

crimp.

✐

Connecting the Air Hoses to a

ResinWork s

Using the two flexible hoses provided, connect the delivery air and return air

manifolds of the ResinWorks to the dryer. Make sure the dryer is located as

close as possible to the sleds (10 ft {3.05 m} of hose supplied).

1 Attach one hose from the

return air inlet of the dryer to

the return air manifold of the

ResinWorks.

2 Attach one hose from the

delivery air outlet of the dryer

to the delivery air manifold of

the ResinWorks.

3 Secure hoses with clamps. The

hose clamp should be secured at

least 1/4 in. {0.64 cm} from the

end of the inlet or outlet tube.

Insulated hose shown not standard.

Return

Air

Dry

Delivery

Air

Return

Air

Dry

Delivery

Air

Page 35

3

In s t all a t i on

In s ta ll at io n l 3 -1 5

Connecting the Dryer to the Hopper

If your dryer hose connection and your hopper HTC hose connection are not the

same size, you will need a hose adapter. Contact Conair Parts 1 800-458-1960.

Connecting the Dryer to

ResinWork s

If your dryer hose connection and the connection on your ResinWorks sled are not

the same size, you will need to use a hose adapter. Contact Conair Parts

1 800-458-1960.

NOTE: Because the W600 - 5000 models require a separate heat source for the

delivery air, all references to this heat source will be identified as “HTC” (Hopper

Temperature Controller). When using this dryer with a HTC, reference the User

Guide supplied with the HTC for installation instructions.

✐

NOTE: Because the W600 - 5000 models require a separate heat source for the

delivery air, all references to this heat source will be identified as ResinWorks.

When using this dryer with a ResinWorks sled reference the User Guide supplied

with the ResinWorks sled for installation instructions.

✐

Page 36

3- 1 6 l I ns ta ll at io n

Connecting Air Hose Adapters

Depending on the hopper you purchased you may need to install an air hose

adapter to connect the hopper to your dryer.

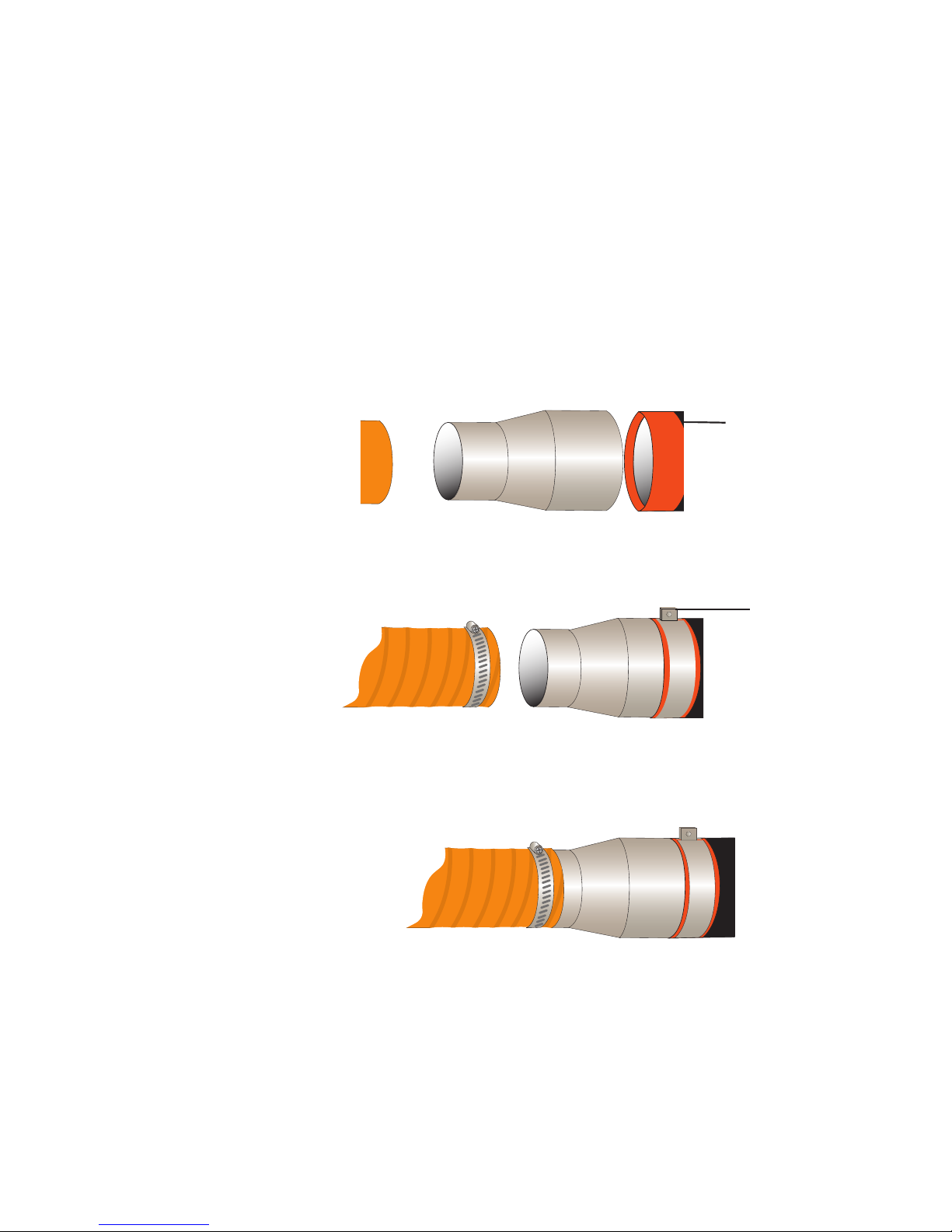

To connect the air hose adapter:

1 Place high temperature gasket half way down over the dry air delivery

outlet.

2 Place hose adapter inside high temperature gasket flush to the dryer outlet,

secure with pressure clamp.

3 Attach the hopper inlet hose over the adapter, secure with clamp.

Dryer

Inlet/Outlet

Connection

Pressure Clamp

Page 37

In s ta ll at io n l 3 -1 7

3

In s t all a t i on

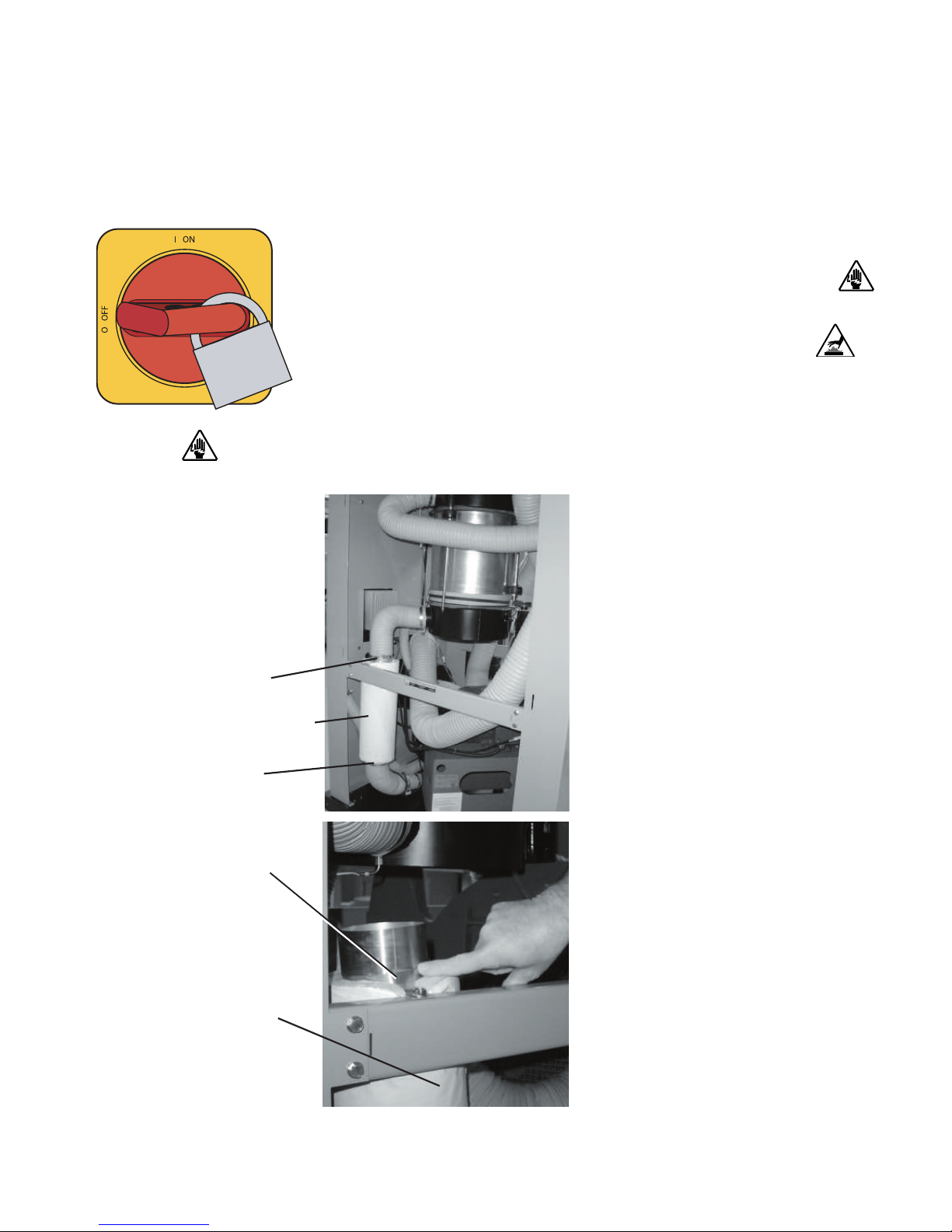

Connecting the After cooler and

Optional Precooler (W600 - 1000)

The aftercooler and/or optional precooler require a source of city, tower, or chiller

water and a discharge or return line. You can use water at temperatures of 45 to

85°F {7 to 29°C}. But the water flow should be at least 3 gal/min {11.4

liters/min}.

1 Connect the water supply line to

the aftercooler or precooler inlet.

If a manual shut off valve is used,

it should be mounted on the inlet

line.

2 Connect the water discharge or

return line with the pressure

relief valve to the aftercooler or

precooler outlet. Use the bracket

supplied to secure the pressure

relief valve to the back of the

dryer.

IMPORTANT: Turn the water off when the dryer is not in use to prevent

condensation.

Aftercooler Inlet

Aftercooler Outlet

✒

TIP: Make the water supply and dis-

charge / return connections with

flexible hoses at least 24 in.

(61 cm) long. This allows you to

easily remove the aftercooler

assembly for cleaning.

✒

TIP: If an optional flow control is

also being installed with the after cooler, the manual shut off valve

should be installed on the inlet line

for the flow control.

NOTE: Models W600-1000

dryer aftercooler and dry air

delivery configuration shown.

Location on larger models

are different. Refer to the

labeling on your dryer.

✐

Page 38

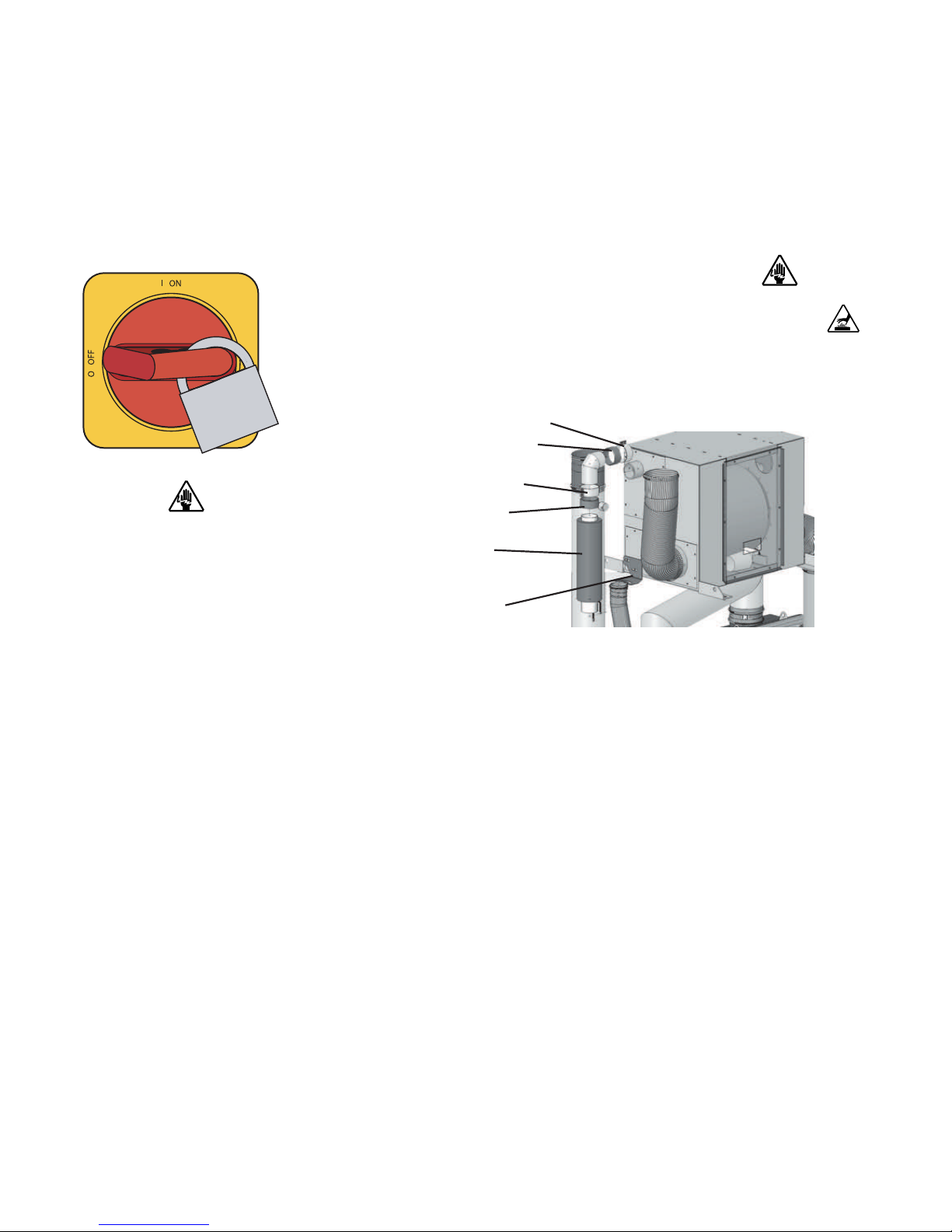

3- 1 8 l I ns ta ll at io n

Connecting the Inter cooler and

Optional Precooler

(W1600 - 5 0 0 0 )

The intercooler and/or optional precooler require a source of city, tower, or chiller

water and a discharge or return line. You can use water at temperatures of 45 to

85°F {7 to 29°C}. But the water flow should be at least 3 gal/min {11.4

liters/min}.

1 Connect the water supply line to

the intercooler or precooler inlet.

If a manual shut off valve is used,

it should be mounted on the inlet

line.

2 Connect the water discharge or

return line with the pressure

relief valve to the intercooler

or precooler outlet. Use the

bracket supplied to secure the

pressure relief valve to the back of

the dryer.

IMPORTANT: Turn the water off when the dryer is not in use to prevent

condensation.

Intercooler Inlet

Intercooler Outlet

✒

TIP: Make the water supply and dis-

charge / return connections with

flexible hoses at least 24 in.

(61 cm) long. This allows you to

easily remove the intercooler

assembly for cleaning.

✒

TIP: If an optional flow control is

also being installed with the inter cooler, the manual shut off valve

should be installed on the inlet line

for the flow control.

Page 39

Mounting a Loader on the Hoppe r

If you have a Conair loader or vacuum receiver, you can

use the flange and mounting clips provided on the top of

the hopper. Refer to the manual that came with your

receiver or loader for detailed installation instructions.

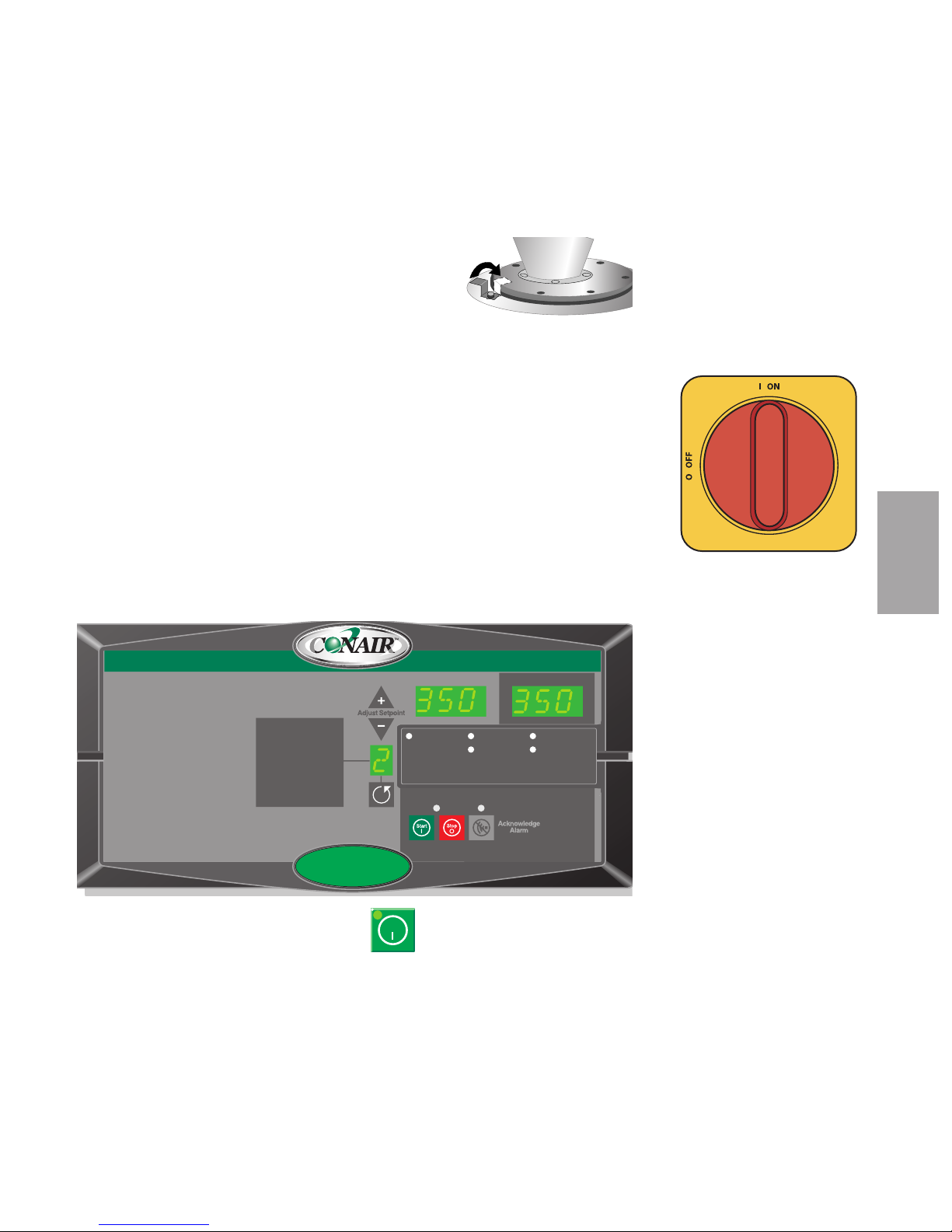

Testing the I nstallation

You have completed the installation. Now it’s time to make sure everything works.

1 Make sure there is no material in the hopper. If you have mounted a loader

or vacuum receiver on the hopper, disconnect the material inlet hose at the

source.

2 Turn on the main power to the dryer. Make sure the dryer’s disconnect dial is

in the ON position. This powers up the control and the display lights will illuminate.

3 Press the START button.

If everything is installed correctly:

• The green light on the start button will illuminate.

• The regeneration and process blowers and LEDs will turn on.

• The regeneration heater and LED will turn on.

• The LEDs will illuminate.

• The desiccant wheel starts turning.

(continued)

Auto Start

Dryer Status

Process Blower Regen. Blower

Regen. Heater

Set Point Actual

1 Process Temp.

2 Regen. Temp.

3 Return Air Temp.

4 Auto Start

5 Load Time (MDC)

6 Activate Setback Temp.

7 Setback Temp.(Process)

8 Dewpoint

Shutdown Alarms

A1 Process High Temp

A2 Process Loop Break

A3 Process Heater High Temp

A4 Regen Heater High Temp

A7 Return Air High Temp

A49 Process Protection High Temp

A53 Process Blower Overload

A55 Wheel Rotation Failure

Passiv e Alarms

P1 Process Temp Deviation

P3 Regen Temp Deviation

P5 Return Air Mid High Temp

P17 MDC Conveying Demand

1000

Start

IMPORTANT: Be sure the cable tie

has been removed from the desiccant wheel. (W600-1000 models)

In s ta ll at io n l 3 -1 9

3

In s t all a t i on

Page 40

3- 2 0 l I ns ta ll at io n

Testing the I nstallation (c ont inu ed )

4 Press the STOP button.

If everything is installed correctly:

• The blowers will continue running as needed to cool the heaters.

(until regeneration heaters are less than 150°F {66°C})

5 The test is over. If the dryer performed the normal operating sequences as

outlined, you can load the hopper and begin operation. If it did not, refer to

the Troubleshooting section of the User Guide.

Stop

Page 41

S E C T I O N

4

4

Op e r a tio n

Operation

Caro u sel Plus W Se r ies Dr y e r:

cont r ol p anel DC- 1 . . . . . . . . . . . . . . . . 4-2

Caro u sel Plus W Se r ies Dr y e r D C-1

cont r ol f unct i ons . . . . . . . . . . . . . . . . . 4-3

Cont r ol f unct i o n f low cha r t . . . . . . . . . . . . . 4-3

Cont r ol f unct i o n d escri p tion s . . . . . . . . . . . 4 -5

To s t a rt dry i ng . . . . . . . . . . . . . . . . . . . . 4-15

To s t o p d ryi n g . . . . . . . . . . . . . . . . . . . . . 4-1 6

Usin g th e a u to s tart co u n tdo w n f u ncti o n . . . 4 - 17

How to dis a ble the auto st a rt o n t he

DC-1 co n t rol . . . . . . . . . . . . . . . . . . . 4-17

Usin g de w poin t co n trol . . . . . . . . . . . . . . . 4-1 8

Op e ra ti on l 4-1

Page 42

4- 2 l Op er at io n

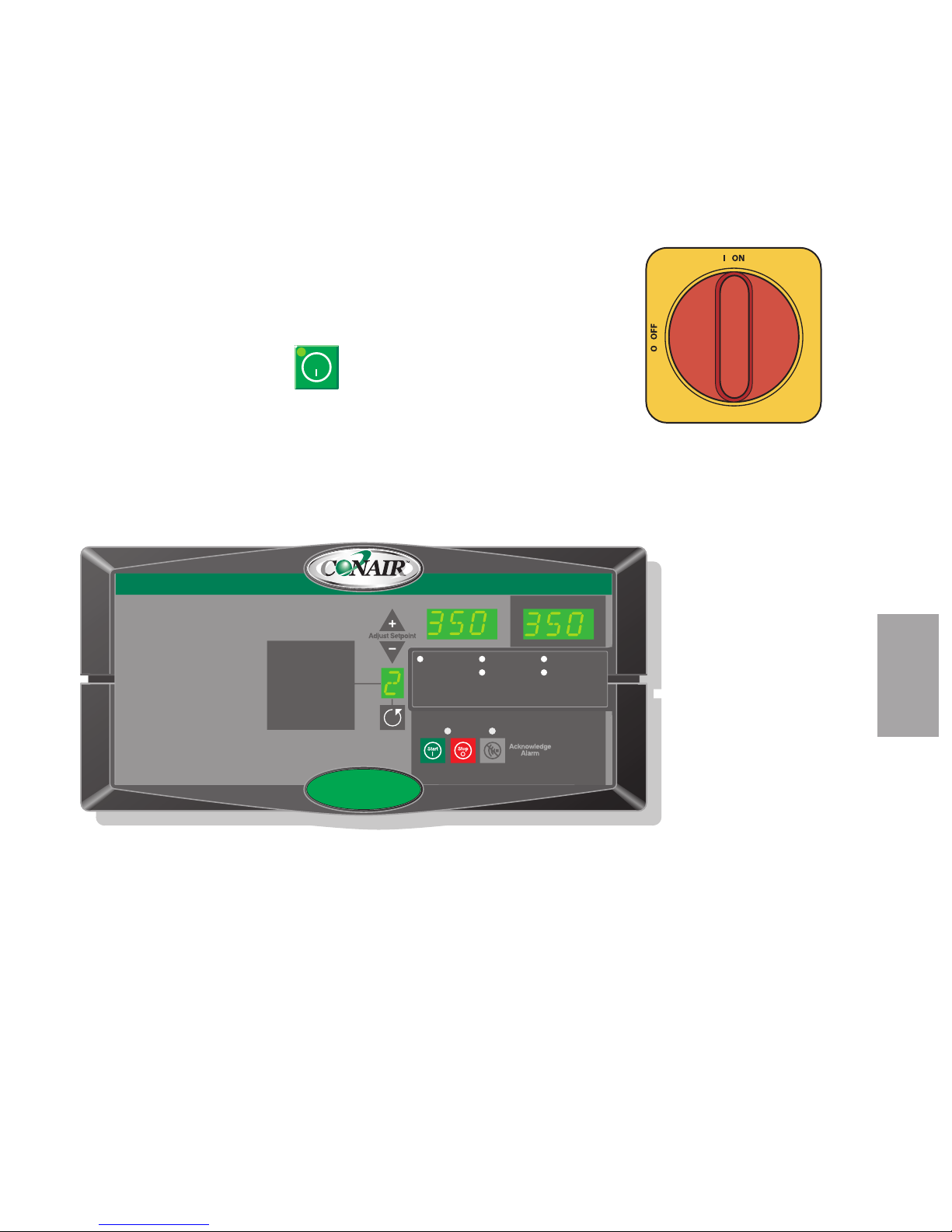

Auto Start

Dryer Status

Process Blower Regen. Blower

Regen. Heater

Set Point Actual

1 Process Temp.

2 Regen. Temp.

3 Return Air Temp.

4 Auto Start

5 Load Time (MDC)

6 Activate Setback Temp.

7 Setback Temp.(Process)

8 Dewpoint

Shutdown Alarms

A1 Process High Temp

A2 Process Loop Break

A3 Process Heater High Temp

A4 Regen Heater High Temp

A7 Return Air High Temp

A49 Process Protection High Temp

A53 Process Blower Overload

A55 Wheel Rotation Failure

Passiv e Alarms

P1 Process Temp Deviation

P3 Regen Temp Deviation

P5 Return Air Mid High Temp

P17 MDC Conveying Demand

1000

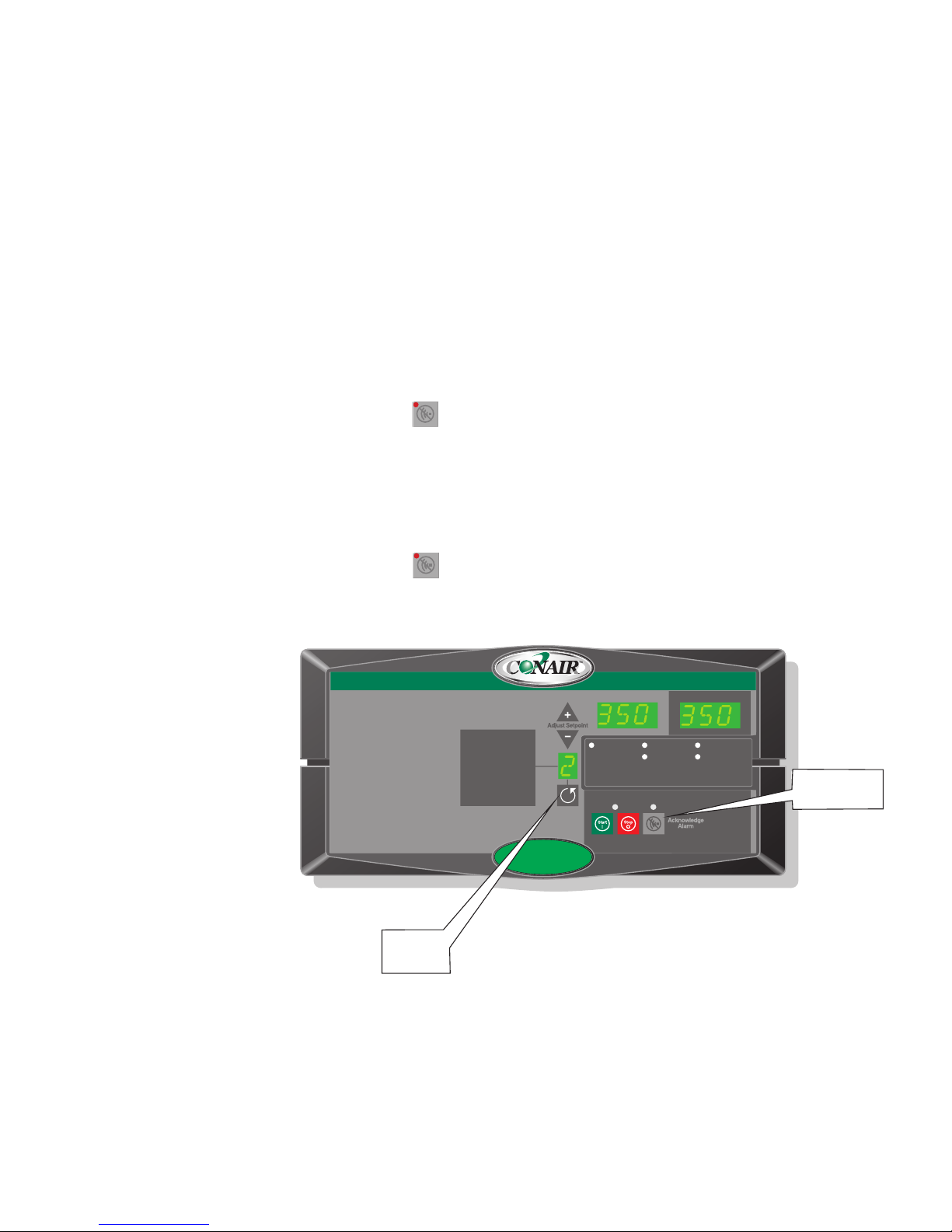

Carousel Plus W Series Dr yer: Control Panel DC-1

Se tp oi nt

Di sp la y

Shows the setpoint

value.

Me nu Li st

Numbers 2, 3, and 4 are standard items that will

always be present. Number 8 is a screen associated with options. If the option is not installed, the

screens will not be displayed.

NOTE: #1 Process is not displayed when

the unit is configured as a central dryer.

Ac kn ow led ge

Al ar m But to n

Press once to

silence the optional audible alarm

and display alarm

messages. Press

again to clear the

alarm. If pushed

when no active

alarm is present,

the most recent

alarm will be

displayed.

St ar t and St op

Bu tt on s

Press “Start” to start the dryer.

Press “Stop” to stop the dryer.

In cr em ent /De cr em ent

Bu tt on s

Used to increase and/or decrease the setpoint of a control function.

Ac tu al

Di sp la y

Shows the actual

temperature value.

Me nu

Nu mb er

Di sp la y

Displays the

menu number

corresponding to what

is shown in

the setpoint

and actual

displays.

Can also display letters

for alarms

and setup.

Sc ro ll

Bu tt on

Press to

scroll

through the

closed loop

menu list.

Pressing the

Scroll button

moves you

down the list.

Al ar m Cod es

See Troubleshooting section for a

more complete listing of alarms.

NOTE:

Process related

alarms are not

applicable

when the unit

is configured

as a central

dryer.

✐

✐

Page 43

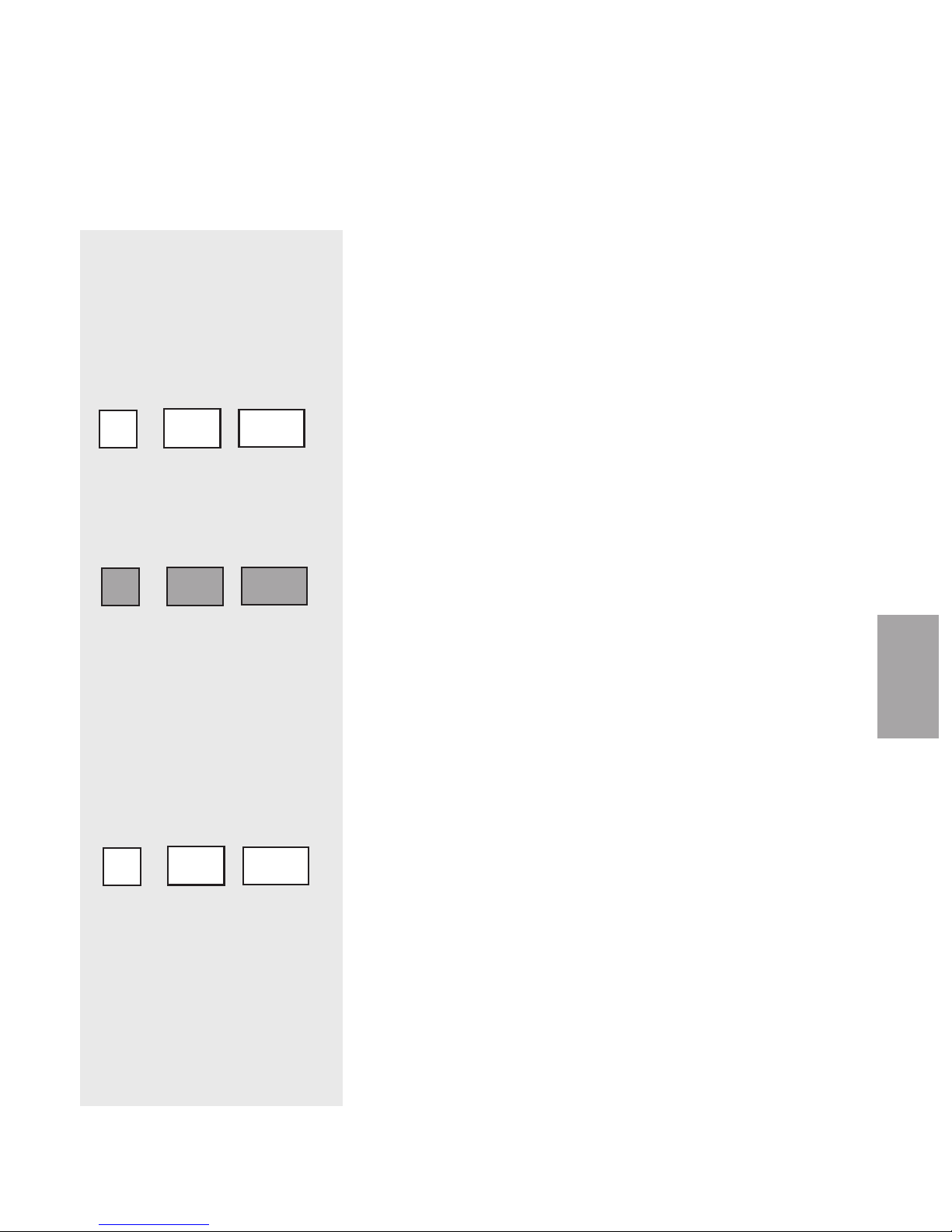

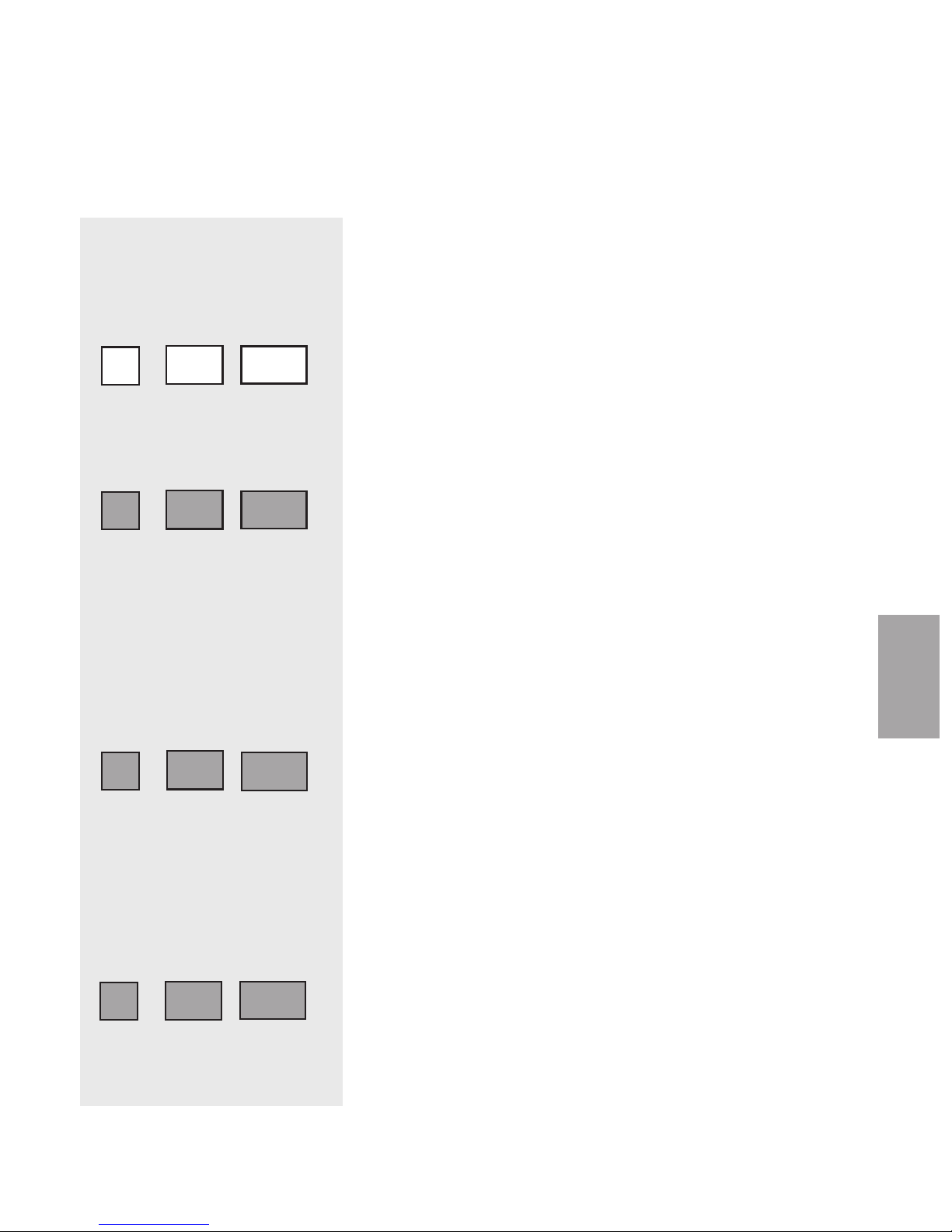

Carousel Plus W Series Dr yer DC-1

Control Functions

Dryer functions are values that you can set or monitor. Press the Scroll button to

access the function within a Menu list until the function you want to set or monitor

appears in the LED display.

NOTE: Grey shaded screens denote optional functions. If the options were not

purchased with the dryer, those screens will not appear.

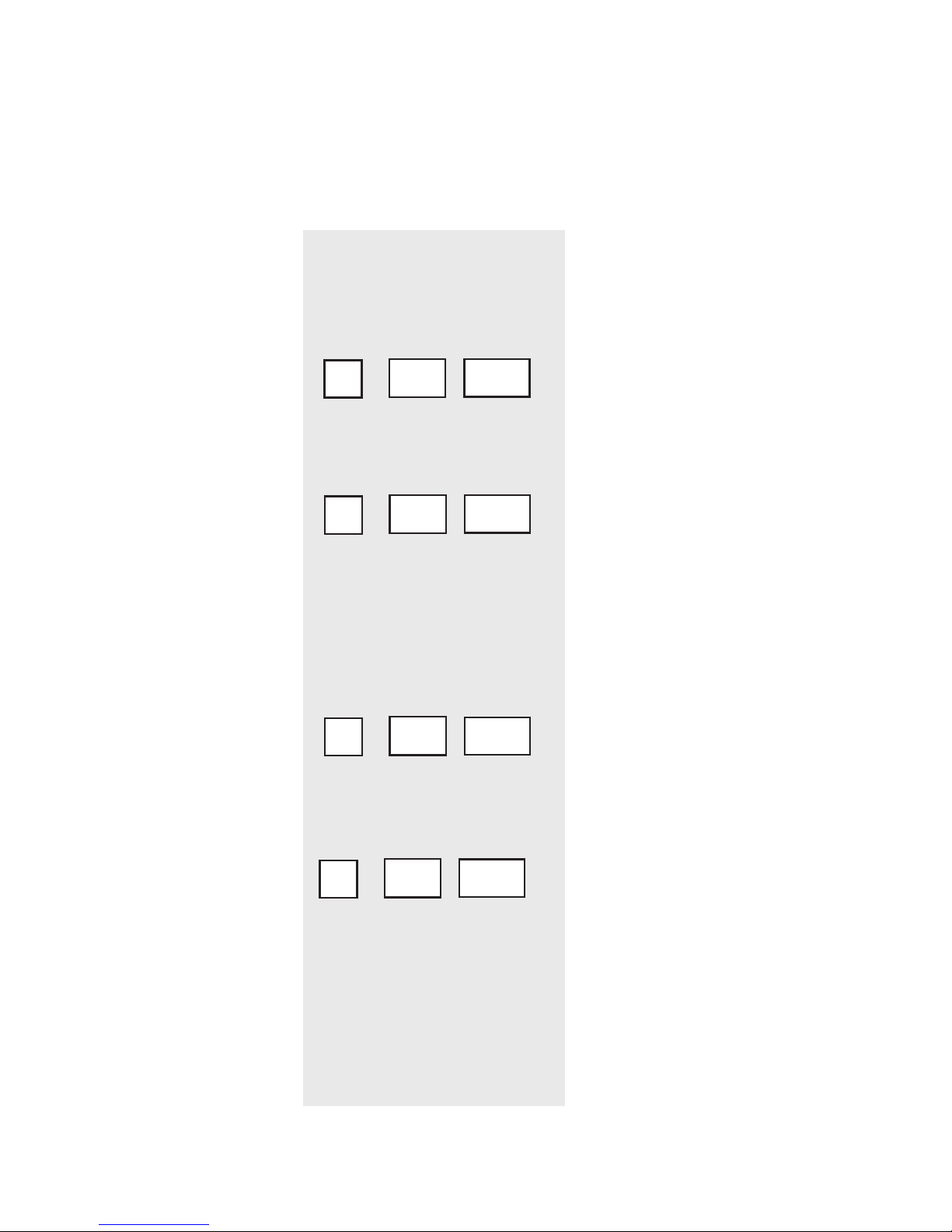

Control Function Flo w Chart

The following flow chart provides a quick summary of the control functions. For

an explanation of each control function, see Control Function Descriptions (page

4-5).

The Main Menu functions can be accessed by pressing the Scroll button when on

Screen 5. To access the Setup, Test Mode, and Alarm History Menus, the appropriate access code must be entered. Refer to the instructions for Screen 14

(page 4-7).

Op e ra ti on l 4-3

4

Op e r a tio n

✐

Page 44

POWER ON

s

creen #

1

Pr up

5 sec

2

CP 600

5 sec - Model Disignator

3

C v2.0 3.00

1 sec - Control Software Version

4

dv2.0 3.00

1 sec - Display Software Version

5

1

CNT DRY

Configured as a Central Dryer

6

2350350

Regen Temp

7

3100100

Return Air Temp

8

416On

Auto Start

13

9-30-40

Dewpoint Monitor or Dewpoint Control

14

00

Password Screen

754 755

756

28

Hoff 1

44

A1P3

44

A2A1

30

Hoff 3

44

A3A5

18

C350C04

31

Hoff 4

44

A4A4

19

CoffC05

32

Hoff 5

44

A5P1

33

Hoff 6

44

A6P5

21

C20C07

34

Hoff 7

44

A7A1

35

Hoff 8

44

A8A7

24

CoffC10

44

A9A2

37

Hoff 10

44

A10A6

38

Hoff 11

40

Hoff 13

41

Hoff 14

42

Hoff 15

43

Hoff 16

Setup Menu

Access Code

Te st Mode Menu

Access Code

Alarm History Menu

Access Code

47

CFC15

MAIN MENU

22

C200C08

4- 4 l Op er at io n

NOTE: In the event new control boards are installed, screens showing Process and MDC may be present. The boards

will need to be configured for a central dryer. If this is not done, alarms will occur.

✐

Display Menu

Number

Setpoint

Display

Actual

Display

NOTE: Screens 1-4 are only

displayed during initialization.

✐

Page 45

4

Op e r a tio n

Op e ra ti on l 4-5

Once power is turned on, this screen is displayed for 5 seconds while the control

goes through self-checking.

Once power is turned on and screen 1 is

displayed for 5 seconds, this screen is displayed for another 3 seconds. It shows the

dryer model number for which the control

is configured.

After the model number is displayed, this

screen flashes for 1 second and displays

the control board software version.

After the control version is shown, the

screen flashes again for 1 second and displays the display board software version.

Indicates configuration as a central dryer.

Shows the regeneration air setpoint and

actual temperature. The setpoint can not be

changed from this screen; it is shown only

as a reference.

Screen

SCREEN 1

SCREEN 2

SCREEN 3

SCREEN 4

SCREEN 5 (Default Screen)

SCREEN 6

Pr

Function

Control Function Des criptions

up

CP

600

v2.0

3.00

C

v2.0

3.00

d

350

350

2

CNT

DRY

1

Page 46

4- 6 l Op er at io n

Screen

SCREEN 7

SCREEN 8

100

Function

Control Function Des criptions

(c on ti nue d)

This screen shows the actual return air

temperature measured at the inlet to the

process blower. (The return air temperature

on W1600-5000 dryers is measured at the

inlet to the desiccant wheel. W1600-5000

dryers designed prior to August 2007, the

return air temperature is measured at the

inlet to the process blower.) If the optional

aftercooler/intercooler flow control is

installed, a setpoint will be displayed on

this screen as well. The (+) or (-) buttons

can be used to change the set point.

Holding the (+) or (-) buttons in will allow

the number to ramp up faster the longer

the button is held.

This screen is used to set the dryer to auto

start. The dryer must be on but not running to set auto start. The value shown is

the countdown time setpoint. It is

adjustable from 0.1 hours to 150 hours.

Once the countdown time is set, press the

“START” button. The display will show

ON to tell the operator that the auto start is

ON and counting. The auto start LED on

the display also flashes green when the

auto start is armed and counting down.

The LED will turn solid green when the

dryer starts. The dryer will begin operating when the control has finished counting

down.

100

3

16

On

4

Page 47

Op e ra ti on l 4-7

Screen

SCREEN 13 (Dewpoint Monitor/

Dewpoint Control Option)

SCREEN 14

Function

Control Function Des criptions

(c on ti nue d)

If the dryer has the dewpoint monitor

option installed, this screen will show the

actual dewpoint of the process delivery air.

With the dewpoint monitor option

installed, there will only be an actual display (no setpoint value). Although the

dryer is capable of producing dewpoints

much lower than -40°F {-40°C}, the minimum sensor range is -40°F {-40°C}.

Dewpoint control will automatically adjust

the regeneration temperature to maintain

dewpoint setpoint. Dewpoint control is not

active with -40°F {-40°C} setpoint.

This is the password entry screen that

gives the user access to the Set Up, Test

Mode, and Alarm History screens. The

user can get to the password protected control functions through this screen by pressing the Scroll button and the adjust setpoint button (-) at the same time. This

works only if you are on menu #1 (Screen

5). The access codes are as follows:

Set Up Screens 754

Test Mode Screens 755

Alarm History Screens 756

To exit the password section, enter 500

and press scroll or cycle the power.

(continued)

-30

-40

8

0

0

4

Op e r a tio n

Page 48

Screen

Screens 18-24 require access

code 754.

SCREEN 18 (Set up Screen)

SCREEN 19 (Set up Screen)

SCREEN 21 (Set up Screen)

Regeneration Differential

Temperature

Function

Control Function Des criptions

(c on ti nue d)

This is the regeneration setpoint screen.

NOTE: There is normally no need to change

this temperature. Consult Conair prior to

changing this setting.

This is the regeneration heater autotune

screen. The autotune function can be

turned on by pressing the (+) key. Once

the (+) key is pressed, the screen will show

“On” and then start the autotune process.

This may take a minute or so to complete.

When finished the display will read "don".

The new PID values are automatically

saved. An autotune should be performed

on a cold dryer. It will autotune to the

setpoint value entered on Screen 18.

This screen shows the minimum differential temperature between the regeneration

inlet and the outlet at the desiccant wheel.

If the actual temperature differential is

under the set value, the dryer will alarm

(P31), but will still run. The temperature

range is 5 to 100°F {-15 to 38°C}. The

default temperature is 20°F {-7°C}.

350

C04

C

off

C05

C

✐

✐

4- 8 l Op er at io n

20

C07

C

Page 49

4

Op e r a tio n

Op e ra ti on l 4-9

Screen

Screens 18-24 require access

code 754.

SCREEN 22 (Set up Screen)

Regeneration Air Temperature

SCREEN 24 Aftercooler/

Intercooler Flow Control Enable

(Option)

Screen 28-43 require access

code 755.

SCREEN 28 (Test Mode Screen)

Function

Control Function Des criptions

(c on ti nue d)

This screen shows the actual temperature

of the regeneration air at the outlet of the

desiccant wheel.

This screen is the Aftercooler/Intercooler

Flow Control Enable screen. By pressing

the (+) or (-) keys, this function can be

turned on or off. When off, the dryer will

not open the optional flow control valve to

control the return air temperature. There

will also be no setpoint value on Menu #3,

Screen 7. This screen is not visible if the

aftercooler/intercooler flow control option

is not installed on the dryer.

This is the Test Mode screen for the

process blower. By pressing the (+) or (-)

keys, the setting can be changed. When

set to "On", the process blower output will

be turned on for 3 seconds and then shut

off automatically.

(continued)

✐

off

C10

C

off

1

H

200

C08

C

✐

Page 50

4- 1 0 l Ope r at io n

Control Function Des criptions (con tin ue d)

Screen

Screen 28-43 require access

code 755.

SCREEN 30 (Test Mode Screen)

SCREEN 31 (Test Mode Screen)

SCREEN 32 (Test Mode Screen)

SCREEN 33 (Test Mode Screen)

Function

This is the Test Mode screen for the regeneration blower. By pressing the (+) or (-)

keys, the setting can be changed. When

set to "On", the regeneration blower output

will be turned on for 3 seconds and then

shut off automatically.

This is the Test Mode screen for the regeneration heater. By pressing the (+) or (-)

keys, the setting can be changed. When

set to "On", the regeneration heater output

will be turned on for 3 seconds and then

shut off automatically.

NOTE: The isolation contactor will not be

engaged so no electricity will go the heater.

The solid state relay contacts should close.

This is the Test Mode screen for the wheel

motor. By pressing the (+) or (-) keys, the

setting can be changed. When set to "On",

the wheel motor output will be turned on

for 3 seconds and then shut off automatically.

This Test Mode screen is not used in the

current program.

off

3

H

off

5

H

off

4

H

✐

off

6

H

✐

Page 51

4

Op e r a tio n

Op e ra ti on l 4-1 1

Screen

Screen 28-43 require access

code 755.

SCREEN 34 (Test Mode Screen)

SCREEN 35 (Test Mode Screen)

SCREEN 37 (Test Mode Screen)

SCREEN 38 (Test Mode Screen)

Function

Control Function Des criptions

(c on ti nue d)

This is the Test Mode screen for the isolation contactor. By pressing the (+) or (-)

keys, the setting can be changed. When

set to "On", the isolation contactor output

will be turned on for 3 seconds and then

shut off automatically.

This is the Test Mode screen for the alarm

output (horn and/or red light). By pressing

the (+) or (-) keys, the setting can be

changed. When set to "On", the alarm output will be turned on for 3 seconds and

then shut off automatically.

NOTE: The alarm light on the membrane

switch will not come on. If the optional

alarm horn or red light is not installed nothing will happen.

This is the Test Mode screen for the aftercooler/intercooler flow control valve. By

pressing the (+) or (-) keys, the setting can

be changed. When set to "On", the aftercooler/intercooler flow control valve output will be turned on for

3 seconds and then shut off automatically.

NOTE: If the optional aftercooler/intercooler

flow control valve is not installed nothing will happen.

This screen is not used in the current

program.

off

8

H

off

7

H

off

10

H

✐

✐

off

11

H

✐

Page 52

4- 1 2 l Ope r at io n

Screen

Screen 28-43 require access

code 755.

SCREEN 40 (Test Mode Screen)

SCREEN 41 (Test Mode Screen)

SCREEN 42 (Test Mode Screen)

SCREEN 43 (Test Mode Screen)

Function

Control Function Des criptions

(c on ti nue d)

This screen is not used in the current

program.

This screen is not used in the current

program.

This is the Test Mode screen for the alarm

output (yellow light). By pressing the (+)

or (-) keys, the setting can be changed.

When set to "On", the alarm output will be

turned on for 3 seconds and then shut off

automatically.

NOTE: If the optional tricolor light is not

installed nothing will happen.

This is the Test Mode screen for the alarm

output (green light). By pressing the (+)

or (-) keys, the setting can be changed.

When set to "On", the alarm output will be

turned on for 3 seconds and then shut off

automatically.

NOTE: If the optional tricolor light is not

installed nothing will happen.

off

13

H

off

15

H

off

14

H

off

16

H

✐

✐

✐

Page 53

4

Op e r a tio n

Op e ra ti on l 4-1 3

Screen

Access code 756 required.

SCREEN 44 (Alarm Screen)

Function

Control Function Des criptions (con tin ue d)

1

P3

A

This is the first Alarm History screen. In

this section, the last 10 alarms that have

occurred are saved, starting with the

most recent alarm. The number in the

setpoint screen shows the list of alarms

1-10. The alarm code shows up in the

actual screen. Some of the alarm codes

are shown on the display label. Please

refer to the alarm section of this manual

for all alarm code definitions.

These are the additional alarm screens.

See the explanation above.

2

A1

A

3

A5

A

4

A4

A

5

P1

A

6

P5

A

7

A7

A

8

A2

A

9

A6

A

10

P2

A

✐

Page 54

4- 1 4 l Ope r at io n

Screen

Screen 47 require access

code 754.

SCREEN 47 (Degree F/Degree C)

Function

Control Function Des criptions

(c on ti nue d)

This is the temperature units screen. It is

used to change the temperature display

from °F to °C or °C to °F. Use the (+) or

(-) keys to toggle between °C and °F.

F

C15

C

✐

Page 55

Op e ra ti on l 4-1 5

To Start Dr ying

1 Make sure there is material in the hopper.

2 Turn on the main power to the dryer. Make sure the dryer’s disconnect dial

is in the ON position. This powers up the control and the display lights will

illuminate.

3 Press the START button.

If everything is installed correctly:

• The green light on the start button will illuminate.

• The process and regeneration blowers turn on and the LEDs will

illuminate.

• The regeneration heater turns on and the LED will illuminate.

• The desiccant wheel starts turning.

Auto Start

Dryer Status

Process Blower Regen. Blower

Regen. Heater

Set Point Actual

1 Process Temp.

2 Regen. Temp.

3 Return Air Temp.

4 Auto Start

5 Load Time (MDC)

6 Activate Setback Temp.

7 Setback Temp.(Process)

8 Dewpoint

Shutdown Alarms

A1 Process High Temp

A2 Process Loop Break

A3 Process Heater High Temp

A4 Regen Heater High Temp

A7 Return Air High Temp

A49 Process Protection High Temp

A53 Process Blower Overload

A55 Wheel Rotation Failure

Passiv e Alarms

P1 Process Temp Deviation

P3 Regen Temp Deviation

P5 Return Air Mid High Temp

P17 MDC Conveying Demand

1000

NOTE: Once the dryer has been started, go to the ResinWorks or HTC and set the setpoint, then turn on the unit.

✐

Start

4

Op e r a tio n

Page 56

4- 1 6 l Ope r at io n

To Stop Drying

1 Press the STOP button. The Stop LED blinks red.

• The blowers continue running for a few minutes

to cool the heaters.

2 Be sure to disconnect and lockout the main power if you have stopped the

dryer to perform maintenance or repair.

IMPORTANT: Do not use the main power switch to stop the dryer. Turning off power to the

control and dryer during normal operation prevents the necessary cool-down period, and

can trigger the shutdown/high temperature alarm during your next drying cycle.

CAUTION: Improper shut down can cause damage to your dryer.

NOTE: Turn off the ResinWorks or HTC and allow the heaters to cool (3 to 5 minutes)

before turning off the dryer.

✐

Stop

Page 57

Using the Auto Start Countdown

Function

The countdown function allows the user to set the Carousel Plus W Series

Dryer to automatically start at a predetermined time. The countdown time can

be set from 0.1 to 150.0 hours.

To set the countdown time:

1 Use the Scroll button to access the function (Menu 4, Screen 8).

Auto Start

2 Use the Setpoint Adjust keys to set the desired countdown time in hours.

3 Press the Start button. The Auto Start LED will blink to indicate that Auto Start

is armed.

How to Disable the Auto Start on

the DC-1 Control

To disable auto start once armed cycle the power off and on.

16

ON

4

Op e ra ti on l 4-1 7

4

Op e r a tio n

Page 58

4- 1 8 l Ope r at io n

NOTE: For more information concerning specific dewpoint control screens, see Control

Function Descriptions, page 4-5.

✐

Using Dewpoint Contr ol

Dewpoint control is a feature that can help you to reduce energy consumption. It

does this by varying the temperature of the regeneration air from its default setpoint of 350° F {177° C}, to maintain a setpoint that you have entered on the

process dewpoint screen (Screen 11).

Example:

If your material is not difficult to dry, it may dry adequately with -20° F

{-29° C} dewpoint air. When -20° F {-29° C} is entered as the setpoint (Screen

11), the dryer will gradually lower the regeneration air temperature to a point

where the dryer’s delivery air is controlled at -20° F {-29° C} dewpoint.

The dewpoint control is active with setpoint values of -39° F {-39.4° C} and

higher. When the setpoint is -40° F {-40° C} or lower, the regeneration tempera-

ture will be maintained at the default temperature of 350° F {177° C} and the

dewpoint control is inactive.

Page 59

Maintenance

Prev e ntat i ve m aint e nance ch e c klis t . . . . . . . 5 - 2

Chec k ing the dewp o int . . . . . . . . . . . . . . . . 5-3

Clea n ing the hopp e r. . . . . . . . . . . . . . . . . . 5- 5

Clea n ing the proc e ss filte r . . . . . . . . . . . . . 5-6

Clea n ing the rege n erat i on filte r . . . . . . . . . . 5- 8

Clea n ing the afte r coole r /int e r cool e r c o ils . . . 5-9

Clea n ing the prec o oler coi l s . . . . . . . . . . . 5- 1 1

Clea n ing the vola tile tra p o n t h e d emist e r . . 5-11

Insp e cting ho s e s a nd gaske t s . . . . . . . . . . 5-11

S E C T I O N

5

Ma i n ten a n ce

5

Ma i nt en an ce l 5- 1

Page 60

5- 2 l M a in te na nc e

Preventative Maintenance

Checklist

Routine maintenance will ensure optimum operation and performance of the

W Series Carousel Plus Dryer. We recommend the following maintenance

schedule and tasks.

• Whenever you change materials

❒ Drain and clean the hopper.

• Wee k ly, or as ofte n a s ne eded

❒Clean or replace the process and regeneration filters.

You may need to clean filters more often than weekly. Frequency

depends on how much material you process and how dusty or full of fines it is.

❒Inspect hoses and hose connections.

Check for damage, kinks, or loose hose clamps. Replace any hoses that

show signs of damage or wear. Reposition and tighten loose hose clamps.

• M o nthly

❒

Clean the aftercooler/intercooler and optional precooler coils.

You may need to clean the coils more often than monthly. Frequency will

depend on the type and volume of material you process.

• E v ery six mo n ths

❒Inspect gaskets for damage or wear.

Damaged gaskets can allow moisture to seep into the closed-loop drying

system. Replace any gasket that is torn or cracked.

❒Inspect the overhead process air duct connections.

(W3200-5000) Ensure that all connections are tighten properly and have .

no air leaks.

❒Verify dewpoint readout and performance with calibrated portable

instrument.

❒Measure current draw on all 3 legs of heater wires. This is to ensure

that the heater is working properly.

Page 61

5

Ma i n ten a n ce

Ma i nt en an ce l 5- 3

✐

NOTE: Portable dewpoint monitors purchased from Conair are

provided with a male connector

that plugs into the dewpoint

check port. If you purchased

your portable instrument elsewhere, the male connector is

available through the Conair

parts department.

NOTE: The dewpoint check port

was not included on early

dryers. It can be added easily.

Contact the Conair parts

department or follow the

alternate procedure.

✐

Replacement dewpoint

monitors, male connectors

and dewpoint check ports

are available from Conair.

Contact Conair Parts

(800) 458 1960

From outside of the

United States, call:

(814) 437 6861

Checking the Dewpoin t

It is a good idea to monitor the dewpoint performance of your dryer periodically

with a calibrated portable dewpoint monitor, to ensure it is performing at

maximum capacity. Even if your dryer has a dewpoint readout, comparing it

to a portable instrument periodically will confirm that the dewpoint sensor and

readout is performing properly.

To check dewpoint:

1 Connect your portable dewpoint meter to the

dewpoint check port of the dryer.

2 Turn on the portable instrument, and ensure

there is positive airflow through the sensor.

3 Monitor the readout and allow ample time for it to stabilize before discon-

necting the portable dewpoint monitor. Some dewpoint monitors require a